Drum-type friction plate prepared from double-layer friction material, and preparation method thereof

A technology of friction materials and friction plates, which is applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve problems such as waste of resources, achieve the effects of reducing formula costs, ensuring bonding strength, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

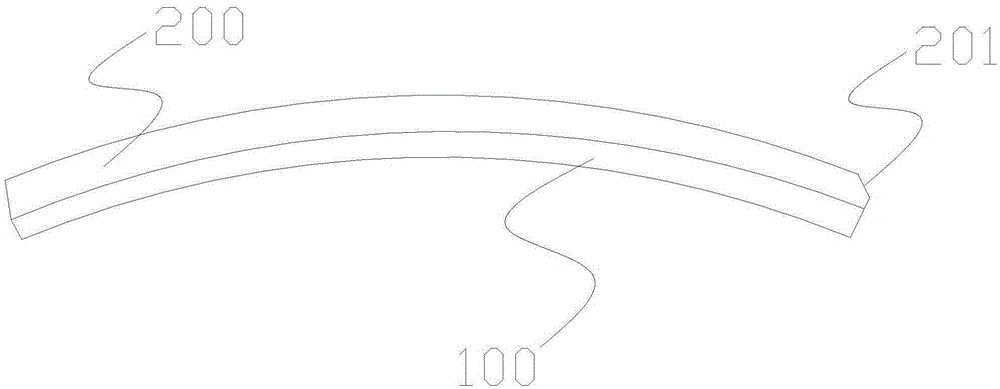

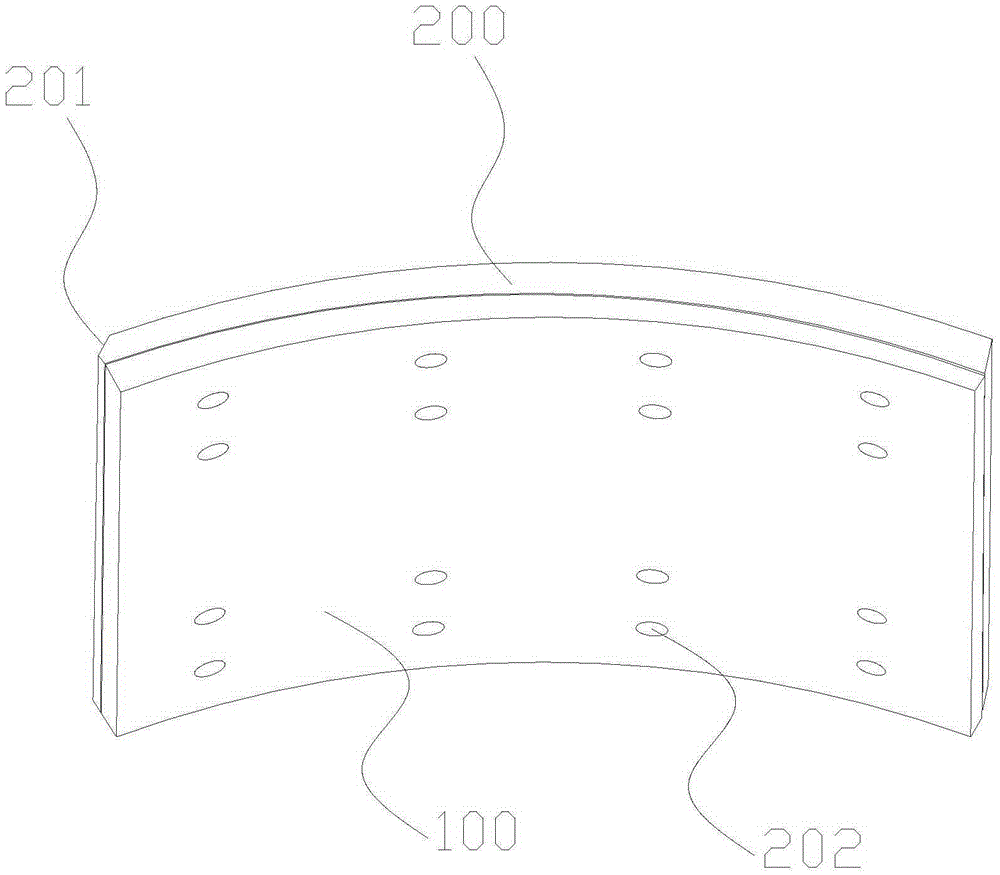

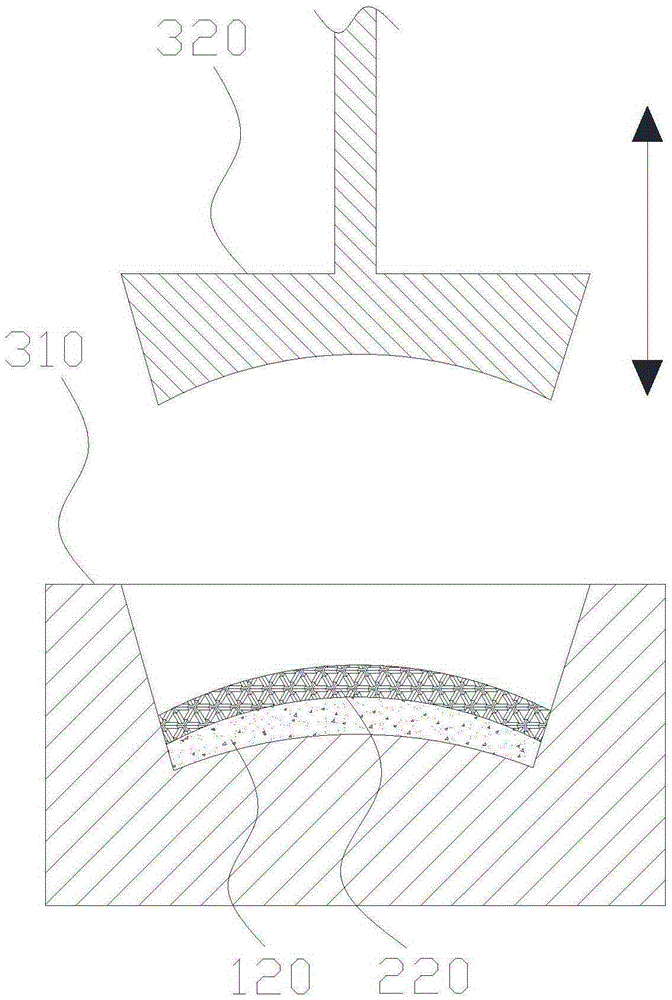

[0034] Such as figure 1 and figure 2 As shown, a drum friction plate made of double-layer friction material 220 includes a bottom layer 100 made of primer 120 and a friction layer 200 made of friction material 220, and the friction layer 200 is fixed on the outside of the bottom layer 100 . The friction layer 200 and the bottom layer 100 adopt two different formulations of the friction material 220 and the primer 120 respectively. The friction material 220 uses the internationally leading non-asbestos formula system to ensure that the product has excellent friction and wear characteristics. The formulation of the primer 120 is used The formula system mainly uses the dust and drilling chips produced during the grinding of drum friction discs to make it have excellent mechanical properties. The friction material 220 can meet the friction performance, and the base material 120 can meet the mechanical properties. Since the base material 120 is not used in use, there is no requi...

Embodiment 1

[0051] Formula of friction material 220:

[0052] 8 parts of phenolic resin, 5 parts of glass fiber, 2 parts of nitrile rubber powder, 1 part of carbon fiber, 10 parts of mineral fiber, 20 parts of barium sulfate, 10 parts of calcium carbonate, 1 part of alumina, 2 parts of zircon powder, 2 parts of kaolin, 1 part of vermiculite, 2 parts of flake graphite, 3 parts of synthetic graphite, 3 parts of coke powder, 5 parts of calcium hydroxide.

[0053] The composition of base material 120

[0054] 3 parts of phenolic resin, 30 parts of ground dust granulation, 10 parts of mineral fiber, 10 parts of barium sulfate, 3 parts of glass fiber, and 5 parts of calcium carbonate.

[0055] Grinder granulated ingredients in primer 120

[0056] 3 parts of liquid NBR, 3 parts of liquid phenolic resin, 0.25 parts of vulcanization system, and 80 parts of collected dust.

[0057] The temperature of the forming mold 310 during the preparation of the drum friction plate prefabricated block descr...

Embodiment 2

[0059] Formula of friction material 220:

[0060] 11 parts of phenolic resin, 7.5 parts of glass fiber, 2.5 parts of nitrile rubber powder, 1.5 parts of carbon fiber, 15 parts of mineral fiber, 27.5 parts of barium sulfate, 15 parts of calcium carbonate, 2 parts of alumina, 3 parts of zircon powder, 3.5 parts of kaolin , 2.5 parts of vermiculite, 3.5 parts of flake graphite, 4 parts of synthetic graphite, 4 parts of coke powder, and 7.5 parts of calcium hydroxide.

[0061] The composition of base material 120

[0062] 4 parts of phenolic resin, 40 parts of ground dust granulation, 12.5 parts of mineral fiber, 15 parts of barium sulfate, 4 parts of glass fiber, and 7.5 parts of calcium carbonate.

[0063] Grinder granulated ingredients in primer 120

[0064] 5 parts of liquid NBR, 5 parts of liquid phenolic resin, 0.375 parts of vulcanization system, and 85 parts of collected grinding dust.

[0065] The temperature of the forming mold 310 during the preparation of the drum-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com