Handle gluing device for manufacturing paper bag

A technology of gluing device and paper bag, which is used in bag making, packaging, paper making, etc., can solve the problems of uneven glue dipping and slow sticking speed by the handle, and achieve the effect of dipping glue evenly and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

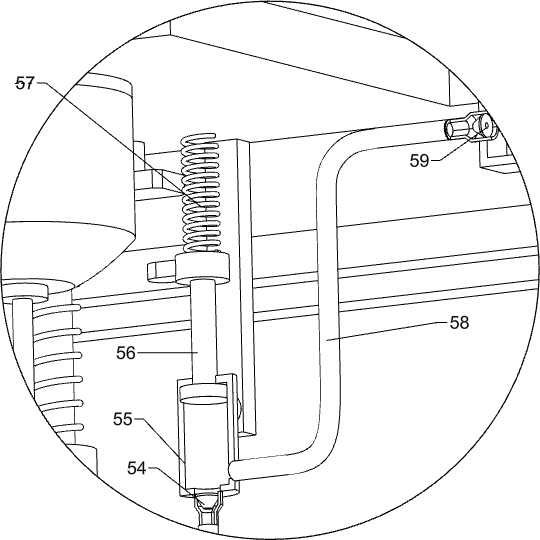

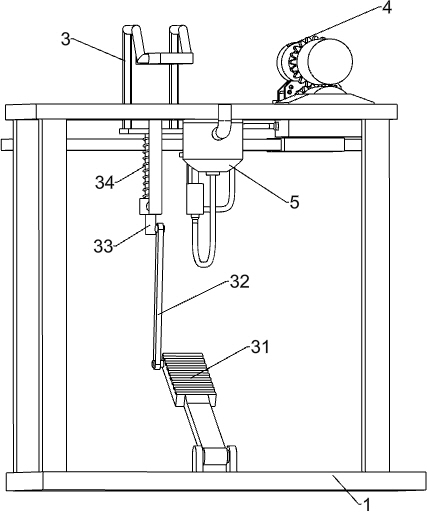

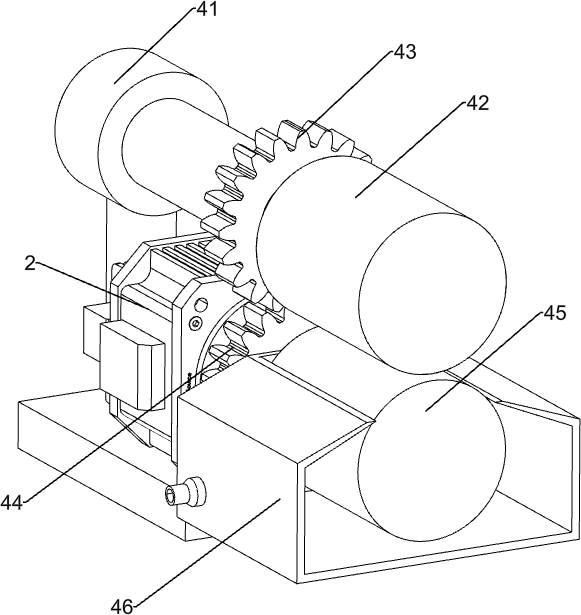

[0020] A handle gluing device for making paper bags, such as Figure 1-5 As shown, it includes a workbench 1, a servo motor 2, a clamping mechanism 3 and a gluing mechanism 4. The servo motor 2 is arranged on the upper right side of the workbench 1, and the gluing mechanism 4 is arranged on the upper right side of the workbench 1. The gluing mechanism 4 is located on the front side of the servo motor 2, the gluing mechanism 4 is connected with the servo motor 2, and the upper part of the workbench 1 is provided with a clamping mechanism 3, which is used to clamp the paper bag with the handle attached, and the clamping mechanism 3 is located on the left side of the gluing mechanism 4.

[0021] When making handles for paper bags, it is necessary to apply glue to the handles and the pieces of paper connected to them. This equipment can be used. First, turn on the servo motor 2, and apply glue to the handles that need to be pasted through the gluing mechanism 4. , paste the glued...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com