Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

A cement concrete and prestressed technology, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks, can solve the problems that affect the popularization and use of prefabricated cement concrete pavement, increase the urban heat island effect, and open traffic delays, etc., to achieve road surface The effect of reasonable structural design, effective quality control and accelerated production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

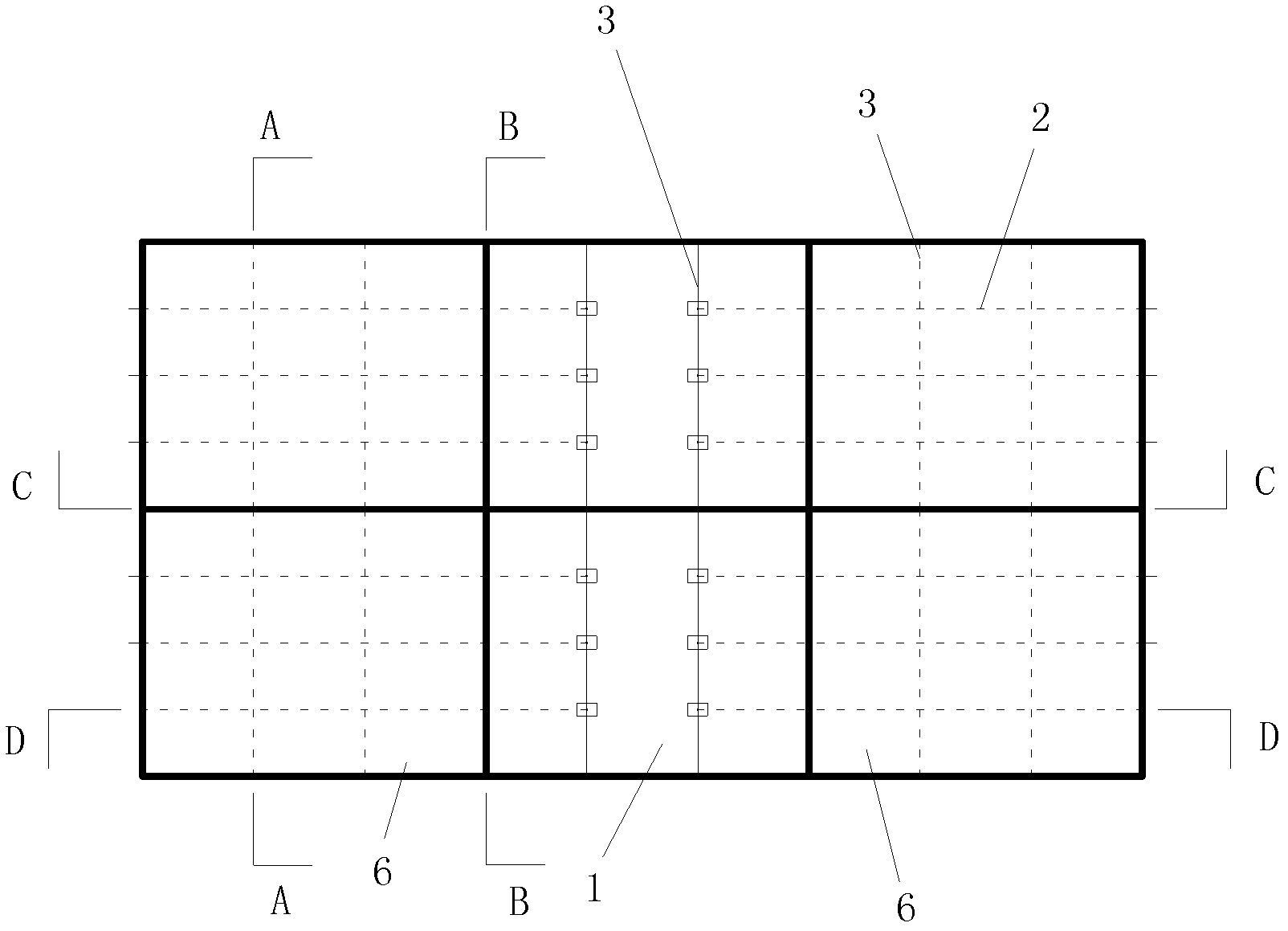

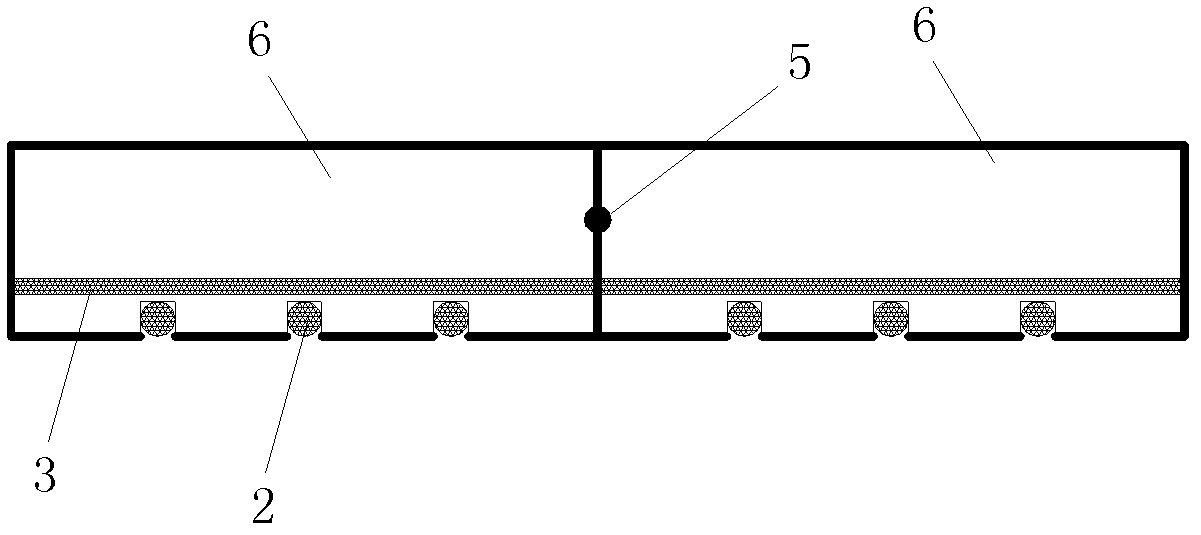

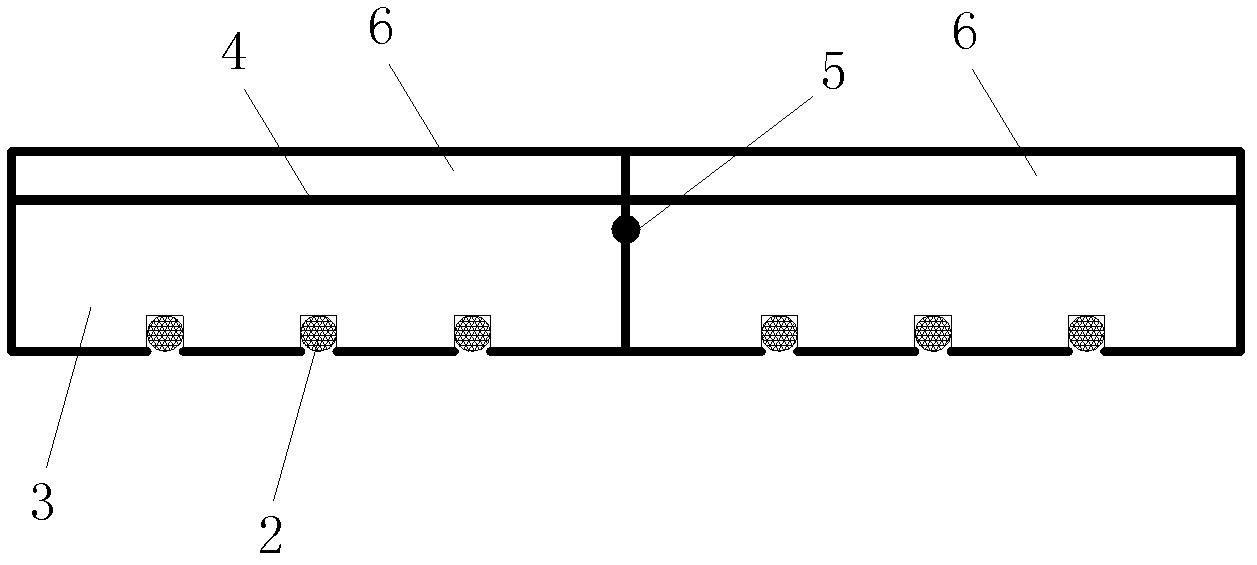

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the assembled prestressed heat-resistant cement concrete pavement adopted in the present invention is an integral pavement composed of multiple assembled prestressed heat-resistant road panels laid side by side on the road base to be paved. The structure of prestressed heat-resistant road panels is the same, and the number, lateral width and layout position of the multi-channel prestressed heat-resistant road panels are consistent with the number, lateral width and layout position of the lanes set on the road to be paved , and the longitudinal lengths of the multiple assembled prestressed heat-resistant road panels along the driving direction are the same.

[0059]The assembled prestressed heat-resistant road slab includes an assembled prestressed road slab and a vermiculite concrete heat-resistant pavement laid on the assembled prestressed road slab, and the thickness of the vermiculite con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com