Patents

Literature

145results about How to "High hardness value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing and tempering bainite wear-resistant steel and steel pipe

InactiveCN102534432AImprove stabilityGuaranteed recrystallizationFurnace typesHeat treatment furnacesWear resistantAlloy

The invention provides a method for manufacturing and tempering bainite wear-resistant steel and steel pipe. The bainite wear-resistant steel contains the following main ingredients of: C, Mn, Si, Cr, Ni, Cu, V, Al, P, S and the balance of Fe. The method for manufacturing the bainite wear-resistant steel pipe comprises the following steps of: alloying the raw material ingredients of bainite wear-resistant steel to form an alloy, refining the alloy by using a refining furnace, forming a pipe blank by using continuous casting, then, heating up the pipe blank, carrying out heat insulation to homogenize, then, perforating, carrying out tandem rolling, and sizing; carrying out pipe-making by using on-line rolling, then, carrying out air cooling or accelerated cooling; and after air cooling or accelerated cooling, carrying out tempering and heat insulation for 1-48 hours at the tempering temperature of 180-380 DEG C. Compared with the prior art, the method has the advantages that: the occurrence of mixed-metal texture is avoided, the recrystallization is fully guaranteed after the alloy is homogenized, two difficult problems in composite pipes internationally and domestically are solved, and a pipeline formed by directly adopting the bainite wear-resistant steel pipe is pressure-proof and wear-resistant.

Owner:TSINGHUA UNIV +1

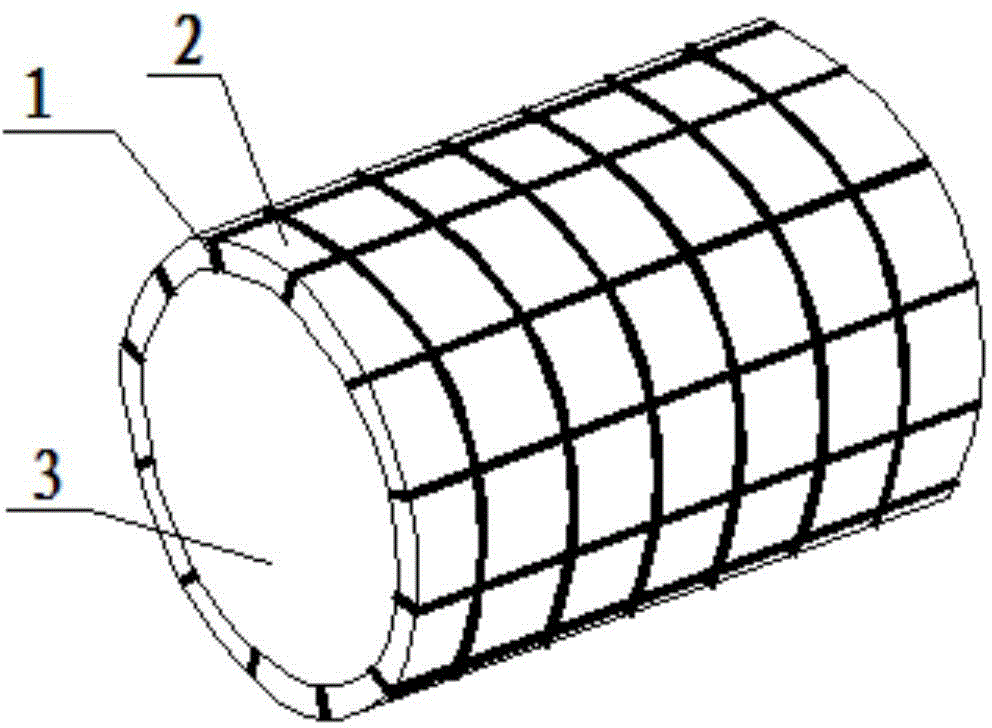

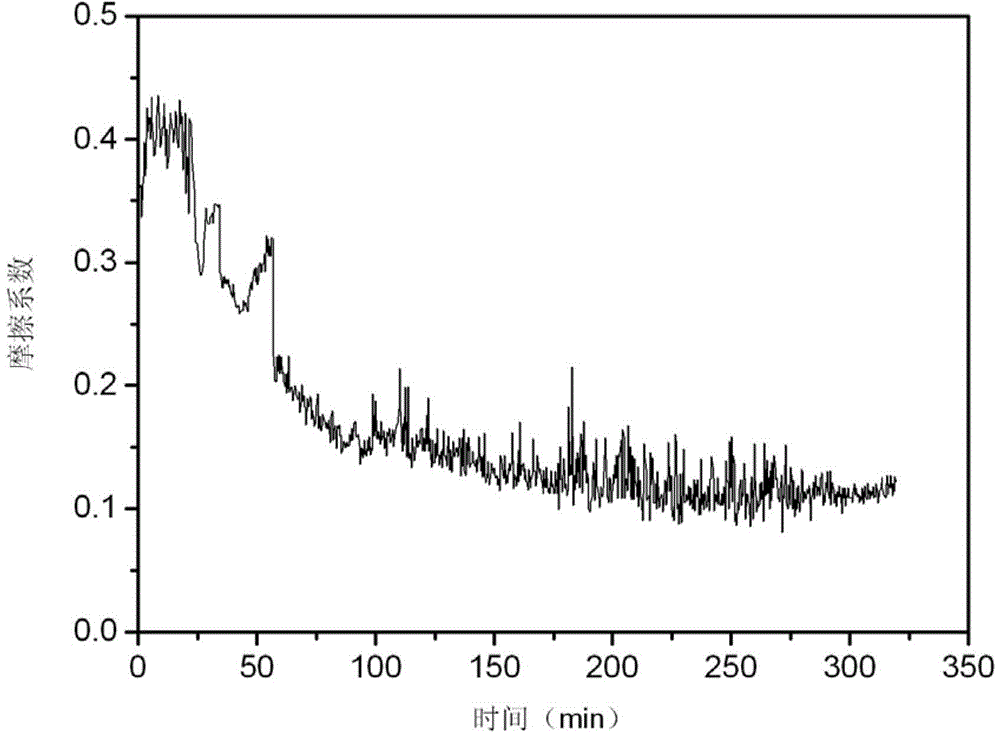

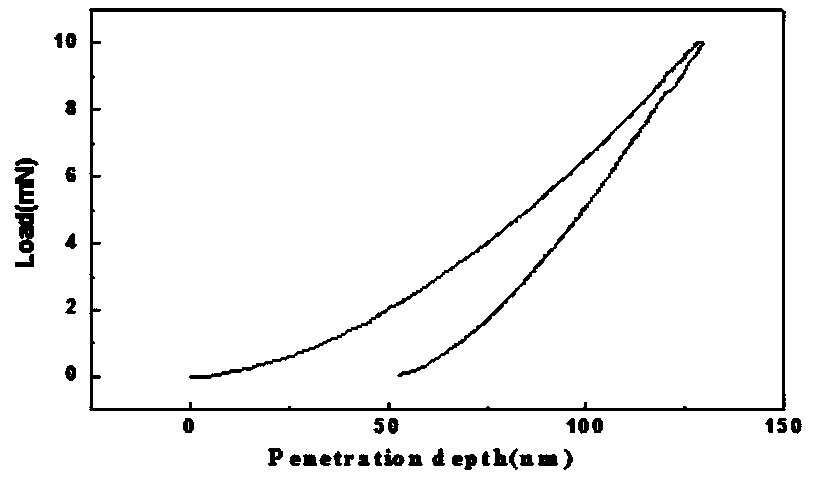

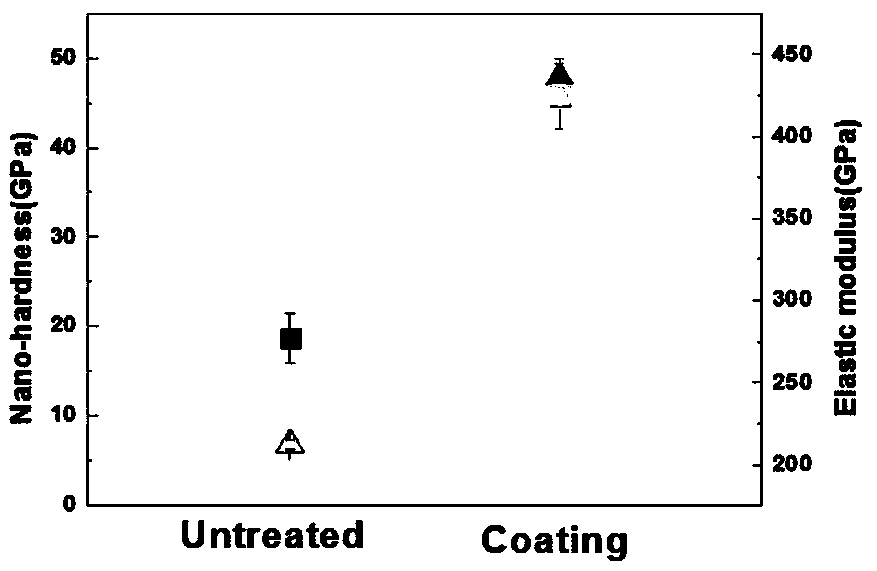

Method for preparing antifriction wear-resistant coating on metal matrix surface

ActiveCN104962909APrevents the accumulation of plastic deformationHigh hardness valueLiquid surface applicatorsMolten spray coatingWear resistantHardness

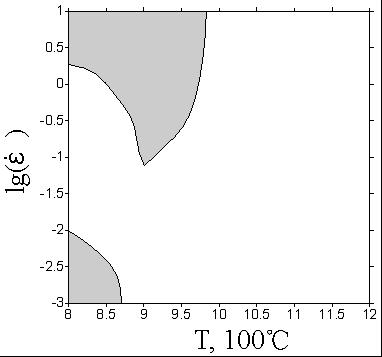

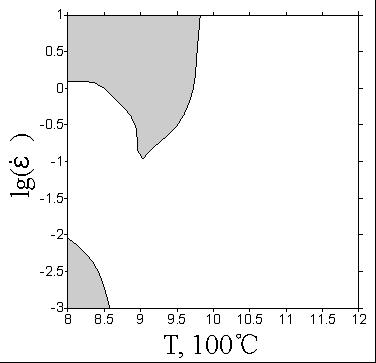

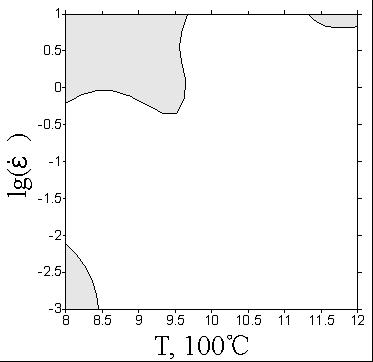

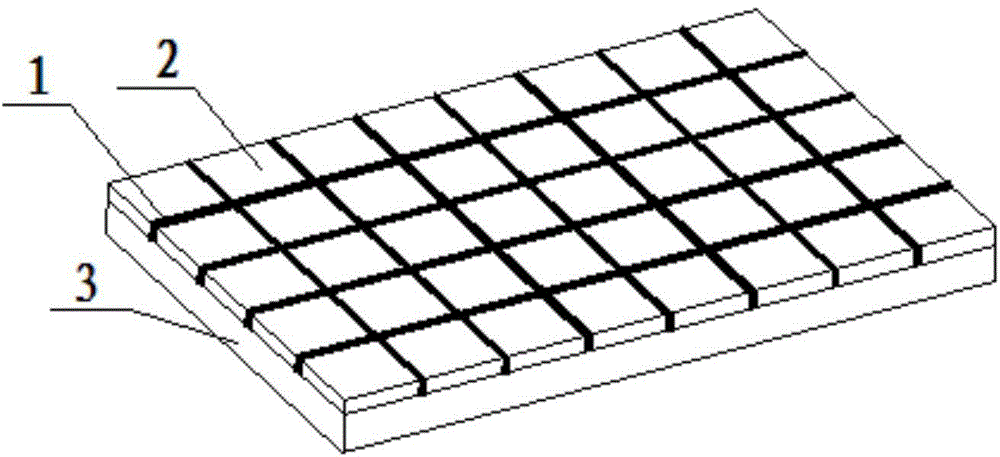

The invention discloses a method for preparing an antifriction wear-resistant coating on a metal matrix surface. The method comprises the following steps: (I) uniformly mixing wear-resistant powder with metal powder to obtain cladding powder; (II) performing laser cladding on the metal matrix surface by use of the cladding powder to form multiple cladding belts in horizontal-longitudinal crossing, wherein the cladding belts in horizontal-longitudinal crossing form a cladding skeleton of a mesh structure; and (III) filling the metal matrix surface with a lubricating phase, and polishing to obtain the antifriction wear-resistant coating on the metal matrix surface. According to the method disclosed by the invention, the cladding skeleton prepared on the metal matrix surface through the laser cladding process has a remarkably high hardness value; the cladding skeleton can realize a load dispersing function in a wear process to effectively prevent accumulation of plastic deformation on the metal matrix surface; and meanwhile, the mesh structure of the cladding skeleton realizes a support effect on the follow-up film forming process of the lubricating phase.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Hard tinned plate suitable for stamping processing and production process thereof

InactiveCN101603147AProduction control is less difficultLow costRoll force/gap control deviceTinningSteelmaking

The invention relates to a hard tinned plate which is suitable for stamping processing and is produced from low carbon Al-killed steel. The original plate comprises the chemical components by weight percentage: 0.08 to 0.13 percent of C, less than or equal to 0.025 percent of Si, less than or equal to 0.65 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, 0.02 to 0.06 percent of solAl, less than or equal to 0.03 percent of Ti, less than or equal to 0.005 percent of N, and Fe and unavoidable impurities accounting for the margin. The production process adopts the steps of steelmaking with molten iron->continuous casting-hot rolling->push-pull mode pickling->HC rolling mill cold rolling->electrolytic degreasing->hydrogen bell furnace annealing(BA)->double-machine leveling->electrolytic tinning, and finally the hard tinned plate can be obtained. The hard tinned plate of the invention has the advantages of low cost, high hardness, favorable stamping processability, and the like, and can be widely used as packing materials for food, drinks, etc.

Owner:武钢集团有限公司

Cutting tool comprising multilayer coating

ActiveCN103201410AImprove wear resistanceExtended service lifeTurning toolsSuperimposed coating processTitanium aluminium nitrideTitanium

The invention relates to a cutting tool comprising a main part and a multilayer coating applied thereon. A first layer A made of a hard material is applied on the main part, said hard material being selected from titanium aluminum nitride (TiAIN), titanium aluminum silicon nitride (TiAISiN), chromium nitride (CrN), aluminum chromium nitride (AICrN), aluminum chromium silicon nitride (AICrSiN), and zirconium nitride (ZrN), and a second layer B made of silicon nitride (Si3N4) is applied directly over the first layer A.

Owner:WALTER AG

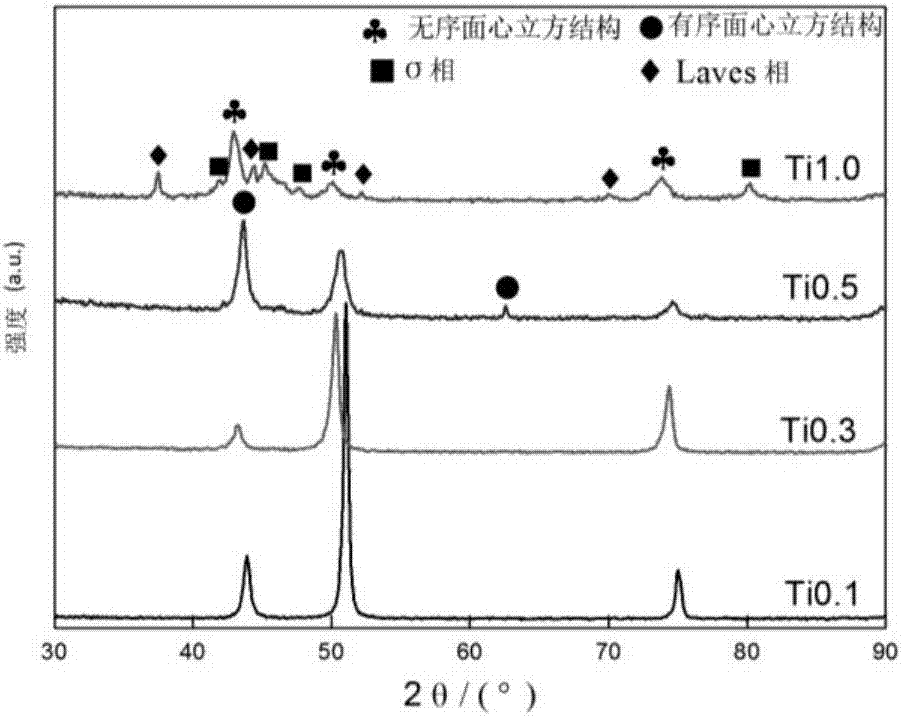

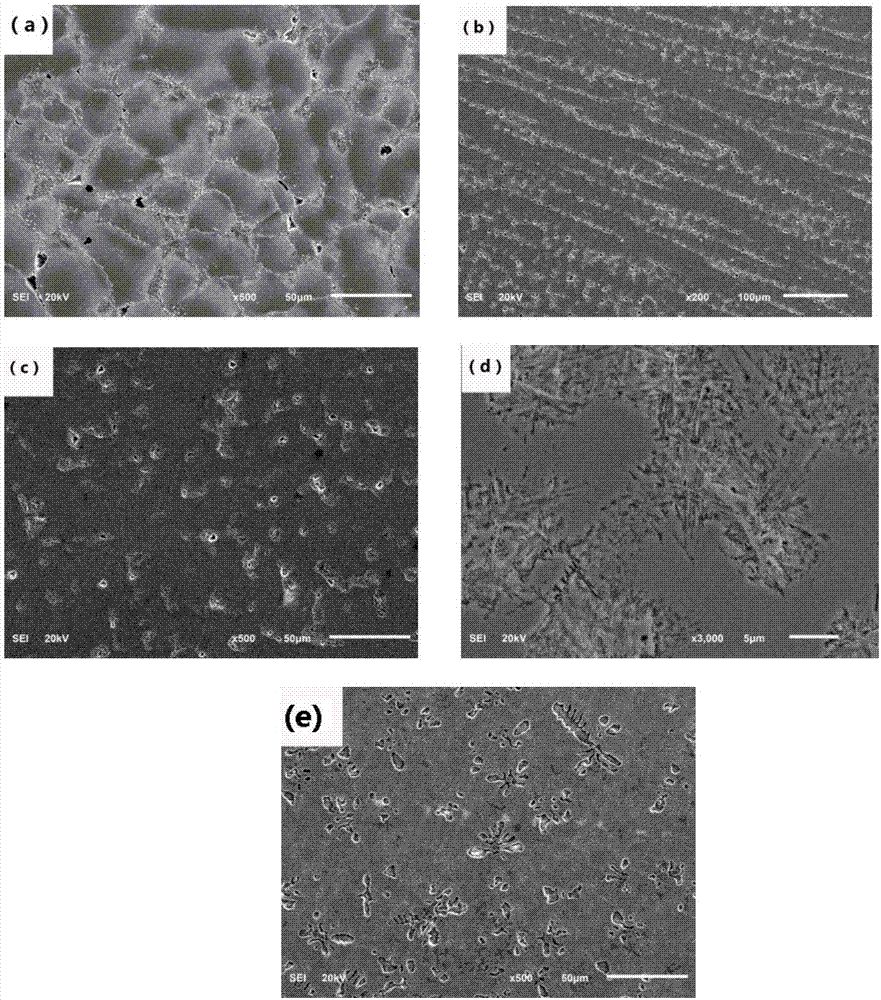

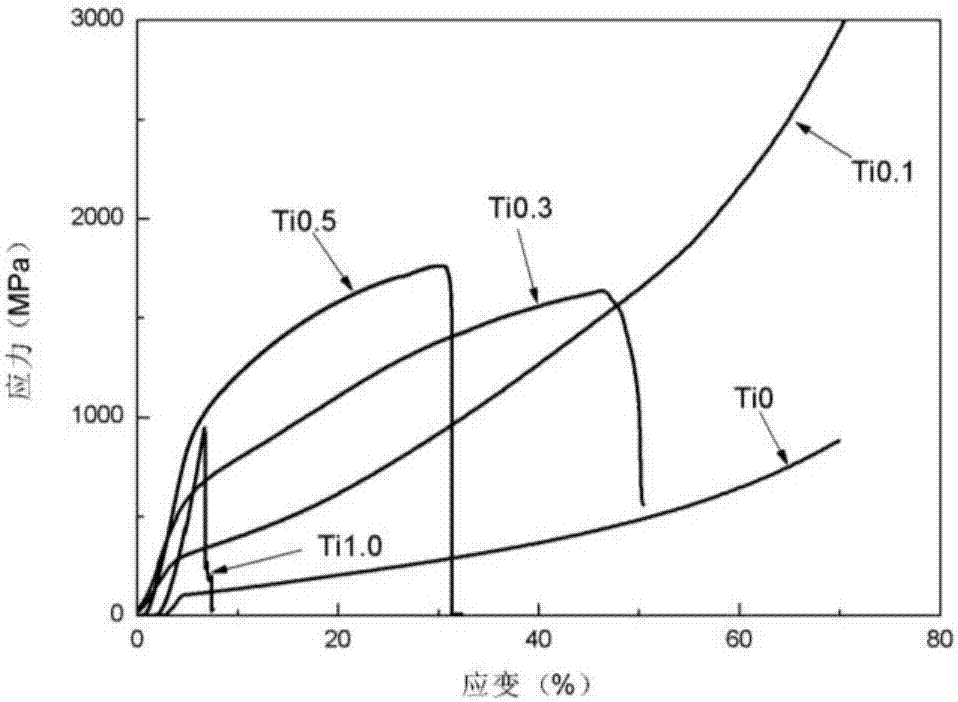

Hexabasic high-entropy alloy and preparation method thereof

The invention discloses a hexabasic high-entropy alloy material. The hexabasic high-entropy alloy material is prepared from, by atomic percent, 18.18%-22.22% of Co, 18.18%-22.22% of Cr, 9.1%-11.12% of Cu, 18.18%-22.22% of Fe, 18.18%-22.22% of Ni and 2.17%-18.18% of Ti, wherein the element Ti has the large atomic radius, and the severe lattice distortion effect of the element Ti can effectively enhance a solid solution phase. In addition, the element Ti has the small valence electron concentration and tends to form a compound phase, and therefore the precipitation enhancing function is achieved. An obtained hexabasic CoCrCu0.5FeNiTi0.5 high-entropy alloy has high strength and plasticity, wherein the yield strength is 850 MPa, the compressive strength reaches 1,650 MPa, and meanwhile the plasticity reaches 31.5%. The alloy has good strength and plasticity cooperation, and a preparation method is simple and reliable. The invention further discloses the preparation method of the hexabasic high-entropy alloy material.

Owner:JIANGSU UNIV OF SCI & TECH

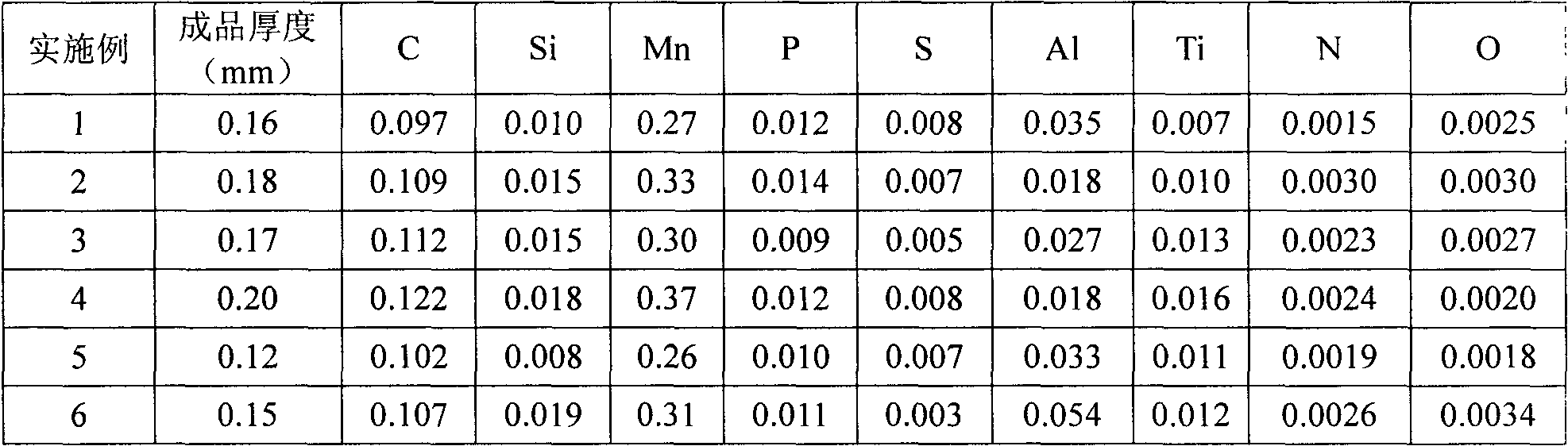

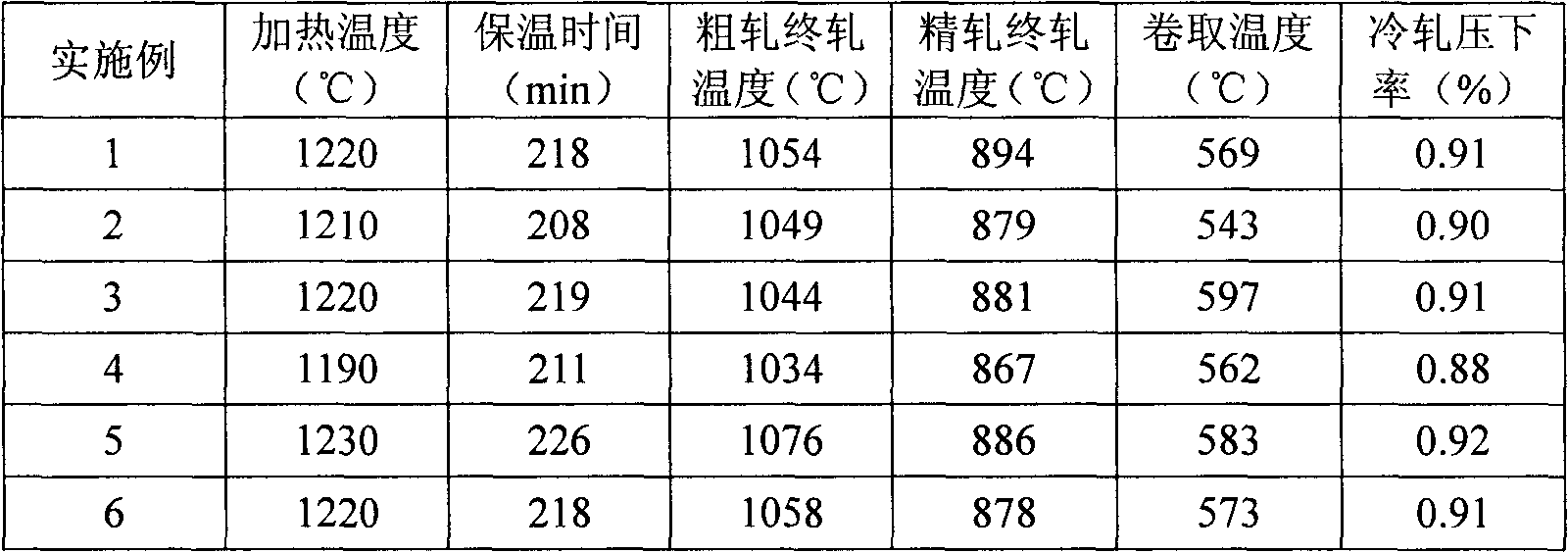

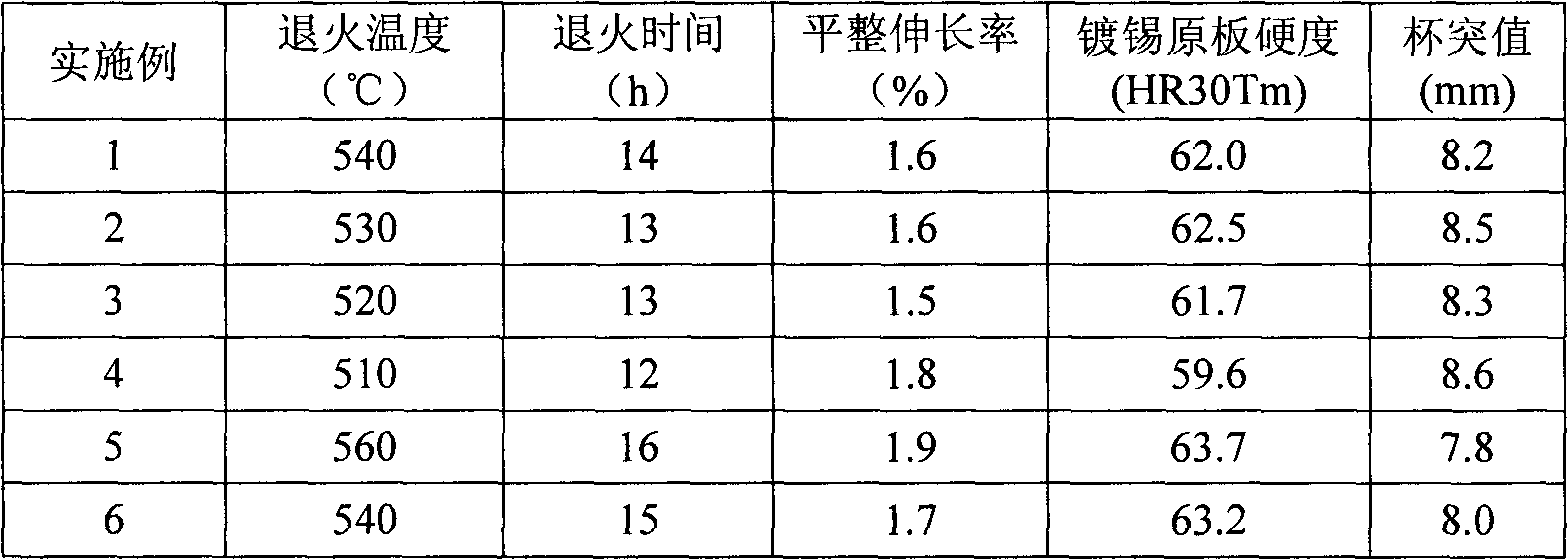

Hard tinned original plate with thin specification and manufacture method thereof

The invention provides a hard tinned original plate with a thin specification and a manufacture method thereof, wherein the original plate comprises components of C 0.095%-0.130%, Si <= 0.020%, Mn 0.25%-0.40%, P <=0.015%, S <=0.015%, Als 0.015%-0.055%, Ti 0.005%-0.020%, N <= 0.003% and the balance being Fe. The method comprises smelting, continuous casting, hot rolling, acid pickling, cold rolling, electrolytic degreasing, full hydrogen cover annealing and flattening. The size of nonmetallic inclusions in steel after smelting is smaller than 10 [mu]m and lower than 0.04 unit / m2. Zero defect continuous casting is adopted. The heating temperature of hot rolling slabs is 1190-1250 DEG C and the heating time thereof is no shorter than 200 minutes, and the rough rolling temperature, finish rolling temperature and coiling temperature are 1030-1090 DEG C, 860-900 DEG C and 540-600 DEG C respectively. A CVC rolling mill is used in cold rolling, the total reduction rate being 86%-93%. The annealing temperature is no higher than 560 DEG C and the annealing time is no shorter than 12 hours. The flattening elongation percentage is 1.5%-2.0%. The alloy of the invention has low cost, small and few nonmetallic inclusions, excellent stamping performance, high product hardness value and small thickness.

Owner:ANGANG STEEL CO LTD

Method for strengthening composite coating by using nano silicon dioxide sol and rare-earth

ActiveCN101397657AUniform particle distributionHigh hardness valueLiquid/solution decomposition chemical coatingChemical platingSulfate

The invention relates to a method which adopts nano silicon dioxide sol and rare earth to strengthen a composite deposite. The method comprises the following main steps: the preparation of a nano sol, the preparation of a plating solution and electroless composite plating, and is characterized in that: the nano SiO2 sol is directly added into the Ni-P chemical plating solution containing rare earth cerous sulfate to carry out plating, obtained nano SiO2 particles in the composite deposite are evenly distributed and the rigidity of the deposite is obviously improved. The method also has the advantages of convenient operation without mechanical stirring during the plating process, low cost, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

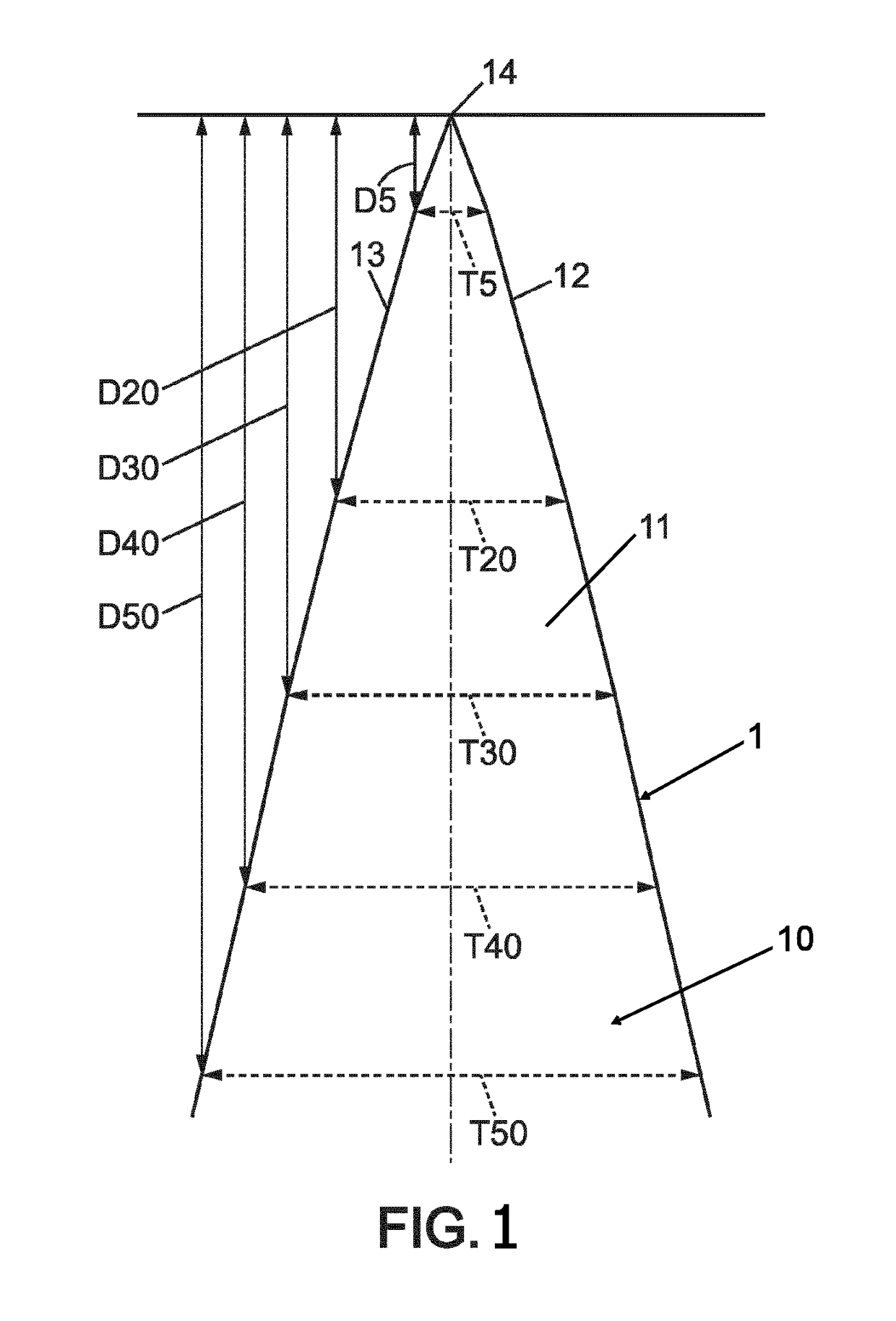

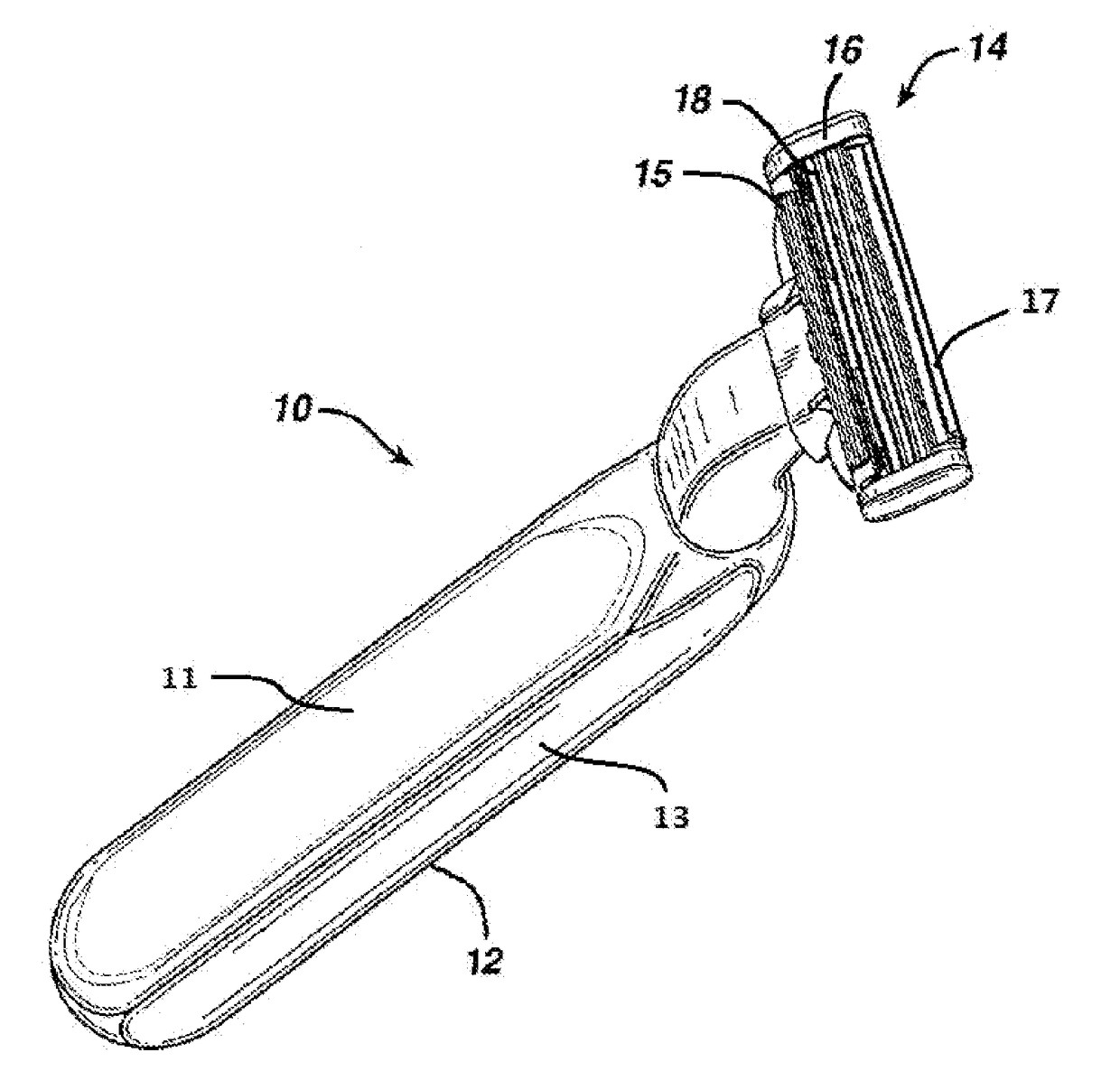

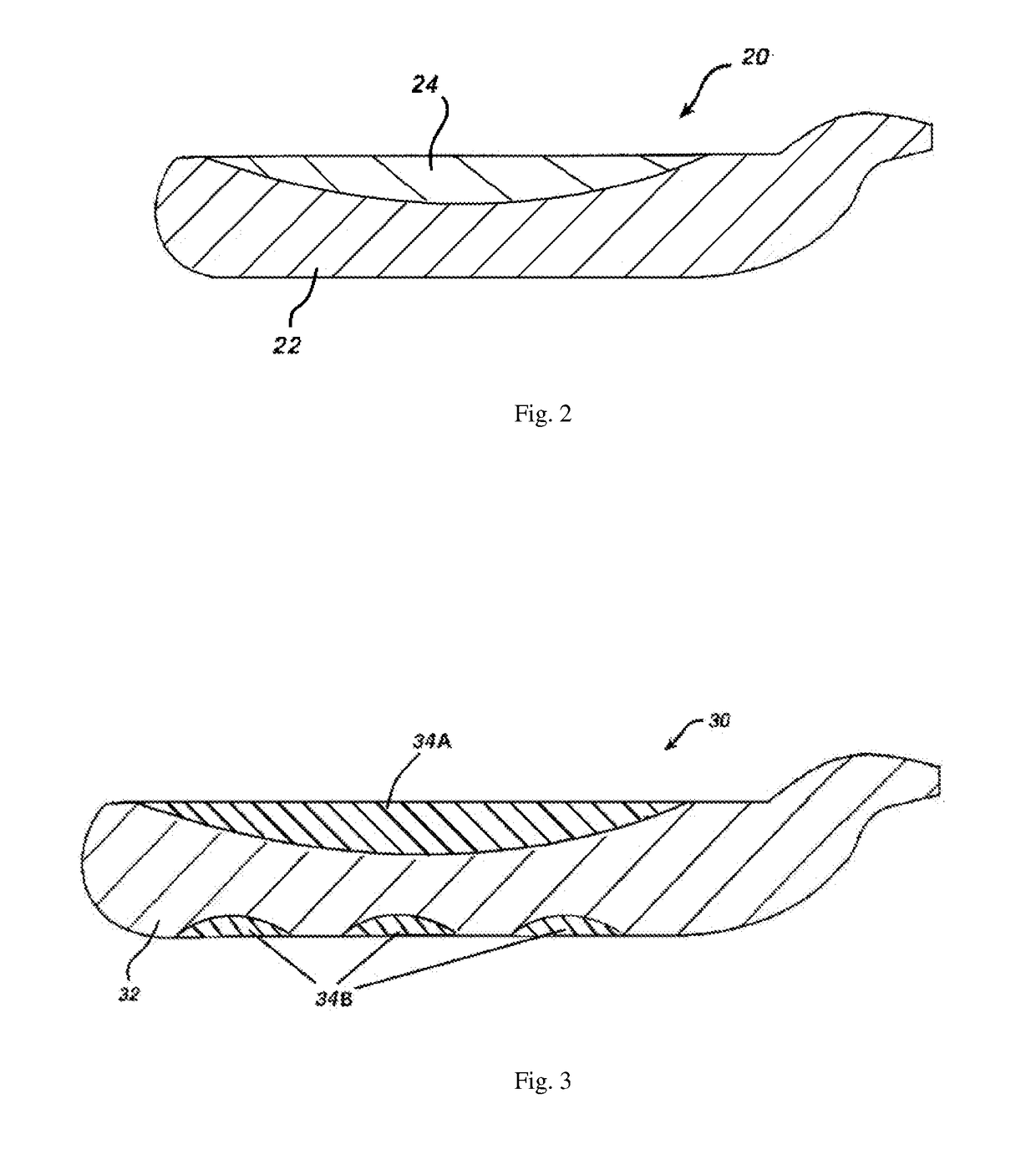

Razor blade

ActiveUS20170136641A1Reduce thicknessHardness value can be increasedVacuum evaporation coatingSputtering coatingEngineeringDeposition process

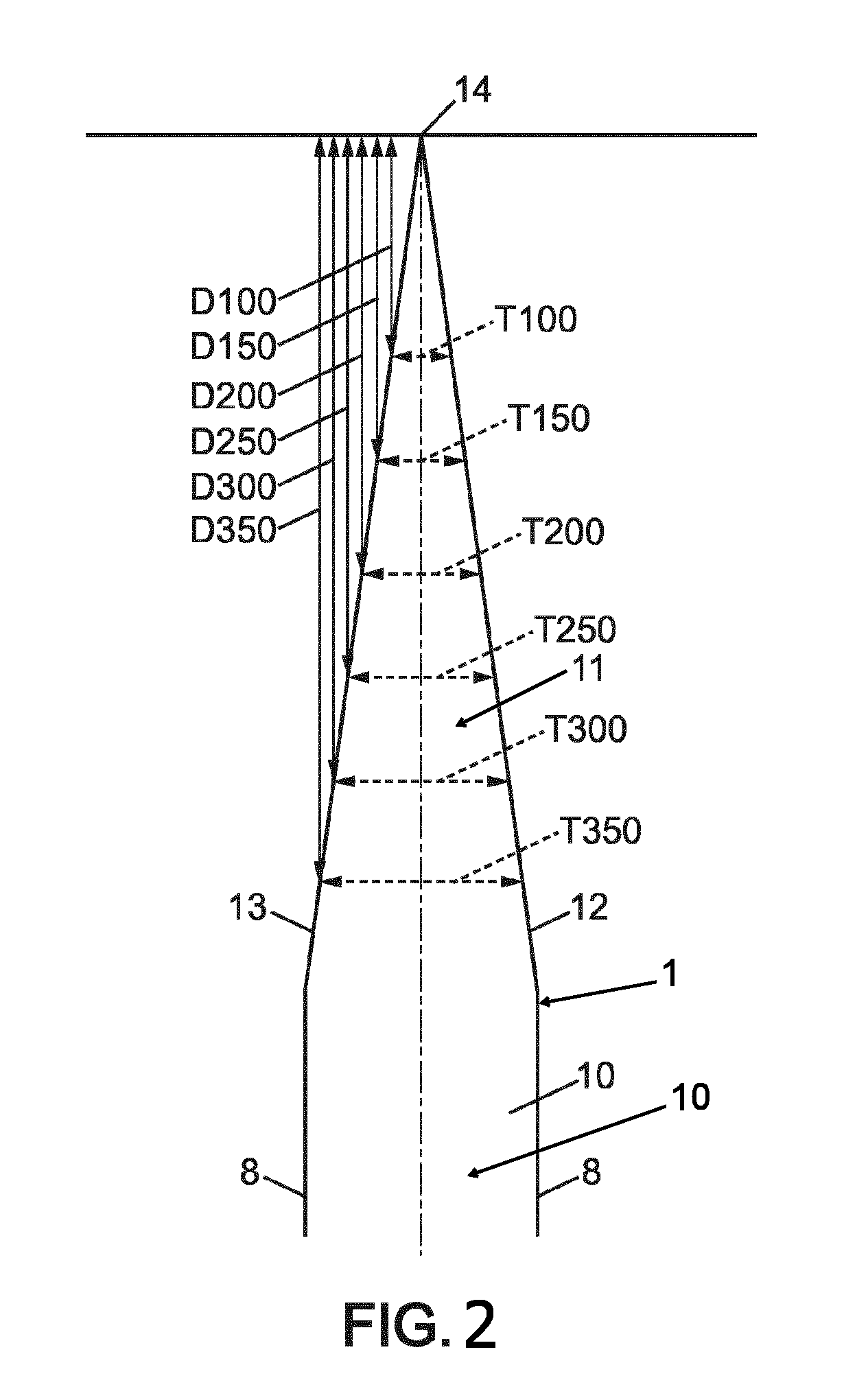

A razor blade comprising a blade substrate with a blade edge substrate portion ending in blade tip. The razor blade is covered by a strengthening coating deposited on the blade edge substrate portion via a deposition process. The deposition process causes a hardness value of the strengthening coating layer to be increased, which, among other factors, allows for a decreased thickness of the blade substrate with coating. The blade substrate with coating has (i) a thickness of between about 1.57 and 2.37 micrometers measured at a distance of about five micrometers from the coating tip, (ii) a thickness of between about 4.62 and 6.74 micrometers measured at a distance of about twenty micrometers from the coating tip, and (iii) a thickness of between about 19.82 and 27.52 micrometers measured at a distance of about one hundred micrometers from the coating tip.

Owner:BIC VIOLEX SA

Orodispersible tablets

InactiveUS20120077888A1Short disintegration timeHighly robustBiocideAntipyreticMANNITOL/SORBITOLActive agent

A directly compressed orodispersible tablet comprises 0.1 to 50% of a ungranulated active agent (w / w), 10 to 80% of a sugar-based direct compression base, and 10 to 80% of a microcrystalline cellulose (MCC) direct compression base, and has a hardness of at least 60N, and a disintegration time of less than 40 seconds. The sugar-based direct compression base is a DC sugar alcohol, especially direct compression mannitol, and the MCC base is a silicified MCC, especially a Prosolv. The active is a hydrophobic active, typically a high-dose active. Also disclosed is a method of producing an orodispersible tablet comprising the steps of directly compressing a mixture of components at a compression force of at least 5 k N to form the tablet, wherein the mixture of components comprises 0.1 to 50% of an active agent (w / w), 10 to 80% of a sugar-based direct compression base (w / w); and 10 to 80% of a microcrystalline cellulose (MCC) direct compression base (w / w).

Owner:ROYAL COLLEGE OF SURGEONS & IRELAND

High-silicon high-manganese hot-work die steel and preparation method thereof

The invention discloses a high-silicon high-manganese hot-work die steel, comprising the chemical elements in percentage by mass: 0.3-0.4% of C, 1.2-1.8% of Si, 0.6-1.5% of Mn, 3.5-4.5% of Cr, 0.8-1.0% of Mo, 0.3-0.5% of V, less than or equal to 0.03% of P, less than or equal to 0.03% of S, and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a preparation method of the high-silicon high-manganese hot-work die steel. The high-silicon high-manganese hot-work die steel not only has high tempering resistance and good impact toughness, but also can become a low-cost economic type hot-work die steel due to reduction of the content of noble alloy elements such as chromium, molybdenum and the like.

Owner:宝武特种冶金有限公司

Silane-Crosslinkable Coating Formulations

InactiveUS20080160200A1Improve scratch resistanceHigh hardness valuePretreated surfacesCoatingsSilanesMoisture

Owner:WACKER CHEM GMBH

Glass material and method of preparing said glass

InactiveUS20060128551A1Improve mechanical propertiesHigh hardness valueGlass making apparatusNitrideGlass material

A nitride glass with the general formula αxβyγz is provided wherein α is a glass modifier comprising at least one electropositive element. β comprises Si, B, Ge, Ga and / or Al. γ is N or N together with O, whereby the atomic ratio of O:N is in the interval from 65:35 to 0:100.

Owner:DIAMORPH AB

Aqueous dispersed polyester resin compositions

InactiveUS20110217478A1High hardnessHigh hardness valueInksPolyester coatingsPolyester resinCompound c

The invention relates to a radiation curable aqueously dispersed polyester resin composition containing an emulsifier D and the reaction product AC of a hydroxy functional polyester resin A and an olefinically unsaturated compound C which can be radically polymerised and which is attached to the polyester resin backbone by an ester linkage or a urethane linkage. The invention also relates to a process for its preparation and to a method of use thereof.

Owner:CYTEC SURFACE SPECIALTIES INC

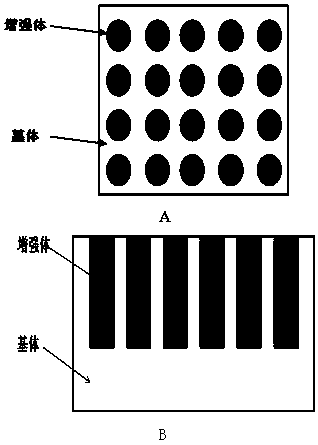

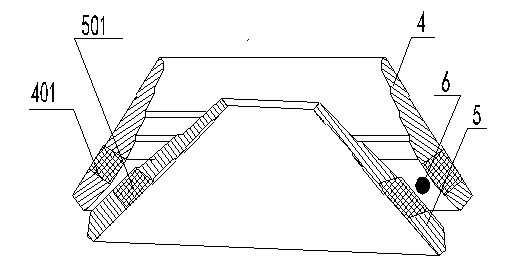

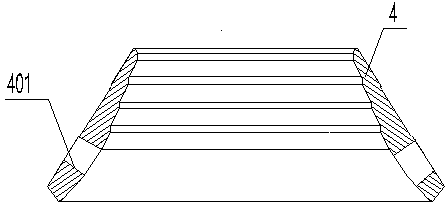

Reinforced steel-based surface-layer spatial-configuration composite containing rear earth and modified particles and preparation method thereof

The invention discloses a reinforced steel-based surface-layer spatial-configuration composite containing rear earth and modified particles and a preparation method thereof, and belongs to the technical field of powder metallurgy and composite preparation. The composite is composed of a reinforced body and a base body; the reinforced body is mixed powder of rear earth powder, the reinforced particles and 45 steel metal powder, and the base body is mixed powder of rear earth powder and 45 steel metal powder, wherein the rear earth powder is yttrium powder or neodymium powder; the preparation method comprises the steps that ball-milling is conducted on the reinforced body powder and the base body powder; the base body powder is put into a lower die, and corresponding holes are formed by means of upper dies in different shapes and filled with the reinforced body powder; vibration and pre-bulking are conducted, then forming is conducted by means of SPS, and finally, the reinforced steel-based surface-layer spatial-configuration composite containing the rear earth and the modified particles is obtained through heating treatment. According to the composite and the preparation method thereof, the technology is simple, the cost is low, the evenness of distribution of the reinforced particles with the spatial configuration in the base body is good, the bonding strength is high, and thecomposite has good durability and capability of impact resistance, corrosion resistance and oxidation resistance.

Owner:KUNMING UNIV OF SCI & TECH

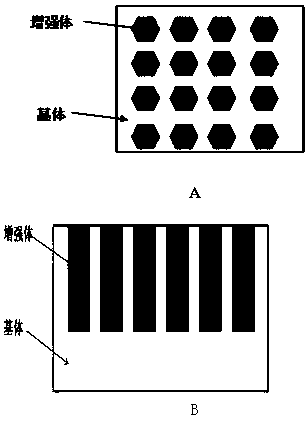

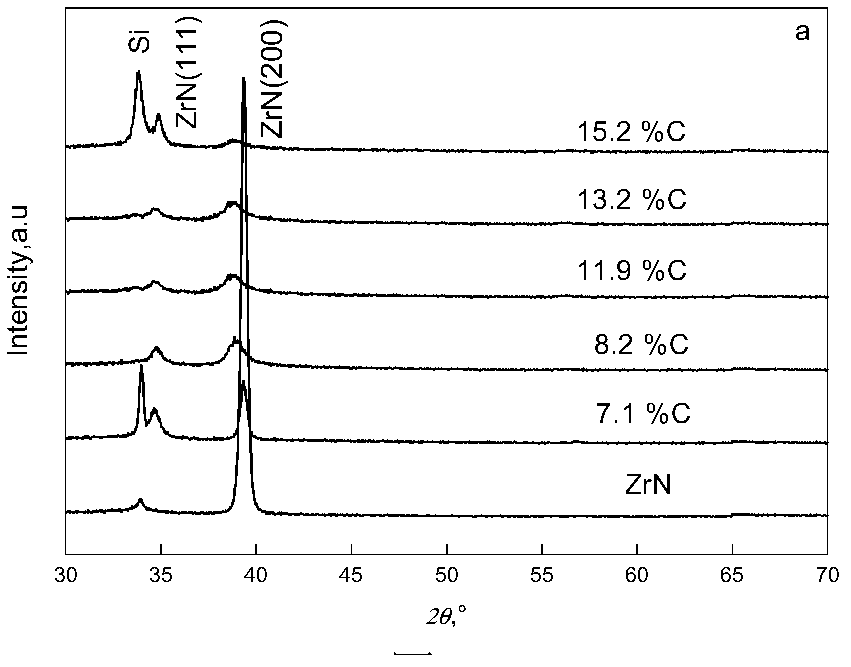

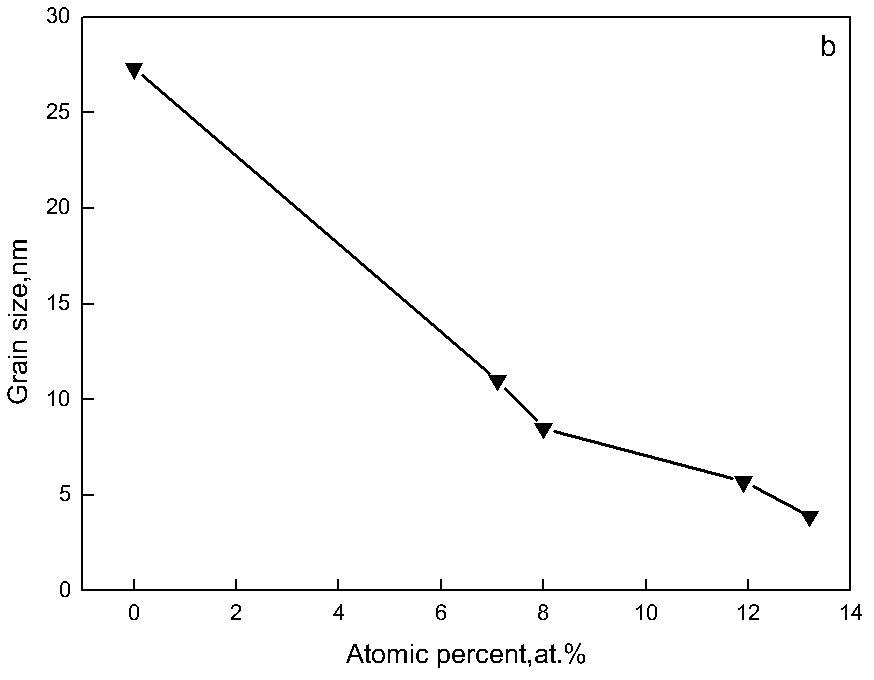

ZrCN nanometer composite membrane and preparation method thereof

InactiveCN102660729AExcellent friction and wear propertiesHigh hardness valueVacuum evaporation coatingSputtering coatingRadio frequencyComposite membrane

The invention discloses a ZrCN nanometer composite membrane which is prepared through a double-target radio-frequency reactive sputtering method and uses stainless steel as a stratum base. The thickness of the ZrCN nanometer composite membrane is 1-3 micrometers, 7.2at.%<=C<=11.9at.%, atomic ratio of (C+N) / Zr is less than 1, C enters ZrN interstitial void to totally form interstitial solid solution, and the hardness of the ZrCN nanometer composite membrane is larger than or equal to 29GPa; or 13.2at.%<=C<=15.4at.%, atomic ratio of (C+N) / Zr is larger than 1, the remaining C (except for the part of C entering the ZrN interstitial void to totally form interstitial solid solution) forms amorphous CN or C elementary substance, and the hardness of the ZrNC nanometer composite membrane is larger than or equal to 18.5GPa.

Owner:JIANGSU UNIV OF SCI & TECH

Handle for shaving device comprising a thermochromic material

InactiveUS20180142141A1Avoid complicationsImprove shaving experienceThermometers using physical/chemical changesThermometer applicationsThermochromismColor changes

A handle for a shaving razor including at least one thermochromic material which can provide color change when exposed to a pre-determined temperature.

Owner:THE GILLETTE CO

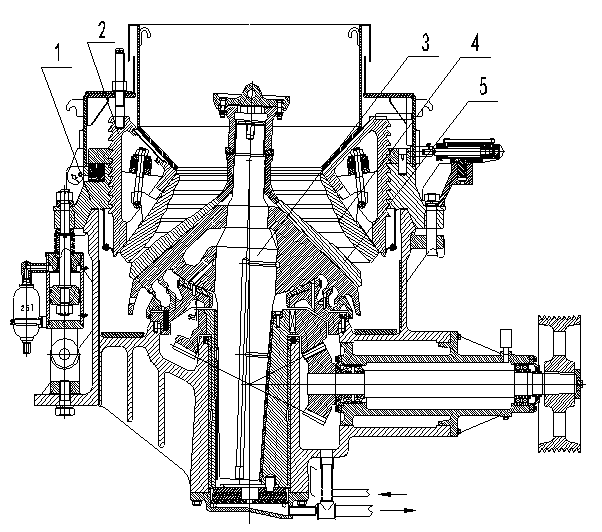

All-weather conical sand maker and self-adjustment method

The invention relates to an all-weather conical sand maker and a self-adjustment method. When an adjustable turnbuckle and an upper cover in the conical sand maker rotate clockwise, the rotation direction of a main shaft of the conical sand maker is anticlockwise, on the contrary, when the adjustable turnbuckle and the upper cover in the conical sand maker rotate anticlockwise, the rotation direction of a main shaft of the conical sand maker is clockwise. Hardness of a sand-making rolling compaction wall of a high-chromium cast iron wear-resistant mobile sleeve and hardness of a sand-making rolling compaction wall of a high-chromium cast iron wear-resistant fixed sleeve in the conical sand maker are higher than the hardness of high-chromium cast iron at the lower part of a sand-making rolling compaction opening. An axial semicircle surface of the inner wall of a copper sleeve of the main shaft in the conical sand maker is provided with an axial groove with a concave arc shape. The wall of the axial groove with the concave arc shape is provided with a fuel feed hole. An assembling axle hole in the lower part of the lower cover in the conical sand maker of the main shaft is provided with an annular boss. The external circular surface of a water cooling circular sleeve is provided with a plurality of loops of annular grooves. The external circular surface of the water cooling circular sleeve is matched with the inner wall of the assembling axle hole of the main shaft so as to form a multi-loop water cooling cavity.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Silane-crosslinkable coating formulations

InactiveUS7357960B2Improve scratch resistanceHigh hardness valueLayered productsPretreated surfacesHydrogenSilanes

The invention relates to coating formulations (B) which can be hardened to form coatings having a pencil hardness according to ISO 15184 of at least HB. Said formulations contain prepolymers (A) having alkoxysilane functions of general formula (6) —X—CH2—Si(OR)3-xR′x, wherein R represents hydrogen, an alkyl, cycloalkyl or aryl radical respectively having between 1 and 6 atoms, and the carbon chain can be broken by non-adjacent oxygen, sulphur or NR″ groups; R′ represents an alkyl, cycloalkyl, aryl or arylalkyl radical respectively having between 1 and 12 C atoms, and the carbon chain can be broken by non-adjacent oxygen, sulphur or NR″ groups; R″ represents hydrogen, an alkyl, cycloalkyl, aryl, aminoalkyl, or aspartate acid ester radical; X represents oxygen, sulphur or a group of general formula (20) —O—CO—NR″—; and x represents 0 or 1.

Owner:WACKER CHEM GMBH

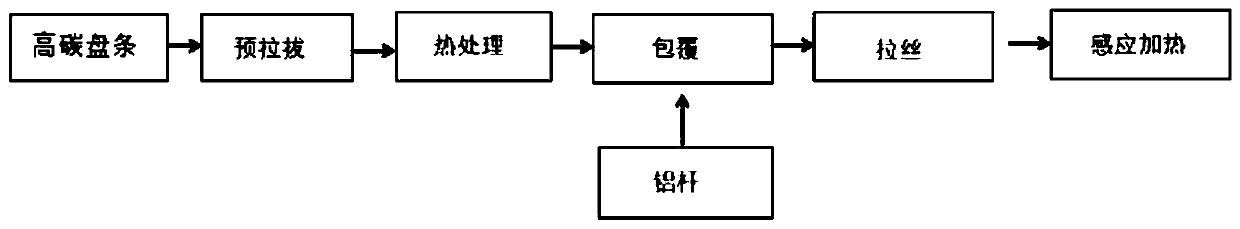

Production method of large-elongation aluminum clad steel wire

InactiveCN110125211AIncrease productivityHigh elongationApparatus for heat treatmentReduction of cables/conductors sizeWire rodSurface layer

The invention provides a production method of a large-elongation aluminum clad steel wire. The production process comprises the following steps of (1) derusting and drawing a high-carbon hot rolled wire rod to form a steel wire with the required wire diameter; (2) conducting austenitizing on the steel wire and conducting isothermal transformation through a lead bath to obtain the steel wire with the sorbite structure; (3) conducting online acid pickling on the steel wire with the sorbite structure to remove lead slag and oxide skin on the surface layer to obtain the steel wire with the clean surface; (4) cladding an aluminum layer on the surface layer of the steel wire with the clean surface through continuous extrusion cladding treatment to obtain a clad blank; (5) drawing the clad blankto be deformed to form the aluminum clad steel wire; and (6) conducing ageing treatment on the aluminum clad steel wire through an induction heating device. Through the production method, the production efficiency is high; and the problem that the hardness of an aluminum layer of the aluminum clad steel wire subjected to ageing treatment is reduced, and the aluminum clad steel wire is scratched inthe subsequent stranding process is solved. Compared with a traditional method that it needs to take 4-24 h of conduct heating and heat preservation during low-temperature long-time ageing treatment,the production method provided by the invention has the advantage that the induction heating device only needs 0.1-2.0 min to conduct online ageing treatment.

Owner:SOUTHEAST UNIV

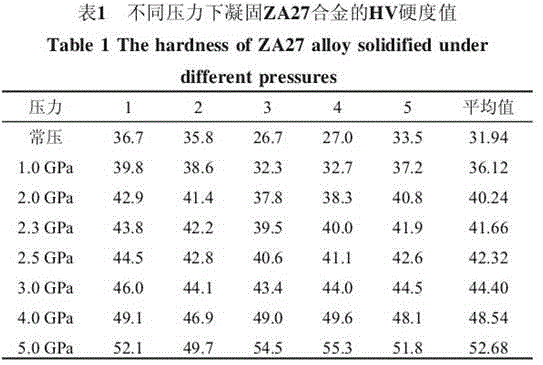

High-pressure treatment process for Zn-Al-Cu-Mg alloy

The invention discloses a high-pressure treatment process for Zn-Al-Cu-Mg alloy. The high-pressure treatment process is characterized in that the Zn-Al-Cu-Mg alloy comprises, by mass, 27.1% of Al, 0.6% of Cu, 0.02% of Mg, and the balance Zn, and raw materials comprise No.1 Zn, No.0 Al, pure magnesium ingots and Al-Cu intermediate alloy; the raw materials are smelted in a 6kW resistance furnace, the alloy is heated to 660-680 DEG C during smelting, and the temperature is regulated to 620 DEG C through part of the Zn material; after modification, refining and slagging-off, a metal mold test bar is cast at the temperature of 550-600 DEG C; a metal mold is used as a metal mold, and the metal mold is preheated to 150-200 DEG C before casting; a high-pressure test is carried out on a CS-1B type high-pressure cubic press; a test specimen is wrapped by BN powder, and pyrophyllite is used as a seal as well as a pressure transfer material; after pressure is increased to assigned pressure, heating is started until the alloy smelting temperature is reached, and heating is stopped after heat preservation and pressure preservation are conducted for 5 min; and when the test specimen is cooled to the room temperature, pressure relief is conducted, and the test specimen is taken out.

Owner:黄晓艺

Method for adjusting and controlling running off of microorganisms and juice of unfrozen fresh-cut fruits through pretreatment

PendingCN110447712AControl quantityReduce churnFood freezingFruits/vegetable preservation by irradiation/electric treatmentEscherichia coliPretreatment method

The invention relates to a method for adjusting and controlling running off of microorganisms and juice of unfrozen fresh-cut fruits through pretreatment, and belongs to the technical fields of processing of fruits and vegetables and safety control. According to the method, epsilon-polylysine and ultrasonic waves are in synergistic treatment, kelp carbon quantum dot / chitosan film coating bacterialpretreatment can be combined, and microorganisms on surfaces of fresh-cut fruits can be effectively controlled; and then through infrared-vacuum drying pre-dehydrating, the fresh-cut fruits are quickly frozen to minus 18 DEG C at the temperature of minus 40 DEG C, and then the quick-frozen fresh-cut fruits are stored at the temperature of minus 18 DEG C. By the bacterial pretreatment method, thetotal quantity of the microorganisms can be effectively controlled to be within 10<3> CFU / g, and coliform groups (or escherichia coli) can reach the standard (negative). After frozen fruits obtained through pretreatment adjustment and control are unfrozen, the texture of the fruits can be maintained to the maximum extent, and the hardness value is increased by 13%-17% than that of frozen fruits not be subjected to pretreatment adjustment and control treatment; and besides, the running off rate of the juice of the fruits and the running off of nutrient components of the fruits are reduced, andthe running off rate of the juice of the fruits is reduced by 13%-16% than that of fruits not subjected to pretreatment adjustment and control.

Owner:JIANGNAN UNIV +1

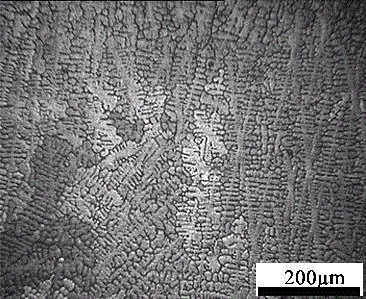

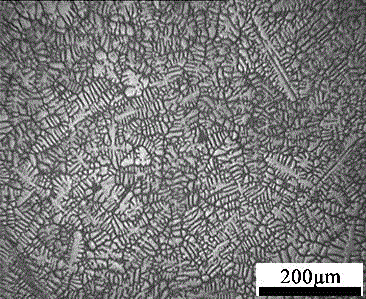

Aluminum-manganese alloy layer hot-dip process

InactiveCN103266291AHigh surface hardnessLess weight loss due to erosion and wearHot-dipping/immersion processesSingle elementManganese

The invention discloses an aluminum-manganese alloy layer hot-drop process. The aluminum-manganese alloy layer hot-drop process comprises the following steps of: respectively forming Al-2%wtMn, Al-9%wtMn, Al-13%wtMn aluminum-manganese alloy coatings and an Al-Mn-Mg alloy coating on the surface of Q235 steel, wherein the surface of the pure aluminum coating is formed into a thick dendritic crystal structure, and block-shaped aluminum-manganese compound phases appear on the aluminum-manganese alloy coatings; the aluminum-manganese alloy coatings mainly consist of Al, FeAl3, Fe2Al5 and MnAl6. An HAD modified layer comprises two parts, wherein the outermost layer is an aluminum-manganese alloy layer; and a thick-tooth shaped iron-aluminum compound transition layer is arranged below the aluminum-manganese alloy layer. The manganese and the magnesium elements are added, so that surface hardness of the hot-dip aluminum layer is remarkably improved. The hardness of the Al-9%Mn and Al%-4Mn-4%Mg alloy coatings is respectively 26.7 HBS and 34.6 HBS. Compared with the 15.3 HBS hardness of the pure aluminum coating, the hard values are respectively increased by 75% and 126%. Compound addition strengthening effects of the manganese and magnesium within a certain range are better than the single element addition strengthening effect.

Owner:XINJIANG UNIVERSITY

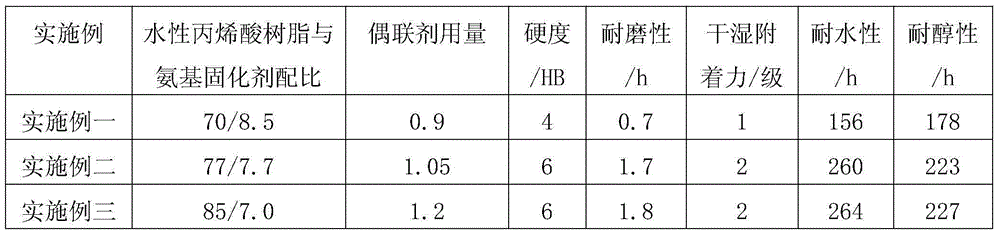

Environment-friendly water-based glass baking lacquer

The invention relates to environment-friendly water-based glass baking lacquer. The glass baking lacquer is composed of, by weight, 90-120 parts of water, 7-8.5 parts of amidogen curing agents, 70-85 parts of water-based acrylic resin, 0.35-0.8 part of antifoaming agents, 0.25-0.35 part of wetting agents, 0.2-0.3 part of flatting agents, 0.9-1.2 parts of coupling agents, 0.15-0.25 part of anti-scratching agents, and 0.5-0.7 part of PH modifiers, wherein the amidogen curing agents are amino resin curing agents, and the coupling agents are siloxane coupling agents. According to the environment-friendly water-based glass baking lacquer, the performance of the water-based glass baking lacquer is changed by regulating the ratios of the water-based acrylic resin and the amidogen curing agents and the usage of the coupling agents, the prepared environment-friendly water-based glass baking lacquer has a high hardness value, high water resistance, high alcohol resistance, high abrasion resistance and high dry and wet adhesive force, service life is long, and environment friendliness is high.

Owner:ANQING LIANTAI ELECTRONICS TECH

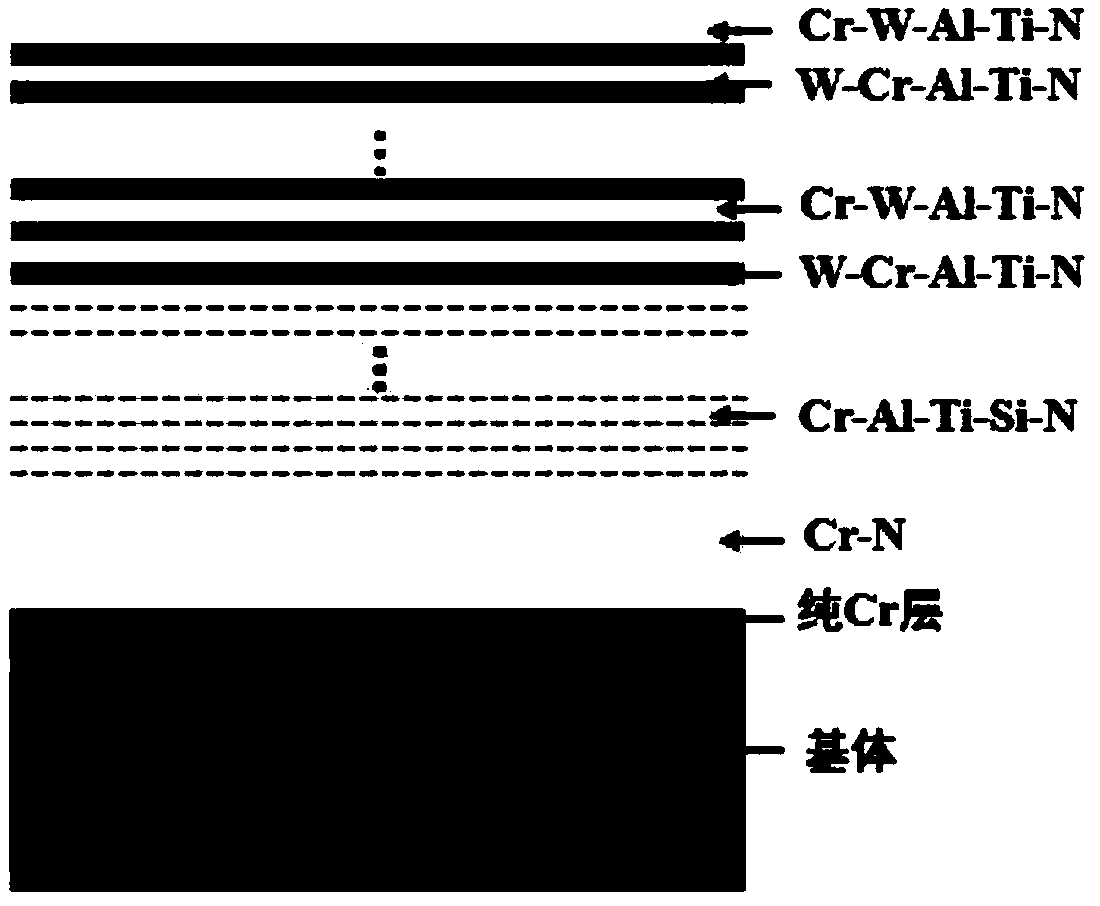

Ultra-hard W-Cr-Al-Ti-N nano gradient multilayer film material and preparation method thereof

ActiveCN109097743AHardness exceedsImprove toughnessVacuum evaporation coatingSputtering coatingHardnessFilm material

The invention provides an ultra-hard W-Cr-Al-Ti-N nano gradient multilayer film material and a preparation method thereof. Multi-arc ion plating technology is adopted in the preparation method, a tungsten element is introduced into a multilayer film, and NH3 and N2 are adopted as reaction gases together to prepare the nano gradient multilayer film material, so that the bonding force between film layers is strengthened, and the hardness of the film layers is greatly improved.

Owner:YANTAI UNIV

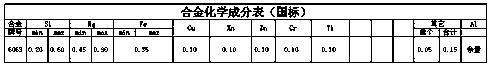

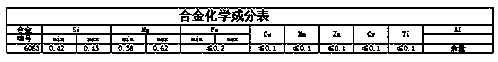

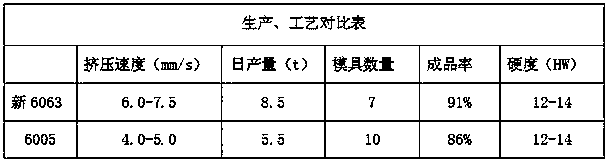

6063 aluminum alloy material for solar energy aluminum frame production

The invention discloses a 6063 aluminum alloy material for solar energy aluminum frame production. The 6063 aluminum alloy material comprises following components in percentage by weight: 0.42 to 0.45% of Si, 0.58 to 0.62% of Mg, 0 to 0.20% of Fe, 0 to 0.10% of Cu, 0 to 0.10% of Mn, 0 to 0.10% of Zn, 0 to 0.10% of Cr, 0 to 0.10% of Ti, and the balance being Al, wherein the total percentage by weight is 100%. The formula of aluminum alloy (natural standard 6063) is improved; the performances are directly optimized; the hardness of 6063 aluminum alloy is increased by 4-6 HW, the production costis reduced, and the work efficiency is improved.

Owner:YONZ TECH CO LTD

Production process of steel ball of racing car generator bearing

The invention provides a production process of a steel ball of a racing car generator bearing. The production process of the steel ball of the racing car generator bearing comprises the following steps of cold heading, buffing, heat treatment, grinding I, surface reinforcement treatment, grinding II, fine grinding, cleaning, automatic appearance grading and packaging. The service life of the steel ball under the conditions that the optimum stress of the steel ball reaches a high rotation speed is achieved through control over various parameters of several process points of materials, heat treatment, the surface reinforcement process and the grading technology of critical defects of the steel ball, the fatigue life of the produced steel ball is tested, the experiment value L10T of the basic rated life is longer than 1800 hours, the ratio of the experiment value L10T of the basic rated life to the basic rate life L10 is larger than 18, and the reliability degree RE reaches 100 percentage. The service life of the steel ball is longer than the experiment value of the service life of a steel ball produced through a common production and machining process by 3-5 times, and the steel ball meets the requirement for a high rotation speed, high temperature and continuous operation of the racing car generator bearing.

Owner:TSUBAKI HOOVER TAICANG

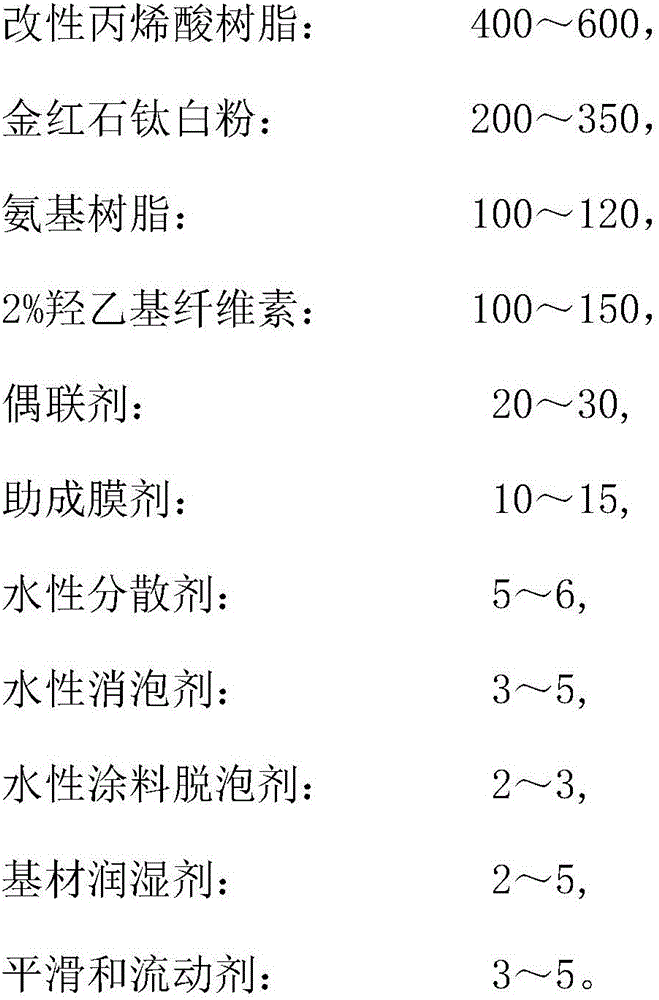

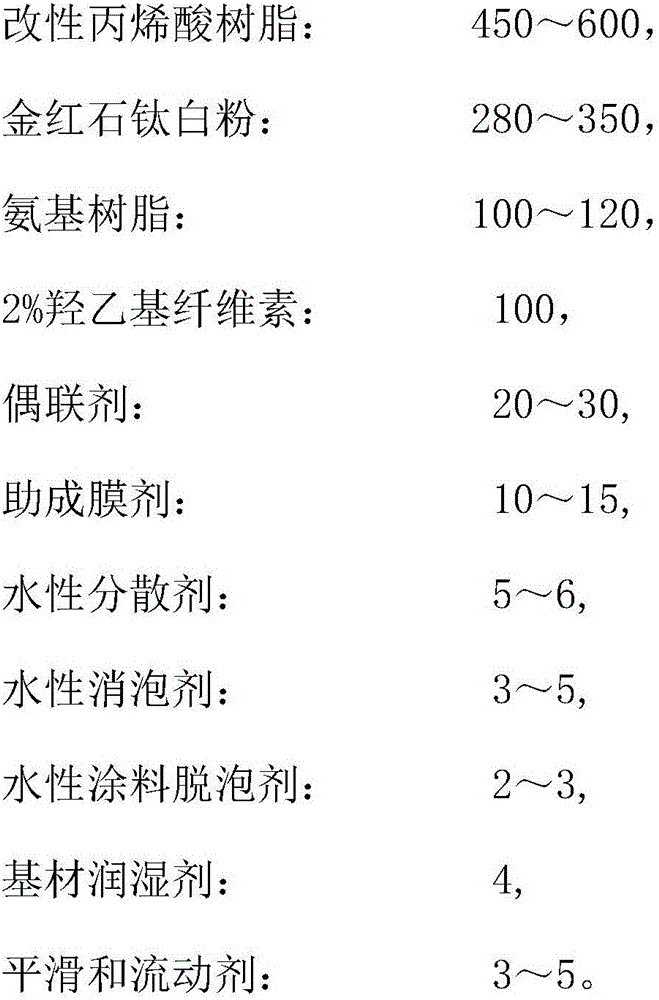

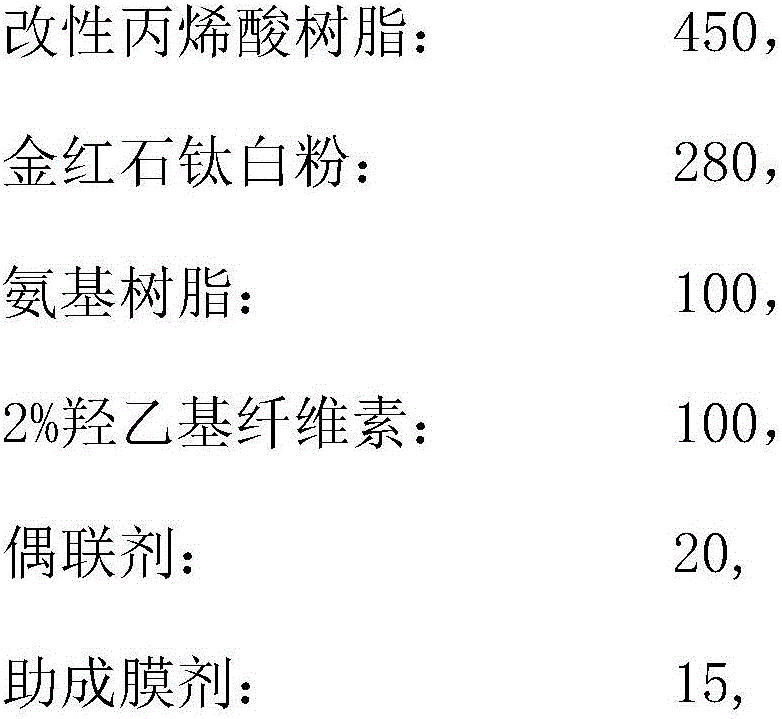

Waterborne glass baking paint and preparation method thereof

InactiveCN105949914AHigh hardness valueGood water resistanceCoatingsDefoaming AgentsEnvironmentally friendly

The invention discloses waterborne glass baking paint. The waterborne glass baking paint is characterized by being prepared from, by weight, 400-600 parts of modified acrylic resin, 200-350 parts of rutile titanium dioxide, 100-120 parts of amino resin, 100-150 parts of 2% hydroxyethyl cellulose, 20-30 parts of a coupling agent, 10-15 parts of a coalescing agent, 5-6 parts of a waterborne dispersing agent, 3-5 parts of a waterborne defoaming agent, 2-3 parts of a waterborne paint defoaming agent, 2-5 parts of a substrate wetting agent and 3-5 parts of a smoothing and flowing agent. The waterborne glass baking paint is environmentally friendly and good in adhesive force, alcohol resistance and water resistance. The invention further provides a preparation method of the waterborne glass baking paint.

Owner:中山市汉艺涂料有限公司

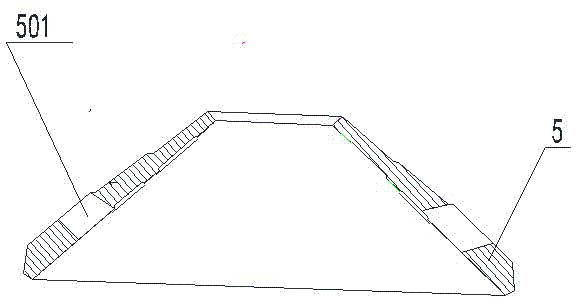

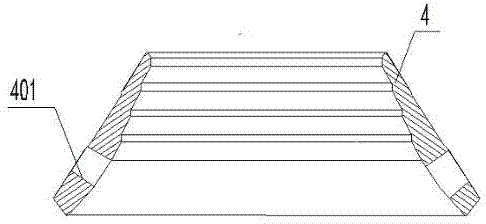

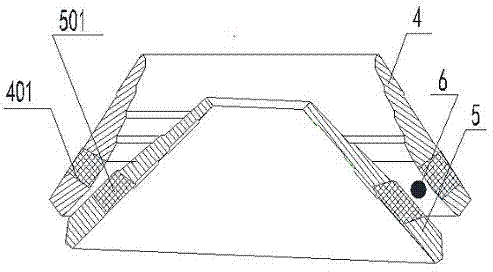

Anti-wear movable sleeve of super wear-resistant sand-making roller compaction opening of conic sand making machine and forming method

InactiveCN103769264ASolve the disadvantages of high cost of sand makingHigh densityGrain treatmentsWear resistantEngineering

The invention relates to an anti-wear movable sleeve of a super wear-resistant sand-making roller compaction opening of a conic sand making machine and a forming method, and adopts a technical scheme that each sand-making roller compaction opening in the conic sand making machine is formed by a high-chromium iron anti-wear movable sleeve sand-making roller compaction wall and a high-chromium iron anti-wear fixed sleeve sand-making roller compaction wall, and the hardness of the high-chromium iron anti-wear movable sleeve sand-making roller compaction wall is higher than that of the high-chromium iron at the lower part of the edge of the sand-making roller compaction opening. The anti-wear movable sleeve of the super wear-resistant sand-making roller compaction opening of the conic sand making machine and the forming method have the advantages as follows: firstly, the defects that the service lives of each entire anti-wear movable sleeve and each entire anti-wear fixed sleeve are reduced greatly, and the sand making cost is high, which are caused by that since the hardness of each sand making opening formed by one anti-wear movable sleeve and one anti-wear fixed sleeve in the existing conic sand making machine is equal to that of the corresponding anti-wear movable sleeve and the corresponding anti-wear fixed sleeve, the sand making opening is worn into a groove in advance in the sand making process, are overcome radically; secondly, as each anti-wear movable sleeve and each anti-wear fixed sleeve are casted by adopting high-frequency vibration, gas and impurities in the liquid metal are enabled to be effectively discharged out, and a metallographic structure of the high-chromium iron is also enabled to be more reasonable in distribution, and higher in density.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

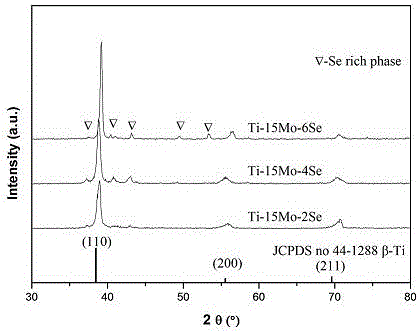

Dental titanium alloy material

ActiveCN105821245AImprove wear resistanceLow melting pointImpression capsDentistry preparationsRare-earth elementBeta phase

The invention discloses a dental Ti-Mo-Zr-Se titanium alloy material. The titanium alloy material comprises the following components: titanium, molybdenum, zirconium, selenium and trace elements, wherein the weight percentage of Mo is 10-15%, the weight percentage of Zr is 0-6%, the weight percentage of Se element is 1-6%, the weight percentage of the trace elements is 0.05-0.2%, and the balance of Ti. The trace elements can be adjusted according to the performance coupling requirement, at least one of rare earth elements lanthanum and cerium, and phase composition is mainly a beta phase and a few Se-rich phase. The performance index of the material is characterized in that Vickers hardness is 350-450 HV, yield strength is 1250-1400 MPa, and compressive strength is 1380-1910 MPa.

Owner:SICHUAN UNIV

Turning tool machining technology capable of reducing heat damage and improving tempering quality

InactiveCN104128777AReduce heating deformationDegree of reductionFurnace typesHeat treatment furnacesThermal insulationHardness

The invention discloses a turning tool machining technology capable of reducing heat damage and improving tempering quality. The turning tool machining technology comprises the processes of blank blanking, forging, cutting, heat treatment and grinding in sequence. A blank is W2MoCr4V2Co8 high-speed tool steel. The heat treatment process includes preheating, heating and heat insulation, quenching and tempering in sequence. Preheating is conducted in a staged mode with the temperature gradually increased. An annealing step is further set between the forging step and the cutting step, and according to the annealing step, the forged blank is heated step by step. The turning tool machining technology is simple in circuit, the heat treatment effect is good, the hardness number of the turning tool can be more than 70 HRC, and the good wear resistance and the good heat hardness are achieved.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com