Low-noise heat-fade-resistant resin-base friction material

A technology of anti-thermal decay and friction materials, which is applied in the field of friction materials, can solve the problems of friction material surface temperature rise, friction coefficient drop, and accidents, and achieve low wear resistance, low braking noise, and strong resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

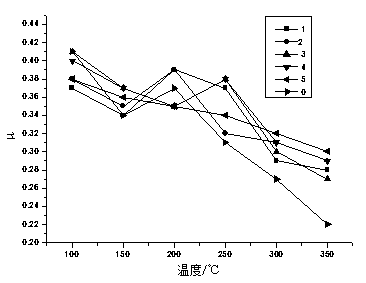

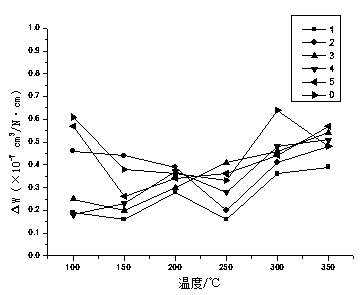

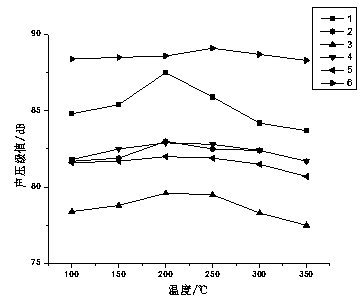

Image

Examples

Embodiment 1

[0020] A low-noise, heat-fading resistant resin-based friction material, including the following components by mass percentage: 10% nano-alumina modified phenolic resin, 3% aramid pulp, 8% glass fiber, and 10% potassium titanate whisker , graphite 6%, antimony trisulfide 4%, coke 6%, alumina 1%, iron oxide 4%, cashew oil friction powder 6%, expanded vermiculite 3%, diatomite 2%, nitrile rubber 3% , and the balance is barium sulfate; the preparation method of the material is as follows: put the above-mentioned mixed components into the mixer, fully stir, and put them into the mold after uniform mixing; preheat the die to 150-160°C, Prepare for pressing; the pressing process conditions are: pressing temperature 160°C, pressing pressure 30 Mpa, degassing once or twice after 30 s, heat preservation and pressure holding time 60 s / mm; put the pressed product sample in an oven, the temperature Raise the temperature to 130°C and keep it for 1 hour; raise the temperature to 165°C and k...

Embodiment 2

[0022] A low-noise, heat-fading resistant resin-based friction material, including the following components by mass percentage: 10% nano-alumina modified phenolic resin, 3% aramid pulp, 8% glass fiber, and 10% potassium titanate whisker , graphite 6%, antimony trisulfide 4%, coke 6%, alumina 1%, iron oxide 4%, cashew oil friction powder 6%, expanded vermiculite 6%, diatomaceous earth 6%, nitrile rubber 3% , the balance being barium sulfate; the preparation method of the material is as described in Example 1. (Recipe 2)

Embodiment 3

[0024] A low-noise, heat-fading resistant resin-based friction material, including the following components by mass percentage: 10% nano-alumina modified phenolic resin, 3% aramid pulp, 8% glass fiber, and 10% potassium titanate whisker , graphite 6%, antimony trisulfide 4%, coke 6%, alumina 1%, iron oxide 4%, cashew oil friction powder 6%, expanded vermiculite 9%, diatomaceous earth 2%, nitrile rubber 9% , the balance being barium sulfate; the preparation method of the material is as described in Example 1. (recipe 3)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com