Patents

Literature

521results about How to "Prevent falling off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

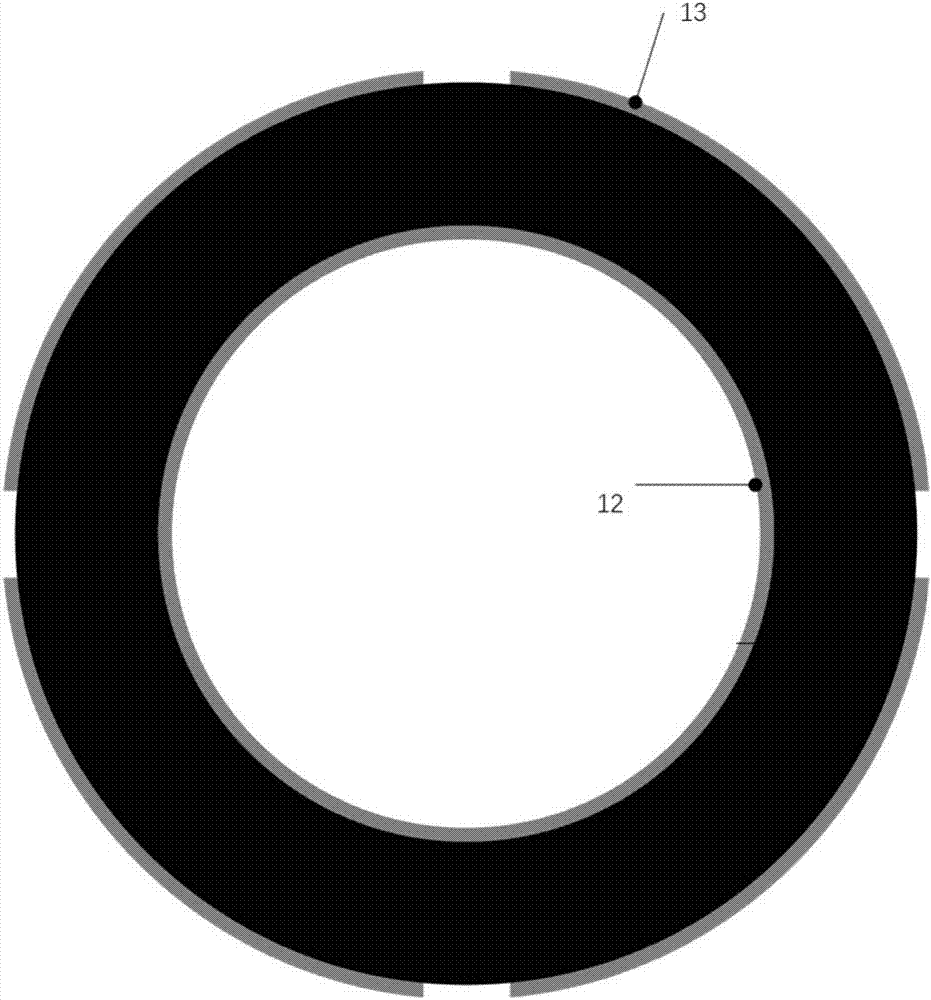

Pressure vessel and process for producing the same

InactiveUS6190481B1Prevent falling-offIncrease fixing strengthGas handling applicationsHollow articlesInternal pressureEngineering

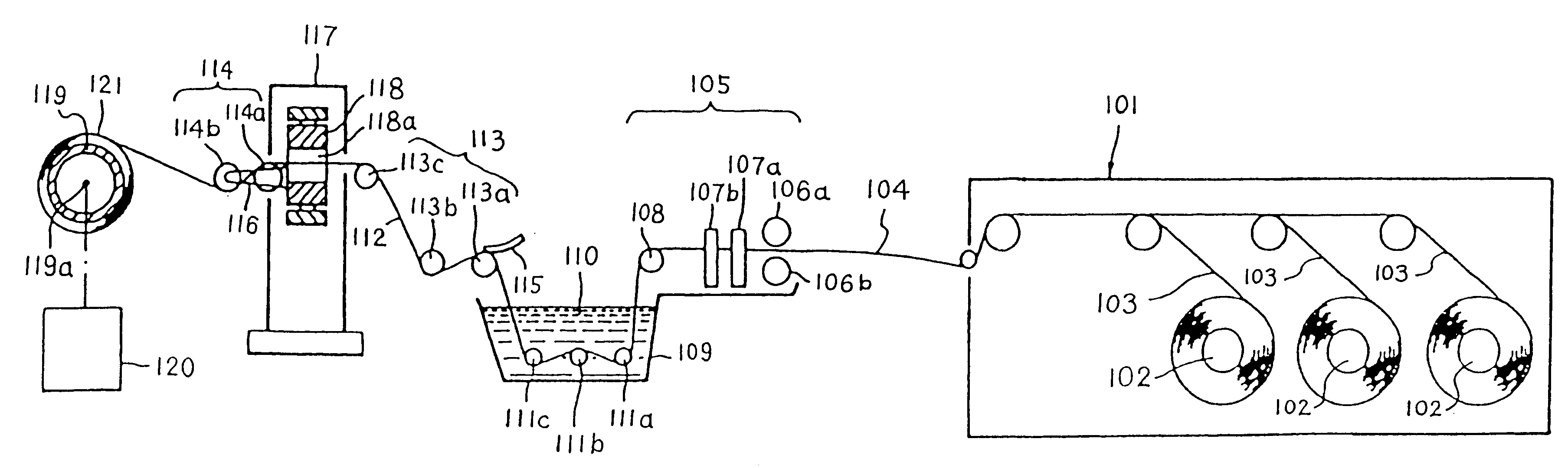

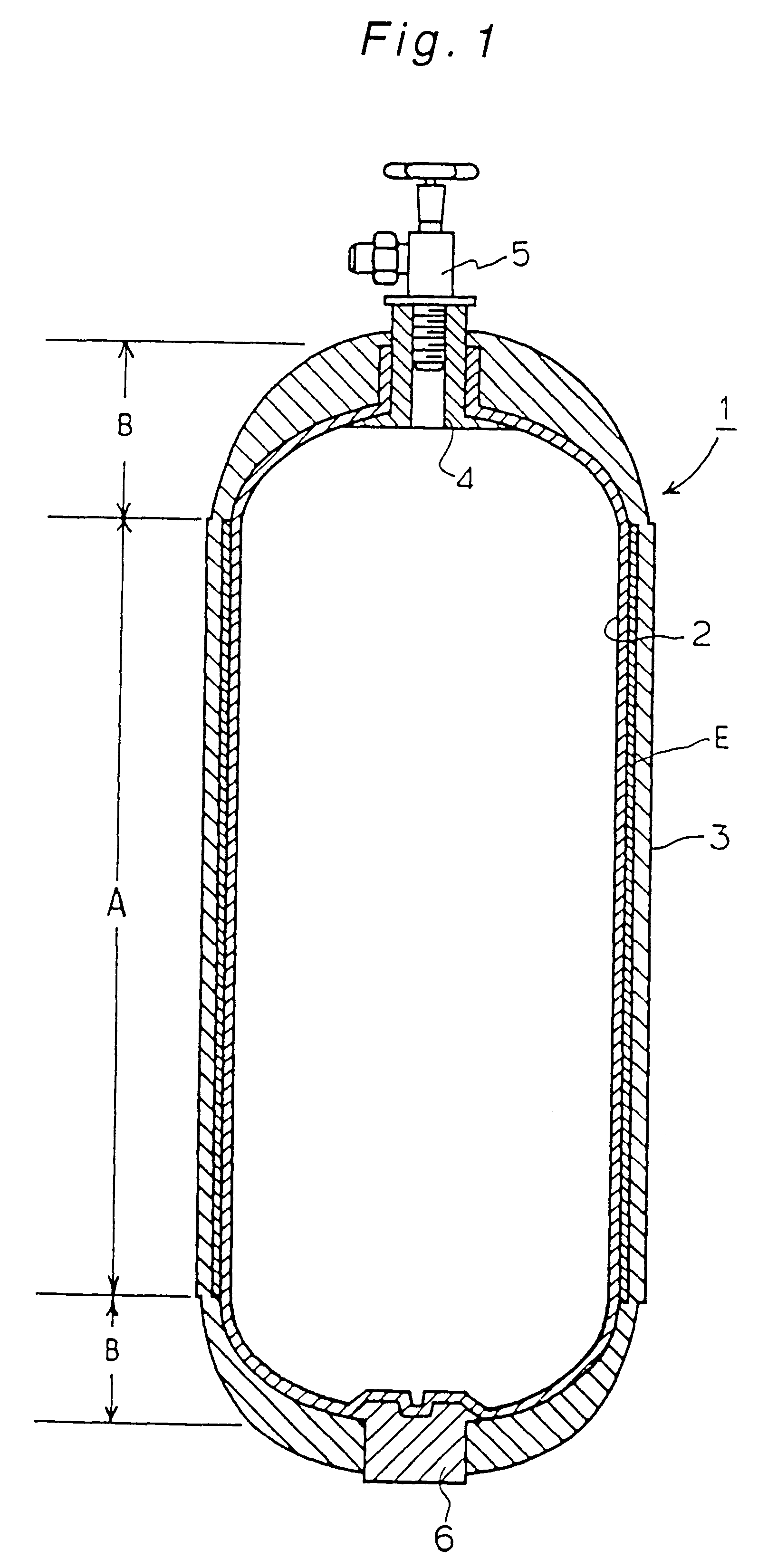

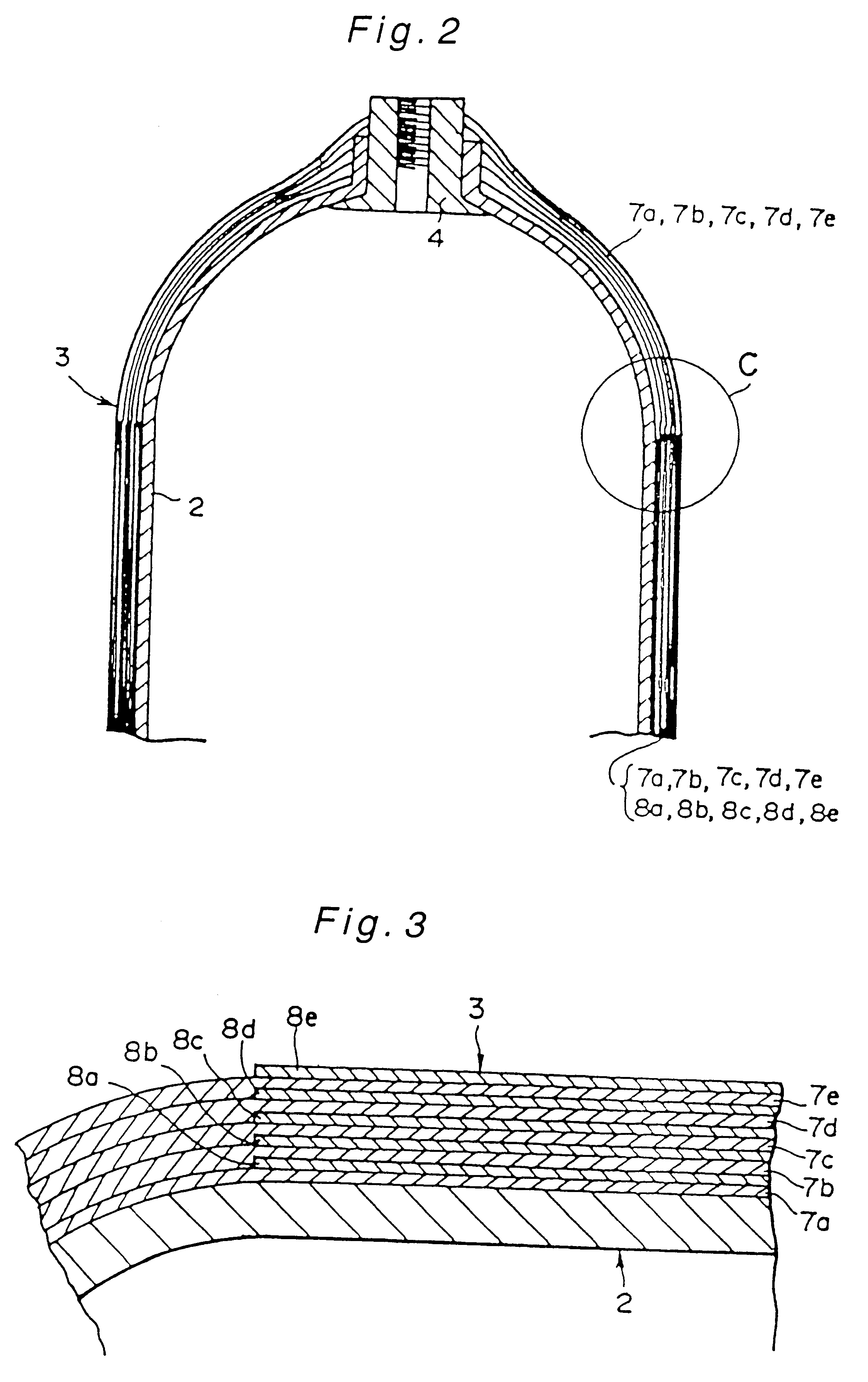

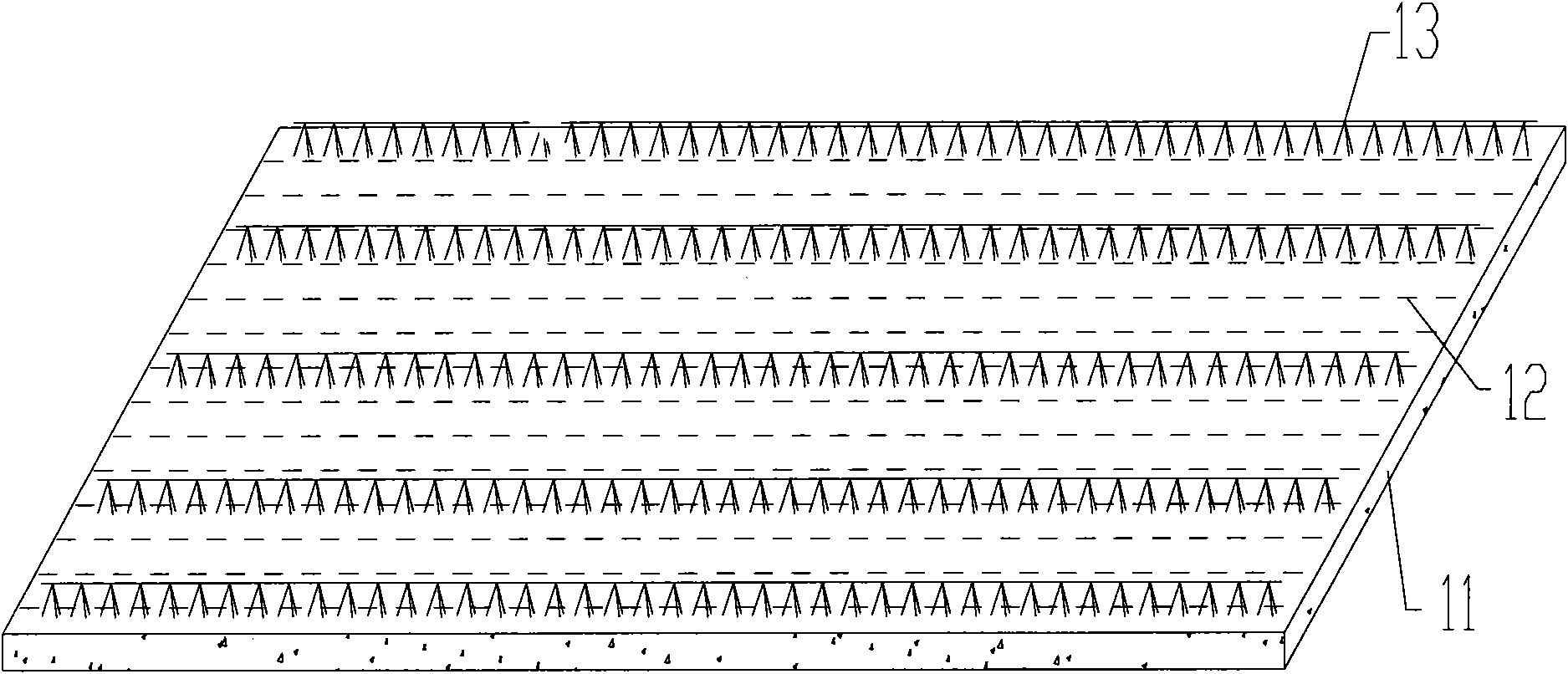

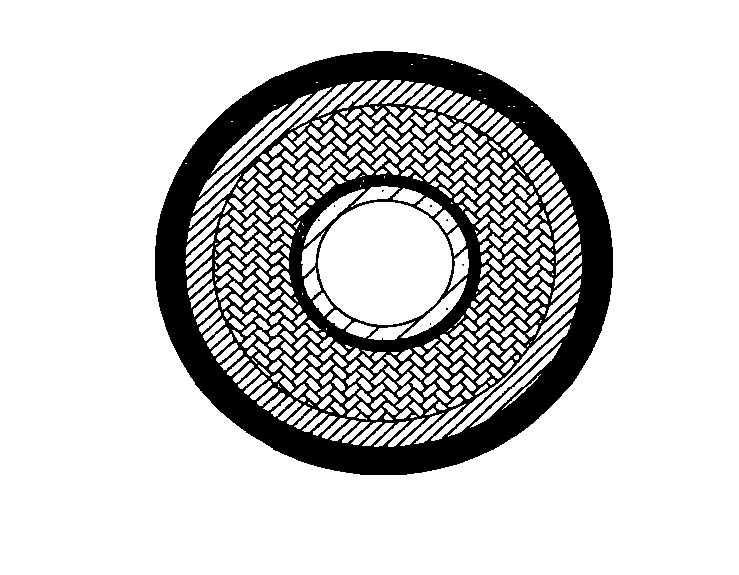

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight, but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability. The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

Left auricle plugging device and production method thereof

The invention provides a left auricle plugging device and a production method thereof. The left auricle plugging device comprises a nickel-titanium alloy net support, wherein the nickel-titanium alloy net support is tubular, a left disc surface and a right disc surface are arranged on two ends of the nickel-titanium alloy net support, the left disc surface is connected to the right disc surface through a moving part, and flow resisting films are respectively arranged in the left disc surface and the right disc surface in a horizontal direction. The production method of the left auricle plugging device comprises the following steps of knitting to be slender net shaped, and then carrying out initial thermal treatment, shaping and final thermal treatment so as to produce one left auricle plugging device. The left auricle plugging device has the advantages of simple structure and convenience for use, an operation process is simplified, the operation time is shortened, and meanwhile, when the left auricle plugging operation is carried out by utilizing the left auricle plugging device, X-ray is not needed, so that the harm to doctors and patients is greatly reduced. The left auricle plugging device produced by the production method of the invention has good performance and reliable use.

Owner:SHANGHAI SHAPE MEMORY ALLOY

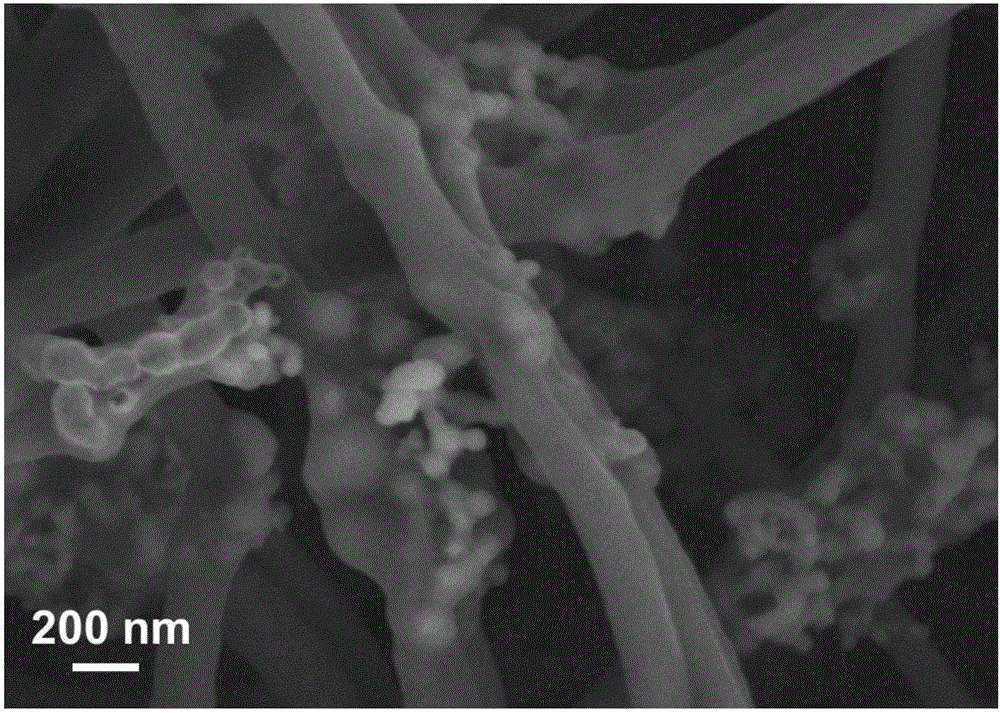

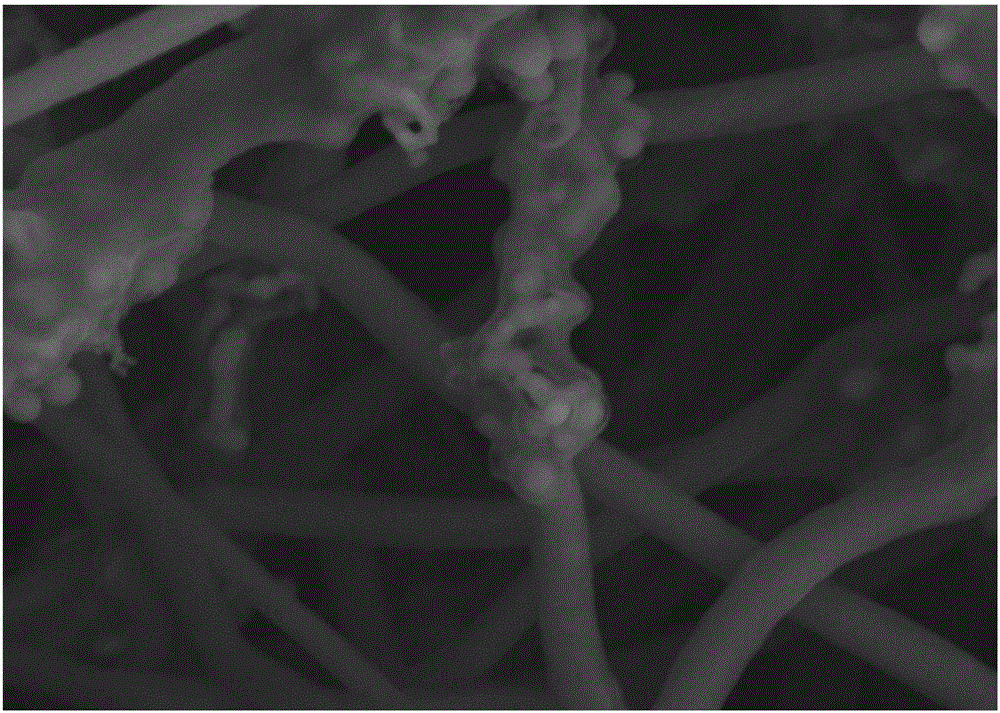

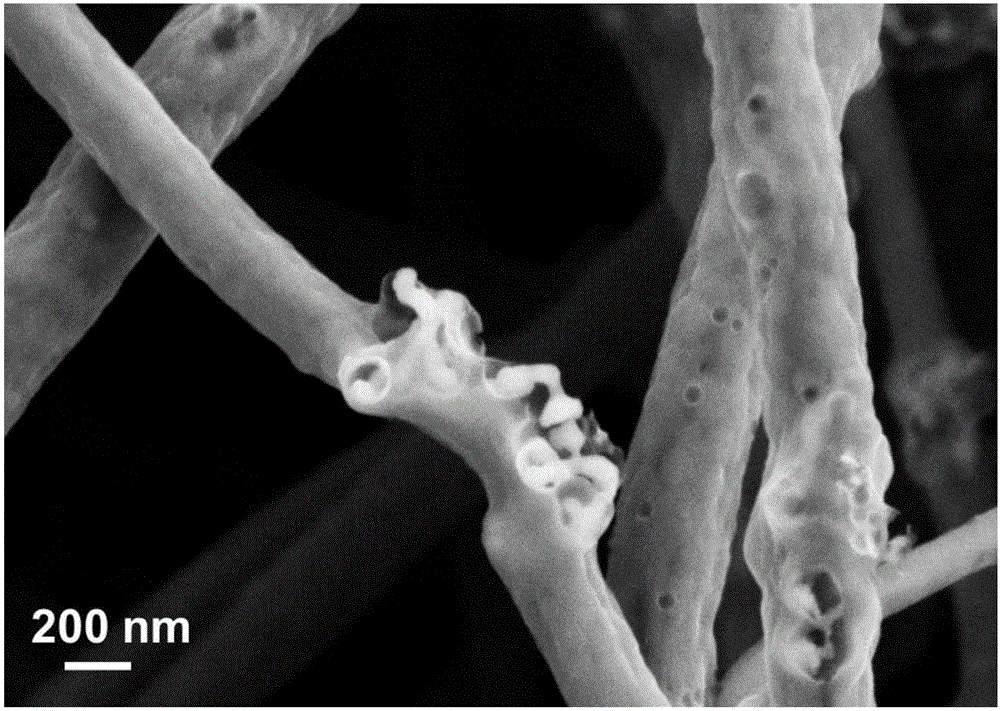

Silicon/carbon nano composite fiber and application thereof

InactiveCN106129367APrevent falling offReduces deactivation and electrical contact lossMaterial nanotechnologyCell electrodesElectrospinningSilicon particle

The invention relates to the field of silicon-based negative electrode materials of lithium-ion batteries, in particular to a silicon / carbon nano composite fiber and an application thereof. The silicon / carbon nano composite fiber comprises the silicon / carbon nano composite fiber; and certain gaps exist between silicon particles and a carbon layer to accommodate volume changes of the silicon particles, so that the structure stability and the cycling stability of an electrode are improved. A silicon dioxide layer is introduced to the surfaces of the silicon nanoparticles through a sol-gel method; Si@SiO2 particles with a core-shell structure are dispersed into the carbon fiber through electrostatic spinning and subsequent carbonization processes; and finally the silicon dioxide layer in a sample is selectively removed through a hydrofluoric acid to obtain the hollow carbon sphere / carbon nano fiber embedded with the silicon nanoparticles.

Owner:ZHEJIANG SCI-TECH UNIV

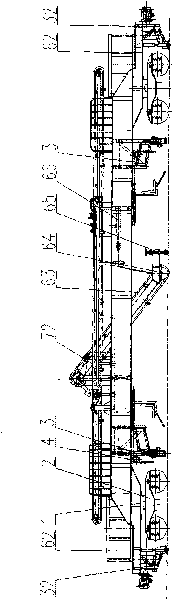

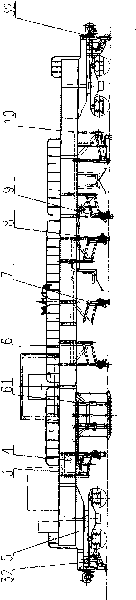

Fast rail-exchanging vehicle for jointless track and rail-exchanging method

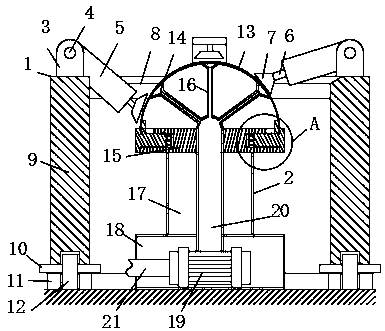

InactiveCN101718066AReduce forcePrevent falling offRailway track constructionBogieFront and back ends

The invention relates to a fast rail-exchanging vehicle for a jointless track and a rail-exchanging method. The front and back ends of a travel mechanism of a fast rail-exchanging vehicle for a railway are provided with a guardrail recovering device; a crosstie-pressing device, a steel rail retraction device for clamping and moving a new steel rail and an old steel rail, a steel rail clincher and an operating position are arranged at intervals below the vehicle body between two bogies of the travel mechanism, the operating position is arranged according to the need; and the crosstie-pressing device and the steel rail clincher are arranged respectively close to the bogies at the two ends; and the vehicle can perform the marshalling operation together with the auxiliary vehicles, such as a fastener recovered vehicle, and the like. When the fast rail-exchanging vehicle for the railway is adopted for construction, the operation is divided into two parts of the old steel rail retraction operation and the new steel rail retraction operation which are synchronously carried out. The vehicle can reach the rail-exchanging speed of more than 2km / h, can be applied to the fast rail-exchanging need of the jointless track, complete the rail exchanging within 50 meters and is suitable for the construction needs of the section with less curve radius. The invention has the advantages of safety and high degree of automation.

Owner:株洲新通铁路装备有限公司

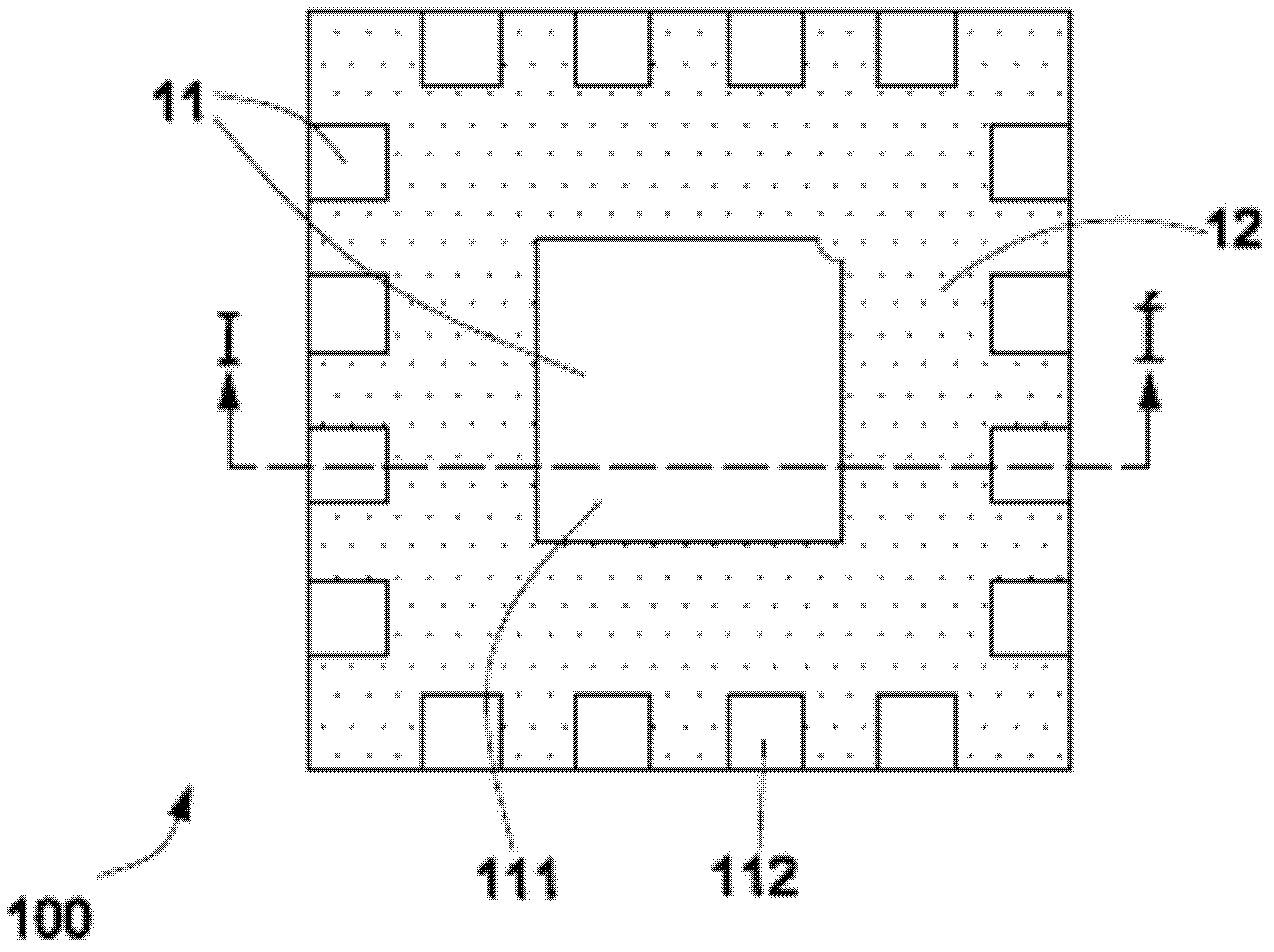

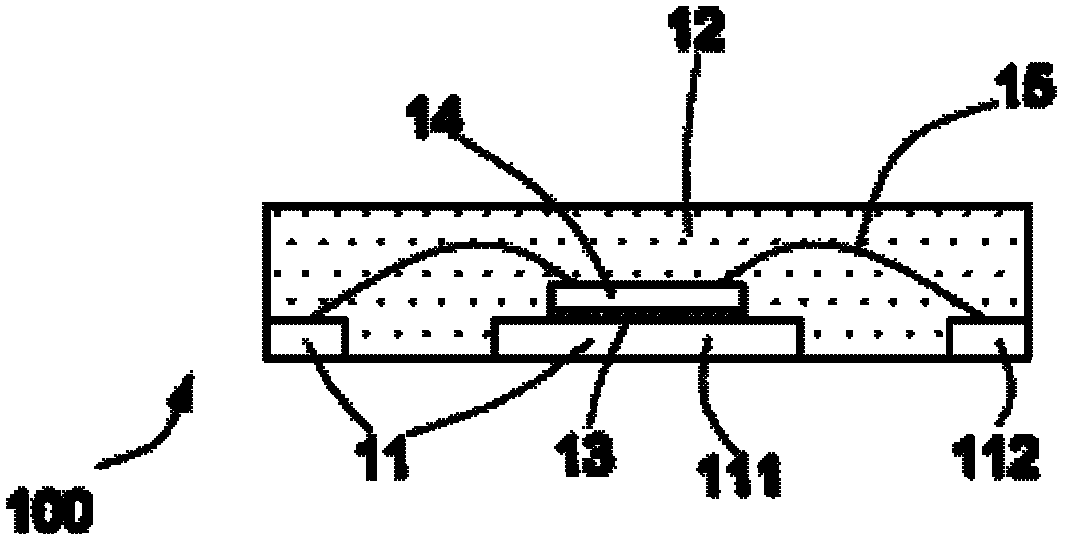

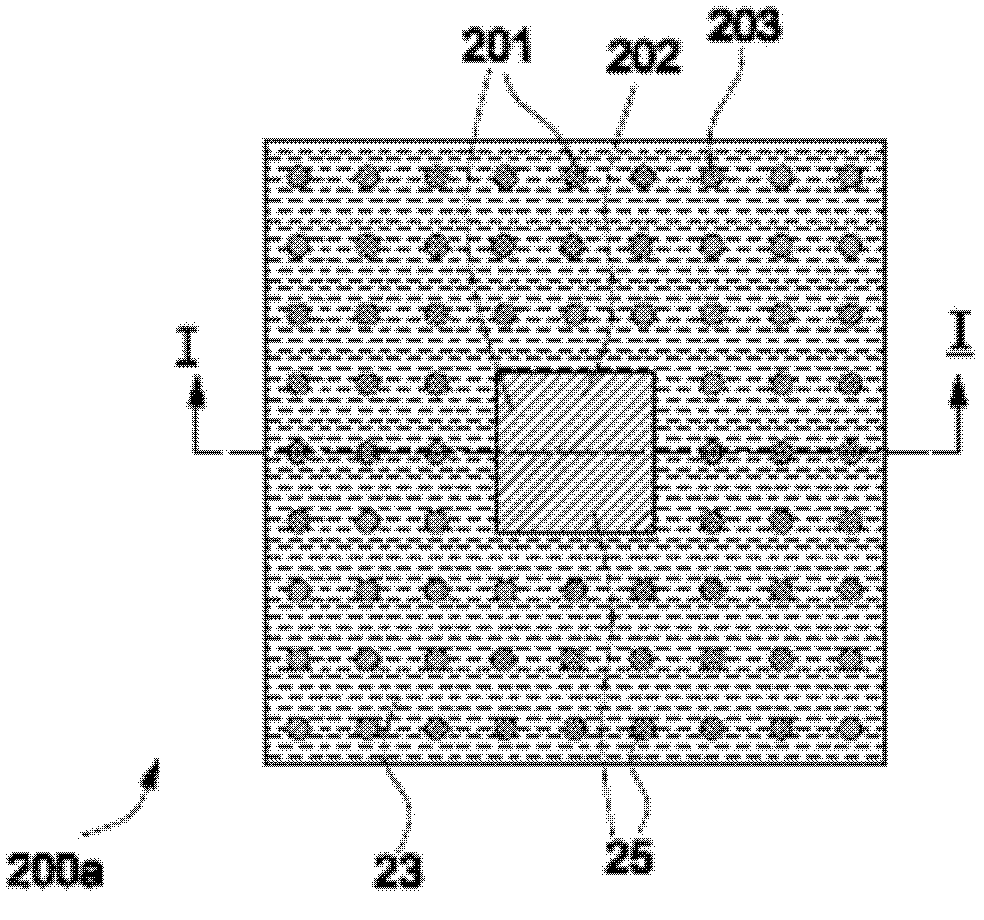

Quad flat non-lead (QFN) package with high density and manufacturing method

InactiveCN102354691AHigh I/O densityPrevent falling offSemiconductor/solid-state device detailsSolid-state devicesFilling materialsMetallic materials

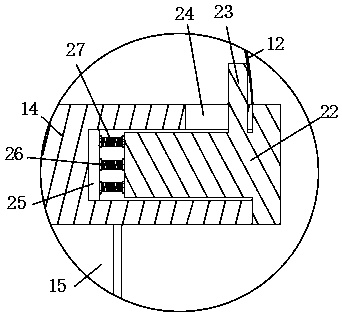

The invention discloses a quad flat non-lead (QFN) package with high density and a manufacturing method. The package comprises a lead frame 201, metal material layers 25, an IC chip 27, insulating filling materials 23, bonding materials 26, metal conductors 28 and plastic package materials 29, wherein the lead frame comprises a chip carrier 202 and a plurality of leads 203 arranged in multiple circles around the chip carrier; the metal material layers are arranged on the upper and lower surfaces of the lead frame; the IC chip is arranged on a metal material layer on the upper surface of the lead frame; the insulating filling materials are arranged below stepped structures 22b of the lead frame; the bonding materials are arranged between the IC chip and the metal material layer on the upper surface of the lead frame; the IC chip is connected to the inner leads of the multiple circles of leads and the upper surface of the chip carrier respectively by the metal conductors; the plastic package materials wrap and seal the IC chip, the bonding materials, the metal conductors, partial regions of the lead frame and partial metal material layers; and the chip carrier and the outer leads exposed out of the bottom surface of a package structure, are provided with raised parts. The package and the manufacturing method have the following beneficial effects: the bottleneck of low I / O quantity is broken through and the package reliability is improved.

Owner:BEIJING UNIV OF TECH

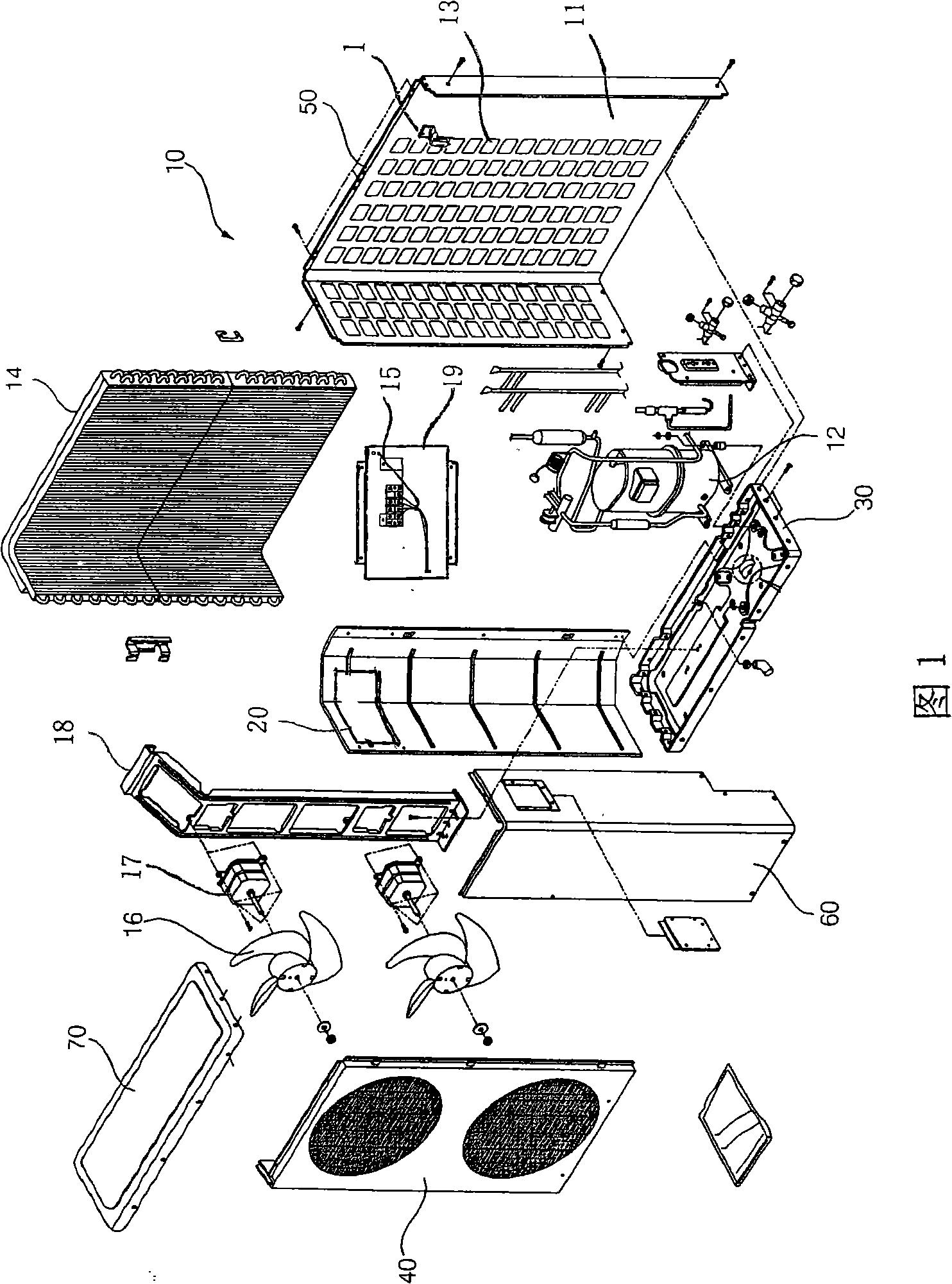

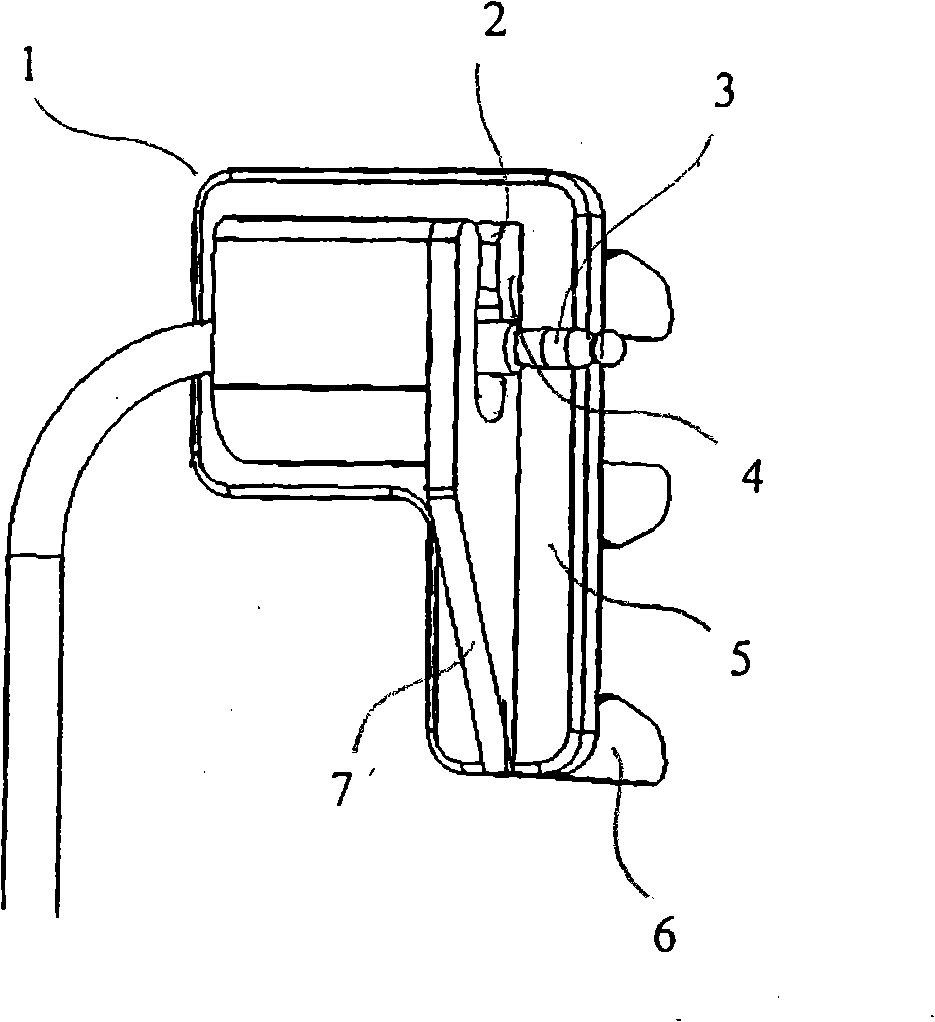

Temperature sensor fixing structure for outdoor set of air-conditioner

InactiveCN101307933AFixed firmlyPrevent falling offSpace heating and ventilation safety systemsLighting and heating apparatusSensor holderTemperature sense

The invention belongs to the air conditioner technical field, in particular a temperature sensor fixing structure of an air conditioner outdoor unit which keeps constant distance with a condenser, is difficult to drop off and displace in production and transportation and is not influenced by operation of defrosting and heating, solving the problems of easy displacement and dropping-off, and abnormal operation of the air conditioner of the prior temperature sensor fixing structure due to incorrect and unstable temperature sensing in the process of defrosting and heating. The invention adopts the technical proposal that the inside of a shell is provided with an air conditioner outdoor unit, a temperature sensor support and a sensor, wherein the air conditioner outdoor unit consists of a compressor, an outdoor heat exchanger, an outdoor fan, a reversing valve, an expansion valve and a control box; and the temperature sensor support is fixed at a suction inlet of a rear panel of the air conditioner outdoor unit; the sensor support is formed by a support body which comprises a U-shaped temperature sensor bayonet and a screw hole right angle fixing part, the U-shaped temperature sensor bayonet is formed by means of injection moulding on one side and the screw hole right angle fixing part is formed on the other side, the temperature sensor is clamped in the U-shaped temperature sensor bayonet, and the fixing part is fixed on the edge of an inner wall of a right ribbed plate of a rectangle suction grill hole of the rear panel by screw holes and screws.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

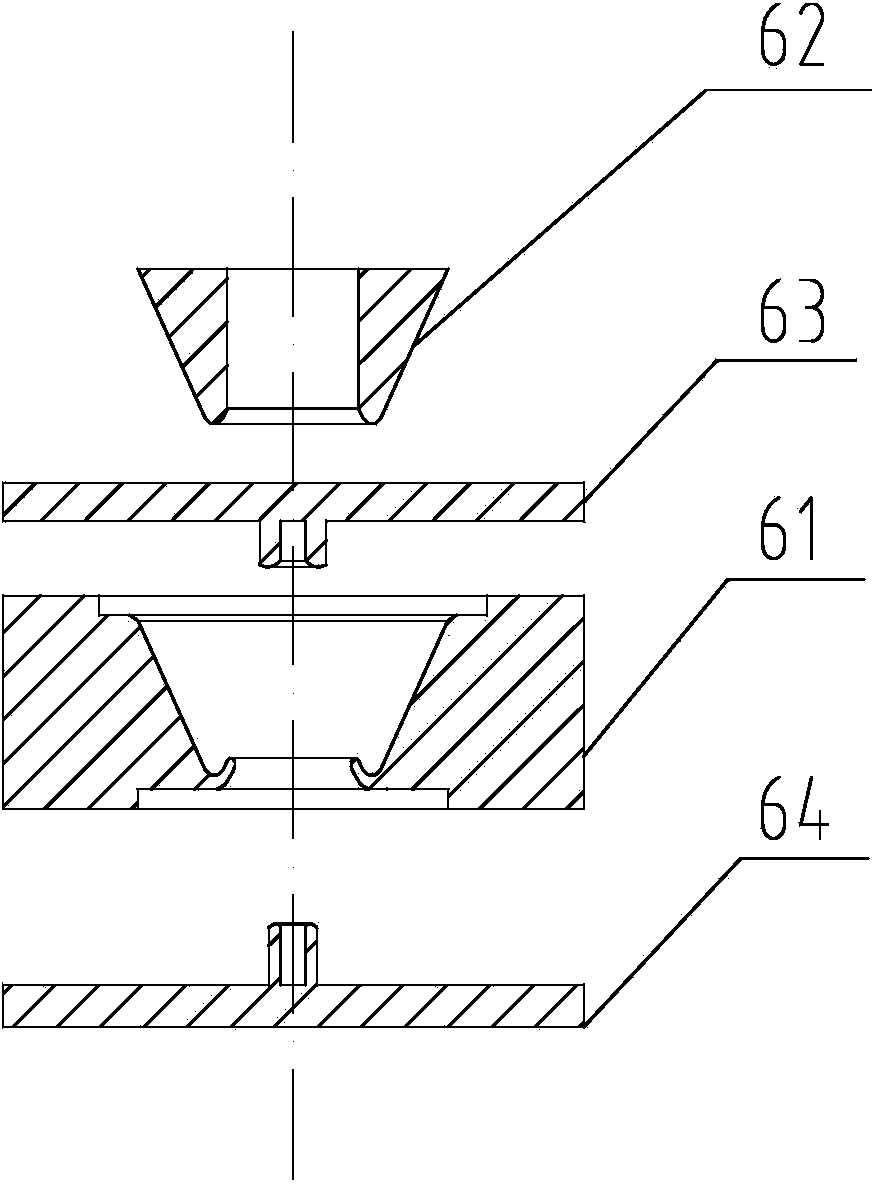

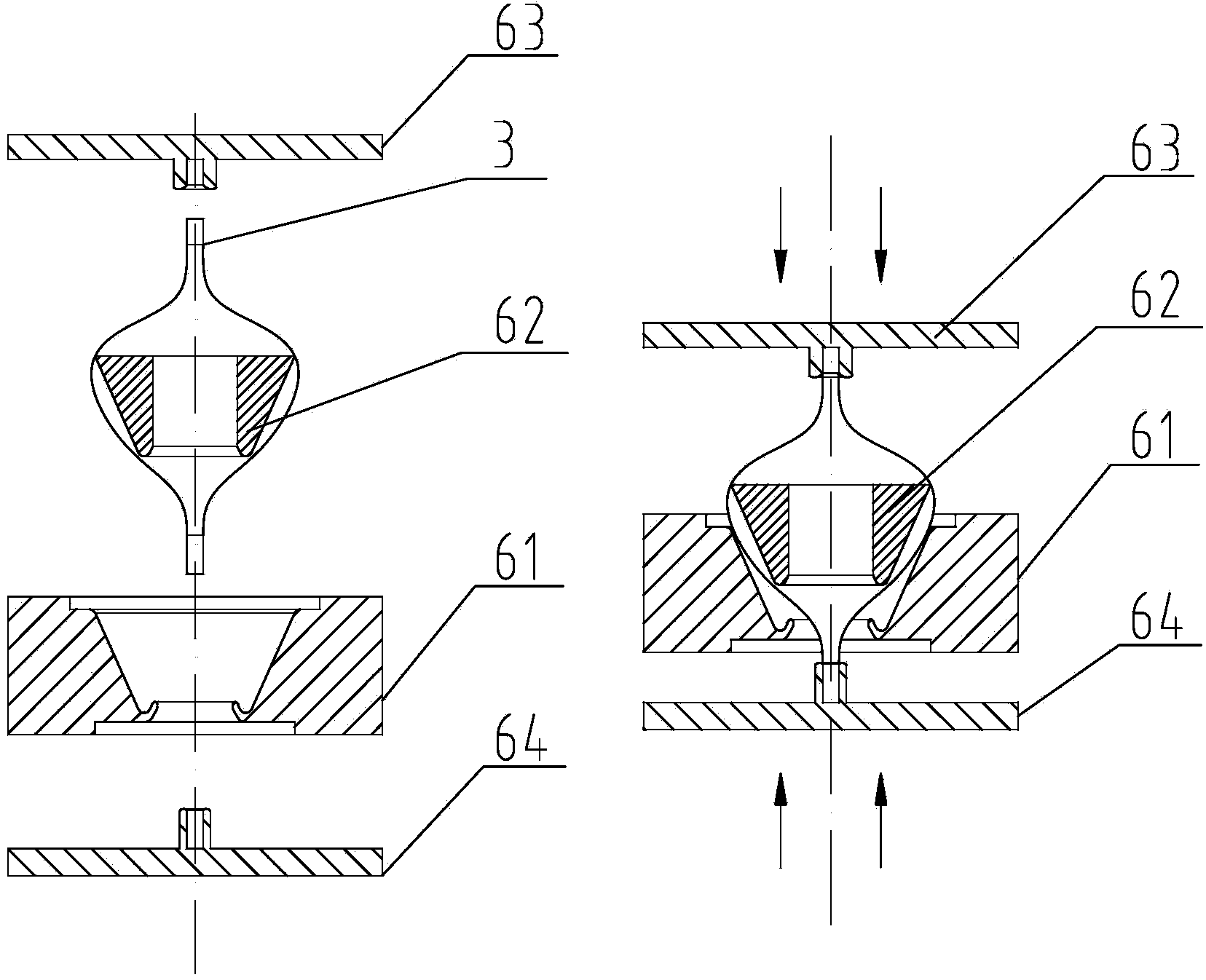

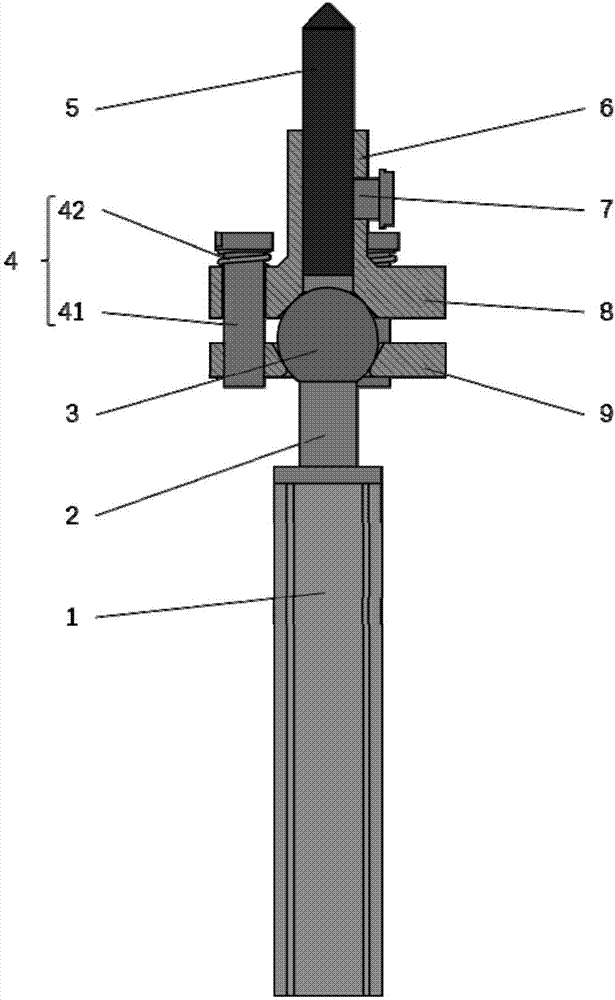

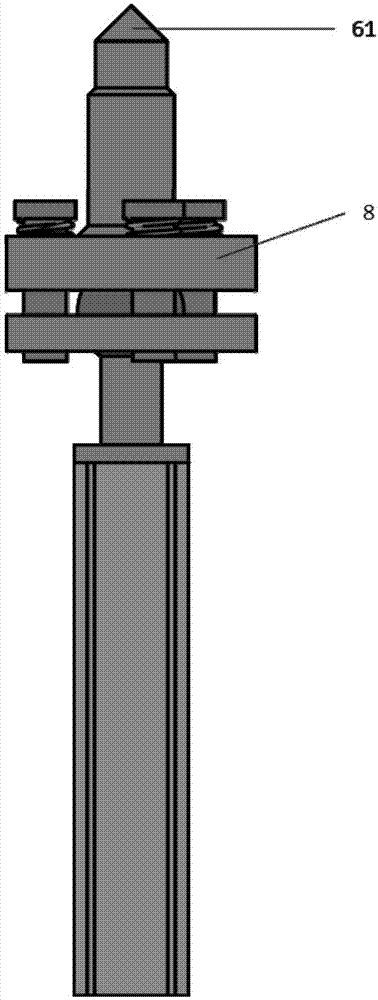

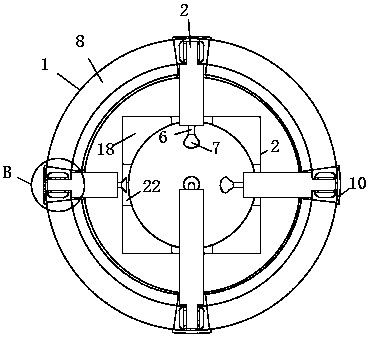

Nanometer positioner for transmission electron microscope sample rods

InactiveCN107576823AImprove stabilityPrevent falling offMaterial analysis using wave/particle radiationElectric discharge tubesTransmission electron microscopySacroiliac joint

Disclosed is a nanometer positioner for transmission electron microscope sample rods. The nanometer positioner comprises a positioner head used for loading samples and a positioner body driving displacement of the samples; the positioner body is of a piezoelectric ceramic tube, conducting regions are arranged on the outer peripheral wall and the inner peripheral wall of the piezoelectric ceramic tube, multiple pairs of the conducting regions are arranged on the outer peripheral wall, and each paired conducting regions are symmetrical to the axis of the piezoelectric ceramic tube, the conducting regions on the outer peripheral wall are evenly arranged in a mutually independent manner, and a joint ball is fixed to the head end of the piezoelectric ceramic tube; the positioner head is mainlyformed by an upper pressing piece, a lower pressing piece and an elastic connection assembly, the joint ball is located between the upper pressing piece and the lower pressing piece, and each of the upper pressing piece and the lower pressing piece is provided with a slot matched with the joint ball. The nanometer positioner has the advantages of performance stability in reuse.

Owner:ZHEJIANG UNIV

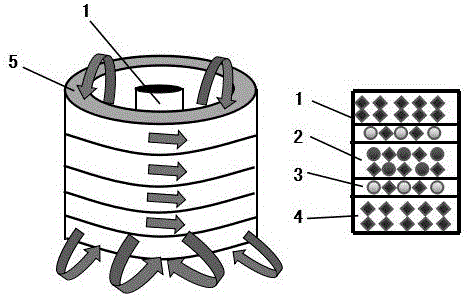

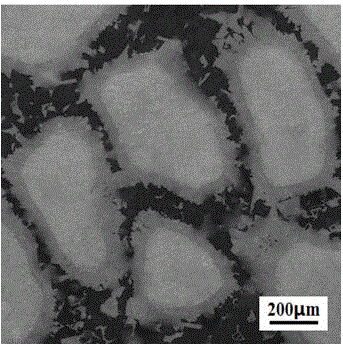

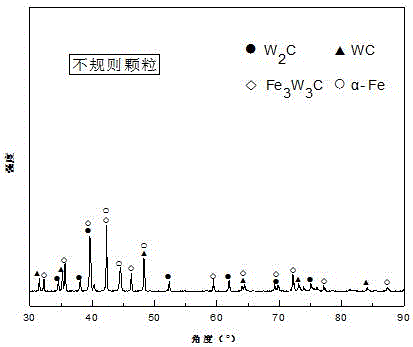

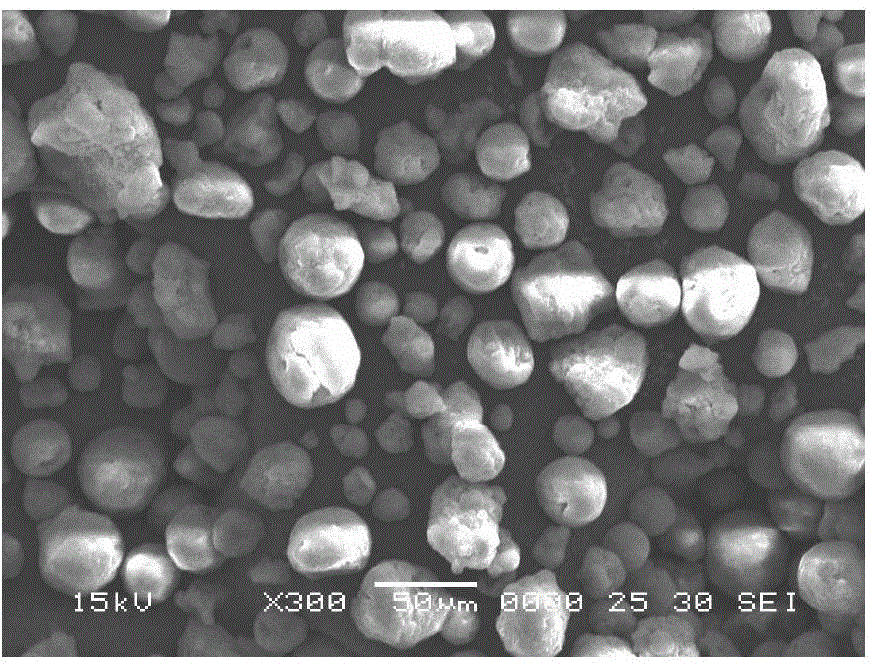

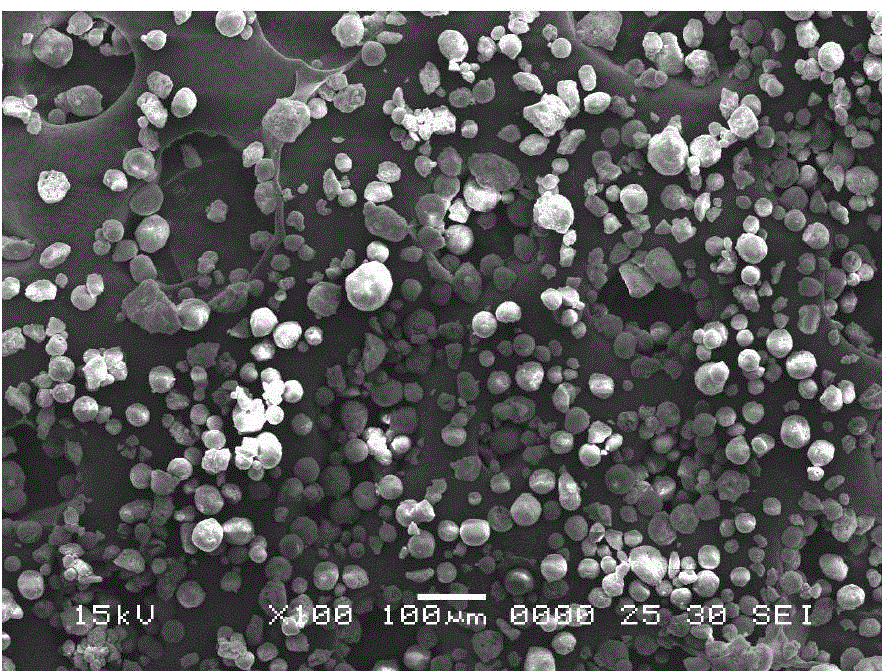

Tungsten carbide particle reinforced steel matrix surface-layer composite material and preparation method thereof

The invention discloses a tungsten carbide particle reinforced steel matrix surface-layer composite material and a preparation method thereof and belongs to the technical field of preparation of a wear-resistant material. The composite material is composed of three layers which are respectively a composite layer, a transition layer and a base material layer; the transition layer is positioned between the composite layer and the base material layer; the composite layer is mixed powder of tungsten carbide particles and 45 steel metal powder; the transition layer is mixed powder of tungsten powder and 45 steel metal powder; the base material layer is 45 steel metal powder; the preparation method of the tungsten carbide particle reinforced steel matrix surface-layer composite material comprises the following steps: firstly preparing powder, subsequently pressing a prefabricated blank and finally performing vacuum sintering to obtain the tungsten carbide particle reinforced steel matrix surface-layer composite material; according to the preparation method disclosed by the invention, the preparation temperature is relatively low; reinforcing particles are uniformly distributed in a base body commendably; the prepared tungsten carbide particle reinforced steel matrix surface-layer composite material is free of impurities, relatively high in performances, beneficial for environmental protection, capable of serving under complicated working conditions such as shock chilling, shock heating, impact and abrasion, and relatively good in impact resistance and oxidation resistance.

Owner:KUNMING UNIV OF SCI & TECH

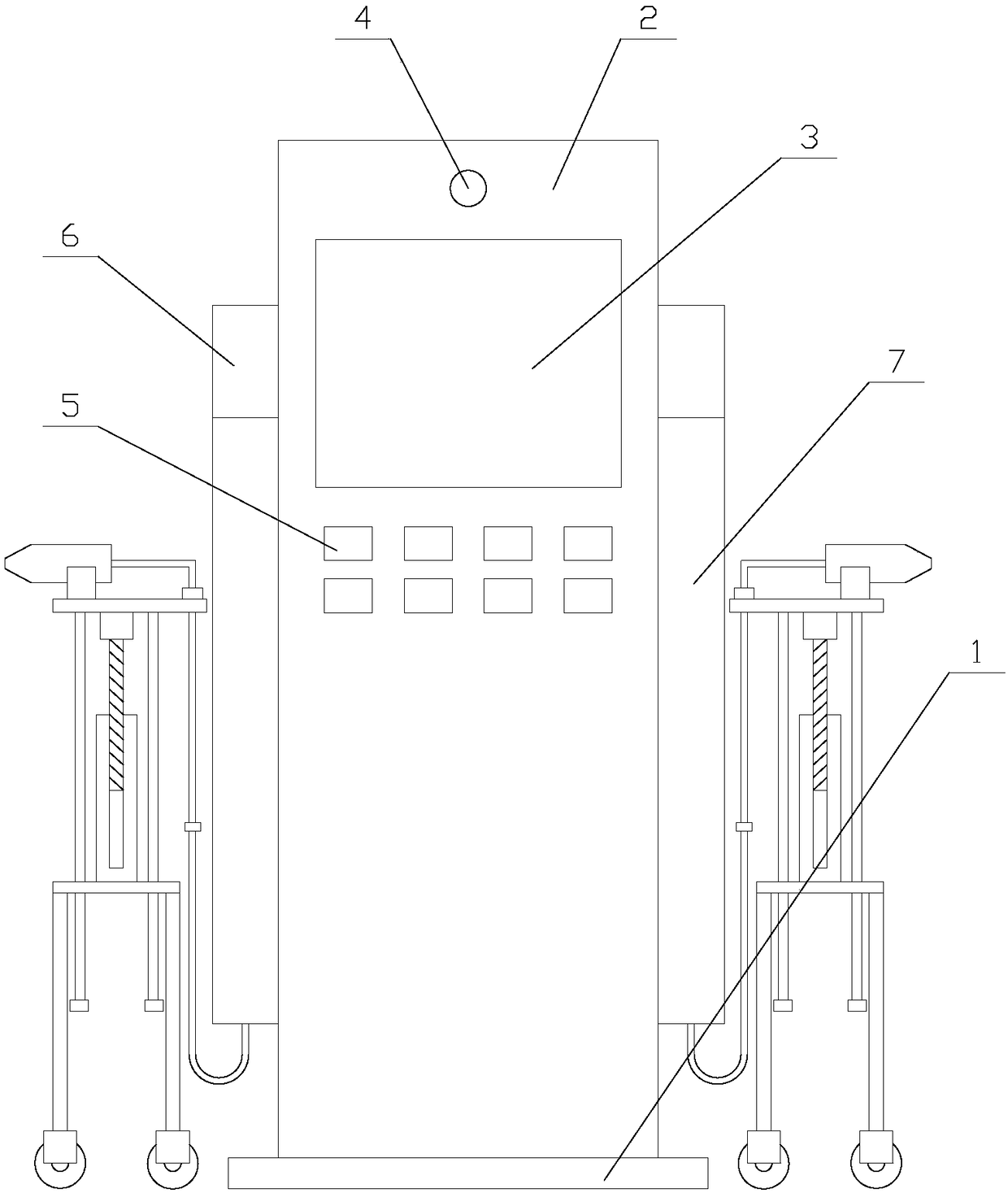

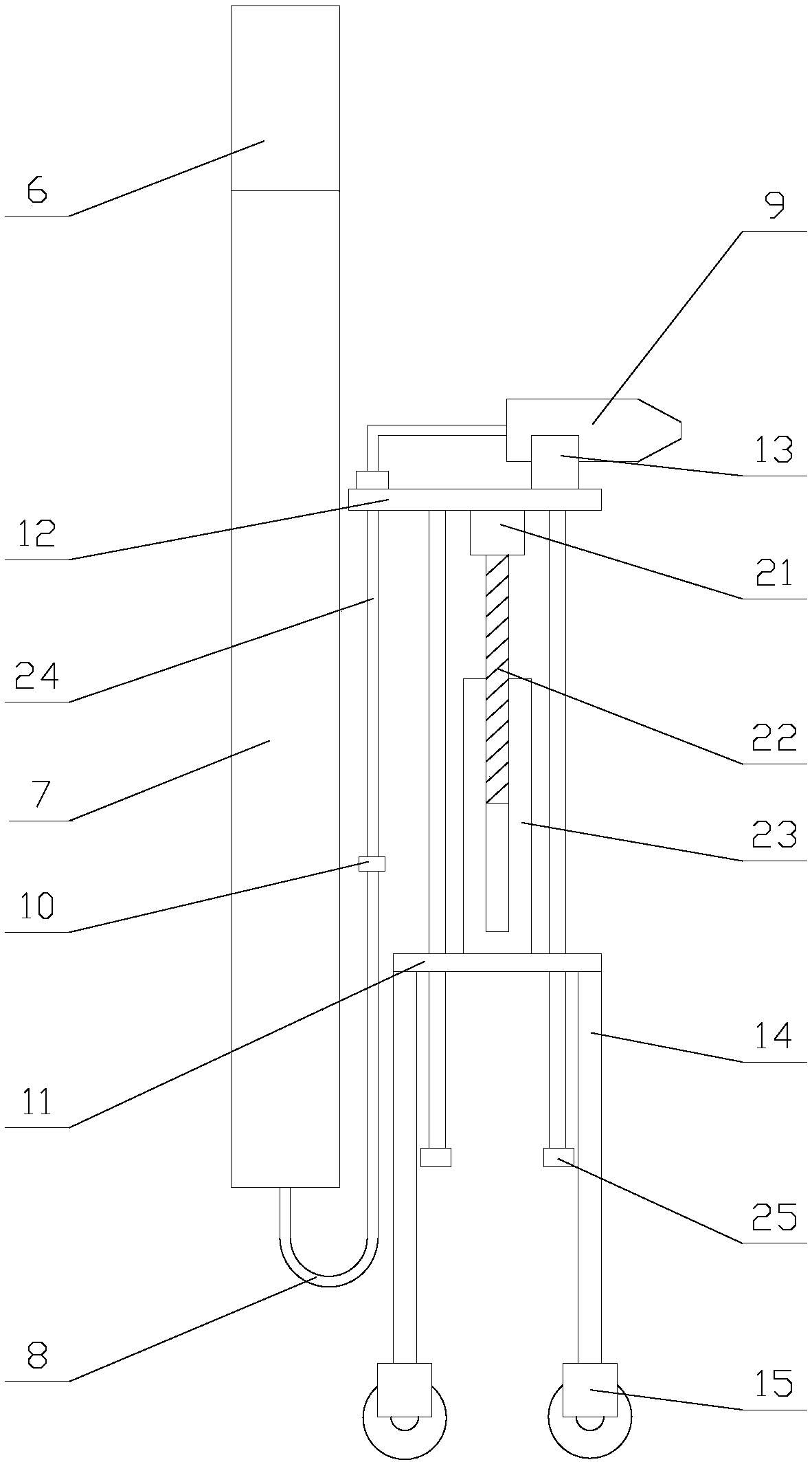

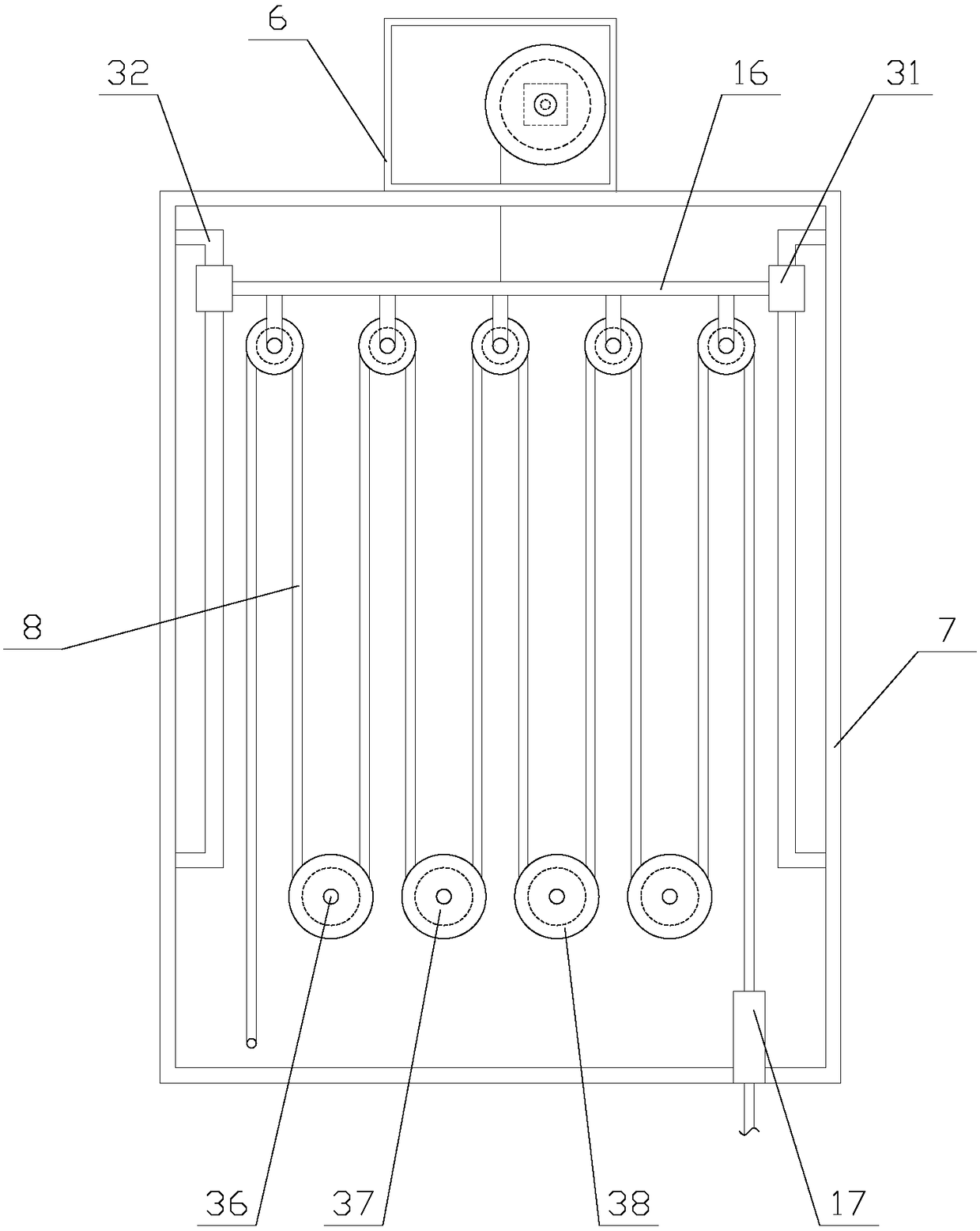

Safe and reliable intelligent new energy vehicle charging pile convenient to use

InactiveCN108544929AFlexible structurePrevent falling offCharging stationsElectric vehicle charging technologyAutomotive engineeringNew energy

The invention relates to a safe and reliable intelligent new energy vehicle charging pile convenient to use. The safe and reliable intelligent new energy vehicle charging pile convenient to use comprises a base, a main body and two charging mechanisms; each charging mechanism comprises a driving box, a storage box, a cable, a plug, a supporting mechanism and two convex blocks; each supporting mechanism comprises a bottom plate, a supporting plate, a supporting block, a lifting assembly and four supporting legs; driving assemblies are arranged in the driving boxes; storage mechanisms are arranged in the storage boxes; and each storage mechanism comprises a lifting plate, a cable outlet pipe, a plurality of guiding assemblies and a plurality of rotating assemblies. According to the safe andreliable intelligent new energy vehicle charging pile convenient to use, as the plugs are arranged above the supporting plates by using the supporting mechanisms, and the moving distances of the cables on the supporting plates are limited by using the convex blocks, the phenomenon that the plugs fall on the ground to cause potential safety hazards is prevented; and moreover, the cable storage functions of the storage mechanisms are realized by using the driving assemblies to drive the lifting plates to lift; during charging, the cables are convenient to pull out to charge a vehicle by loweringthe lifting plates so that the practicability of the charging pile is enhanced.

Owner:SHENZHEN NAISHIDI TECH DEV CO LTD

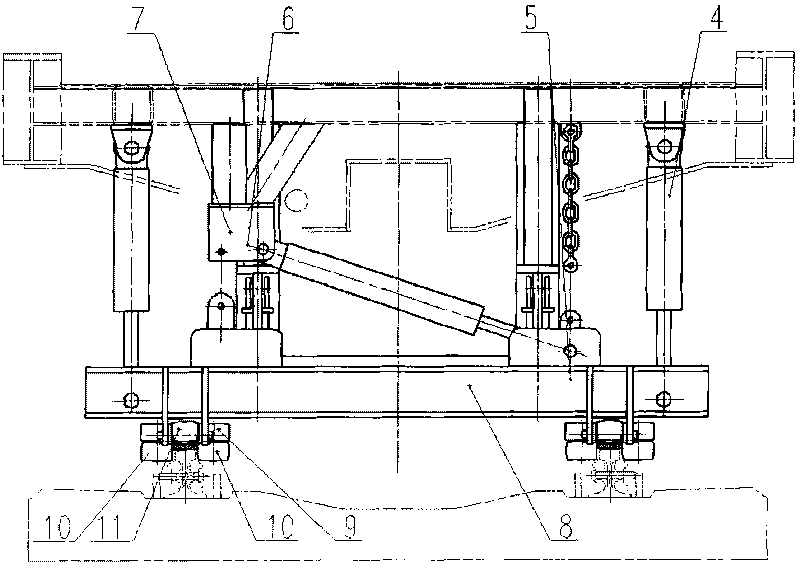

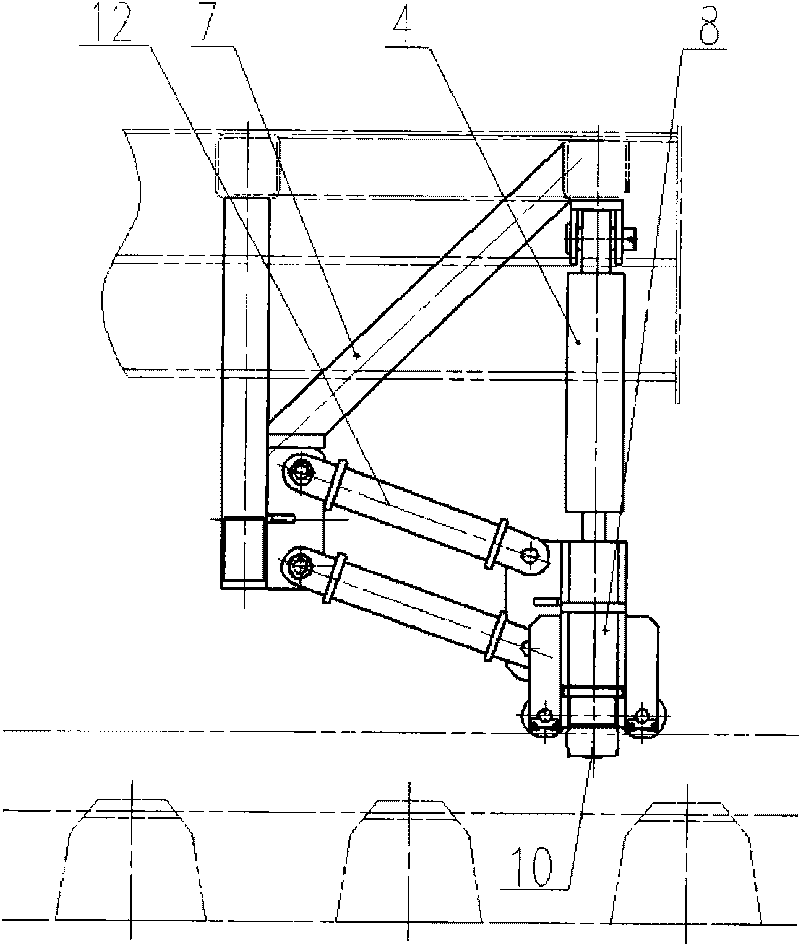

Railway construction machine guard rail hoisting device and rail replacing locomotive guard rail hoisting device

InactiveCN101725095ASmooth entryWalking smoothlyRailway track constructionBogieAutomotive engineering

The invention relates to a railway construction machine guard rail hoisting device and a rail replacing locomotive guard rail hoisting device, comprising a guard rail hoisting apparatus and an anti-loosing device, wherein the guard rail hoisting apparatus is arranged below a railway construction machine, such as a rail replacing operation vehicle traveling mechanism vehicle body and can integrally lift and transversely move a railway construction machine vehicle body, and the anti-loosing device is arranged on each steering frame of a steel rail traveling machine to enable the steering frames and the vehicle body to be vertically fixed into a whole. The guard rail hoisting apparatus comprises an elongated supporting body, a guard rail suspension bracket and a control device, wherein the supporting body is fixedly suspended below the vehicle body through the guard rail suspension bracket, the control device is used for controlling the movement of the supporting body, a guard rail assembly is respectively arranged at both ends below the supporting body, the control device comprises two telescopic guard rail vertical oil cylinders and telescopic guard rail integral swinging oil cylinders, and the guard rail suspension bracket is provided with two downward stretching struts which are respectively hinged with both ends of the supporting body through two guard rail support rods. The invention enables a railway which needs to be born but is not completely fixed to be kept in an upright state in the construction process, farthest prevents the occurrence of a turning-way accident, and also enables the turning-way railway construction machine to rapidly hoist and safely reset.

Owner:株洲新通铁路装备有限公司

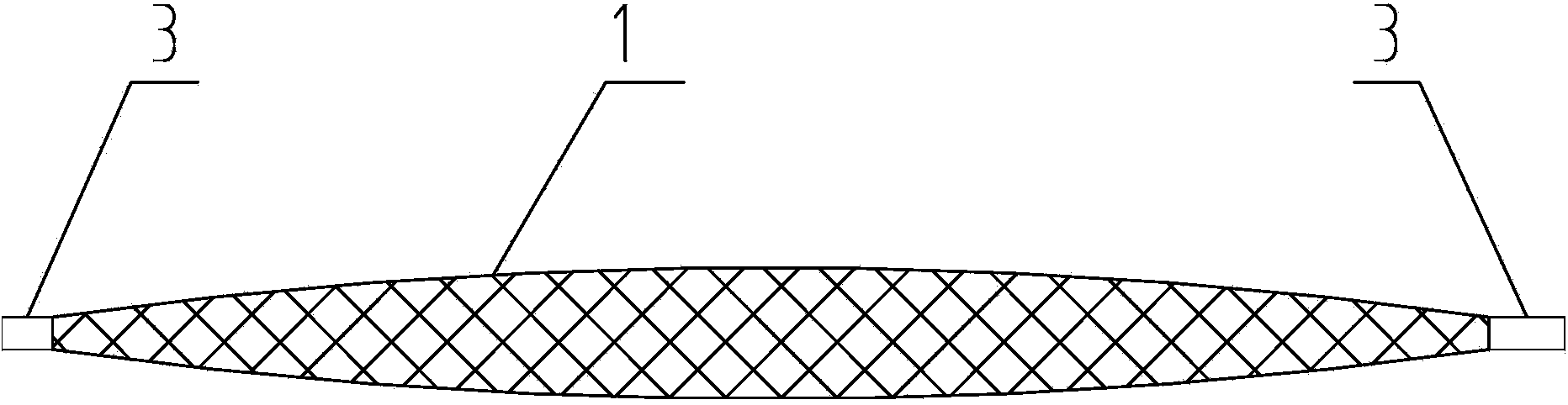

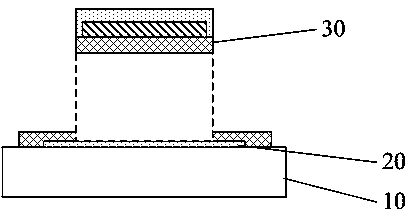

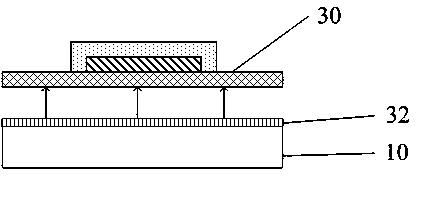

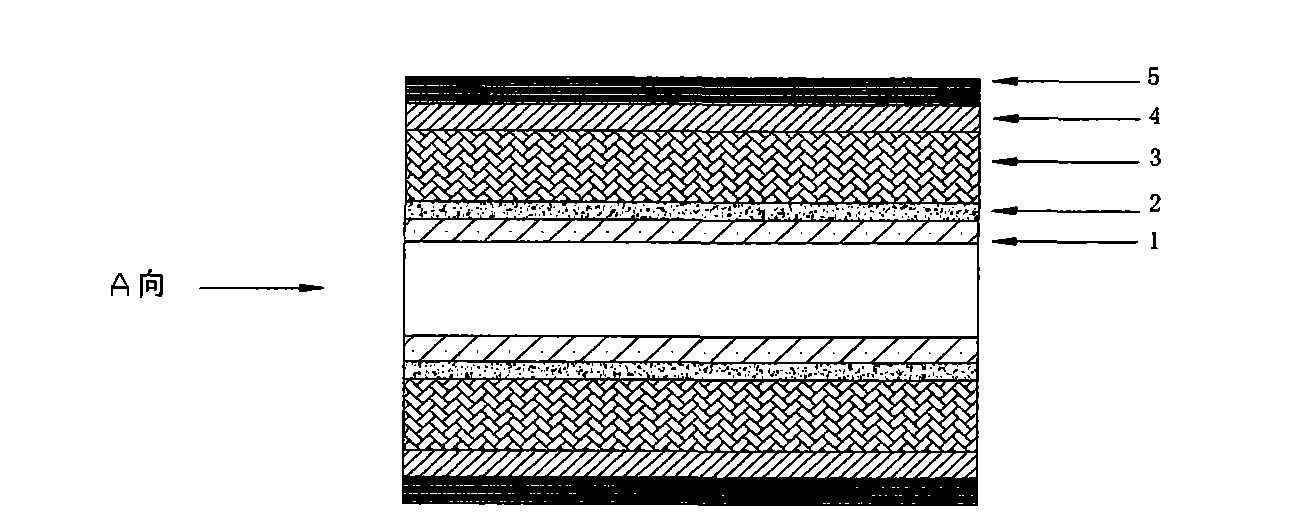

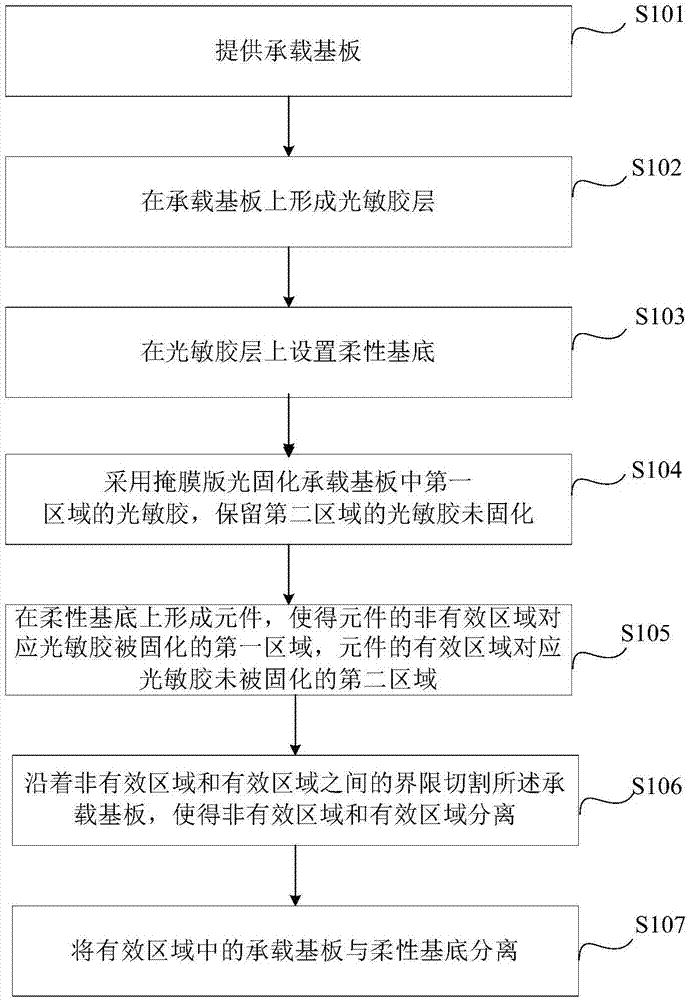

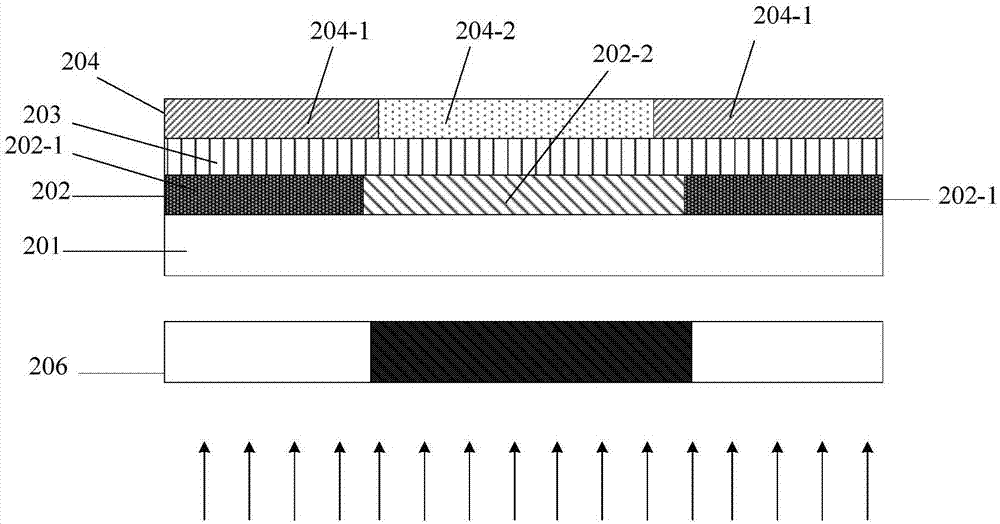

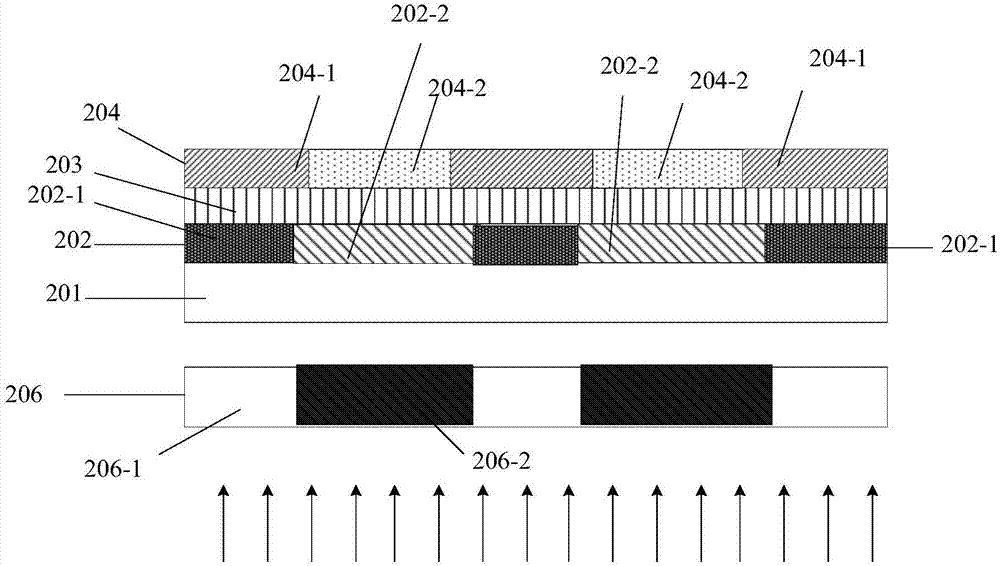

Flexible photoelectric device substrate, flexible photoelectric device and preparation method

ActiveCN103531715APrevent falling offInhibit sheddingFinal product manufactureSolid-state devicesEdge regionElectronic paper

The invention discloses a flexible photoelectric device substrate, a flexible photoelectric device and a preparation method. The flexible photoelectric device substrate comprises a glass baseplate and a metal thin film which is used for buffering expansion amount difference between a macromolecule thin film and the glass baseplate so that the macromolecule thin film can be prevented from falling off from the glass baseplate. The metal thin film is arranged on the edge area of the surface of the glass baseplate. The metal thin film is enclosed on the surface of the glass baseplate so that a panel forming area used for processing the flexible photoelectric device is formed. The flexible photoelectric device substrate is used for preparing the flexible photoelectric device. With application of the flexible photoelectric device substrate, the macromolecule thin film can be prevented from falling off from the glass baseplate. The flexible photoelectric device substrate provided by the invention is applicable to preparation of an OLED, OLED lighting, electronic paper display, a touch screen and other non-display technologies.

Owner:TCL CORPORATION

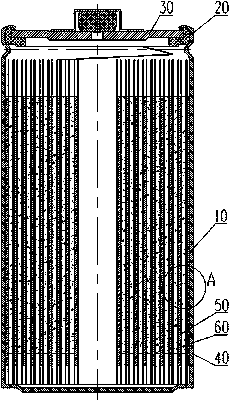

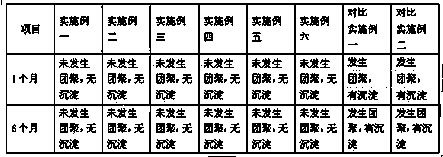

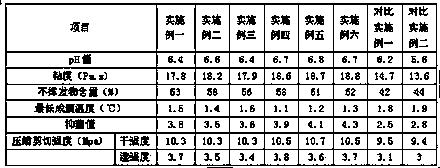

Preparation method of low self-discharge nickel-metal hydride battery

InactiveCN104362390ASmall self-dischargeImprove charge retentionFinal product manufactureElectrode carriers/collectorsCharge retentionLithium hydroxide

The invention discloses a preparation method of a low self-discharge nickel-metal hydride battery. The preparation method comprises steps as follows: preparation of a semi-finished product of a positive pole, preparation of a semi-finished product of a negative pole, preparation of glue for soaking bottom ends of the positive pole and the negative pole, soaking, electrolyte preparation, assembly and the like. According to the preparation method of the low self-discharge nickel-metal hydride battery, a positive pole substrate adopts foamed nickel, positive pole substances comprise a spherical nickel hydroxide active substance, a conductive agent, a bonding agent and an additive, the additive comprises cobalt monoxide and cobaltous hydroxide, the electrolyte is ternary electrolyte comprising potassium hydroxide, sodium hydroxide and lithium hydroxide, and further, a positive plate adopts a bottom gumming technology and diaphragm paper for a bottom welding technology during a manufacturing process, so that positive powder is prevented from falling to the bottom of a steel shell and is contacted with the negative pole, and self-discharge of the battery is reduced; and the test proves that the electrical charge retention rate of the battery prepared with the preparation method can still be higher than 88% after stored for two years at the normal temperature of 25 DEG C.

Owner:ANHUI INNOVATION NEW ENERGY

LDH (layered double hydroxide) microspheres for sewage treatment and preparation method

InactiveCN107670642AStrong adsorptionPrevent falling offOther chemical processesWater contaminantsCvd grapheneChemistry

The invention relates to the field of sewage treatment materials, in particular to LDH (layered double hydroxide) microspheres for sewage treatment and a preparation method. The LDH microspheres for sewage treatment are prepared with the method as follows: (1) after a calcium salt solution and a ferric salt solution are mixed uniformly, a dispersant and graphene are added, a precipitator is added,the mixture is subjected to a hydrothermal reaction, and ferric-calcium LDH containing graphene is obtained, cooled, centrifuged, subjected to water washing until the pH is 6.5-7.5, subjected to alcohol washing 1-2 times and then dried; (2) the dried ferric-calcium LDH containing graphene in the step (1) and molten waste glass are subjected to collision with a spraying method, and the LDH microspheres fixed by porous glass are formed. Heavy metals are transferred to the LDH through adsorption for storage; the porous glass not only fixes graphene oxide to prevent graphene oxide from falling off, but also can be recycled.

Owner:LINYI UNIVERSITY

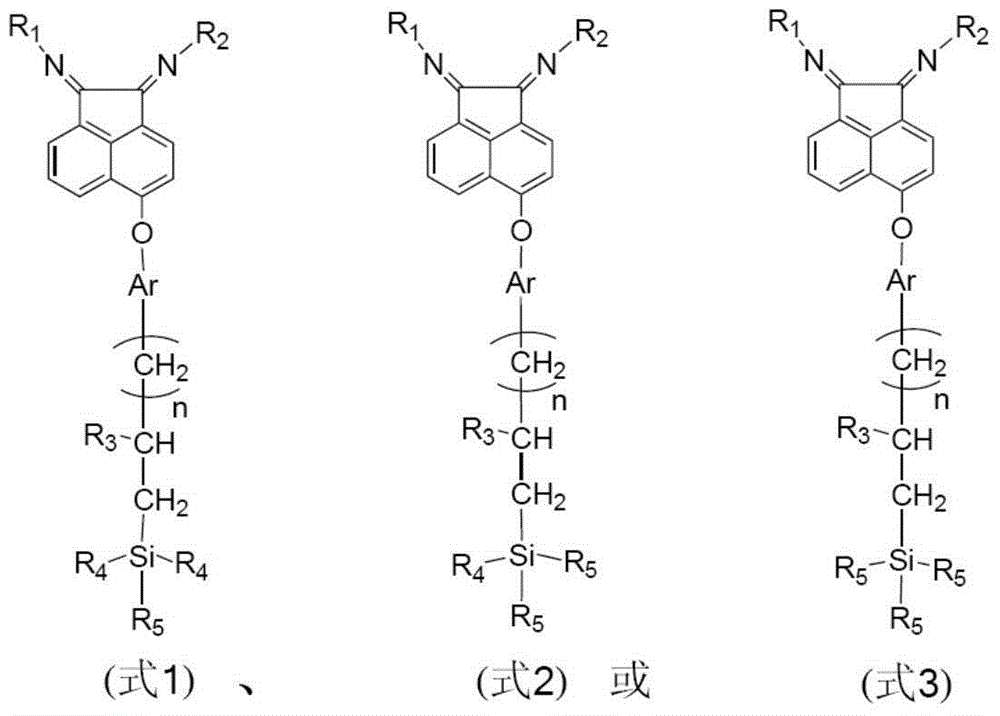

Supported alpha-diimine compound and application of supported alpha-diimine compound in olefin polymerization

InactiveCN104804030AStrong chemical bondPrevent falling offSilicon organic compoundsNickel organic compoundsOlefin polymerizationCoordination complex

The invention relates to a supported alpha-diimine compound and an application of the supported alpha-diimine compound in olefin polymerization. The compound has the following structural formula as shown in the specification, wherein R1 and R2 are identical or different C6-C60 aromatic alkyl; R3 is H or C1-C20 alkyl; R4 is C1-C20 alkyl; R5 is C1-C20 alkoxyl or a chlorine atom; n is 1, 2, 3, 4, 5, 6 or 7; an alpha-diimine compound reacts with a carrier to be supported on the carrier in a covalent bonding manner to form the supported alpha-diimine compound; the supported alpha-diimine compound is matched with a metal compound of nickel (II) and palladium (II) to form a supported alpha-diimine metal complex; and the supported alpha-diimine compound is applied to the olefin polymerization as a main catalyst and can regulate polymerization activity, as well as a molecular chain structure, molecular weight and distribution of a polymer.

Owner:TIANJIN POLYTECHNIC UNIV

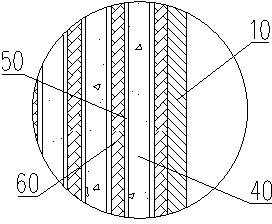

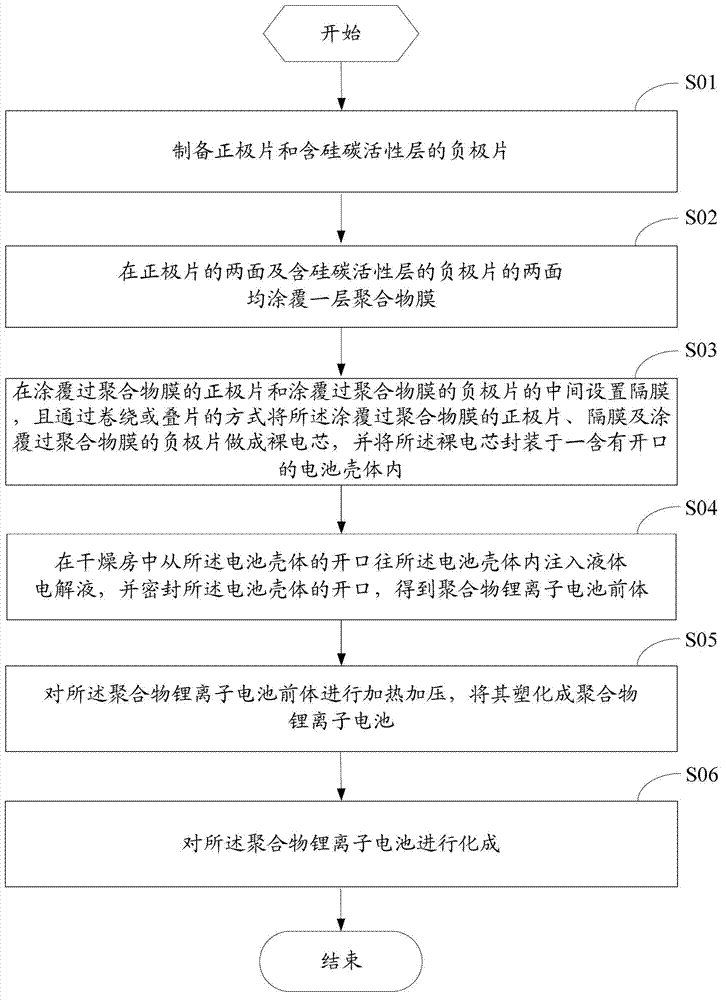

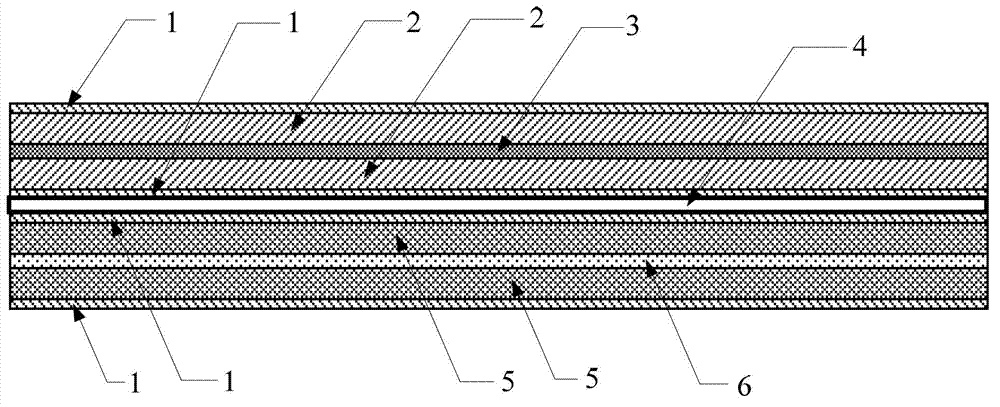

Preparation method of polymer lithium ion battery and polymer lithium ion battery

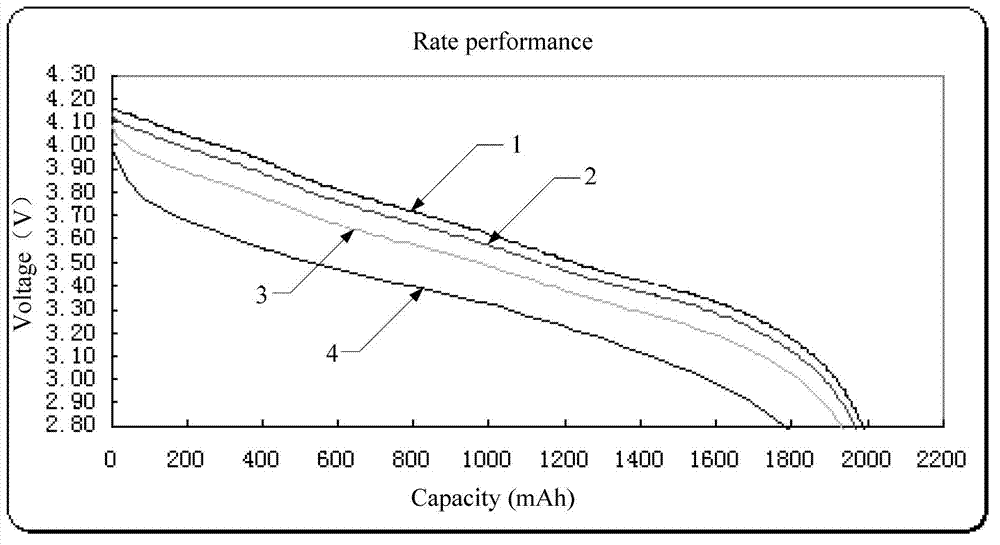

ActiveCN102769149APrevent falling offImprove cycle performanceCell electrodesFinal product manufactureChemistryCharge and discharge

The invention discloses a preparation method of a polymer lithium ion battery and the polymer lithium ion battery. The preparation method comprises the following steps of: preparing a positive plate and a negative plate which contains a silicon carbon active layer; coating a layer of polymer film on the two surfaces of the positive plate and the negative plate; arranging a diaphragm in the middle of the positive plate and the negative plate so that the positive plate, the diaphragm and the negative plate are prepared into a bare battery cell, and packaging the bare battery cell into the battery shell; injecting liquid electrolyte into the battery shell in a drying room, and sealing the opening of the battery shell to obtain a polymer lithium ion battery precursor; heating and pressurizing the polymer lithium ion battery precursor, and plasticizing to form the polymer lithium ion battery; and performing formation on the polymer lithium ion battery. The volume energy density of the polymer lithium ion battery is improved, the phenomenon that the silicon carbon active layer is powdered or drops from a negative current collector in the process of charging and discharging the negative plate which contains the silicon carbon active layer in the polymer lithium ion battery is avoided, and the cycle performance of the battery is improved.

Owner:韩志娟

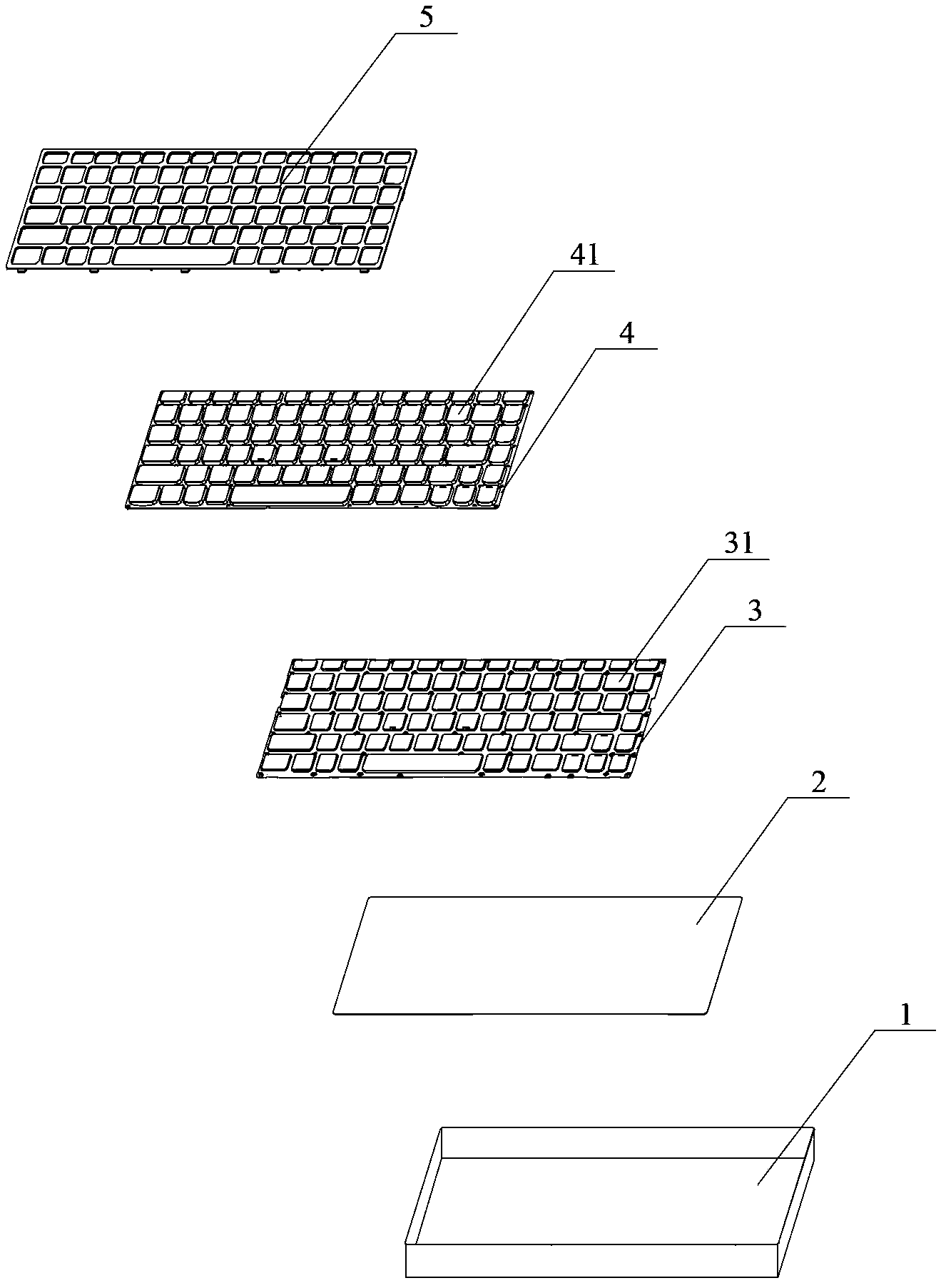

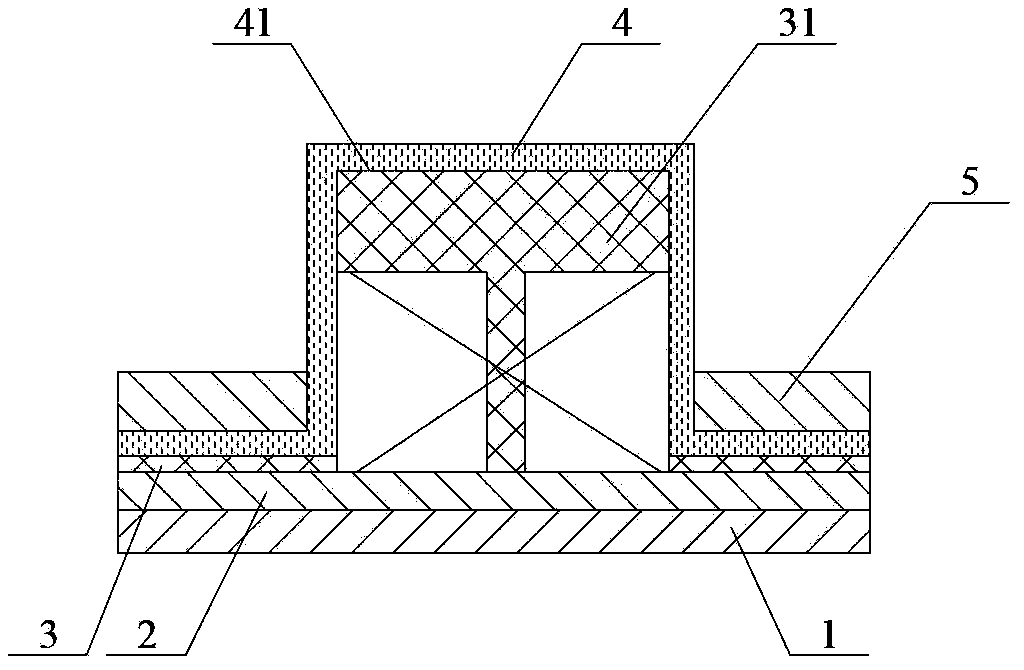

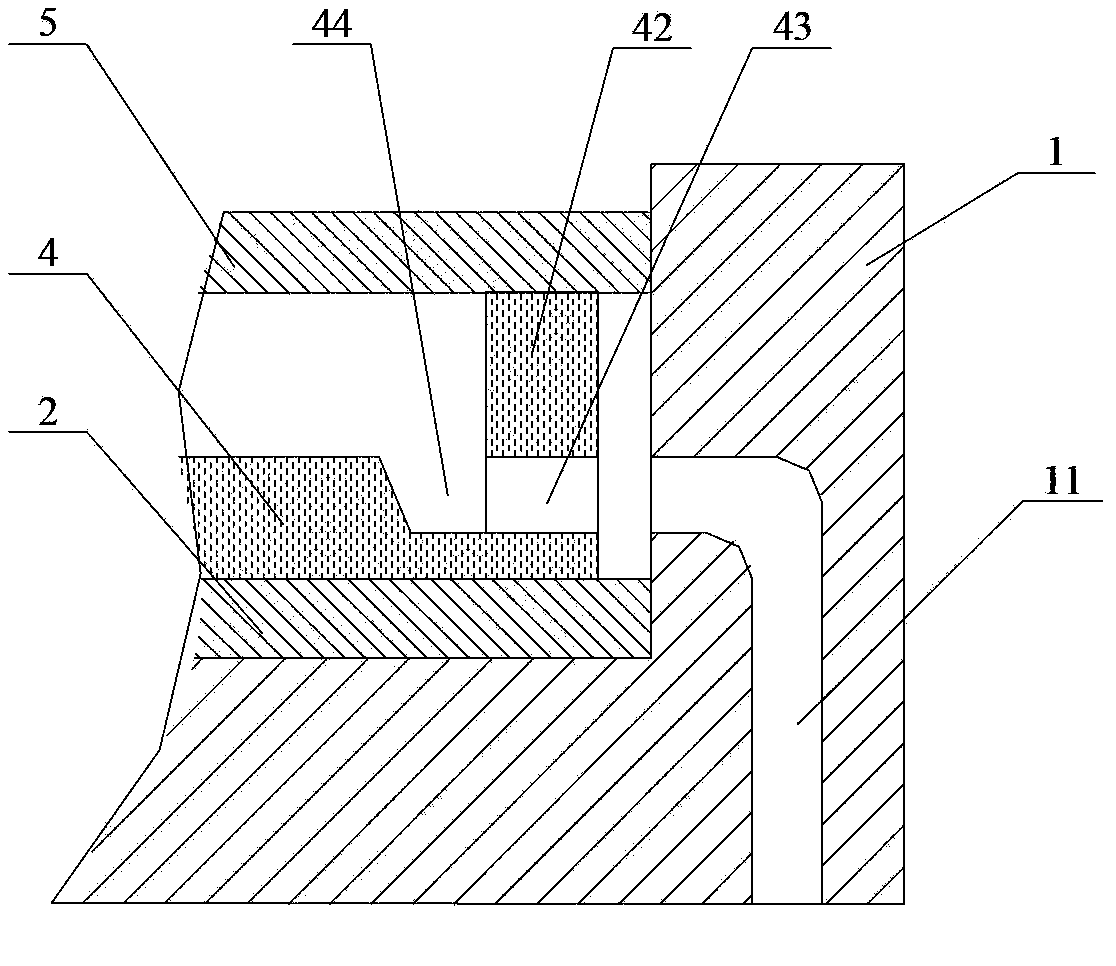

Keyboard

InactiveCN103515130ABeautiful appearancePrevent falling offElectric switchesEngineeringElectrical and Electronics engineering

Owner:LENOVO (BEIJING) CO LTD

Centrifugal ceramic composite vertical mill roller sleeve and manufacturing method thereof

The invention discloses a centrifugal ceramic composite vertical mill roller sleeve and a manufacturing method thereof. The centrifugal ceramic composite vertical mill roller sleeve comprises an inner layer and an outer layer. The outer layer is high-chromium cast iron, and ceramic particles are embedded in the outer layer. The high-chromium cast iron is prepared from, by weight, 2.3-3.3% of C, 0.3-1.0% of Si, 0.6-1.2% of Mn, 18-22% of Cr, 0.7-1.7% of Ni, 1.5-3.0% of Mo, 0-0.03% of P, 0-0.03% of S and the balance Fe and inevitable impurities. According to the vertical mill roller sleeve, the material proportion of the inner layer and the outer layer is optimized; high-alloy elements are adopted by the outer layer, the matrix can be effectively reinforced by increasing the content of alloy such as C, Cr, Mo and V, the total amount of carbide is increased, and therefore the smoothness of a friction surface can be effectively improved; the outer layer of the roller sleeve is made to be high in abrasion resistance, high in strength and enough in toughness, and the service life of the roller sleeve is effectively prolonged. According to the manufacturing method, a heat treatment technique of annealing, quenching and tempering is adopted, the purposes of improving the carbide form, promoting structural transformation and refining structures are achieved, so that the abrasion resistance and fracture toughness of the roller sleeve are improved.

Owner:河北津西钢铁集团重工科技有限公司

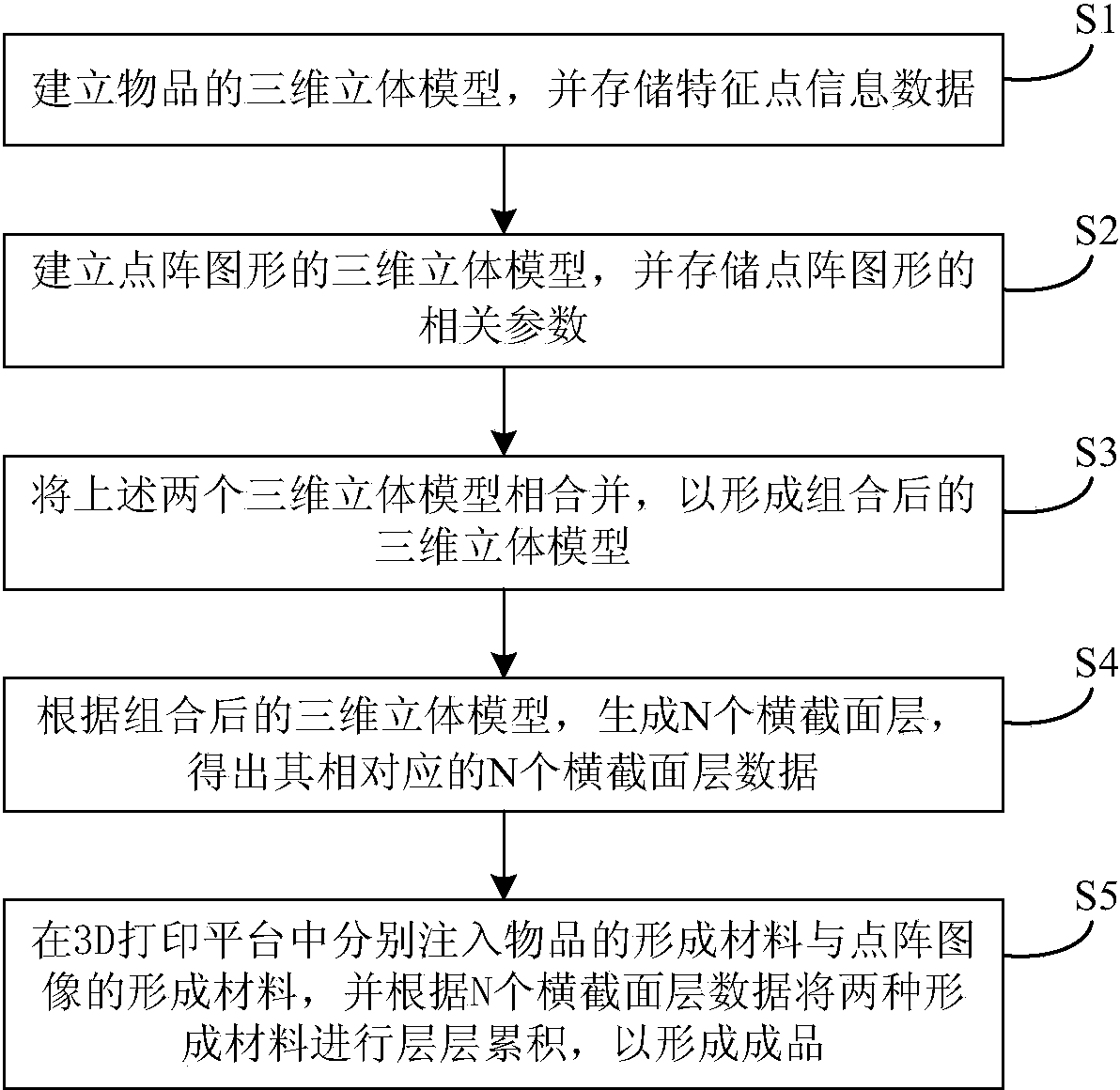

Method for forming needed article and dot-matrix graphic by utilization of 3D printing platform

The invention provides a method for forming a needed article and a dot-matrix graphic by the utilization of a 3D printing platform. The method includes the steps that a 3D model of the article is established, and feature point information data are stored; a 3D model of the dot-matrix graphic is established, and parameters relevant to the dot-matrix graphic are stored; the 3D model of the article and the 3D model of the dot-matrix graphic are combined to form a combined 3D model; according to the combined 3D model, N cross section layers are generated to obtain N corresponding cross section layer data; forming material of the article and forming material of the dot-matrix graphic are injected into the 3D printing platform, and the two kinds of forming material are accumulated layer upon layer to form a finished product according to the N cross section layer data. The dot-matrix graphic and the article can form an integrated structure, the solidifying performance between the dot-matrix graphic and the article is improved, and the dot-matrix graphic is prevented from falling off the surface of the article; through two times of verification, it can be guaranteed that the finished product and the combined 3D model are uniform.

Owner:SUZHOU DESIMIER SMART TECH CO LTD

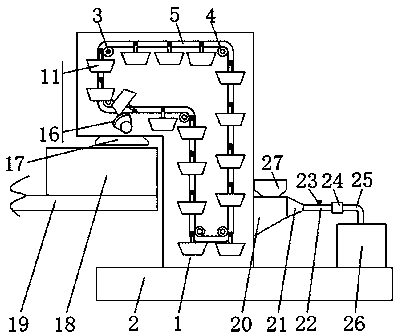

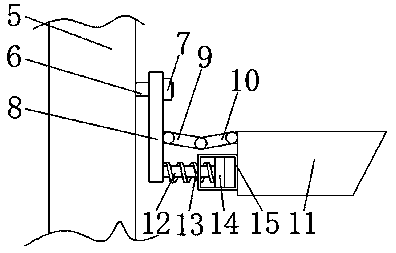

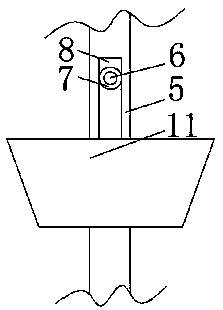

Material hoist for construction site

InactiveCN107555076AGuaranteed stabilityPrevent falling offConveyorsLoading/unloadingMotor shaftMechanical failure

The invention relates to the technical field of construction equipment, and discloses a material hoist for a construction site, comprising a device body, the bottom of the device body is fixedly connected with a base, and a plurality of electric shafts are fixedly installed on the inner wall of the device body , the outer surface of each electric shaft is sleeved with a runner, and the outer surface of the runner is wound with a conveyor belt. The material hoist used on the construction site effectively ensures the stability of the loading hopper during transportation and prevents the fixed rod from falling off during movement, effectively prevents dust from floating inside the equipment body and affects the normal operation of the equipment, ensuring The material can be cleared, which solves the problem that often occurs that the material falls inside the equipment, causing mechanical failure, and the dust is seriously scattered during material transportation. If it is not cleaned for a long time, it will affect the conveying rate of the equipment and accelerate the speed of equipment parts. The wear and tear is also very inconvenient when cleaning.

Owner:高文英

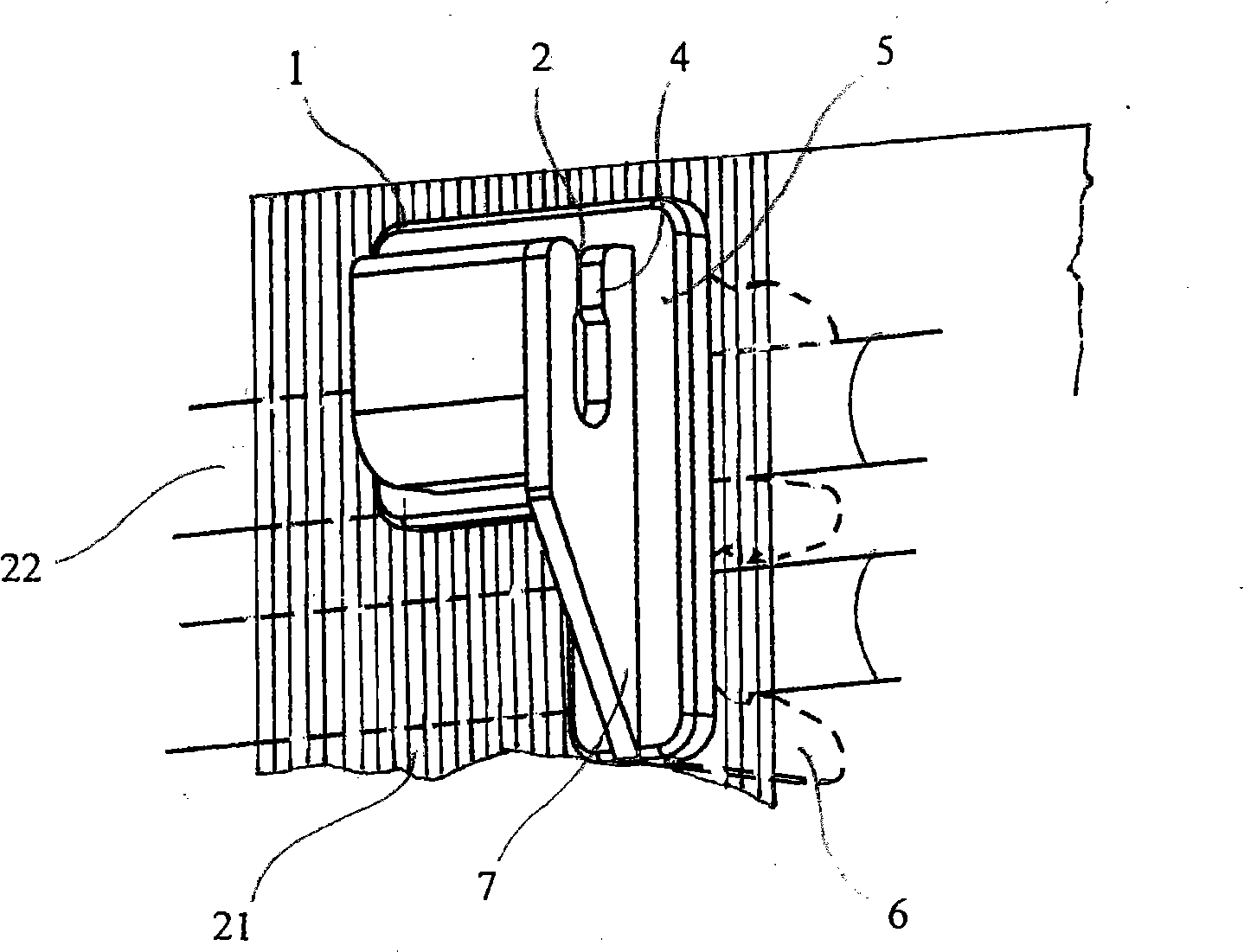

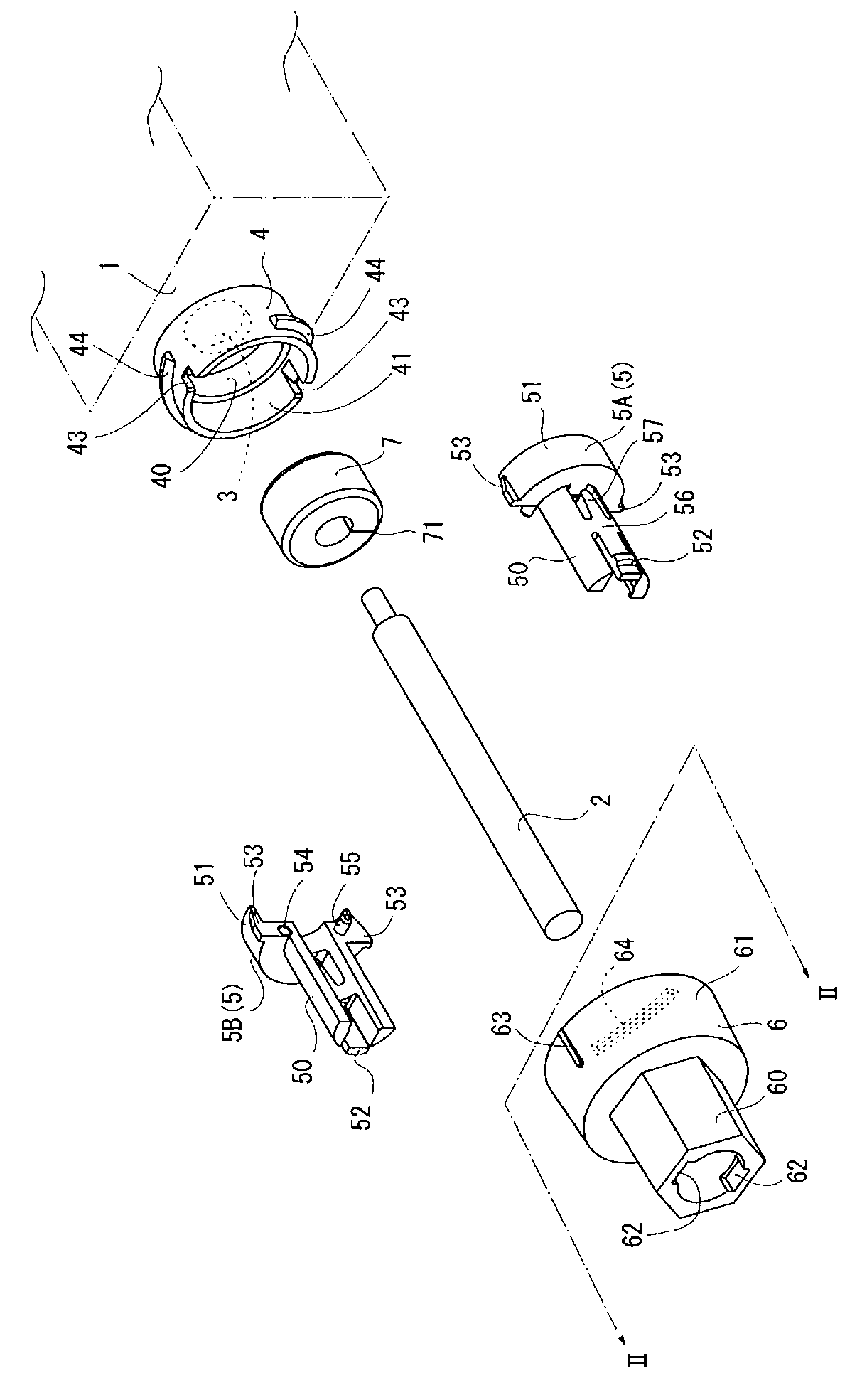

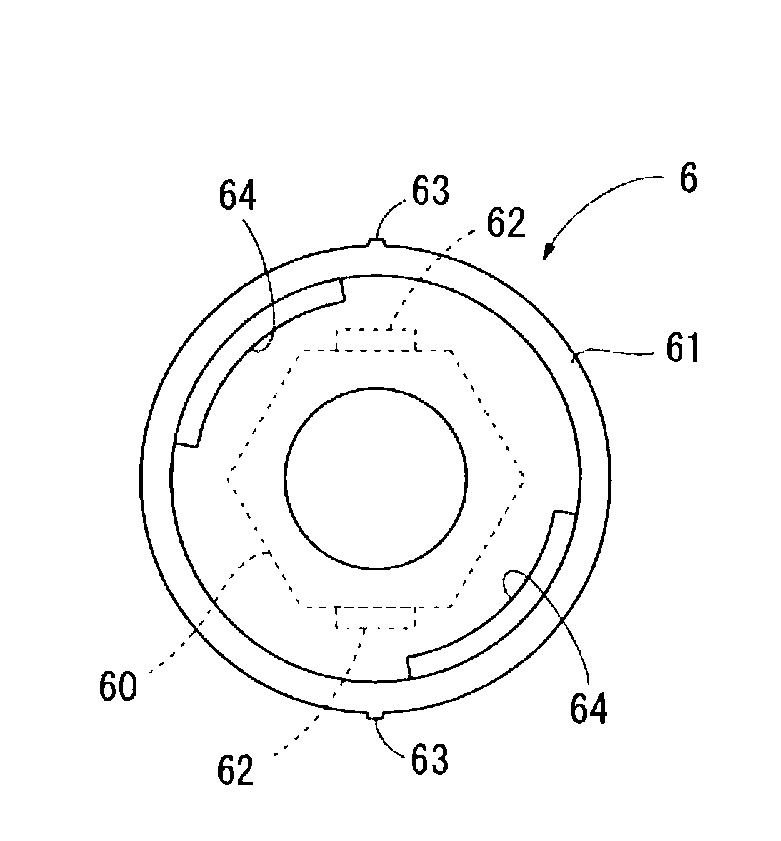

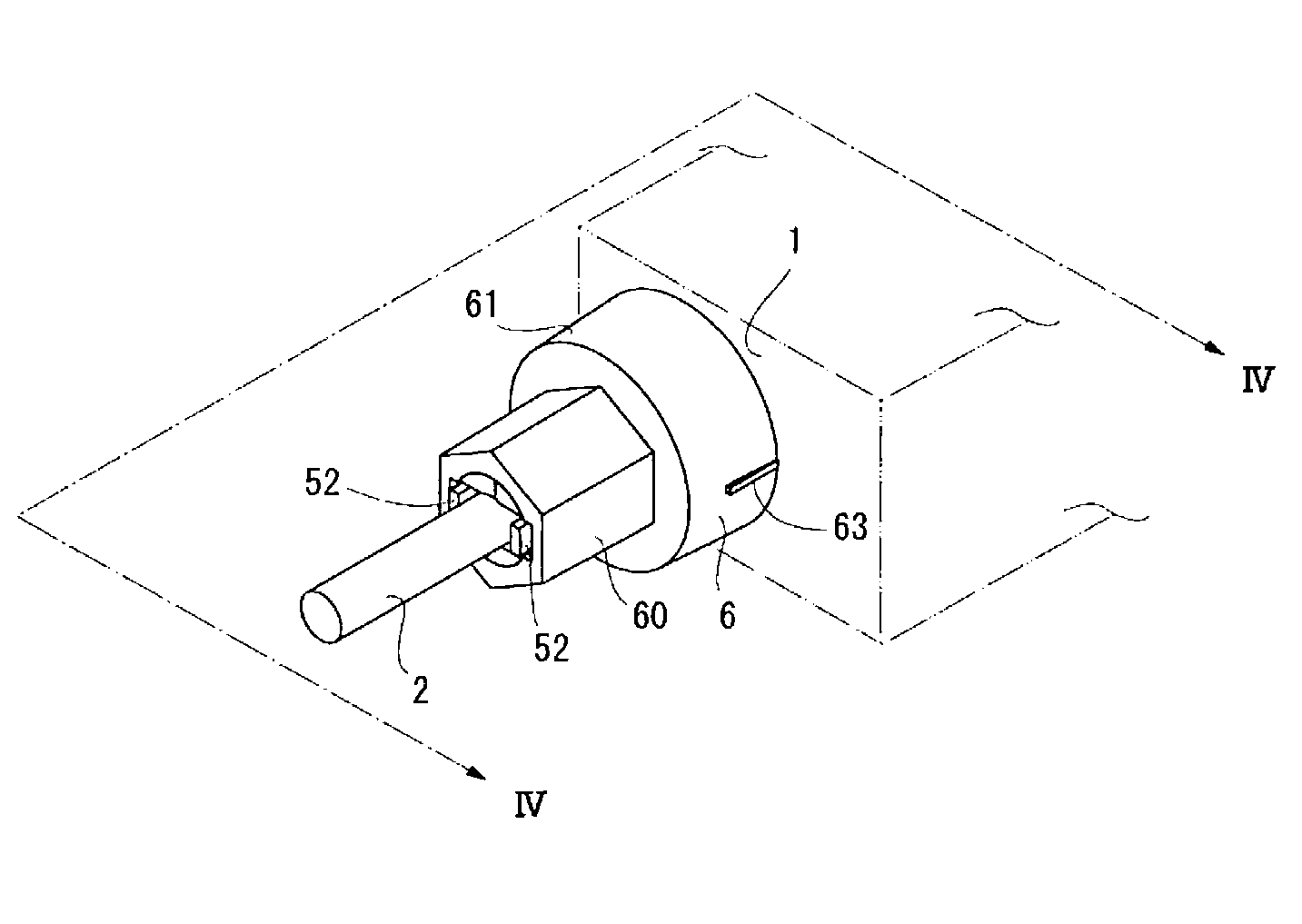

Cable bush

InactiveCN103229608APrevent falling offReduce operational burdenPipesElectrical apparatus contructional detailsEngineeringMechanical engineering

Provided is a cable bush that can reliably prevent detachment while simplifying assembly. Slit portions (43) and projecting portions (53) are formed in the cable bush in order to restrict the rotation betweem a base member (4) and fitting portions (51) of a cable-holding portion (5). A base ridge (44) is formed on the outer peripheral surface of the base member (4), and a cap ridge (64) is formed on the inner peripheral surface at the rear end side of a cap member (6). The cap member (6) can be twisted and pressed into the base member (4). In order to restrict the rotation between the cable-holding portion (5) and the cap member (6), and to prevent the detachment of the cap member (6) from the cable-holding portion (5), engaging portions (52) are formed in the cable-holding portion (5), and engagement receptacles (62), with which the engaging portions (52) engage with the engagement receptacles (62) in the rotation direction and the front-back direction, are formed in the cap member (6).

Owner:ASAHI DENSHI

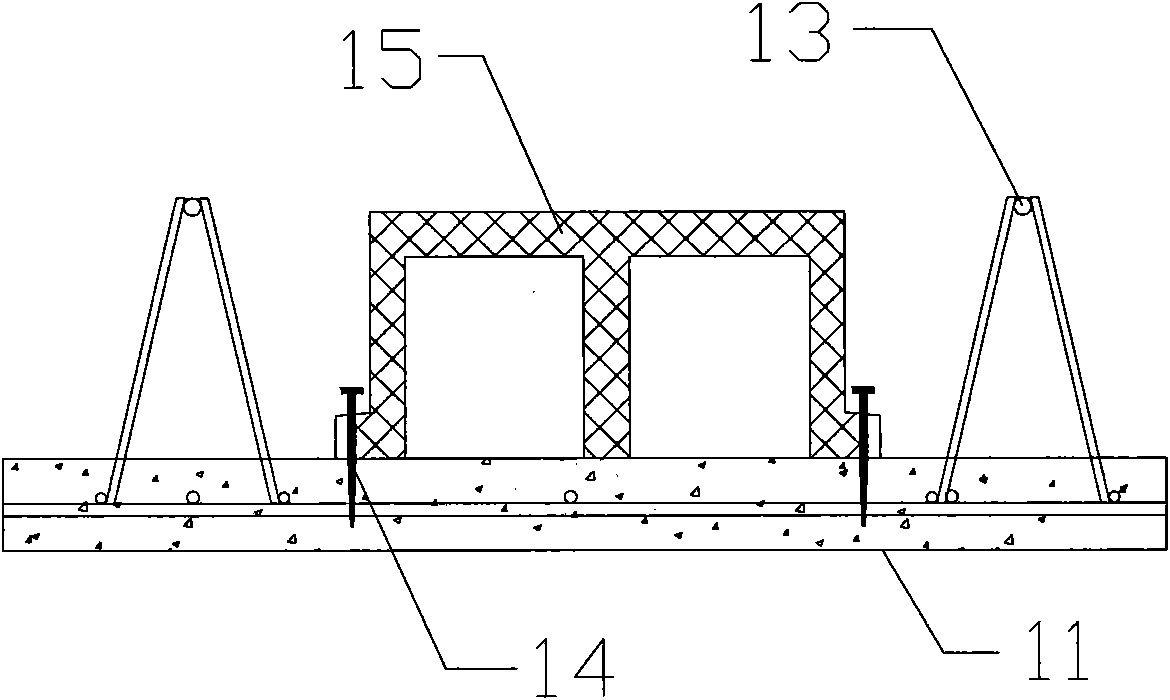

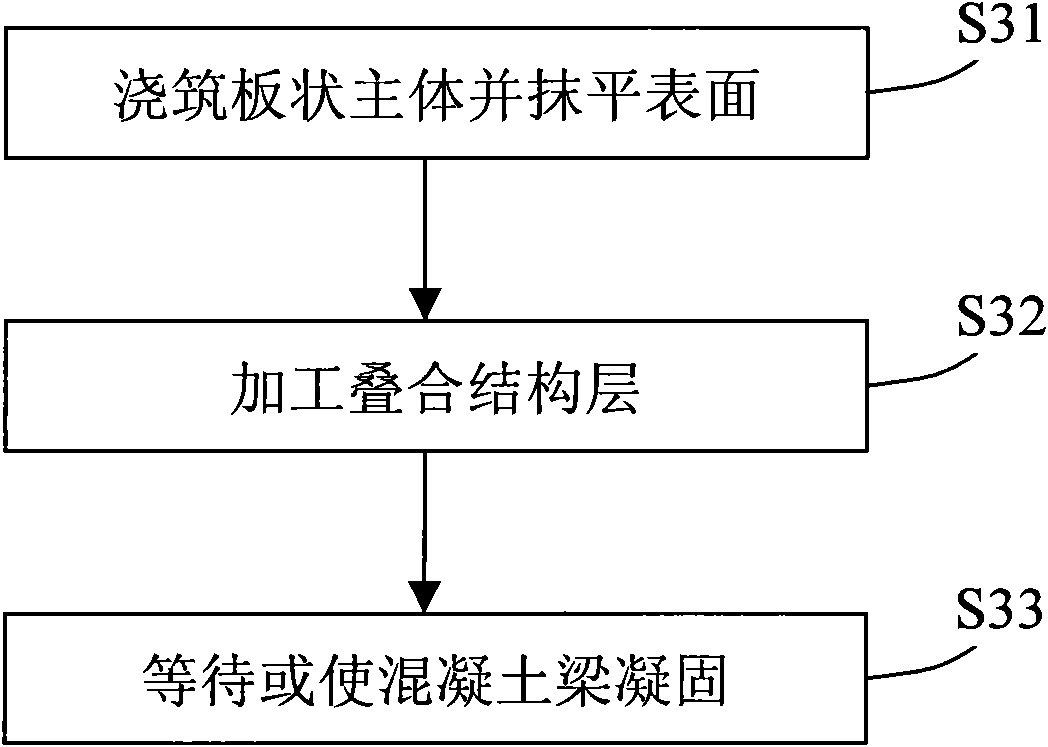

Precast concrete slab and preparation method thereof

The invention relates to a precast concrete slab which comprises a slab-shaped main body consisting of steel bars and concrete covering the steel bars, the upper surface of the slab-shaped main body comprises a lapping structure layer, and the surface of the lapping structure layer is provided with combing marks, pressing marks and / or swash marks with 2-10mm. The invention is also provided with a preparation method of the precast concrete slab. The invention realizes tight combination of the precast concrete slab and a cast-in-place part through the lapping structure layer integrating with the slab-shaped main body, and can effectively prevent a combination part from shedding, sliding and the like.

Owner:VANKE

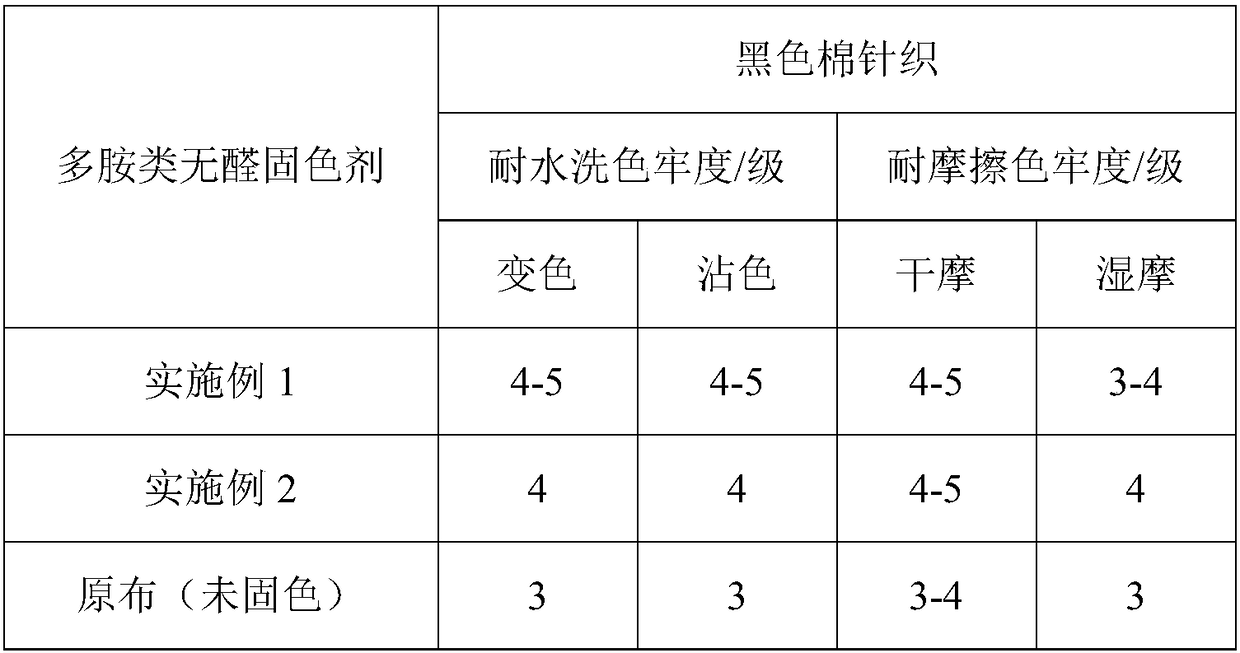

Polyamine formaldehyde-free fixing agent as well as preparation and application method thereof

InactiveCN108660810APrevent falling offImprove color fastnessDyeing processQuaternary ammonium surfactantIon

The invention provides a polyamine formaldehyde-free fixing agent as well as preparation and application method thereof. The polyamine aldehyde-free fixing agent is prepared from the following components in parts by weight: 8 to 15 parts of organic amine monomer, 5 to 15 parts of N-aminoethyl piperazine, 10 to 20 parts of quaternary ammonium cationizing agent, 15 to 25 parts of dicyandiamide, 2 to5 parts of organic acid, 8 to 15 parts of organic solvent, 5 to 15 parts of epichlorohydrin, 10 to 20 parts of cationic etherifying agent, 5 to 10 parts of polyvinyl alcohol (PVA) and 40 to 60 partsof deionized water. The polyamine formaldehyde-free fixing agent provided by the invention is green and environmentally friendly, and can eliminate reddish color produced during dyeing while fixing, thus avoiding repairing dyeing, and effectively improving various color fastnesses of fabrics, such as washing fastness, friction fastness and boiling water fastness.

Owner:苏州联胜化学有限公司

High-temperature-resistant heat insulation composite cable sleeve and manufacturing method thereof

ActiveCN103839618AHigh tensile strengthPrevent falling offInsulated cablesCable/conductor manufactureWear resistantContact temperature

The invention discloses a high-temperature-resistant heat insulation composite cable sleeve and a manufacturing method thereof. The composite cable sleeve comprises a first glass fiber sleeve body, a second glass fiber sleeve body, a heat insulation flame-retardant coating and a flame-retardant wear-resistant coating, wherein the outer surface of the first glass fiber sleeve body is evenly dip-coated with a rubber layer firstly and then evenly dip-coated with the heat insulation flame-retardant coating after being vulcanized in a vertical electric dry oven, and then the first glass fiber sleeve body is dried for 45 min- 60 min at a contact temperature of 120+ / -10 DEG C; the first glass fiber sleeve body provided with the rubber layer and the heat insulation flame-retardant coating is sleeved with the second glass fiber sleeve body, and the outer surface of the second glass fiber sleeve body is evenly dip-coated with the flame-retardant wear-resistant coating. The cable sleeve has the advantages of being resistant to inflaming, resistant to high temperature and resistant to wearing, and normal working of internal cables is guaranteed.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Anti-slippage composite base material boiler body outer surface polishing and grinding machine

PendingCN108544360AImprove the degree of adsorptionImprove stabilityGrinding carriagesPolishing machinesPulp and paper industryBolt connection

The invention provides an anti-slippage composite base material boiler body outer surface polishing and grinding machine. The anti-slippage composite base material boiler body outer surface polishingand grinding machine comprises a polishing mechanism and a clamping mechanism. Supporting columns are arranged on the outer side of the polishing mechanism. Polishing rack fixing bases are arranged atthe upper ends of the supporting columns an integral forming manner. The polishing rack fixing bases are in bolt connection to the tail ends of polishing racks through fastening bolts. Polishing wheel shafts are fixedly connected to the front ends of the polishing racks. The front ends of the polishing wheel shafts are fixedly connected with polishing wheels. Stable plates are arranged at the lower ends of the supporting columns and internally fixedly connected with sliding wheels. The sliding wheels are in sliding connection into sliding grooves, and the sliding grooves are in a circular ring shape and are fixedly formed outside the clamping mechanism. A containing plate is arranged at the upper end of the clamping mechanism, each of the four side edges of the containing plate is fixedlyconnected with a spring buckle, and a vacuum suction pipe is arranged in the middle of the containing plate. According to the anti-slippage composite base material boiler body outer surface polishingand grinding machine, the angle of the polishing racks can be adjusted, the polishing wheels can face the surfaces of boiler bodies different in height for grinding along the surfaces of the boiler bodies, polishing is more comprehensive and more thorough, the anti-slippage composite base material boiler body outer surface polishing and grinding machine can adapt to polishing of the boiler bodiesdifferent in height, and usage is more convenient.

Owner:PINGDINGSHAN MEIYI METAL PROD

Flexible substrate and method for manufacturing the same, flexible display device and flexible display apparatus

InactiveCN107482022AGuaranteed a tight fitPrevent falling offFinal product manufactureSolid-state devicesEngineeringLight cure

Owner:BOE TECH GRP CO LTD +1

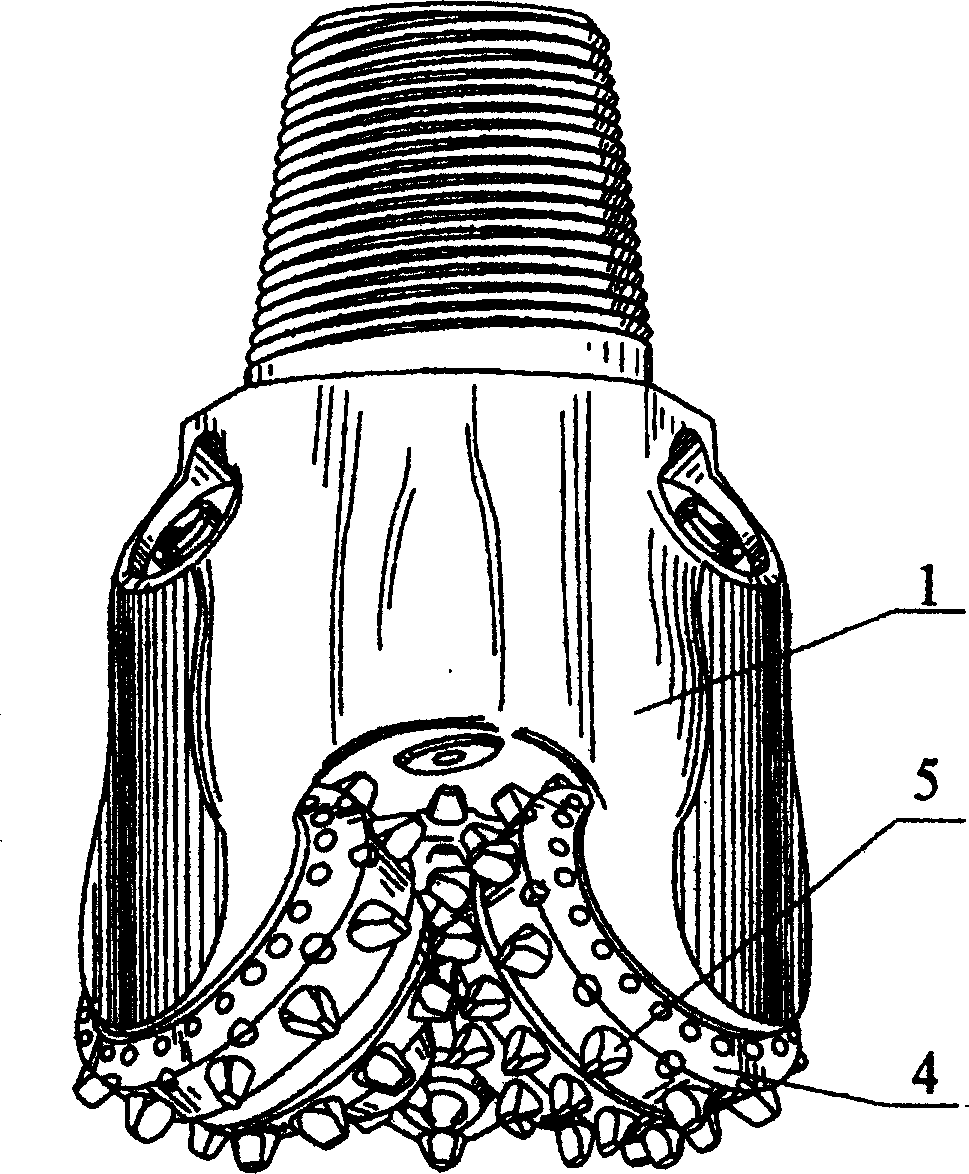

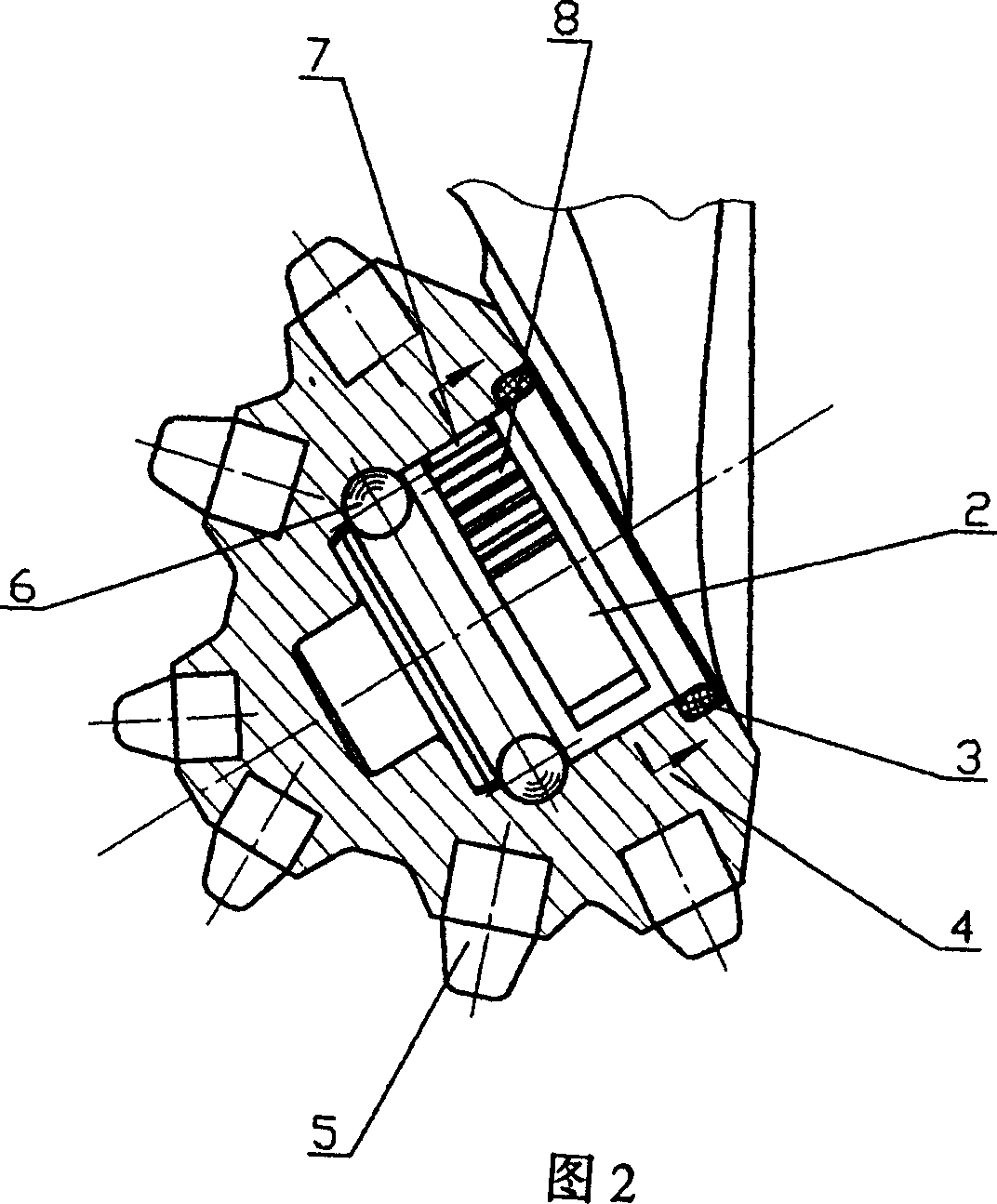

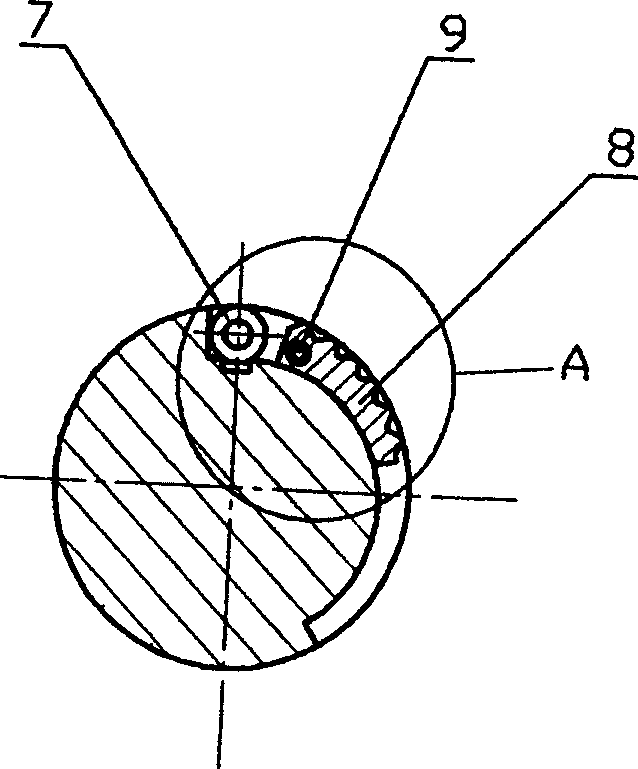

Roller bit with roller pull-off prevention alarm apparatus

The present invention relates to roller cutter bit and features an early warning device set on the toothed claw shaft neck for prevent pineapple from falling off. The device consists of circumferential rollaway nest, roller inside the nest and locking wedge. After the bearing pair is abrased to preset dangerous limit, the pineapple is clamped in the shaft neck, the working torque and speed of the roller cutter bit will change abruptly, so that the bit to be failed may be replaced timely. The present invention can prevent pineapple from falling off and lower well drilling cost, and the locking wedge in the device has great bearing capacity so that the present invention can meet the requirement of different work conditions, especially great drilling pressure.

Owner:SOUTHWEST PETROLEUM UNIV

Method for restoring vegetation on high and steep slopes by aid of coiled plant materials

The invention discloses a method for restoring vegetation on high and steep slopes by the aid of coiled plant materials. The method includes operation steps of 1), cleaning slope surfaces; 2), constructing anchor rods; 3), hanging nets; 4), laying the coiled plant materials; 5), secondarily hanging nets; 6), fixing the nets and the coiled plant materials; 7), watering and maintaining the slope surfaces. The method has the advantages that the stability of substrates on the slope surfaces can be effectively maintained, the substrates are high in erosion resistance, construction processes are simple, the vegetation can be managed and maintained easily and conveniently in later periods, the slope surfaces can be effectively closed, and weathering and peeling of the slope surfaces can be prevented.

Owner:SICHUAN UNIV

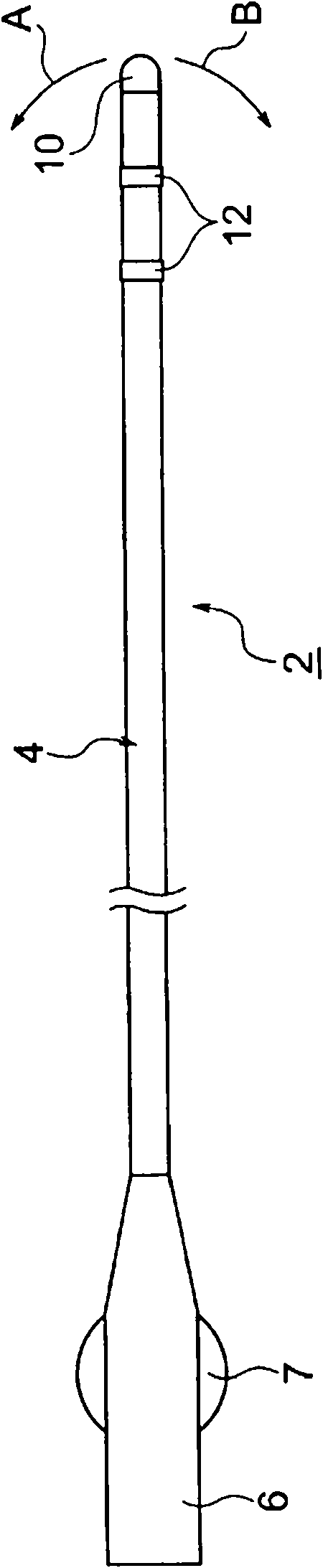

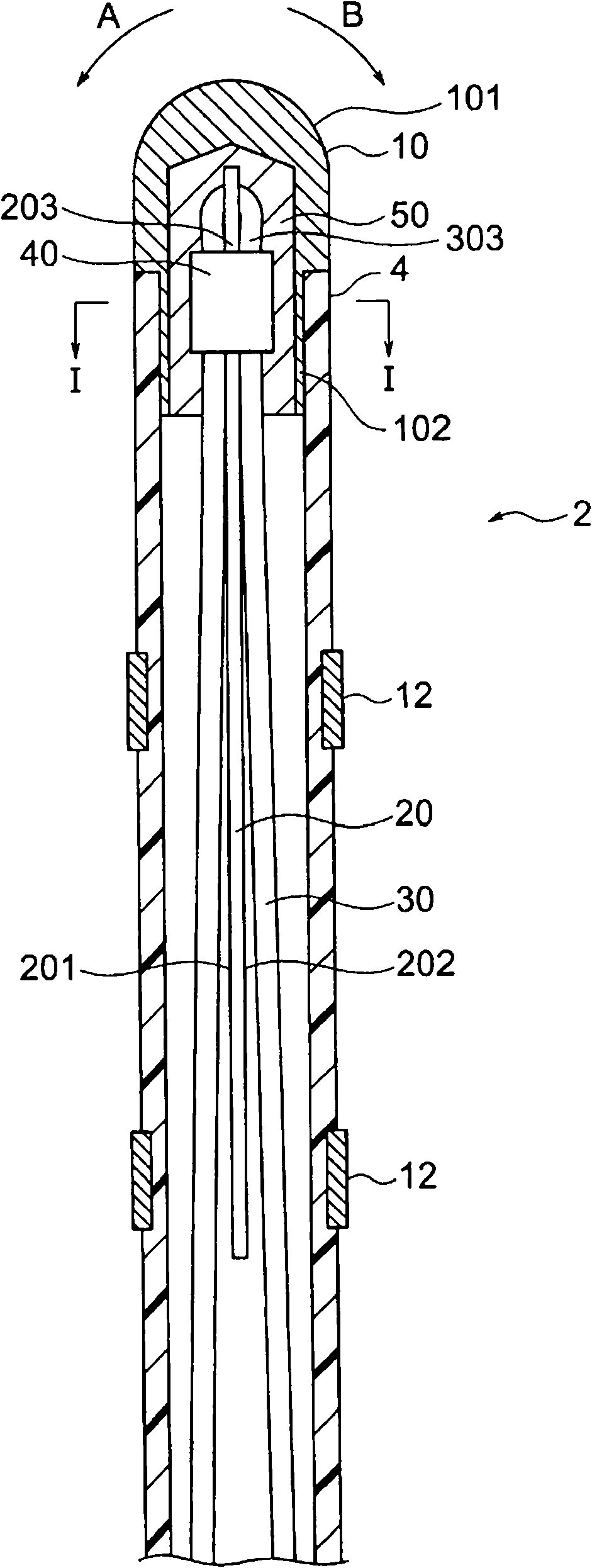

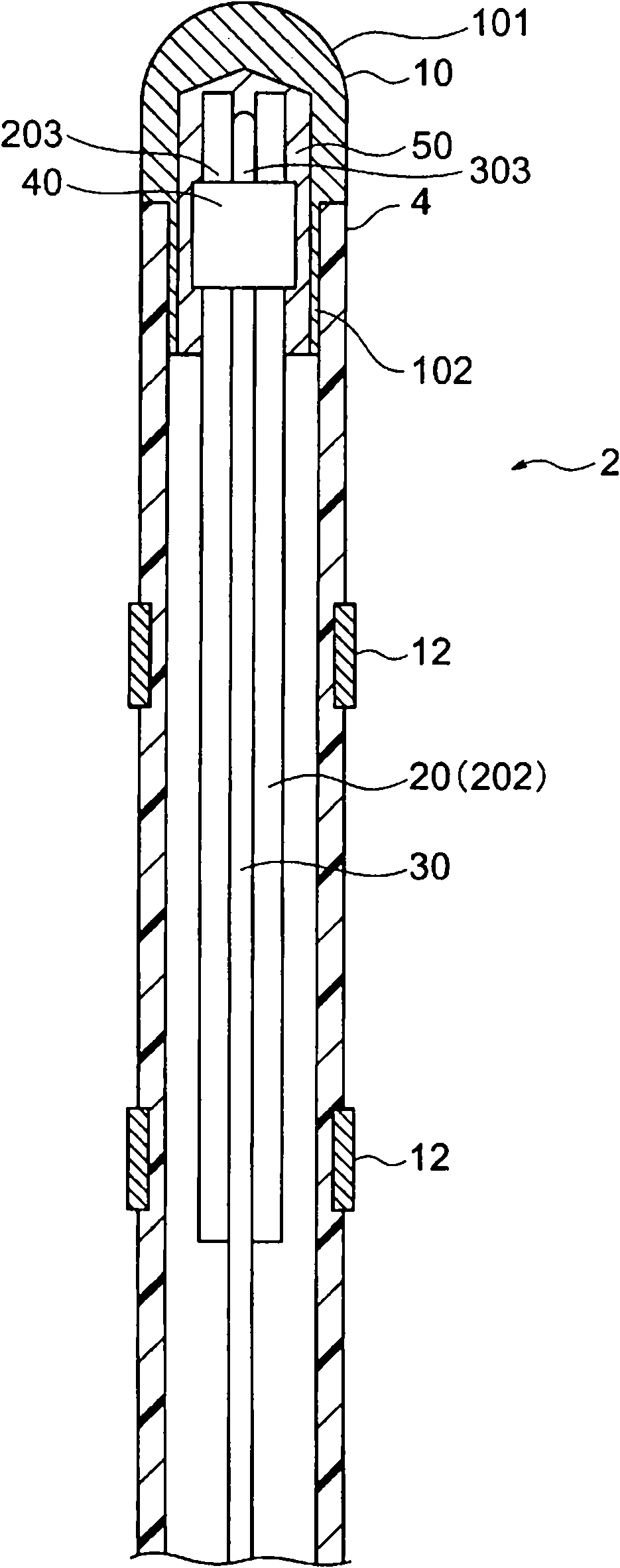

Catheter having deflectable leading end

ActiveCN102159278APrevent falling offPrevent prolapseInternal electrodesCatheterLeaf springCatheter device

Provided is a catheter having a deflectable leading end, which can connect and fix an operation wire firmly on a leaf spring whatever material the leaf spring and the operation wire might be made of, so that the operation wire may not leave the surface of the leaf spring while the catheter is being used. The catheter comprises a catheter tube (4), a leading tip electrode (10) fixed at the distal end of the catheter tube (4), an oscillating leaf spring (20) arranged along the axial direction inside of the distal end side of the catheter tube (4) and made deformable in a warping direction, an operation wire (30) arranged to extend in the axial direction inside of the catheter tube (4) and made pullable at the proximal end thereof, and a ring-shaped member (40) for caulking and fixing the distal end portion (303) of the operation wire (30) on one face (201) and / or the other face (202) of the distal end portion (203) of the leaf spring (20).

Owner:JAPAN LIFELINE CO LTD

Method for recovery of DNA by using magnetic nanocomposite and reagent kit therefor

The invention discloses a recycling method of DNA and agent box through magnetic nanometer composite material in the biological technical domain, which comprises the following steps: (a) blending magnetic nanometer composite material and recycled sample; forming solid-liquid dispersing suspension; (b) adsorbing DNA to separate magnetic nanometer composite material from solid phase; obtaining magnetic nanometer composite material with adsorbed DNA; (c) washing impurity; evolving DNA from magnetic nanometer composite material. The magnetic nanometer composite agent box to recycle DNA possesses magnetic nanometer composite material solution, dissolving liquid, washing liquid I and washing liquid II and eluent.

Owner:JILIN UNIV

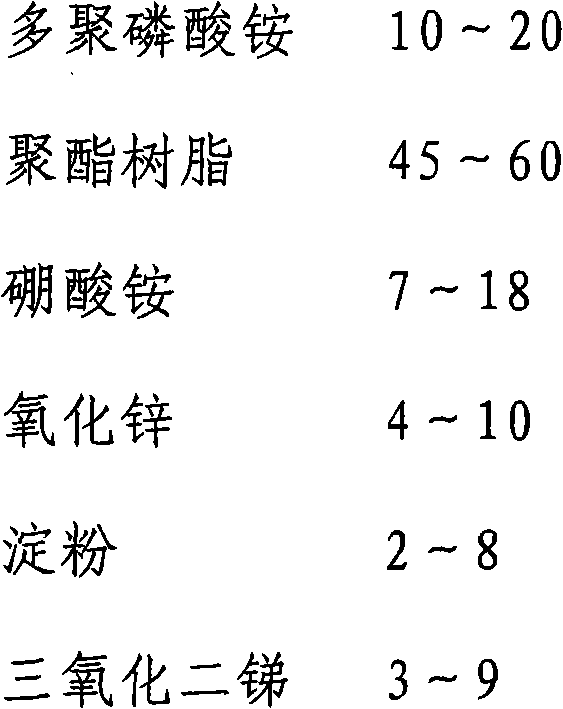

Bamboo fiber towel product prepared through modified adhesive

ActiveCN104264478AImprove adhesionPrevent falling offDomestic applicationsVegetal fibresFurfuryl alcoholMagnesium

The invention relates to a textile, in particular to a bamboo fiber towel product prepared through a modified adhesive. The bamboo fiber towel product is manufactured by the following steps: bamboo fiber preparation; towel product preparation which comprises the steps of cloth turning, weft yarn cutting, head sewing, single-sided singeing, desizing, scouring, bleaching, mercerizing, dyeing, weft yarn finishing, adhesive dipping and tentering, wherein the adhesive dipping step comprises the steps of dipping fabric in the modified adhesive for 18-25 minutes and draining the adhesive for 5-8 minutes; the modified adhesive consists of the following raw materials in part by weight: phthalic anhydride, furfuryl alcohol, triethylene glycol, glutaric acid, butantriol, zinc oxide powder, magnesium oxide, chloroprene rubber, 70-95 parts of elastic rubber, 2-3 parts of softening oil, dimethyl carbonate, benzoyl peroxide, ethyl acetate, an emulsifier, 20-30 parts of flour, 5*10 <-5> to 9*10 <-5> parts of nanometer silver, flame retardant, 0.8-2.5 parts of a catalyst, 3-7 parts of a bamboo vinegar water solution and 6-13 parts of bamboo carbon powder with the grain diameter of 0.01-0.06mm; the elastic rubber comprises first elastic rubber and second elastic rubber which are mixed according to a weight ratio of (1-3):1. The bamboo fiber towel product prepared by the invention has great softness and anti-bacterial activity.

Owner:安吉登冠竹木开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com