Patents

Literature

99results about How to "Easy to dip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

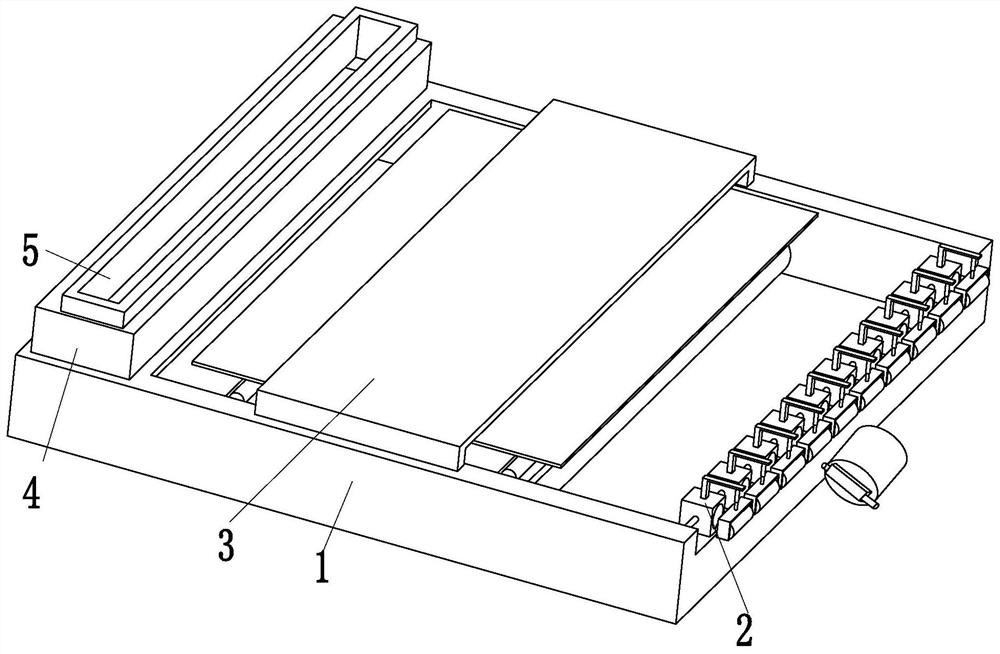

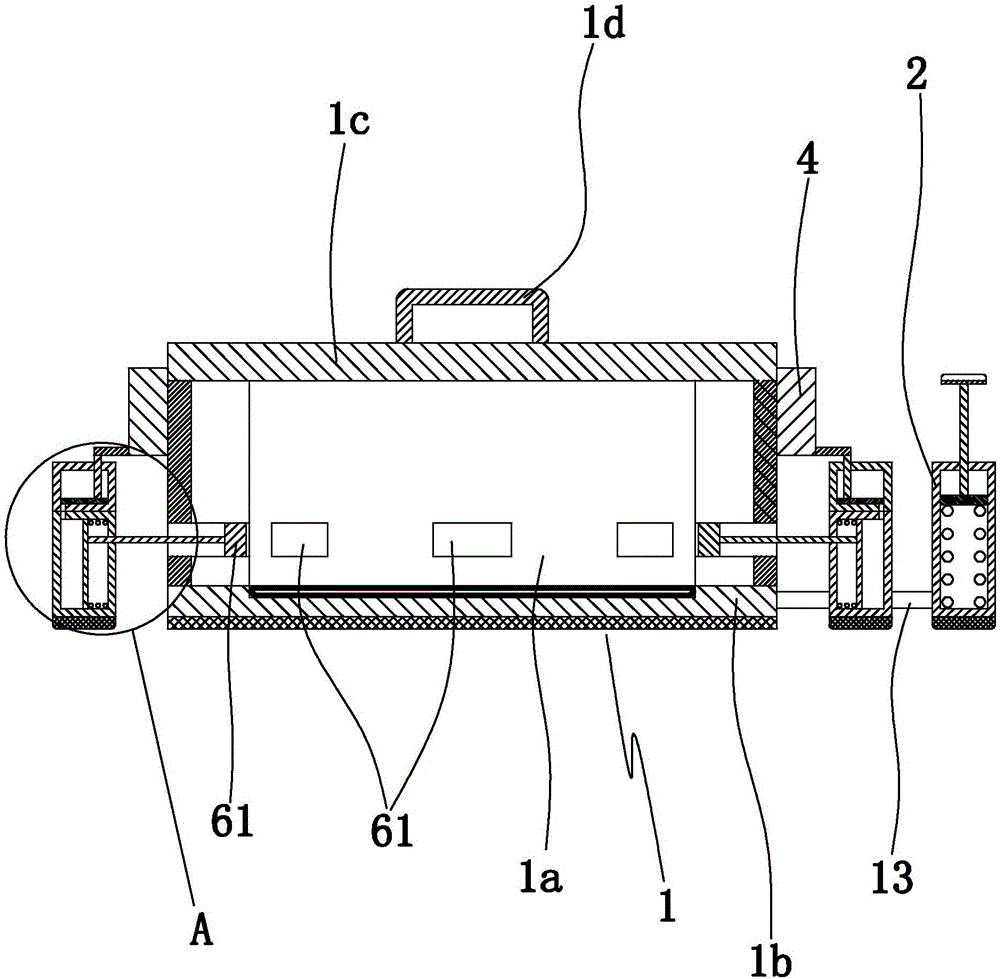

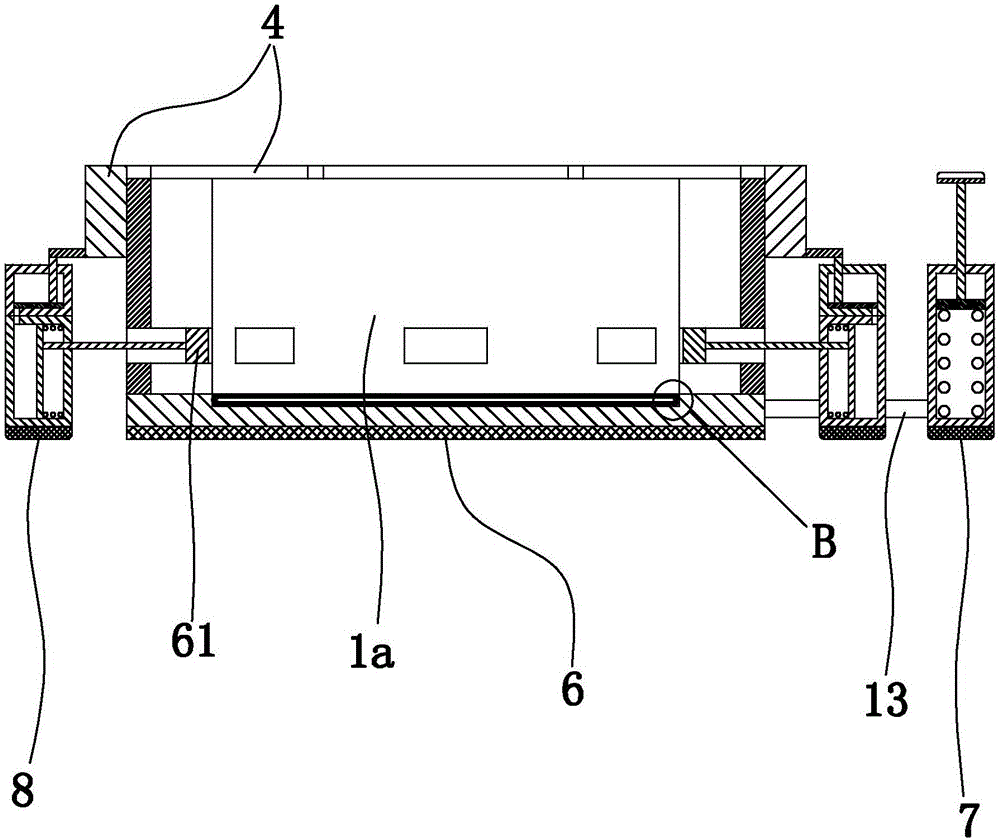

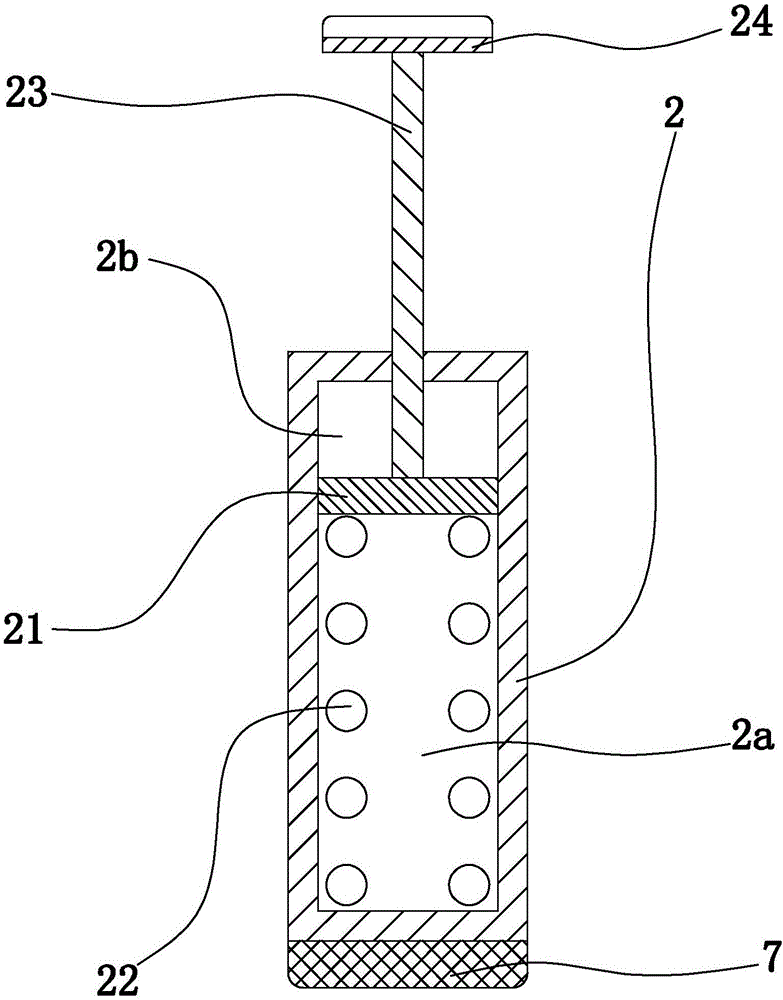

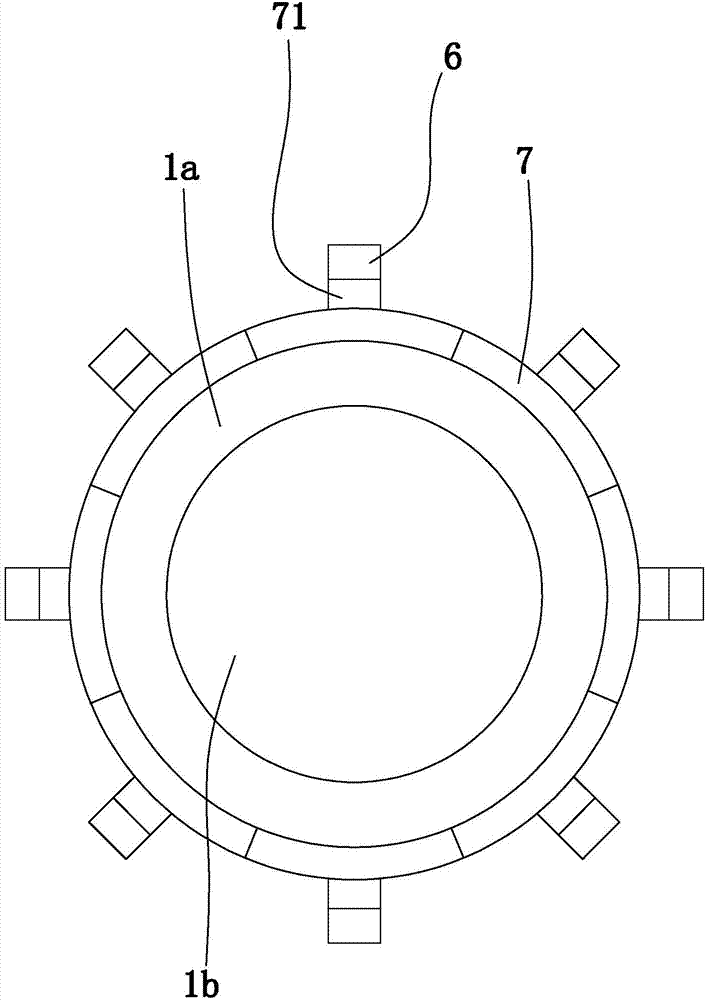

Cloth soaking and coloring automatic equipment and operation method thereof

PendingCN111826853AUniform colorImprove production efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFuel tankElectric machinery

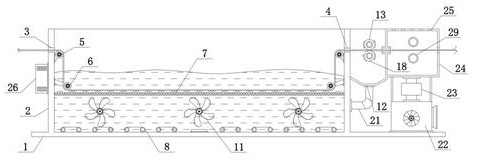

The invention discloses cloth soaking and coloring automation equipment and an operation method thereof, and belongs to cloth soaking and coloring automation equipment. The cloth soaking and coloringautomation equipment comprises a base, wherein the upper end of the base is fixedly connected with a dye box; and a feeding hole and a discharging hole are formed in the two sides of the upper end ofa fuel tank respectively. During cloth dyeing, driving motors in the motor box are started and drive a stirring paddle to rotate, and the stirring paddle stirs liquid in the dye box, so that the liquid in the dye box is always kept uniform; the uniform coloring of the cloth during dyeing can be ensured; and the situation of secondary processing of unqualified products is avoided. Moreover, an airbellow works to suck and blow external air flow into a heating box, the heating box heats and conveys the blown air into the drying box, and the hot air flow can dry the cloth in an accelerated manner, so that the cloth making efficiency can be improved, and the cloth can be dried more quickly.

Owner:常胜男

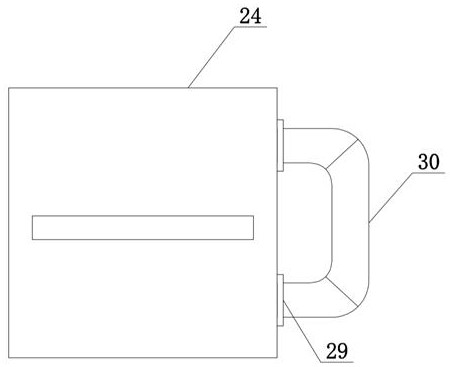

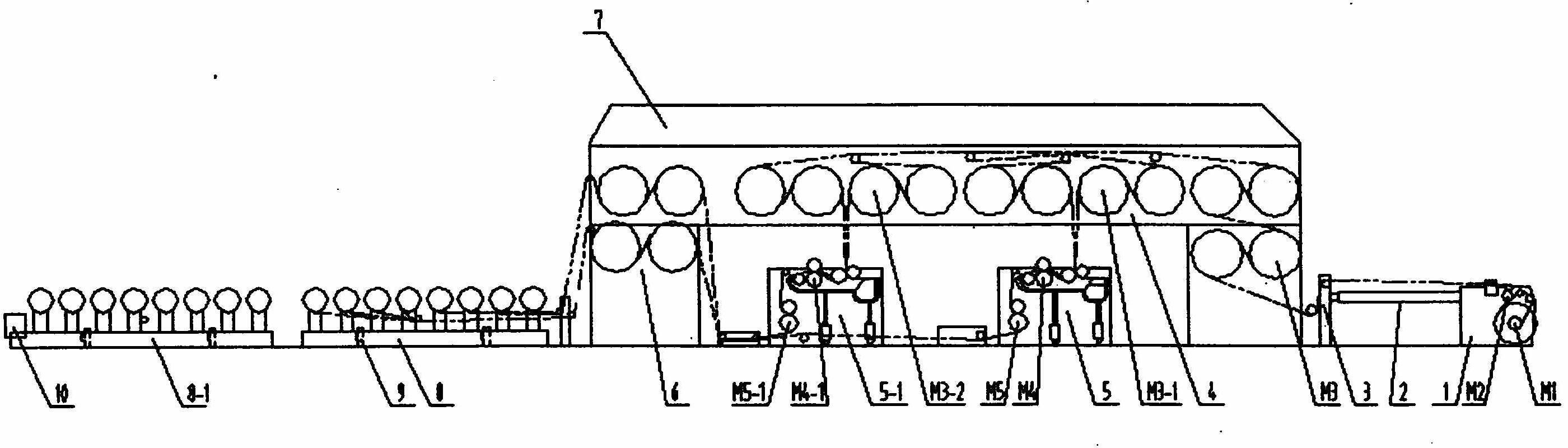

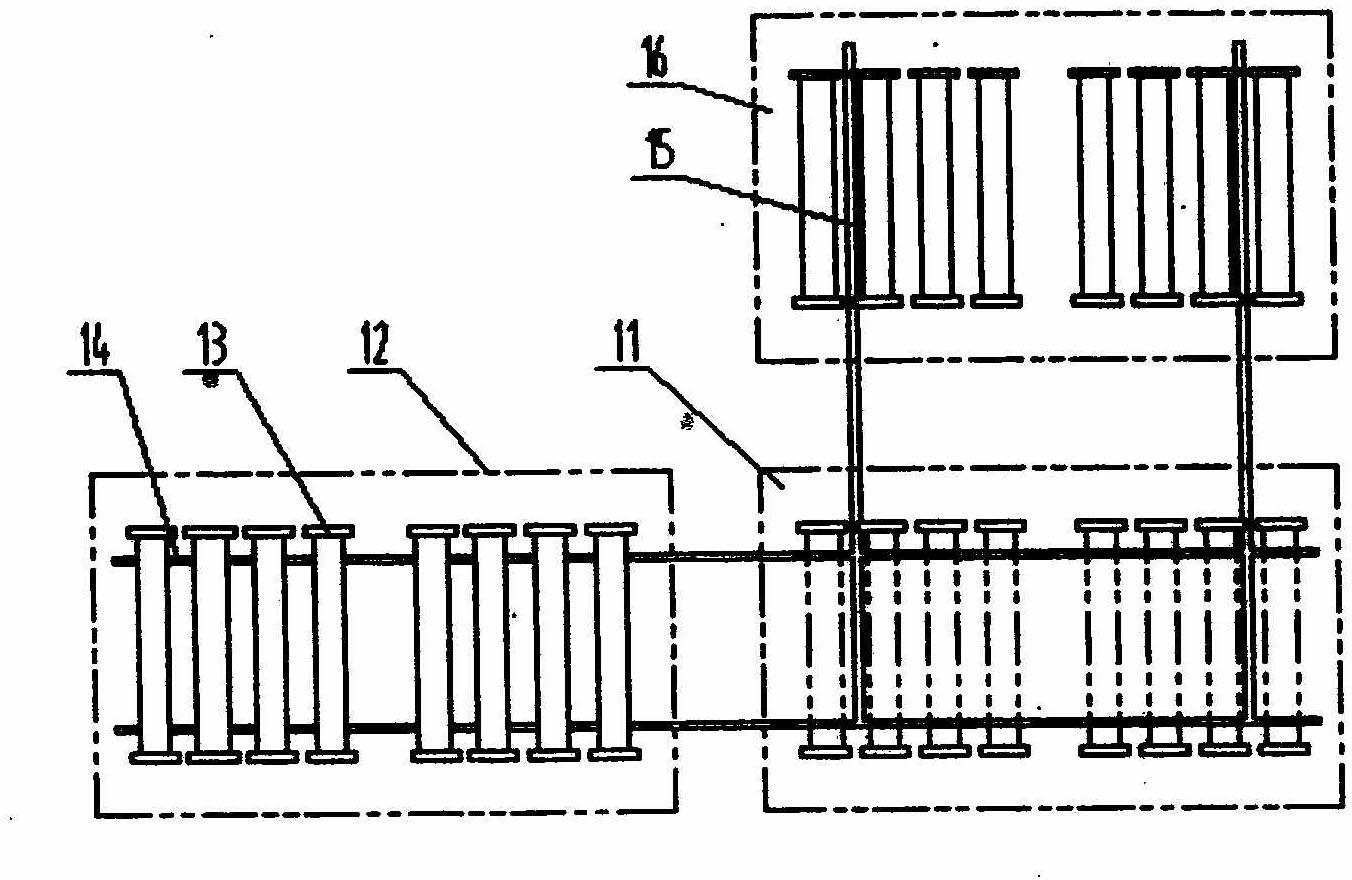

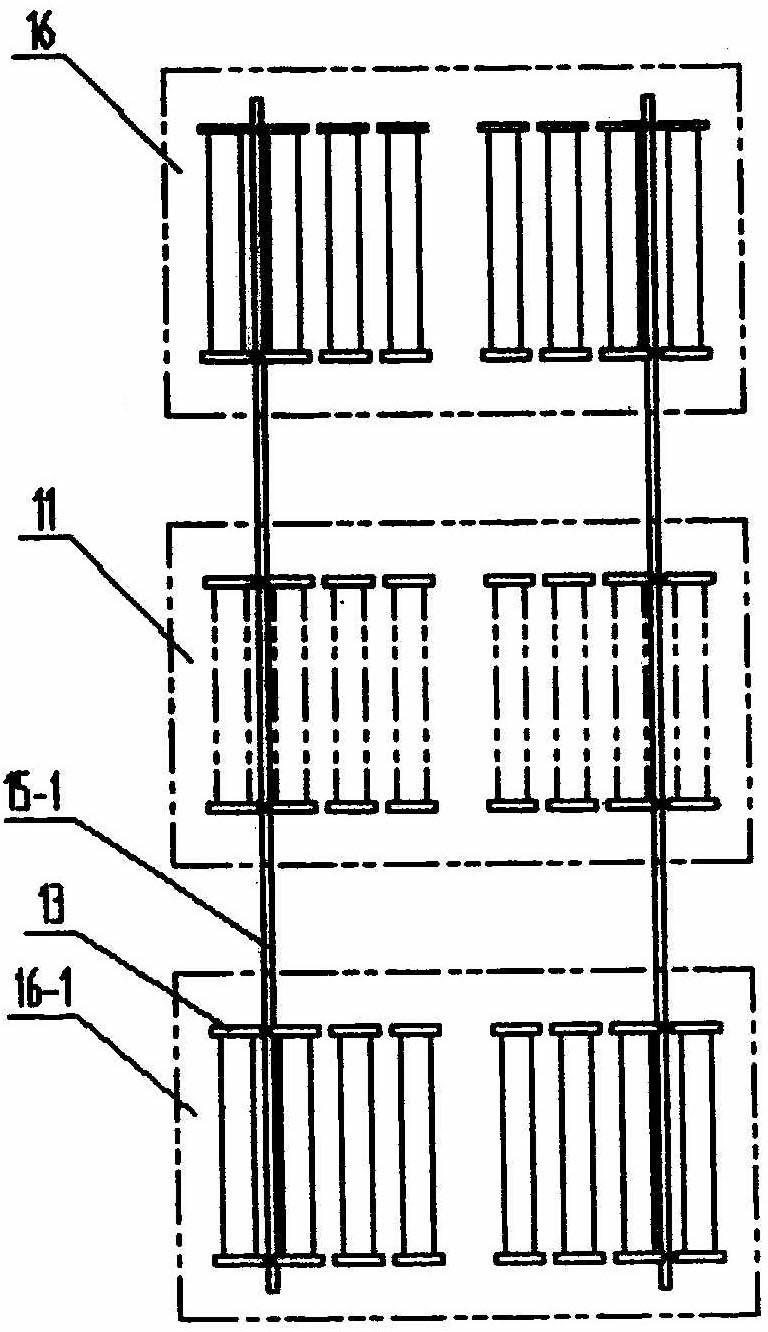

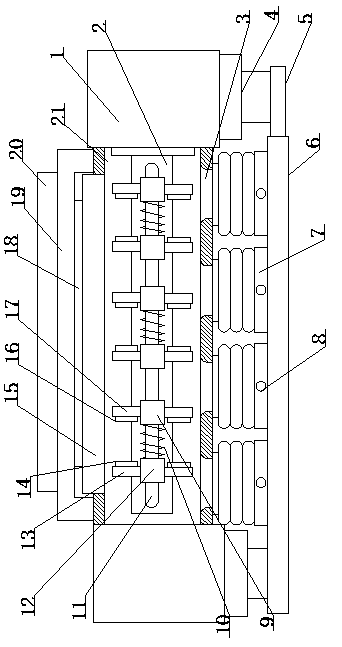

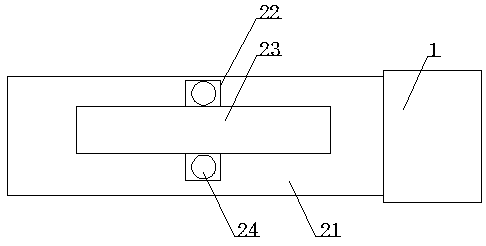

Beam dyeing sizing machine suitable for dyed sizing production

InactiveCN102146623ASolve production timeRealize continuous productionLiquid/gas/vapor removalOther manufacturing equipments/toolsMulti unitAutomatic control

The invention discloses a beam dyeing sizing machine suitable for dyed sizing production, which comprises a winding headstock, a dry leasing device, a tension waxing device, a main drying room, double parallel size vats, a dyed yarn pre-drying room, beam creels and an overall transmission and control system. The beam dyeing sizing machine is characterized in that: the beam creels are in two groups of mobile structures, the mobile beam creels are provided with dragging motors and moving wheel sets, and ground rails of the two groups of beam creels are arranged in a ''7'' shape or ''-'' shape. The beam dyeing sizing machine has the advantages that: 1, two groups of alternated mobile beam creels are adopted, so the production time occupied by frequently hoisting beams up and down is solved, inter-varietal continuous production is realized and the production efficiency is improved; 2, the loose beams can be directly intensively placed on the beam creels of the sizing machine for sizing, and a multifunctional composite chuck is designed, so the clamping and loading problems of multiple loose beams are solved; and 3, by adopting multi-unit synchronous control, piece yarn tension difference between the two size vats due to total warp number difference is solved, and automatic control of tension in each area is realized.

Owner:CHTC HEAVY IND

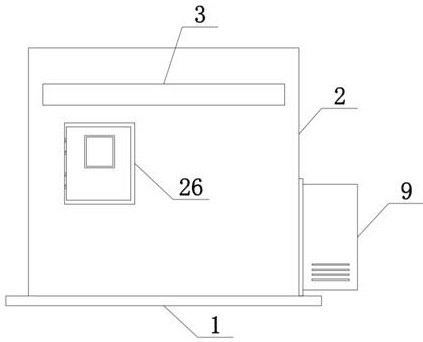

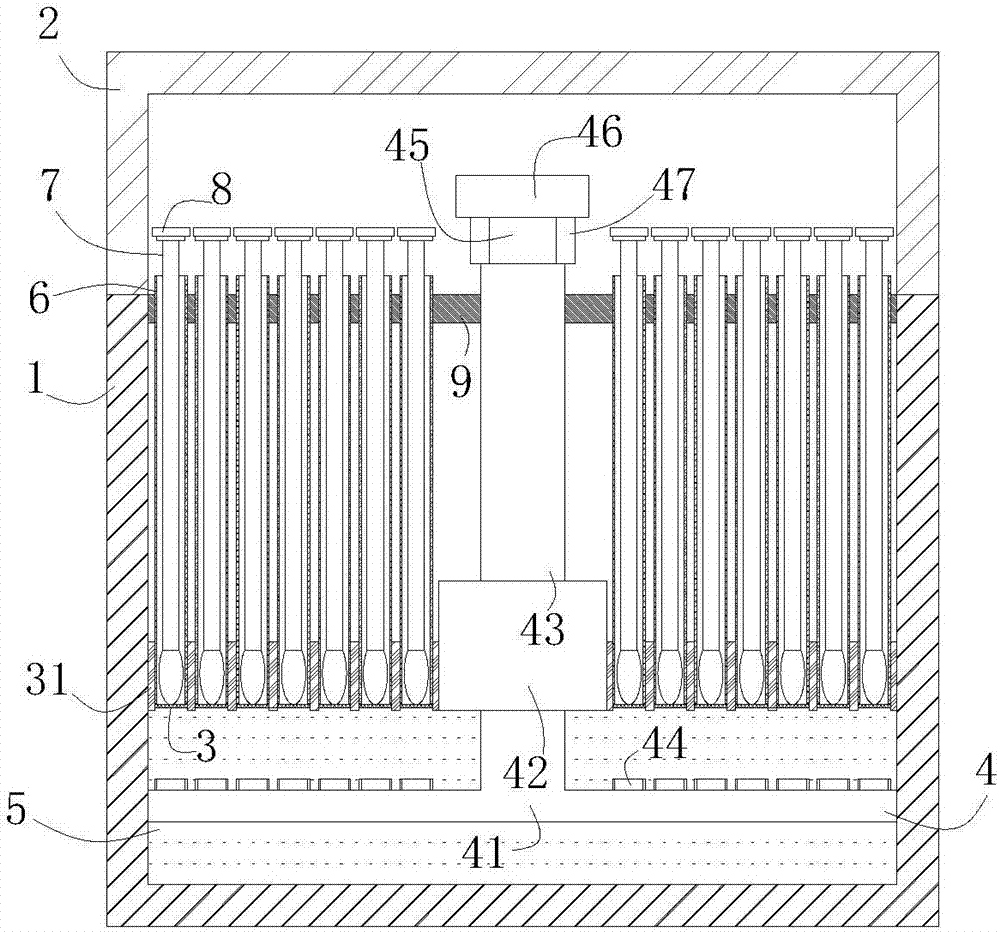

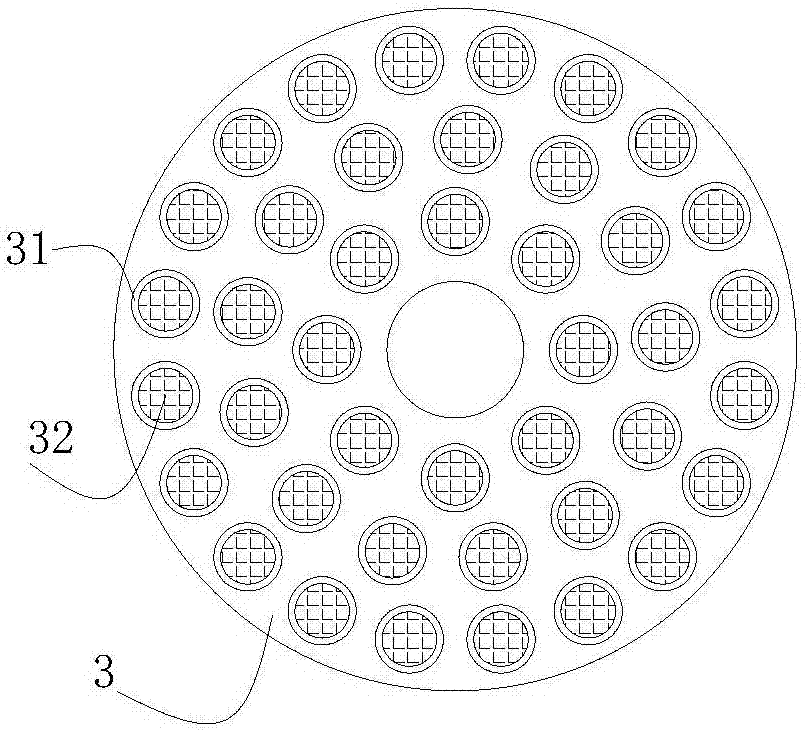

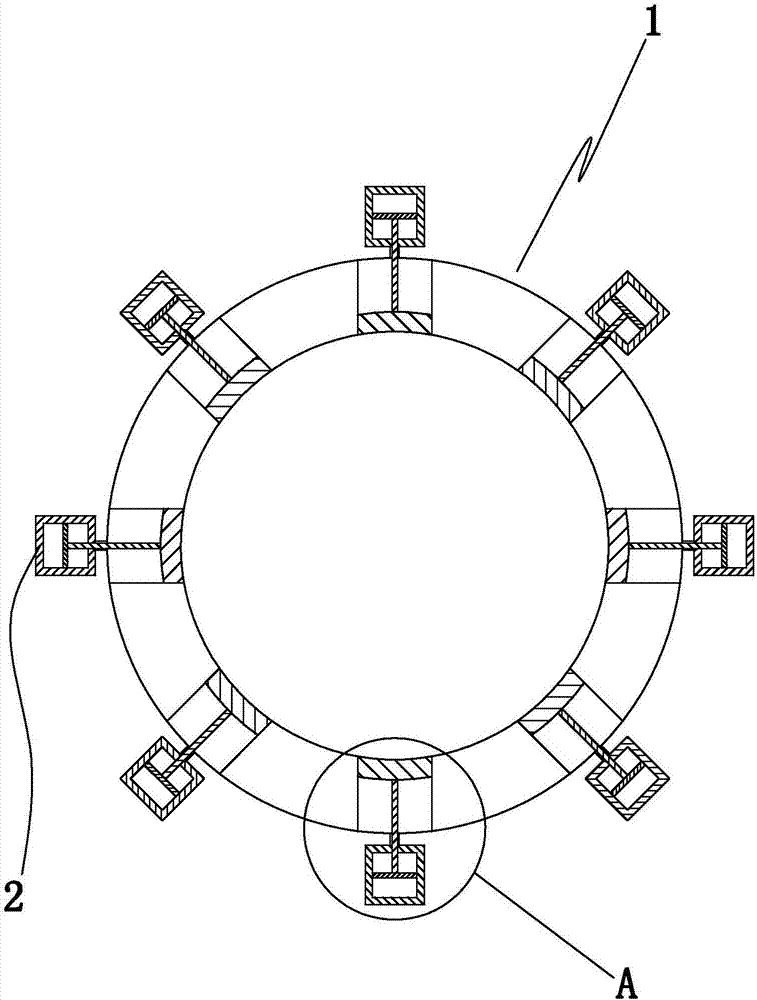

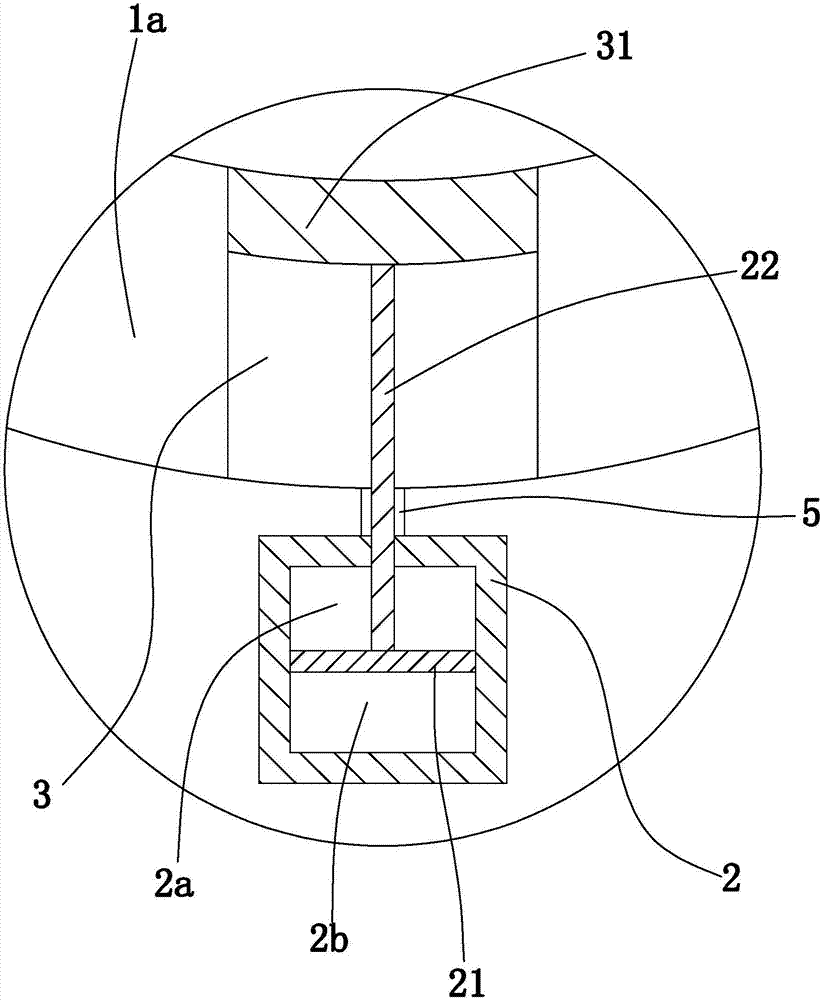

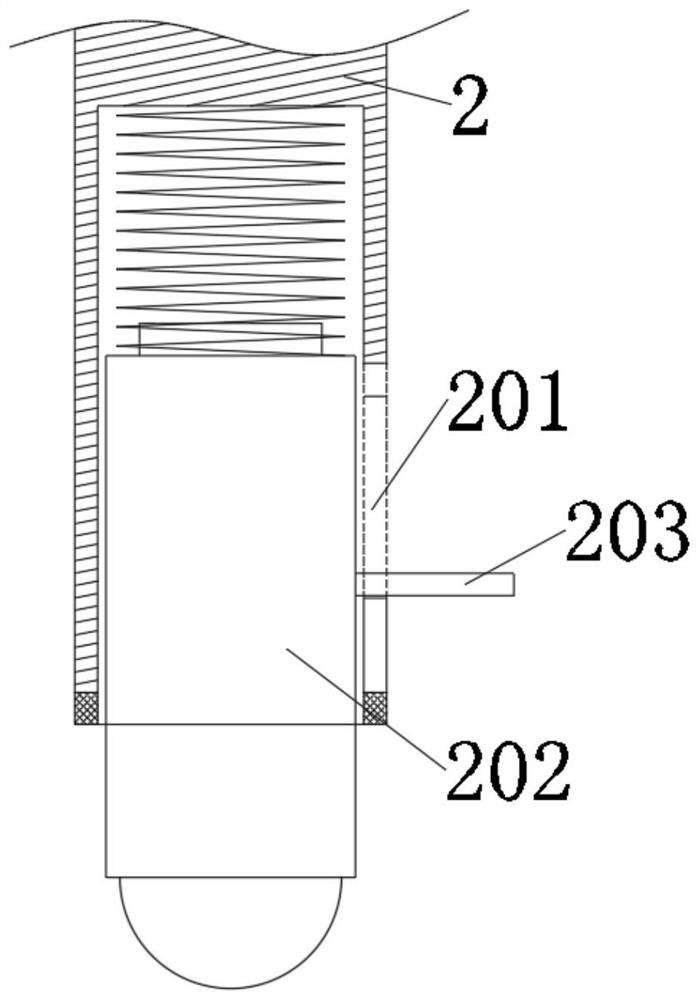

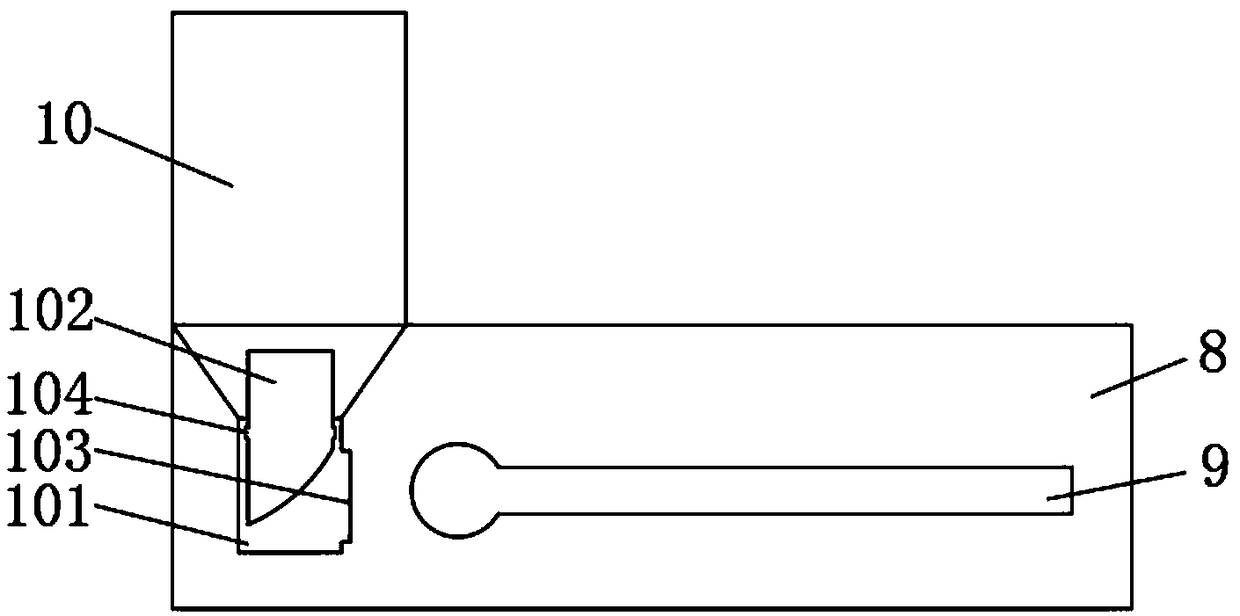

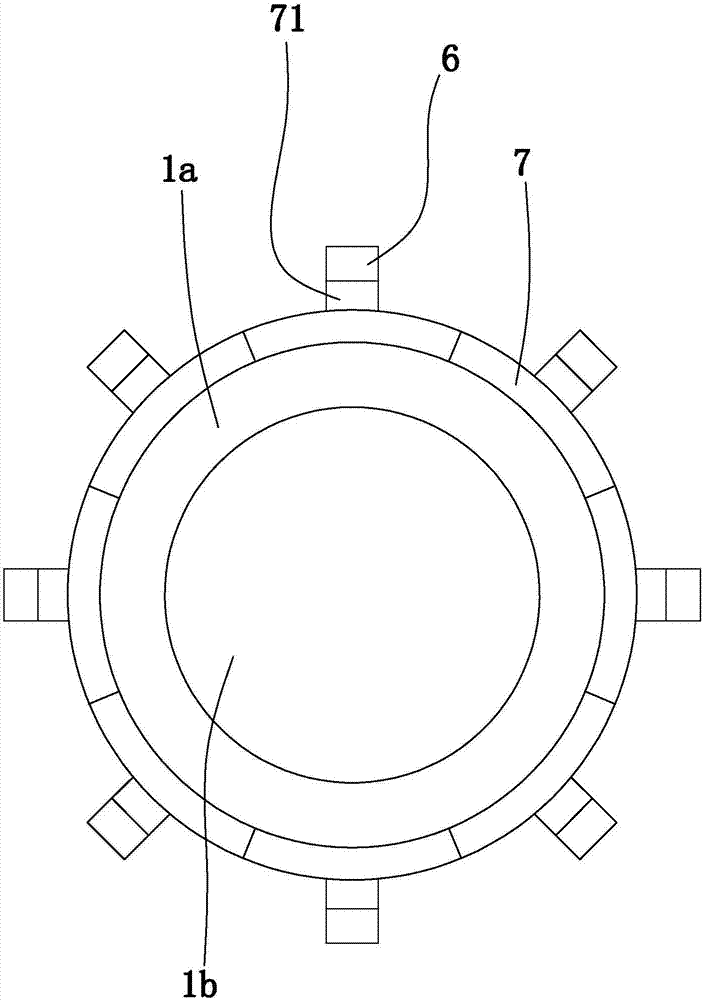

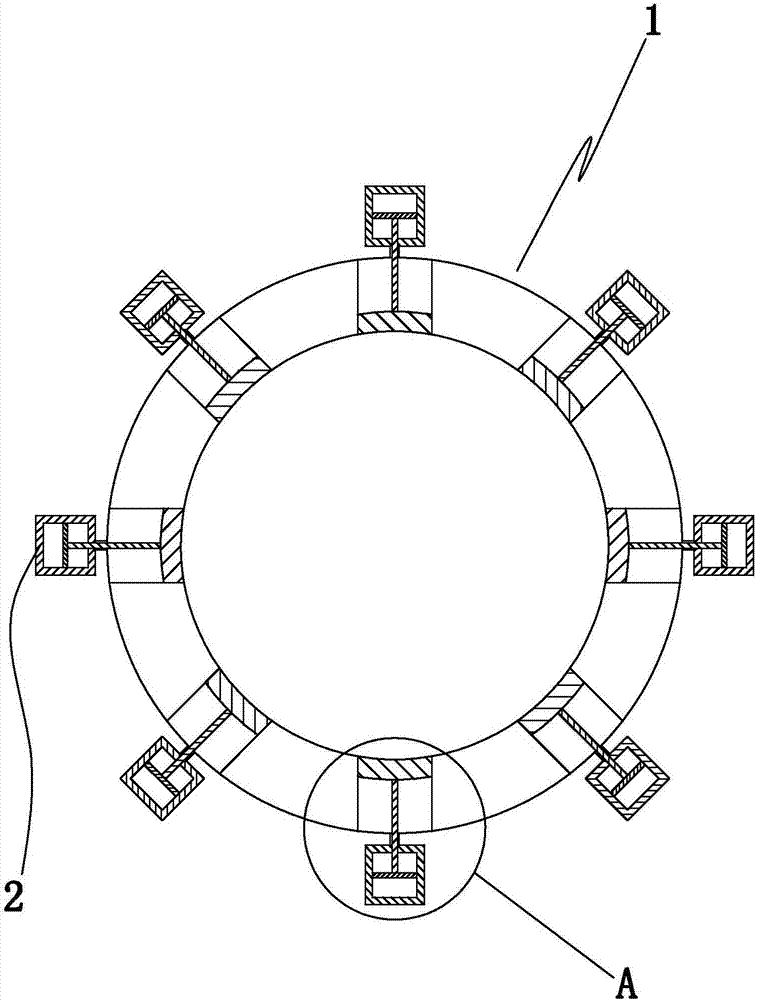

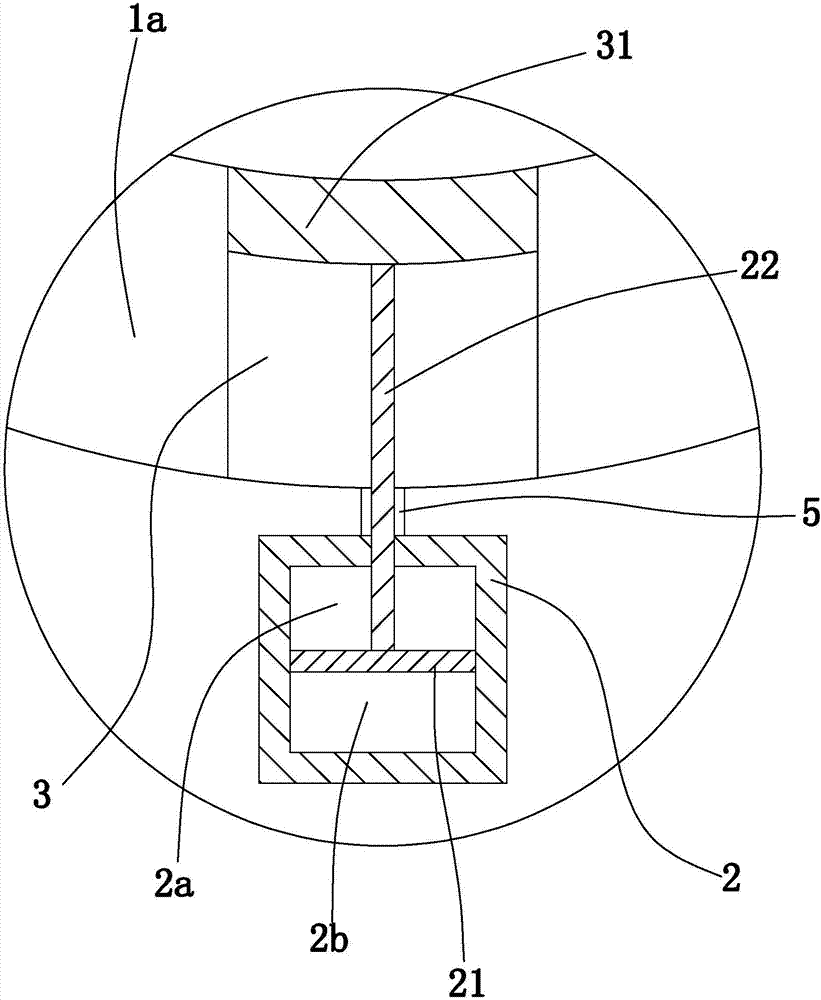

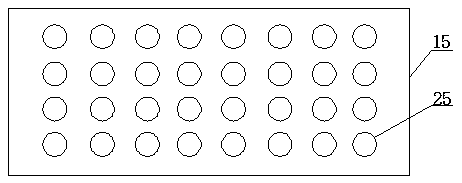

Storage box for medical cotton swabs

PendingCN107352131AEasy to dipImprove work efficiencyContainers with multiple articlesInternal fittingsPhysicsLiquid storage

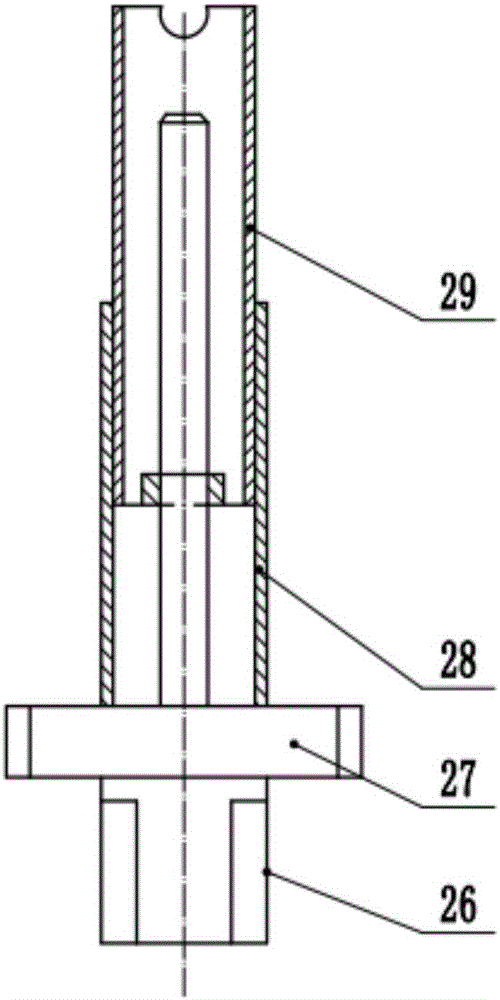

The invention relates to a storage box for medical cotton swabs. The storage box comprises a box body and a cover. A separation disk is arranged on the lower portion in the box body, a fixing disk is arranged on the upper portion of the box body, the separation disk is provided with a plurality of separation positioning holes, separation films are arranged in the holes, and positioning cylinders are arranged in the separation positioning holes. The fixing disk is provided with a plurality of limiting holes. The positioning cylinders are internally provided with corresponding working sleeves, the upper portions of the working sleeves penetrate the limiting holes in the fixing disk, and the lower ends of the working sleeves are attached to the separation films. The working sleeves are internally provided with the cotton swabs, the bottoms of the cotton swabs are close to the separation films, and the tops of the cotton swabs are provided with rubber sleeves. A through hole in the middle of the separation disk is provided with a film dismounting device, and a cavity which is defined by the box body and the separation disk is a liquid storage chamber. The film dismounting device comprises a film dismounting disk. The film dismounting disk is provided with film dismounting columns which correspond to the separation films. The upper end of the film dismounting disk is provided with a connection base, a connection sleeve is arranged above the connection base and internally provided with a connection shaft, the bottom end of the connection shaft is connected with the film dismounting disk through threads, and the top of the connection shaft is connected with a handle through threads.

Owner:TIANJIN HAIMAI MEDICAL TECH

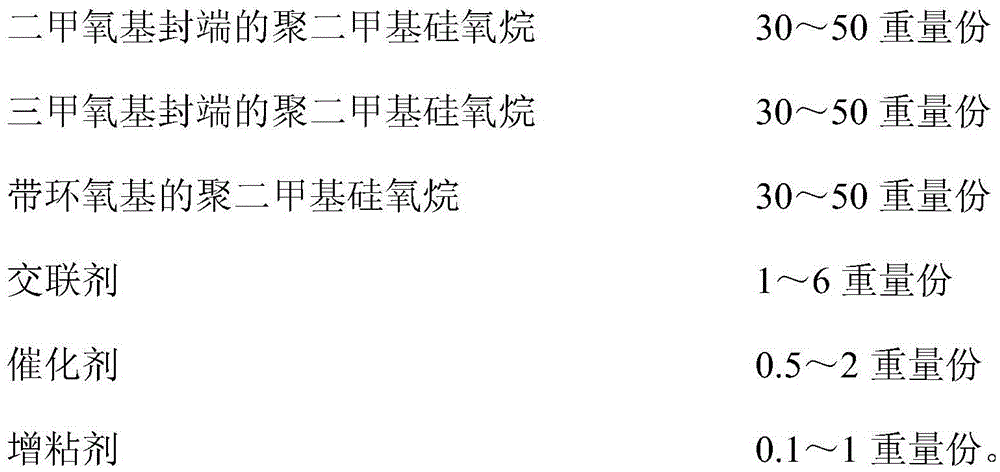

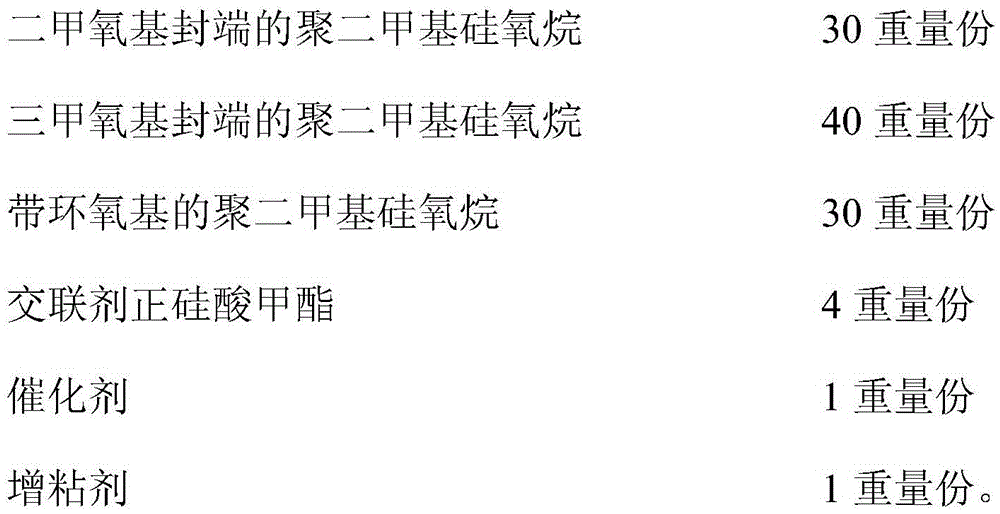

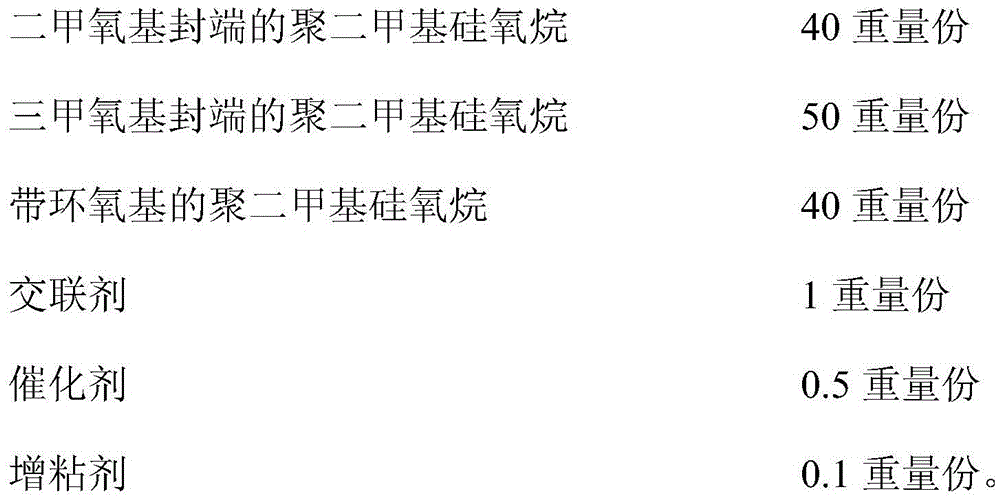

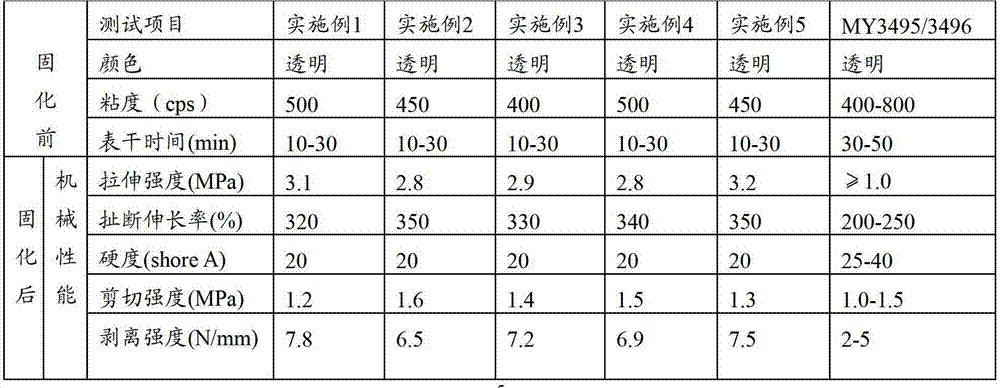

Organic silicone coated adhesive and preparation method and application thereof

The invention provides organic silicone coated adhesive and a preparation method and application thereof. The organic silicone coated adhesive is prepared from, by weight, 30-50 parts of dimethoxy terminated polydimethylsiloxane, 30-50 parts of triethoxy terminated polydimethylsiloxane, 30-50 parts of polydimethylsiloxane with an epoxy group, 1-6 parts of a cross-linking agent, 0.5-2 parts of a catalyst and 0.1-1 part of tackifier. The organic silicone coated adhesive has excellent comprehensive performance, viscosity is low (500-1000 dpas), the preparation process is free of peak viscosity, the organic silicone coated adhesive is resistant to a high temperature and a low temperature, can be used at the temperature ranging from minus 60 DEG C to 200 DEG C and can be heated and solidified, is high in solidification speed (surface drying time is less than 5 minutes at the temperature of 80 DEG C) and has high stability, and all properties scarcely change after the organic silicone coated adhesive is stored at the room temperature for one year.

Owner:兆舜科技(广东)有限公司

Low-viscosity neutral organic silicone and application thereof

ActiveCN103205234AGood high and low temperature resistanceImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPlasticizerSilica gel

The invention relates to low-viscosity neutral organic silicone and an application of thereof. Raw materials for preparing the organic silicone includes, by weight, 100 parts of polydimethylsiloxane of hydroxyl end, 20-50 parts of plasticizer, 5-10 parts of cross-linking agent, 0.5-2 parts of catalyst and 5-7 parts of film enchanter. The low-viscosity neutral organic silicone is fast in setting time and strong in viscosity; and stripping performance of the low-viscosity neutral organic silicone is significantly improved by above 5N / mm.

Owner:YANTAI DARBOND TECH

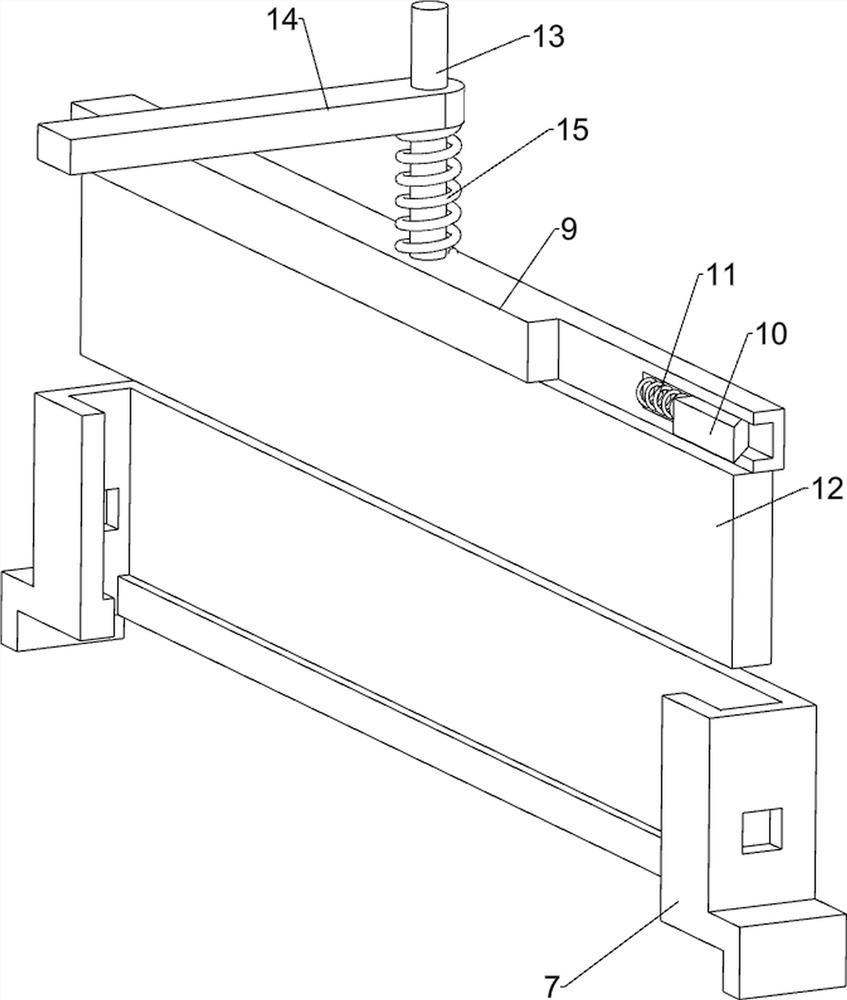

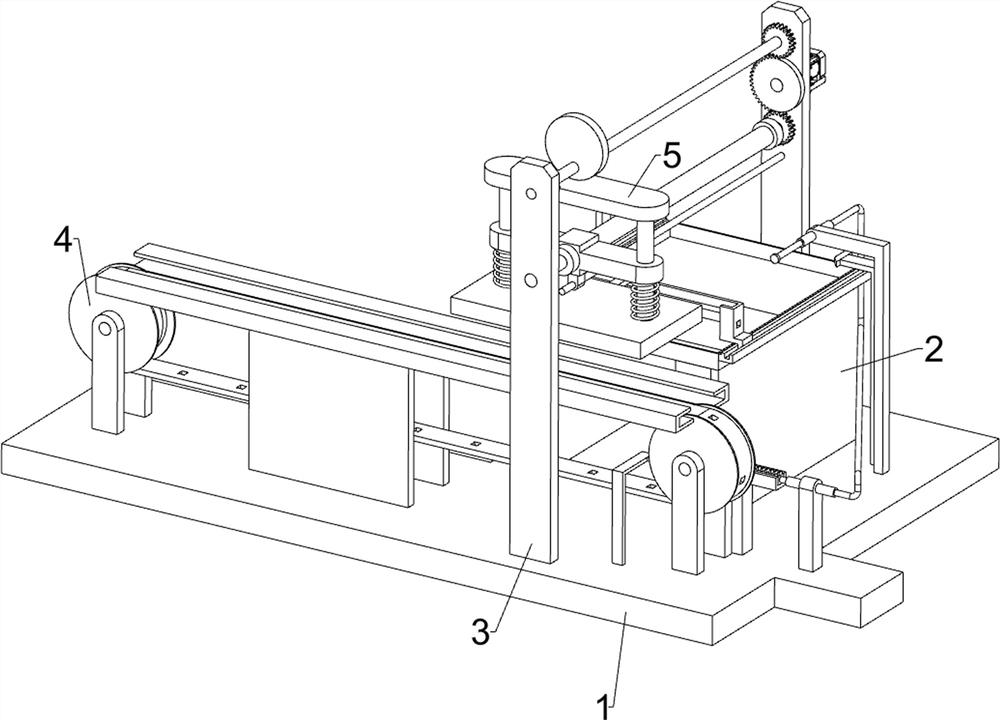

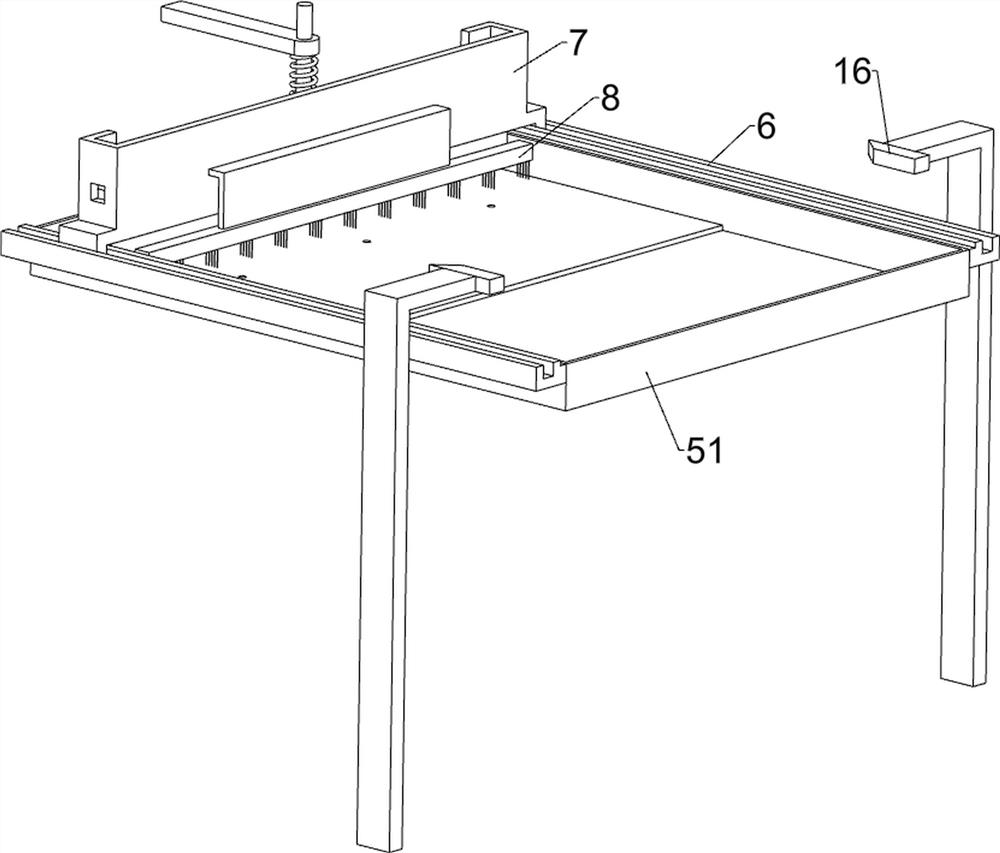

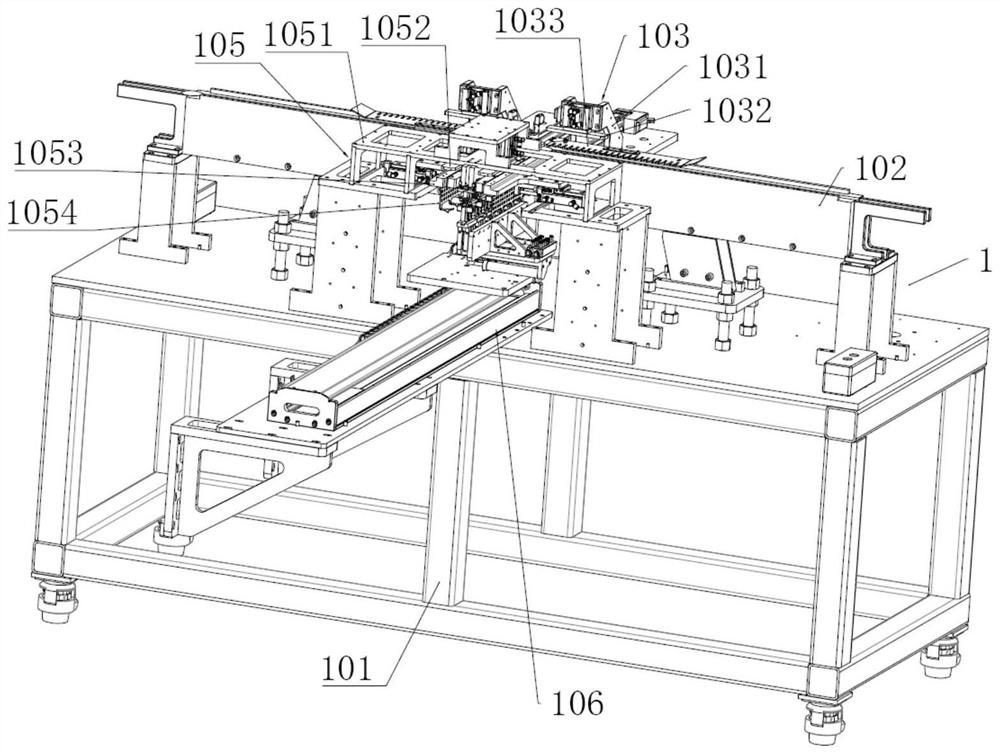

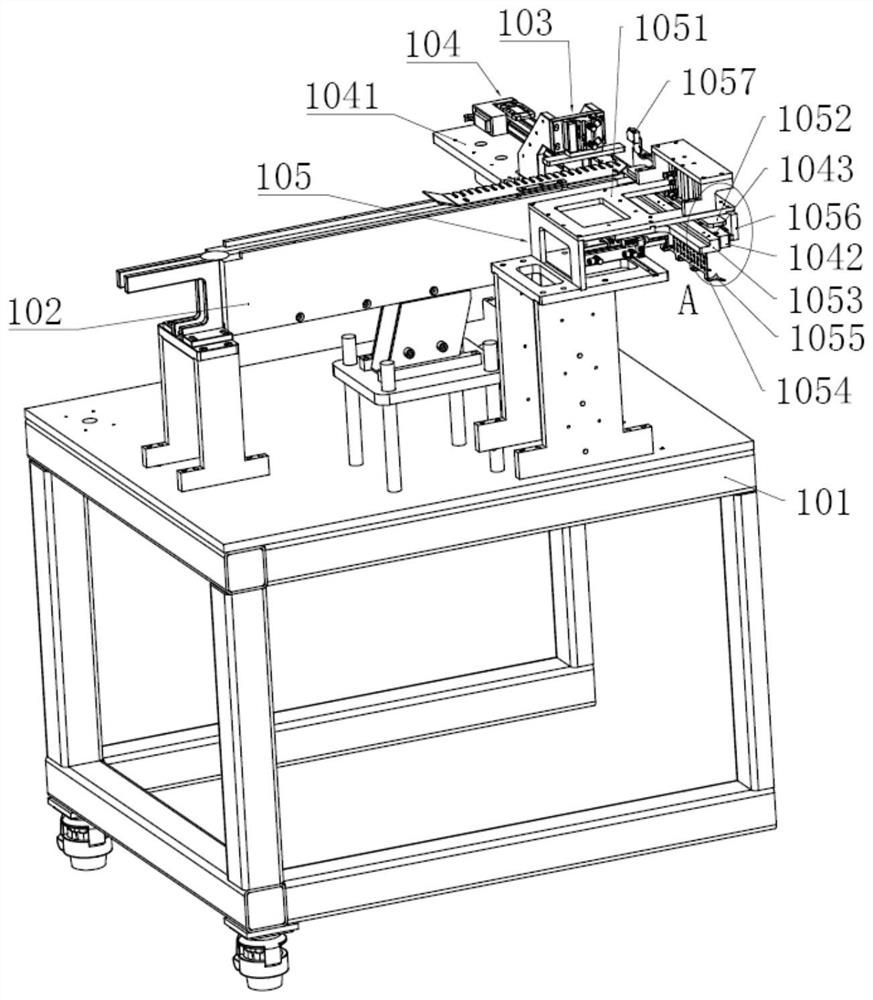

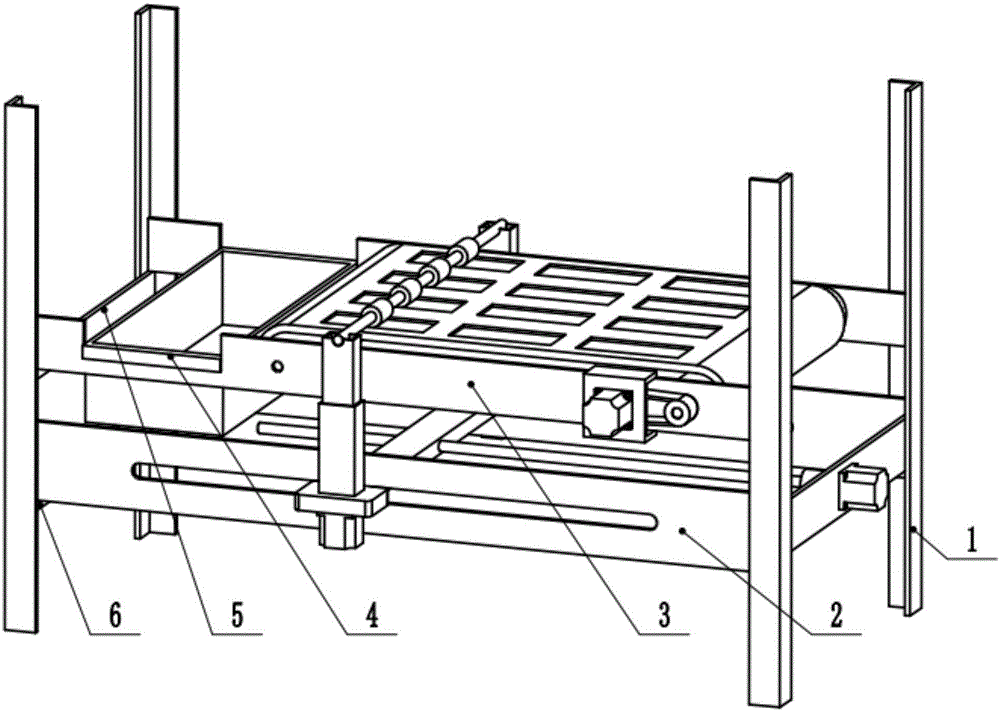

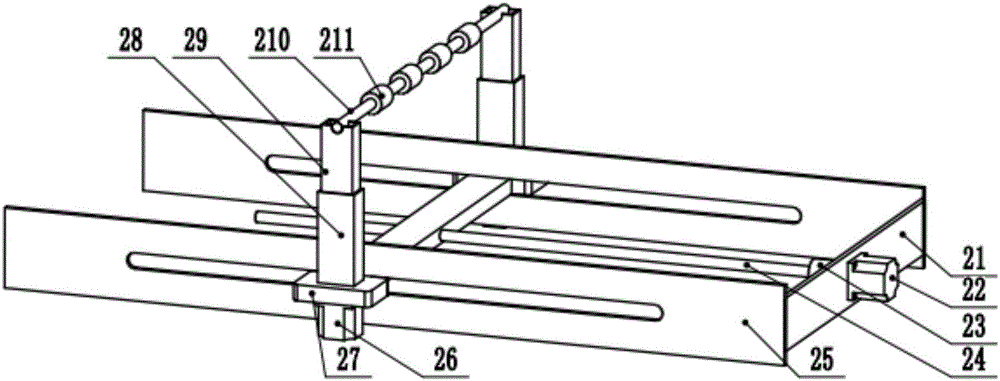

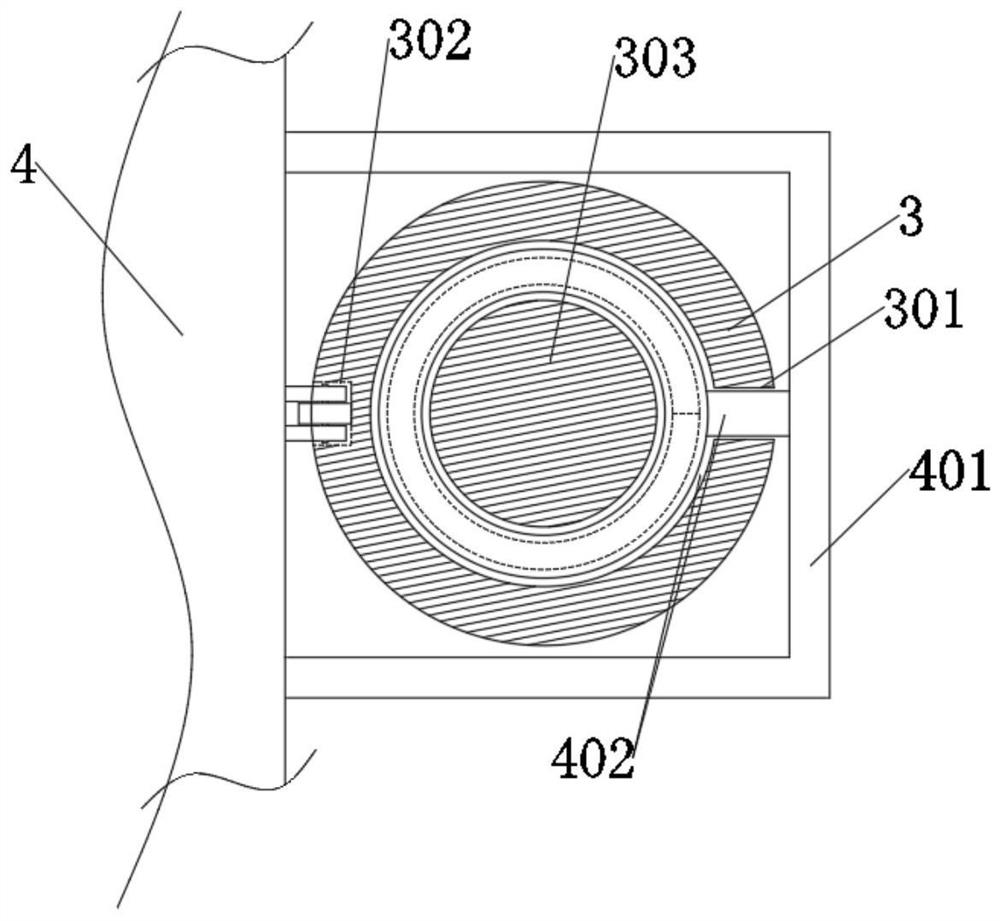

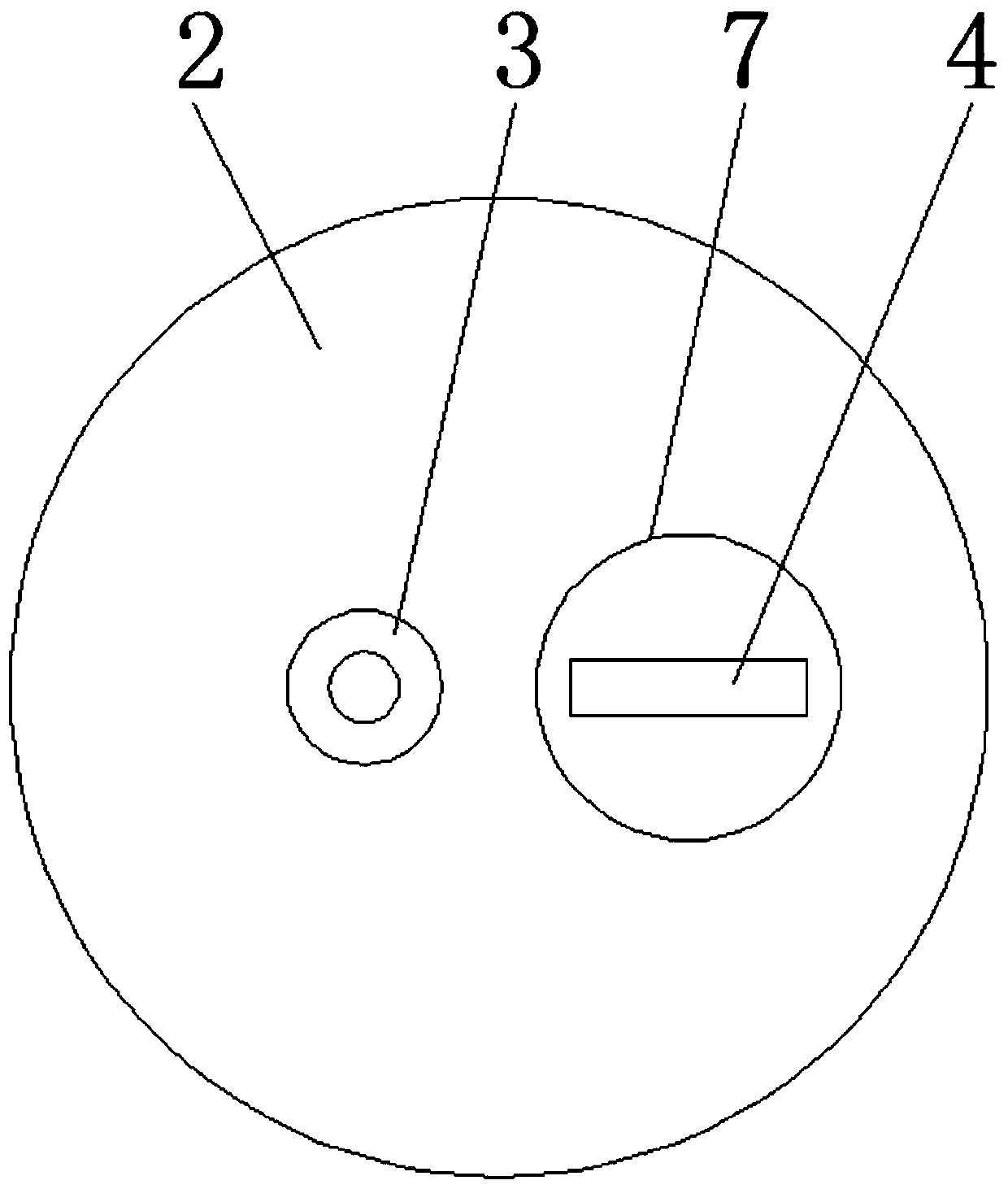

Trademark pad printing machine for earphone round cover

InactiveCN112208198AAchieve rotationThe location of the trademark is consistentRotary pressesConveyor partsPad printingHeadphones

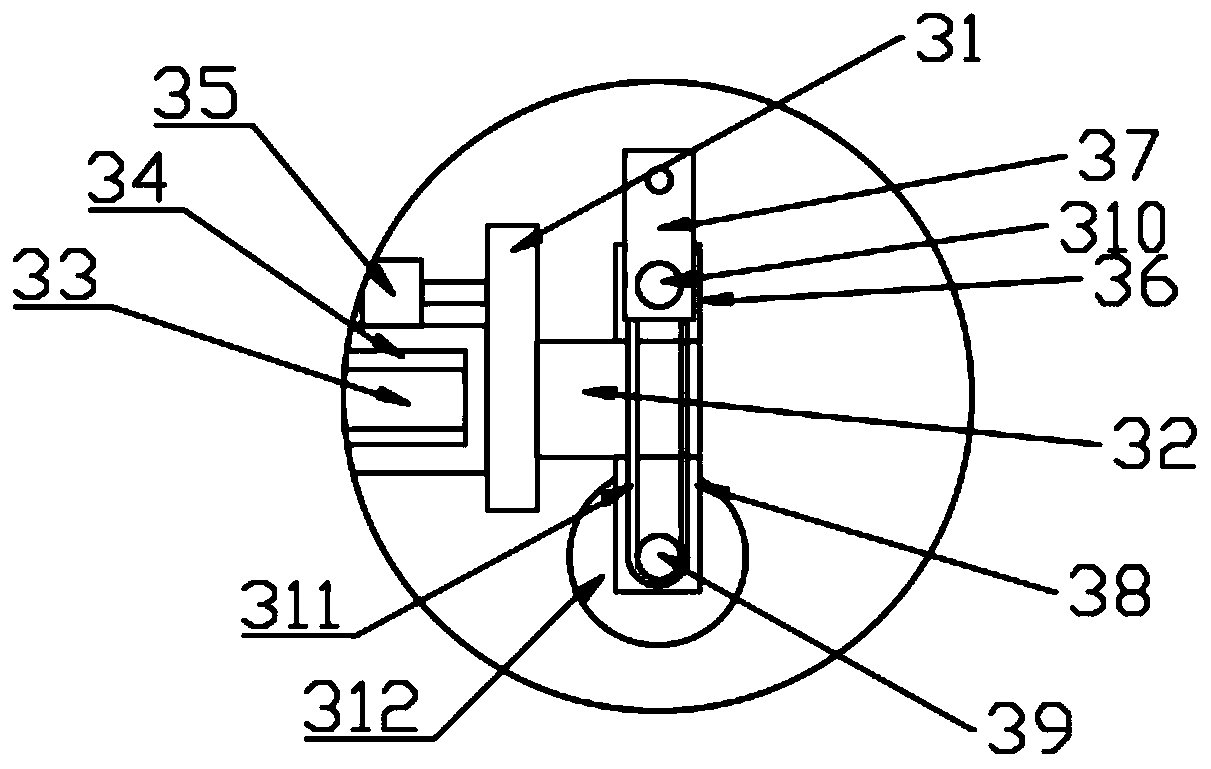

The invention relates to a pad printing machine, in particular to a trademark pad printing machine for an earphone round cover. The trademark pad printing machine for the earphone round cover providedby the invention is easy to operate, and pigment is not prone to staining other parts of an earphone in the printing process. The trademark pad printing machine for the earphone round cover comprisesa bottom plate, first bearing bases, a conveying mechanism, a pad printing mechanism, wherein a workbench is arranged at the top of the bottom plate; the first bearing bases are symmetrically arranged on the side, close to the workbench, of the top of the bottom plate; the conveying mechanism is arranged at the top of the bottom plate; and the pad printing mechanism is arranged between the firstbearing bases. By starting a servo motor, rotation of a second rotating shaft is achieved; and then through cooperation of the conveying mechanism and the pad printing mechanism, when the earphone moves to the position below the pad printing mechanism, the pad printing mechanism prints a trademark on the earphone, and the position of the trademark on the earphone is consistent.

Owner:许从平

High-performance cotton thread moistening device for textile production

InactiveCN110592843AImprove work efficiencyFast processTextile treatment machine arrangementsTextile treatment with treating outlet contectElectric machineryFuel tank

The invention belongs to the field of textiles, and particularly relates to a high-performance cotton thread moistening device for textile production. The device comprises a box body, an oil storage tank is fixedly connected to the upper end of the box body, a horizontally arranged rotating inner pipe is rotationally connected to the inner side wall of the box body, multiple through oil outlet holes are formed in the side wall of the rotating inner pipe, a motor is fixedly installed on the side wall of the box body, an output shaft of the motor penetrates through the box body and is coaxiallyand fixedly connected with the rotating inner pipe, an oil outlet pipe is fixedly communicated with the side wall of the oil storage tank, the lower end of the oil outlet pipe sequentially penetratesthrough the box body and the rotating inner pipe and is rotationally connected with the rotating inner pipe, and a movable outer pipe sleeves the rotating inner pipe. Accordingly, by means of relativerotation of the rotating inner pipe and the movable outer pipe, cotton threads can be rubbed, and meanwhile the movable outer pipe periodically shakes in the rotating inner pipe to extrude the cottonthreads so that silicon oil can immerse into the cotton threads rapidly; the thread moistening effect is better, and the efficiency is high.

Owner:任晓倩

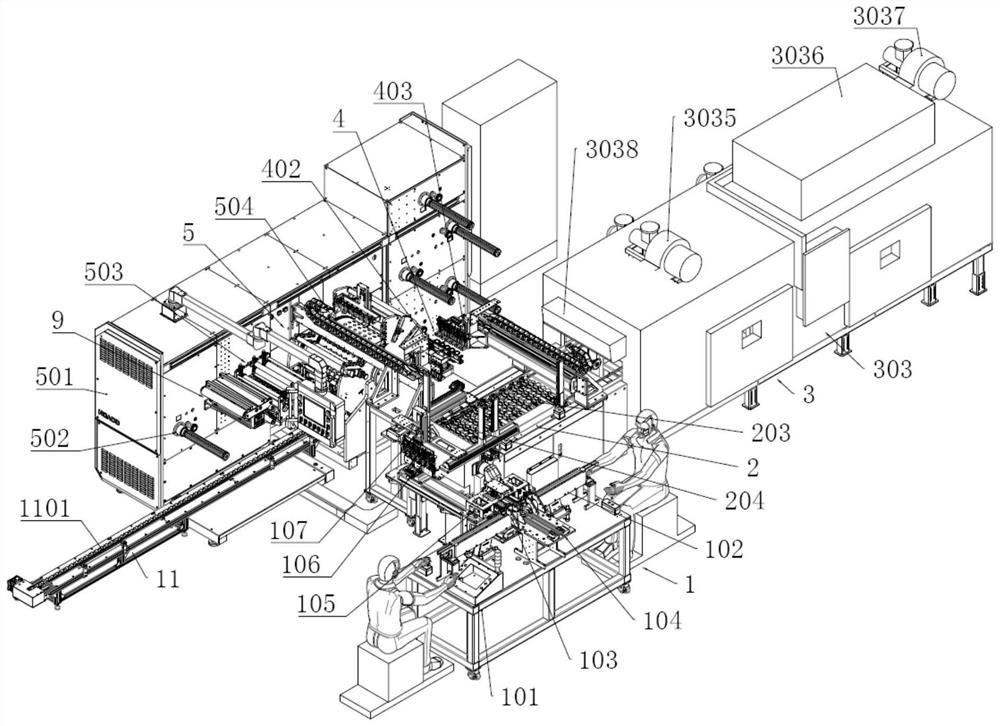

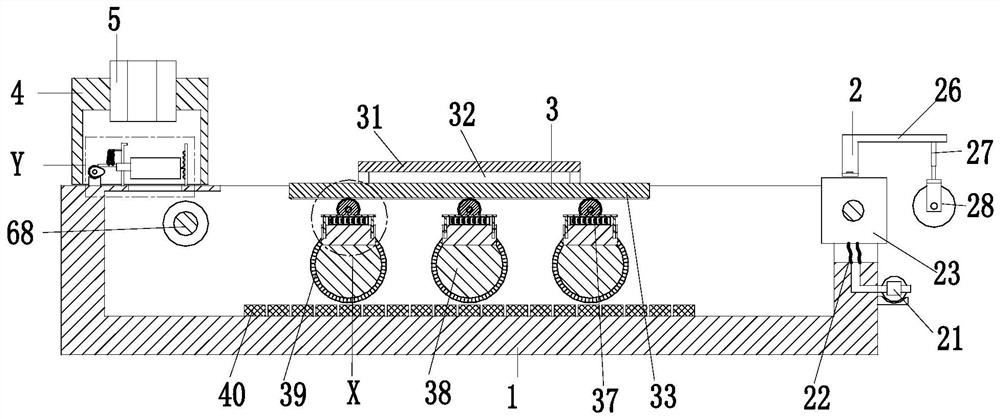

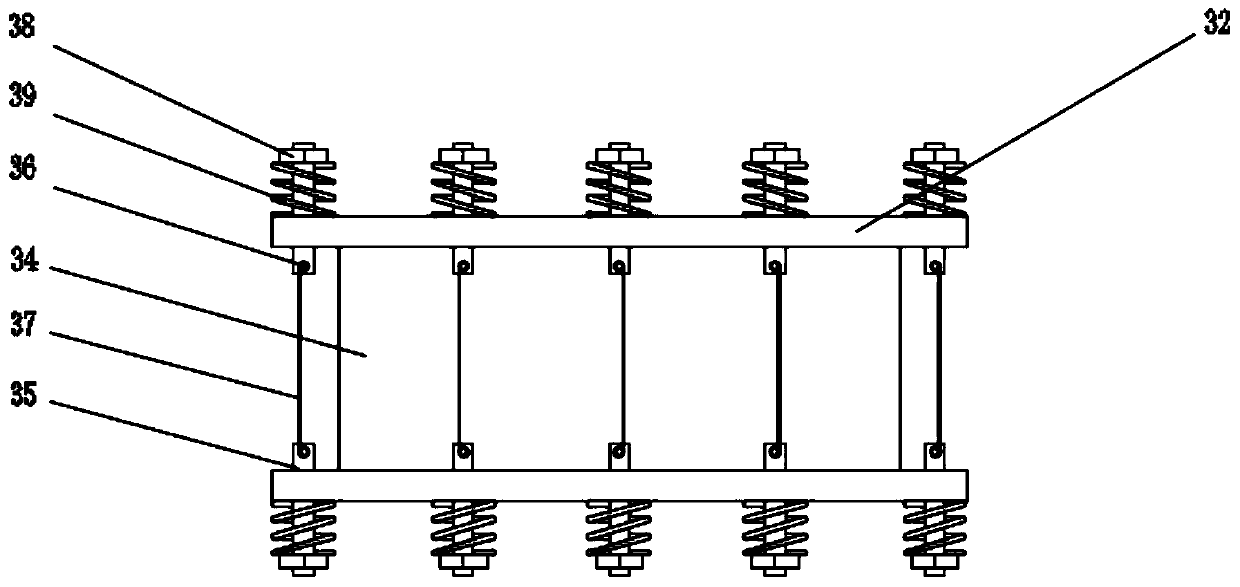

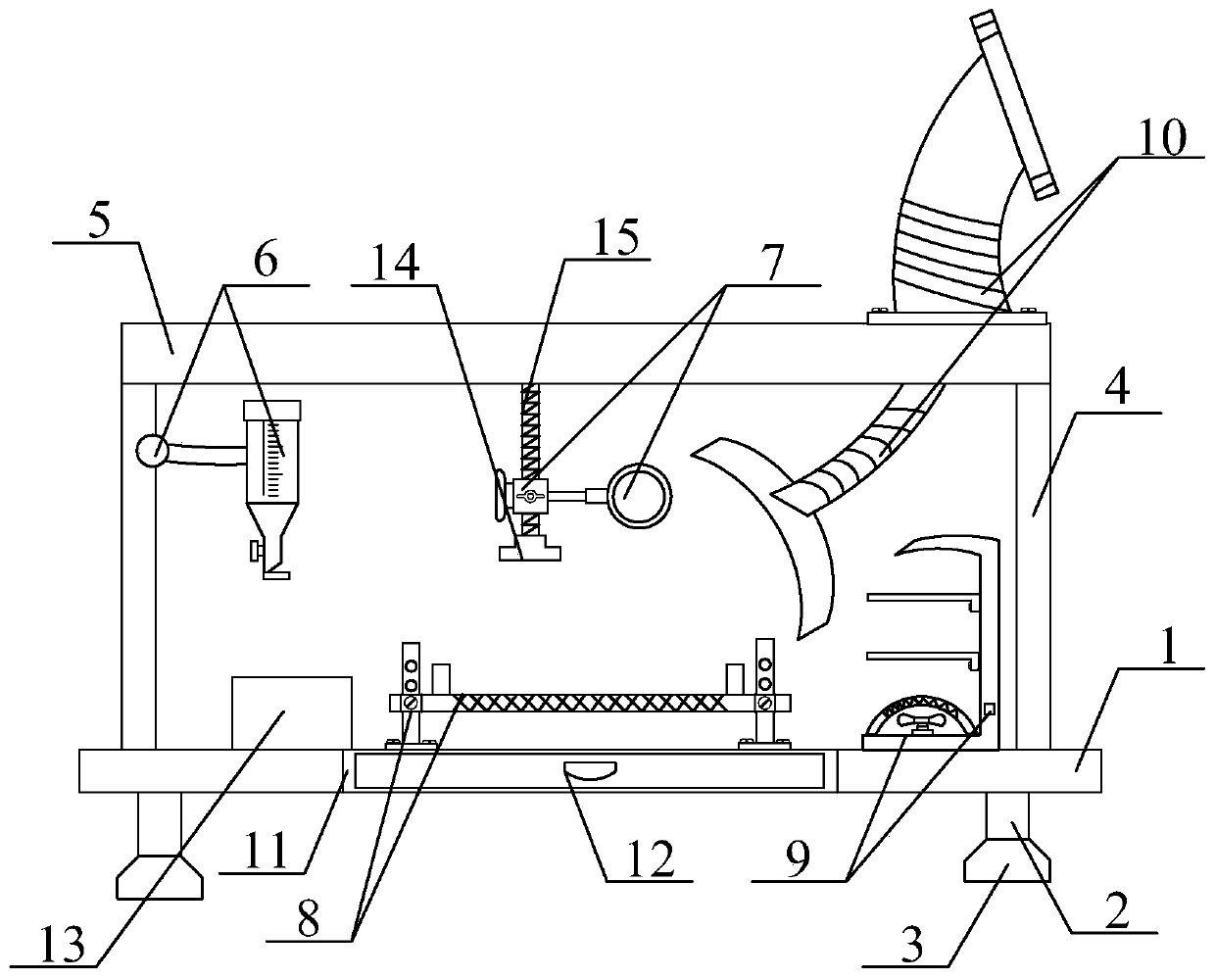

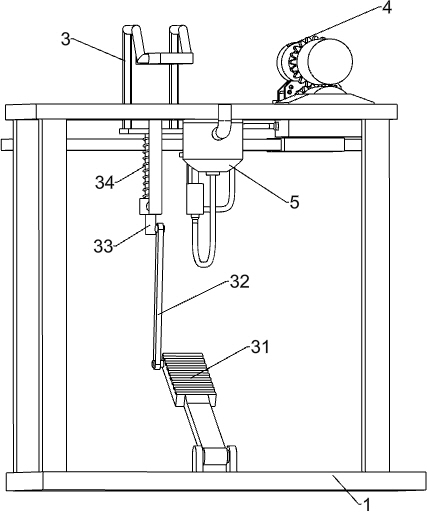

Plunger paste production line and production process

ActiveCN113955395AEasy to transportEasy to dipLiquid surface applicatorsConveyorsMaterial transferIndustrial engineering

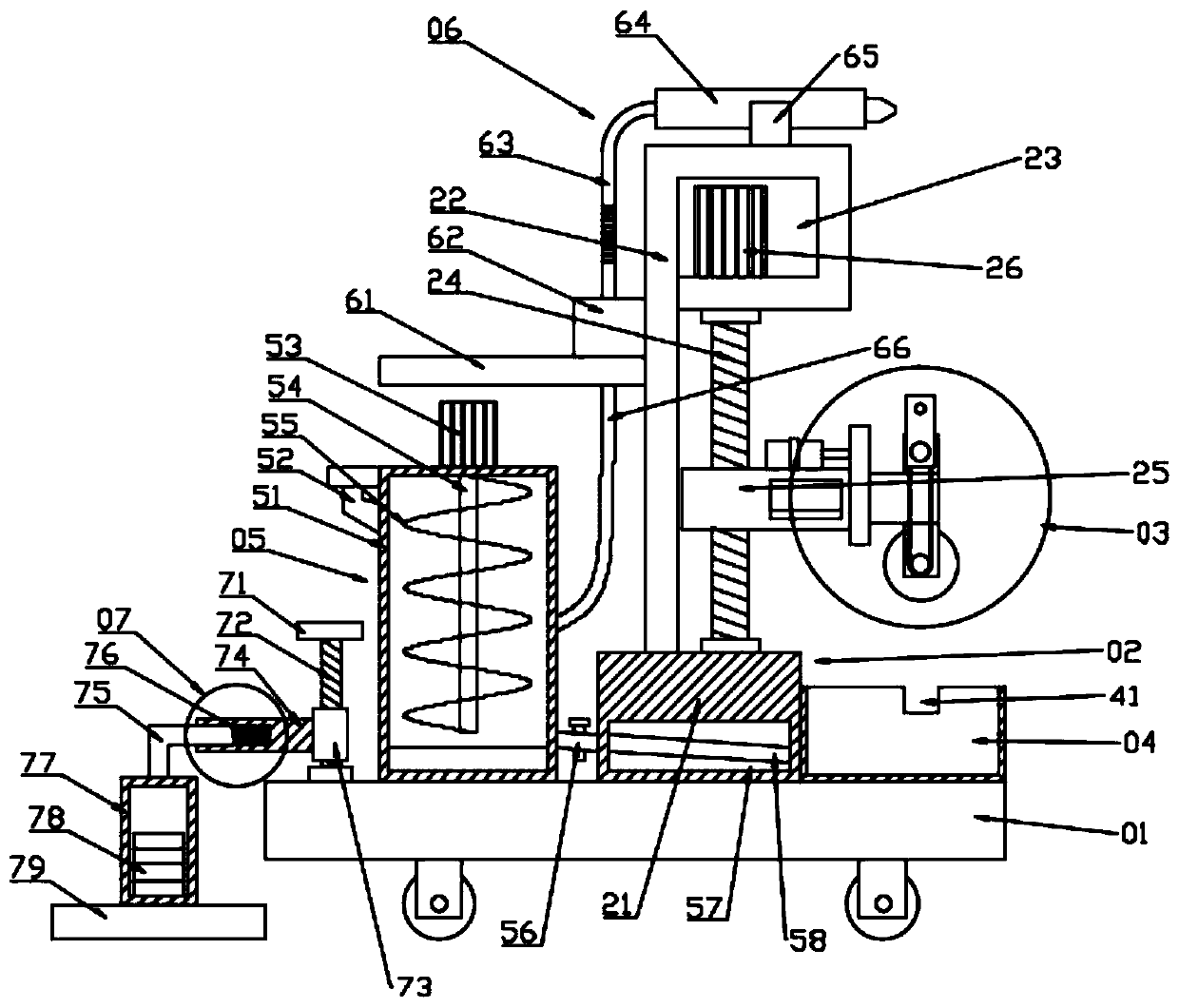

The invention relates to the technical field of plunger paste production, and provides a plunger paste production line and a production process. The plunger paste production line comprises a rotary conveying device, the rotary conveying device is connected with a gum dipping and drying device, the gum dipping and drying device is connected with a material transferring device, and the material transferring device is connected with a plunger paste assembling device; the rotary conveying device comprises a rotary conveying frame, a rotary chain and a positioning jig; the gum dipping and drying device comprises a gum dipping mechanism, a gum homogenizing mechanism and a drying box body; the material transferring device comprises a material transfer table, a material transfer mechanism and a material taking and placing mechanism; and the plunger paste assembling device comprises an assembling frame, and an axial adjusting type material shaft, a slotting assembly, a satellite type rotating assembly, a finished product taking mechanism and a multi-action material moving mechanism are arranged on the assembling frame. The production process of automatic feeding of plunger paste semi-finished products, gum dipping, drying, transferring, plunger paste assembling and attaching, and automatic discharging and collection of finished plunger paste in the plunger paste production process is achieved, and the plunger paste production efficiency is greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

Efficient reagent smearing machine

ActiveCN106583141AReduce the overall heightImprove convenienceLiquid surface applicatorsCoatingsEngineeringGlass slide

The invention provides an efficient reagent smearing machine and belongs to the field of medical articles. The efficient reagent smearing machine comprises four vertical brackets, a reagent smearing module, a conveyor belt module, a reagent accommodation box, a first horizontal bracket and a second horizontal bracket and is characterized in that the four vertical brackets are of a structure of a V-shaped plate and are arranged at the four corners of the whole machine respectively; the reagent accommodation box is composed of a box body and a hook structure; the conveyor belt module is installed at the middle upper parts of the vertical brackets; the reagent accommodation box is installed on the conveyor belt module with the height lower than that of a conveyor belt; the reagent smearing module is installed at the lower parts of the vertical brackets and under the conveyor belt module; the first horizontal bracket is installed below the conveyor belt module; and the second horizontal bracket is installed below the reagent smearing module. The efficient reagent smearing machine can automatically smear a reagent on a glass slide efficiently.

Owner:衡阳药谷医药科技有限责任公司

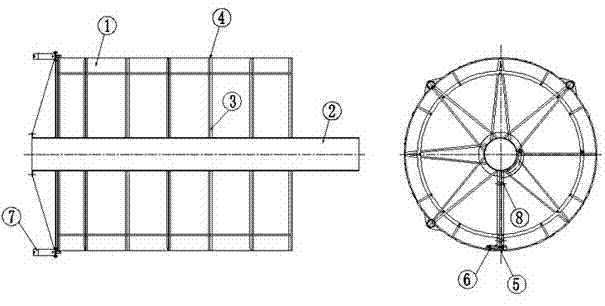

Preparation method of collapsible steel die for manufacturing large-scale glass fiber reinforced plastic chimney

The invention discloses a preparation method of a collapsible steel die for manufacturing a large-scale glass fiber reinforced plastic chimney. The preparation method mainly comprises preparation of a die body and a demoulding apparatus. The preparation method of the die for manufacturing the large-scale glass fiber reinforced plastic chimney provided by the invention has strong operationality and high production efficiency; the die is convenient for demoulding product and non-deformable, and can be used continuously for many times; and the product has good quality of an interior surface and accurate dimension. The method can overcome the disadvantages of poor quality of internal layer, low size precision and difficulty in jointing of a product manufactured by a die for glass fiber reinforced plastic chimney in the prior art, so as to improve quality of the glass fiber reinforced plastic chimney product and increase production efficiency.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

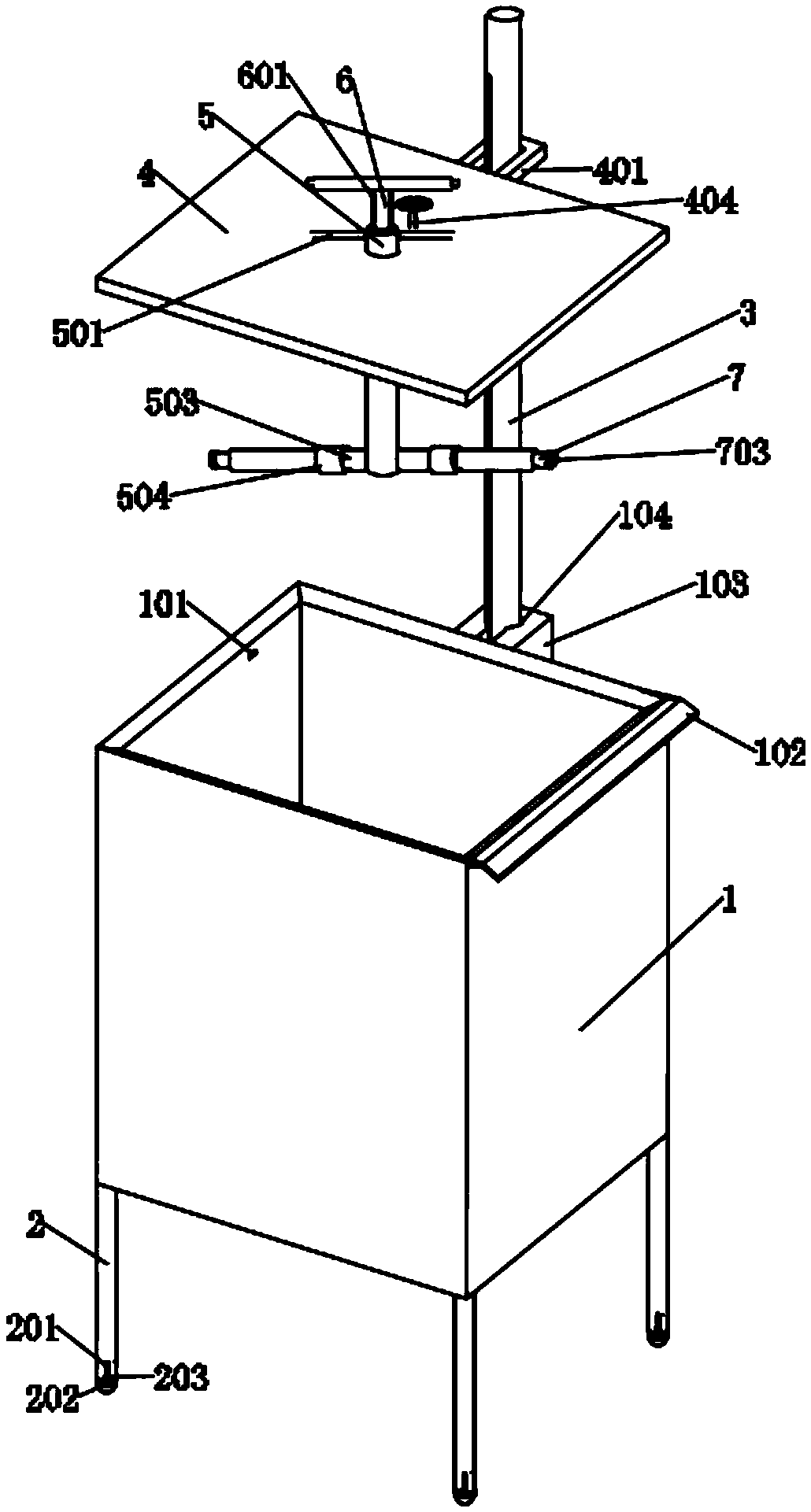

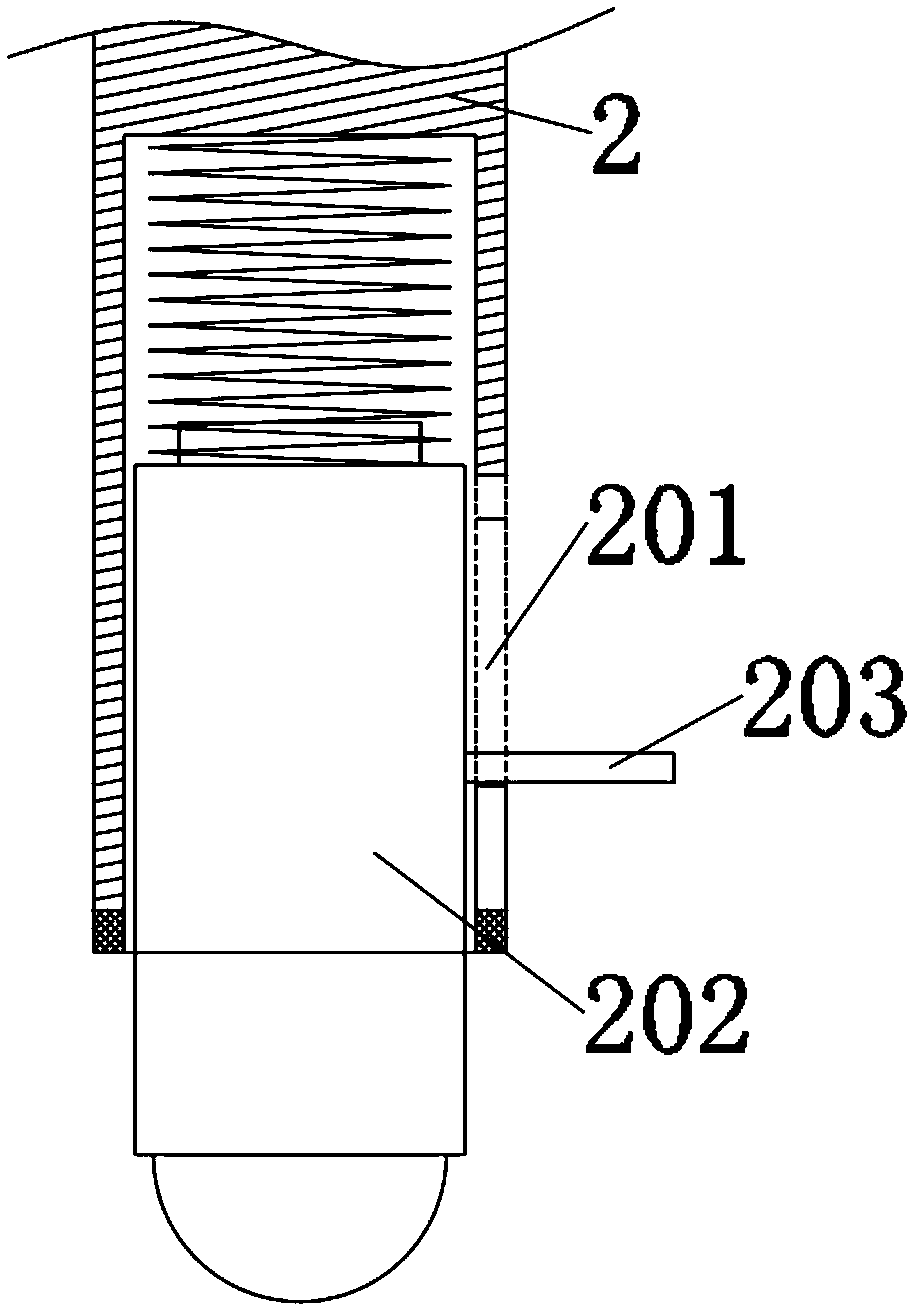

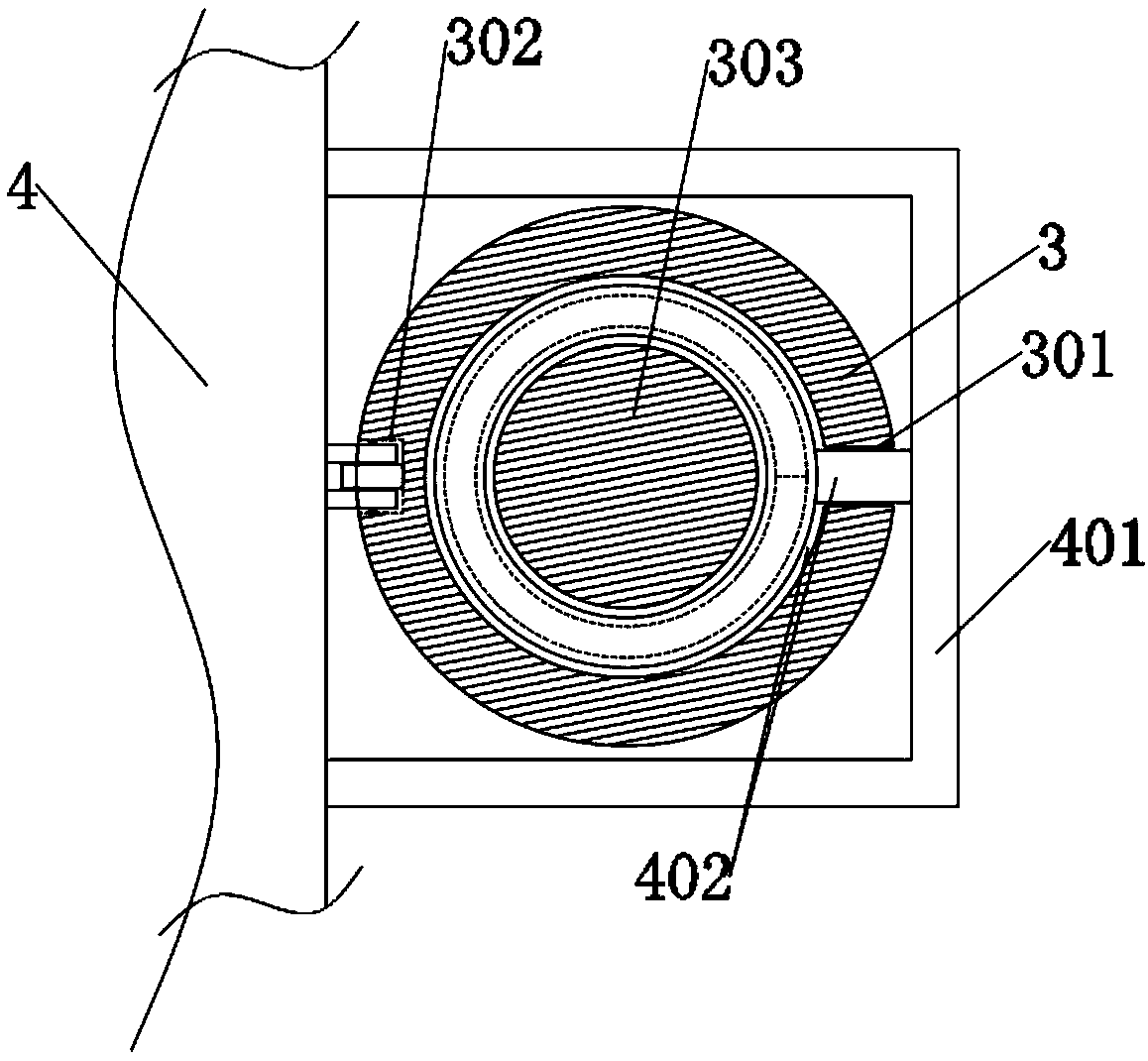

Building wall surface painting device

InactiveCN111593868AEasy to dipImprove dipping effectBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a building wall surface painting device, and relates to the technical field of building decoration. The building wall surface painting device comprises a base, a connecting assembly is fixed to the base, a painting assembly is movably connected to the connecting assembly, and a material collecting box is arranged below the painting assembly; a material preparing assembly isfurther arranged on the base, and the material preparing assembly communicates with the material collecting box; and a handheld spraying assembly is arranged on the connecting assembly, and a limiting adjusting assembly is further arranged on the base. According to the building wall surface painting device, the painting assembly is arranged so that a wall surface can be painted; the material collecting box is arranged below the painting assembly so that painting coating can be conveniently dipped, dipping in a coating barrel is not needed, and the painting efficiency is improved; and the limiting adjusting assembly can be integrally limited at the current position, meanwhile, painting of the wall surface cannot be influenced, and the painting effect is improved.

Owner:袁池保

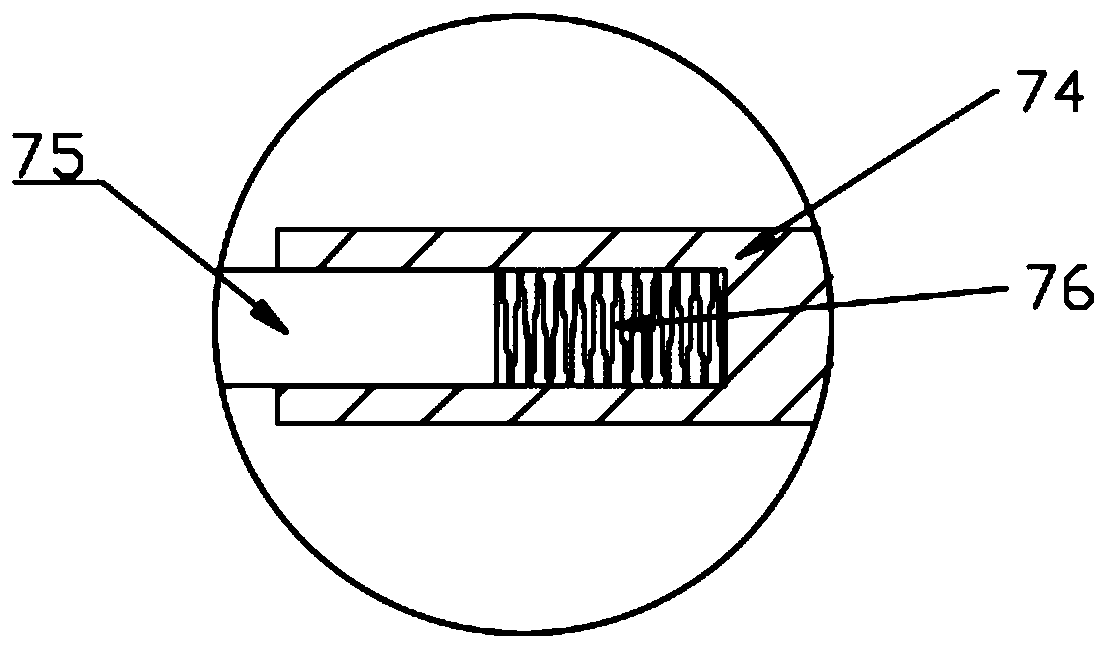

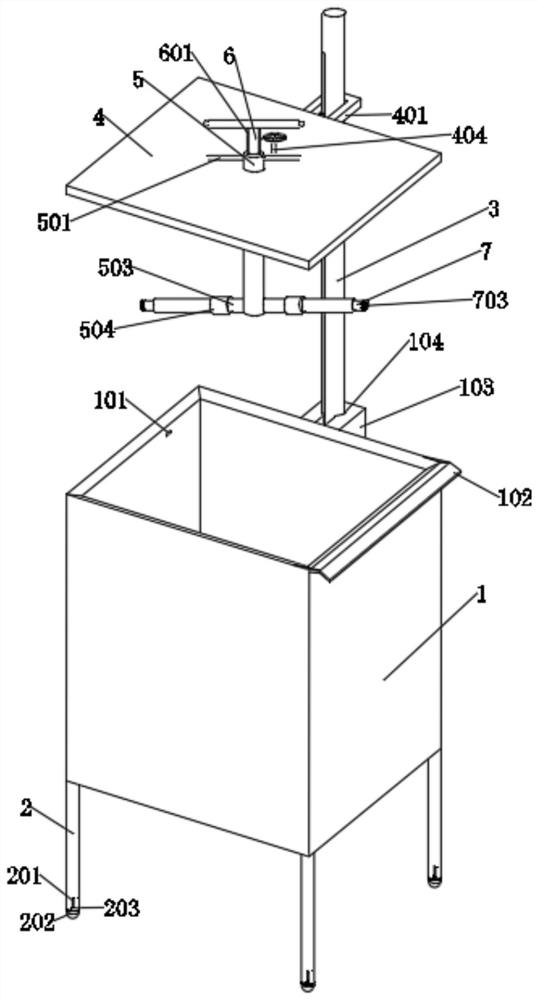

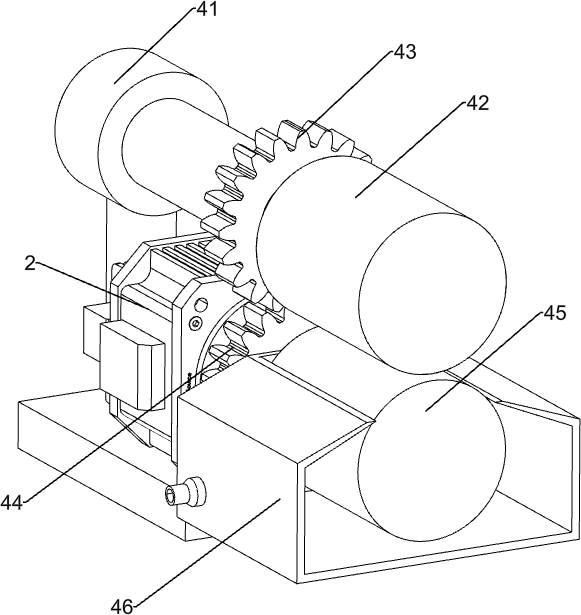

Paint dipping equipment for manufacturing of motor shells

The invention provides paint dipping equipment for manufacturing of motor shells. The equipment comprises a rotating member, a bottom rod, a bottom bin, a contact member, a falling rod, a guiding member, an inner rod, a baffle ring, a spring and an antiskid pad; a top plate is of a rectangular plate-shaped structure; an embedding block is arranged at the bottom of the top plate; an embedding member is mounted above an outer support spring in a support column; the side edge of a pulley is embedded in an insertion slot; a hand wheel is mounted at the top end of a rotating shaft through a weldingmanner; a limiting plate is mounted at the bottom of the top plate through a connector; a clamping tooth is arranged on the inner side of the limiting plate; and the clamping mouth is in contact witha gear. A support member plays a role in carrying out convenient switching when fixing or movement is required, so that when the equipment needs to move, a universal wheel at the bottom of a mountingpiece can be utilized, and when the equipment needs to be fixed, a breakoff rod is pulled to ensure that the mounting member and the universal wheel are retracted.

Owner:SUZHOU YUANLIAN SCI & TECH PIONEER PARK MANAGEMENT CO LTD

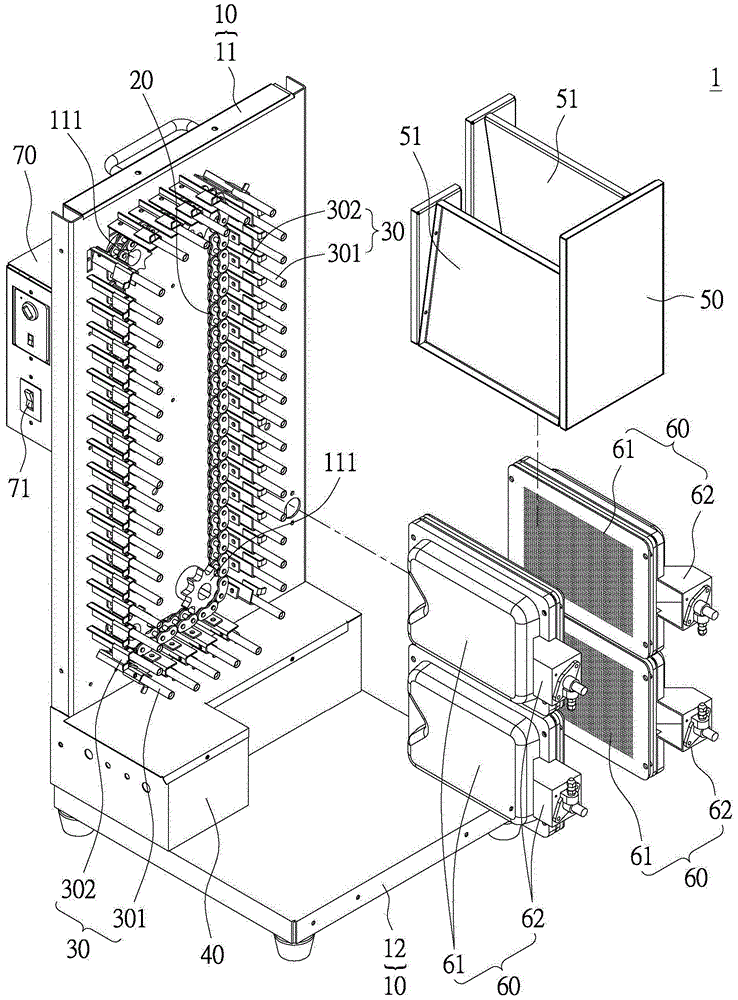

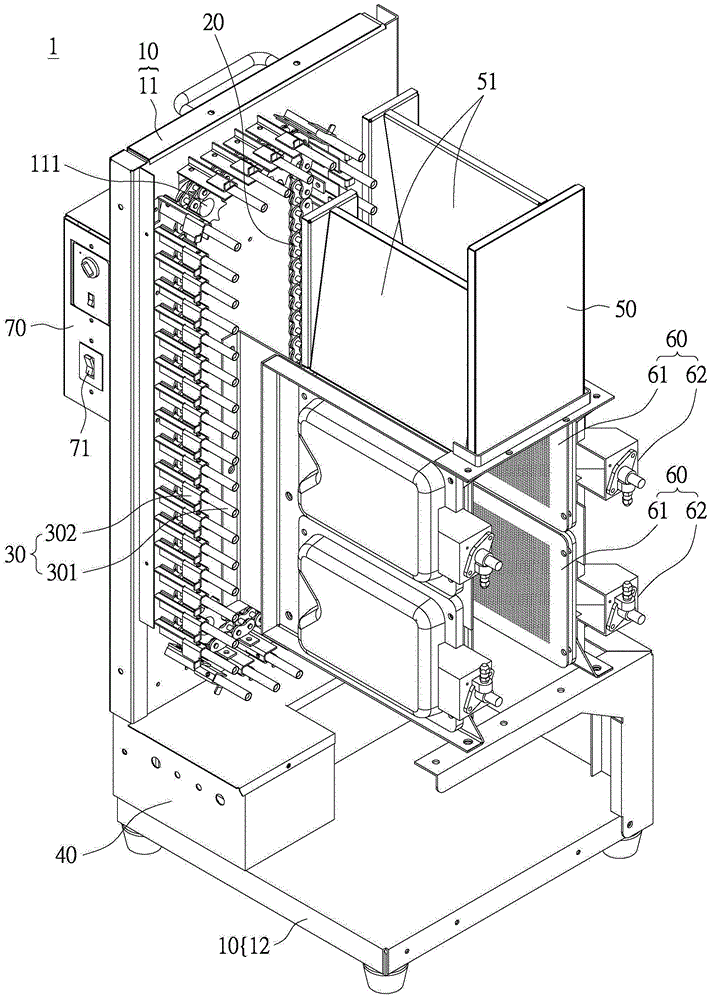

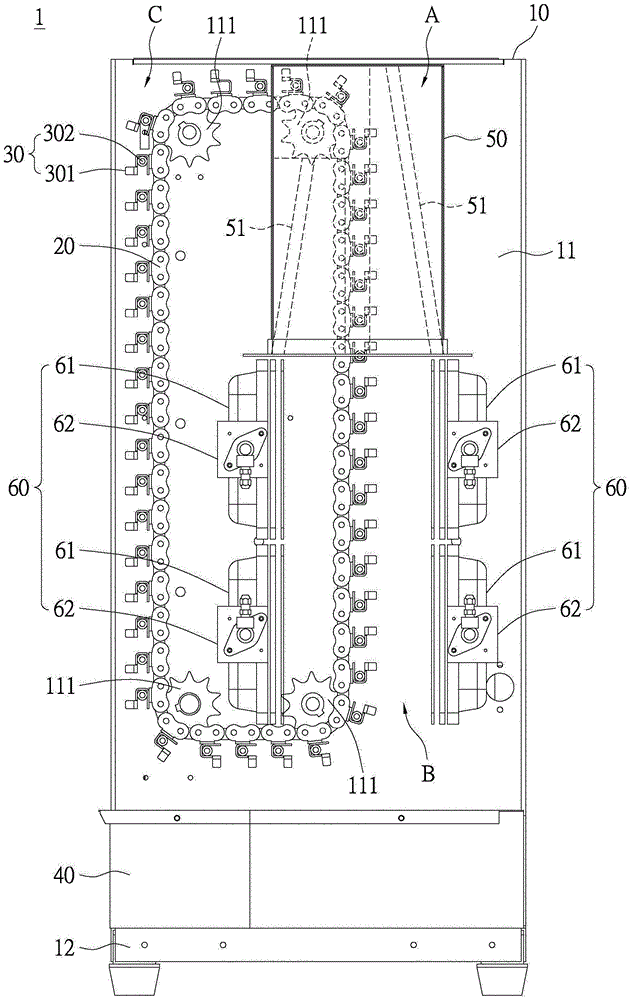

Vertical type food material baking device and method

InactiveCN104856579AMake sure it's well doneNot easy to loseRoasters/grillsThermal insulationComputer module

The invention provides a vertical type food material baking device and method. The vertical type food material baking device comprises a body, a conveying chain belt, a drive module, multiple material storage units, a thermal insulation hood and a heating module, wherein the body comprises a vertical platform perpendicular to a horizontal surface; the conveying chain belt is arranged on the vertical platform; the drive module is used for driving the conveying chain belt; the multiple material storage units are provided with food material insertion pieces and arranged on the conveying chain belt at intervals; the heating module is arranged on one section of the conveying chain belt, so that a direct heating area is formed on the section; the thermal insulation hood is arranged above the heating module and used for collecting heat energy produced by the heating module to form a baking area. Food materials arranged on the food material insertion pieces are baked in the baking area firstly and then enter the direct heating area to be heated under drive of the conveying chain belt along with the material storage units.

Owner:江启瑞

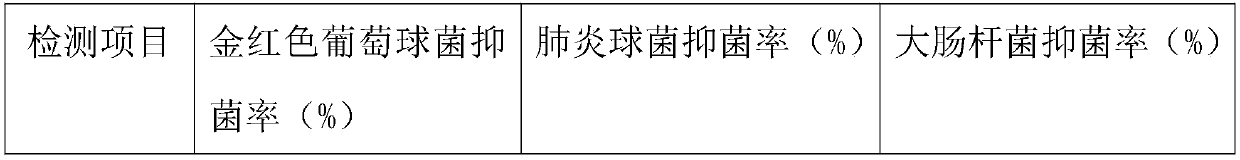

Preparation technology of antibacterial radiation-proof enteromorpha fiber composite fabric

ActiveCN109610062ASolve the pollution of the environmentSolve wasteCarbon fibresBiochemical fibre treatmentCarbon fibersSilver plate

The invention discloses a preparation technology of antibacterial radiation-proof enteromorpha fiber composite fabric. The method comprises the steps of enteromorpha pretreatment, preparation of enteromorpha carbon fibers, preparation of a silver plating solution, preparation of silver plating enteromorpha carbon fibers, preparation of titanium-based enteromorpha fibers and formation of an antibacterial radiation-proof enteromorpha fiber composite material. The silver plating enteromorpha carbon fibers and the titanium-based enteromorpha fibers are prepared in the process; in addition, an environment-friendly antibacterial radiation-proof enteromorpha fiber composite fabric can be prepared by blending the silver plating enteromorpha carbon fibers and the titanium-based enteromorpha fiberswith other fibers; the antibacterial radiation-proof enteromorpha fiber composite fabric has the advantages of obviously-strengthened water absorption and breathable effects, obvious sterilization andradiation protection functions and suitability for underwear and fabrics for pregnant women; meanwhile, the enteromorpha carbon fibers and the enteromorpha fibers are prepared by raw materials easy to obtain; the problems of environment pollution from a large number of enteromorpha and waste of enteromorpha biomass resources are solved.

Owner:青岛万源生物科技有限公司

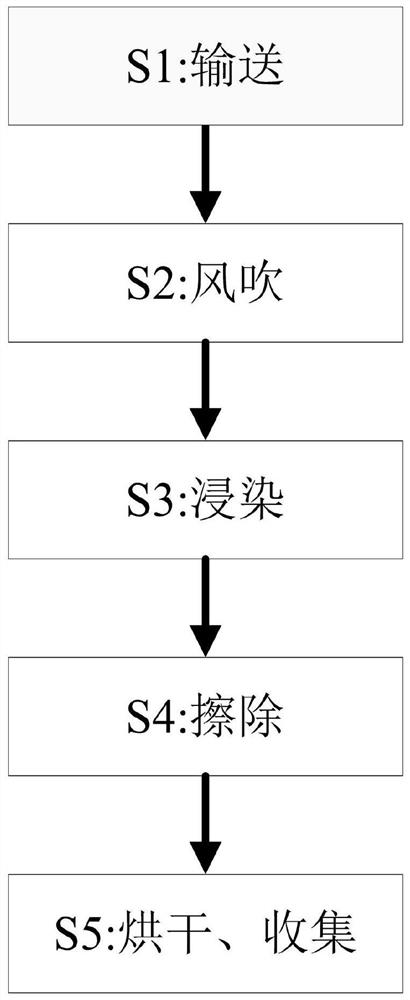

Batch dyeing and drying treatment process for textile yarn

InactiveCN112391757AFast soaking speedUniform soaking effectLiquid/gas/vapor removal by squeezingTextile treatment carriersTextile yarnProcess engineering

The invention provides a batch dyeing and drying treatment process for textile yarn. The process is completed through cooperation of a base, a tightening type turning device, an accelerated dipping device, a sealing cover, a drying frame and a wiping device, and can solve the problems that dust particles may be attached to the surface of the yarn in a conveying process, and the state during conveying is not in a tightening state, so that the above-mentioned conditions influence a dip dyeing effect; and the traditional dip dyeing time is short, the yarn is possibly not soaked thoroughly, dye separation is facilitated, and the dye on the separated yarn is distributed unevenly, so that part of the redundant dye is directly attached to the yarn after being dried, and thus a solidified fuel layer appears on the surface of the yarn, and the percent of pass of the yarn is influenced.

Owner:黄远明

Handheld paint bucket

The invention provides a handheld paint bucket. The handheld paint bucket comprises a bucket body and a lifting handle. The bucket body comprises a bottom wall and a side wall extending upwards from the bottom wall. The bottom wall and the side wall are provided with an inner surface and an outer surface which are both continuous. A cavity for containing paint is defined by the inner surface, and the lifting handle is fixedly connected with the outer surface of the bucket body. A space is reserved between the lifting handle and the outer surface, the lifting handle comprises a lock catch belt, a connecting belt and a key part, wherein the lock catch belt is fixedly connected to the portion, adjacent to an opening, of the outer surface, the connecting belt is fixedly connected to the bottom wall, the key part is fixedly arranged on the lock catch belt, the connecting part can penetrate through the key part to be connected with the lock catch belt, the position of the connecting belt can be adjusted through operation of the key part, the size of the space can be further adjusted, a user can hold the paint bucket with one hand, the handheld paint bucket can be suitable for various work occasions, certain human body burdens are reduced, and the handheld paint bucket is more convenient to use.

Owner:MERIDIAN INT

Rapid mixing type dining table condiment container

The invention discloses a rapid mixing type dining table condiment container. The rapid mixing type dining table condiment container comprises a box and a rapid mixing cylinder body, wherein the box comprises a box body, a box bottom and a bottom cover; a rapid mixing groove is formed in the groove bottom; a bottom airbag is fixed in the rapid mixing groove; the rapid mixing cylinder body is connected with the box body through an external connecting rod; the rapid mixing cylinder body is internally provided with a rapid mixing piston; the rapid mixing piston is used for separating the inner part of a wave collection cylinder body into a rapid mixing air cavity and a rapid mixing cavity communicated with the outer side; the rapid mixing air cavity is internally provided with a supporting spring; one end of the supporting spring is connected with the rapid mixing piston; the other end of the supporting spring is connected with the rapid mixing cylinder body; an outer piston rod is arranged on the rapid mixing piston; and the rapid mixing air cavity is communicated with the bottom airbag through an outer air pipe. The rapid mixing type dining table condiment container has the beneficial effects that liquid condiments can be stored and diners can conveniently dip the condiments; the rapid mixing type dining table condiment container has a rapid condiment mixing capability and can guarantee that the mixing uniformity of the condiments is good; and the rapid mixing type dining table condiment container has an anti-shaking-out function, can be used for preventing the liquid condiments from being shaken out due to shaking and rapid movement of the box body and has good whole stability.

Owner:驻马店市阳光舒适家暖通设备有限公司

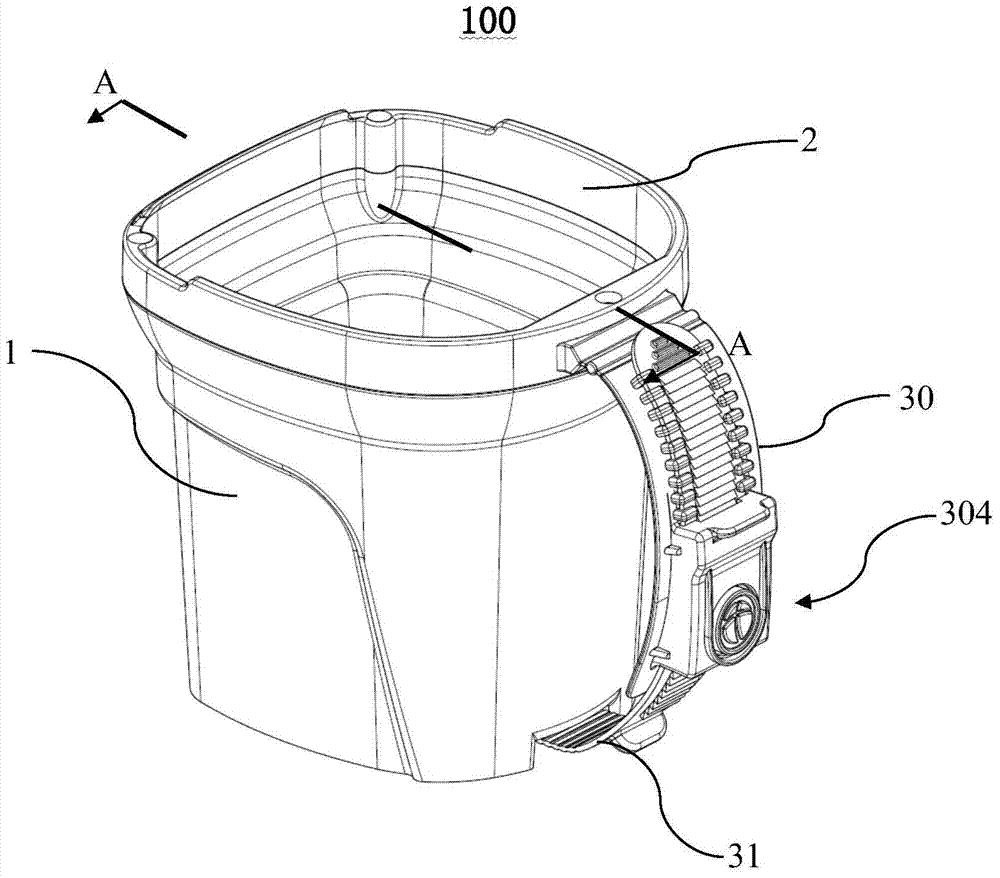

Dipping sauce box used during meals

InactiveCN107374236AShaking out preventionEasy to dipDomestic vesselsEngineeringMechanical engineering

The invention discloses a dipping sauce box used in meals. The dipping source box comprises a box body formed by a box case and a box bottom, the box case is vertically arranged and is provided with a plurality of wave-resisting mechanisms, and each wave-resisting mechanism comprises a wave-collecting cylinder, a wave-collecting piston, a lower piston rod, a transverse slide hole, an inner wave-resisting plate, a secondary wave-resisting groove and a wave-resisting air bag; the wave-resisting mechanism is characterized in that the wave-collecting piston divides the interior of the wave-collecting cylinder into an air regulating cavity and an air transmitting cavity, a first conduction hole communicated with the air transmitting cavity is arranged in the wave-collecting cylinder, an air return spring is arranged in an air inflation cavity, one end of the air return spring is connected with the wave-collecting piston while the other end of the same is connected with the wave-collecting cylinder, the lower piston rod is connected with the wave-collecting piston and the inner wave-resisting plate, a rigid air pipe fixed with the box case is arranged on the wave-resisting cylinder, and the air regulating cavity is communicated with the wave-resisting air bag. The dipping sauce box has the advantages of reasonable structure, liquid dipping sauce can be stored, convenience is brought to a diner to dip sauces, an shaking-out prevention function is achieved, shaking out of the liquid sauces due to shaking and rapid moving of the box can be prevented, and integral stability is good.

Owner:胡劼

Artificial granite composite material and preparation method thereof

ActiveCN107216064AHigh compressive strengthAdhesive immersion is easyPre treatmentConstruction aggregate

The invention discloses an artificial granite composite material and a preparation method thereof. The method comprises the steps of cleaning, crushing sieving and drying aggregates; weighing coarse aggregates of which the particle sizes are greater than 2.36mm according to grading requirements, and adding the coarse aggregates to a binder which is heated in advance for pretreatment; weighing resin, a curing agent and a diluent again according to the weight ratio, mixing evenly, adding an aggregate mixture, mixing evenly by using a forced mixer, and casting the mixture into a mold coated with a release agent; and fixing the mold on a vibration table for vibration molding, and carrying out room-temperature curing and conserving to form a finished product. Compared with a conventionally prepared artificial granite composite material, the obtained artificial granite composite material has the advantages that surface cracks and defects of the coarse aggregates are filled and repaired through immersion in the heated binder, the aggregates and the binder system are bonded more firmly, and the compressive strength is improved by 10-15%.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Tipping paper drum wheel device with automatic cleaning function

The invention discloses a tipping paper drum wheel device with an automatic cleaning function. The tipping paper drum wheel device comprises a clamping mechanism and a cleaning mechanism, wherein theclamping mechanism comprises an installing plate and a moving slide plate; the installing plate and the moving slide plate are adjacent at the left side and the right side; two slide rails are fixedlyarranged at one side of the installing plate; two slide strips are fixedly arranged at one side, opposite to the installing plate, of the moving slide plate. The tipping paper drum wheel device has the characteristics that the structure is compact; the cleaning effect is good; the effective action time is long. The device has the concrete work flow processes that bristles on the outer side of thecleaning roller can be used for cleaning the outer wall of the wheel roller; the accumulation of glue water and impurities on the outer wall of the wheel roller can be avoided; after the bristles aredipped with glue water, the cleaning roller continuously rotates, so that the problem that the bristles are too dirty is solved; the cleaning effect is improved; then, the bristles are repeatedly scraped by silk yarns, and can be pulled to a scattered state; the bristles can conveniently dip with the glue water again.

Owner:林初煌

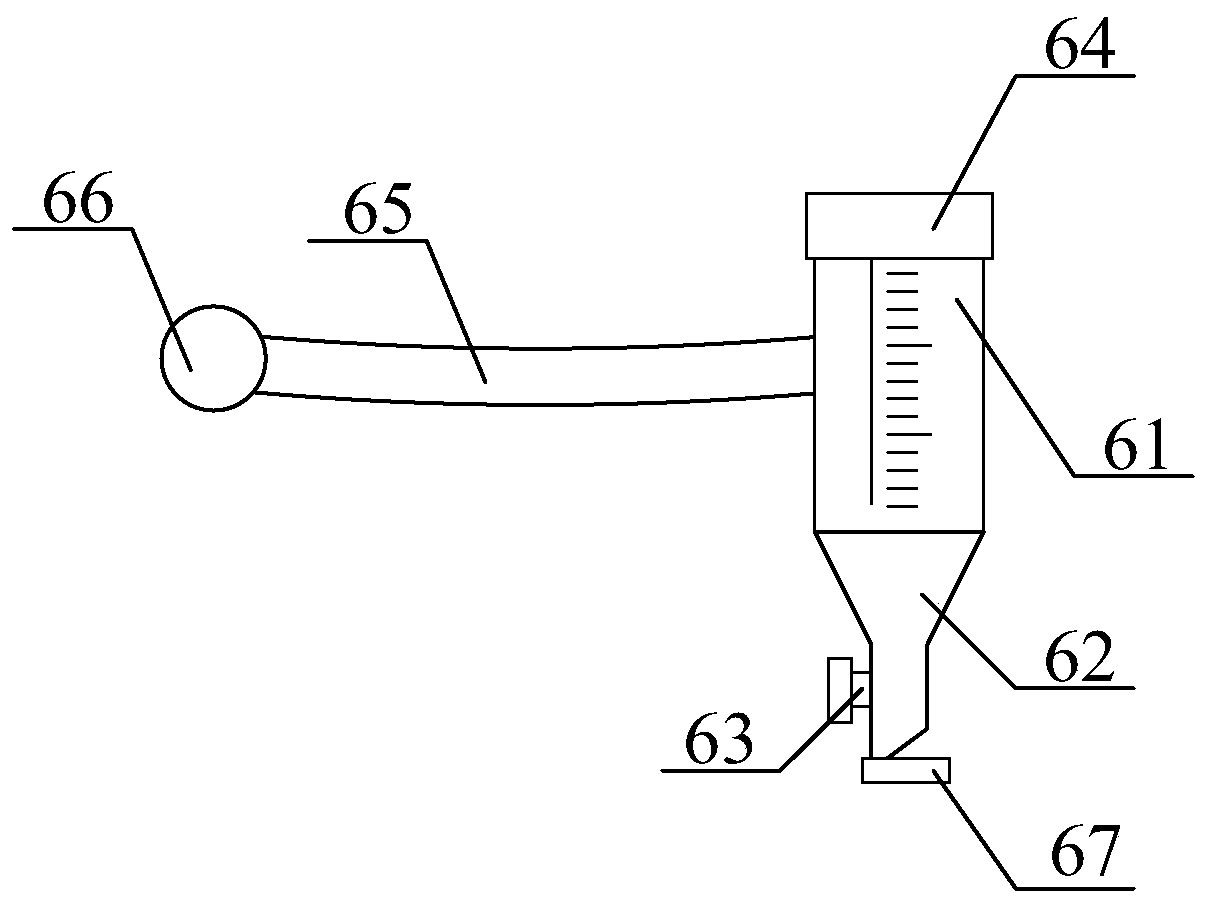

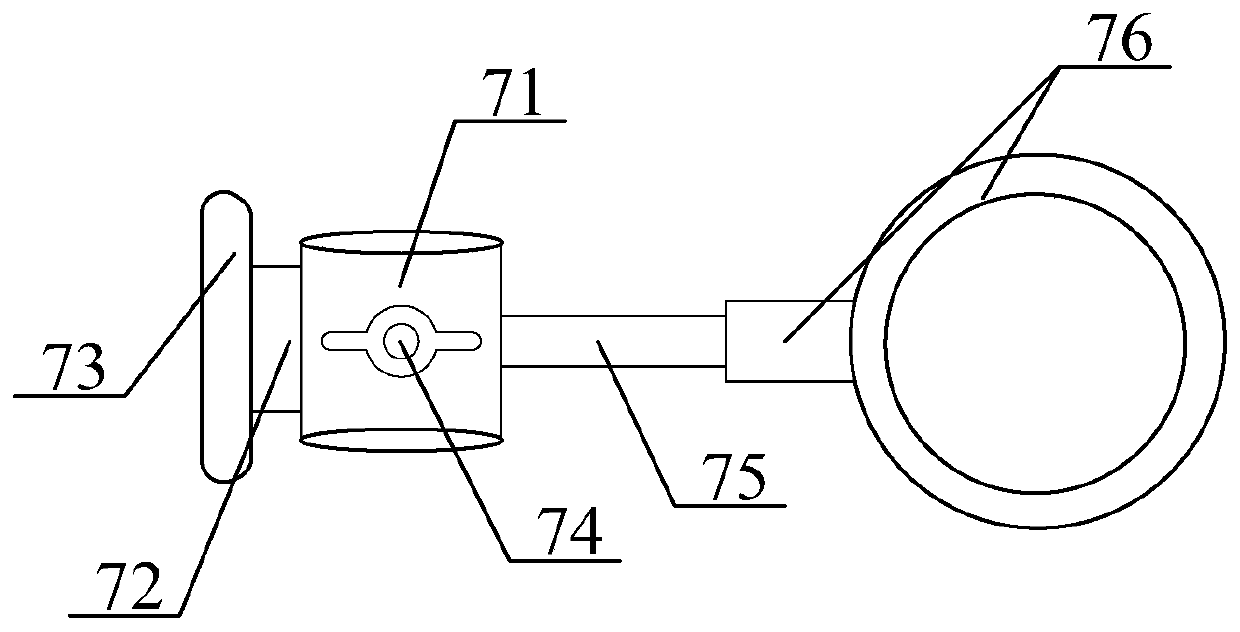

Multifunctional processing device for printed circuit board

PendingCN109951968AEasy to dipImprove conveniencePrinted circuit assemblingDirt cleaningBall valveSolder paste

The invention provides a multifunctional processing device for a printed circuit board. The device comprises a supporting base plate, a support screw lever, a rubber disc, a support column, a protective top plate, an adjustable solder paste storage bottle structure, a convenient-to-wipe adjustable magnifying lens structure, an adjustable circuit board processing support screen plate structure, a layered cooling placement frame structure, a convenient-to-connect flue gas absorption connection cylinder structure, a drawer groove, a drawer plate, a welding seat, a limiting stop cap and a screw rod column. Due to the arrangement of the solder paste storage bottle, a solder paste guide hopper, a manual control ball valve, a dustproof cover, a stainless steel flexible pipe, a rotary universal ball and a solder paste buffer box, the solder paste can be conveniently taken during the welding of a printed circuit board. Therefore, the use convenience is improved. Due to the arrangement of an adjusting sleeve, a magnet block, a wiping sponge pad, an adjusting screw and a welding magnifying lens, the magnifying welding operation is facilitated when small parts are welded on the printed circuitboard. Therefore, the wiping sponge pad can be used for wiping the lens welded with the magnifying lens.

Owner:江西中信华电子工业有限公司

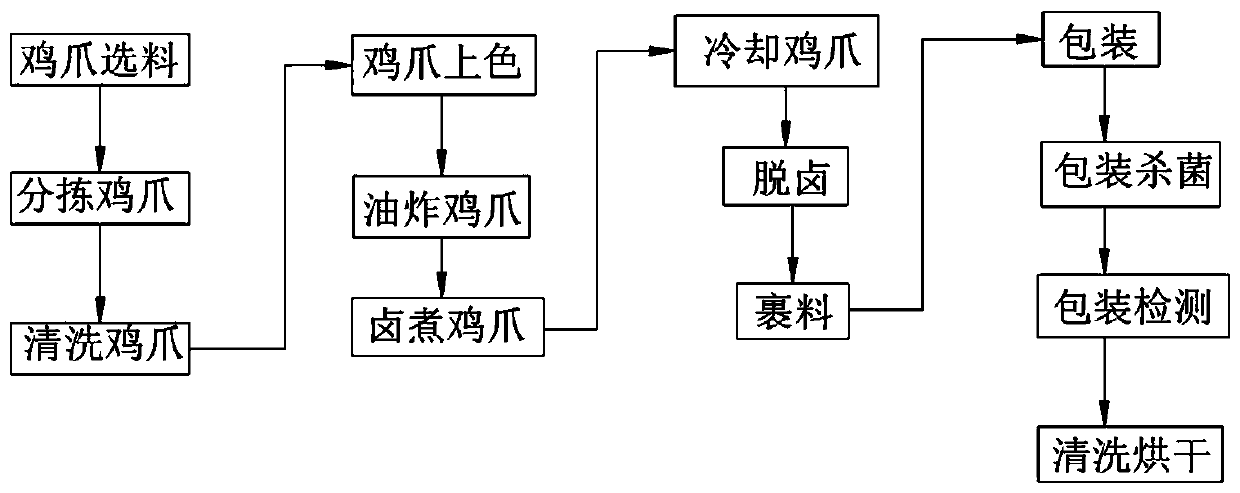

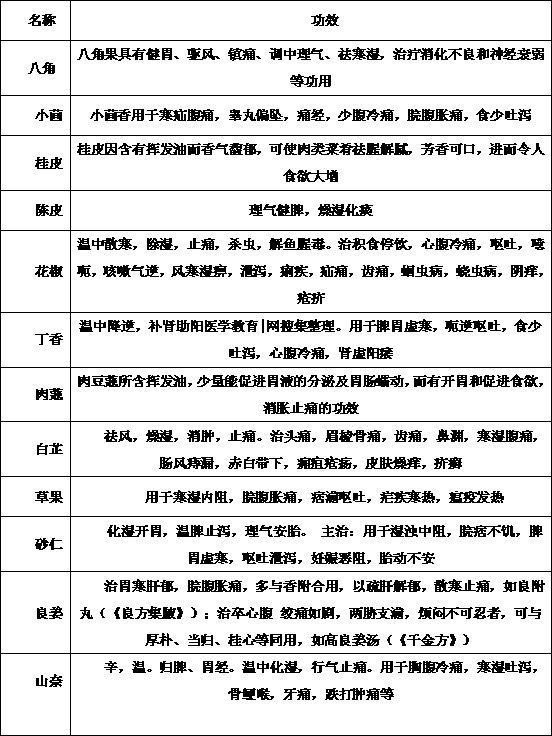

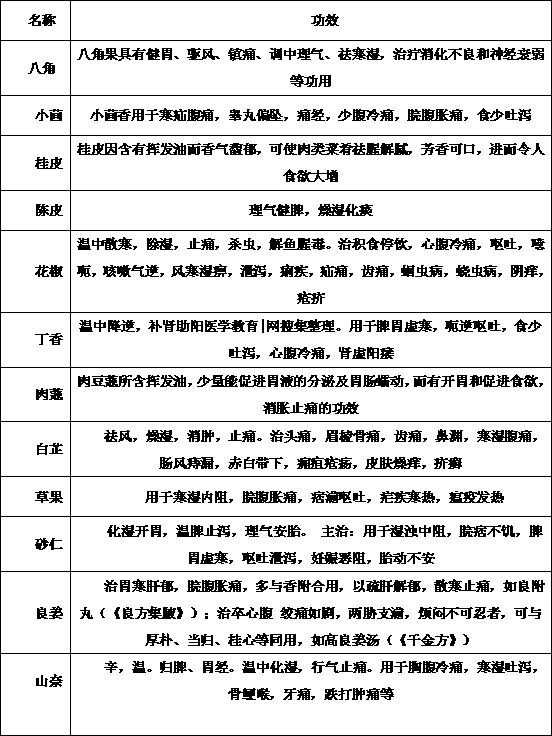

Chicken claw processing technology

PendingCN110558488AReduce moistureNo debondingClimate change adaptationFood scienceRoast chickenChicken-claws

The invention belongs to the technical field of food processing, and particularly, relates to a chicken claw processing technology comprising the following steps: selecting chicken claws, sorting thechicken claws, cleaning the chicken claws, coloring the chicken claws, deep-frying the chicken claws with oil, marinating and boiling the chicken claws, cooling the chicken claws, demarinating, wrapping the chicken claws with materials, packaging, sterilizing the package, detecting the package, cleaning and drying; in the demarinating and material wrapping process, a marinating soup in the marinated chicken claws is removed through a demarinating machine, the moisture in the chicken claws is reduced, the materials on the chicken claws after the subsequent material wrapping process can be morefully attached and absorbed; the sterilized chicken claws do not have a deboning phenomenon; the mouthfeel is more chewy, flavoring is richer and more thorough, and dipping and adhesion of powder arefacilitated by using an oil material on the chicken claws firstly; the paste can further fix the powder on the chicken claws, the taste is unique and delicious, the formula is improved, natural spicesfor marinating roast chicken and roast chicken soup stock are added, the soup stock is richer in the marinating process, the chicken claws absorb the fragrance of the natural spices, the fishy smellof the chicken claws is removed, and the taste of the chicken claws is better.

Owner:SUZHOU HUIXIANGYUAN FOOD CO LTD

Preparation method of hot curing emulsion slurry for integration of rubber shoe upper and sole

ActiveCN102321440AImprove adhesionSmall fluctuationNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention discloses a preparation method of hot curing emulsion slurry for the integration of a rubber shoe upper and a sole, which comprises the steps that: KOH solution, nekal BX solution, penetrant JFC solution and the mixture of stabilizer H and polyacrylamide are prepared and are uniformly mixed with natural rubber latex to prepare the hot curing emulsion slurry for the integration of the rubber shoe upper and the sole. Compared with traditional latex, the preparation method greatly improves the stability and improves the working efficiency and reduces the consumption of an emulsion slurry brush, so that the emulsion slurry brushing performance is improved, the slurry which is brushed on the upper is increased, the emulsion slurry is easier to dip by the emulsion slurry brush and the emulsion slurry cannot easily fall off, and the brushing heights are easier to maintain consistent, the applied slurry is increased and the attraction is improved; and the adhesion of the upper and the sole is significantly improved, so that the quality defect of the product that the glue of an enclosing strip is cracked when the product is in use is reduced.

Owner:JIHUA 3539 SHOE MAKING

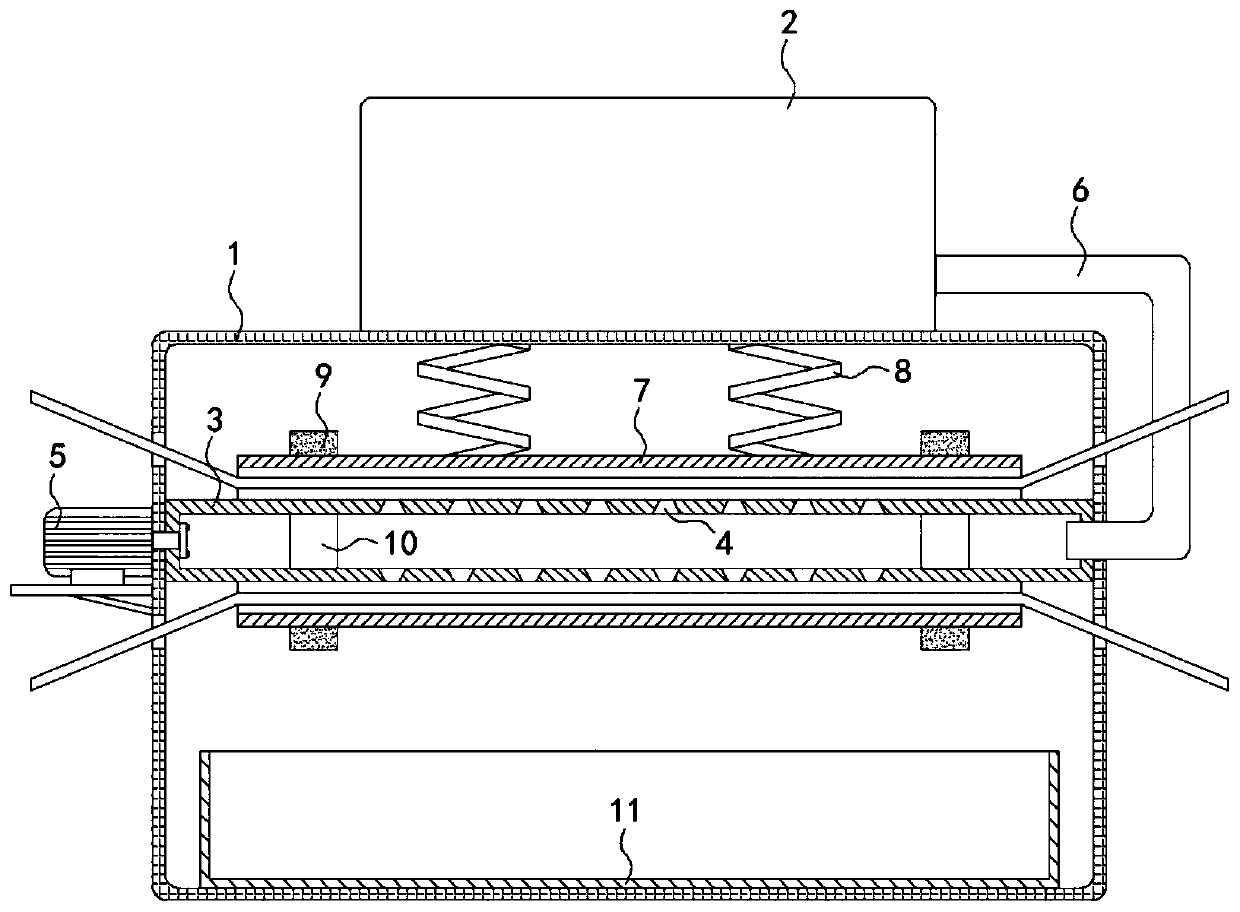

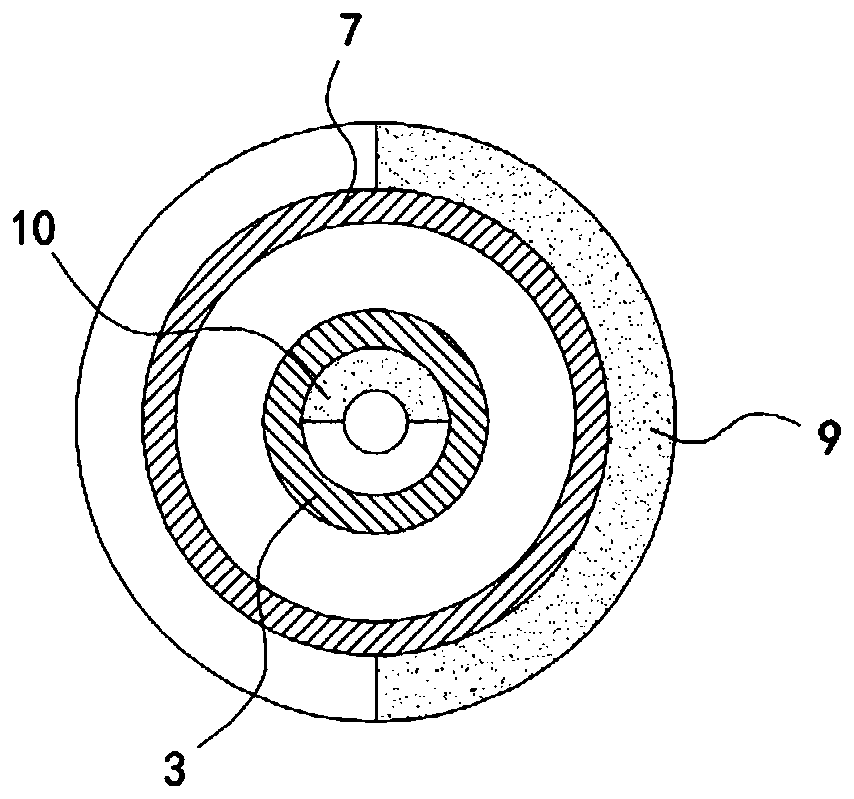

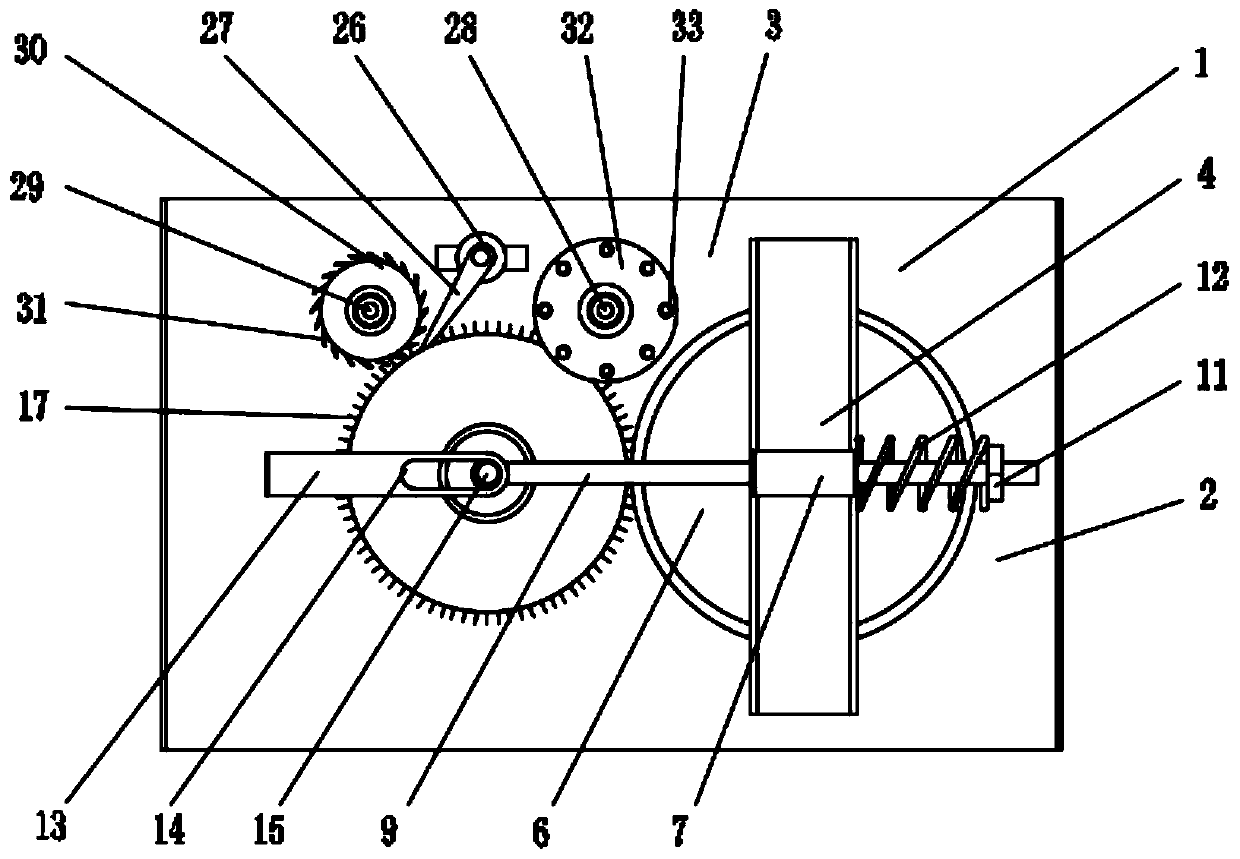

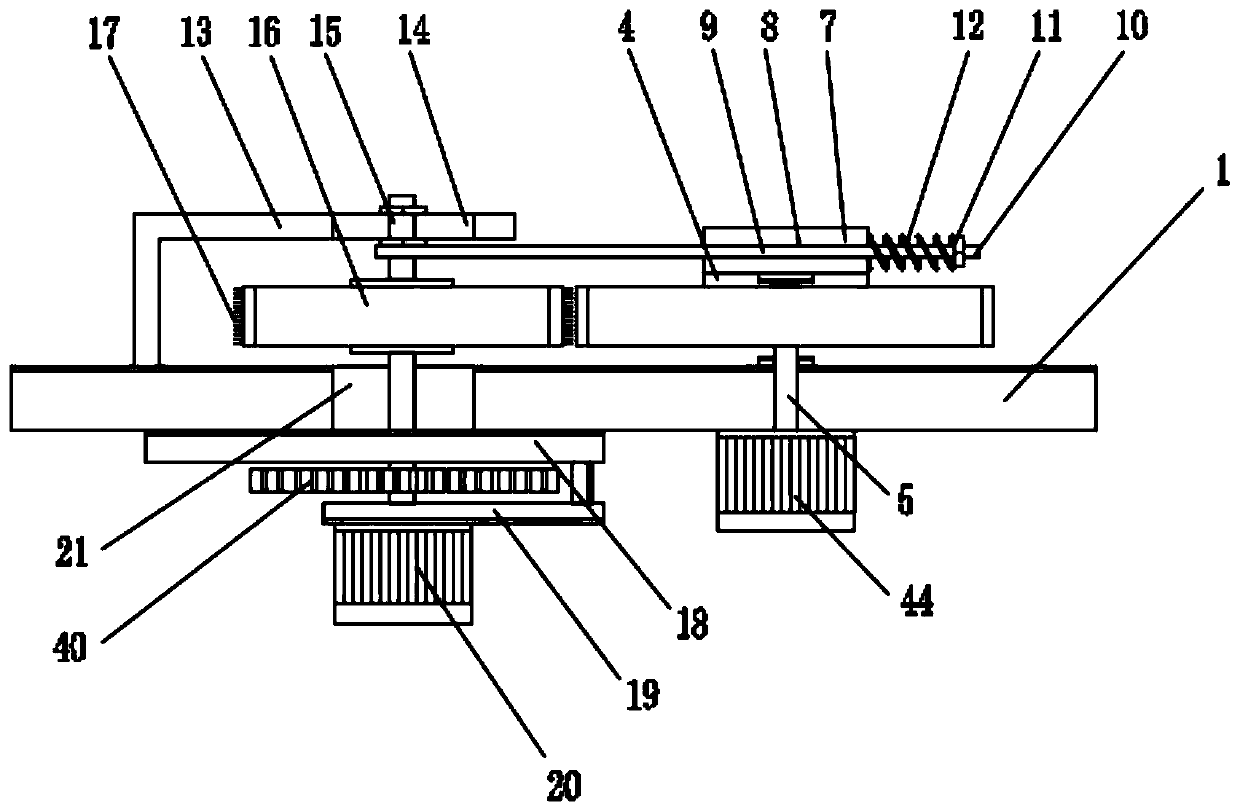

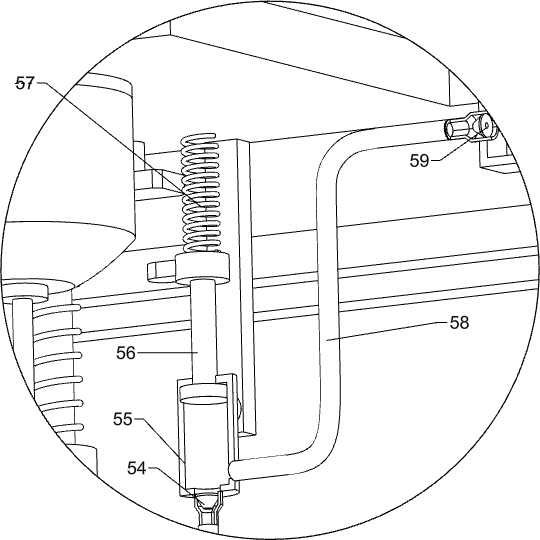

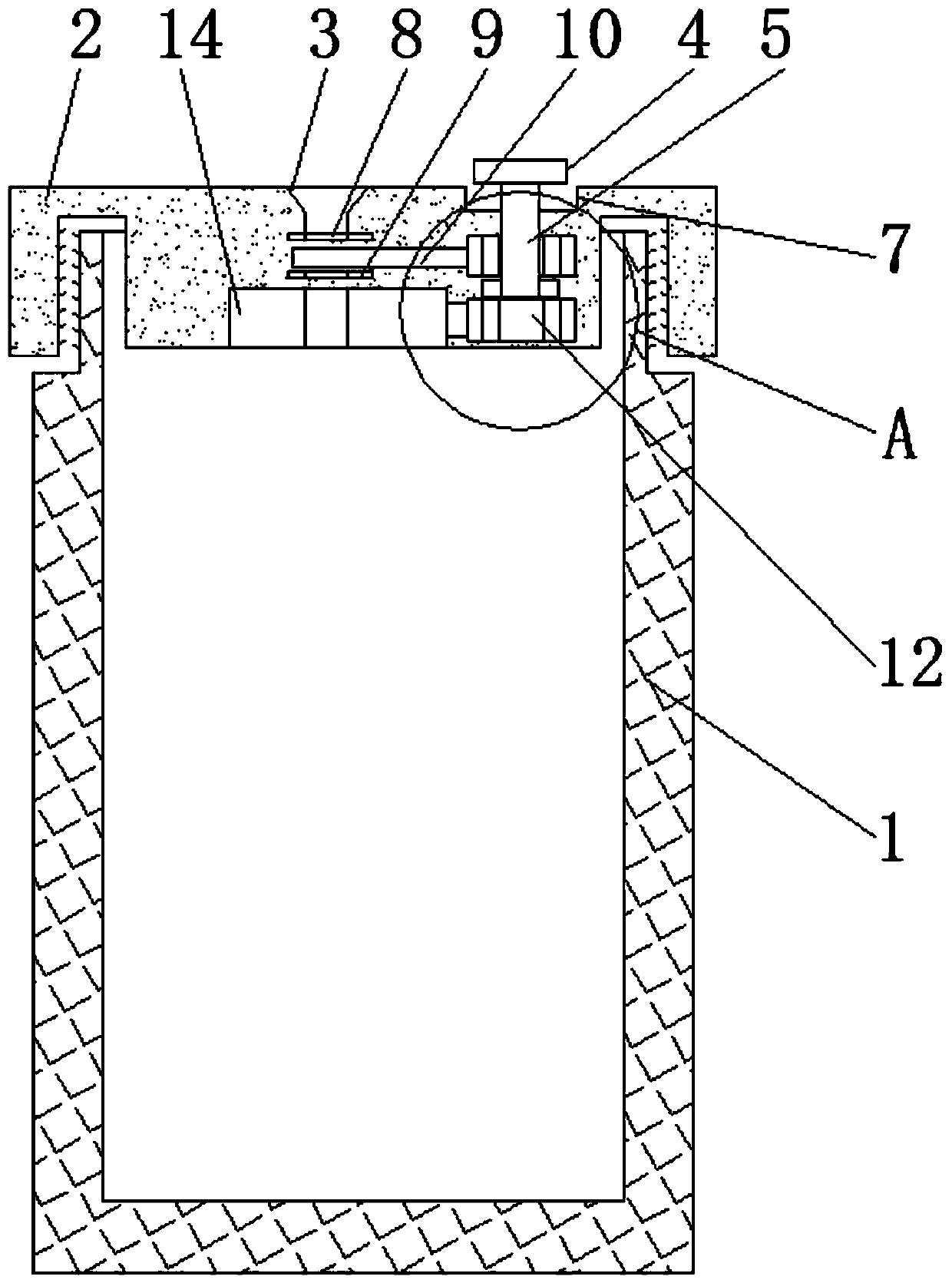

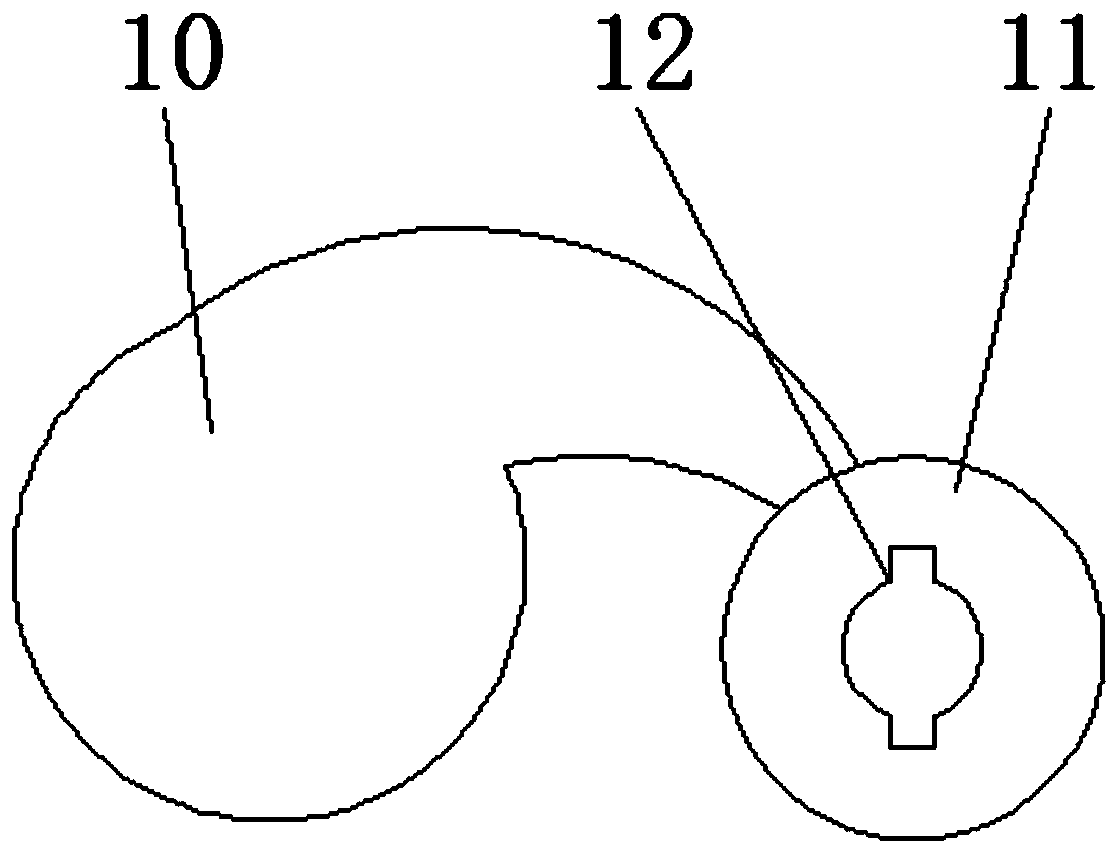

A kind of impregnation equipment for the manufacture of motor shells

ActiveCN109347281BEasy to moveEasy to dipManufacturing dynamo-electric machinesElectric machineGear wheel

The invention provides paint dipping equipment for manufacturing of motor shells. The equipment comprises a rotating member, a bottom rod, a bottom bin, a contact member, a falling rod, a guiding member, an inner rod, a baffle ring, a spring and an antiskid pad; a top plate is of a rectangular plate-shaped structure; an embedding block is arranged at the bottom of the top plate; an embedding member is mounted above an outer support spring in a support column; the side edge of a pulley is embedded in an insertion slot; a hand wheel is mounted at the top end of a rotating shaft through a weldingmanner; a limiting plate is mounted at the bottom of the top plate through a connector; a clamping tooth is arranged on the inner side of the limiting plate; and the clamping mouth is in contact witha gear. A support member plays a role in carrying out convenient switching when fixing or movement is required, so that when the equipment needs to move, a universal wheel at the bottom of a mountingpiece can be utilized, and when the equipment needs to be fixed, a breakoff rod is pulled to ensure that the mounting member and the universal wheel are retracted.

Owner:SUZHOU YUANLIAN SCI & TECH PIONEER PARK MANAGEMENT CO LTD

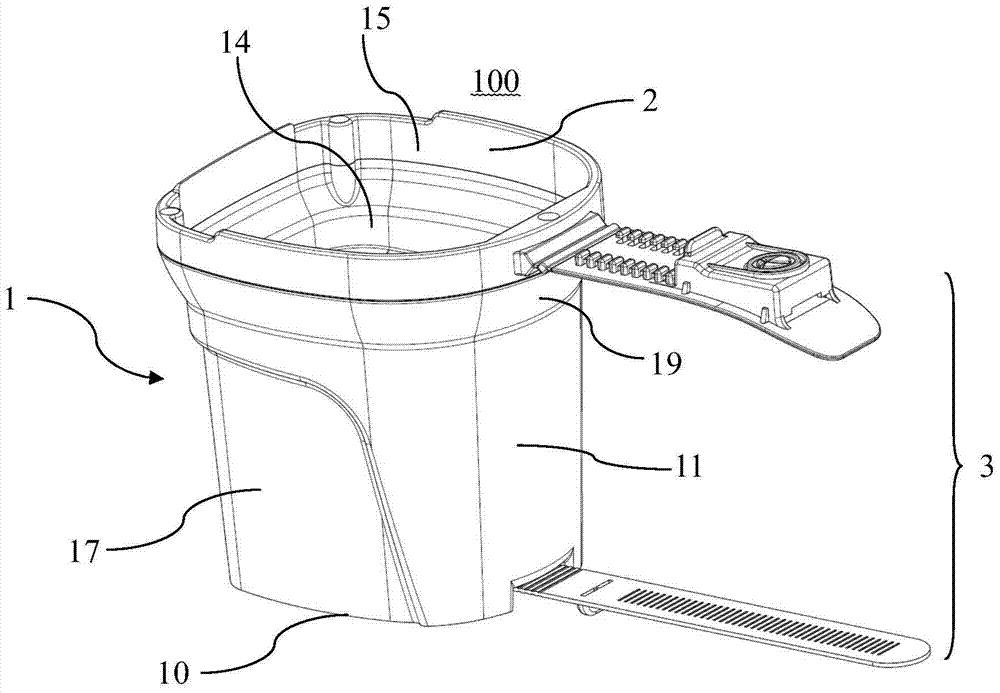

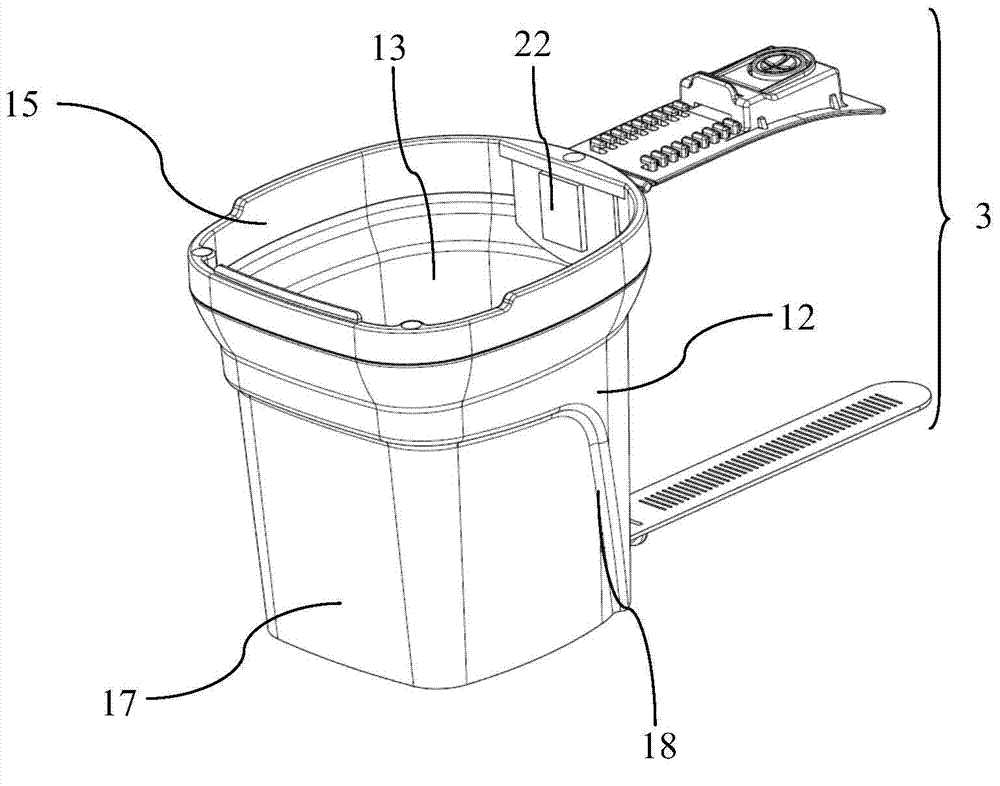

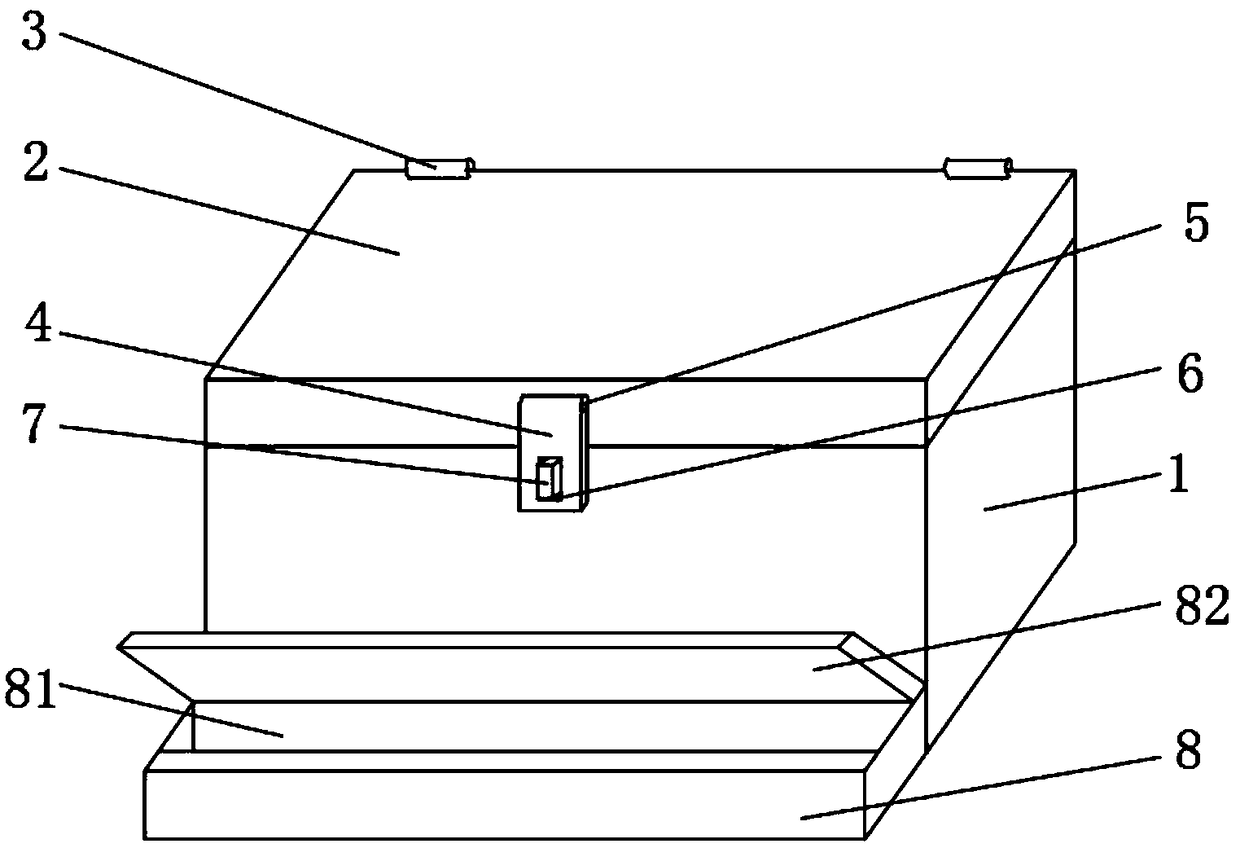

Novel cotton swab box

The invention discloses a novel cotton swab box. The novel cotton swab box comprises a box body; a box cover is movably installed on the outer surface of the upper end of the box body; hinges are movably installed between the rear end of the box cover and the box body; a buckle is movably installed in the middle of the outer surface of the front end of the box cover, a bolt is movably installed between the buckle and the box cover, and the outer surface of the front end of the buckle is provided with a clamping groove; a clamping block is fixedly installed in the middle of the upper end of theouter surface of the front end of the box body; a swab taking platform is fixedly installed at the lower end of the outer surface of the front end of the box body, and an alcohol bottle is movably installed on one side of the outer surface of the upper end of the swab taking platform; and cotton swabs are arranged in the box body, and the bottom end of the interior of the box body is provided with a slope. According to the novel cotton swab box, by arranging the series of structures, in the using process of the novel cotton swab box, a single cotton swab can be independently taken out from the cotton swab box, the situation that other cotton swabs are exposed and contaminated because of making contact with dust in air is avoided, the cotton swabs can be dipped into alcohol conveniently, and the using process is optimized.

Owner:宝应县富康医疗器械有限公司

Handle gluing device for manufacturing paper bag

The invention relates to a gluing device, in particular to a handle gluing device for manufacturing a paper bag, and aims to solve the technical problem of providing the handle gluing device which ishigher in handle gluing speed and more uniform in handle glue dipping. The handle gluing device comprises a working table, a servo motor, a gluing mechanism and the like; the servo motor is arranged on the rear right side of the upper part of the working table; and the gluing mechanism is arranged on the right side of the upper part of the working table. The handle gluing device realizes the effects that the handle gluing speed is higher and the handle dips the glue more uniformly; glue is poured in a storing barrel; a supplementing component enables a user to conveniently dip glue during thehandle gluing process; and as a second roller is close to an upper opening of a gluing box, the upper opening of the gluing box thins redundant glue on the second roller when glue on the second rolleris excessive during the handle gluing process.

Owner:湖北卓领包装有限公司

Dipping sauce box for meals

The invention discloses a dipping sauce box for meals. The dipping sauce box comprises a box body; the box body comprises a box main body and a box bottom, wherein the box main body is vertically arranged, and is provided with a plurality of wave-proof mechanisms; each wave-proof mechanism comprises a wave collecting cylinder body, a wave collecting piston, a lower piston rod, a transverse sliding hole, an internal wave-proof plate, a secondary wave collecting groove and a wave-proof air bag; in one wave-proof mechanism, the interior of the wave collecting cylinder body is divided into an air adjusting cavity and an air transmission cavity by the wave collecting piston, the wave collecting cylinder body is provided with a first conduction hole communicated with the air transmission cavity, an air inflation cavity is internally provided with an air return spring, the air return spring is connected with the wave collecting piston and the wave collecting cylinder body, the lower piston rod is connected with the wave collecting piston and the internal wave-proof plate, the wave collecting cylinder body is provided with a rigid air pipe fixed with the box main body, and the air adjusting cavity is communicated with the wave-proof air bag. The dipping sauce box has the beneficial effects that the dipping sauce box is reasonable in structure, can be used for storing liquid dipping sauce, and is convenient for a diner to dip food into sauce; furthermore, the dipping sauce box has a shake-out prevention function so as to prevent the liquid dipping sauce from being shaken out of the box due to shaking or rapidly moving the box body, and is good in overall stability.

Owner:胡劼

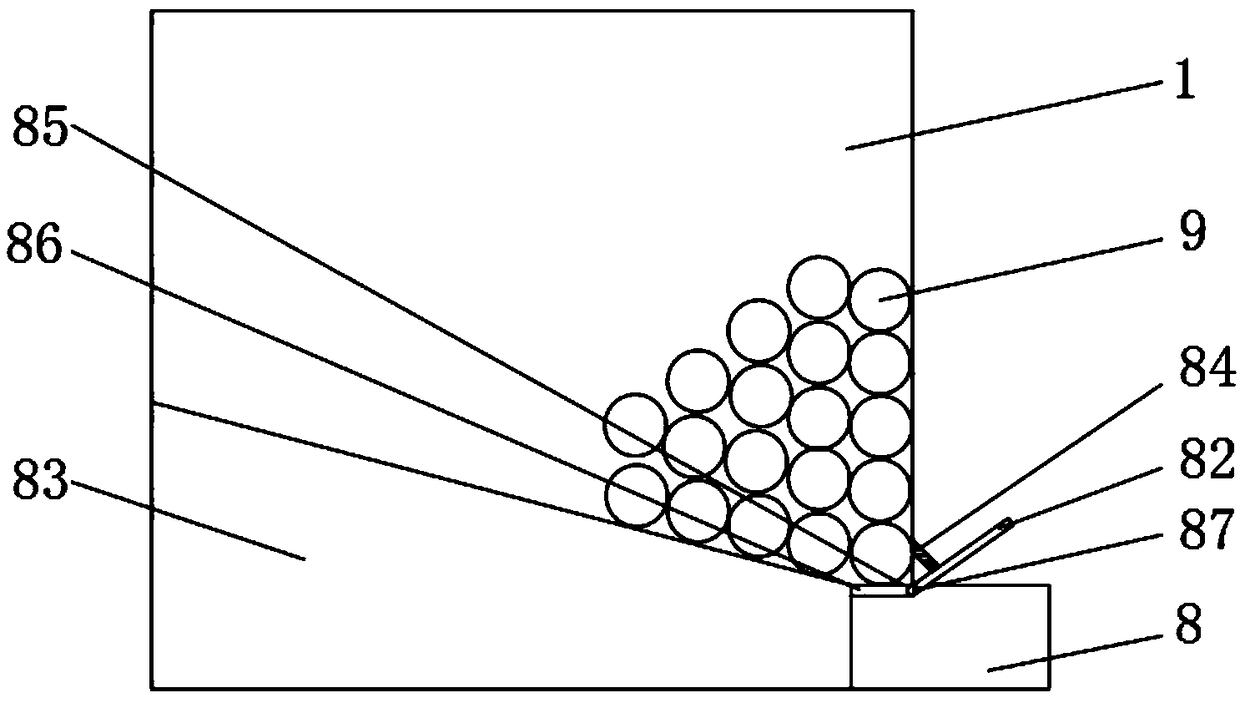

Absorbent ball alcohol dipping device facilitating alcohol amount control

PendingCN109985306AEasy to dipEasy and controlled dippingMedical applicatorsAqueous alcoholEngineering

The invention discloses an absorbent ball alcohol dipping device facilitating alcohol amount control. The absorbent ball alcohol dipping device comprises a bottle body, a handle and clamping grooves;a bottle cap is arranged on the upper side of the bottle body, an upper sealing ring is arranged at the bottom of a guide hole, the handle is arranged in a storage groove, a transmission rod is connected to the bottom of the handle, a protruding block is arranged at the bottom of the transmission rod, the clamping grooves are formed in a first movable disc and a second movable disc respectively, amovable plate is connected to the outer side of the first movable disc and arranged between the upper sealing ring and a lower sealing ring, a fixed sheet is arranged on the front side of the bottomof the lower sealing ring, and the top of the right side of a movable sheet is fixedly connected with the second movable disc. By means of the absorbent ball alcohol dipping device facilitating alcohol amount control, an absorbent ball can be guided to dip alcohol, the alcohol dipping amount of the absorbent ball can be controlled, and alcohol can be saved; besides, alcohol can be sealed, and thusthe alcohol can be used for a long time.

Owner:河南省蓝天医疗器械有限公司

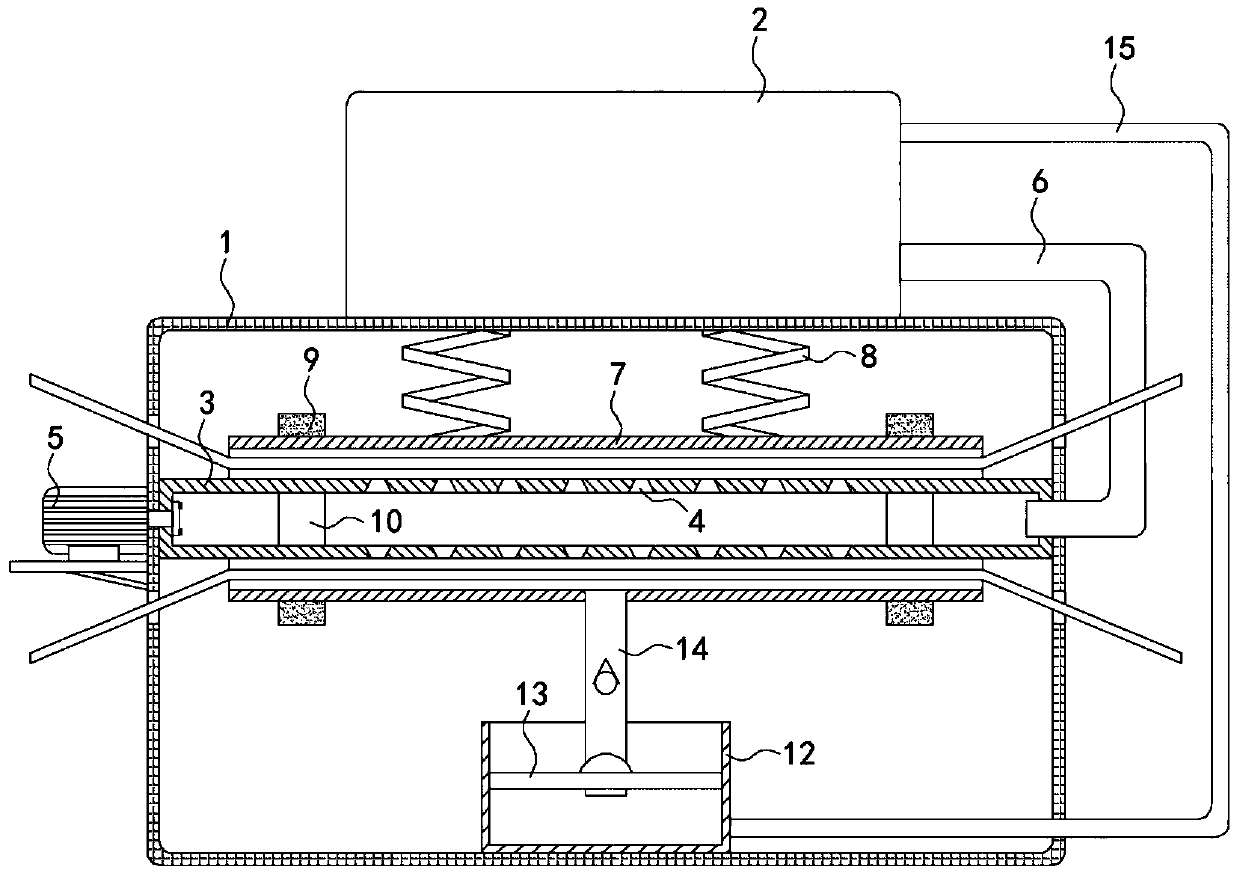

Bamboo ware gum-dipping and drying integrated mechanism

InactiveCN109500975AEasy to dipKeep dryDomestic articlesLignocellulosic moulding material treatmentHydraulic cylinderFixed frame

The invention discloses a bamboo ware gum-dipping and drying integrated mechanism, aiming at solving the problems that current gum-dipping and drying are performed separately, two pieces of equipmentare needed for operation, operation is troublesome, and resources are wasted. The mechanism comprises a motor, a rotary shaft, through grooves, a hydraulic cylinder, a connecting plate, a supporting plate, telescopic air bags, feed inlets, second lantern rings, spiral springs, a guide rod, first lantern rings, first clamping plates, first anti-skid layers, a heating plate, second anti-skid layers,second clamping plates, a connecting column, a fixing frame, a power supply, a containing barrel, fixing blocks, a door and fastening screws. The containing barrel is arranged on the left side of themotor, and the door is arranged on the surface of the containing barrel. The bamboo ware gum-dipping and drying integrated mechanism has the advantages that through cooperation of the heating plate and the telescopic air bags, gum-dipping and heating drying can be operated on the same equipment, the machining cost is lowered, the gum amount can be controlled through the telescopic air bags, bamboo ware of different sizes can be gummed, accordingly, gum resources are saved, in addition, operation is convenient, and the mechanism deserves to be popularized.

Owner:贾海亮

Formaldehyde-free impregnated film adhesive and preparation method thereof

PendingCN112921707APromote environmental protectionImprove fullnessSpecial paperPaper/cardboardWeather resistancePolymer chemistry

The invention relates to the technical field of film adhesives, in particular to formaldehyde-free impregnated film adhesive and a preparation method thereof. A base material of the film adhesive is soaked in a formaldehyde-free dipping glue solution, and then the dipped base material is taken out and dried so as to obtain the film adhesive. The formaldehyde-free dipping glue solution is prepared from the following raw materials in parts by weight: 30-60 parts of water-based PUA resin, 8-15 parts of an emulsifier, 5-10 parts of a dispersing agent, 5-10 parts of a penetrating agent special for wood, 3-8 parts of a wetting agent and 50-100 parts of water. According to the invention, the base material can be directly dipped in the formaldehyde-free dipping glue solution, the formaldehyde-free dipping glue solution fully permeates the base material, and the prepared film adhesive really does not contain formaldehyde and has good environmental protection property. In addition, due to full dipping of the dipping glue solution, the prepared film adhesive has excellent fullness, luster, hardness, solvent resistance and weather resistance, does not change color or turn yellow during high-temperature baking, and is high in product quality.

Owner:东莞市贝辉装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com