High-temperature-resistant acrylic ester pressure sensitive adhesive and preparation method thereof

An acrylate, high-temperature-resistant technology, which is applied in the field of high-temperature-resistant acrylate pressure-sensitive adhesives and their preparation, can solve problems such as loss of bonding performance, yellowing, and poor heat resistance, and achieve easy peeling and good heat and humidity resistance. , the effect of small peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

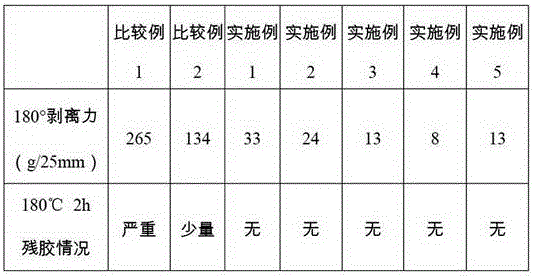

Examples

Embodiment 1

[0037] A preparation method of pressure-sensitive adhesive, comprising the steps of:

[0038] 1) Weigh 4g of methyl methacrylate, 0.5g of trans-stilbene, 27g of butyl acrylate, 0.5g of acrylic acid, 0.5g of hydroxyethyl acrylate, 1g of glycidyl methacrylate, 1g of acrylamide, N- Phenylmaleimide 0.5g, initiator AIBN: 0.105g (accounting for methyl methacrylate, trans-stilbene, butyl acrylate, acrylic acid, hydroxyethyl acrylate, glycidyl methacrylate, propylene Amide, N-phenylmaleimide 0.3% of the total weight), ethyl acetate 60g and methanol 5g. Mix methyl methacrylate, trans-stilbene, butyl acrylate, acrylic acid, hydroxyethyl acrylate, glycidyl methacrylate, acrylamide, and N-phenylmaleimide to obtain a monomer mixture , Mix ethyl acetate and methanol to obtain a mixed solvent. Take 21g of the above-mentioned monomer mixture and 29.3g of the mixed solvent, pour it into a four-necked flask equipped with mechanical stirring, a thermometer, and a condenser tube and heat it to ...

Embodiment 2

[0044] A preparation method of pressure-sensitive adhesive, comprising the steps of:

[0045] 1) Weigh 4g of methyl methacrylate, 0.5g of trans-stilbene, 24.5g of butyl acrylate, 1g of acrylic acid, 1g of hydroxyethyl acrylate, 2g of glycidyl methacrylate, 1.5g of acrylamide, N- Phenylmaleimide 0.5g, initiator AIBN: 0.105g (accounting for methyl methacrylate, trans-stilbene, butyl acrylate, acrylic acid, hydroxyethyl acrylate, glycidyl methacrylate, propylene Amide, N-phenylmaleimide 0.3% of the total weight), ethyl acetate 60g and methanol 5g. Mix methyl methacrylate, trans-stilbene, butyl acrylate, acrylic acid, hydroxyethyl acrylate, glycidyl methacrylate, acrylamide, and N-phenylmaleimide to obtain a monomer mixture , Mix ethyl acetate and methanol to obtain a mixed solvent. Take 21g of the above-mentioned monomer mixture and 29.3g of the mixed solvent, pour it into a four-neck flask equipped with mechanical stirring, a thermometer, and a condenser tube and heat it to 73...

Embodiment 3

[0051] A preparation method of pressure-sensitive adhesive, comprising the steps of:

[0052] 1) Weigh 6g of methyl methacrylate, 0.5g of trans-stilbene, 18.5g of butyl acrylate, 2g of acrylic acid, 2g of hydroxyethyl acrylate, 4g of glycidyl methacrylate, 1.5g of acrylamide, N- Phenylmaleimide 0.5g, initiator AIBN: 0.105g (accounting for methyl methacrylate, trans-stilbene, butyl acrylate, acrylic acid, hydroxyethyl acrylate, glycidyl methacrylate, propylene Amide, N-phenylmaleimide 0.3% of the total weight), ethyl acetate 60g and methanol 5g. Mix methyl methacrylate, trans-stilbene, butyl acrylate, acrylic acid, hydroxyethyl acrylate, glycidyl methacrylate, acrylamide, and N-phenylmaleimide to obtain a monomer mixture , Mix ethyl acetate and methanol to obtain a mixed solvent. Take 21g of the above-mentioned monomer mixture and 29.3g of the mixed solvent, pour it into a four-necked flask equipped with mechanical stirring, a thermometer, and a condenser tube and heat it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com