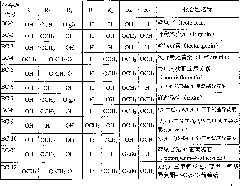

Patents

Literature

72results about How to "Small recession" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum conductive paste for silicon solar cell back surface field and preparation method thereof

InactiveCN101621082ASmall recessionImprove conductivityFinal product manufactureNon-conductive material with dispersed conductive materialIonOrganic solvent

The invention relates to aluminum conductive paste for a silicon solar cell back surface field and a preparation method thereof. The paste is prepared by dissolving ethyl cellulose into terpineol, adding organic solvent and additive into the mixture, then stirring the solution, adding aluminum powder, stannum powder, gallium powder, stibium powder and magnalium alloy powder, stirring the solution and rolling by a three-roller muller. A silicon solar cell prepared by the paste has high photoelectric conversion efficiency, good conductivity of an aluminum film, smooth surface, no aluminum pills, no foaming and firm attachment of an aluminum sheet. In the invention, the stannum powder is used as inorganic binder and has extremely little pollution to silicon sheet heavy metal ions accordingly, and a manufactured solar cell has slower declination during using. The invention solves the problems of poor conductivity, bend silicon sheet, heavy metal pollution and the like existing in an aluminum film made of aluminum paste in the prior silicon solar cell. The aluminum conductive paste is especially suitable for fast sintering process in the prior silicon solar cell production line.

Owner:付天恩

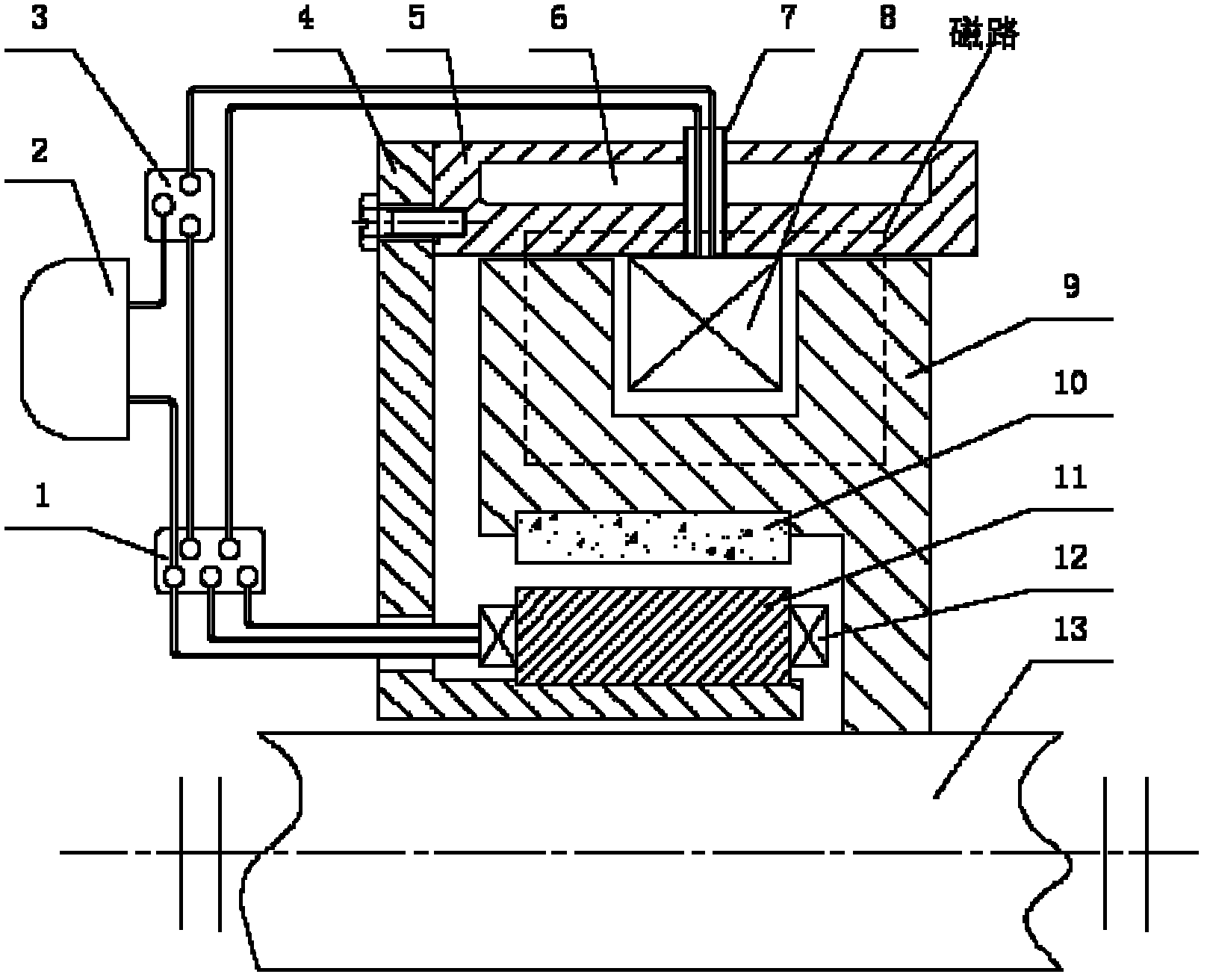

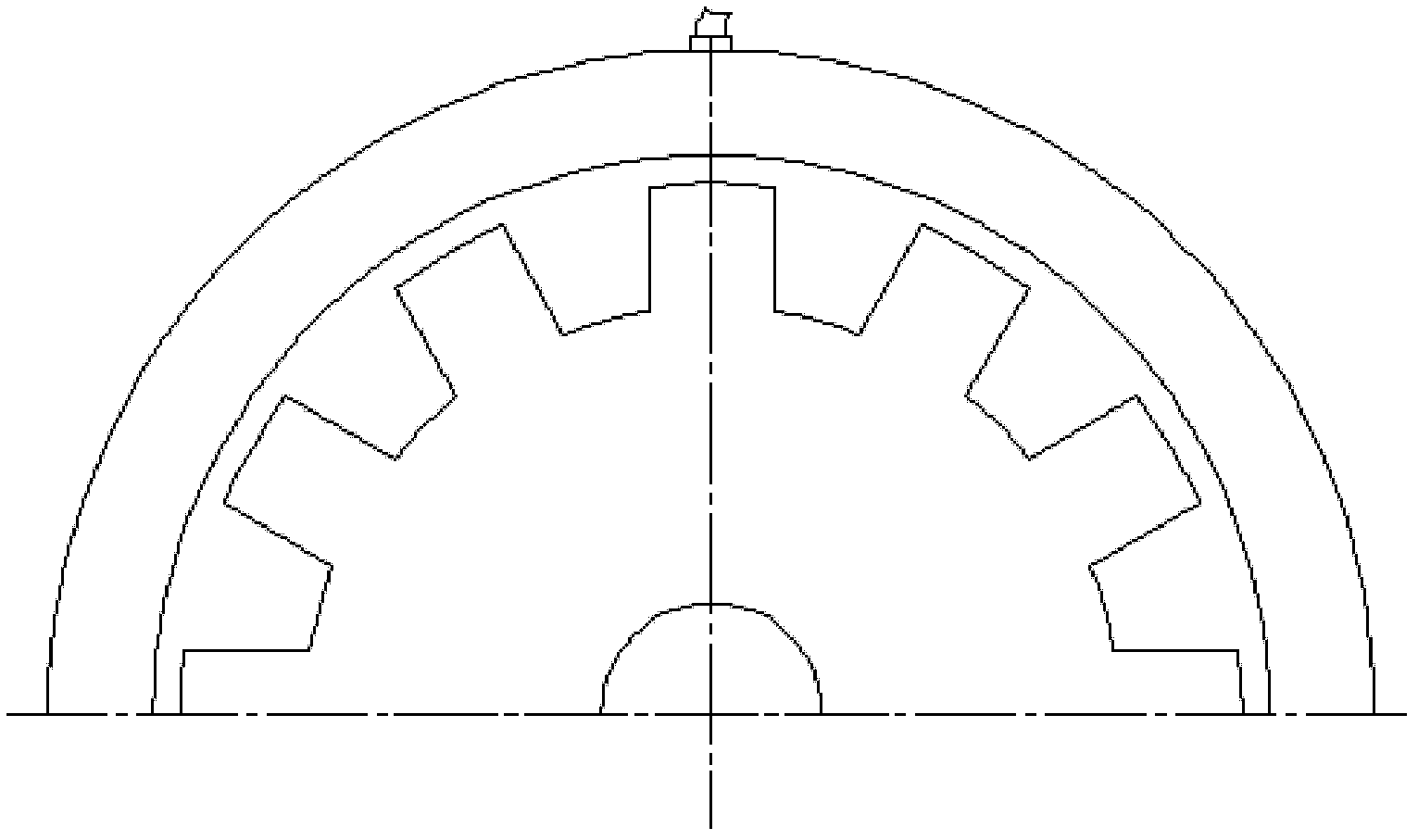

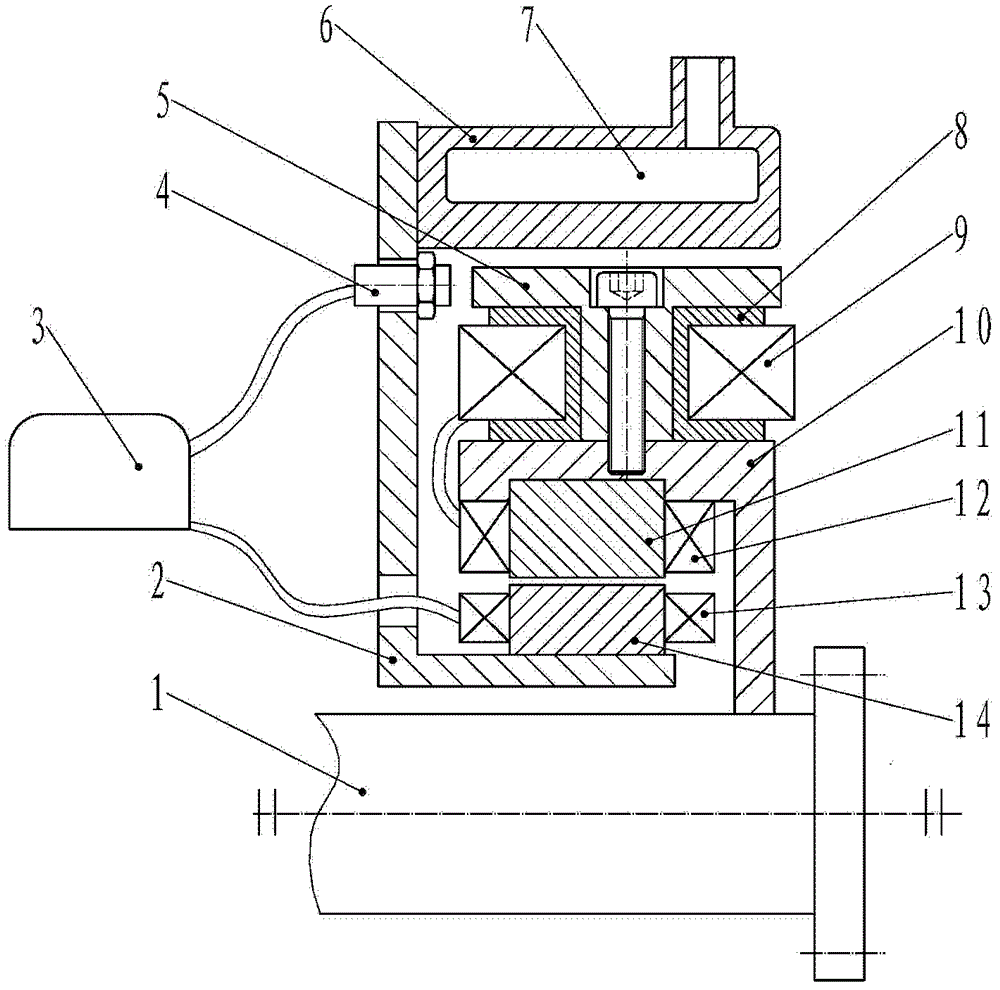

Liquid cooling self-excitation type eddy current retarder with salient pole structure

ActiveCN102594090ASave electricityAvoid big shocksMagnetic circuit rotating partsMagnetic circuit stationary partsElectric energyDynamo

The invention provides a liquid cooling self-excitation type eddy current retarder with a salient pole structure, belonging to the field of automobile braking. The liquid cooling self-excitation type eddy current retarder comprises a retarder rotor (9), a retarder stator (5), a retarder coil (8), a retarder generator and a control module, wherein the retarder rotor (9) is a tooth-shaped rotary plate; the axial half-section of the tooth-shaped rotary plate is a reverse h shape; two bulges at the both sides of a dentate disc are two salient poles of the retarder rotor (9); the retarder rotor (9) is connected with a transmission shaft (13); the inner circle of the retarder stator (5) and the outer circle of the retarder rotor (9) are coaxial; and the retarder coil (8) is an individual coil, is mounted between the two salient poles of the retarder rotor (9), and is fixedly connected with the retarder stator (5). According to the liquid cooling self-excitation type eddy current retarder provided by the invention, the electric energy is saved and the large impact to an automobile storage battery when the retarder is started is avoided by using a self-generating manner; and the coil is sleeved in the middle of a rotor disc by using the individual coil which is wound in a concentrated manner, so that the winding, the installation and the control of the coil can be simplified.

Owner:YANGZHOU ANXING ELECTROMECHANICAL TECH

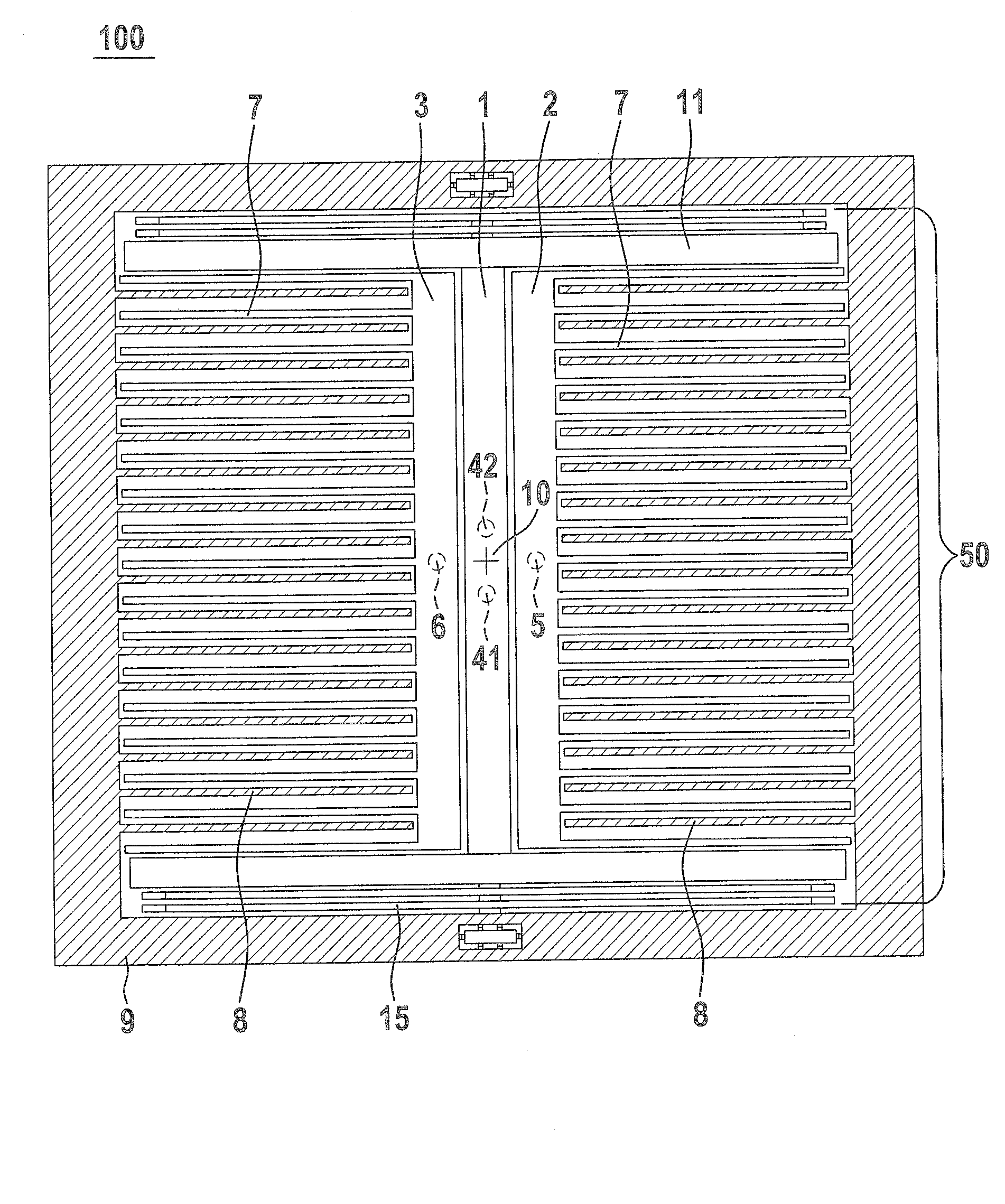

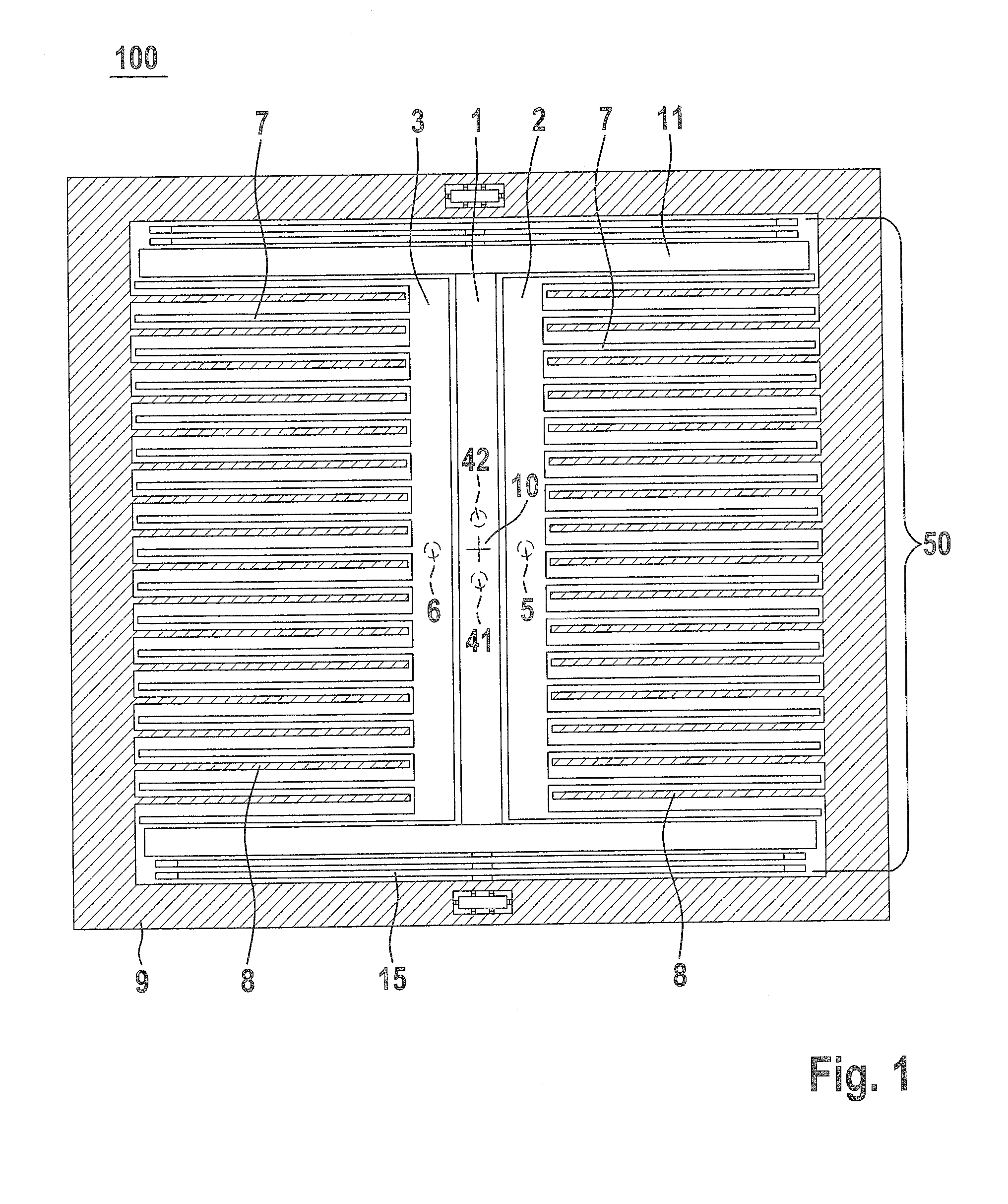

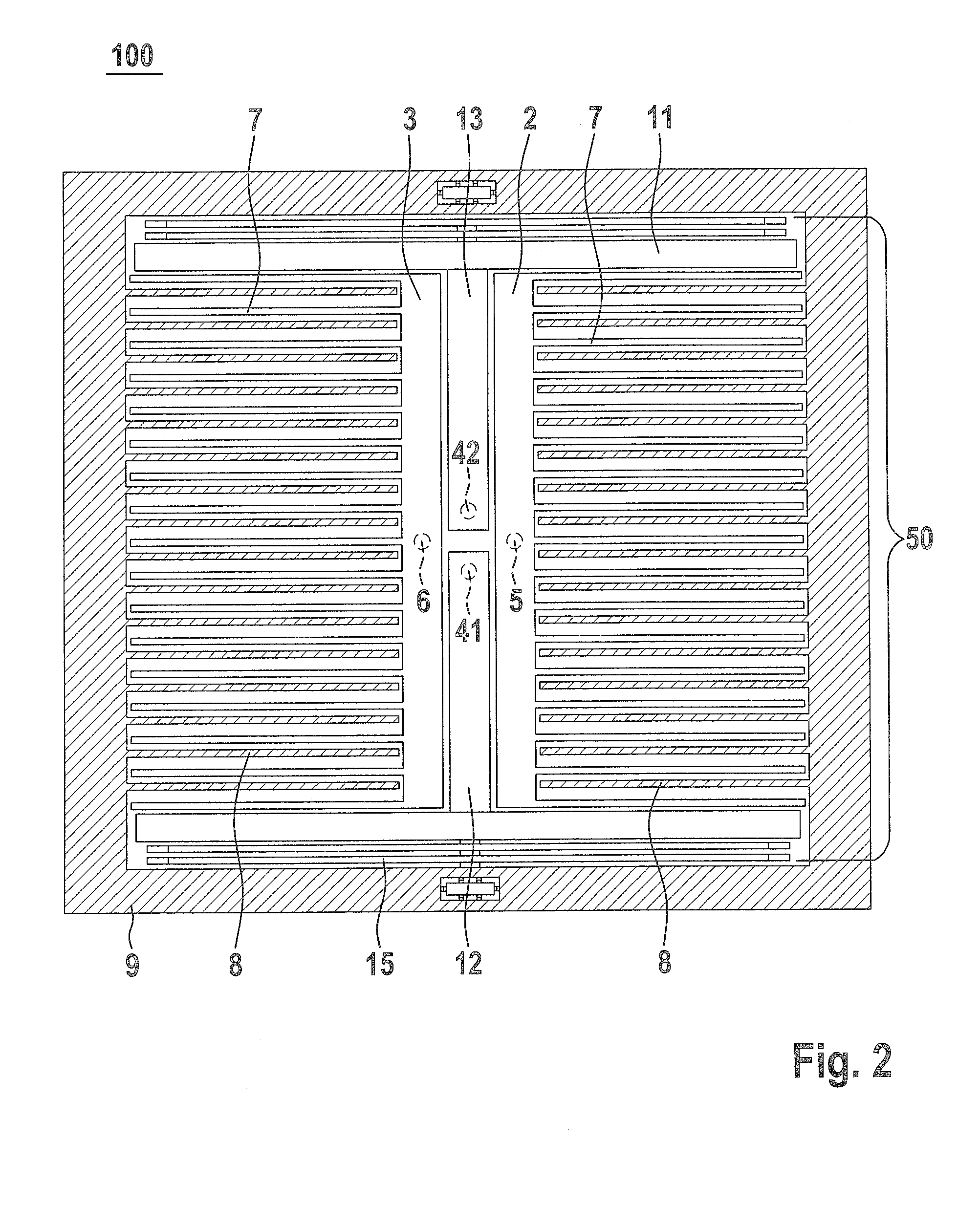

Acceleration sensor having a surrounding seismic mass

InactiveUS20090282914A1Sturdy against deformationMore recessionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massGravitation

A micromechanical acceleration sensor has a substrate, a suspension, a seismic mass, and stationary capacitive electrodes, which seismic mass is suspended over the substrate with the aid of the suspension. The seismic mass has a mass center of gravity, and the suspension has at least two anchors on the substrate, the at least two anchors being situated next to the mass center of gravity at a distance which is small compared to a horizontal extension of the seismic mass. The stationary capacitive electrodes are provided in recesses of the seismic mass. The seismic mass directly surrounds the suspension.

Owner:ROBERT BOSCH GMBH

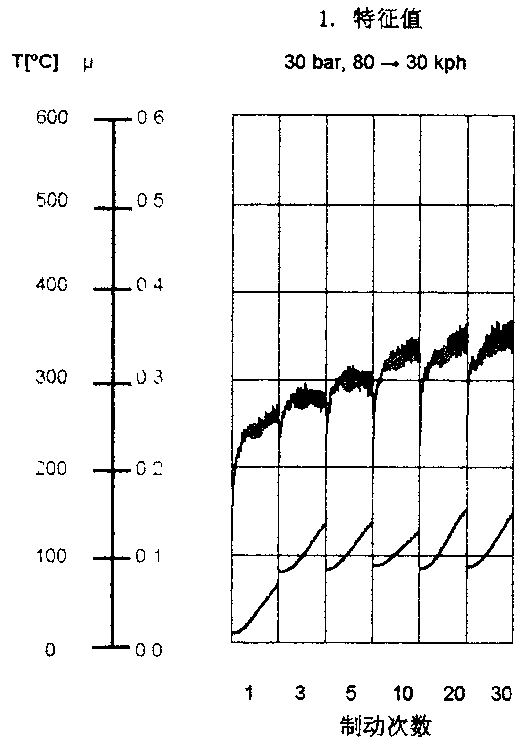

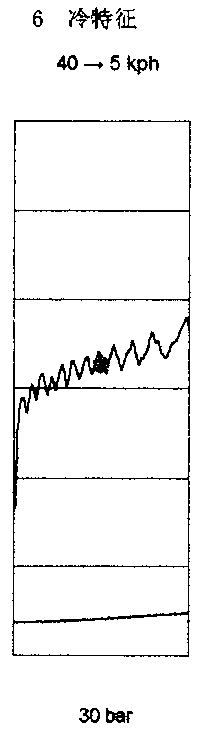

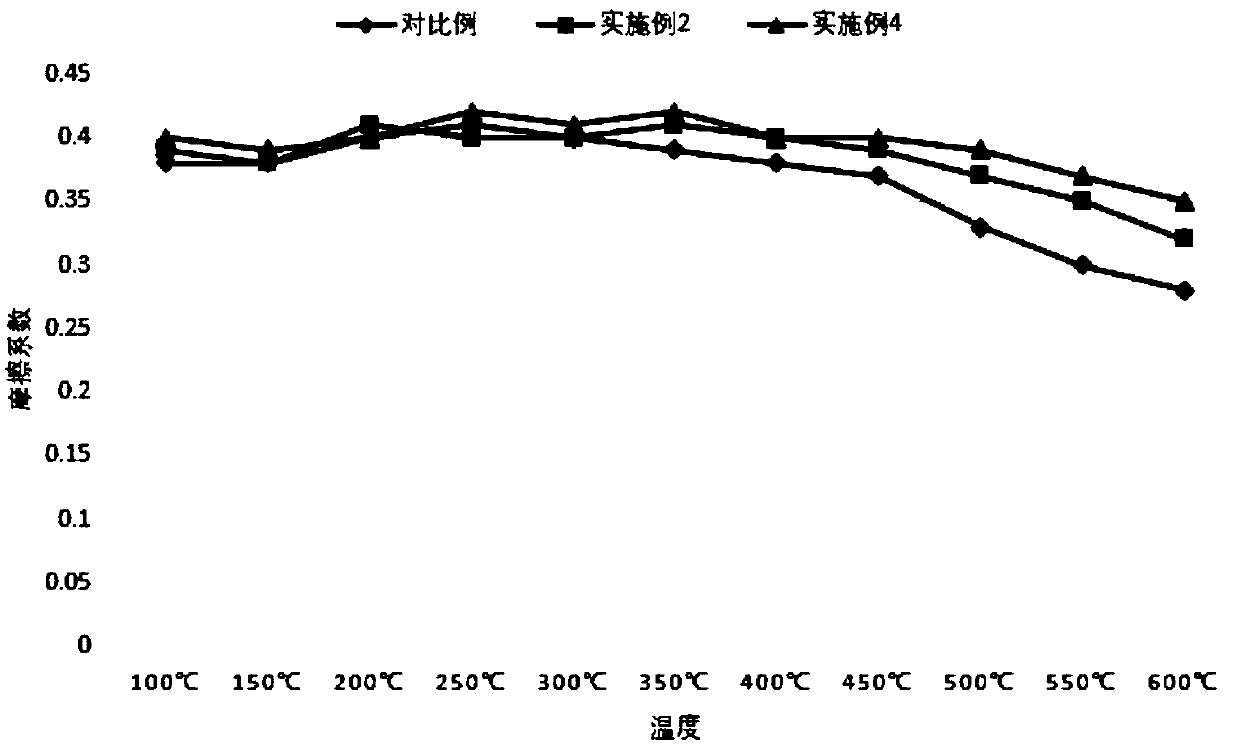

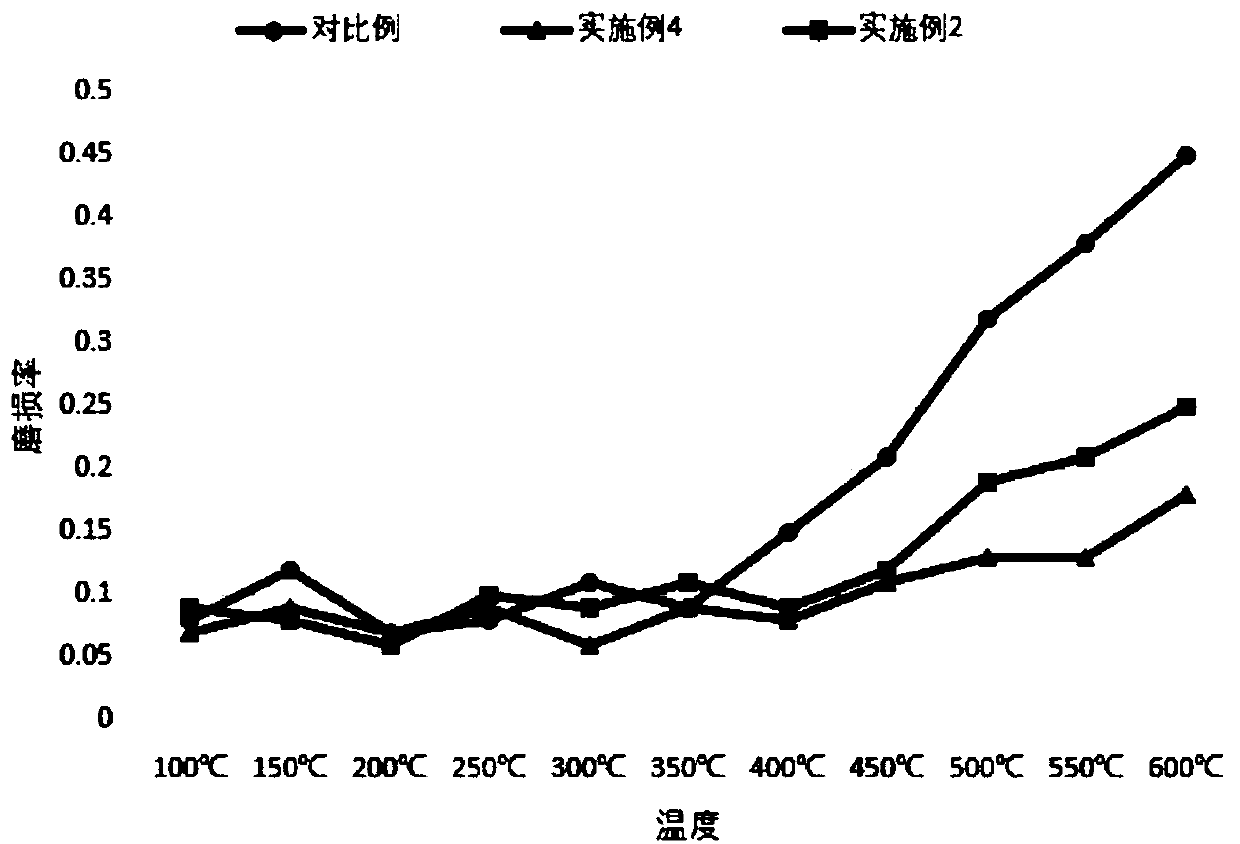

Environmental-protection high-speed car brake sheet and warm-pressing process of brake sheet

ActiveCN102141101ASmall recessionShorter braking distanceFriction liningVulcanizationMaterials science

The invention discloses an environmental-protection high-speed car brake sheet and a warm-pressing process of the brake sheet. A frictional material of the environmental-protection high-speed car brake sheet comprises the following components in parts by weight: 6-8 parts of phenolic resins, 2 parts of acrylonitrile rubber powder, 1-3 parts of Kevlar fibers, 5-7 parts of stannic sulfide, 5-7 parts of artificial graphite, 2 parts of polytetrafluoroethylene, 18-20 parts of steel fibers, 4-6 parts of red copper fibers, 2 parts of aluminum oxide, 3-5 parts of zirconium silicate, 5-7 parts of iron oxide black, 7-9 parts of titanium white, 6-8 parts of mineral fibers, 7-9 parts of white vermiculite, 8-10 parts of grammite and 5-9 parts of barium sulfate. The warm-pressing process of the environmental-protection high-speed car brake sheet comprises the steps of material burdening, material mixing, warm-pressing formation, thermal treatment, grinding and spraying. The high-speed car brake sheet has the advantages of safe and comfortable brake, no noise, low high-temperature and high-speed recession, stable frictional factor, environmental protection, long service life and the like; and the warm-pressing process of the environmental-protection high-speed car brake sheet has the advantages of high rate of finished products, high mechanical degree, high production efficiency and low energy consumption.

Owner:YANTAI WINHERE AUTO PART MFG

Compound bacterium and treatment process for heavy-metal sewage treatment

ActiveCN105274025AImprove stabilityMaintain population dominanceBacteriaWater contaminantsHeavy metalsBacillus megaterium

The invention provides a compound bacterium for heavy-metal sewage treatment. The compound bacterium comprises at least one of Brevibacterium halotolerans strain CAS17, Bacillus sp.4014, Bacillus megaterium NBRC and Bacillus sp.1 PPL-SC1. The four strains are already collected by the China Center for Type Culture Collection on 21st, September, 2015, and collection numbers of the Brevibacterium halotolerans strain CAS17, the Bacillus sp.4014, the Bacillus megaterium NBRC and the Bacillus sp.1 PPL-SC1 are CCTCC No.M2015565, CCTCC No.M2015566, CCTCC No.M2015568 and CCTCC No.M2015567 respectively. The invention further discloses a treatment process for heavy-metal sewage treatment and aims at solving the problems of low treatment efficiency and large consumption of bacterial liquid in existing Bacillus sewage treatment technology.

Owner:SHENZHEN ZHONGNAN ENVIRONMENTAL PROTECTION TECH CO LTD

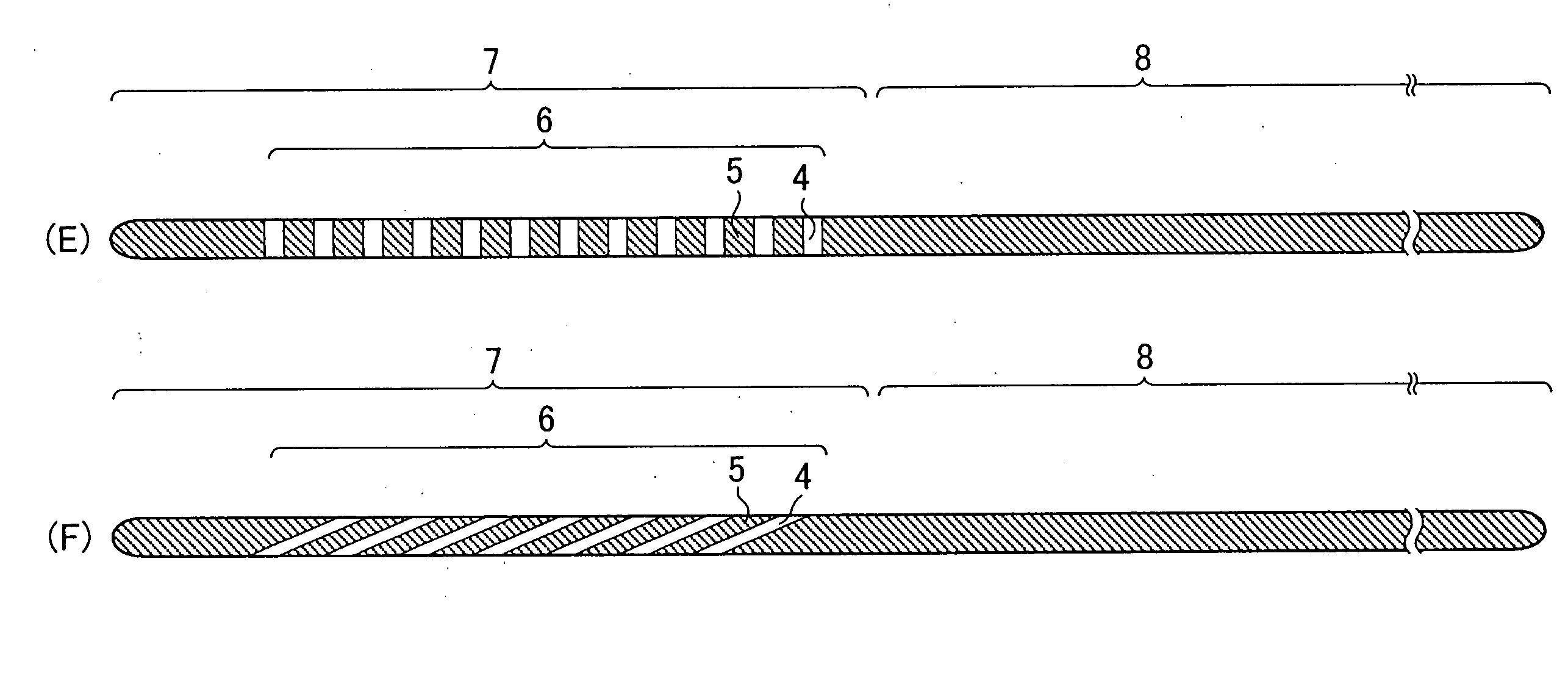

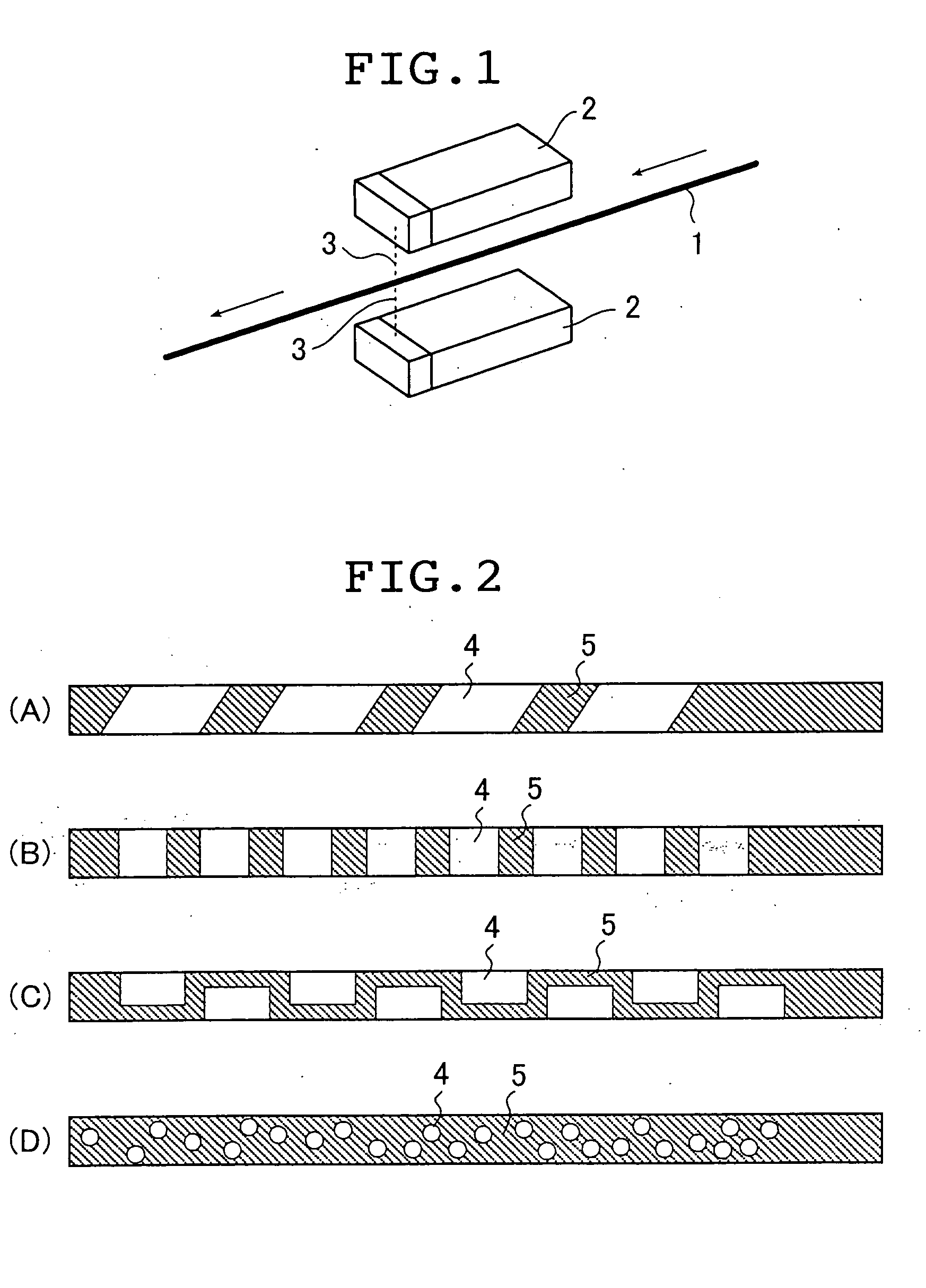

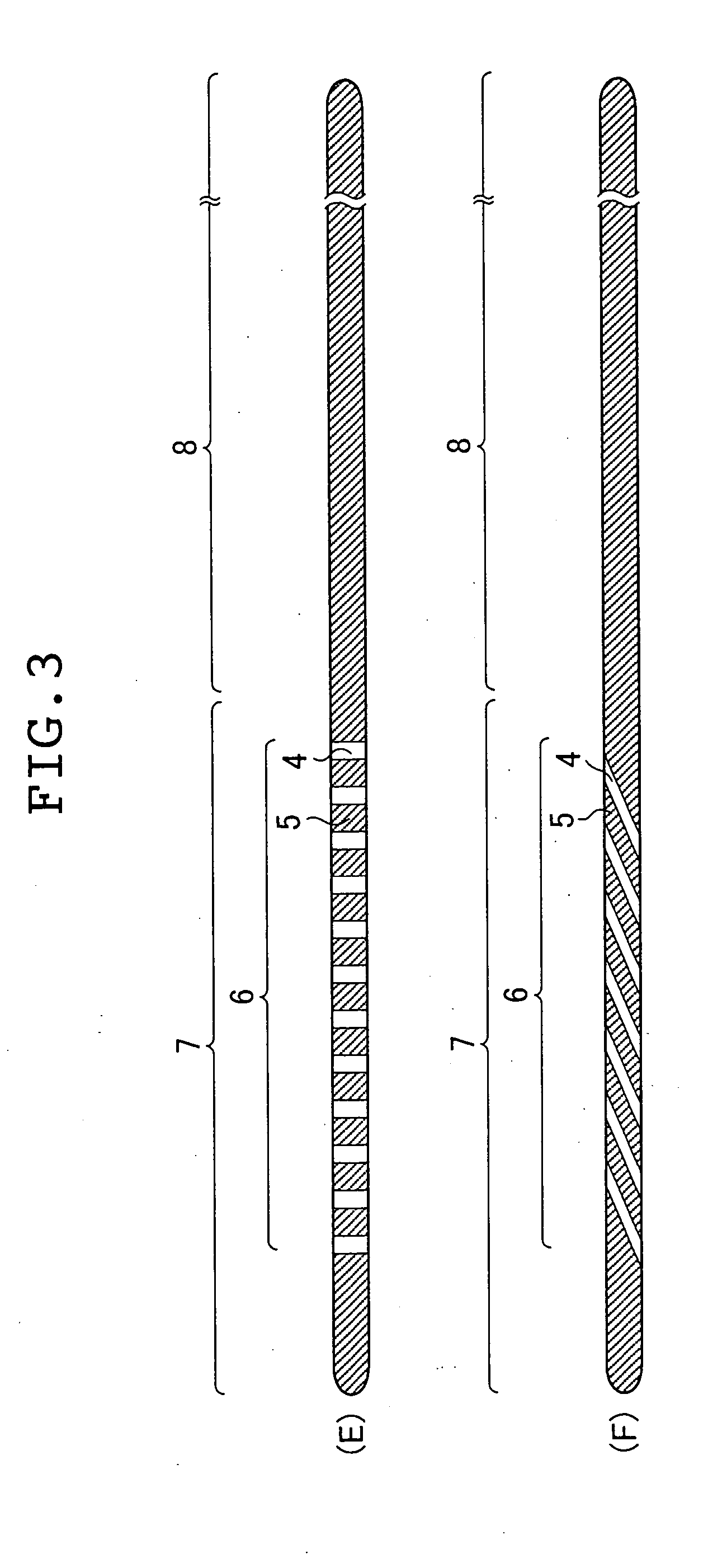

Medical long object and method for producing the same

InactiveUS20050080358A1Good solvent resistanceEasy to seeRadiation applicationsSurgeryLaser lightIrradiation

A medical long object of the present invention has a part made of a polymeric material containing a laser color developing agent at least in a part of the surface thereof, and a light developing portion formed in the part by color development of the laser color developing agent due to irradiation with laser light.

Owner:IWAMI JUN +1

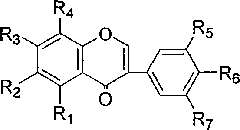

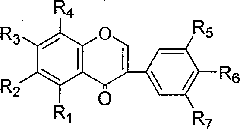

Application of belamcanda chinensis total isoflavone or isoflavone compounds in preparing medicaments and food for preventing and treating women's disease

InactiveCN101797265APromote generationPromote epithelial proliferationOrganic active ingredientsSexual disorderDiseaseBelamcanda chinensis

The invention relates to the technical field of medicaments, in particular to application of 12 isoflavone compound monomers comprising belamcanda chinensis total isoflavone or tecoridin, wild tectoridin, tectorigenin, iridin and the like in preparing medicaments and food for preventing and treating lower women's estrogen level and retarding womb and ovarian failure or climacteric syndrome. Animal experiment results show that the total isoflavone or 12 isoflavone compound monomers in the belamcanda chinensis have remarkable pharmacological effects of improving the estrogen level, promoting the growth of follicle, promoting epitheliosis of womb and vagina, retarding womb and ovarian failure, improving the expression of an epithelial cell estrogen receptor of the vagina and the like, so the total isoflavone or 12 isoflavone compound monomers can be used for preparing the medicaments or food for preventing and treating lower women's estrogen level and retarding womb and ovarian failure or climacteric syndrome. The application provides a new source for seeking a plant estrogen medicament.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

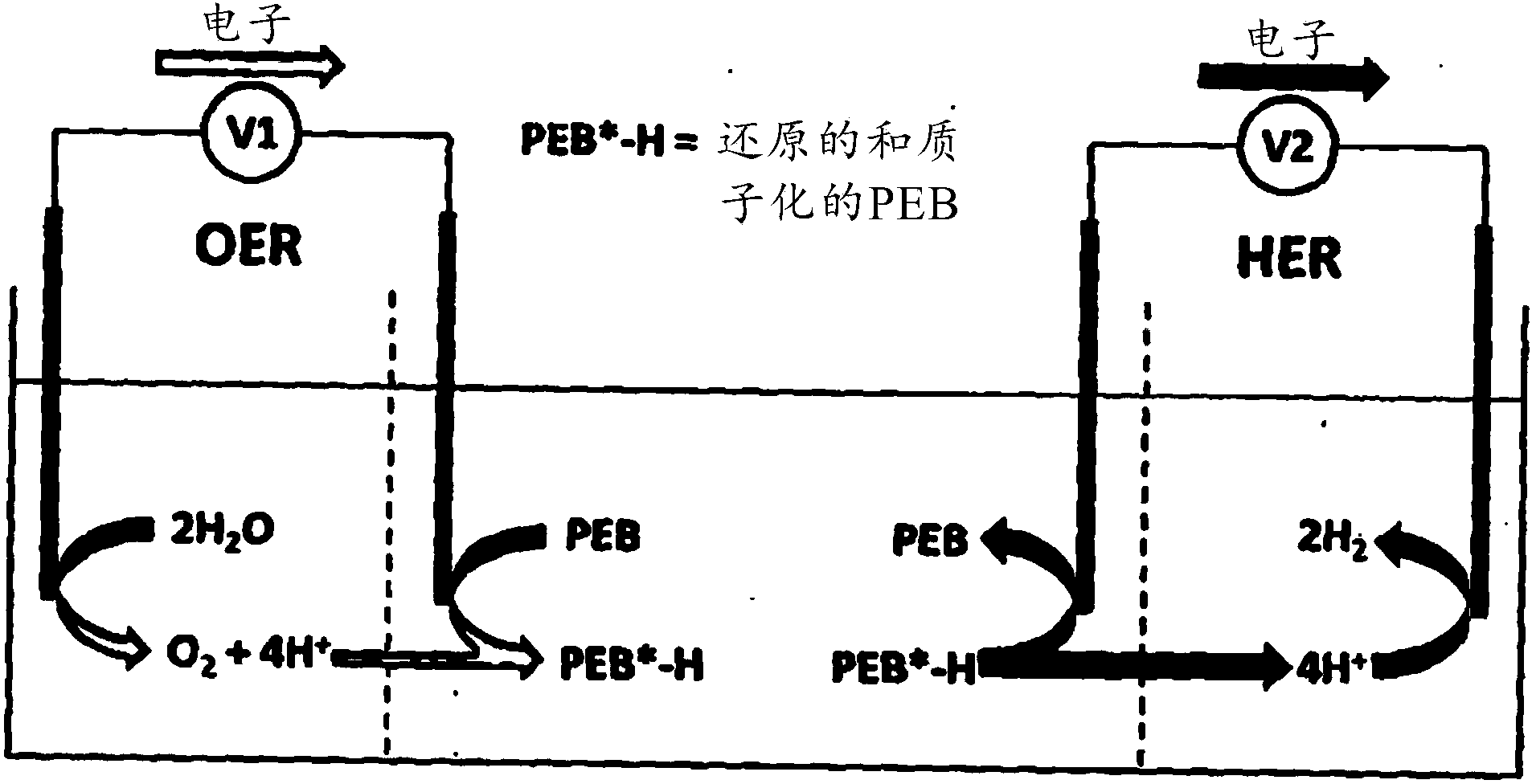

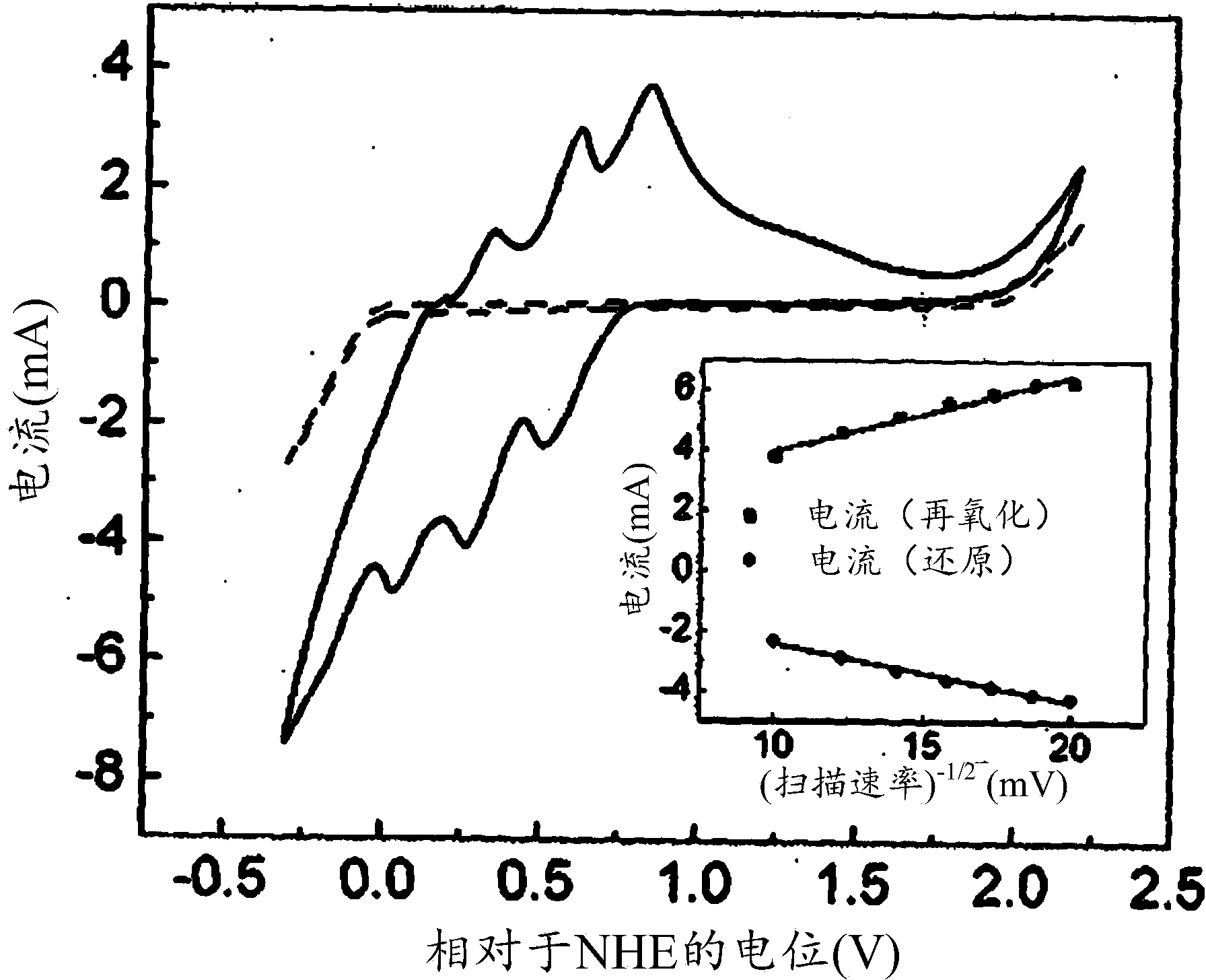

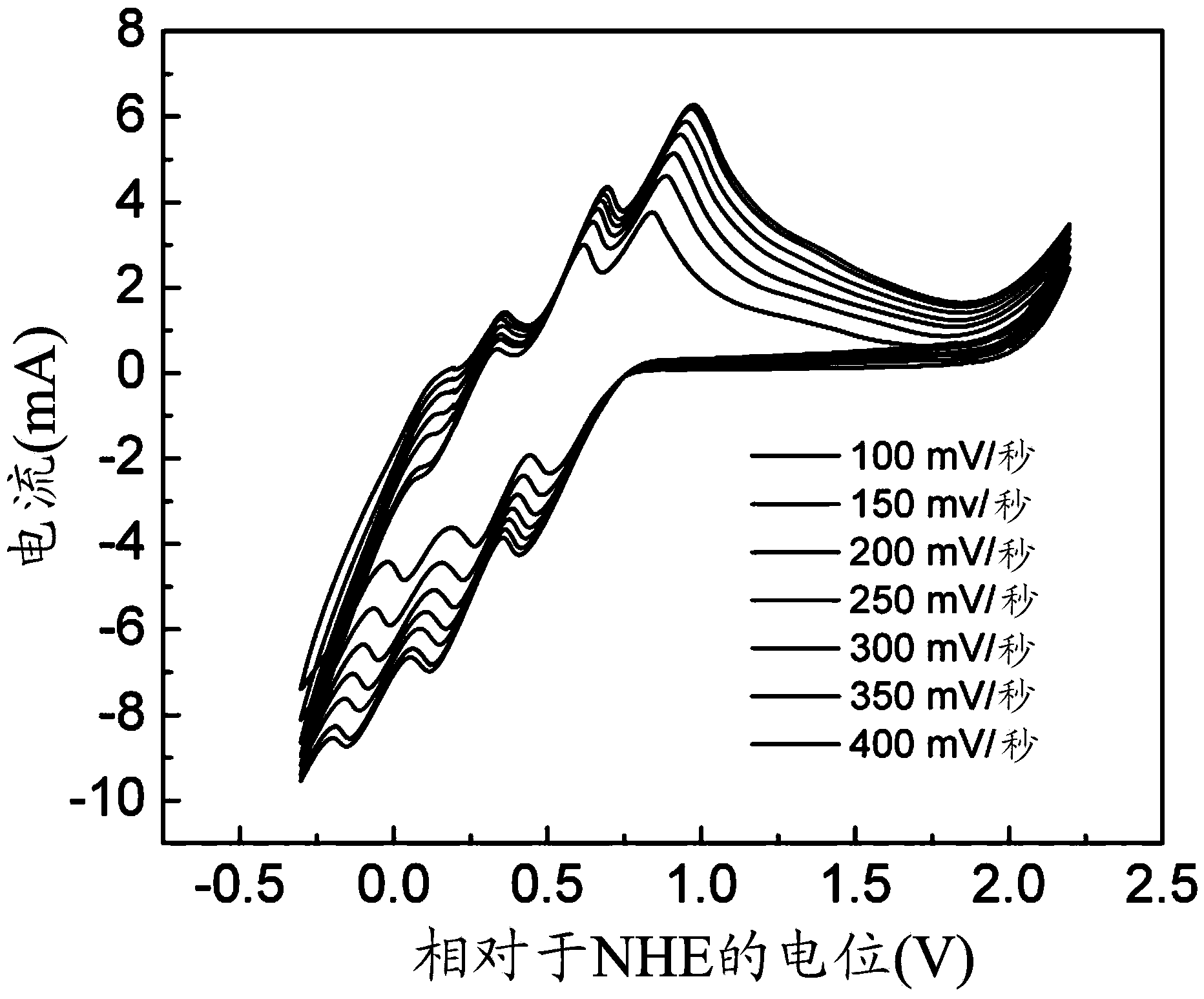

Apparatus and methods for electrochemical generation of oxygen and/or hydrogen

The invention provides methods for producing hydrogen and oxygen, comprising the steps of:(i) oxidising a mediator at a working electrode to yield an oxidised mediator, and reducing protons at a counter electrode to yield hydrogen; and (ii) reducing an oxidised mediator at a working electrode to yield a mediator, and oxidising water at a counter electrode to yield oxygen, wherein the oxygen generation step is performed non-simultaneously to the hydrogen generation step, and the oxidised mediator of step (i) is used as the oxidised mediator of step (ii), or the mediator of step (ii) is used as the mediator of step (i), and the mediator has a reversible redox wave lying between the onset of the oxygen evolution reaction (OER) and the hydrogen evolution reaction (HER).

Owner:格拉斯哥大学行政评议会

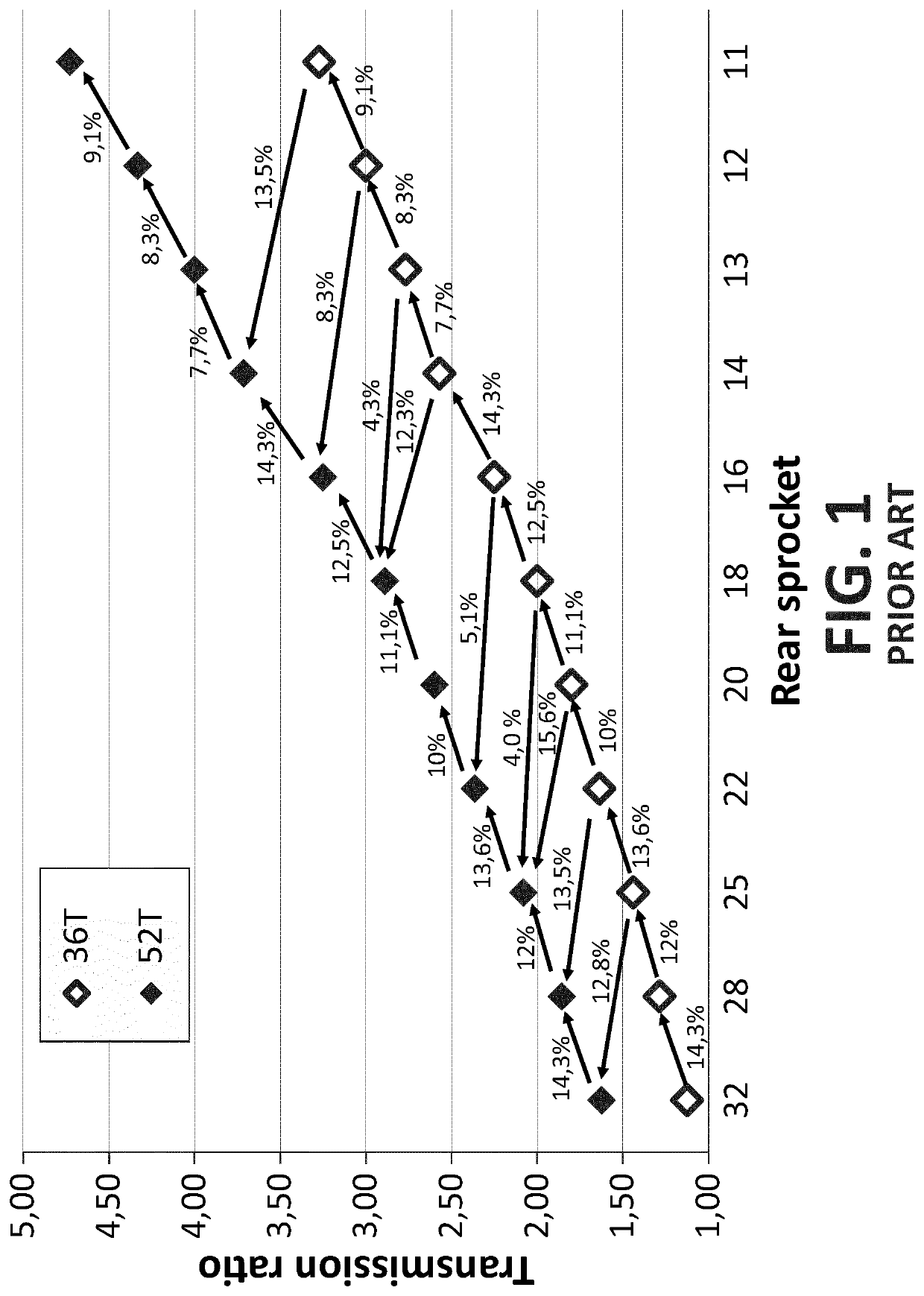

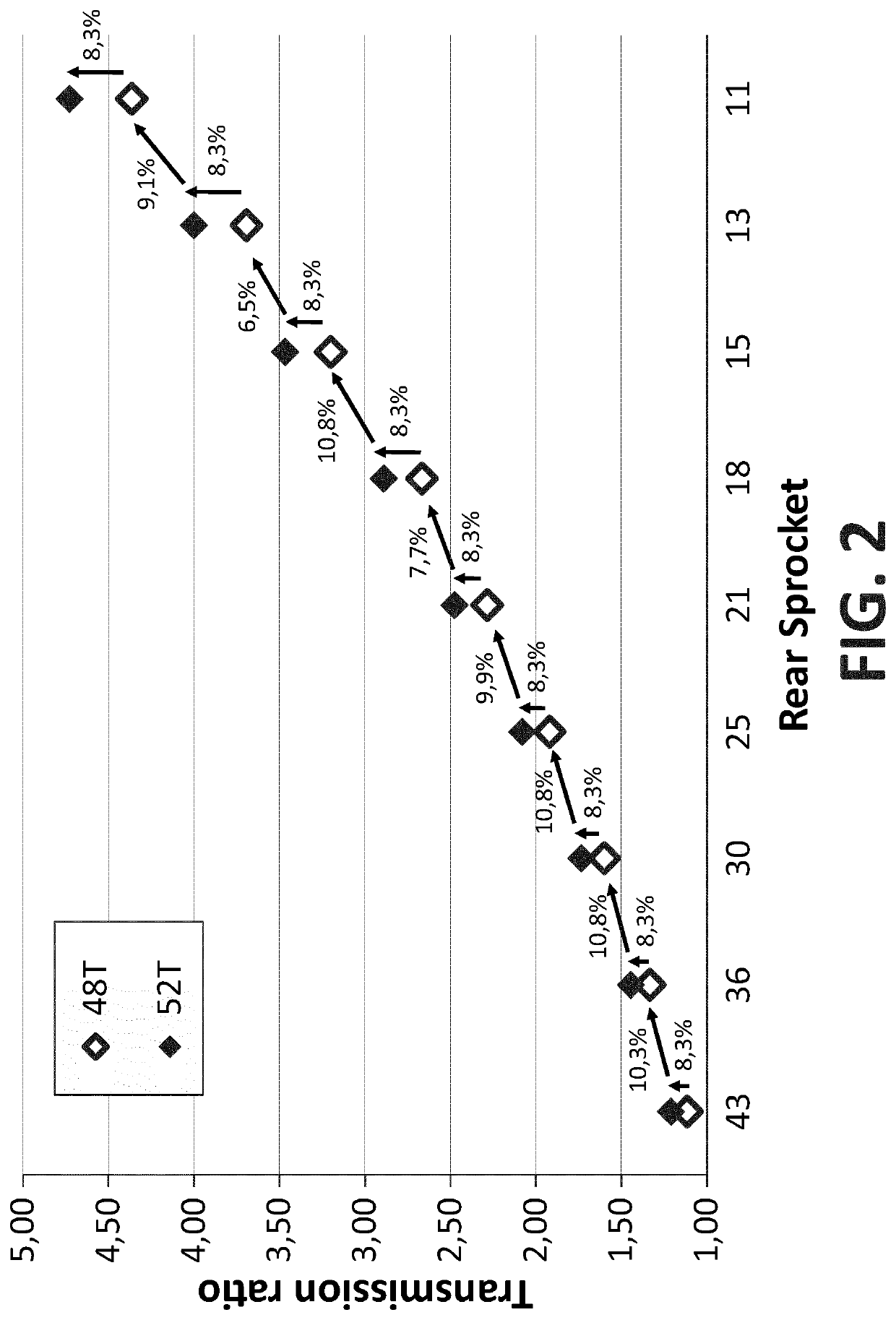

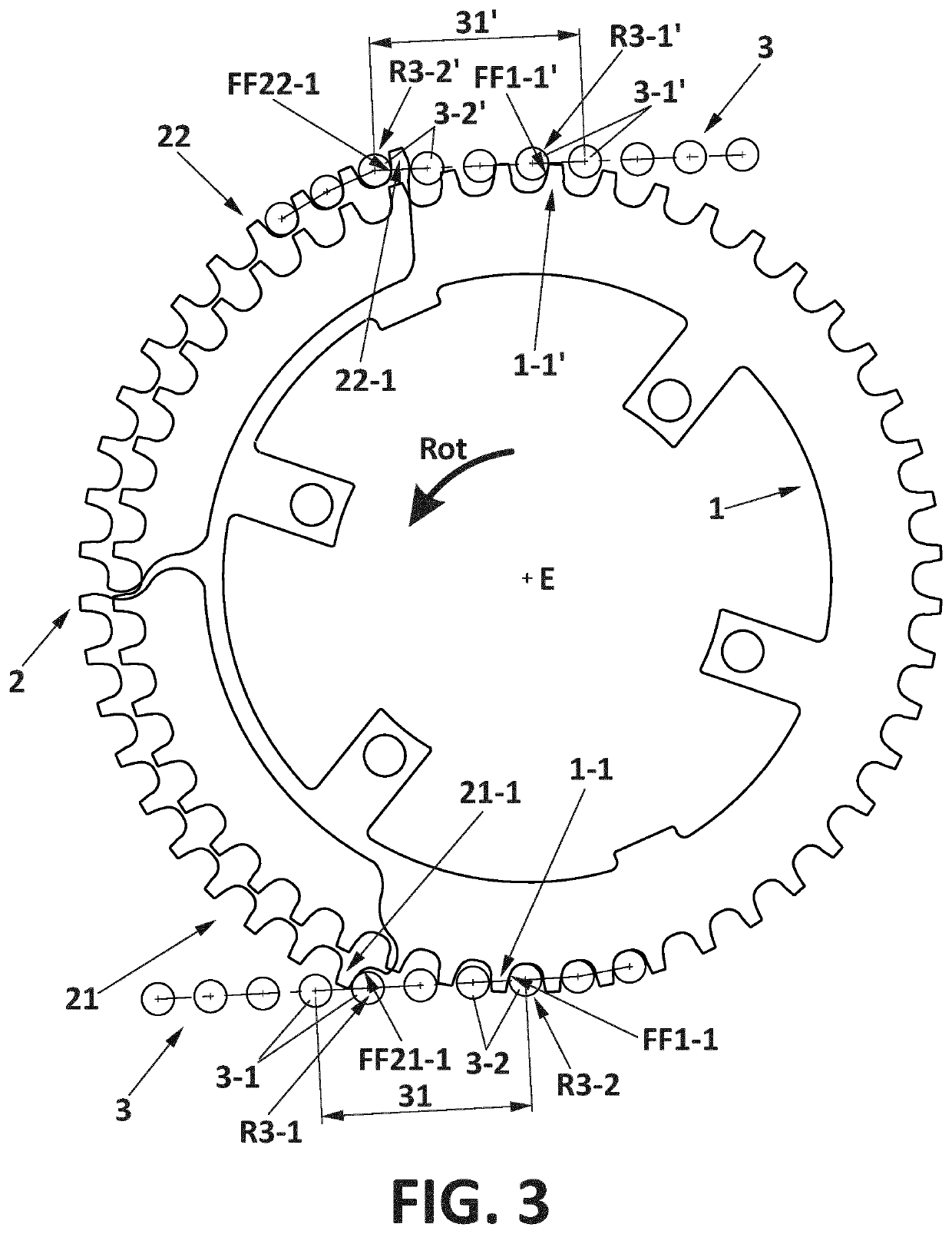

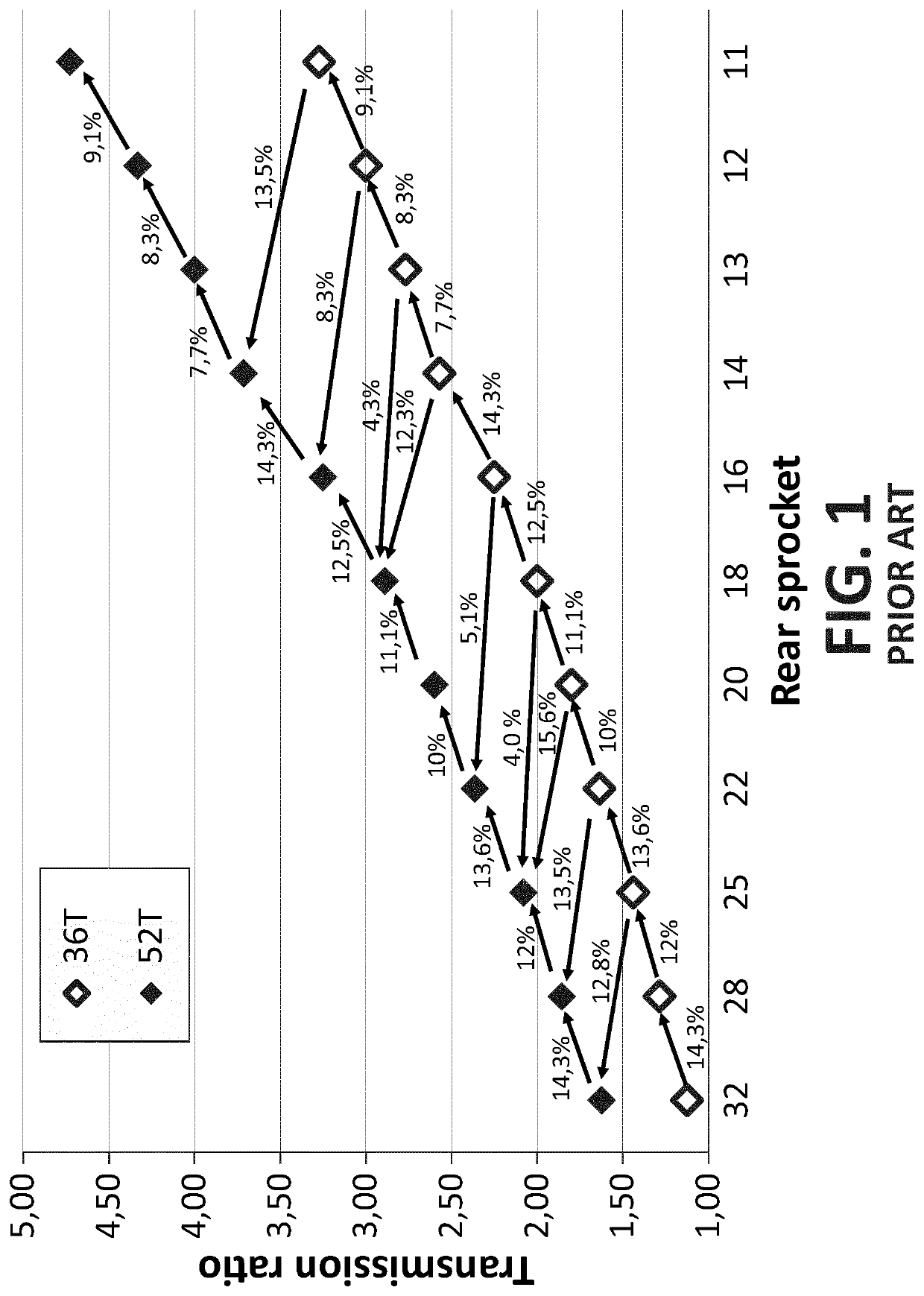

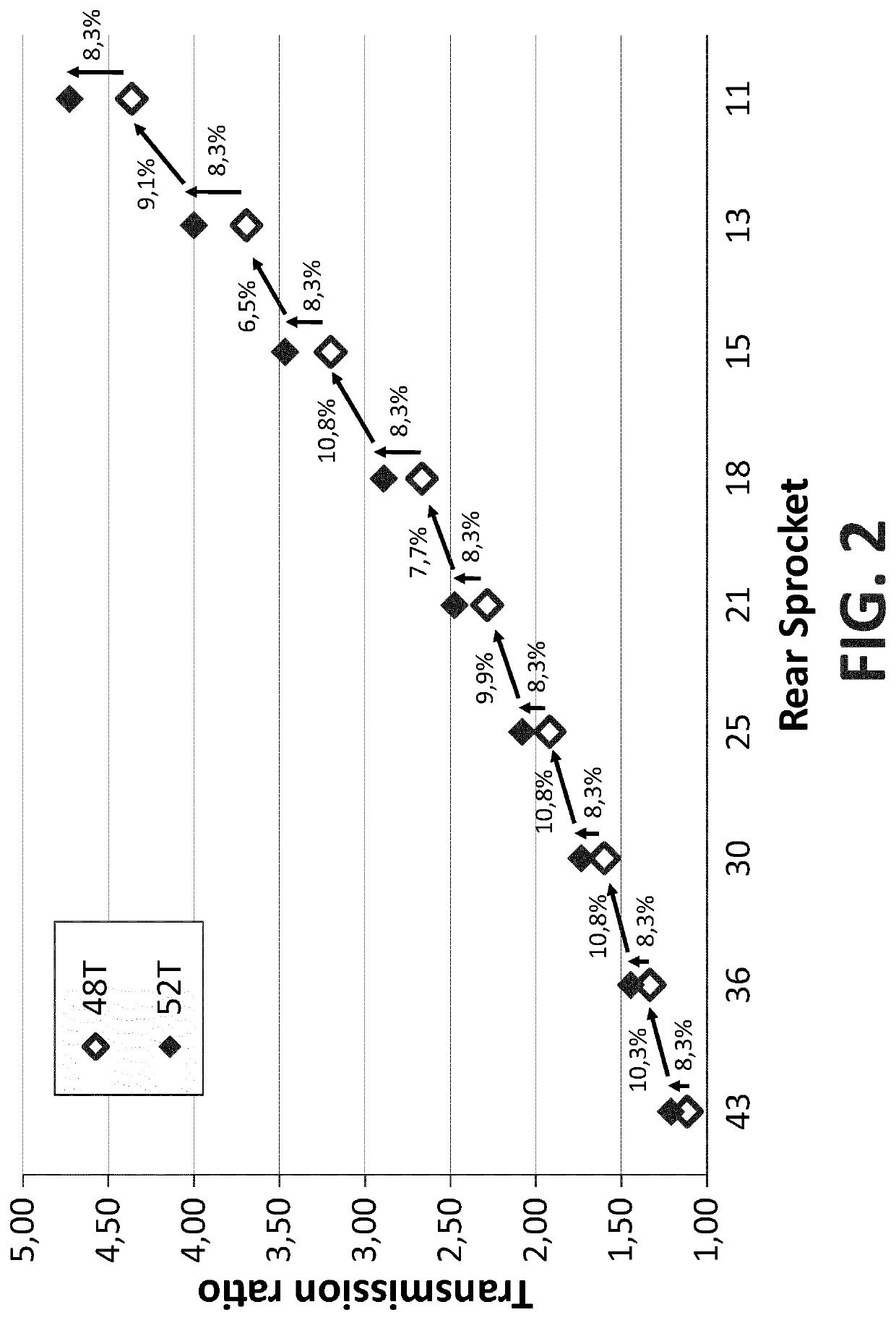

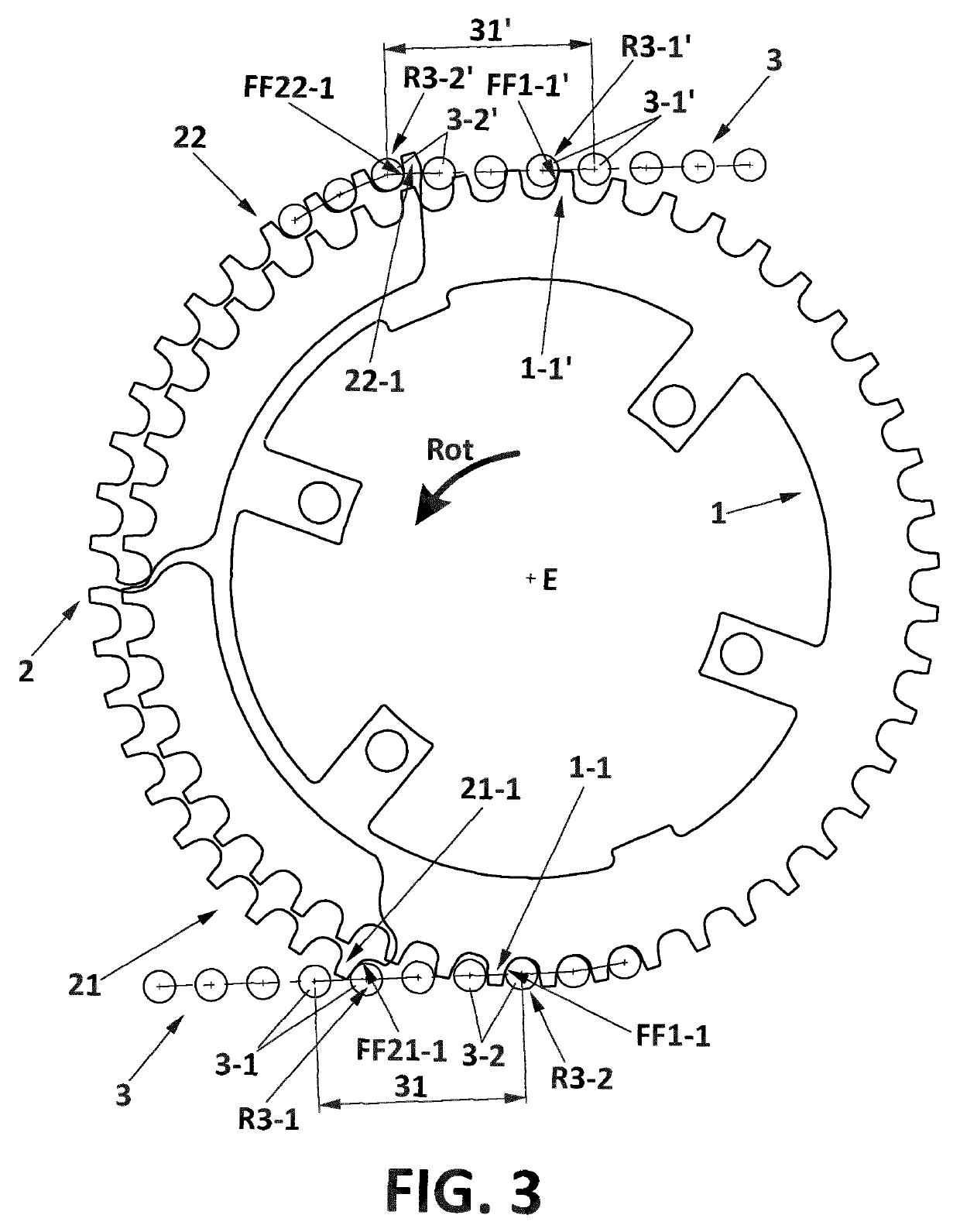

Chain-rings set for a power transmission system provided with segmented chain-rings in different planes

ActiveUS20210031877A1Interference be notImprove structural strengthChain/belt transmissionAxial displacementEngineering

Chain-rings set, for a power transmission system, which includes a chain, a first chain-ring, a second chain-ring where the first chain-ring is formed by a support part of the teeth and a teeth part, where the second chain-ring is formed by segments each formed by a support part of the teeth and a teeth part, which includes axial displacement means of the segments, where an up-shift segment of the segments has a first tooth which is the first which is engaged with the chain in the rotation movement, and where the displacement means are configured for moving the up-shift segment to an engaging position such that the first tooth can engage with an engaging link of the up-shift section of the chain, when the chain is engaged in the small chain-ring, and without the support part of the up-shift segment reaching the same plane than the support part of the first chain-ring, and to successively displace the other independent segments to an engaging position with the chain without the support parts of the independent segments reaching the same plane than the support part of the first chain-ring.

Owner:ZUMA INNOVATION SL

Female healthcare food and preparation method thereof

InactiveCN104886576AImprove fertilityRich in nutritional valueNatural extract food ingredientsFood preparationDiseaseSexual function

The present invention discloses a female healthcare food and a preparation method thereof. The female healthcare food comprises the following raw materials in parts by weight: 30-60 parts of lepidium meyenii, 20-55 parts of kudzu vine root and 10-20 parts of Chinese wolfberry fruits. According to the preparation method, biological health activity molecules are extracted through a modern Chinese medicine technology, and the extracted biological healthcare active molecules are added to edible materials and prepared into tablets, granules, hard capsules or oral solutions. The lepidium meyenii, the kudzu vine root and the Chinese wolfberry fruits are processed by a bionanotechnology, such that bioavailability of the healthcare active molecules can be improved, and a female healthcare food can be prepared by a fine processing. The prepared female healthcare food is safe, effective, non-toxic and harmless. The female healthcare food has collaborative action for improving sexual function, improving fertility, regulating endocrine, reducing bone rarefaction caused by ovarian function decline and other related diseases, and improving immune function.

Owner:JIANGSU HUIBO BIOTECH

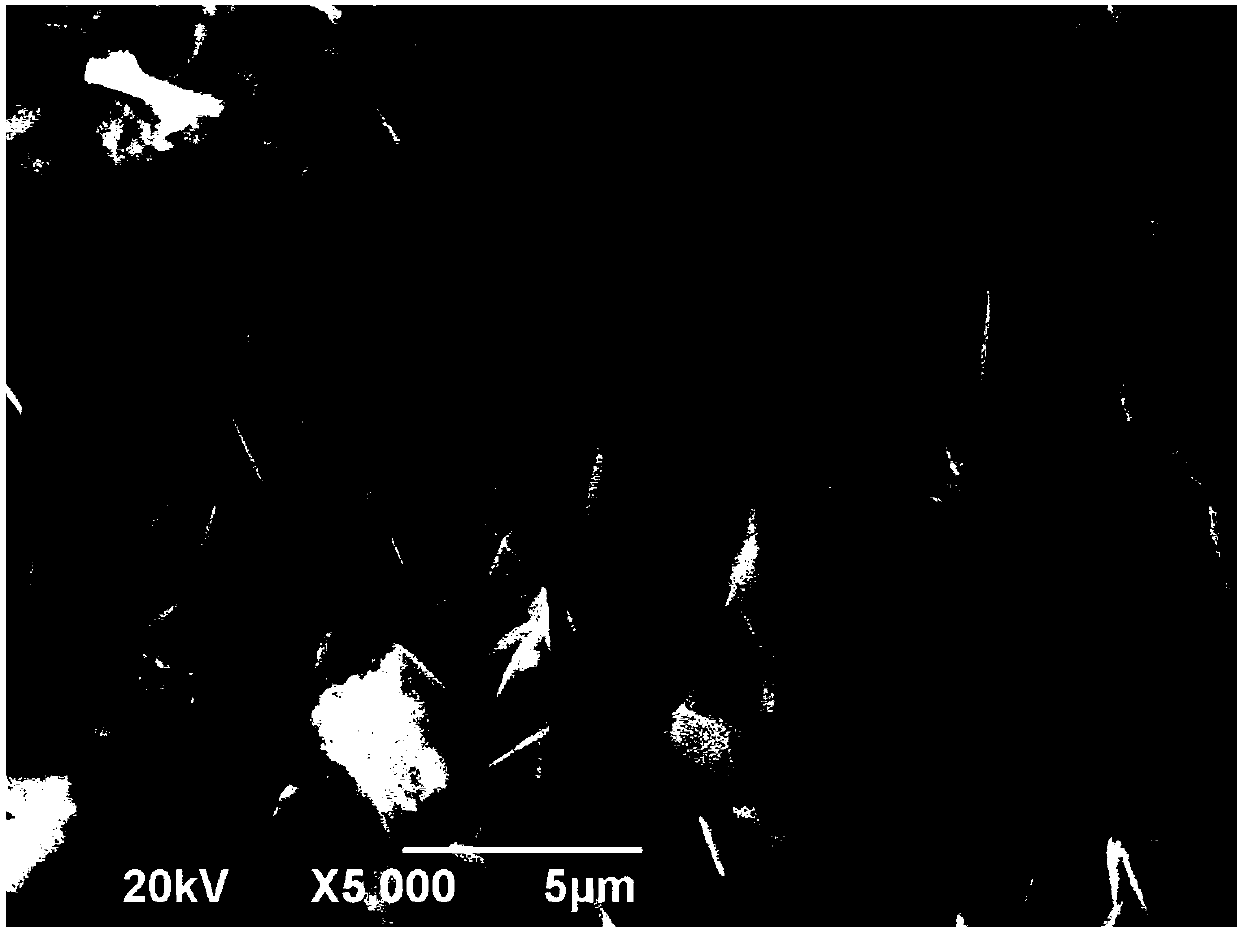

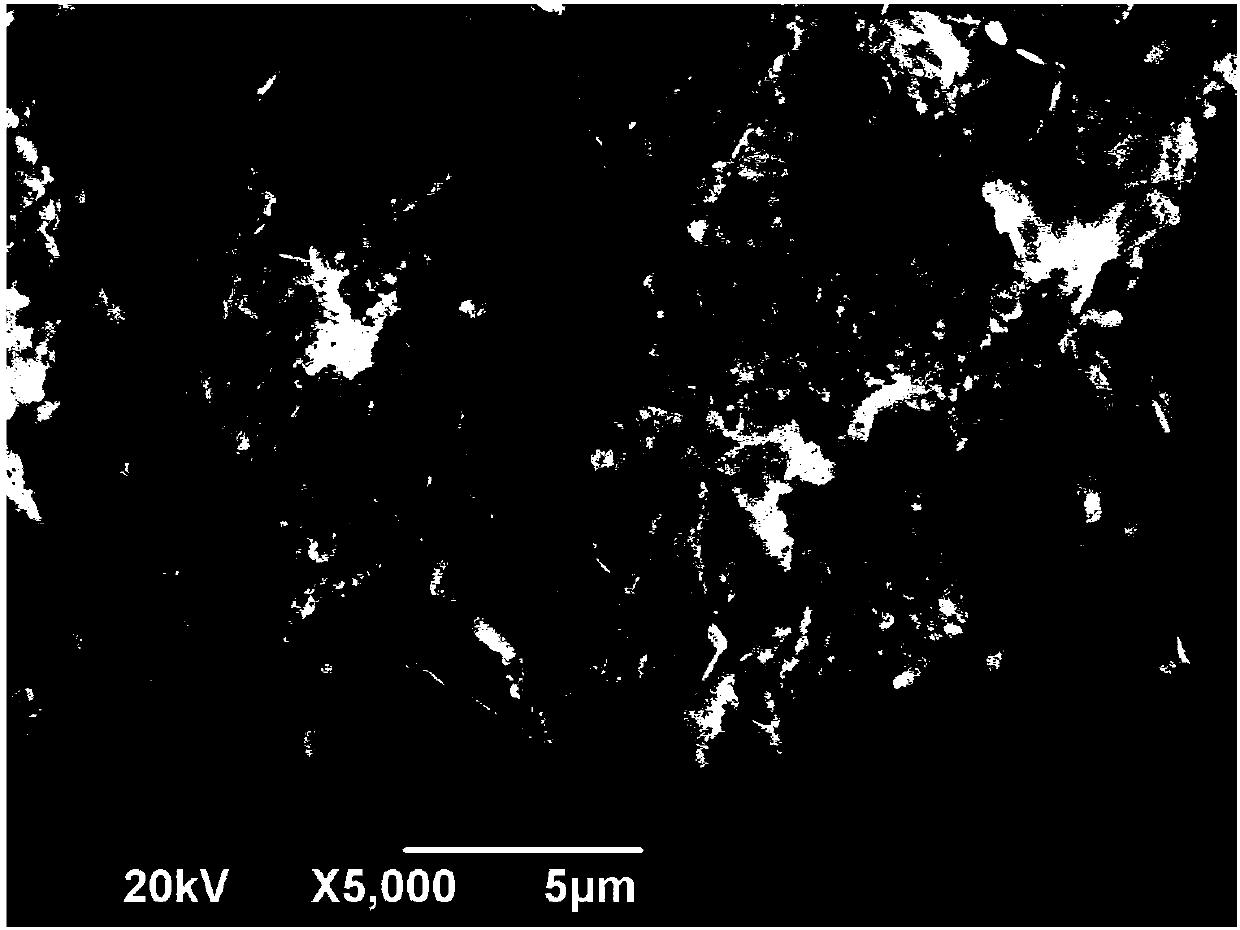

High temperature resistant declining admixture for oil well cement and preparation method thereof

ActiveCN107902933AReduced compressive strengthSmall recessionDrilling compositionSilicon dioxideHigh-temperature corrosion

The invention discloses a high temperature resistant declining admixture for oil well cement and a preparation method thereof, and solves the problem that a cement paste system is not suitable for well cementation of geothermal wells with superhigh temperature and superhigh temperature difference in the prior art. The high temperature resistant declining admixture comprises 40% to 60% of photovoltaic silicon, 15% to 30% of fumed silica, 15% to 30% of dead burned magnesia and 1% to 2% of mineral fiber. According to the high temperature resistant declining admixture, the compressive strength of200 DEG C or more can be effectively guaranteed, and the effect of reducing the declining of the compressive strength is reached.

Owner:成都博世威科技有限公司

Special brake pad for environment-friendly passenger car

InactiveCN103148140ASmall recessionLow speed sensitivityOther chemical processesFriction liningCarbon blackPolytetrafluoroethylene

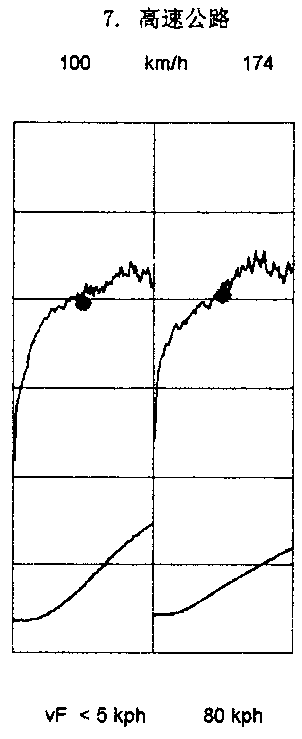

The invention discloses a special brake pad for an environment-friendly passenger car. The special brake pad is characterized by being prepared from the following components in parts by weight: 10-12 parts of phenolic resin, 3-5 parts of epoxy resin, 3-5 parts of mineral fibers, 5-10 parts of tin sulfide, 5-7 parts of synthetic graphite, 2 parts of polytetrafluoroethylene, 18-20 parts of steel fibers, 4-6 parts of red copper fibers, 2 parts of alumina, 3-5 parts of frictional powder, 5-7 parts of carbon black, 7-9 parts of titanium dioxide, 5-10 parts of mineral fibers, 8-10 parts of wollastonite and 5-10 parts of calcium sulfate. The special brake pad for the environment-friendly passenger car has the characteristics that the high-speed high-temperature recession is low; the speed sensitivity is especially low; friction coefficients are very stable when the passenger car is braked from the low speed of 40km per hour to the high speed of 180km per hour; an average friction coefficient is 0.30 micrometers; and a good result can be realized when the high-speed friction coefficient of the passenger car braking is 0.30 micrometers, so that a braking distance of the passenger car during the high-speed movement is reduced and a safety coefficient of the passenger car can be improved.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

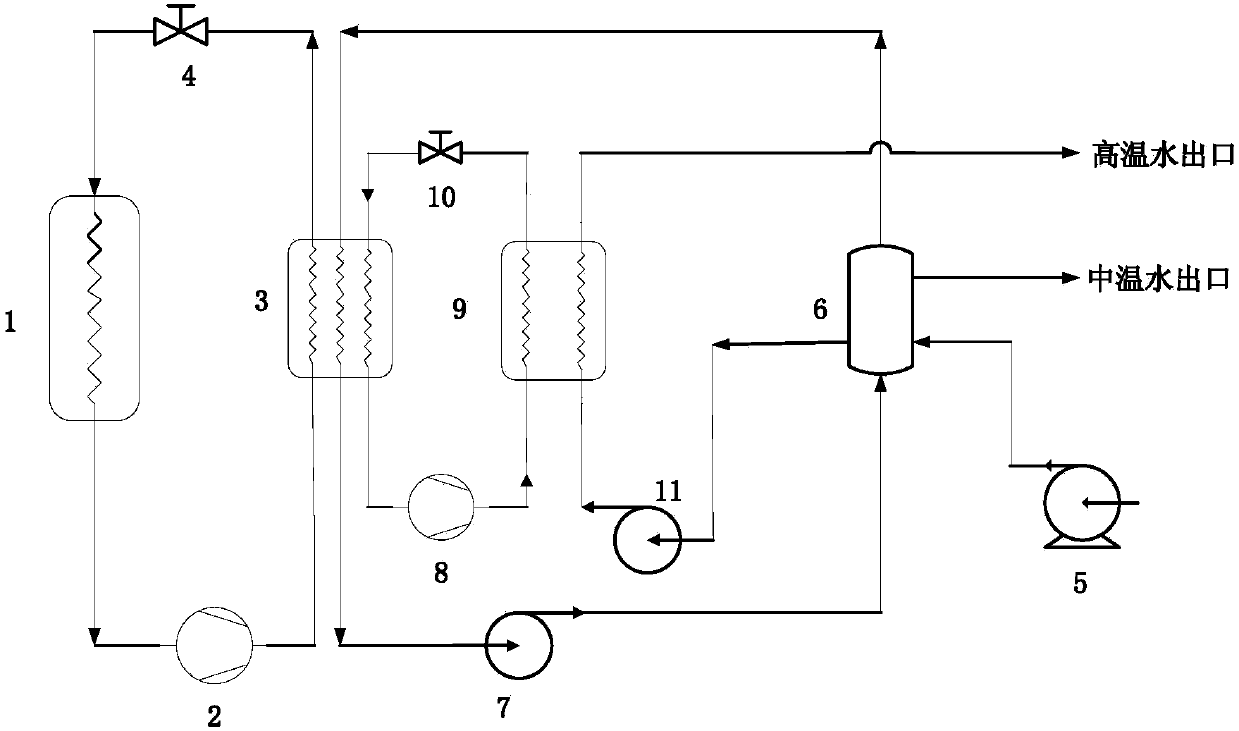

Efficient direct-heating type stair coupling heat pump water heater

InactiveCN108489094AImprove efficiencyReduce heat transfer temperature differenceFluid heatersCompression machines with non-reversible cycleCouplingIntermediate heat exchanger

The invention discloses an efficient direct-heating type stair coupling heat pump water heater. The efficient direct-heating type stair coupling heat pump water heater comprises an evaporator, a firstcompressor, an intermediate heat exchanger, a first throttling valve, a first water pump, a water storage tank, a second water pump and a second compressor. An outlet of the evaporator is connected with an air suction opening of the first compressor, an exhaust opening of the first compressor is connected with a first inlet of the intermediate heat exchanger, a first outlet of the intermediate heat exchanger is connected with an inlet of the first throttling valve, and an outlet of the first throttling valve is connected with an inlet of the evaporator. An outlet of the first water pump is connected with a first inlet of the water storage tank, a first outlet of the water storage tank is connected with a second inlet of the intermediate heat exchanger, a second outlet of the intermediateheat exchanger is connected with an inlet of the second water pump, an outlet of the second water pump is connected with a second inlet of the water storage tank, and a third outlet of the water storage tank is a moderate-temperature hot water outlet. The efficient direct-heating type stair coupling heat pump water heater has the advantages that the efficiency is high, the loads of the compressorsare light in the low-temperature environment, and the service life is prolonged.

Owner:ZHEJIANG UNIV OF TECH

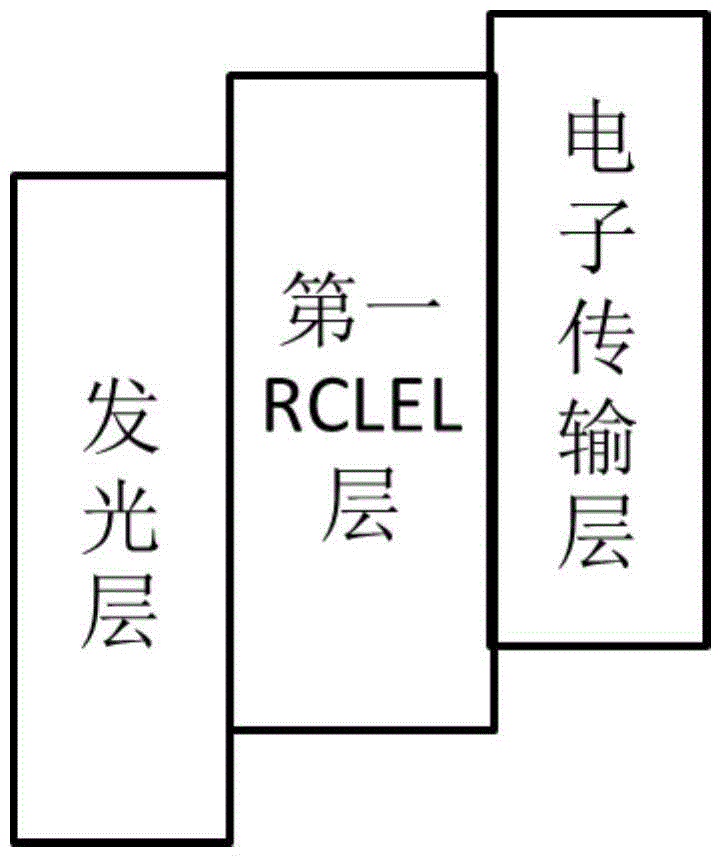

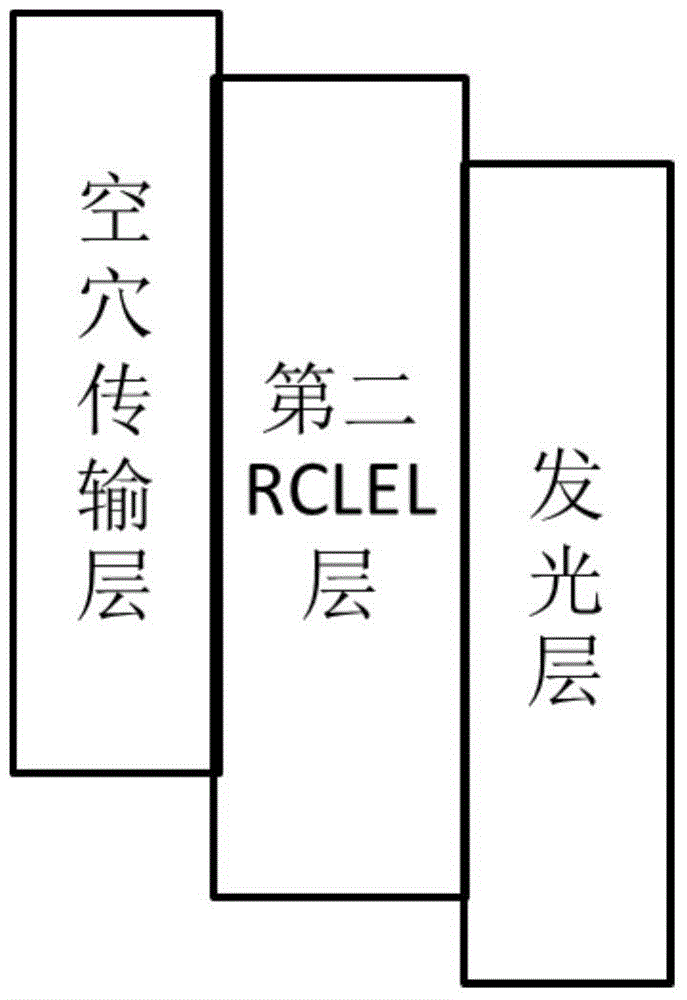

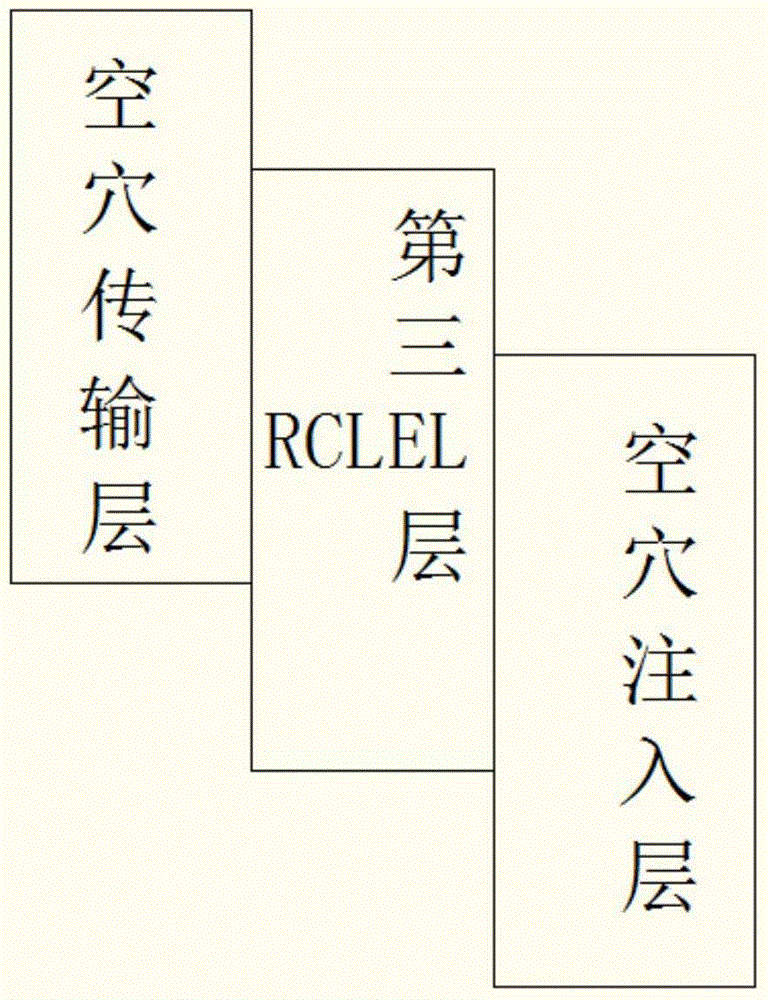

OLED device

InactiveCN106206961ASmall recessionExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerLayer interface

The invention relates to the technical field of a semiconductor, and particularly to an OLED device. An RCLEL layer is arranged between an electron transport layer and a hole transport layer; the RCLEL layer can effectively prevent accumulation of electric charges in a film layer interface between the electron transport layer and the hole transport layer, so that a condition that a non-luminous center is formed on the film layer interface caused by the accumulated electric charges is prevented; in addition, the RCLEL layer also has a reversible electrochemical oxidization reduction property, so that material deterioration caused in the transport process of electrons and holes can be greatly relieved; and diffusible ions and impurities also can be effectively prevented from entering a luminous layer, so that the service life of the device is prolonged.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

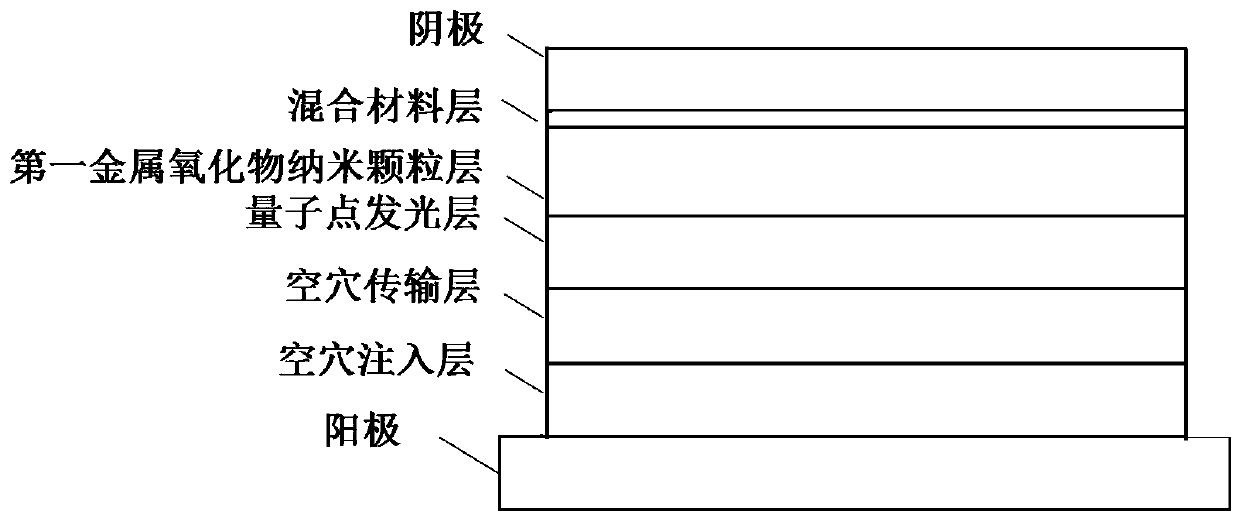

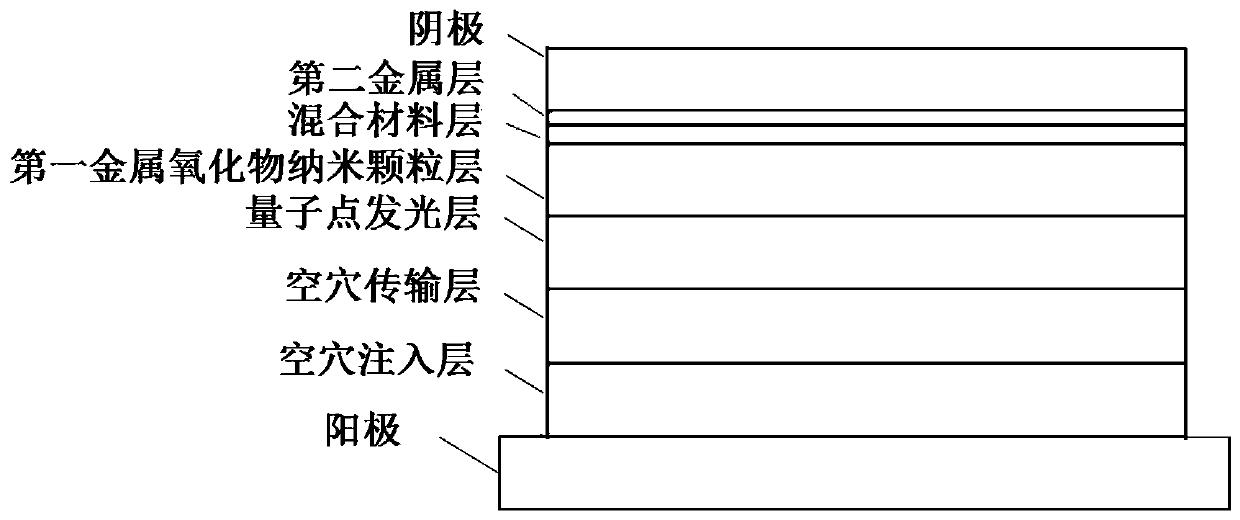

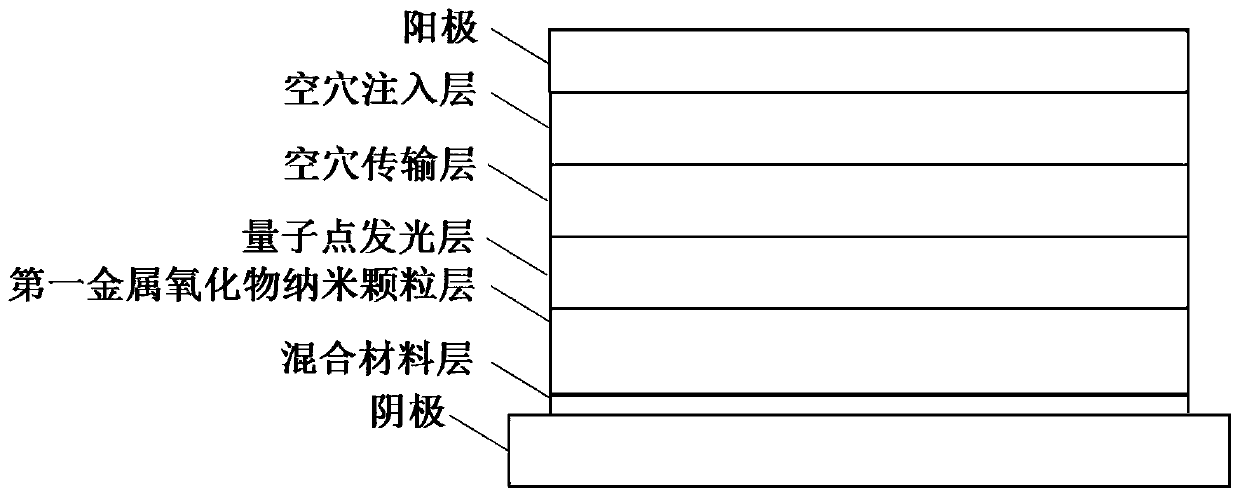

Quantum dot light-emitting diode and preparation method thereof

ActiveCN111384263ASmall recessionReduce heat accumulationSolid-state devicesSemiconductor/solid-state device manufacturingMetal oxide nanoparticlesChemical physics

The invention provides a quantum dot light emitting diode which comprises: a cathode and an anode which are oppositely arranged; a quantum dot light-emitting layer that is arranged between the cathodeand the anode; a lamination layer that is arranged between the cathode and the quantum dot light-emitting layer and comprises a first metal oxide nanoparticle layer and a mixed material layer arranged on the surface, opposite to the quantum dot light-emitting layer, of the first metal oxide nanoparticle layer, wherein the mixed material layer comprises first metal oxide nano particles and secondmetal oxide dispersed in gaps of the first metal oxide nano particles, and the first metal oxide nano particles in the first metal oxide nano particle layer are electron transport materials; in addition, in the mixed material layer, the content of the second metal oxide is gradually increased along the direction from the quantum dot light-emitting layer to the cathode.

Owner:TCL CORPORATION

Aluminum conductive paste for silicon solar cell back surface field and preparation method thereof

InactiveCN101621082BSmall recessionImprove conductivityFinal product manufactureNon-conductive material with dispersed conductive materialBack surface fieldSilicon solar cell

Owner:付天恩

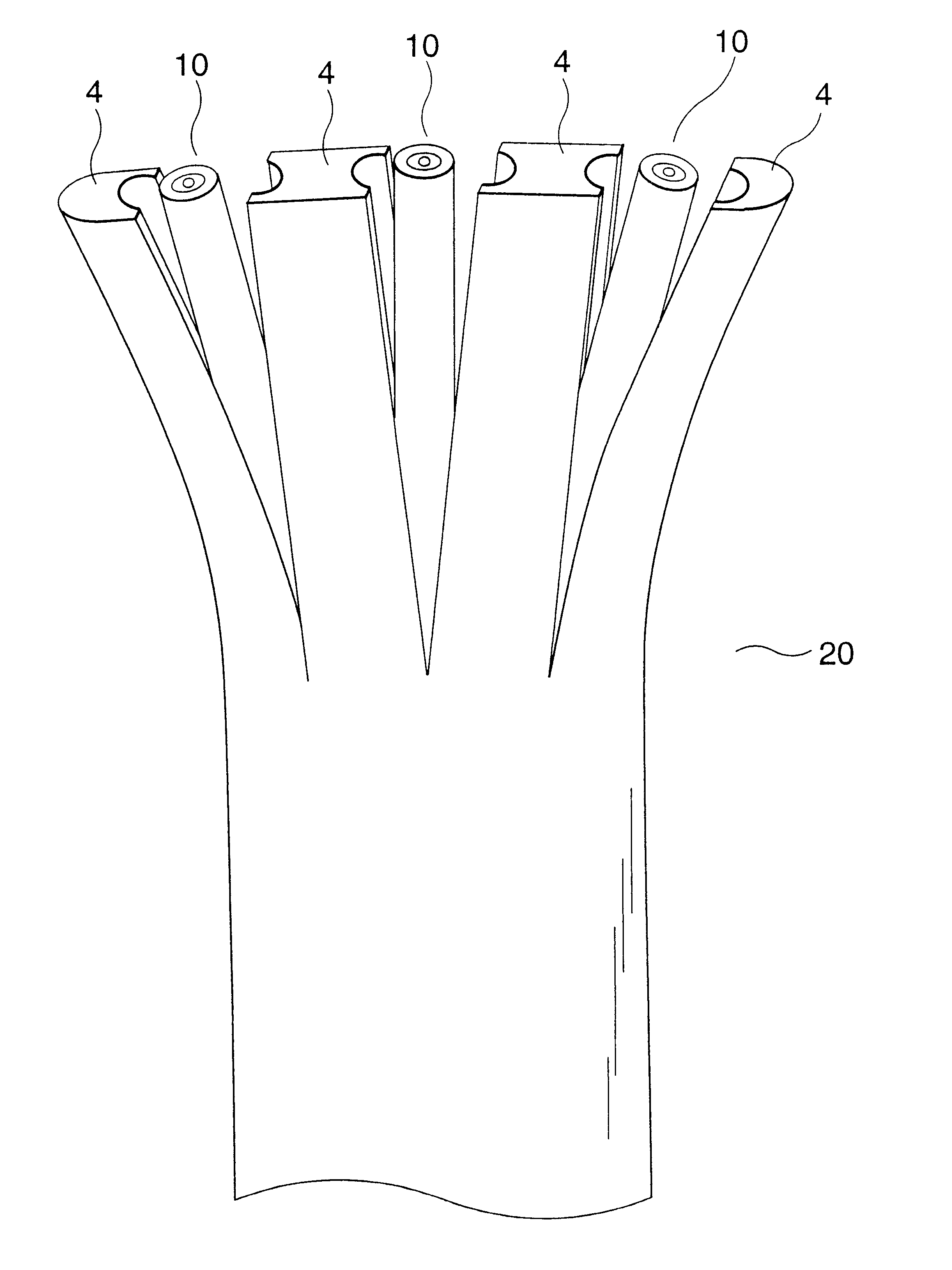

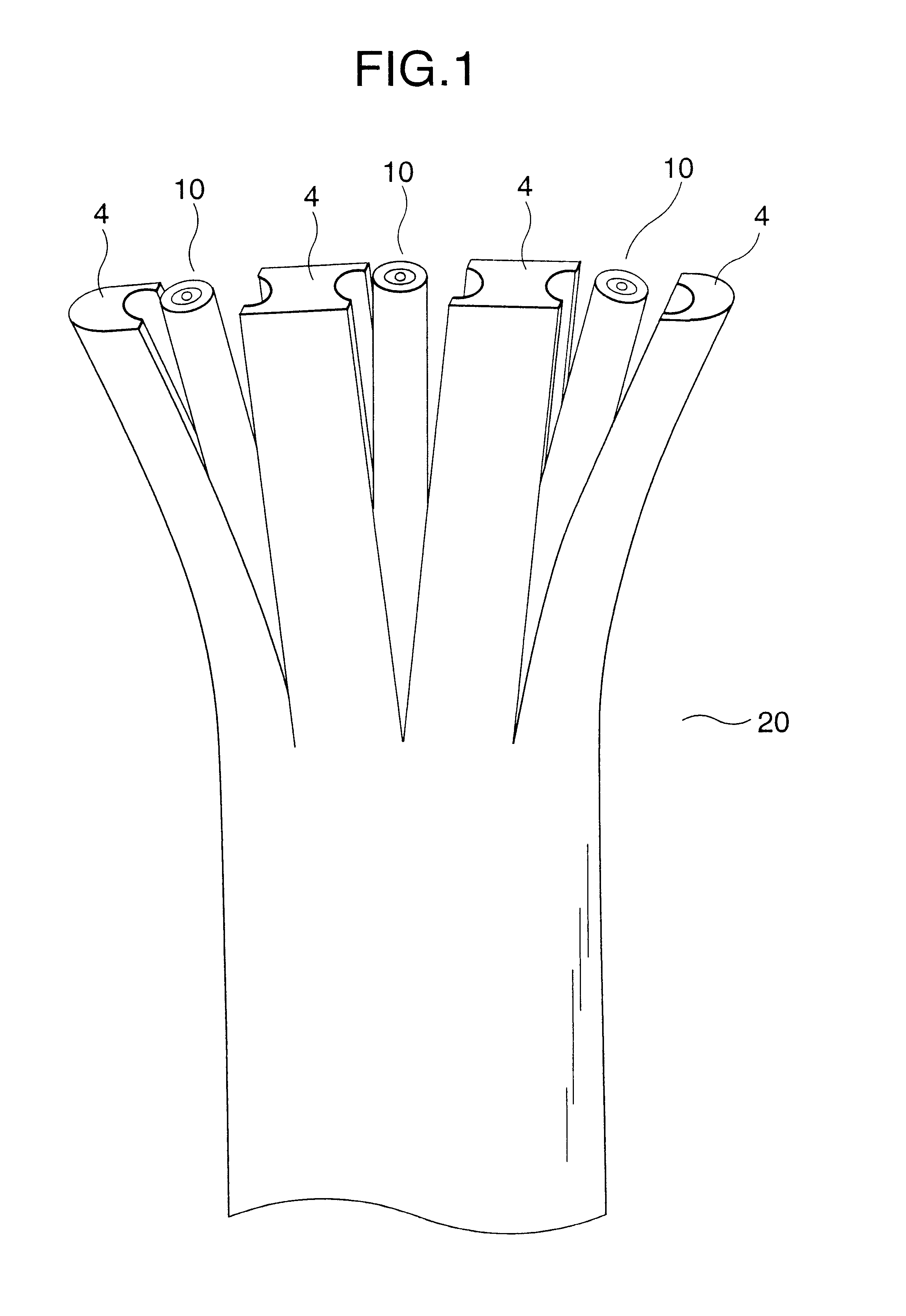

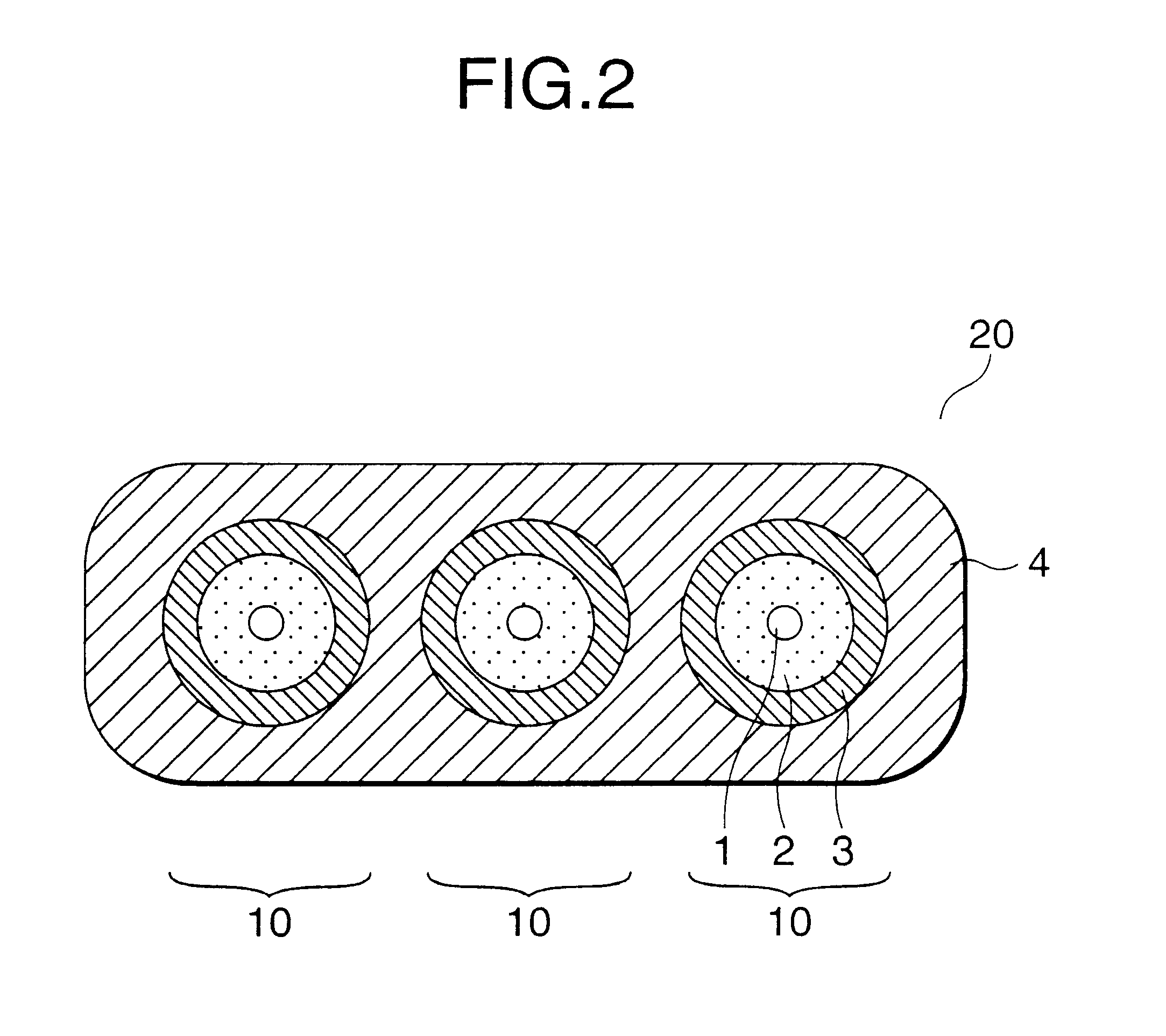

Optical cable

InactiveUS6512869B1Improve efficiencyFlat surfaceFibre mechanical structuresYoung's modulusEngineering

A flat type optical cable is composed of a plurality of optical fiber cords, each including an optical fiber coated with a cord jacket, which are parallel arranged; and a cable jacket which directly coats the cord jackets so that the optical fiber cords are integrated into one optical cable. In the flat type optical cable, the Young's modulus of a coating material forming the cable jacket is lower than the Young's modulus of a coating material forming the cord jacket. Particularly preferably, the Young's modulus of the coating material for forming the cord jacket is in a range of from 9 kg / mm2 to 15 kg / mm2 whereas the Young's modulus of the coating material for forming the cable jacket is in a range of from 4 kg / mm2 to 9 kg / mm2.

Owner:SUMITOMO ELECTRIC IND LTD

Chain-rings set for a power transmission system provided with segmented chain-rings in different planes

ActiveUS11279441B2Improve structural strengthGuarantees proper engagementChain/belt transmissionAxial displacementChain link

Owner:ZUMA INNOVATION SL

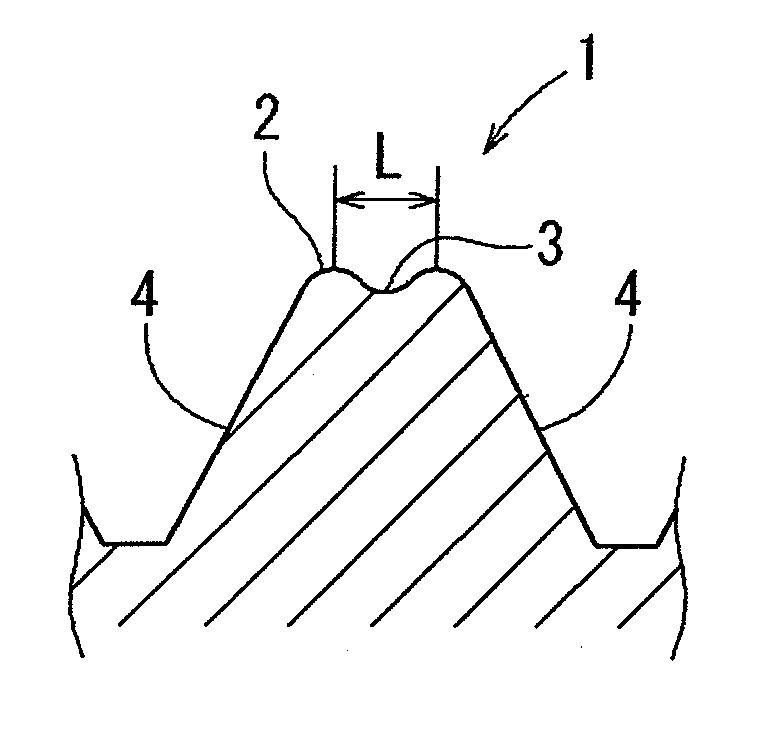

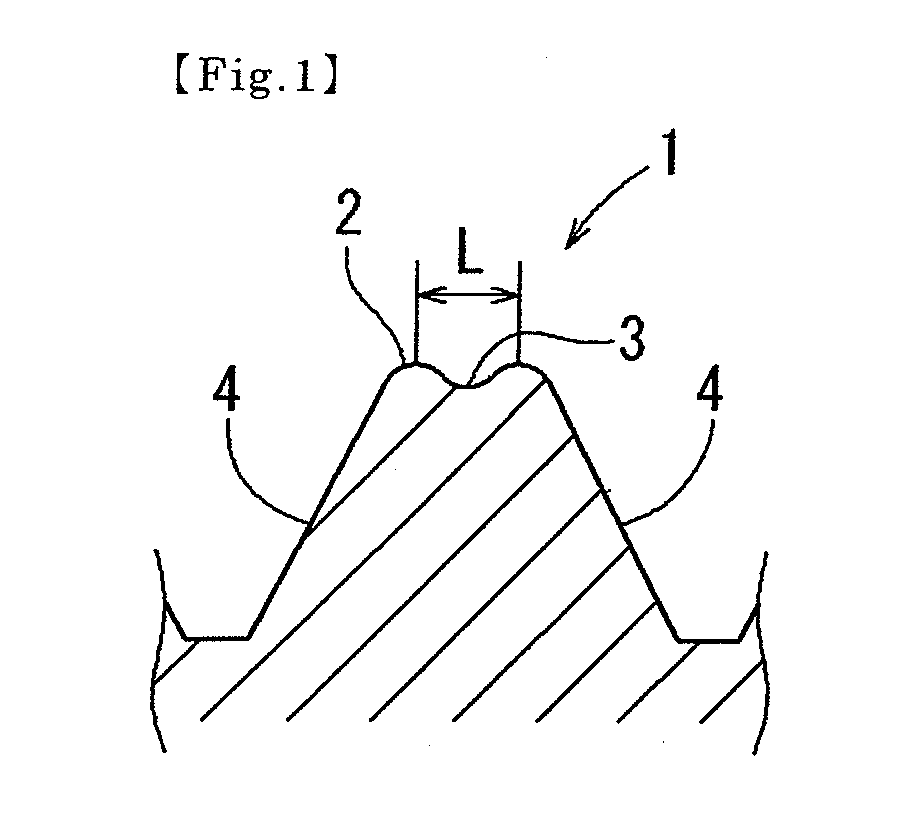

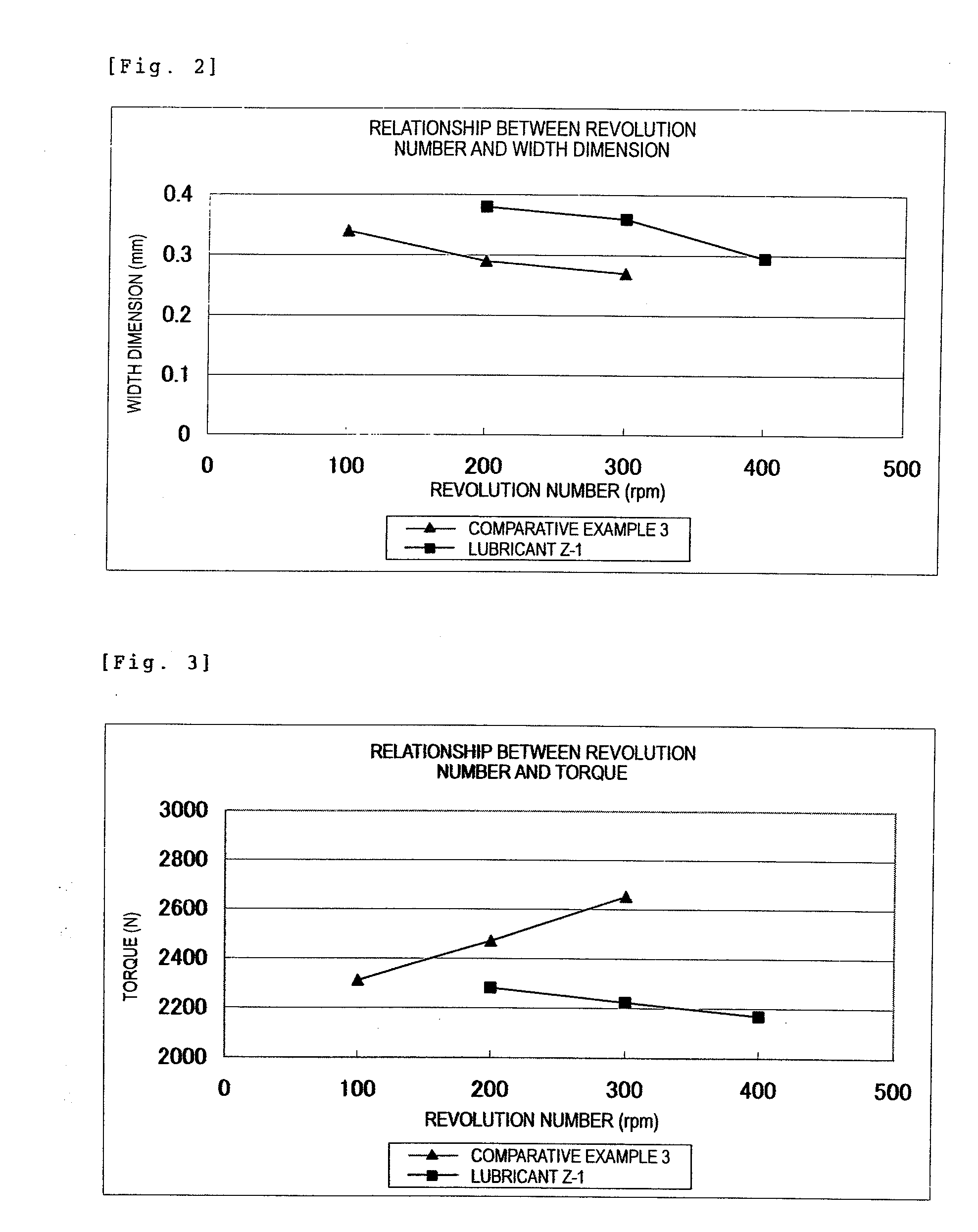

Lubricant for thread rolling and thread rolling method

InactiveUS20090156447A1Increasing the recess of the ridge top portionImprove product qualityAdditivesScrew-threads articlesOrganozinc compoundZinc compounds

A thread rolling lubricant of a nonchlorine species, in which a lubricant base oil is blended with 25 through 35 weight % of (A) a sulfur species extreme pressure agent, 6 through 16 weight % of (B) an organic zinc compound, 2 through 12 weight % of (C) a calcium species additive, and 2 through 13 weight % of (D) an oiliness agent for carrying out thread rolling.

Owner:TOYOTA BOSHOKU KK

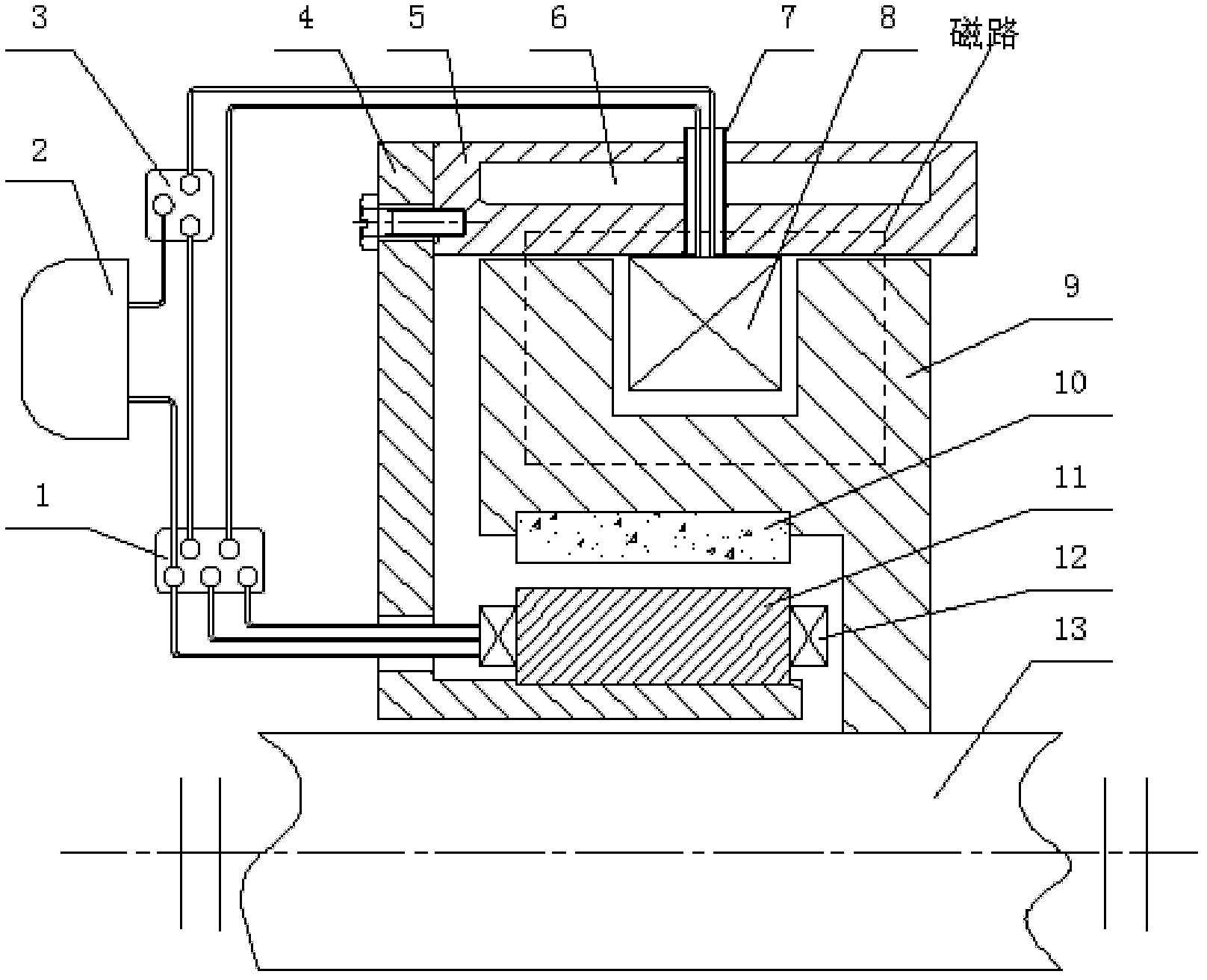

Liquid cooling auto-excitation-type eddy current retarder without electric brush structure

InactiveCN102299608BCompact structureSmall volume and massVehicular energy storageCooling/ventillation arrangementSelf excitedDrive shaft

A self-excited eddy current liquid-cooled retarder is disclosed. The retarder pertains to an auxiliary braking device retarding a vehicle, and comprises a retarder rotor, a retarder stator, a control module and a generator unit. The retarder rotor comprises a retarder coil, an electromagnet core and a core cage. The retarder coil is wound on a coil frame. The electromagnet core is inserted into the coil frame. The electromagnet core, the retarder coil and the coil frame are evenly distributed on the circumference of the core cage. The retarder rotor is connected to a transmission shaft of an automobile. The inner circle of the retarder stator and the outer circle of the electromagnet core of the retarder rotor are coaxial. The generator unit comprises a generator exciting winding, a generator exciting magnetic pole, a generator armature winding and a generator armature core and is received in the retarder rotor.

Owner:YANGZHOU ANXING ELECTROMECHANICAL TECH

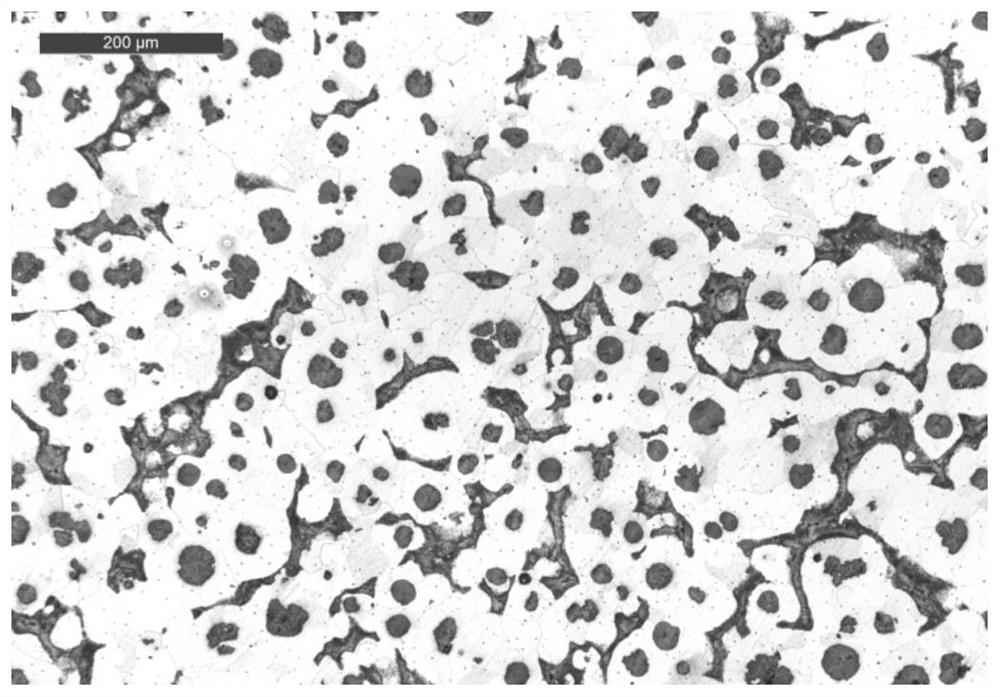

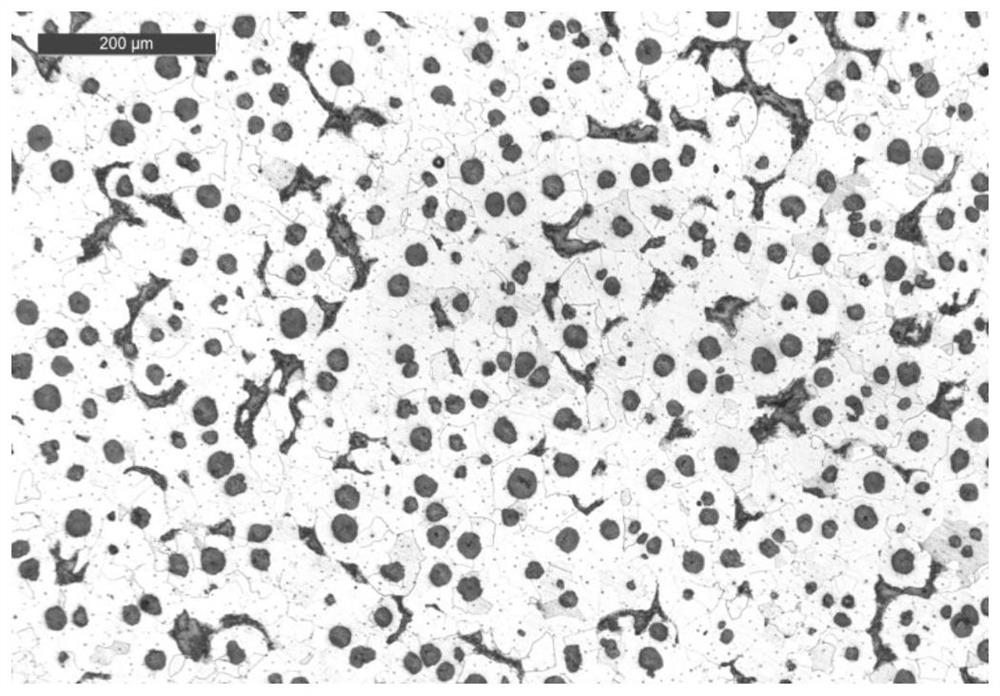

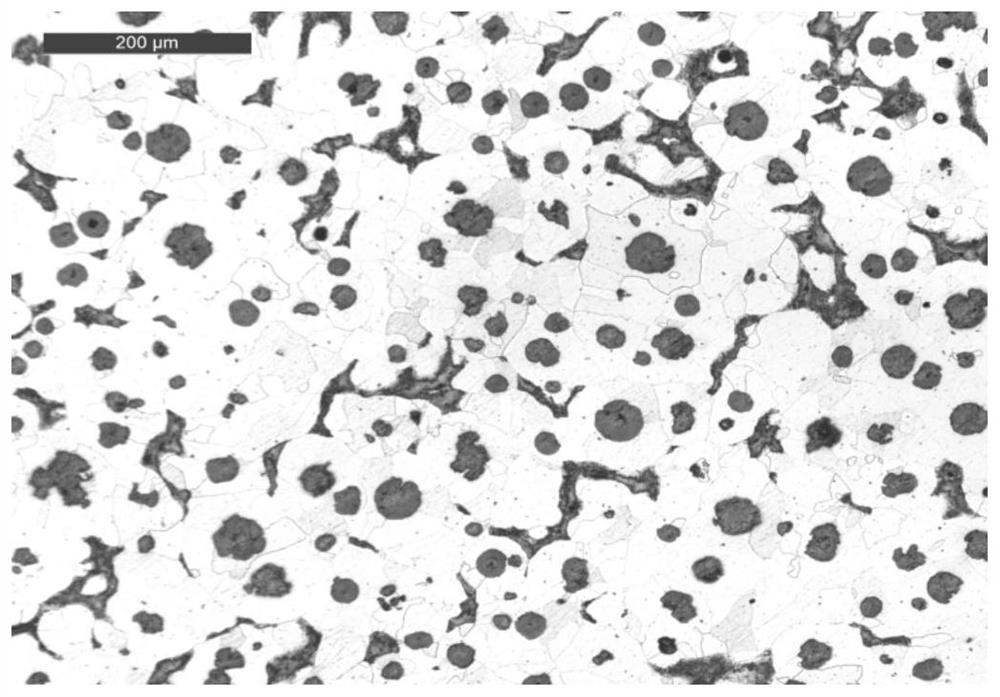

Preparing method for as-cast-condition mixed matrix QT500-14 spheroidal graphite cast iron

The invention provides a preparing method for as-cast-condition mixed matrix QT500-14 spheroidal graphite cast iron. The preparing method includes the steps of raw material selecting and furnace burden matching, alloy component designing, smelting technology controlling, and melt treating and purifying of nucleating agents, spheroidizing agents, metal-stream inoculation agents, foamed ceramic filters and the like; and under the assistance of corresponding melt inoculation and spheroidizing treatment technologies, a good-performance as-cast-condition mixed matrix spheroidal graphite cast iron material is obtained. According to the as-cast-condition mixed matrix QT500-14 spheroidal graphite cast iron material, the content range of pearlite in a matrix structure is 5%-20%, the content range of ferrite in the matrix structure is 75%-90%, the spheroidizing grade is 2, the size of graphite nodules ranges from 6 grades to 7 grades, and the spheroidizing rate of the graphite nodules is largerthan or equal to 90%. The mechanical property of a separated test bar of casting reaches Rm>=500 MPa, Rp0.2>=380 MPa, and A>=14%. Combined with a furan self-hardened resin sand casting technology, thepreparing method can meet the requirement for large spheroidal graphite cast iron part production and technology development, spheroidal graphite cast iron parts high in strength and high in ductility are produced, and the requirements for prolonging the fatigue service life and achieving light design of high-grade parts are met.

Owner:SHANGHAI TOBACCO MACHINERY +1

Method for carrying out in-vitro large-scale culture on umbilical cord mesenchymal stem cells

InactiveCN106434548AGuaranteed biogenicityEnsure safetySkeletal/connective tissue cellsFifth generationFirst generation

The invention relates to a method for carrying out in-vitro large-scale culture on umbilical cord mesenchymal stem cells. The method comprises the steps of: cleaning away most of the residual blood of an umbilical cord; preparing tissue fragments from the umbilical cord, and carrying out digestion by collagenase II; removing the tissue fragments after digestion, adding eluant to carry out centrifugation, and separating out unpurified first-generation umbilical cord mesenchymal stem cells; inoculating the obtained first-generation stem cells to a culture vessel according to 5.0*104 / cm<2> to 1.0*105 / cm<2>; after basal layer adherent cells are fused by 80% or more, carrying out digestion, and carrying out passage inoculation on the digested and dispersed cells to the culture vessel until obtaining cells subjected to four times of passage; inoculating fourth-generation cells to a HYPERFlask culture vessel, and until obtaining fifth-generation cells or sixth-generation cells, ending culture. According to the method disclosed by the invention, the first-generation umbilical cord mesenchymal stem cells are sufficiently subjected to in-vitro high-efficiency amplification by utilizing the HYPERFlask cell culture vessel, and a great quantity of mesenchymal stem cells applied to clinic and research are obtained.

Owner:CHONGQING STEM CELL TECH +7

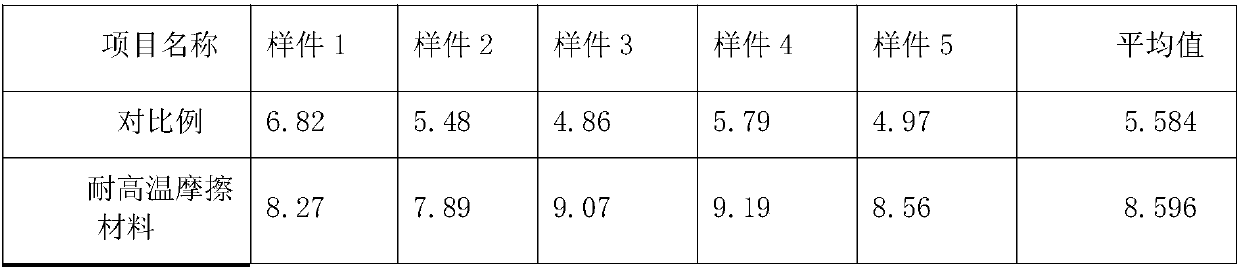

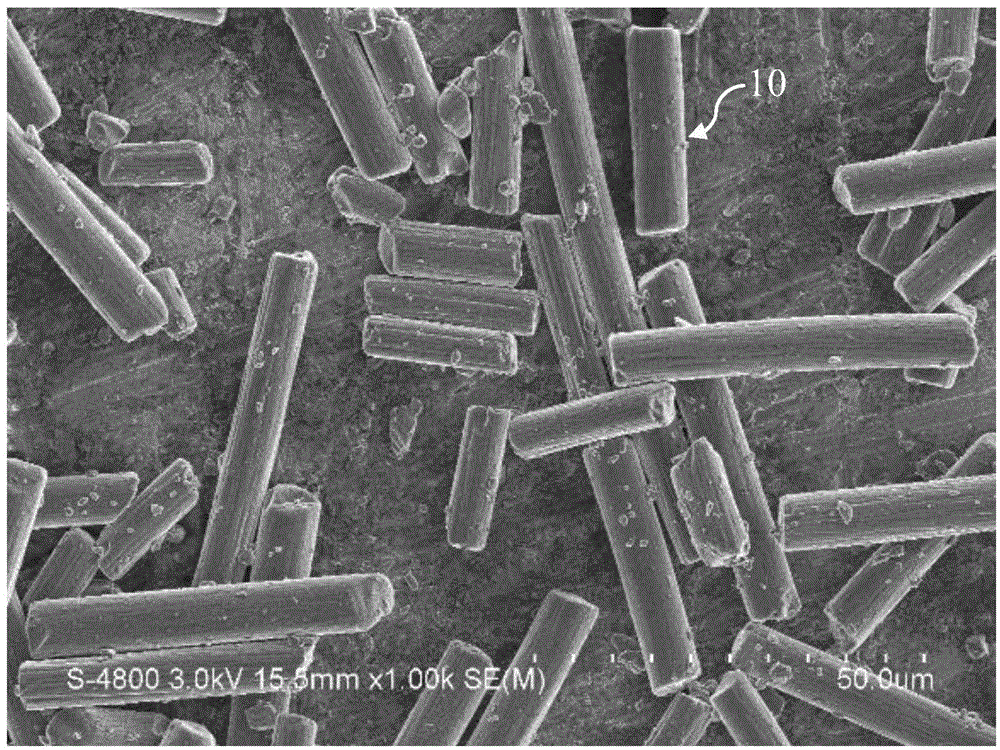

High-temperature resistant friction material and preparation method thereof

InactiveCN107740828AAvoid carbonizationReduce hardnessOther chemical processesFriction liningFiberMass ratio

The invention discloses a high-temperature resistant friction material. The high-temperature resistant friction material comprises heat-conduction mineral fibers, inorganic high-temperature adhesivesand porous mineral powder. A preparation method of the high-temperature resistant friction material comprises the following steps of (1) taking and mixing the heat-conduction mineral fibers, the inorganic high-temperature adhesives and the porous mineral powder according to the mass ratio; (2) cleaning, degreasing and polishing the surface of a steel backing and spraying the adhesives to the surface of the steel backing for standby application; (3) conducting pressing; (4) conducting heat treatment; (5) conducing grinding treatment; and (6) spraying plastic paint to the surface of the steel backing. The high-temperature resistant friction material is scientific in proportion, easy to manufacture and low in cost, has remarkable physical performance and stable friction coefficient. Meanwhile, the high-temperature resistant friction material is stable in friction coefficient, small in degeneration, good in recovery performance, moderate in hardness, comfortable and reliable in braking andcapable of lowering braking noise.

Owner:WUHAN YOUFIN FRICTION MATERIAL

Inoculant for as-cast production of pearlite ductile iron and preparation process thereof

The invention discloses an inoculant for as-cast production of pearlite ductile iron and a preparation process thereof. According to the preparation process, a medium-frequency electric induction furnace is used, an outside-furnace mix-melting method is adopted, and by controlling the adding time, adding mode and melting temperature of metal antimony, the silicon-antimony inoculant with the antimony content range being 0.1%-15% can be prepared. The method is simple, operation is convenient and rapid, the cost is low, the antimony metal yield can be increased by a large margin, energy consumption is reduced, protection of the environment is achieved, the working efficiency is improved, and the benefits are increased.

Owner:南京浦江合金材料股份有限公司

Formula of inoculant suitable for high-grade gray iron member and treatment method therefor

InactiveCN109207666ASmall recessionImprove stabilityProcess efficiency improvementSilicon ironPre treatment

The invention provides a formula of inoculant suitable for a high-grade gray iron member and a treatment method therefor, and relates to the technical field of inoculants. The inoculant includes rareearth silicon iron and an inoculant crude product. The rare earth silicon iron is composed of, by mass, 48-52% of Si, 0.8-1.2% of Y, 0.8-1.2% of Zr, 0.4-0.8% of Mo, 0.4-0.8% of Ti, 0.2-0.6% of V, 0.5-0.9% of Mn, 0.6-1.0% of Co, 1.2-1.6% of W, and the balanced being Fe. The inoculant crude product includes, by mass, 48-52% of Si, 0.75-1.25% of Al, 0.5-1.5% of Ca, 0.6-1.0% of Sr and the balanced being Fe. With various chemical components being filler in the inoculants, the inoculant can effectively alleviate recession of inoculation and increase the stability and enhances tensile strength of thegray iron member. Through pretreatment on the inoculant and addition of the inoculant for three times, graphitization of substances in molten iron is effectively improved. The inoculant has uniformity and good effect in inoculation.

Owner:ANHUI DATIAN CASTING

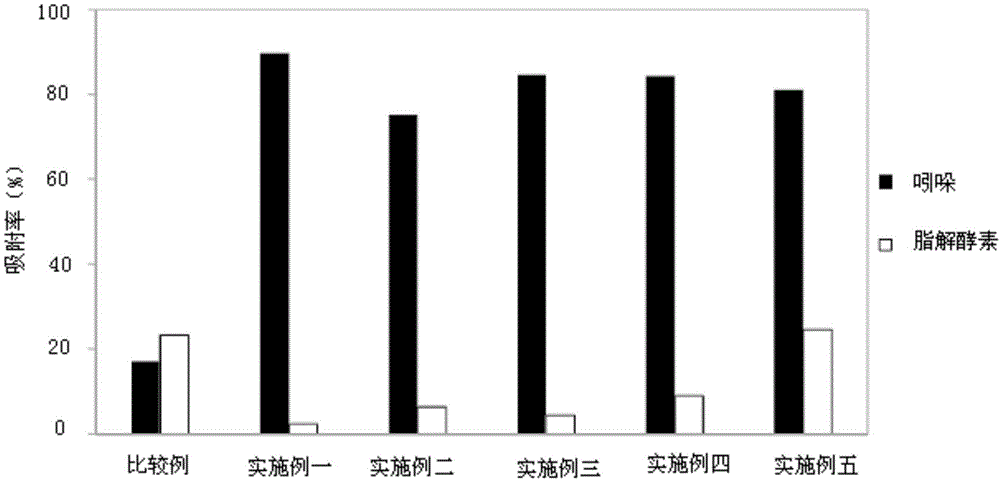

Adsorbent capable of reducing in vivo urotoxin

InactiveCN104666342AReduce accumulationImprove adsorption capacityCarbon active ingredientsAntinoxious agentsFiberMean diameter

The invention discloses an adsorbent capable of reducing in vivo urotoxin. The adsorbent comprises a polyacrylonitrile active carbon fiber with the characteristics that (1) the mean diameter is 5-30 microns; (2) the BET specific surface area is greater than 390m<2> / g; and (3) the total acidic group is greater than 1.2meq / g or the total basic group is greater than 1meq / g. The adsorbent has relatively high adsorption capacity on an urotoxin precursor, but has relatively low adsorption capacity on normal ferment in intestinal tracts. Therefore, the urotoxin adsorbent disclosed by the invention is capable of effectively relieving deterioration of the renal function, and is used as a therapeutic agent or a preventive for kidney diseases.

Owner:JINGYUN BIOLOGICAL TECH SHANGHAI

Compound stabilizer for preserving gingerol and use method of compound stabilizer

The invention discloses a compound stabilizer for preserving gingerol and a use method thereof, which can preserve the activity of gingerol for a long time. It is made by mixing and stirring raw soybean oil, white dextrin, glucose and inorganic salts. The parts by weight of each raw material are: 100-200 parts of soybean oil, 1-3 parts of white dextrin, 5-10 parts of glucose, and 1-3 parts of inorganic salt. Its use method is as follows: heat the composite stabilizer and gingerol to a certain temperature, then quickly mix the two, stir while adding, and keep warm at a suitable temperature for a certain period of time. The invention can keep the gingerol stable in the solution and slow down the decline of activity. The raw material of the invention is easy to obtain, and can maintain gingerol activity within one year at 4°C.

Owner:HUBEI UNIV OF ARTS & SCI

Total-nutrient meal replacement powder containing secoisolariciresinol diglucoside and preparation method of total-nutrient meal replacement powder

InactiveCN111671077AImprove non-specific immunityPrevent diabetesFood scienceBiotechnologyPolygonum fagopyrum

The present invention relates to the field of food processing. Total-nutrient meal replacement powder containing secoisolariciresinol diglucoside comprises the following raw materials in parts by weight: secoisolariciresinol diglucoside, oat, quinoa, buckwheat, barley, black rice, millet, red beans, white kidney beans, chickpeas, mung beans, konjac gum, resistant dextrin, soy protein powder, soy peptides, wolfberry powder, flaxseed microcapsule powder, medium chain fatty acid powder, erythritol, stevioside, silicon dioxide, Vitamin A, Vitamin E, Vitamin B1, Vitamin B2, Vitamin B6, folic Acid,Vitamin C, niacin, pantothenic acid, calcium ascorbate, zinc gluconate, iron pyrophosphate and magnesium gluconate. The prepared total-nutrient meal replacement powder containing the secoisolariciresinol diglucoside has the effects of anti-tumor and increasing satiety.

Owner:宁夏君星坊食品科技有限公司

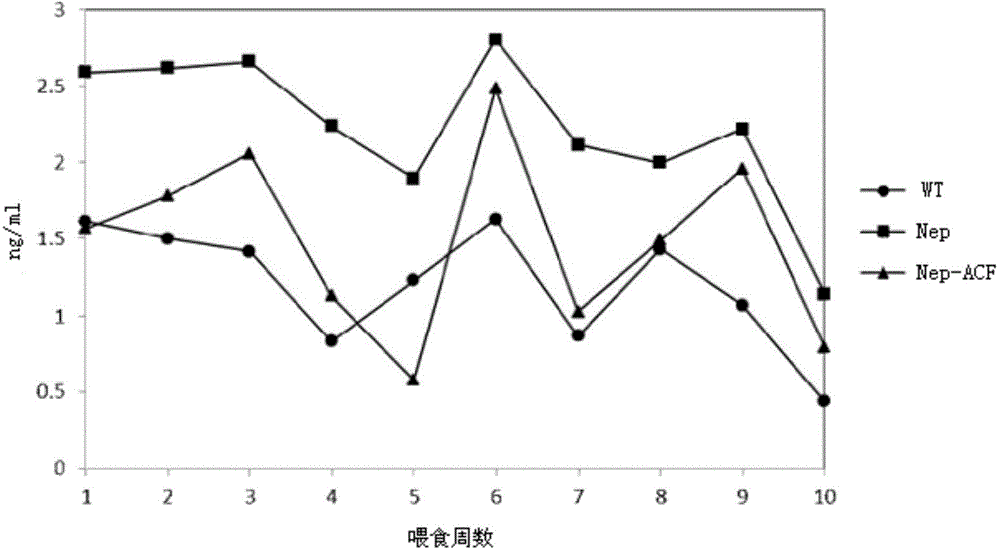

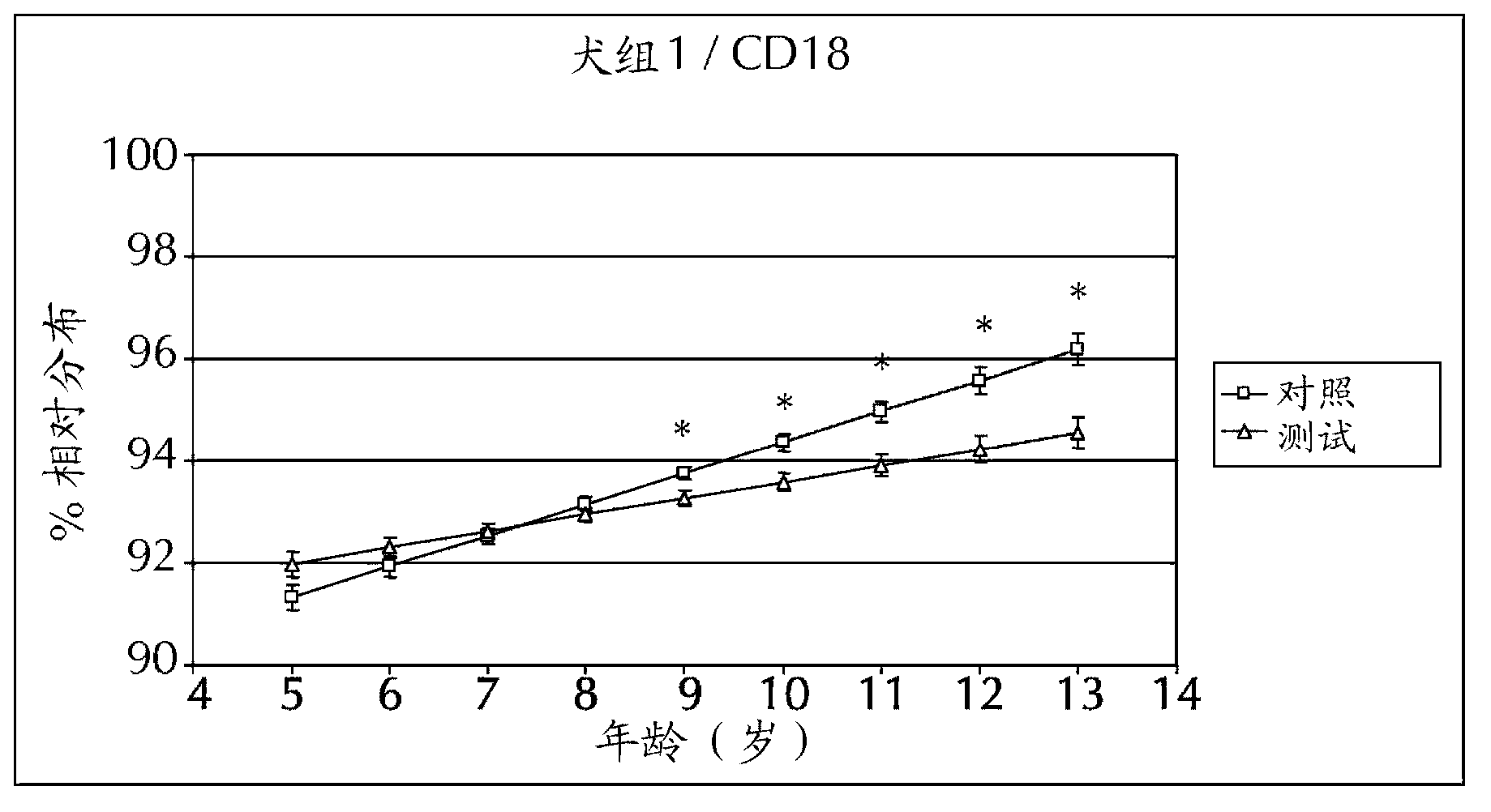

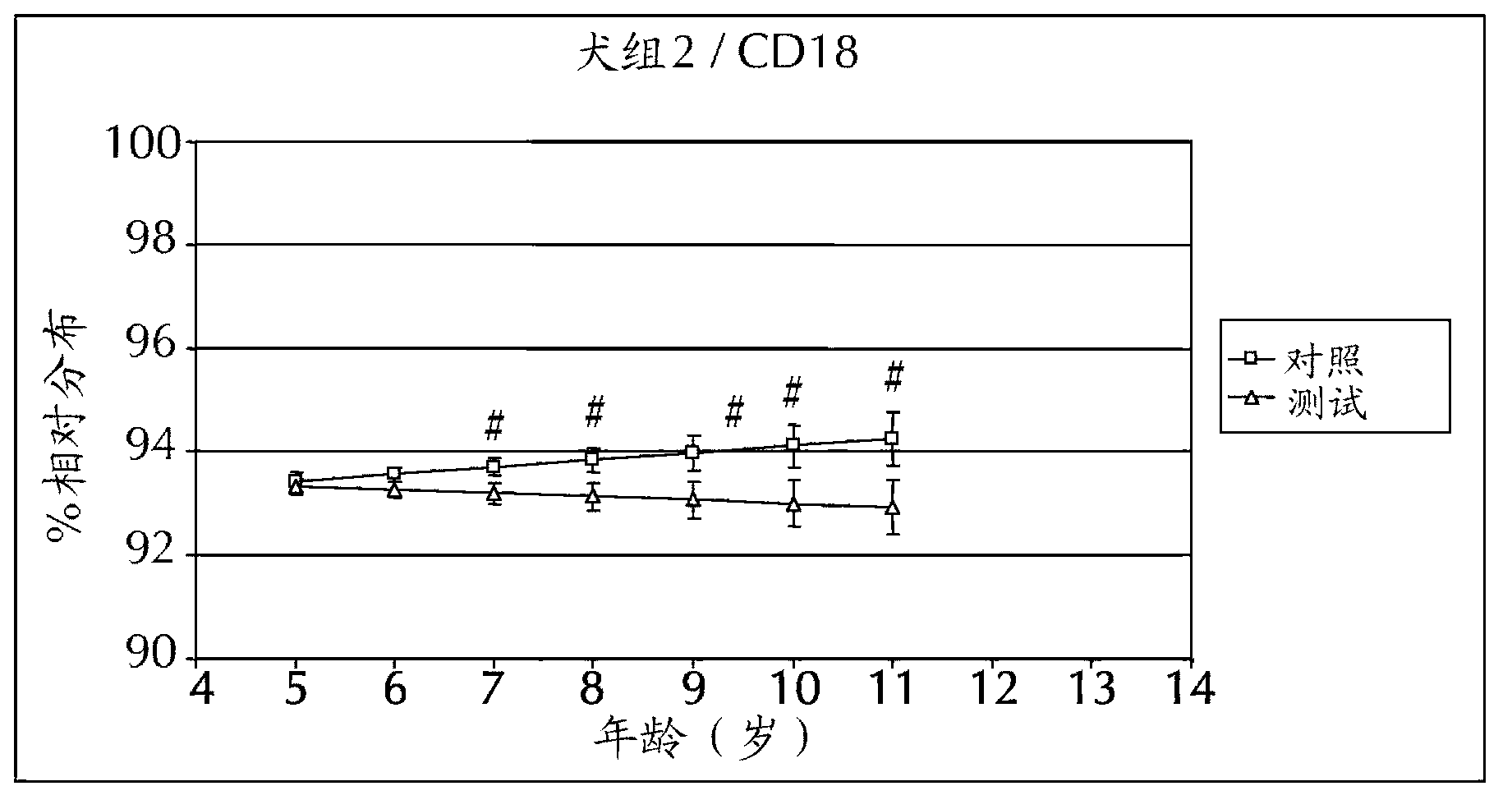

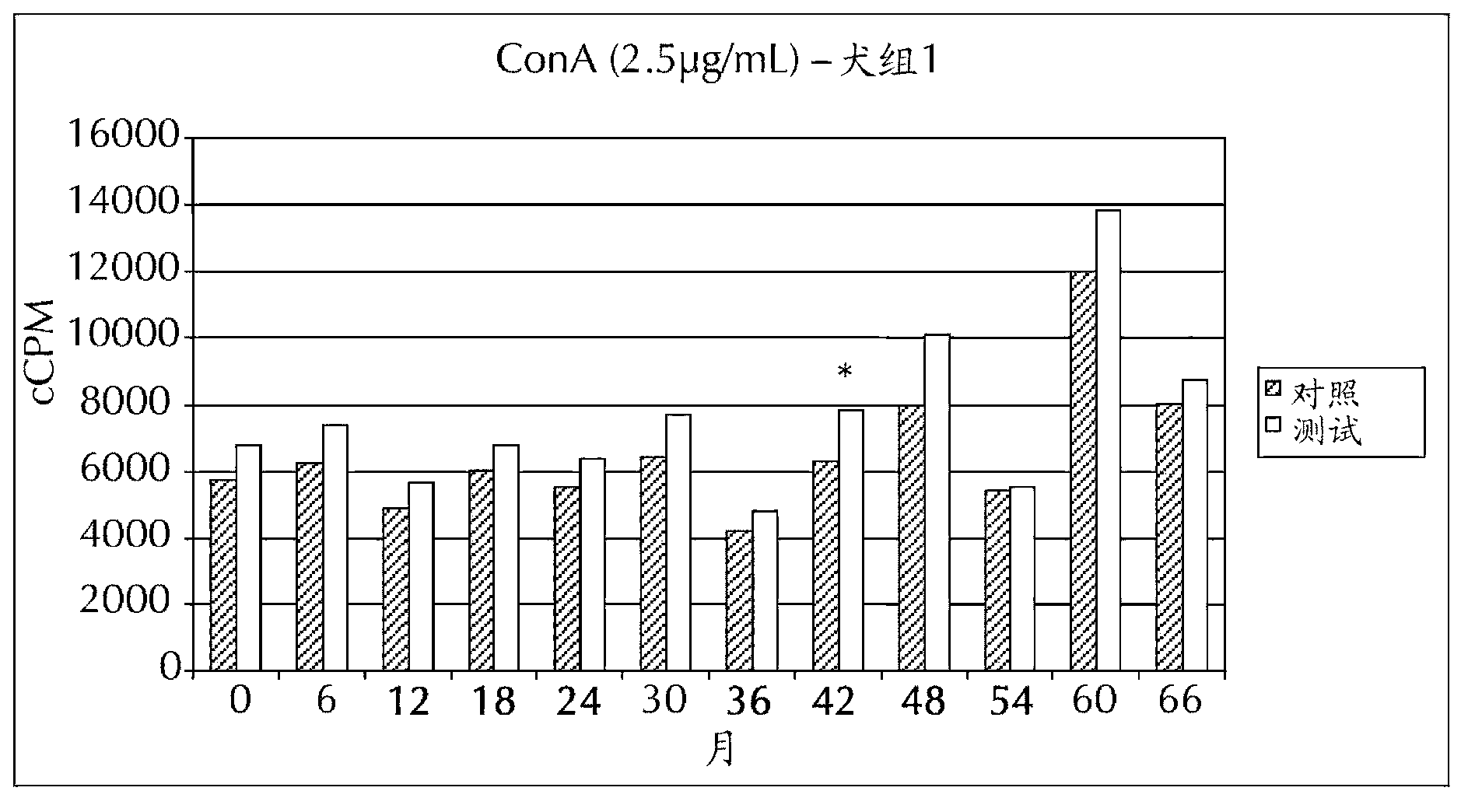

Method for improving the immunity of a companion animal

InactiveCN103338650AImprove immunitySmall recessionAnimal feeding stuffAntinoxious agentsCell phenotypeMannoheptulose

The invention provides a method of improving the immunity of a companion animal. The method can include administering to the companion animal a glucose anti-metabolite. The glucose anti-metabolite can be 2-deoxy-D-glucose; 5-thio-D-glucose; 3-O-methylglucose; 1,5-anhydro-D-glucitol; 2,5-anhydro-D-glucitol; 2,5-anhydro-D-mannitol; mannoheptulose; and mixtures and combinations thereof. The companion animal can be a dog or a cat. Improving the immunity can include altering the proliferative ability of T and B immune cells, and altering the relative distribution of immune cell phenotypes, for example.

Owner:MARS INC

High-strength and low-abrasion automobile brake pad

InactiveCN105587810AImprove wear resistanceHigh carbon contentOther chemical processesFriction liningFiberPorosity

The invention discloses a high-strength and low-abrasion automobile brake pad. The high-strength and low-abrasion automobile brake pad is characterized in that a raw material comprises, by weight, 12-15 parts of nitrile rubber, 15-20 parts of tyre powder, 6-8 parts of polytetrafluoroethylene, 3-5 parts of graphite, 2-4 parts of calcium carbonate, 4-6 parts of modified phenolic resin, 1-1.5 parts of a friction increase agent, 2-3 parts of calcined coke, 0.6-0.8 part of zirconium silicate, 0.8-1.2 parts of lead sulfide, 2-4 parts of mixed fibers and 2-4 parts of titanium dioxide. By means of recycling of the tyre powder in the high-strength and low-abrasion automobile brake pad, waste can be fully utilized, resources and energy can be recycled to create economic benefits, and the beneficial effect of being high in carbon content and porosity is achieved; the friction coefficient and the service life are guaranteed through the mixed fibers, and meanwhile brake noise can be effectively absorbed in the brake process; and the manufactured brake pad is good in abrasion resistance and small in high-speed and high-temperature declining, the average friction coefficient is 0.30 mu, the friction coefficient during automobile high-speed braking is 0.30 mu, and the friction coefficient and safety are high.

Owner:王洪珠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com