Patents

Literature

42results about How to "Excellent friction and wear properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High speed self-lubricating oily bearing made from powder metallurgical material

InactiveCN101187396AGood physical and mechanical propertiesReduce coefficient of frictionBearing componentsGraphiteBronze

A high-speed self-lubricating oilness bearing is made from powder metallurgy material. The powder metallurgy material is constituted by the following weight percentage of P: 0.5-0.7%, MoS 2: 2-3%, graphite: 0.5-1% and the residual is 663 bronze powders. A process for the preparation of the bearing comprises putting raw powders weighted according to the composition into a ball mill barrel with 2 liters, ball milling raw powders 2h on a roller-type ball mill, pressing into a shape through a steel die with a pressing pressure of five ton / cm 2, sintering in a vacuum furnace with sintering temperature of 800 DEG C, then preserving heat 1h, sizing sintered compacts through a sizing die to increase surface fineness and dimensional precision, vacuum soaking T1# special lubricating oil for the high-speed oilness bearing for 2h to prevent corrosion and finish capillary oil storage. The self-lubricating of material is realized by choosing Cu base powdered material along with solid lubricant and base strengthening elements, and the special surface structure is achieved through the powder metallurgy sintering technology controlling pore space of material, and the oilness effect of material is obtained by utilizing capillary effect.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Polyacetal Resin Composition, Process for Producing the Same, and Sliding Member Molded from the Resin Composition

ActiveUS20090298981A1Excellent friction and wear propertiesSmall wear lossSpecial tyresOrganic dyesSilicone oilPolyresin

A polyacetal resin composition which has improved friction-wear characteristics as compared with conventional polyacetal resin compositions and which is less restricted in counter sliding members and can conform to a wide range of friction-wear conditions. A polyacetal resin composition comprising 100 parts by weight of (A) a polyacetal resin, 0.1 to 10 parts by weight of (B) a polyethylene wax having a number average molecular weight of 500 to 15,000, 0.1 to 10 parts by weight of (C) a polyethylene resin having a number average molecular weight of 2×104 to 50×104, and 0.1 to 5 parts by weight of (D) a silicone oil having a kinetic viscosity at 25° C. of 50×104 cSt or more.

Owner:MITSUBISHI ENG PLASTICS CORP

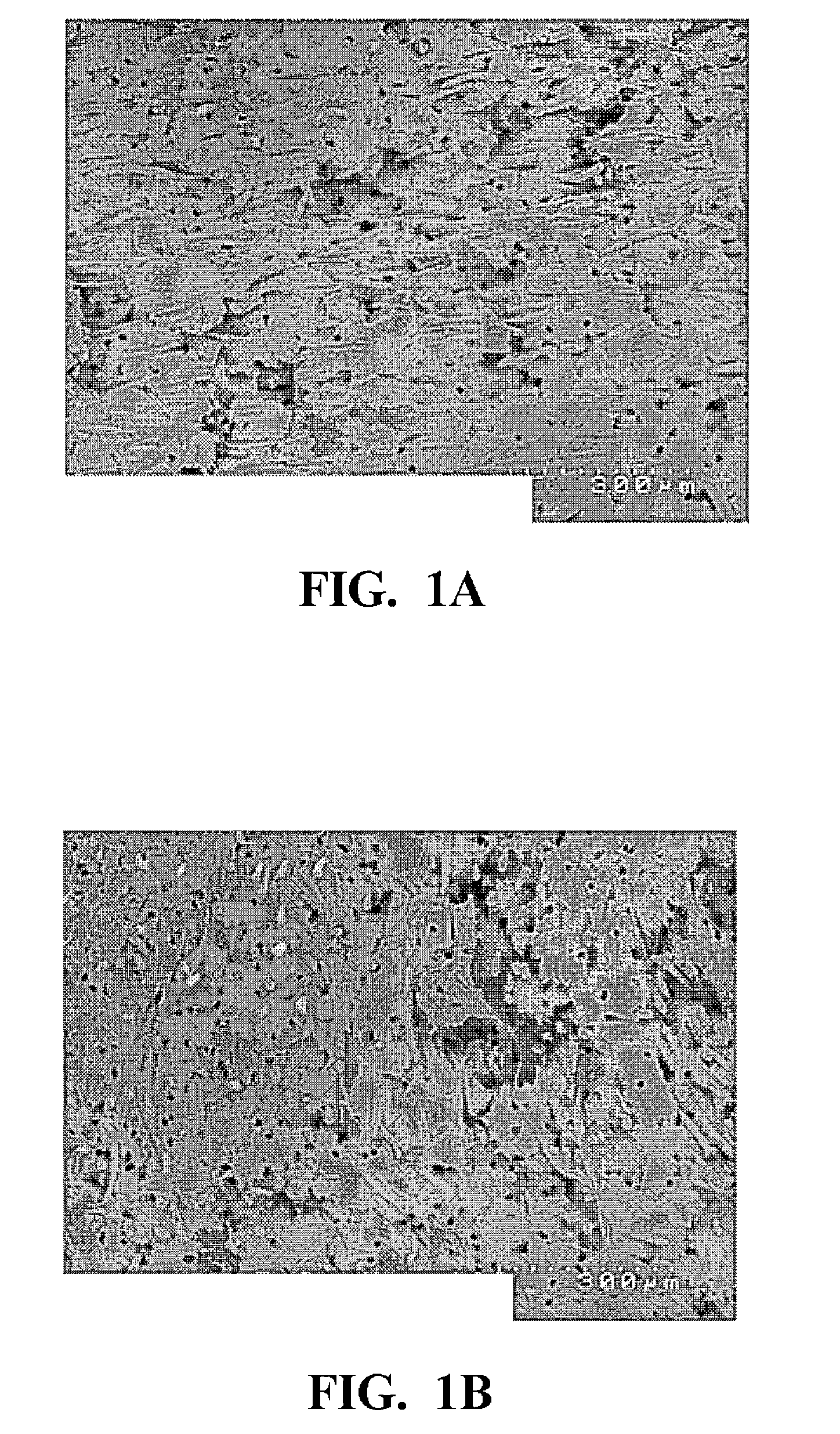

Novel process for making piston ring

InactiveCN1632297AHigh surface hardnessReduce coefficient of frictionPiston ringsMachines/enginesPiston ringHigh energy laser beam

The new processing technology of piston ring involves the processing technology of piston ring. It includes the following process steps: casting→grinding→heat treatment→grinding→gold processing→laser strengthening treatment→heat setting→gold processing. Since the surface layer of the piston ring is processed by laser alloying or laser cladding, and is rapidly melted by a high-energy laser beam, the matrix at a certain depth on the outer surface of the piston ring is rapidly melted and then solidified to form a specific ceramic particle reinforced composite coating. The coating and the piston ring body are metallurgical structures, which will not fall off or peel off under the action of external force. The invention is easy for industrial production, has excellent anti-adhesive wear and anti-abrasive wear capabilities, and has good product technical stability.

Owner:江苏仪征威龙活塞环有限公司 +1

AlNbCN multielement gradient composite coating tool and preparing method thereof

ActiveCN107338411AHigh hardnessHigh strengthVacuum evaporation coatingSputtering coatingHeat stabilityCutting force

The invention belongs to the field of machining cutting tools, and relates to an AlNbCN multielement gradient composite coating tool and a preparing method thereof. The coating tool sequentially comprises a tool base body, a Ti transition layer, an AlNbC transition layer and an AlNbCN multielement gradient composite coating with the nitrogen content gradually changing in a gradient manner from interior to exterior, and the coating tool is prepared in a middle-frequency magnetron sputtering and arc plating composite coating method. According to the AlNbCN ultrahard carbohydrates and nitrogenous compound coating, due to the fact that the Al element and the Nb element are added in the coating at the same time, and the content of the nitrogen which is the structure component of the coating gradually changes in a gradient manner, thecutting machining performance of the tool can be improved. The AlNbCN multielement gradient composite coating tool has very high hardness and strength, low surface friction coefficient, good high-temperature oxidization preventing performance and excellent friction abrasion characters. In the cutting process, tool surface friction and cuttings bonding can be reduced through the tool, the cutting force and the cutting temperature can be reduced by 45% or above, the heat stability of the coating tool is improved by 65% or above, the service life of the tool is prolonged by 60% or above, and durability of the tool is improved by 60% or above.

Owner:JINING UNIV

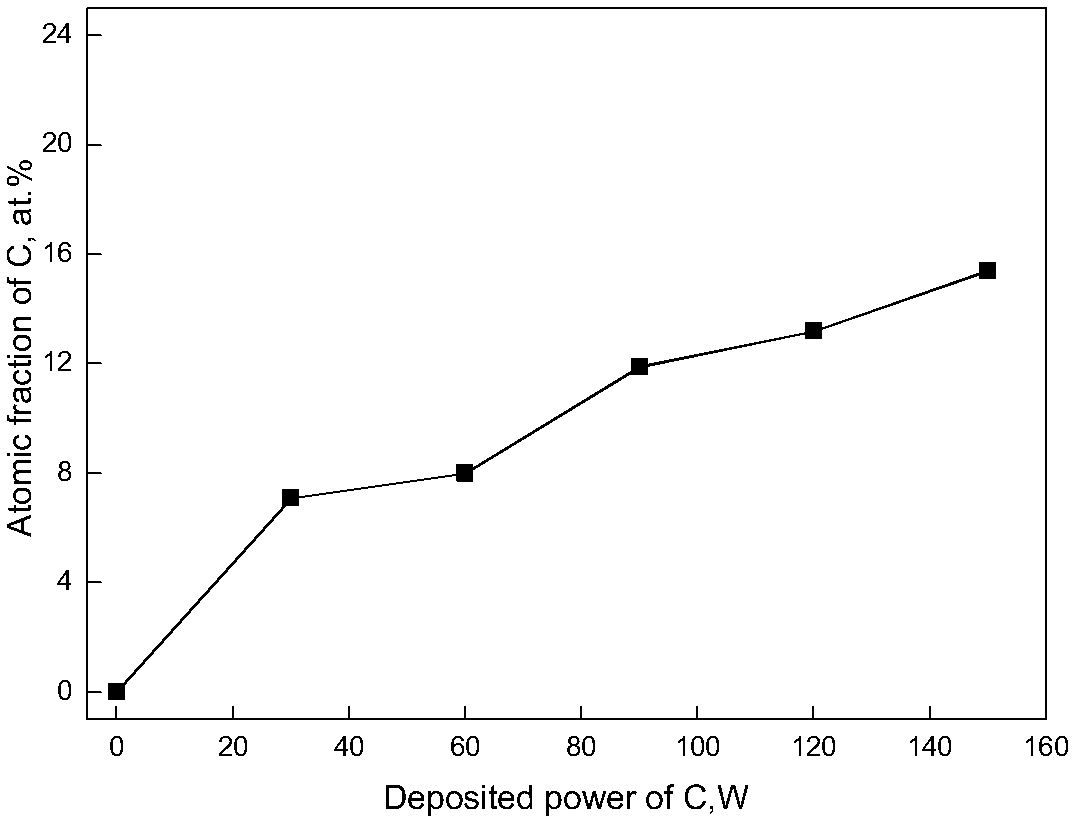

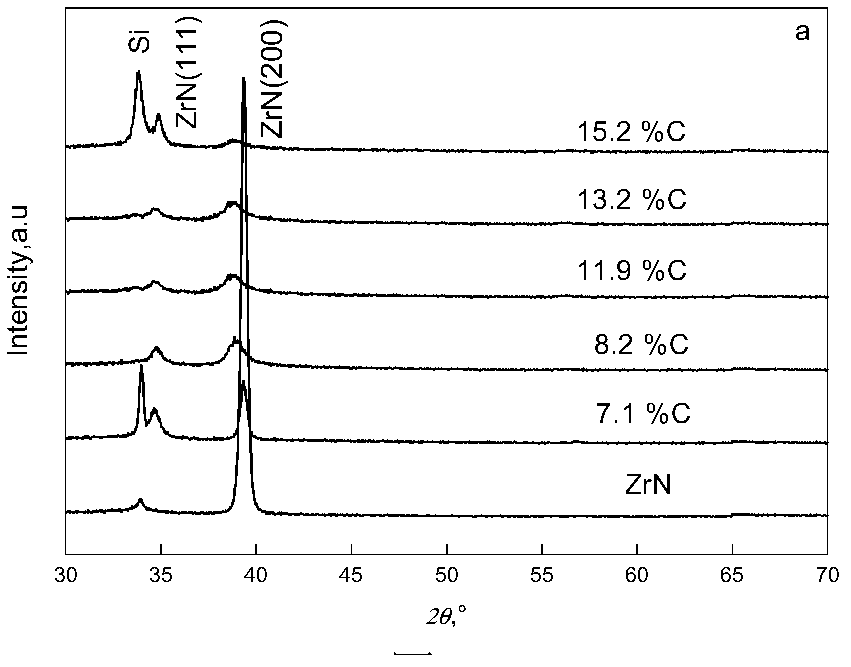

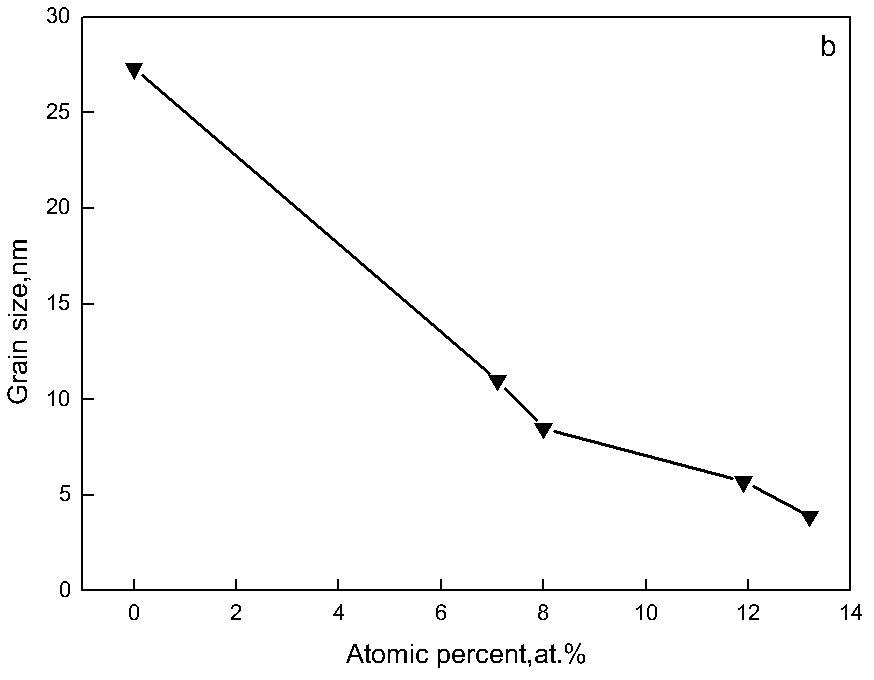

ZrCN nanometer composite membrane and preparation method thereof

InactiveCN102660729AExcellent friction and wear propertiesHigh hardness valueVacuum evaporation coatingSputtering coatingRadio frequencyComposite membrane

The invention discloses a ZrCN nanometer composite membrane which is prepared through a double-target radio-frequency reactive sputtering method and uses stainless steel as a stratum base. The thickness of the ZrCN nanometer composite membrane is 1-3 micrometers, 7.2at.%<=C<=11.9at.%, atomic ratio of (C+N) / Zr is less than 1, C enters ZrN interstitial void to totally form interstitial solid solution, and the hardness of the ZrCN nanometer composite membrane is larger than or equal to 29GPa; or 13.2at.%<=C<=15.4at.%, atomic ratio of (C+N) / Zr is larger than 1, the remaining C (except for the part of C entering the ZrN interstitial void to totally form interstitial solid solution) forms amorphous CN or C elementary substance, and the hardness of the ZrNC nanometer composite membrane is larger than or equal to 18.5GPa.

Owner:JIANGSU UNIV OF SCI & TECH

Nano composite plating paste material and its preparation and electroplating method

InactiveCN1414144ASpecial structureExtraordinary corrosion resistanceElectrolytic coatingsMischmetalAlkaline earth metal

A nano-class composite slurry for electroplating is prepared through mixing alpha-Al2O3 with the oxide is alkali-earth metal and / or transition metal and / or rare-earth metal by ball grinding for 6-10 hr transferring phase at 1200-1500 deg.C, proportionally mixing powder, water and cationic surfactant, and dispersing in ball grinder for 60-100 hr. It can be added to traditional plating liquid to obtain decorative-protective-functional plated layer.

Owner:重庆阿波罗机电技术有限公司

SiZrCN gradient composite coating cutter and preparation method thereof

ActiveCN107177828AHigh hardnessImprove thermal stabilityVacuum evaporation coatingSputtering coatingSputteringHeat stability

The invention belongs to the field of mechanical manufacture cutting cutters, and in particular relates to a SiZrCN gradient composite coating cutter and preparation method thereof. The coating is the SiZrCN gradient composite coating prepared by adopting a composite coating method of unbalanced magnetron sputtering and electric arc plating; the surface of the coating cutter is SiZrCN gradient composite coating with gradually-changed gradient of nitrogen content, a Ti transition layer and a SiZrC transition layer are sequentially arranged between a cutter base body and the coating. By adopting the SiZrCN ultra-hard carbon-nitrogen compound coating, because two metals including Si and Zr are added in the coating at the same time, the nitrogen content of the coating structure component is gradually changed in a gradient manner, so that the cutting machining performance of the cutter can be improved. The coating has high hardness and heat stability, and also has good diffusion prevention and wear prevention performances, good plastic deformation resistance ability and excellent friction and wear resistance property. In the cutting process, the cutter can effectively prevent the occurrence of cracking of cutting edges and hot cracks, guarantee the machining surface quality of the workpieces, and prolong the service life of the cutter by more than 70%.

Owner:JINING UNIV

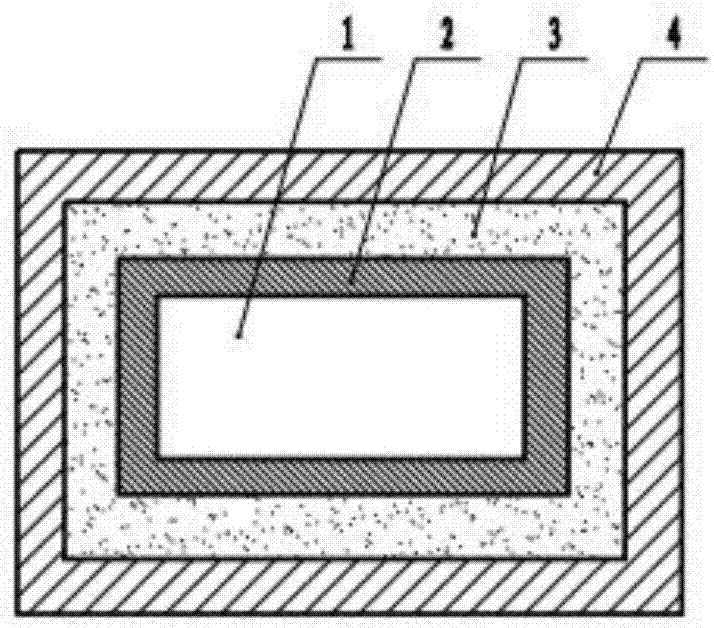

Copper-based dispersive bimetallic self-lubricating material and method for preparing self-lubricating base material

ActiveCN102039414AGood self-lubricating performanceReduce coefficient of frictionWork in processAlloy

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

Polymer-ceramic composite material

The invention discloses a polymer composite material for manufacturing a roller, which is prepared from the following materials in percentage by weight: 35-45% of nylon 6 (PA6), 20-35% of ceramic powder, 15-25% of glass fiber and 3-8% of composite solid lubricant, wherein the composite solid lubricant is prepared by mixing supramoly, graphite and other solid lubricant according to a weight ratio of 1:1-2. After being mixed according to the ratio, all the materials are mixed and extruded by a screw extruder, are subject to water-cooling pelleting, and are processed by an injection molding machine to be molded into a belt roller. The belt conveyor roller made of the composite material combines performance characteristics of polymer materials and ceramic materials, has the advantages of high strength, abrasion resistance, antistatic performance, flame retardance, corrosion prevention, light weight, low noise for high-speed operation, long service life, low price and the like, and can be widely used in industries or fields of smelting, mining, thermal power generation and the like.

Owner:HUNAN YINGHONG SCI & TECH

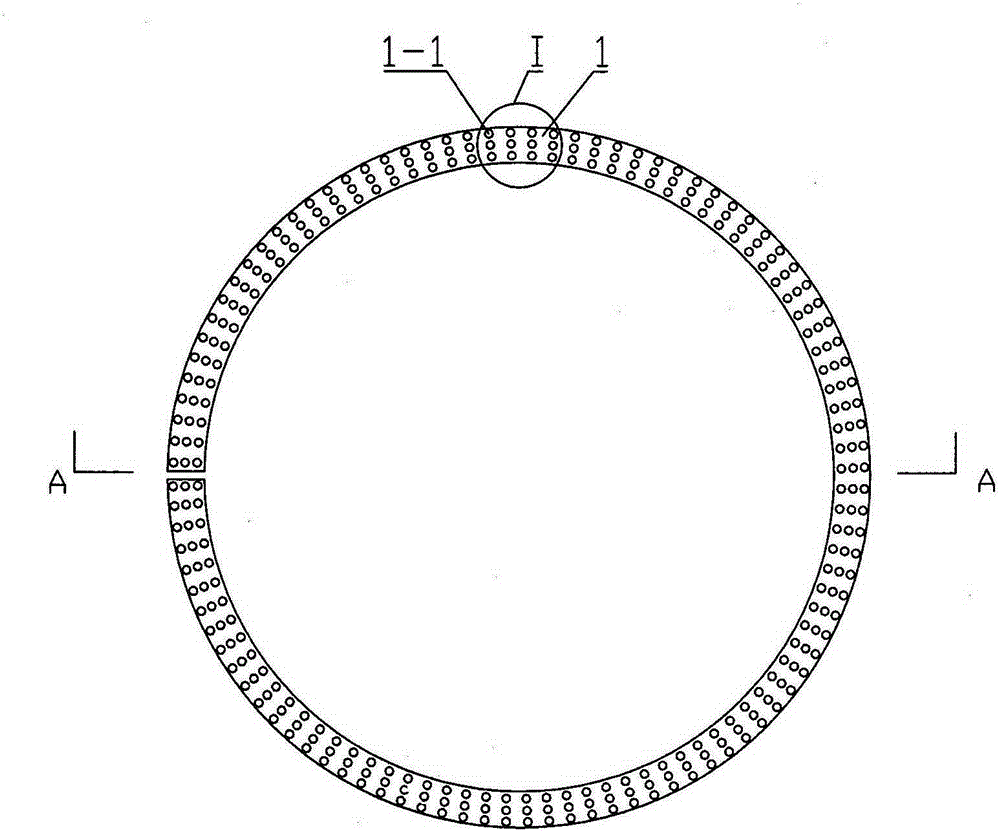

Turbocharger sealing ring subjected to laser surface texturing and machining method

InactiveCN105299233AHigh hardnessImprove protectionEngine sealsLaser beam welding apparatusFriction reductionOccupancy rate

The invention discloses a turbocharger sealing ring subjected to laser surface texturing and a machining method. After laser surface texturing, arc-shaped micro-concave cavities different in diameter and depth are formed in the left end face, the right end face and the inner circle surface of the turbocharger sealing ring and are distributed densely in a well-arranged manner. The machining method of the turbocharger sealing ring comprises the following steps that a surface fluid lubrication theoretical model of the turbocharger sealing ring is built to determine the diameters, depths and area occupancy rates of the arc-shaped micro-concave cavities in the left end face, the right end face and the inner circle surface with the optimal lubrication friction reduction effect through numerical calculation; and then a diode pumping Nd:YAG laser device is selected, under a laser machining graphic software interface, the geometrical parameters and distribution state of the arc-shaped micro-concave cavities are input, and laser surface texturing machining is carried out on the left end face, the right end face and the inner circle surface of the turbocharger sealing ring through a single pulse same-point interval repeated machining technology.

Owner:HUNAN TYEN MACHINERY

Method for preparing ultrathin diamond carbon film

InactiveCN101768010AImprove wear lifeExcellent friction and wear propertiesCarbon filmSelf assembled

The invention discloses a method for preparing an ultrathin diamond carbon film by adopting a self-assembling organic monomolecular film as a modulating layer. By adopting an organic self-assembling monomolecular film as a transition layer, the ultrathin diamond film is prepared. The method has low cost and is easy for operation, and the prepared film has favorable friction and abrasion characteristics.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polyacetal resin composition, process for producing the same, and sliding member molded from the resin composition

ActiveUS8097670B2Excellent friction and wear propertiesSmall wear lossSpecial tyresBearing componentsSilicone oilViscosity

A polyacetal resin composition which has improved friction-wear characteristics as compared with conventional polyacetal resin compositions and which is less restricted in counter sliding members and can conform to a wide range of friction-wear conditions. A polyacetal resin composition comprising 100 parts by weight of (A) a polyacetal resin, 0.1 to 10 parts by weight of (B) a polyethylene wax having a number average molecular weight of 500 to 15,000, 0.1 to 10 parts by weight of (C) a polyethylene resin having a number average molecular weight of 2×104 to 50×104, and 0.1 to 5 parts by weight of (D) a silicone oil having a kinetic viscosity at 25° C. of 50×104 cSt or more.

Owner:MITSUBISHI ENG PLASTICS CORP

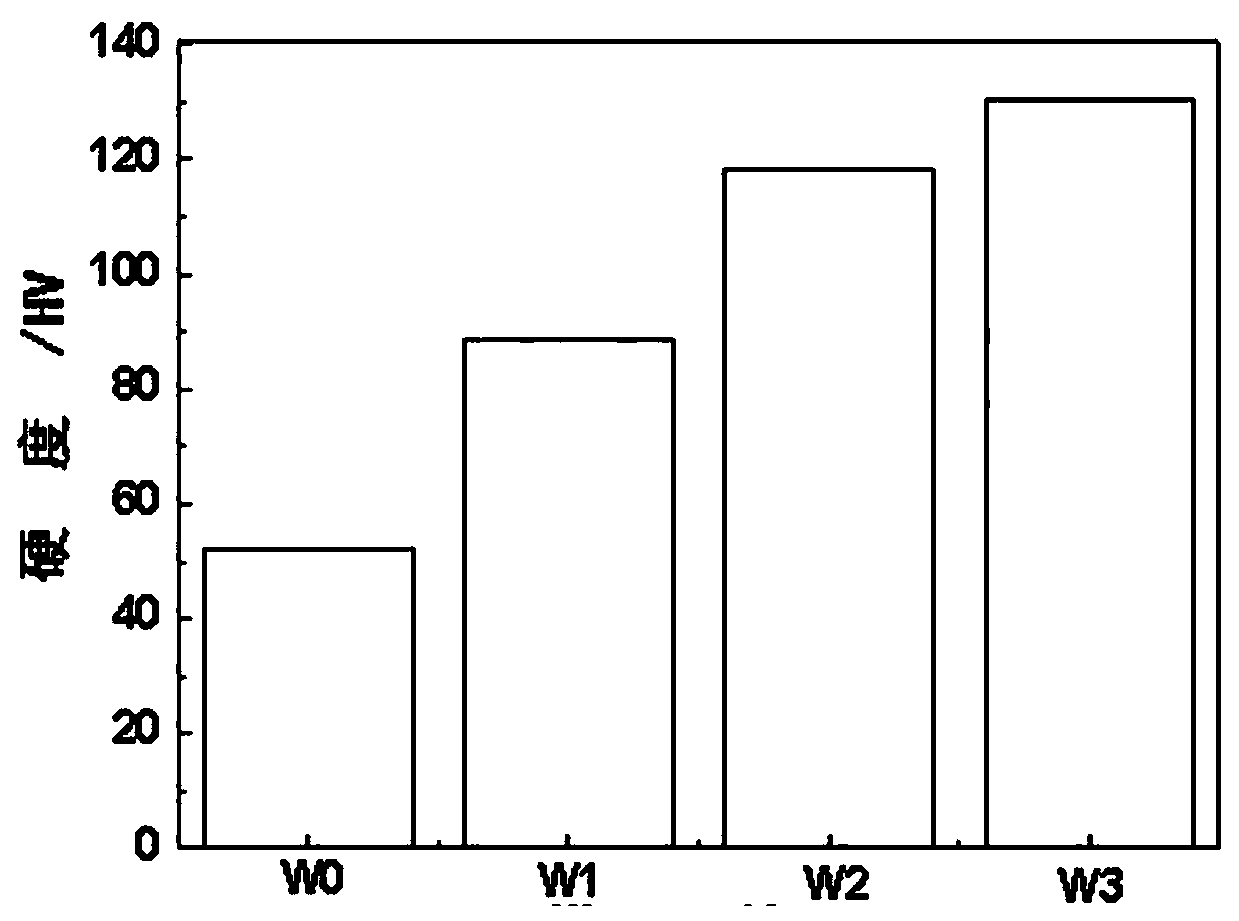

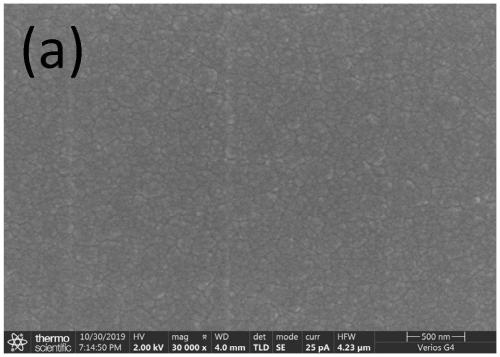

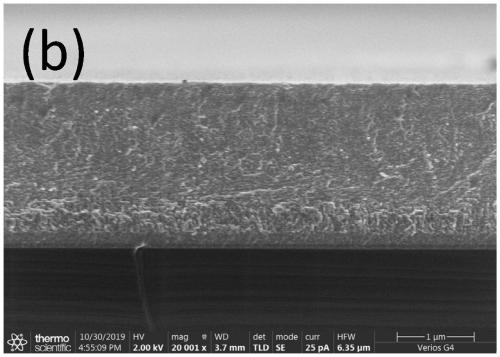

Magnesium alloy surface composite coating and preparation method thereof

InactiveCN110306181AImprove mechanical propertiesImprove carrying capacityAnodisationSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the technical field of magnesium alloy surface modification, and particularly relates to a magnesium alloy surface composite coating and a preparation method thereof. The magnesium alloy surface composite coating is characterized by comprising an aluminum metal layer and a micro-arc oxidation ceramic coating, wherein the aluminum metal layer is sprayed on the surface of amagnesium alloy matrix through cold spraying technology, and the micro-arc oxidation ceramic coating grows in situ on the aluminum metal layer through micro-arc oxidation technology. According to themagnesium alloy surface composite coating and preparation method thereof, the design of preparing a high-performance AL-MAO composite coating through aluminum cold spraying- micro-arc oxidation composite technology is adopted, the AL-MAO composite coating has a better hardness value than a single pure aluminum coating and a MAO coating, the mechanical property and the bearing capacity of the matrix are obviously improved, and the bearing capacity and the friction and wear resistance ability of the magnesium alloy can be effectively improved; the AL-MAO composite coating has relatively high hardness bearing capacity and better friction and wear resistance ability, is more obvious in improving the friction and wear characteristic of the matrix, and shows better reliability and longer servicelife; and a pure aluminum metal layer is introduced between the matrix and the MAO coating, so that the comprehensive performance of the composite coating is improved.

Owner:UNIV OF SCI & TECH LIAONING

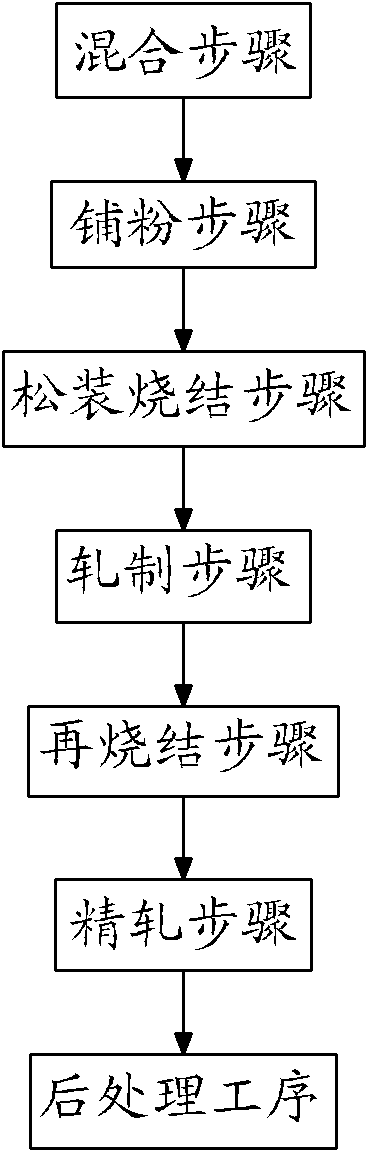

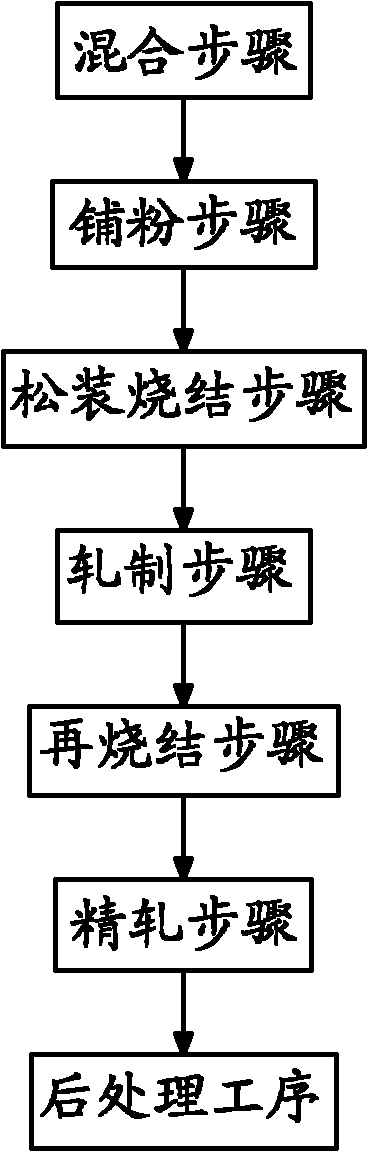

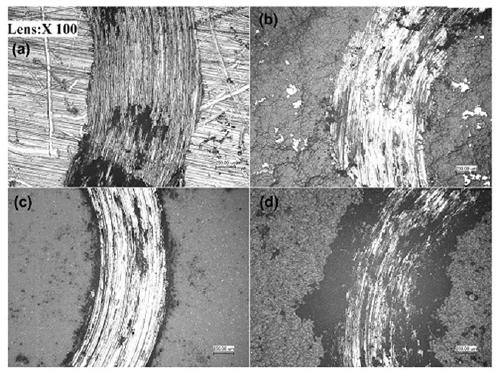

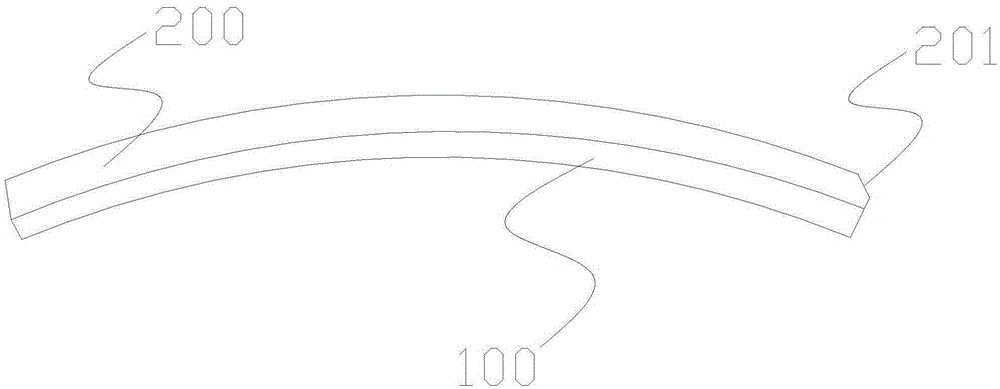

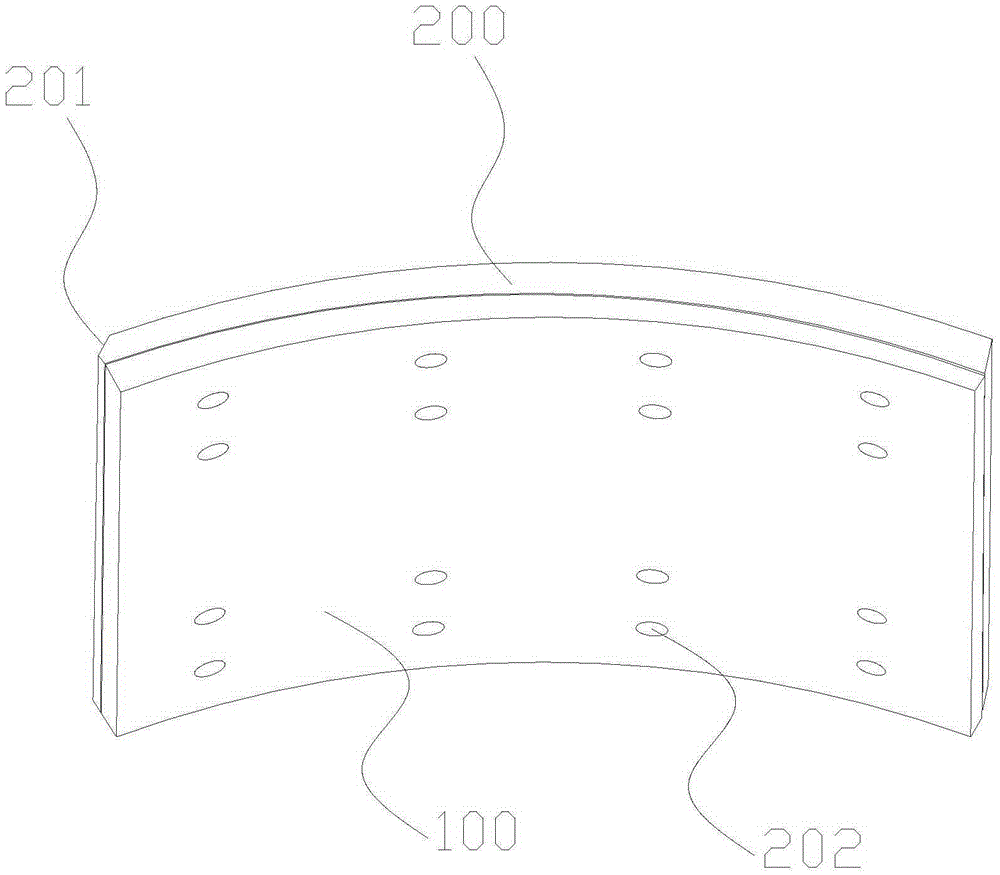

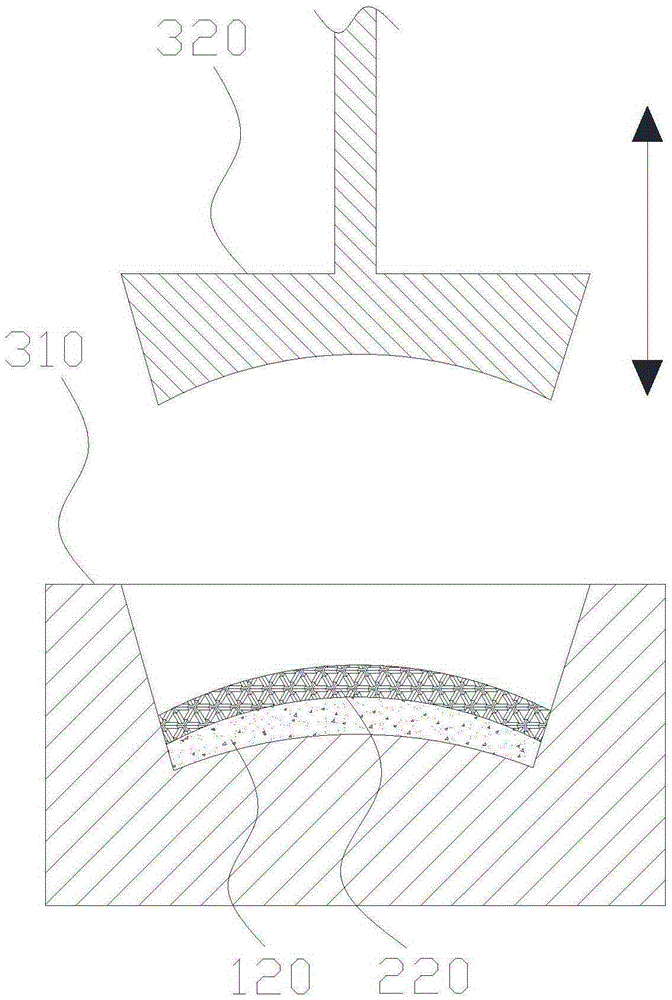

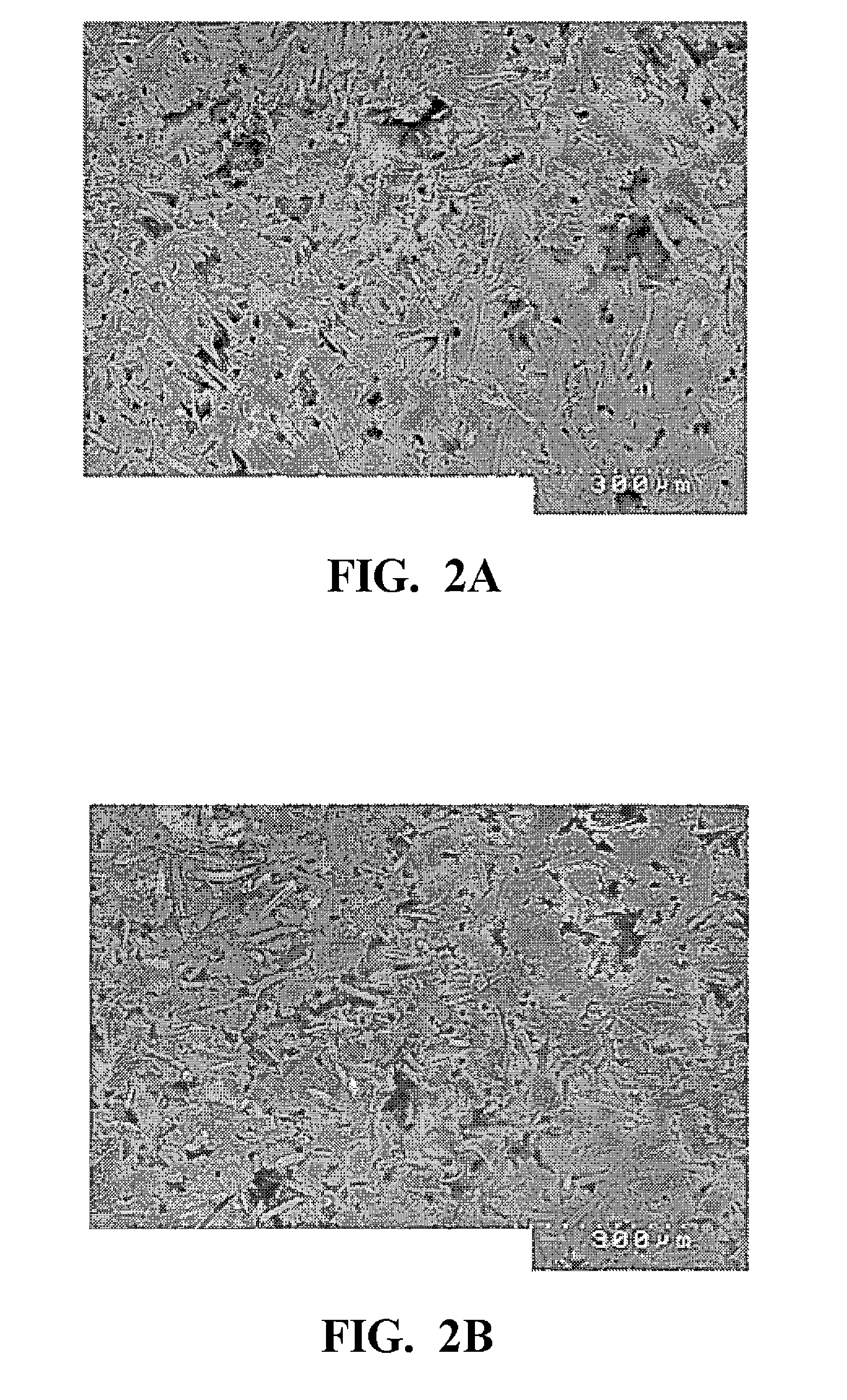

Drum-type friction plate prepared from double-layer friction material, and preparation method thereof

ActiveCN105368396AEfficient use ofExcellent friction and wear propertiesOther chemical processesFriction liningCompressive strengthUltimate tensile strength

The invention discloses a drum-type friction plate prepared from a double-layer friction material, and a preparation method thereof. The drum-type friction plate comprises a base layer prepared from a base material, and a friction layer prepared from a friction material; the friction layer and the base layer are combined via hot press molding. The preparation method comprises following steps successively: prefabricated block preparation, hot press molding, heat treatment, and grinding and drilling. Beneficial effects are that: the friction layer possesses stable friction coefficient and excellent wear resistance; the base layer possesses high impact strength, compressive strength, and internal-shearing strength; welding spot effect of abrasive dust particle in the base material is achieved in premixed material hot press molding process so as to ensure bonding strength of the base material with a surface material; no requirement on the friction performance of the base material is proposed so as to reduce cost; waste dust and drilling cuttings generated in product production process are recycled effectively so as to reduce cost and improve the environment.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

TiMoCN gradient composite coated tool and preparation method thereof

InactiveCN107354431AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingComposite filmCutting force

The invention belongs to the field of cutting tools used for mechanical manufacturing and relates to a TiMoCN gradient composite coated tool and a preparation method thereof. According to a coating of the coated tool, the TiMoCN gradient coated tool is prepared through a composite film coating method combining medium-frequency magnetron sputtering and electric arc plating. The coated tool comprises a tool base body, a Ti transitional layer, a TiMoC transitional layer and the TiMoCN gradient composite coating in sequence from inside to outside, wherein the nitrogen content of the TiMoCN gradient composite coating is gradually varied in a gradient manner. According to the TiMoCN superhard carbon nitride compound coating, two types of metal, namely Ti and Mo, are added to the coating at the same time, the content of nitrogen serving as a structural constitution of the coating is gradually varied in the gradient manner, and therefore cutting machining performance of the tool can be improved. The coated tool has the beneficial effects of being quite high in hardness and strength, low in surface friction coefficient, good in diffusion wear resistance and excellent in frictional wear resistance. In the cutting process, by means of the tool, friction and cutting chip bonding generated in the cutting process can be reduced; the cutting force can be reduced by 30% or above, and the cutting temperature can be lowered by 30% or above; and the service life of the tool can be prolonged by 50% or above, and durability can be improved by 50% or above.

Owner:JINING UNIV

SiNbCN multi-element gradient cutting tool with composite coating and preparation method thereof

InactiveCN107385401AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingCarbon nitrideNitrogen

The invention belongs to the field of machining cutting tools, and particularly relates to a SiNbCN multi-element gradient cutting tool with a composite coating and a preparation method thereof. The SiNbCN multi-element gradient cutting tool with the composite coating sequentially comprises a cutting tool base body, a Ti transition layer, a SiNbC transition layer and a SiNbCN multi-element gradient composite coating from insider to outside, wherein the nitrogen content gradient of the SiNbCN multi-element gradient composite coating is gradually changed. Firstly, arc plating is adopted to deposit a Ti transition layer, and then an unbalanced magnetron sputtering method is adopted to deposit the SiNbC transition layer and the SiNbCN multi-element gradient composite coating with the gradually-changed nitrogen content gradient. The SiNbCN ultrahard carbon nitride compound coating can obviously improve the cutting machining property of the cutting tool because two kinds of elements of Si, Nb and the like are simultaneously added into the coating and the nitrogen content gradient of the coating structural components is gradually changed. The SiNbCN multi-element gradient cutting tool with with composite coating has very high hardness and roughness, good anti-diffusion wear resistance, a capability of resisting plastic deformation and an excellent character of friction and wear.

Owner:JINING UNIV

Molybdenum disulfide/tungsten disulfide multi-layer tantalum-doped thin film and preparation method and application thereof

InactiveCN111172498AGood substrate bonding strengthExcellent friction and wear propertiesVacuum evaporation coatingSputtering coatingThin membraneTitanium

The invention discloses a molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film and a preparation method and application thereof. The molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film comprises a titanium transition layer, a titanium / tantalum / molybdenum disulfide / tungsten disulfide multi-layer gradient transition layer and a molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped layer which are laminated in the thickness of the film in sequence. The preparation method comprises the step that a magnetron sputtering technology is adopted for depositing the titanium transition layer, the titanium / tantalum / molybdenum disulfide / tungsten disulfide multi-layer gradient transition layer and the molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped layer on the surface of a substrate in sequence to obtain the molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film. The molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film has good bonding strength with the substrate, rigidity and elasticity modulus, has good friction and wear resistance, good temperature self-adaptability,damp heat resistance and high-temperature-oxidation resistance at different temperatures in the atmospheric environment, and can meet the demands of aerospace crafts for stable lubrication and long service life.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

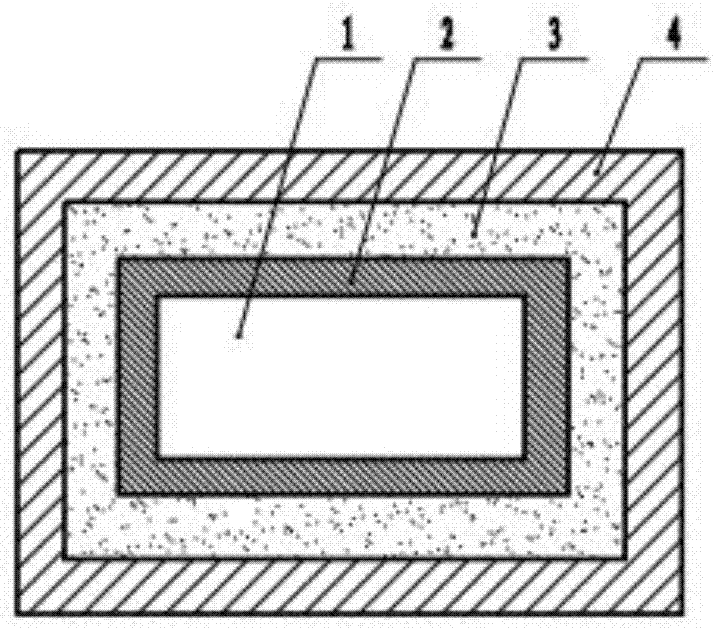

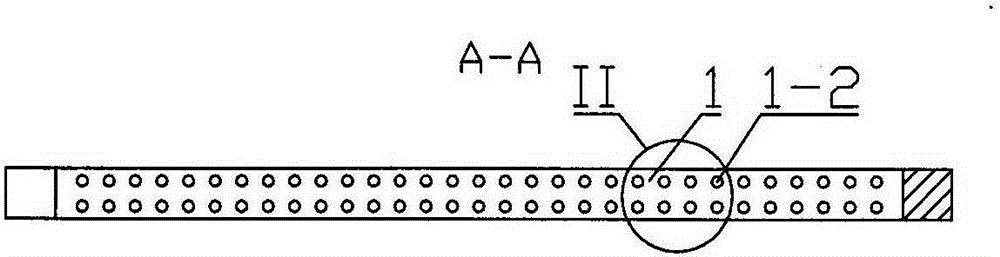

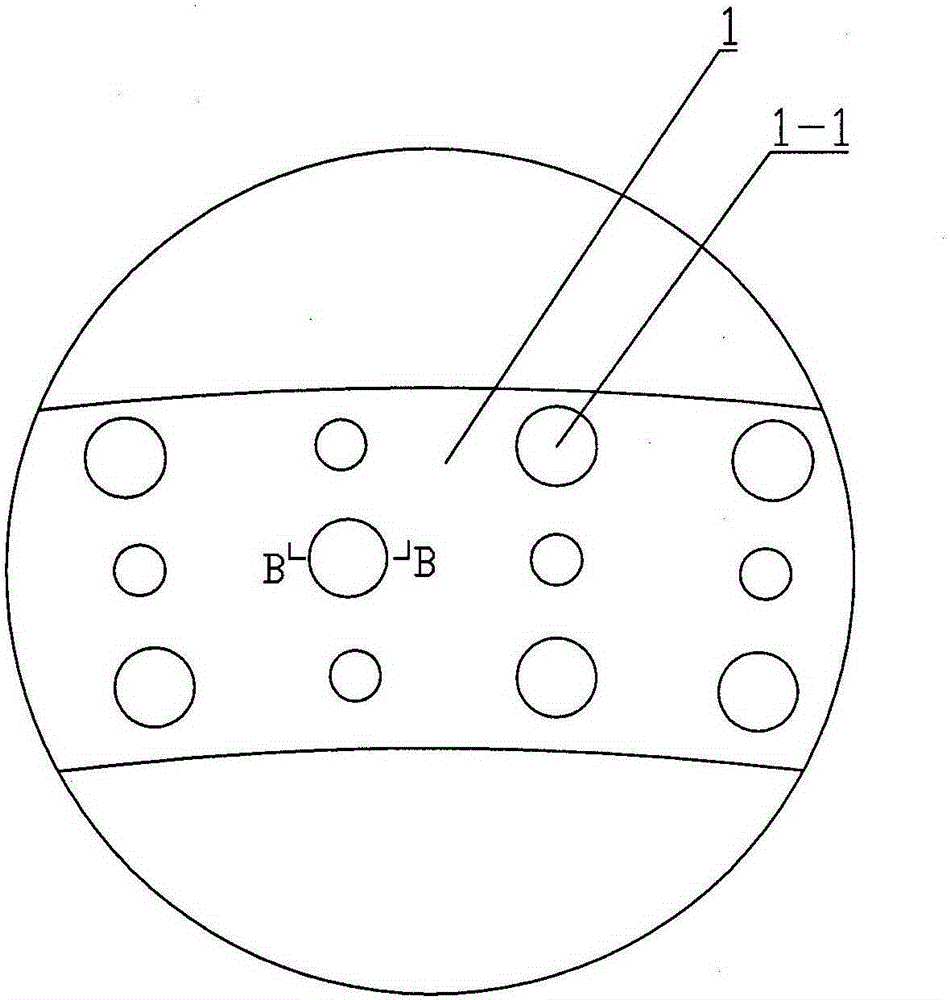

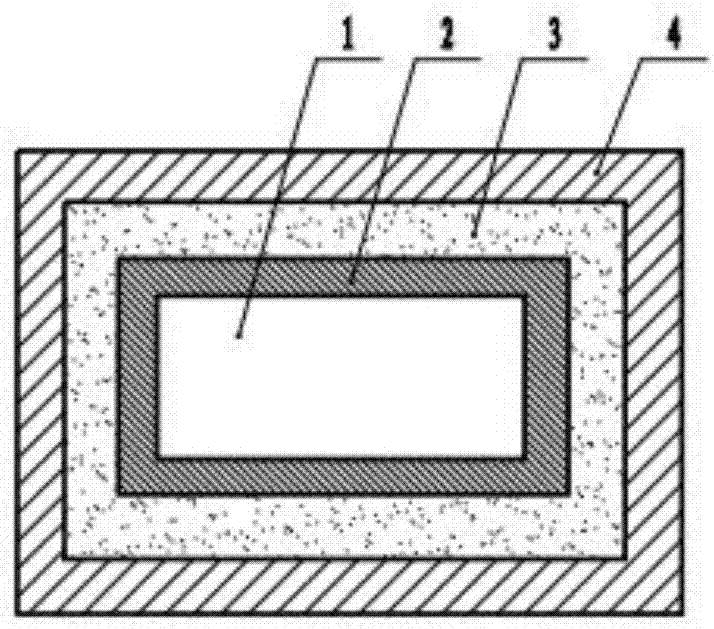

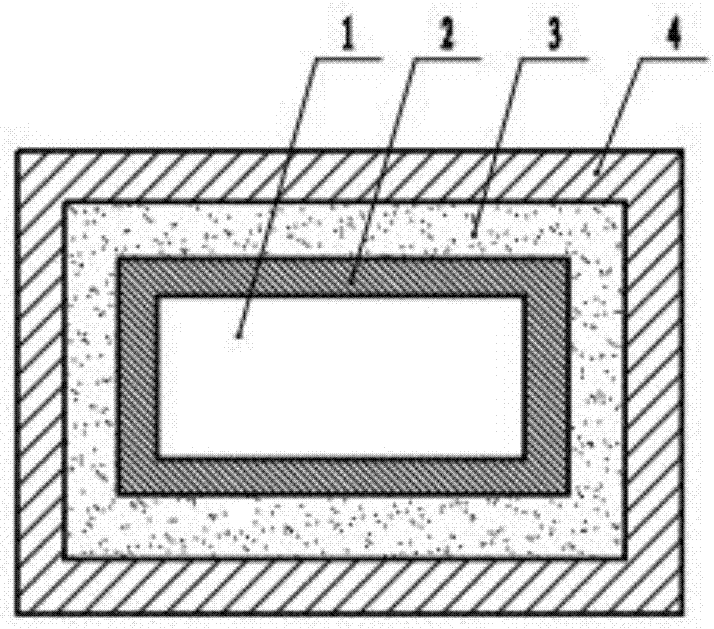

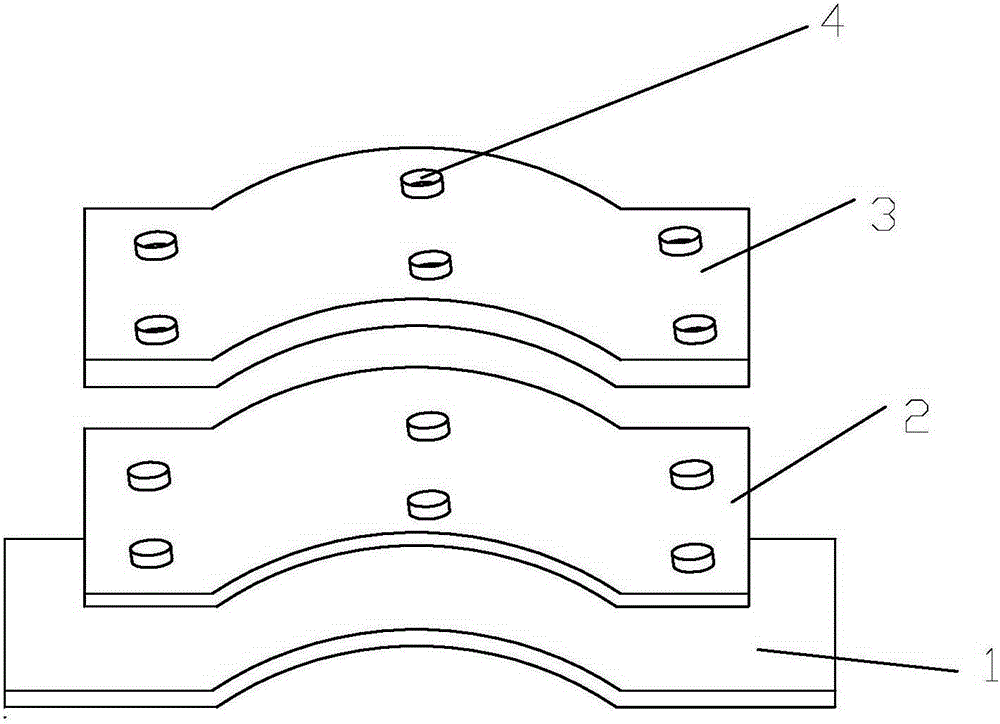

Self-lubricating bearing filled with solidified solid lubricating material and preparation method thereof

ActiveCN108775340AExcellent friction and wear propertiesImprove the lubrication effectBearing componentsAdditivesRoom temperatureVacuum drying

The invention relates to the field of self-lubricating bearings, and in particular relates to a self-lubricating bearing filled with a solidified solid lubricating material and a preparation method thereof. A hole is pre-processed on a metal substrate, the hole is filled with a filler, after aging and curing treatment, the hole and the filler are combined into a whole as the self-lubricating bearing; the filler is prepared from the following components: 30%-35% of a binder, 50% to 60% of a solid lubricating material, and 10% to 15% of a curing agent. The filler is prepared into viscous paste at room temperature, filled into the hole of the self-lubricating bearing, allowed to stand at room temperature for more than 8 hours, placed in a vacuum drying oven, subjected to heat curing treatment, and then cooled to room temperature in a furnace. The solid lubricating material is firmly bonded in the hole of the substrate of the bearing, and the solid lubricating material has good uniformityand compactness. At high temperature of 400DEG C, the solid lubricating material can still be stable for a long time without melting or falling off in the hole of the substrate of the bearing.

Owner:唐山中茂科技有限公司

Preparation method for wear-resistant noise-reducing composite material

InactiveCN105524402AExcellent friction and wear propertiesImprove the noise reduction effectMaterials preparationWear resistant

The invention provides a preparation method for a wear-resistant noise-reducing composite material, which belongs to the field of material preparation. The preparation method is characterized by comprising the following steps: subjecting a composite lubrication system composed of a main lubricant, an assistant lubricant, a noise reducing agent, a friction reducing agent and other related auxiliary agents to uniform mixing via a high-speed mixer and then carrying out extrusion and granulation by using a double-screw extruder; and drying extruded particles and carrying out injection so as to obtain the wear-resistant noise-reducing composite material. The composite material prepared through improved process has excellent frictional wear characteristics, superior noise reduction performance, a high frictional property retention rate, good appearance and mechanical properties and good molding and processing performance; and the preparation method is simple, easy to operate and suitable for promotion and application in related fields.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

Preparation method of multi-element nano composite material suitable for lean oil working condition

InactiveCN112480608AImprove friction and wear resistanceImprove reliability and service lifeFirming agentHydrotalcite

The invention relates to a preparation method of a multi-element nano composite material suitable for lean oil working conditions. The method comprises the following steps: firstly, preparing hydrotalcite sheets and carbon nitride nanosheets; adding 0.1-10% by mass of hydrotalcite sheets and 0.1-10% by mass of carbon nitride nanosheets into 99.8%-80% by mass of epoxy resin, stirring and mixing for15 minutes under the conditions that the vacuum degree is -1 * 10 <5> Pa and the rotating speed is 1,000 r / min, adding a curing agent, and continuously mixing for 5 minutes at the rotating speed of 3,000 r / min to obtain mixed liquid; and finally, pouring the mixed liquid into a mold, and curing at 120 DEG C for 4-8 hours to obtain the self-lubricating composite material. The method is simple andfeasible, and the friction and wear resistance of the composite material can be improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

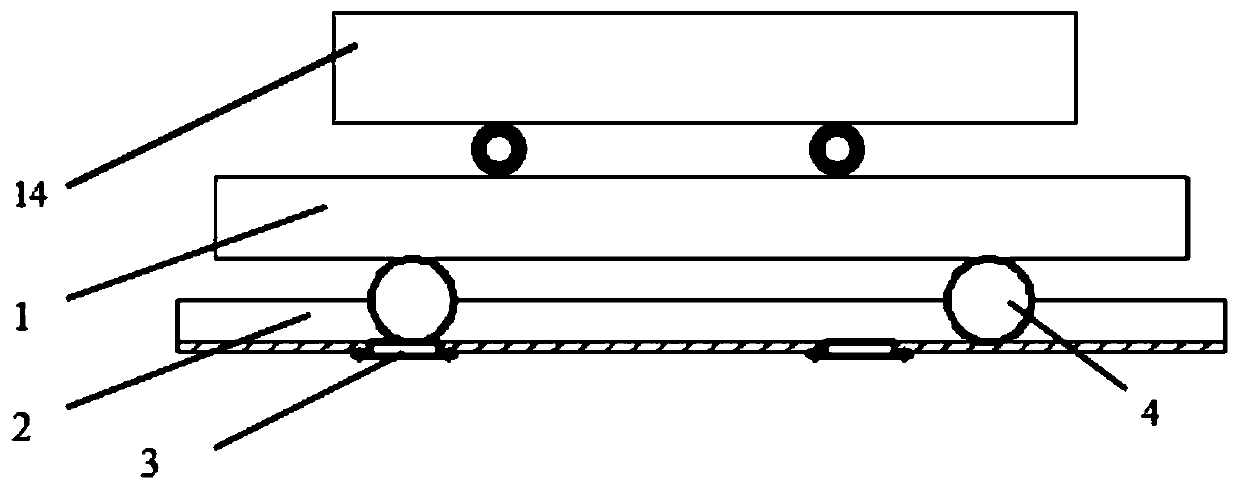

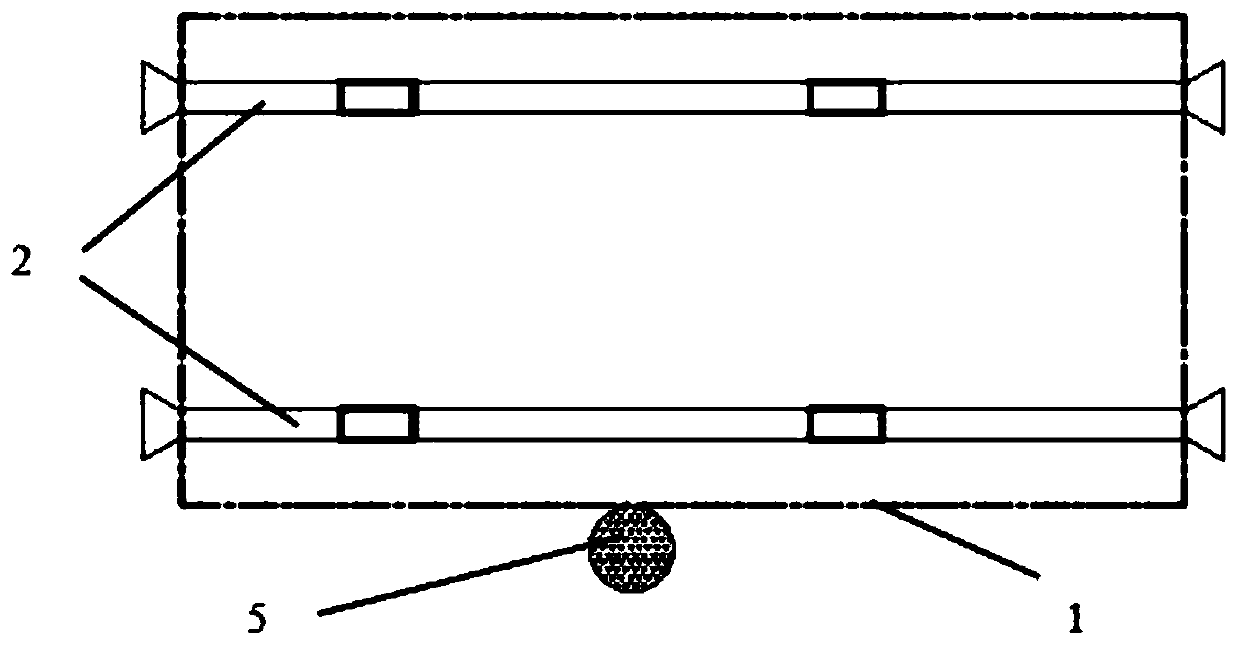

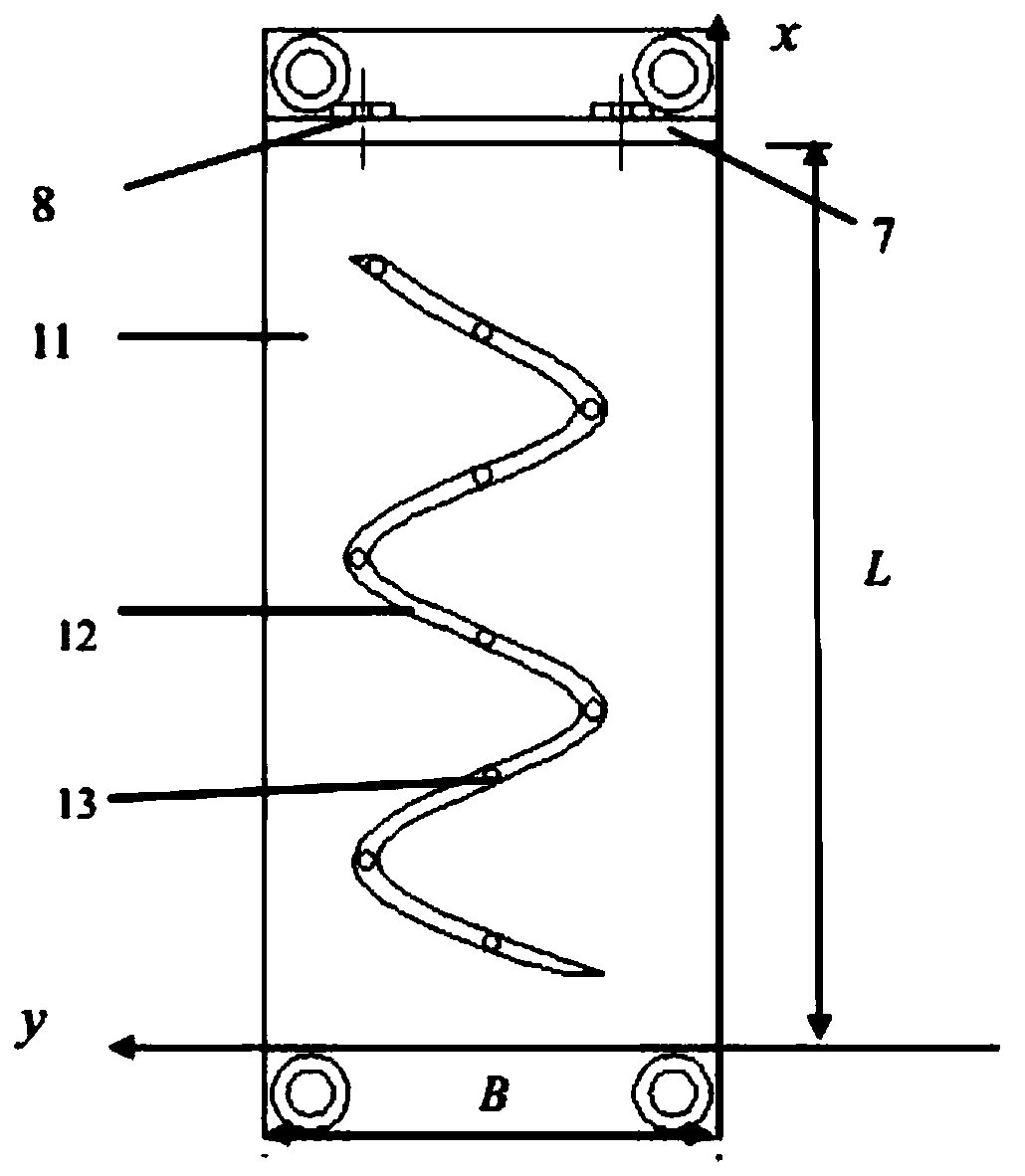

Self-lubricating bionic texture guide rail device for automobile production line switching platform

PendingCN110056572AReduce frictionReduce wearLinear bearingsBearing componentsEngineeringEnergy consumption

The invention discloses a self-lubricating bionic texture guide rail device for an automobile production line switching platform. The device comprises a switching platform, at least two supporting guide rails, a plurality of self-lubricating guide rails and a plurality of supporting rollers carried by the switching platform. The supporting guide rails are arranged in parallel, the lower portions of the supporting rollers are located in the supporting guide rails, each supporting guide rail is at least provided with left and right supporting rollers, the self-lubricating guide rails are embedded in the bottoms of the supporting guide rails, the upper planes of the self-lubricating guide rails are flush with the lowest points of the supporting rollers, and each supporting guide rail is at least provided with left and right self-lubricating guide rails. According to the self-lubricating bionic texture guide rail device for the automobile production line switching platform, self lubricating of the supporting guide rails can be effectively achieved, meanwhile, the effect of capturing abrasive dust can be achieved, the friction and wear characteristics of the guide rails can be improved,switching platform work energy consumption is reduced, and production line work efficiency is improved.

Owner:安徽瑞泰智能装备有限公司

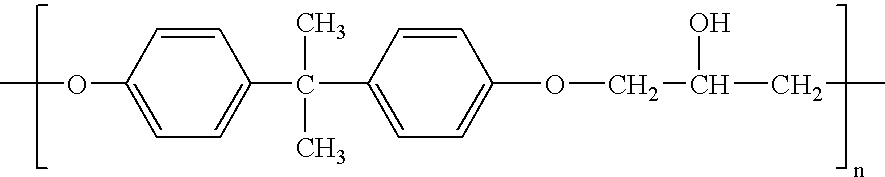

Resin composition for sliding parts and sliding parts using with the same composition

InactiveCN1335338AExcellent friction and wear propertiesBearing componentsAdditivesPolyesterPhosphate

Owner:OILES CORP

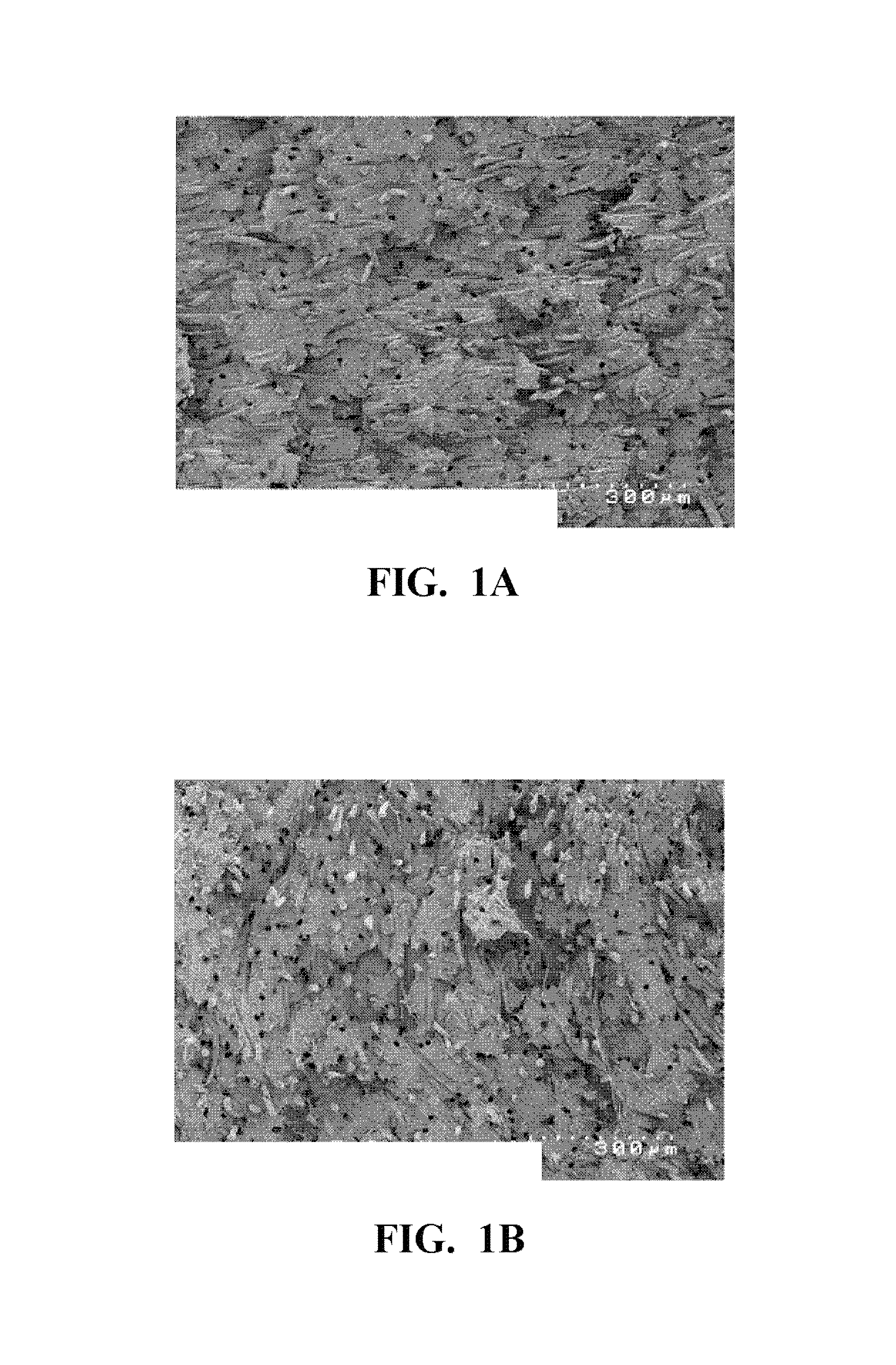

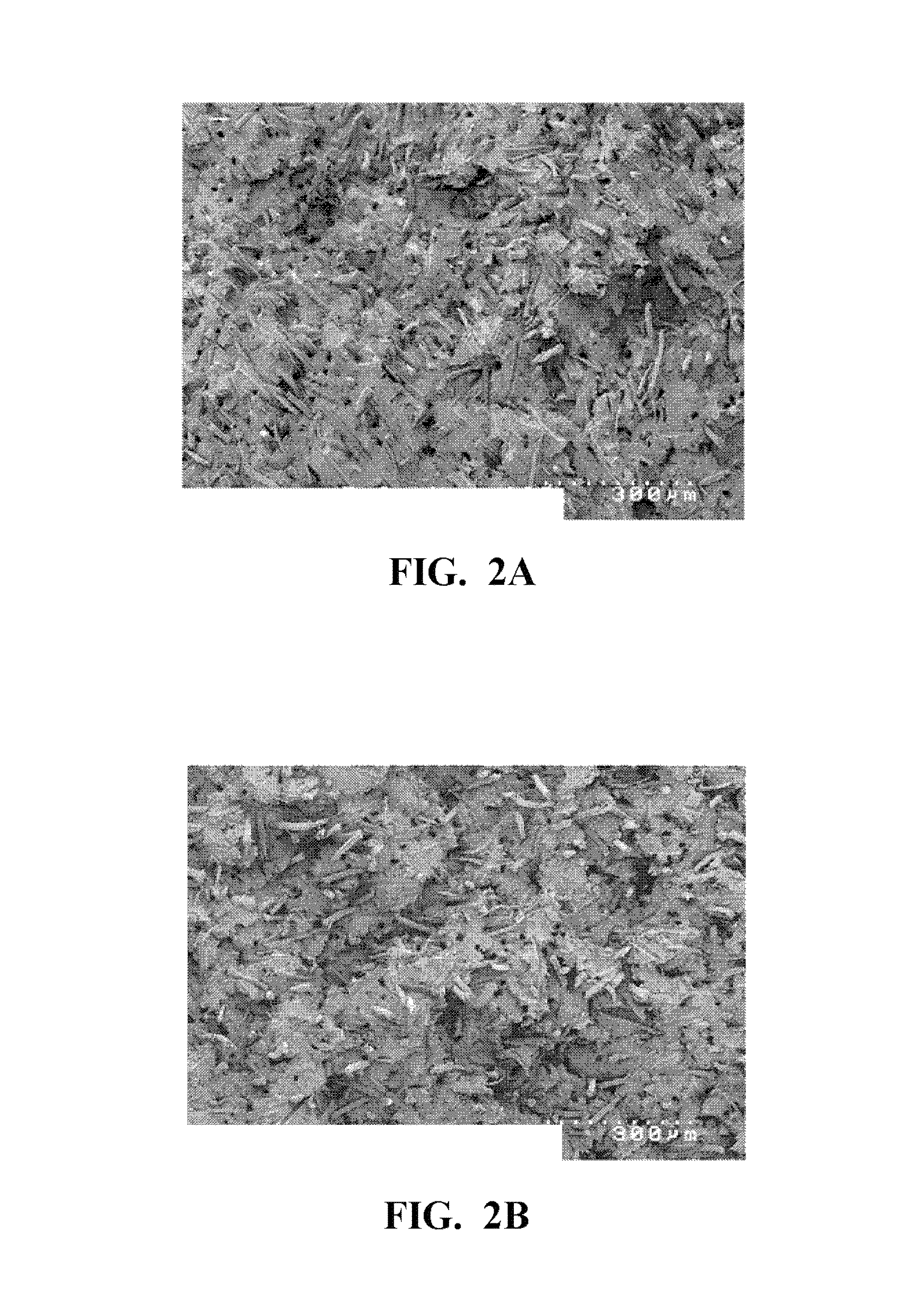

Fluororesin and polyamide fiber composition, and sliding member made therefrom

ActiveUS20140378615A1Present inventionImprove friction and wearShaftsBearing componentsPolymer scienceAramides

Described herein are fluororesin compositions of melt processible fluororesin and wholly aromatic polyamide fibers. The wholly aromatic polyamide fibers have an average fiber diameter of 10-20 μm and an average fiber length of 100-1,000 μm. The compositions are melt processible and can be melt molded into sliding members having low wear when used with sliding counterparts made of metals such as aluminum, copper, zinc or nickel.

Owner:THE CHEMOURS CO FC LLC +1

Composite friction material, brake lining and brake lining production method

InactiveCN105295840AExcellent friction and wear propertiesGood toughnessOther chemical processesFriction liningPowder metallurgyBrake lining

The present invention discloses a composite friction material, a brake lining and a brake lining production method. The composite friction material is divided into two layers along a thickness direction, wherein one layer uses a powder metallurgy friction material, and the other layer uses an organic friction material. According to the brake lining using the composite friction material, the powder metallurgy friction material layer provides a pairing phase friction effect, and the organic friction material layer mainly provides effects of supporting, vibration buffer and sound absorbing; and the expensive high quality raw material can be eliminated, and the material cost can be reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

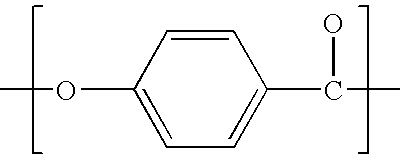

Resin composition for sliding member, and sliding member

InactiveUS20070142538A1Excellent friction and wear characteristicReduce coefficient of frictionWaxPolytetramethylene terephthalate

A resin composition for sliding members which comprises 1 to 10 wt. % hydrocarbon wax, 0.1 to 3 wt. % at least one member selected from the group consisting of phosphates, sulfates, and carbonates, 1 to 20 wt. % phenoxy resin, 0.1 to 5 wt. % compatibilizing agent, and a polybutylene terephthalate resin as the remainder; and a sliding member obtained by molding the resin composition. The resin composition for sliding members and the sliding member obtained by molding the resin composition have excellent frictional and wearing properties even when a soft metal, e.g., an aluminum alloy, is used as a mating material.

Owner:OILES CORP

Novel process for making piston ring

InactiveCN100353047CHigh surface hardnessReduce coefficient of frictionPiston ringsMachines/enginesMetalworkingSurface layer

The new process for piston ring processing relates to a machining process of piston rings. The process comprises the following steps: casting, grinding, heat treating, grinding again, metalworking, laser intensification processing, thermal shaping, and then metalworking again. Since the surface layer of the piston ring is alloyed by laser or executed laser melting-covering processing and then is flash molten through high-energy laser bean, the substrate of finite depth at external surface of the piston ring is flash molten and then solidifies to from specific ceramic granule reinforced composite coating. The coating layer and the piston ring body are of a metallurgy structure and will not fall off or peel off under exogenous process. It is easy to realize the industrialisation production of the present invention, the product possesses excellent anti-adhesive wear, resistance to abrasion grains and excellent technology stability.

Owner:江苏仪征威龙活塞环有限公司 +1

Fluororesin and polyamide fiber composition, and sliding member made therefrom

ActiveUS9260598B2Excellent friction and wear propertiesImprove friction and wearShaftsBearing componentsPolymer scienceShell molding

Described herein are fluororesin compositions of melt processible fluororesin and wholly aromatic polyamide fibers. The wholly aromatic polyamide fibers have an average fiber diameter of 10-20 μm and an average fiber length of 100-1,000 μm. The compositions are melt processible and can be melt molded into sliding members having low wear when used with sliding counterparts made of metals such as aluminum, copper, zinc or nickel.

Owner:THE CHEMOURS CO FC LLC +1

Self-lubricating bearing filled with solid lubricating material and preparation method thereof

ActiveCN108775340BExcellent friction and wear propertiesImprove the lubrication effectBearing componentsAdditivesFirming agentMetal substrate

The invention relates to the field of self-lubricating bearings, and in particular relates to a self-lubricating bearing filled with a solidified solid lubricating material and a preparation method thereof. A hole is pre-processed on a metal substrate, the hole is filled with a filler, after aging and curing treatment, the hole and the filler are combined into a whole as the self-lubricating bearing; the filler is prepared from the following components: 30%-35% of a binder, 50% to 60% of a solid lubricating material, and 10% to 15% of a curing agent. The filler is prepared into viscous paste at room temperature, filled into the hole of the self-lubricating bearing, allowed to stand at room temperature for more than 8 hours, placed in a vacuum drying oven, subjected to heat curing treatment, and then cooled to room temperature in a furnace. The solid lubricating material is firmly bonded in the hole of the substrate of the bearing, and the solid lubricating material has good uniformityand compactness. At high temperature of 400DEG C, the solid lubricating material can still be stable for a long time without melting or falling off in the hole of the substrate of the bearing.

Owner:唐山中茂科技有限公司

Lubricating grease composition and preparation method thereof

InactiveCN104357195AGood stabilityExcellent friction and wear propertiesLubricant compositionChemistryPolypropylene

The invention discloses lubricating grease composition and a preparation method thereof. The lubricating grease composition comprises components in parts by weight as follows: 70-85 parts of base oil, 10-13 parts of monostearate, 2-4 parts of polypropylene wax, 2-3 parts of urea, 0.2-1 part of triethanolamine salt, 0.5-0.8 parts of dioctyl phthalate and 0.05-0.8 parts of diisocyanate. The preparation method comprises steps as follows: (1), performing magnetic stirring on 70-85 parts of the base oil, 2-3 parts of the urea, 0.2-1 part of the triethanolamine salt and 0.05-0.8 parts of the diisocyanate for 30 min; (2), adding 10-13 parts of the monostearate, 2-4 parts of the polypropylene wax, 0.5-0.8 parts of the dioctyl phthalate and 0-1 part of an antioxidant to the mixture, stirring the mixture at the temperature of 80-100 DEG C for 20 min, adjusting the pH value of the mixed solution to 6.7 with 0.1 mol / L of a hydrochloric acid, and stirring the mixed solution for 1 h at the same temperature; (3), performing suction filtration on the product in step (2), washing the product with water thrice, and placing the product into an oven for drying for 3 h to obtain the lubricating grease composition.

Owner:WUXI FEITIAN GREASE

Nano composite plating paste material and its electroplating method

InactiveCN1265029CSpecial structureExtraordinary corrosion resistanceElectrolytic coatingsAlkaline earth metalRare earth

Owner:重庆阿波罗机电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com