Manufacturing process of ultra-soft feed line inner conductor

A manufacturing process and inner conductor technology, applied in the field of communications, can solve the problems of large fluctuations in electrical performance, poor welding quality, large loss of copper strips, etc., to improve production speed and product quality, small fluctuations in wrinkle size, and standing wave ratio. The effect of excellent indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

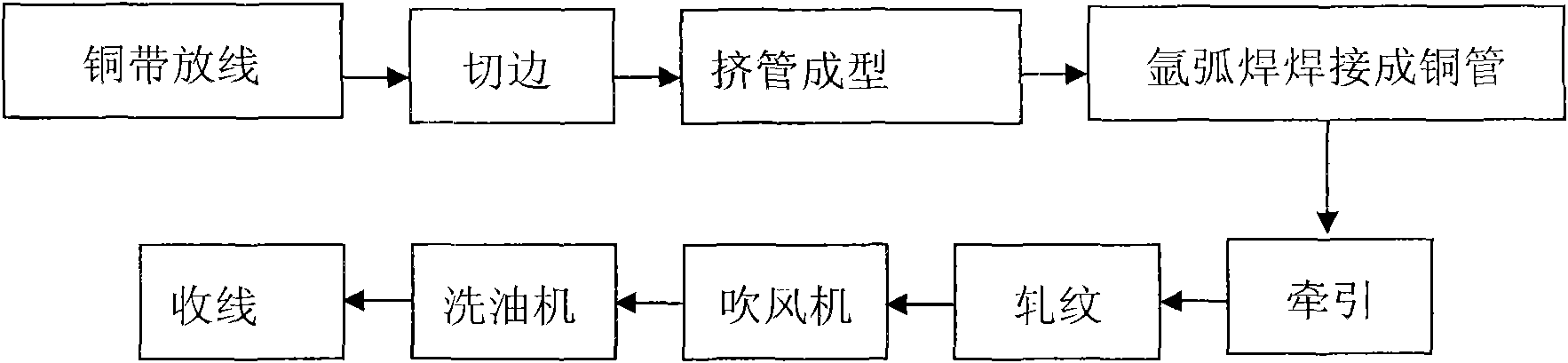

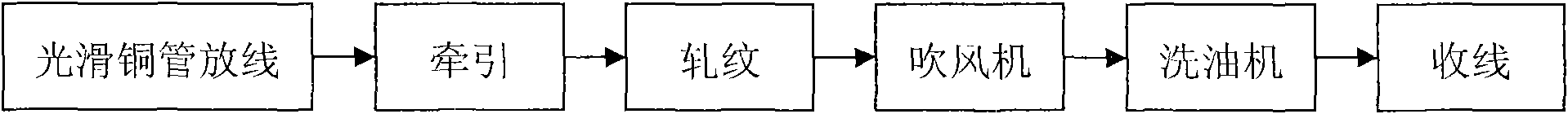

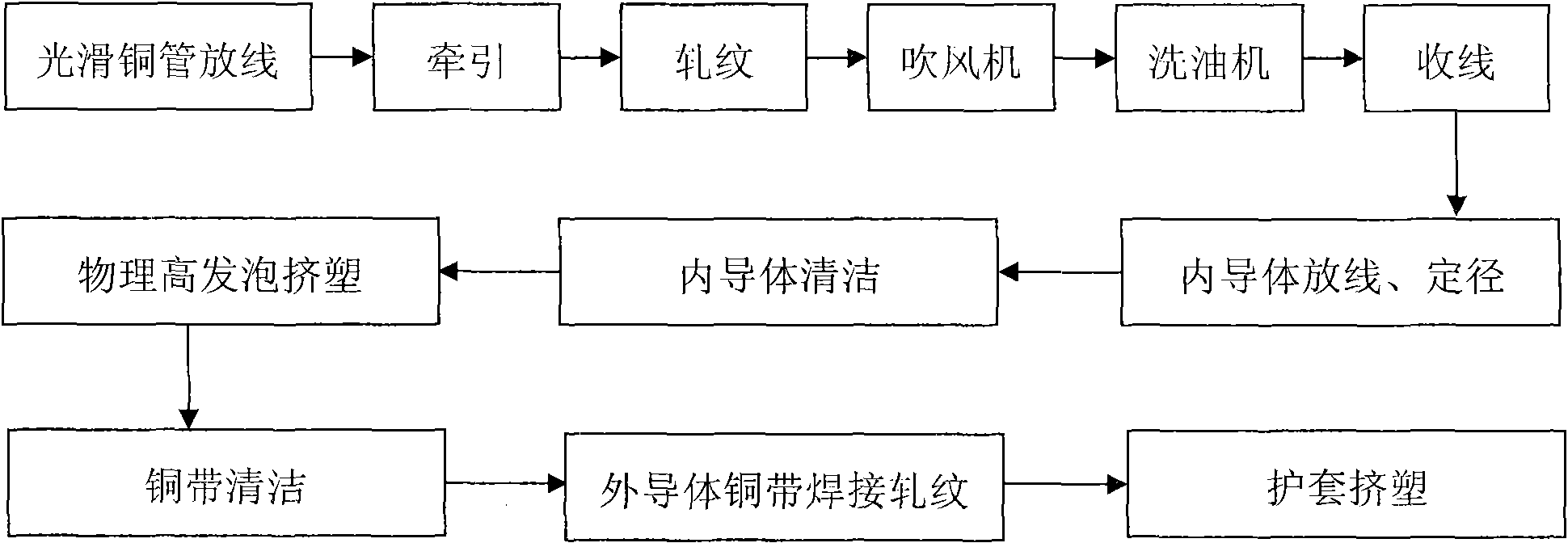

[0012] see figure 2 , is the production process flow chart of the inner conductor of the super-flexible feeder of the present invention, the manufacturing process of the inner conductor of the super-flexible feeder of the present invention improves the production speed and quality of the inner conductor of the existing super-flexible feeder, and replaces the traditional copper strip with a smooth copper tube Direct deep spiral embossing.

[0013] The first is to obtain a smooth copper tube that can be used for corrugating the inner conductors of the superflex feeder. Due to the low tensile strength of the smooth copper tubes used in common feeders, direct embossing of common smooth copper tubes will easily cause the copper tubes to be deformed under pressure, the size of the wrinkles will fluctuate greatly, and the VSWR of the feeder lines will be poor. Through the control of smooth copper tube manufacturing conditions and key technical indicators, the ideal smooth copper tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com