Patents

Literature

707results about How to "Stable coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

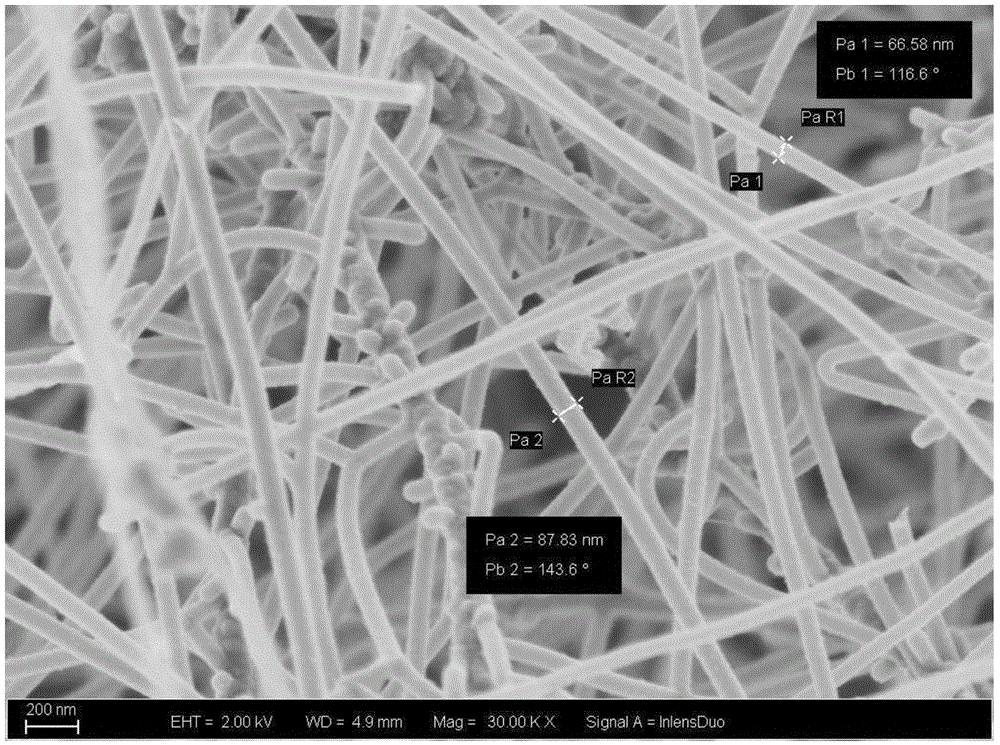

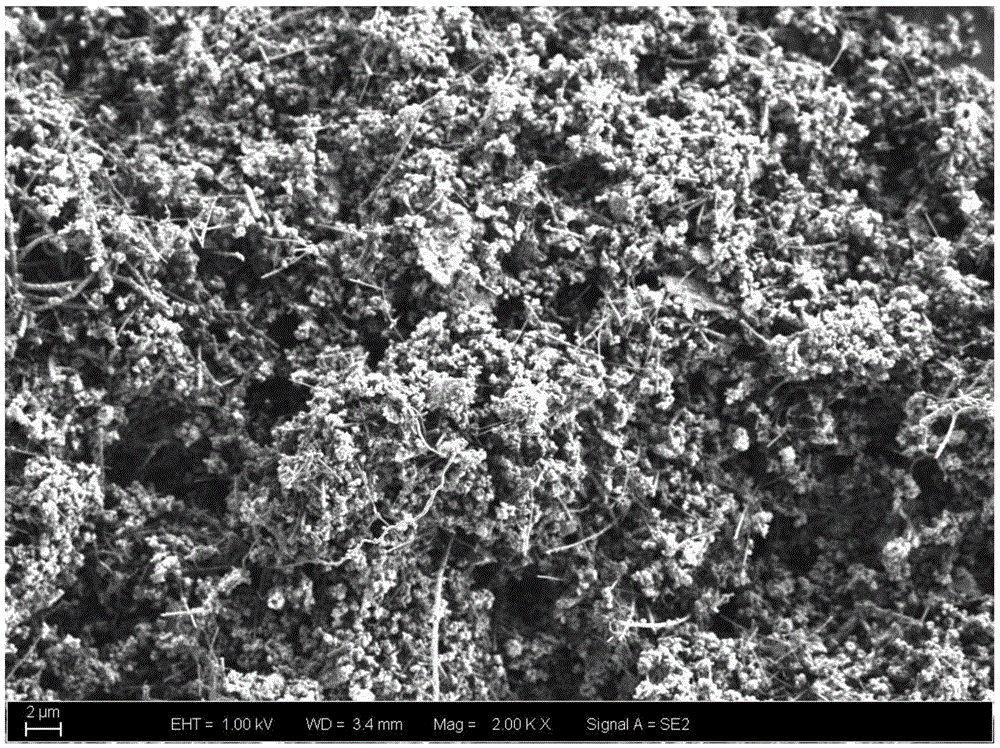

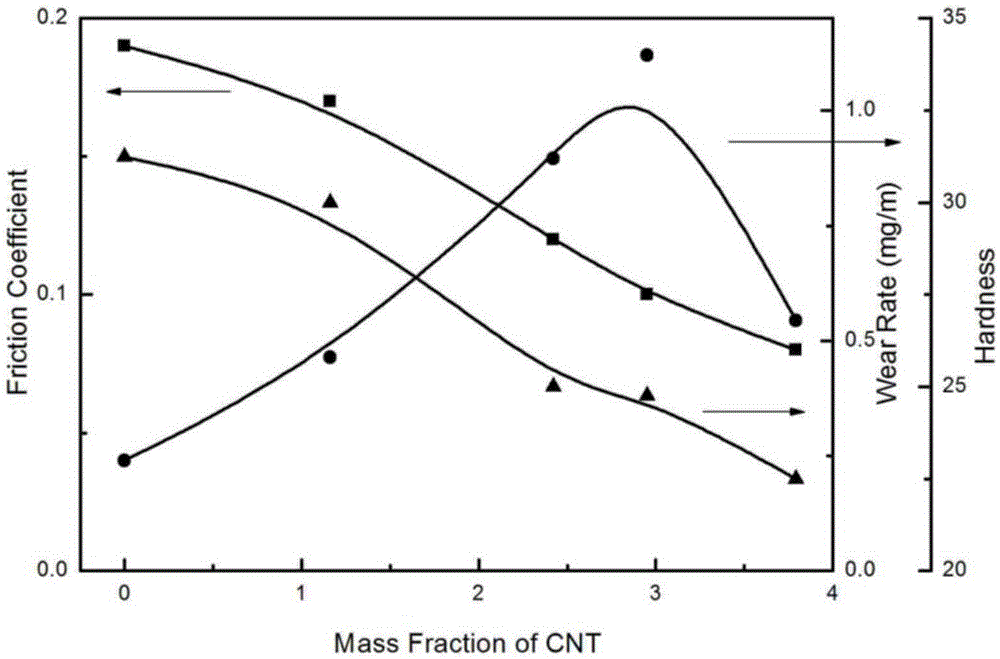

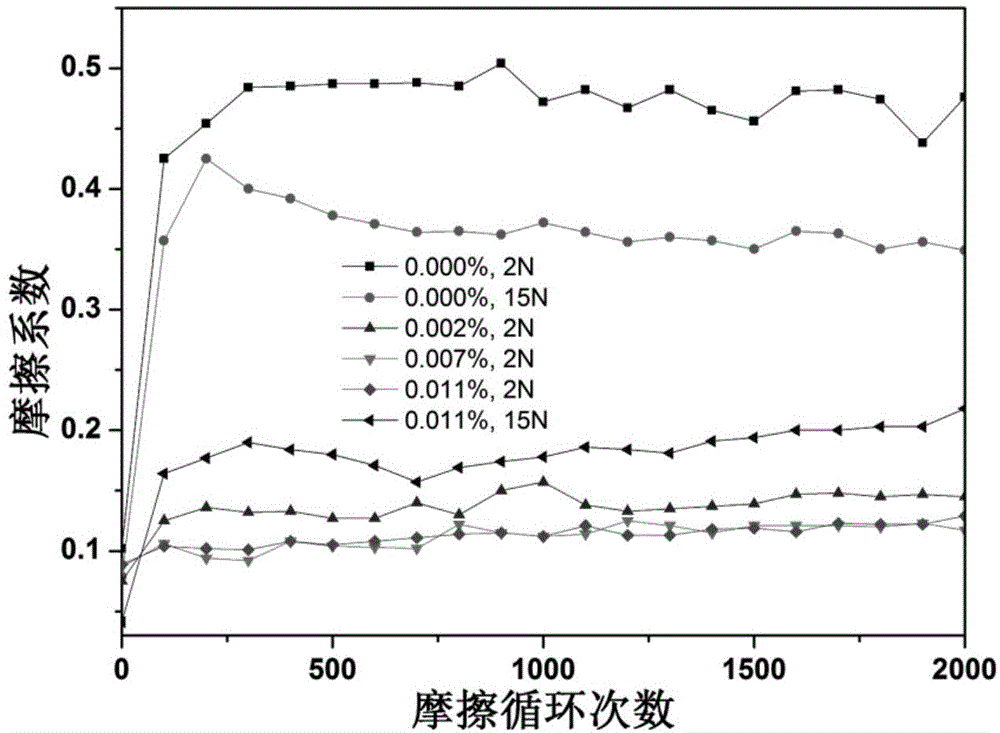

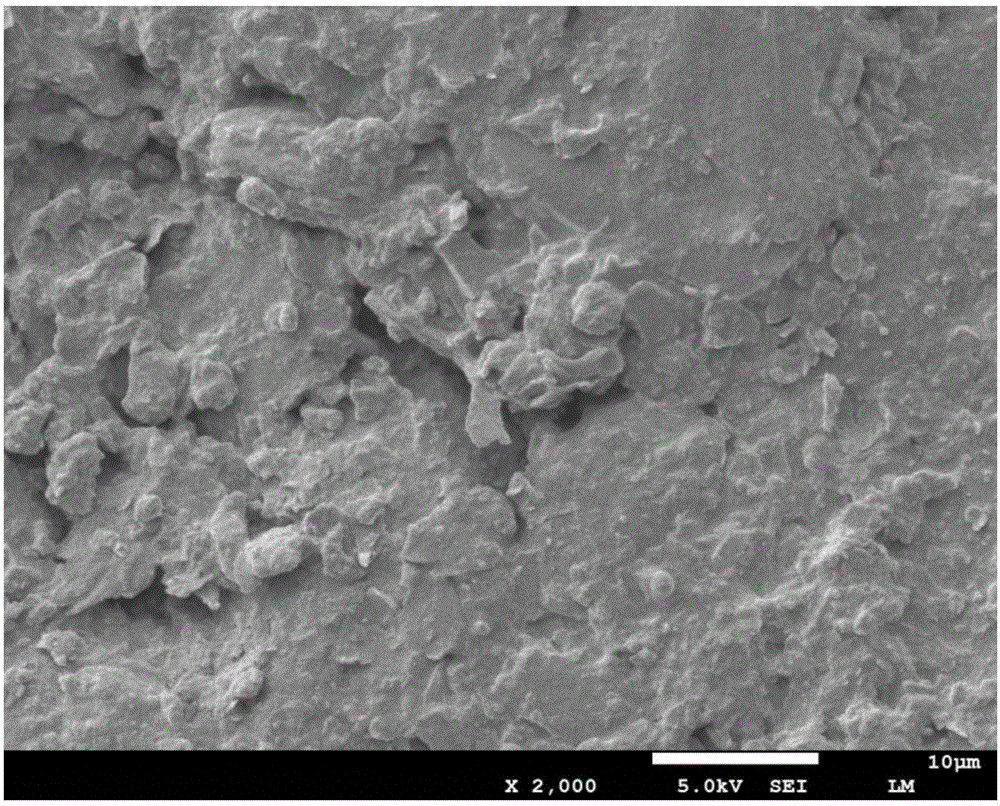

Nano-carbon-reinforced wear-resistant composite material

The invention belongs to the technical field of materials, and specifically relates to a nano-carbon-reinforced wear-resistant composite material. The nano-carbon-reinforced wear-resistant composite material comprises the following components in percentage by mass: 55-99% of metal powder, 0.1-35% of ceramic powder, and 0.01-15% of nano-carbon, wherein the metal powder is used as a composite material matrix; the ceramic powder is used as a wear-resistant filling material; and the nano-carbon comprises single-wall carbon nano-tubes, multi-wall carbon nano-tubes and other materials, and is mainly used for improving the heat-conducting performance, strength, toughness, wear resistance and other performances of the composite material. The wear-resistant composite material disclosed by the invention can keep a stable friction coefficient and a low wear rate under the conditions of a heavy load, a high speed, and long-time braking.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

The invention relates to a metal / ceramic nano complex self-repairing additive, which comprises metal nano micropowder and nano natural ore powder as main material, detergent, catalyst, antioxidant, and solvent, and can be used in lube, grease and ultrasonic medium. The advantages of this invention include: it can form rapidly high-hardness self-repairing protection layer on a plurality of metal friction surfaces with thickness adjustable to optimize gap and improve surface physical and chemical property, and has wide application in friction dual parts.

Owner:JIANGSU MOLEDN PETROCHEM

Reinforced wear-resistant automobile brake composite material and preparation method thereof

ActiveCN103059504AImprove wear resistanceLow costOther chemical processesFriction liningWear resistantCoupling

The invention discloses a reinforce wear-resistant automobile brake composite material which is prepared from the following components in parts by weight: 85-100 parts of resin matrix, 100-150 parts of composite reinforcing fiber, 80-120 parts of filler, 25-40 parts of toughening material, 6-10 parts of curing agent, 4-6 parts of curing accelerator, 30-85 parts of frictional property regulator, 30-40 parts of noise reducer and 4.5-6 parts of releasing agent. The resin matrix is reinforced by the composite reinforcing fiber and matched with proper frictional property regulator, filler, toughening material and noise reducer to display the synergic coupling actions among the resin matrix, reinforcing fiber, filler and frictional property regulator, thereby obtaining the novel automobile brake composite material which has the advantages of stable friction factor, small wear rate, high heat fade resistance, favorable braking effect, shock absorption, noise reduction, high mechanical strength, low cost, long service life and favorable braking property at different temperatures.

Owner:江苏裕铭铜业有限公司

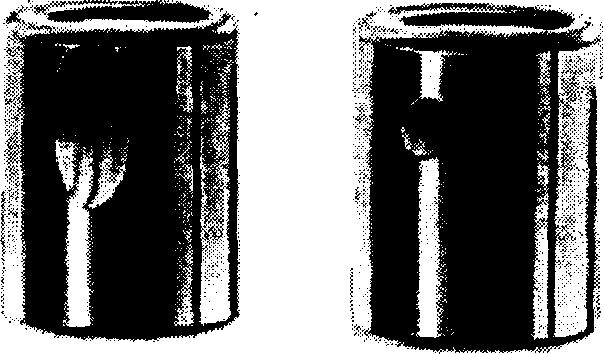

Charcoal/pottery brake lining manufacturing method for industrial brake

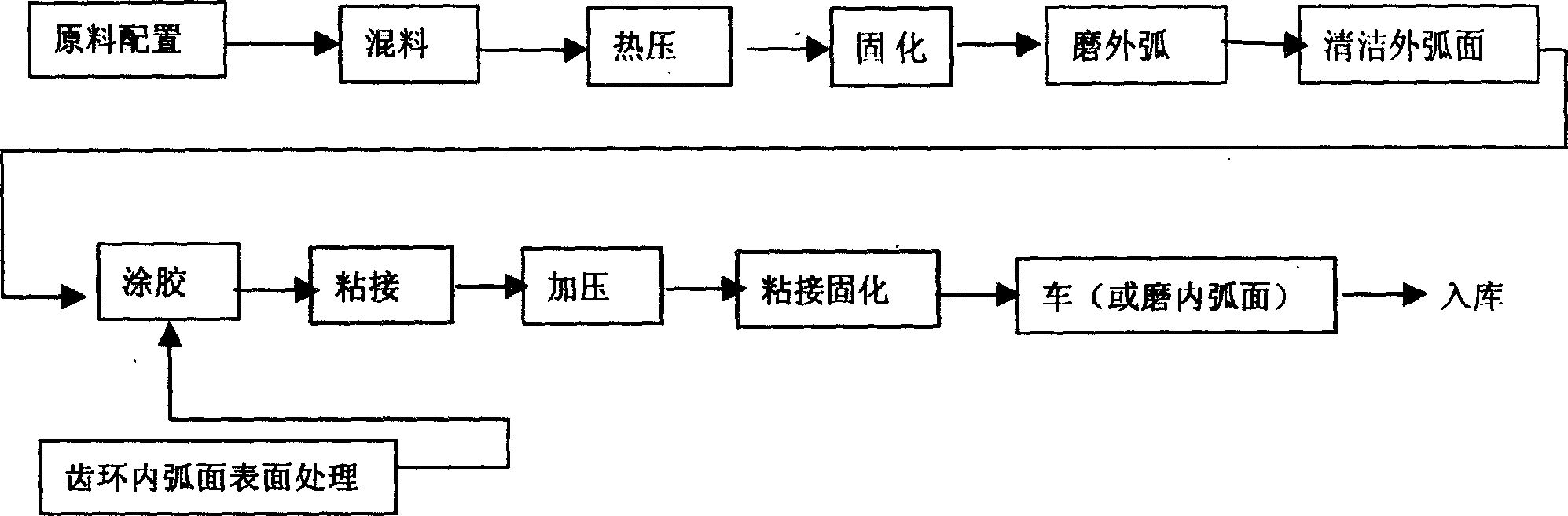

InactiveCN101493126AReduce processing intensityIncrease coefficient of frictionFriction liningGas phaseLow density

The invention discloses a method for manufacturing carbon / ceramic braking linings used in an industrial brake, which comprises the following steps: carbon fiber performs are prepared by a needle method; low-density C / C composite material is prepared by a chemical gas permeation method after the carbon fiber performs are treated in high temperature; the C / C composite material is treated in high temperature, machined and then the molten silicon infiltration is carried out on the C / C material in a high temperature vacuum furnace; Sic is formed by the Si and C reaction to prepare C / C-SiC baking material; and finally after the C / C-SiC baking material is machined, the C / C-SiC baking material is riveted with the steel backing by a rivet in a cold way to prepare the needed C / C-SiC baking material used in an industrial brake. The carbon / ceramic braking lining manufactured by the method has higher mechanical property and excellent frictional wear performance and is used in the industrial brake.

Owner:CENT SOUTH UNIV

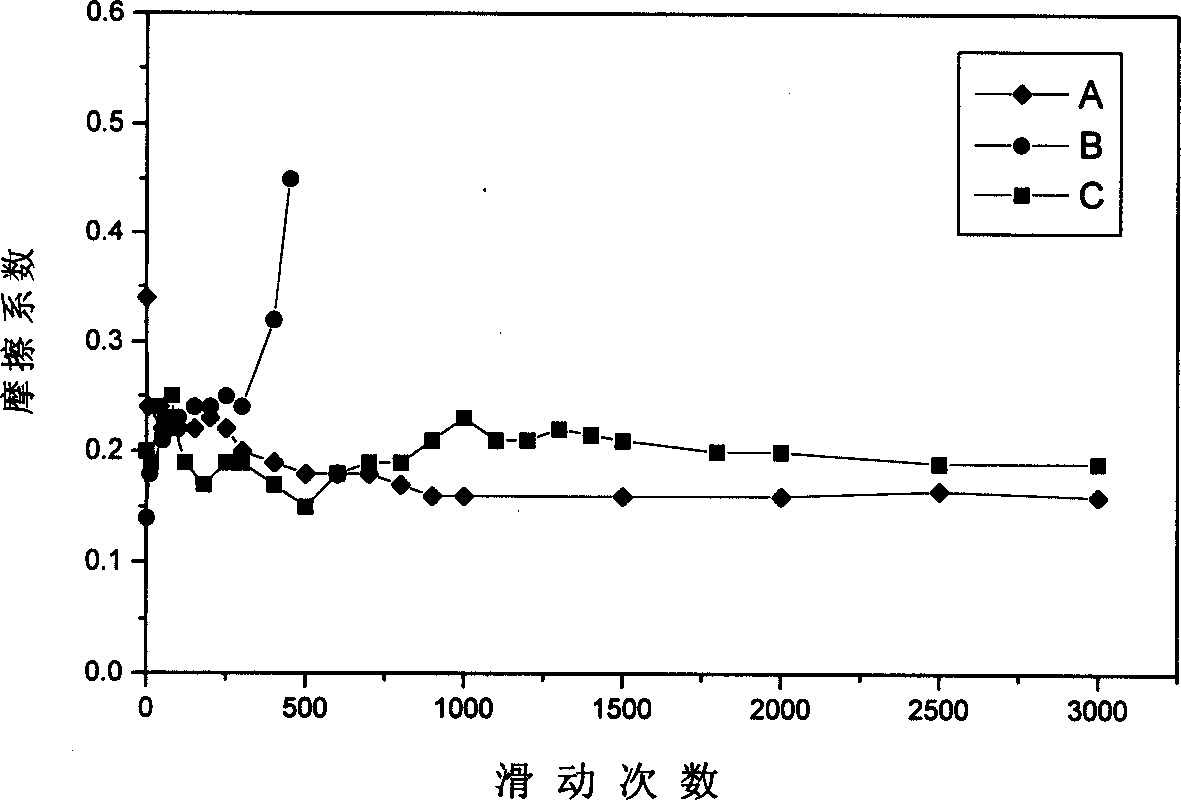

Double hot-rolling composite friction material and its production

A bi-hot pressing composite friction material and its production are disclosed. The process is carried out by the first hot-press forming, crushing for composite friction material, sifting, mixing composite friction material 40-70 wt% and high-temperature-resisting modified resin 15-35 wt% with reinforced fiber 5-15 wt%, rubber powder 5-15 wt% and residual lubrication material, putting them into mould, hot-press forming at 140-165 degree and 12-20 Mpa and keeping temperature to obtain final product. It has stable friction coefficient, less wear rate and friction noise, better surface toughness and higher gas-pocket coefficient.

Owner:SOUTH CHINA UNIV OF TECH

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

Method for preparing brake pad friction material by using rice and wheat straws

InactiveCN103820078AAbundant resourcesReduce recycling costsOther chemical processesFriction liningFiberAtmospheric pollution

The invention discloses a method for preparing a brake pad friction material by using rice and wheat straws and relates to the technical field of composite materials. The brake pad friction material has the following formula: 15 percent of toughened fibers, 16 percent of modified resin, 14 percent of a friction increase agent, 9 percent of sulfur and tin powder, 1.6 percent of carbon black, 2.5 percent of zinc oxide, 8.9 percent of barium sulfate, 10 percent of rice and wheat straw carbon powder, 6 percent of aluminum hydroxide, 14 percent of modified li beads and 3 percent of zinc stearate. The materials are uniformly mixed and stirred, pressed in a mold and subjected to machining such as grinding and chamfering according to a technical requirement to obtain a braking pad. According to the method, the rice and wheat straws are used as raw materials to prepare carbon powder which replaces graphite in a friction material formula, so that the atmospheric pollution caused by severe combustion of straws in each year is alleviated, the production cost of the brake pad is reduced, and the brake performance and the braking effect are enhanced; the friction coefficient is stable; the brake pad is simple in structure, low in brake noise, environment-friendly and pollution-free.

Owner:YANCHENG XINHAO MACHINERY

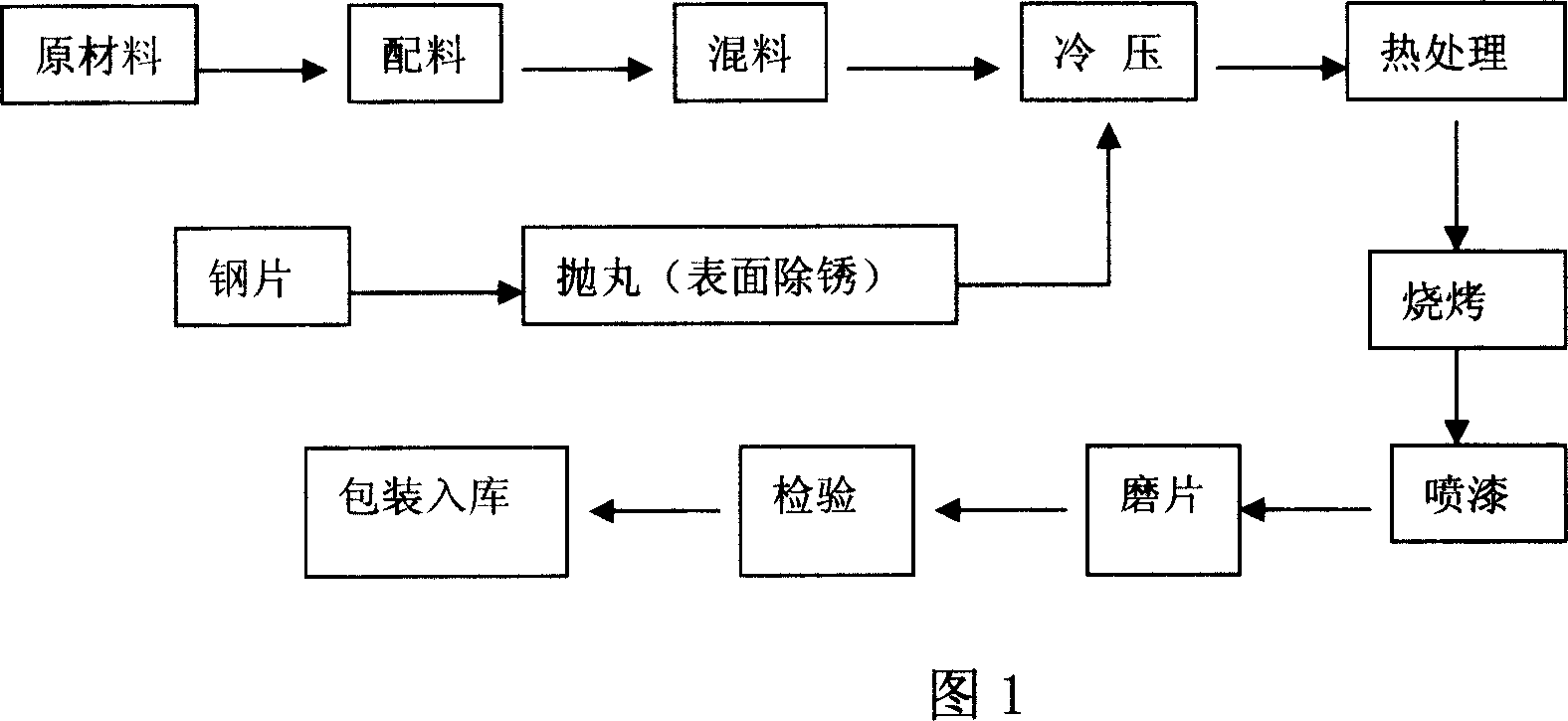

Disk type brake lining of cars and its preparing method

InactiveCN1431408AStable coefficient of frictionModerate thermal conductivityFriction liningFiberBrake lining

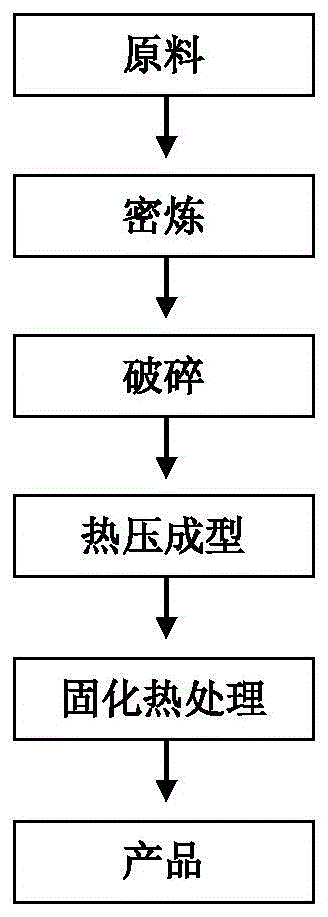

The percentage of each component weight for a vehicle disk brake gasket is: carbon fiber 0-16; steel fiber 5-25; organic fiber 0.5-8, mineral fiber 3-20; friction performance adjuster 37-60; COPNA resin 4-16; phenolic resin 0-8. Its preparation applies a dry technology to weigh, mix and stir matters in certain proportion then to be dried and moulded by chill-pressure, heat-pressure and after heatprocess mechanical process, polish, spraying paint, and packaging to become product with the advantage of no noise, no vibration, no scuffing the opposite side when braking.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

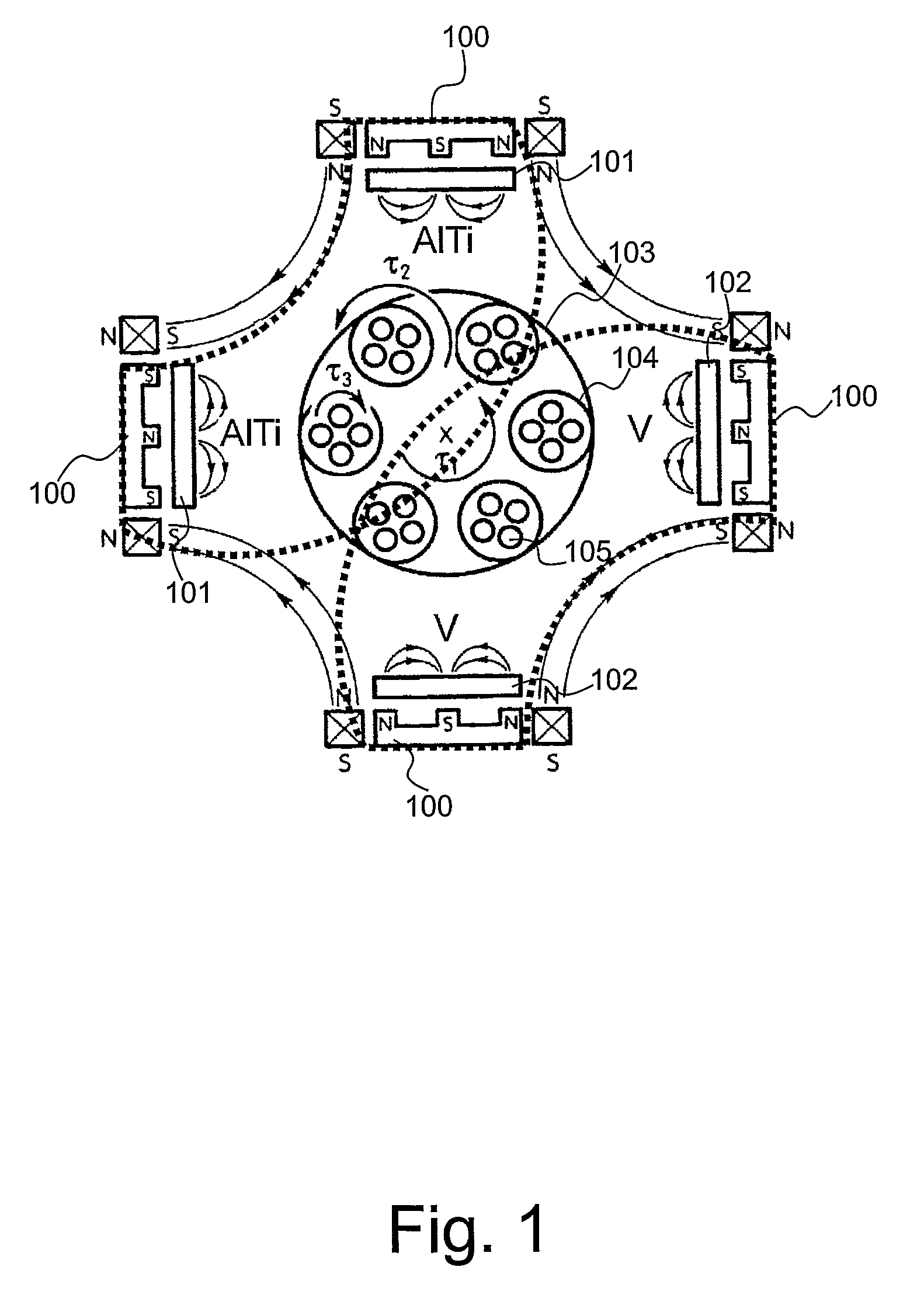

Pvd Coated Substrate

InactiveUS20080260478A1High hardnessReduce coefficient of frictionPigmenting treatmentVacuum evaporation coatingMetal alloyHardness

A PVD coating is disclosed, and in particular a nanoscale multilayer superlattice PVD coating comprising high hardness, a low friction coefficient and increased chemical inertness. The multilayer coating comprises a repeating bilayer represented by (VxMe(i-x))CyN(i-y) / (MezV(1-z))CyN(i-y) where 0.1≦x≦0.9; 0.01<y<0.99 and 0.1≦z≦0.9 and Me is a substantially pure metal or a metal alloy. The composition of the coating through the layers alternates from layer to layer according to a V-rich layer and a Me-rich layer modulated sequence. Vanadium is incorporated within the layer composition and has been found to act as a lubricating agent during sliding wear. Carbon, also incorporated within the coating, serves to further stabilise the friction coefficient thereby increasing the chemical inertness between cutting tool and workpiece material.

Owner:SHEFFIELD HALLAM UNIVERSITY

Asbestos-free small mount of metal disk brake lining used in vehicle and manufacture method therefor

The invention discloses a kind of disk brake staff facing used in cars with none asbestos and little metal and the production technology. Its friction material includes bed charge and plus material. The bed charge includes: mineral fiber 35~50%, barite powder 10~20%, heavy calcium carbonate 10-20%, the oil of cashew shell phenol-formaldehyde resin modified 20~30%, flour acrylonitrile butadiene rubber 2~15%. The match of plus material: kaflar fiber 0.1~3%, steel fiber 20~35%, copper fiber 1~5%, particle graphite 6~18%, oil coke blacking 5~15%, the oil of cashew shell friction-type mix 2~8%, sericite in powder 5~10%, antimony trisulfide 0.5~5%, heavy calcium carbonate 2-8%, barite powder 10~20%, flour acrylonitrile butadiene rubber 2~6%, the oil of cashew shell phenol-formaldehyde resin modified 6~15%. After made the bed charge and the plus material weight them in proportion then chill-pressing confectioning and heat pressing confectioning steps and so on and then rivet accessory at last treatment make up the products. It needs low abrasion and has no noise.

Owner:福建冠良汽车配件工业有限公司

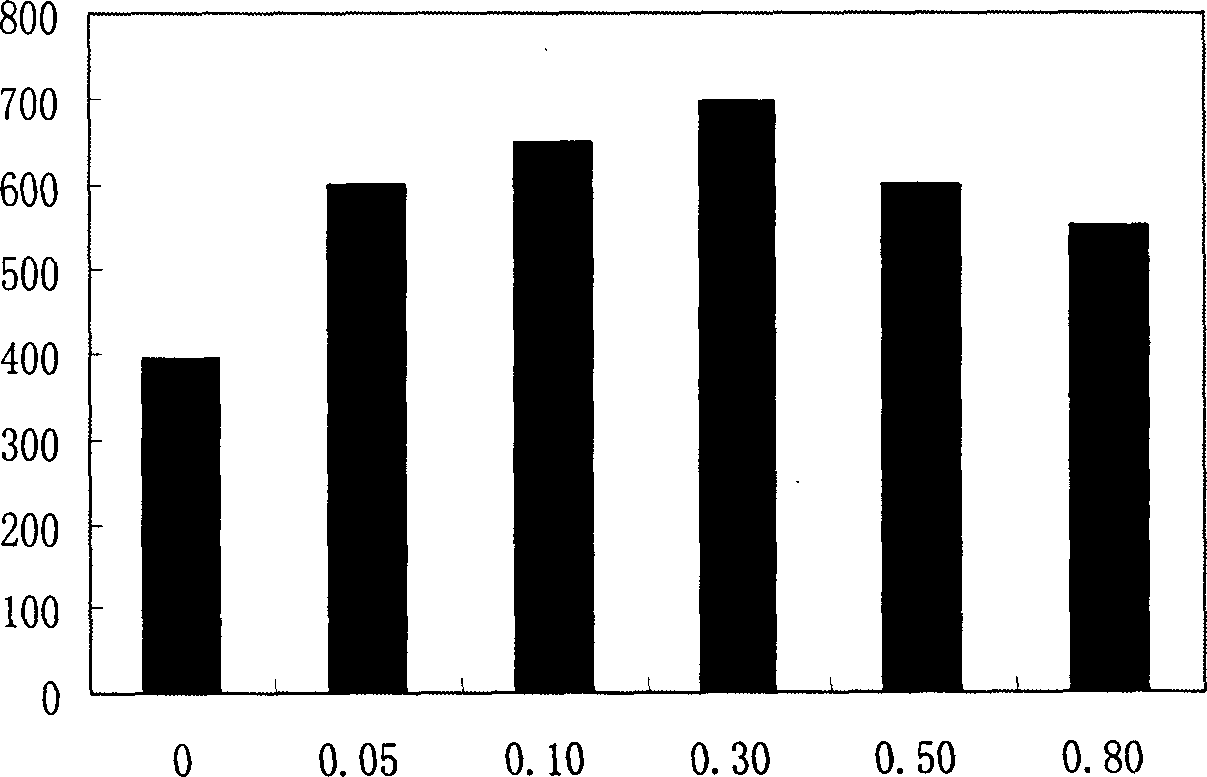

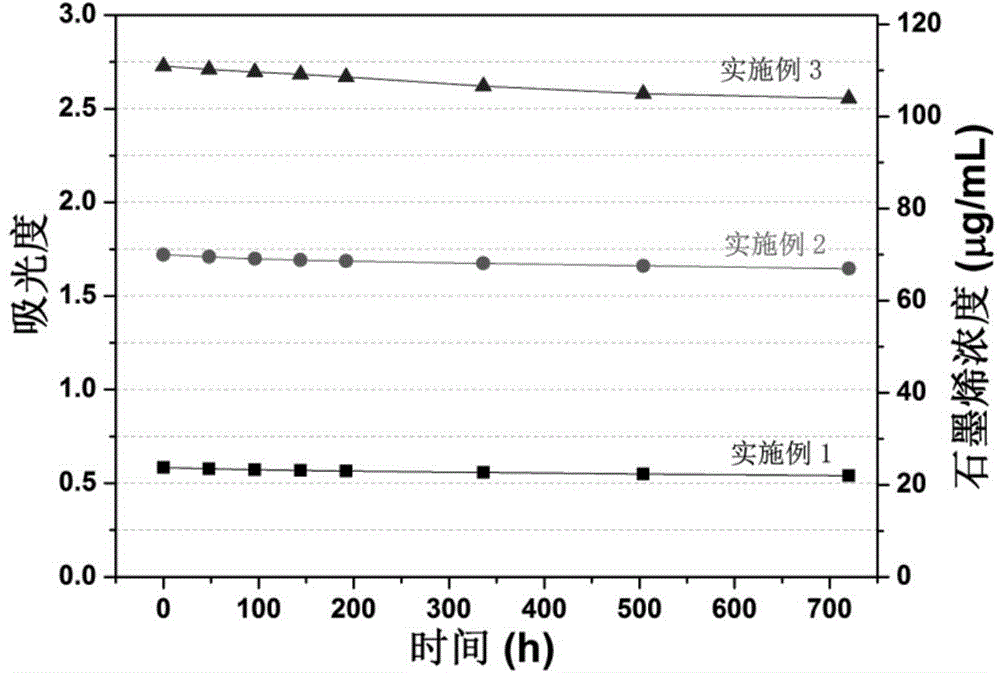

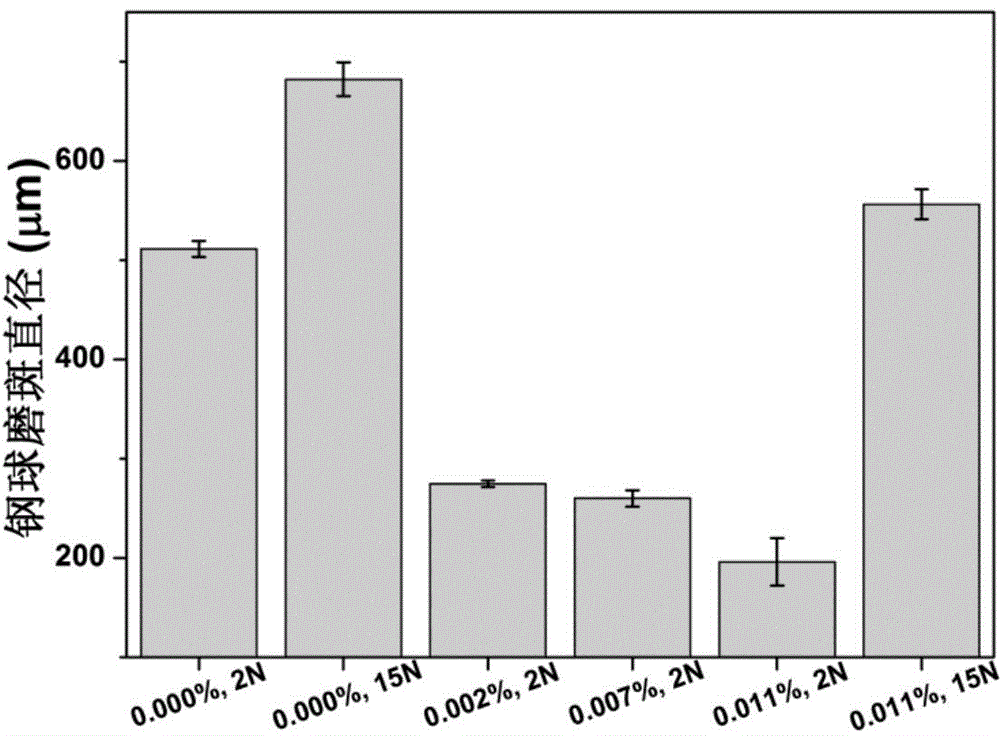

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

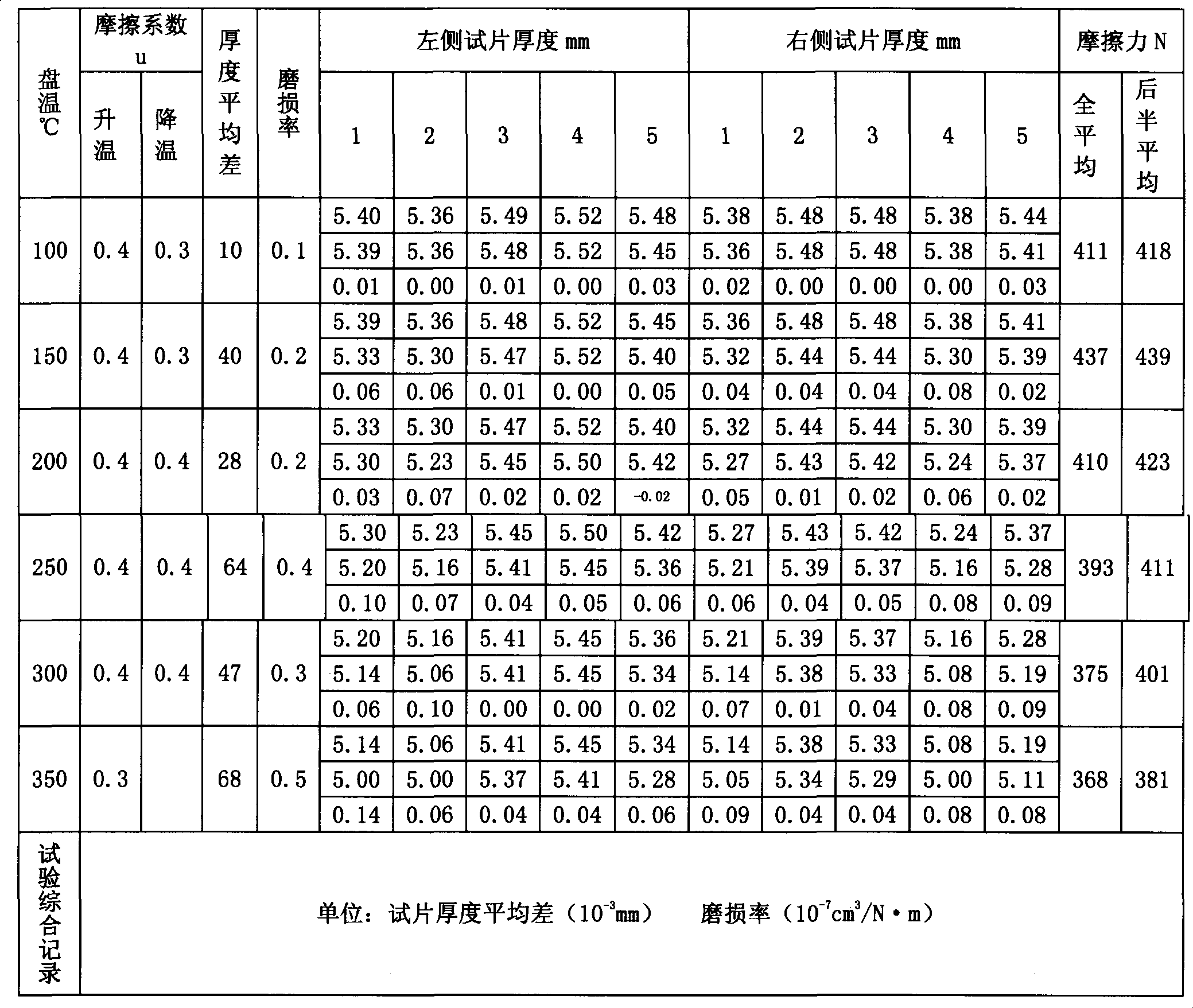

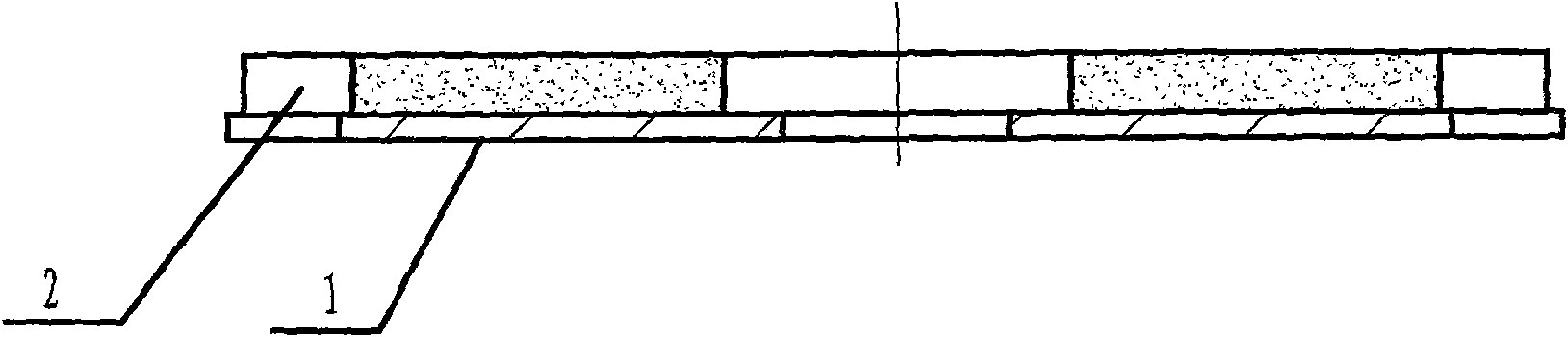

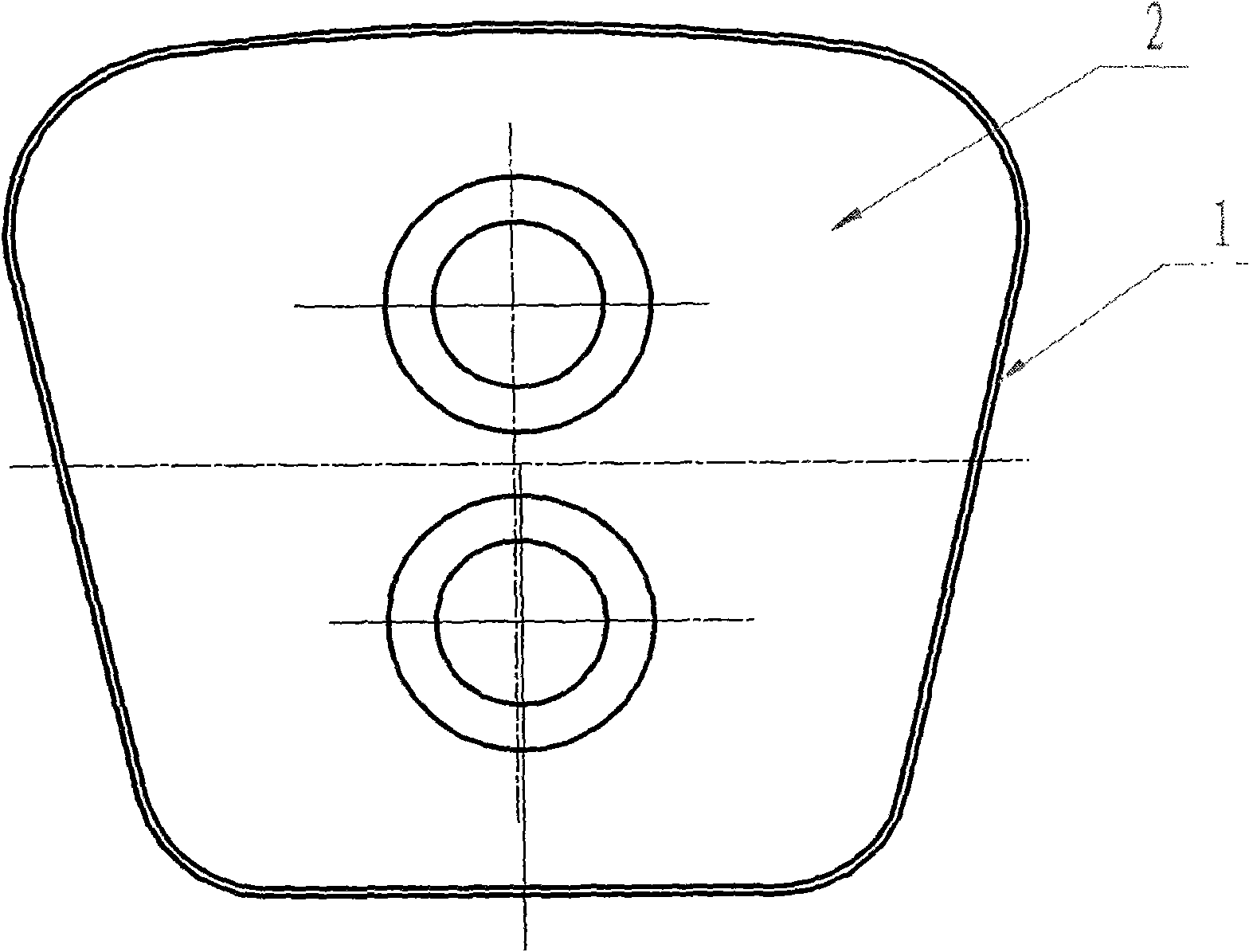

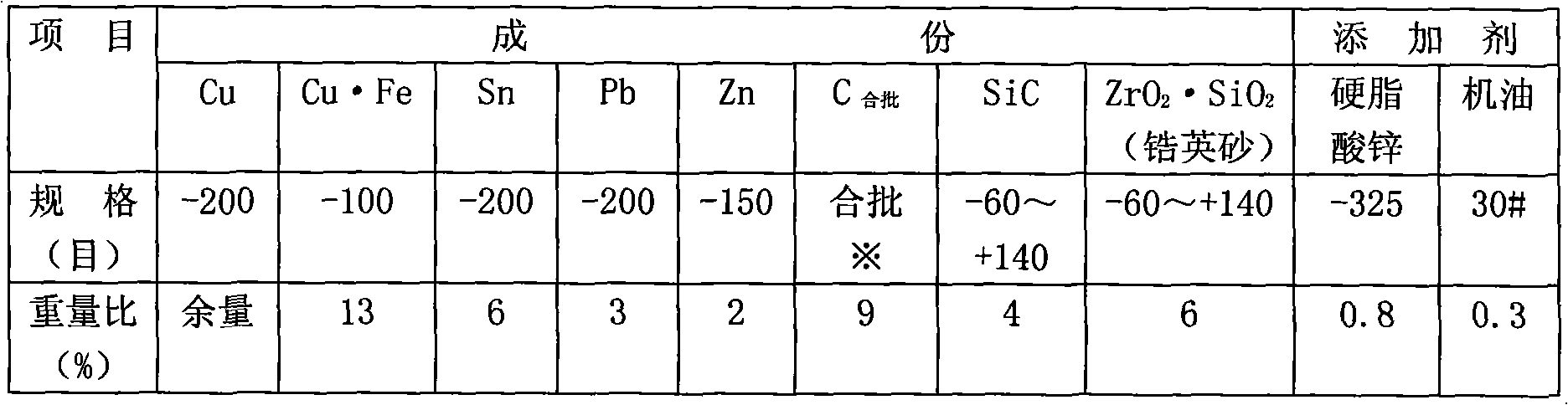

Copper-base powder metallurgy clutch friction body

InactiveCN101666364AGood clutch braking performanceStable coefficient of frictionFriction liningMetal formingMullite

The invention relates to a copper-base powder metallurgy clutch friction body which comprises a steel core plate, and is characterized in that: a copper-base powder metallurgy friction piece is arranged on the steel core plate in an overlapped way, and the copper-base powder metallurgy friction piece and the steel core plate are sintered into a whole under pressurization. The copper-base powder metallurgy friction piece comprises the following components by weight percent: 12-14% of copper-coated iron composite powder, 5-7% of Sn, 2-4% of Pb, 1-3% of Zn, 8-10% of blending graphite powder, 3-5%of SiC, 5-7% of ZrO2.SiO2 (zircon sand) ( or 5-7% of 3Al2O3.2SiO2 (mullite) ) and the balance of Cu; and additives comprise: zinc stearate accounting for 0.8% of the total content and machine oil accounting for 0.3% of the total content. The copper-base powder metallurgy clutch friction body has good clutch braking capability, soft and stable connection and arrangement, and is safe and reliable,not only solves the technical problems of producing the clutch friction body of a railway track locomotive, but also is used for producing and manufacturing clutch dry-type friction braking elements needed by large-scale overload automobiles, engineering metal forming machinery and the like.

Owner:重庆江洲粉末冶金科技有限公司

Friction material of brake sheet for rail transit vehicle brake system, and preparation method and application of friction material

InactiveCN102560183ALow costStable coefficient of frictionFriction liningRail transitMaterials science

The invention discloses a friction material of a brake sheet for a rail transit vehicle brake system, and a preparation method and application of the friction material. The friction material comprises the following components in parts by weight: 40 to 60 parts of Cu, 6 to 15 parts of Fe, 6 to 10 parts of Sn, 2 to 5 parts of Ni, 1 to 5 parts of Mn, 1 to 6 parts of Cr, 8 to 16 parts of C, 2 to 8 parts of Sic and 2 to 8 parts of Mo. The preparation method for the friction material comprises the following steps: mixing the components to obtain a mixture; placing the mixture into a die and pressing; and sintering the pressed mixture to obtain the friction material of the brake sheet for the rail transit vehicle brake system. The invention overcomes the defects in the prior art, has the advantages of stable friction coefficient and low wear rate, can safely brake rail transit vehicles, and can reduce the using cost and the maintenance cost of the rail transit vehicles.

Owner:MIN OF RAILWAY TRANSPORT BUREAU +2

PET (polyester) high-speed spinning finish oil

InactiveCN102115978AImprove the lubrication effectStable coefficient of frictionFibre typesPolyesterPolyethylene glycol

The invention discloses PET (polyester) high-speed spinning finish oil, which comprises the following components in parts by weight: 66-74 parts of smoothing agent, 10-14 parts of emulsifier, 4-8 parts of antistatic agent, 6-10 parts of tow collecting agent and 3-5 parts of additive, wherein the smoothing agent comprises phosphate, polyacrylic ester, and any one or a mixture of plant oil, animal oil, mineral oil and synthetic ester oil, the emulsifier comprises an alkyl ether type surfactant, castor oil polyoxyethylene ether and polyoxyethylene ether laurate, the antistatic agent comprises the cationic surfactant of an ammonium salt and octadecanol phosphate potassium salt, the tow collecting agent comprises polyethylene glycol laurate diester, propylene glycol and rubber pyrolysis oil, and the additive comprises talcum powder, fatty alcohol, fatty acid and acrylic acid. By means of the design disclosed by the invention, the frictional factor is more stable and the oil film strength and the oil flash point are both higher.

Owner:吴江市良燕纺织助剂厂

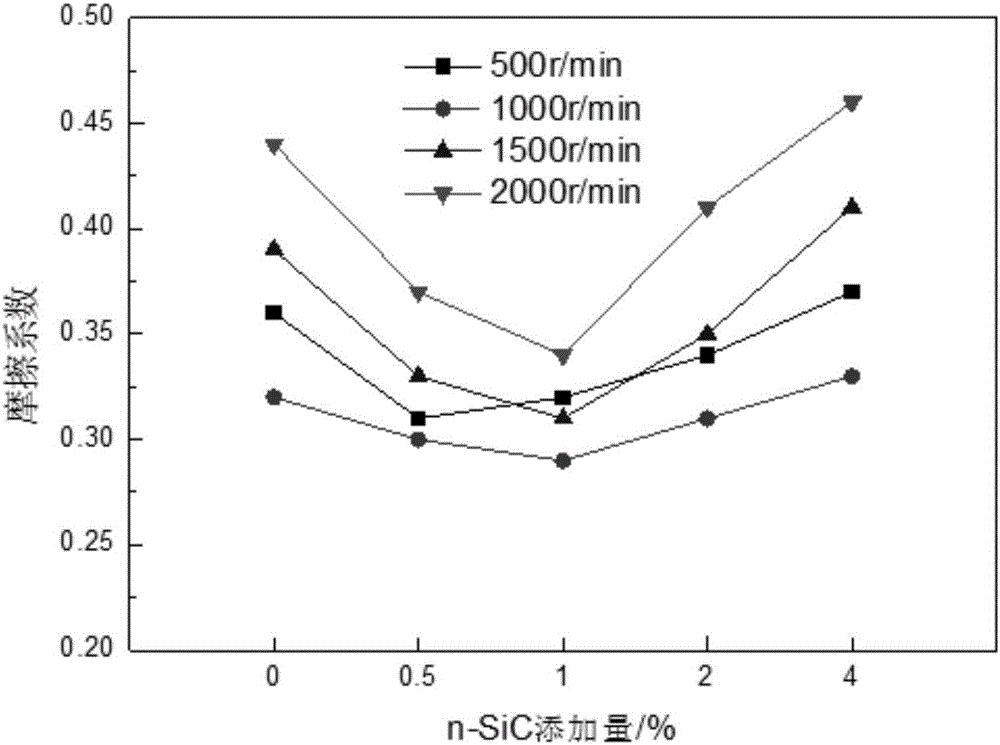

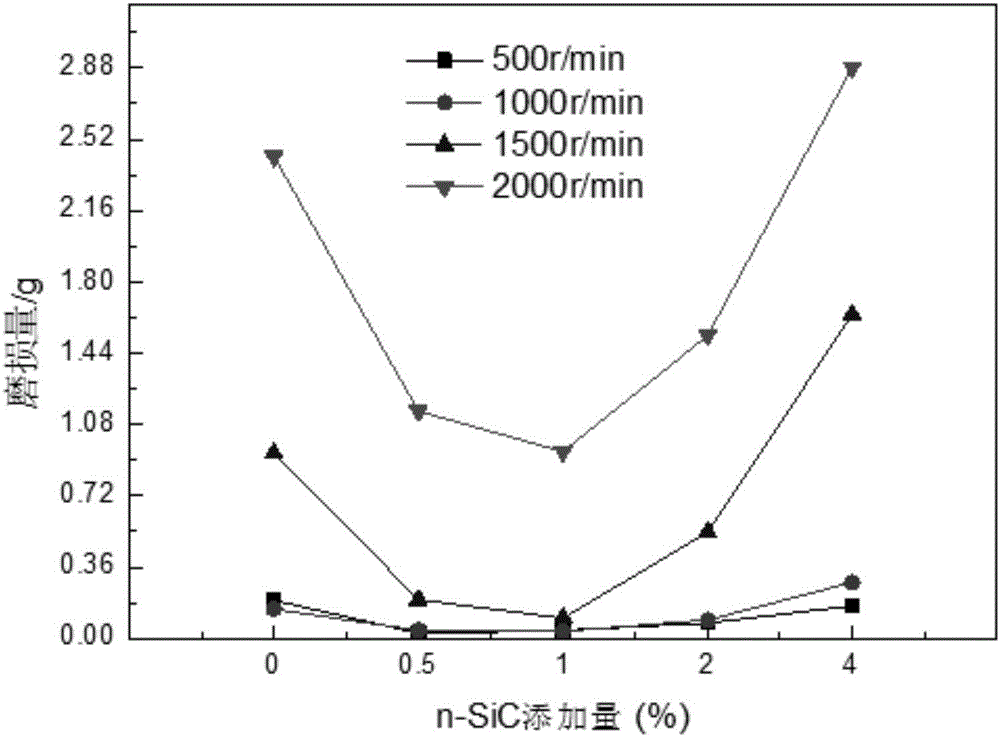

Copper-based powder metallurgy friction material and preparation method thereof

ActiveCN106702204AImprove thermal shock resistanceImprove high temperature friction performanceSlurrySilicon dioxide

The invention relates to a copper-based powder metallurgy friction material and a preparation method thereof, and relates to the technical field of materials. The copper-based powder metallurgy friction material is prepared by sintering raw materials, and comprises the following raw materials in percentage by mass: 6 to 8 percent of tin powder, 3 to 6 percent of iron powder, 4 to 7 percent of nickel powder, 4 to 7 percent of silicon dioxide, 5 to 6 percent of graphite powder, 0.5 to 4 percent of nano silicon carbide, and the balance of copper powder. The wear resistance of the copper-based powder metallurgy friction material is good. The preparation method comprises the following steps: mixing the nano silicon carbide and industrial ethyl alcohol; performing ultrasonic treatment to obtain first mixed slurry; adding the graphite powder, the tin powder, the iron powder, the nickel powder, the silicon carbide and the iron powder into the first mixed slurry; performing ultrasonic treatment and stirring; drying, and pressing the obtain mixed powder through cold pressing; sintering and moulding the obtained press blank; cooling. The strength and the wear resistance of the copper-based powder metallurgy friction material are effectively improved.

Owner:YANCHENG INST OF TECH

Dry type asbestos-free friction sheet

The invention relates to a dry-type friction plate without mineral cotton, comprising a metal frame of powder metallurgy and following compositions with weight, 1-5 iron oxide black, 5-10 cashew shell oil resin friction powder, 30-50 barium sulfate, 1-8 vermiculite, 5-10 molybdenum disulfide, 10-20 colloidal graphite, 15-20 binding agent, 20-30 ceramic fiber, 8-10 epoxide resin solidifying agent, and 5-6 antiaging agent, wherein the binding agent is constituted by 60%-70% formaldehyde-phenol resin and 30%-40% cashew shell oil resin friction powder. The preparation method of the friction plate comprises casting the metal frame by utilizing powder metallurgy, smearing the binding agent on the surface of the metal frame, preparing friction material with even mixture according to the composition, directly pressing the even mixing powder on the metal frame, and sintering 3-15 minutes with 200-220kg / mm2 of pressure in 180-210 DEG C of controlling temperature, and then heat pressing to shape.

Owner:杭州汉乐科新材料科技有限公司

Asbestos-free non-metal friction material and preparation method thereof

The present invention relates to friction material for automobile brake disc, and is especially one kind of friction material reinforced with the mixture of aramid fiber and inorganic mineral fiber and its preparation process. The new non-metal friction material without asbestos consists of aramid fiber, LAPINUS inorganic mineral fiber, phenolic resin, butadiene-acrylonitrile rubber powder, inorganic stuffing and friction regulator. The organic-inorganic composite material reinforced friction material has raised comprehensive performance, stable friction performance and friction coefficient variation with temperature within 10 %. In addition, the present invention also provides high temperature fast curing process to ensure the heat resisting performance of the product and lowered power consumption.

Owner:浙江万赛汽车零部件股份有限公司

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

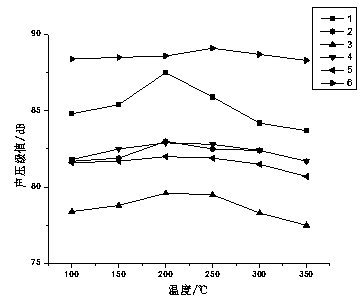

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

Process for preparing modified non-crystal carbon film by metal iron implantation

InactiveCN1363715AImprove wear resistanceNo flaking was foundVacuum evaporation coatingSputtering coatingCarbon filmGas phase

A metal iron implantation process for preparing modified non-crystal carbon film features that the graphite and metal are used to prepare a modified and physical gas-phase deposited layer by CD magnetically controlled sputter and ion implantation. Its advantages are high antiwear and lubricating performance and simple preparing process.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

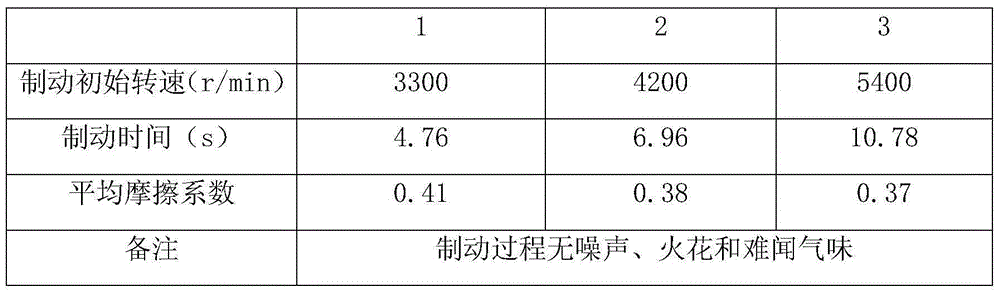

Low copper-containing friction material composition used as brake pad

A low copper-containing friction material composition used for brake pad is provided, which consists of the following components by weight parts: 4˜6 parts of aramid fiber, 2˜2.5 parts of tyre powder, 5˜6 parts of heavy magnesia, 5˜6 parts of red vermiculite, 8˜10 parts of ceramic fiber, 3.5˜5 parts of magnetite, 7˜8 parts of boron-containing phenolic resin, 15˜17 parts of calcium sulfate crystal whisker, 16-18 parts of potassium titanate, 15˜17 parts of barite, 5.5˜7 parts of flake graphite, 6˜8 parts of friction powder of cashew nut oil, 6˜8 parts of calcined petroleum coke, 1.5˜2 parts of boron nitride, 5˜7 parts of flake aluminum powder, 0.4˜0.5 parts of pure copper fiber, 0.4˜0.6 parts of black silicon carbide. Said friction material composition is highly environmental friendly and has low content of heavy metal, wherein the content of copper is lower than 0.5%, and an excellent friction layer and transfer membrane can be formed when using said friction material composition. Said friction material composition has a satisfactory high temperature and thermal decay resistant performance, long service life, good abrasion resistance and stable friction coefficient.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Method for preparing brake block by calcium sulfate crystal whisker

InactiveCN101177601AEasy to compressImproved high-temperature heat-fading propertiesOther chemical processesFriction liningAdhesiveAramid

The invention relates to a method of using calcium sulfate whisker in the friction material field to prepare a brake block. The technical proposal of the invention consists of the following materials by weight: 5-18 portions of adhesive which is produced by employing modified phenolic resin; 20-40 portions of strengthening materials which are mixed by one or several of calcium sulfate whisker and one of aramid fiber, steel fiber, ceramic fiber and mineral fiber and glass fiber; 1-15 portions of grinding agent which is compounded by one or several of aluminum oxide , ferric oxide and magnesium oxide; 5-15 portions of lubricant which is compounded by one or several graphite, molybdenum disulfide and mica; and 10-30 portions of fillers which are compounded by one or several barium sulfate, potassium titanate and vermiculite powder. The brake block prepared by the method is able to lower the thermal fading of organics caused by thermal decomposition under high temperature, and has stable friction coefficient; when in use, the brake block has comfortable brake, being quiet, small abrasion and more than 70,000 kilometers of service life.

Owner:信义集团公司

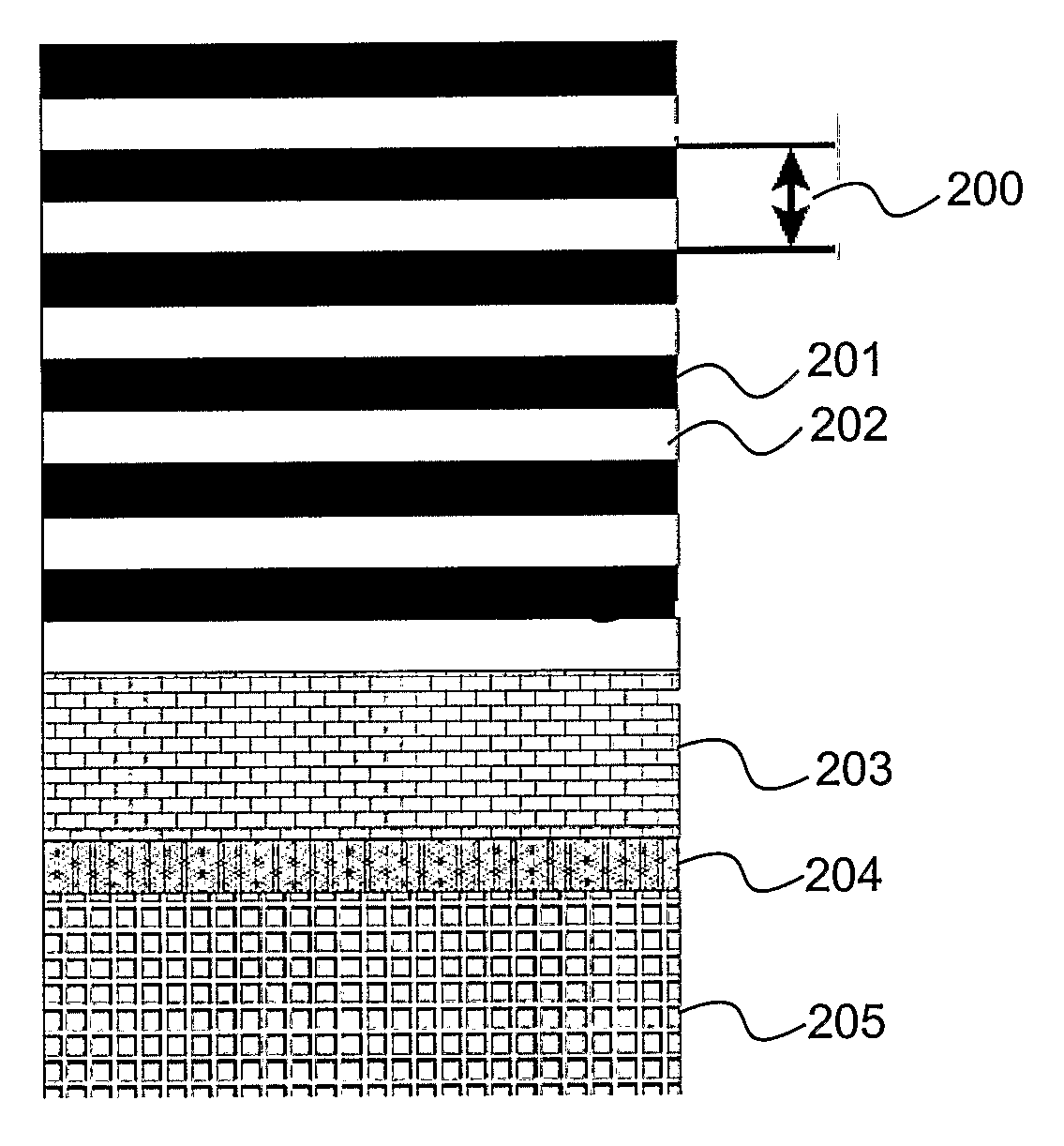

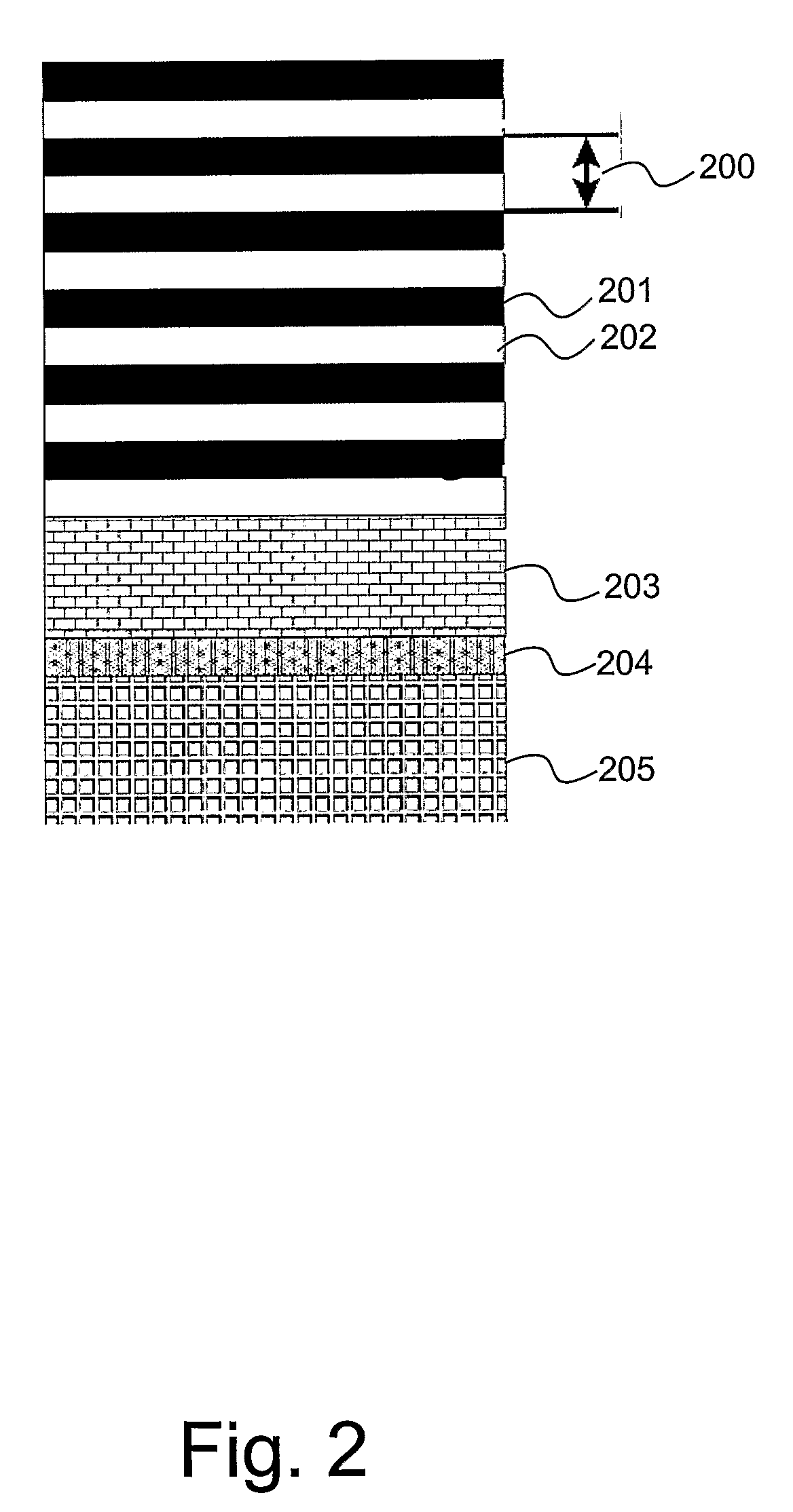

Novel composite wear-resistant material, and preparation method and application thereof

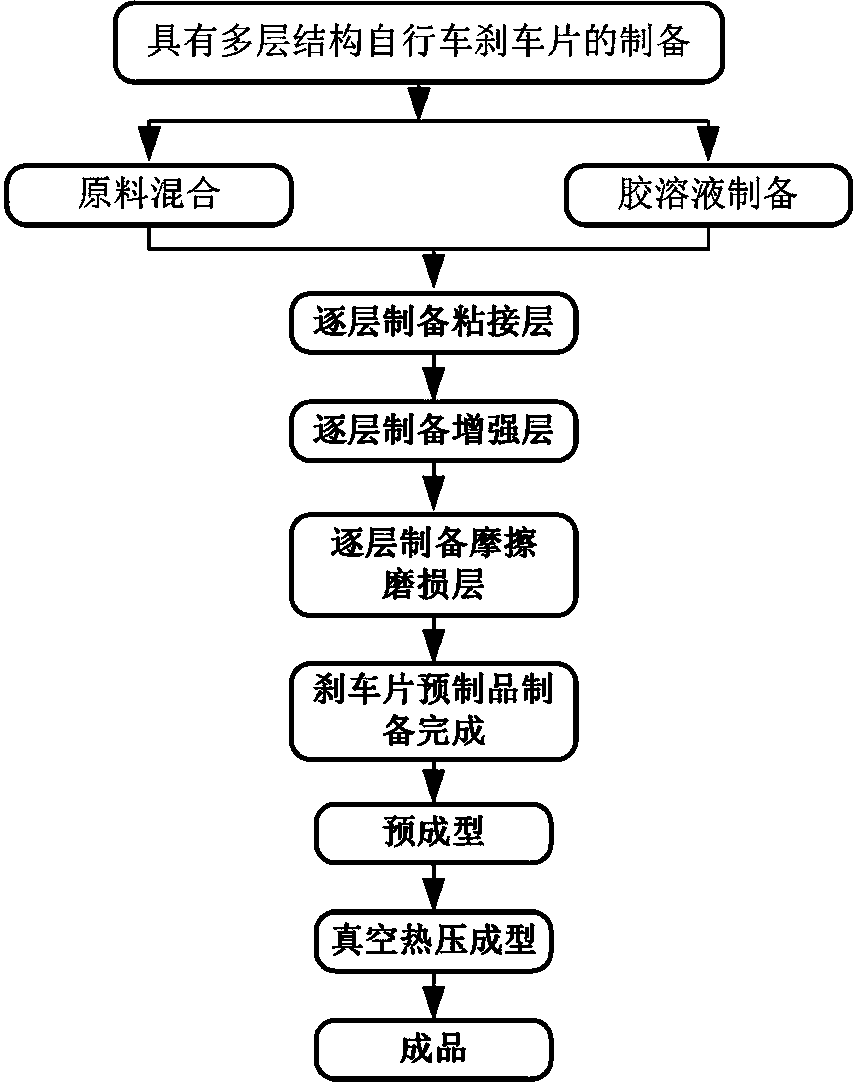

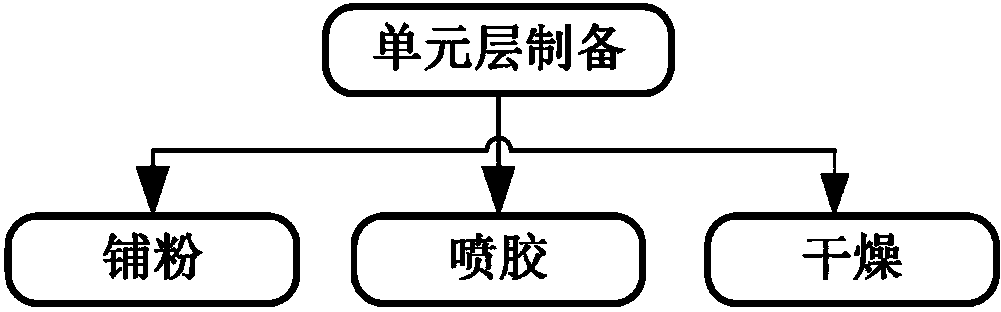

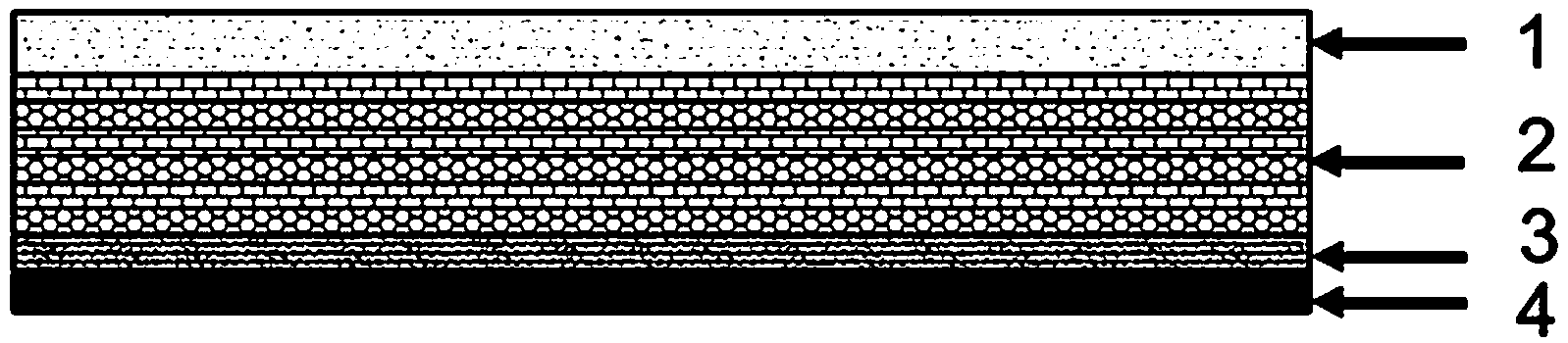

The invention discloses a composite wear-resistant material and a preparation method thereof. The composite wear-resistant material is formed by coating a plurality of layers, namely an adhesive layer, a reinforcing layer and a friction and wear layer in sequence from inside to outside, and curing and molding under vacuum hot-pressing conditions, wherein the adhesive layer, the reinforcing layer or the friction and wear layer consists of a plurality of unit layers of the adhesive layer, unit layers of the reinforcing layer or unit layers of the friction and wear layer with the thickness of 0.10 to 0.50 mm; the material components and the mass fraction of the adhesive layer, the reinforcing layer and the friction and wear layer can be accurately controlled; the preparation process of each unit layer comprises the process links of paving powder, spraying glue, drying and the like; fiber mesh prefabricated pieces are required to be paved when the unit layers of the reinforcing layer is prepared. The novel composite wear-resistant material disclosed by the invention is applied to a bicycle brake pad, and has stable friction and wear performance, high mechanical properties and high adhesive force, so that the comprehensive performance of the overall brake pad is guaranteed.

Owner:CHINA THREE GORGES UNIV +1

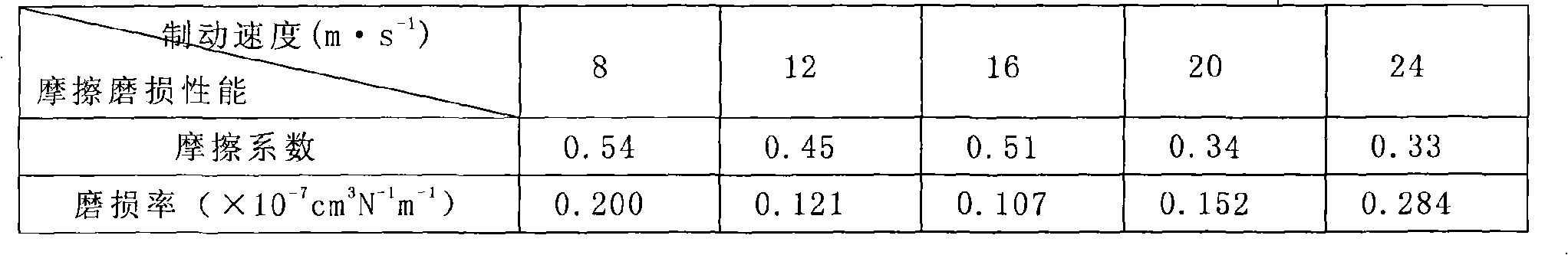

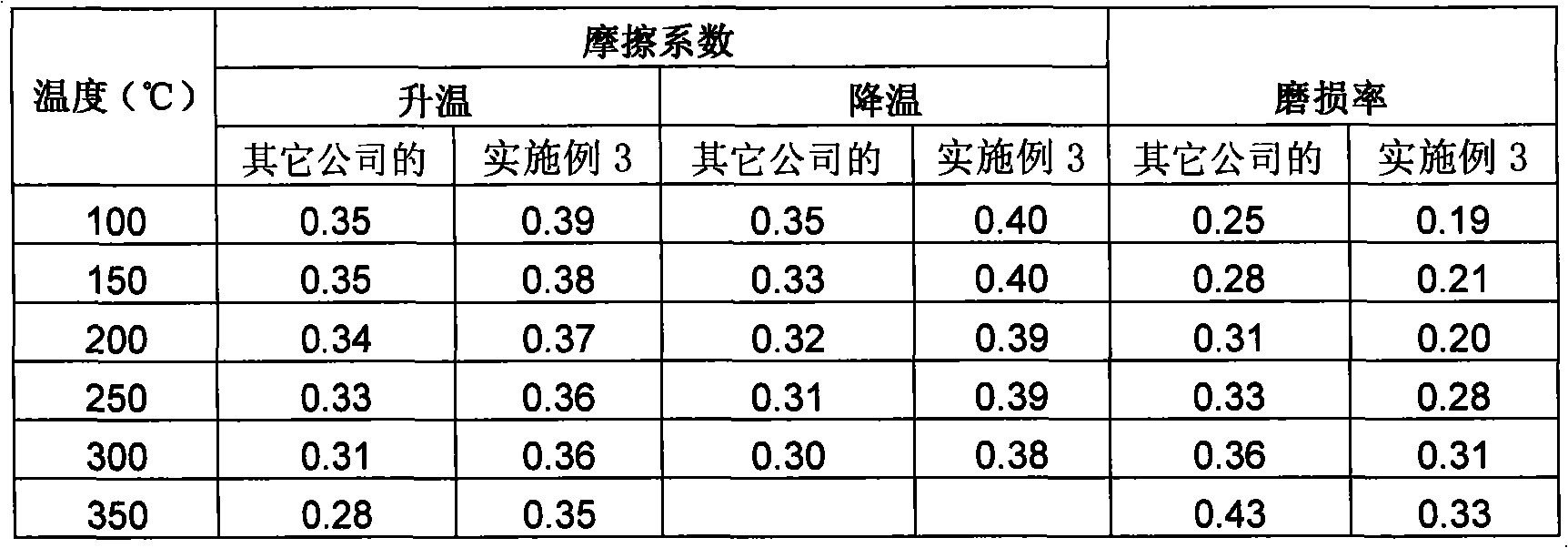

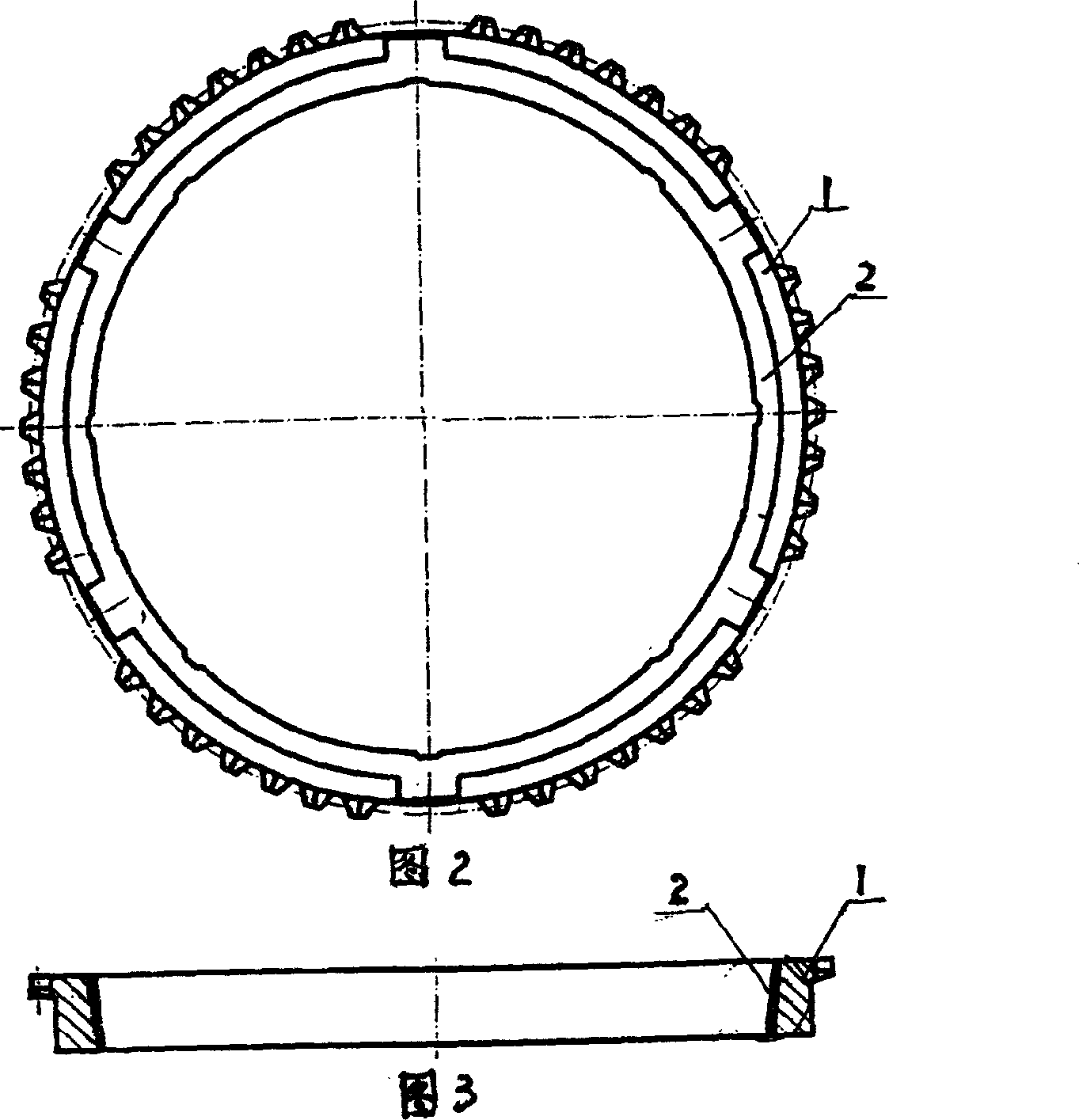

Automobile steel-made synchronizer ring gear carbon fiber friction material and use

InactiveCN1580100AReduce manufacturing costStable coefficient of frictionMolybdenum disulfidePhenol formaldehyde resin

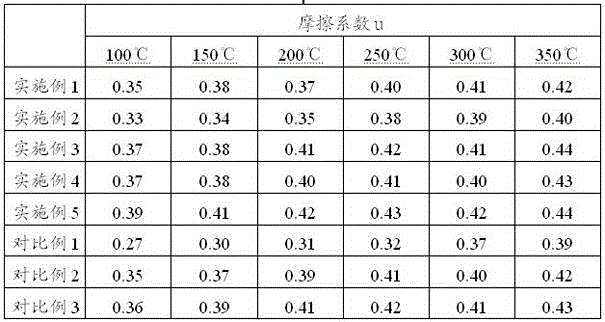

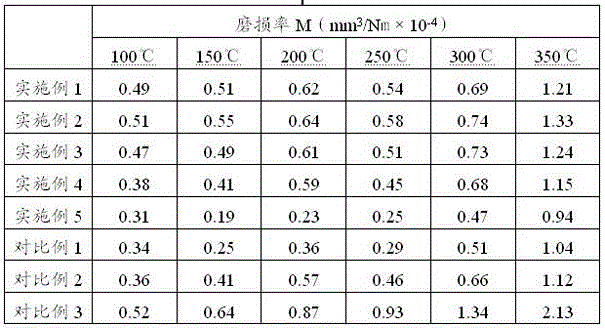

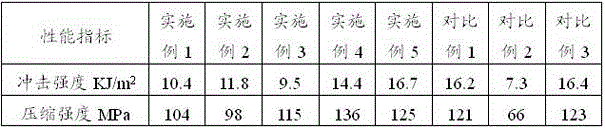

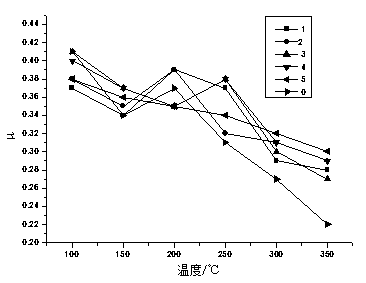

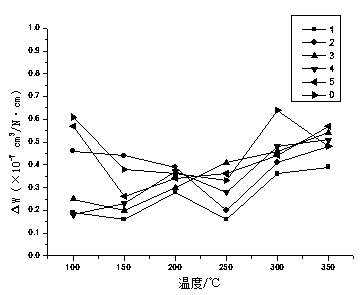

This invention provides a kind of friction material on steel synchronizer of automobiles and its method of application. This friction material chooses acrylonitrile carbon fiber as the reinforcing material and the cashew nut shell oil and melamine phenol-formaldehyde resin modified as the bond and is composed of many frictional-properties-adjusting agents, such as dilatant iron dust, brass powder, synthetic graphite powder, zinc stearate, precipitated barium sulfate and molybdenum disulfide. This kind of friction material is featured by stable friction system, low wear rate and good temperature resistance. Between 100deg.C and 250deg.C, the coefficient of wear is between 0.25 and 0.38 and the wear rate is between 0.04cm3 / N.m and 0.47X10 to the power -7 cm3 / N.m. Compared with the denticulate ring technics of steel synchronizer, it is more simple, has a lower abrasion to the fittings, improves the frictional properties of the denticulate ring of the synchronizer and reduces the production cost.

Owner:WUHAN UNIV OF TECH +1

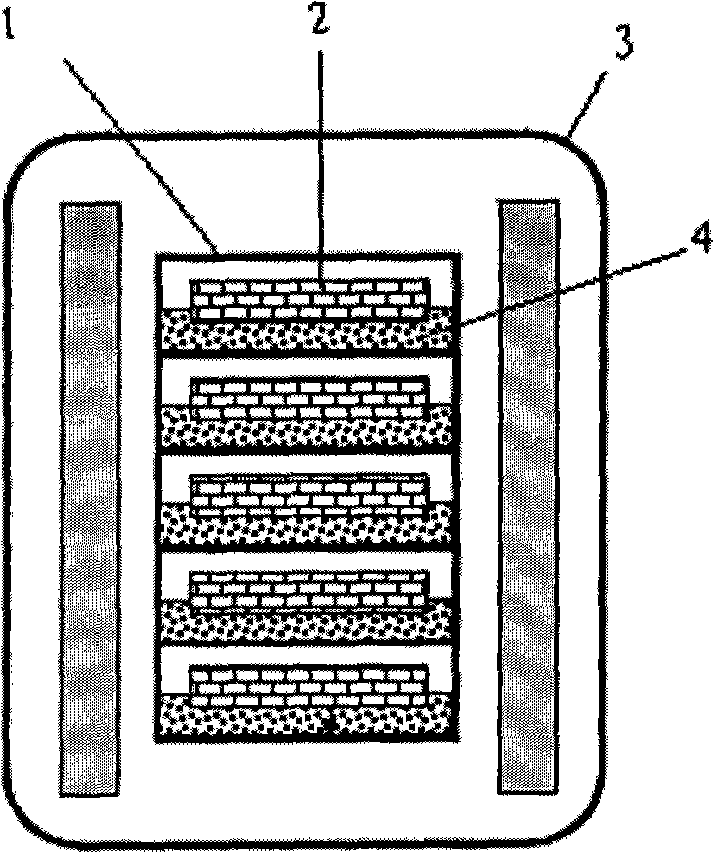

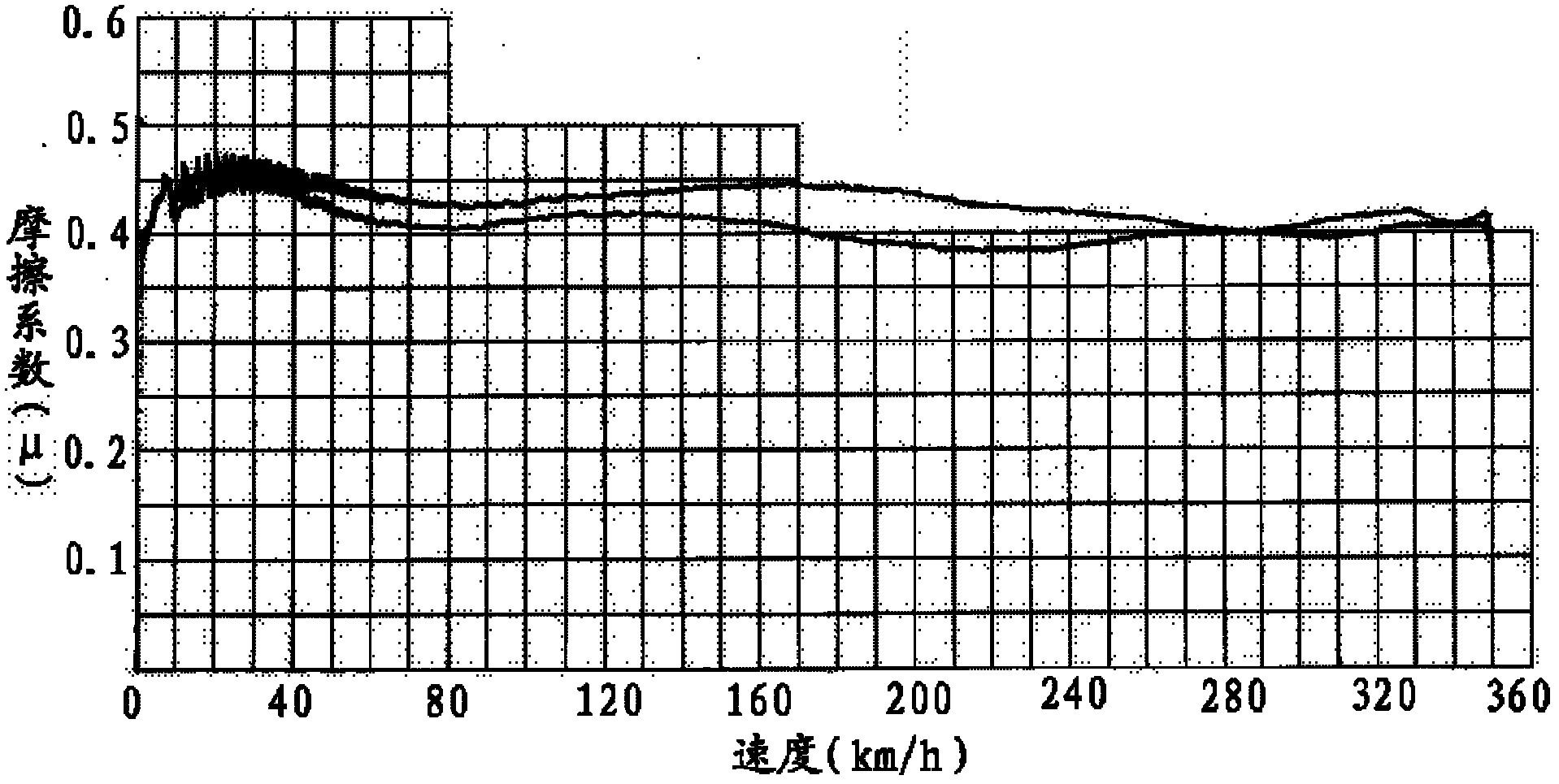

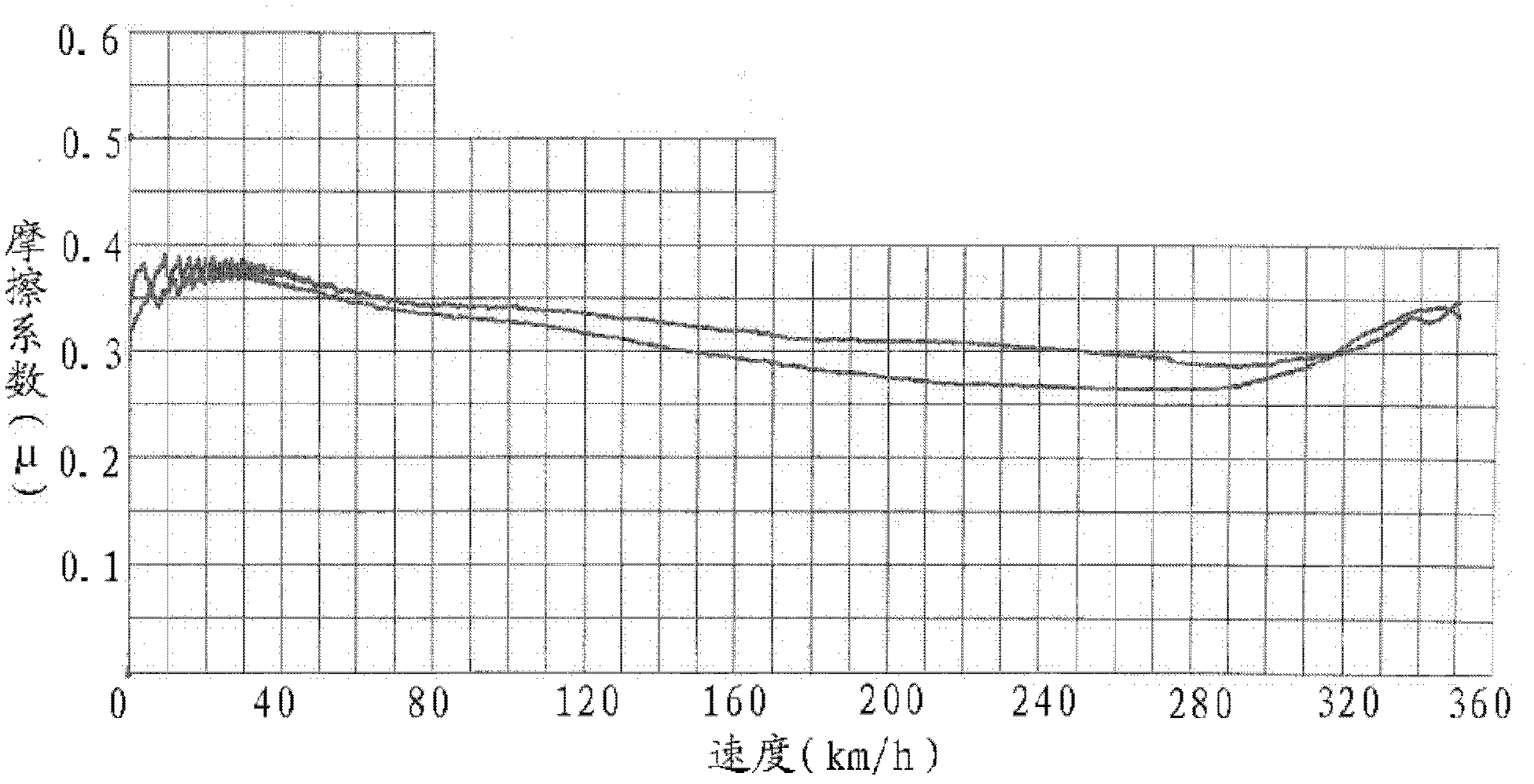

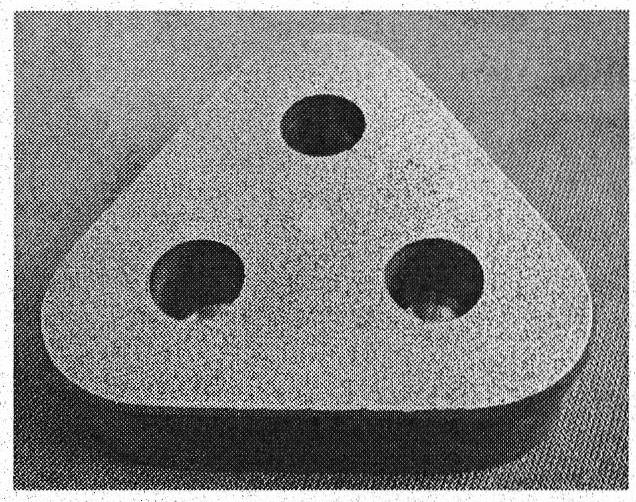

Ceramic/metallic double continuous phase composite material brake pad and preparation method thereof

The invention relates to the field of friction materials for braking of high-speed trains, in particular to a ceramic / metallic double continuous phase composite material brake pad and a preparation method thereof. The brake pad comprises the following components in percentage by weight: 15 to 40 percent of foam silicon carbide ceramics, 10 to 30 percent of friction element and 75 to 30 percent ofmetal. The method comprises the following steps of: preparing the silicon carbide foam ceramics having a three-dimensional network structure by employing a technology combining polymer pyrolysis withcontrollable infiltration reaction sintering; selecting a proper friction element and filling in mesh holes of the foam ceramics; and injecting melt copper alloy into a framework of the foam ceramicsby utilizing an extrusion casting method to obtain the ceramic / metallic double continuous phase composite material brake pad. The composite material brake pad can be paired with a 28CrMoV forged steel brake disc, has the characteristics of proper and stable friction coefficient, low wear rate, high heat resistance, high thermal or mechanical damage resistance, good process performance, low manufacturing cost, long service life and the like, completely meets the brake requirement of a high-speed train at a speed of 200 to 300km / h, and has good competitive advantage on the brake requirement of a high-speed train at the speed of 350km / h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Resin-based yawing brake pad for wind-generated generator and preparation method thereof

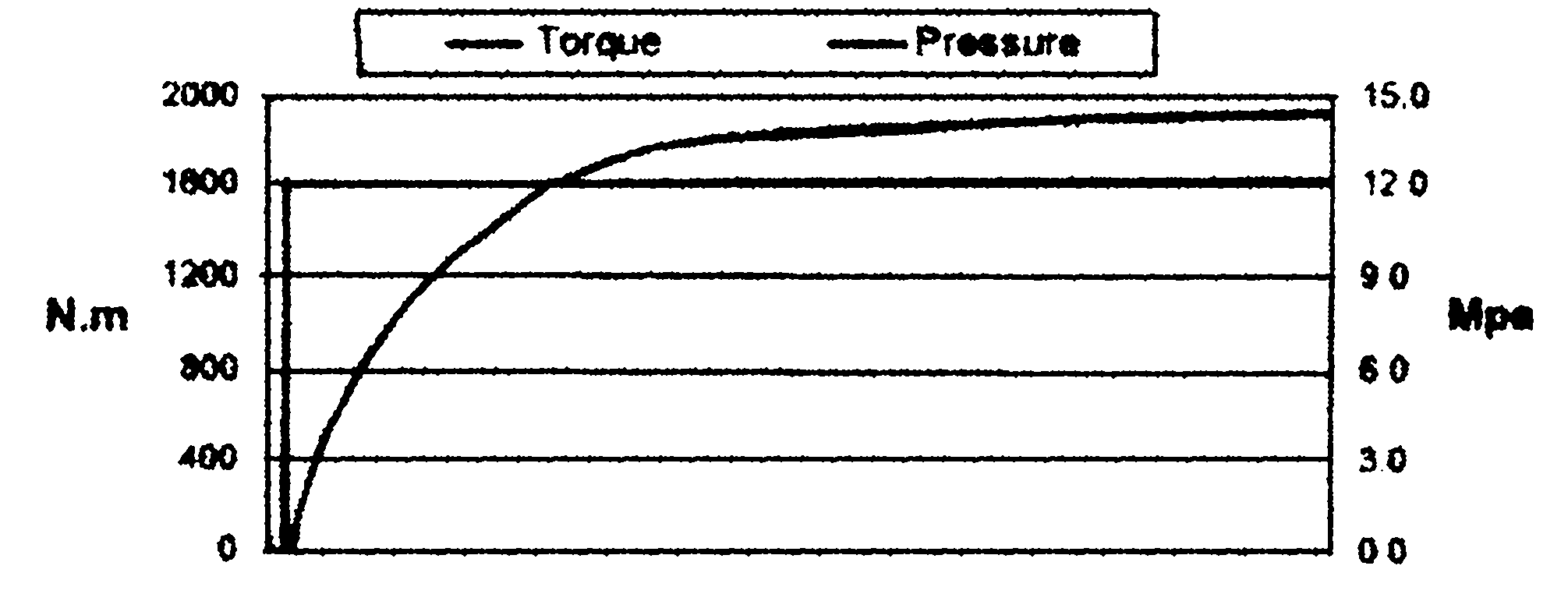

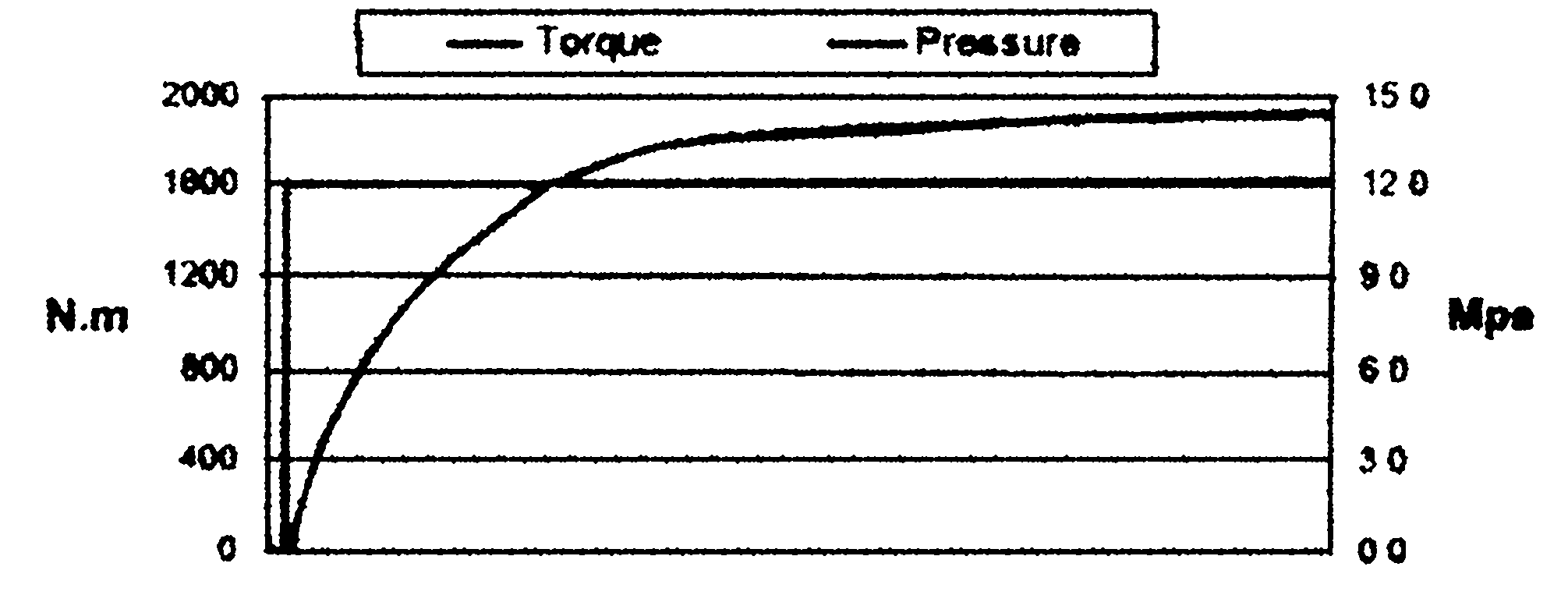

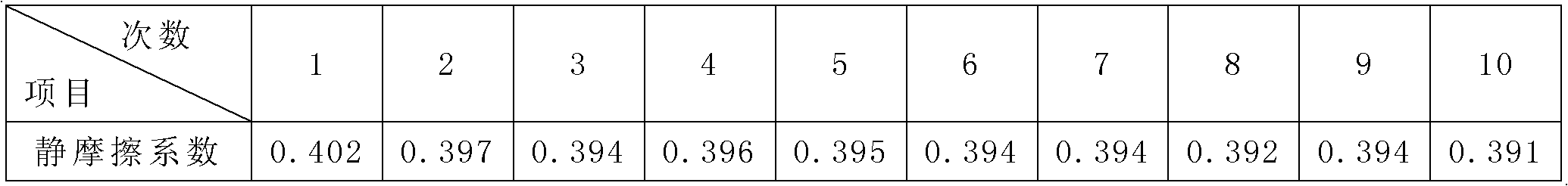

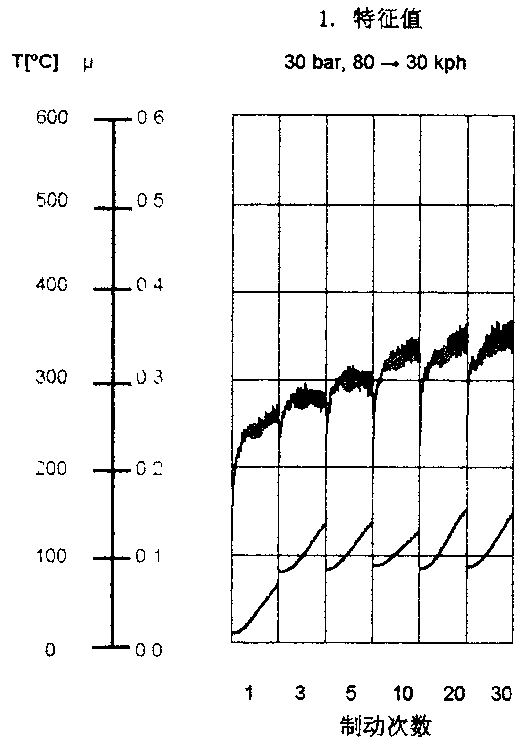

InactiveCN101956775AMeet the requirements of yaw low speed brakingHigh coefficient of static frictionFriction liningLow speedAluminum silicate

The invention discloses a resin-based yawing brake pad for a wind-generated generator and a preparation method thereof. The resin-based yawing brake pad comprises phenolic resin, nitrile butadiene rubber, organic friction powder, chopped steel fiber, red copper fiber, aramid fiber, aluminum silicate / KFK fiber, graphite, barite and the like. The preparation method comprises the following steps of: weighing various components according to the formula; mixing the components by a plow harrow type blender mixer at high speed; ensuring that each fiber is fully dispersed uniformly; hot pressing forming at the temperature of 160-200DEG C; carrying out heat treatment in a heat treatment tank; cooling to the room temperature along the temperature of the furnace; and finally, machining to obtain the resin-based yawing brake pad. Compared with the general powder metallurgy brake pad, the yawing brake pad has the advantages of proper static friction coefficient, stable friction coefficient, low brake noise, smaller antithesis wear and lower manufacturing cost and can fully meet the yawing low-speed brake of the wind-generated generator.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Environmental-protection high-speed car brake sheet and warm-pressing process of brake sheet

ActiveCN102141101ASmall recessionShorter braking distanceFriction liningVulcanizationMaterials science

The invention discloses an environmental-protection high-speed car brake sheet and a warm-pressing process of the brake sheet. A frictional material of the environmental-protection high-speed car brake sheet comprises the following components in parts by weight: 6-8 parts of phenolic resins, 2 parts of acrylonitrile rubber powder, 1-3 parts of Kevlar fibers, 5-7 parts of stannic sulfide, 5-7 parts of artificial graphite, 2 parts of polytetrafluoroethylene, 18-20 parts of steel fibers, 4-6 parts of red copper fibers, 2 parts of aluminum oxide, 3-5 parts of zirconium silicate, 5-7 parts of iron oxide black, 7-9 parts of titanium white, 6-8 parts of mineral fibers, 7-9 parts of white vermiculite, 8-10 parts of grammite and 5-9 parts of barium sulfate. The warm-pressing process of the environmental-protection high-speed car brake sheet comprises the steps of material burdening, material mixing, warm-pressing formation, thermal treatment, grinding and spraying. The high-speed car brake sheet has the advantages of safe and comfortable brake, no noise, low high-temperature and high-speed recession, stable frictional factor, environmental protection, long service life and the like; and the warm-pressing process of the environmental-protection high-speed car brake sheet has the advantages of high rate of finished products, high mechanical degree, high production efficiency and low energy consumption.

Owner:YANTAI WINHERE AUTO PART MFG

Low-noise heat-fade-resistant resin-base friction material

InactiveCN104109342AStable coefficient of frictionReduce noiseOther chemical processesLow noisePolymer science

The invention discloses a l-noise heat-fade-resistant resin-base friction material which is prepared from the following components in percentage by mass: 10-15% of nano aluminum oxide modified phenol aldehyde resin, 3-6% of aramid fiber pulp, 12-18% of mineral fiber, 5-7% of graphite, 3-5% of antimony trisulfide, 5-7% of coke, 0.5-1.5% of aluminum oxide, 3-5% of ferric oxide, 5-7% of cashew oil friction powder, 3-9% of expanded vermiculite, 2-6% of kieselguhr, 3-9% of nitrile-butadiene rubber and the balance of barium sulfate. The material has the advantages of appropriate and stable friction factor, favorable heat fade resistance, low abrasion ratio, low braking noise, high plastic deformation resistance, high shock resistance and the like, and conforms to the operating requirements.

Owner:YANCHENG INST OF TECH

Copper-free friction material composition for brake pads

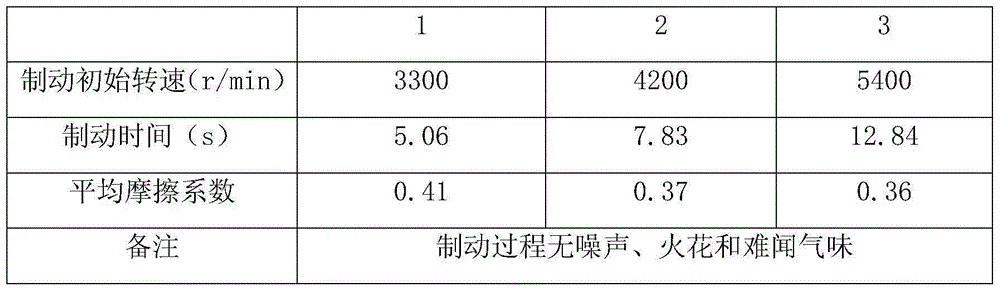

InactiveUS20140357758A1Promote environmental protectionSatisfactory high-temperature and thermal decay resistant performanceFriction liningActuatorsPotassiumThermal decay

A copper-free friction material composition for brake pads consists of the following components by weight parts: 0.43 parts of aramid fiber, 1.9 parts of tyre powder, 6 parts of heavy magnesia, 2.55 parts of calcined petroleum coke, 8 parts of ceramic fiber, 6.5 parts of phenolic resin, 14 parts of aluminium silicate fiber, 22 parts of potassium hexatitanate crystal whisker, 25 parts of barite powder, 5 parts of granular graphite, 2 parts of antimony sulfide, 2.8 parts of friction powder of cashew nut oil, 0.9 part of boron nitride, 5 parts of flake aluminum powder, and 0.6 parts of tantalum carbide. The friction material of the present invention is environment-friendly material and contains little heavy metals; hence the friction material is highly environment friendly. And trials show that it has satisfactory high temperature and thermal decay resistant performance, long service life, good abrasion resistance and stable friction coefficient. With the friction material of the present invention used, the brake pad of vehicles is sensitive and stable during braking, produces no screech, is comfortable and has no damage on coupling plate.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com