Patents

Literature

41results about How to "Easy to wind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

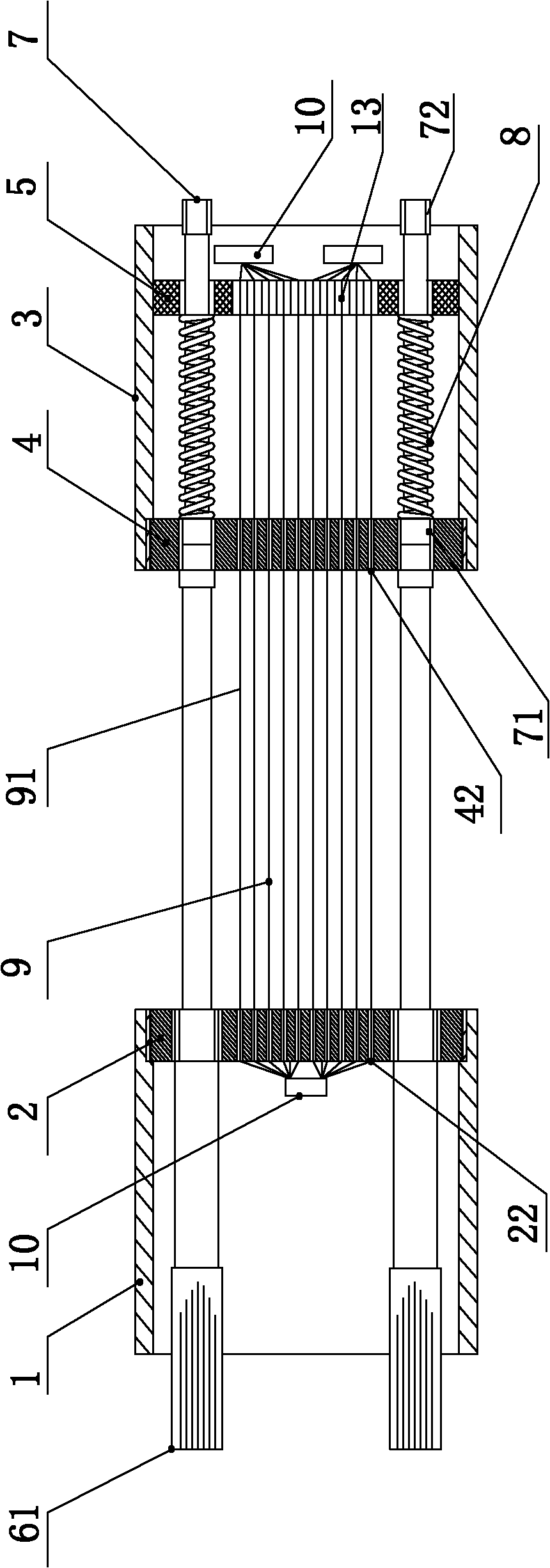

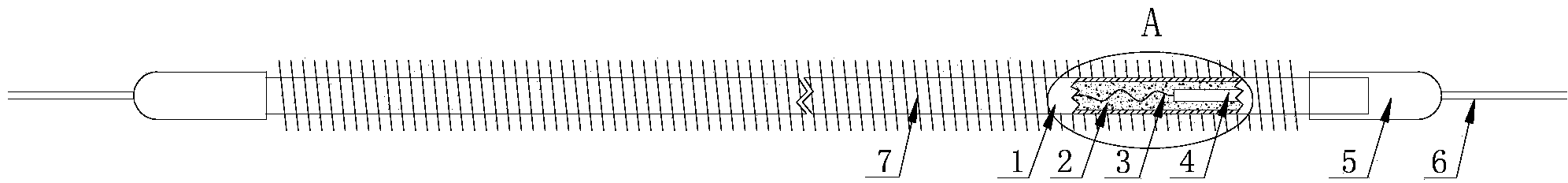

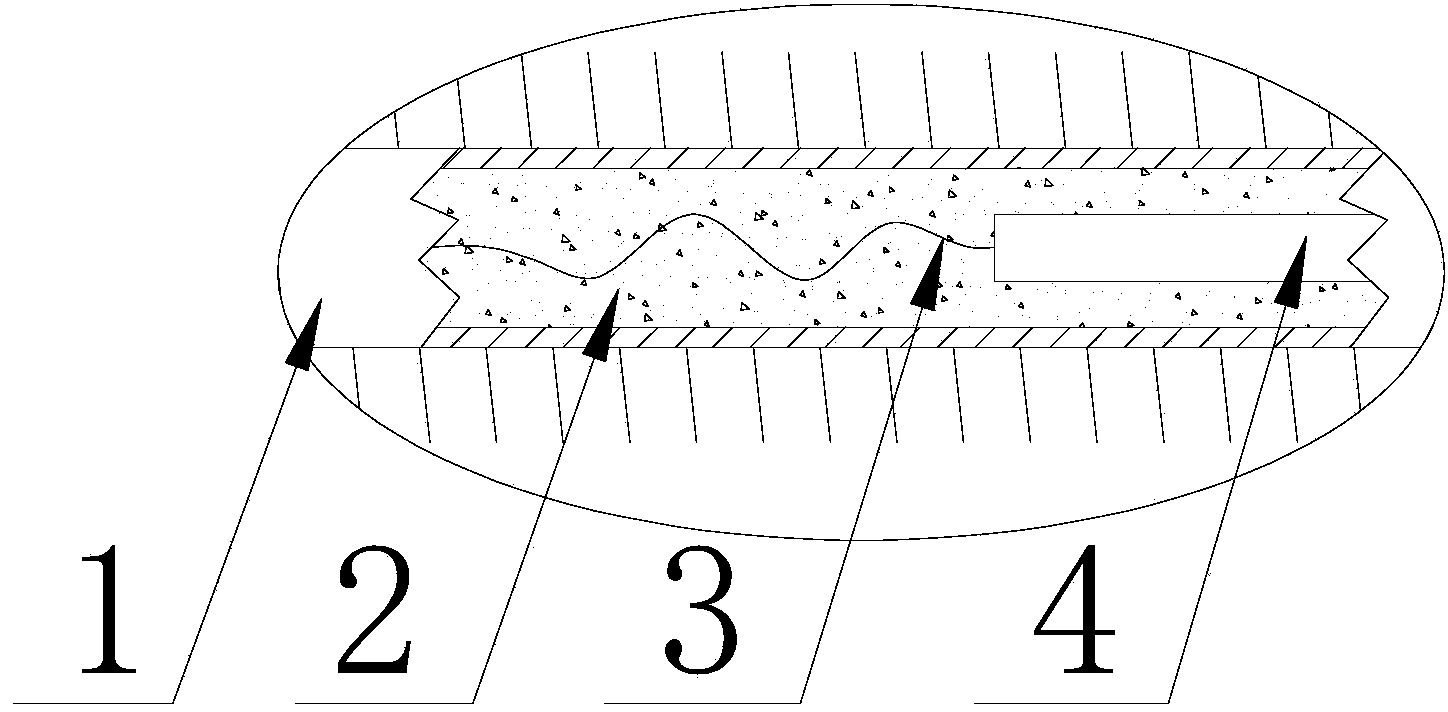

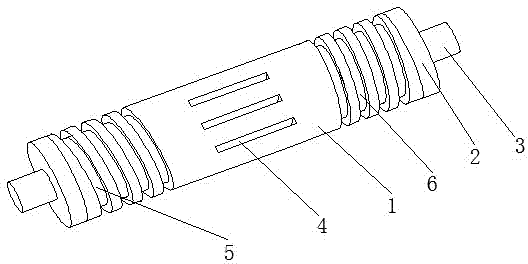

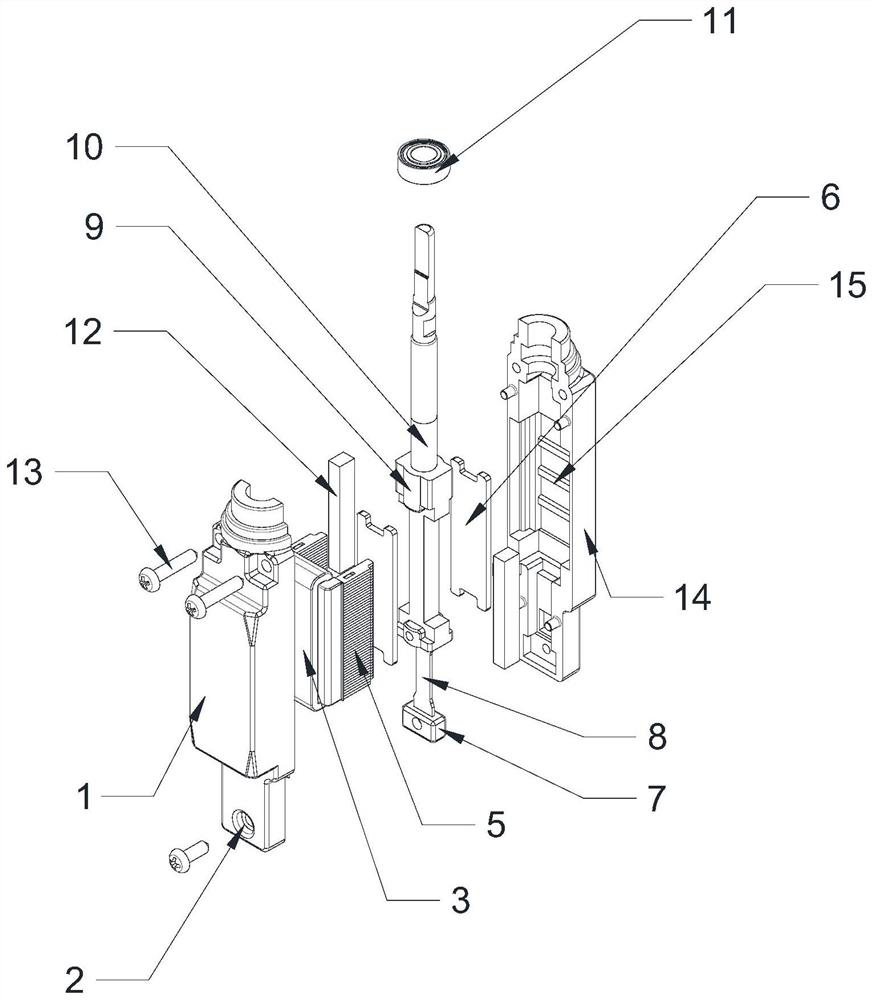

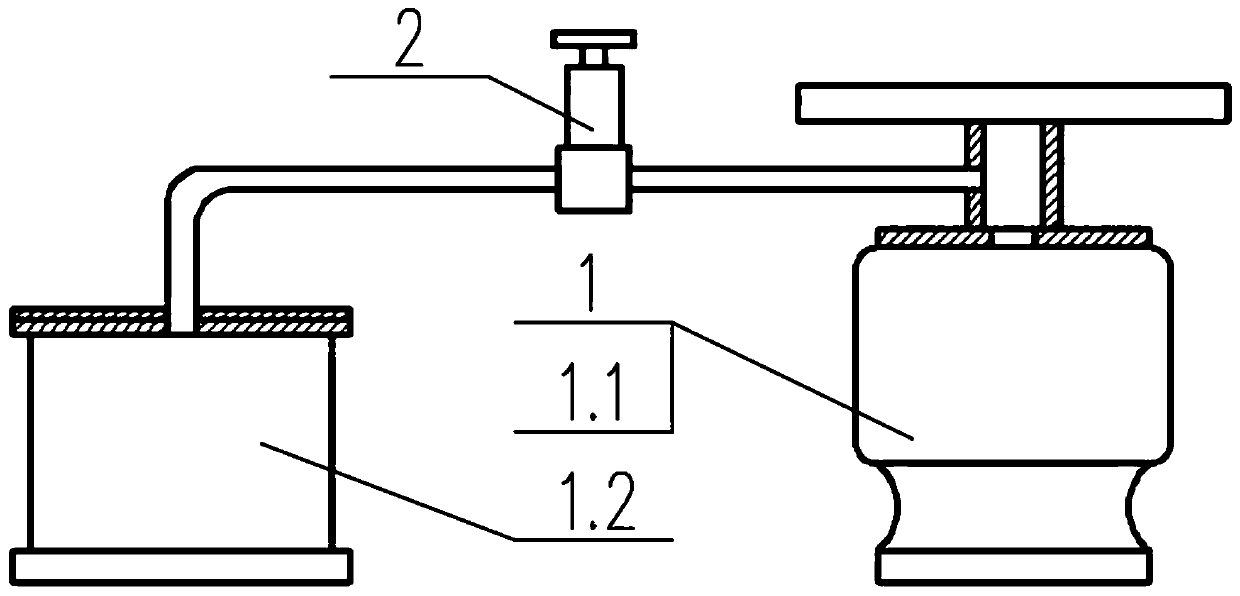

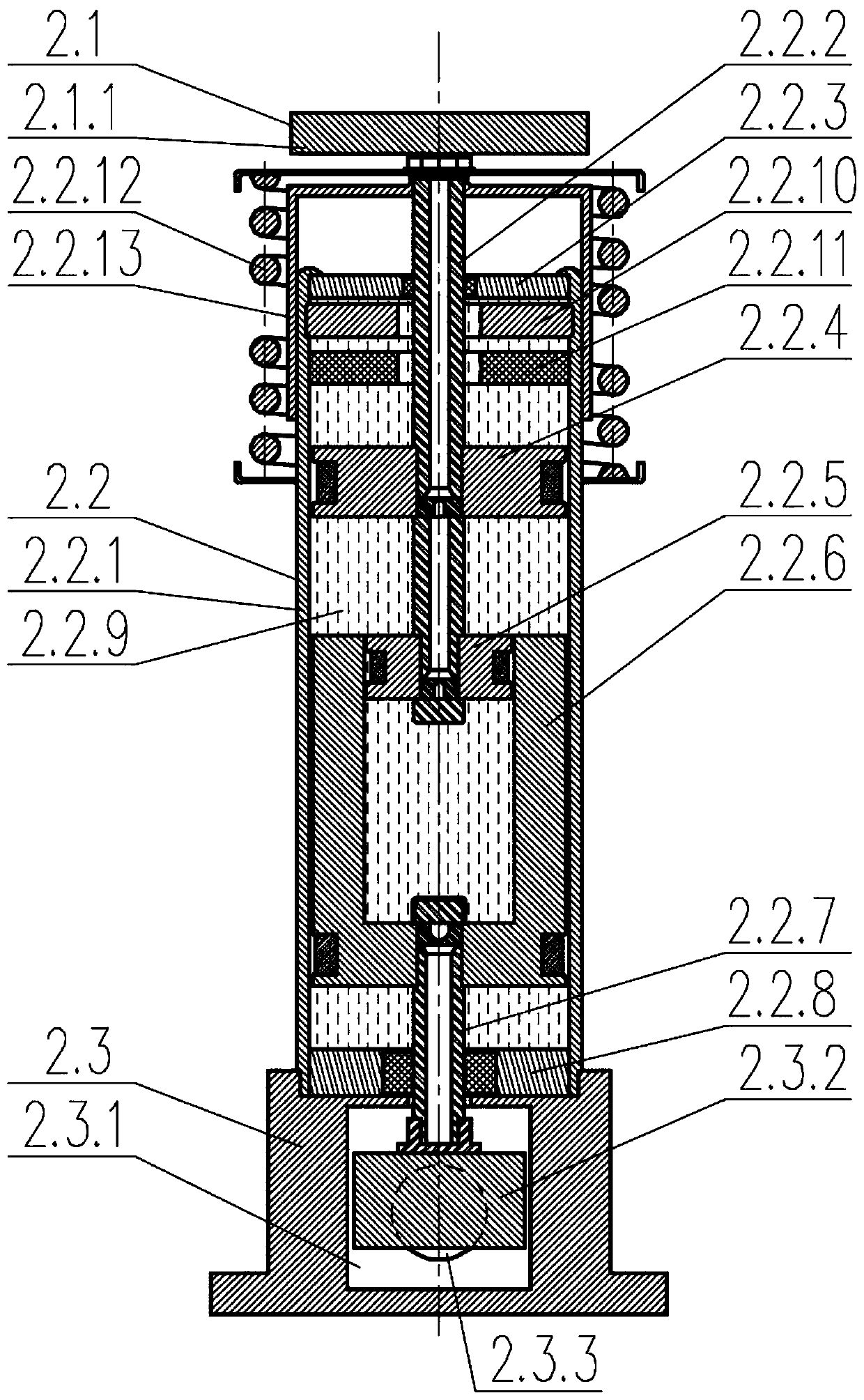

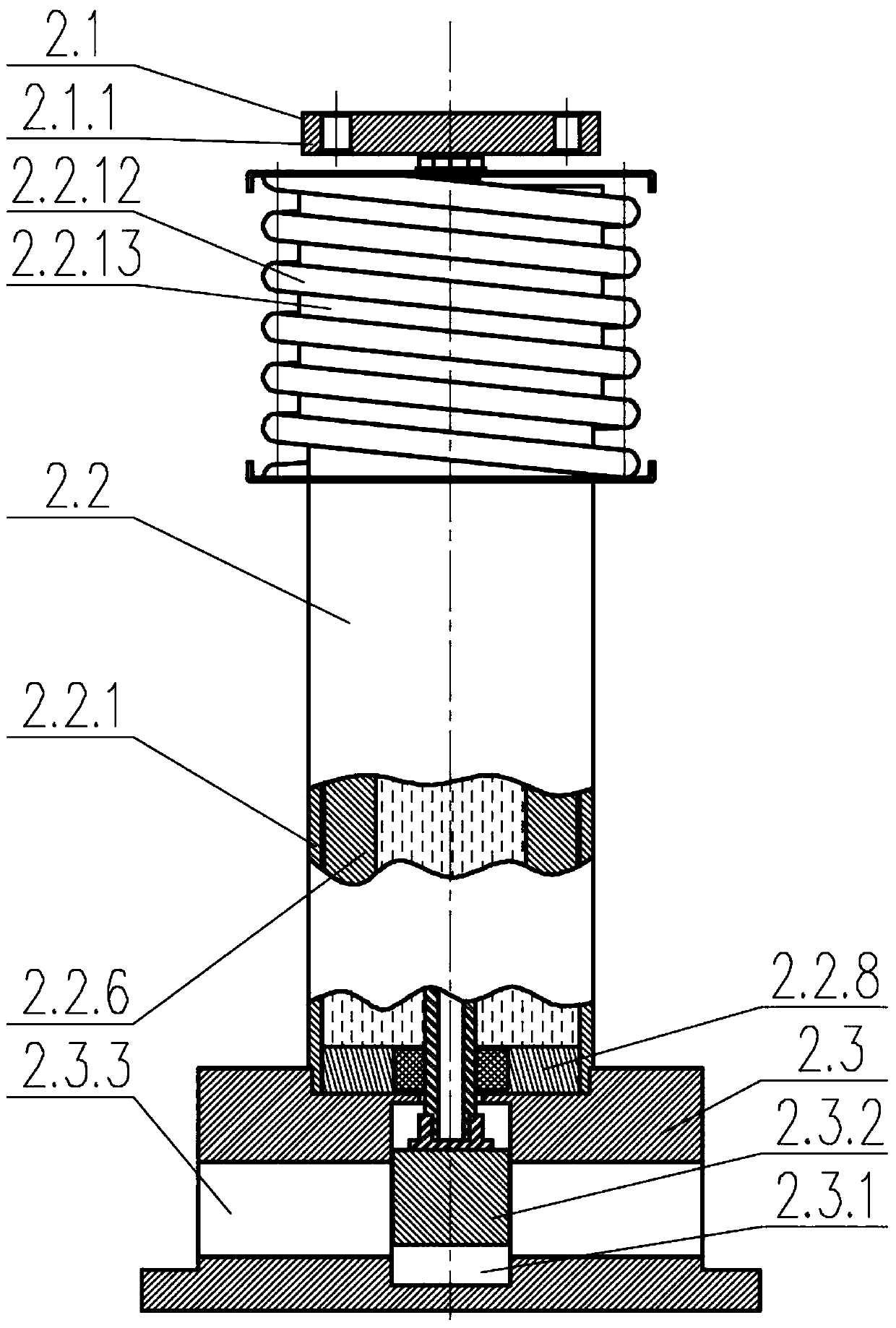

Parallel wire-array Z-pinch load

InactiveCN101868112ASuccessful loadPrecise positioningX-ray tube with very high currentX-ray apparatusMagnetohydrodynamicsInstability

The invention relates to a parallel wire-array Z-pinch load which comprises an anode sleeve, a cathode sleeve, an anode plate, a cathode plate, a wire array, an insulating positioning sheet, two springs, two double-step positioning rods and two spring positioning rods, wherein the anode plate is fixed in the anode sleeve; the cathode plate is fixed in the cathode sleeve; and the wire array is arranged between the anode plate and the cathode plate. The invention solves the technical problem that the current column load is subjected to magneto fluid mechanics to cause instability in the pinch process to an axis, and the invention has the advantage that tight and uniformly distributed parallel wire-array Z-pinch load is provided in a pinch experiment.

Owner:NORTHWEST INST OF NUCLEAR TECH

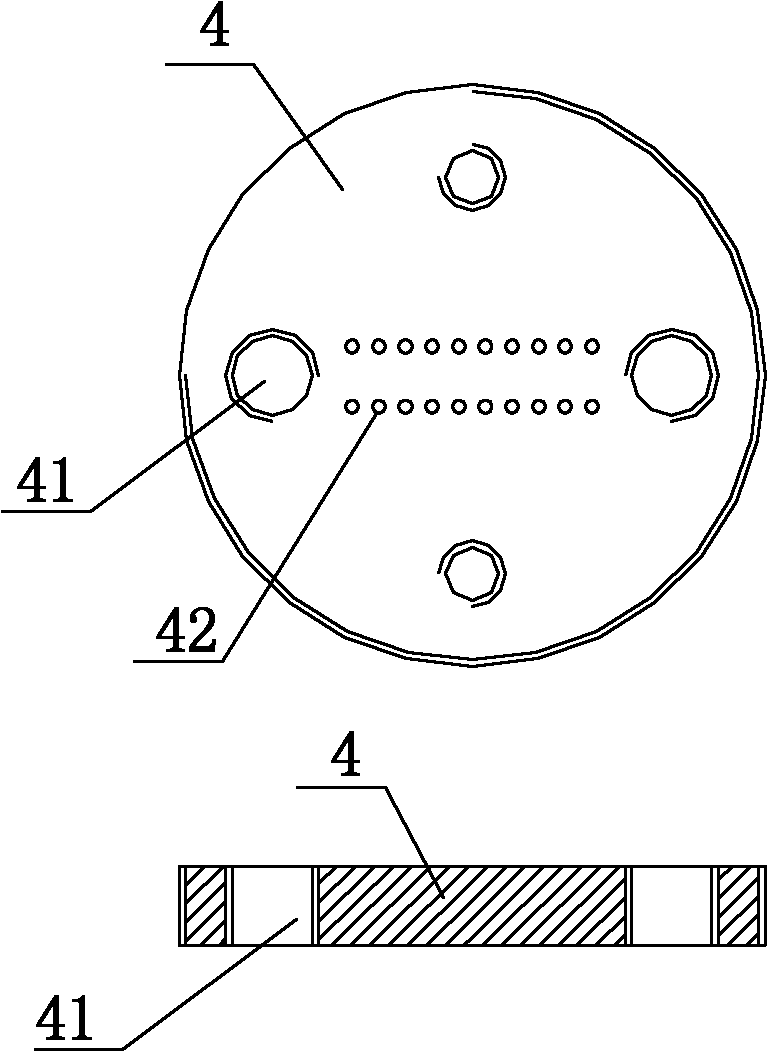

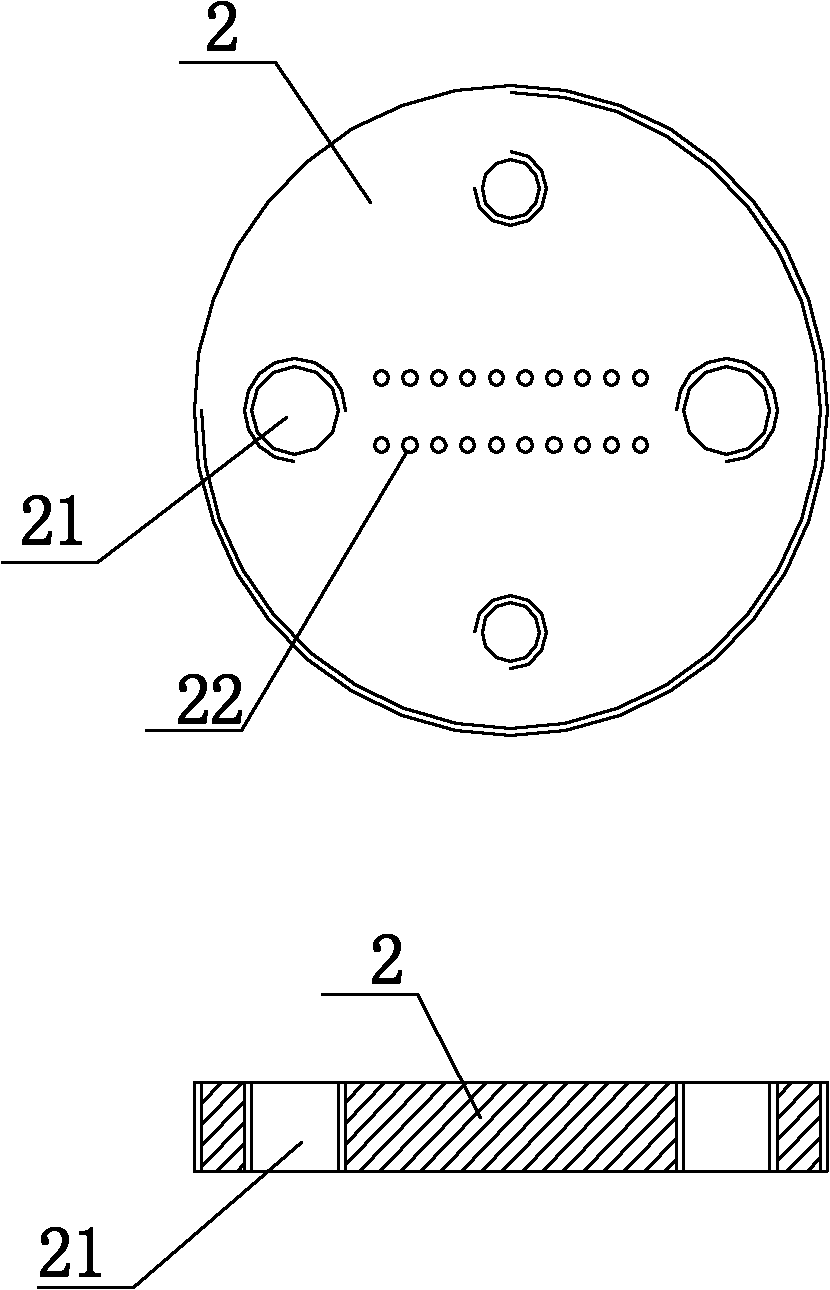

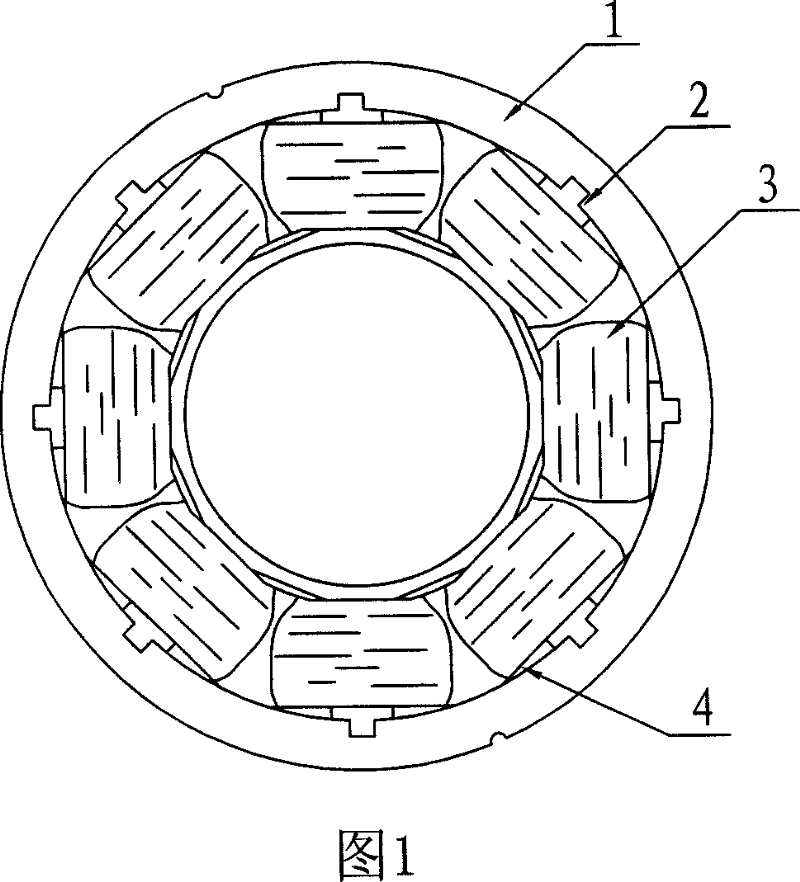

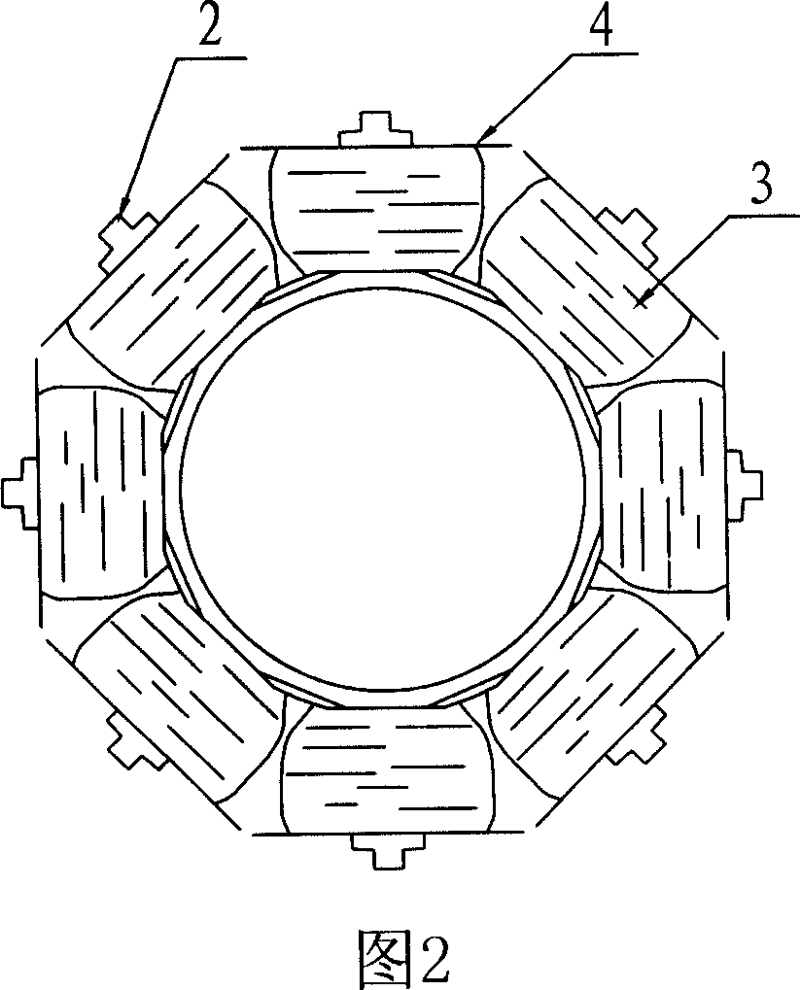

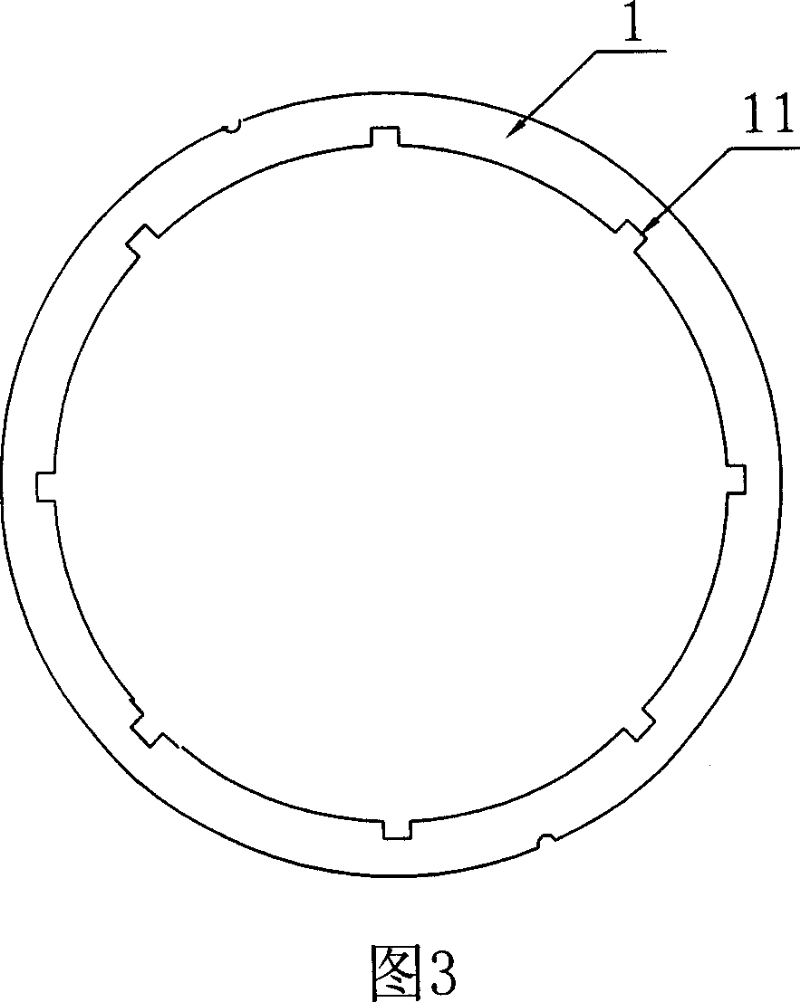

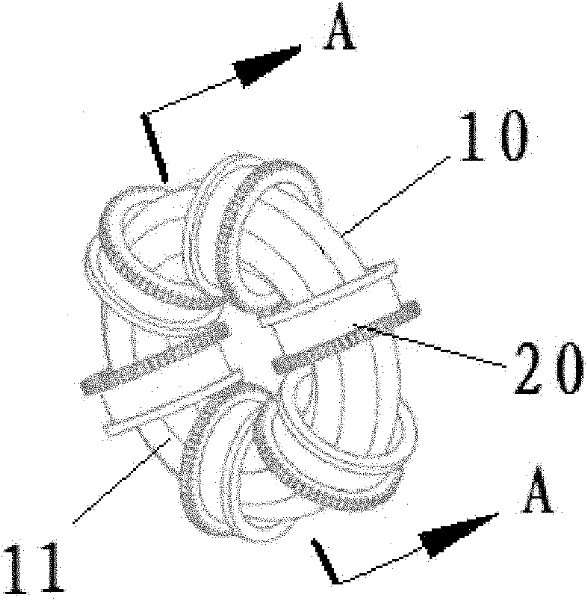

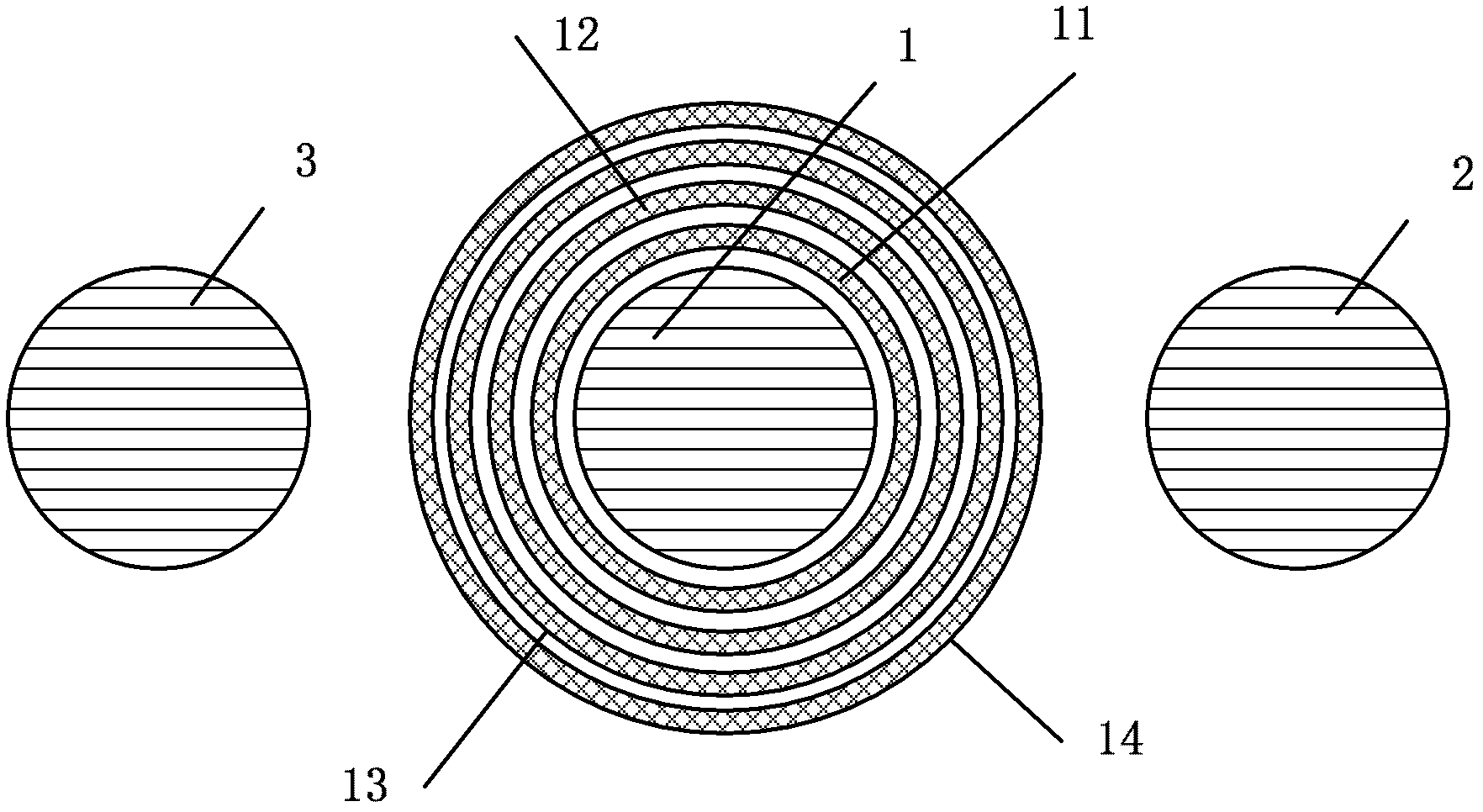

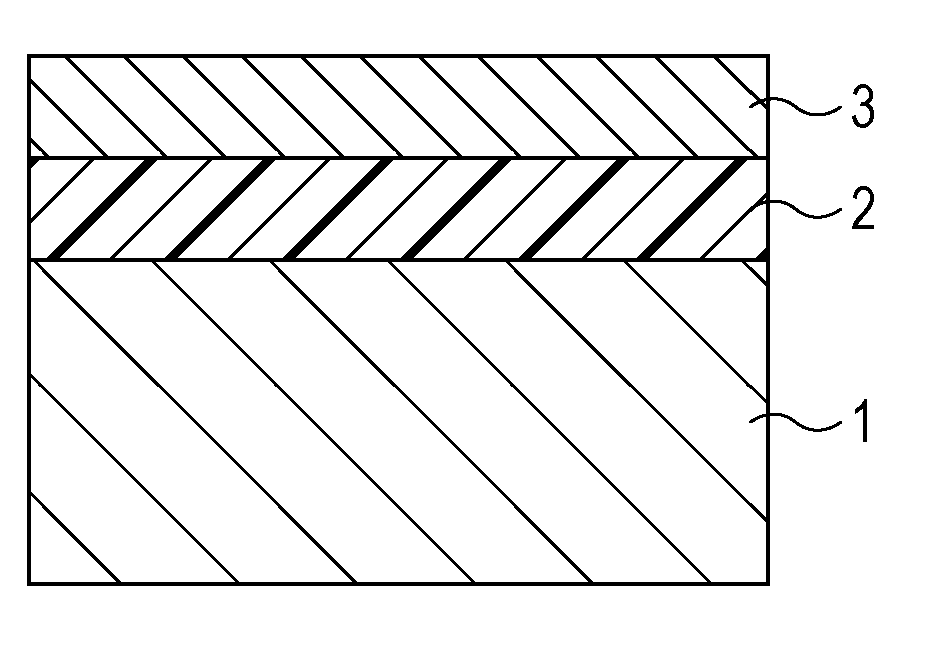

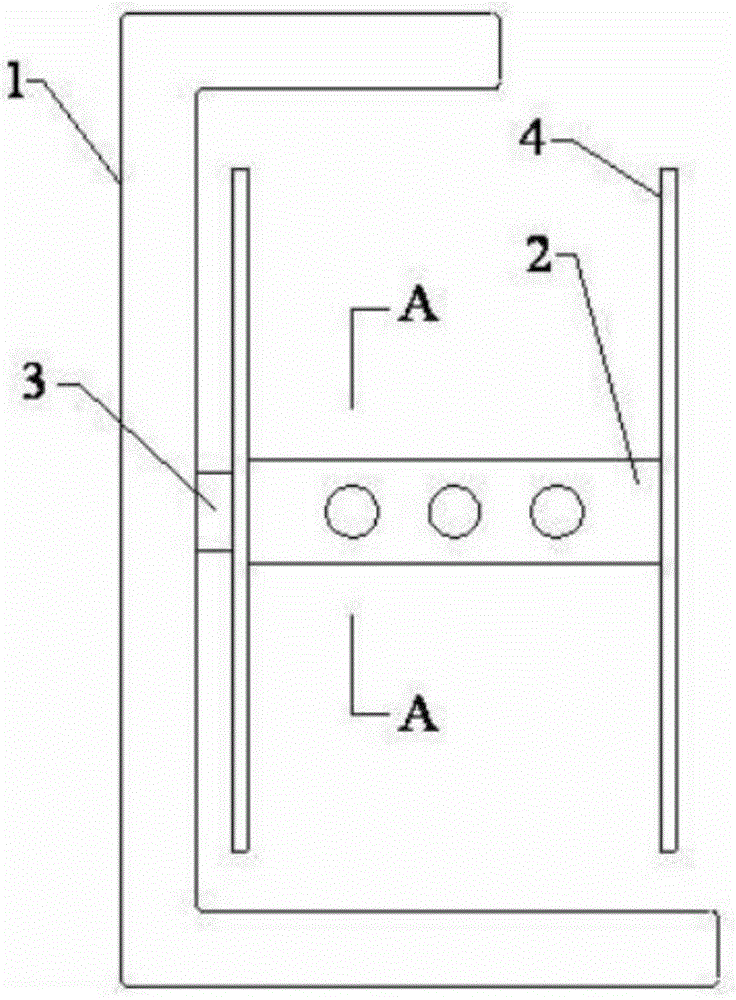

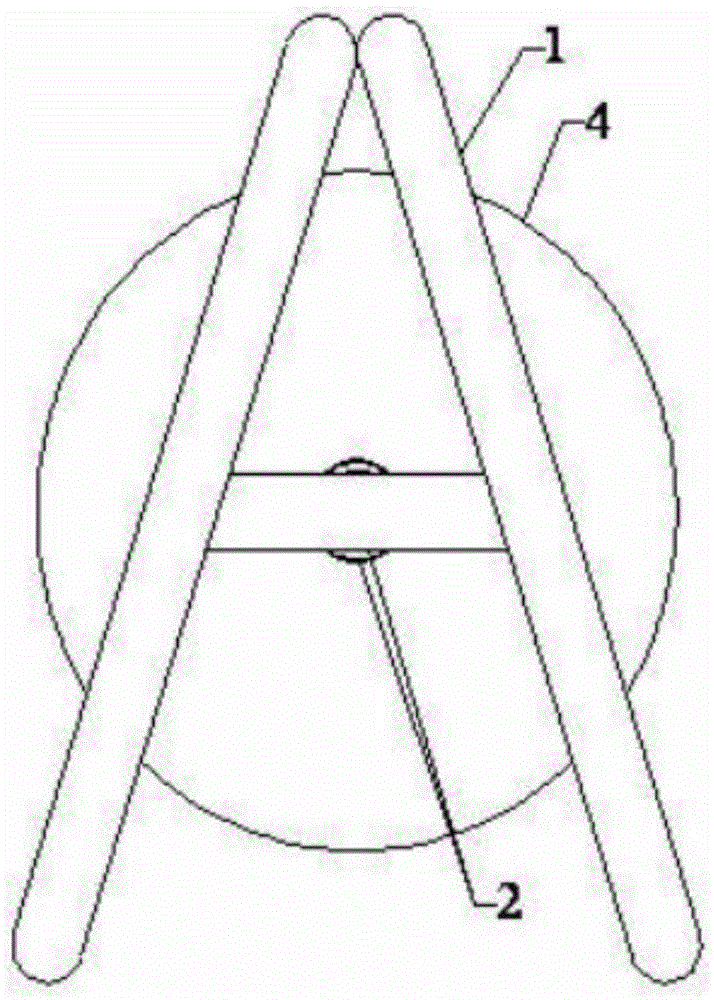

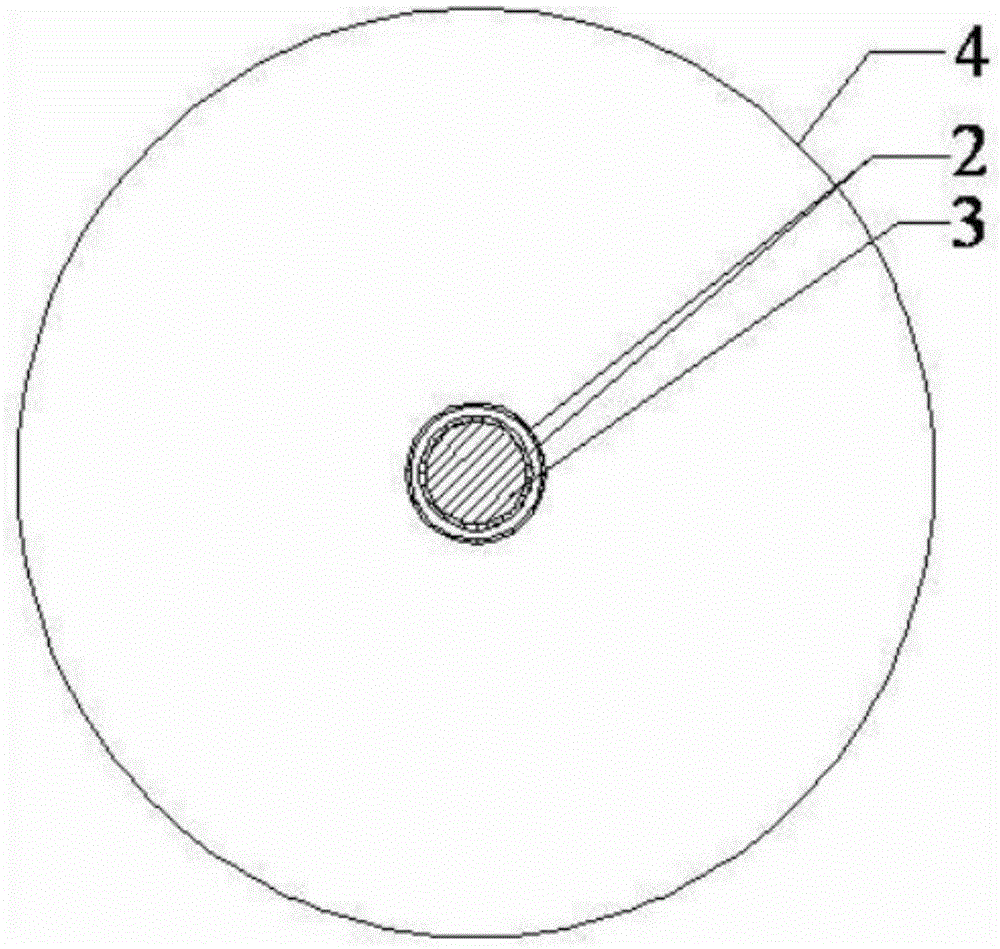

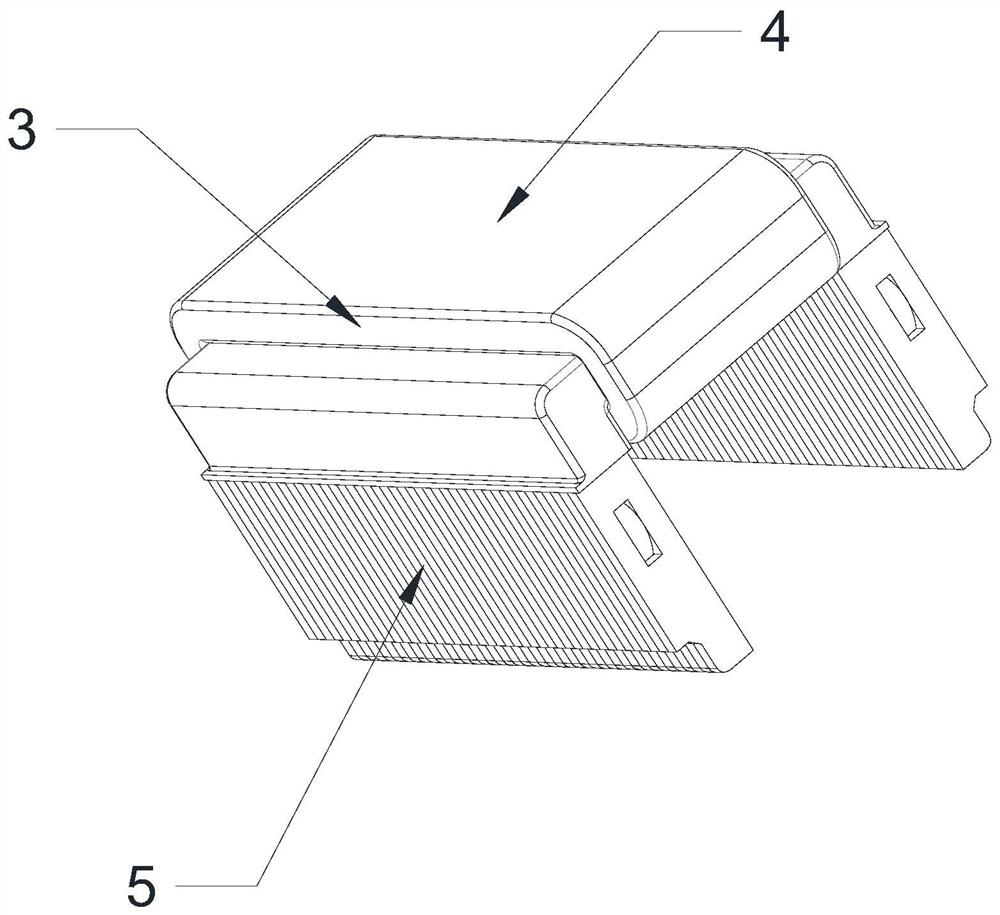

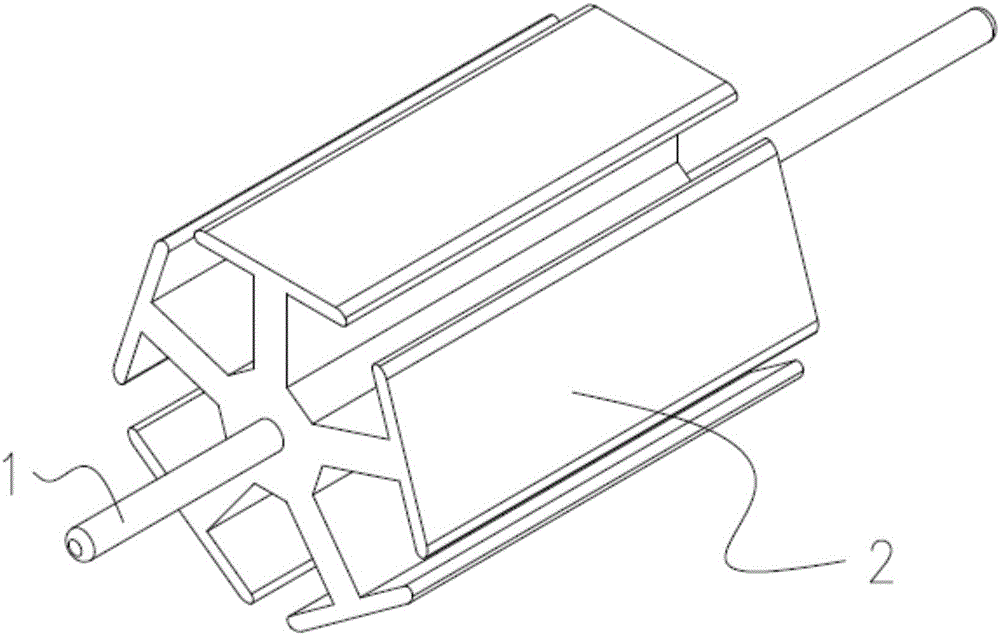

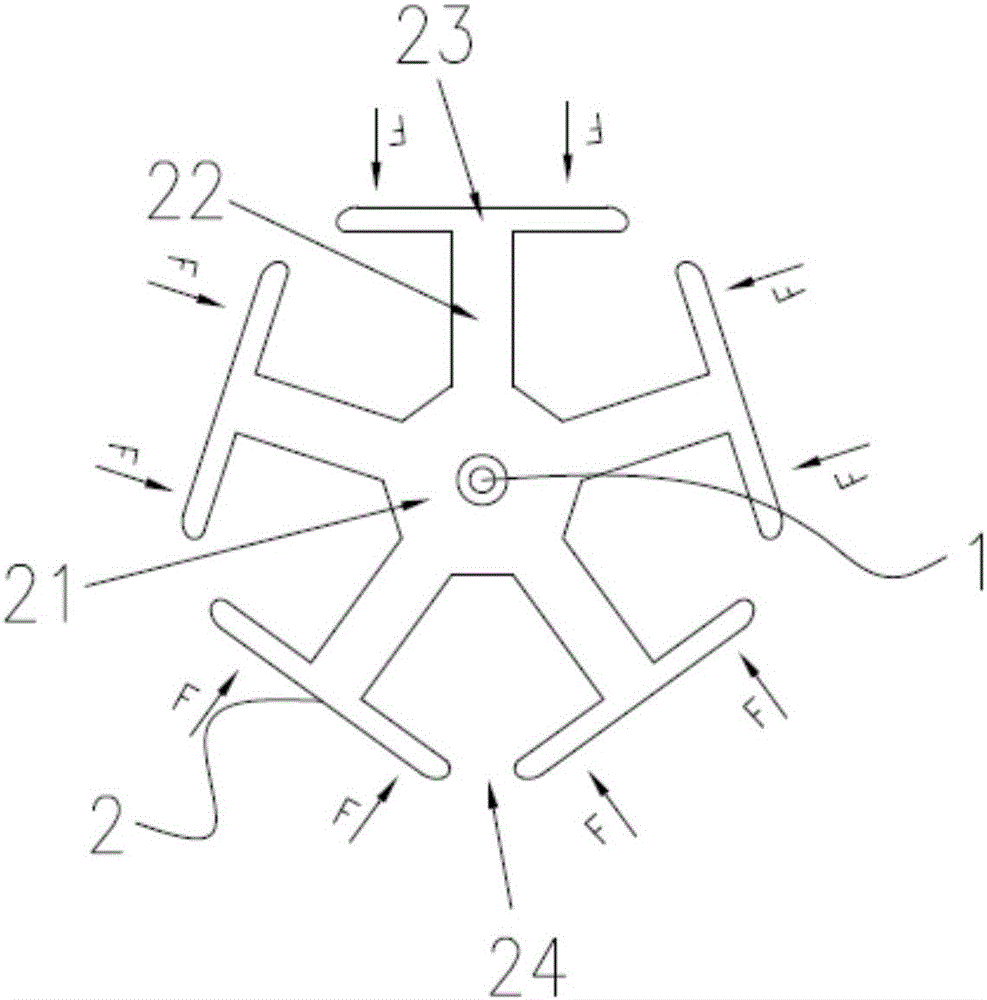

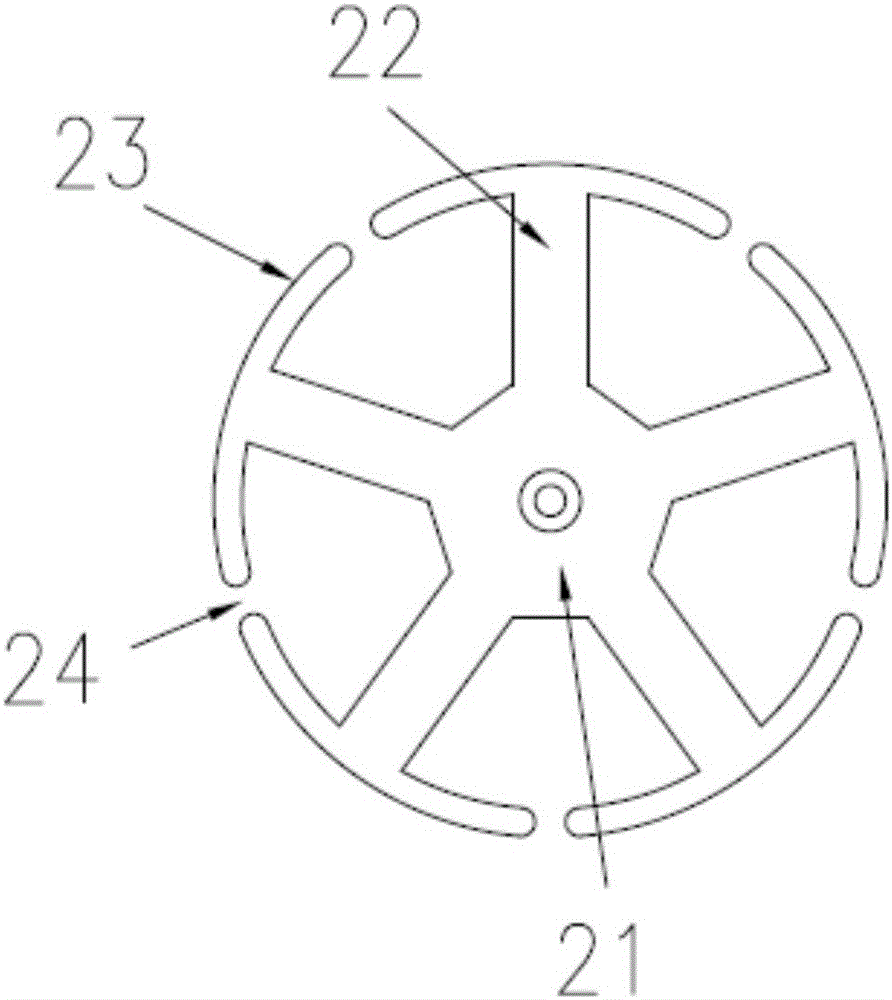

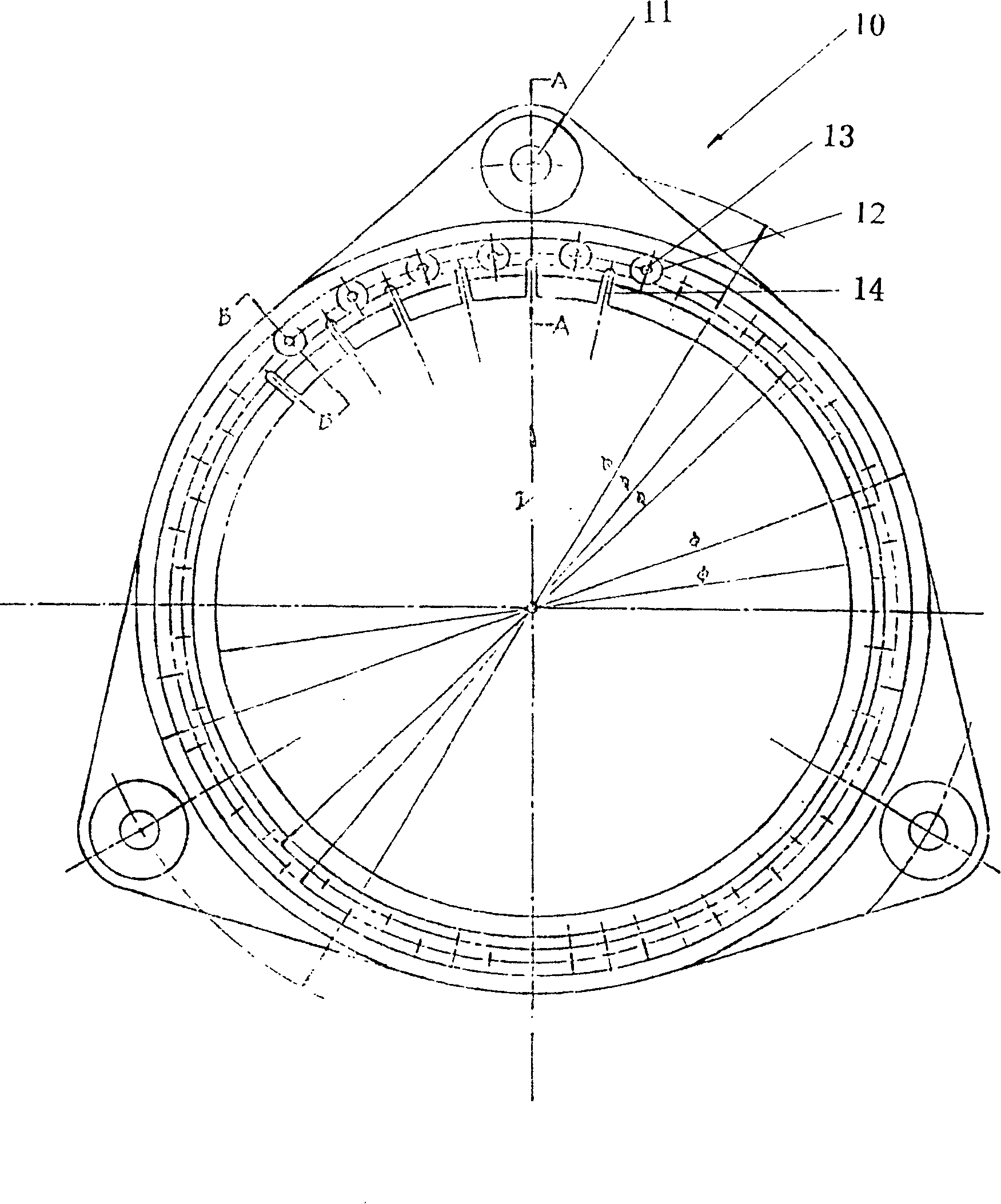

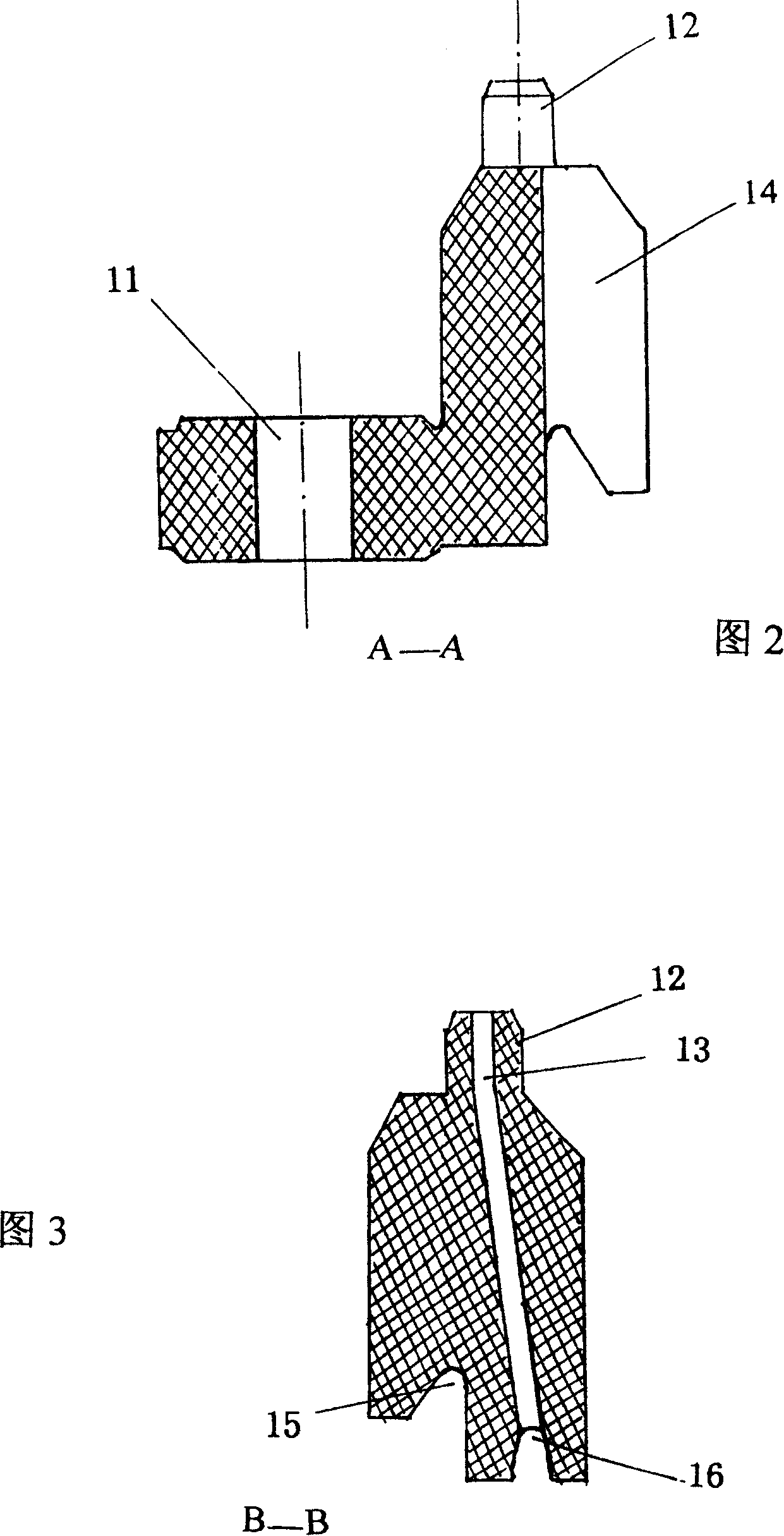

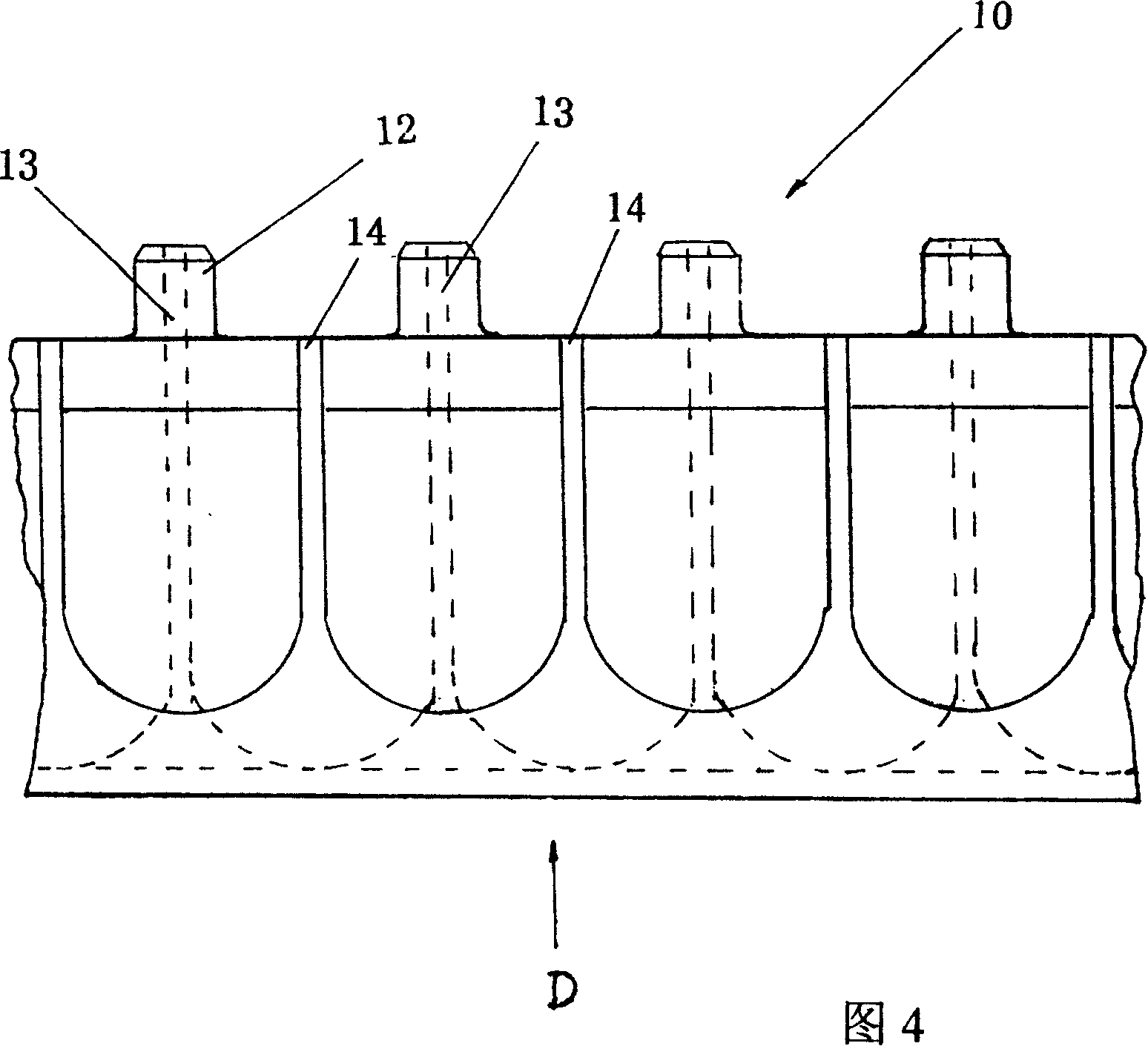

Stator assembly for asynchronous motor and method for making same

InactiveCN101043154AEasy to windReasonable designWindings insulation shape/form/constructionAsynchronous induction motorsEngineeringConductor Coil

The invention is stator assembly and preparation method which is used in asynchronous motor. The invention includes stator iron core, winding (3) and insulated frame (4). That characterized in that the stator iron core includes slot tooth part (2) and outer choke part (1), the slot tooth part is spoke, several teeth are set along the radial direction, the insulated frame (4) which possesses winding (3) is suited on the teeth (21) of slot tooth part (2), the outer choke part (1) is circle, and mounted on the slot tooth part (2). The preparation method of the stator assembly includes steps as following: processing the slot tooth part (2) and the outer choke part (1); enamel wire winding (3) is circled the insulated frame (4); the insulated frame (4) is suited on part of the teeth (21) of the slot tooth part (2); the outer choke part (1) is mounted on the slot tooth part (2). The invention is easy to wind, and structure is simple. The preparation method is easy, the efficiency is high.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

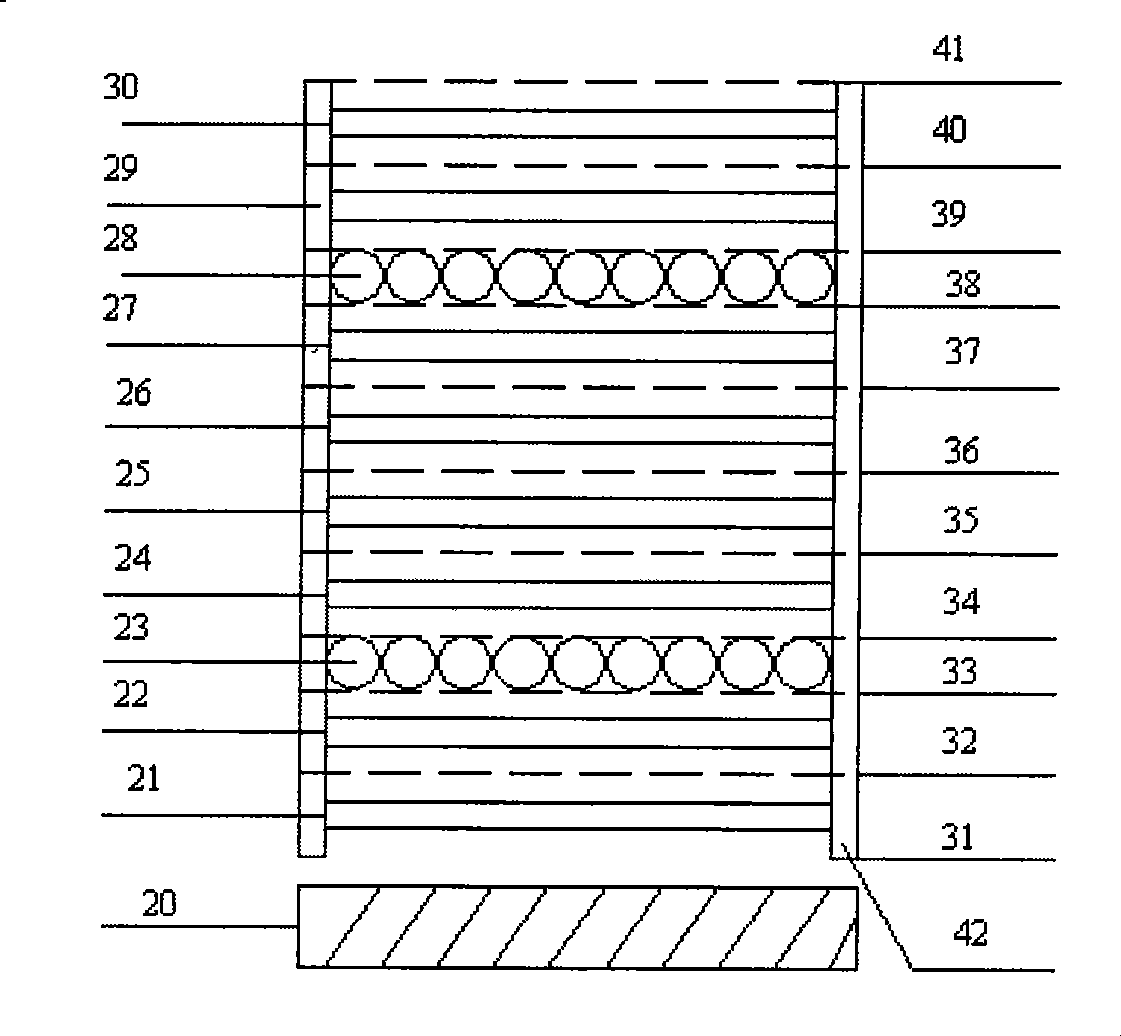

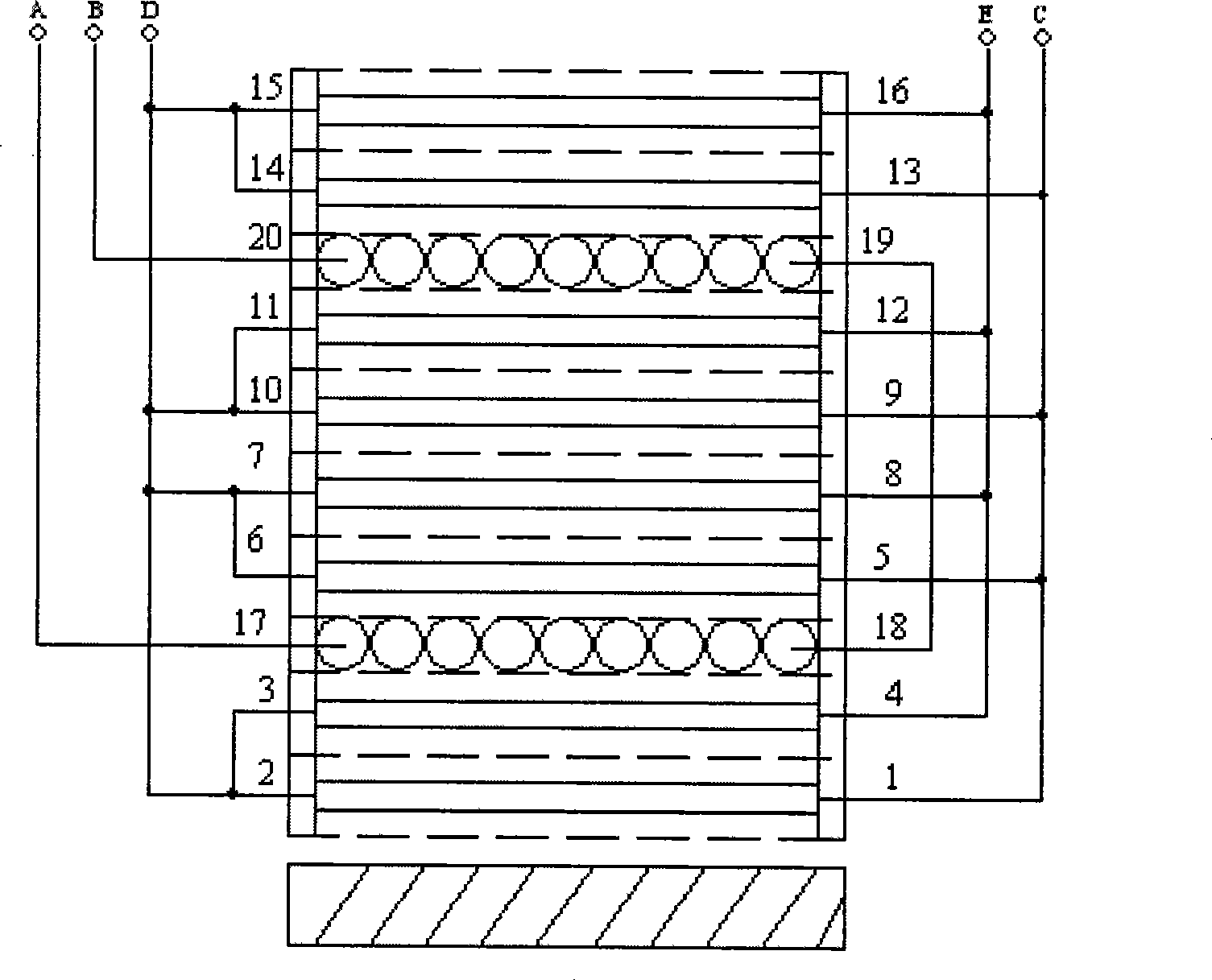

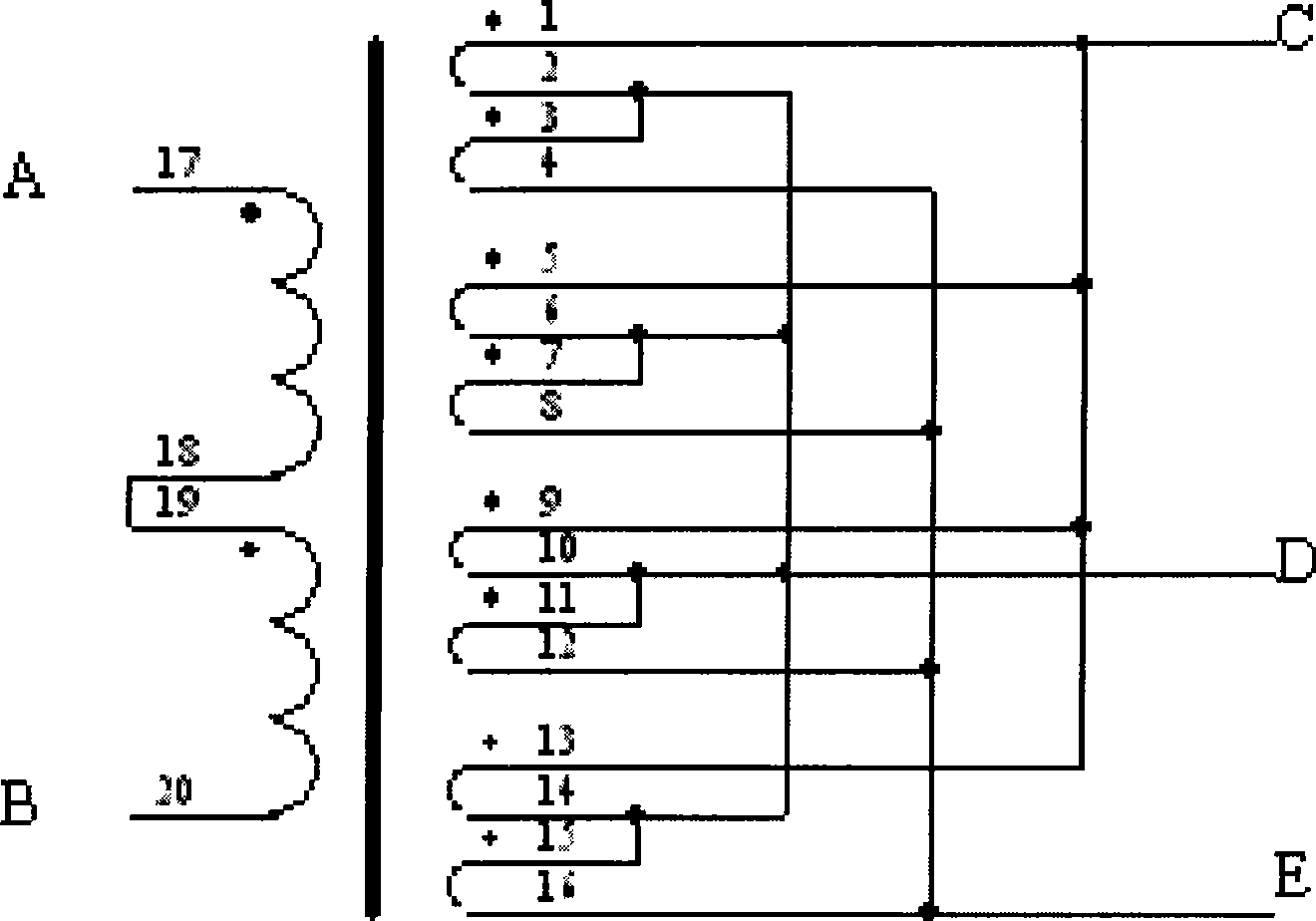

High-frequency transformer of spot welding machine

ActiveCN101430963AEasy to windEasy to exportTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInsulation layerTransformer

The invention discloses a high-frequency transformer used for a spot welding machine, comprising a magnetic core, primary coils and secondary coils; the primary coil and the secondary coil are alternatively wound by layer; an insulation layer is arranged between two adjacent layers; the primary coil is laminated between two primary coil layers; the internal layer and the external layer of the primary coil layer are provided with the secondary coil layers; the secondary coil is wound by thin copper strip layer by layer with one turn for each layer. The structure of the high-frequency transformer is convenient for the winding of the transformer, reduces the volume, weight, inductance leakage and loss of the copper passage, is convenient for educing the secondary heat, and is beneficial for the high-frequency transformer to output larger current and higher power.

Owner:SHENZHEN HONGBAI TECH IND

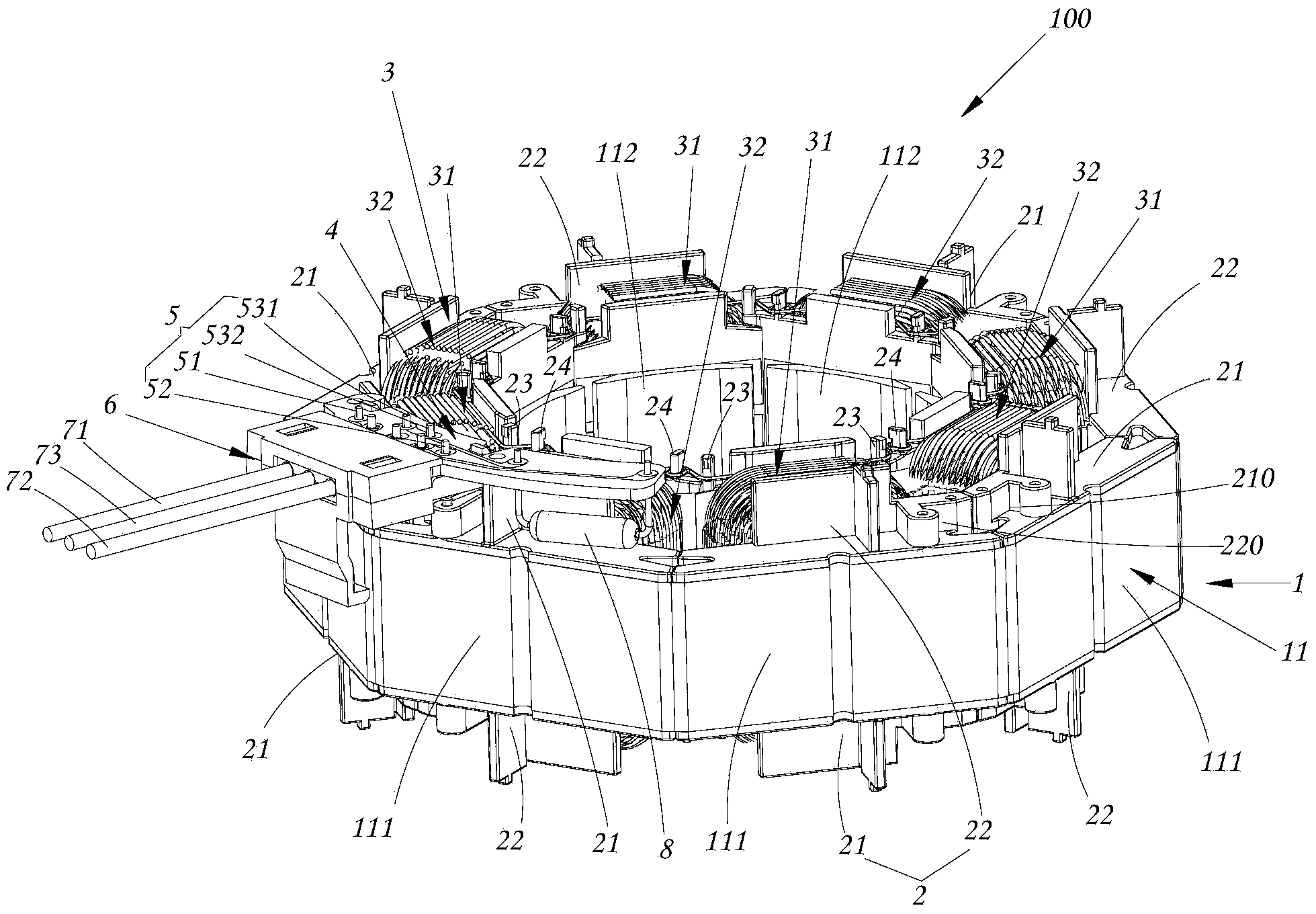

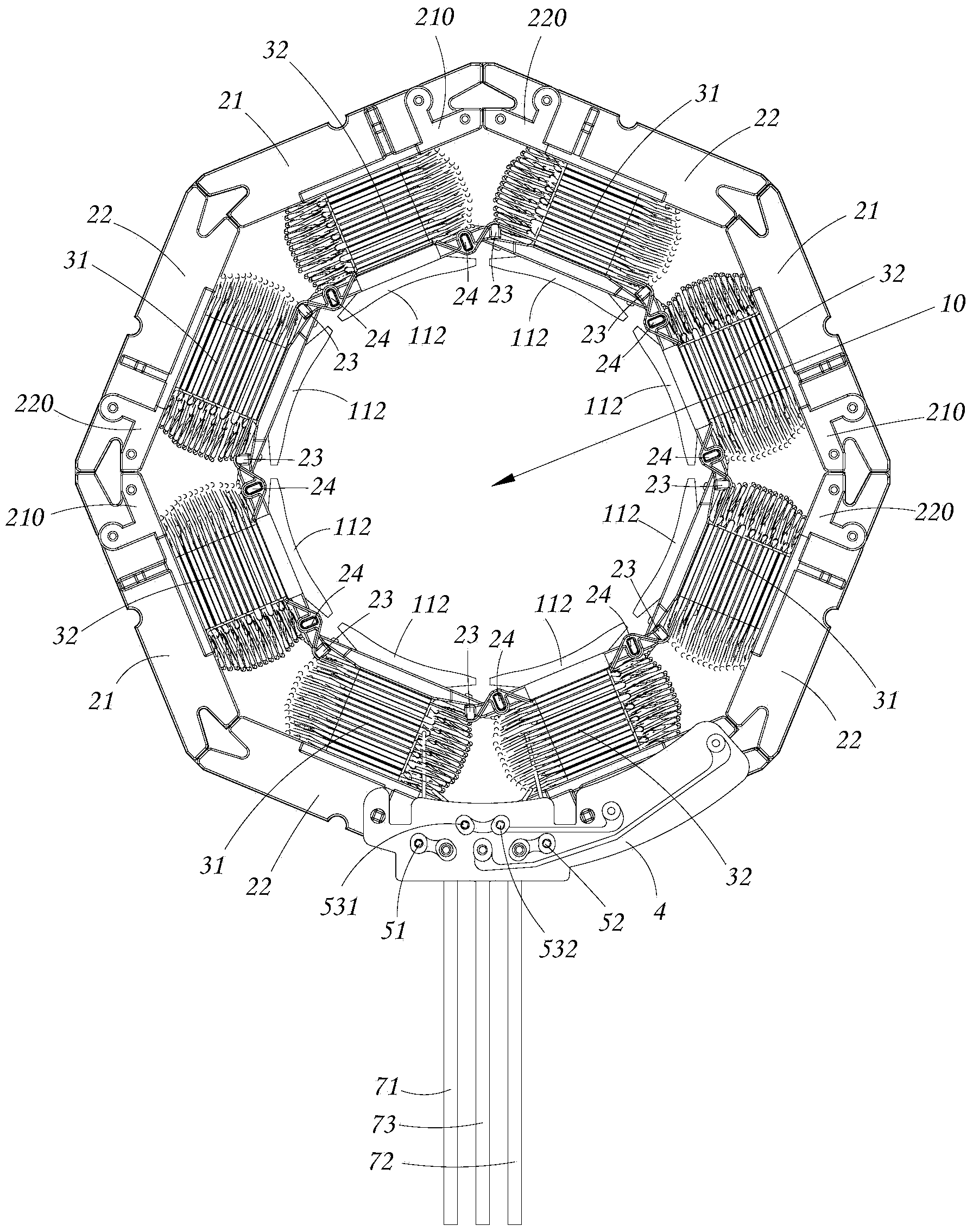

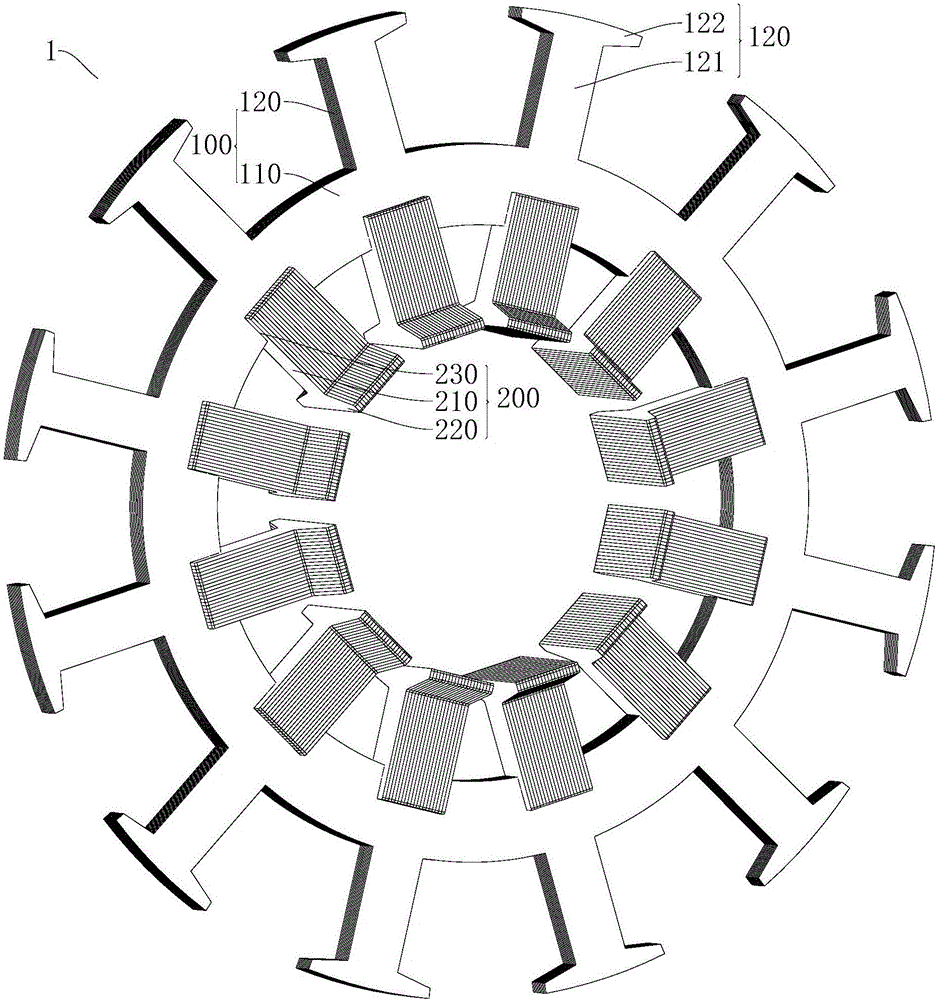

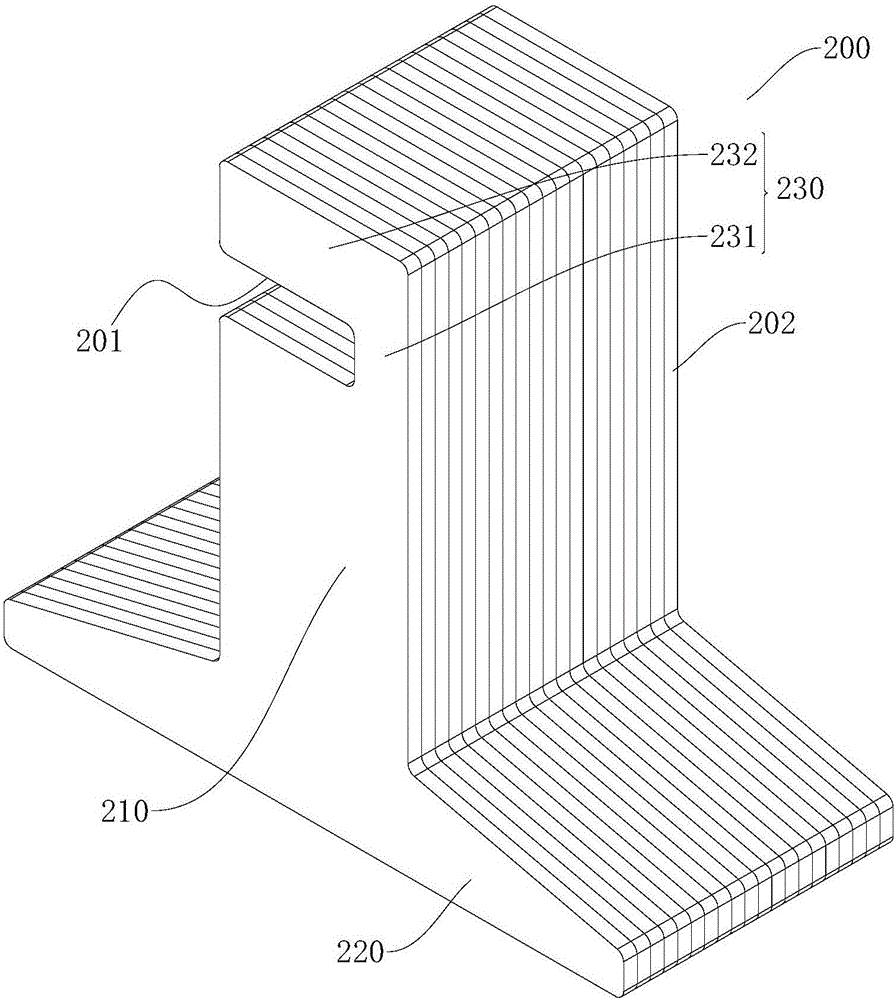

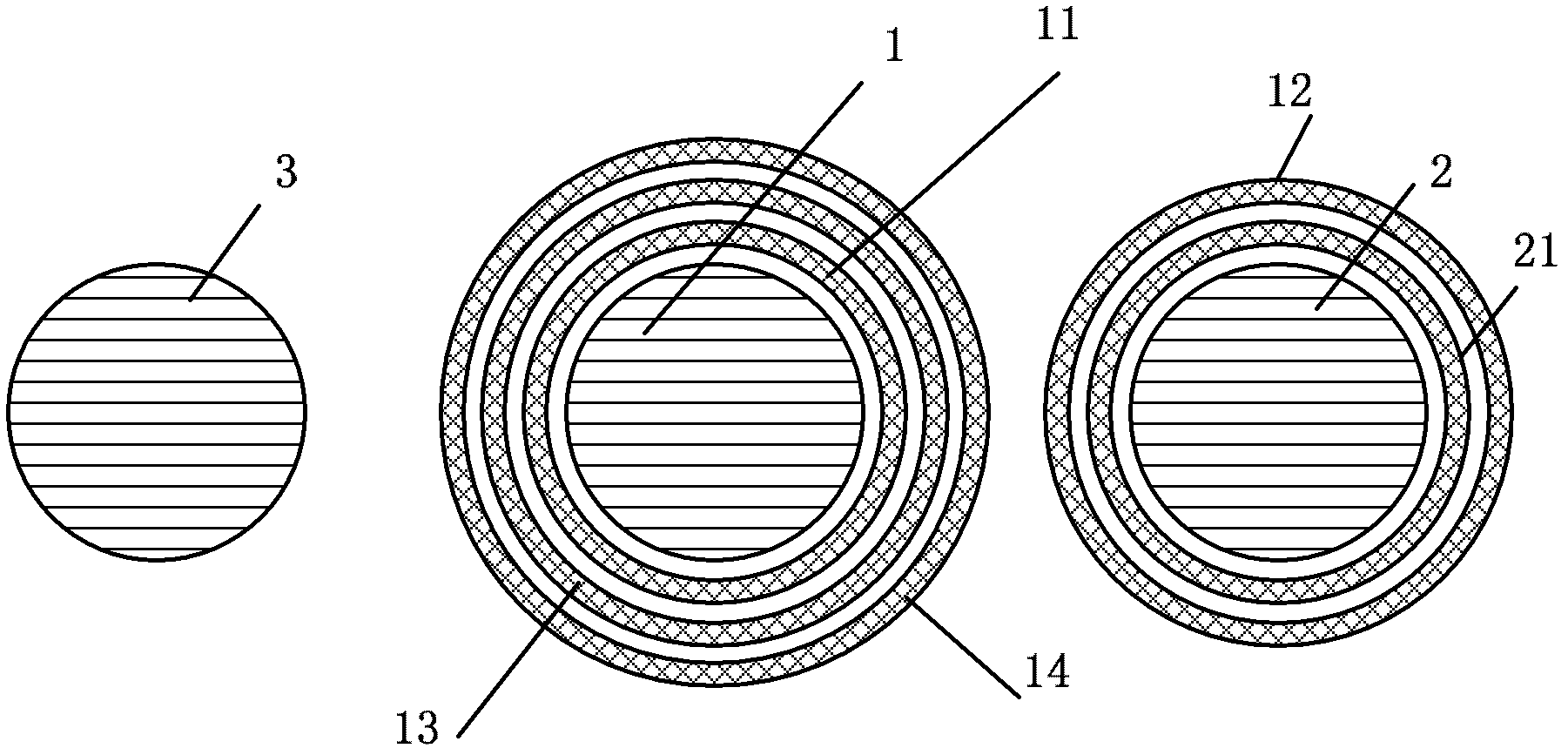

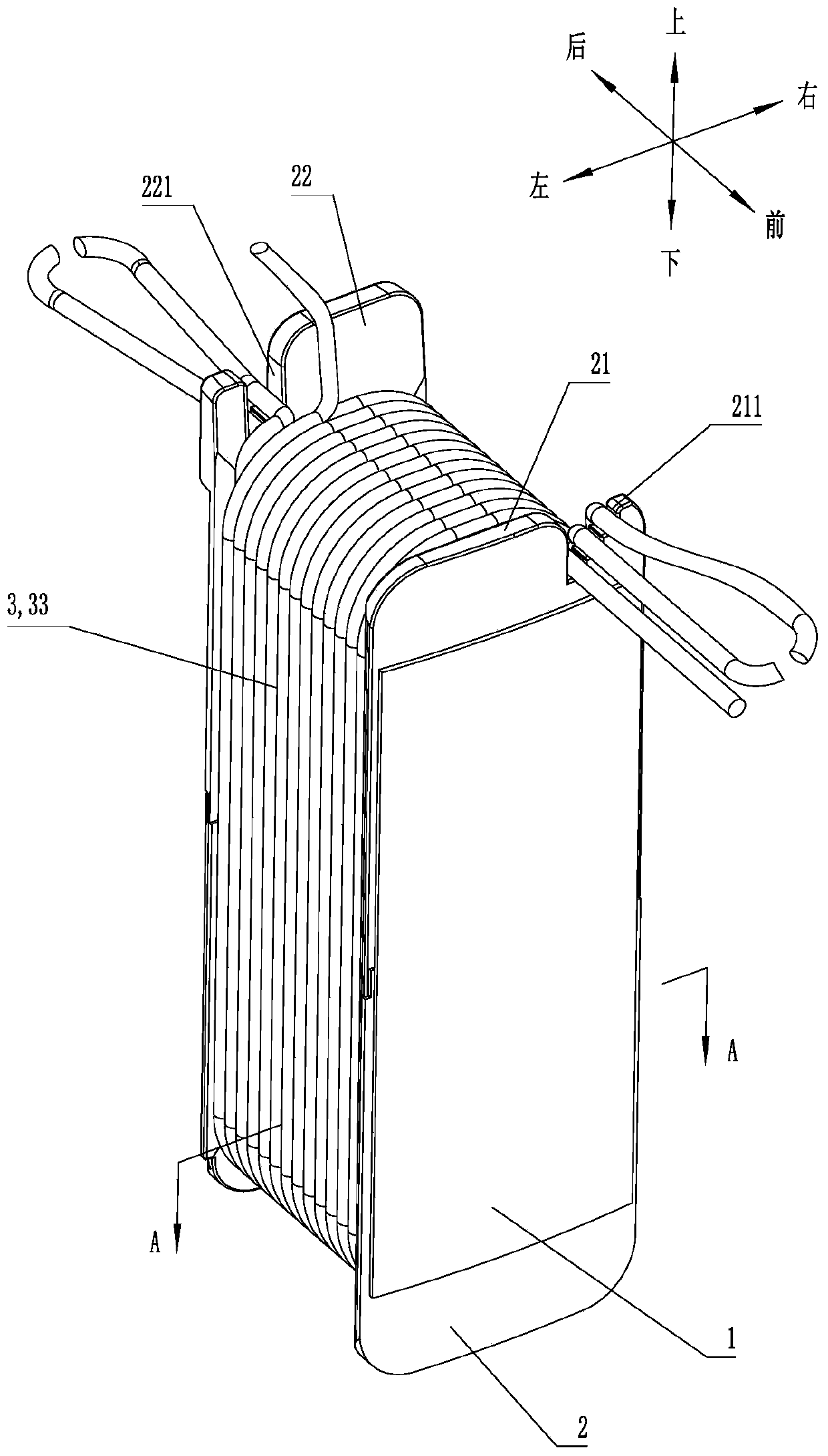

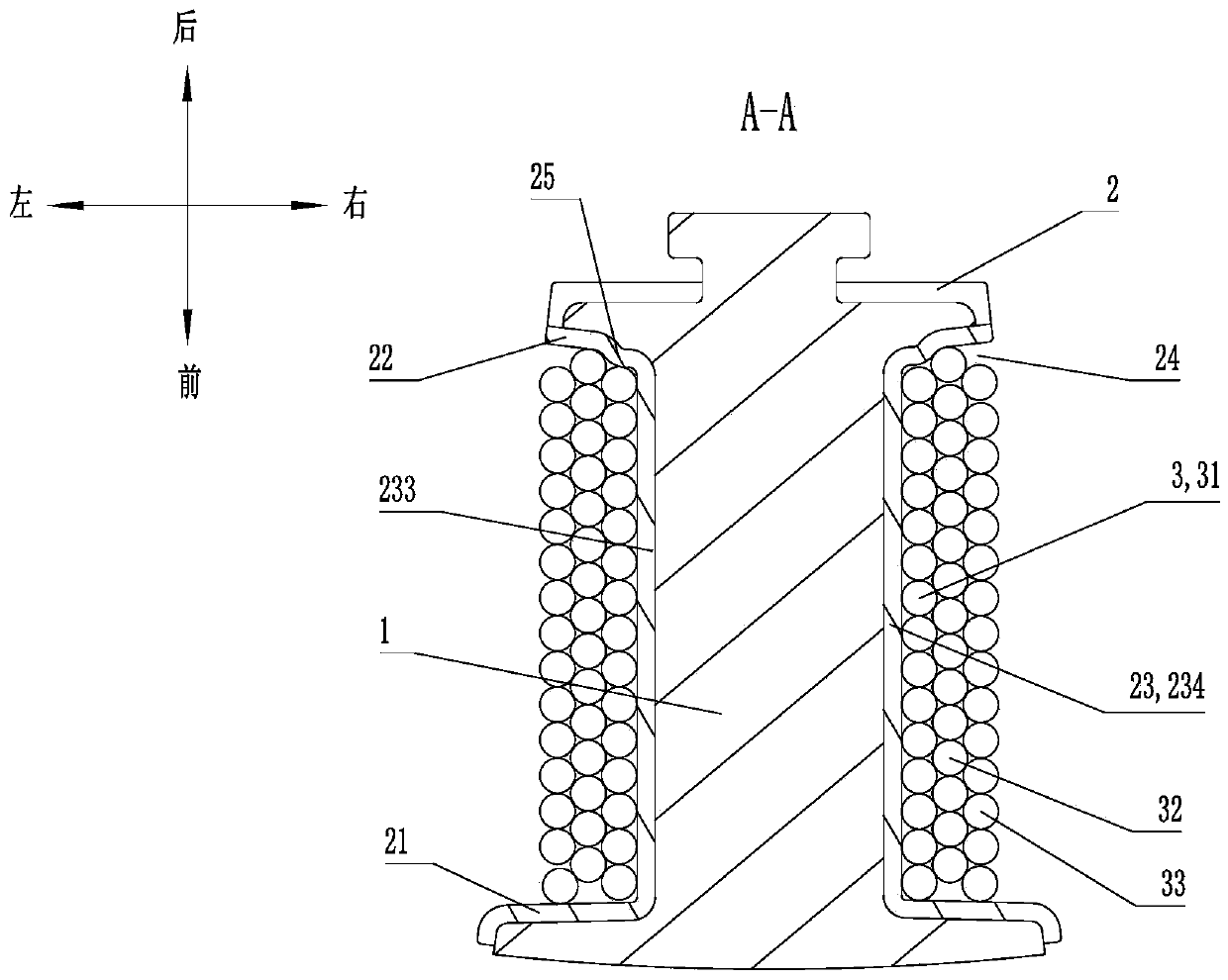

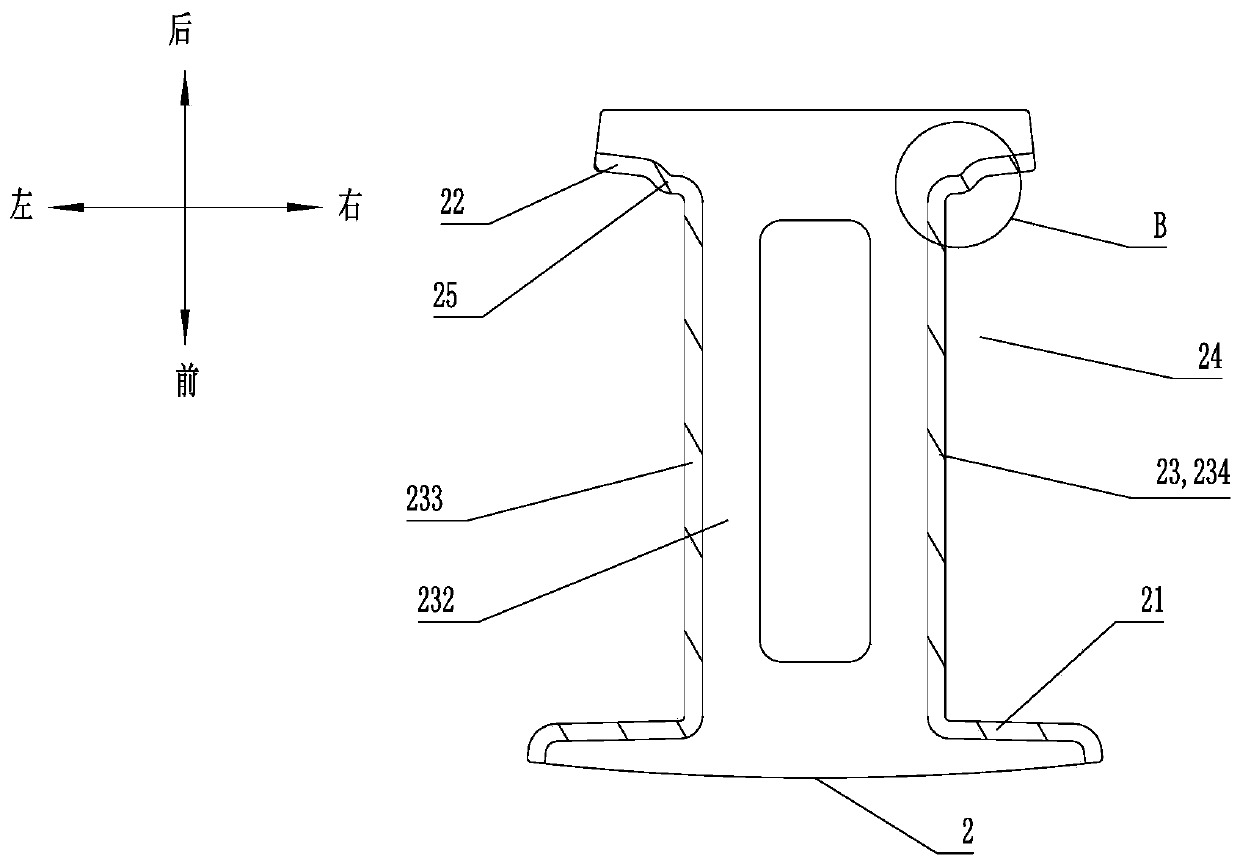

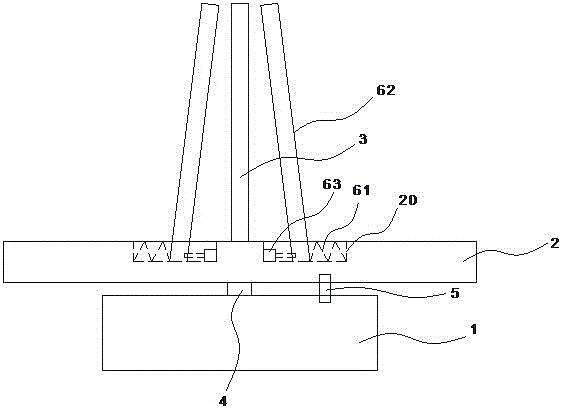

Motor stator assembly and assembling method thereof, and motor

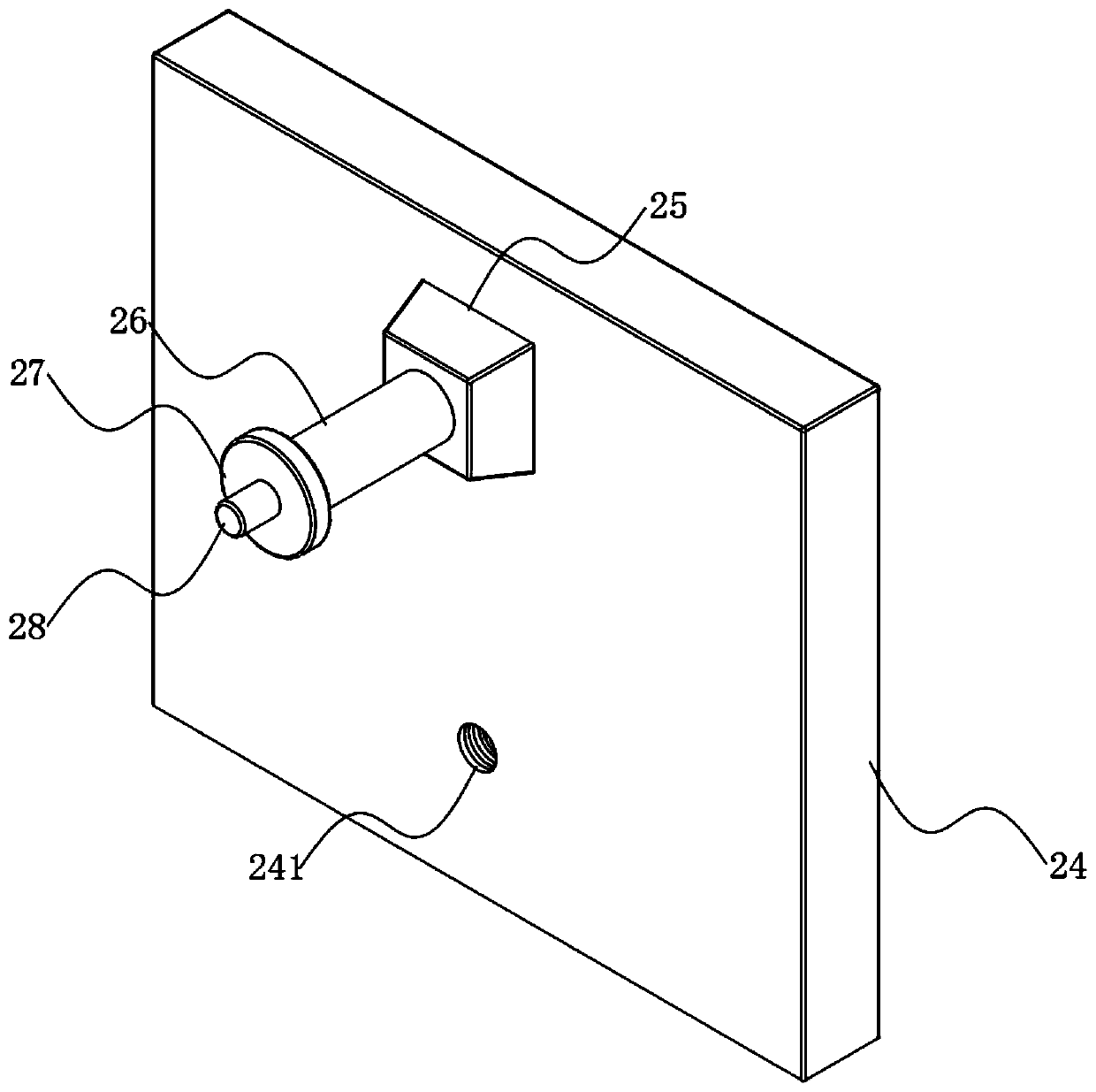

ActiveCN104113149AEasy to windFacilitate the installation of lead wire clipsWindingsMagnetic circuit stationary partsWinding machineStator

The invention provides a motor stator assembly and an assembling method thereof, and a motor. The motor stator assembly and a threading column of the motor are arranged at an internal edge, which is close to an iron core tooth part, of an insulating component. A connecting column assembly is arranged at an external side part of the insulating component so that the connecting column and an external winding machine can be arranged at the same side, winding is facilitated, and installation of a lead-out wire clamp is facilitated. Besides, lead-out distance from the connecting column to the external side of a stator is greatly reduced, and axial space occupation of the motor is reduced so that miniature design of the motor is facilitated. According to the assembling method of the motor stator assembly, multiple iron core single bodies from which an iron core is composed are divided into two groups with the identical number and assembled via a circular tooling respectively. The two groups of the iron core single bodies are respectively wound with a motor primary winding and a motor secondary winding via a winding machine, and then the complete stator assembly is assembled together. Winding is quite convenient due to a vacancy winding machine arranged between the adjacent iron core single bodies on the iron core single body groups so that winding difficulty is greatly reduced and production efficiency of the motor is enhanced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

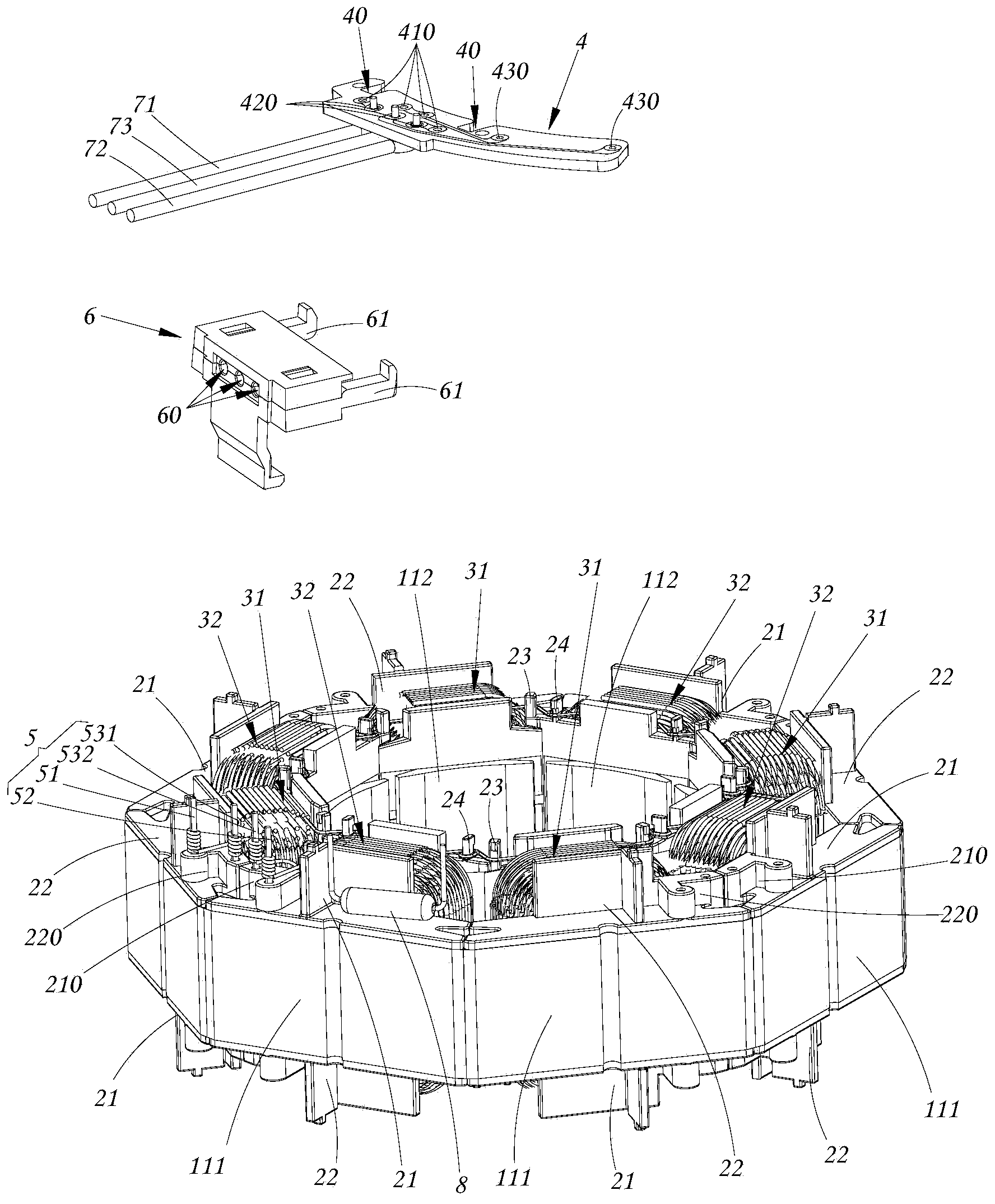

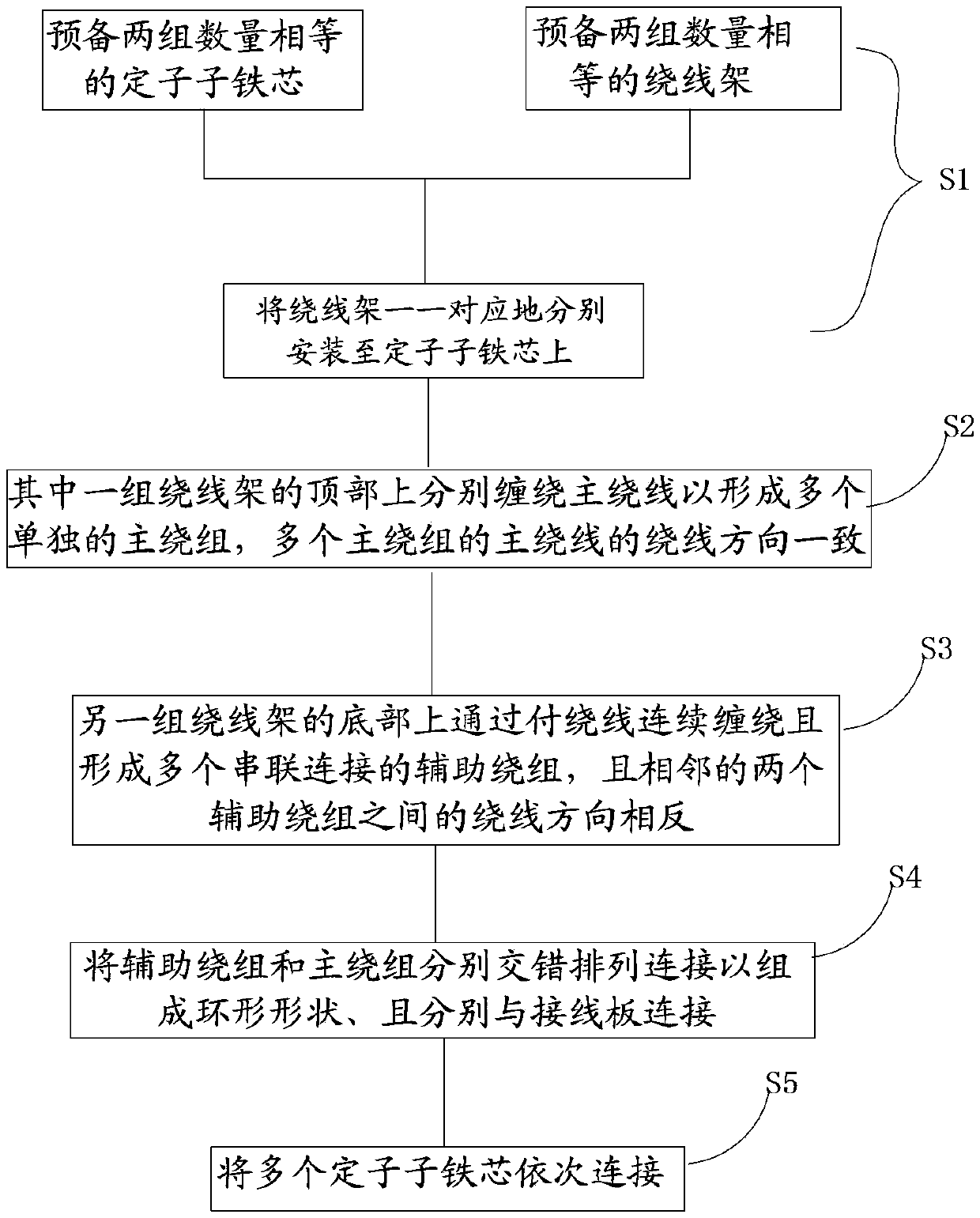

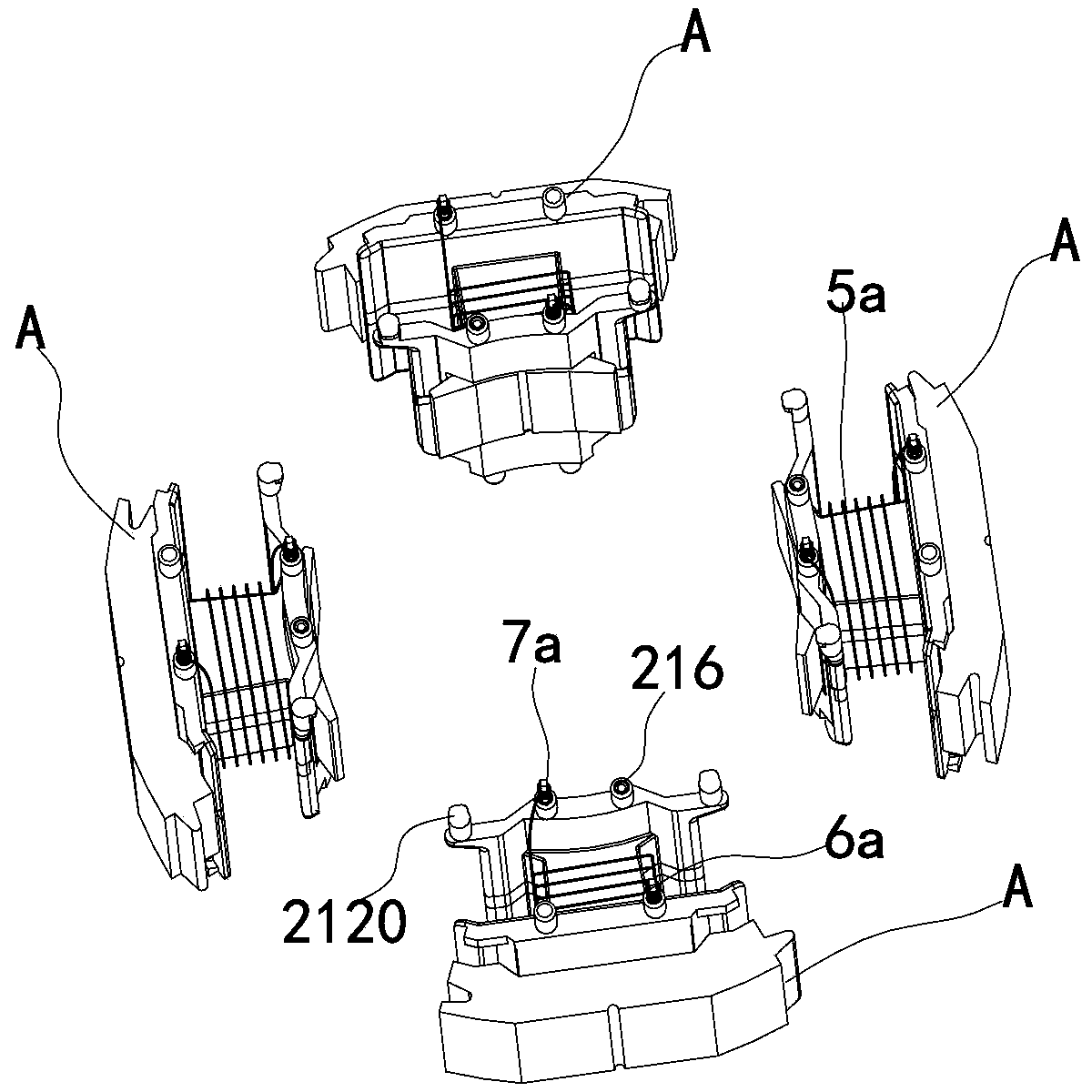

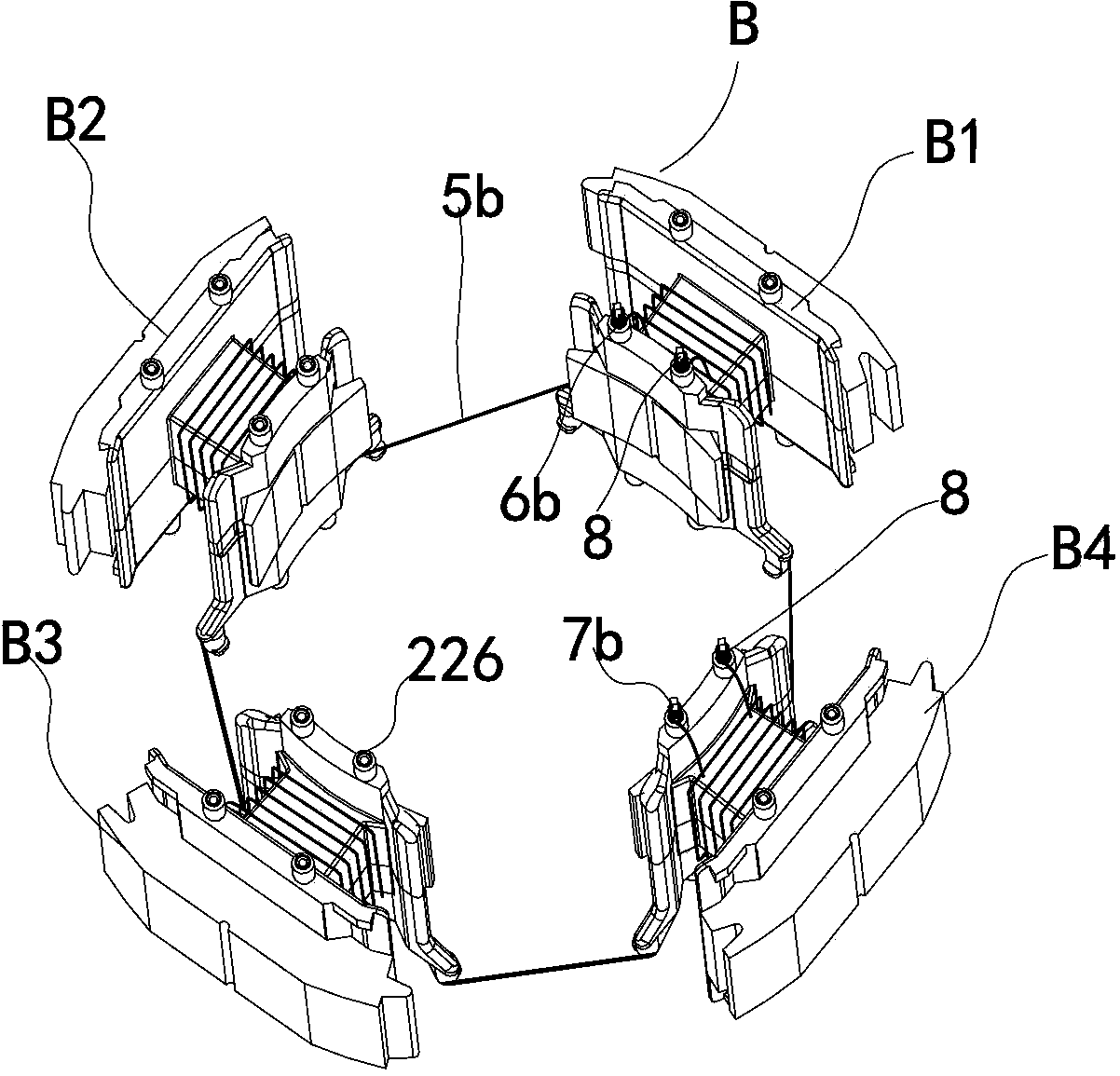

Block stator assembly and manufacturing method of block stator assembly

ActiveCN103973056AEasy to windAccelerateMagnetic circuit stationary partsManufacturing dynamo-electric machinesStatorEngineering

The invention discloses a block stator assembly and a manufacturing method of the block stator assembly. The manufacturing method includes the following steps; respectively preparing two sets of stator sub-iron-cores equal in number and two sets of reels, and installing the reels on the stator sub-iron-cores respectively; winding one set of reels with main wound wires respectively in the coincident wire winding directions to form multiple disconnected main windings; continuously winding the other set of reels with an auxiliary wound wire to form multiple auxiliary windings connected in series, wherein the wire winding directions of every two adjacent auxiliary windings are opposite; respectively and alternately arranging the auxiliary windings and the main windings in a connected mode, and enabling the auxiliary windings and the main windings to be respectively connected with a wiring board; sequentially connecting the multiple stator sub-iron-cores. By means of the manufacturing method, the wire winding directions of the stator sub-iron-cores of the main windings are coincident, and the instantaneous currents of every two adjacent main windings are opposite in direction through the wiring board, so that on the basis that the performance is not reduced, wire winding is convenient to achieve and high in speed, and the wire winding error rate is lowered.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

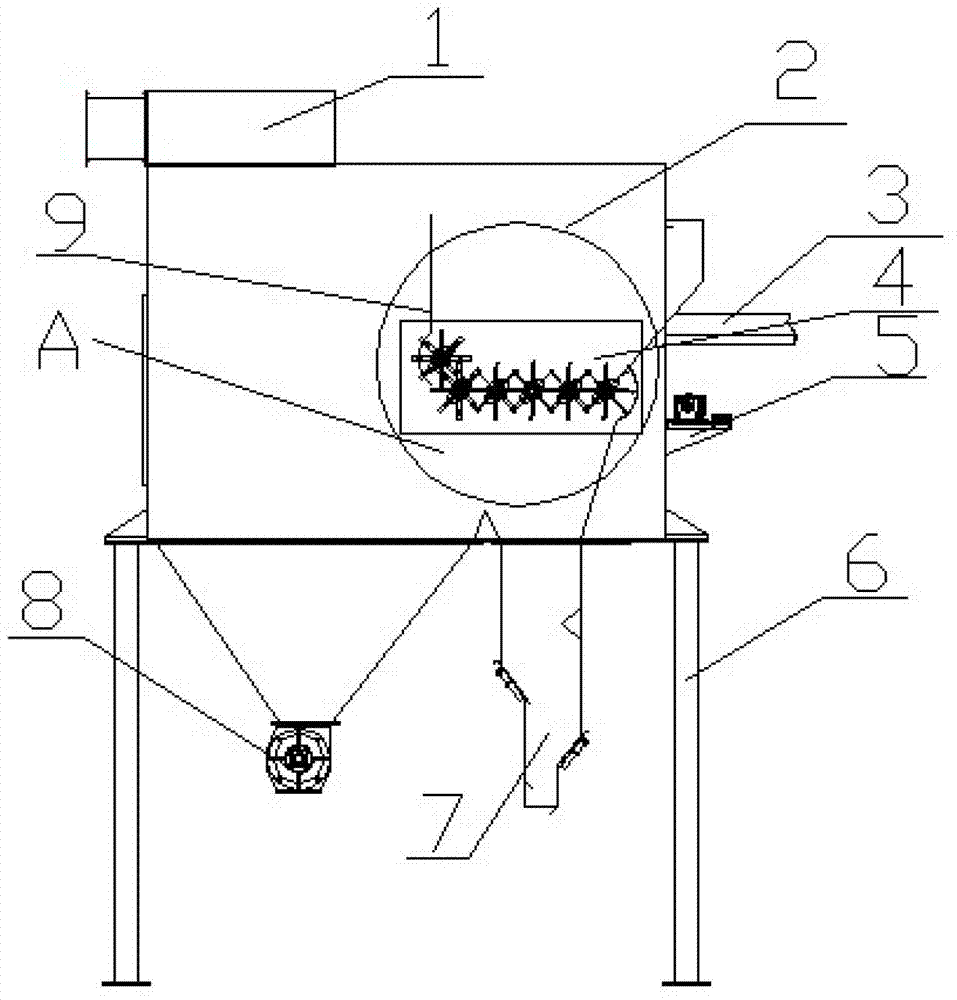

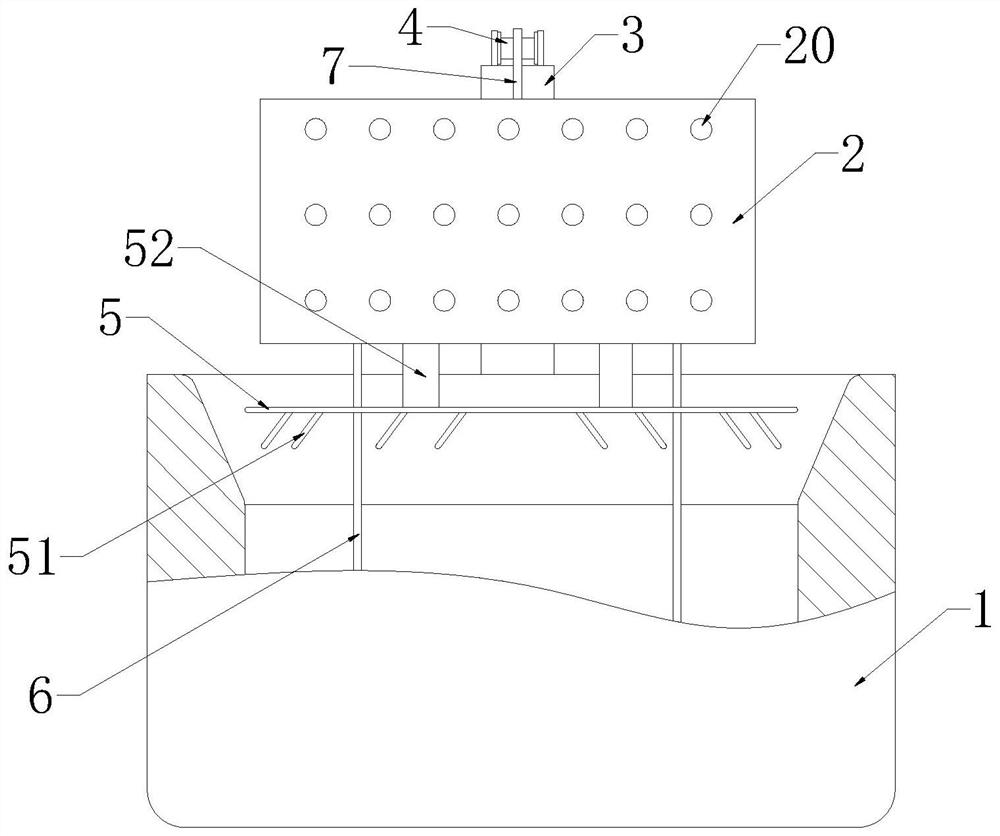

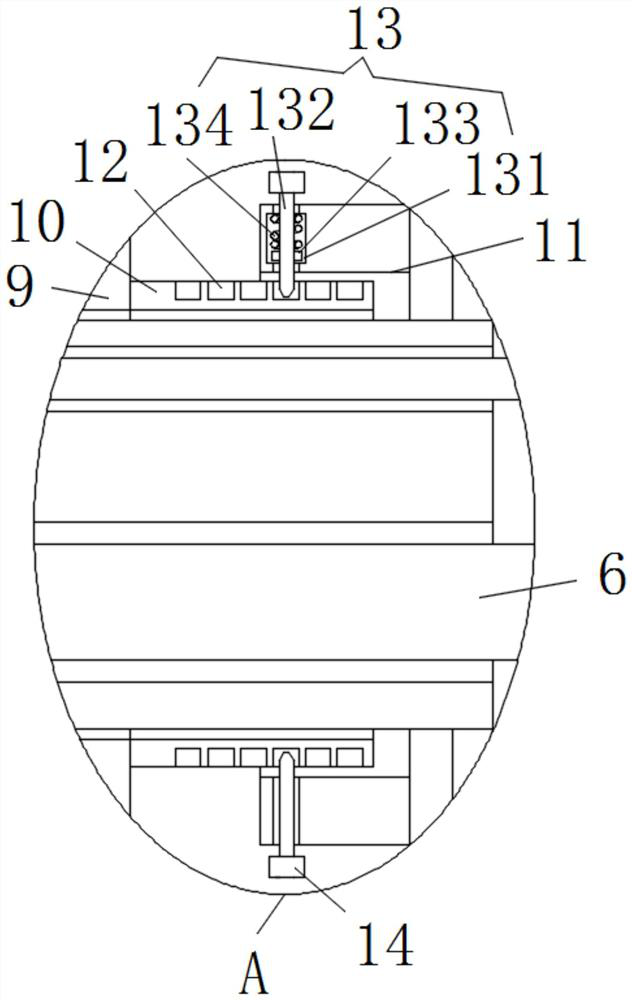

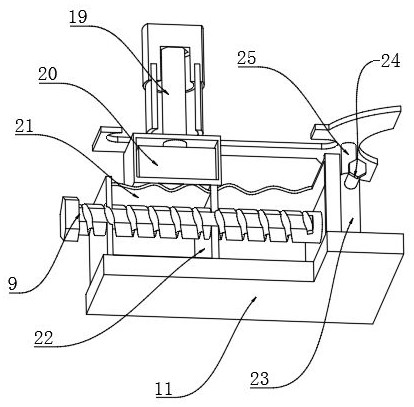

Novel tobacco shred screening and shortening equipment

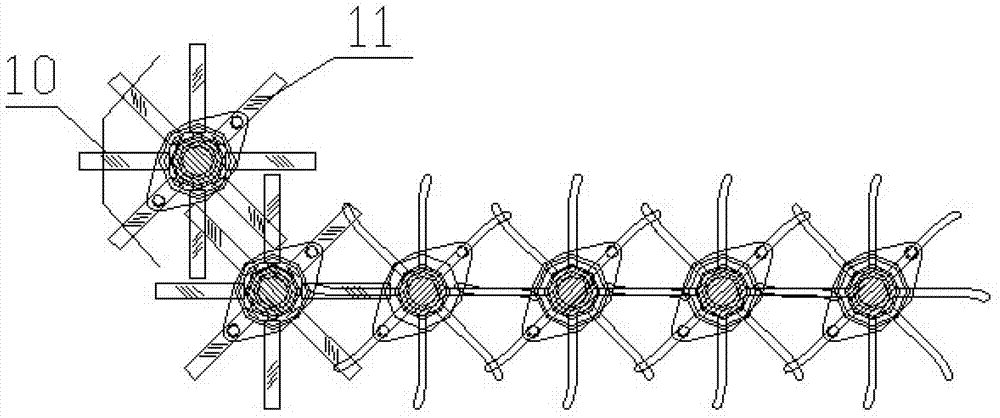

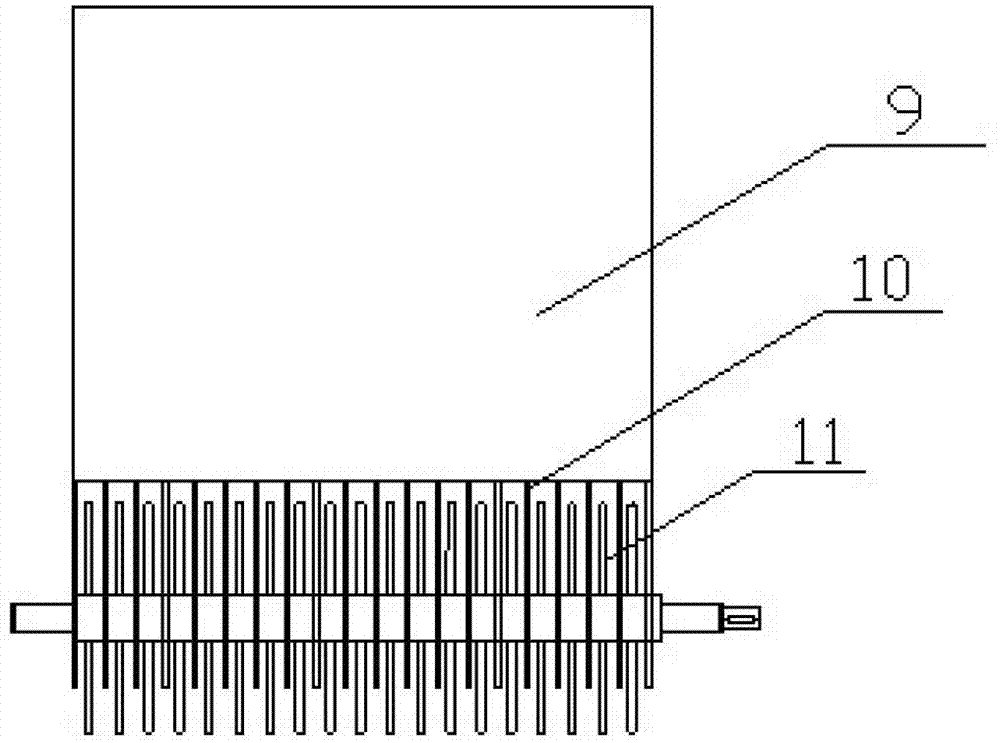

InactiveCN102823930AEasy to windImprove uniformityTobacco preparationTobacco treatmentMaterial SeparationEngineering

The invention discloses novel tobacco shred screening and shortening equipment which belongs to the technical field of mechanical equipment. The novel tobacco shred screening and shortening equipment comprises an air material separation box and a blanking box body, wherein the air material separation box and the blanking box body are fixedly connected; a winnowing impurity removal box is fixedly connected to the lower part of the blanking box body; and a discharge air lock is arranged on the lower part of the blanking box body, and the blanking box body is fixed on a bracket. The novel tobacco shred screening and shortening equipment also comprises a tobacco shred poking device, an electromotor and a baffle plate, wherein the electromotor is arranged on a side part of the blanking box body; the tobacco shred poking device is arranged in the blanking box body; the electromotor and the tobacco shred poking device are connected in a transmission mode; the tobacco shred poking device consists of a cut-off device and a plurality of loosing devices; the cut-off device is arranged sideward above the loosing devices, and the plurality of loosing devices are simultaneously rotated; the rotation speed of the various loosing devices are different, and the cut-off device is reversely rotated; and the baffle plate is arranged on a side part of the cut-off device. The novel tobacco shred screening and shortening equipment has the advantages that tobacco shred rolls can be more easily loosed, and meanwhile, long tobacco shreds can be cut off so as to improve the uniformity of the tobacco shreds and the efficiency of winnowing impurity removal.

Owner:张辉

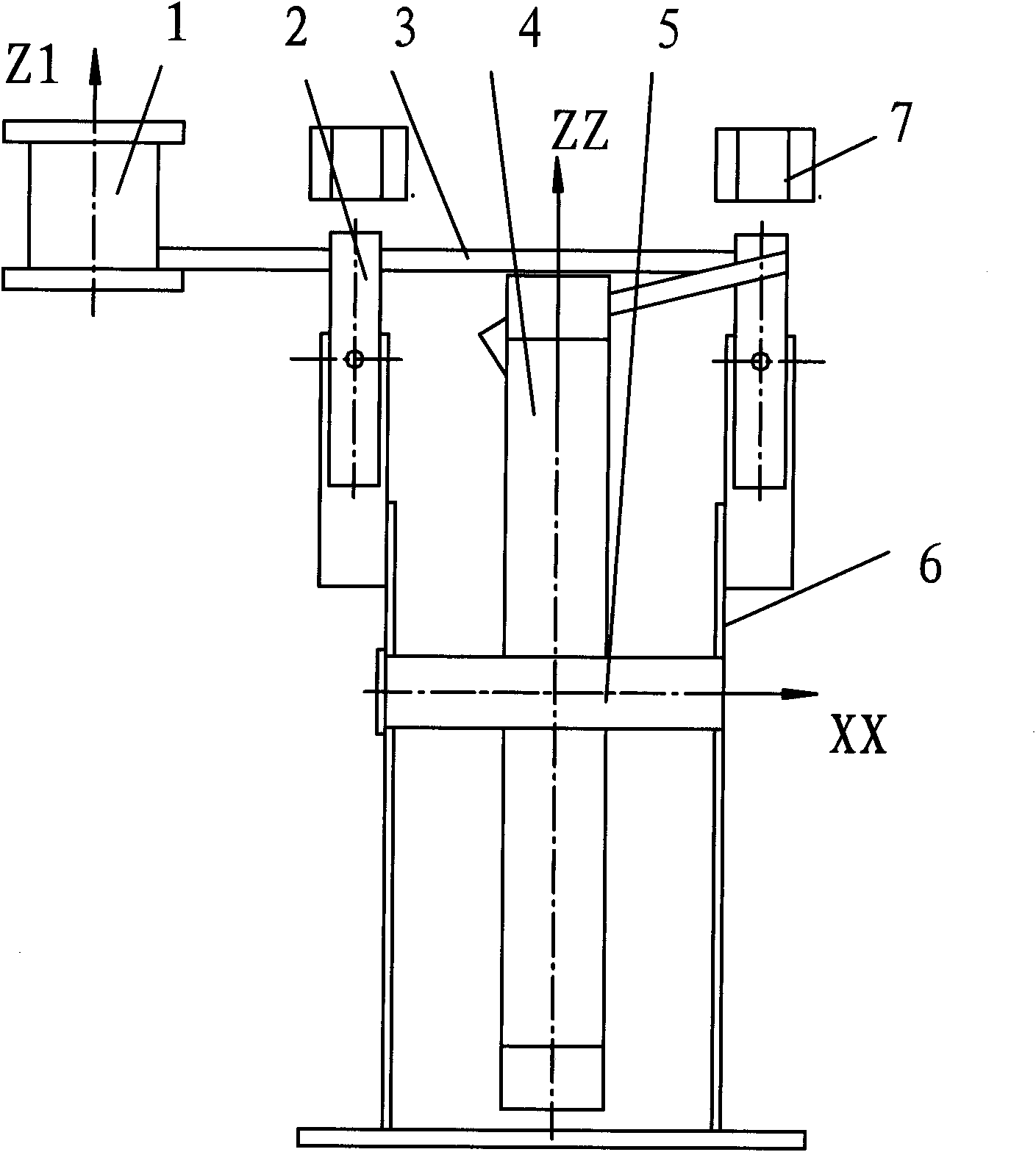

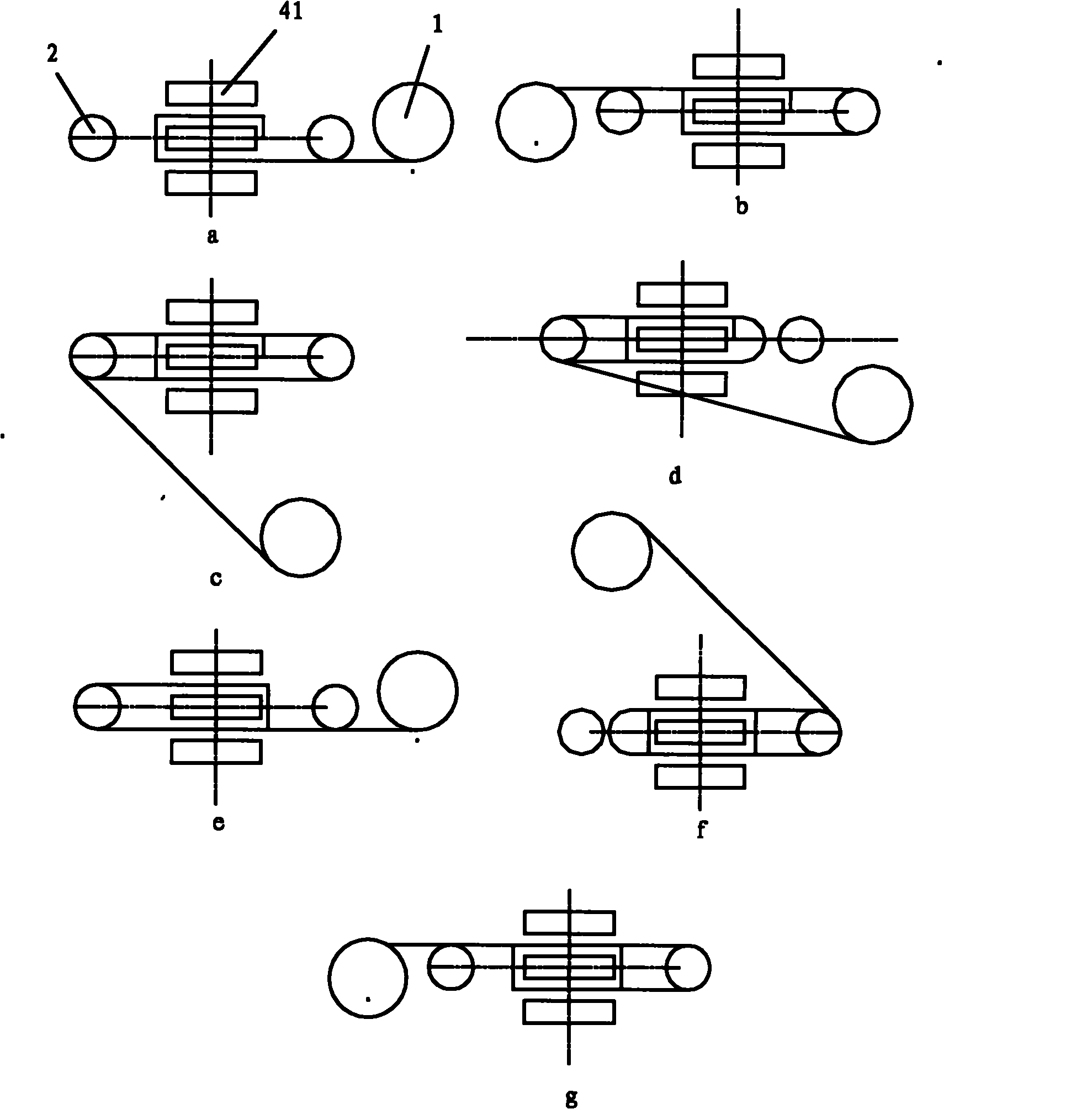

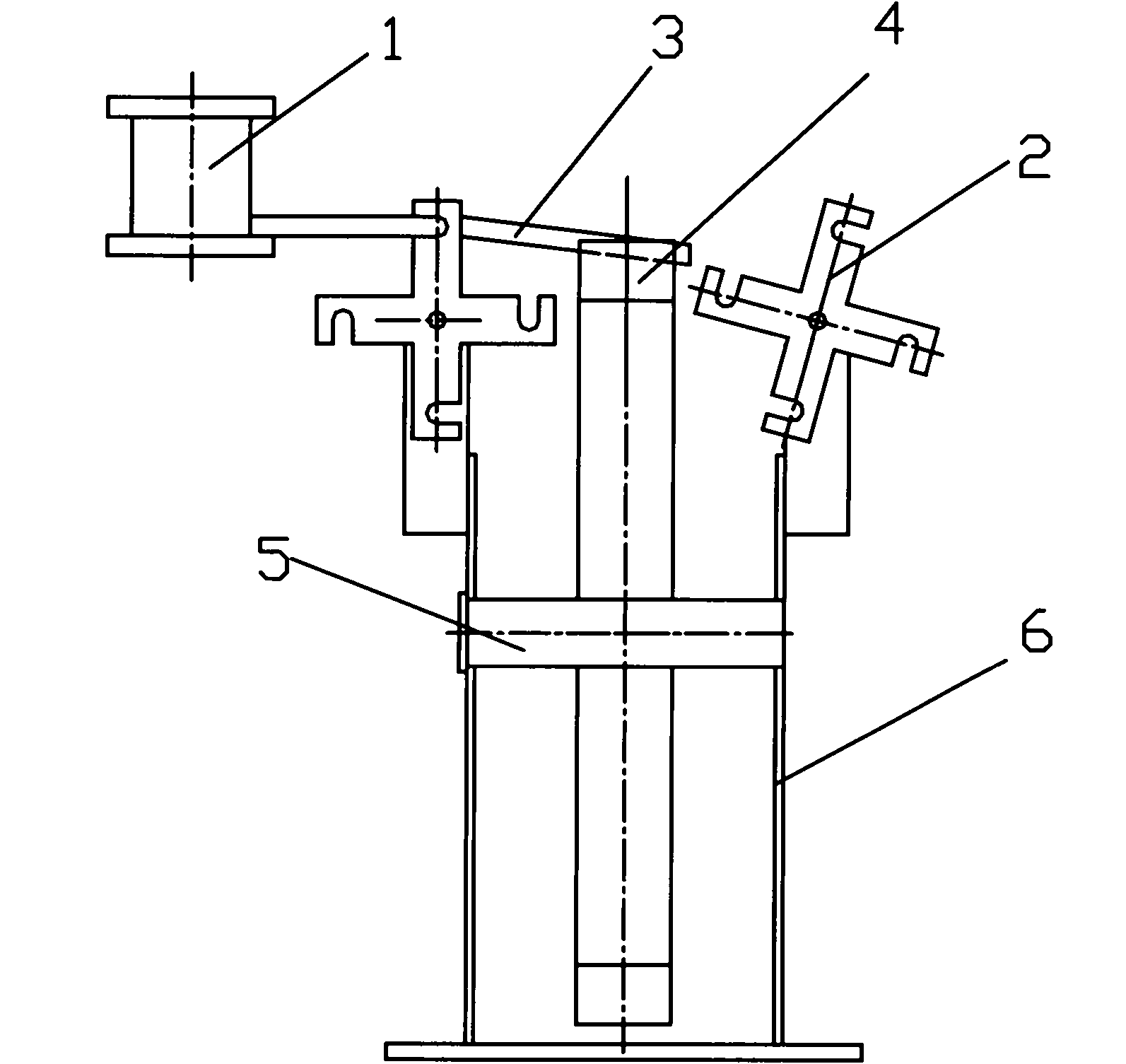

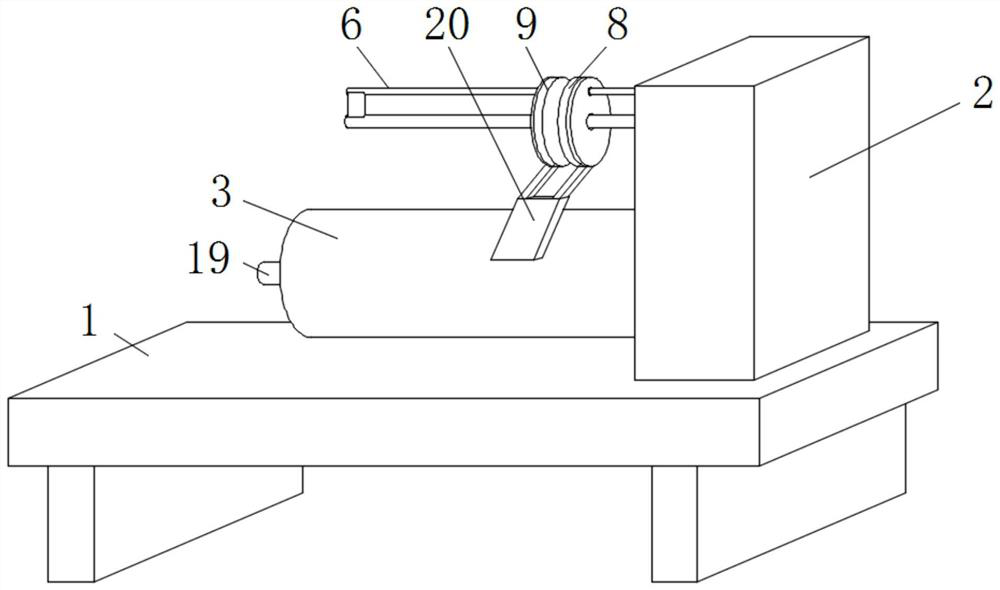

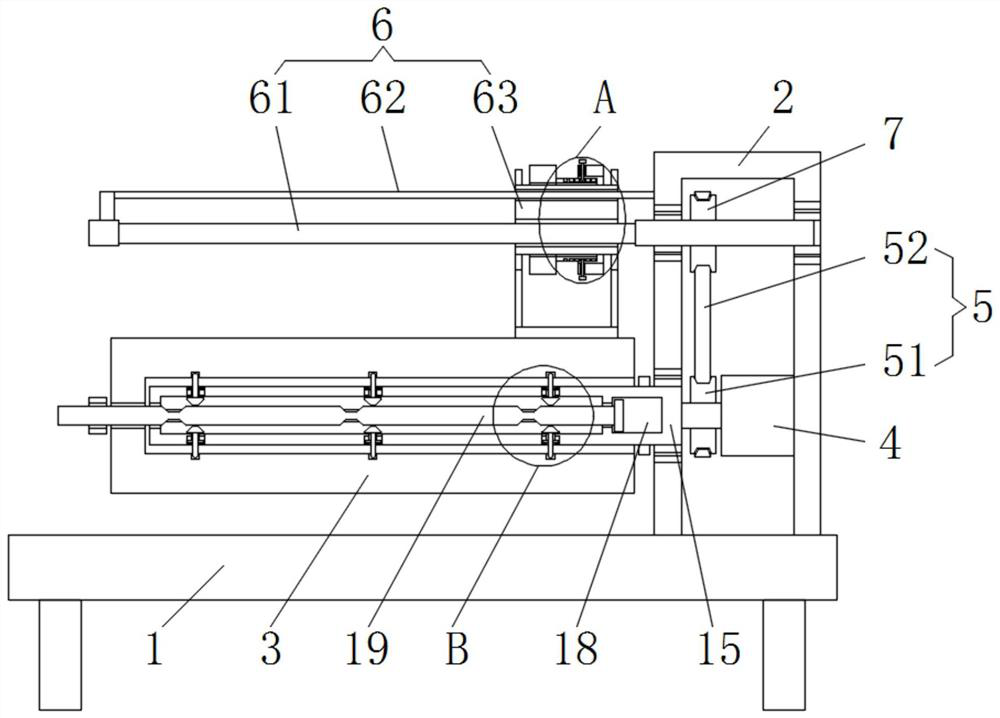

Winding device and winding method of motor armature of electric motor vehicle

InactiveCN101860145AEasy to windLabor savingElectric machinesManufacturing dynamo-electric machinesPower componentElectric vehicle

The invention discloses a winding device and a winding method of a motor armature of an electric motor vehicle. The winding device comprises a winding stand, a wire coil and an iron core fixed shaft which are arranged on the wire coil, the wire coil rotates around a winding shaft of the stand; two winding suspension mechanisms are respectively arranged on two sides of the stand; each winding suspension mechanism comprises a suspension part and a power component which is connected with the suspension part to control the suspension part to rotate; and each suspension part is provided with two stations, i.e. a first station for the upper end of the suspension part positioned in a paying-off plane of the wire coil to wind the winding and a second station for the upper end of the suspending mechanism of the winding to swing to the inner side of the stand and release the winding. Compared with the prior art, in the method, the winding to be wound is firstly wound on the suspension part of the suspending mechanism, the suspension part is swung by swinging the suspending mechanism to release the winding on the suspension part from the suspension part, the winding can be automatically furled into a wire trough under the action of the tension of the wire coil, the winding is convenient and fully automatic, the labor force is saved and the winding efficiency is high.

Owner:崔建伟

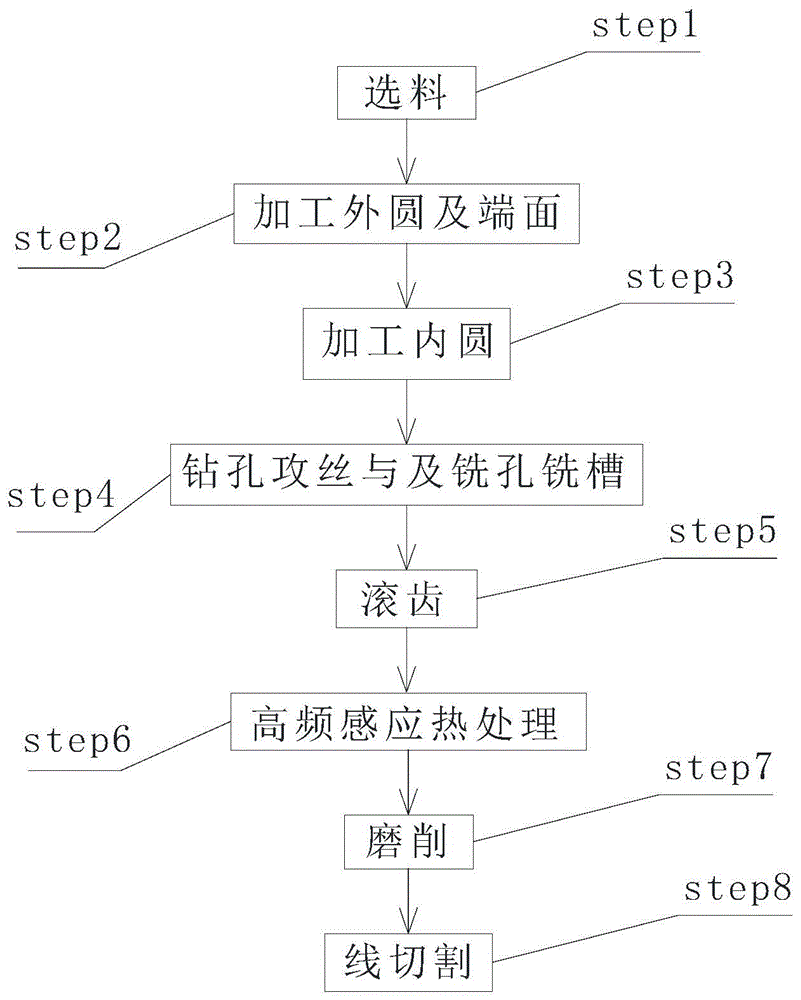

Process for machining special winding gears for transformers with roll iron cores

The invention discloses a process for machining special winding gears for transformers with roll iron cores. The process includes steps of selecting materials; machining outer circles and end surfaces; machining inner circles; drilling holes, tapping threads and milling the holes and grooves; hobbing gears; carrying out high-frequency induction heat treatment on the gears; grinding the gears; linearly cutting the gears; positioning, clamping and machining the gears, and the like. The process for machining the special winding gears for the transformers with the roll iron cores has the advantages that positioning triangles are arranged on workpieces, each workpiece is cut into halves, and accordingly the special winding gears and frameworks of winding machines can be conveniently mounted and conveniently assembled; T-shaped bosses are arranged on the workpieces by means of machining, low-voltage line holes and oblong slotted holes are formed in the workpieces by means of machining, and accordingly winding can be facilitated to a great extent; the integral workpieces are made of number-45 steel, high-frequency induction heat treatment and grinding treatment are combined with each other, accordingly, the hardness, the abrasion resistance and the precision of the integral gears can be guaranteed, and the gears are long in service life.

Owner:广东华力通变压器有限公司

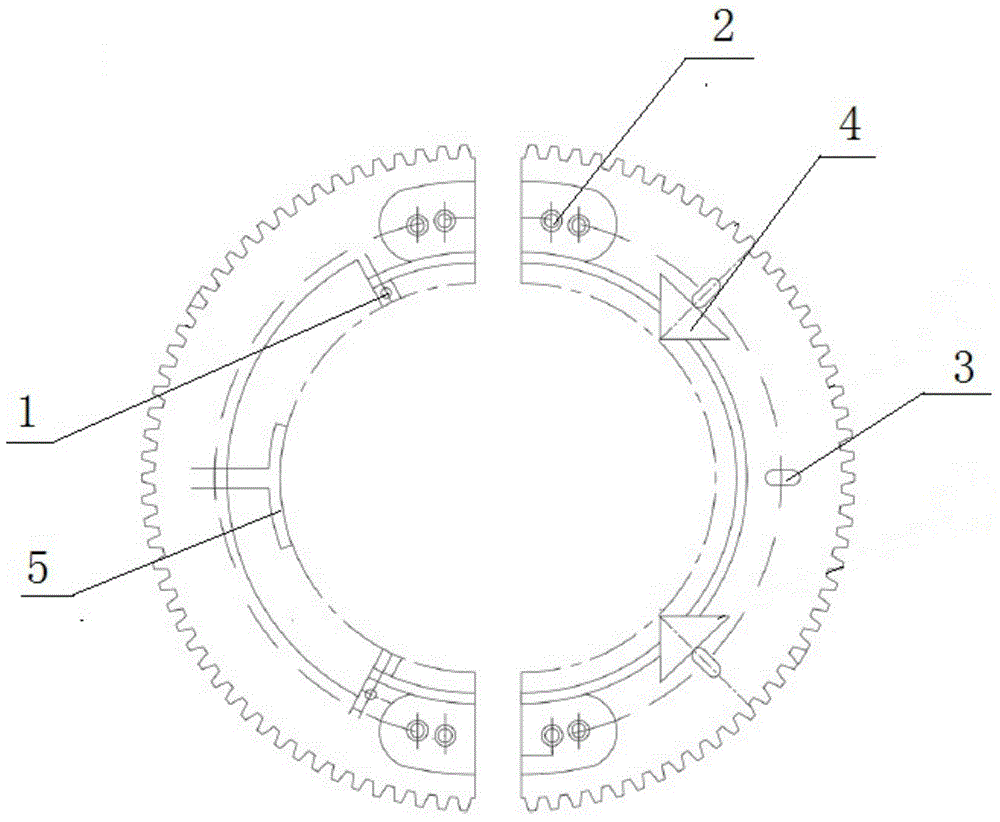

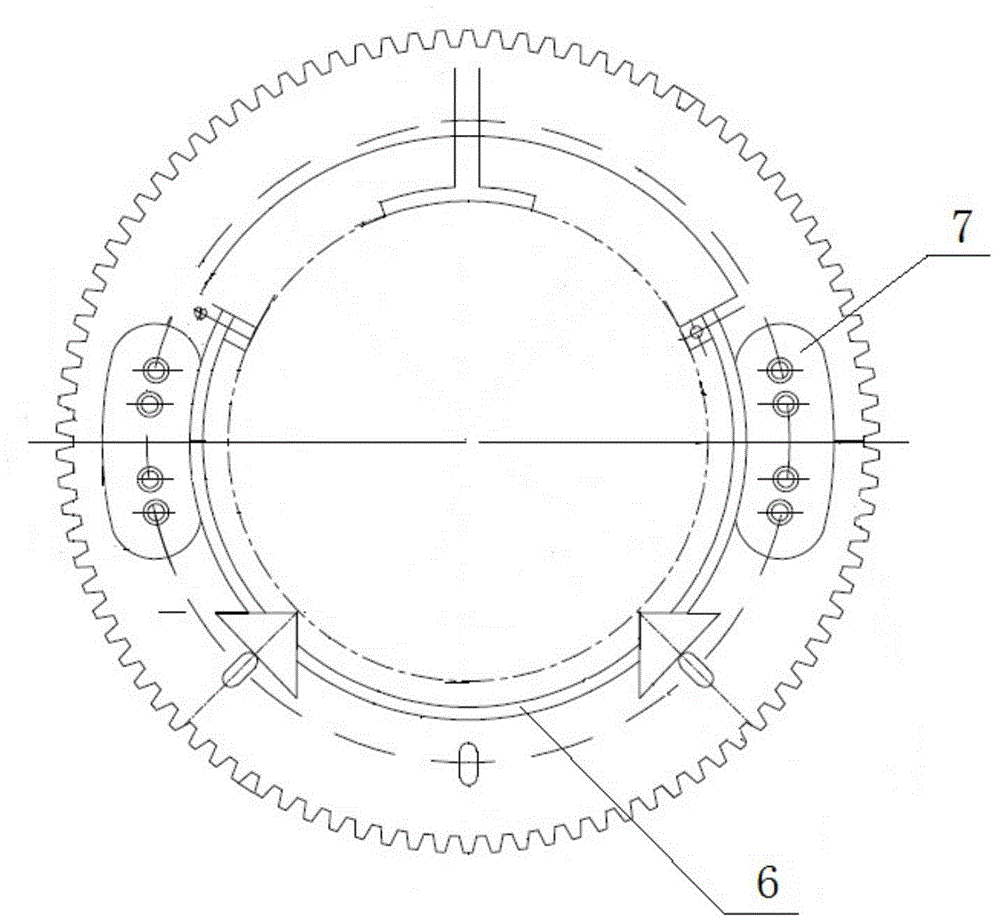

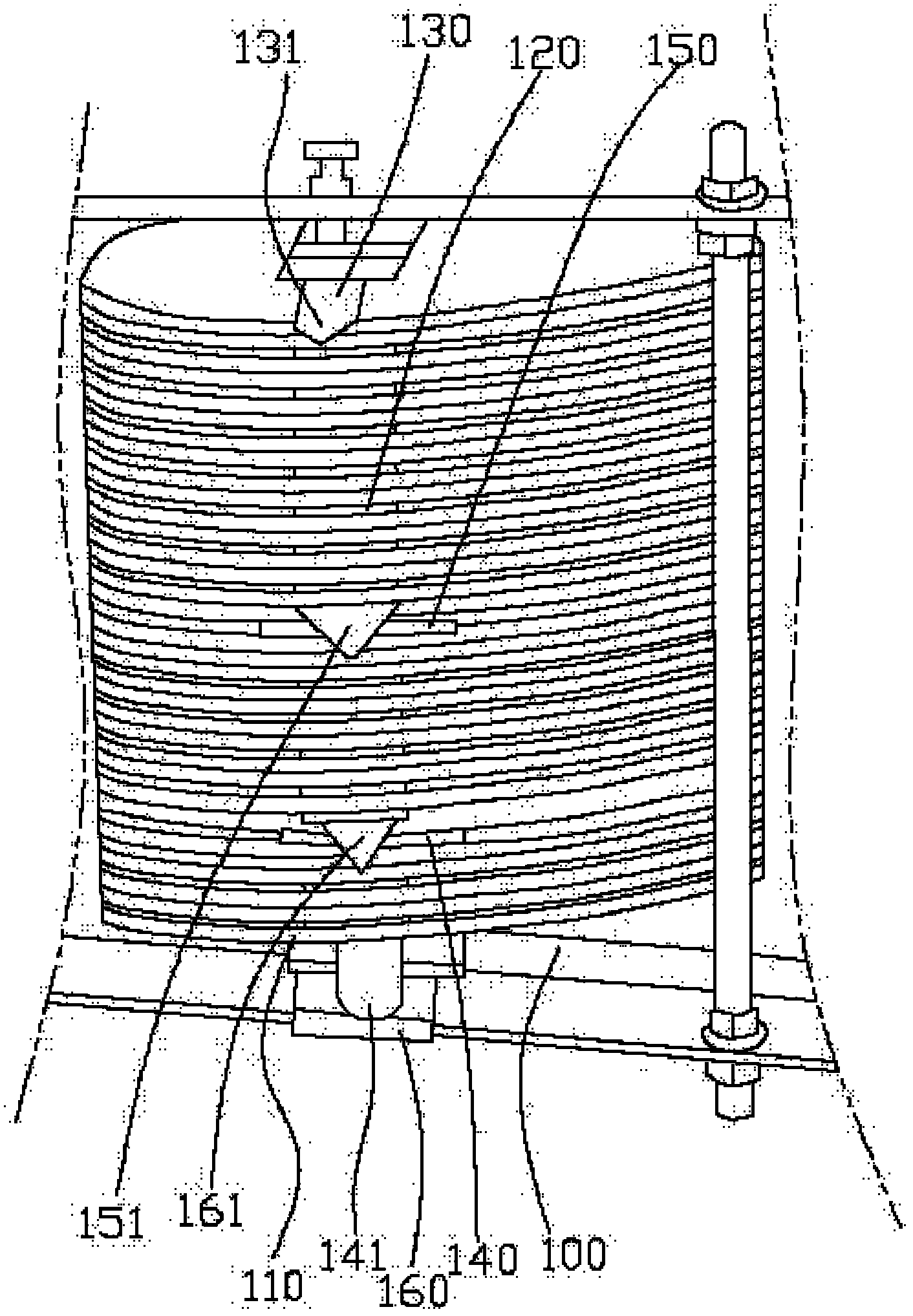

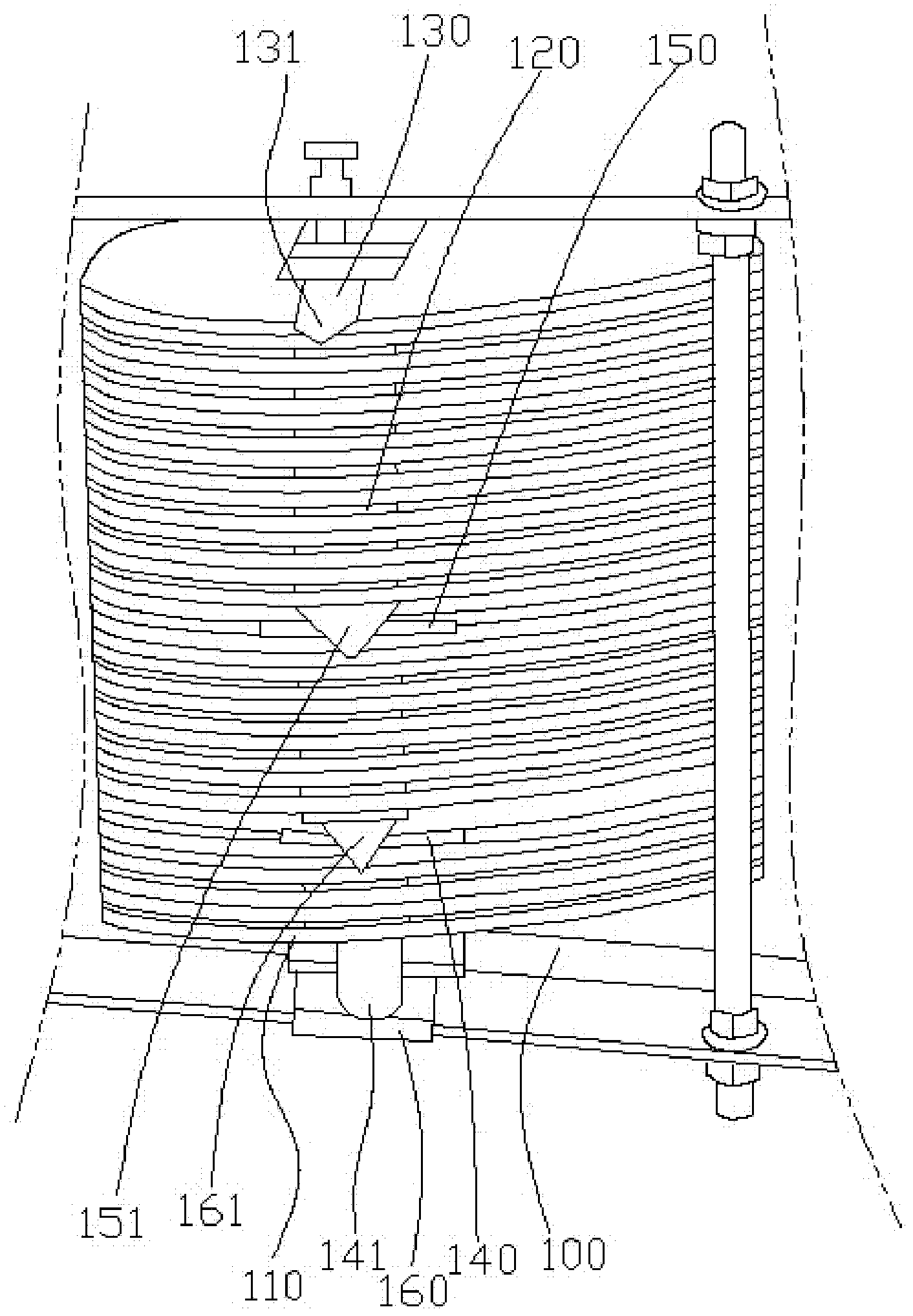

Vertical winding die of stereoscopic reeled iron core with voltage of 110kV and more

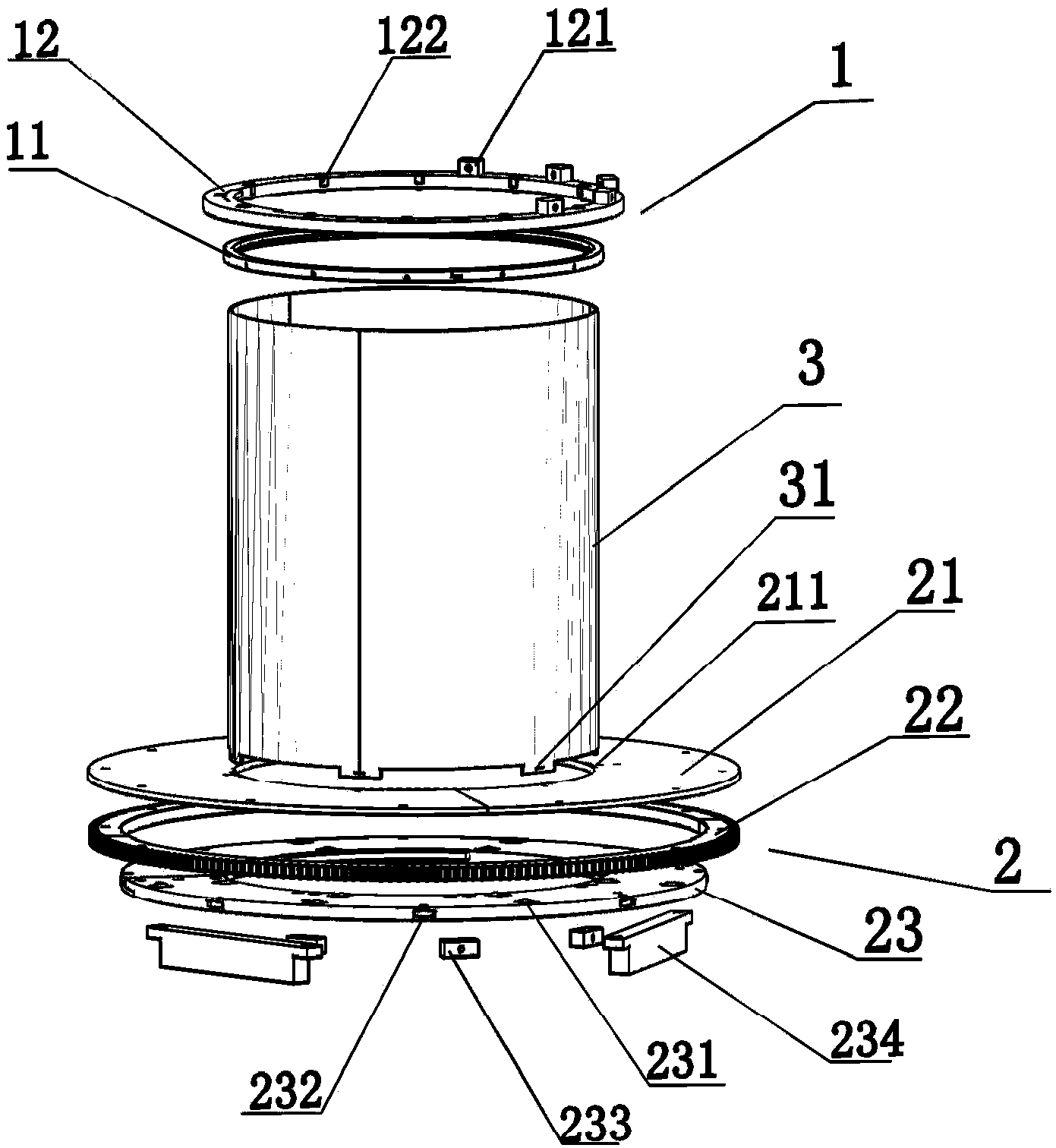

ActiveCN104103416AEasy to windHigh quality and fast windingFilament handlingCoils manufactureVoltageEngineering

The invention discloses a vertical winding die of a stereoscopic reeled iron core with voltage of 110kV and more. The vertical winding die comprises an upper die, a lower die and a winding die body, wherein the upper die comprises an upper die inner ring and an upper die outer ring, and the upper die outer ring rotationally sleeves the periphery of the upper die inner ring; the lower die comprises a gear die turn plate, a gear ring and a gear die tray, and the gear ring rotationally sleeves the periphery of the gear die tray; the winding die body is of a cylindrical structure, divided into at least three parts along the axial direction, and provided with clamping pins at the bottom; the upper die inner ring sleeves the upper end of the winding die for locking and fixing the shape of the same; the gear die turn plate is provided with a clamping groove, the winding die body is inserted into the clamping groove through the clamping pins to be locked and connected to the lower die; the upper die, the lower die and the winding die are respectively of a detachable structure, thus being convenient to be combined with the closed stereoscopic reeled iron core to wind a coil after disassembly; the vertical winding die is simple in structure, convenient to operate and wide in applicability, can ensure quality and rapid winding of the coil, solves the problem of cumbersome process steps in the winding of stereoscopic reeled iron core, and is greatly reduced in production cost.

Owner:HAIHONG ELECTRIC CO LTD

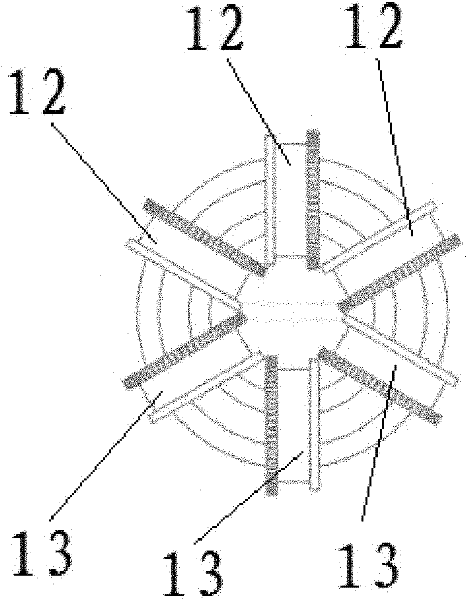

Transformer

InactiveCN102208256AEasy to windReduce processing difficultyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringConductor Coil

The invention discloses a transformer and belongs to the field of electronic products. The transformer comprises an annular closed iron core; an annular framework is encircled on the wall of the annular closed iron core; at least four annular frameworks serving as insulation frameworks are provided; and a wire is coiled on the outer surface of each of the annular frameworks so as to form a winding. As the windings of the transformer are coiled on the annular frameworks, the coiling is easy to realize, the processing difficulty is reduced, the production efficiency is improved and the product cost is reduced; and as at least four annular frameworks are arranged on the transformer and set to be primary windings and secondary windings as required, the heat dissipation effect is good and the performance of the transformer is guaranteed effectively. Furthermore, by the transformer, the two difficulties of the conventional transformer are reduced basically, so the transformer is easy to popularize.

Owner:SHENZHEN SANMA ELECTRONICS APPLIANCES CO LTD

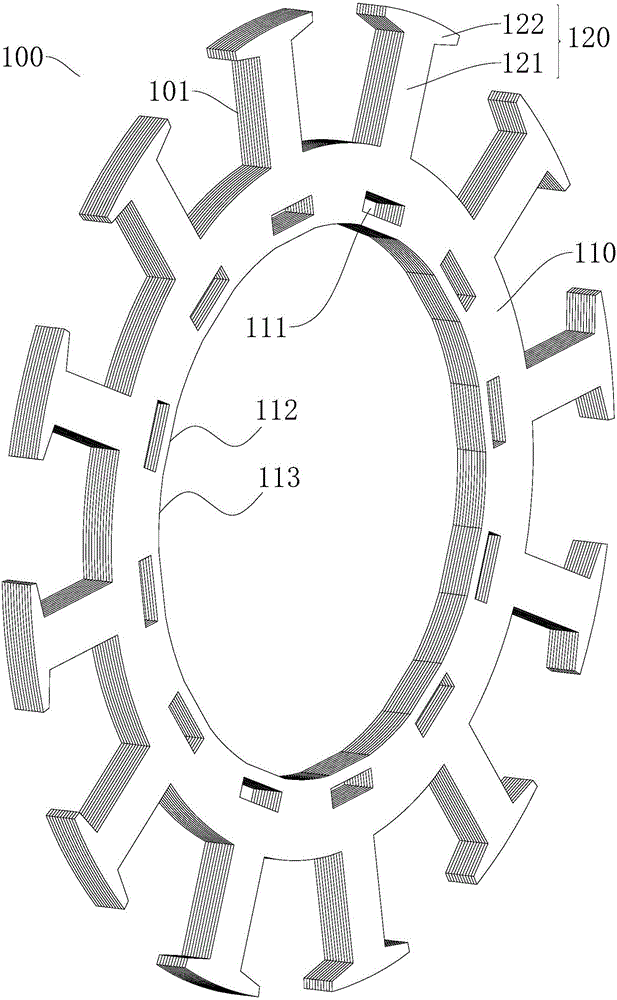

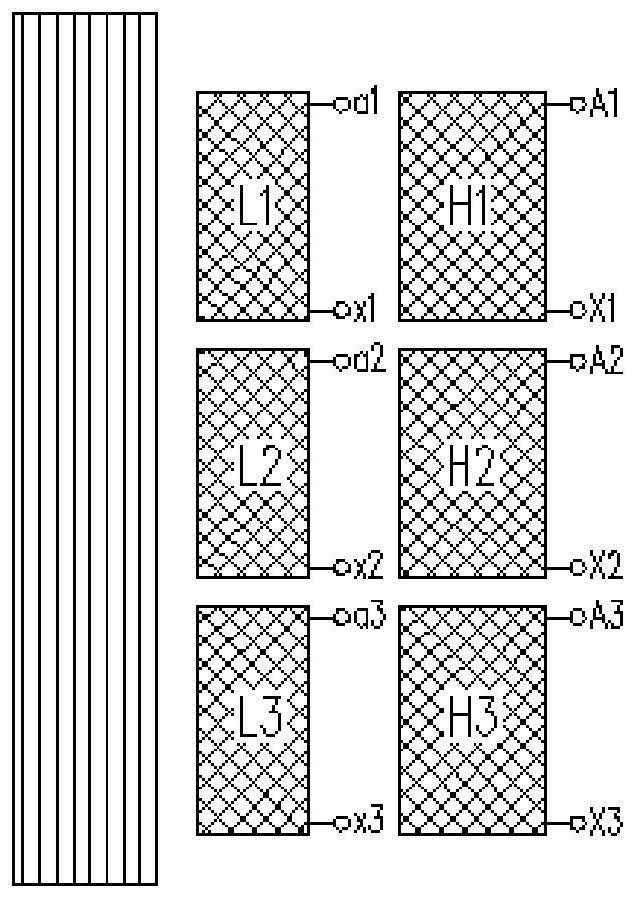

Stator core for birotor motor, stator, and birotor motor

ActiveCN106300713AEasy to windIncrease productivityMagnetic circuit stationary partsPhysicsConcentration effect

The invention discloses a stator core for a birotor motor, a stator, and a birotor motor. The stator core for the birotor motor includes an iron core main body and a plurality of inner stator teeth, the iron core main body includes a circular stator yoke part and a plurality of outer stator teeth integrally formed with the stator yoke part, the plurality of outer stator teeth are arranged on the outer peripheral surface of the stator yoke part and are circumferentially spaced along the stator yoke part, the plurality of inner stator teeth are detachably arranged on the inner peripheral surface of the stator yoke part and are circumferentially spaced along the stator yoke part, and the thickness direction of the stator yoke part is parallel to the thickness direction of the outer stator teeth and the width direction of the inner stator teeth. The stator core for the birotor motor has the advantages of convenient winding, high production efficiency, and high magnetic concentration effect.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

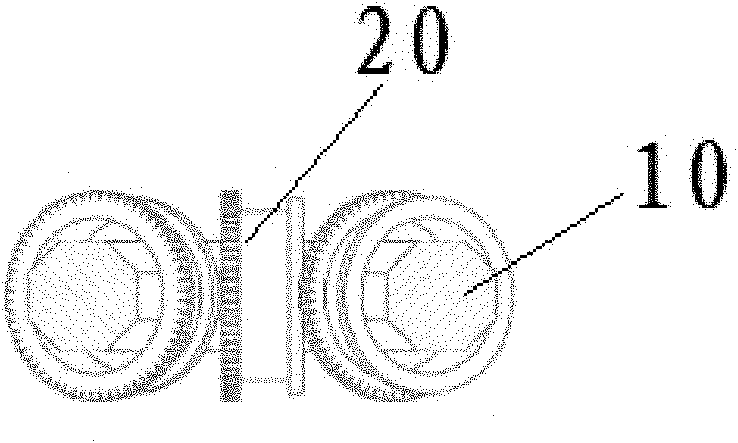

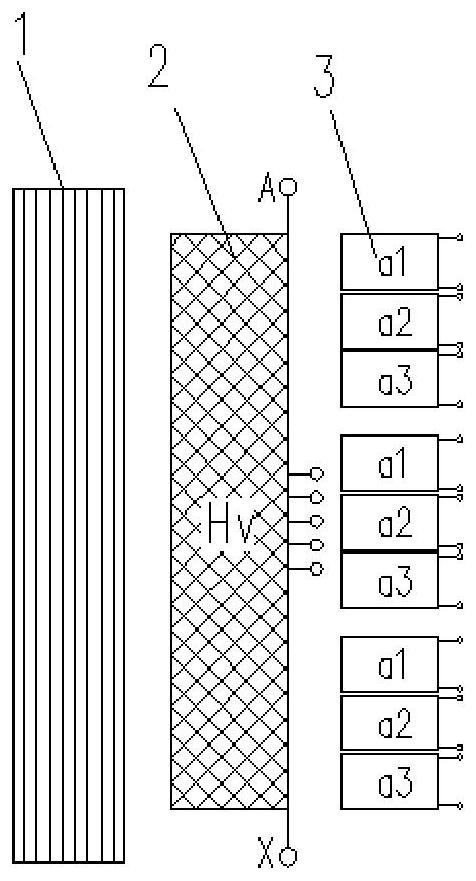

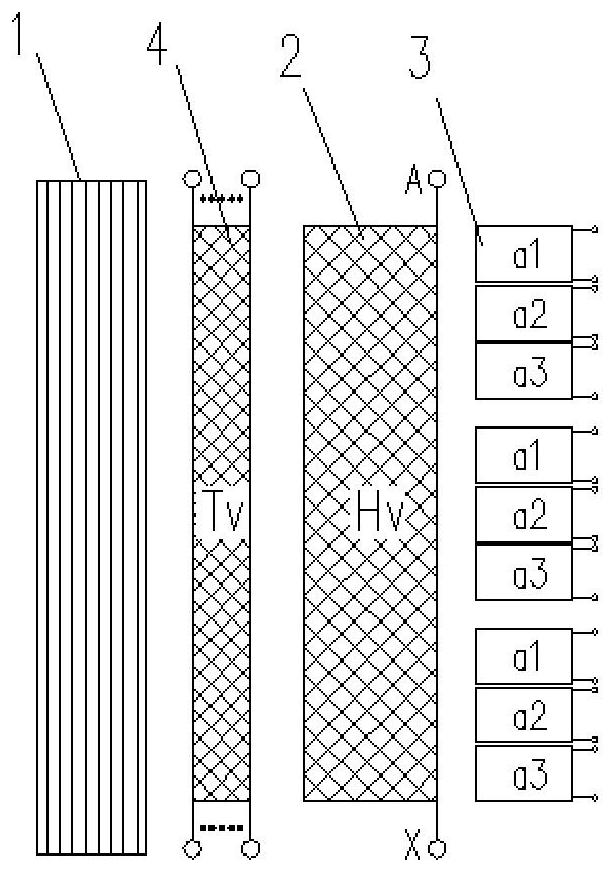

Single-phase transformer

ActiveCN102403106AEasy to windImprove operational reliabilityTransformers/inductances coils/windings/connectionsFixed transformersTransformerLow voltage

The invention discloses a single-phase transformer. The single-phase transformer comprises an iron core main column, a first iron core side column and a second iron core side column, wherein a low-voltage coil, a medium-voltage coil and a high-voltage coil are sleeved on the iron core main column from the inside to the outside in turn; an excitation coil and a voltage regulation coil are sleeved on the first iron core side column from the inside to the outside in turn; and the excitation coil is connected with the medium-voltage coil sleeved on the iron core main column in parallel in order to regulate the voltage of the voltage regulation coil. By sleeving the voltage regulation coil on the first iron core side column, the coil is convenient to wind, manufacturing risks are reduced, the operation reliability of the transformer is improved, and the overall width of the transformer is effectively reduced.

Owner:STATE GRID CORP OF CHINA

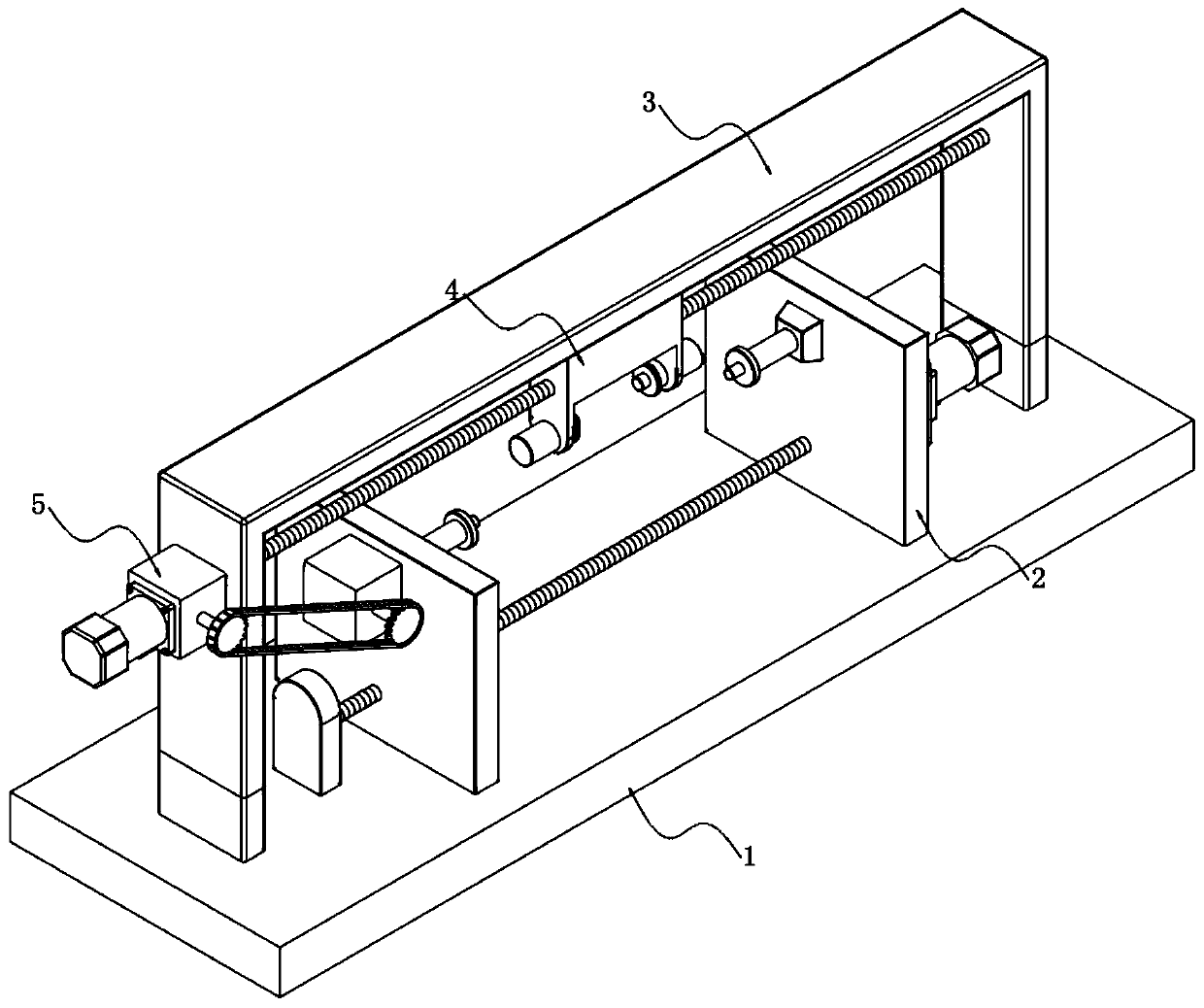

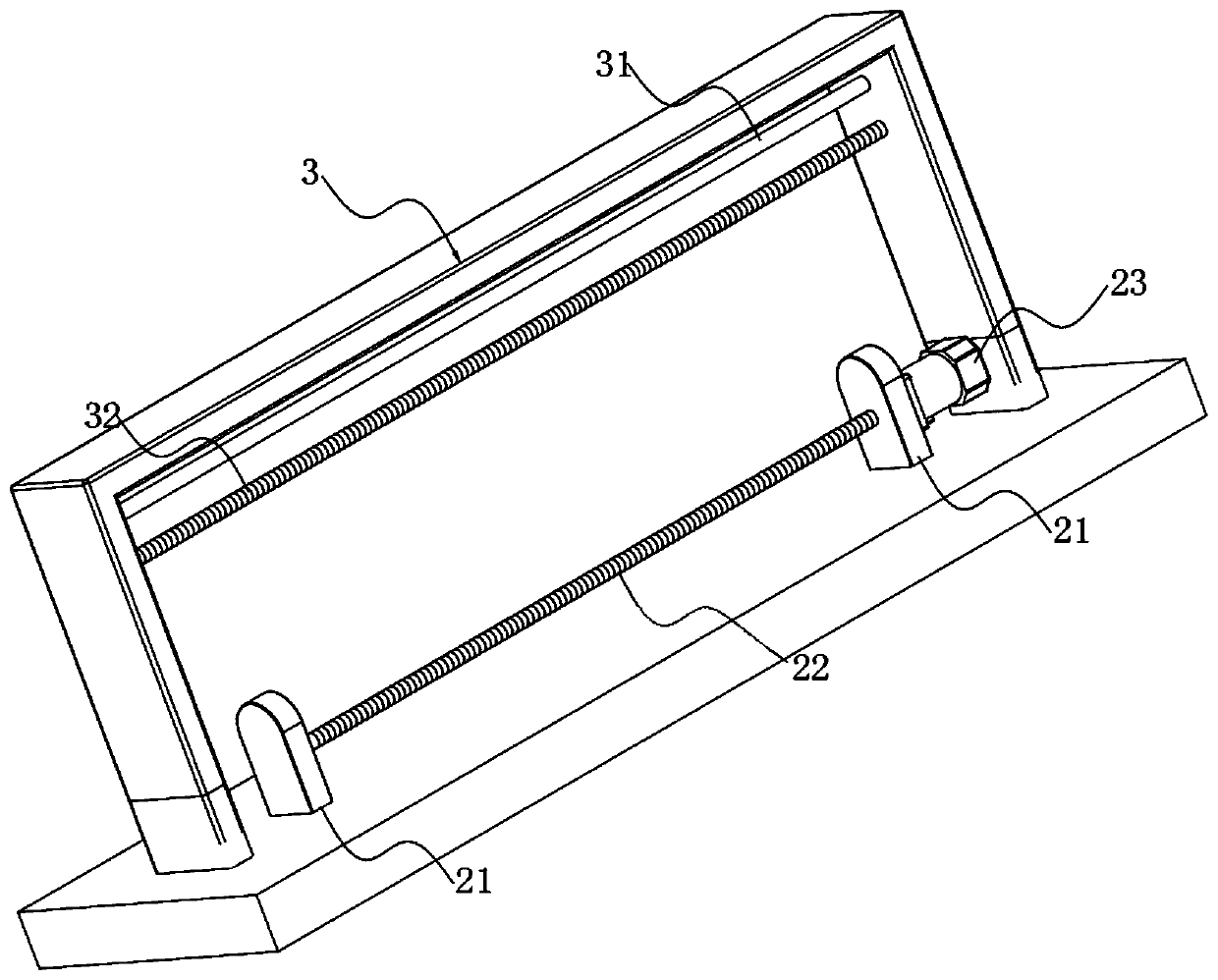

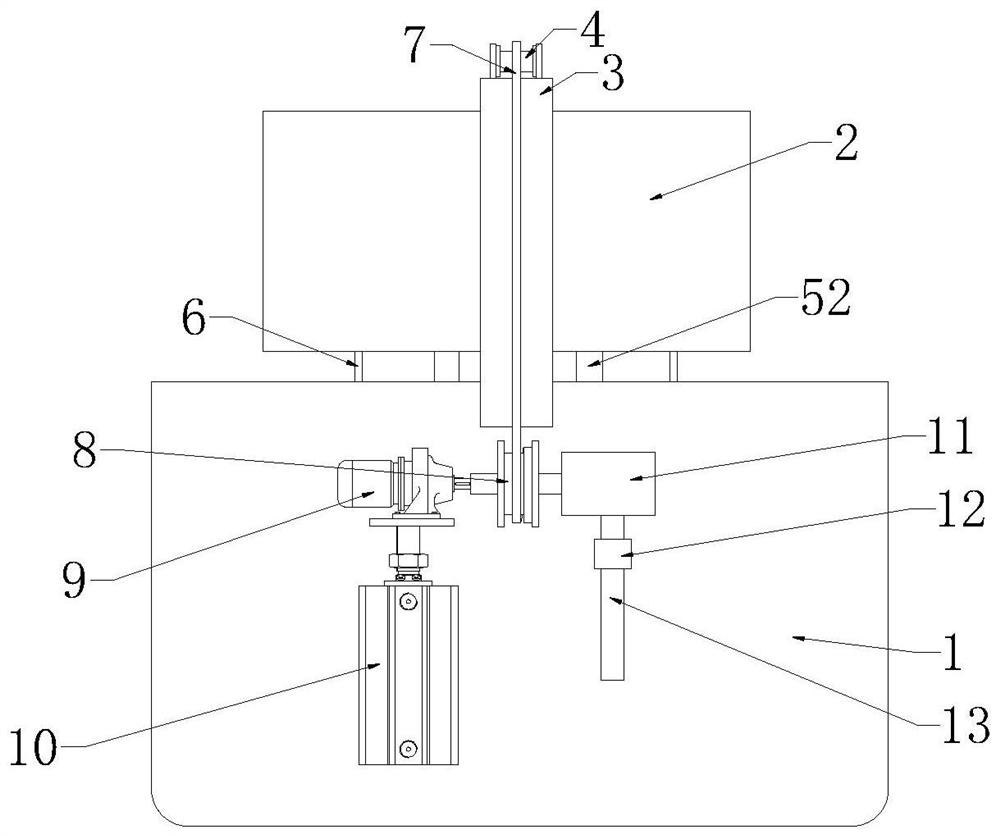

Automatic winding machine for transformer production

InactiveCN110752090AEasy to windHigh degree of automationCoils manufactureProcess engineeringWinding machine

The invention relates to the technical field of transformer production, and specifically relates to an automatic winding machine for transformer production. The automatic winding machine comprises a base, wherein the top surface of the base is provided with a transformer winding mechanism, and a portal frame is arranged above the transformer winding mechanism. According to the automatic winding machine for transformer production, the arrangement of the transformer winding mechanism facilitates the clamping of the transformer and the winding. Meanwhile, the automatic winding machine is providedwith a coil fixing mechanism, thereby being convenient for fixing a wire coil, and facilitating the winding of a wire on the wire coil to the transformer. In addition, the automatic winding machine is provided with a synchronous transmission mechanism, and it is convenient to perform spiral winding on the transformer under the driving of the synchronous transmission mechanism. According to the design, mechanical driving is adopted, the automation degree is high, and the labor force is saved. Meanwhile, the design is simple and easy to operate, and the manufacturing cost is low, thereby beingsuitable for being used in small factories, and solving the problem that the existing winding equipment is high in manufacturing cost and not suitable for being used in the small factories.

Owner:HUNAN CITY UNIV

Stator tooth module, stator, motor and winding method of winding in stator tooth module

PendingCN109756039AEasy to windLower requirementWindings insulation shape/form/constructionMagnetic circuit stationary partsWinding machineStator

The invention relates to a stator tooth module. The stator tooth module comprises stator teeth, an insulation framework and a winding, wherein a winding groove is formed in the insulation framework, and the winding is wound in the winding groove; a vertical convex strip is arranged at each of the rear ends of the outer surfaces of a left supporting plate and a right supporting plate of a supporting sleeve; the first coil group of the winding is wound on the supporting sleeve between the vertical convex strip and a front baffle; the second coil group of the winding is wound on the first coil group; the coil at the last end in the second coil group is tightly pressed on the coil at the last end in the first coil group and a rear baffle plate and / or the vertical convex strip; and any other coil in the second coil group is tightly pressed on two adjacent coils in the first coil group. The invention further relates to a stator comprising the stator tooth module, a motor comprising the stator and a winding method for the winding in the stator tooth module. The invention has the advantages that the requirement for the winding machine is low, the manufacturing cost of the winding can be effectively reduced, the full rate of the motor groove is high, and the performance of the motor is good.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

Novel energy-efficient fin type electric heating pipe

The invention relates to a novel energy-efficient fin type electric heating pipe which comprises a shell, a heating wire and heat-conducting insulating padding. A strip-shaped cooling fin is spirally wound on the outer surface of the shell and provided with continuously-distributed fan-shaped concave-convex structures, the shrinkage end of each structure is close to the surface of the shell, the unfolded end of each structure is close to the outer edge of the fin, and a smooth arc transition face is arranged between each unfolded end and the outer edge of the cooling fin. Mounting seats are connected with the shell in a sealed mode, power lines are arranged on the end portions of the mounting seats, and the power lines are connected with the heating wire in the shell through the mounting seats. The continuous concave-convex structures which are arranged at intervals are adopted by the cooling fin, the fin can be conveniently wound on the shell, and internal stress of the cooling fin is effectively eliminated. Welding machining is facilitated, the width of the fin is not limited, the cooling area is enlarged, the cooling effect is better, and the service life of the electric heating pipe is longer. Cooling efficiency of the fin is enhanced, the power of the electric heating pipe can be properly lowered, and the purposes of efficiency raising and energy saving are achieved.

Owner:江苏大唐电器制造有限公司

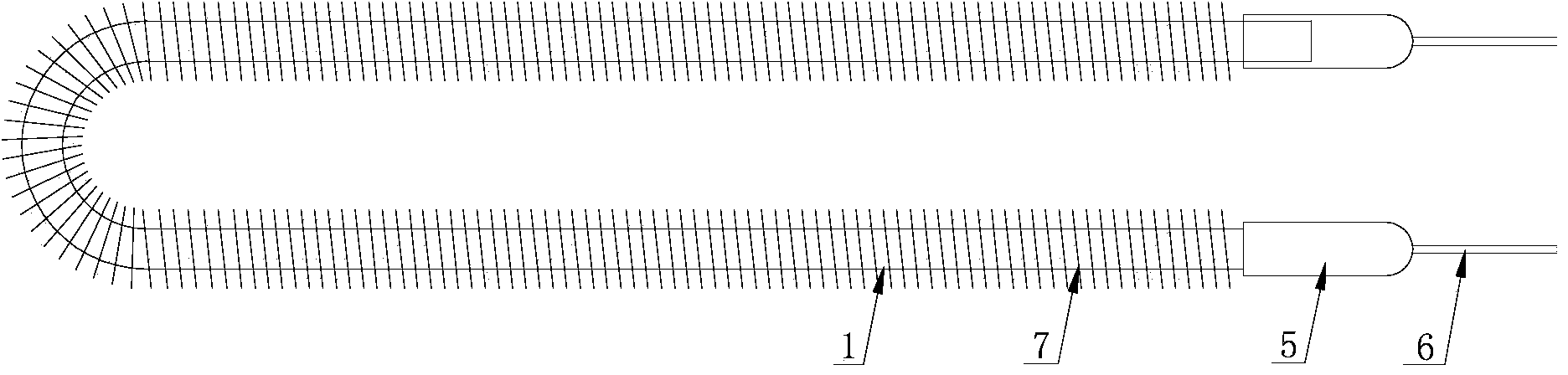

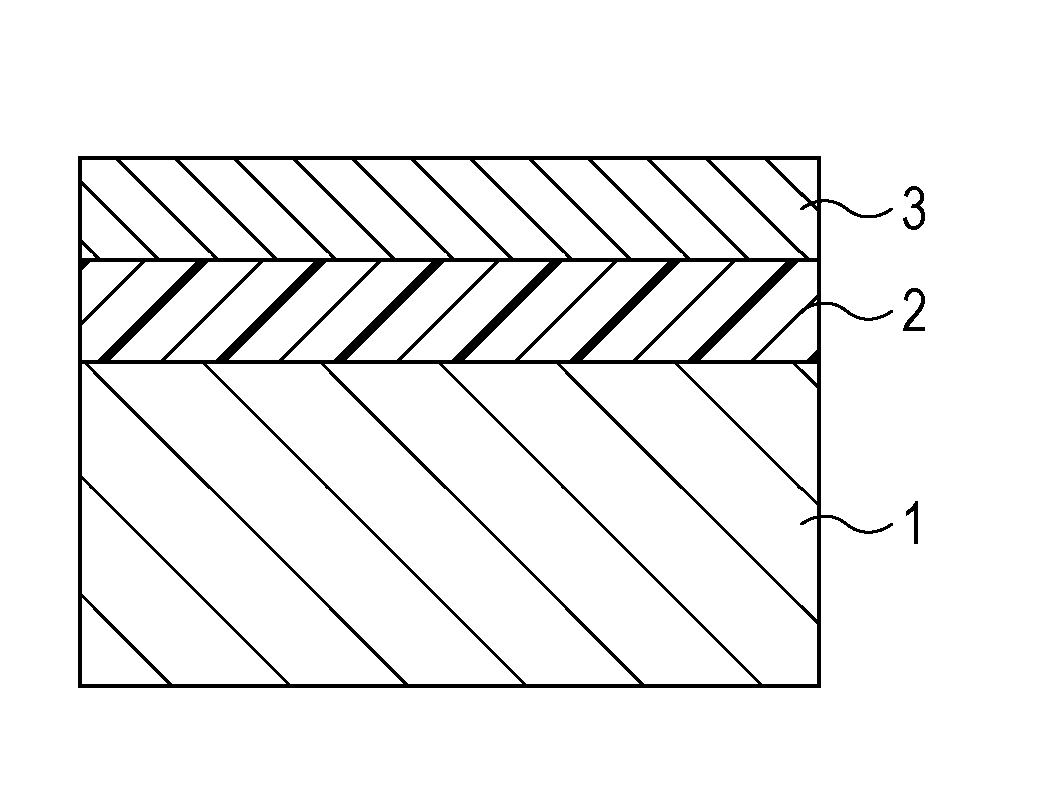

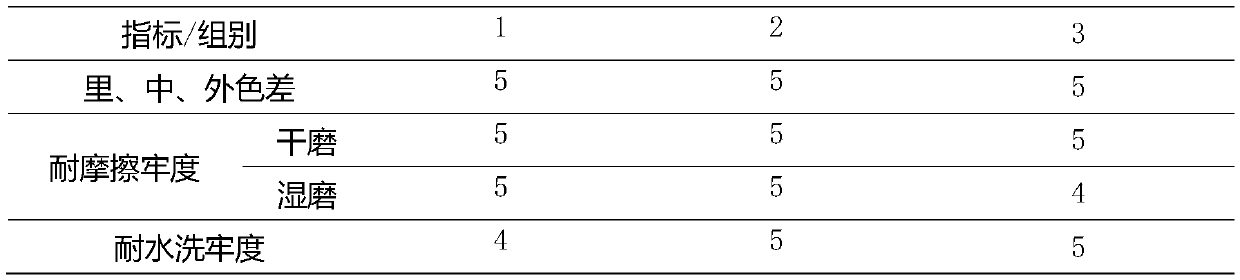

Recording medium

A recording medium includes a base paper, a polymer layer disposed on the base paper, and an ink-receiving layer disposed on the polymer layer. The base paper has a thickness of 50 μm or more and 130 μm or less. The polymer layer has a thickness of 20 μm or more and 60 μm or less. The polymer layer has an arithmetic average surface roughness Ra1 of 0.12 μm or more and 0.18 μm or less. The polymer layer has a roughness curve element average length RSm of 0.01 mm or more and 0.20 mm or less. The recording medium has an arithmetic average surface roughness Ra2 of 0.13 μm or less.

Owner:CANON KK

Novel cloth roller

The invention discloses a novel cloth roller. The cloth roller comprises a roller body, choke plugs and a roller shaft, wherein the choke plugs are fixedly arranged at the two ends of the roller body, and the roller shaft is installed in center holes of the choke plugs. The roller body is of a hollow cylindrical structure, a plurality of long grooves are formed in the middle of the roller body and evenly distributed in the axial direction of the roller body, a left spiral groove is formed in the left end of the surface of the roller body, and a right spiral groove is formed in the right end of the surface of the roller body and opposite to the left spiral groove in rotation direction. The cloth roller is of the hollow cylindrical structure, so that the weight of the cloth roller is reduced; friction force is increased through the long grooves formed in the middle, so that cloth is not prone to slipping in the winding process and wound on the cloth roller more easily. The left spiral groove and the right spiral groove which are opposite in rotation direction are formed in the two ends of the roller body, so that the two ends of the cloth do not wrinkle or curl, and the cloth is more convenient and easier to wind.

Owner:吴江金名来丝绸进出口有限公司

High-power rectifier transformer of charger

InactiveCN102522189AEasy to windSoldering output terminals is easyTransformers/inductances coils/windings/connectionsVariable inductancesAluminiumEngineering

The invention discloses a high-power rectifier transformer of a charger, and the high-power rectifier transformer comprises an iron core limb, and a primary side coil and a secondary side coil wound on the iron core limb. The high-power rectifier transformer is characterized in that the secondary side coil is formed by vertically winding a flat aluminum bar; the secondary side coil is divided into multiple layers of wire cakes; the wire cakes are separated by adopting insulating bakelite blocks; the secondary side coil is provided with two coil output ends and a plurality of intermediate taps; the coil output ends are arranged at two ends of the secondary side coil; the intermediate taps are arranged at the intermediate position of the secondary side coil; and output terminals are welded on the coil output ends and the intermediate taps. The high-power rectifier transformer has the advantages that the winding is convenient, the output terminals are welded more easily, the additional loss of the secondary side coil is small, the short-circuit-resistant mechanical strength is better, and the structure is compact. In addition, as the wire cakes of the secondary side coil are separated by utilizing the insulating bakelite blocks, not only is the insulation between the wire cakes achieved, but also the ventilation and the heat radiation of the secondary side coil are improved.

Owner:上海施能电器设备有限公司

Grounding wire winder

A grounding wire winder comprises a support, an axis rod, a winding wheel and baffles. The axis rod and the support are fixedly connected. The winding wheel is arranged on the axis rod in a sleeving manner. The support is of a triangular structure. The winding wheel is of a double-layer structure, and the inner layer and the outer layer of the winding wheel are both fixedly connected with the baffles coaxially. A hole is formed in the outer layer of the winding wheel, and the purpose of holing is to fix a wire end conveniently. The winding wheel is layered so that after the wire end is inserted, friction cannot happen during winding, and the protection function is achieved. Round winding is adopted and convenient, the speed is high, and a wire cannot be easily abraded. By means of the triangular structure support, stability and durability are achieved, storing and taking are more convenient through a handle at the top end, and after the winding manner is unified, the wire is more tidy and attractive during storage, and misoperation is not likely to happen during taking and using.

Owner:STATE GRID SHANDONG LINQU POWER SUPPLY +2

Winding frame

The invention provides a winding frame. The winding frame is simple in structure and convenient to operate, and the occupied area of the winding frame is reduced. The winding frame comprises a base, a rotary table, a center rod and a plurality of supporting rod mechanisms. The rotary table is movably connected to the upper portion of the base. The center rod is fixedly arranged at the center of the rotary table. The supporting rod mechanisms are arranged on the rotary table and located on the periphery of the center rod in an annular mode. Each supporting rod mechanism comprises a supporting rod, a hydraulic cylinder, a spring and a groove formed in the rotary table, wherein the spring, the supporting rod and the hydraulic cylinder are sequentially arranged in the groove, and the spring is located on the outer side of the groove. When the winding frame works, the rotary table rotates relative to the base, so that wire winding can be conducted conveniently; the supporting rods are conical, and thus coils can be connected to the supporting rods in a sleeving mode conveniently, and the reliability is high; the supporting rods can move outwards under the effect of the hydraulic cylinders to be separated into a plurality of independent winding rods, in this way, operation is convenient, and the occupied area is reduced. The winding frame is convenient to machine and low in cost.

Owner:湖州辰丰线缆有限公司

Ultra high voltage tank cage insertion mould

PendingCN108447680AEasy to windSolve wasteInductances/transformers/magnets manufactureTransformerUltra high voltage

The invention discloses an ultra high voltage tank cage insertion mould, and mainly relates to the technical field of power transformer equipment. The mould comprises a central shaft, central guidingis arranged in the middle of the central shaft, sliding assemblies are respectively arranged on both sides of the central guiding and the central shaft, umbrella-shaped supports are arranged at four-corner positions of the sliding assemblies, the umbrella-shaped supports are rotatably connected to the sliding assemblies, the other ends of the umbrella-shaped supports are disposed on tank cage supports, the umbrella-shaped supports and the tank cage supports are connected through hinges, the two ends of the tank cage supports are connected with end guiding, a driving mechanism is disposed on one side of one end guiding, one side of the driving mechanism and one side of the other end guiding are respectively provided support assemblies, the support assembles are connected by cage supports, the outer surfaces of the cage supports are fixedly provided with tank cage rod members, grooves are formed in the upper surfaces of the tank cage members for installing outer round supporting strip blocks and outer round supporting strips, and the problem of waste of materials and working hours during winding and the problem of support of neutral internal supporting strips are effectively solved.

Owner:SHANDONG JULI ELECTRO MACHINERY

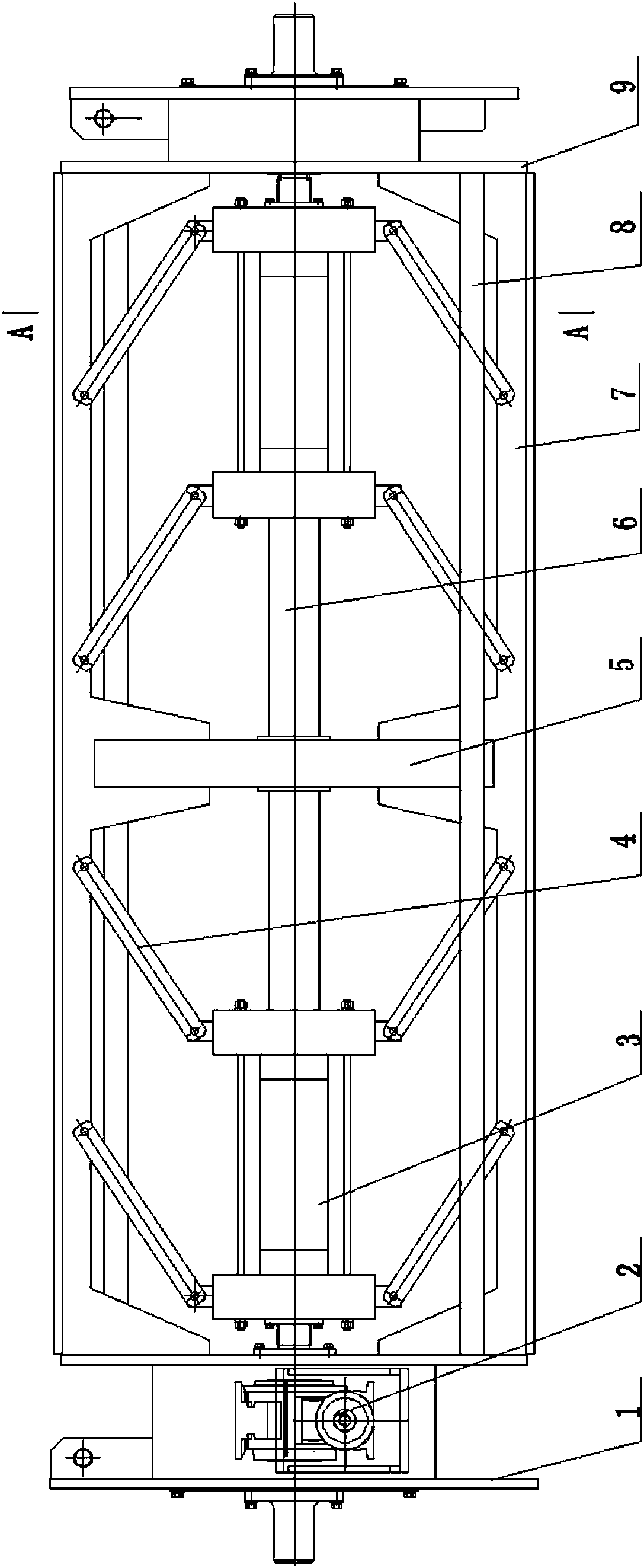

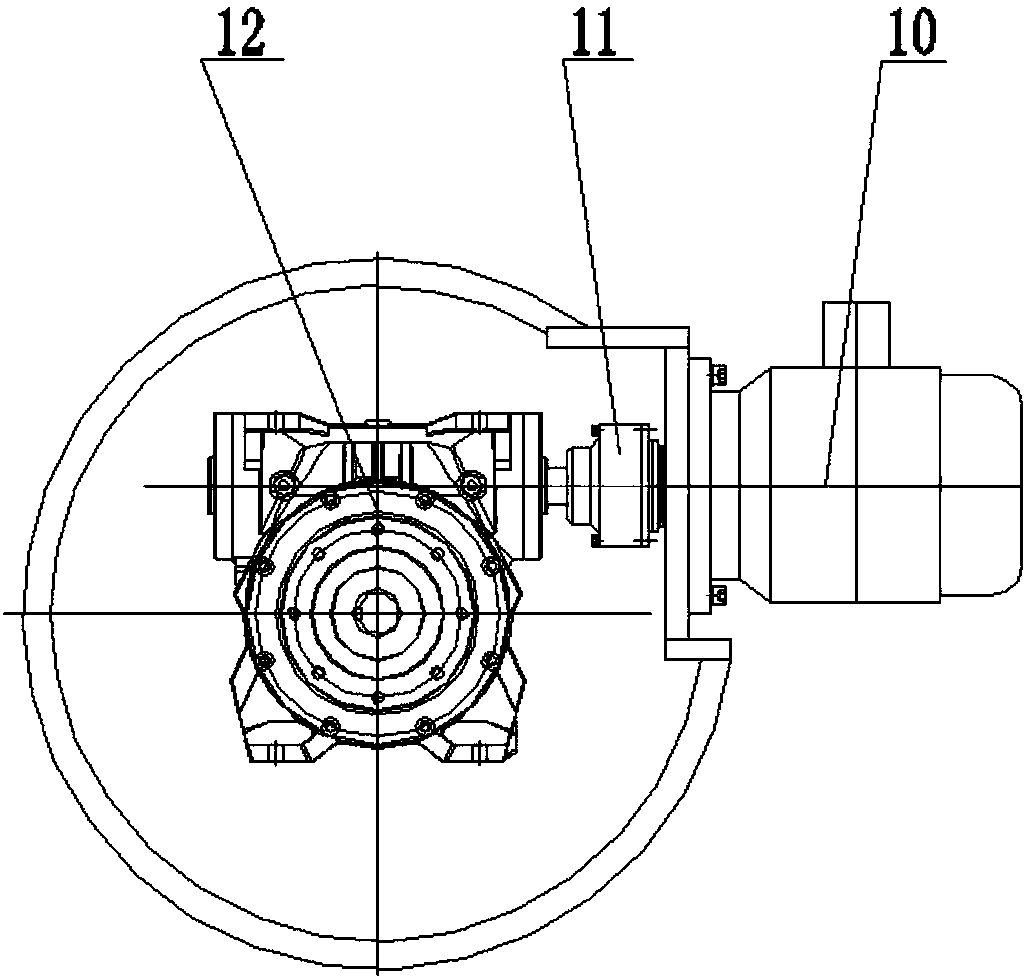

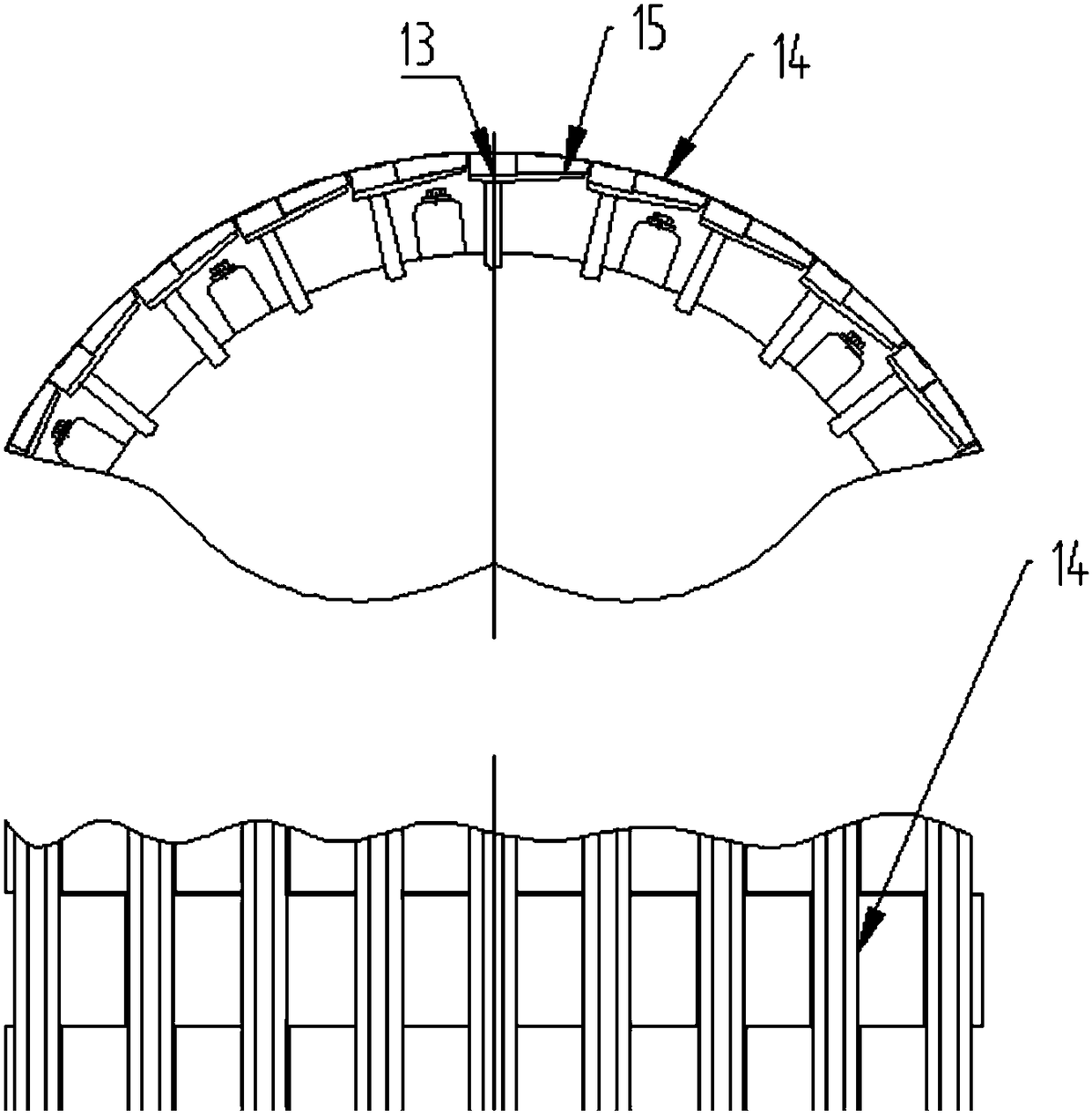

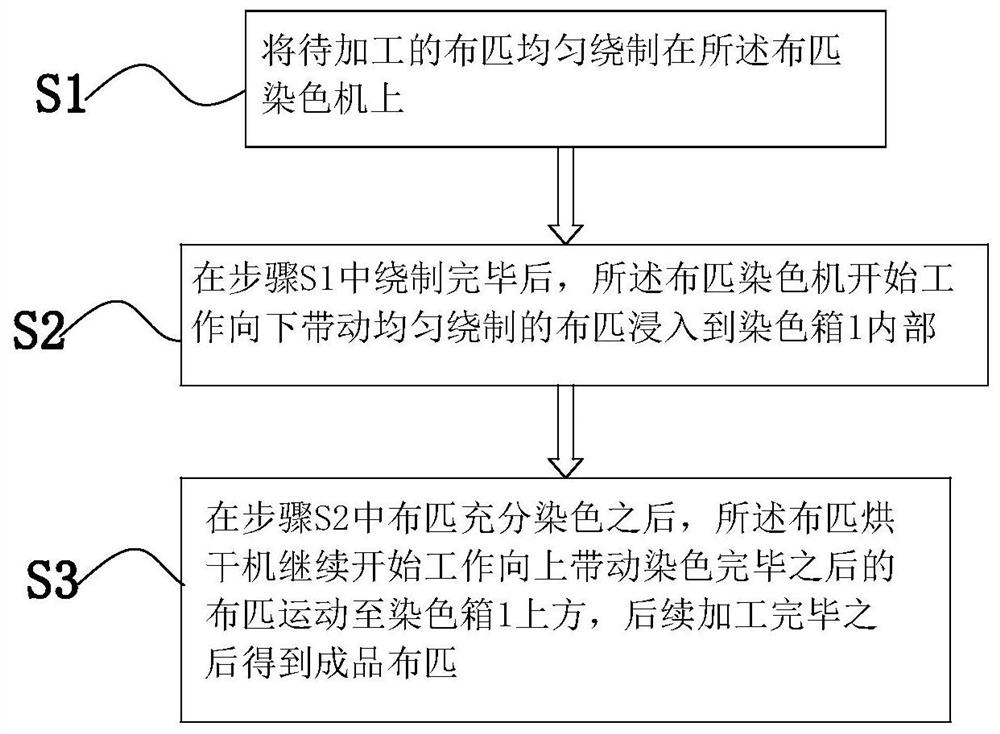

Cloth dyeing process

InactiveCN111893663AEasy to windEasy to dyeLiquid/gas/vapor removalTextile treatment machine arrangementsPolymer scienceEngineering

The invention provides a cloth dyeing process. The cloth dyeing process is mainly completed through cooperation of a cloth dyeing machine. A cloth drying machine comprises a dyeing box. The cloth dyeing process specifically comprises the following steps that S1, cloth to be processed is evenly wound around the cloth dyeing machine; S2, after winding in the step S1 is completed, the cloth dyeing machine starts to work to drive the evenly-wound cloth downwards to be immersed into the dyeing box; and S3, after the cloth in the step S2 is fully dyed, the cloth drying machine continues to work to drive the dyed cloth upwards to move to the position above the dyeing box, and finished cloth is obtained after subsequent processing is completed; a supporting block plate is fixed to the rear portionof the upper end of the dyeing box of the cloth dyeing machine involved in the steps S1 to S3, a supporting plate is installed at the front end of the supporting block plate, and at least two guide rollers are evenly installed at the front end of the supporting plate. The cloth dyeing process is reasonable in structure, the dyeing effect is improved, and the use effect is good.

Owner:潘秋萍

Rectangular spring winding equipment and using method thereof

The invention discloses rectangular spring winding equipment and a using method thereof, and relates to the technical field of building construction equipment. The rectangular spring winding equipment specifically comprises a base, a power box body and a winding roller; the power box body is fixedly connected to the top of the base; a motor is fixedly connected to the right side of the inner wall of the power box body; and a transmission structure is arranged on the surface of the motor. By arranging an elastic positioning structure, a movable block, a fixing block, a lead screw structure, a movable clamping structure and a connecting shaft structure, the effects that rectangular steel wires with different widths can be conveniently positioned, and a winding roller can be conveniently taken down and replaced are achieved; and the problems that a winding roller in existing winding equipment is very prone to abrasion after being used for a long time, the winding roller is very inconvenient to disassemble, the quality of the wound rectangular spring is worse if the winding roller is continuously used, the rectangular steel wires with different widths are difficult to adjust, the steel wires with different thicknesses cannot be wound, and the practicability is lower are solved.

Owner:王志伟

Bobbin dyeing process of elastic velvet feather yarn

The invention discloses a bobbin dyeing process of an elastic velvet feather yarn. The process comprises ten steps including yarn preparation and steaming, winding, cage loading, boiling, cleaning, dyeing, color fixing, dewatering and drying, color inspection and the like. The physical and chemical characteristics of a velvet yarn and a feather yarn are comprehensively considered, and the featheryarn is shrunk first through yarn preparation and steaming to be soft and moist, so that winding is convenient. During winding, feathers of the feather yarn are wound from small ends to large ends, sothat dip dyeing in a dyeing solution is facilitated without depositing the dyeing solution in the included angles of the feathers. During dyeing, a double-stage slow heating strategy is adopted, theheating time and the dip dyeing heat preservation time are prolonged, and correspondingly bobbin yarn is fully immersed in a color to ensure that dyeing is uniform and full. After dyeing is finished,color inspection is carried out, and the dyeing degree is more accurate; reworking is not required in the middle of dyeing, so that the standardized time flow in the dyeing process and the dyeing timetemperature node control are ensured, current production is facilitated, and the production efficiency is improved.

Owner:张家港市华益纺织有限公司

Single-coil toothbrush vibration motor

PendingCN114337175AEasy to windLow costMagnetic circuit stationary partsSupports/enclosures/casingsColloidal particleEngineering

The invention discloses a single-coil toothbrush vibration motor, which comprises a first plastic shell, a [-shaped stator, a single winding coil, a 2pcs steel magnetic conductive sheet, square colloidal particles, a spring sheet, a rubber core, a rotating shaft, a ball bearing and a 2pcs neodymium iron boron magnet, and is characterized in that the [-shaped stator is arranged in the first plastic shell, and an insulating outer layer is arranged on the outer surface of the [-shaped stator; single winding coils are arranged at the two ends of the [-shaped stator, square colloidal particles are arranged at the bottom end in the first plastic shell, a spring piece is arranged at the upper end of the square colloidal particles, a rubber core is arranged at the upper end of the spring piece, a rotating shaft is arranged at the upper end of the rubber core, a ball bearing is arranged on the outer surface of the rotating shaft, and a 2pcs steel magnetic conductive sheet and a 2pcs neodymium iron boron magnet are arranged on the outer surface of the rubber core. The motor has better durability, and only one group of coils is needed to be wound on the [-shaped stator, so that the winding of the structure is more convenient; and the two steel magnetic conductive sheets are used for replacing silicon steel laminations in a common motor, so that the cost is saved, and the assembly is simpler.

Owner:艾博金电气制造(深圳)有限公司

Rotor to undergo coiling and process of performing coiling on rotor

InactiveCN106059221AEasy to windImprove speed and efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesMechanical engineeringLow noise

The invention discloses a rotor to undergo coiling. The rotor comprises straight sides. The process of performing coiling on a rotor comprises the following steps of a, manufacturing rotor blades of which the integral shapes are regular-polygonal, wherein coiling openings for coiling are arranged between the straight sides of the regular polygons, and the rotor blades sleeve a rotating shaft; b, performing spraying for connecting the rotor blades and connecting the rotor blades with the rotating shaft; c, performing coiling on the rotor by an enameled wire through the coiling openings; and d, after coiling, pressing the straight side for forming an arc-shaped side through applying a pressure which moves in the rotating shaft direction on two ends of each straight side, thereby changing the integral shape of the rotor from regular-polygonal to circular. The invention discloses the rotor and a manufacture process thereof. The rotor and the manufacture process have advantages of convenient coiling, short manufacture period, high use effect and low noise.

Owner:宁波普林斯电机有限公司

High-tension winding ceramic disc of electronic insects killing lamp

InactiveCN100399889CAnti-creepage windingEasy to windInsect catchers and killersPower gridEngineering

Disclosed is a high-voltage winding ceramic disc of electronic insects killing lamp to be equipped on the upper end and lower end of the high voltage network in the electronic insecticidal lamp, wherein the high voltage wiring ceramic disc is in the shape of round loop with a plurality of securing openings, its upper end surface is provided with a plurality of projection columns, the center of the projection columns is provided with a plurality of outer layer holes crossing through the loops, the adjacent outer layer hole bottoms are provided with outer layer grooves, the loops between the projection columns are provided with inner layer grooves with inward notches and crossing through the upper and lower end surfaces, the adjacent inner layer groove lower ends are provided with inner layer recesses.

Owner:胡玉莲

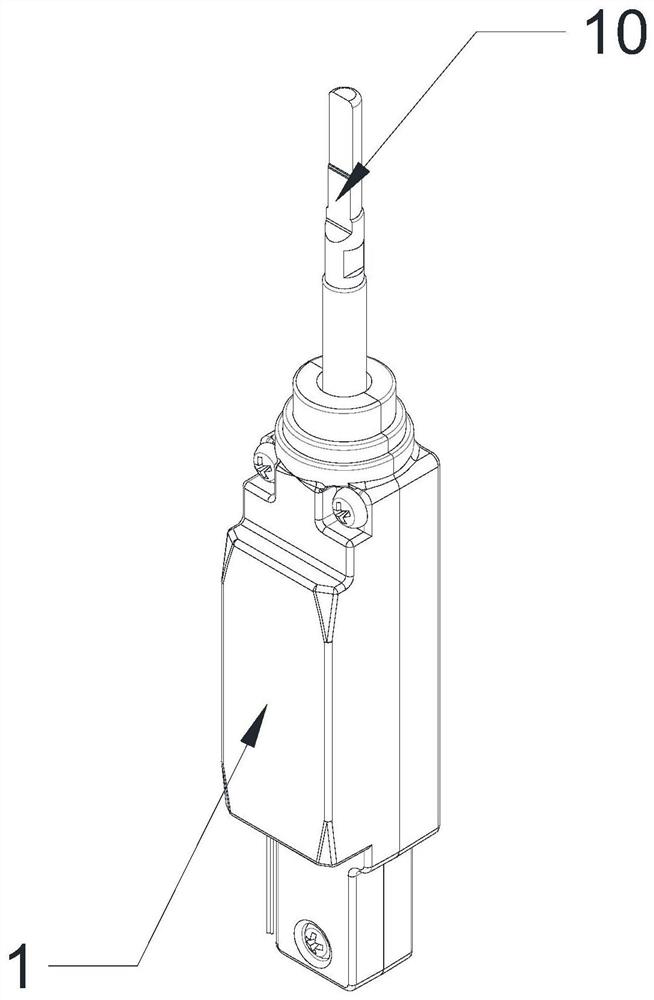

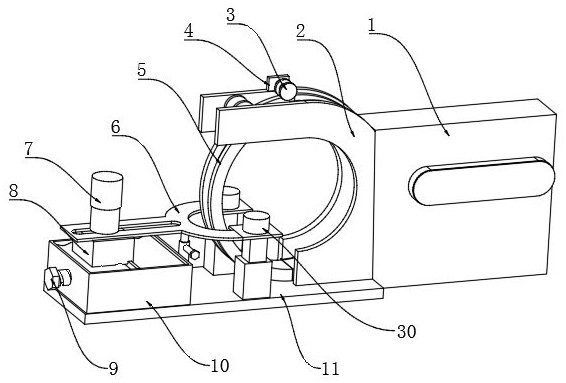

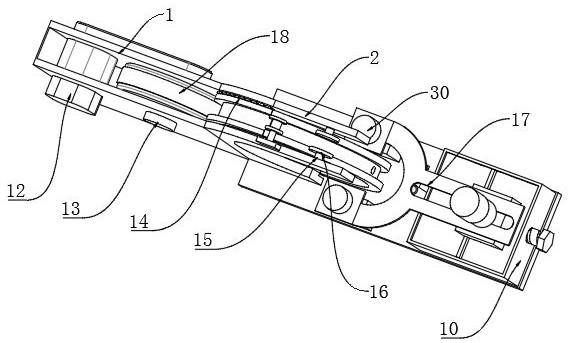

High-speed train secondary suspension semi-automatic control device

ActiveCN110836233AAdjustable stiffnessGood vibration reduction effectSpringsNon-rotating vibration suppressionManufacturing cost reductionAutomatic control

The invention discloses a high-speed train secondary suspension semi-automatic control device. The device comprises an air spring mechanism and a control device mechanism; the control mechanism comprises a coupling assembly, a cylinder body assembly and a fixing base; the cylinder body assembly comprises a cylinder barrel, the interior of the cylinder barrel is filled with magnetorheological fluid, and the interior of the cylinder barrel is sequentially provided with a piston rod I, a cylinder cover, a damping piston I, a damping piston II, a damping inner cylinder sleeve, a piston rod II anda cylinder bottom cover from top to bottom; the damping inner cylinder sleeve is a blind hole sleeve structure with an open upper end and a closed lower end, and an excitation coil is arranged on theouter cylindrical surface of the damping inner cylinder sleeve in the circumferential direction; and the damping piston II which is in clearance fit with the inner diameter dimension of the damping inner cylinder sleeve is arranged in the damping inner cylinder sleeve, and an excitation coil is arranged on the outer cylindrical surface of the damping piston II in the circumferential direction. According to the device, the opening degree of a throttling hole of an air spring system can be adaptively adjusted, the structure complexity is reduced on the premise of improving the adaptability of atrain to different operating conditions, and then the manufacturing cost is reduced.

Owner:XUZHOU NORMAL UNIVERSITY

Cutting device for motor coil production

ActiveCN112615487AEasy to windGuaranteed rotational stabilityManufacturing dynamo-electric machinesCopper wireMagnet

The invention discloses a cutting device for motor coil production and relates to the technical field of motor coil cutting. A problem that the cutting process is tedious during motor wire coil production is solved. Specifically, an outer wall of one side of a machine shell is fixedly connected with an arc-shaped baffle through screws; a winding ring is arranged on the inner wall of one side of the arc-shaped baffle; the outer wall of one side of the winding ring is connected with a connecting ring through a hinge; a magnet layer is arranged on the outer wall of one side of the winding ring; a square through groove is formed in the inner wall of the other side of the winding ring; a supporting spring is arranged on the inner wall of one side of the connecting ring; the outer wall of one side of the supporting spring is fixedly connected with an arc-shaped stop lever; the outer wall of one side of the connecting ring is slidably connected with a cutter. By arranging the square through groove, the square hole, the cutting rod, the cutting tool, the supporting spring and the arc-shaped stop lever, the cutting rod is pressed down, the arc surface of the arc-shaped stop lever is extruded by one side of the square hole to move downwards, so the cutting tool extends out of a cutting copper wire, and meanwhile the fixed circular ring relation between the winding ring and the connecting ring is relieved.

Owner:KUNGFU SCI TECH CO LTD

Split coil structure and transformer

ActiveCN112117102ASolve the problem of severe ampere-turn imbalance between high and low voltage windingsSolve the problem of severe ampere-turn imbalanceTransformers/inductances coils/windings/connectionsVariable inductancesVoltage variationControl theory

The present invention discloses a split coil structure. The split coil structure comprises an iron core, a high-voltage winding and a low-voltage winding, the high-voltage winding and the low-voltagewinding are sequentially wound on the iron core, the low-voltage winding comprises n identical winding units arranged in the axial direction, n is larger than or equal to 3, each winding unit comprises m split windings, and m is larger than or equal to 3. The corresponding split windings in each winding unit are respectively connected in parallel. Correspondingly, the invention further discloses atransformer comprising the split coil structure. By adopting the split coil structure, the problem that ampere-turns between high-voltage windings and low-voltage windings of a traditional axial split transformer are seriously unbalanced can be solved, mutual interference of magnetic flux leakage between the split windings can be reduced, the problem that short-circuit impedance between the splitwindings is not matched is solved, and voltage changes output by the split windings are reduced; meanwhile, load loss of the transformer can be reduced, and high efficiency and energy conservation are achieved.

Owner:TBEA INTELLIGENT ELECTRIC CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com