Tungsten carbide particle reinforced steel matrix surface-layer composite material and preparation method thereof

A technology of tungsten carbide particles and composite materials, which is applied in the field of composite material preparation, can solve the problems of insufficient metallurgical reaction between the reinforced particles and the matrix, the inability to produce structurally dense parts, and the impact on the service life of composite materials, etc., so as to facilitate sintering And environmental protection, good compactness, good impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

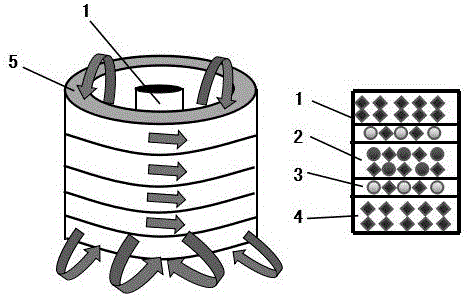

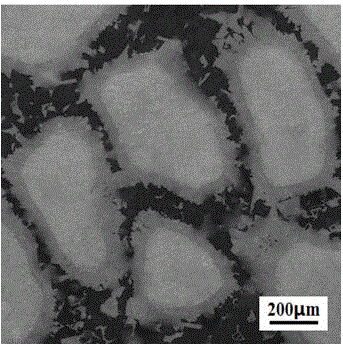

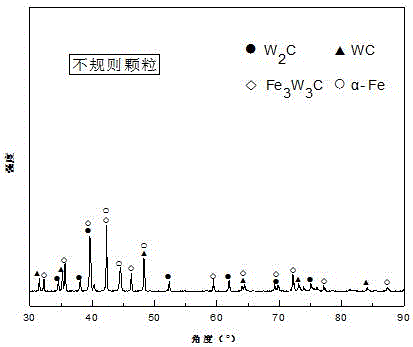

Embodiment 1

[0029] The tungsten carbide particle-reinforced steel-based surface layer composite material in this embodiment consists of three layers: a composite layer, a transition layer, and a base material layer, with thicknesses of 12 mm, 9 mm, and 12 mm, respectively. The transition layer is located between the base material layer and the composite layer. The composite layer is a mixed powder of tungsten carbide particles and 45 steel metal powder, the transition layer is a mixed powder of tungsten powder and 45 steel metal powder, the base layer is 45 steel metal powder, and the mass percentage of 45 steel metal powder in the mixed powder of the transition layer The mass percentage of tungsten powder is 30%, the particle size of tungsten powder is 0.6~30μm, the volume percentage of 45 steel metal powder in the composite layer mixed powder is 60%, the volume percentage of tungsten carbide particles is 40%, tungsten carbide The particles are cast tungsten carbide particles, which are i...

Embodiment 2

[0037] The tungsten carbide particle-reinforced steel-based surface layer composite material in this embodiment is composed of three layers: a composite layer, a transition layer, and a base material layer, with thicknesses of 10 mm, 8 mm, and 10 mm, respectively. The transition layer is located between the base material layer and the composite layer. The composite layer is a mixed powder of tungsten carbide particles and 45 steel metal powder, the transition layer is a mixed powder of tungsten powder and 45 steel metal powder, the base layer is 45 steel metal powder, and the mass percentage of 45 steel metal powder in the mixed powder of the transition layer 90%, the mass percentage of tungsten powder is 10%, the particle size of tungsten powder is 0.6~15μm, the volume percentage of 45 steel metal powder in the composite layer mixed powder is 90%, the volume percentage of tungsten carbide particles is 10%, tungsten carbide The particles are cast tungsten carbide particles, whi...

Embodiment 3

[0045] The tungsten carbide particle-reinforced steel-based surface layer composite material in this embodiment consists of three layers: a composite layer, a transition layer, and a base material layer, with thicknesses of 8mm, 8mm, and 8mm respectively. The transition layer is located between the base material layer and the composite layer. The composite layer is a mixed powder of tungsten carbide particles and 45 steel metal powder, the transition layer is a mixed powder of tungsten powder and 45 steel metal powder, the base layer is 45 steel metal powder, and the mass percentage of 45 steel metal powder in the mixed powder of the transition layer The mass percentage of tungsten powder is 50%, the particle size of tungsten powder is 15~30μm, the volume percentage of 45 steel metal powder in the composite layer mixed powder is 50%, the volume percentage of tungsten carbide particles is 50%, tungsten carbide The particles are cast tungsten carbide particles, which are mixed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com