Patents

Literature

499 results about "Paper sack" patented technology

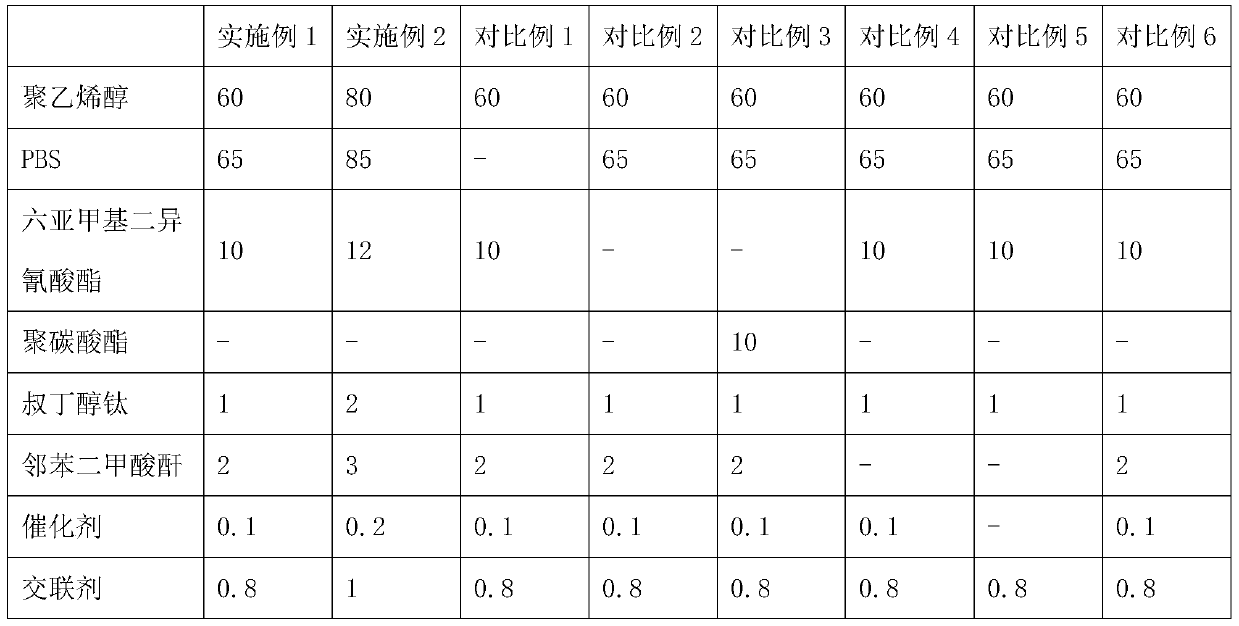

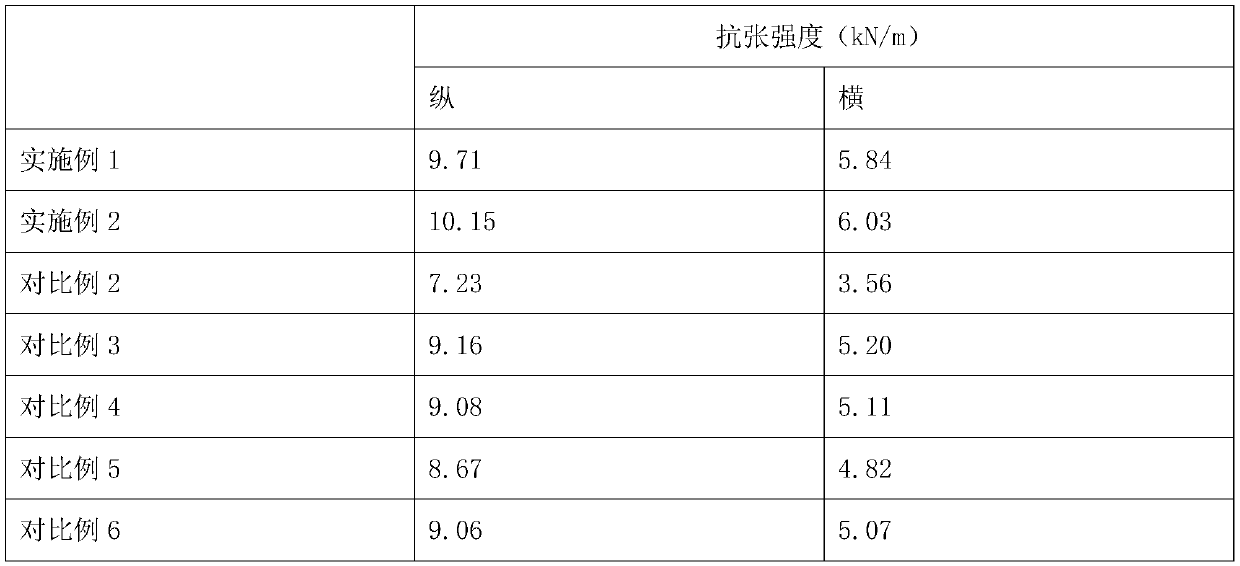

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A paper sack is shipping container made of high quality and weight paper, usually kraft virgin fiber, which is normally used for transporting powder materials, such as flour, cement, animal feed, etc. Multi-wall paper bags usually have several layers of heavy duty kraft paper, sometimes with a highly printed paper on the outside. Plastic films and coated papers are sometimes used as inner layers to provide a moisture barrier, and resistance to rodents and insects.

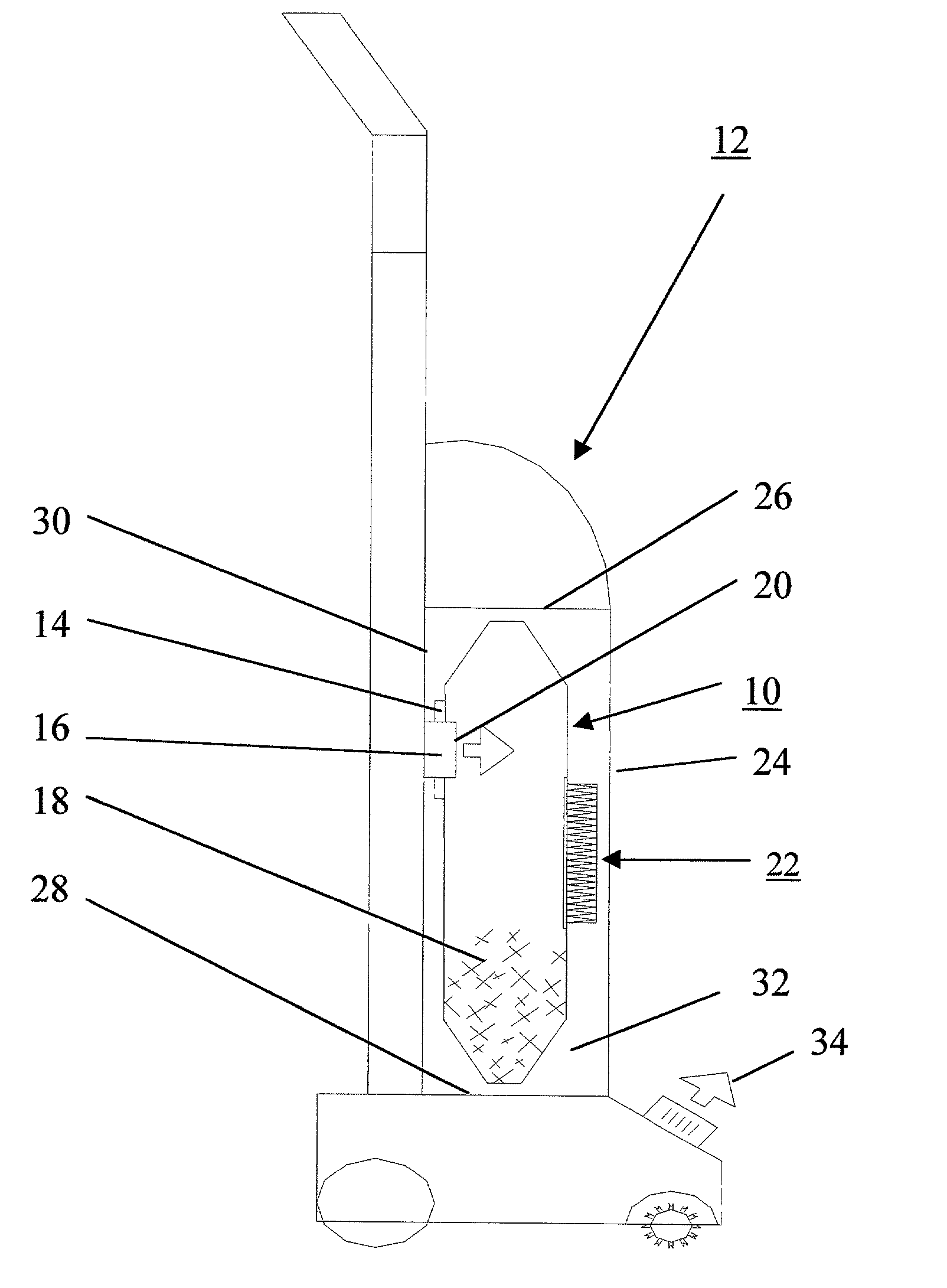

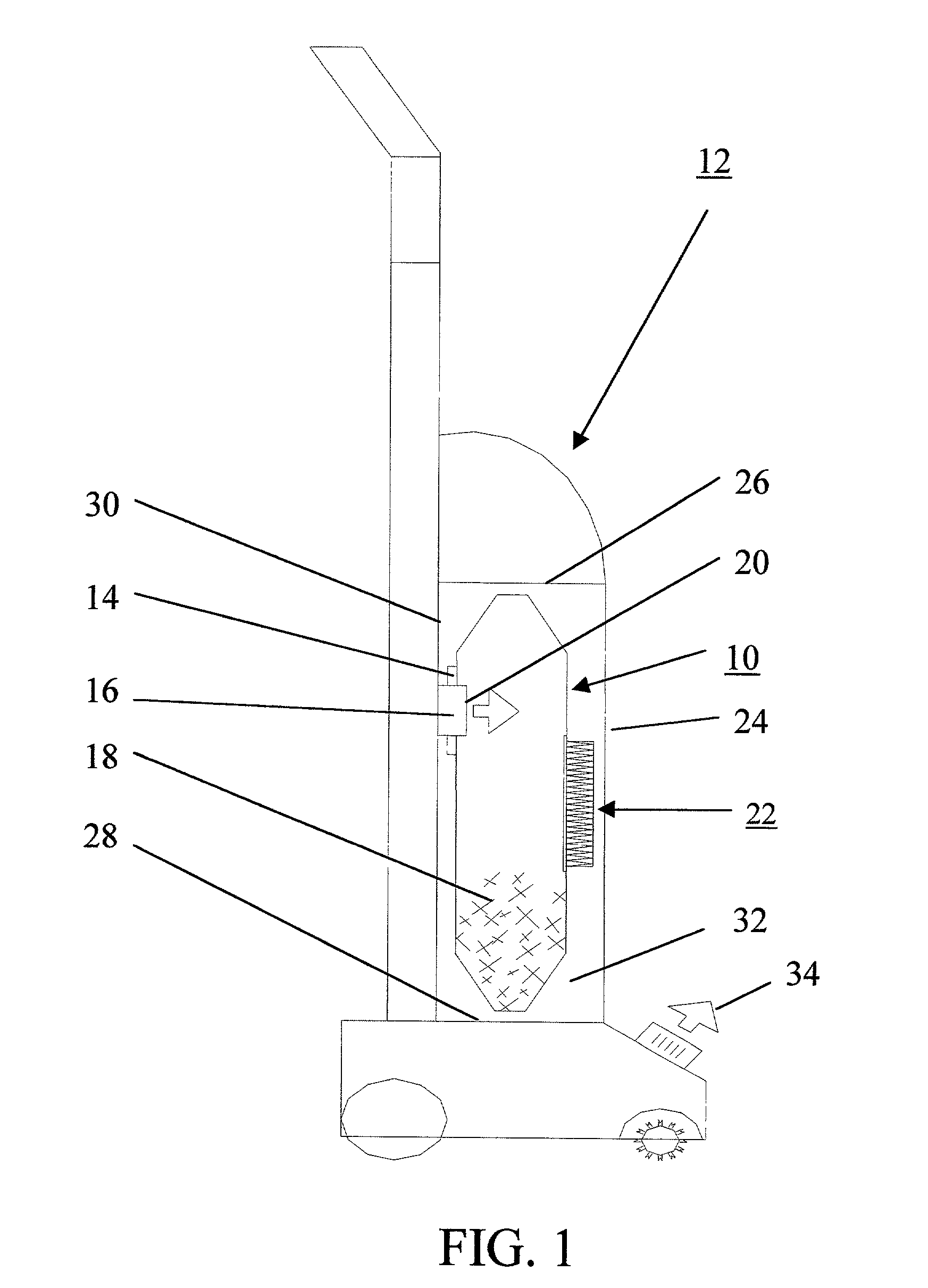

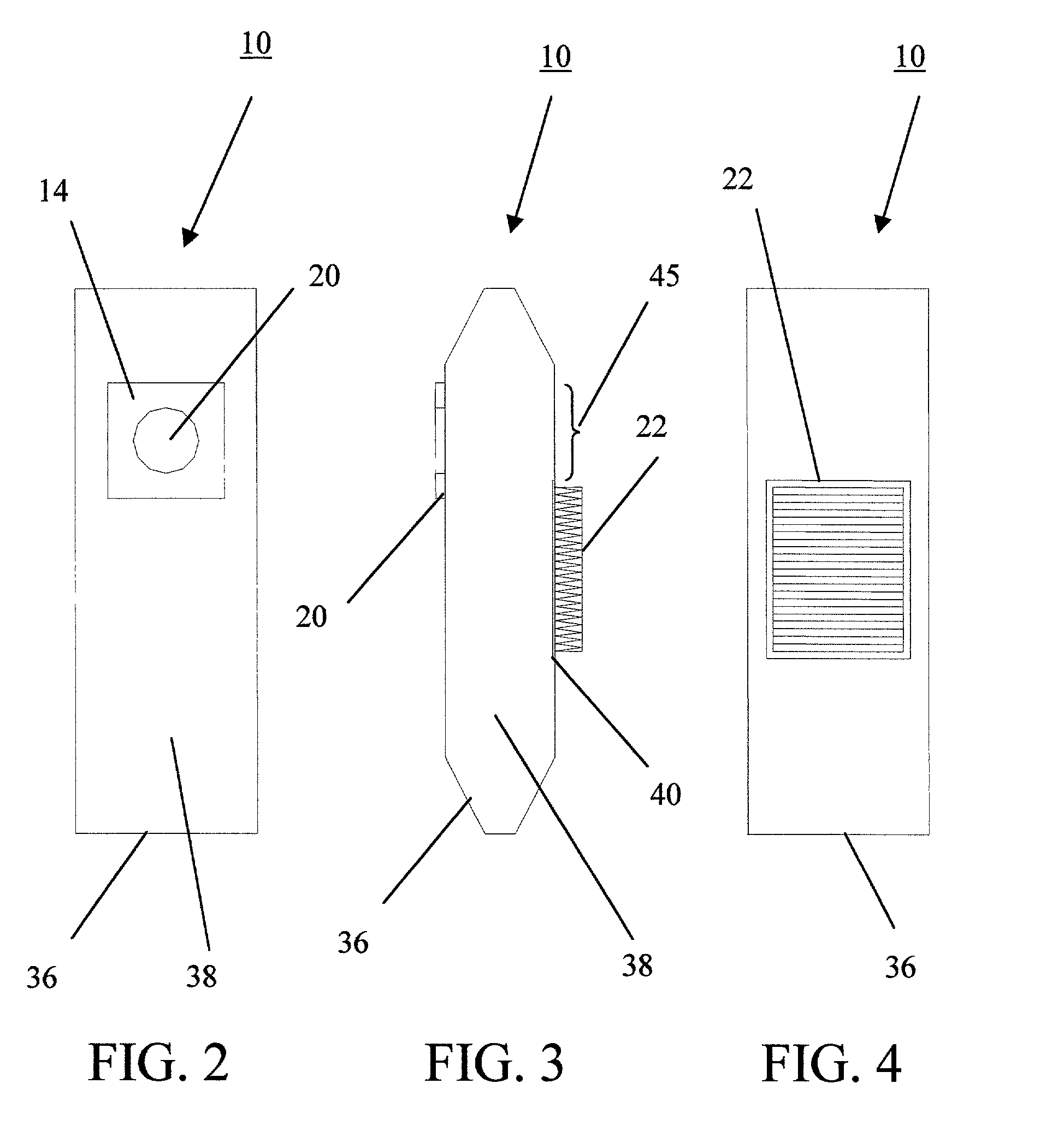

Vacuum collection bag and method of operation

InactiveUS20020166449A1Low costEasy to cleanCombination devicesEnvelopes/bags making machineryFiltrationPulp and paper industry

The present invention is an improved vacuum collection bag for vacuum cleaners and other appliances. By employing an impermeable bag and an air-permeable particle separator together with a tight seal against a vacuum system dirt tube in place of a conventional paper bag filter, it has been determined that the vacuum cleaner bag can be reused and significantly improve the filtration performance of the vacuum system.

Owner:WL GORE & ASSOC INC

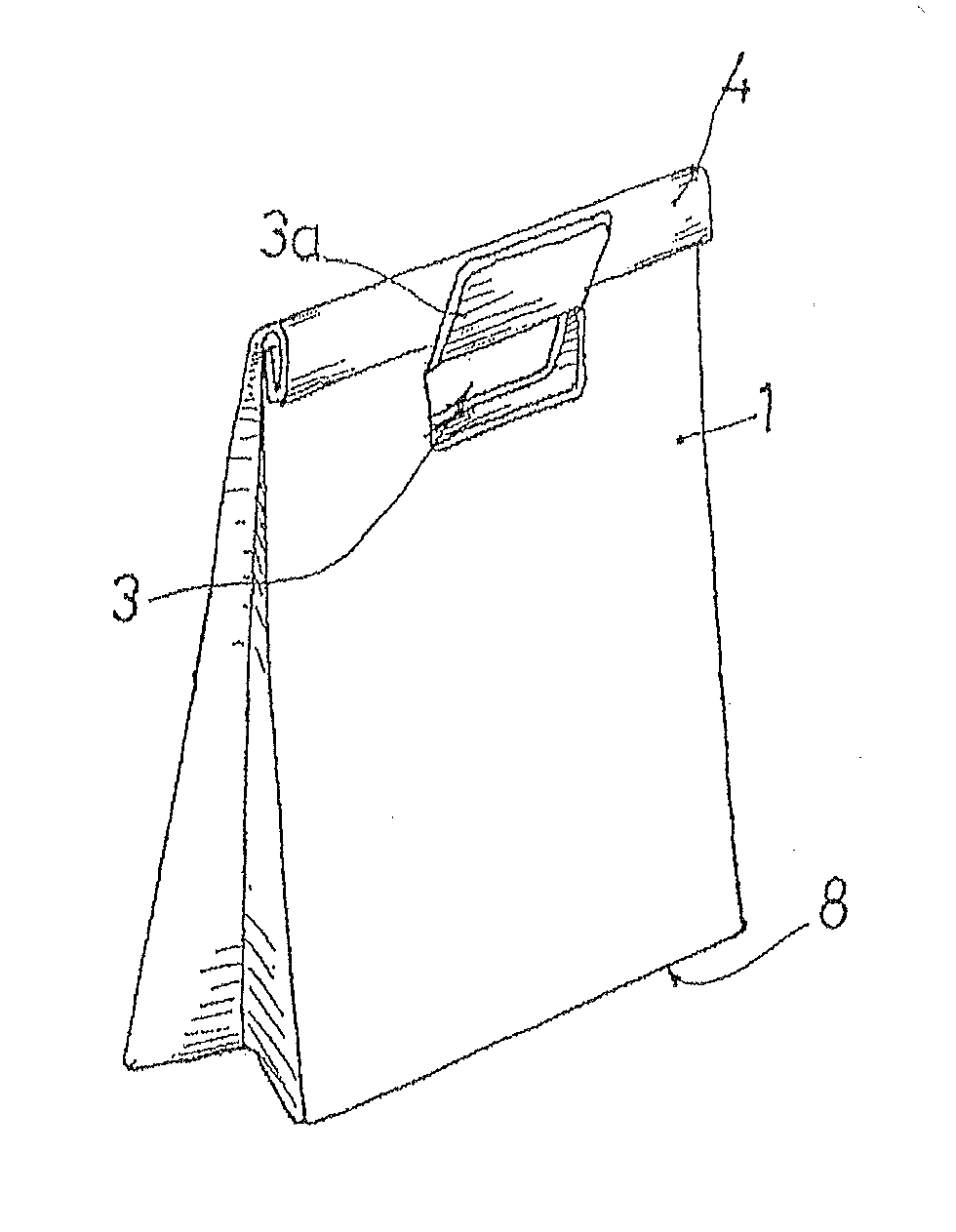

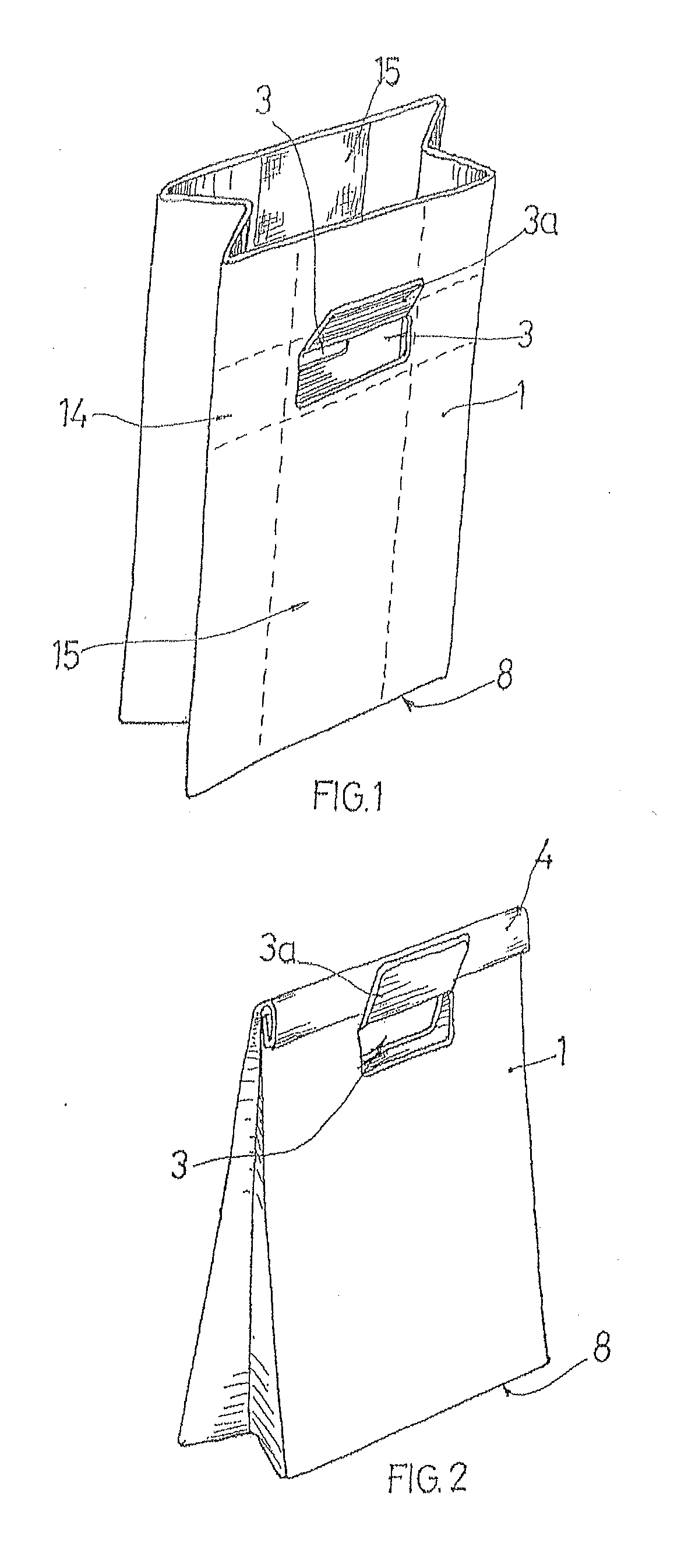

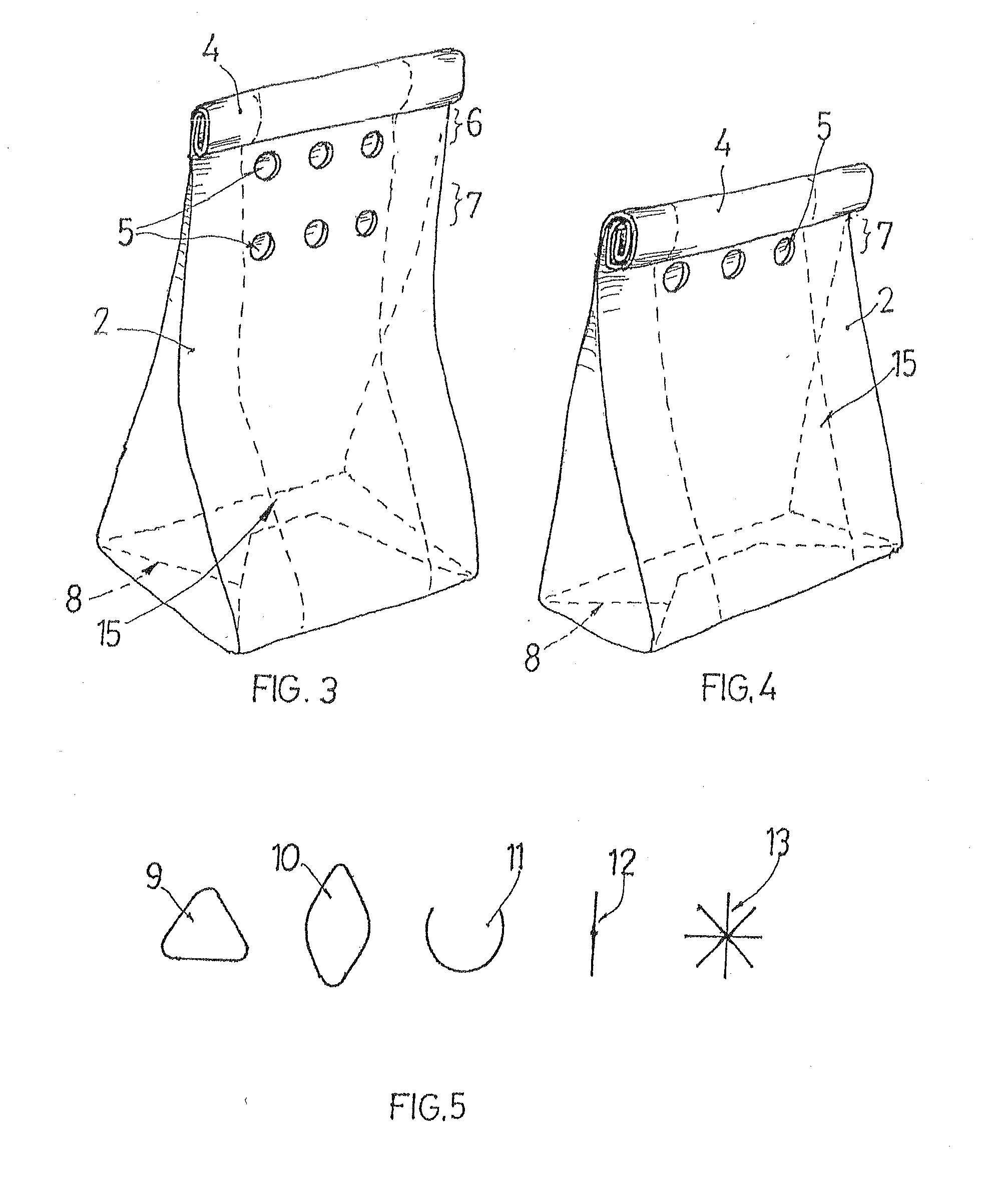

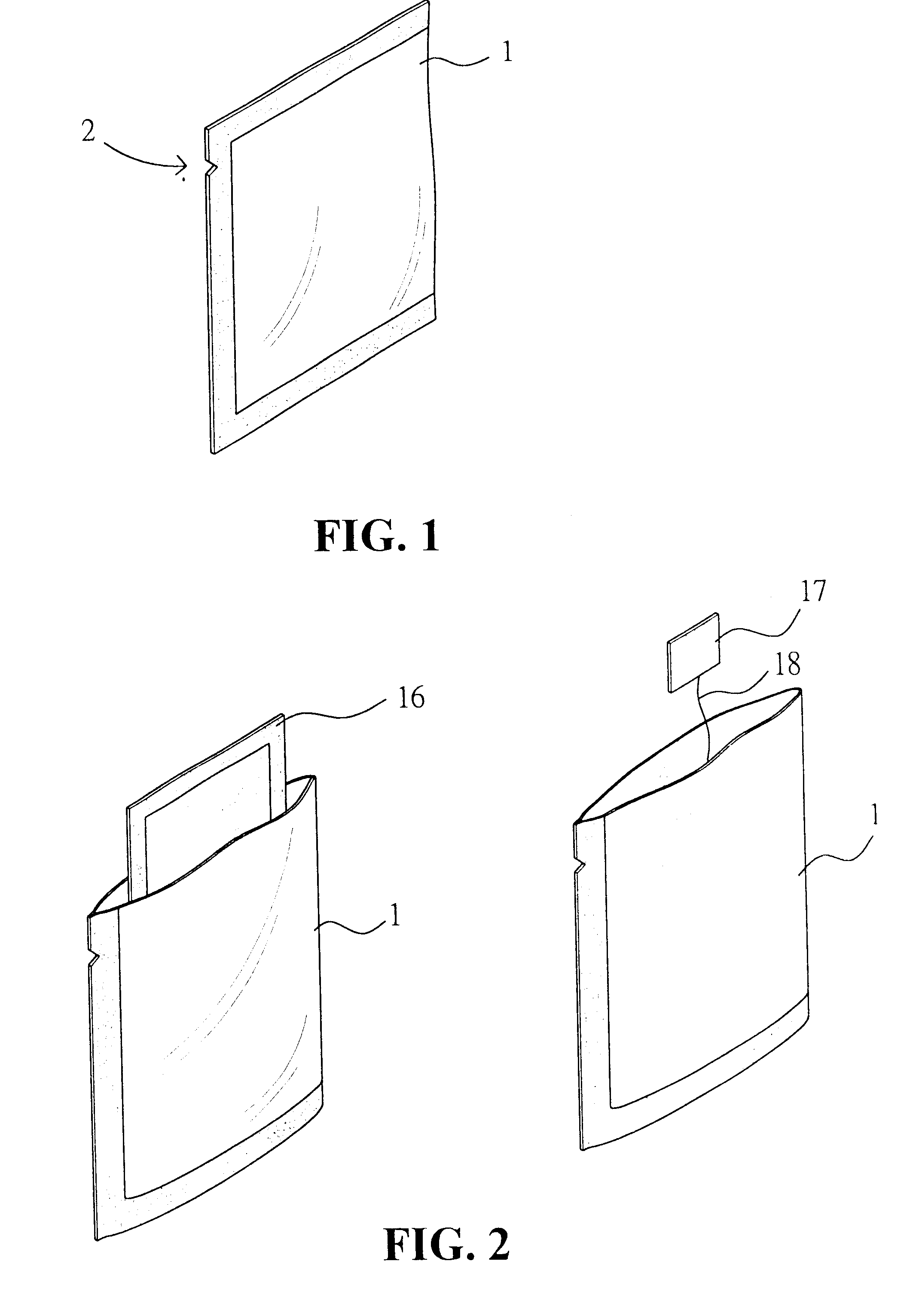

Paper bag with integrated handle

On the top part of the pleated-style bag (1) or “American”-style bag (2), without pleat, and near its open edge, it has some die cut drill holes with a rectangular (3) or circular (5) shape, located at a sufficient distance from the top edge to allow performing some folds (4) to close the bag (1) or (2), being said die cut drill holes (3) or (5) located just below said folds (4), defining the height, from the folds (4) to the base (8) of the bag, for its usable capacity. In the “American”-style bag (2) there is a second area (7) of die cut drill holes, which allows performing more folds (4) when closing the bag (2). It optionally has two reinforcements made of paper, fabric or cotton mesh, attached to the inner sides and in the area of the die cut drill holes, which can have a rectangular shape (3) with its flap (3a), and a circular (5), triangular (9), ovoid (10), semi-circular (11) slanted (12) or multi-slanted (13) shape.

Owner:TEIXIDO VIDAL JOSEP +1

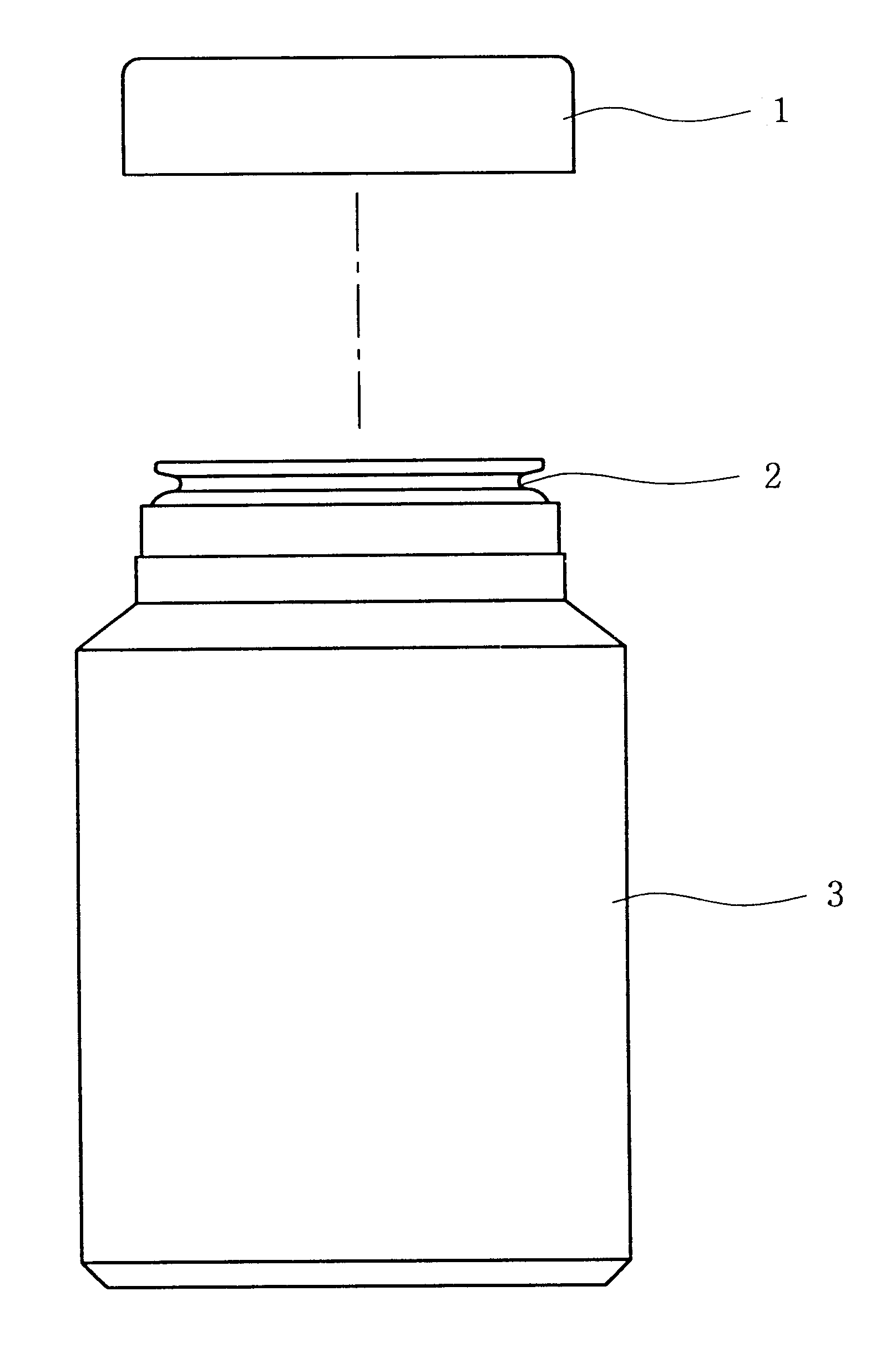

Beauty-maintaining tea and preparation process thereof

The invention discloses a beauty-maintaining tea and a preparation process thereof. The beauty-maintaining tea is processed by rose, salvia miltiorrhiza, fructus Lycii, semen cassiae, hawthorn, licorice and jujube. The product is prepared by the following steps of: respectively drying, crushing and screening cleaned and selected raw materials; weighing and preparing the processed raw materials in proportion; uniformly mixing, sterilizing and disinfecting the raw materials; filling the raw materials in a paper bag; filling the paper bag in a tank; and packaging the tank. The beauty-maintaining tea has the effects of removing food retention, removing blood stasis, relaxing the bowels, nourishing blood vessels, clearing heat and reducing fat, and also has the function of soothing liver and eliminating stasis in case of regular taking.

Owner:SUZHOU TIANLING CHINESE TRADITIONAL MEDICINE SLICE

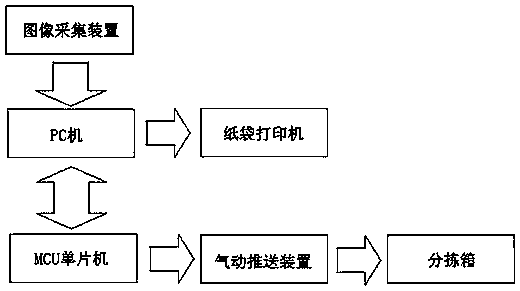

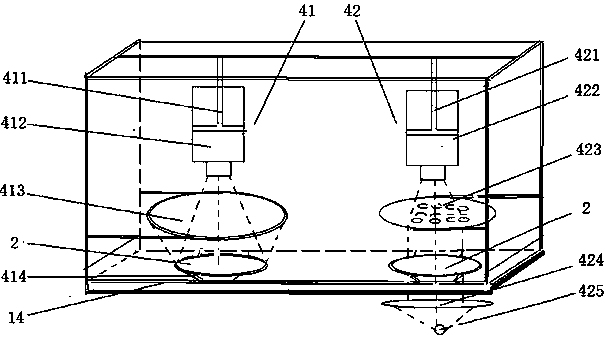

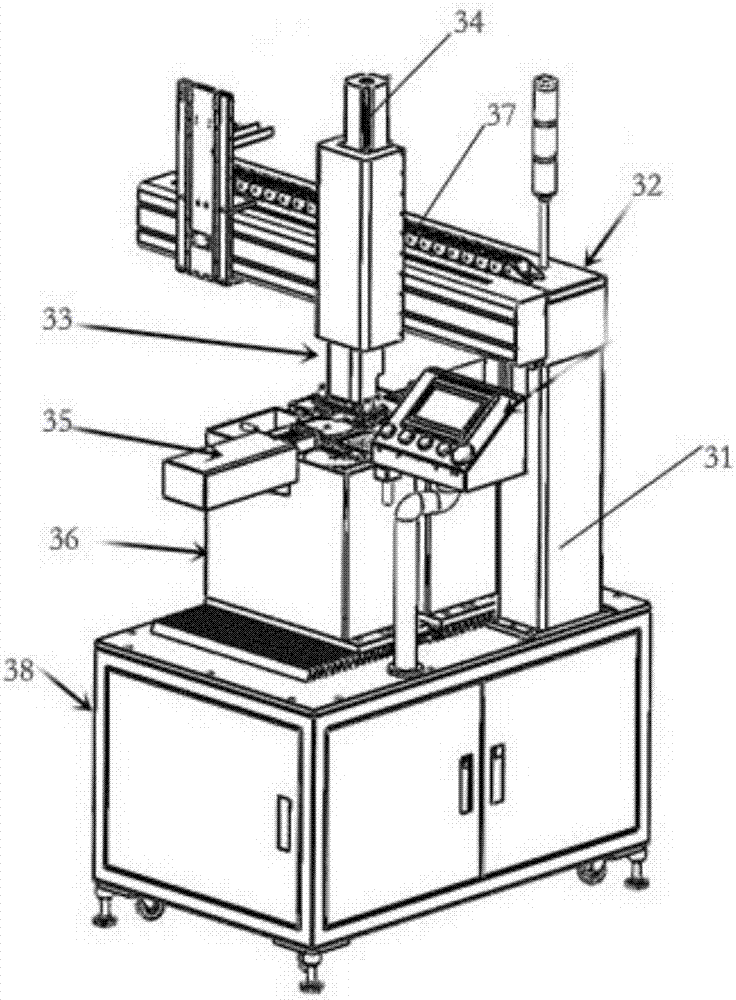

Automatic sorting device with lens detection function

ActiveCN104198157AEliminate manual inspectionImprove work efficiencySortingOptical apparatus testingComputer hardwareMachine vision

The invention discloses an automatic sorting device with a lens detection function. The device comprises an image acquisition device, a detecting platform, a feed conveying belt, a discharge conveying belt, a motor, pneumatic pushing devices, a control device and sorting boxes, and the image acquisition device is used for classifying lenses and measuring focal power of the lenses. Lens classification and focal power measurement are performed through the image acquisition device by adopting automated pipeline operation and utilizing machine vision analysis, so that artificial detection is omitted, working efficiency is improved, and meanwhile human health is protected; due to the arranged pneumatic pushing devices, the lenses detected by the image acquisition device can be pushed into the different sorting boxes to realize automatic sorting; meanwhile, a paper bag printer is arranged to print related information of each lens on a paper bag, and then the lenses are subpackaged by class; by the aid of machine vision analysis, accuracy in detection is improved greatly, product quality is guaranteed effectively, and consistent standards are reached in the industry.

Owner:未来光电科技(江苏)有限公司

Okra tea bag and production process of okra tea bag

The invention relates to an okra tea bag, the main raw material of which is selected from one of a fresh okra pod and a young okra fruit. The preparation of the okra tea bag comprises the following steps of: A. preparing a raw material: cleaning and drying an okra pod which is 10-20cm in length; B. cutting into pieces: cutting the okra pod into pieces; C. drying: drying the laminar okra in a drier; D. crushing: crushing the okra pieces via a hammer crusher; E. screening: re-crushing the okra pod which cannot be screened via a 40-mesh sieve; and F. packaging by weight: packaging the okra powder into tea bags which are 3-5g in weight via cotton paper bags. The okra tea bag disclosed by the invention has the advantages as follows: the fresh okra pod or the young okra fruit is dried and crushed into powder and then packaged via the cotton paper bags, so that the product is convenient to carry; when being drunk, the cotton paper bag is put into a tea cup, then boiling water is poured into the tea cup, and then the mixture can be drunk after a period of time; tea leaves can be simply treated only by taking out the cotton paper bag; and the tea-making rate of the fresh okra pod or the young okra fruit can achieve a maximum value.

Owner:XIHUA UNIV

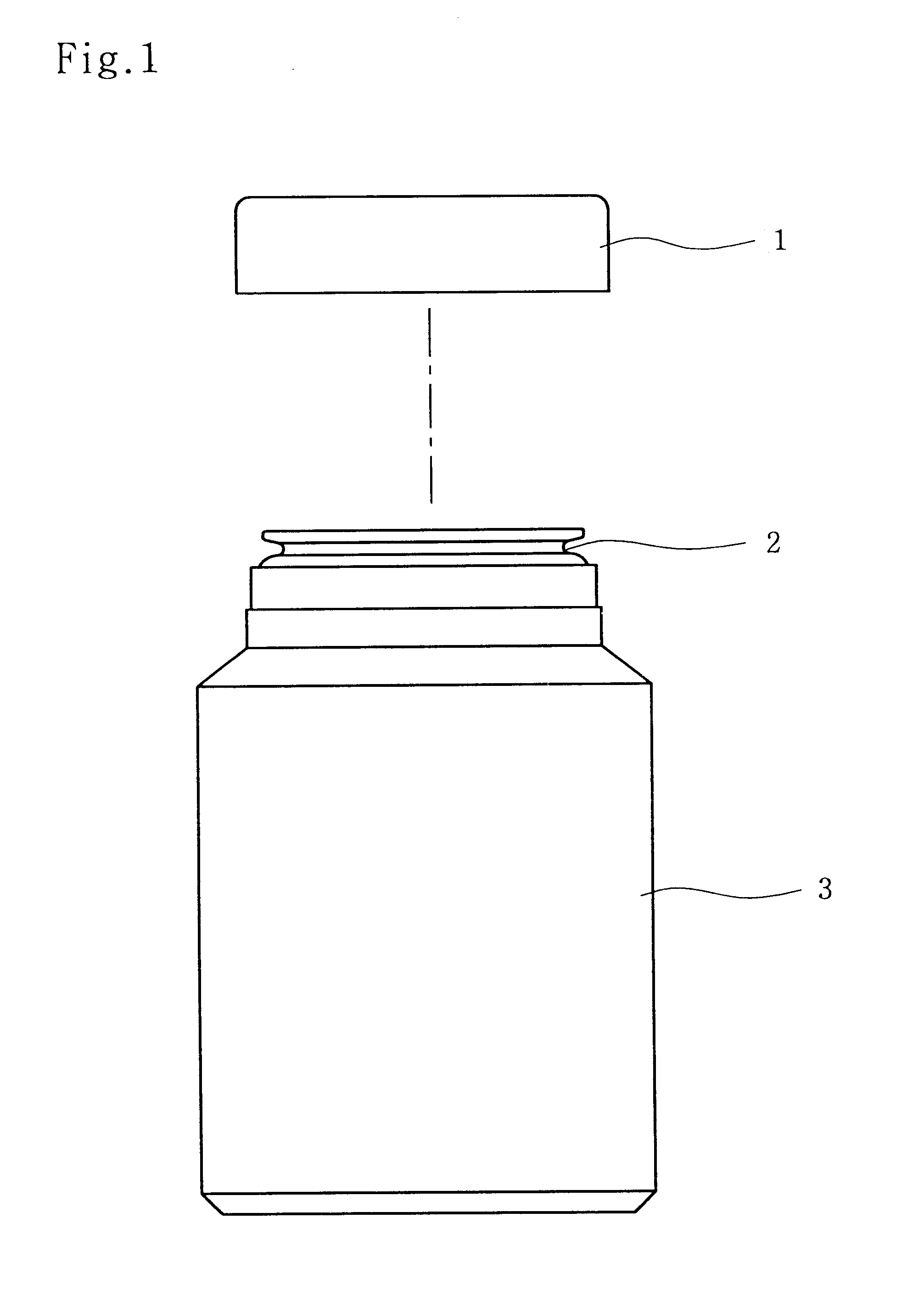

Paper bag

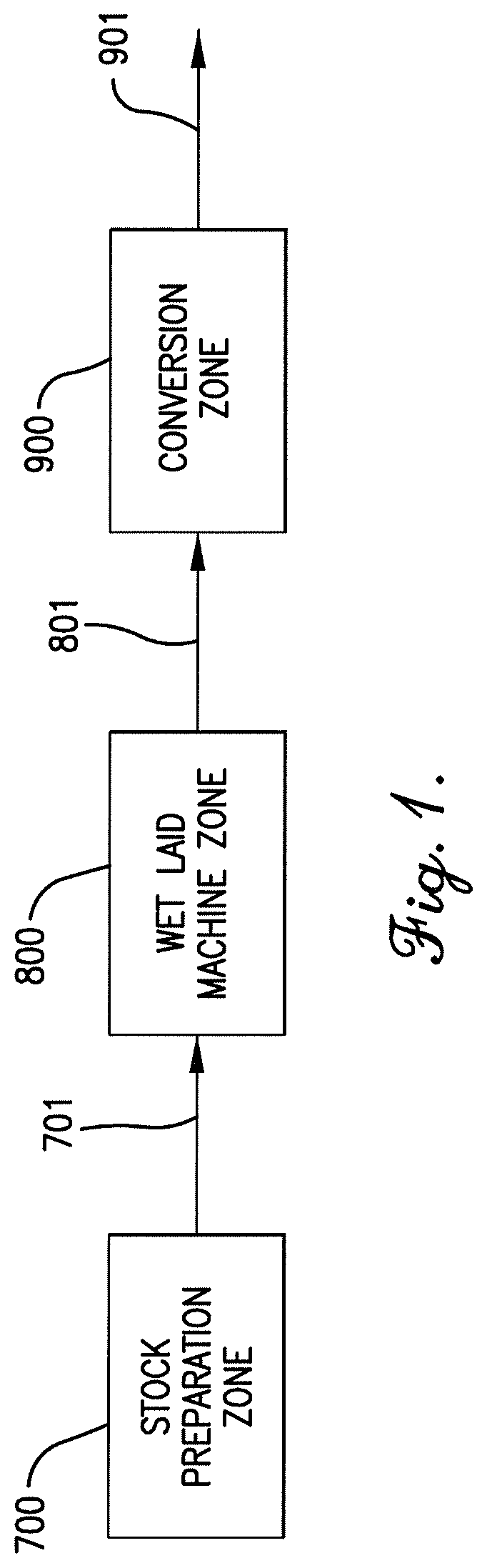

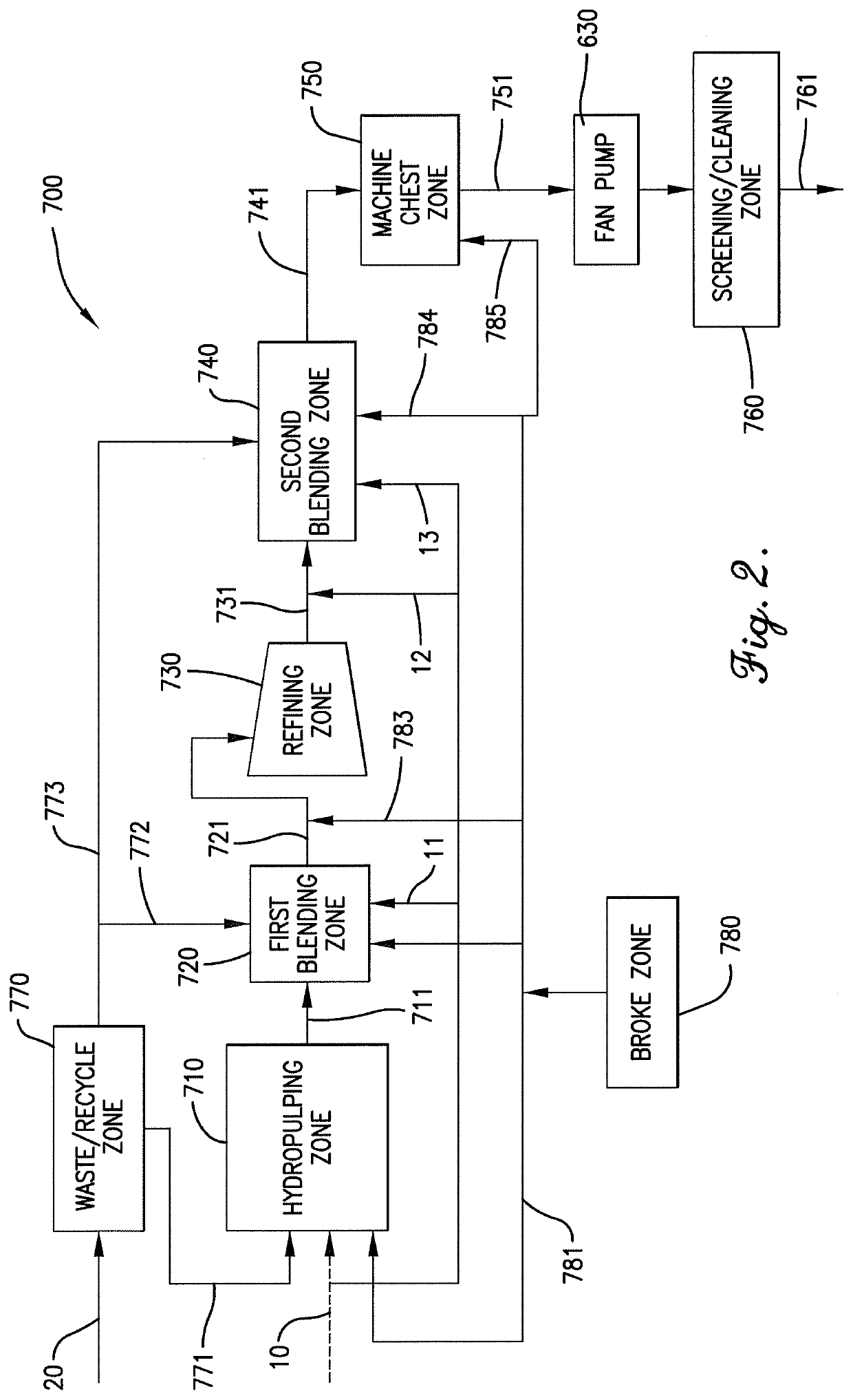

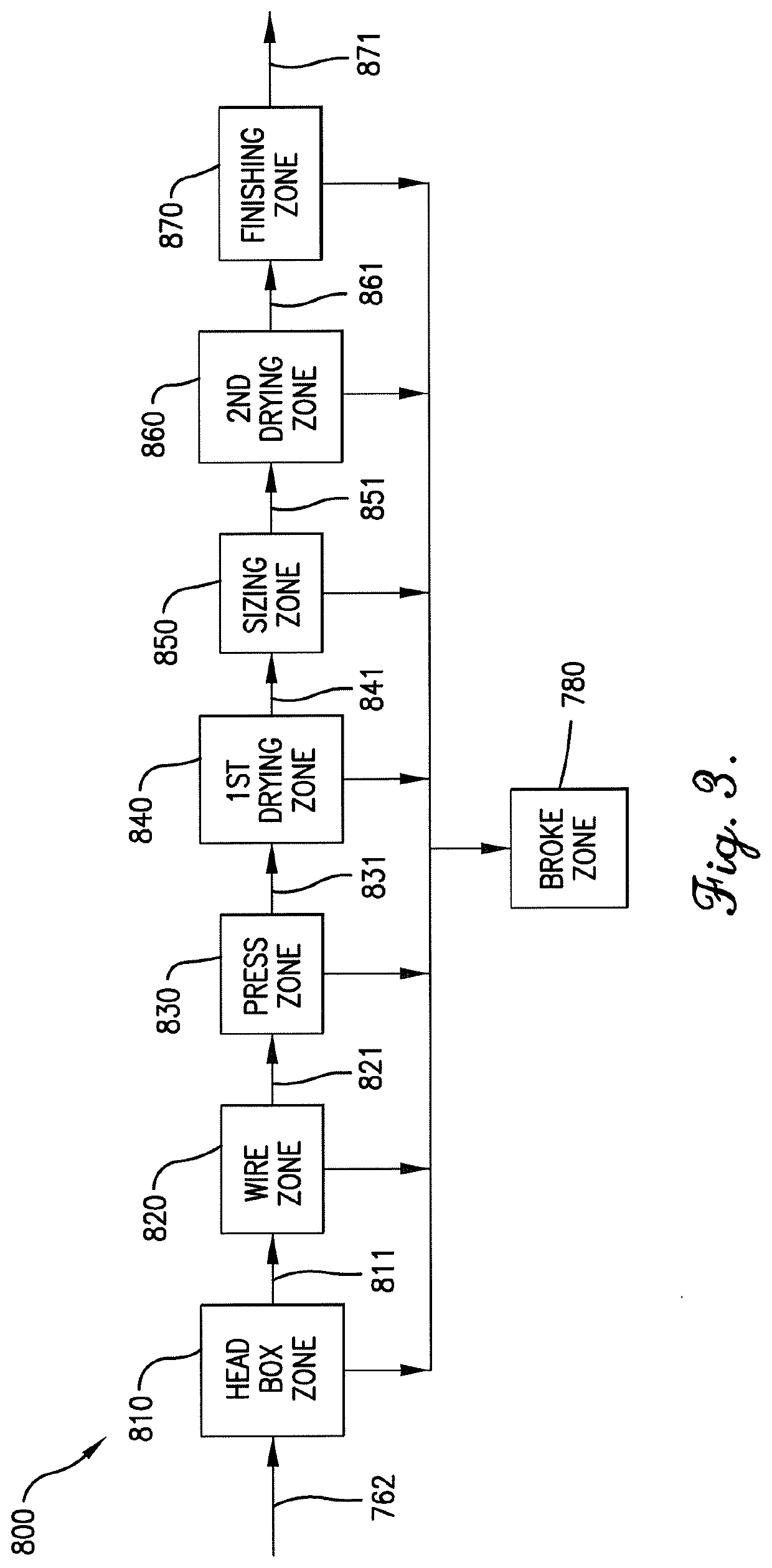

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. This invention also relates to a biodegradable bag.

Owner:EASTMAN CHEM CO

Preparation method for chitosan fruit moistureproof freshness protection package

InactiveCN102926287AAnti-collisionMoisture-proofSpecial paperPaper coatingProcess engineeringWater soluble

The invention discloses a preparation method for a chitosan fruit moistureproof freshness protection package, which comprises the following steps; firstly, performing pulping, beating, refining, preparing and size mixing on wood pulp and / or straw pulp and manufacturing with pulp to obtain paper through a paper machine; secondly, preparing waterproof emulsion; thirdly, coating the waterproof emulsion on the surface of wood pulp paper and obtaining fruit bagging paper with a waterproof layer through baking processing; fourthly, spraying a chitosan liquid on the inner surface of the fruit bagging paper with the waterproof layer and drying to obtain the paper; and fifthly, cutting the paper into an appropriate size and manufacturing to obtain a paper package. According to the invention, the manufactured product has the advantages of collision resistance, moisture protection, bacterium resistance and freshness retaining, overcomes the defects that the chitosan has poor water-solubility, is difficult in production operation, influences the flavor of fruits and vegetables and is difficult to dry, and is suitable for application to various fruits.

Owner:张建新

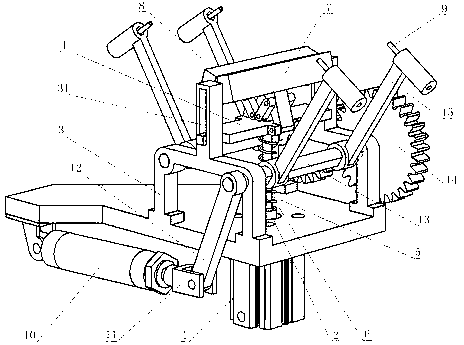

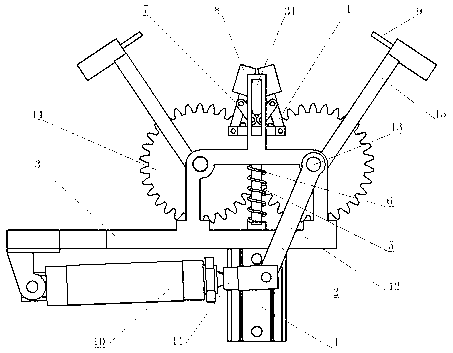

Fruit paper bag bagging device

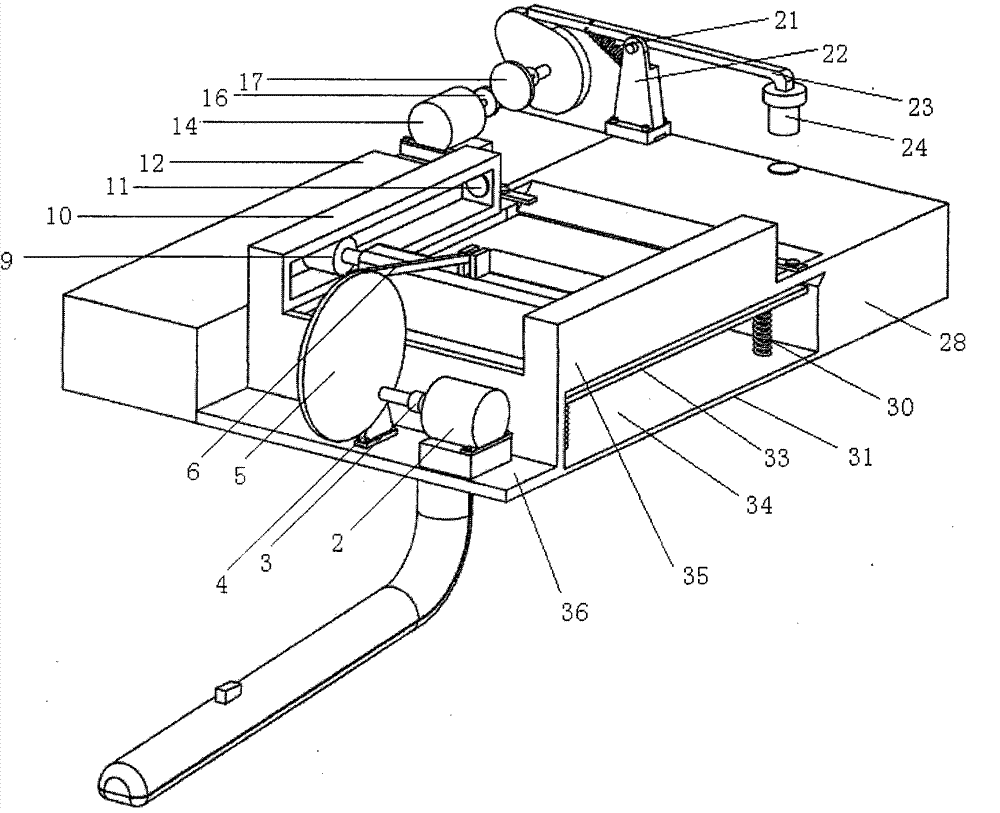

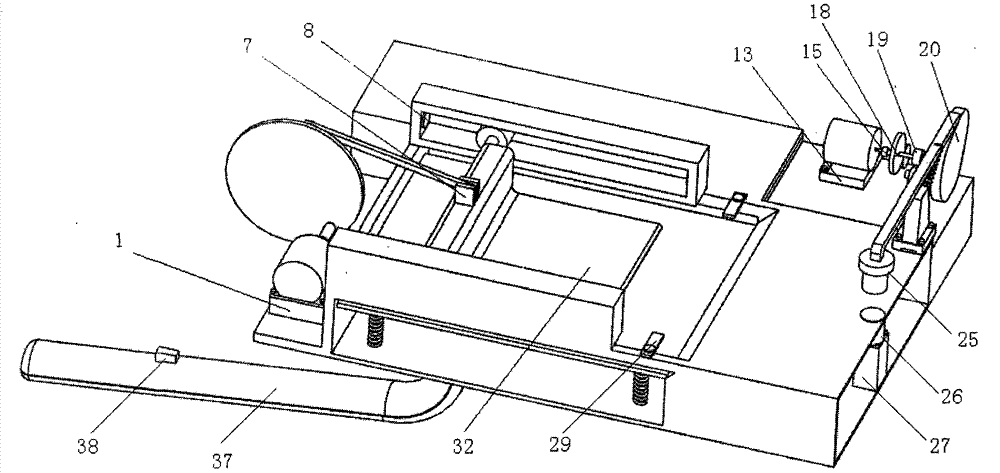

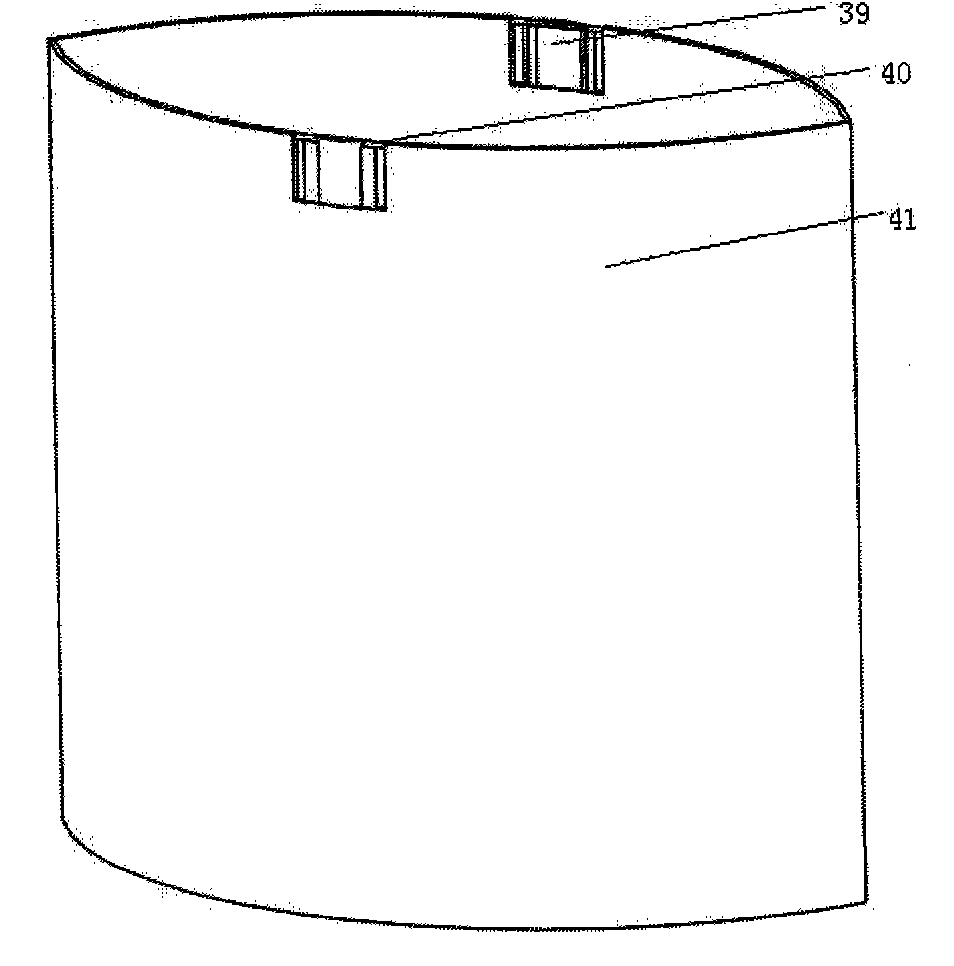

InactiveCN103828663AEasy to operateFast baggingPlant protective coveringsPulp and paper industryEngineering

The invention discloses a fruit paper bag bagging device. The bagging device comprises a bag placing device, a bag delivering device, a bag opening and sealing device, special paper bags and a fruit paper bag bagging control device. The special paper bags are delivered into a bag opening and sealing base through an eccentric wheel mechanism, and then bag opening and sealing operation is achieved through a cam mechanism and direct-current sucker type electromagnets. Semi-automation of fruit bagging is achieved, efficiency of fruit bagging is improved, besides, fruit stems can be prevented from being damaged in the process of fruit bagging, and the fruit paper bag bagging device has very good practical value and broad market prospects.

Owner:NORTHWEST A & F UNIV

Biodegradable plastic container having a moisture permeability

InactiveUS6706345B1High strengthAvoid problemsBottlesSynthetic resin layered productsOfficinalDesiccant

The present invention relates to a plastic container which has a good biodegradability and a moisture permeability manufactured by using a novel polyester resin composition under a specific injection and extrusion molding conditions in the forms of a bottle, a blister pack, a medicated paper pouch and the like, which thus enables to preserve the contents of the container such as pharmaceutical drugs, food and beverages dry without the addition of desiccants and can be disposed of without causing environmental contamination.

Owner:BOO YOON TECH

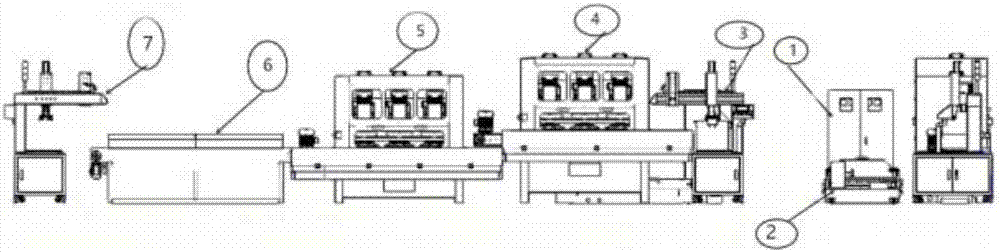

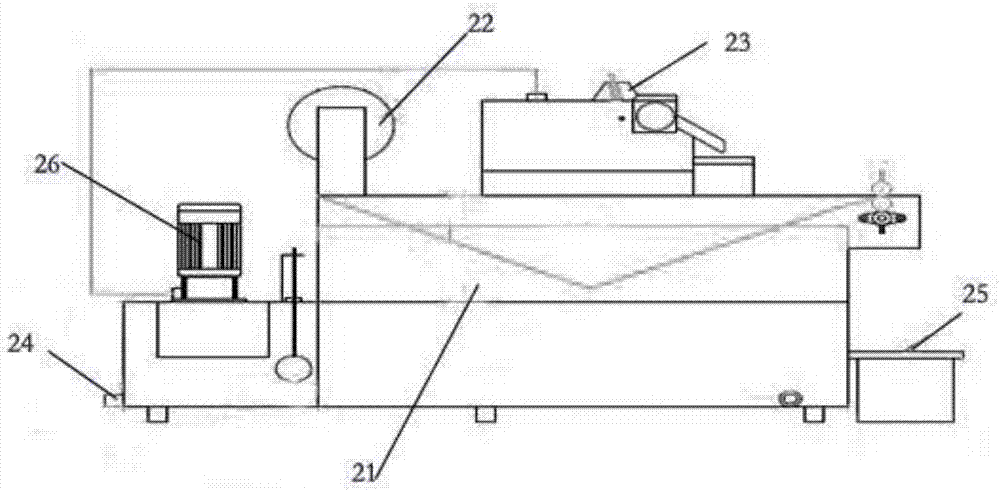

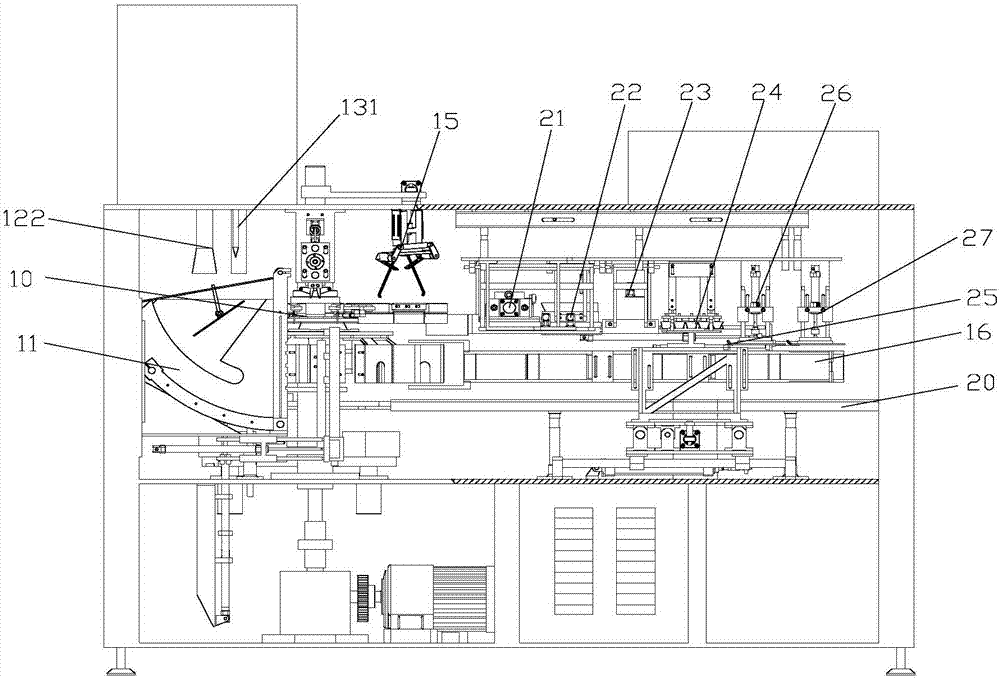

Automatic double-sided deburring and cleaning-drying production line

PendingCN107414642AImprove machining accuracyImprove processing efficiencyEdge grinding machinesDrying gas arrangementsProduction lineFiltration

The invention discloses an automatic double-sided deburring and cleaning-drying production line. The automatic double-sided deburring and cleaning-drying production line comprises an electric appliance cabinet controlling a whole system to run, a loading manipulator, a first deburring machine, a second deburring machine, a cleaning-drying all-in-one machine and an unloading manipulator, wherein the loading manipulator is arranged just above an input end of the first deburring machine, and conveys a workpiece onto an advancing rail of the first deburring machine through a magnetic attraction disc of the loading manipulator; the workpiece enters an input port of the second deburring machine through a magnetic turnover roller of the first deburring machine; the first deburring machine and the second deburring machine are connected with a paper bag-type water circulation and filtration system separately and form a circulation system; a hidden demagnetizer is arranged on an output part of the second deburring machine; the hidden demagnetizer demagnetizes the workpiece, and the workpiece enters an input end of the cleaning-drying all-in-one machine; the unloading manipulator is arranged in the vertical direction of an output end of the cleaning-drying all-in-one machine; and whole equipment is operated through a PLC programming controlled push-to-start machine. The automatic double-sided deburring and cleaning-drying production line is energy-saving and environment-friendly due to the complete water filtration and circulation system; and the production line is safe and stable, high in machining accuracy, high in machining efficiency, intelligent and high in efficiency due to totally-enclosed running and a transparent observation window.

Owner:万创(苏州)智能装备有限公司

Waterproof recycled paper and production method thereof

InactiveCN103397559AExtended use timeWith waterproof functionWater-repelling agents additionInorganic compound additionSulfite saltPlant fibre

Owner:区锦泉

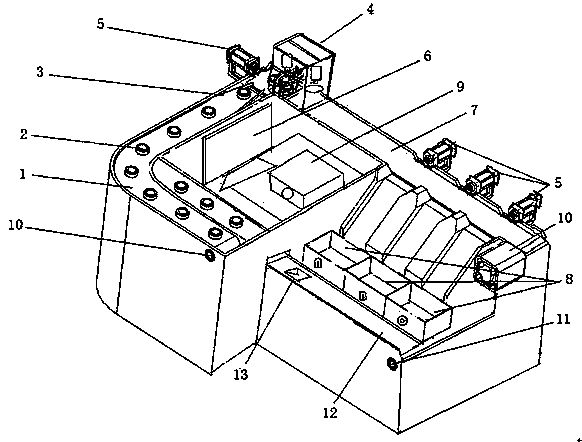

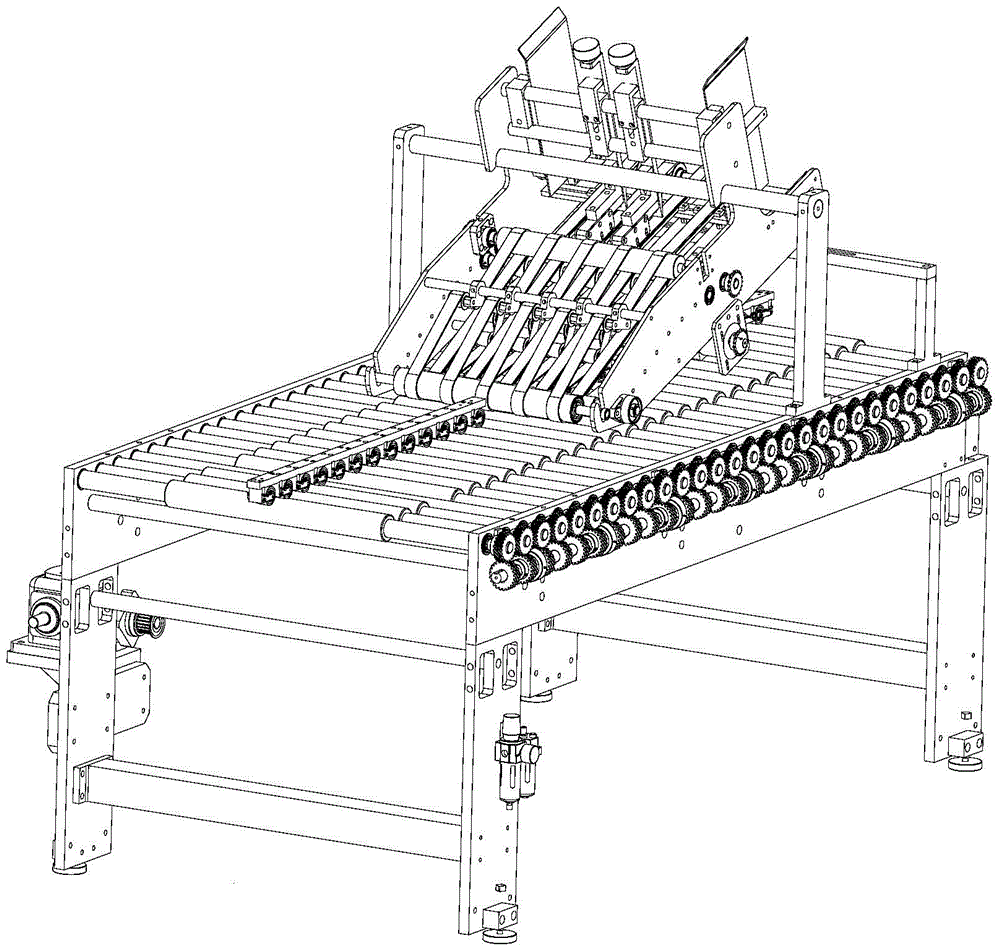

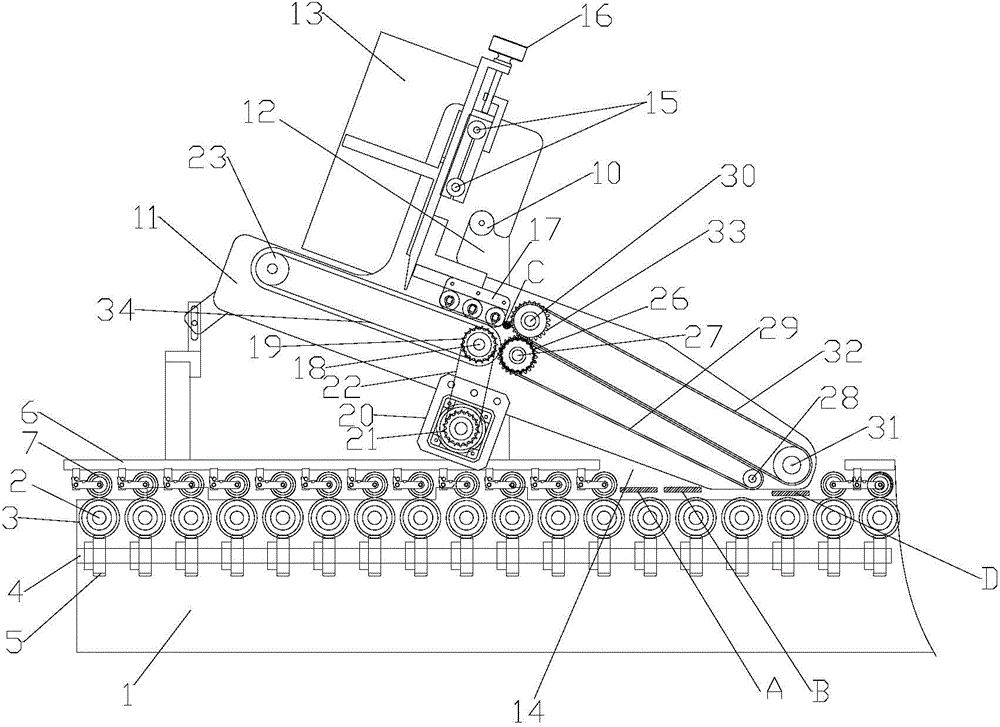

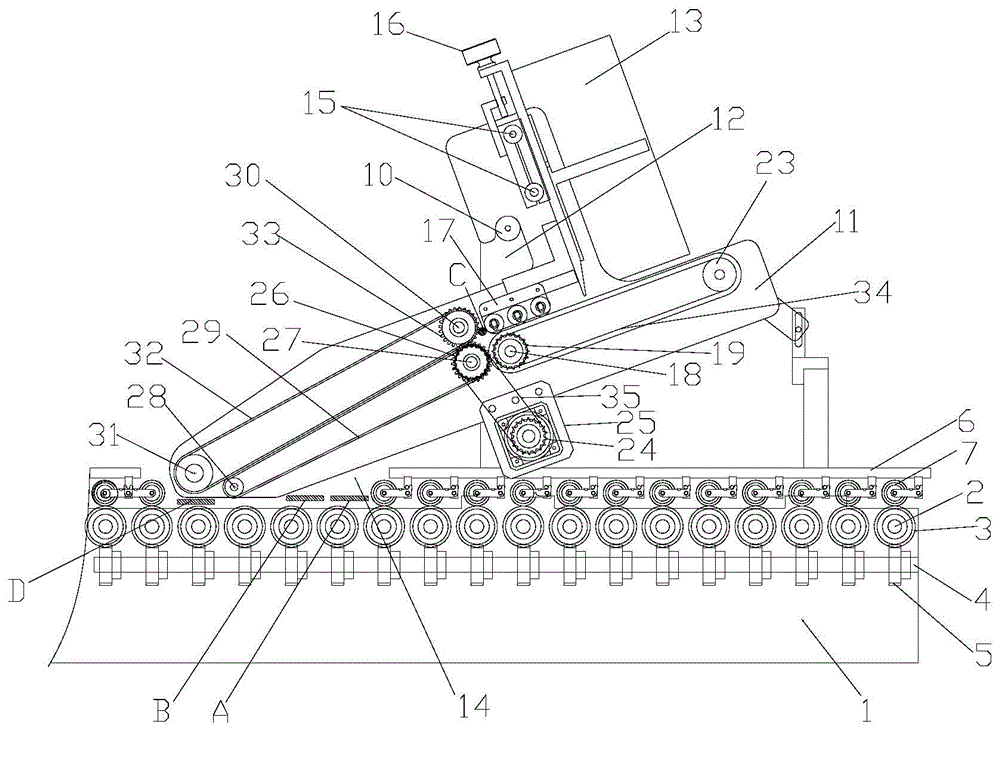

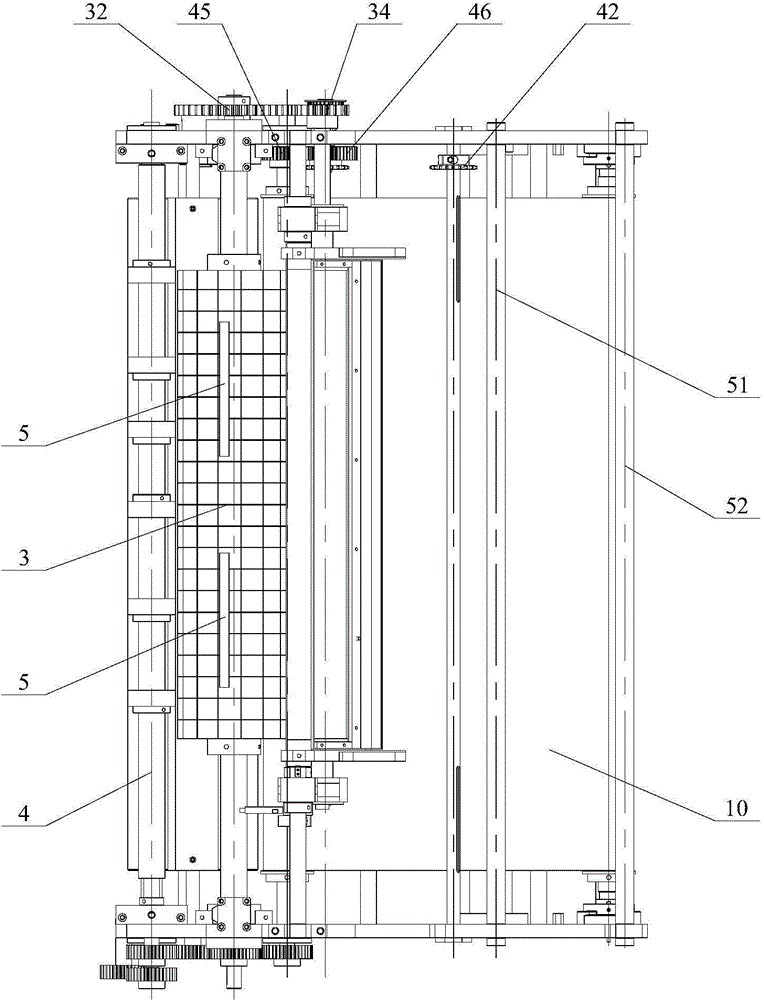

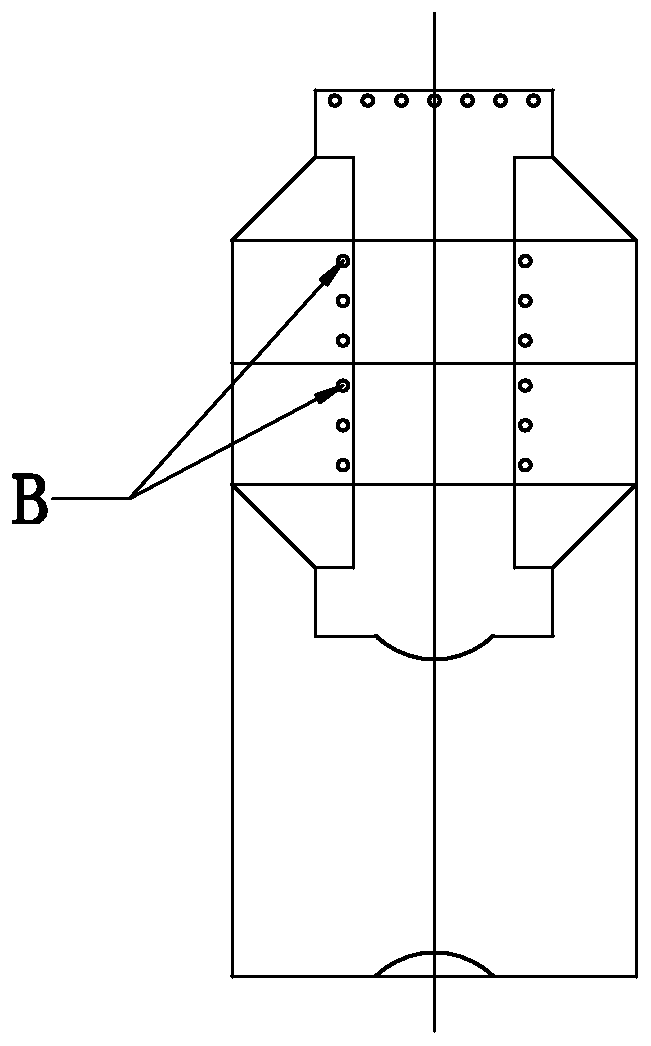

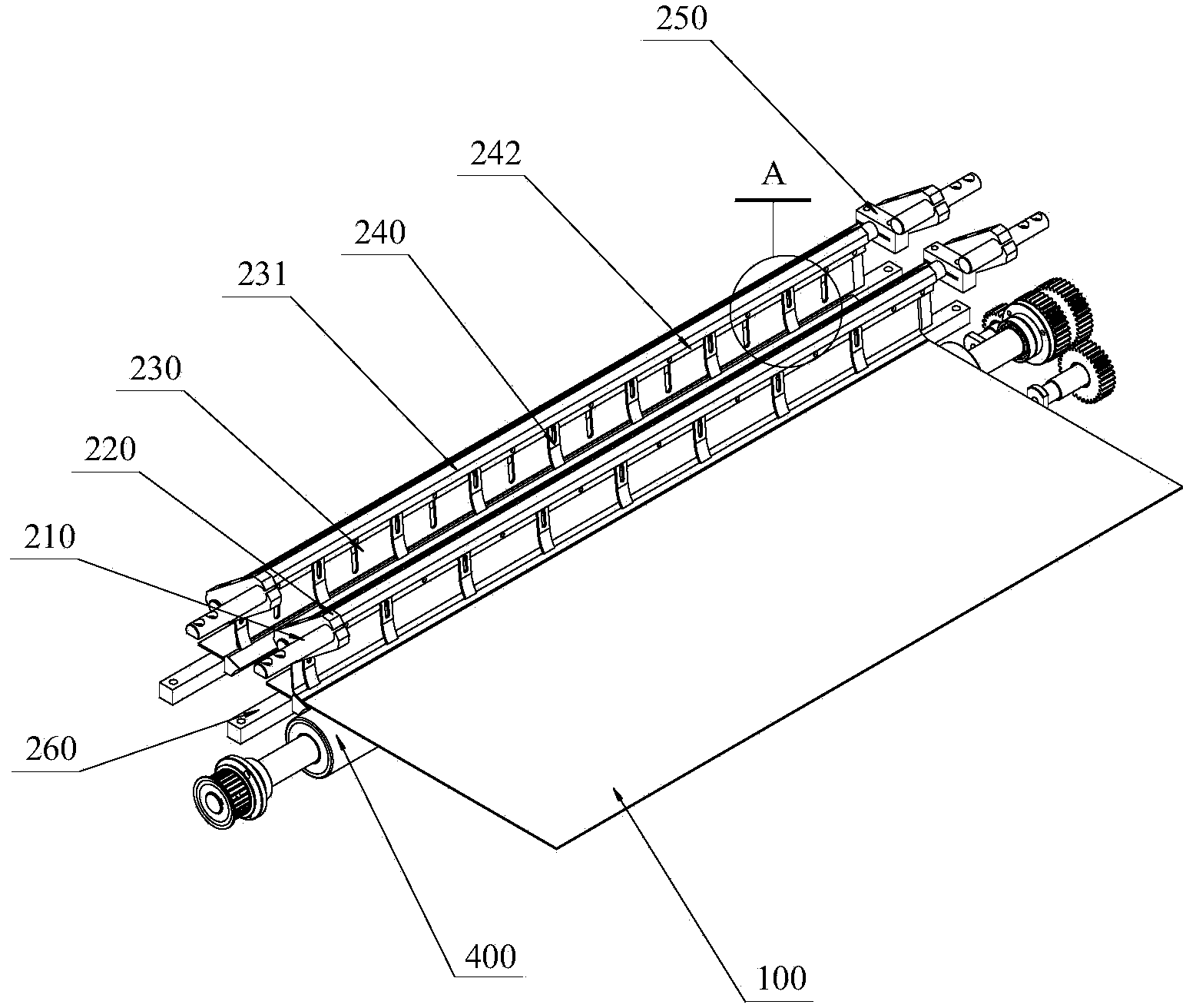

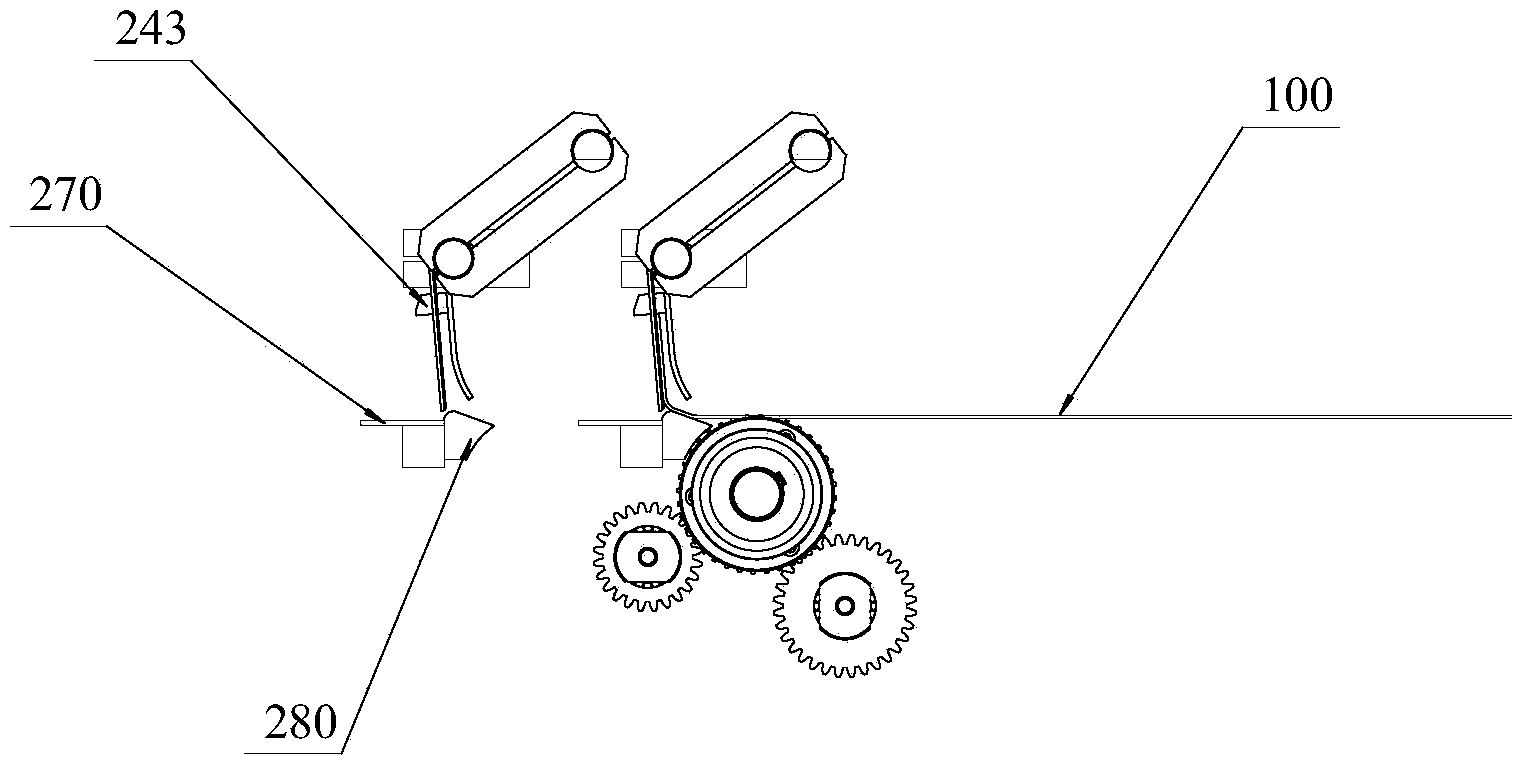

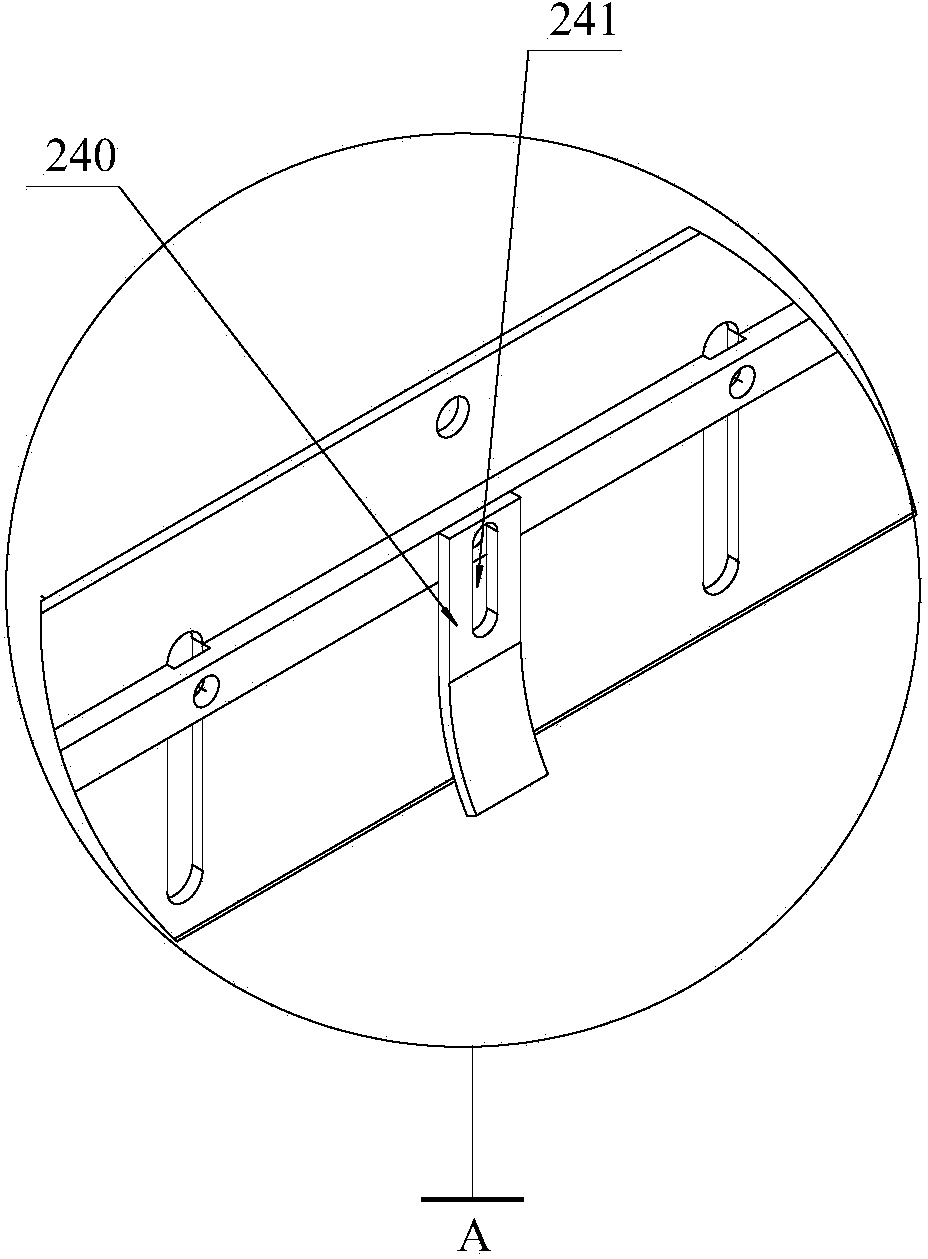

Paper bag machine and automatic bottom board placing device thereof

ActiveCN104608425AEasy to produceSolve the problem that there is no automatic bottom card functionBox making operationsPaper-makingPulp and paper industryMaterial resources

The invention discloses a paper bag machine and an automatic bottom board placing device of the paper bag machine. The automatic bottom board placing device comprises a paper bag conveying mechanism, a bottom board distribution mechanism and a bottom board conveying mechanism which are all sequentially connected to the paper bag machine. Through the combined application of the paper bag machine, the paper bag conveying mechanism, the bottom board distribution mechanism and the bottom board conveying mechanism, bottom boards can be automatically and independently placed in corresponding paper bags before the paper bags are pasted to barrels and the bottoms are folded or pulled for forming, the problem that the automatic bottom board placing function of a traditional paper bag machine is not available is solved, convenience is provided for achieving paper bag full-mechanical production of the paper bag machine, a large amount of labor and a large number of material resources are saved, and production efficiency is greatly improved.

Owner:WENZHOU ZENBO PRINTING MACHINERY

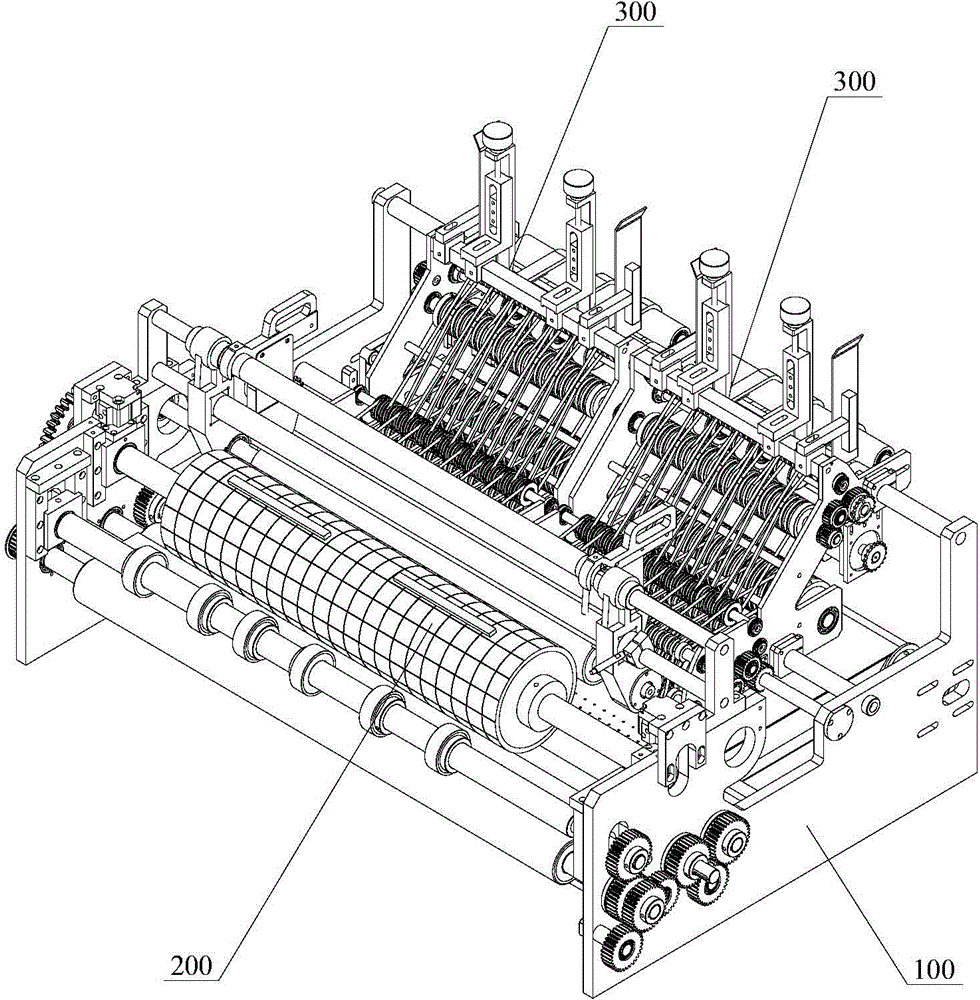

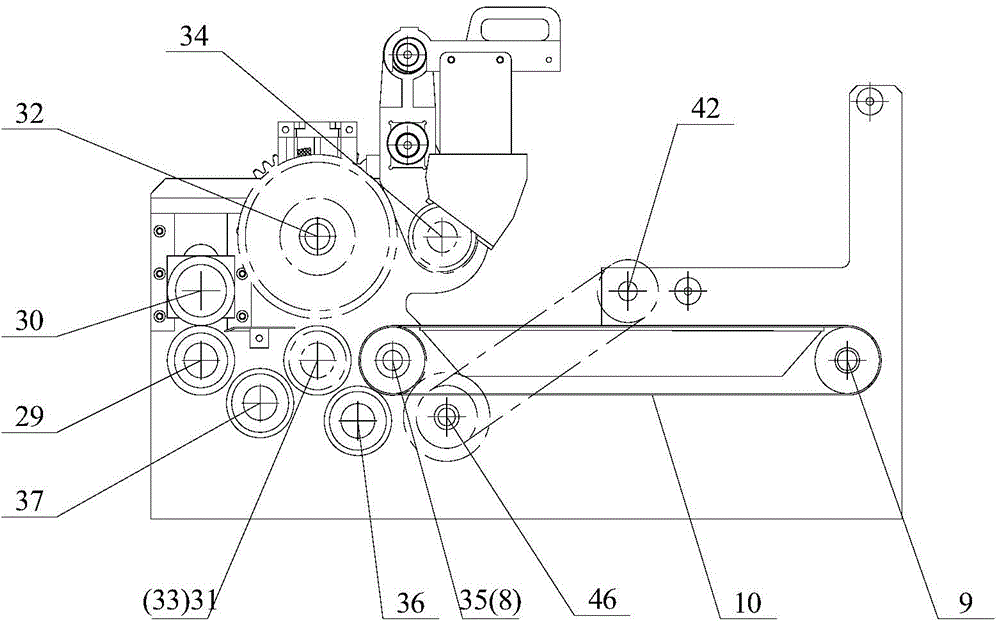

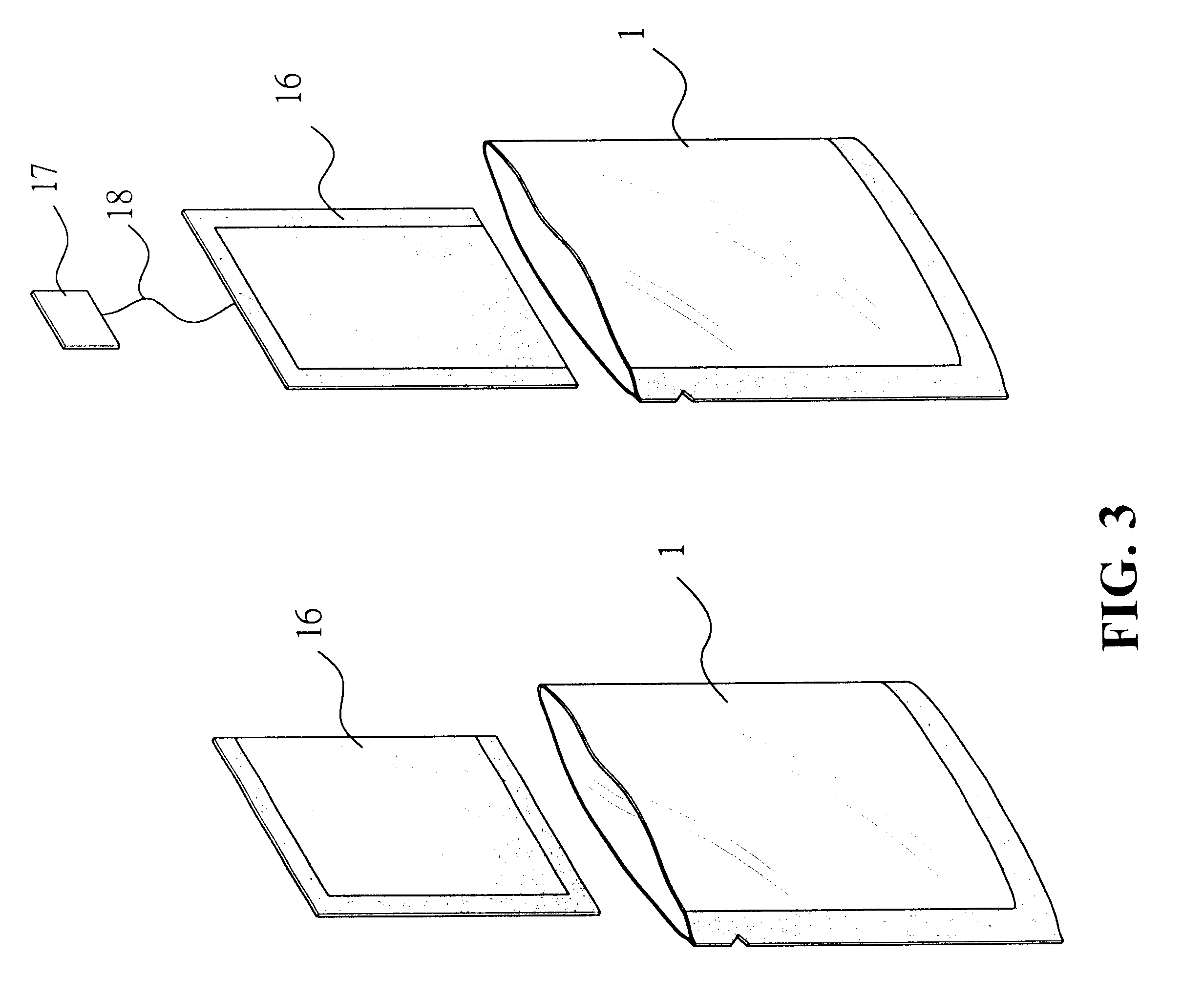

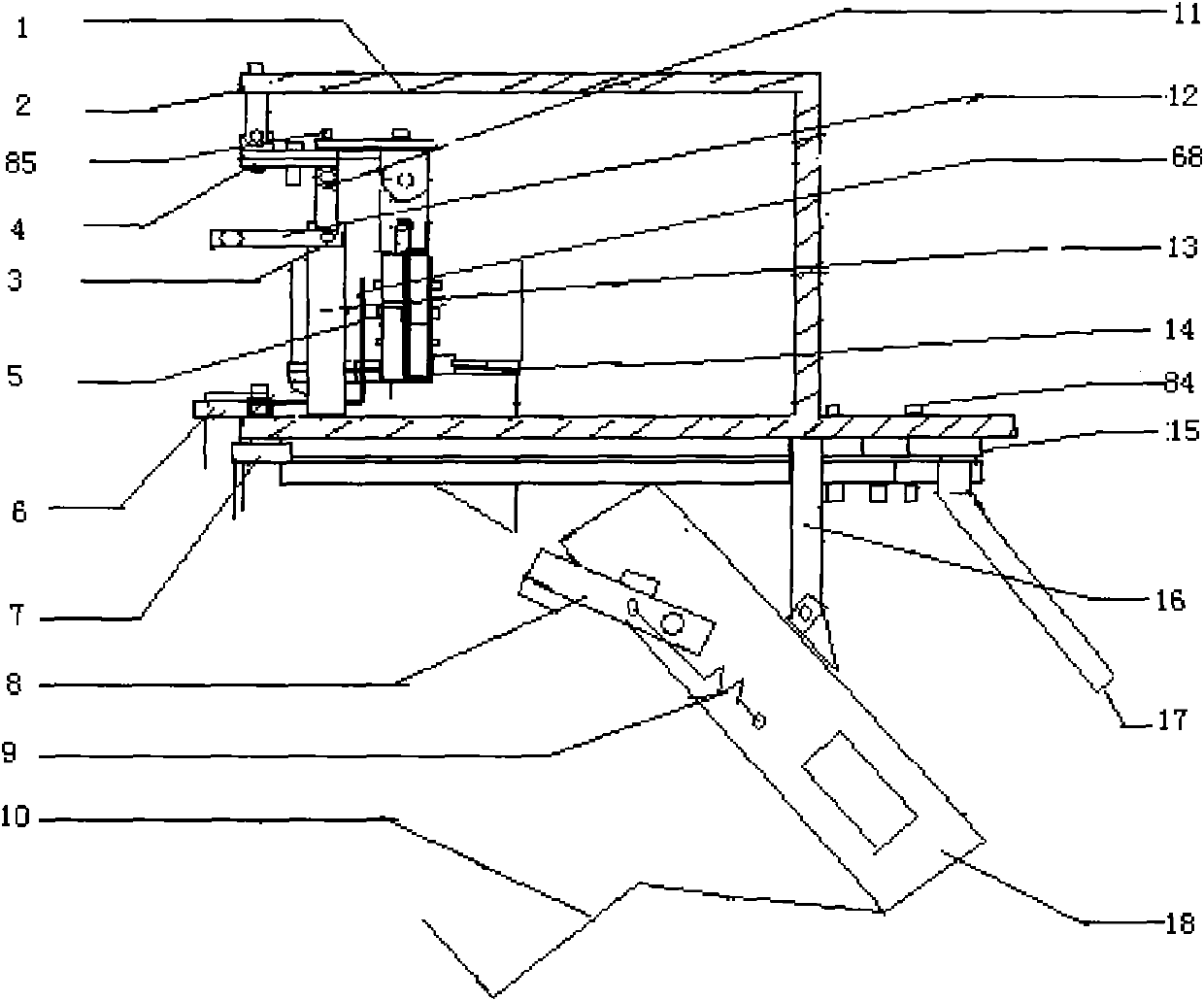

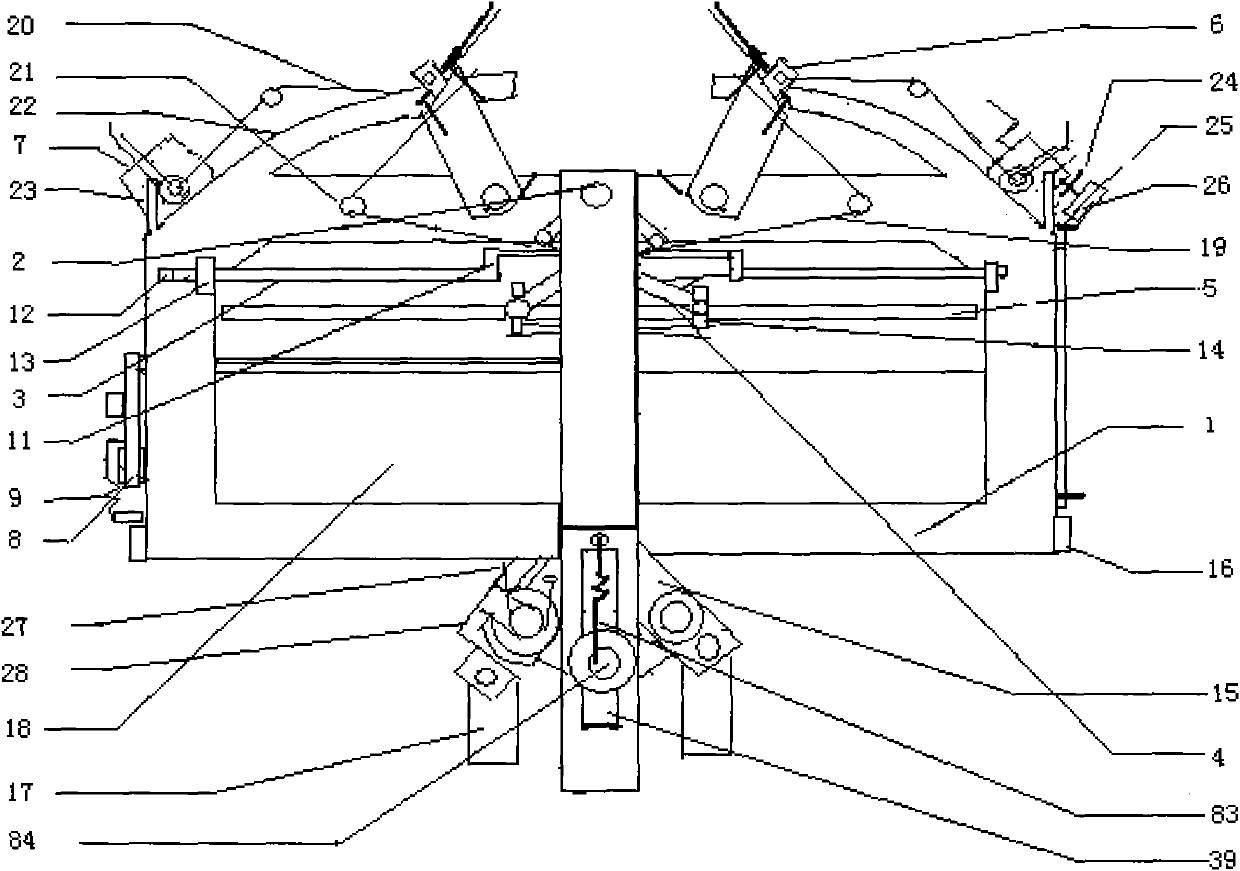

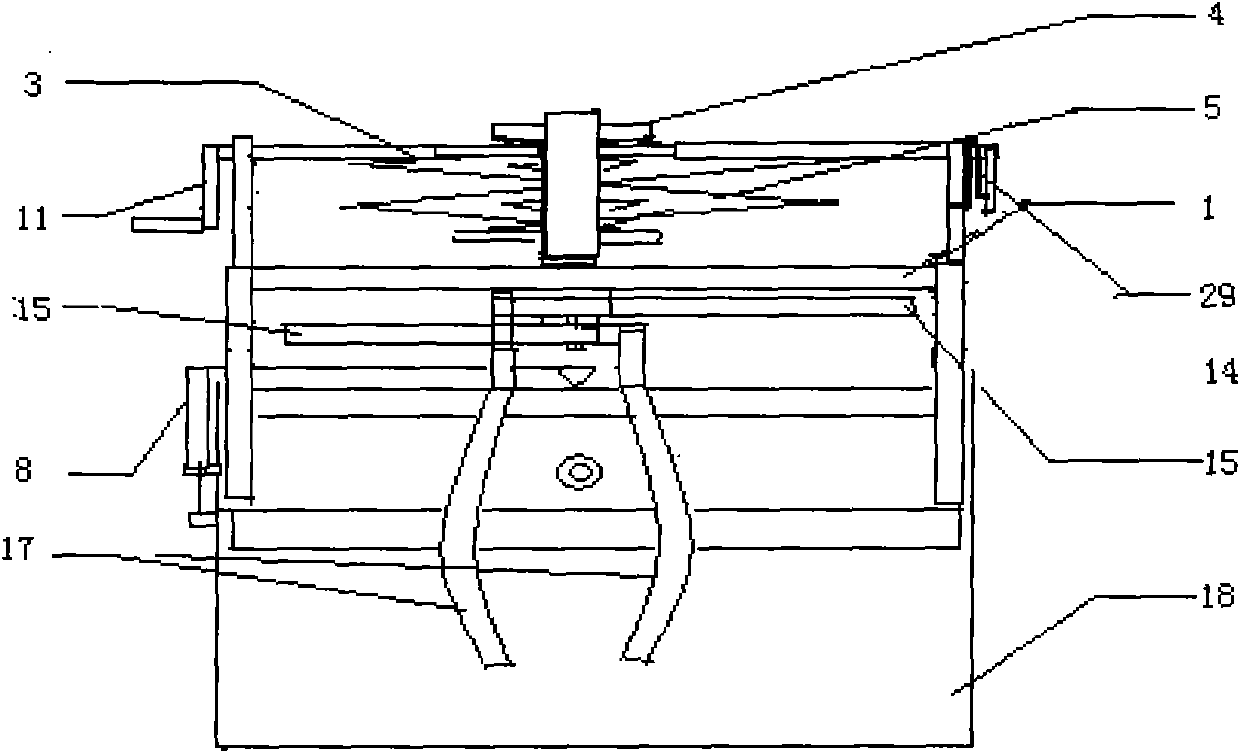

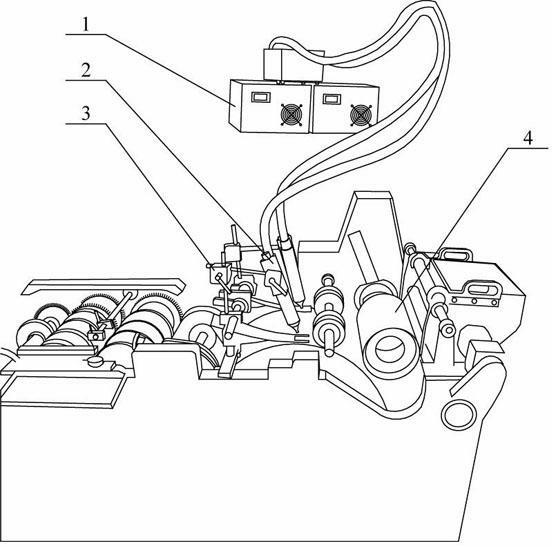

Carry bag machine and automatic head card gluing device thereof

ActiveCN104786555AIncrease production capacityImprove work efficiencyContainer making machineryDrive shaftFixed frame

The invention discloses a carry bag machine and an automatic head card gluing device thereof. The automatic head card gluing device of the carry bag machine comprises a fixed frame, a paper inputting and glue printing assembly, two head card conveying and gluing assemblies and a driving device, wherein the paper inputting and glue printing assembly, the two head card conveying and gluing assemblies and the driving device are arranged on the fixed frame. The paper inputting and glue printing assembly comprises a first paper conveying roller, a second paper conveying roller, a glue printing roller and a paper pressing roller which are rotationally arranged on the fixed frame. Each head card conveying and gluing assembly comprises a head card support fixedly arranged on the fixed frame, wherein a head card driving shaft and a head card driven shaft are rotationally arranged on the head card support. The driving device comprises a paper bag driving device used for driving the paper bag inputting and glue printing assembly to work and a head card driving device used for driving the head card conveying and gluing assemblies to work. As the carry bag machine and the automatic head card gluing device of the carry bag machine are adopted, a great deal of manpower is not needed, the working efficiency is high, the finished product ratio is increased effectively, and the requirement for large-scale batch production is met.

Owner:WENZHOU ZENBO PRINTING MACHINERY

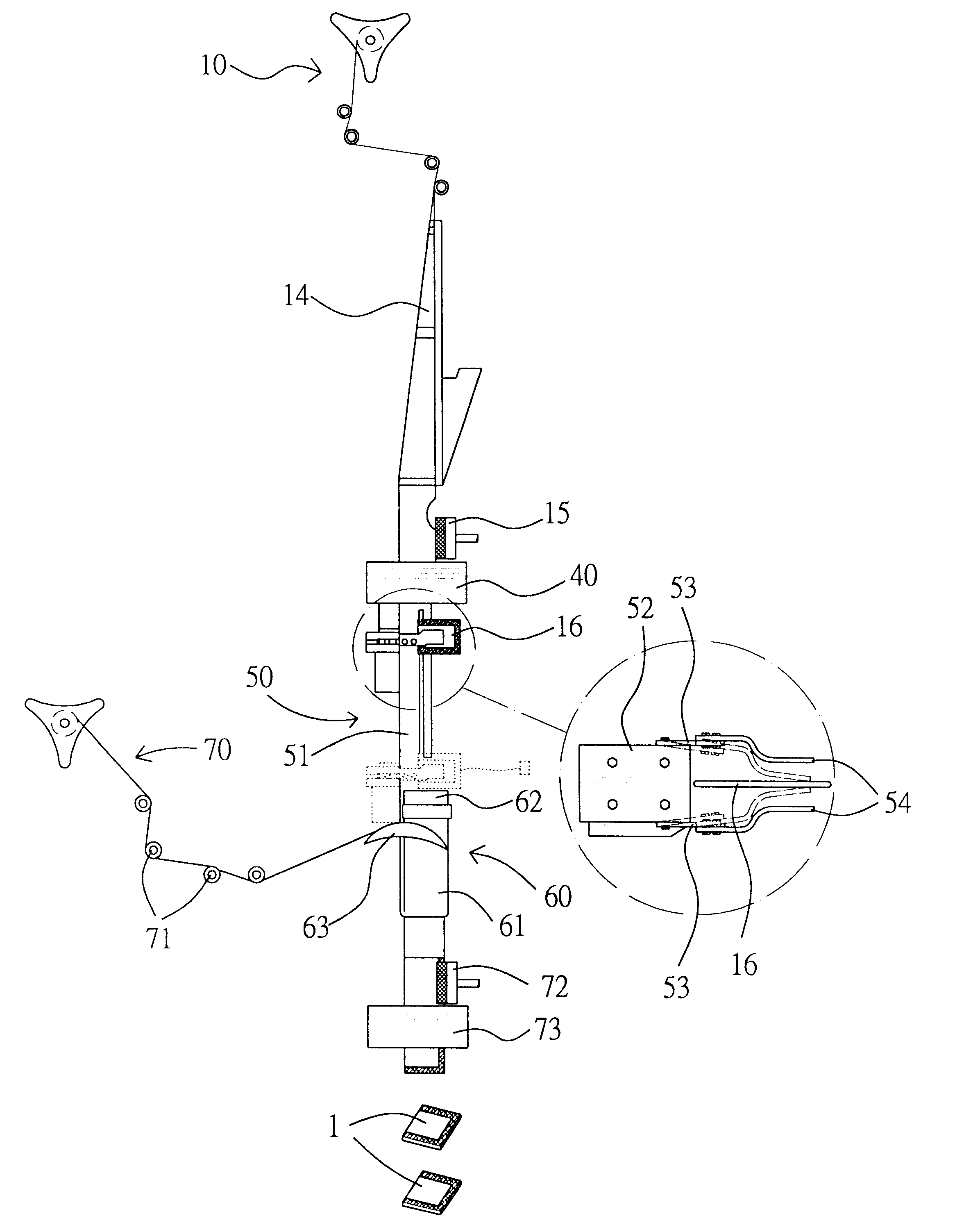

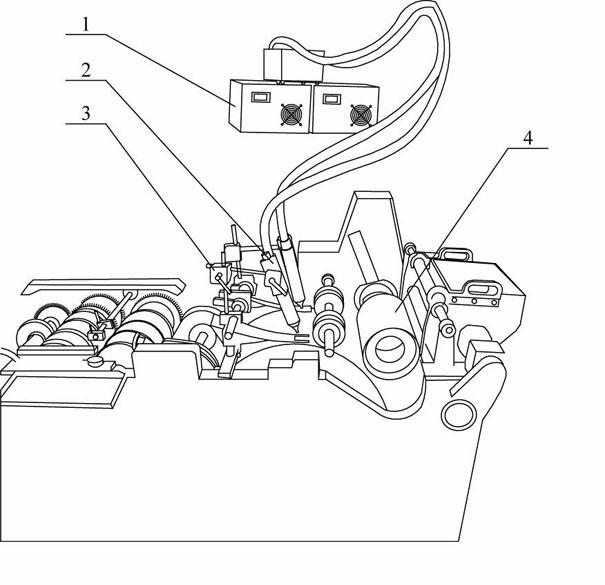

Filling device of a dual layered filling and packing device

A filling device of a dual-layered filling and packing device having a cotton paper device within the packing device which guides cotton paper via a guide rack to fold the paper and to fill a paper bag with fixed amount of tea leaves, by means of a roller, the paper bag with tea leaves being sealed at the edges thereof, and by means of a gripping structure, the tea bag being held to a funnel tube of the folding structure, a plurality of rollers delivered packing foil from an insertion section through space between a folding slot and the funnel tube, characterized in that the gripping structure composes a magnetic cylinder interconnected to a Y-shaped pneumatic cylinder and the gripping section is extended with two corresponding folding board and the folding structure comprises a folding slot covered a gap outside the funnel tube, the cross-section of the funnel tube has a flat body and the folding slot is a U-shaped plate body having a top end folded outward to form the insertion section.

Owner:HSIEH SHUI YUNG

Insecticidal coating for use on cellulosic substrates

InactiveUS20070003586A1Effective barrierLow toxicityBiocideOrganic active ingredientsCelluloseCardboard

An insecticidal coating composition is provided for use on cellulosic substrates such as packaging materials to provide protection against insects. The insecticidal coating includes a polyvinyl acetate emulsion; a vinyl acetate ethylene copolymer emulsion; and an insecticide having an LD50 value of between about 14,500 to 15,500 mg / kg. The coating may also include additives such as fillers, defoaming agents, leveling agents, preservatives, and humectants. The insecticidal coating composition may be applied to a variety of cellulosic substrates including corrugated board, linerboard, paper, paper bags, wooden pallets, and paper composite pallets.

Owner:WALLA WALLA ENVIRONMENTAL

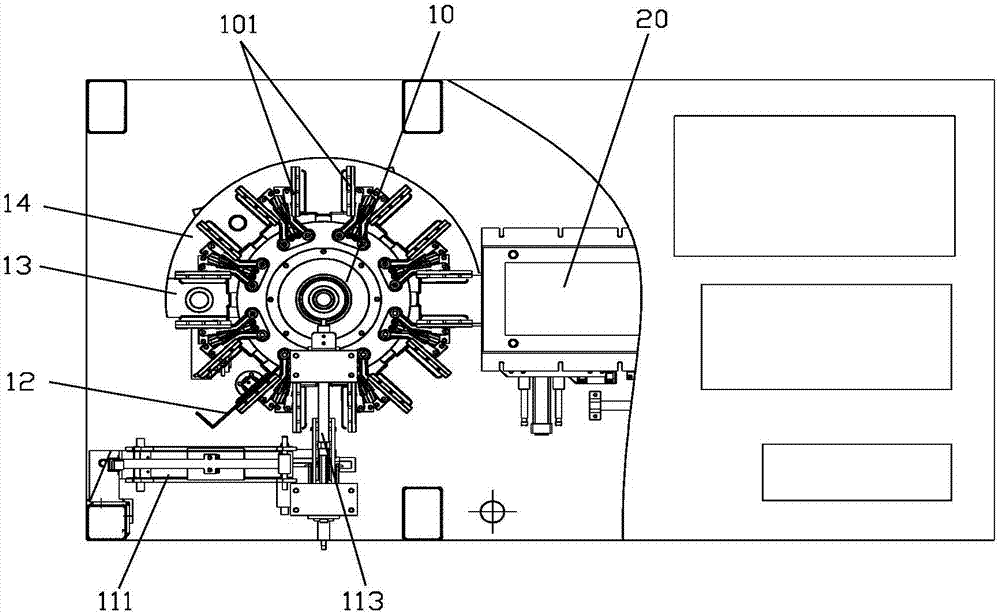

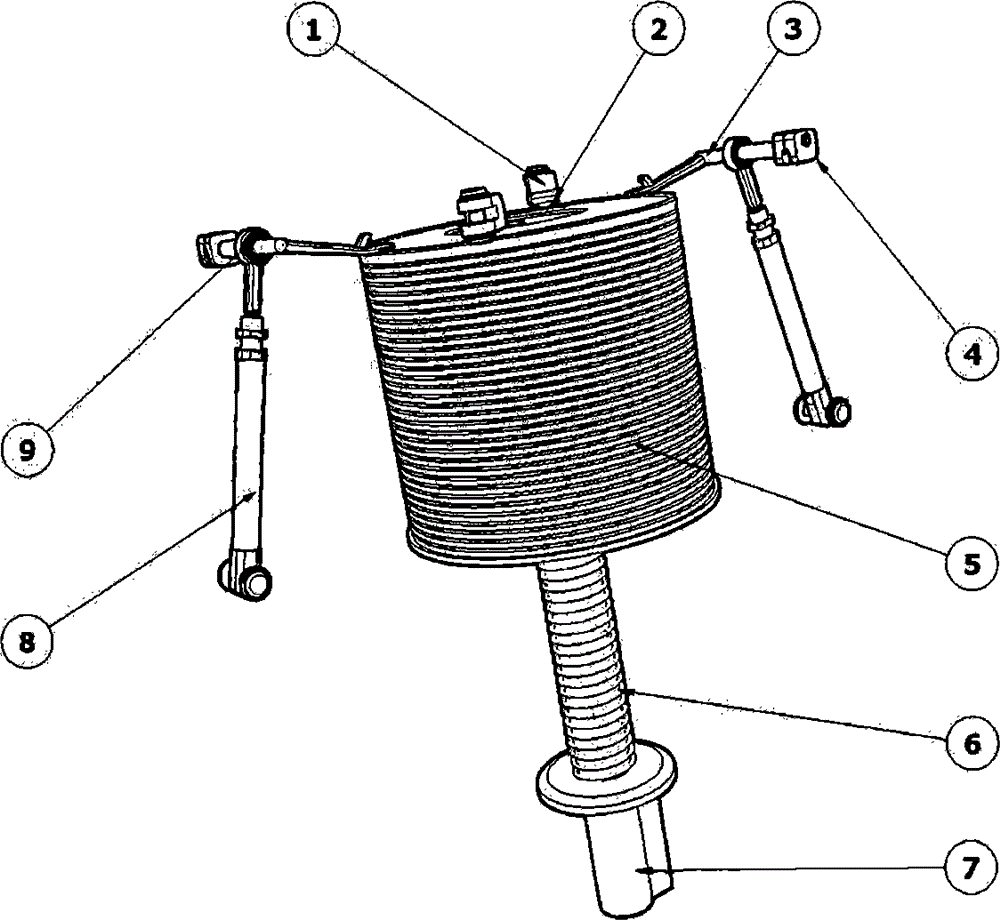

Bagging machine for apple paper bags

InactiveCN102084795AReduce labor intensityLow investment costPlant protective coveringsMechanical engineeringIndustrial engineering

The invention relates to a bagging machine for apple paper bags, belonging to the field of farm machinery. The bagging machine comprises a main frame, a mouth supporting system, a mouth closing system and a bag basket, wherein the mouth supporting system comprises a transverse expansion bend, a longitudinal expansion bend, a bag supporting mechanism and a rocker arm; the mouth closing system comprises an inner mouth closing mechanism and a side mouth closing mechanism; and the bag basket is an opened paper bag basket. The bagging machine has the advantages of being simple in operation and convenient to use, and is capable of greatly reducing the labor intensity of workers, thereby reducing the investment cost of apple production.

Owner:刘进玉

Full-automatic packing machine for flat bottom paper bag

PendingCN106965956AFast packingImprove packaging efficiencyWrapper twisting/gatheringPackaging automatic controlDust controlStructural engineering

The invention discloses a full-automatic packing machine for a flat bottom paper bag. The full-automatic packing machine comprises a bag containing device and a bag sealing device; the bag containing device comprises a rotation large disc, a bag taking mechanism, a bag neatening mechanism, a padding mechanism, a material neatening mechanism and an angle folding mechanism; and the bag sealing device comprises a transverse base, a tailoring mechanism, a first edge rolling mechanism, a second edge rolling mechanism, a rolling mechanism, a gluing mechanism, a first press fit mechanism and a second press fit mechanism. Compared with the prior art, the packing machine can achieve bag taking, bag feeding, bag opening, foot opening detection, quantified filling, dust removal, jolt ramming, angle folding, tailoring, edge rolling, glue coating, press fit, weighing detection and other functions at a time, the full-automatic packing process of the flat bottom paper bag is completed, the packing speed of the flat bottom paper bag is greatly increased, and the packing efficiency is improved.

Owner:ANHUI ZENGRAN PACKAGING SCI & TECH

Processing method for laminated paper bag

InactiveCN102320409ADurable and stable surface propertiesKeep for a long timePaper-makingBox making operationsPack materialPlastic film

The invention discloses a processing method for a laminated paper bag which relates to the technical field of packaging materials and aims at the problems that the strength of the Dyne value of the surface of an existing corona-processed laminated paper bag is low; the timeliness is short; and the stored film cannot achieve the required surface tensile for adhesive bonding. The method disclosed by the invention comprises the following steps of: (1) paper printing: printing a design pattern on the paper to prepare a printed matter; (2) laminating after printing: covering a layer of transparent plastic film on the surface of the printed matter to prepare a laminated printed matter; (3) die cutting processing: performing die cutting and creasing processing for the laminated printed matter; (4) plasma processing technology: performing plasma treatment for the area to be bonded of the laminated printed matter subjected to the die cutting; and (5) case bonding technology: coating a binder on the area to be bonded subjected to the plasma treatment, jointing the area to be bonded; and solidifying the binder to prepare the laminated paper bag. The method disclosed by the invention is used for processing and manufacturing the laminated paper bag to enhance the binding strength of the joint of the paper bag.

Owner:SHANGHAI WANHONG PRINTING

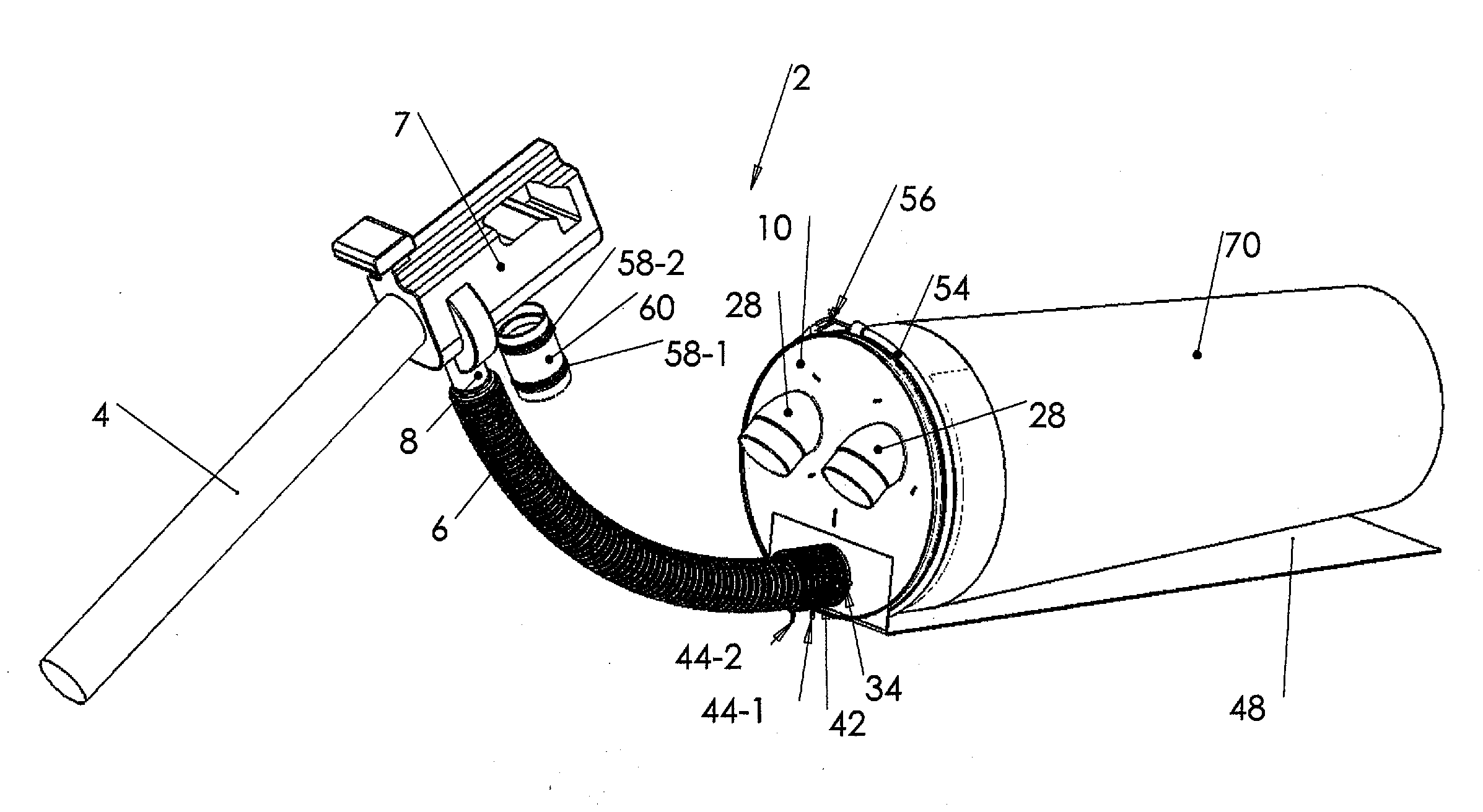

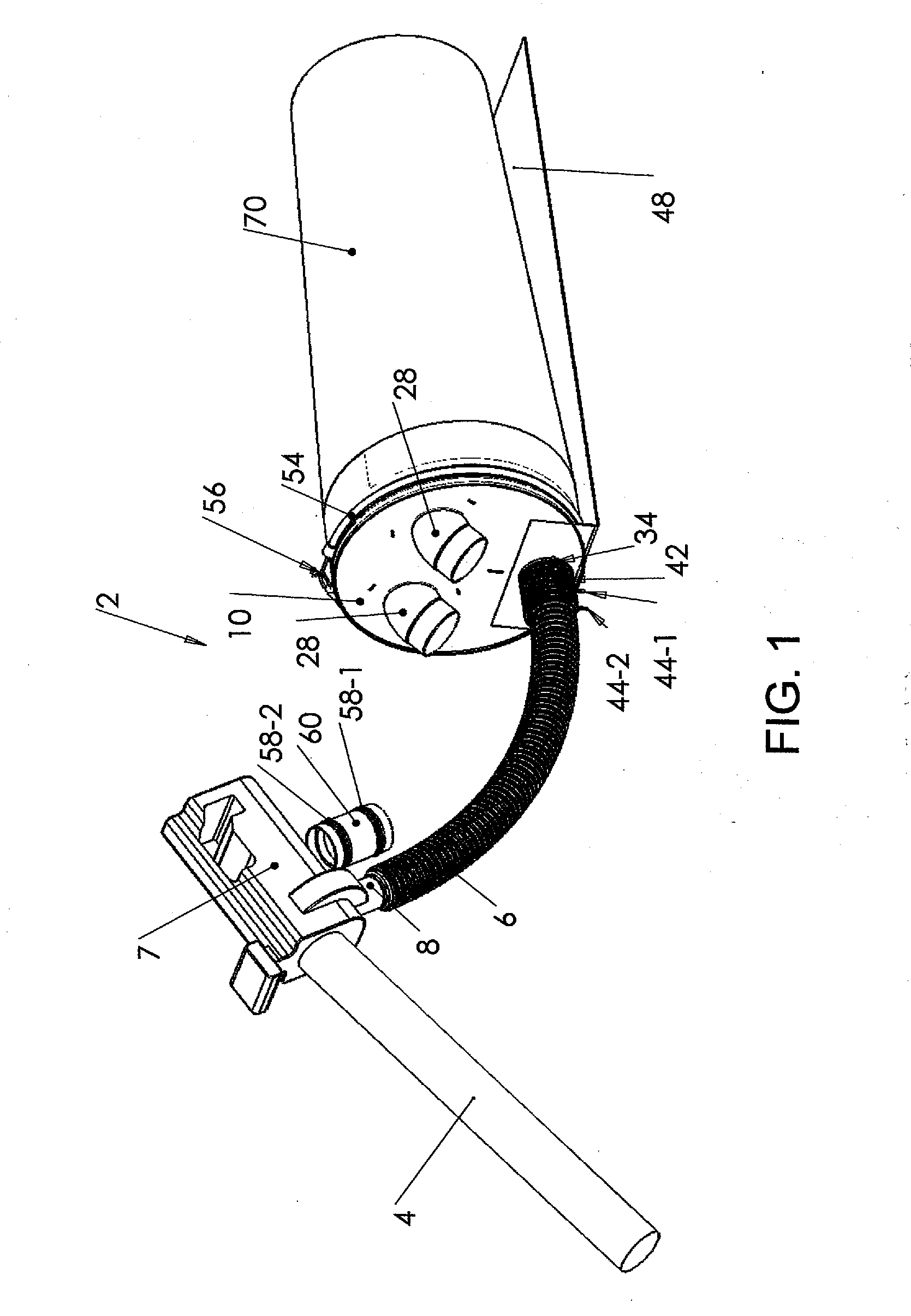

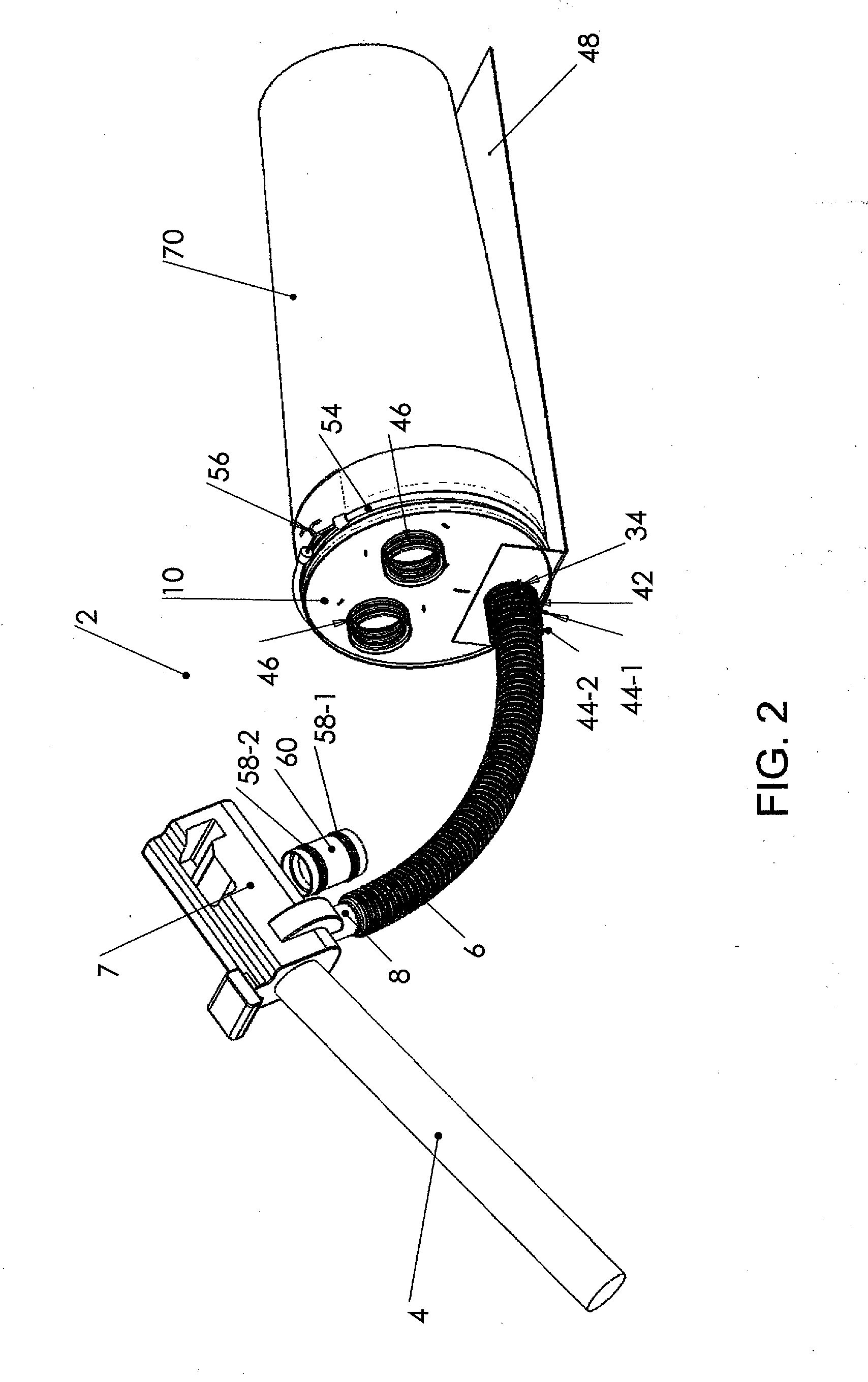

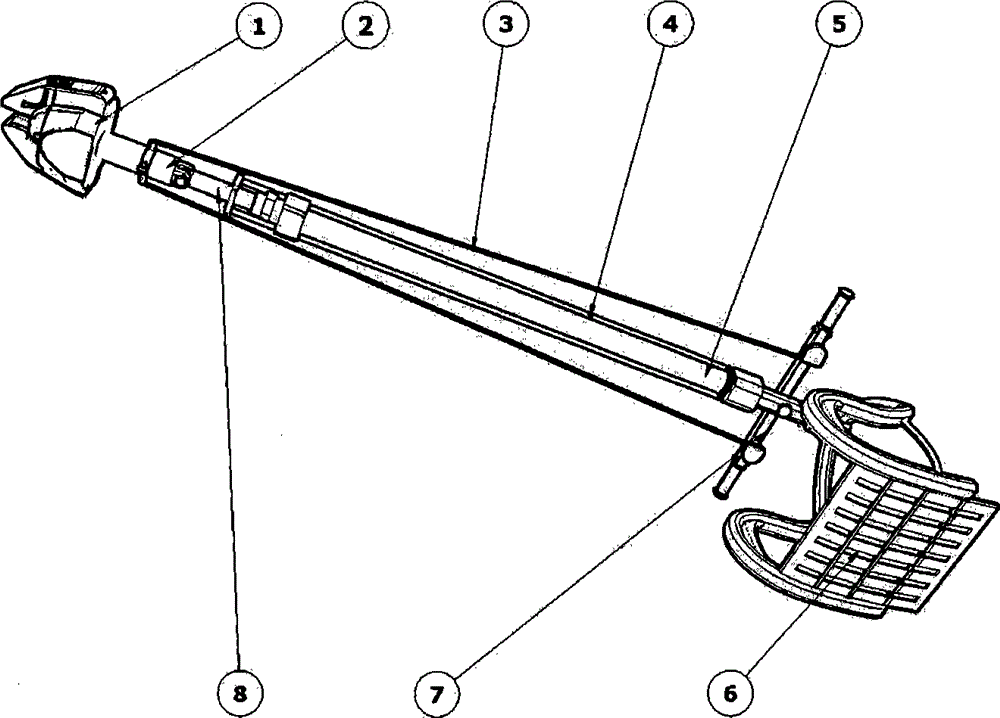

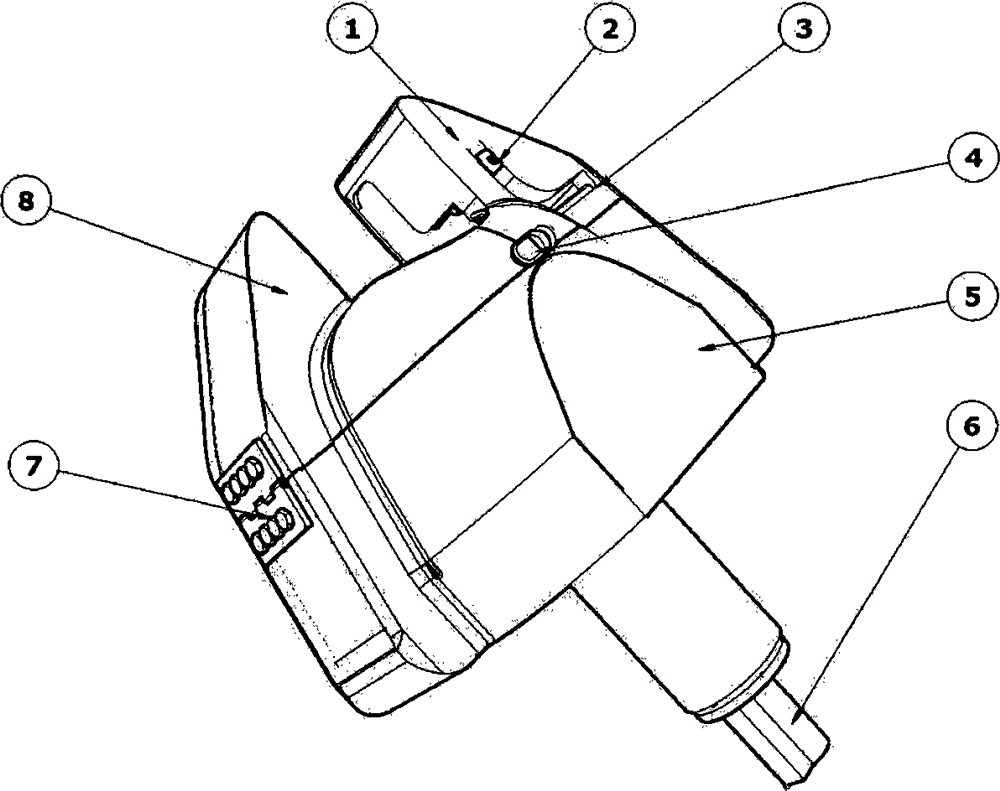

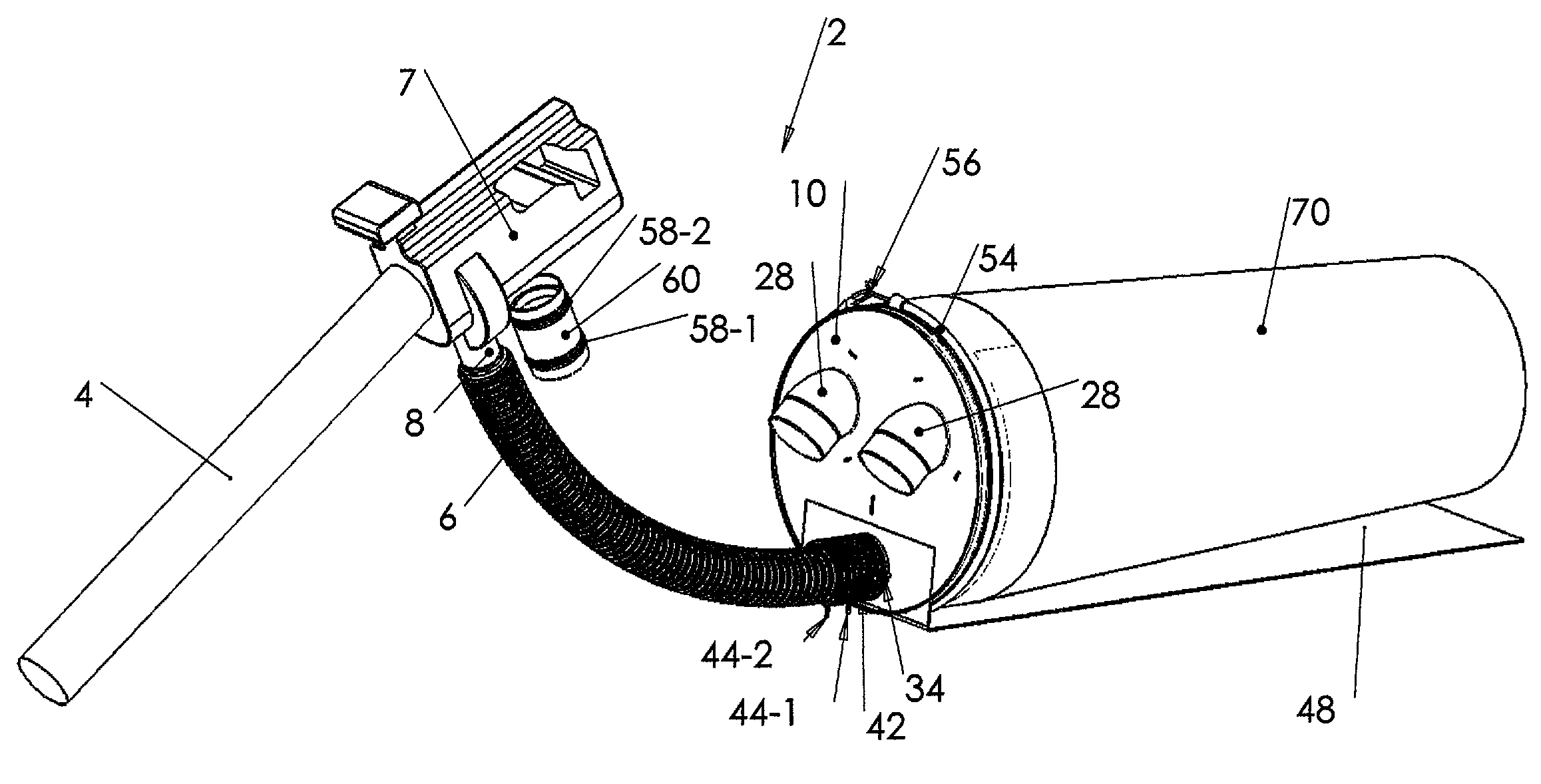

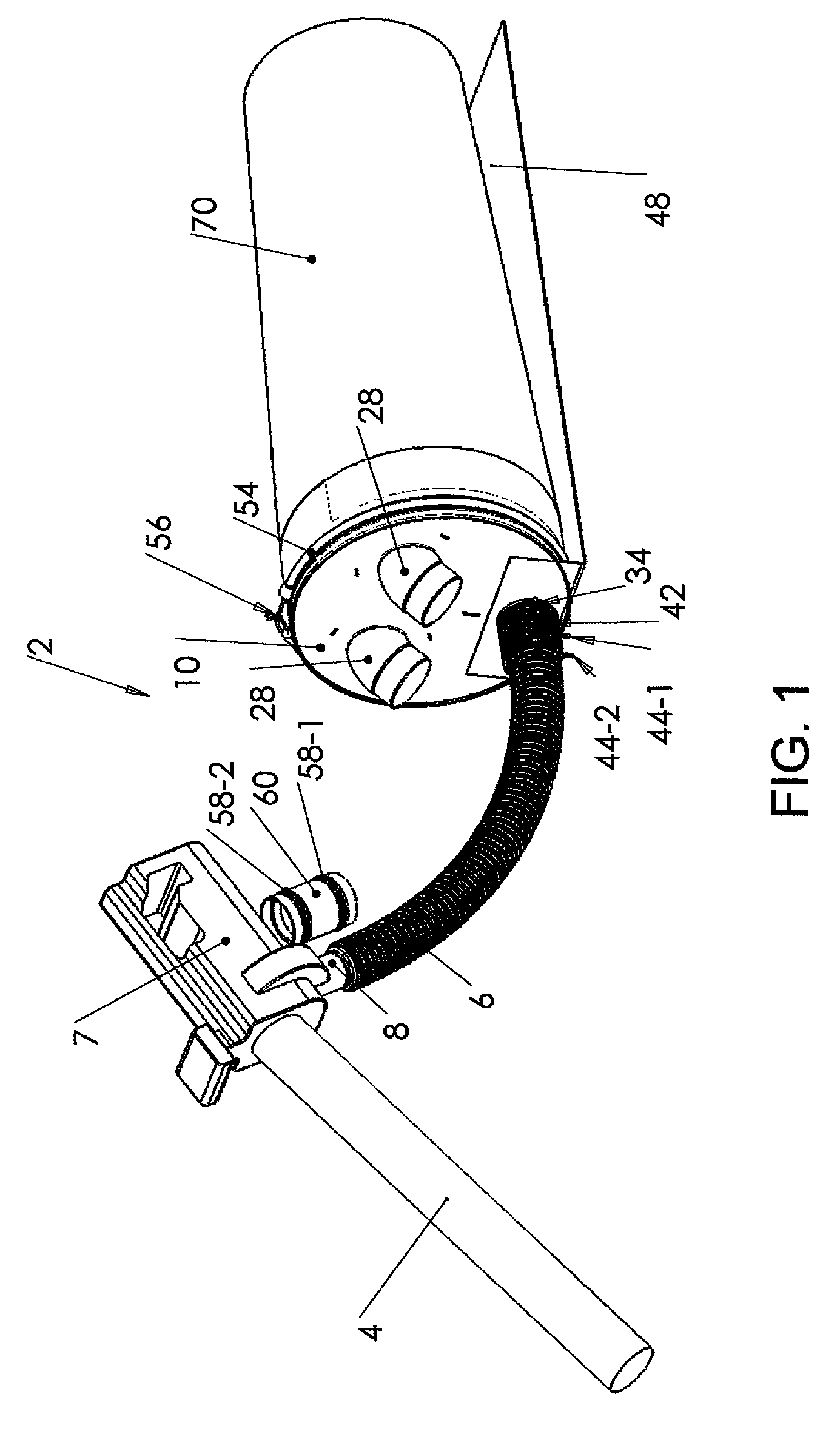

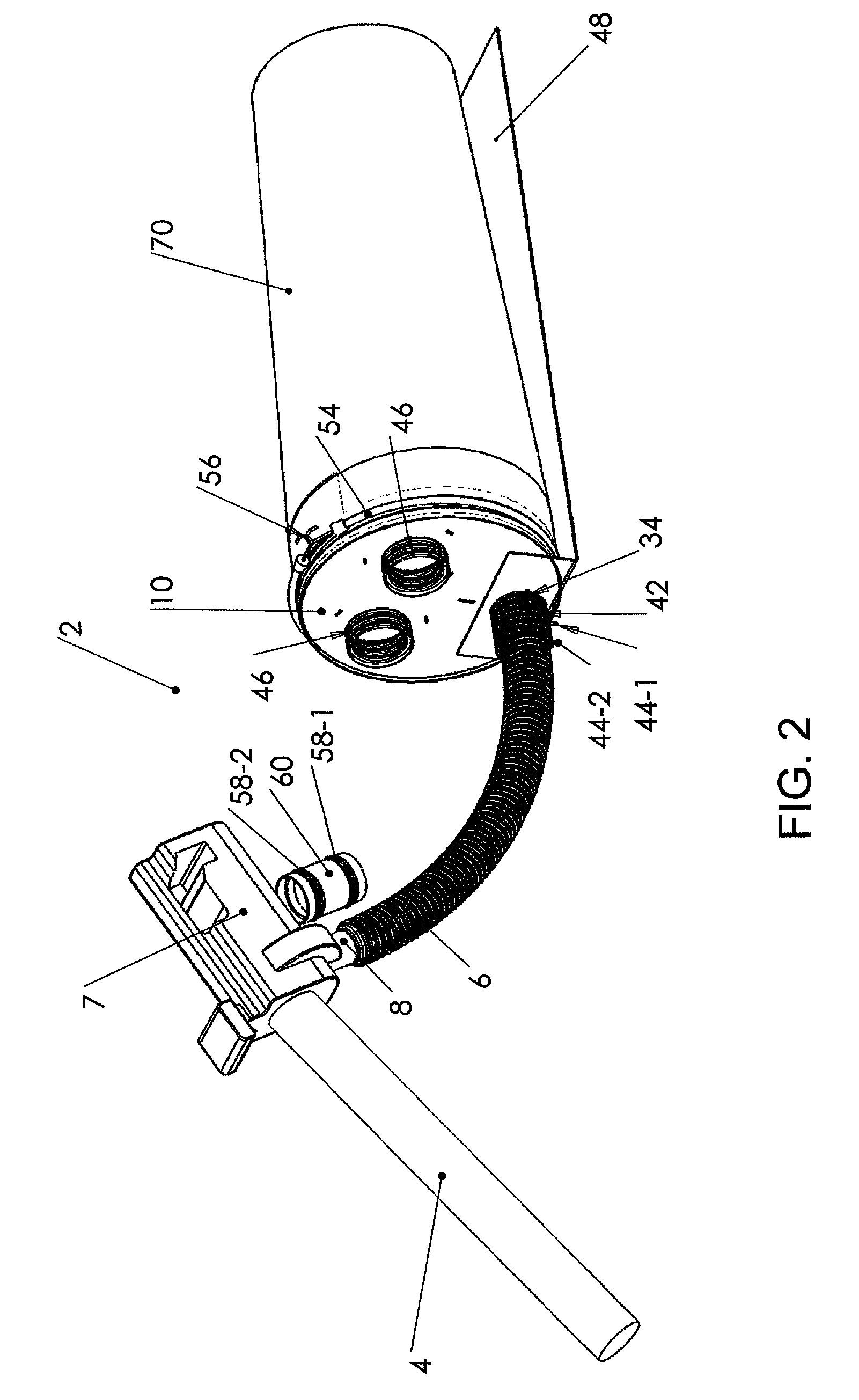

Leaves collection system for use with a portable blower/vacuum and a lid allowing the rejection and the retention of debris in a bag

InactiveUS20130031740A1Promote sportsSuction filtersHops/wine cultivationCollection systemEngineering

A leaves collection system for use with a portable blower / vacuum in the vacuum mode with a lid allowing the rejection of debris in a plastic or paper bag. The lid (of round shape with a lateral groove) has three main openings, one for the entrance of debris and two for the outlet of air as well as holes to attach the various elements to the lid with cable ties. The lid is inserted into the opening of the bag and the bag is held in place on the lateral edge of the lid by a bungee cord in the groove. Ribbed pipe connects the fan outlet of the blower / vacuum to the lid and sends debris towards the lid and the bag. A membrane under the bag protects the bag from the roughness of the ground.

Owner:LALIBERTE WILLIAM +1

Two-sided offset paper for paper bags and preparation method of two-sided offset paper

InactiveCN103397560ASolve the technical defects of poor strength and not suitable for application on paper bagsImprove folding resistanceWater-repelling agents additionInorganic compound additionFiberFolding endurance

The invention provides a piece of two-sided offset paper for paper bags. The two-sided offset paper is prepared from raw materials including fiber pulp and chemical additives, wherein the fiber pulp comprises the following components in percentage by weight: 50-100 percent of broadleaf wood bleached chemical pulp, 0-50 percent of needlebush bleached chemical pulp and 0-30 percent of high-yield pulp, and the Schopper-Riegler degree is 23-36SR; the chemical additives include the following components in terms of kg / ton of paper: 70-500kg of packing and 8-20kg of an internal sizing agent. According to the two-sided offset paper provided by the invention, the matching and pulp grinding of fiber are adjusted by selecting the types of fibers in the production process, and the brooming degree of pulp grinding is improved; meanwhile, the pressure of calendaring at the rear stage is adjusted and is controlled to be 10-30kg / cm<2>, the surface properties of the paper are improved, and the strength is effectively improved; according to the novel two-sided offset paper for the paper bags, the folding endurance range is 100-500 times, and the pressure of a squeezing part of a paper machine is increased, so that the traction force of paper at the rear section is reduced, the calendaring degree of a curling part is reduced, the stiffness of the paper is improved, and finally the printing performance of terminal customers is improved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Production process of degradable paper bag

ActiveCN110735360AImprove waterproof performanceImprove toughnessNon-fibrous pulp additionPaper/cardboardPolymer scienceEngineering

The invention relates to the technical field of packaging, and discloses a production process of a degradable paper bag. The degradable paper bag comprises a paper bag main body; and the paper bag main body comprises packaging paper and a waterproof film. The production process of the paper bag main body comprises the following steps: S1, a film spraying machine is adopted for conducting hot melting on the waterproof film, then spraying the waterproof film on the surface of the packaging paper for coating to form a waterproof layer, and carrying out hot melting on the waterproof layer for primary bonding with the packaging paper; and S2, blowing out hot air by using a hot air bag making machine, so that the waterproof film is further bonded with the packaging paper to prepare the water-proof paper bag. Compared with the prior art, the advantages are as following: the packaging paper is coated with the water-proof film using the film spraying machine, so that the water resistance of thepackaging paper is improved, and in addition, a toughening film is compounded, so that the toughness of the paper bag is improved.

Owner:浙江超凡科技股份有限公司

Agricultural pneumatic aerial fruit bagging machine

InactiveCN104663332AObstruction of normal trajectory movementSmooth motionPlant protective coveringsVertical planeAgricultural engineering

The invention relates to an agricultural pneumatic aerial fruit bagging machine and belongs to the technical field of manufacturing of agricultural garden machinery and tools. The agricultural pneumatic aerial fruit bagging machine comprises a housing, a sleeve, a main cylinder, a fastener ring and its extension arm, a support pillar, a manual rocker, a symmetrical measuring tape, a back-pack support and the like. The housing is driven to rise to specified height by charging of a large cylinder and elongating of a piston rod; the housing is swung in a vertical plane and aligned with an apple and a rail entry, by adjusting a telescopic device; small cylinders in the housing positively charge for driving, bearings and paper bag hooks are controlled, sliders are moved in a fixed direction on a rail, and a single bagging-sealing process is finished; a spring below a supporting base drives a paper bag holder and remaining paper bags to rise along a paper bag support pillar to specified height; the parts then reset. The agricultural pneumatic aerial fruit bagging machine has the advantages such as reasonable design, simple structure and convenience in use; labor intensity is reduced for laborers, and operational safety is guaranteed for the laborers.

Owner:刘轩 +3

Environmentally-friendly shopping paper bag water-proof outer film

InactiveCN105885165AAvoid pollutionImprove waterproof performanceLow-density polyethyleneMicrocrystalline wax

The invention discloses an environmentally-friendly shopping paper bag water-proof outer film, and relates to the technical field of plastic films. The environmentally-friendly shopping paper bag water-proof outer film is prepared from the following raw materials in parts by weight: 35-40 parts of low-density polyethylene, 10-15 parts of polypropylene, 6-10 parts of hydrogenated rosin, 6-10 parts of chitosan, 5-8 parts of filling mineral powder, 5-8 parts of hydrogenated castor oil, 4-6 parts of soybean protein gel, 4-6 parts of rice bran wax, 3-5 parts of sodium carboxymethyl starch, 2-3 parts of glyceryl stearate, 2-3 parts of polyether, 1-2 parts of butadiene rubber, 1-2 parts of microcrystalline wax, 0.5-1 part of urea and 0.5-1 part of antimonous oxide. The environmentally-friendly shopping paper bag water-proof outer film can be attached to the outside of a shopping bag to make an environmentally-friendly shopping bag, so that the water resistance, aging resistance and mechanical performance of the shopping bag are improved, and the problems of tendency to breakage and moisture absorption due to use of paper bags are solved; moreover, the film is biodegradable, so that environmental pollution caused by use of the plastic bag is avoided.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

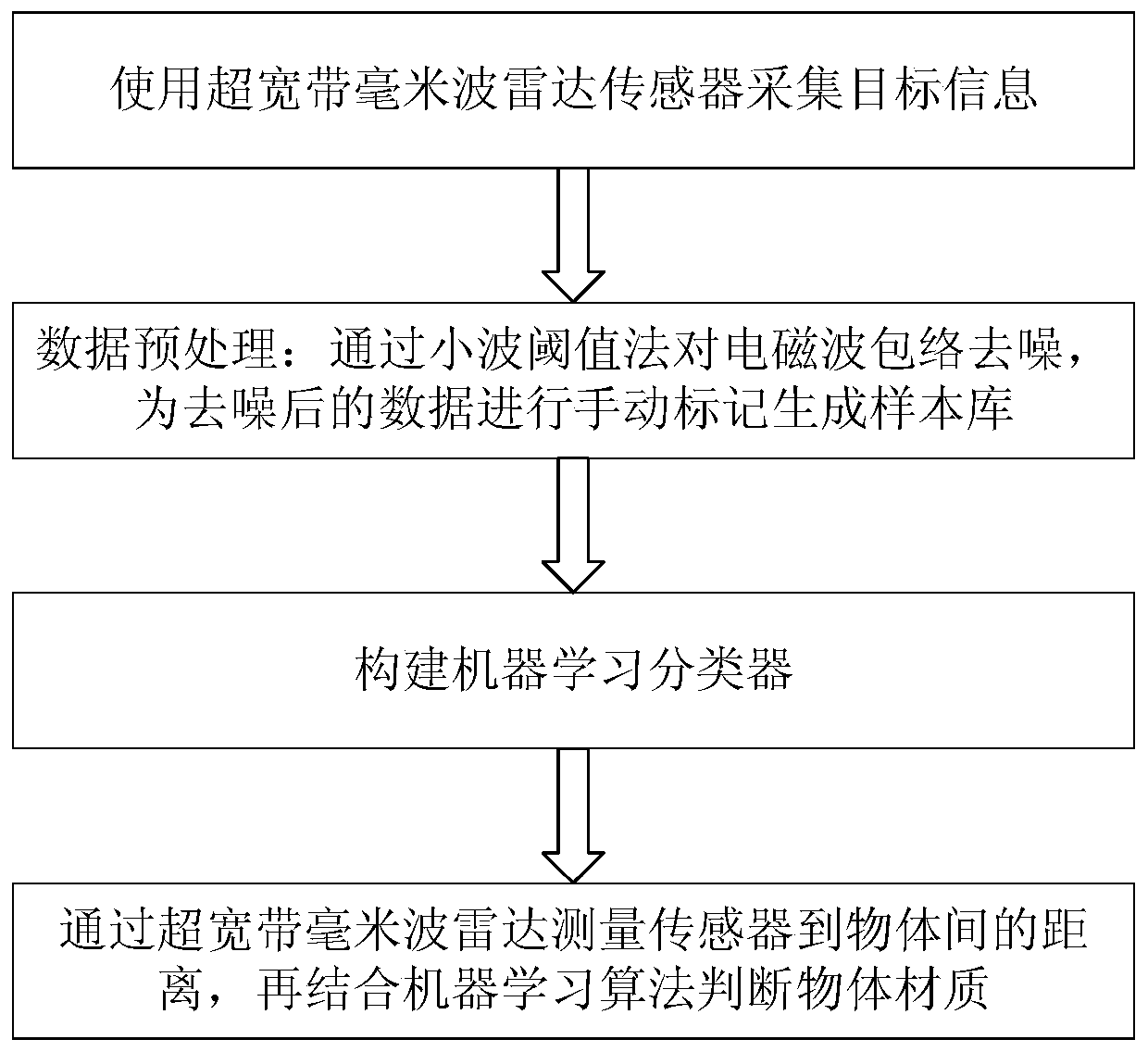

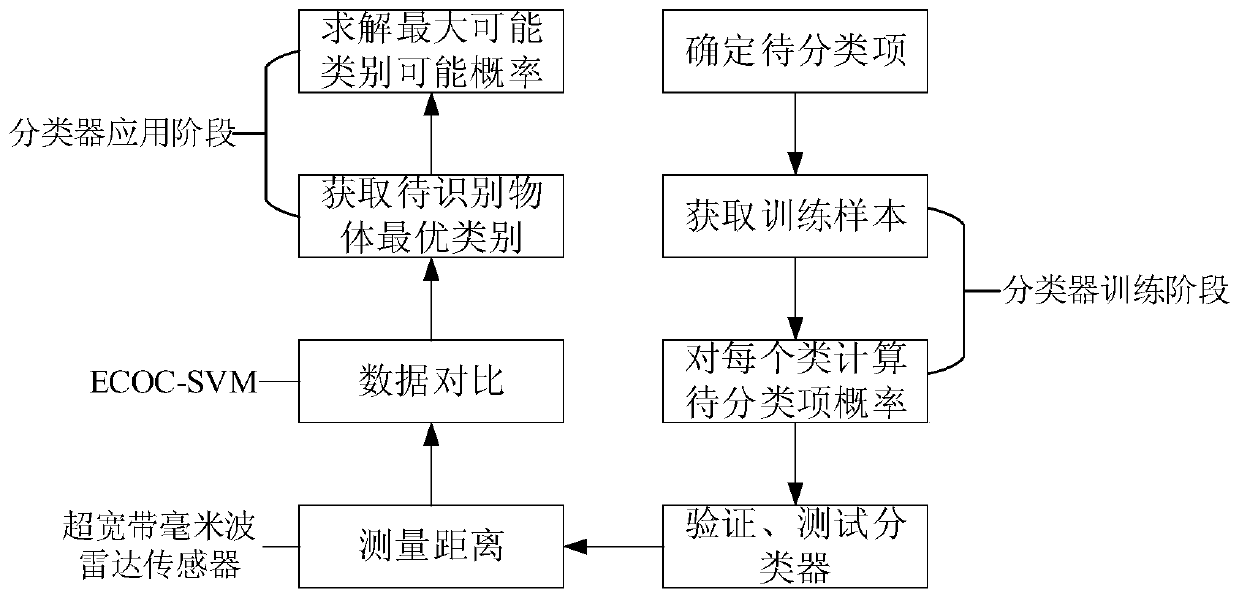

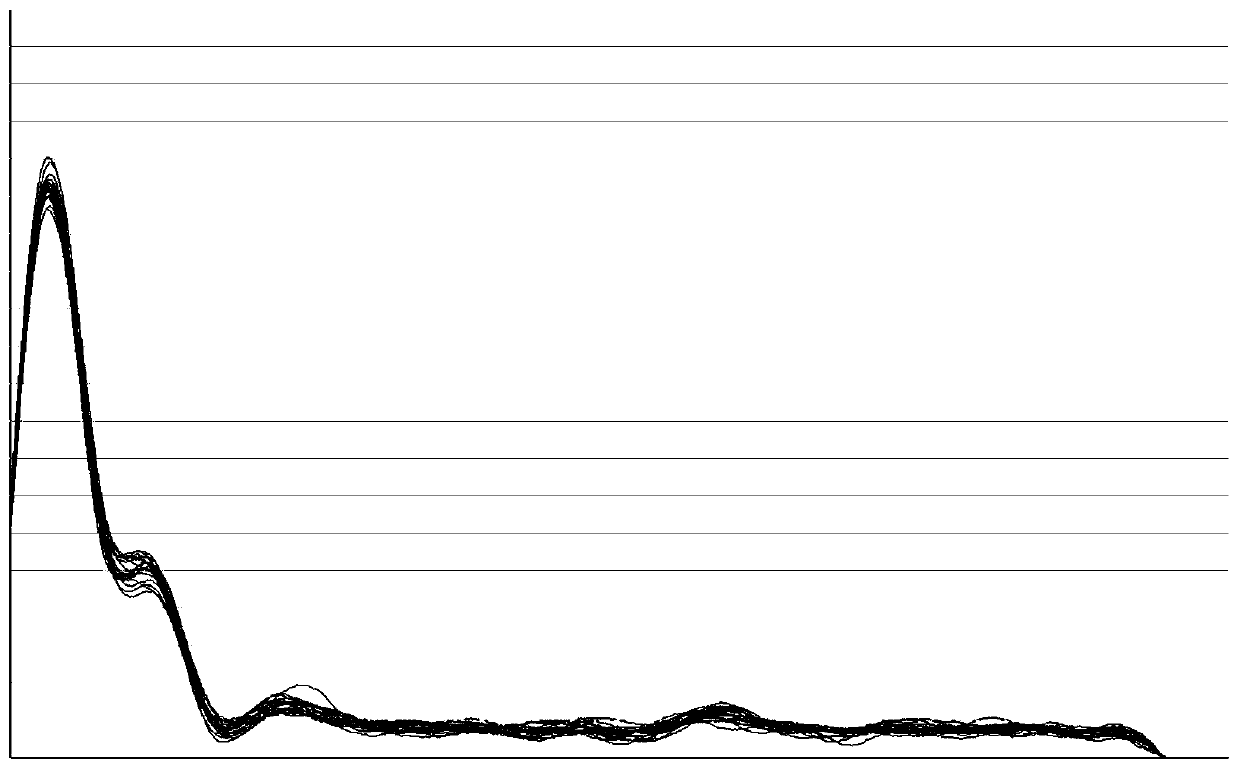

Millimeter wave radar material identification method based on machine learning

PendingCN110766067AReduce volumeStrong penetrating powerCharacter and pattern recognitionNeural architecturesPattern recognitionAlgorithm

The invention provides a millimeter-wave radar material identification method based on machine learning, and relates to the technical field of material identification, and the method comprises the steps: collecting target envelope information through a millimeter-wave radar sensor; de-noising the electromagnetic wave envelope, and manually marking the de-noised data to generate a sample library; constructing a machine learning classifier; measuring the distance between a sensor and an object through millimeter-wave radar, and judging the material of the object by combining a machine learningclassifier. Object materials are marked by detecting millimeter waves to obtain a large number of samples, a sample library is generated, a classifier is trained through a machine learning method, andfinally the object materials are judged in combination with the machine learning classifier and the envelope of electromagnetic waves reflected by a detection object. Compared with an existing identification method, the method has the advantages of being free of damage, low in power consumption, low in cost and low in complexity, and materials of to-be-detected targets or targets made of different materials can be normally identified in non-transparent plastic bags or paper bags or plastic boxes or paper boxes.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

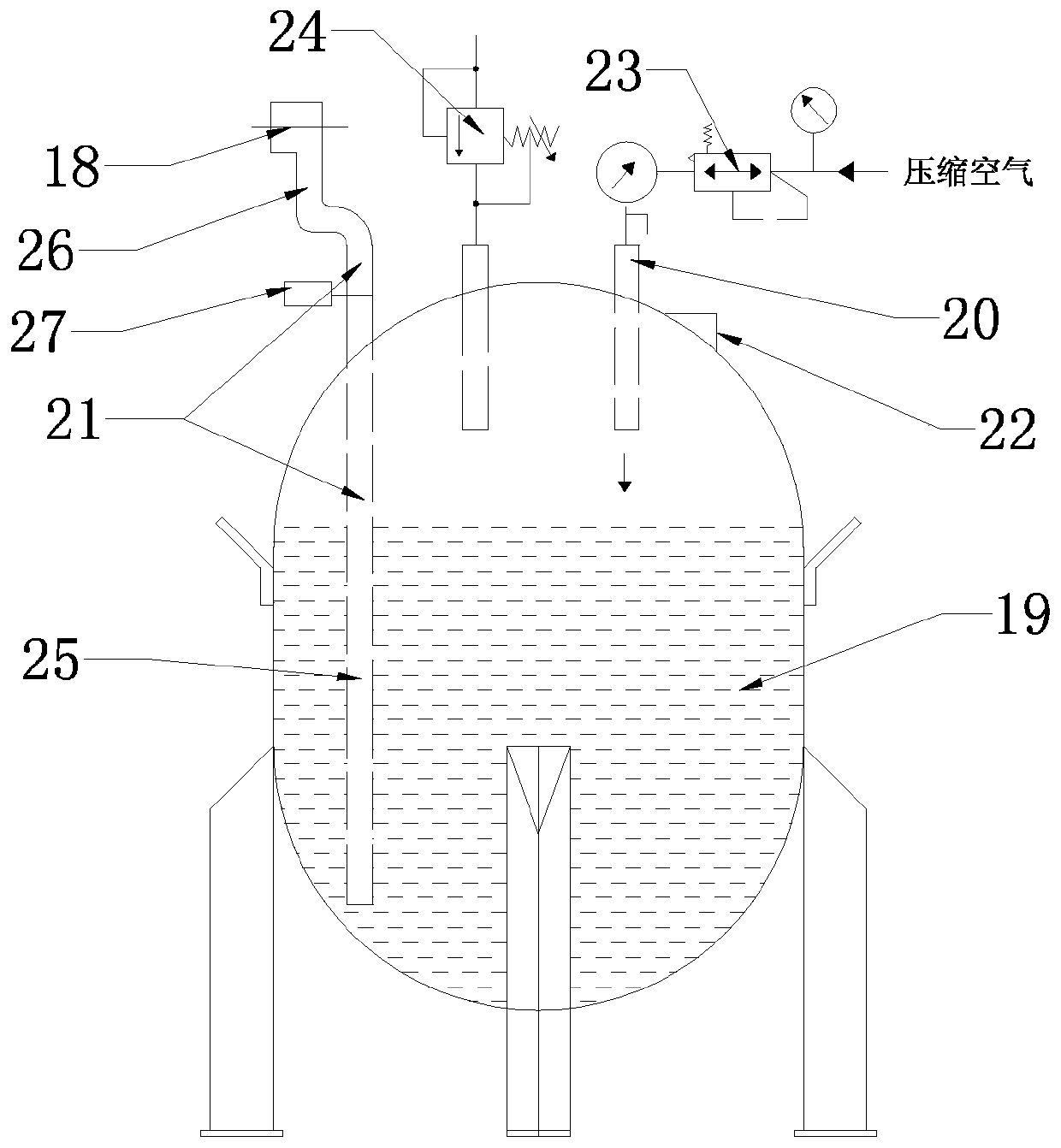

High-speed paper bag bottom gluing device

PendingCN111114010AEasy to fold and shapeSolve efficiency problemsBag making operationsPaper-makingAdhesive glueSpring force

The invention discloses a high-speed paper bag bottom gluing device. The high-speed paper bag bottom gluing device comprises a glue applying shaft, a glue spraying roller arranged on the glue applyingshaft in a sleeving mode and a plurality of glue spraying heads, wherein the glue spraying roller is installed on the glue applying shaft in a sealed mode, so that an annular cavity allowing glue tobe fed from an inlet pipeline is formed between the glue spraying roller and the glue applying shaft, each glue spraying head comprises a valve seat installed on the glue spraying roller, a valve element arranged in the corresponding valve seat, a compressed spring abutting against the bottom of the corresponding valve element and a sealing ring arranged at a glue outlet of the corresponding valveseat, the upper ends of the valve elements can stretch out of the glue outlets formed in the tops of the valve seats and can seal the glue outlets by using the sealing rings under the action of the compressed springs, and the glue spraying heads can enable the valve elements to overcome spring force to enable the glue outlets to discharge the glue in the glue applying process. The high-speed paper bag bottom gluing device has the advantages that high-speed running of more than 500 paper bags per minute can be achieved, the glue is not thrown, the bottoms of the paper bags are stably and automatically coated with the glue, the paper bags can be conveniently folded and formed, so that the gluing quality is guaranteed, continuous automatic production can be achieved, and then the problem ofthe efficiency of a paper bag machine is solved.

Owner:上豪包装机械(镇江)有限公司

Method for preparing wrapping paper from pineapple leaf fibers and banana caulo pulp

InactiveCN109112891AAntibacterial effect hasHigh strengthFlexible coversWrappersFiberUltimate tensile strength

The invention discloses a method for preparing composite wrapping paper from pineapple leaf fibers and banana caulo pulp. The method comprises the following steps: separately preparing the pineapple leaf fibers and the banana caulo pulp at first; and then mixing the pineapple leaf fibers and the banana caulo pulp according to a ratio of 1: 50 to 1: 100 to prepare the composite paper. During preparation of the refined pineapple leaf fibers, a combined ultrasonic wave-biological enzyme process is preferred for degumming, so high efficiency and low environmental influence are realized. The invention also discloses a process for preparing the composite paper by braiding the pineapple leaf fibers into a grid which is used as a keel and then mixing the keel with the banana caulo pulp. The prepared paper has high strength, and the environmental protection, physical property detection and antibacterial effect detection results of the paper can meet requirements on packaging paper bags.

Owner:SHENZHEN POLYTECHNIC +1

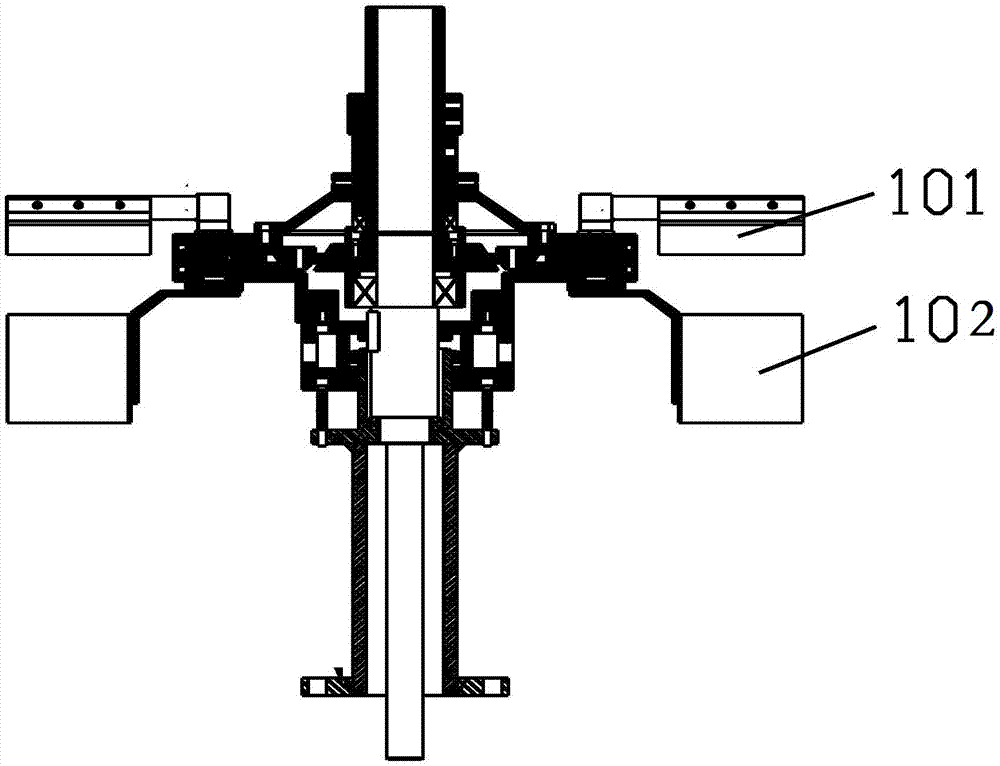

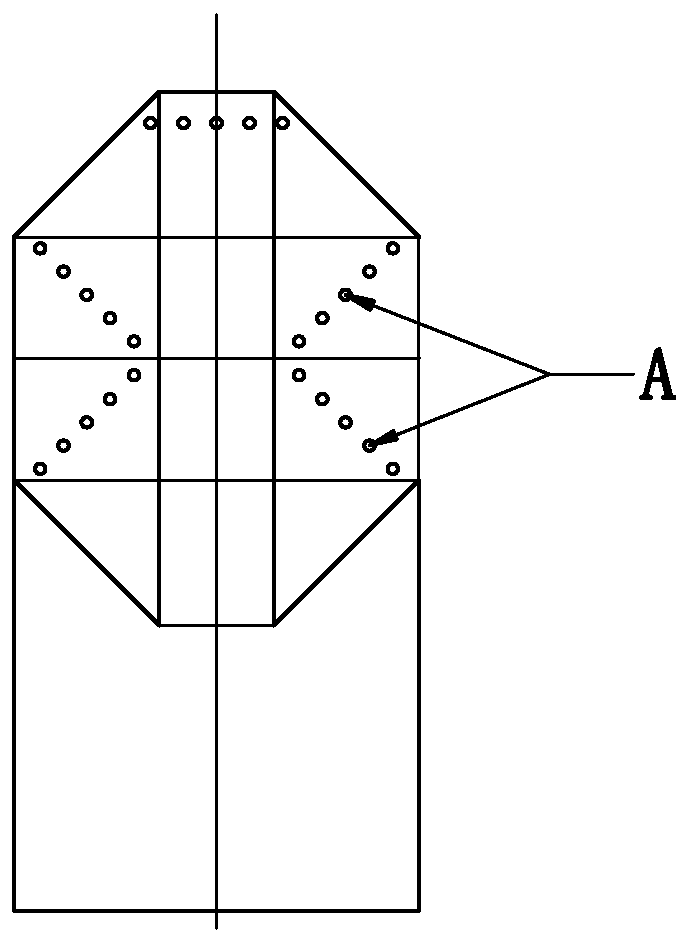

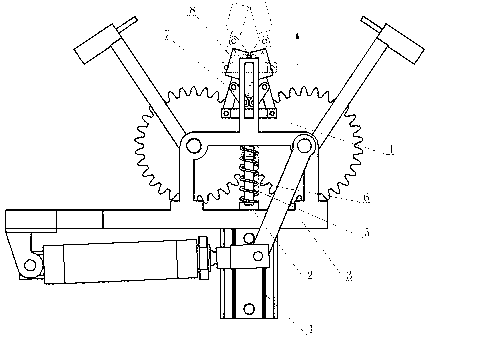

Punching device for formed portable paper bag

The invention discloses a forming device for punching a gift rope hole in a portable bag production line. The forming device is characterized in that a long groove and two symmetrical round holes are formed in a stand; a piston rod is connected with an ejection rod; the head of the ejection rod is hinged with a connecting rod; the other end of the connecting rod is hinged with the middle of a receiving plate; the bottom end of the receiving plate is hinged with a travel plate; two ends of the travel plate are inserted into the long groove of the stand; a spring is arranged between the travel plate and a piston; swing shafts are sleeved in the round holes of the stand; a pair of gears with the same tooth number is arranged at the rear ends of the swing shafts; two swing arms are symmetrically arranged on the swing shafts; punching heads are arranged on the swing arms; and a dual-lug connector at the head of a swing tail air cylinder is connected with a force arm which is connected with one swing shaft. During work, the travel plate is pushed by the spring to move forwards along the long groove of the stand, the receiving plate also moves forwards and is inserted into a bag opening of the portable bag; the force arm drives one swing shaft to rotate; another swing shaft is driven by the gear at the rear end of the previous swing shaft to rotate reversely; and the swing arms on the swing shafts drive the punching heads to swing towards the direction of the receiving plate, and thus the aim of punching is achieved.

Owner:HANGZHOU BITE GREENPACK CO LTD

Paper bag machine and paper upper-opening folding device

ActiveCN104260417AEasy to assembleEasy to debugBag making operationsBox making operationsCardboardPulp and paper industry

The invention discloses a paper bag machine and a paper upper-opening folding device. The paper upper-opening folding device comprises a support assembly and an upper-opening folding assembly, wherein the support assembly comprises a support rod, a paper through plate and a paper cushion block, the paper through plate is arranged on the upper surface of the support rod, the outer end of the paper through plate is bulged on the outer side surface of the support rod, the rear side surface of the paper cushion block is in close fit with the support rod and the inner end surface of the paper through plate, and the upper surface of the paper cushion block is in the shape of a downwards-inclined slope; the upper-opening folding assembly comprises a stop plate and a bent piece, the stop plate is fixed at the upper end of a stop plate fixing rod, the bottom surface of the stop plate is in fit with the upper surface of the paper cushion block, the bent piece is arranged at the upper end of the stop plate, a slide groove is formed in the upper end of the bent piece, and the upper and lower positions of the bent piece can be adjusted with the slide groove. According to the paper bag machine and the paper upper-opening folding device disclosed by the invention, a paper upper-opening folding process is finished for the conveyed paper according to upper-opening indentations by using the stop plate and the bent piece; the paper bag machine and the paper upper-opening folding device are simple in structure, convenient for operating personnel to assemble and debug the device, capable of realizing the upper-opening folding process on the paper bag machine, multi-purpose, capable of increasing the production efficiency, and wide in practicability.

Owner:WENZHOU ZENBO PRINTING MACHINERY

Leaves collection system for use with a portable blower/vacuum and a lid allowing the rejection and the retention of debris in a bag

A leaves collection system for use with a portable blower / vacuum in the vacuum mode with a lid allowing the rejection of debris in a plastic or paper bag. The lid (of round shape with a lateral groove) has three main openings, one for the entrance of debris and two for the outlet of air as well as holes to attach the various elements to the lid with cable ties. The lid is inserted into the opening of the bag and the bag is held in place on the lateral edge of the lid by a bungee cord in the groove. Ribbed pipe connects the fan outlet of the blower / vacuum to the lid and sends debris towards the lid and the bag. A membrane under the bag protects the bag from the roughness of the ground.

Owner:LALIBERTE WILLIAM +1

Honeycomb buffer shockproof, moisture-proof and flame-retardant express bag or packaging bag and bag making production line thereof

InactiveCN111907904AReasonable designIngenious ideaMechanical working/deformationEnvelopesHoneycombEngineering

The invention relates to a honeycomb buffer shockproof, moisture-proof and flame-retardant express bag or packaging bag and a paper bag production line thereof. The express bag or packaging bag is formed by folding and adhering composite paper, wherein the composite paper comprises a middle layer, an upper surface layer and a lower surface layer. The express bag or packaging bag is characterized in that the upper surface layer and the lower surface layer are both kraft paper, the middle layer is in a corrugated shape formed by stretching honeycomb paper, and the three layers are connected through glue; the honeycomb paper is flame-retardant paper with a plurality of longitudinal tearing lines and / or cutting marks evenly distributed on the upper face, the longitudinal tearing lines and / or cutting marks are distributed in a matrix mode, and every two adjacent rows of longitudinal tearing lines and / or cutting marks are staggered; and the honeycomb paper is stretched, the longitudinal tearing lines and / or cutting marks are torn open, the flame-retardant paper between every two adjacent tearing lines and / or cutting marks is twisted, and the corrugated shape is formed. The corrugated shape formed by stretching the honeycomb paper is adopted for replacing previous small bubbles, buffer and shockproof functions are achieved, and meanwhile the whole express bag or packaging bag is madeof paper, is easy to degrade and cannot affect the environment.

Owner:杨介思

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com