Composite fiber material product, preparation method thereof and application thereof

A composite fiber and product technology, applied in the field of fiber material panel products, can solve the problems of high mold requirements, poor scratch resistance and corrosion resistance, low work efficiency, etc., and achieve excellent impact resistance, scratch resistance and durability Effects of corrosion, wide range of applications, and excellent connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

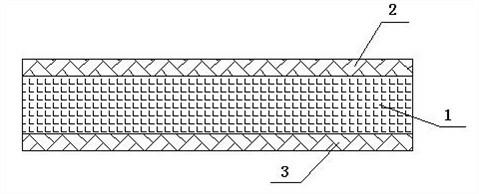

[0033] Wherein the fiber material cloth (1) is a woven cloth made of carbon fiber material, and the upper surface film (2) and the lower surface film (3) are matte films made of PVC material.

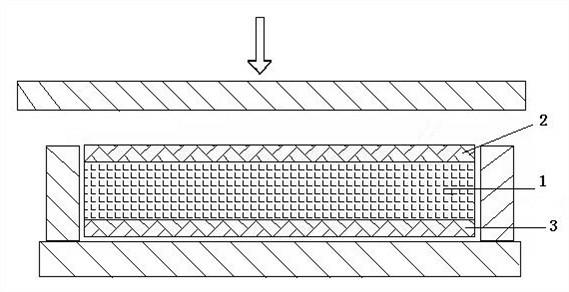

[0034] 2. The preparation method of composite fiber material products is to take the fiber material woven cloth (1) made of carbon fiber material and spread it flat, and lay the upper surface matte made of PVC material respectively above and below the carbon fiber material woven cloth (1). film (2) and lower surface matte film (3), and then neatly put into the forming mold, such as figure 2 As shown, close the mold, at 150°C and 2MPa, make the matte film on the upper surface (2), the carbon fiber material woven cloth (1) and the matte film on the lower surface (3) sequentially bonded into one, cool to room temperature, Open mold, take out and obtain the composite fiber material product that surface becomes matte film.

[0035] Example 2

Embodiment 2

[0037] Among them, the fiber material cloth (1) is a two-way prepreg cloth made of basalt fiber material, the upper surface film (2) and the lower surface film (3) are both hard films made of PE material, and the upper surface film (2) and Letters and patterns are printed on the inner surface of the lower surface film (3).

[0038] 2. The preparation method of composite fiber material products is to take the fiber material bidirectional prepreg (1) made of basalt fiber material and spread it flat, and lay the two-way prepreg cloth (1) made of PE material on the top and bottom of the basalt fiber material bidirectional prepreg cloth (1). The upper surface hard film (2) and the lower surface hard film (3) are then neatly put into the forming mold, and the mold is closed. The prepreg (1) and the lower surface hard film (3) are sequentially bonded into one, cooled to room temperature, opened, and taken out to obtain a composite fiber material product with a hard film on the surfac...

Embodiment 3

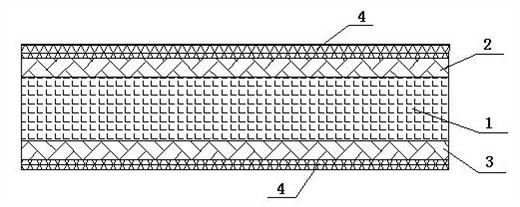

[0041] Wherein the fiber material cloth (1) is a unidirectional cloth made of glass fiber material, the upper surface film (2) and the lower surface film (3) are mirror films made of PC material, and the thickness of the upper and lower glass fiber cloth is 0.05mm.

[0042] 2, the preparation method of composite fiber material product, take the fiber material unidirectional cloth (1) that glass fiber material is made and pave, and lay the fiber material unidirectional cloth (1) that is made of PC material respectively above and below the glass fiber material unidirectional cloth (1). The upper surface mirror film (2) and the lower surface mirror film (3), and then on the outer surfaces of the upper surface mirror film (2) and the lower surface mirror film (3), respectively lay a layer of thickness of 0.05mm glass fiber cloth ( 4), and then neatly put into the forming mold, such as Figure 4 As shown, the mold is closed, and at a temperature of 300°C and 0.8MPa, the glass fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com