Flexible substrate and method for manufacturing the same, flexible display device and flexible display apparatus

A flexible substrate and manufacturing method technology, applied in the field of flexible display devices, can solve the problems of display device damage, difficulty in ensuring uniformity, huge investment, etc., and achieve the effect of ensuring tight fit and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example one

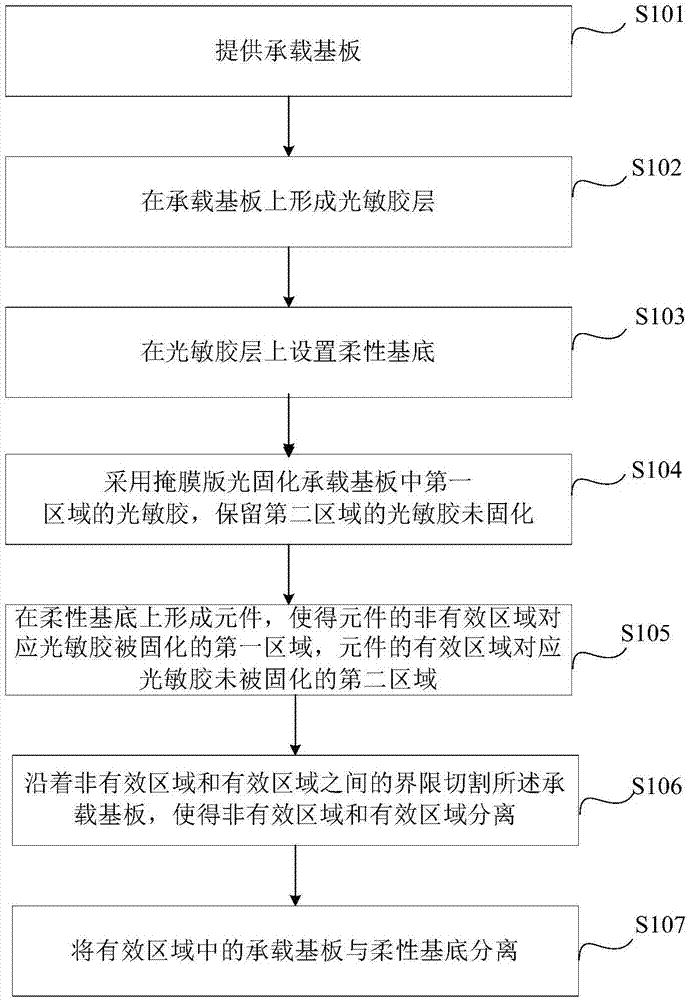

[0021] The embodiment of the present invention provides a method for manufacturing a flexible substrate, figure 1 It is a process flow chart of a method for manufacturing a flexible substrate according to an embodiment of the present invention.

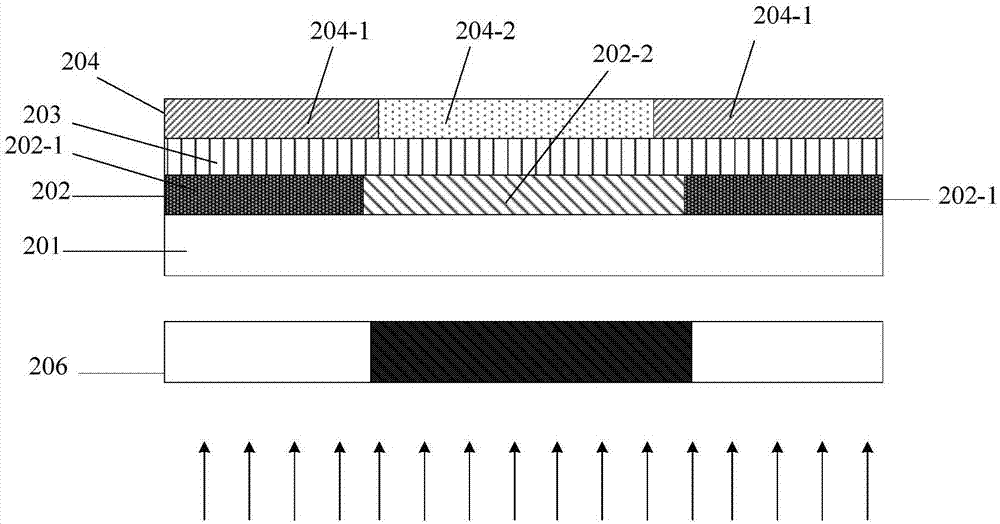

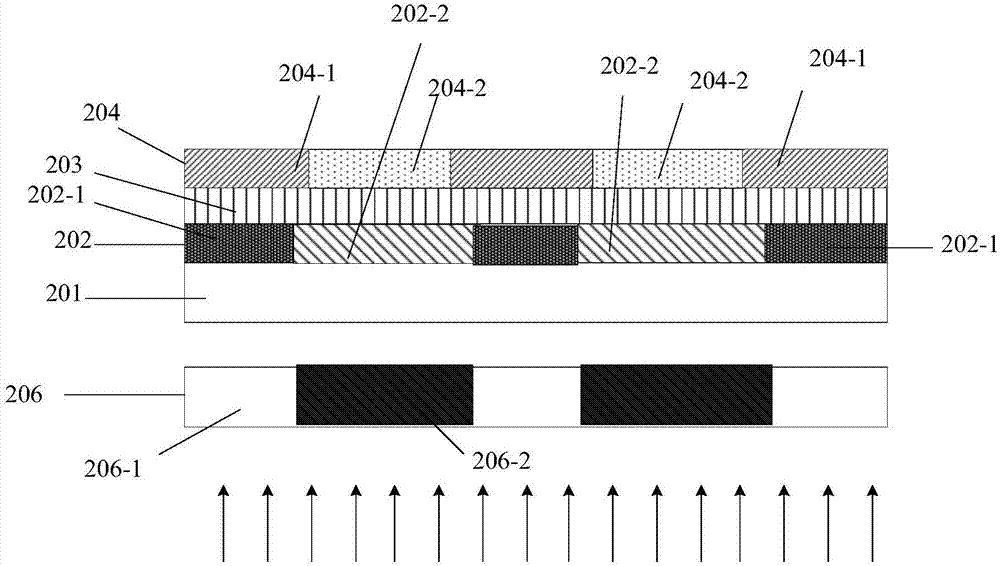

[0022] Such as figure 1 As shown, the method includes: first, in step S101, a carrier substrate 201 is provided; then in step S102, a photosensitive adhesive layer 202 is formed on the carrier substrate 201; then in step S103, a flexible adhesive layer 202 is provided on the photosensitive adhesive layer 202. 基基203。 Base 203. The method of setting the flexible substrate 203 can directly attach a flexible substrate film after the photosensitive adhesive layer is coated to form a flexible substrate; or apply a flexible liquid material on the photosensitive adhesive layer, and then solidify to form a flexible substrate, by coating a flexible liquid material Then, the thickness of the flexible substrate formed by the metho...

Example Embodiment

[0035] Example two

[0036] The embodiment of the present invention provides a flexible substrate manufactured using the method provided in the first embodiment, and also provides a flexible display device manufactured using the method provided in the first embodiment. The device is a display device, including a liquid crystal display and an organic light emitting device. A diode or electrophoretic display also provides a flexible display device, including the above-mentioned flexible display device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com