Patents

Literature

899results about How to "Strong heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluororesin radiating paint and preparation method thereof

ActiveCN103131274AReduce thermal contact resistanceHigh thermal conductivityCoatingsCarbon nanotubeElectron transfer

The invention discloses fluororesin radiating paint and a preparation method thereof. The paint mainly comprises an electron transfer type organic compound, graphene, a carbon nanotube, titanium white, other additives and fluororesin, wherein the fluororesin is a paint brand having the highest comprehensive property at present; the electron transfer type organic compound can greatly enhance the thermal radiation rate of the paint; the graphene and the carbon nanotube can further accelerate thermal conduction; and the electron transfer type organic compound, the carbon nanotube and the graphene finally form a full three-dimensional network distribution of granules (electron transfer type organic compound), wires (carbon nanotube) and planes (graphene) in a fluid. The fluororesin radiating paint disclosed by the invention has high thermal radiation rate, high thermal conductivity and low thermal resistance, can realize radiation cooling, and simultaneously has the effects of self cleaning, acid / alkali resistance and super high insulativity, thereby having high practical value.

Owner:明朔(北京)电子科技有限公司

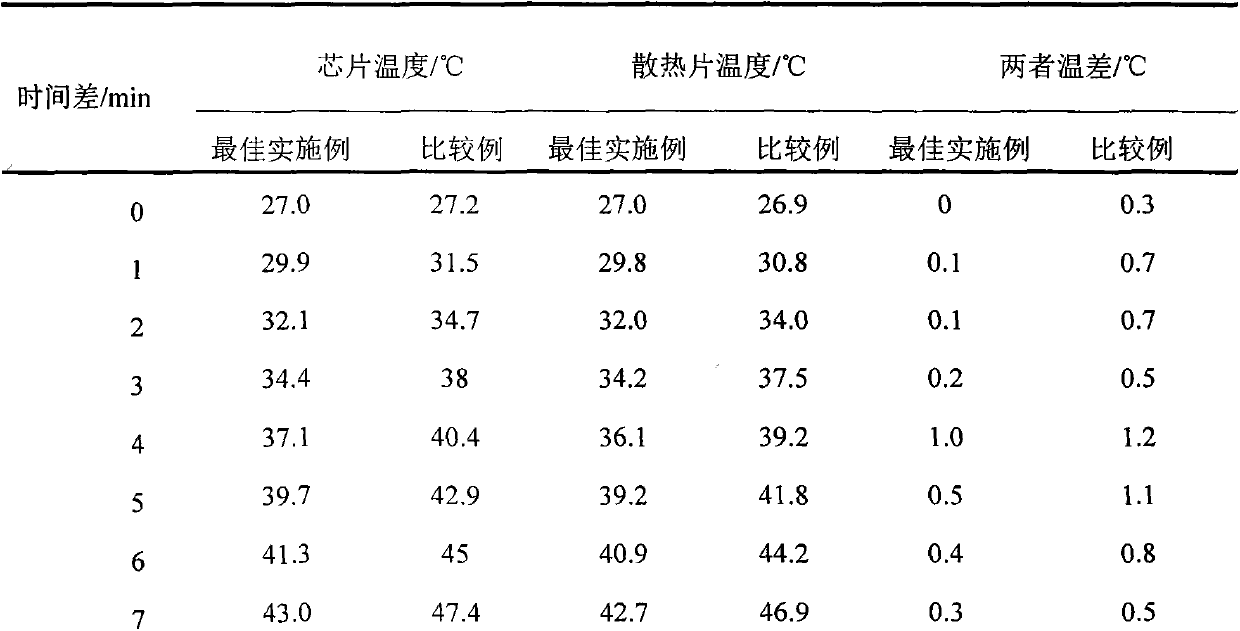

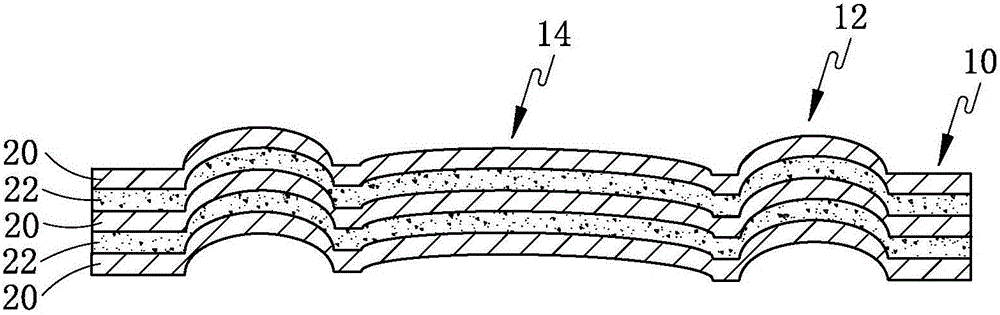

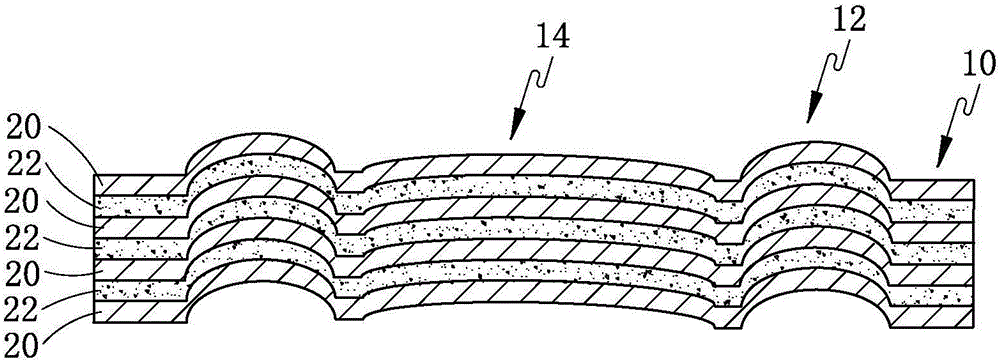

Vibrating diaphragm and micro acoustic generator equipped with vibrating diaphragm

ActiveCN105933831AImprove rigidityStrong heat resistancePolymeric diaphragmsNon-planar diaphragms/conesDamping factorTotal harmonic distortion

The invention discloses a vibrating diaphragm and a micro acoustic generator equipped with the vibrating diaphragm, and relates to the technical field of electroacoustic products. The vibrating diaphragm has a multilayer composite structure which comprises thermoplastic elastomer layers and adhesive film layers which are alternately stacked together. According to the vibrating diaphragm and the micro acoustic generator equipped with the vibrating diaphragm, the technical problems in the prior art that a micro loudspeaker has poor F0 stability and high total harmonic distortion can be solved. The vibrating diaphragm and the micro acoustic generator equipped with the vibrating diaphragm are low in total harmonic distortion and damping coefficient, higher in F0 stability and high in sound quality so that the requirements of people for the high sound quality of electronic equipment can be met.

Owner:GOERTEK INC

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

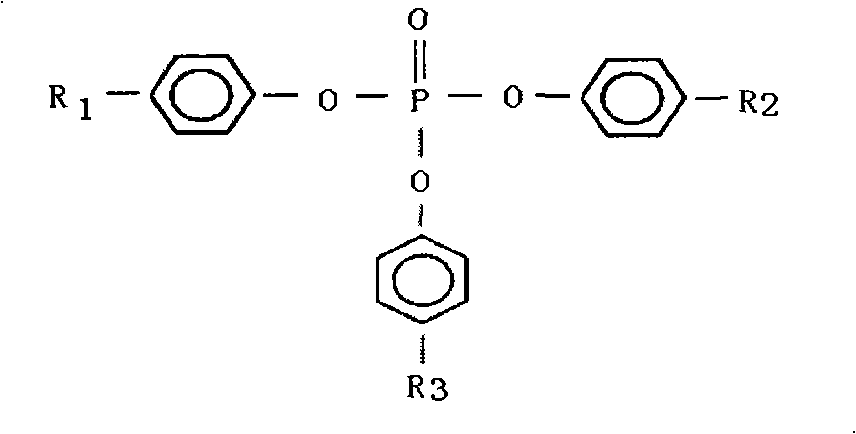

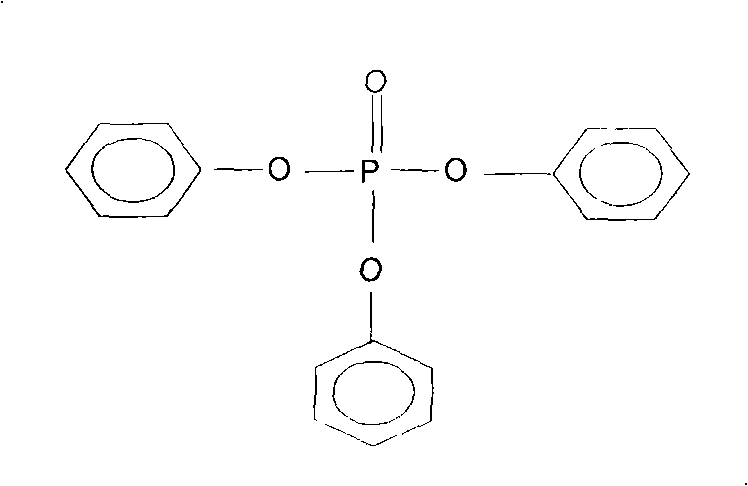

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Low-temperature SCR (Selective Catalytic Reduction) catalyst based on active coke loaded manganese-cerium composite oxide and preparation method of low-temperature SCR catalyst

ActiveCN103433034AHigh catalytic activityEnhance oxygen circulationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrogen oxides

The invention provides a low-temperature SCR (Selective Catalytic Reduction) catalyst based on an active coke loaded active component and a preparation method of the low-temperature SCR catalyst. The catalyst is suitable for SCR reaction of nitrogen oxides under the condition of low temperature. A Mn and Ce composite oxide is loaded on an active coke particle with a relatively high special surface area and mechanical strength, so that the SCR reaction temperature is reduced, the adsorption capability and mechanical wear resistance of the catalyst are improved, and the whole sulfate resistance and regeneration capability of the catalyst are improved. The preparation method provided by the invention is simple in step, artful in process design and convenient for industrial production. The catalyst provided by the invention takes the active coke particle as a carrier on which the Mn and Ce composite oxide is loaded. Oxides of modified elements can also be loaded on the carrier of the catalyst, wherein the modified elements are selected from one or more of the following elements: Fe, Zr, Si, Ti, V, Mo, W, Cr, Au, Ag, Pt, Pd, Rh and Co.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

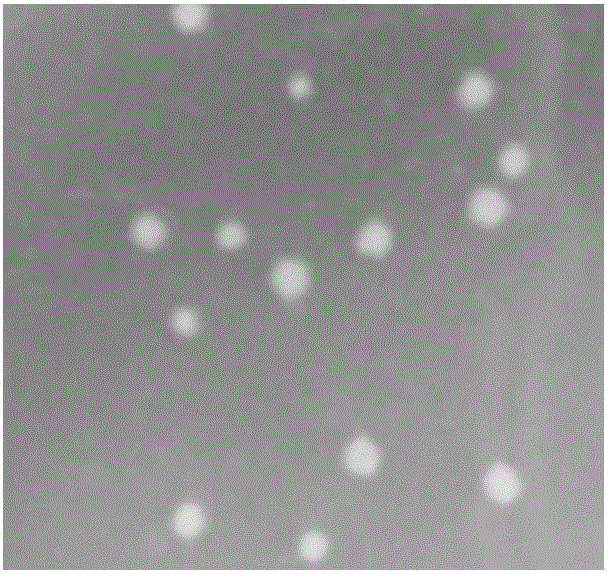

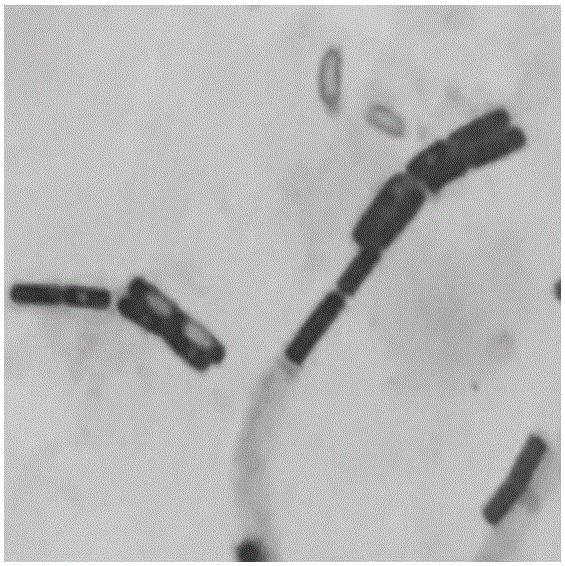

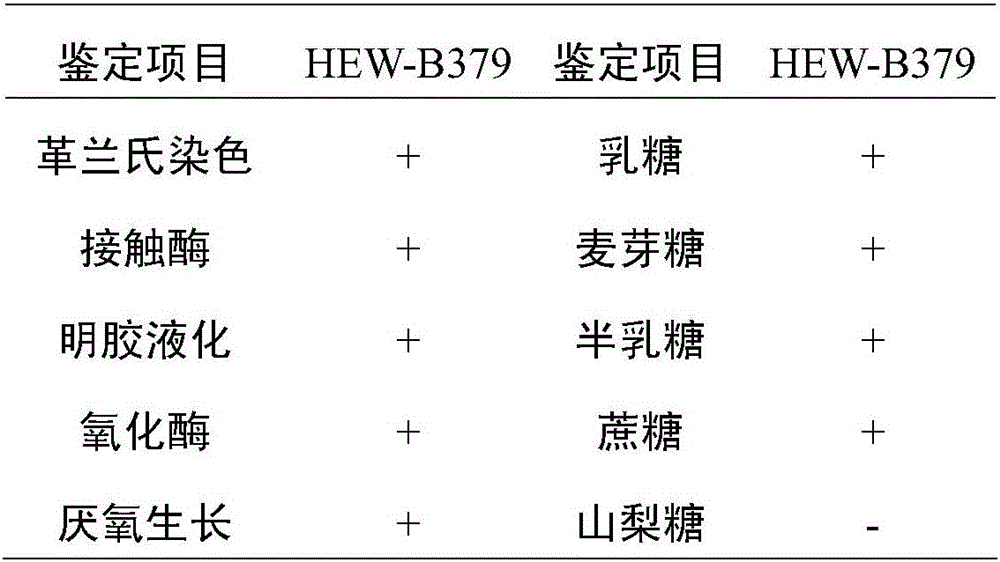

Bacillus coagulans HEW-B379 with probiotic effect, and application thereof

ActiveCN106011036AStrong heat resistanceStrong fermentation abilityAntibacterial agentsBacteriaEscherichia coliFeed conversion ratio

The invention provides a Bacillus coagulans HEW-B379 with a probiotic effect. The above strain is named as HEW-B379, and the preservation number of the strain is CGMCC No.12553. The Bacillus coagulans HEW-B379 has a substantial probiotic property, and can effectively inhibit growth breeding of enteropathogenic Escherichia coli, Staphylococcus aureus, Salmonella typhi, salmonella, Shigella, Proteus species, Shewanella putrefaciens and Pseudomonas aeruginosa. The Bacillus coagulans HEW-B379 has strong stress resistance, can resist high temperature and simulated gastric juice and simulate bile salt environment, can keep the survival rate of 99-100%, and can effectively adjust microbial balance of animal intestinal tracts, inhibit growth of harmful microbes, promote nutrition absorption of animals, improve the conversion rate of a feed and improve the productivity of the animals.

Owner:BEIJING HESWOF BIOTECH CO LTD

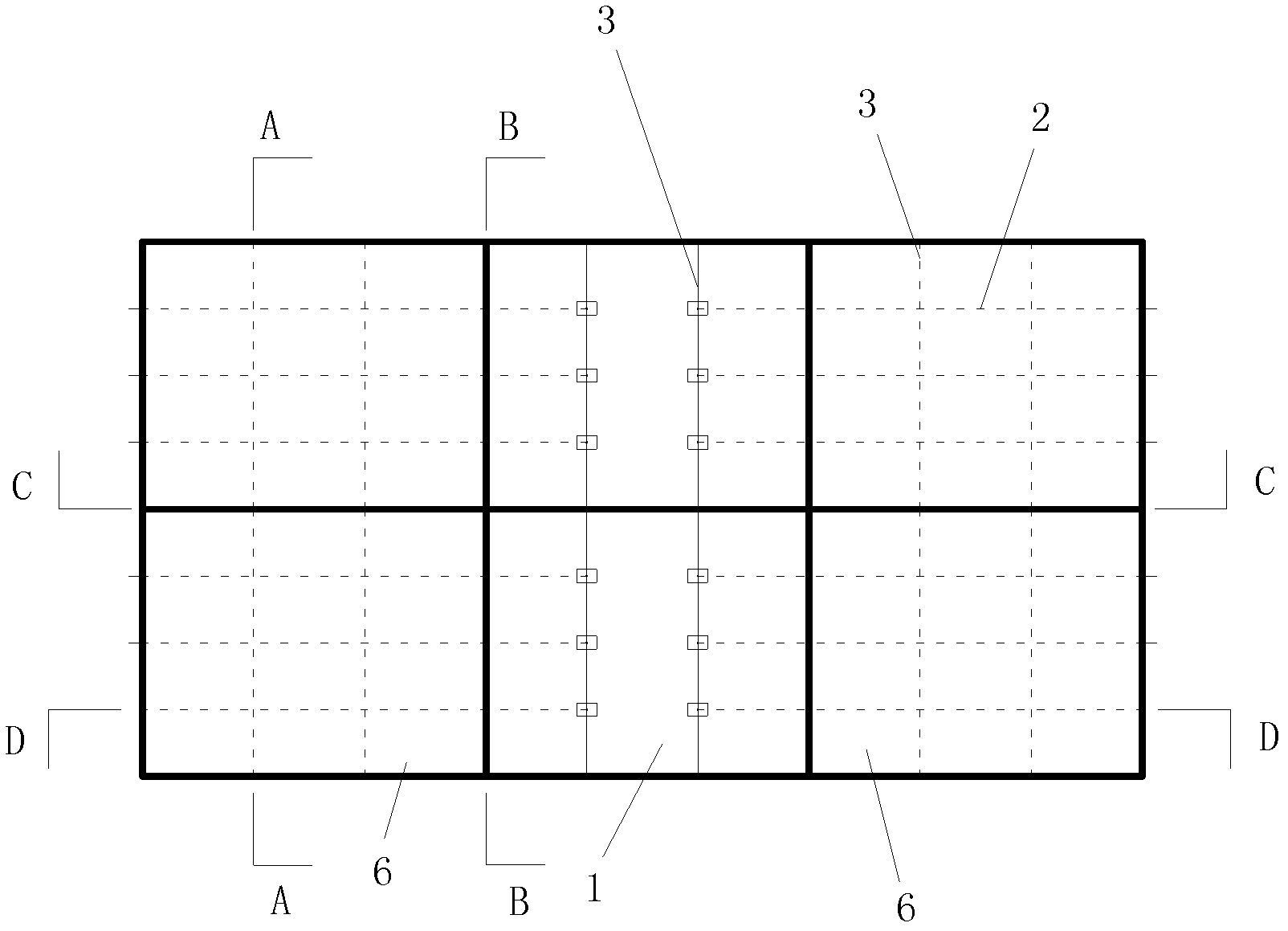

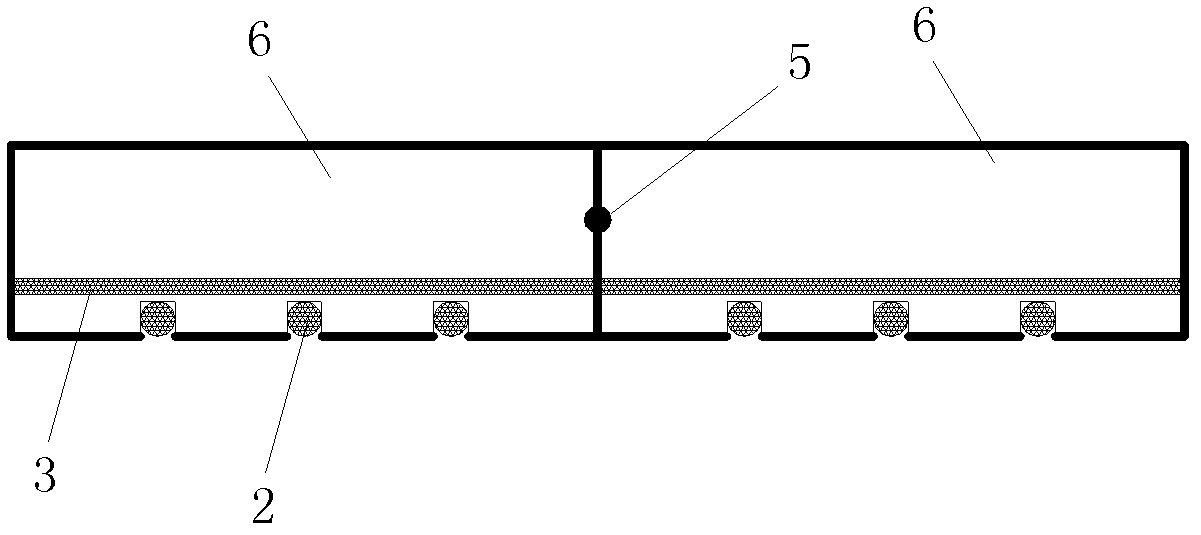

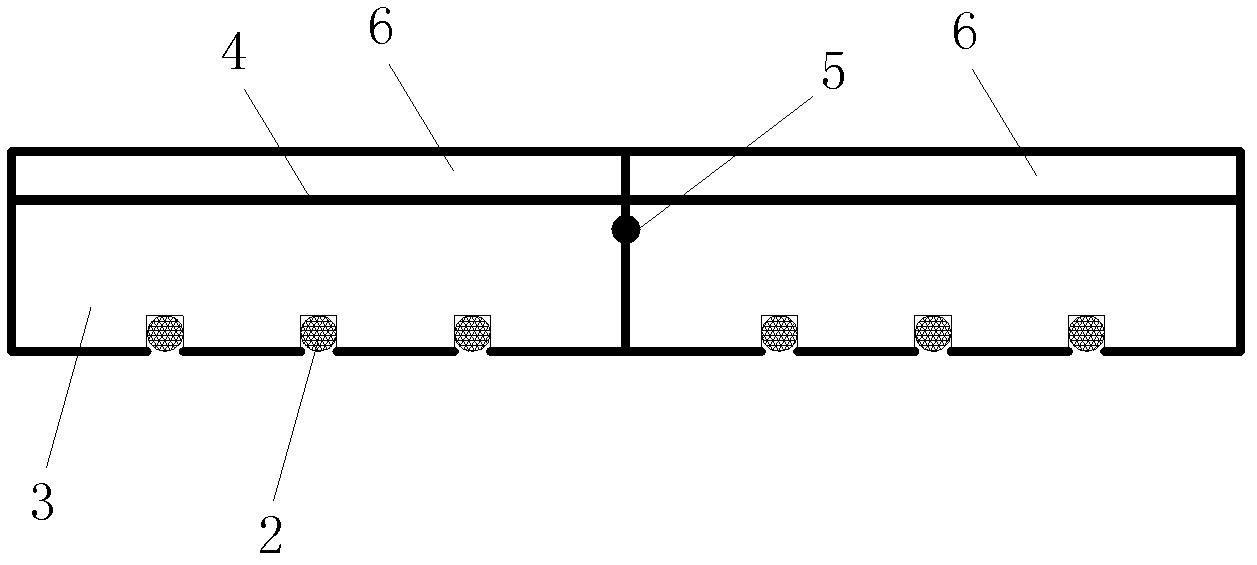

Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

ActiveCN102535295AReasonable structural designEasy to laySingle unit pavingsPaving detailsHeat resistancePre stress

The invention discloses a fabricated prestressed heat-resistant cement concrete pavement and a construction process thereof. The pavement is formed by splicing a plurality of fabricated prestressed heat-resistant pavement plates which are parallelly paved and connected into a whole through transverse prestressed steel stranded wires, wherein each fabricated prestressed heat-resistant pavement plate comprises a fabricated prestressed pavement plate which consists of a plurality of pavement plate blocks connected through connecting plates, and a vermiculite concrete heat-resistant paving layer which is paved on the fabricated prestressed pavement plate; each pavement plate block comprises a plurality of common plates which are connected into a whole through longitudinal prestressed steel stranded wires; and the connecting plates and the common plates are cement concrete prefabricated plate blocks. The construction process comprises the following steps of: 1, prefabricating the cement concrete prefabricated plate blocks; 2, transporting the cement concrete prefabricated plate blocks; and 3, paving the pavement. The pavement is reasonable in structural design, convenient to construct, low in input cost and short in construction period, and has heat resistance, construction quality is easy to ensure, and various practical problems of the traditional fabricated cement concrete pavement can be solved.

Owner:CHANGAN UNIV

Flame-retardant anti-dropping resin composition

InactiveCN101348603AExcellent and durable flame retardantLittle impact on mechanical propertiesPolyesterFiber

The invention discloses a flame-retardant anti-dripping resin compound, consisting of 100 weight portions of thermoplastic resin, 0.01-5 weight portions of modified polytetrafluoroethylene anti-dripping agents and 20 to 40 weight portions of environment-friendly flame retardant containing phosphorus and / or nitrogen. The resin compound has strong anti-dripping effect and heat resisting performance, is level and smooth in exterior appearance, and can endow polyester fiber products with excellent enduring flame retardancy without using halogen (Cl and Br) flame retardant. The resin compound has the advantages of high oxygen index, droplet resistance, low heat release rate, no halogen, little toxicity, low smoke dust emission, little influence on the mechanical properties of base materials, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Magnesium alloy non-chromium dacro solution paint and its preparation method

InactiveCN1786091AStrong adhesionGood weather resistanceLiquid surface applicatorsAnti-corrosive paintsCross-linkHeat resistance

The present invention discloses a magnesium alloy chrome-free dyclo solution coating and its production method. It is characterized by that the organic silicon and nano powder body undergone the process of nano dispersing liquor treatment are dispersed in the resin made up by using several resins through the process of polymerization and cross-linking reaction to make modification, and mixed with zinc powder and aluminium powder so as to obtain the invented acid-resistant, alkali-resistant, salt fog resistant, impact-resistant and corrosion-resistant magnesium alloy chrome-free dyclo solution coating.

Owner:长春吉大化学有限公司

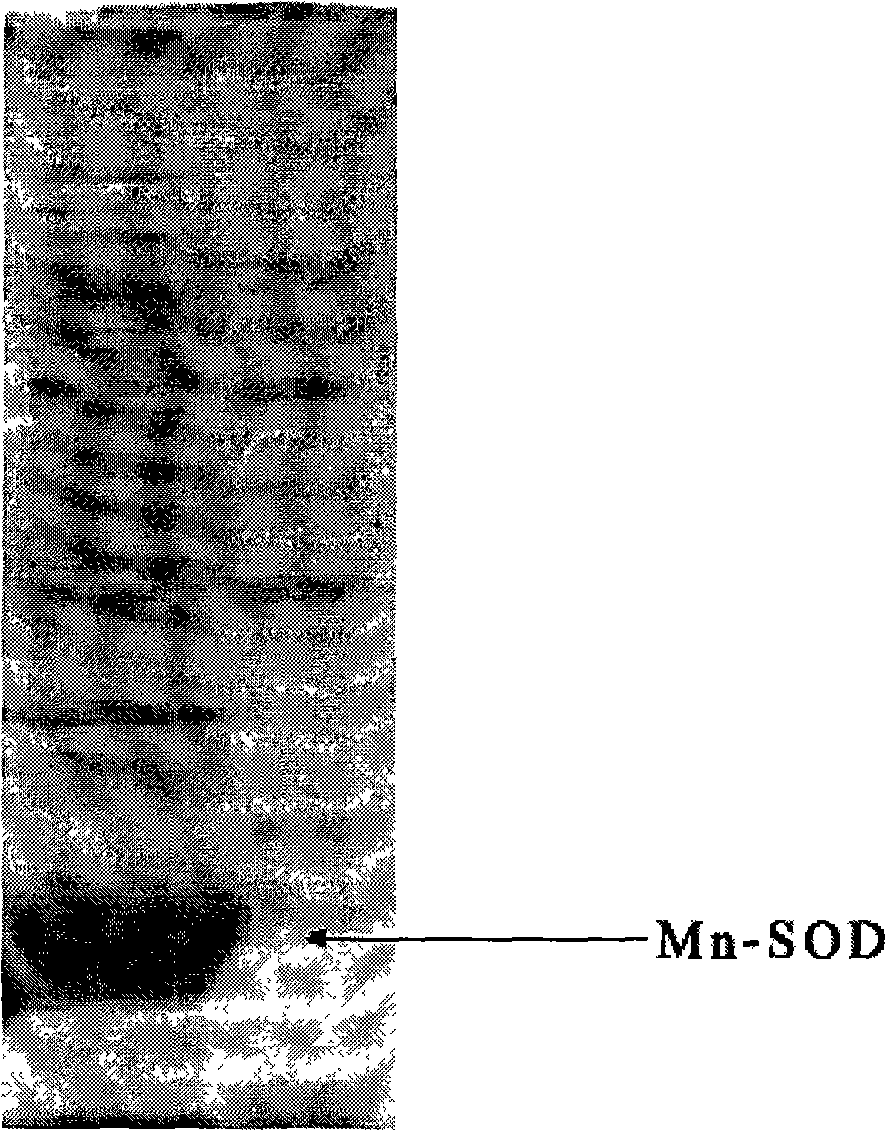

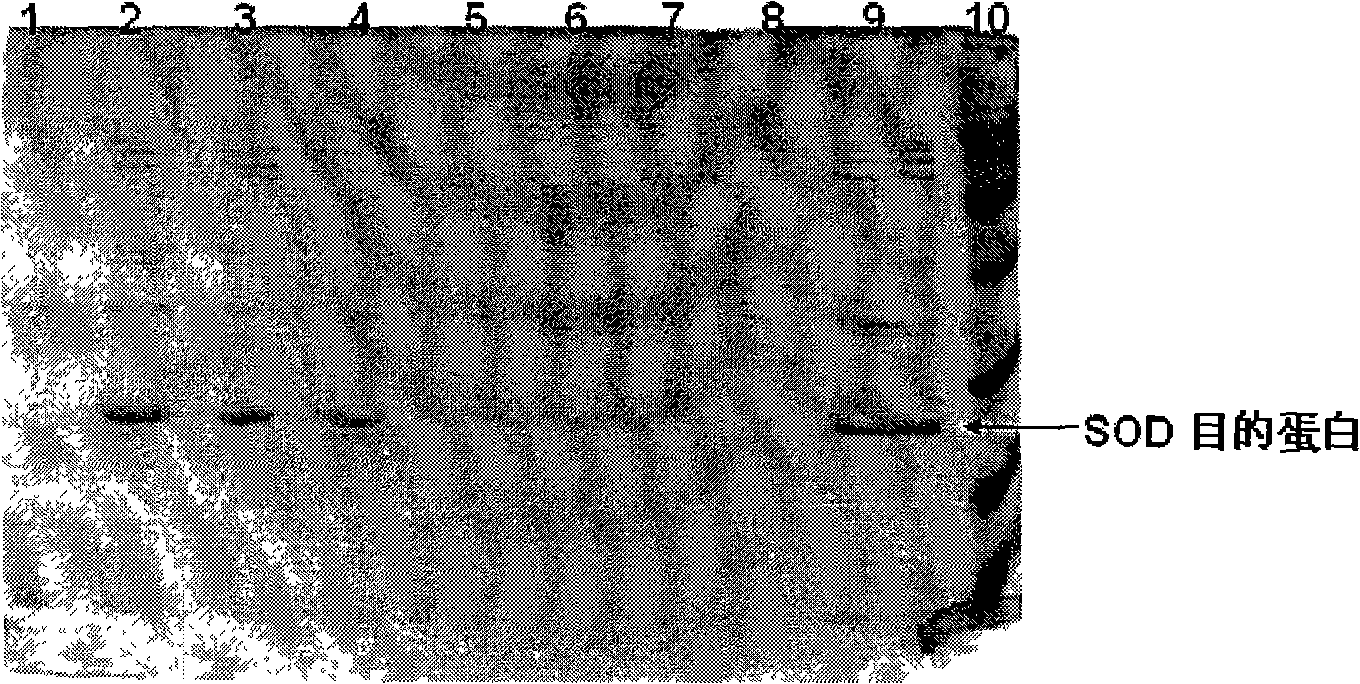

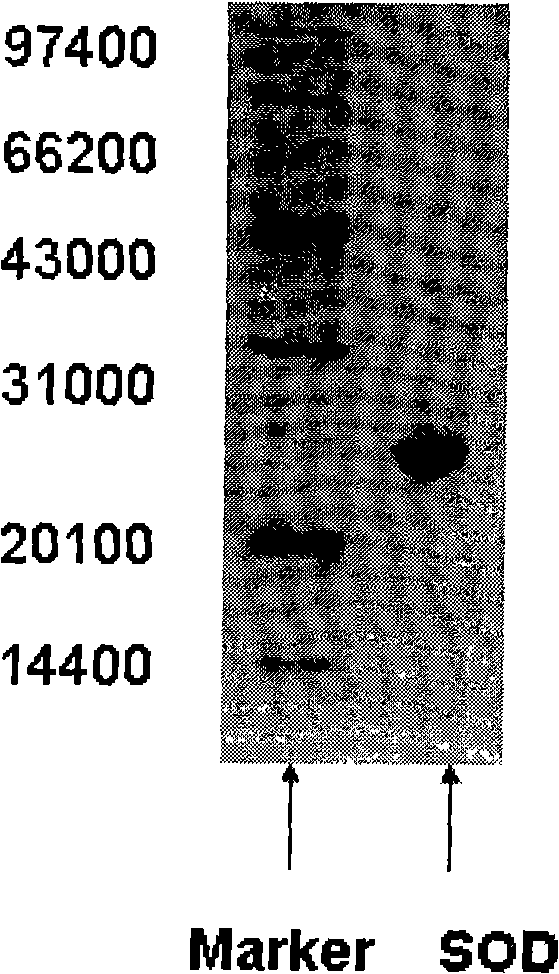

High-density fermentation and purification process for recombination high temperature-resistant hyperoxide dismutase

InactiveCN101275144AAvoid pollutionSimple purification processBacteriaMicroorganism based processesEscherichia coliDismutase

The present invention provides a high density fermentation and a purification process of a recombination high temperature resistance superoxide dismutase, the construction method of the invention includes: using gene coded for SOD in a thermophilic bacteria as a template, designing specific primer amplification target gene having restriction enzyme sites, after double digestion, connecting to plasmid vector pET28a after the same double digestion, constructing a recombinant plasmid, named for pSOD, transforming plasmid pSOD to competence escherichia coli BL21(DE3) by chemical transformation method, obtaining strain having high SOD yield after screening, completing the construction of SOD engineering bacteria; the fermentation process includes four steps of first order seed culture, secondary order feed culture, batch fermentation and induced expression, fermentation product SOD is finally obtained; the fermentation process realizes high level expression of SOD, the expression of the target protein is more than 60% of the bacterial protein total; SOD has excellent thermal stability and heat resistance, the expression product accounts for more than 60% of the whole proteins, and fully soluble protein, avoiding any trouble in the course of inclusion body renaturation; the purification process is simple, having high yield, lower cost, the final product SOD has high purification, high activity and strength stability.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +1

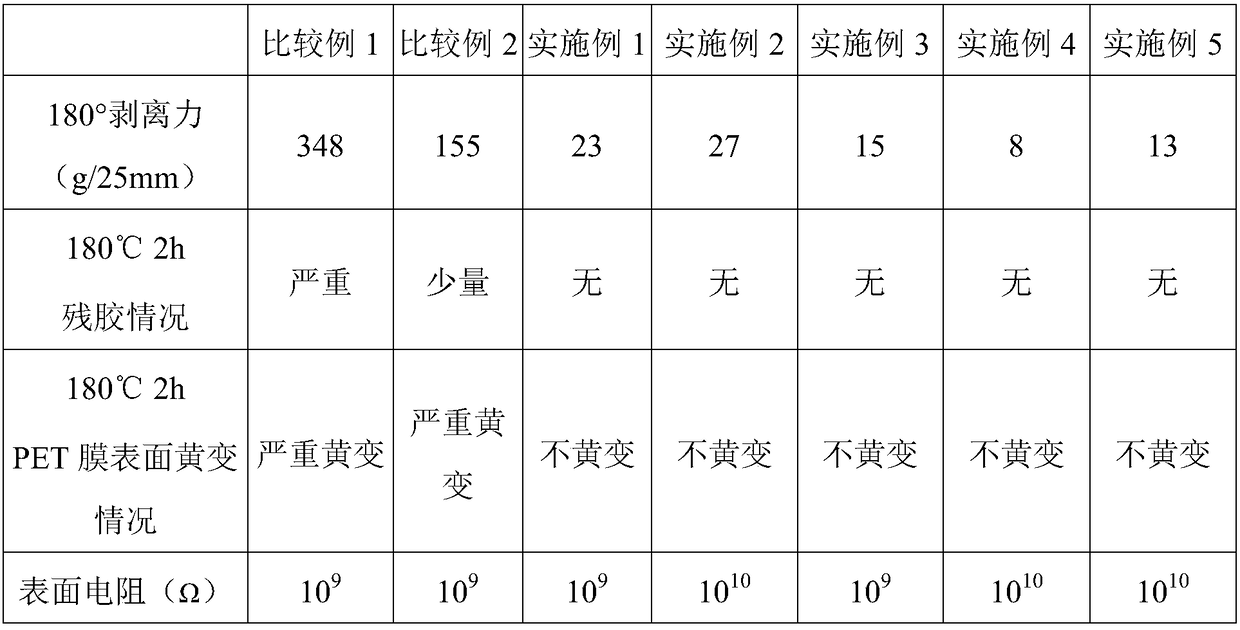

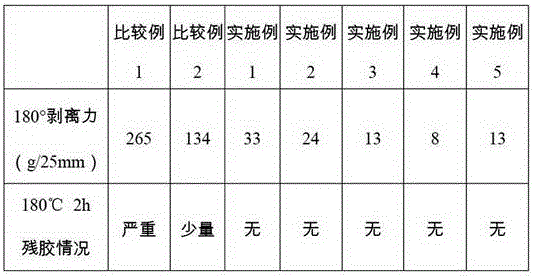

An antistatic high-temperature resistant acrylate pressure-sensitive adhesive, and a preparation method and application thereof

InactiveCN108753196AImprove antistatic performanceStrong heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFunctional monomerAntistatic agent

An antistatic high-temperature resistant acrylate pressure-sensitive adhesive, and a preparation method and application thereof are disclosed. The pressure-sensitive adhesive includes a component (A)and a component (B). The component (A) is prepared from, by weight, 4-8% of a hard monomer, 18-28% of a soft monomer, 2-8% of a functional monomer, 1-3% of a heat-resistant monomer, 65% of a solvent,and an initiator the weight of which is 0.1-0.5% of the total weight of the hard monomer, the soft monomer, the functional monomer and the heat-resistant monomer. The component (B) includes one or more selected from a curing agent, an auxiliary agent and an antistatic agent. The weight of the curing agent, the weight of the auxiliary agent and the weight of the antistatic agent account for 2-5%, 0.1-1% and 0.1-1% respectively of the total weight of the component (A). The pressure-sensitive adhesive has good heat resistance and good antistatic performance and is free of softening, yellowing andresidual adhesive at high temperature.

Owner:WUXI HAITE NEW MATERIAL RES INST

Preparation method and product of low-roughness polyimide film and application of product

ActiveCN104672477AReduce roughnessReduce surface roughnessPhotovoltaic energy generationSemiconductor devicesCeiling temperaturePolyamide

The invention discloses a preparation method and a product of a low-roughness polyimide film and application of the product. The preparation method comprises four steps, including synthesis and treatment of polyamide acid, curtain coating, pre-drying of the film and imidization, and the preparation method comprises the following concrete steps: taking biphenyl diamine and dianhydride as polyamide acid synthesizing monomers; controlling the temperature of a curtain coating substrate to be above 30 DEG C before film formation; drying and imidizing the film by adopting a programmable temperature increment mode, wherein the highest drying temperature is 130 DEG C; the highest imidization temperature is not lower than 450 DEG C. The prepared polyimide film is flat in surface, smaller than or equal to 10nm in surface roughness, larger than 300MPa in tensile strength, larger than 330 DEG C in glass-transition temperature, smaller than 1% in thermal shrinkage rate and smaller than 20ppm / DEG C in thermal expansion coefficient (CTE). The preparation method disclosed by the invention is safe in overall technological process, free of use of expensive equipment, simple in operation procedures and easy in control on surface appearance of the film.

Owner:CHINA LUCKY FILM CORP

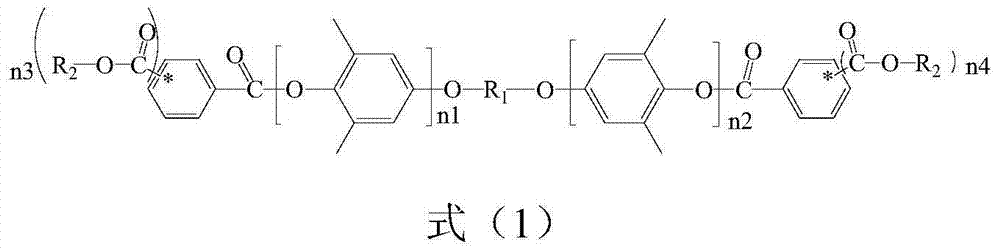

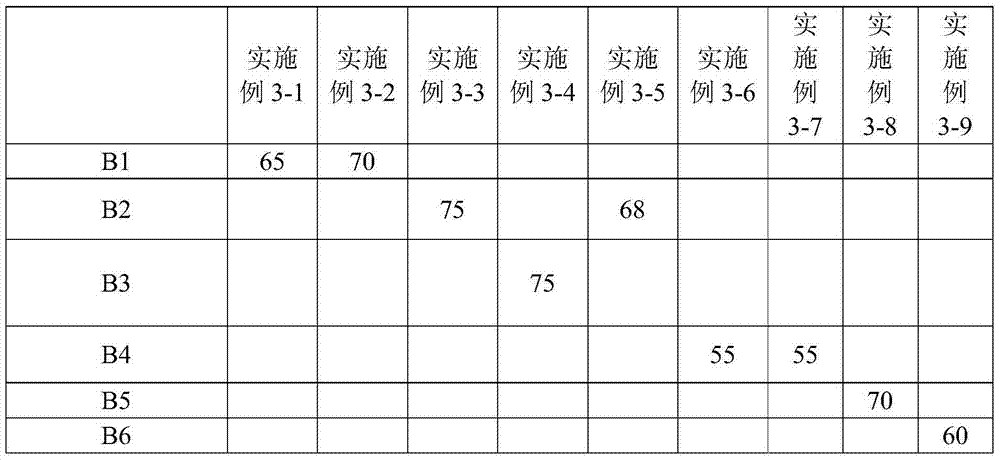

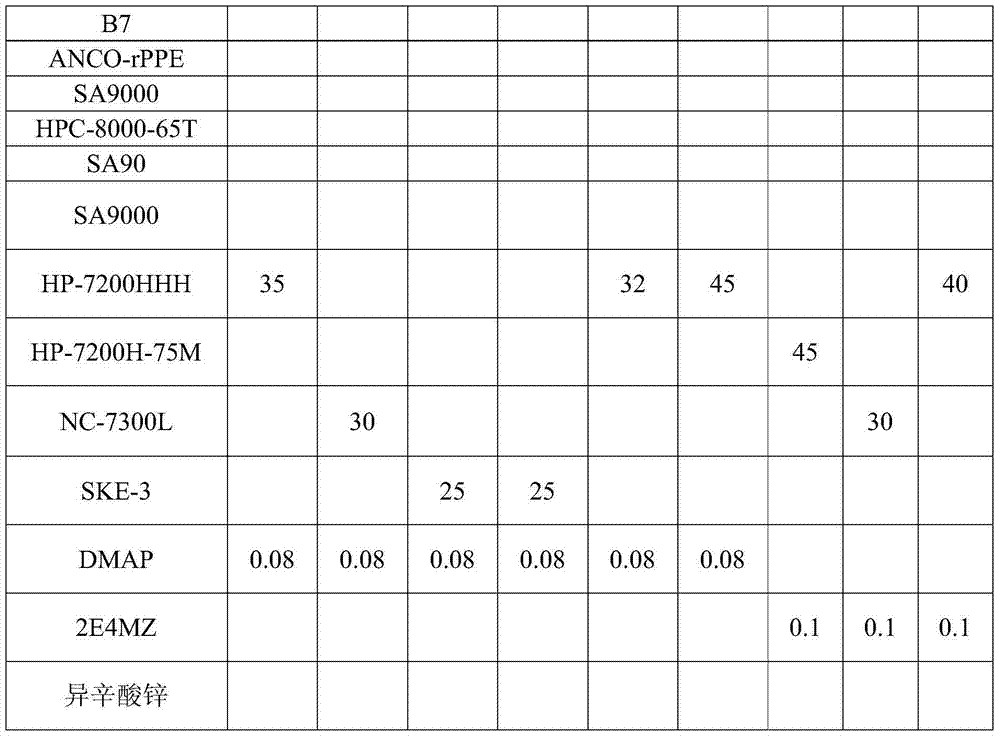

Active ester, thermosetting resin composition containing active ester, prepreg and laminated board

InactiveCN104761719AImprove heat resistanceStrong heat resistanceSynthetic resin layered productsPrinted circuit aspectsEpoxyHeat resistance

The invention provides active ester, a thermosetting resin composition containing the active ester, a prepreg and a laminated board. The active ester is a double-ended polyfunctional active ester containing a PPO main chain, and the thermosetting resin composition comprises epoxy resin and the double-ended polyfunctional active ester containing the PPO main chain. The prepreg, the laminated board and a copper-clad plate prepared from the thermosetting resin composition containing the double-ended polyfunctional active ester containing the PPO main chain has excellent dielectric properties, damp-heat resistance, heat resistance, extremely low water absorption and high bending strength.

Owner:GUANGDONG SHENGYI SCI TECH

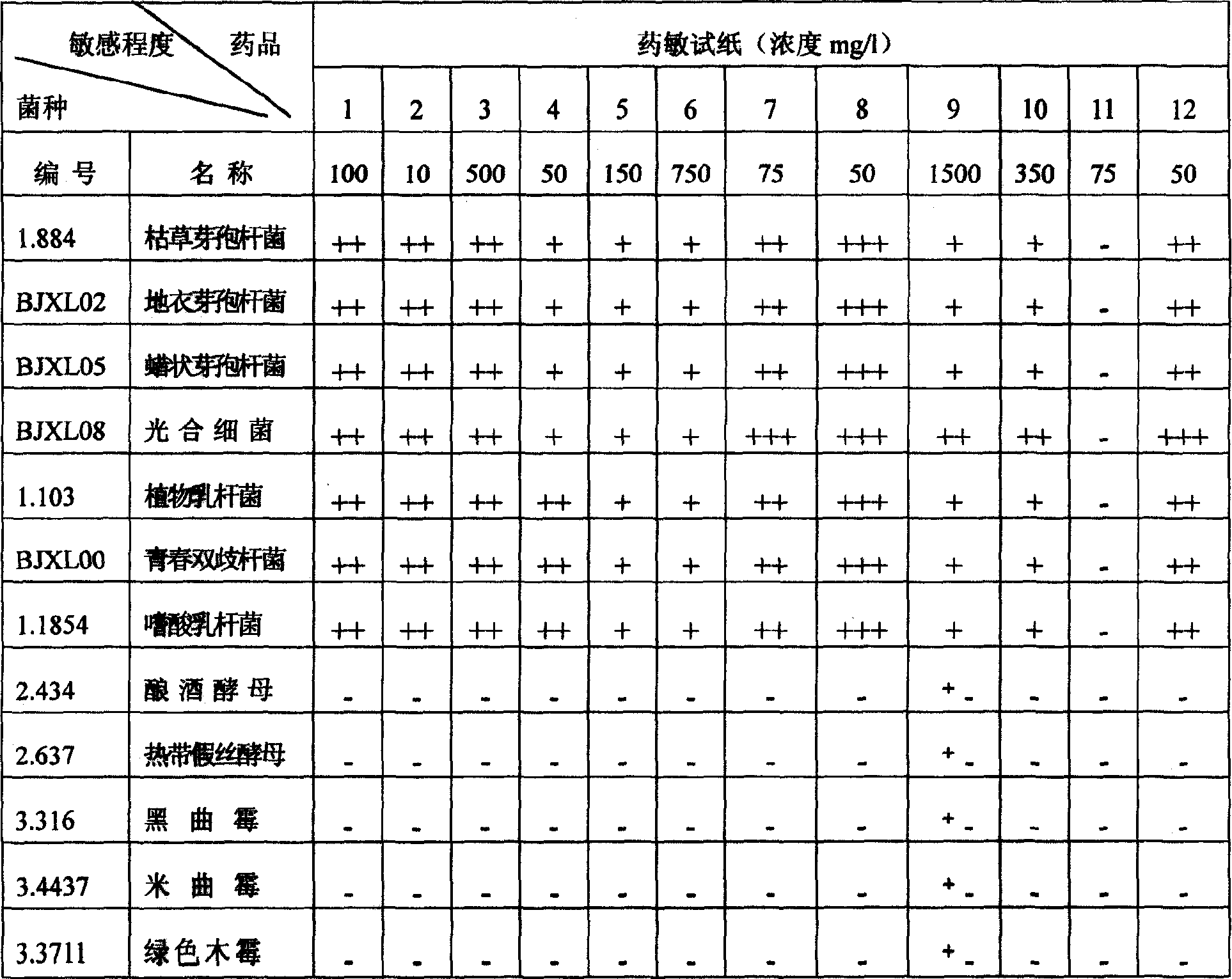

Highly efficient oligosaccharide high yielded enzyme composite animal microecological formulation without public hazard and its preparing method

InactiveCN1653932AHigh activityStrong ColonizationAnimal feeding stuffAccessory food factorsBacillus licheniformisCandida tropicalis

The composite microecological animal preparation consists of Bacillus cereus 10-15 wt%, Bacillus subtilis 10-15 wt%, Bacillus licheniformis 10-15 wt%, Saccharomyces cerevisiae 1-5 wt%, Candida Tropicalis 1-5 wt%, photosynthetic bacterium 1-5 wt%, plant lactobacillus 0.5-3 wt%, acidophilic lactobacillus 0.5-3 wt%, ephebic bifidobacterium 1-3 wt%, Aspergillus niger 0.5-3 wt%, Aspergillus oryzae 0.5-3 wt%, viridin 0.5-3 wt%, oligosaccharide 5-10 wt% and carrier 30-50 wt%. Its preparation process includes the following steps: 1) high temperature resisting domestication of the said strain, drug resisting domestication, preservation and strain passage; 2) activating the preserved strain, fermentation, coating with microcapsule and drying; and 3) crushing dried strain, and mixing with oligosaccharide and carrier. The present invention is one kind of high efficiency green feed additive.

Owner:宝鸡市星星协力生物有限公司

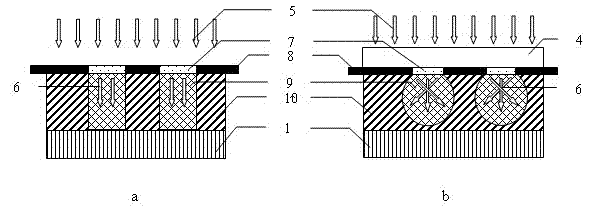

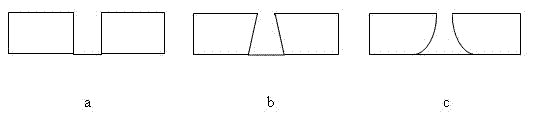

Negative photoresist-based diffuser photo-etching process

InactiveCN102520591AStrong heat resistanceImprove stabilityDiffusing elementsPhotomechanical exposure apparatusLithography processPhysical chemistry

The invention relates to a negative photoresist-based diffuser photo-etching process, which comprises the following steps that: firstly, photoresist is coated on the surface of an underlay, then the underlay which is coated with the negative photoresist in a rotating way is prebaked so as to remove solvent of the negative photoresist; then exposure is carried out, a diffuser is arranged on a mask plate, and the diffuser and the mask plate are used as a mask to perform ultraviolet exposure on the negative photoresist; finally the post-baking and developing are carried out, the negative photoresist in an exposure area is cross-linked in the post-baking process and is free from being dissolved in developing liquid, and a structure with a particular cross section is obtained; and the diffuser and the mask plate are collectively used as the mask to anticipate the exposure of the photoresist. The negative photoresist-based diffuser photo-etching process has advantages of wide application range, simple technique process, good technical repeatability, unnecessary modification of present photo-etching equipment, low cost, easiness in mass production and the like.

Owner:SOUTHEAST UNIV

High-temperature-resistant acrylic ester pressure sensitive adhesive and preparation method thereof

ActiveCN106675462AStrong heat resistanceSmall peeling forceEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerSolvent

The invention discloses a high-temperature-resistant acrylic ester pressure sensitive adhesive. The pressure sensitive adhesive is prepared from raw materials in percentage by weight as follows: 4%-8% of hard monomers, 18%-28% of soft monomers, 2%-8% of functional monomers, 1%-3% of heat-resisting monomers and 65% of a solvent. The pressure sensitive adhesive has higher heat resistance and smaller stripping resistance and does not have residues when cooled to the room temperature after being treated at the high temperature of 180 DEG C, adhesive water does not get yellow under the high temperature condition, and the pressure sensitive adhesive is easy to strip and good in damp heat resistance and well solves the problem of use under high-temperature conditions in all industries. Besides, an actual solution is provided for the fields such as electronic technology, medical treatment, military affairs, aerospace and the like.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

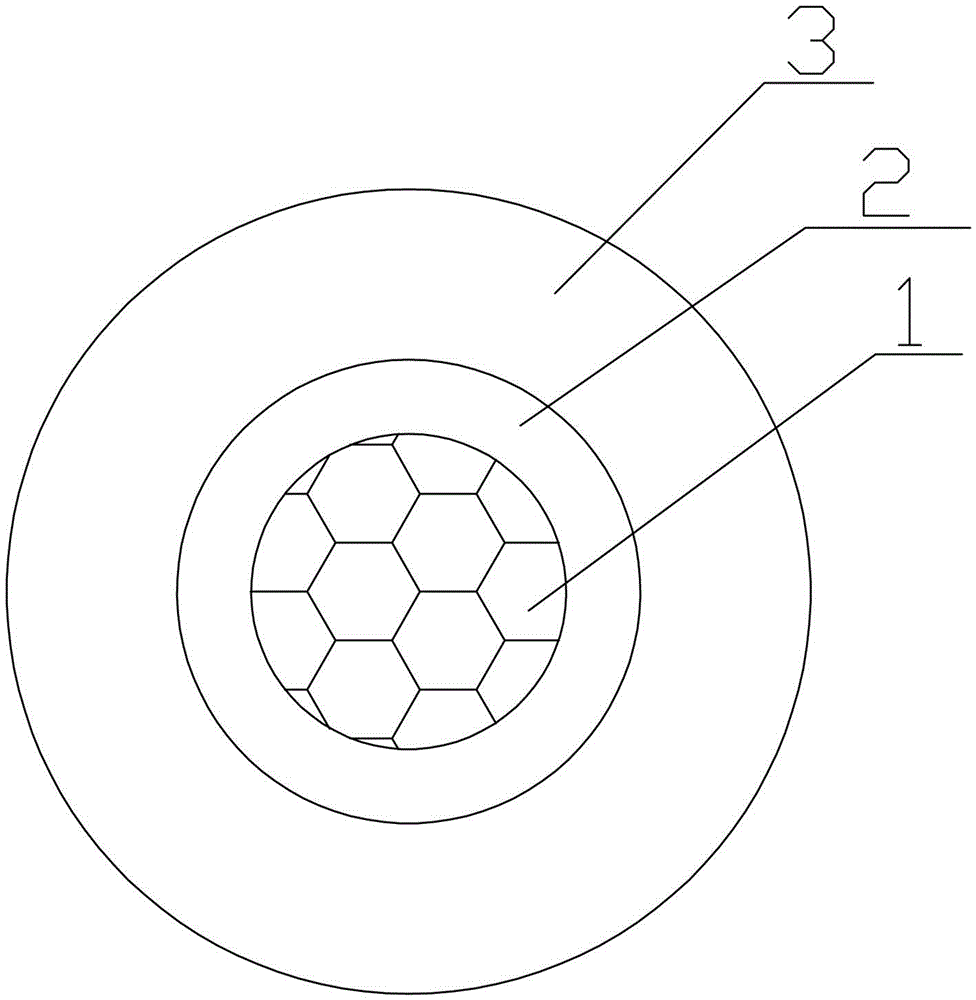

Anti-icing cable

ActiveCN105390189AAchieving Hydrophobic PropertiesAchieve strengthPower cables with screens/conductive layersInsulated cablesGlass fiberAntioxidant

The invention discloses an anti-icing cable. The cable comprises a core, a shielding layer and an anti-icing layer arranged in sequence from inside to outside, wherein the anti-icing layer comprises the following raw materials by weight: 60-75 parts of fluorosilicon resin, 20-30 parts of methyl vinyl silicone rubber, 10-15 parts of SiO2-glass fiber gel, 5-8 parts of polypropylene fiber powder, 3-5 parts of nano SiO2, 4-6 parts of nano TiO2, 0.5-1 part of a dispersing agent, 0.5-1.5 parts of a flame retardant, 1-2 parts of a silane coupling agent and 1-2 parts of an antioxidant. The anti-icing cable has excellent hydrophobic property and anti-icing performance, and is excellent in insulating performance, high in compressive strength, high in flexibility and anti-aging; and the anti-icing layer of the anti-icing cable can replace the insulating layer in the cable and a sheath outside the cable, so that the cable mass is lowered and the service life of the cable is prolonged.

Owner:STATE GRID HENAN DENGZHOU POWER SUPPLY CO

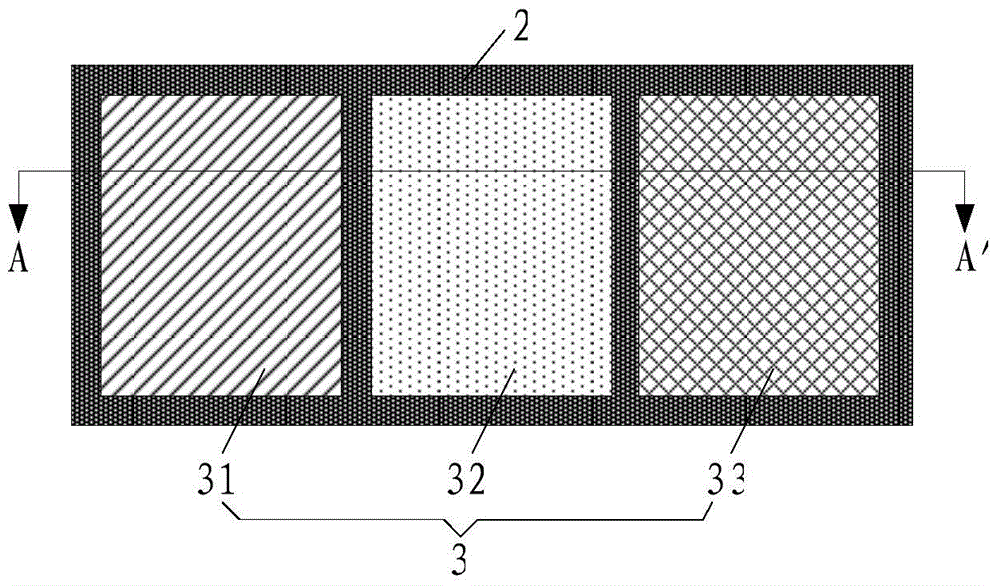

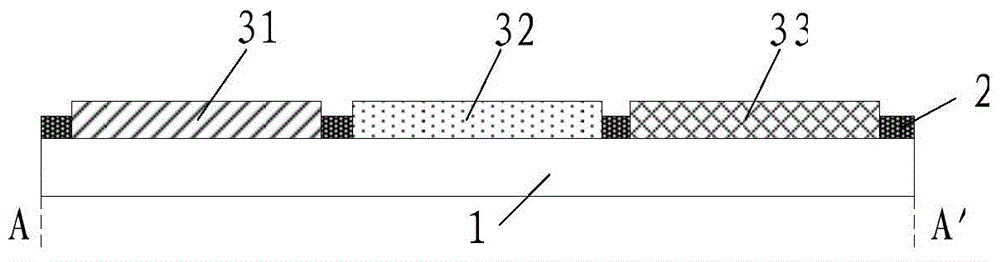

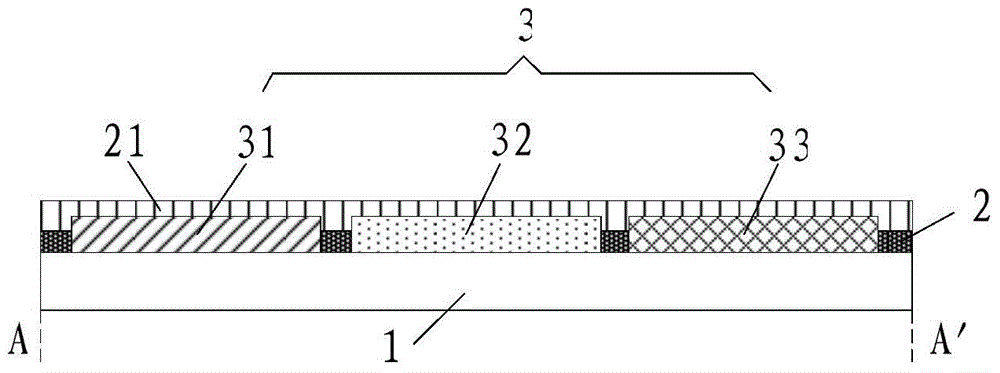

Displaying base plate, manufacture method thereof and display device

InactiveCN104090413AStrong heat resistanceHigh color purityNon-linear opticsOptical elementsHeat resistanceQuantum dot

The invention provides a displaying base plate, a production method thereof, and a display device, relates to the field of display technology, and solves the problems of poor heat resistance and low color saturation in a conventional color film. The displaying base plate comprises a substrate base plate, a color film arranged on the substrate base plate, and a first blocking layer positioned on the color film; the material of the color film comprises quantum dots, and the first blocking layer is used for enabling the color film to be isolated from air.

Owner:BOE TECH GRP CO LTD +1

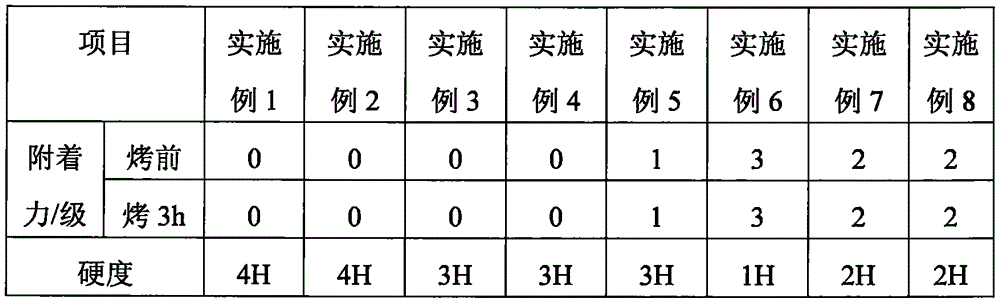

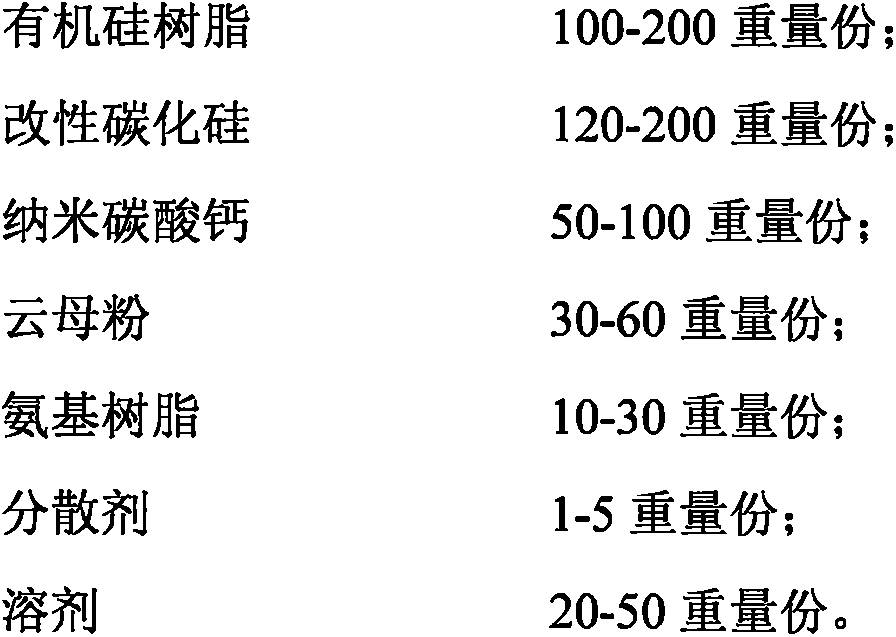

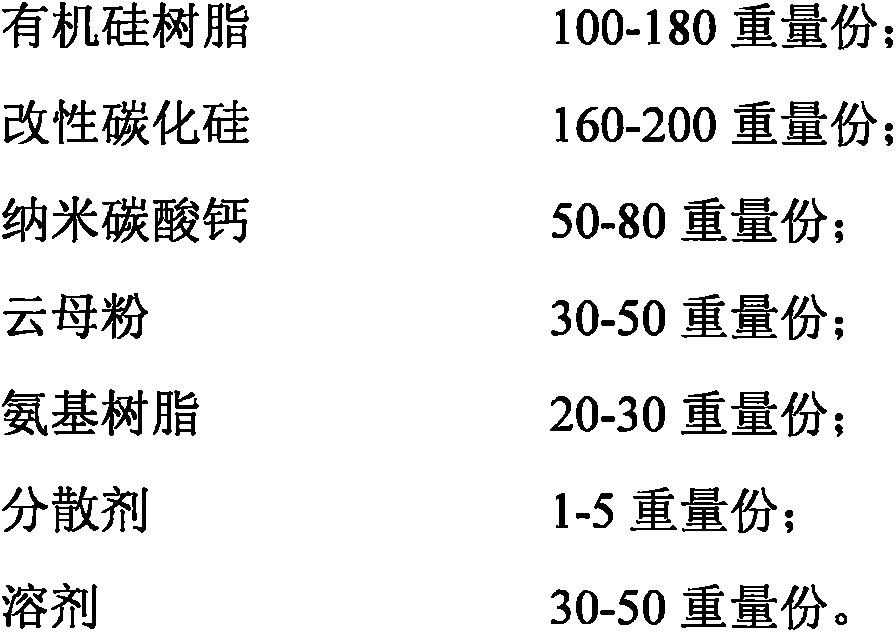

Nonstick pan coating layer, and production method and nonstick pan thereof

ActiveCN105925176AHigh hardnessImprove heat resistanceCooking-vessel materialsAnti-corrosive paintsPorositySolvent

The invention provides a nonstick pan coating layer, and a production method and a nonstick pan thereof. The production method comprises the following steps: mixing organosilicone resin, modified silicon carbide, nanometer calcium carbonate, mica powder, amino resin, a dispersant and a solvent, grinding the obtained mixture, dispersing the ground mixture, and filtering the dispersed mixture to obtain a coating; and spraying the coating on the surface of a metal pan matrix, and baking the sprayed metal pan matrix at 200-300DEG C for 10-30min to obtain the nonstick pan coating layer. The organosilicone resin, saturated modified silicon carbide and the nanometer calcium carbonate are simultaneously applied to the nonstick pan coating layer in order to form the coating layer with excellent performances of above three components. The modified silicon carbide has good thermal stability, corrosion resistance and thermal conduction performance, and guarantees the thermal distribution uniformity of the coating layer; the nanometer calcium carbonate makes the microscopic surface of the organosilicone coating layer be tight and have zero porosity, protects the matrix, and enhances the nonstick effect of the coating layer, and the nanometer calcium carbonate and the modified silicon carbide have synergism, and enhance the hardness and the heat resistance of the nonstick pan coating layer.

Owner:宁波贝得厨具有限公司

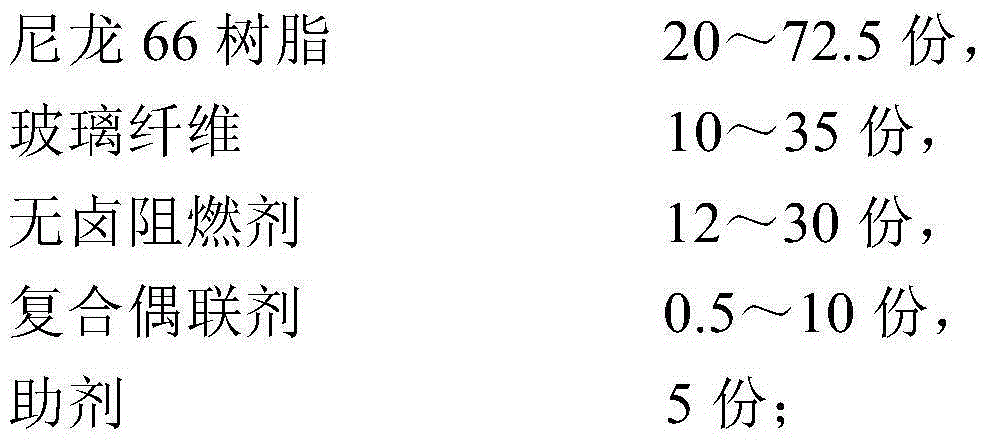

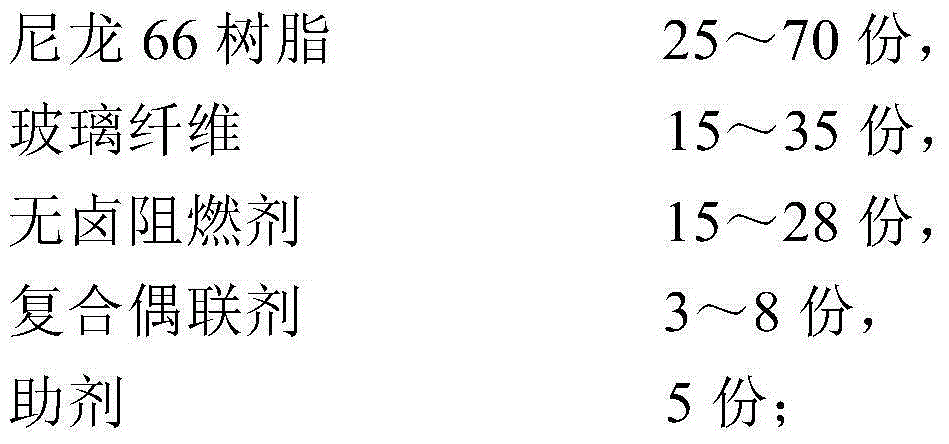

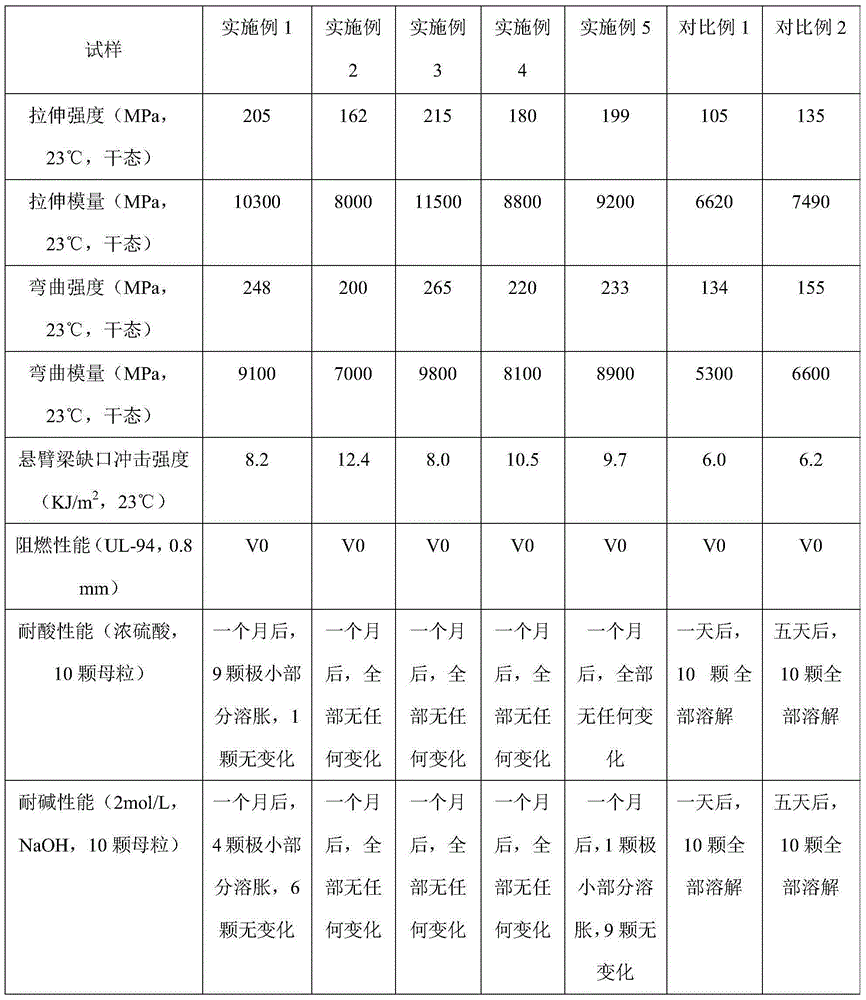

Halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance and preparation method of PA66 composite material

InactiveCN105062050AGood acid and alkali resistanceStrong acid and alkali resistanceEpoxyGlass fiber

The invention discloses a halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance. The PA66 composite material comprises raw materials in parts by weight as follows: 20-72.5 parts of PA66 resin, 10-35 parts of glass fiber, 12-30 parts of a halogen-free flame retardant, 0.5-10 parts of a composite coupling agent and 5 parts of an auxiliary, wherein the composite coupling agent is selected from a mixture formed by mixing gamma-aminopropyl triethoxysilane with gamma-epoxy propoxy propyl trimethoxysilane or epoxy resin in the weight ratio being 1: (1-50). The composite material has higher acid and alkali resistance, good processing fluidity as well as excellent mechanical properties, heat resistance and flame retardation, the problem of insufficient acid and alkali resistance of PA products in the prior art is particularly solved, the acid and alkali resistance is improved remarkably, and the composite material has broad market prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

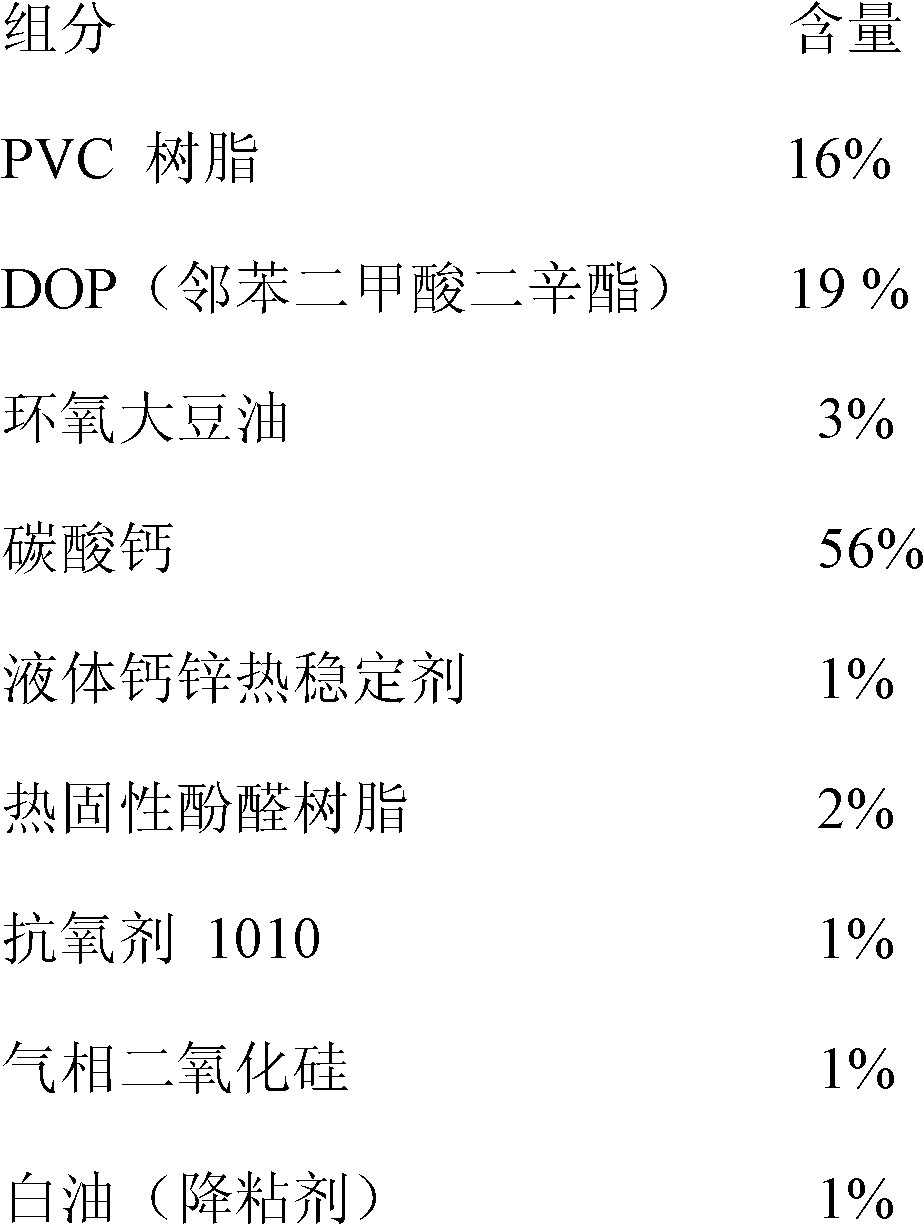

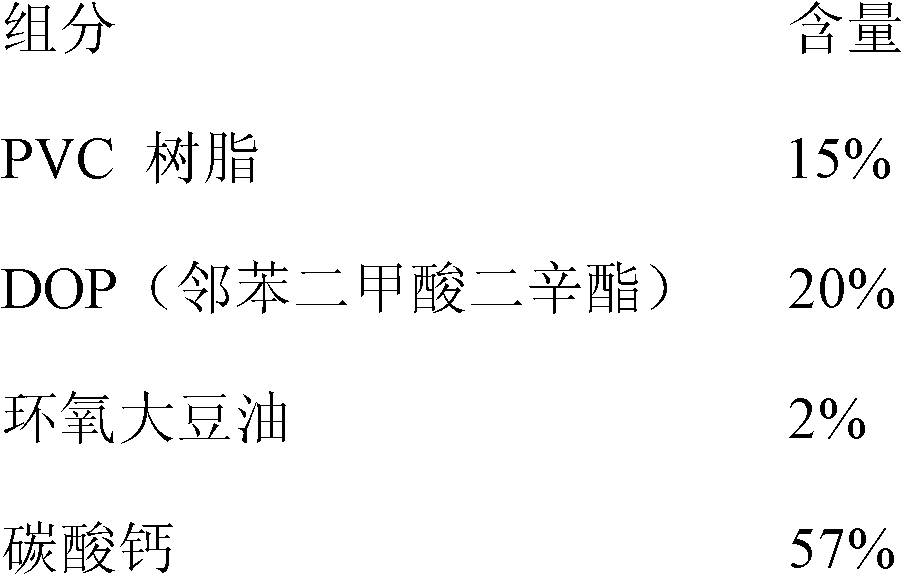

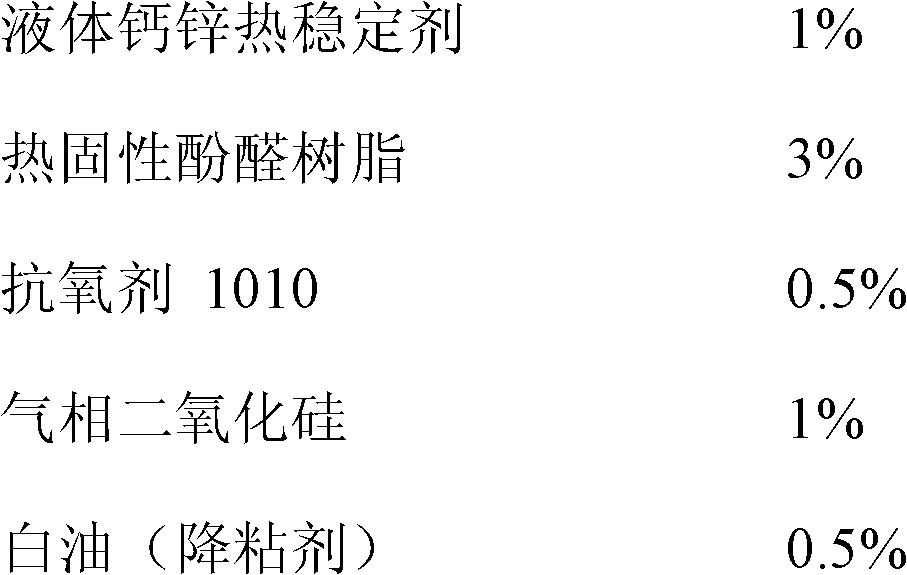

High temperature resistant adhesive for automobile filter

InactiveCN102277105AStrong heat resistanceImprove heat resistanceAldehyde/ketone condensation polymer adhesivesAdhesiveAntioxidant

The invention relates to a high-temperature resistant adhesive for a filter cleaner of an automobile. The adhesive comprises the following raw materials in percentage by weight: 13 to 16 percent of polyvinyl chloride (PVC) resin, 19 to 22 percent of dioctyl phthalate, 2 to 3 percent of epoxidized soybean oil, 55 to 60 percent of calcium carbonate, 0.2 to 1 percent of liquid calcium zinc heat stabilizer, 2 to 5 percent of thermosetting phenolic resin, 0.3 to 1 percent of antioxidant, 1 to 2 percent of thixotropic agent and 0 to 2 percent of white oil. In the high-temperature resistant adhesive, phenolic resin modified polyvinyl chloride is adopted, the thermosetting phenolic resin has high infiltration capacity, so the adhesive is diffused and infiltrated to the surface of a bonding material fully to promote Brownian movement to make polar groups or chain knots on two interfaces get close to each other; and when the distance between the adhesive and adherend molecules is between 5 and 10 angstroms, mutually-attractive force is formed among interface molecules, and the distance among the molecules is further shortened to the maximum stable state, so the adhesive force of the adhesive can be enhanced; and the phenolic resin has the characteristics of high heat resistance, flame retardance and the like, so that the high-temperature resistant performance of the adhesive and filter cleaner products is enhanced.

Owner:佛山市豹王滤芯制造有限公司

Carbon fiber composite line for automobile clutch surface patch, preparation method and application thereof

The invention provides a carbon fiber composite line for automobile clutch surface patch and the application thereof in preparation of an automobile clutch. The carbon fiber composite line for the automobile clutch comprises a carbon fiber long filament and a carbon fiber core spun yarn with the carbon fiber long filament as the core yarn, and does not comprise metal wires; the carbon fiber composite line also can comprise glass fiber twistless roving, a glass fiber twistless extrusion yarn and chemical fiber roving. The invention also provides the automobile clutch surface patch comprising the carbon fiber composite line. With the adoption of the carbon fiber composite line, the environmental pollution and waste of resources caused by copper wires and other metal wires in the automobile clutch are solved, and the performances of the automobile clutch are also improved.

Owner:NANTONG XINYUAN SPECIAL FIBER

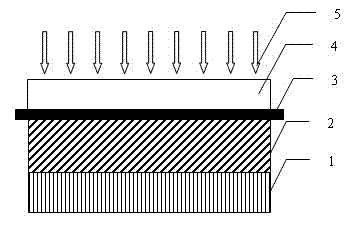

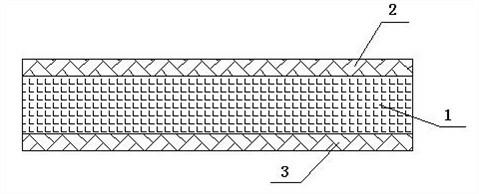

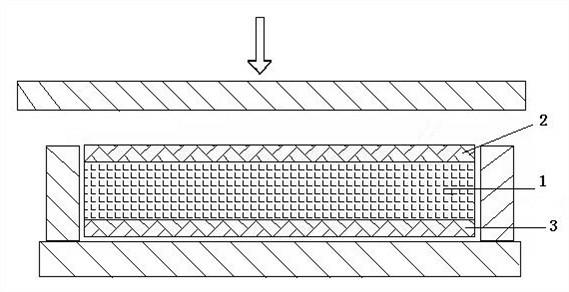

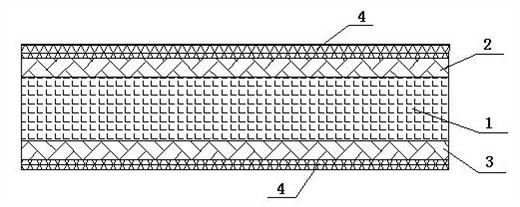

Composite fiber material product, preparation method thereof and application thereof

InactiveCN102166857AHigh hardnessStrong impact resistanceSynthetic resin layered productsLaminationFiberCorrosion resistant

The invention discloses a composite fiber material product, a preparation method thereof and an application thereof. The composite fiber material product comprises a piece of middle fiber material cloth (1), an upper surface film (2) arranged above the fiber material cloth (1) and a lower surface film (3) arranged under the fiber material cloth (1), wherein the outer surfaces of the upper surface film (2) and the lower surface film (3) are further provided with a layer of glass fiber cloth (4). The upper surface film and the lower surface film of the composite fiber material product can be respectively and internally printed with characters or patterns, the surfaces can be respectively formed to be a mirror surface or matting, and the composite fiber material product is attractive in appearance, free of air vents and needle eyes, good in rigidity, strong in impact resistance and mar resistance, and strong in heat resistance and corrosion resistance, so that the composite fiber material product can be widely used for manufacturing shells of various electronic products, electrical equipment, aviation and spaceflight equipment, and the like. The preparation method of the composite fiber material product is low in mould requirement, can be used for preparing the composite fiber material product with a surface which has the mirror surface or is matting. The follow-up treatment to the surface of the product can be avoided, such as polishing and the like, so that the invention is convenient to operate, and high in yield and production efficiency.

Owner:宜兴市中碳科技有限公司

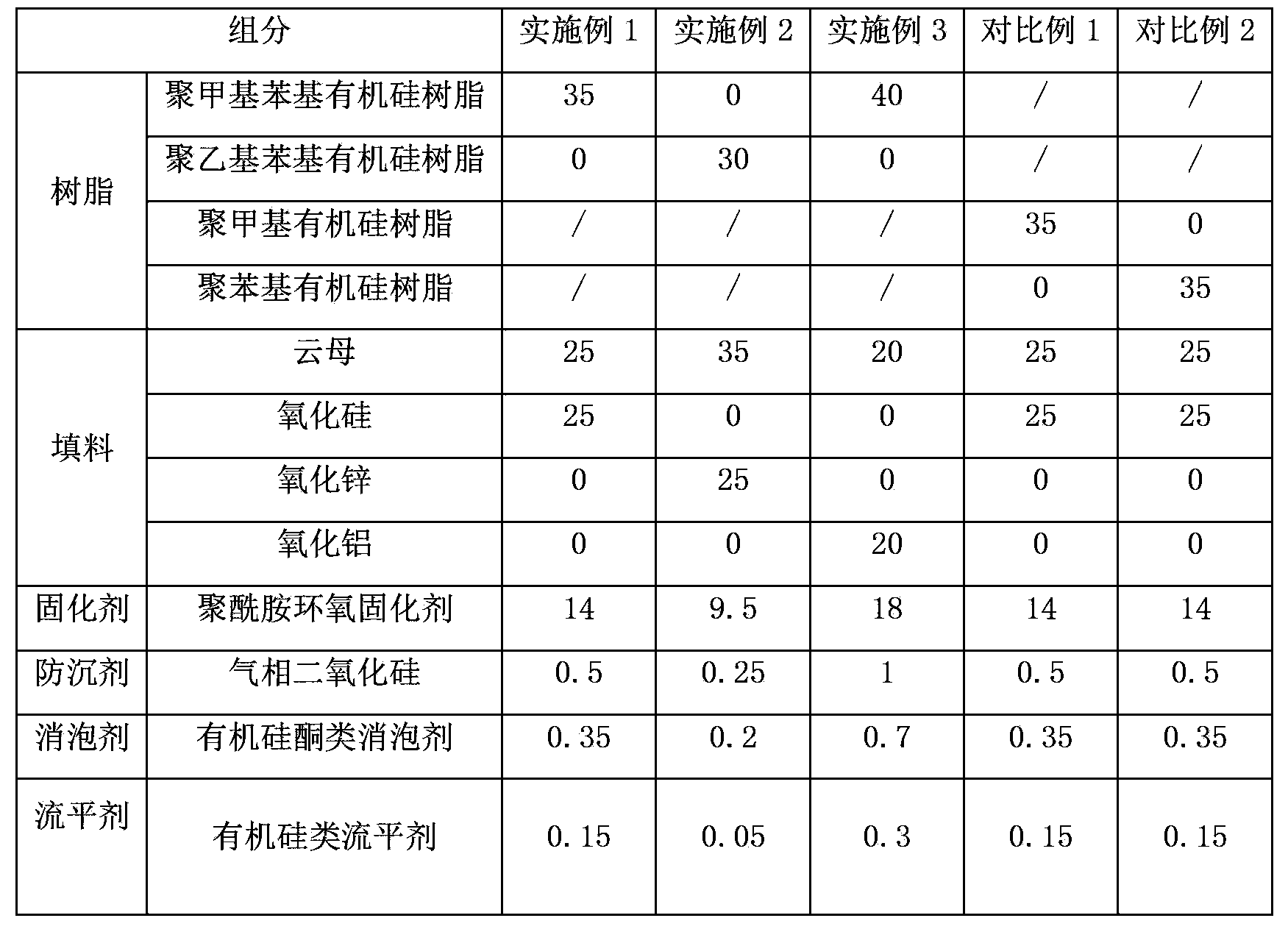

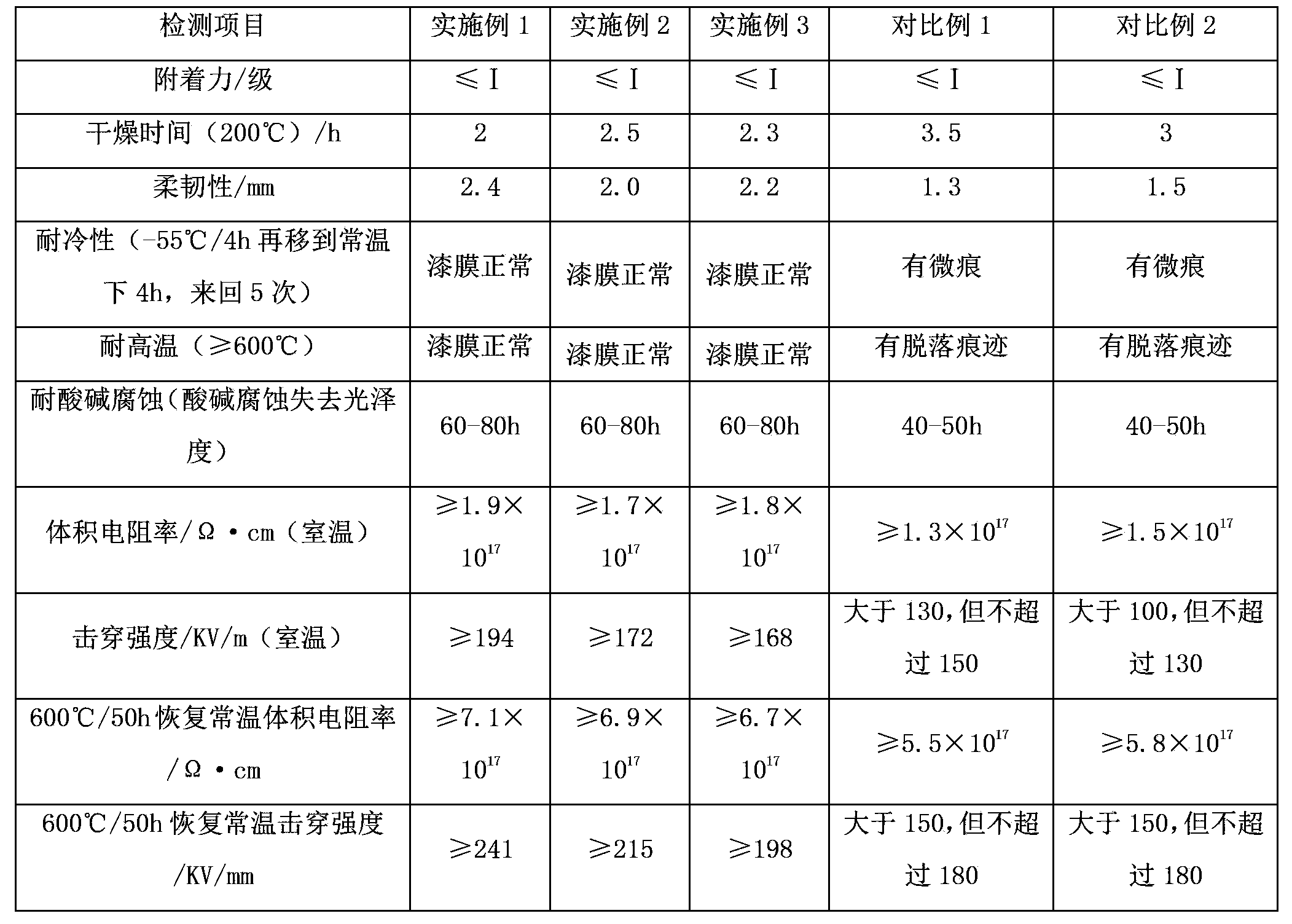

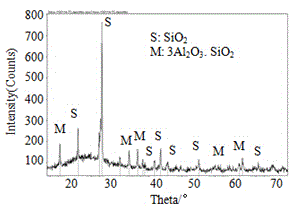

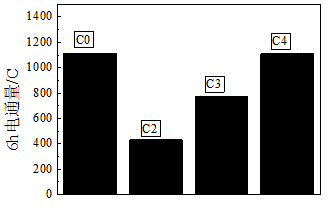

Novel high-temperature resistance insulation coating

The invention provides a novel high-temperature resistance insulation coating. The coating comprises following components in parts by weight: 30 to 40 parts of poly alkyl aryl organic silicon resin, 40 to 60 parts of stuffing material, 1 to 28 parts of curing agent, 0.01 to 0.1 part of anti-settling agent, 0.01 to 0.7 part of antifoaming agent, and 0.01 to 0.3 part of levelling agent. The poly alkyl aryl organic silicon resin is poly methyl phenyl organic silicon resin or poly ethyl phenyl organic silicon resin; the stuffing material is composed of one component or a plurality of components selected from following components: silicon oxide, zinc oxide, alumina, and mica; and the curing agent is an epoxy polyamide curing agent. The novel high-temperature resistance insulation coating has the advantages of high thermal resistance, capability of being used at the temperature of 600 DEG C while still having good mechanic performance and stability, good insulation performance, and long service life. Furthermore, the preparation method of the coating is simple, and meets the requirement of saving cost.

Owner:江苏达胜热缩防护用品有限公司

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

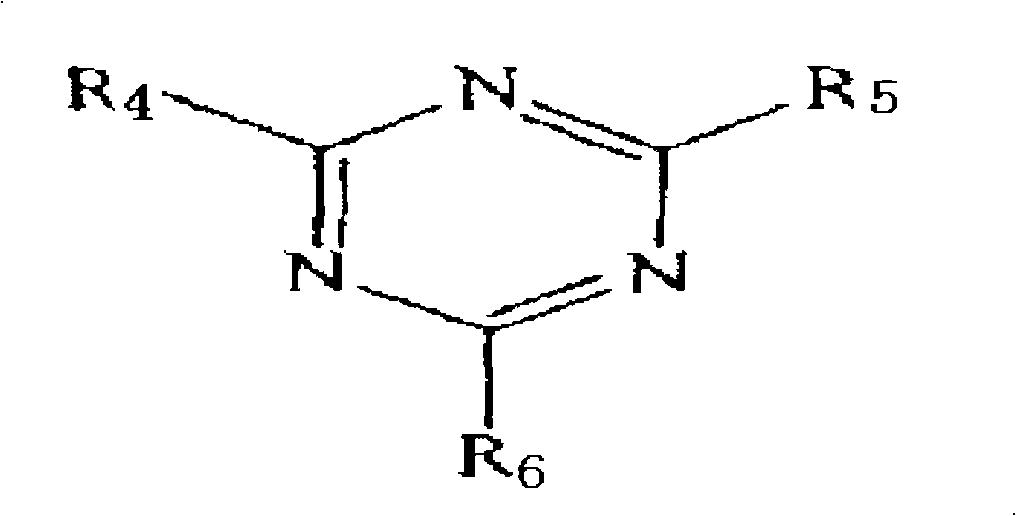

Water-boiling-resistant and flame-retardant polypropylene composite material with high glow-wire ignition temperature and preparation method

ActiveCN107434878ASolve serious problemsImprove flame retardant charcoal efficiencyPolypropylene compositesAntioxidant

The invention provides a water-boiling-resistant and flame-retardant polypropylene composite material with a high glow-wire ignition temperature and a preparation method. The water-boiling-resistant and flame-retardant polypropylene composite material with the high glow-wire ignition temperature is composed of the following materials: 72-76 parts of PP resin, 24-28 parts of a nitrogen phosphorus intumescent-type flame retardant, 0.1-0.2 part of an anti-dripping agent, 0.2-0.3 part of an antioxidant, 0.4-0.6 part of a lubricant, and 0.1-0.2 part of a high-efficiency synergist. The flame-retardant polypropylene composite material prepared by the method guarantees the material to pass a UL94 1.6mm-V0 test and achieve high-efficiency flame retardance, and at the same time the flame-retardant polypropylene composite material has performance such as a high glow-wire ignition temperature (875 DEG C, GWIT), water boiling resistance (100 DEG C), precipitation resistance, low smoke and thermal oxygen ageing and discoloring resistance (150 DEG C).

Owner:ORINKO NEW MATERIAL CO LTD

Chocolate essence and preparation method thereof

InactiveCN102894339AFragrant and saturatedLong aftertasteFood preparationMaillard reactionPhenylalanine

The invention relates to a chocolate essence and a preparation method thereof. The chocolate essence is prepared from the raw materials by weight percent: 30-50% of protein hydrolysate, 0.2-6.0% of glucose, 0.1-2.0% of alanine, 0.1-1.5% of glutamic acid, 0.2-2.0% of phenylalanine, 0.0-1.0% of leucine and 20-60% of propylene glycol. The preparation method comprises the steps of weighing the raw materials according to the weight percent; carrying out maillard thermal reaction on the protein hydrolysate, the glucose, the alanine, glutamic acid, the phenylalanine and the leucine; mixing the reaction product with propylene glycol; and evenly stirring and then screening by 40-mesh sieve to obtain the chocolate essence, wherein the protein hydrolysate is obtained by stirring, mixing and hydrolyzing soy isolate protein, water and protease. The chocolate essence is strong in nature feel, rich in flavor with lingering aftertaste and high in heat resistance.

Owner:TIANJIN CHUNFA BIO TECH GRP

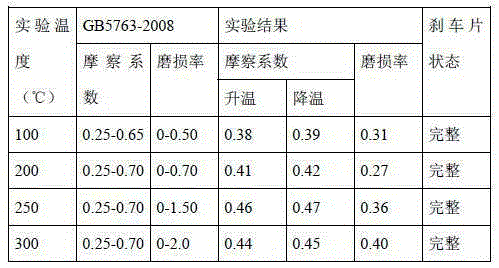

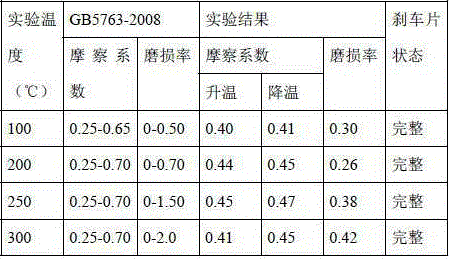

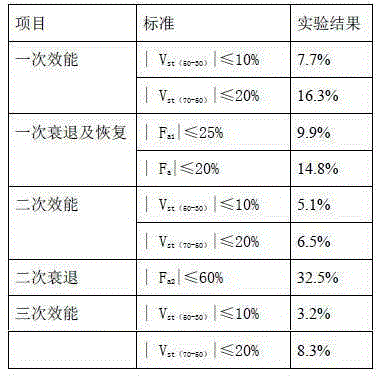

Vanadium-contained semimetallic brake block

ActiveCN105240429ANot easy to produceReduce wear rateOther chemical processesFriction liningAluminum silicateCellulose fiber

The invention discloses a vanadium-contained semimetallic brake block. The vanadium-contained semimetallic brake block includes, by weight, 5-7 parts of red copper fibers, 3-6 parts of potassium hexatitanate whiskers, 4-5 parts of barium sulfate, 15-25 parts of ferrovanadium powder, 4-6 parts of frictional powder, 13-15 parts of short stainless steel fibers, 6-10 parts of graphite, 2-4 parts of cellulosic fibers, 7-9 parts of coke blacking, 1-5 parts of modified resin nitrile fibers, 3-7 parts of chromite ore fine, 1-5 parts of nitrile rubber, 5-9 parts of ceramic adhesive agents and 8-10 parts of spray-bounded aluminum silicate fibers. The brake block obtained by material mixing, steel backing treatment, press molding, heat treatment, packaging and storage is low in wear rate, not prone to being dusty, high in density, good in heat dissipation, small in vibration, low in noise and high in corrosion resistance. The whole manufacturing process is simple, stability is good, cost is low and the cost-performance ratio is high.

Owner:盐城加能汽车部件有限公司

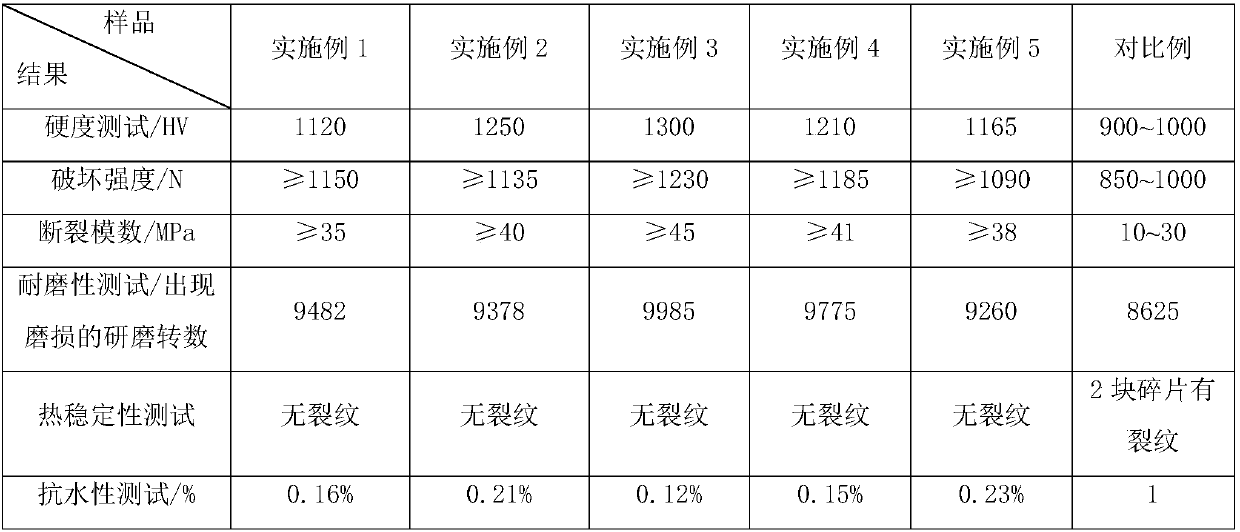

Wear-resistant and high-hardness ceramic product and preparation method thereof

PendingCN109608168AHigh densityImprove corrosion resistanceCeramic materials productionClaywaresWear resistantCalcite

The invention discloses a wear-resistant and high-hardness ceramic product and a preparation method thereof. The wear-resistant and high-hardness ceramic product comprises a green body and a glaze layer applied on the green body. The green body comprises the following raw materials by weight: 45-55 parts of kaolin, 5-10 parts of zirconia, 12-18 parts of bentonite, 15-25 parts of waste ceramic residue, 10-15 parts of silicon nitride, 17-23 parts of potassium feldspar, and 8-16 parts of albite. The glaze layer consists of the following raw materials by weight: 25-35 parts of kaolin, 12-16 partsof talc powder, 10-15 parts of spodumene, 6-12 parts of lithium china stone, 10-15 parts of quartz, 5-10 parts of silicon carbide and 7-14 parts of calcite. By the above way, the ceramic product provided by the invention has high hardness and wear resistance, high compressive strength and strong thermal stability.

Owner:FOSHAN UNIVERSITY

Environment-friendly formaldehyde-free building glue and preparation method thereof

InactiveCN103694929ASimple preparation processReduce manufacturing costNon-macromolecular adhesive additivesAmide/imide polymer adhesivesPolyvinyl alcoholPreservative

The present invention relates to a glue, in particular relates to a health, environment-friendly formaldehyde-free building glue. The building glue is characterized by comprising the following components in parts by weight: 50-60 parts of polyvinyl alcohol solution, 3-5 parts of polyacrylamide, 0.2-0.5 parts of hydrochloric acid solution, 3-5 parts of urea, 0.5-2 parts of sodium hydroxide, 0.1-0.5 parts of a preservative, and the balance being water. The preparation technology is simple, the production cost is low, and the formaldehyde-free building glue is improved on the basis of a polyvinyl formal glue, so that the formaldehyde-free building glue has advantages of safety, innocuity, good initial adhesion, good operationality, high bonding force, high compressive strength, and high heat resistance.

Owner:栾晓健

High-power high-stability cable material and preparation method thereof

InactiveCN104559203AStable chemical propertiesGood physical and mechanical propertiesRubber insulatorsFiberPolyvinyl chloride

The invention discloses a high-power high-stability cable material which is prepared from the following raw materials in parts by weight: 6-8 parts of oxidized polyethylene wax, 15-25 parts of PVC (polyvinyl chloride) resin, 3-4 parts of epoxy soybean oil, 3-5 parts of soluble polytetrafluoroethylene, 2-4 parts of nano titanium dioxide, 5-7 parts of ethylene-octylene copolymer, 3-4 parts of carbon fiber, 2-3 parts of benzotriazole, 4-5 parts of red phosphorus, 2-3 parts of nano graphite, 1-2 parts of accelerator CZ, 45-55 parts of nitrile silicone rubber, 6-7 parts of nano calcium carbonate, 2-5 parts of maleic anhydride grafted polypropylene and 8-12 parts of filler. The cable material has favorable chemical property stability, physical and mechanical properties, electrical insulation properties, aging resistance and flame retardancy, and can satisfy the demands for cable manufacturing industry.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com