Carry bag machine and automatic head card gluing device thereof

A handbag machine and header card technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of low yield, difficult to meet the needs of large-scale mass production, low work efficiency, etc., and achieve high yield Improvement, saving manpower and material resources, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings.

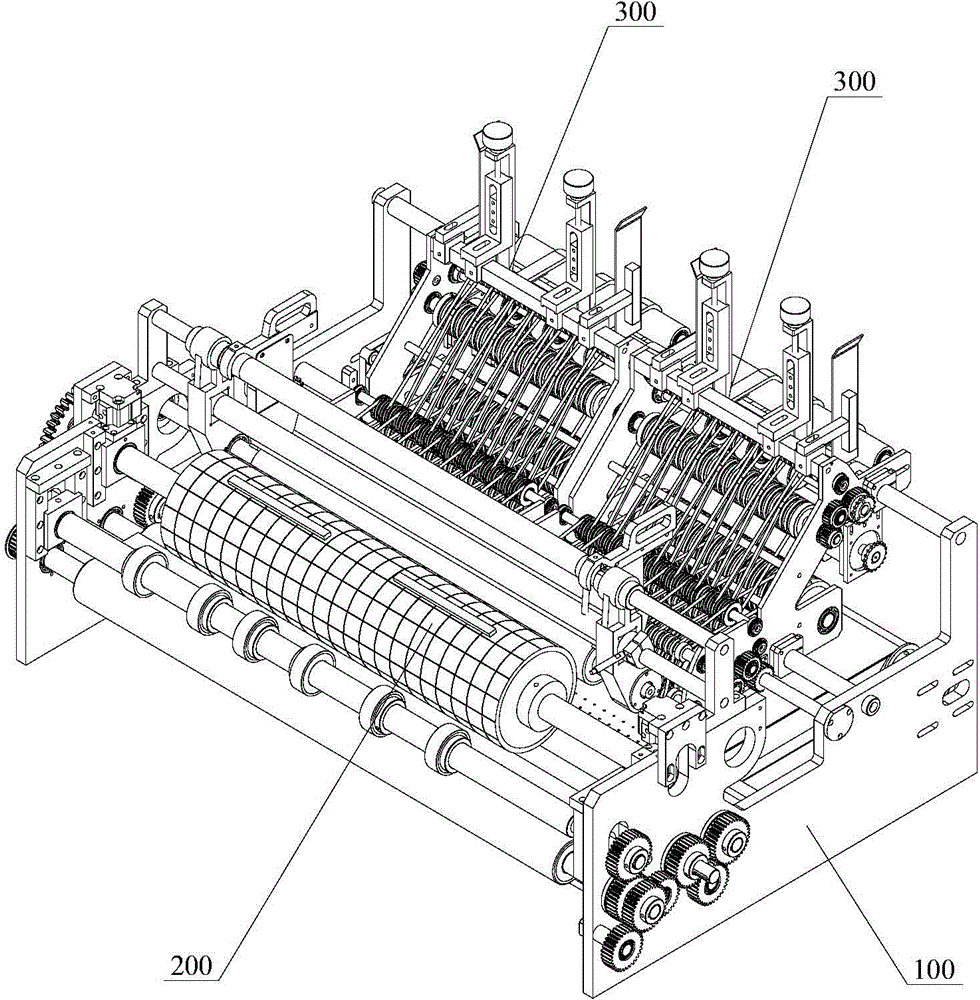

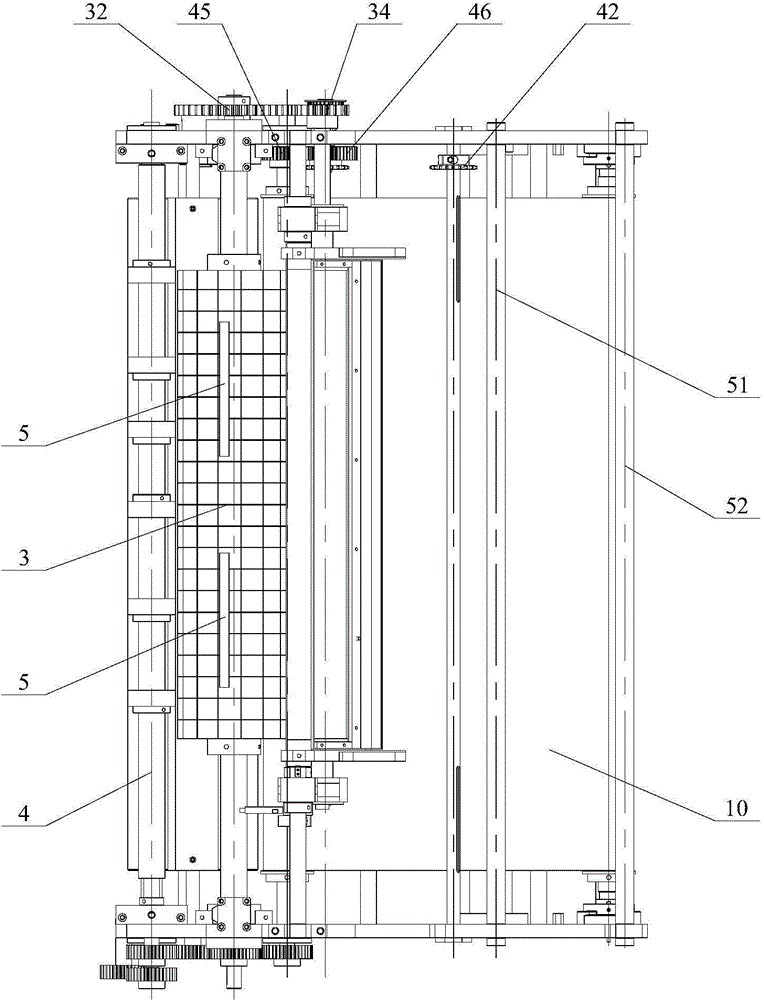

[0029] like Figure 1 to Figure 8 As shown, the present invention provides an automatic head card sticking device for a handbag machine, including a fixing frame 100, a paper input printing glue assembly 200 arranged on the fixing frame, two sets of head card conveying and bonding assemblies 300, and a driving device.

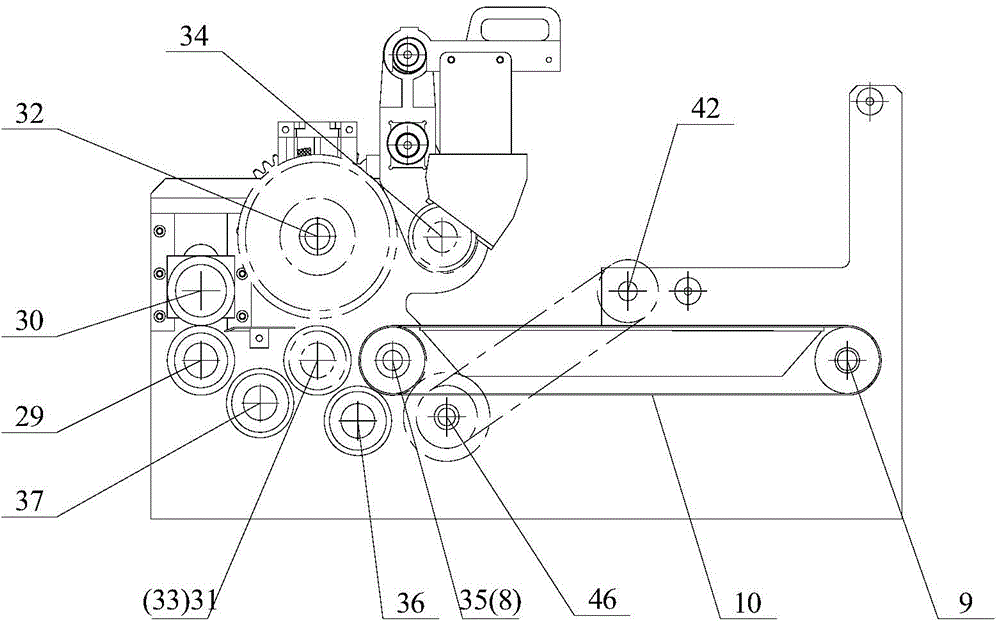

[0030] like Figure 2 to Figure 4 As shown, the paper input printing rubber assembly includes a first paper feeding roller 1, a second paper feeding roller 2, a printing rubber roller 3 and a paper pressing roller 4 that are rotatably arranged on the fixed frame, and the paper pressing roller and the printing rubber roller are respectively set correspondingly On the upper ends of the first paper feeding roller and the second paper feeding roller, the first and second paper feeding rollers are arranged in parallel correspondingly, and two sizing sponges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com