Patents

Literature

182results about How to "Small peeling force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant UV visbreaking glue composition and UV visbreaking protective film

InactiveCN105778806AImprove peel forceSmall peeling forceFilm/foil adhesivesPolyureas/polyurethane adhesivesCross-linkTectorial membrane

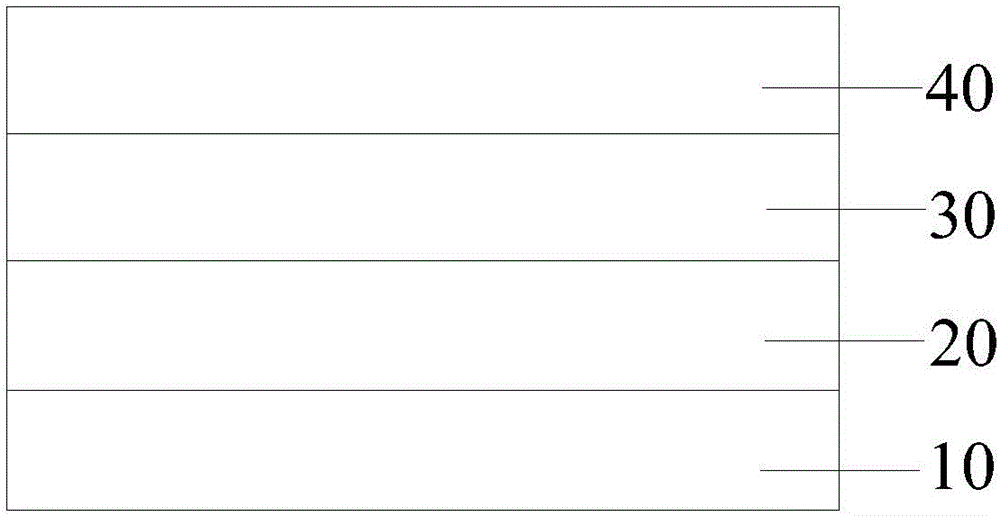

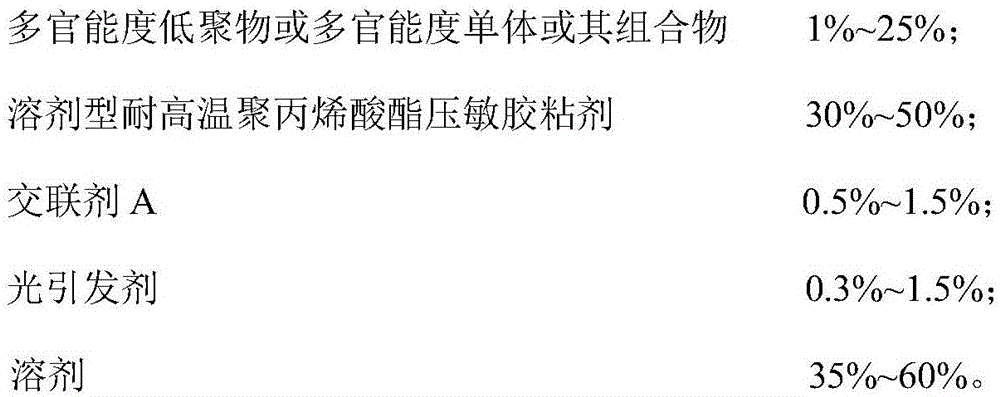

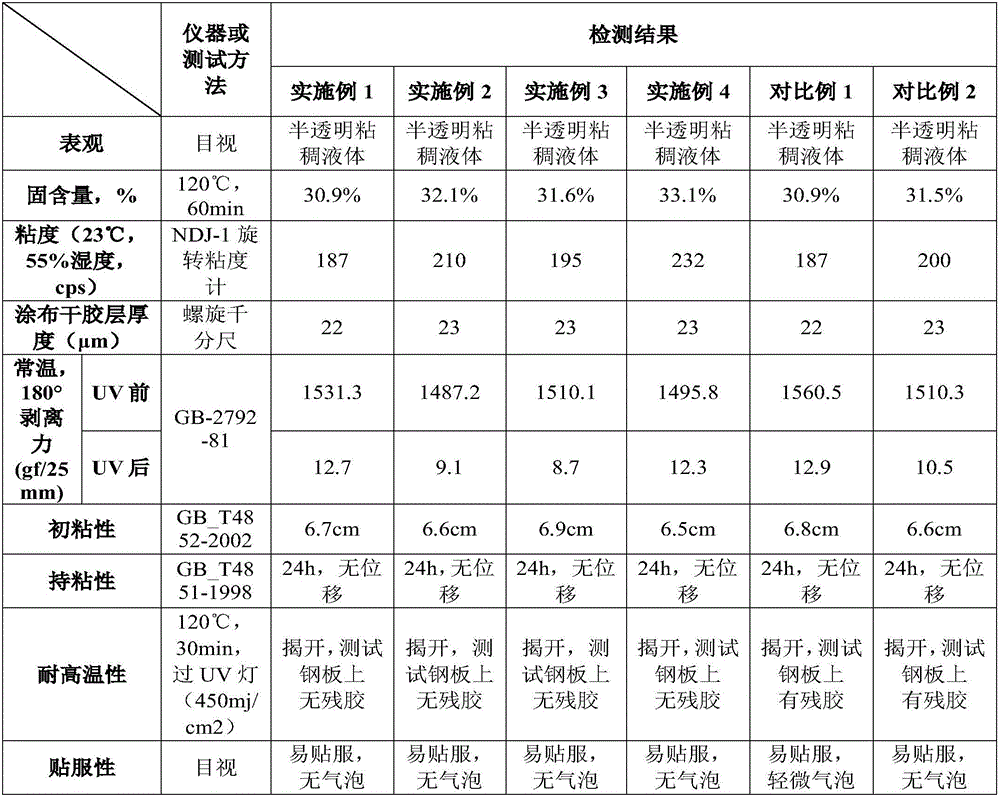

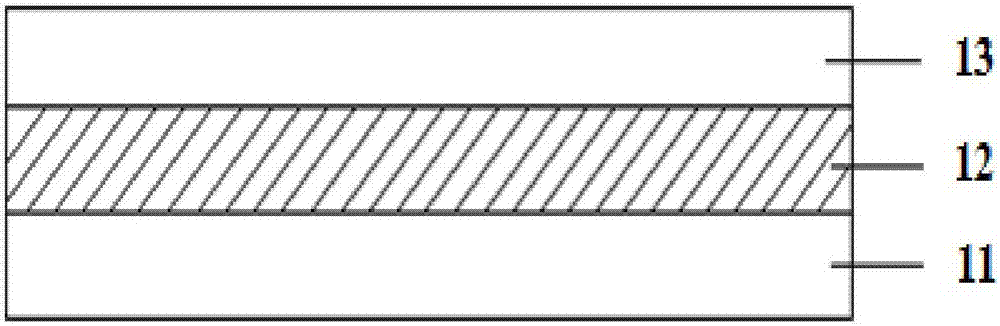

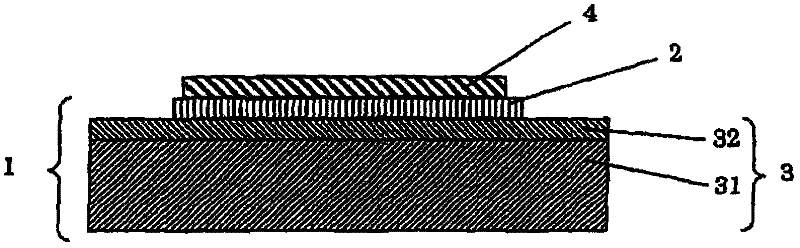

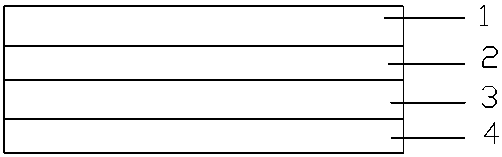

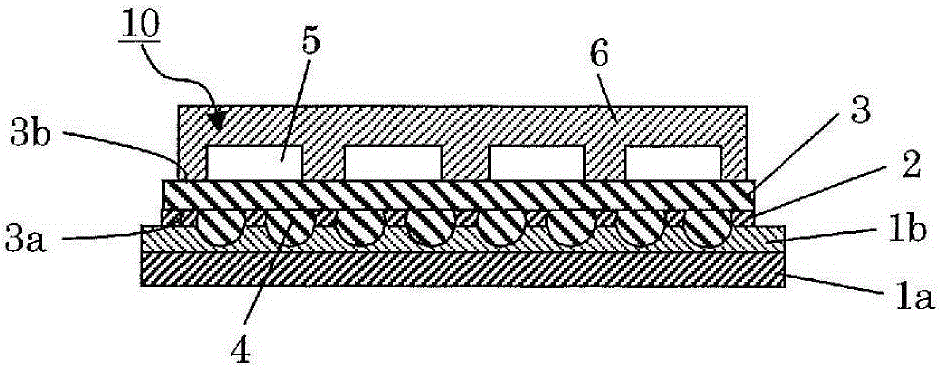

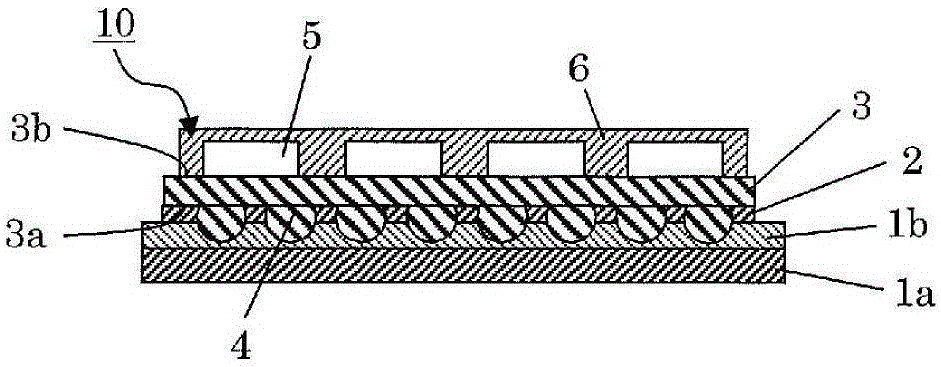

The invention discloses a heat-resistant UV visbreaking glue composition and a UV visbreaking protective film prepared with this composition. This composition is made from the following materials according to parts by weight: 1-25% of a polyfunctional oligomer or polyfunctional monomer or its composition, 30-50% of a solvent type high-temperature-resistant polyacrylate pressure-sensitive glue, 0.5-1.5% of a cross-linking agent, 0.3-1.5% of a photo-initiator, and 35-60% of a solvent. The heat-resistant UV visbreaking protective film comprises a base (10), a bottom coating layer (20) applied to the surface of the base (10), a UV visbreaking glue layer (30) applied to the bottom coating layer (20), and a release film (40). The heat-resistant UV visbreaking protective film prepared herein can resist a high temperature of 120 DEG C and has the advantages of high UV pre-illumination release force, low UV post-illumination release force and no glue residue.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Heat-resistant UV viscosity breaking film and preparation method thereof

ActiveCN106995665AImprove peel forceImprove adhesionMacromolecular adhesive additivesOrganic non-macromolecular adhesiveTemperature resistancePressure sensitive

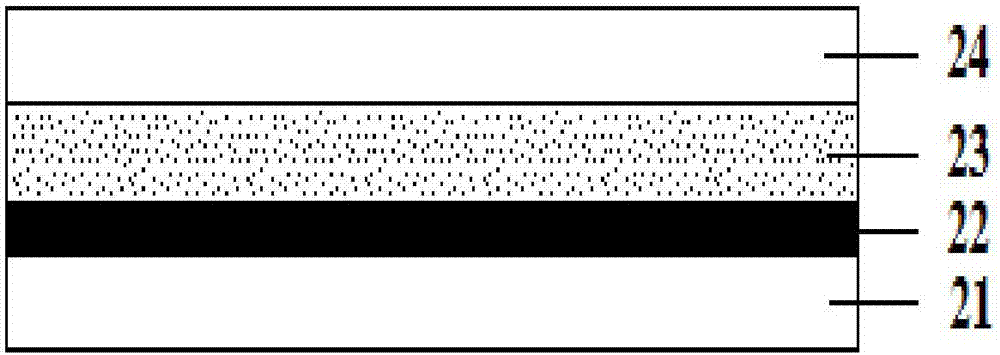

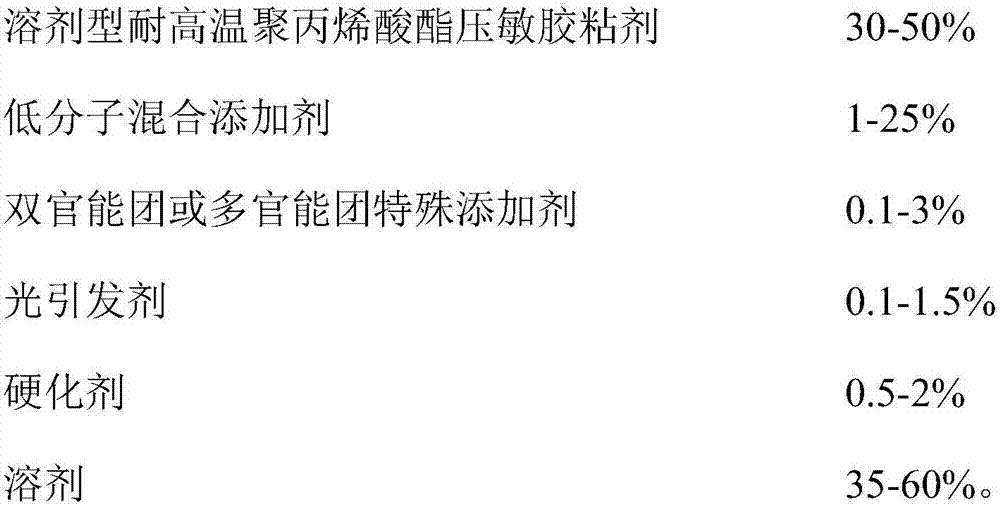

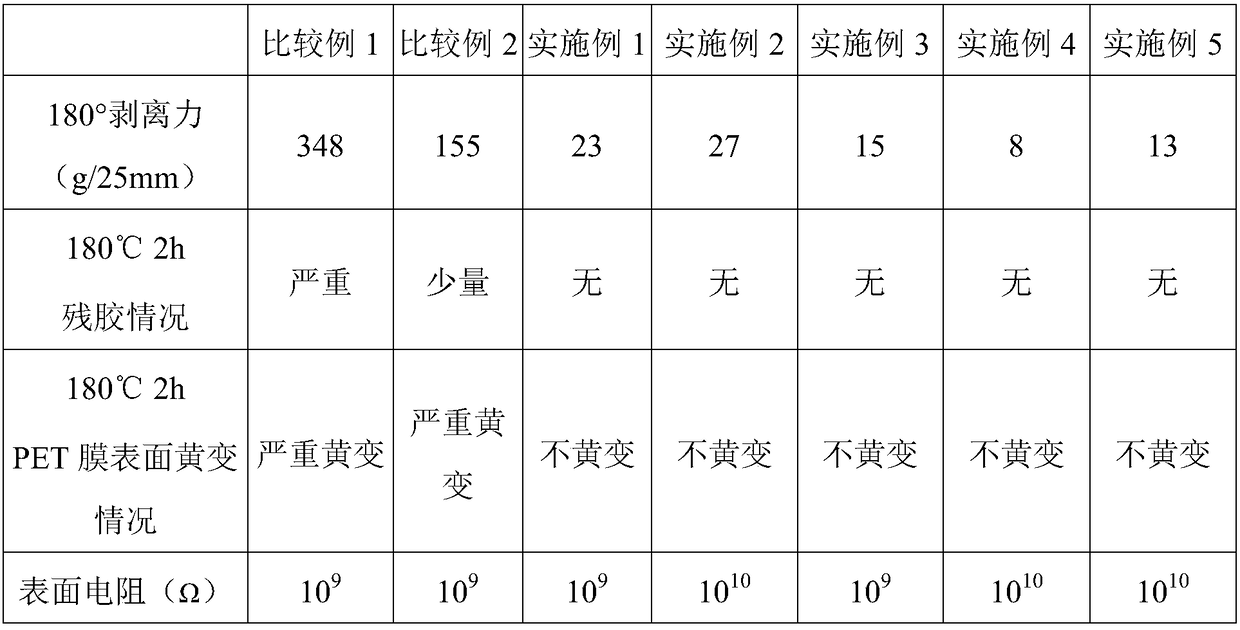

The invention provides a heat-resistant UV viscosity breaking film. The heat-resistant UV viscosity breaking film comprises a substrate layer, a UV photosensitive adhesive layer and a release film layer sequentially. The invention further provides a preparation method of the UV photosensitive adhesive layer. The UV photosensitive adhesive layer comprises the ingredients in percentage by weight: 30% to 50% of solvent type high-temperature resistant polyacrylate pressure-sensitive adhesive, 1% to 25% of micromolecular mixed additives, 0.1% to 3% of difunctional or polyfunctional special additive, 0.1% to 1.5% of photoinitiator, 0.5% to 2% of curing agent and 35% to 60% of solvent. The invention further provides a preparation method of the heat-resistant UV viscosity breaking film. According to the heat-resistant UV viscosity breaking film and the preparation method thereof, the sealing performance and high-temperature resistance of a UV photosensitive adhesive to corona PET substrates are improved, base coat treatment technologies are reduced, and the product structure is optimized.

Owner:新纶电子材料(常州)有限公司

High-temperature-resistant and low-peel-strength acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN106520032ASmall peeling forceLow temperature resistanceEster polymer adhesivesFunctional monomerSolvent

The invention discloses a high-temperature-resistant and low-peel-strength acrylate pressure-sensitive adhesive. The pressure-sensitive adhesive is prepared from raw materials in parts by weight as follows: 50-90 parts of soft acrylate monomers, 5-25 parts of hard acrylate monomers, 0.5-15 parts of reactive functional monomers, 0.2-10 parts of high-temperature-resistant active monomers, 0.2-3 parts of an initiator, 0.5-5 parts of a curing agent and 60-200 parts of a solvent. All the monomers and part of the initiator are dissolved in the solvent firstly, the total concentration of the monomers is controlled to be not lower than 60wt%, and then the material is heated for a reflux reaction for 3-6 h; then the rest of the initiator is dropwise added to reaction liquid, a reaction is carried out for 0.5-2 h after adding dropwise is completed, and then the obtained product is diluted and reacts step by step; and the obtained material and the curing agent are evenly mixed, so that the high-temperature-resistant and low-peel-strength acrylate pressure-sensitive adhesive is obtained. The pressure-sensitive adhesive can still stick a stuck object at the relatively high use temperature, and an adhesive layer is free of residues and traces after being peeled.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

An antistatic high-temperature resistant acrylate pressure-sensitive adhesive, and a preparation method and application thereof

InactiveCN108753196AImprove antistatic performanceStrong heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFunctional monomerAntistatic agent

An antistatic high-temperature resistant acrylate pressure-sensitive adhesive, and a preparation method and application thereof are disclosed. The pressure-sensitive adhesive includes a component (A)and a component (B). The component (A) is prepared from, by weight, 4-8% of a hard monomer, 18-28% of a soft monomer, 2-8% of a functional monomer, 1-3% of a heat-resistant monomer, 65% of a solvent,and an initiator the weight of which is 0.1-0.5% of the total weight of the hard monomer, the soft monomer, the functional monomer and the heat-resistant monomer. The component (B) includes one or more selected from a curing agent, an auxiliary agent and an antistatic agent. The weight of the curing agent, the weight of the auxiliary agent and the weight of the antistatic agent account for 2-5%, 0.1-1% and 0.1-1% respectively of the total weight of the component (A). The pressure-sensitive adhesive has good heat resistance and good antistatic performance and is free of softening, yellowing andresidual adhesive at high temperature.

Owner:WUXI HAITE NEW MATERIAL RES INST

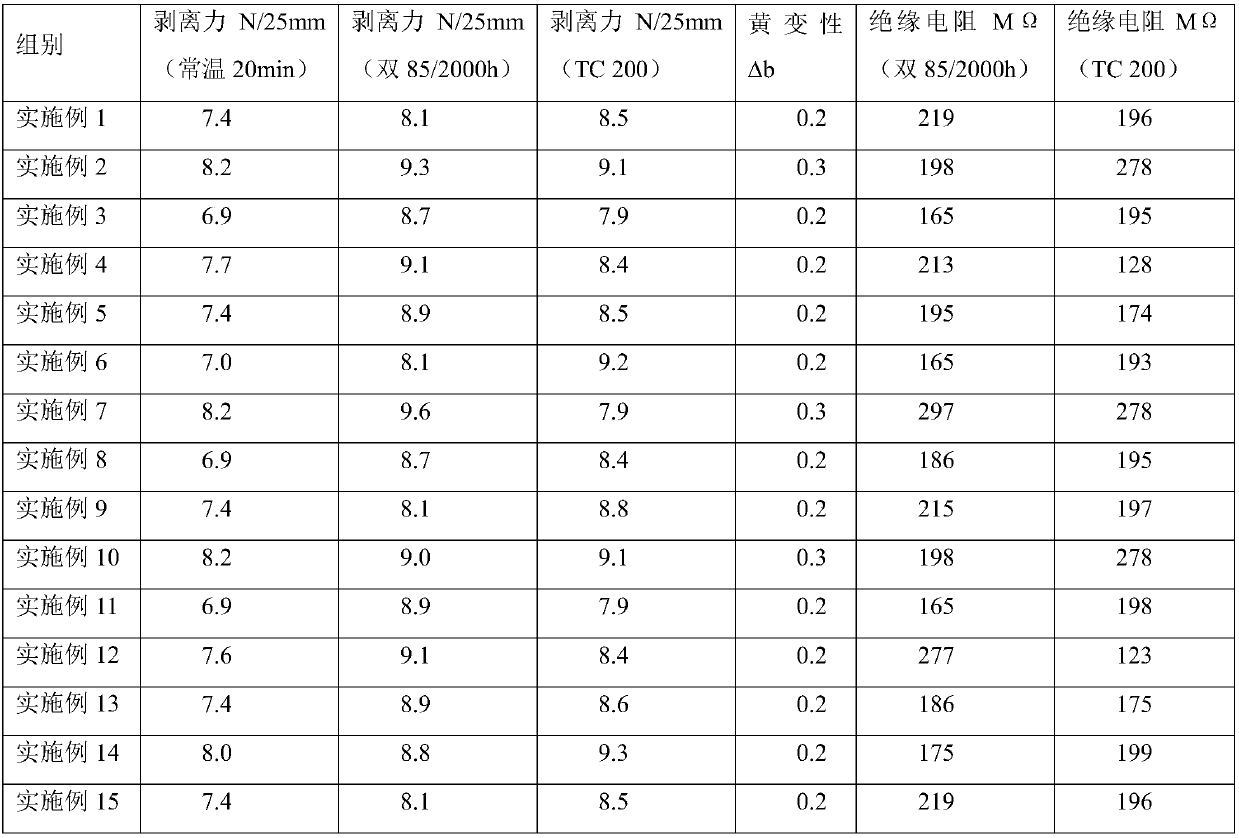

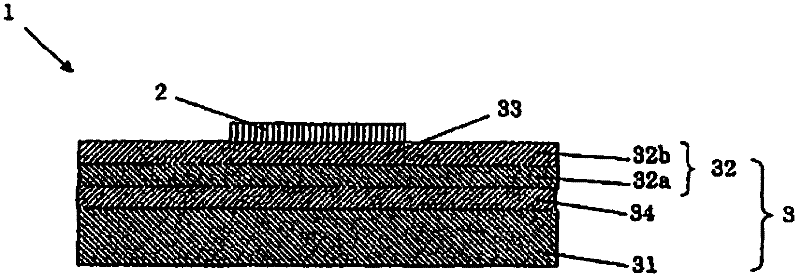

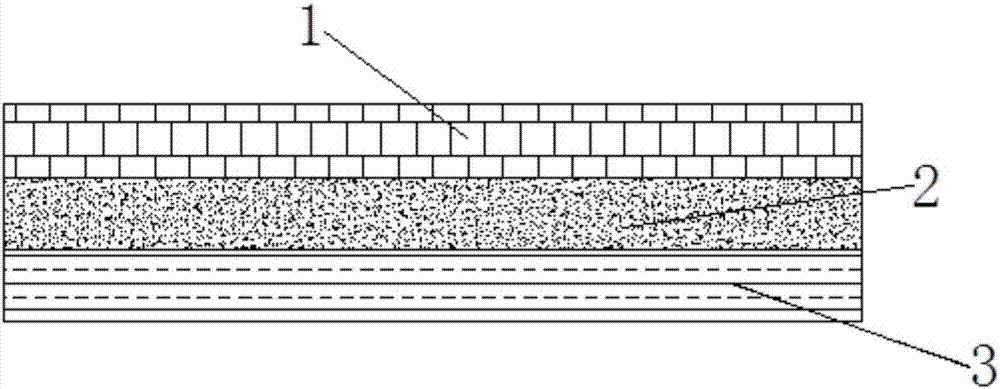

High-performance repairing adhesive tape for photovoltaic module back panel and preparation method

InactiveCN107841259AGood weather resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyesterAdhesive cement

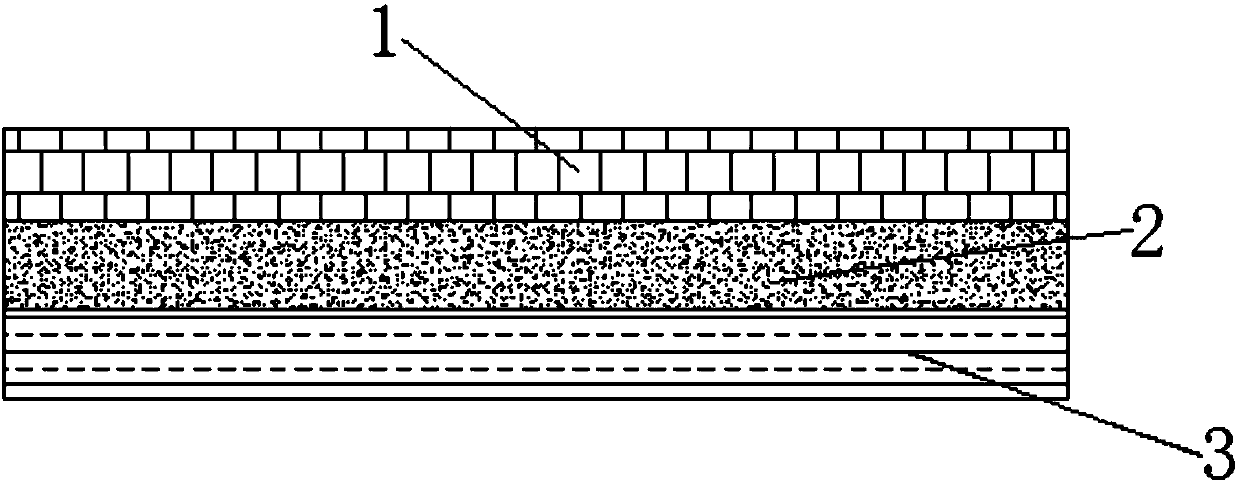

The invention discloses a high-performance repairing adhesive tape for a photovoltaic module back panel. The high-performance repairing adhesive tape comprises a base material layer, a functional adhesive layer and a release material layer which are arranged in sequence from top to bottom, wherein the base material layer is composed of a polyester thin film type material; the functional adhesive layer is composed of a high-weather-resistance adhesive. According to the high-performance repairing adhesive tape for the photovoltaic module back panel and the preparation method, disclosed by the invention, the weather-resistance base material layer is selected so that the effects of water resistance, insulation, ultraviolet radiation resistance and the like can be realized and the effect of anindependent back panel is realized; the high-weather-resistance adhesive is selected for the functional adhesive layer, so that the weather resistance, high temperature resistance and yellowing resistance of the adhesive tape can be improved; the adhesive tape has great bonding strength and is not easy to fall off; meanwhile, the adhesive tape is convenient to stick and convenient to construct.

Owner:CYBRID TECHNOLOGIES INC

Thermally releasable sheet-integrated film for semiconductor back surface, method of collecting semiconductor element, and method of producing semiconductor device

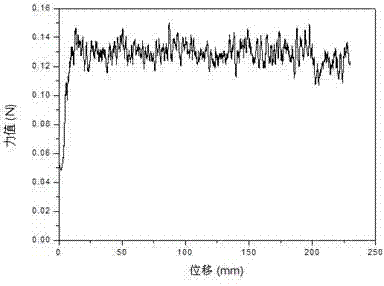

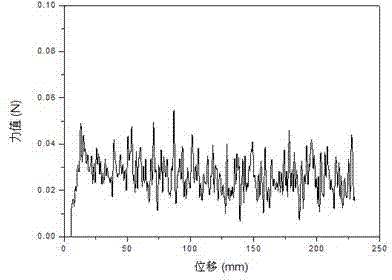

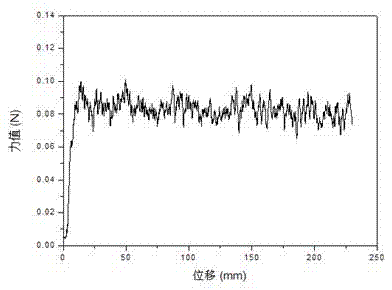

ActiveCN102373022AInhibit or prevent damageSmall peeling forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringPeel force

The present invention relates to a thermally releasable sheet-integrated film for semiconductor back surface, which includes: a pressure-sensitive adhesive sheet including a base material layer and a pressure-sensitive adhesive layer, and a film for semiconductor back surface formed on the pressure-sensitive adhesive layer of the pressure-sensitive adhesive sheet, in which the pressure-sensitive adhesive sheet is a thermally releasable pressure-sensitive adhesive sheet whose peel force from the film for semiconductor back surface decreases upon heating.

Owner:NITTO DENKO CORP

High-temperature-resistant acrylic ester pressure sensitive adhesive and preparation method thereof

ActiveCN106675462AStrong heat resistanceSmall peeling forceEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerSolvent

The invention discloses a high-temperature-resistant acrylic ester pressure sensitive adhesive. The pressure sensitive adhesive is prepared from raw materials in percentage by weight as follows: 4%-8% of hard monomers, 18%-28% of soft monomers, 2%-8% of functional monomers, 1%-3% of heat-resisting monomers and 65% of a solvent. The pressure sensitive adhesive has higher heat resistance and smaller stripping resistance and does not have residues when cooled to the room temperature after being treated at the high temperature of 180 DEG C, adhesive water does not get yellow under the high temperature condition, and the pressure sensitive adhesive is easy to strip and good in damp heat resistance and well solves the problem of use under high-temperature conditions in all industries. Besides, an actual solution is provided for the fields such as electronic technology, medical treatment, military affairs, aerospace and the like.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

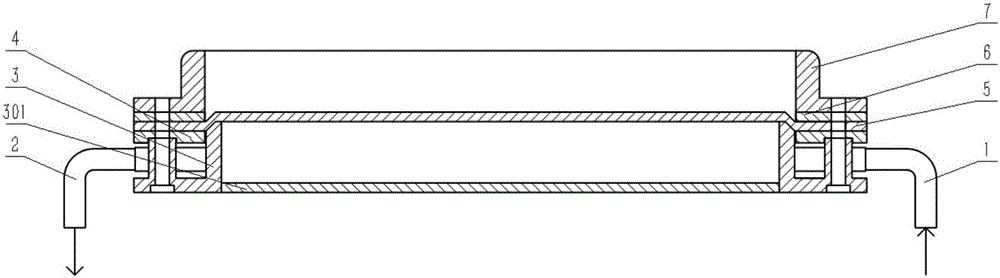

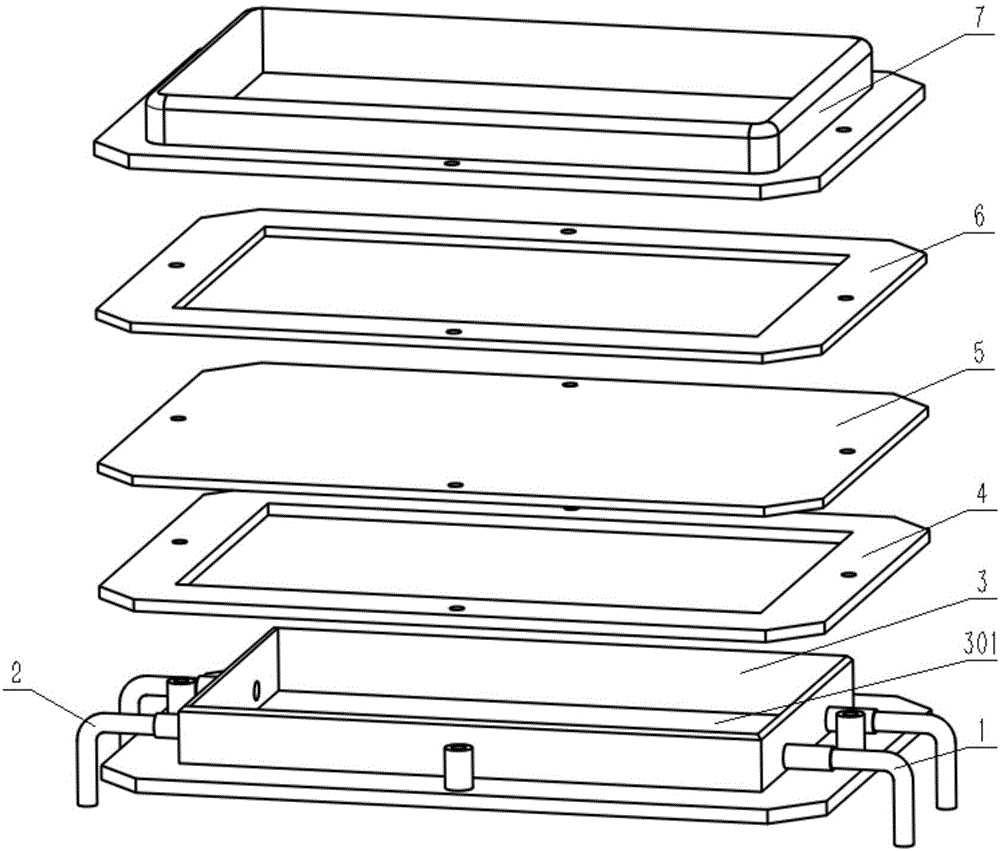

Forming window for high-speed continuous photocuring 3D printing

ActiveCN106273516AEfficient printingTroubleshoot quick fixesAdditive manufacturing apparatusCooling chamberEngineering

The invention discloses a forming window for high-speed continuous photocuring 3D printing. The forming window applied to a photocuring 3D printer comprises a window box and an oxygen supply cooling module. The photocuring 3D printer is divided into an upper cavity and a lower cavity through a middle partition. The window box and the oxygen supply cooling module are arranged in the upper cavity of the case of the photocuring 3D printer. The window box and the oxygen supply cooling module are fixedly mounted on the middle partition in a combined manner. Two ends of an oxygen supply cooling chamber are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline, and the oxygen supply cooling chamber, the o cooling gas inlet pipeline and the cooling gas outlet pipeline form the oxygen supply cooling module. The forming window has the advantages that low-cost and efficient continuous printing of large-size optional-shape parts can be achieved, the forming window is wide in applicable materials, the precision and quality of the printed parts are high, the printed parts are good in consistency, and process stability and reliability are achieved. In addition, the forming window is high in industrial application value and applicable to a desktop-level 3D printer and industrial 3D printing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

High performance repairing adhesive tape used for photovoltaic module backboards, and preparation method thereof

InactiveCN107267086AGood weather resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyesterAdhesive

The invention discloses a high performance repairing adhesive tape used for photovoltaic module backboards. The high performance repairing adhesive tape comprises a substrate layer, a functional glue layer, and a release material layer from top to bottom successively; the substrate layer is composed of a polyester film material; the functional glue layer is composed of a high weatherability adhesive. According to a preparation method, the substrate layer with weatherability is capable of providing the high performance repairing adhesive tape with water resistance, insulation performance, and ultra violet radiation resistance, and backboard independence effect is achieved; the functional glue layer is prepared from the weatherability adhesive, so that the weatherability, high temperature resistance, and yellowing resistance of the functional glue layer are improved, the adhesive tape bonding force is increased, shedding is not easily caused, fitness is improved, and construction is convenient.

Owner:CYBRID TECHNOLOGIES INC

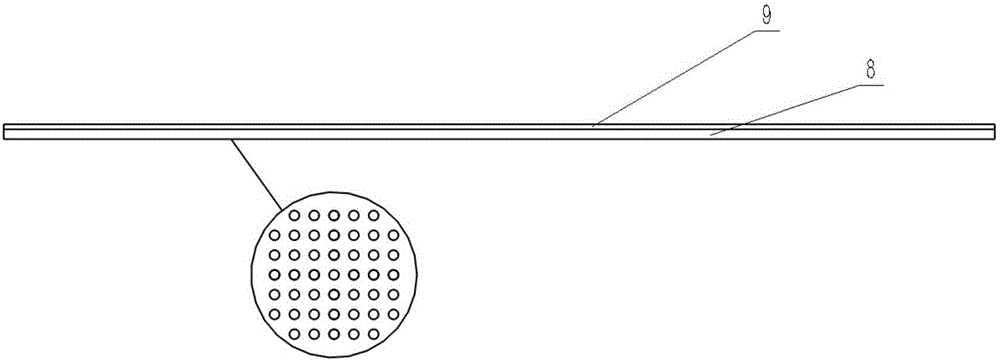

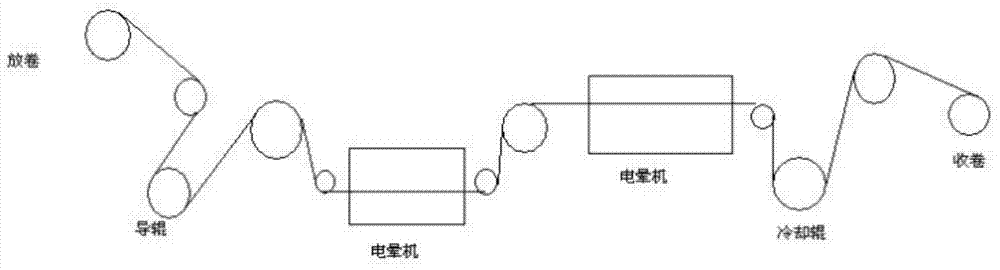

Modified no-rainbow organic silicon release film taking biaxially oriented poly benzoic acid gylcol ester film and preparation method thereof

InactiveCN102218874AIncrease surface tensionGood optical claritySynthetic resin layered productsCoatingsEpoxyBenzoic acid

The invention discloses a modified no-rainbow organic silicon release film taking biaxially oriented poly benzoic acid gylcol ester film and a preparation method thereof, relating to an organic silicon release film and a preparation method thereof. By using modified no-rainbow organic silicon release film, the problems of low organic silicon release film surface tension and poor organic solvent resistant performance can be solved. The release film is prepared from a base material and coating liquid, wherein the coating liquid is prepared from acrylic acid, butyl acrylate, methyl methacrylate, styrene, vinyl dimethyl siloxane prepolymer, epoxy resin E-44, benzoyl peroxide and toluene. The method comprises the following steps: adding parts of acrylic acid, butyl acrylate, methyl methacrylate, styrene and toluene and whole vinyl dimethyl siloxane prepolymer into a reactor; carrying out a reaction in two steps to obtain emulsion; preparing into coating liquid; coating onto the biaxially oriented poly benzoic acid gylcol ester film; and drying to obtain the modified no-rainbow organic silicon release film. The surface tension of the release film is 29-31mN / m, stripping resistance is 19-24g / cm, and the modified no-rainbow organic silicon release film can be used for the field of optical products.

Owner:HARBIN INST OF TECH

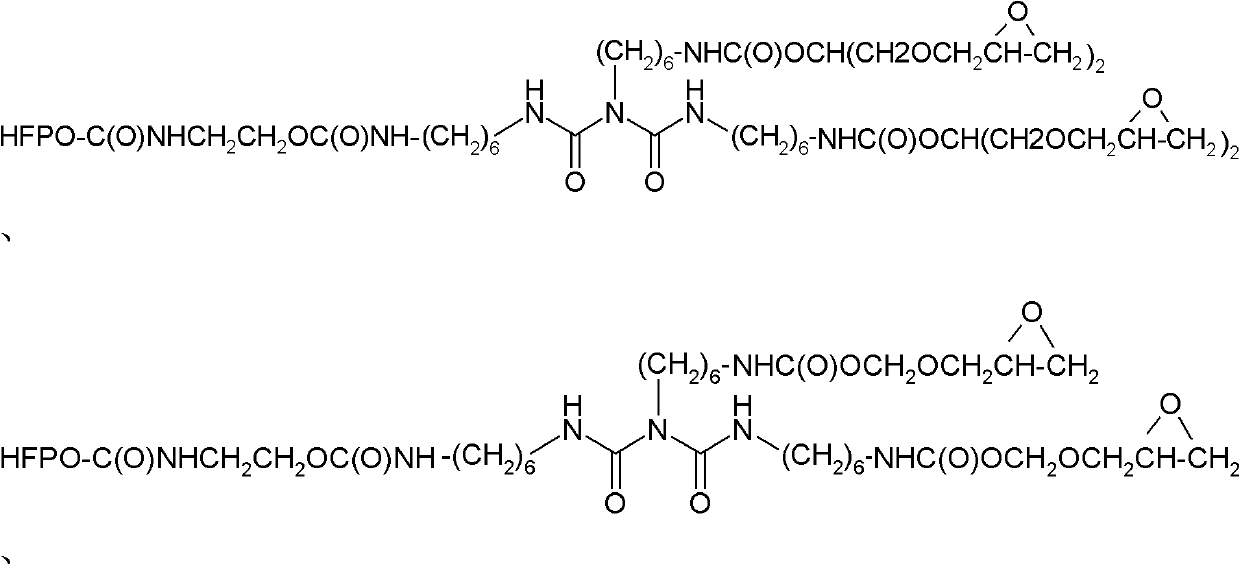

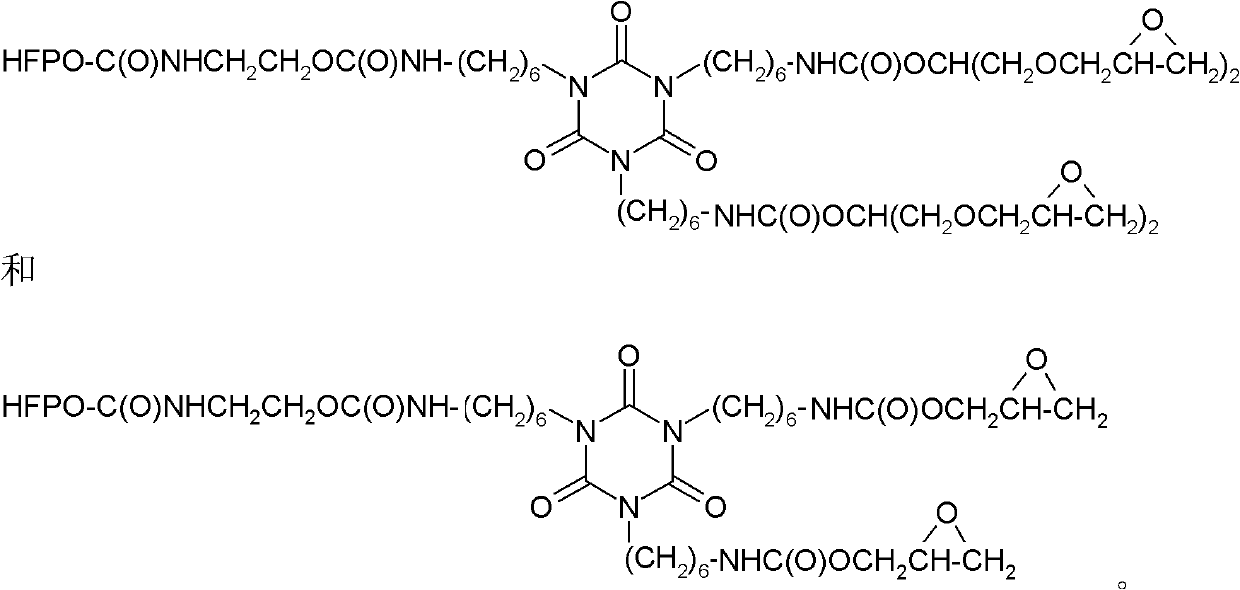

Epoxy-functionalized perfluoropolyether polyurethanes

InactiveCN102498156AReduce hardnessLow transparencyPhotomechanical apparatusPolyurea/polyurethane coatingsEpoxyPerfluoropolyether

Disclosed are epoxy-functionalized perfluoropolyether polyurethane compounds having the following general structure (RfQX1C(O)NH)m-Ri-(NHC(O)X2Q(E)o)n wherein Rf is a monovalent perfluoropolyether moiety; Q is independently a connecting group of valence at least 2, which may contain heteroatoms; X1 is O, S, or NR, wherein R is H or a lower alkyl of 1 to 4 carbon atoms; Ri is a residue of a multi-isocyanate; X2 is O, S, or NR, wherein R is a lower alkyl of 1 to 4 carbon atoms; E is an organic group having at least one oxirane ring; m is at least 1; n is at least 1; o is 1, 2 or 3; and m + n is from 2 to 10.

Owner:3M INNOVATIVE PROPERTIES CO

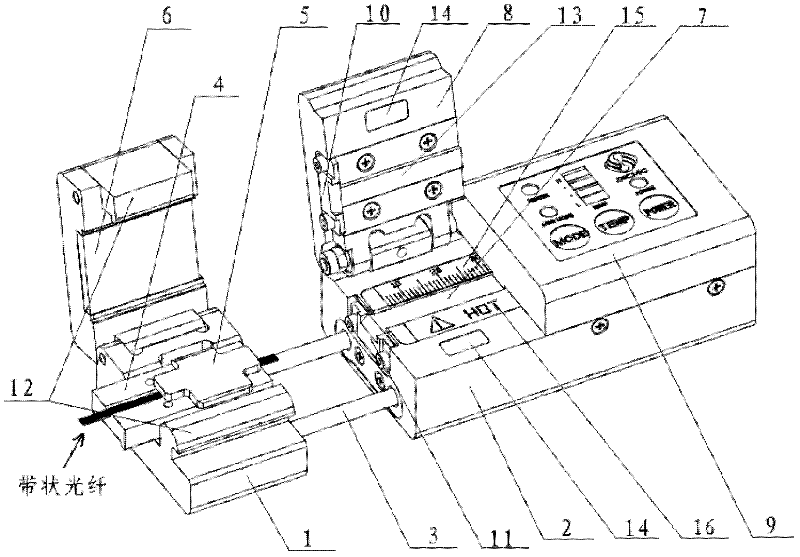

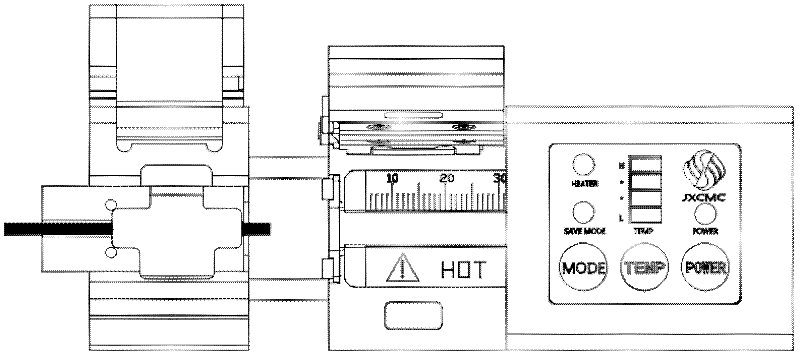

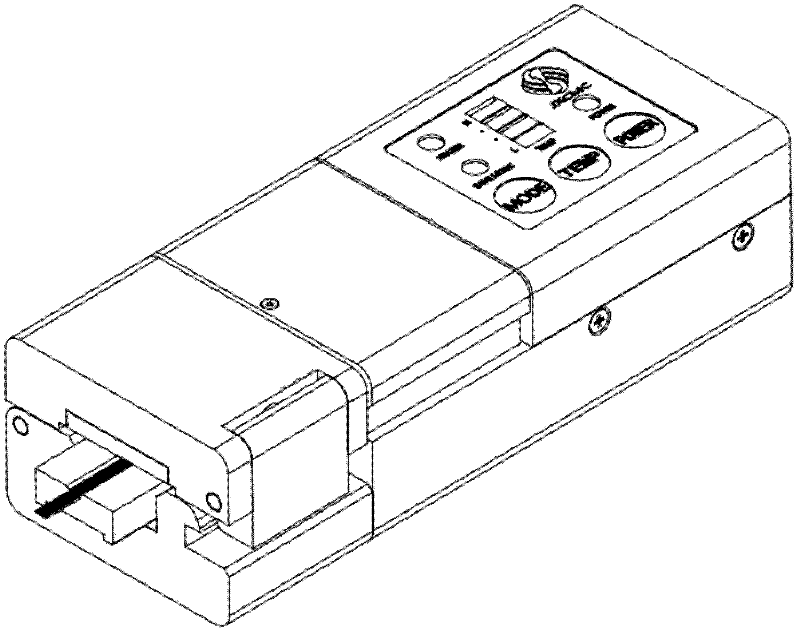

Hot stripping pliers for ribbon fiber

The invention discloses hot stripping pliers for a ribbon fiber. The hot stripping pliers comprise an optical fiber clamp part and a cutting heating part connected through a linear bearing in a sliding manner. The cutting operation adopts a parallel cutting design of an upper blade and a lower blade, and is applicable to fiber stripping operations of a single-core fiber and the ribbon fiber; according to the heating operation, an intelligent heating system is arranged and an optical fiber coating is softened to facilitate the fiber stripping operation of the optical fiber. A design of the linear bearing is adopted, so the release force is small; and the safety and the stability of the operation can be ensured when the optical fiber is drawn to peel off after an optical fiber protecting layer is cut off, and the operation can be finished by one time. The middle heating part adopts a magnet clamping mode so as to facilitate reliable joint of a fiber stripping blade and better strip the coating of the optical fiber. Simultaneously, the skill requirement on an operator is greatly reduced and the popularizing rate of the tool can be greatly improved.

Owner:BENGBU JIXIN COMM MACHINERY

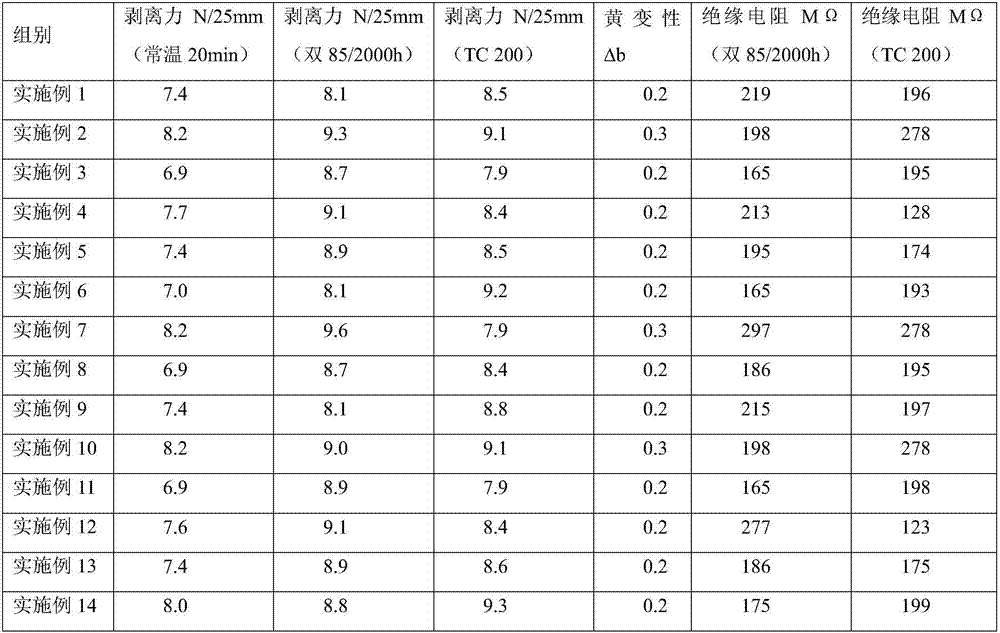

High-temperature-resistence viscosity-reducing adhesive tape and preparation method thereof

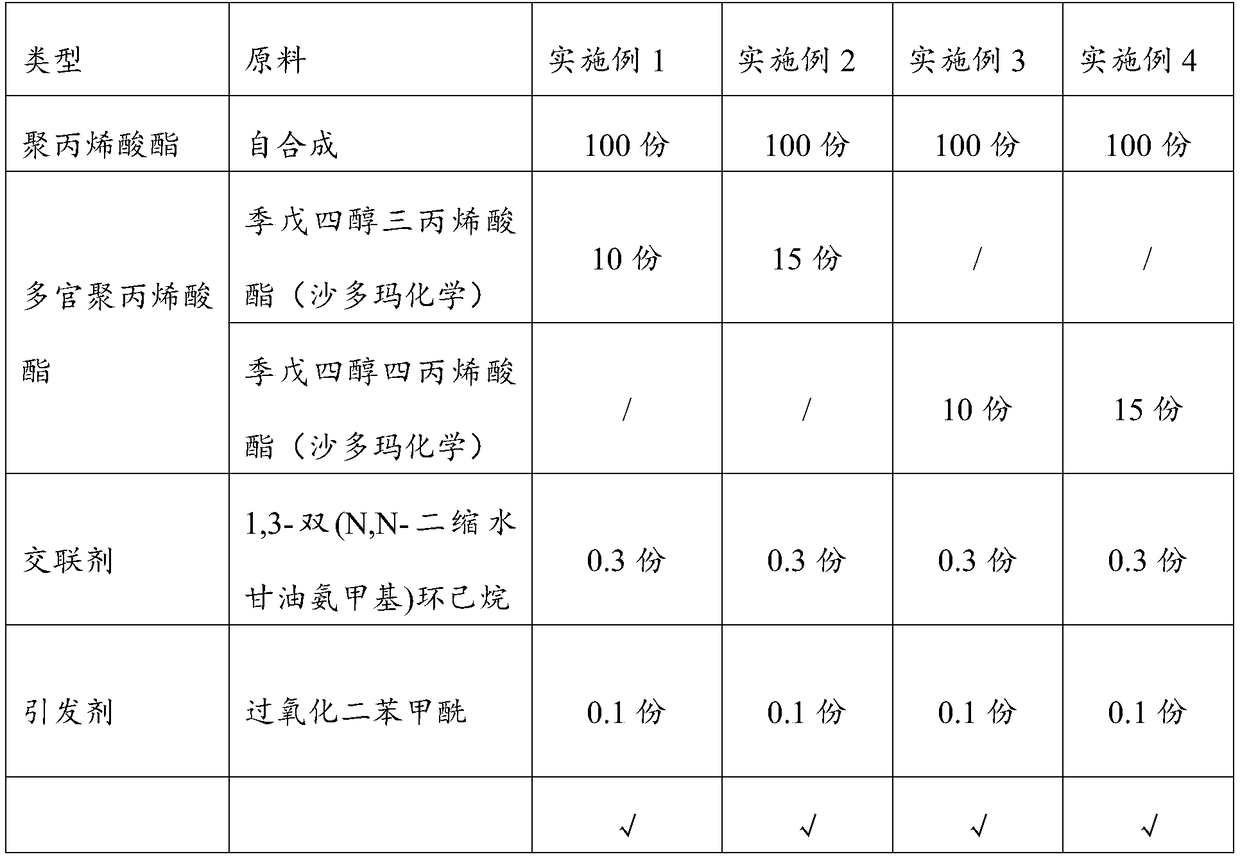

ActiveCN109266236ASmall peeling forceEasy to peelOrganic non-macromolecular adhesivePressure sensitive film/foil adhesivesCross-linkPentaerythritol

The invention relates to a high-temperature-resistence viscosity-reducing adhesive tape. The high-temperature-resistence viscosity-reducing adhesive tape comprises a base material membrane and high-temperature-resistence viscosity-reducing polyacrylate pressure sensitive adhesive smeared on the base material membrane; and the high-temperature-resistence viscosity-reducing adhesive tape is preparedfrom 100 parts of polyacrylate, 10 to 15 parts of multi-functional acrylate, 0.3 part of cross-linking agent and 0.1 part of initiator; and the multi-functional acrylate is any one of pentaerythritoltriacrylate or pentaerythritol tetraacrylate. The base material membrane is any one of a PET membrane or PI membrane. The polyacrylate comprising the high-temperature-resistence cross-linked functional group in the high-temperature-resistence viscosity-reducing adhesive tape is further cross-linked with the multi-functional acrylate at a high temperature, so that the stripping force is greatly reduced, and the high-temperature prepared adhesive tape is easier to strip; and the high-temperature-resistence viscosity-reducing adhesive tape disclosed by the invention is heated and used for 20 to30 minutes at 120 to 160 DEG C, the stripping force is apparently reduced, the adhesive tape is easier to strip, the adhesive residue risk is reduced, and the production efficiency is improved.

Owner:YANTAI DARBOND TECH

Preparation method of pressure sensitive adhesive for polaroid protection film and protection film thereof

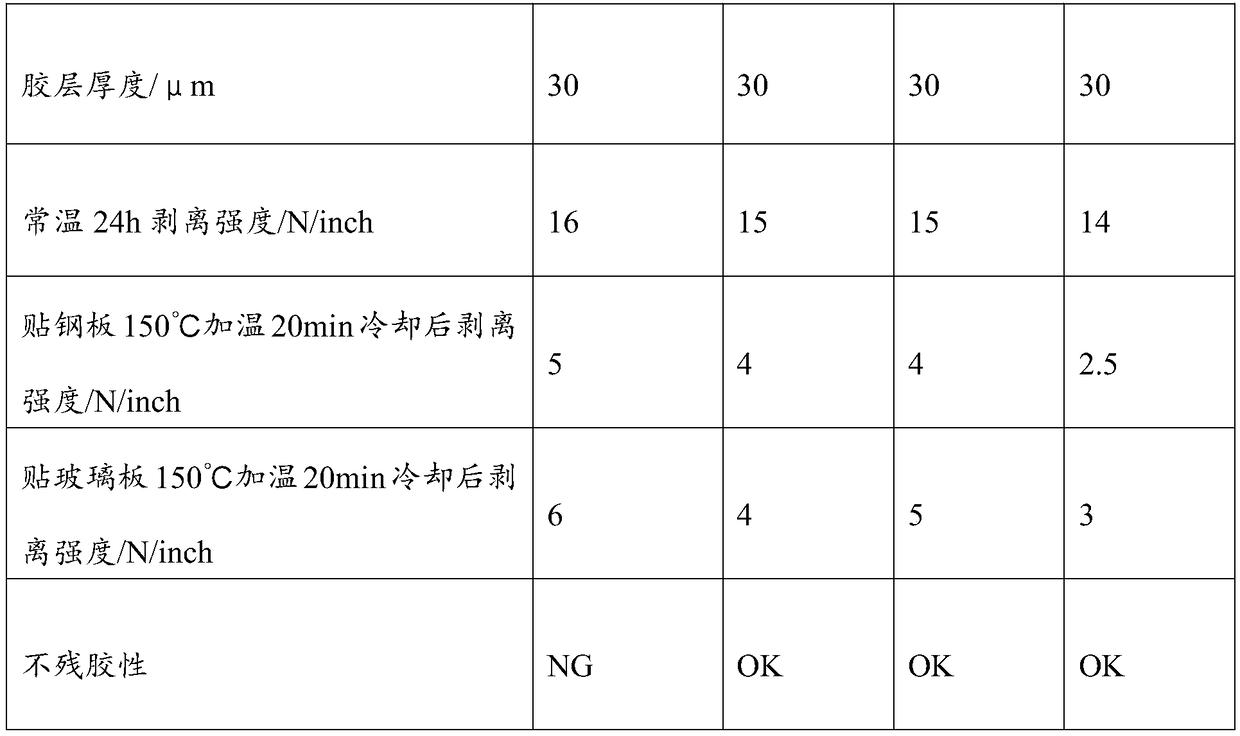

InactiveCN108384476ASave glue dispensing processLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterTectorial membrane

The invention discloses a preparation method of a pressure sensitive adhesive for a polaroid protection film and a protection film thereof. The pressure sensitive adhesive is prepared from the following raw materials in parts by weight: 10 to 40 weight parts of soft monomers, 5 to 15 weight parts of hard monomers, 2 to 6 weight parts of fluorine containing acrylate monomers, 0.8 to 3 weight partsof crosslinking monomers, 0.8 to 2 weight parts of vinylsilane, 0.5 to 2 weight parts of anti-static agents, 0.5 to 1.5 weight parts of initiators and 80 to 190 weight parts of solvents. The pressuresensitive adhesive can be directly covered on the surface of a polyester film; the additional addition of the curing agents and the anti-static agents is not needed; the adhesive layer resistance is 1010 ohm or less; the anti-static performance is realized. When the polaroid protection film adhesive layer is pasted on the surface of a polaroid, after the high-temperature and high-humidity tests for 500h, the protection film and the polaroid are tightly attached; no bubble bulges exist; no adhesive is remained when the protection film is torn away; defects such as hard shadow do not exist.

Owner:昆山乐凯锦富光电科技有限公司 +1

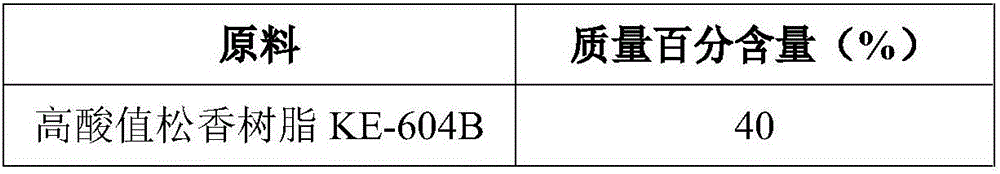

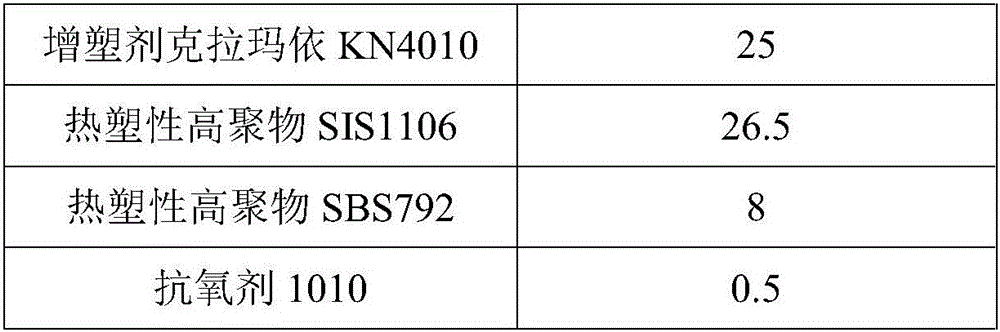

Washable hot melt adhesive and application thereof

InactiveCN106085351ASmall peeling forceIncrease usageNon-macromolecular adhesive additivesOil/fat/wax adhesivesSolid particleCompanion animal

The invention discloses a washable hot melt adhesive and application thereof. The hot melt adhesive is composed of the following raw materials by mass percentage: 30-80% of high-acid value resin; 0-40% of a plasticizer; 10-40% of a thermoplastic high polymer; and 0-1% of an antioxidant. The hot melt adhesive provided by the invention selects high-acid value resin as the tackifier, which contains carboxyl or hydroxyl and other hydrophilic functional groups, and can rapidly react with alkaline water so as to destroy the structure of the hot melt adhesive and lower the stripping force of the hot melt adhesive. The hot melt adhesive is partially dissolved and dispersed into small solid particles so as to completely break away from an adherend, thus being easily removed from the surfaces of PET, PP, PE, glass, ceramics, metals, leather, wood, paper products, plastic products, textile products or others. The washable hot melt adhesive provided by the invention has the bonding performance of conventional hot melt adhesives, and has the advantages of strong initial adhesion, environmental protection and safety, the preparation process is simple, the requirements for the process and equipment are low, the production efficiency is high, and the production cost is low.

Owner:GUANGZHOU THE BOND CHEM

Silicone composition for release paper or release film, release paper, and release film

ActiveCN107636108AExcellent curabilityImprove curing effectOther chemical processesSynthetic resin layered productsPolymer scienceAdhesive

Provided are: an additive reaction-type silicone composition that is for release paper or for a release film, that is non-migratory, and that exhibits light releasability with respect to various adhesives, said silicone composition for release paper or for a release film making it possible to form a cured film that does not adversely affect residual adhesive strength or releasability; and a release paper or a release film obtained by applying the composition to a substrate and curing the result. In a silicone composition for release paper or a release film cured by additive reaction, an organopolysiloxane containing an alkenyl group having a terminal unsaturated bond is used as a base polymer, and a specific amount of an organopolysiloxane that has a lower molecular weight than the base polymer and that contains an alkenyl group having a terminal unsaturated bond is mixed with the base polymer.

Owner:SHIN ETSU CHEM CO LTD

Polybutadiene rubber modified waterborne polyurethane adhesive and preparation method thereof

ActiveCN103409101AIncrease elasticityImprove low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolymer science

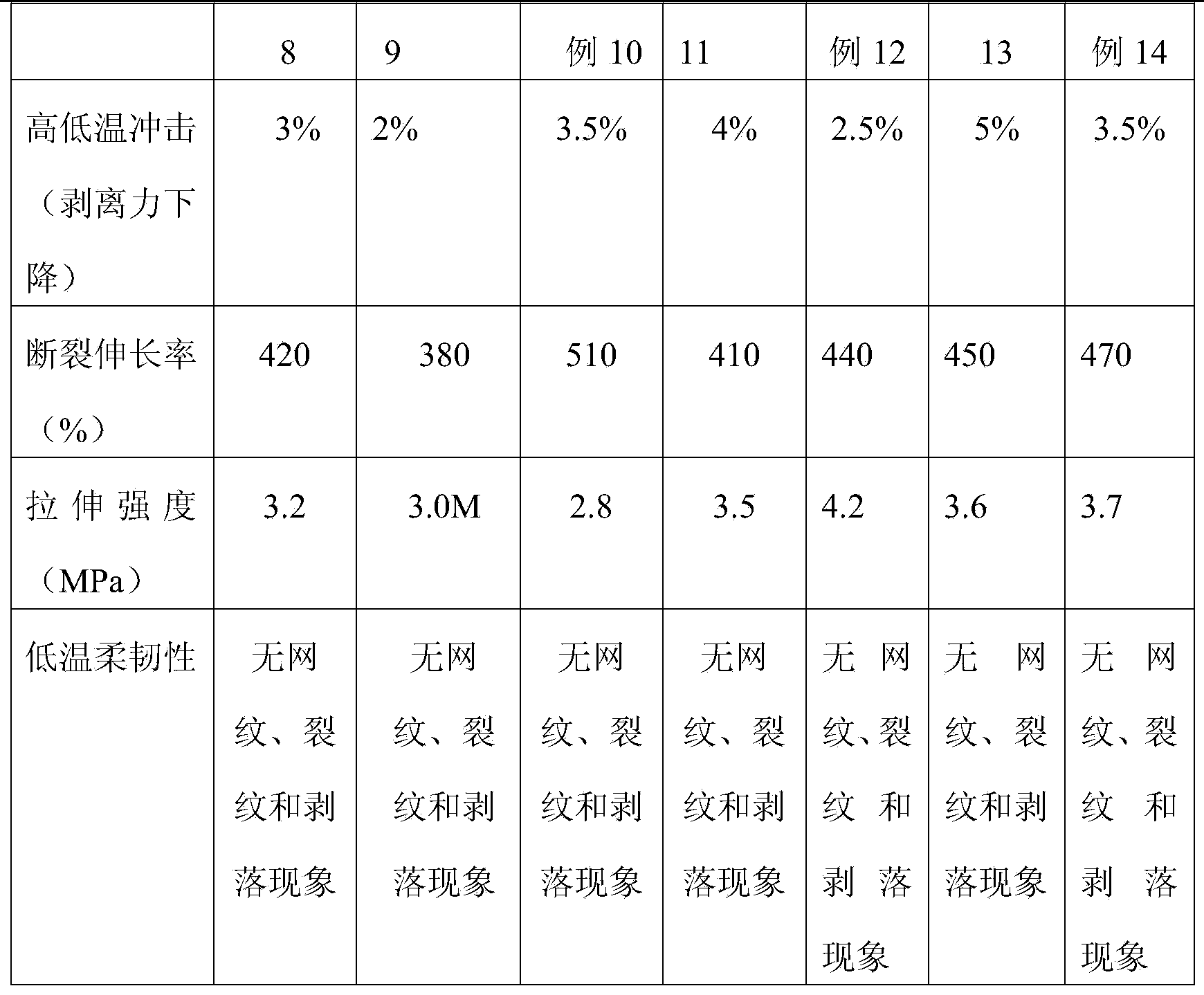

The invention discloses a polybutadiene rubber modified waterborne polyurethane adhesive and a preparation method thereof, which belong to the field of waterborne polyurethane adhesives and are used for solving the problems that an existing polybutadiene rubber modified waterborne polyurethane adhesive is high in thermal activation temperature, low in solid content and poor in primary viscosity and peeling strength. In order to solve the problems, the adhesive disclosed by the invention comprises the following components in parts by weight: 75-100 parts of polybutadiene rubber modified waterborne polyurethane, 3-5 parts of white carbon black, 0.2-0.5 part of 3-amino propyl triethoxysilane, 0.15-0.3 part of waterborne thickening agent, 8-15 parts of plasticizer and 3-7 parts of waterborne curing agent. The invention further provides a preparation method of the polybutadiene rubber modified waterborne polyurethane adhesive. After the adhesive disclosed by the invention is adhered with a sample and impacted for 5 cycles at a high-low temperature between -65 DEG C and 120 DEG C, the peeling strength is reduced by not more than 5%, the elongation at break is as high as 380%-510%, and the tensile strength is as high as 2.8 MPa-4.2MPa.

Owner:CHANGCHUN SANHUA IND

PET (Polyethylene Terephthalate) protection film for cover plate glass manufacturing procedure or delivery process and preparation method thereof

ActiveCN108864977ASolve the problem of energy consumptionSmall peeling forceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTectorial membranePolyethylene terephthalate

The invention discloses a PET (Polyethylene Terephthalate) protection film for a cover plate glass manufacturing procedure or a delivery process and a preparation method thereof. The PET protection film comprises an optical-grade PET substrate layer, a solvent-free UV-curing low-stripping-force antistatic pressure sensitive adhesive layer and a non-silicon release film layer; the preparation method of the PET protection film comprises the following steps: 1) preparing a solvent-free UV-curing low-stripping-force antistatic pressure sensitive adhesive; 2) coating the optical-grade PET substratelayer with the solvent-free UV-curing low-stripping-force antistatic pressure sensitive adhesive; 3) carrying out UV illumination curing and laminating a non-silicon release film. According to the PET protection film disclosed by the invention, the utilized UV-curing low-stripping-force antistatic pressure sensitive adhesive has extremely excellent cohesive strength and has relatively good instant adhering performance on cover plate glass. When the protection film is used for the cover plate glass manufacturing procedure or the delivery process, the stripping force is stable, no residual adhesive is formed and no pollution is caused; meanwhile, the protection film has relatively small influences on surface tension on a glass surface, and the secondary printing performance and OCA (OpticalClear Adhesive) adhesive adhering performance are not influenced.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Lower exposure type ceramic photocuring 3D printing equipment and manufacturing method thereof

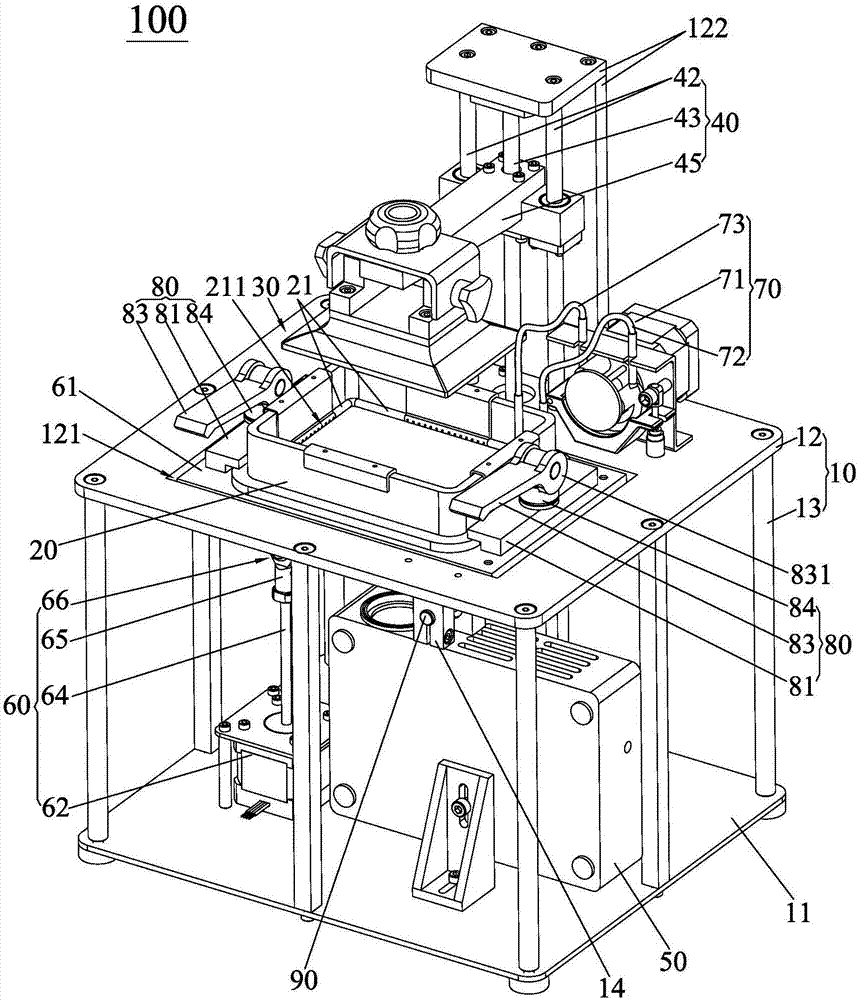

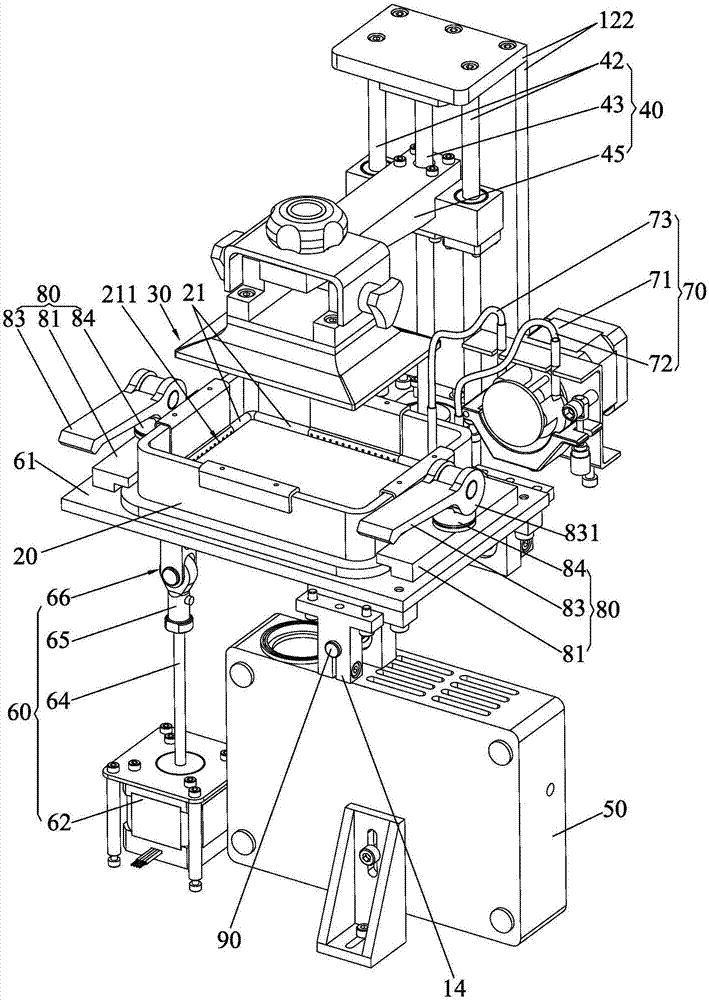

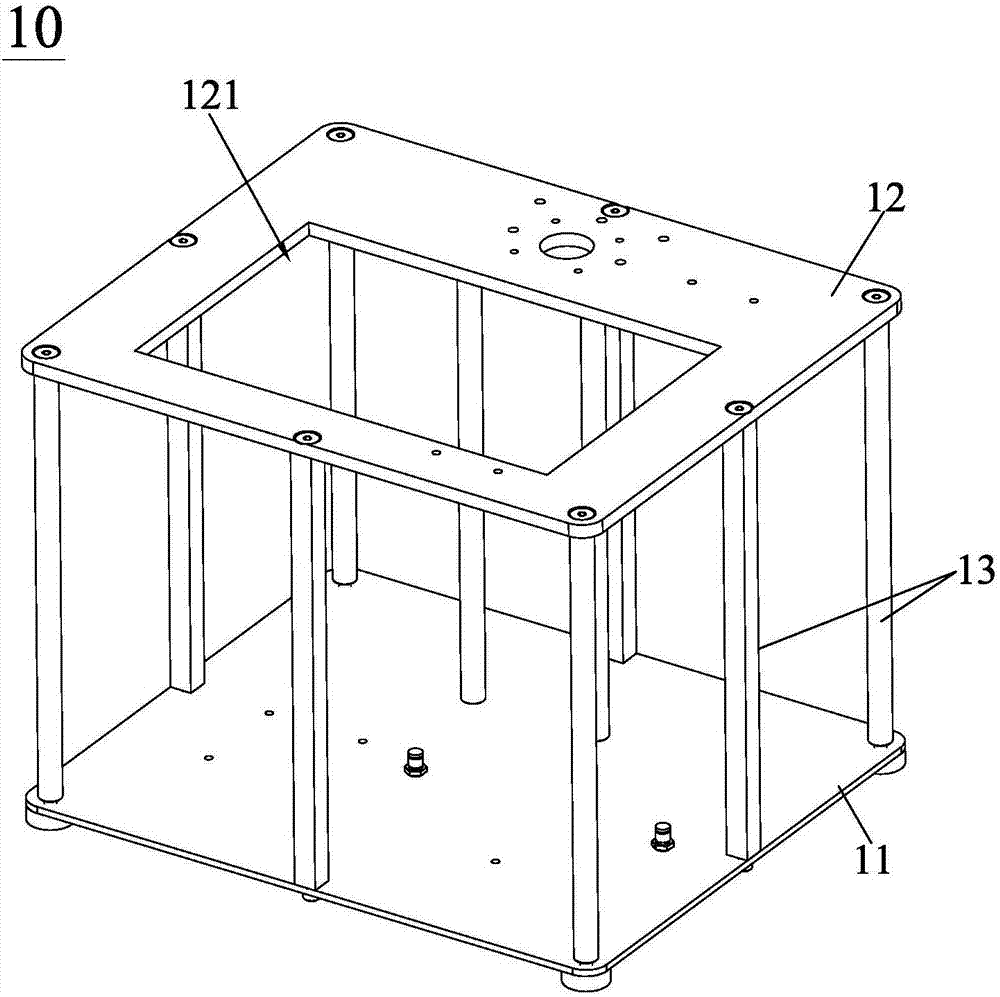

InactiveCN107030852ASmooth peelingImprove printing accuracyAdditive manufacturing apparatusAuxillary shaping apparatusThree dimensional modelCirculating pump

The invention discloses lower exposure type ceramic photocuring 3D printing equipment and a manufacturing method thereof. The lower exposure type ceramic photocuring 3D printing equipment comprises a machine table, a stripping mechanism, a precipitating preventing mechanism, a trough, a printing platform located over the trough, a lifting mechanism driving the printing platform to ascend and descend relative to the trough, and a projector located on the corresponding lower portion of the trough. The stripping mechanism comprises a pivot swing table and a pivot swing driver, the pivot swing table is pivoted on the machine table around a horizontally arranged pivotal shaft, and the pivot swing driver drives the pivot swing table to vertically pivotally swing around the pivotal shaft. The pivot swing driver is mounted on the machine table, and the trough is mounted on the pivot swing table. The precipitating preventing mechanism comprises a circulating pump, a recycling hose and an output hose. The recycling hose is connected between an inlet of the circulating pump and the trough, and the output hose is connected between an outlet of the circulating pump and the trough. The circulating pump is mounted on the machine table and drives photocuring liquid in the trough to circulate. A three-dimensional model and the trough can be separated more easily, and the situation that the photocuring liquid precipitates, and consequently the forming reliability of the three-dimensional model is influenced is avoided.

Owner:DONGGUAN UNIV OF TECH

Antistatic UV (Ultraviolet) viscosity-reducing composition, protection film and preparation process thereof

InactiveCN107022319AReduce adsorptionImprove adsorption capacityNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneAcrylic resin

The invention discloses an antistatic UV (Ultraviolet) viscosity-reducing composition. The antistatic UV viscosity-reducing composition is prepared from the following raw materials in parts by weight: 10 to 20 parts of 4-functional group polyurethane acrylic resin, 5 to 10 parts of polyacrylic resin, 5 to 10 parts of a light initiation monomer, 1 to 3 parts of a light initiator, 50 to 70 parts of a diluting agent, 0.5 to 1 part of polythiophene antistatic resin and 0.5 to 1 part of isocyanate. The invention further discloses an antistatic UV viscosity-reducing protection film and a preparation process thereof. The product disclosed by the invention has a reasonable structural design and has a good viscosity-reducing performance; before the product is irradiated by UV rays, a peeling force is high; after the product is irradiated by the UV rays, the peeling force is low; meanwhile, the product has relatively low surface resistance, a condition that static electricity is generated in a utilization process can be effectively avoided and the adsorption of dust is reduced. The process disclosed by the invention is simple and easy to operate; the production efficiency can be effectively improved, the labor intensity is reduced, the yield of the product is improved and the production cost is powerfully reduced.

Owner:DONGGUAN RETECK COATING TECH CO LTD

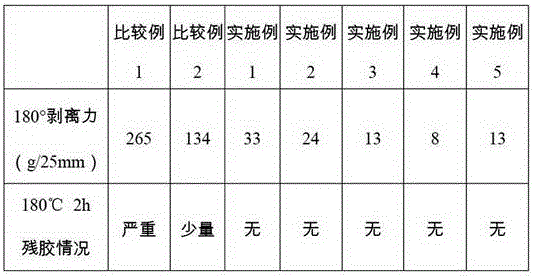

Stripping-force-controllable pressure-sensitive adhesive and preparation method thereof

ActiveCN106749874ANo need to change the structureNo process changes requiredEster polymer adhesivesPressure sensitive film/foil adhesivesEnvironmental resistanceFunctional monomer

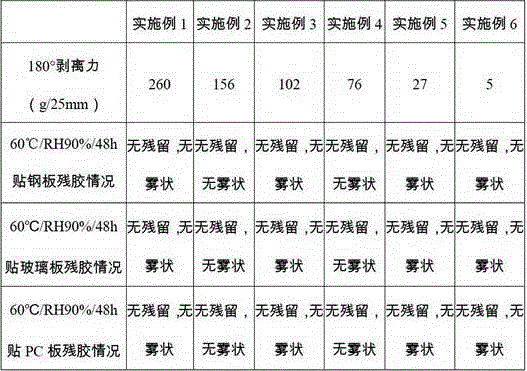

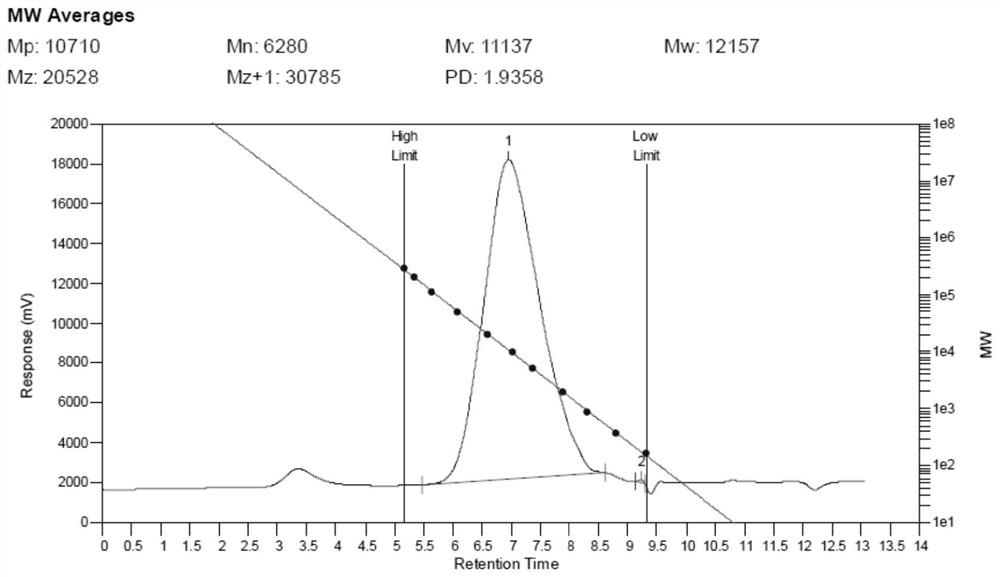

The invention discloses a stripping-force-controllable pressure-sensitive adhesive, which is characterized by being prepared from the following raw materials in percentage by weight: 4 to 8 percent of hard monomer, 26 to 34 percent of soft monomer, 2 to 6 percent of functional monomer and 60 percent of solvent. The pressure-sensitive adhesive is controllable in stripping force and wide in adaptive range; the 180-degree stripping force is 5g to 260g per 25mm; further, the stripping force is changed little along with temperature; glue is low in viscosity and further stable; the pressure-sensitive adhesive is good in humidity and heat resistance, has no residual adhesive, has no fogginess, and has favorable environmental resistance performance; a preparation method of the pressure-sensitive adhesive is simple and effective; the pressure-sensitive adhesive is low in cost, and can be widely applied to an electronic product, a building material product, a furniture product and the like.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

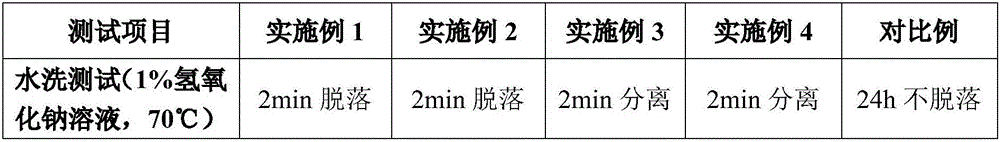

Anchoring agent and preparation method and application thereof

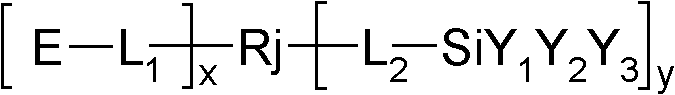

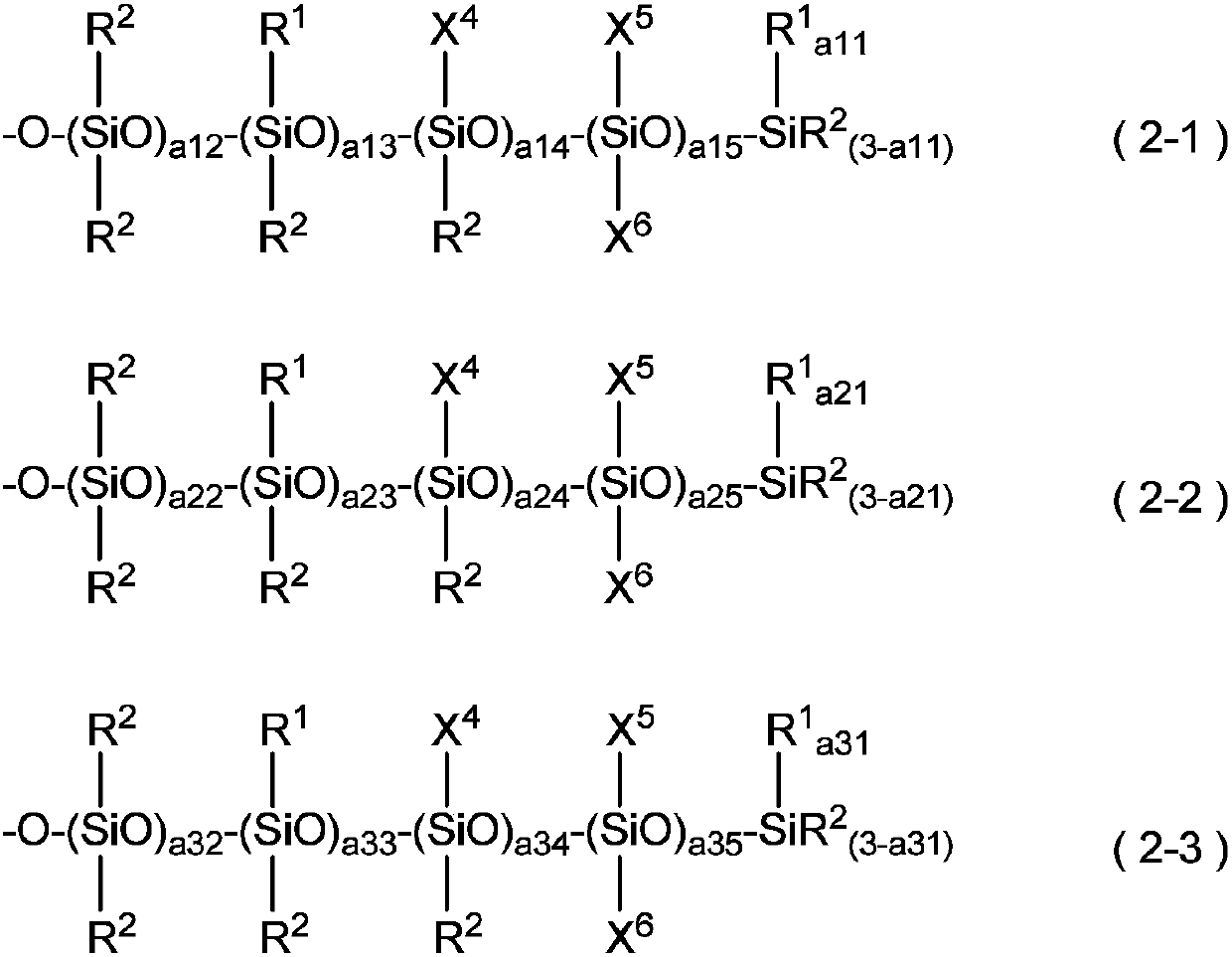

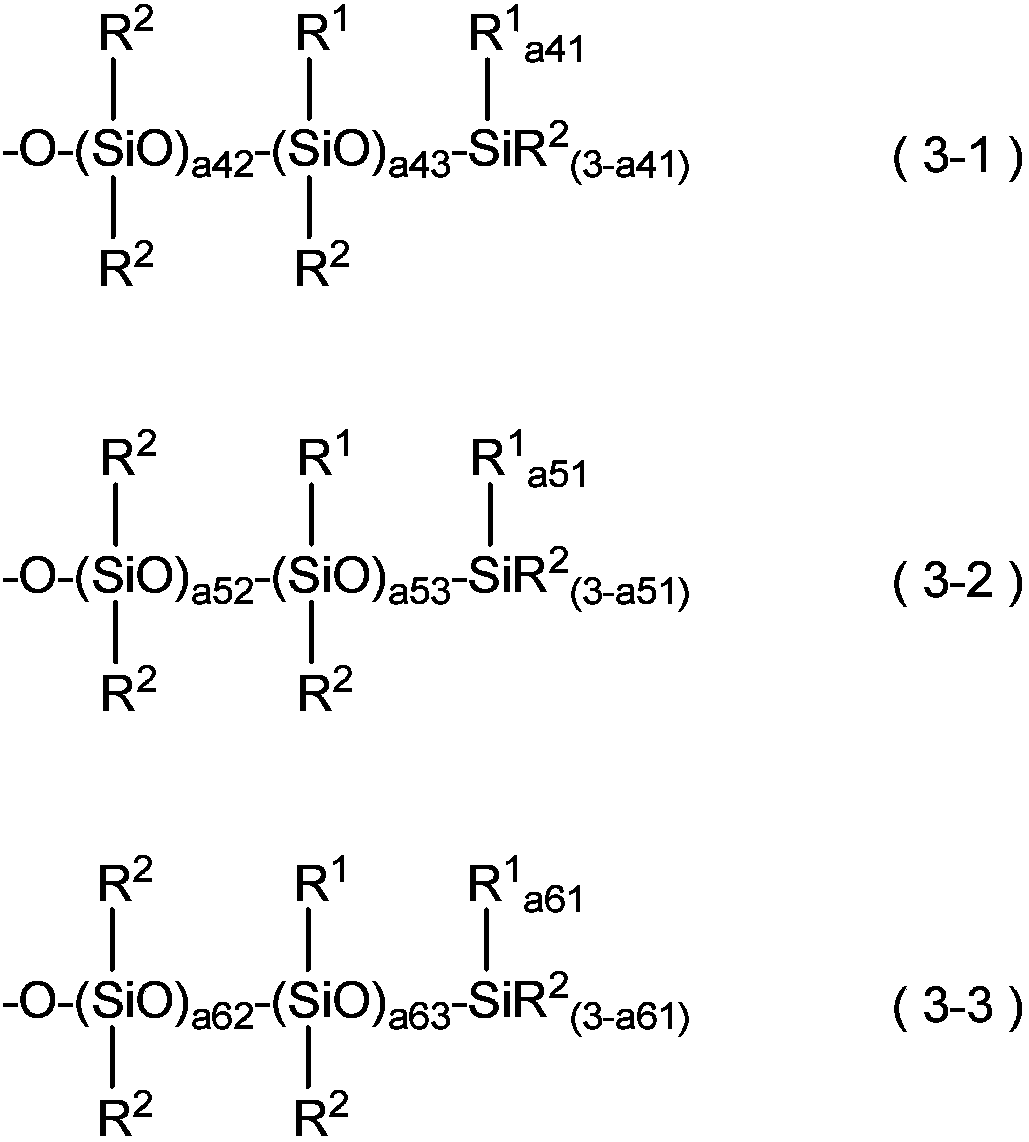

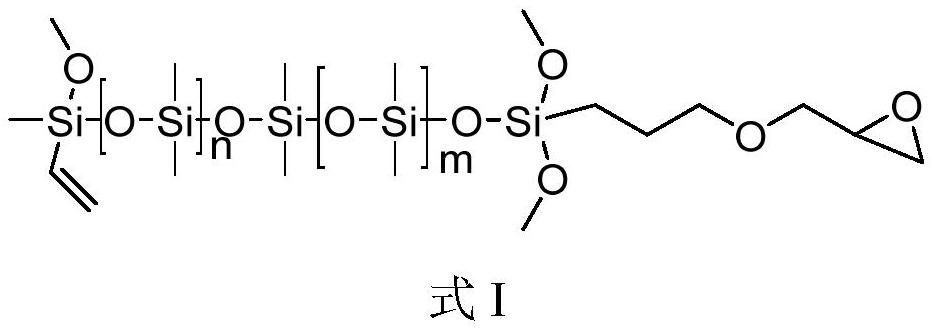

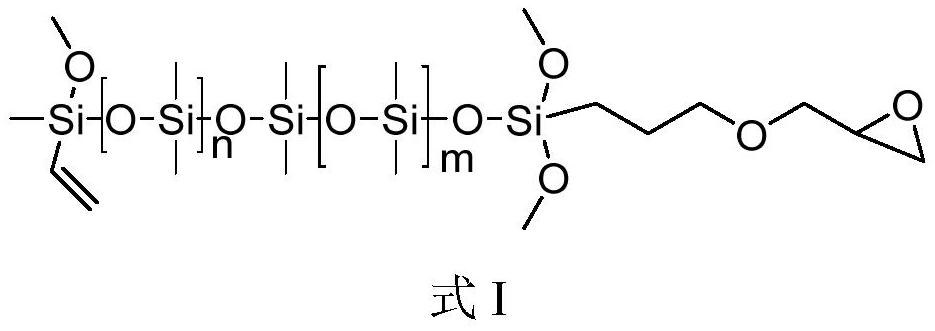

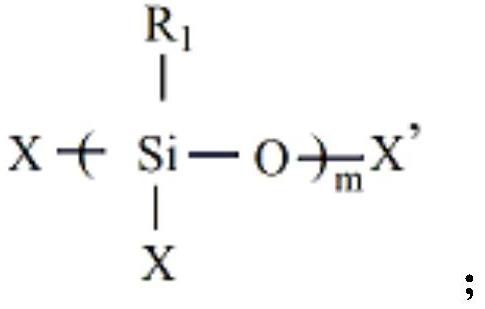

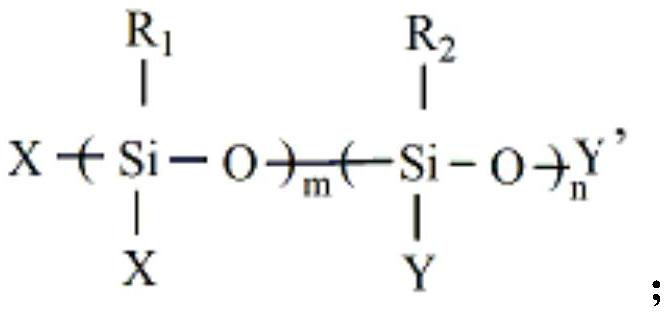

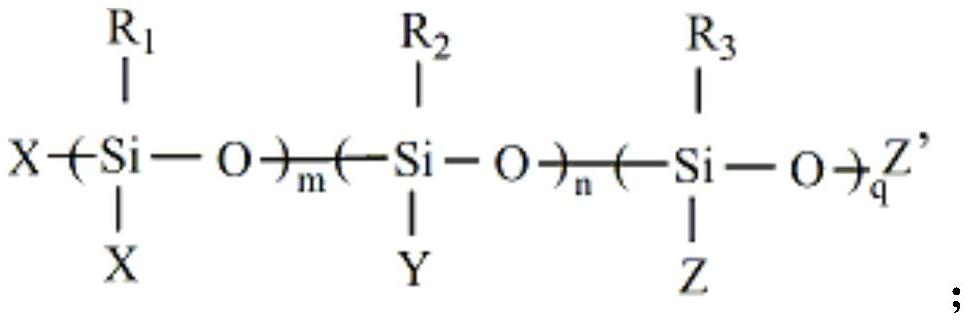

PendingCN112608476AAffect stickinessStable storageFilm/foil adhesive release linersSilane compoundsPolymer science

The invention provides a preparation method and application of an anchoring agent for an organic silicon release agent. The anchoring agent has a structure as shown in a formula I. In the preparation process of the anchoring agent, polyorganosiloxane containing hydroxyl and an alkoxy silane compound containing a vinyl group are directly selected for polycondensation reaction, impurities generated in the reaction process can be reduced, the performance of the anchoring agent is further improved, and when the prepared release agent interacts with a base material (such as paper and a polymer film), high adhesion and low strippable performance are realized at the same time, and the storage stability of the anchoring agent at room temperature can be improved.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD +1

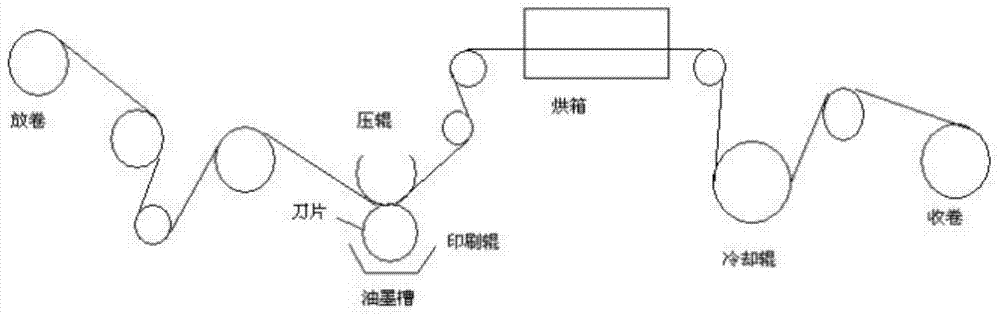

Making method for anti-fake soundless adhesive tape

ActiveCN104513635AHigh bonding strengthImprove adhesionFilm/foil adhesivesEster polymer adhesivesWater basedMicrometer

The invention discloses a making method for an anti-fake soundless adhesive tape. Specifically, the technological steps include: 1. conducting corona treatment on the front surface and back surface of a BOPP film by a corona machine; 2. printing ink on the front surface of the corona treated BOPP film by a printing roller with printing tension of 15-25kgf; 3. coating the back surface of the ink printed BOPP film with a light release force release agent through an anilox roller with coating tension of 20-25kgf, then coating the ink layer on the BOPP film front surface with a LOGO release agent through a LOGO sign printing roller; and 4. coating the LOGO release agent layer on the front surface of the release agent treated BOPP film with a water-based acrylic glue through a gumming roller with coating tension of 20-30kgf, and adjusting the gumming thickness to 20 micrometers by a winding bar under the assistance of a press roller.

Owner:斯迪克新型材料(江苏)有限公司

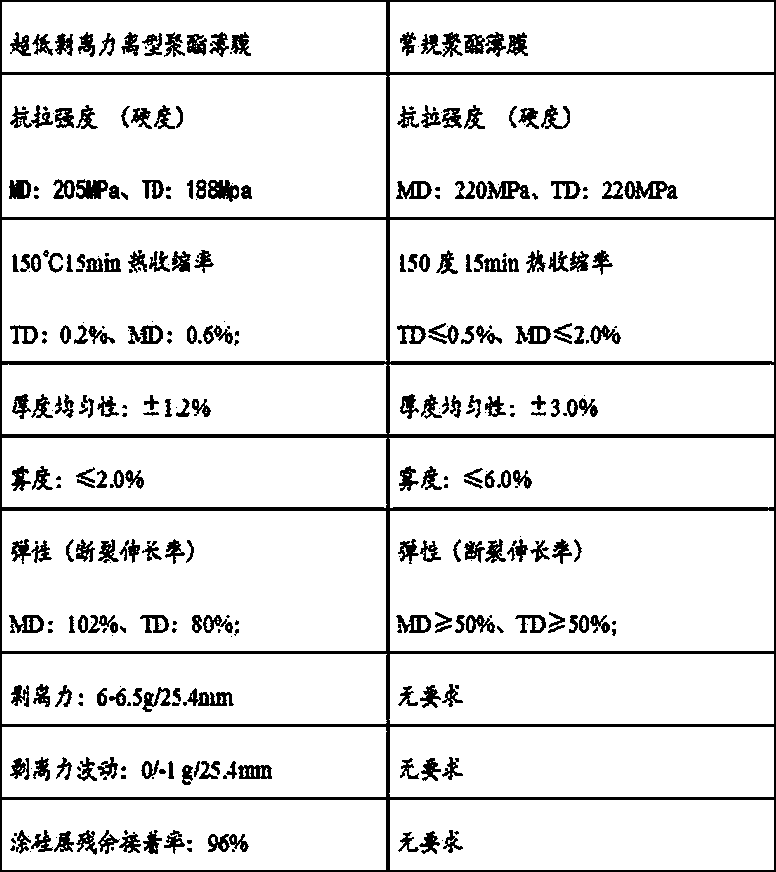

Online-coated ultralow-release force release type polyester film and preparation method thereof

PendingCN108943957ASolve the problem of high peel forceSmall peeling forceSynthetic resin layered productsPolyesterSilicone coating

The invention provides an online-coated ultralow-release force release type polyester film. The polyester film comprises a silicone coating layer, an upper polyester matte layer, a core layer and a lower polyester matte layer, wherein the upper polyester matte layer is arranged below the silicone coating layer, and the core layer is arranged below the upper polyester matte layer; and the lower polyester matte layer is arranged below the core layer, and the total thickness of the film is 36-40 microns. According to the online-coated ultralow-release force release type polyester film provided bythe invention, the necessary strength and elasticity are provided through the combination of a four-layer structure; and by adding a low release force adjusting agent on the original basis, the release force is reduced, so that the problem that the online coating release force is slightly high is solved, and the problems that partial labels fall and are not separated due to the fluctuation of therelease force of the release film in the high-speed labeling production are solved.

Owner:汕头海洋第一聚酯薄膜有限公司

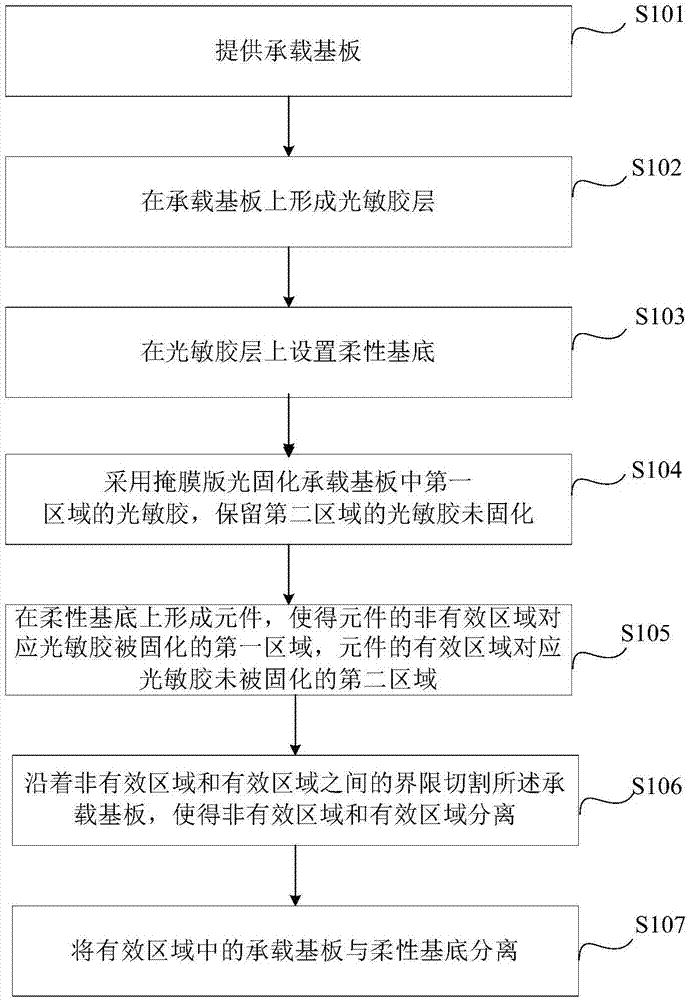

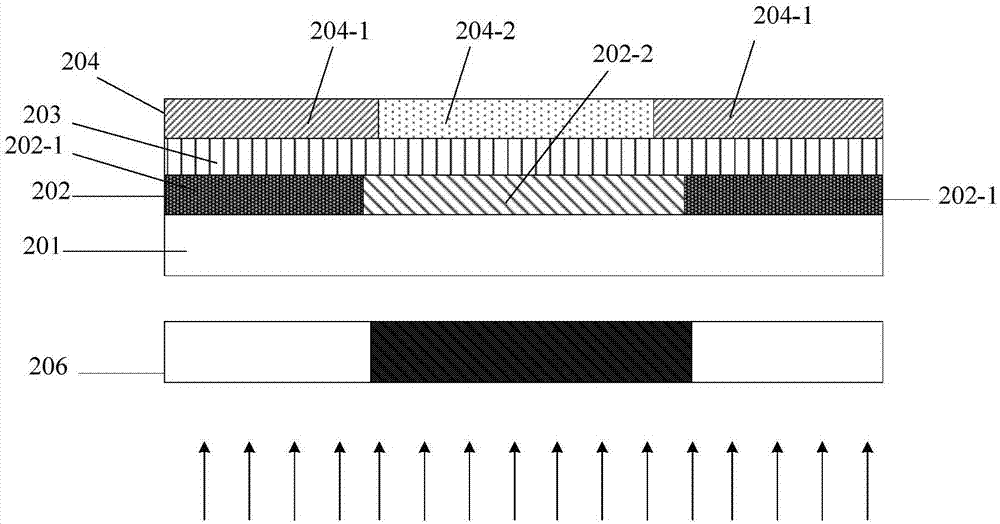

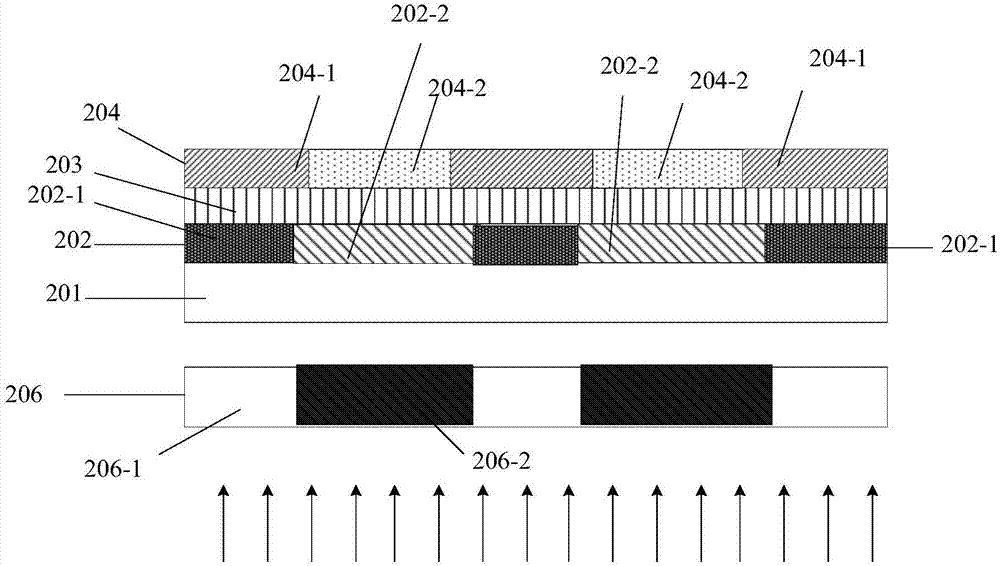

Flexible substrate and method for manufacturing the same, flexible display device and flexible display apparatus

InactiveCN107482022AGuaranteed a tight fitPrevent falling offFinal product manufactureSolid-state devicesEngineeringLight cure

Owner:BOE TECH GRP CO LTD +1

Preparation method of lithium battery negative pole material

ActiveCN106410200AIncrease spacingSmall peeling forceMaterial nanotechnologyCell electrodesNano siliconFreeze-drying

The invention discloses a preparation method of a lithium battery negative pole material. The preparation method comprises the following steps: 1) preparing graphene nanoplatelets: stirring and mixing H2SO4 and (NH4)2S2O8, adding graphite powder after (NH4)2S2O8 is dissolved, further stirring, dropwisely adding H2O2, standing to obtain expanded graphene aggregate, washing with water to neutral, and drying; and adding the dried graphene aggregate into an N-methylpyrrolidone solution, pulverizing to obtain a graphene solution, centrifuging, washing with water, and freeze-drying to obtain graphene nanoplatelet powder; and 2) adding the graphene nanoplatelet powder prepared in the step 1) together with nano silicon powder, polyacrylonitrile and artificial graphite into a container containing dimethylformamide, performing ultrasonic dispersion, freeze-drying to obtain a graphene / nano silicon powder / polyacrylonitrile / artificial graphite mixture, calcining the mixture to obtain a graphene / nano silicon powder / cyclized polyacrylonitrile / artificial graphite compound, and crushing the compound to obtain the graphene / nano silicon powder / cyclized polyacrylonitrile / artificial graphite mixed negative pole material.

Owner:ZHEJIANG JILI POWER NEW ENERGY

Laser alumite stamping foil with controllable peel strength and preparation method thereof

InactiveCN103192621AIncrease productivityStrong process adaptabilitySynthetic resin layered productsCoatingsHot stampingStamping process

The invention relates to a holographic anti-counterfeit alumite material used in the printing industry, especially to a laser alumite stamping foil with controllable peel strength and a preparation method thereof. The invention provides the laser alumite stamping foil with the advantages of capacity of bearing alumite laser anti-counterfeit information, adjustable peel strength of a coating, high resistance to heat, wear, weather and scratches and suitability for a subsequent procedure of single-plate / seamless molding and the preparation method thereof. The laser alumite stamping foil comprises, by mass, 10 to 15 parts of a thermoplastic hard acrylic resin, 3 to 6 parts of a thermoplastic soft acrylic resin, 1 to 11 parts of cellulose ester, 80 to 95 parts of a solvent and 0.1 to 0.2 part of an auxiliary agent. The laser alumite stamping foil can be directly fed into a machine for coating, thereby realizing energy saving and emission reduction to be realized; the peel strength of the coating is adjusted through changing of the addition amount of cellulose ester, the peel strength is reduced when the usage amount of cellulose ester is increased, and the peel strength is allowed to change in a range of 2 to 15 KN / m; the laser electrochemical aluminum stamping foil can meet requirements on peel strength by different hot stamping substrates and different hot stamping processes and has a wide application scope.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

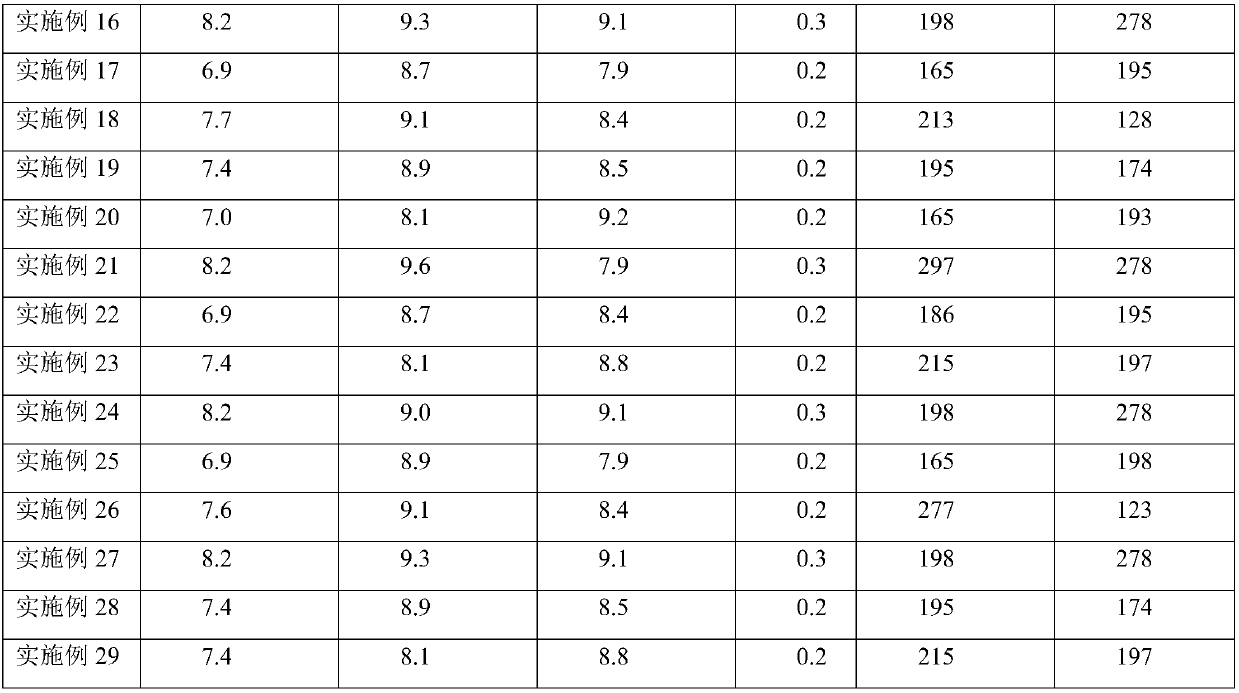

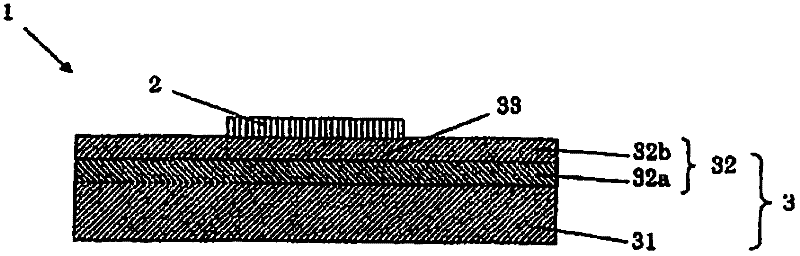

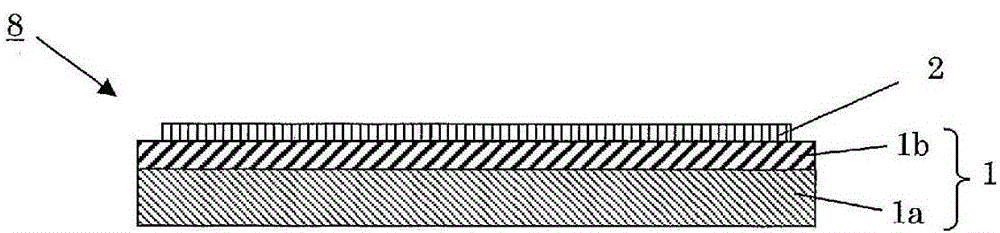

Reinforcing sheet and process for producing semiconductor device through secondary mounting

InactiveCN105051890ASmall peeling forceEasy to peelSemiconductor/solid-state device detailsSynthetic resin layered productsBreaking strengthUltimate tensile strength

Provided is a reinforcing sheet with which it is possible to produce, through secondary mounting, a semiconductor device that has excellent impact resistance and to make steps for the secondary mounting efficient. Also provided is a process for producing a semiconductor device through secondary mounting using the reinforcing sheet. This reinforcing sheet is for reinforcing a semiconductor device produced through secondary mounting in which a semiconductor device that was produced through primary mounting and has bump electrodes formed on a first main surface thereof has been electrically connected to a wiring board through the bump electrodes. The reinforcing sheet comprises a base layer, a pressure-sensitive adhesive layer, and a thermosetting resin layer in this order, wherein the pressure-sensitive adhesive layer has a breaking strength of 0.07 MPa or greater and a melt viscosity at 60-100ºC of 4,000 Pa·s or less.

Owner:NITTO DENKO CORP

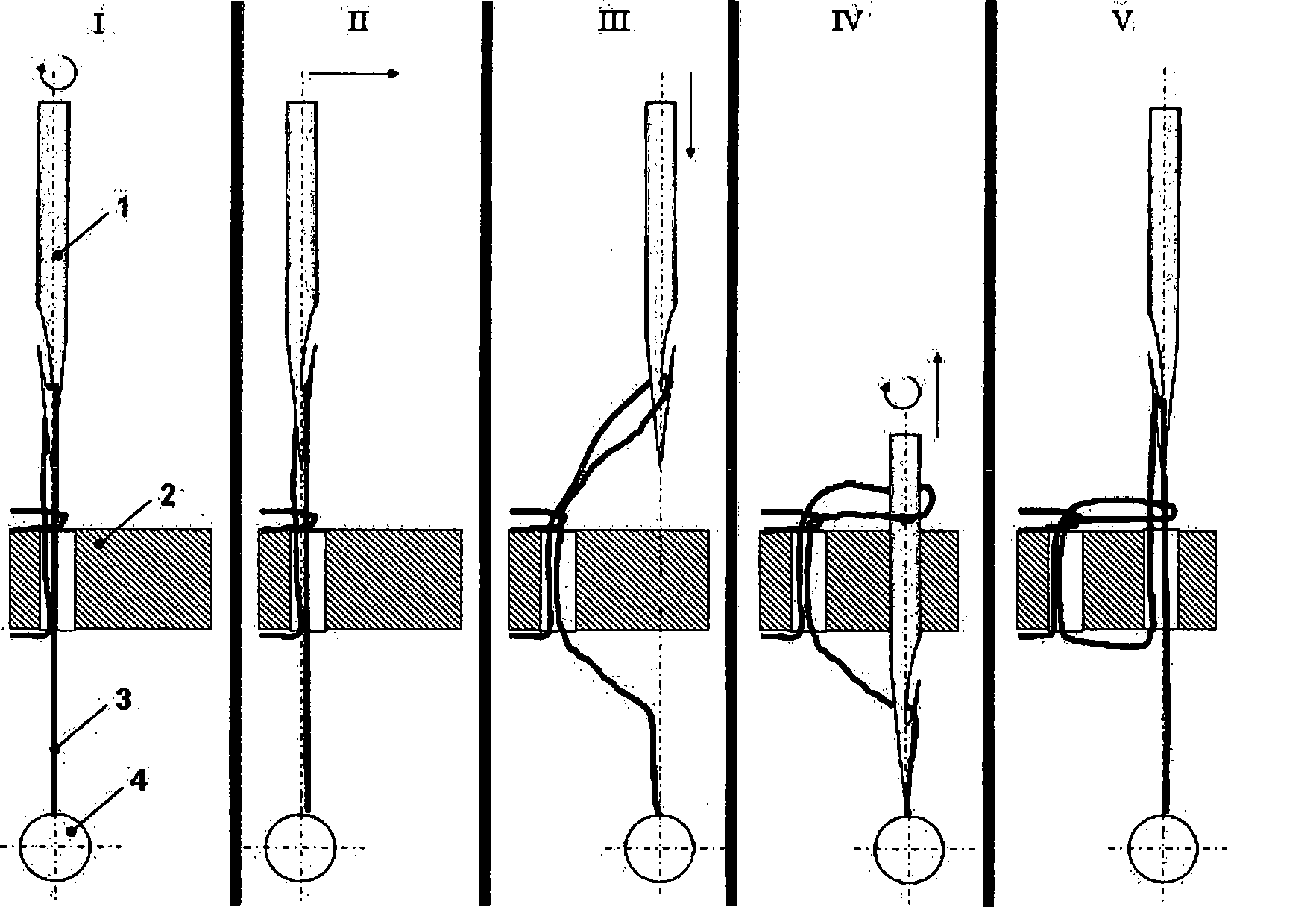

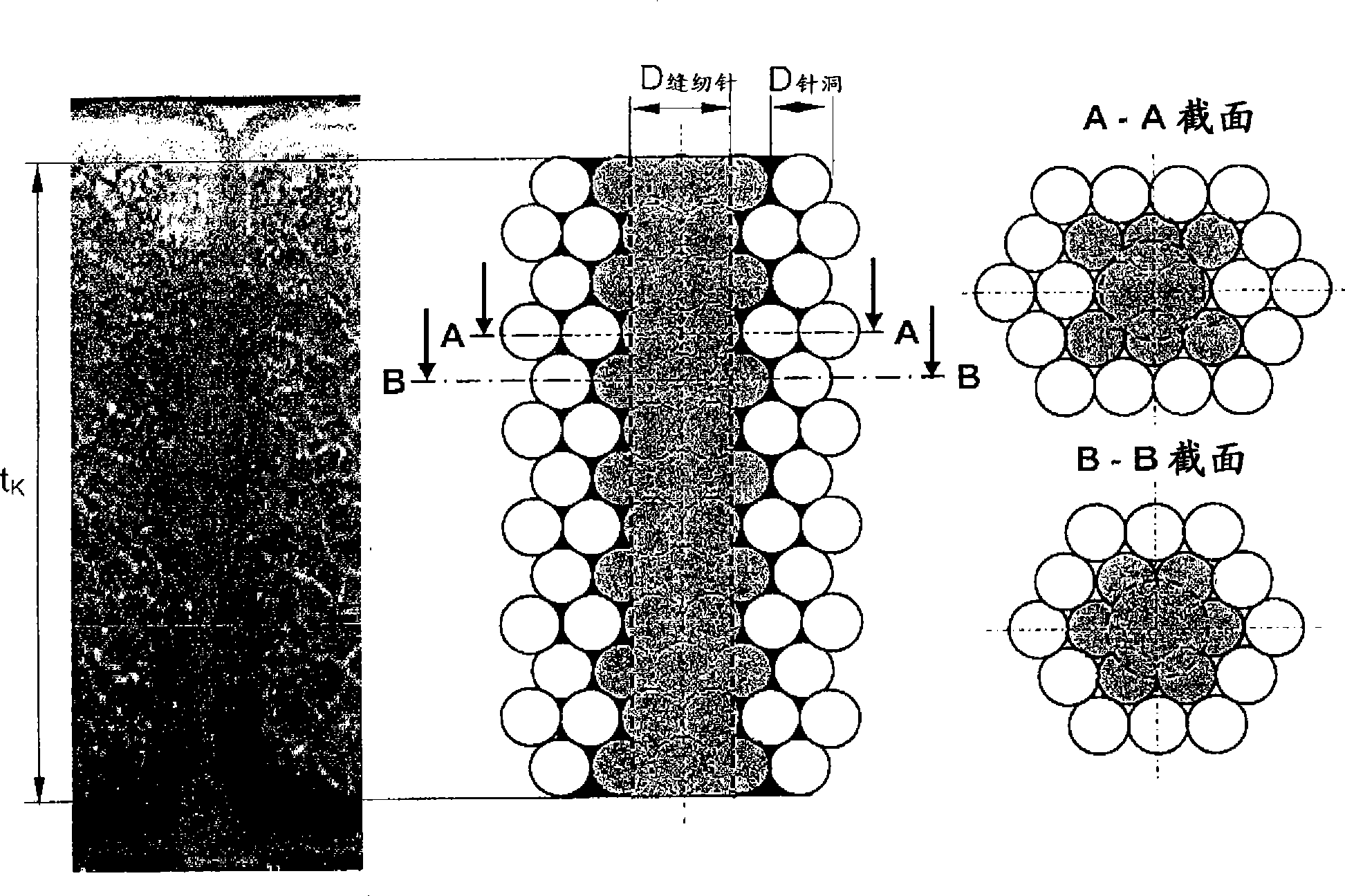

Two-sided single-needle under-thread stitching process

InactiveCN101417518AAvoid displacementAvoid curlConstruction materialNon-magnetic metal hullsFiberPolymer science

The invention relates to a method for enhancing an interlayer structure. The surface layer of the interlayer structure can be made of fibre-plastic compound materials (FKV) preferably, and the core layer material is made of polymeric rigid foams.

Owner:EVONIK ROEHM GMBH

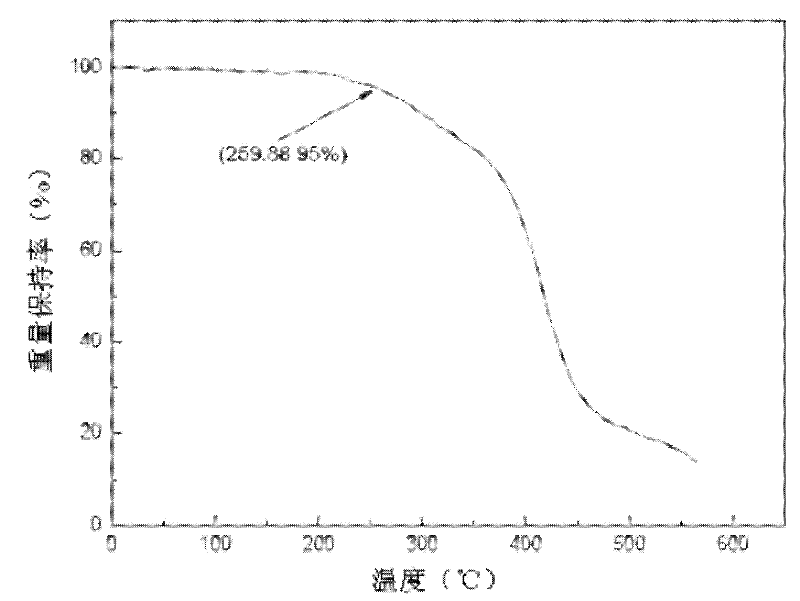

Multifunctional packaging adhesive film and preparation method thereof

PendingCN111961422AImprove the attenuation effectExcellent anti-PID performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceOligomer

The invention provides a multifunctional packaging adhesive film and a preparation method thereof. The multifunctional packaging adhesive film comprises, by mass, 90 to 99% of a polymer and 1 to 10% of an auxiliary agent, and the auxiliary agent comprises a silane oligomer. The prepared multifunctional packaging adhesive film has excellent peeling force attenuation resistance and PID resistance, and can meet the requirements of packaging adhesive films with different functions.

Owner:CYBRID TECHNOLOGIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com