ZrCN nanometer composite membrane and preparation method thereof

A nano-composite and sputtering technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of insufficient wear resistance and insufficient hardness, and achieve the effect of excellent friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

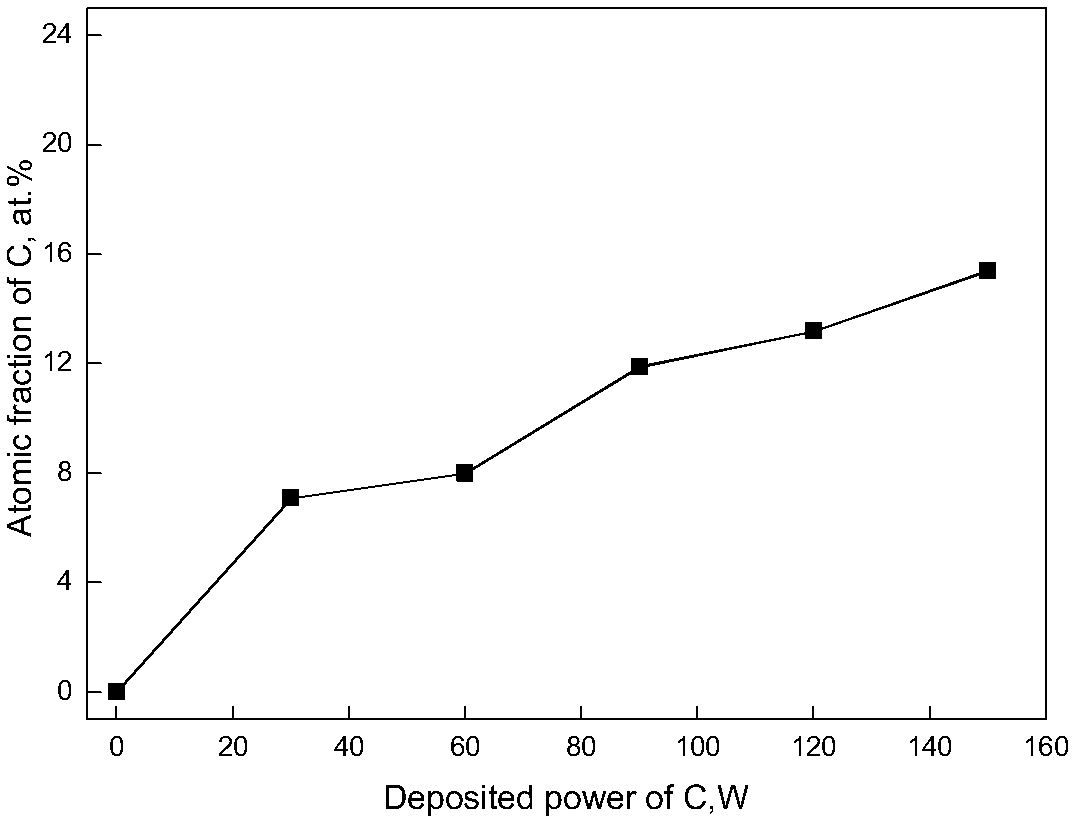

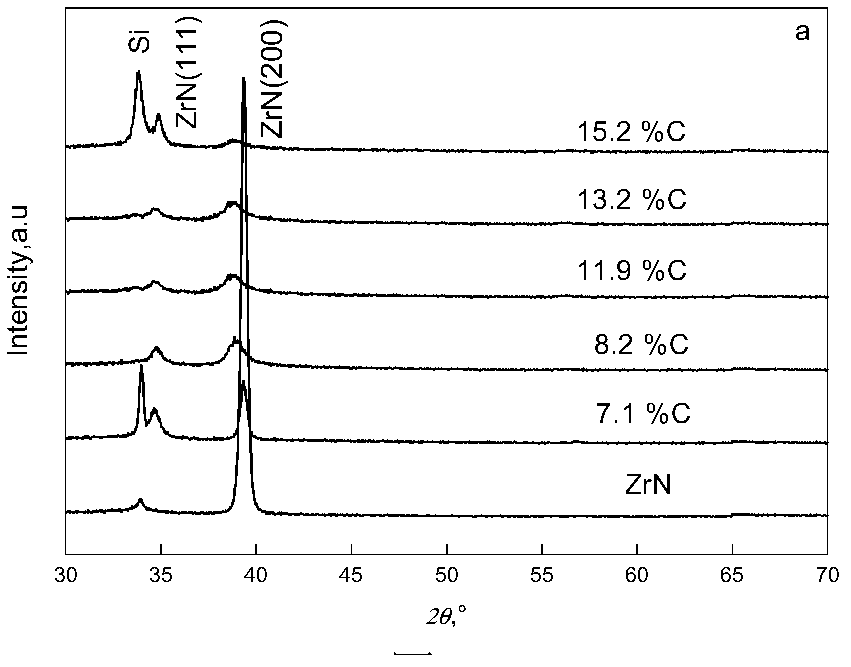

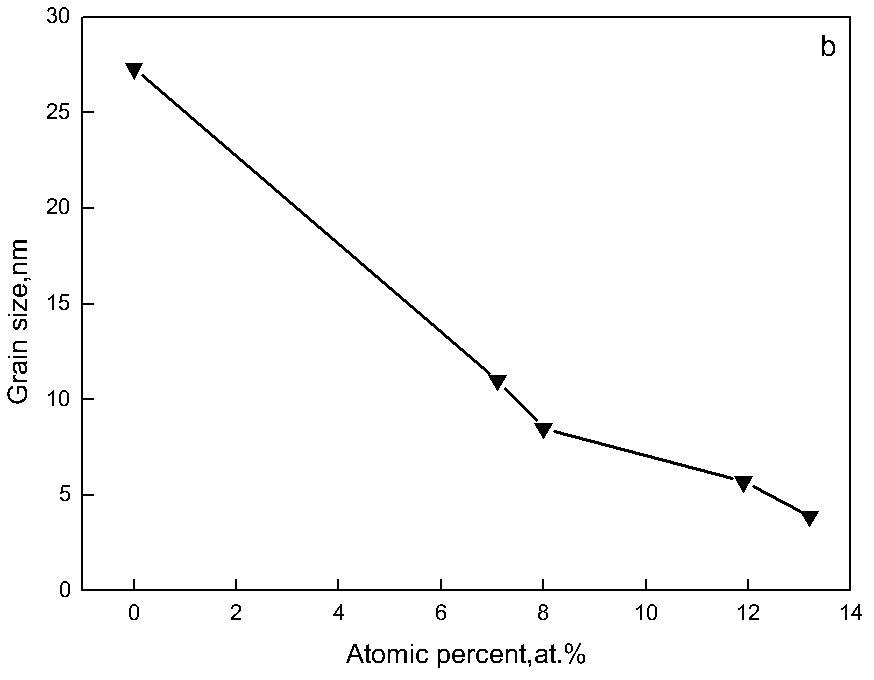

[0030] The concrete process parameter of the preparation method of ZrCN composite thin film of the present invention is: Ar gas flow rate is 10sccm, N 2 The air flow is 2 sccm. The sputtering power of the Zr target is 200W, the sputtering power of the C target is 30W, the deposition is 2h, and the film thickness is about 2 microns. The Zr content in the ZrCN composite film thus obtained is 52.2% (atomic fraction, the same below), the C content is 7.1%, the (C+N) / Zr atomic ratio is less than 1, and C enters the ZrN lattice gap to form an interstitial solid solution , the hardness of the film is 29.4GPa, the coefficient of friction is 0.62, and the surface roughness is 31 ?.

Embodiment 2

[0032] The concrete process parameter of the preparation method of ZrCN composite thin film of the present invention is: Ar gas flow rate is 10sccm, N 2 The air flow is 2 sccm. The sputtering power of the Zr target is 200W, the sputtering power of the C target is 60W, the deposition time is 2h, and the film thickness is about 2 microns. The Zr content in the ZrCN composite film thus obtained is 52.4%, the C content is 8%, the (C+N) / Zr atomic ratio is less than 1, C enters the ZrN lattice gap to form a solid solution, and the hardness of the film is 29.7GPa , the coefficient of friction is 0.59, and the surface roughness is 26 ?.

Embodiment 3

[0034] The specific process parameters of the preparation method of the ZrCN composite thin film of the present invention are: the Ar gas flow rate is 10 sccm, and the N2 gas flow rate is 2 sccm. The sputtering power of the Zr target was 200W, the sputtering power of the C target was 90W, the deposition was 2h, and the film thickness was about 2 microns. The Zr content in the resulting ZrCN composite film is 49.4%, the C content is 11.9%, the (C+N) / Zr atomic ratio is less than 1, C enters the ZrN lattice gap to form a solid solution, and the hardness of the film is 33.3GPa , the coefficient of friction is 0.41, and the surface roughness is 14 ?.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com