Patents

Literature

38results about How to "Eliminate manual inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

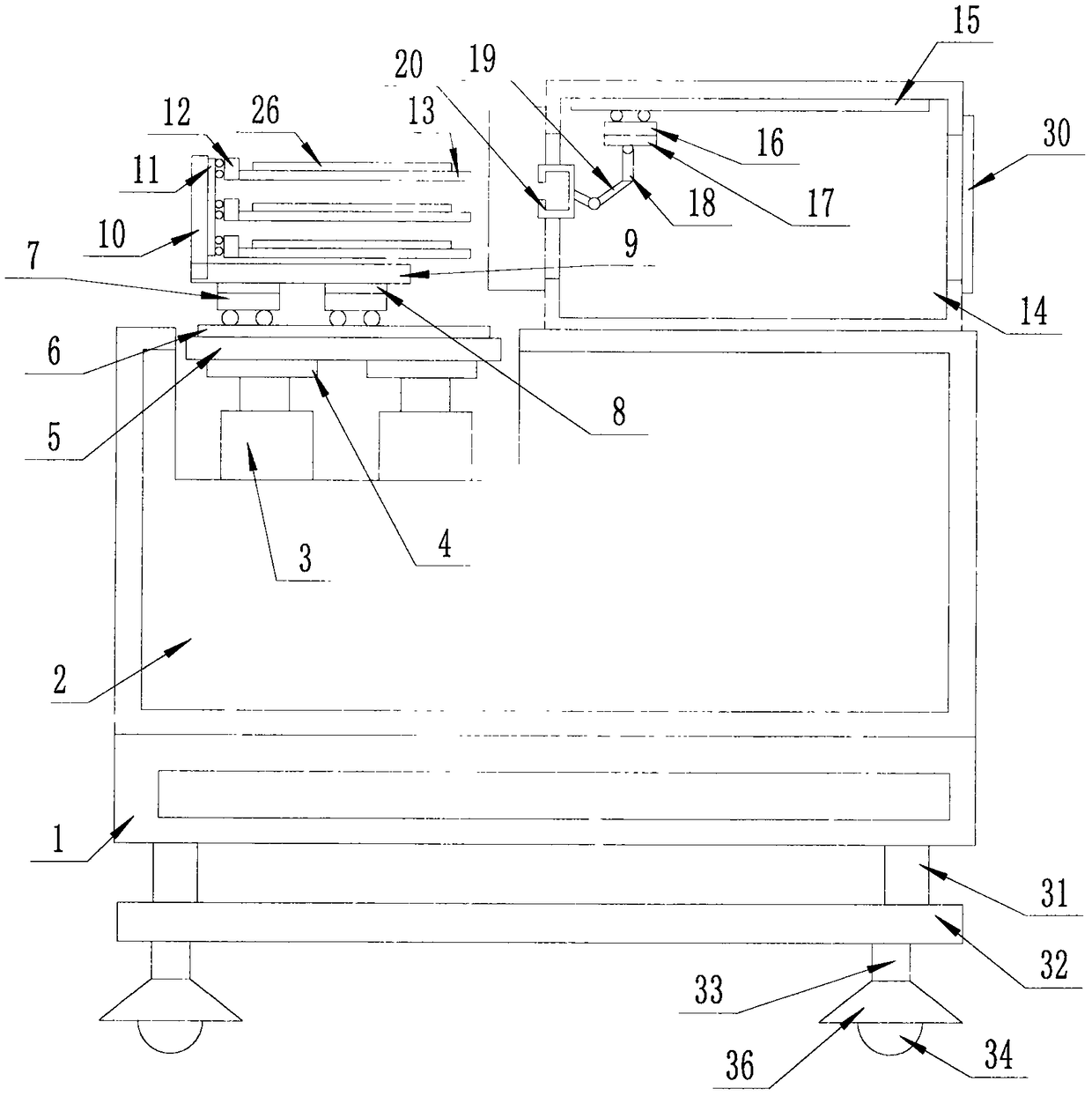

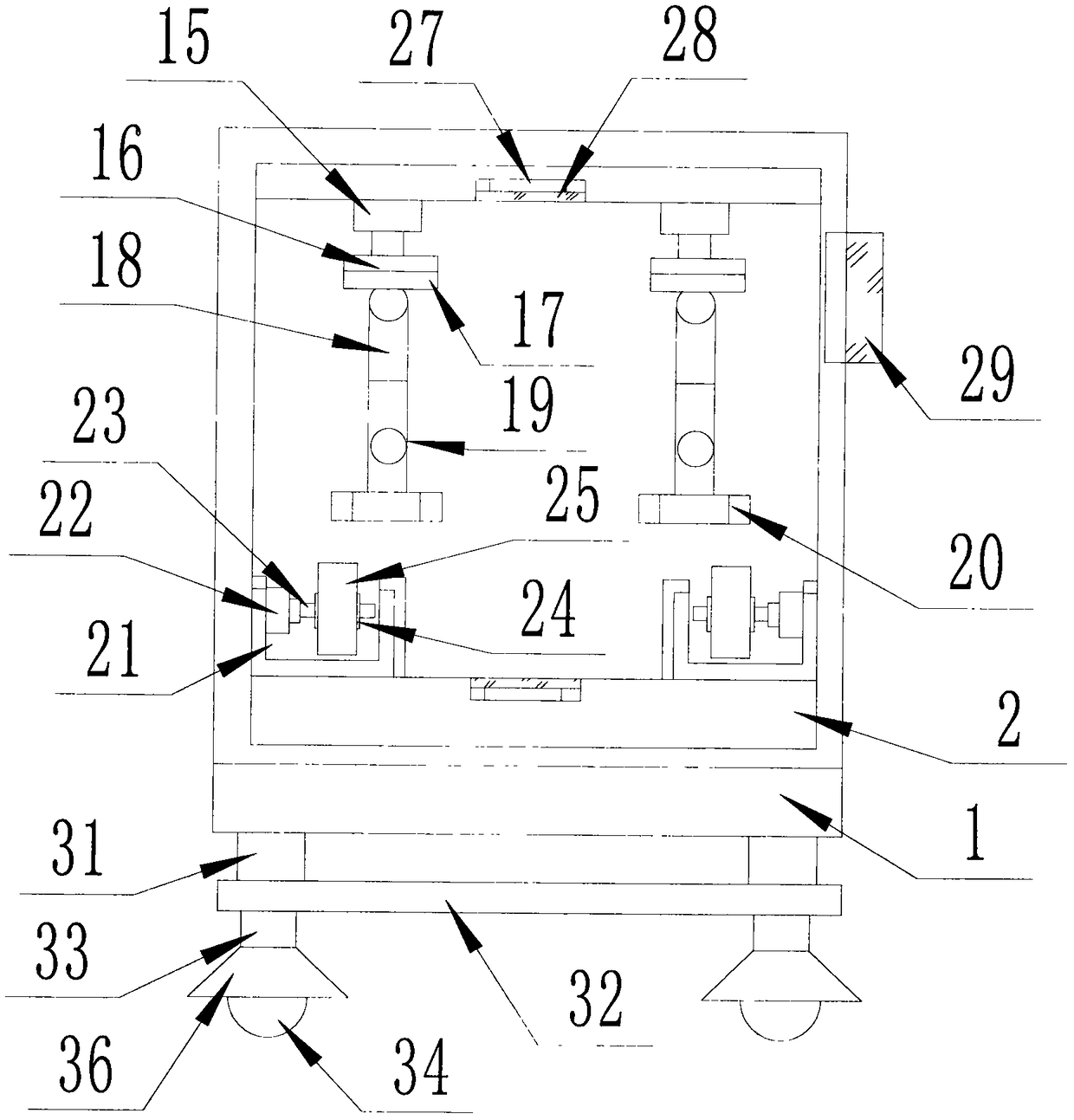

Method for detecting soldering points of electronic product complete machines and performing tin soldering on electronic product complete machines

ActiveCN104668695ASave human effortAvoid inaccuracyMetal working apparatusWelding apparatusSolderingData memory

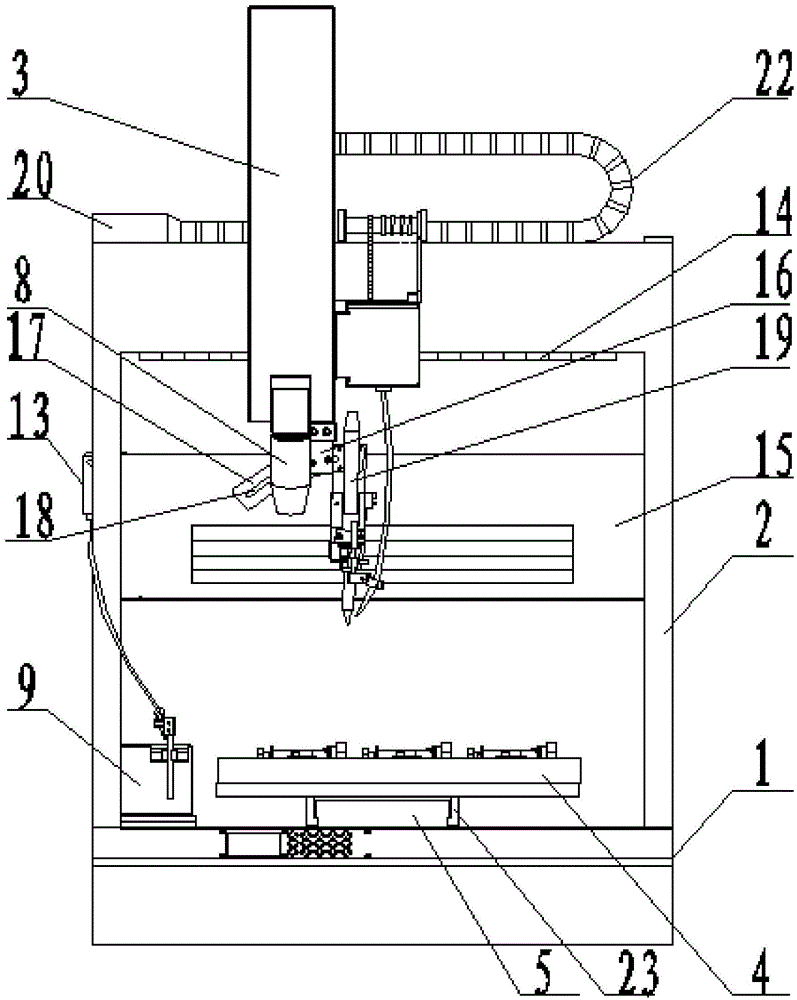

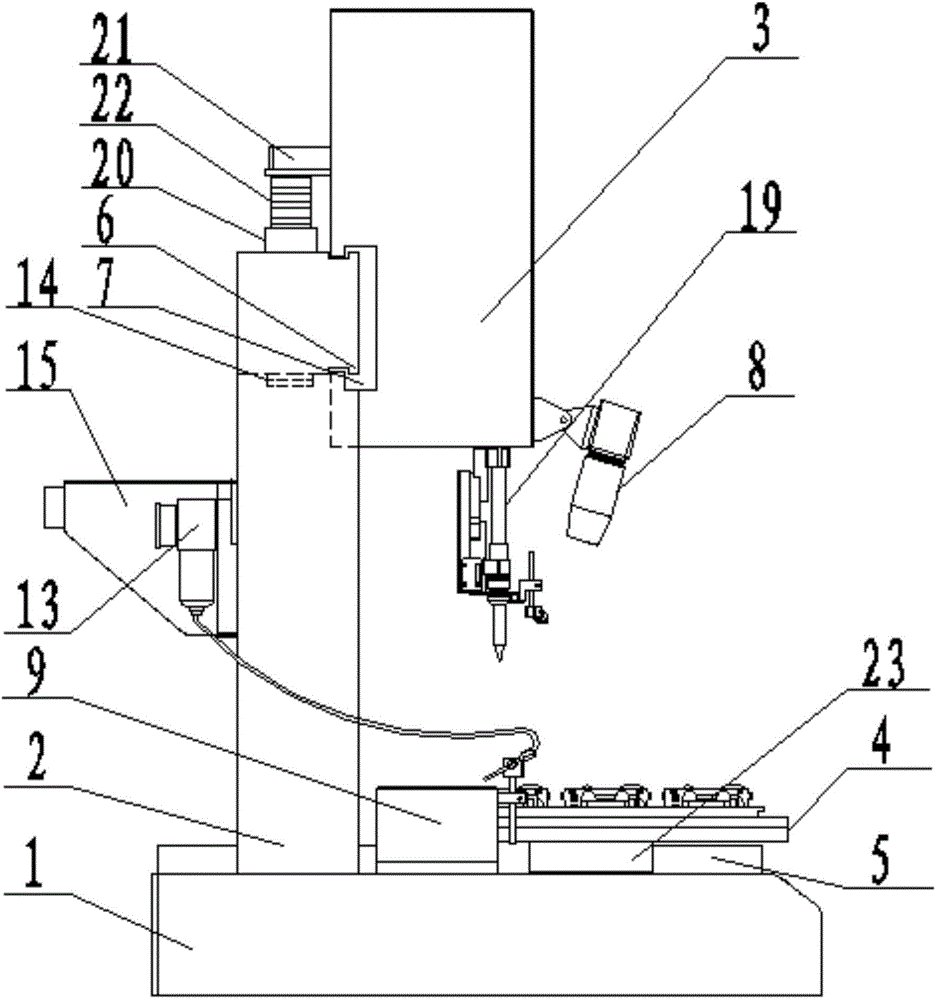

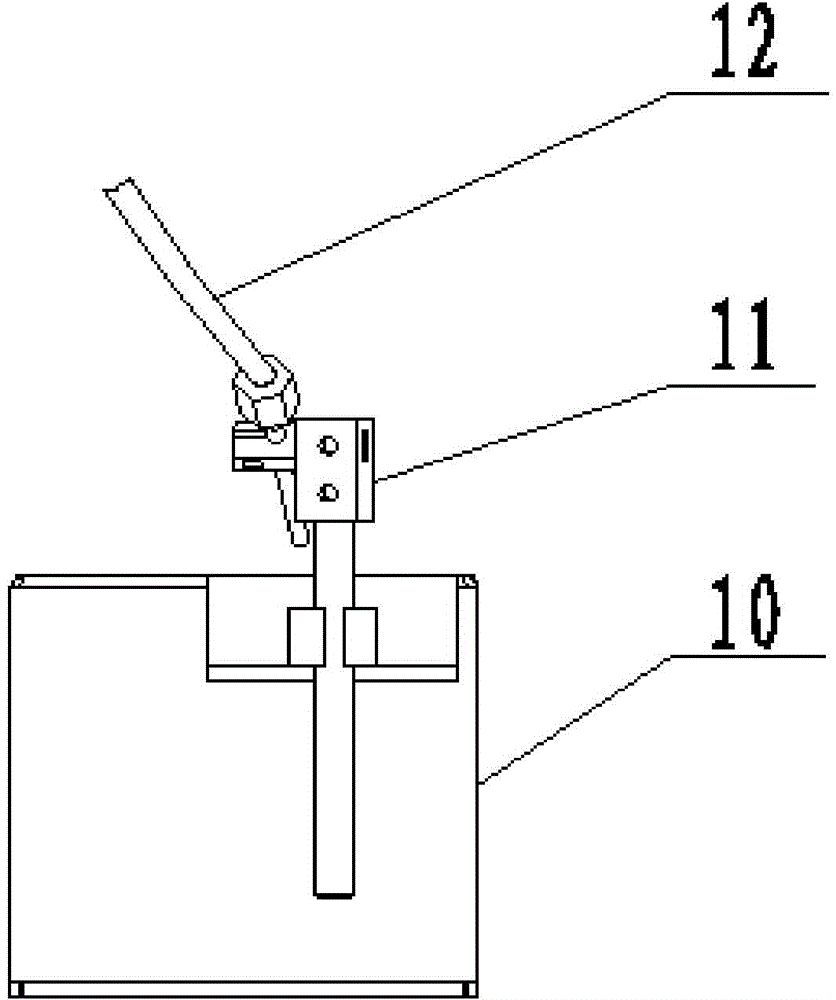

The invention provides a method for detecting soldering points of electronic product complete machines and performing tin soldering on the electronic product complete machines. The method is implemented by the aid of an automatic tin soldering machine with a CPU (central processing unit). The automatic tin soldering machine structurally comprises a workbench, an X-axis, a Y-axis, a Z-axis and a four-axis numerical control system, wherein the four-axis numerical control system is formed around a rotating shaft of the Z-axis. A soldering head is fixed on the Z-axis which is fixedly provided with an industrial camera. The method includes that standard image information of various kinds of qualified electronic product complete machines is stored in a data storage unit of the CPU, the industrial camera acquires an image of a to-be-detected electronic product complete machine, the image is stored in the data storage unit and is transmitted to a data processor, the data processor compares to-be-detected image information with the standard information in the data storage unit, if the image information is identical to the standard information, tin soldering points of the to-be-detected complete machine are qualified, or otherwise, the tin soldering points are unqualified, the data storage unit displays differences of the to-be-detected image on a display screen in a partial enlarged manner, repair soldering is performed, and if the soldering points are still unqualified, manual detection is performed.

Owner:河北科瑞达仪器科技股份有限公司

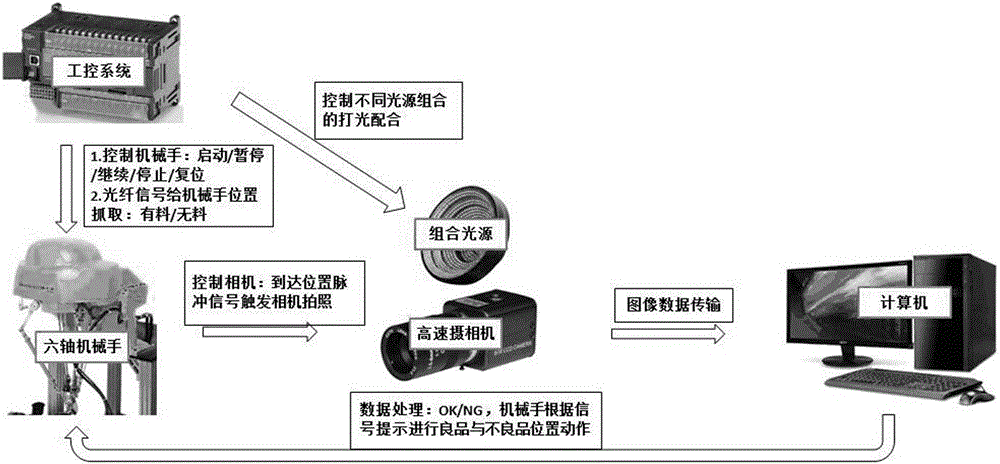

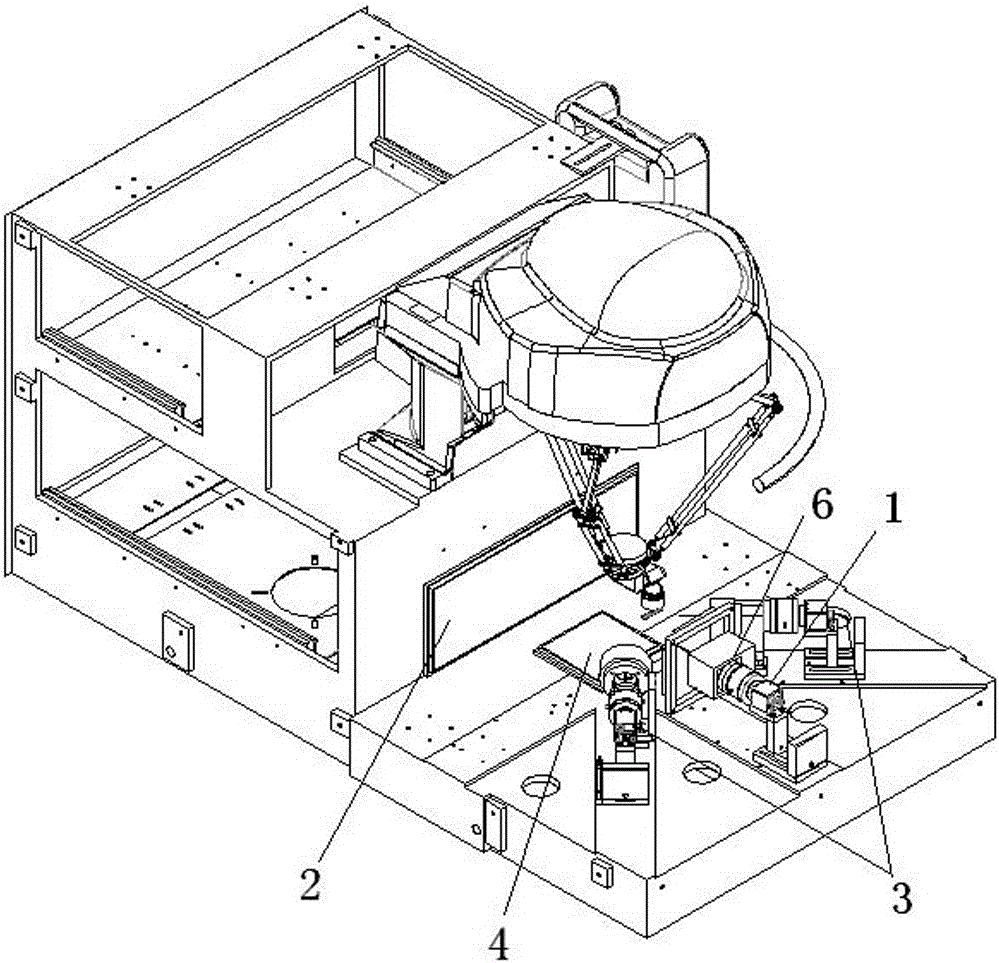

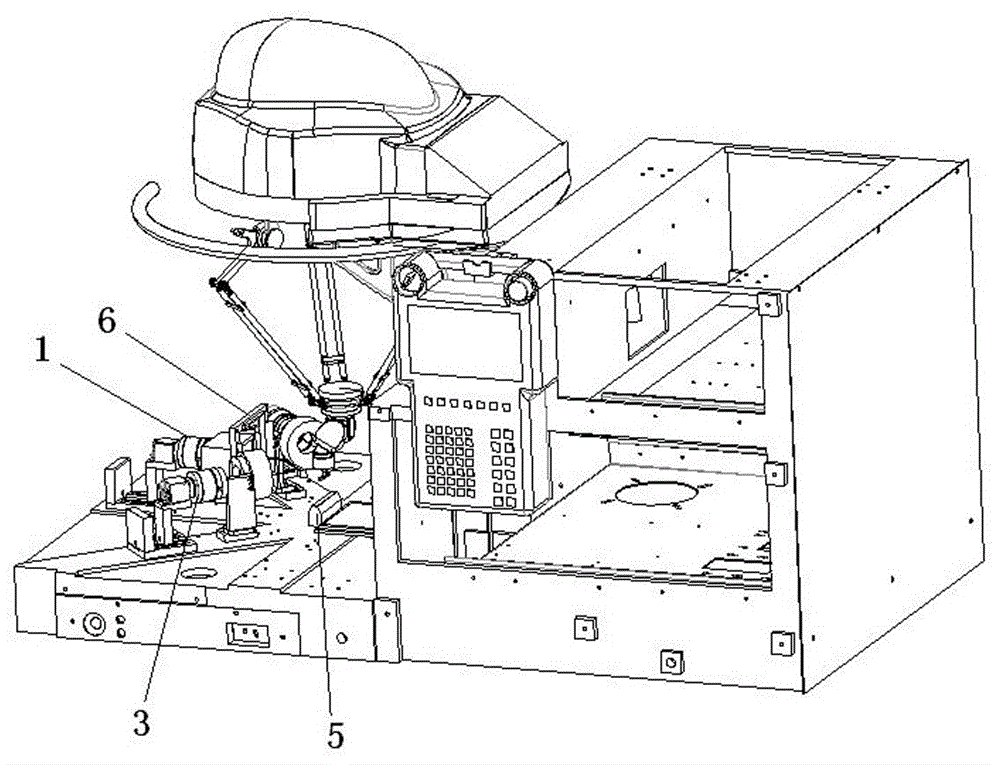

Universal image visual inspection robot

InactiveCN105890669AShorten the timeCost savingsProgramme-controlled manipulatorMeasurement devicesStereo cameraVisual inspection

The invention discloses a universal image visual inspection robot which comprises the following parts mounted in a robot body: a precision six-axis manipulator, a combined light source, a high-speed camera, a computer and an industrial control system, wherein the computer is connected with and controls the combined light source and the precision six-axis manipulator; the industrial control system controls the operation of the precision six-axis manipulator and opening / closing and selection of the combined light source; the high-speed camera is connected with the computer and instantaneously transmits the image information to the computer. The universal image visual inspection robot disclosed by the invention has the advantages that 1) the production cost is reduced; 2) missing detection is eliminated; 3) the universality is high.

Owner:KUNSHAN VINTAGE PRECISION MACHINERY

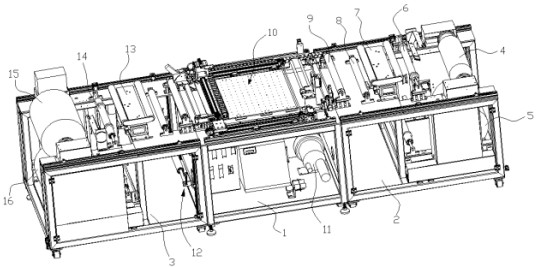

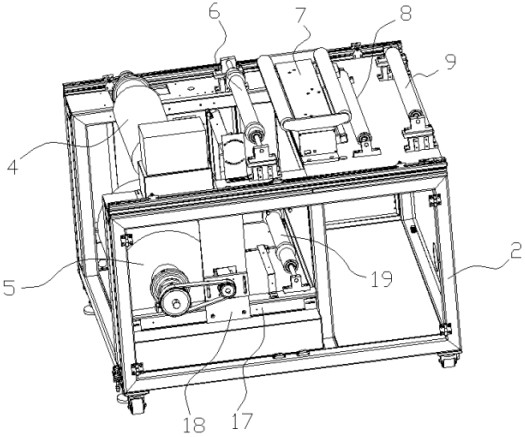

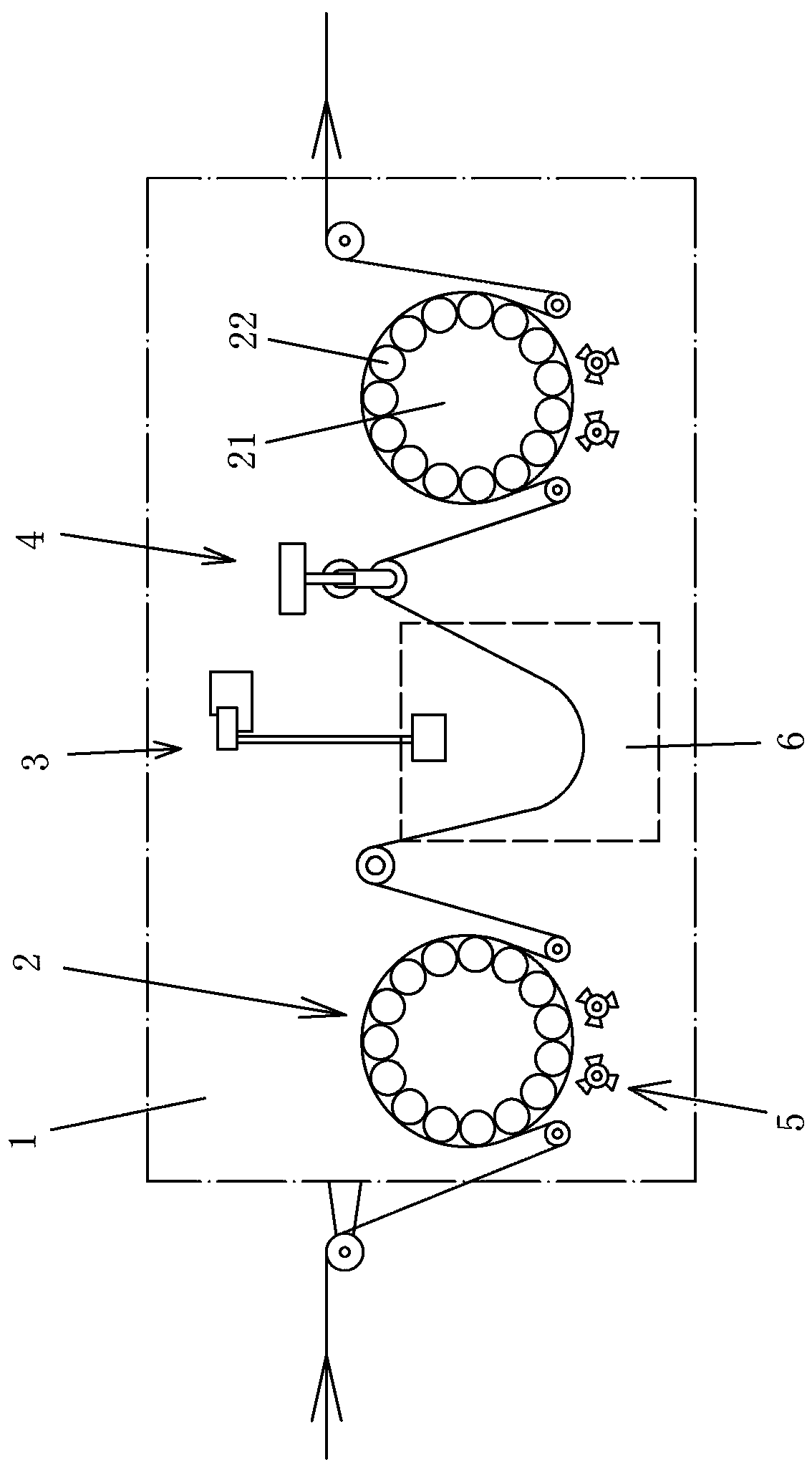

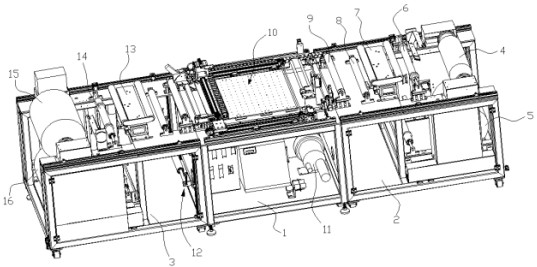

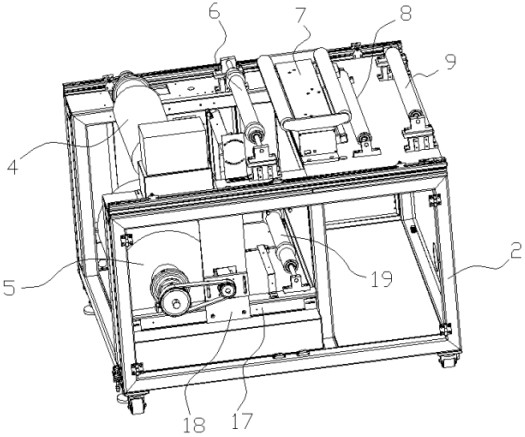

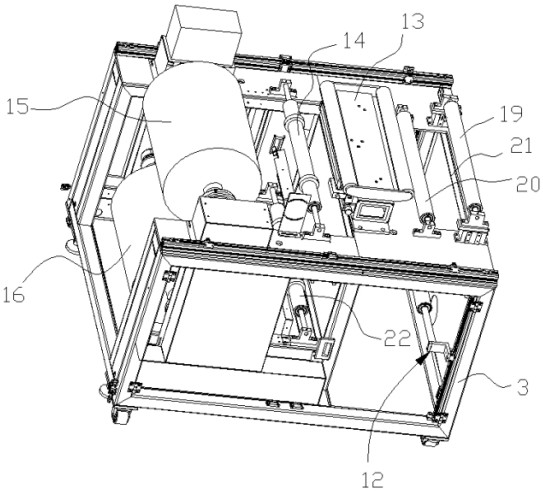

Flexible circuit board reinspection equipment

ActiveCN113777114AReduce labor intensityEliminate manual inspectionMaterial analysis by optical meansWebs handlingFlexible circuitsStructural engineering

Owner:佛山市坦斯盯科技有限公司

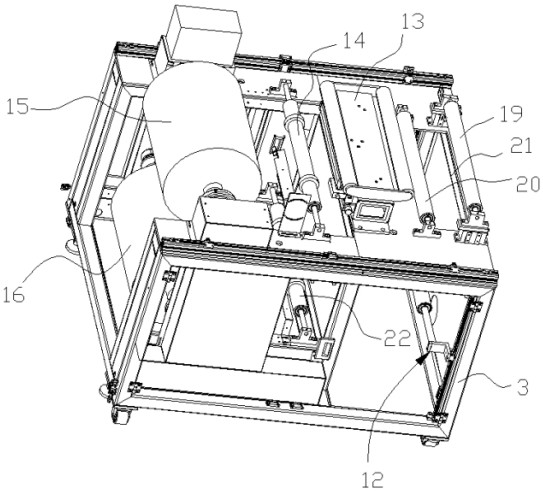

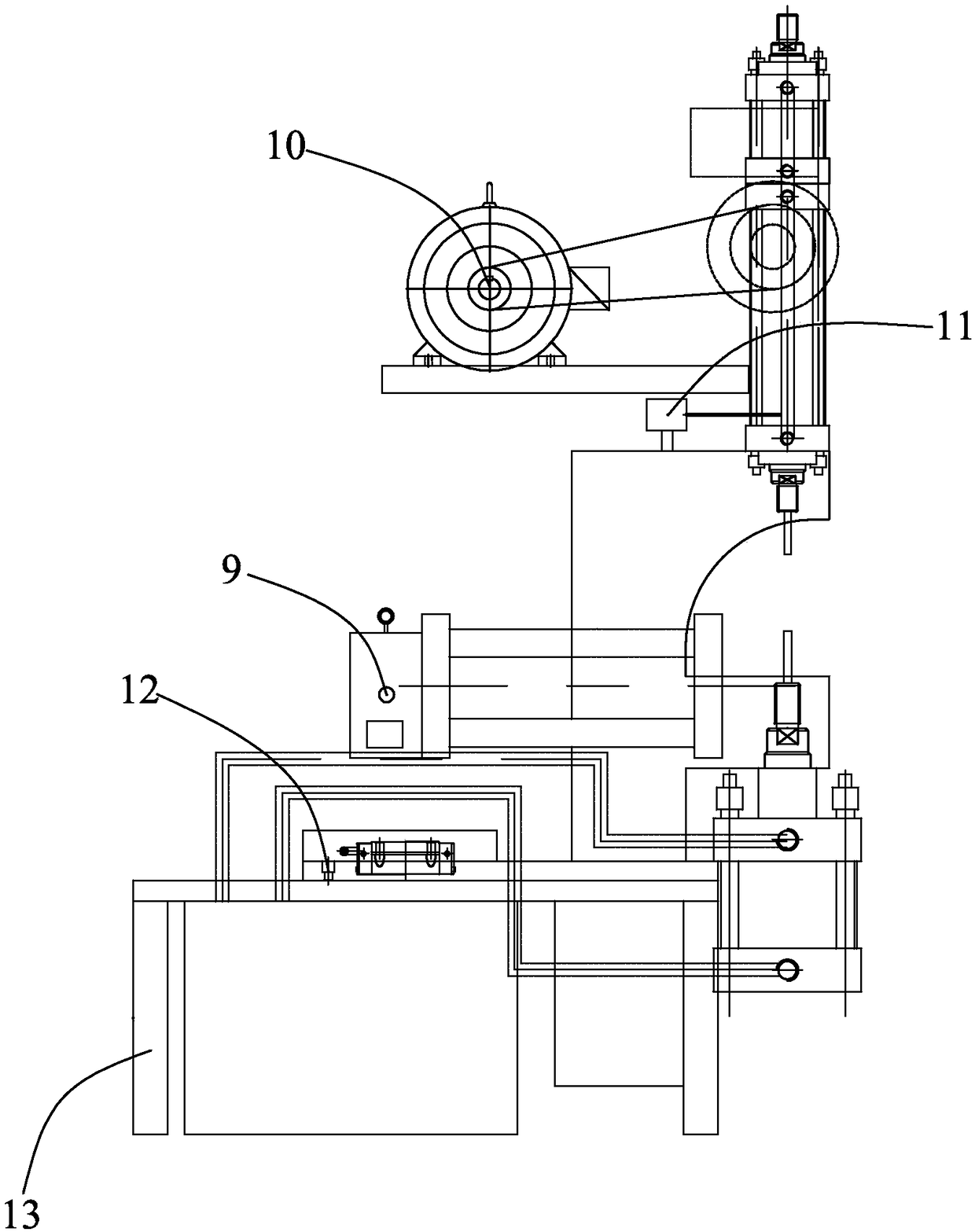

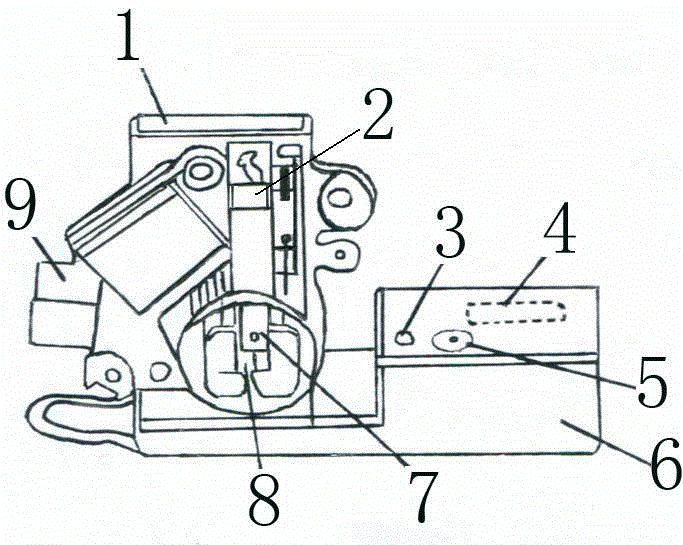

Full-automatic riveting machine

The invention discloses a full-automatic riveting machine. The machine comprises a pressurizing air cylinder, an automatic feeding mechanism, an auxiliary air cylinder, a PLC, a clamp, an upward jacking oil cylinder, a hydraulic station, an electric control box, an index plate, a motor, a pressure sensor, a rail line and a support table; the pressurizing air cylinder is arranged in the vertical direction, the automatic feeding mechanism is located on one side of the pressurizing air cylinder, the PLC and the auxiliary air cylinder are located on the lower side of the automatic feeding mechanism, the PLC is connected with the auxiliary air cylinder, the clamp is arranged on the lower side of the pressurizing air cylinder, the upward jacking oil cylinder is located on the lower side of the clamp, the hydraulic station and the electric control box are located on the two opposite sides of the upward jacking oil cylinder, the support table is located on the lower side of the index plate, and the rail line is supported on the support table. The full-automatic riveting machine is simple and reasonable in structure, easy and convenient to operate, and convenient to maintain, a worker can easily learn and know the machine, labor intensity of the worker is reduced, production efficiency is improved, the riveting quality is ensured, and production cost of an enterprise is saved.

Owner:靖江市恒大汽车部件制造有限公司

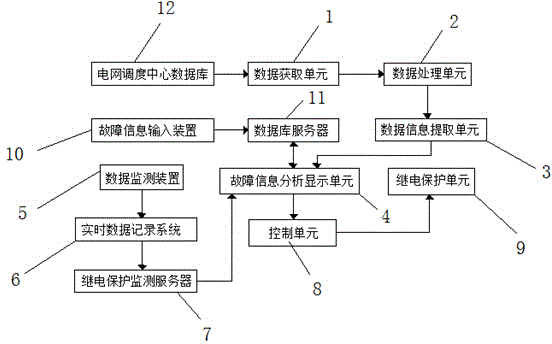

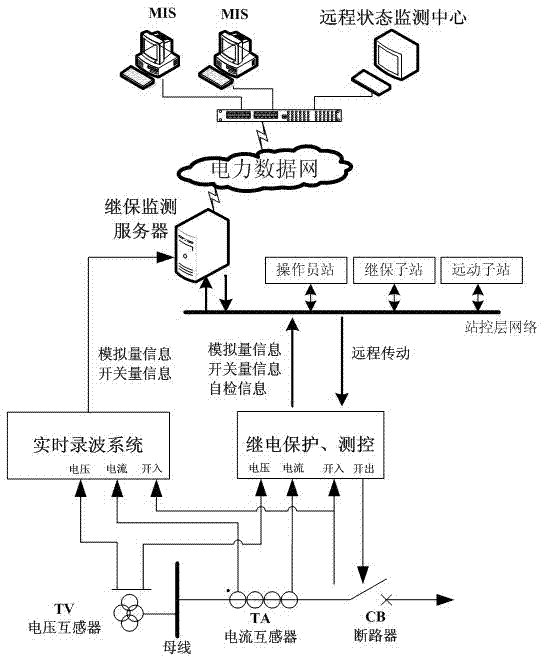

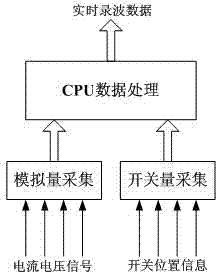

Auxiliary relay protection monitoring processing system and processing method thereof

InactiveCN104795804AReliable relay protectionAccurate judgment of relay protectionEmergency protective circuit arrangementsInformation technology support systemInformation analysisData information

The invention discloses an auxiliary relay protection monitoring processing system and a processing method thereof. The auxiliary relay protection monitoring processing system comprises a data obtaining unit, a data processing unit, a data information extraction unit, a data monitoring device, a real-time data recording system, a relay protection monitoring server, a fault information analysis display unit, a control unit and a relay protection unit; an input end of the data processing unit is connected with a power grid dispatching center and an output end is connected with an input end of the relay protection unit respectively through the data processing unit, the data information extraction unit, the fault information analysis display unit and the control unit; an output end of the data detection device is connected with the fault information analysis unit sequentially through the real-time data recording system, the relay protection monitoring server and the fault information analysis display unit. The auxiliary relay protection monitoring processing system and the method can accurately position the fault reason and fault points, reduces the power failure time for overhaul, improves the utilization relate and the operation reliability of equipment and meanwhile reduces overhaul costs.

Owner:STATE GRID CORP OF CHINA +1

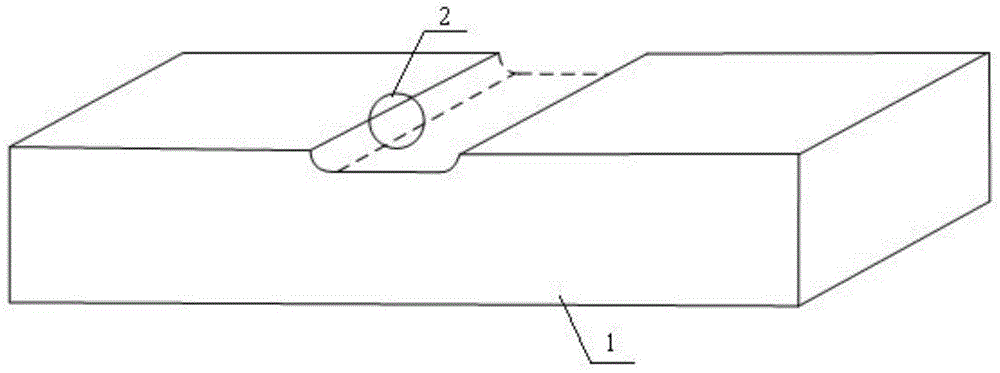

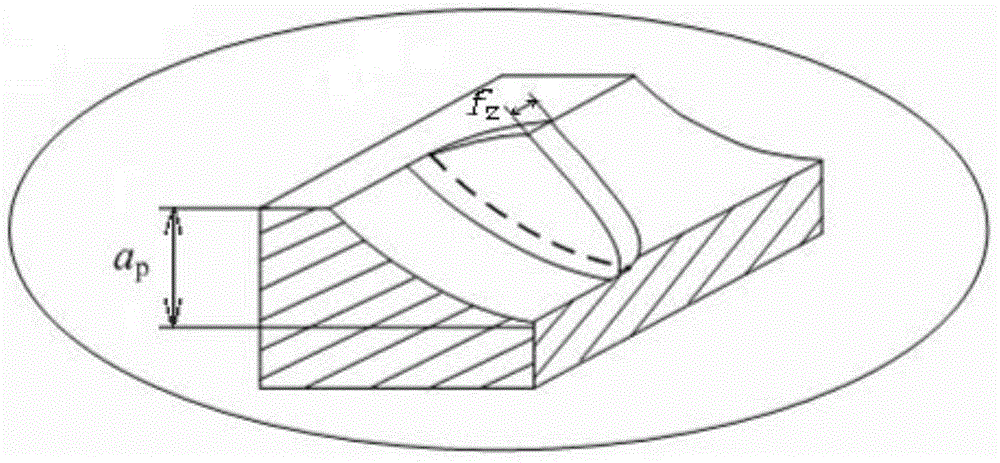

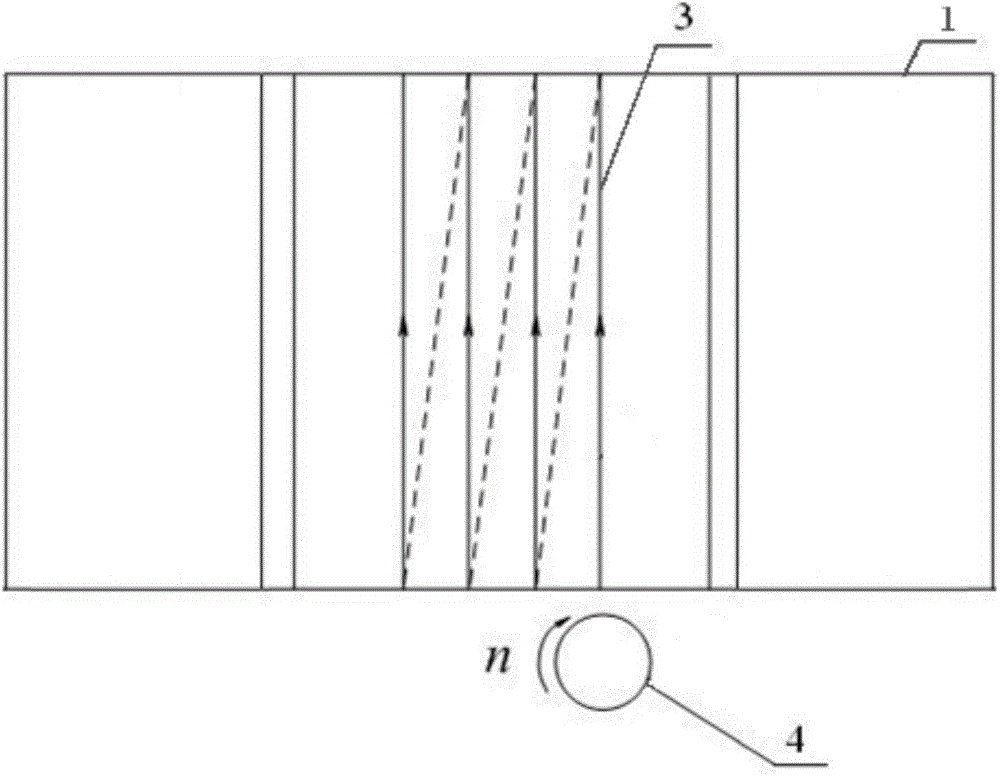

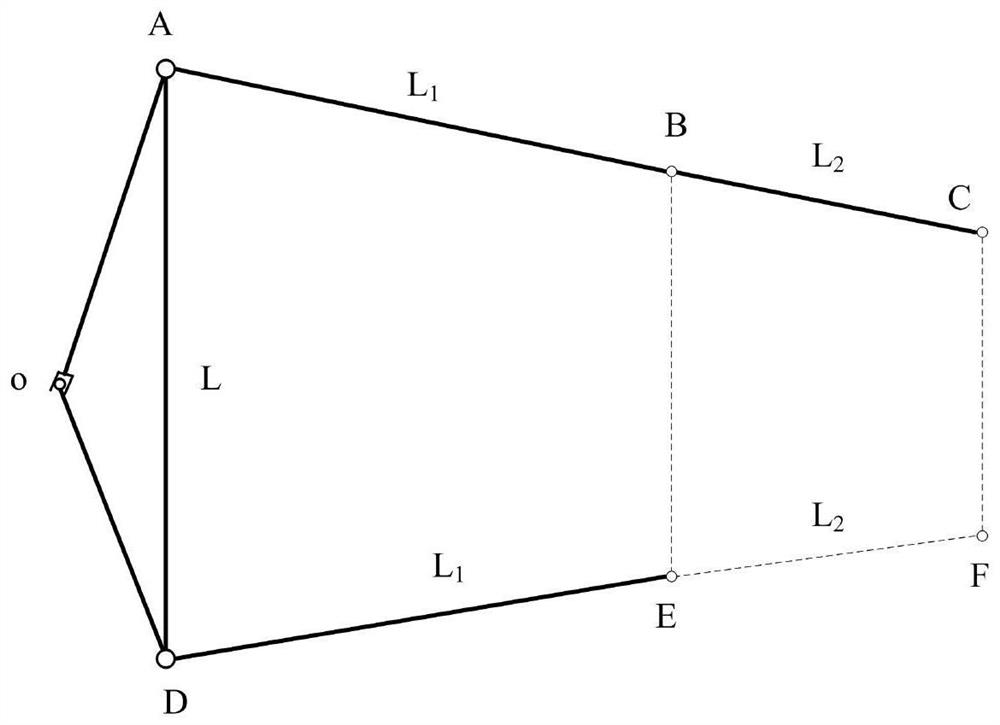

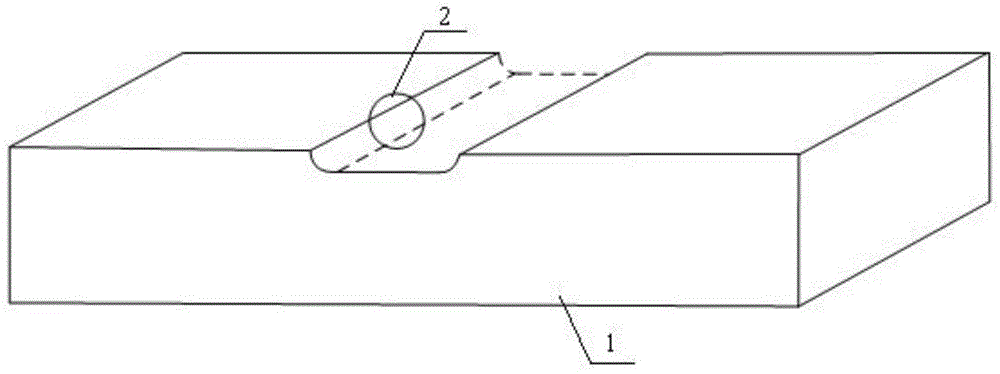

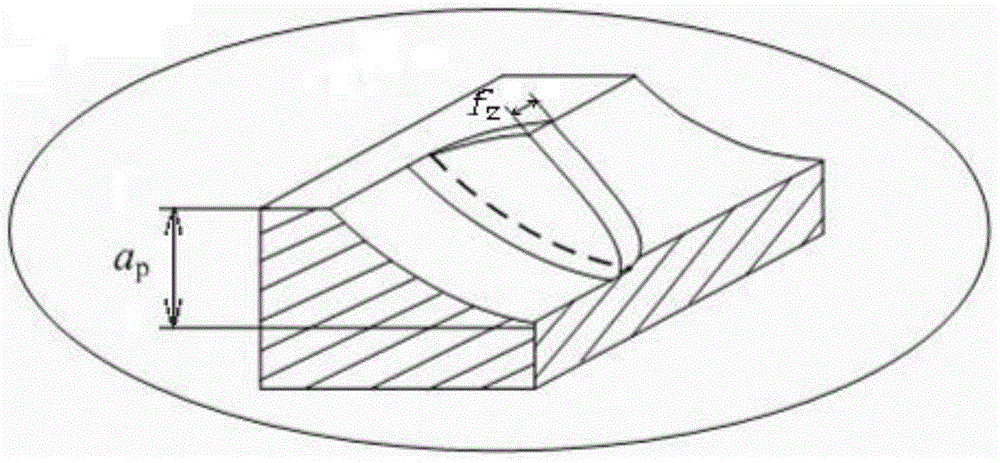

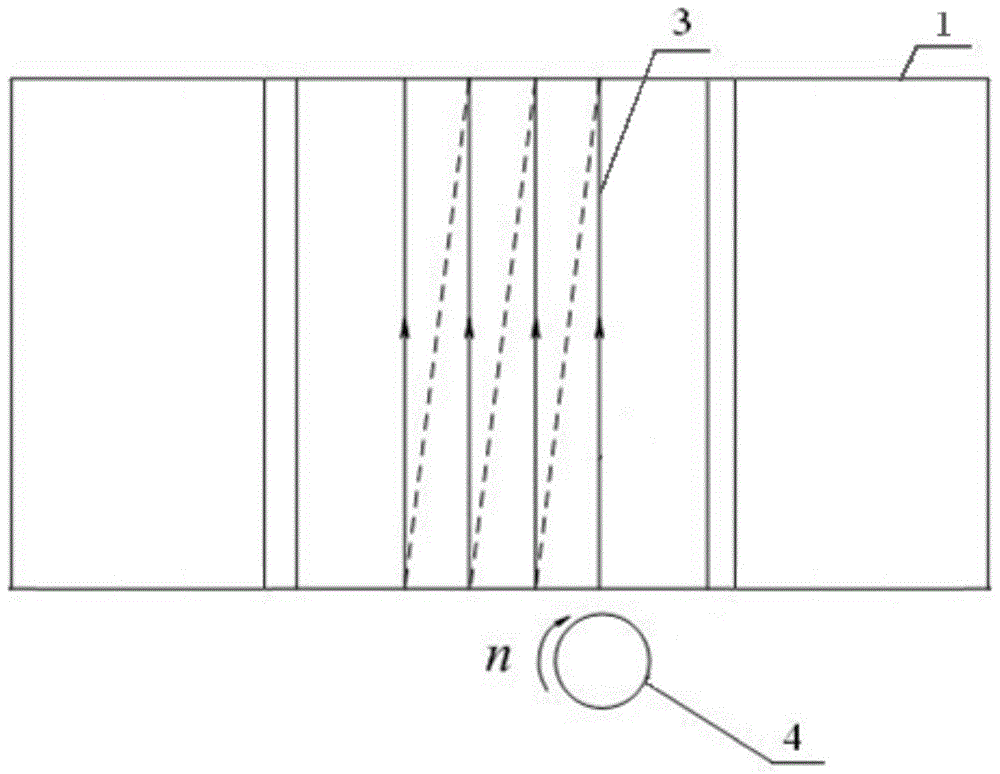

Minimum cutting thickness determination method of workpiece material

InactiveCN104128646AImprove processing qualityEasy to measureMilling equipment detailsDepth of fieldAnalysis method

The invention relates to a minimum cutting thickness determination method of a workpiece material. At present, a theoretical analysis method during the processing of obtaining the minimum cutting thickness value of a workpiece material is tedious and has poor applicability, and a calculation result obtained is not accurate enough. The method comprises the following steps: milling trace of a workpiece material is observed under a super field-depth microscope, the surface is divided into a cutting area, a ploughing area and a rubbing area, and the total length l of the ploughing area-the rubbing area is measured; an intersection A of an interface of the ploughing area-the cutting area and a boundary line between a first cutter tooth and the surface of the workpiece is taken, central positions of the first cutter tooth and a second cutter tooth of the cutter starting to cut into the workpiece material are taken as points O1 and O2, a coordinate system is established with the point O1 as the origin of coordinates, a cutting cross section perpendicular to XO1Y is made by crossing the point O2 and the point A, and a projection point O1' of the point O1 on the section is obtained; a vertical line of XO1Y is made by crossing the point A, an intersection of the vertical line and the outline of the lower end of the cutting cross section is a point B, an intersection of O2B and the outline of the upper end of the cutting cross section is a point C, and hD=R-|O2C| is calculated in a triangle O2CO1' by the cosine law. The method is used for determining the minimum cutting thickness of a workpiece material during processing of a cutter.

Owner:HARBIN UNIV OF SCI & TECH

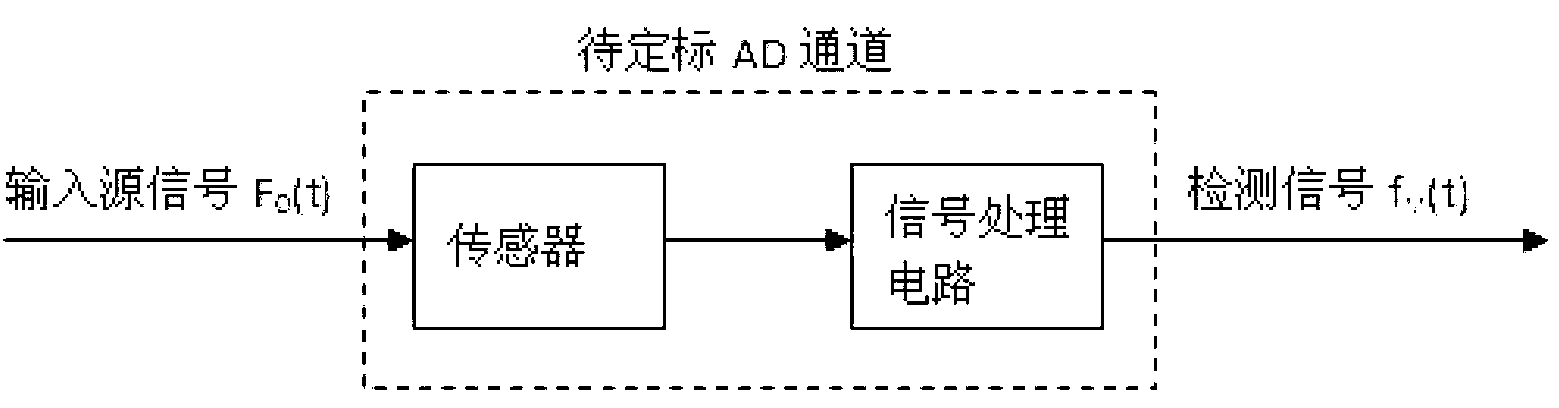

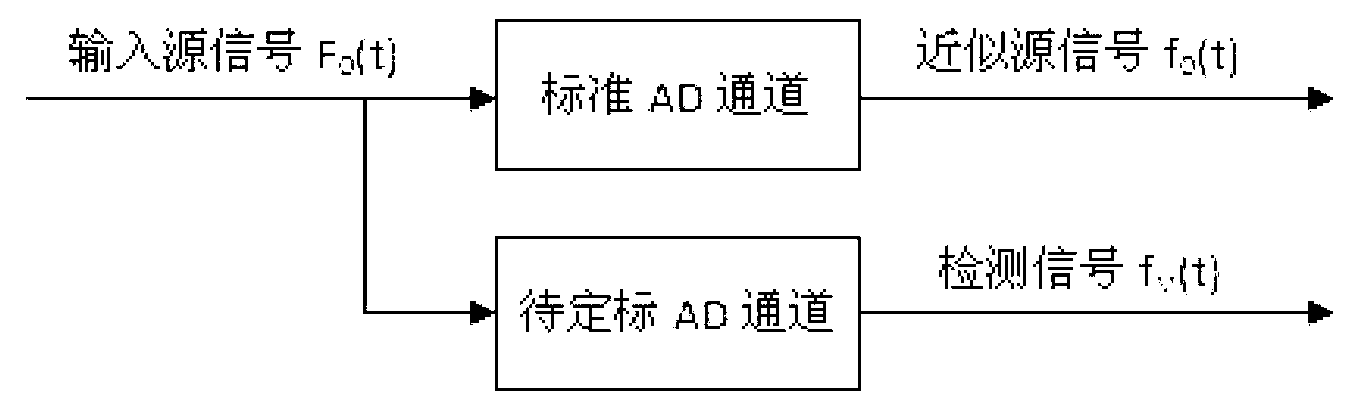

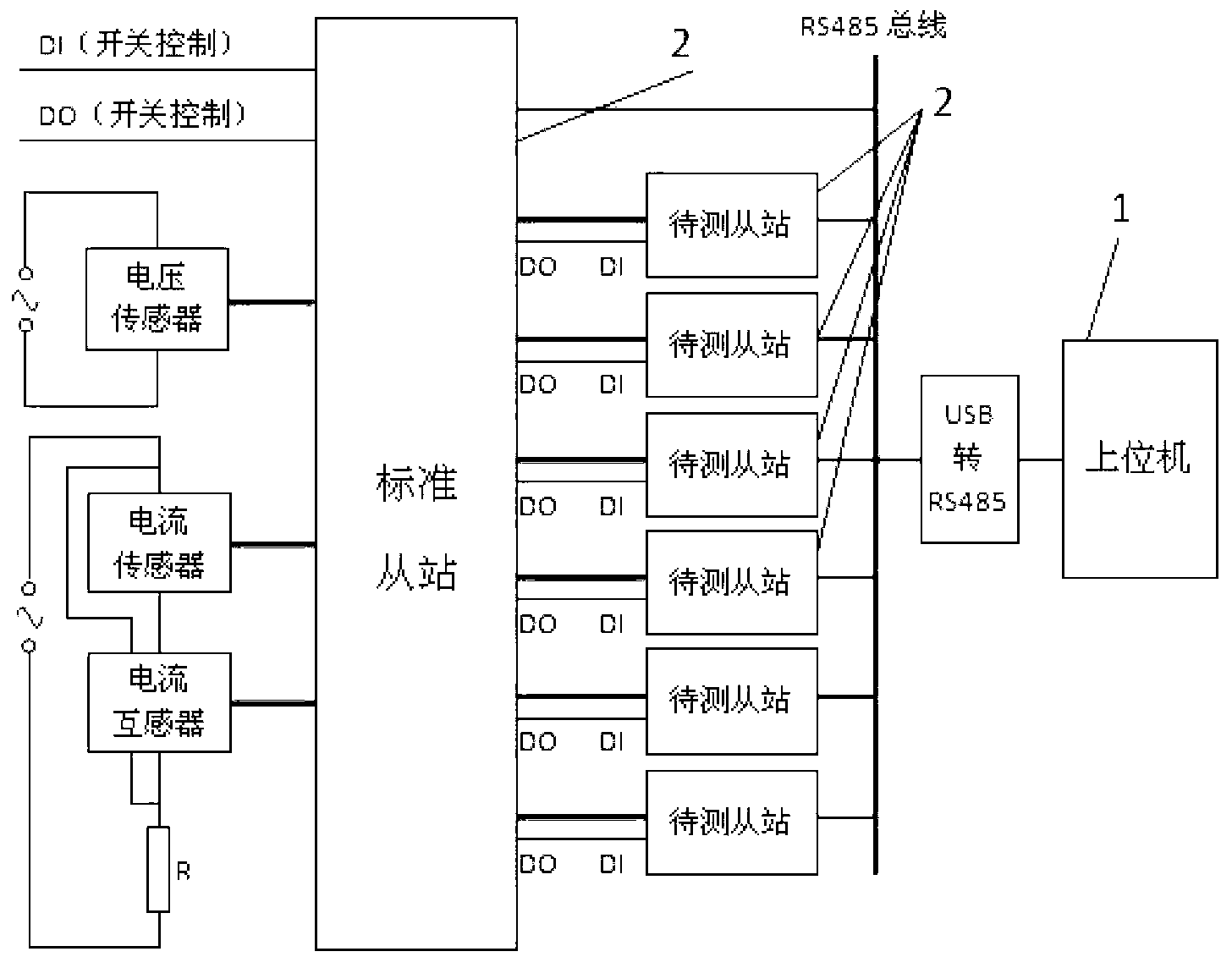

Device and method for calibrating and detecting sensor and AD convertor of multiple devices

ActiveCN103018699AGuaranteed uptimeConvenient detection workElectrical measurementsAnalogue/digital conversion calibration/testingUnit groupSecondary side

The invention provides a device and a method for calibrating and detecting a sensor and an AD convertor of multiple devices. An acquisition processing module comprises a plurality of acquisition processing units, and the acquisition processing units are connected in parallel; a plurality of signal sensing units of a signal sensing unit group are respectively connected with each acquisition processing unit, an input source signal is converted into a secondary side signal corresponding with acquisition requirements through the signal sensing unit group, and the secondary side signal is converted into a digital signal through the acquisition processing units and then is transmitted to an upper computer through a 485 communication circuit; and the upper computer processes and displays signal data. The device and the method for calibrating and detecting the sensor and the AD convertor of multiple devices have the advantages that a large linear error in collected data due to an own characteristic of operational amplification in the sensor and the AD convertor is avoided, the technical problems of deviation and scaling of the collected data are solved, and furthermore normal operation of a wind power frequency converter is guaranteed. The device and the method for calibrating and detecting the sensor and the AD convertor of multiple devices have the advantages that a skillful engineer only needs 1-3 minutes to complete adjusting a single wind power frequency converter, a personal error is small and the like.

Owner:天津瑞源电气有限公司

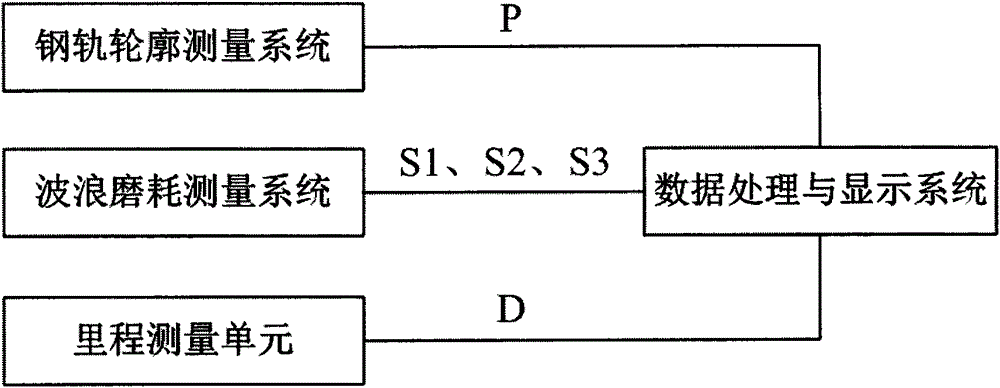

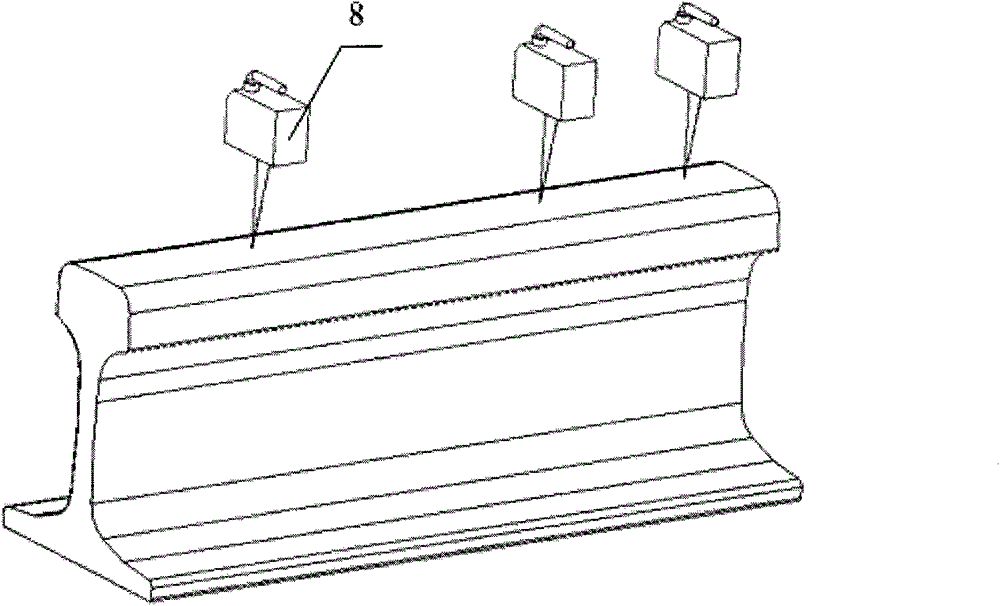

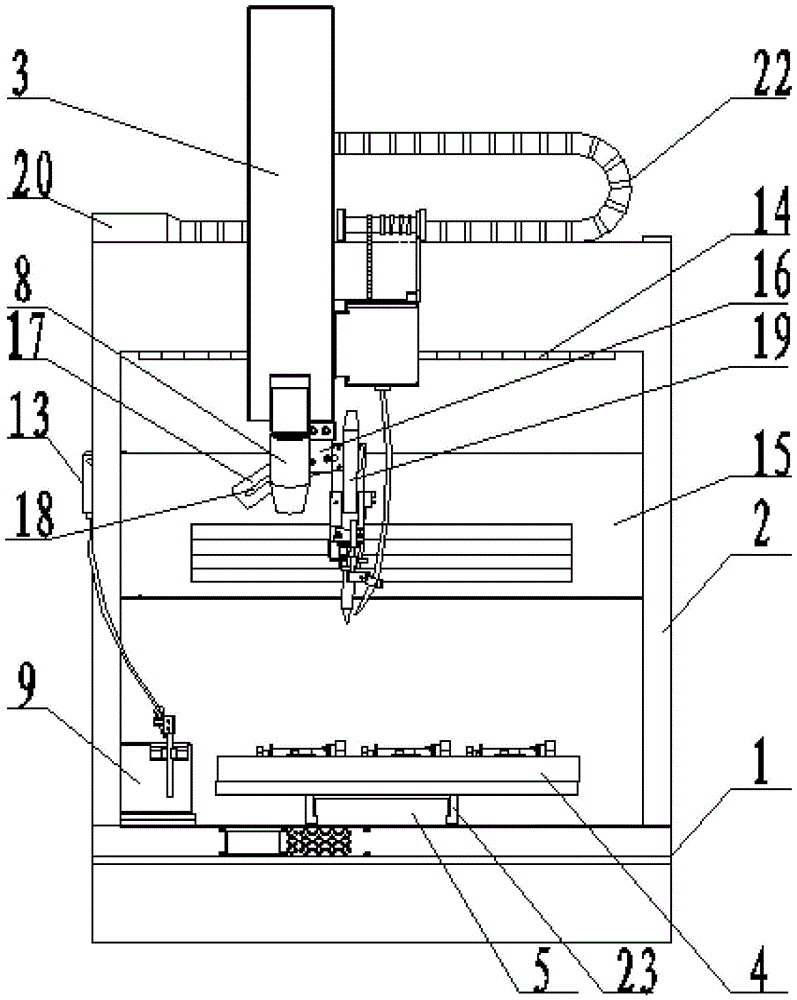

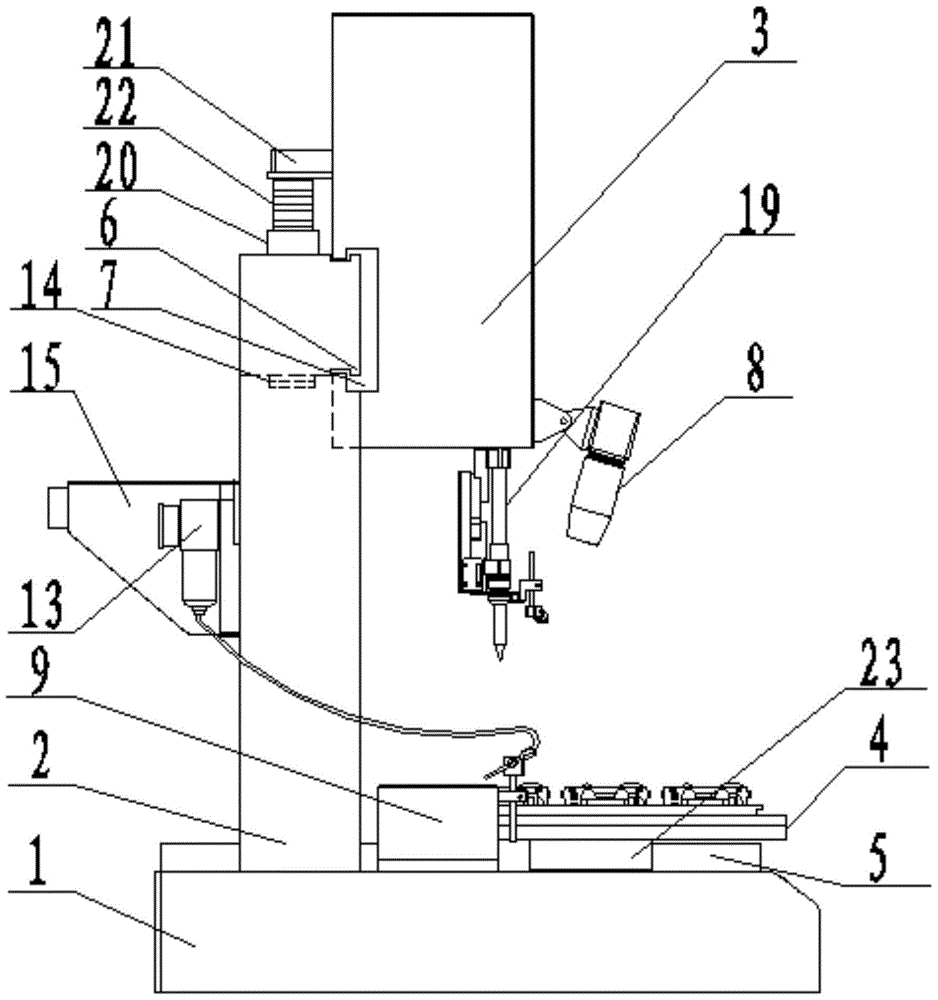

Steel rail milling and grinding machine operation accuracy real-time detecting device

InactiveCN104417583AReal-time detectionQuick checkRailway auxillary equipmentRailway profile gaugesRail profileEngineering

The invention relates to a steel rail milling and grinding machine operation accuracy real-time detecting device. The device comprises a steel rail profile measuring system, an undulatory wear measuring system, a mileage measuring unit, and a data processing and displaying system, wherein the steel rail profile measuring system, wherein the wave wear measurement system, the undulatory wear measuring system, the mileage measuring unit are respectively connected with the data processing and displaying system. The device can quickly detect operation accuracy of a steel rail milling and grinding machine in real time, detection labor intensity is reduced, and e the efficiency of railway track maintenance is improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

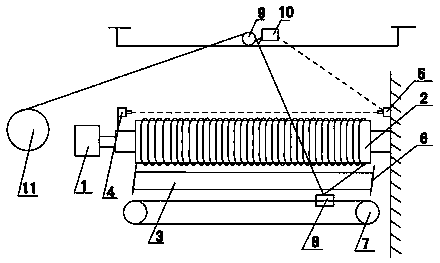

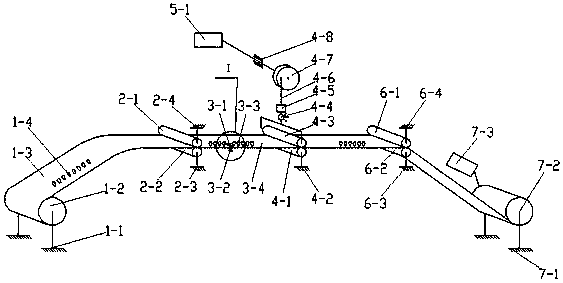

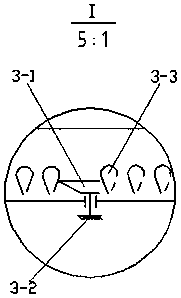

Wire winding machine with automatic cutter

The invention discloses a wire winding machine with an automatic cutter. The wire winding machine comprises a winding shaft, a signal control mechanism is arranged by the side of the winding shaft, and the signal control mechanism comprises an infrared transmitter and an infrared receiver which are arranged at the two ends of the winding shaft respectively. The signal end of the infrared transmitter and the signal end of the infrared receiver are connected with control modules. The distance from an infrared ray irradiating to the infrared receiver from the infrared transmitter to the outer wall of the winding shaft is equal to the melt-blowing thickness of a plastic wire of a wire winding filter element bar. The wire winding machine further comprises a wire winding device, and the wire winding device comprises a transmission mechanism which is arranged below the winding shaft and a wire drawing mechanism which is arranged above the rotating shaft. The transmission mechanism comprises two gears which are connected through a toothed chain, the toothed chain is fixedly connected with a wire drawing block, and the gears are controlled by a motor to conduct positive rotation and negative rotation. A wire penetrates through the wire drawing mechanism and the wire drawing block to be fixedly connected to the rotating shaft, and wire winding is conducted on the rotating shaft through the reciprocating motion of the wire drawing block so that the wire winding filter element bar can be formed. By means of the wire winding machine with the automatic cutter, the thickness of a wire winding filter element can be effectively monitored, and thus the wire can be cut off automatically.

Owner:苏州工业园区拓朴环保净化有限公司

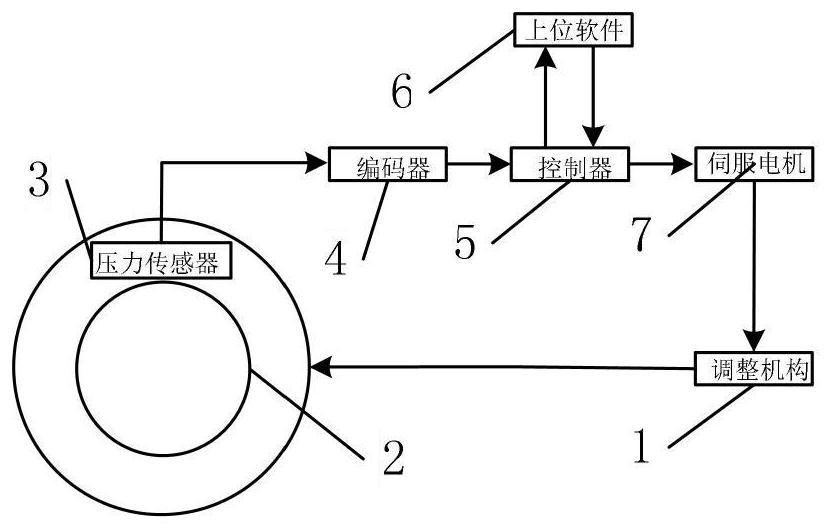

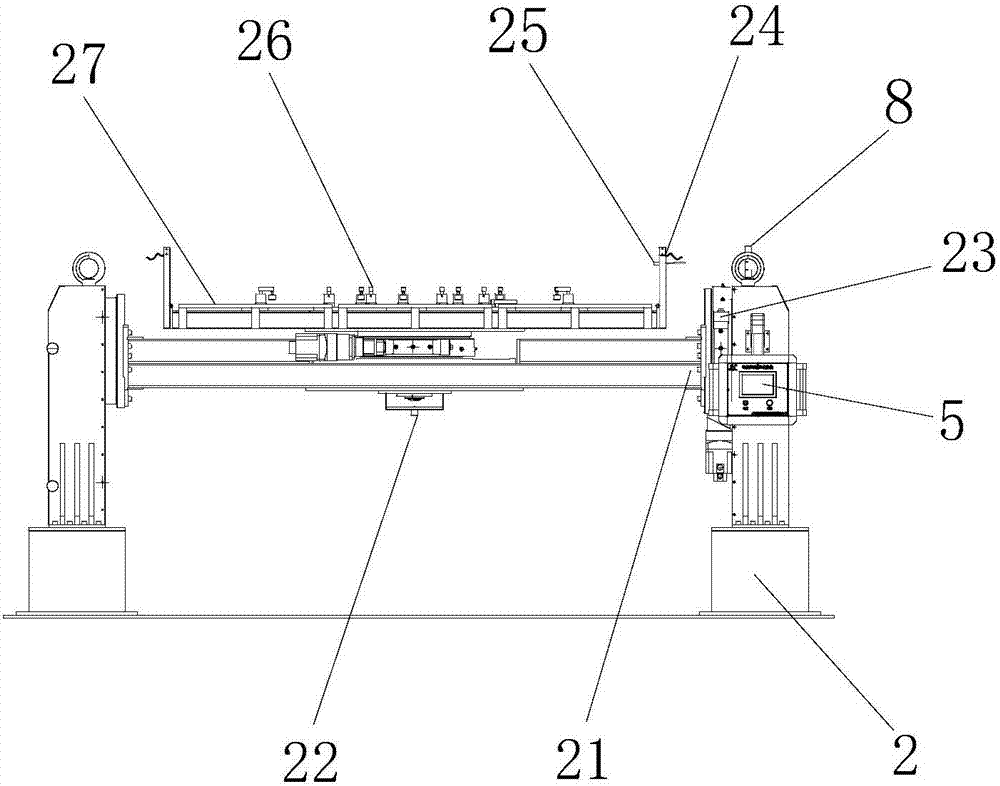

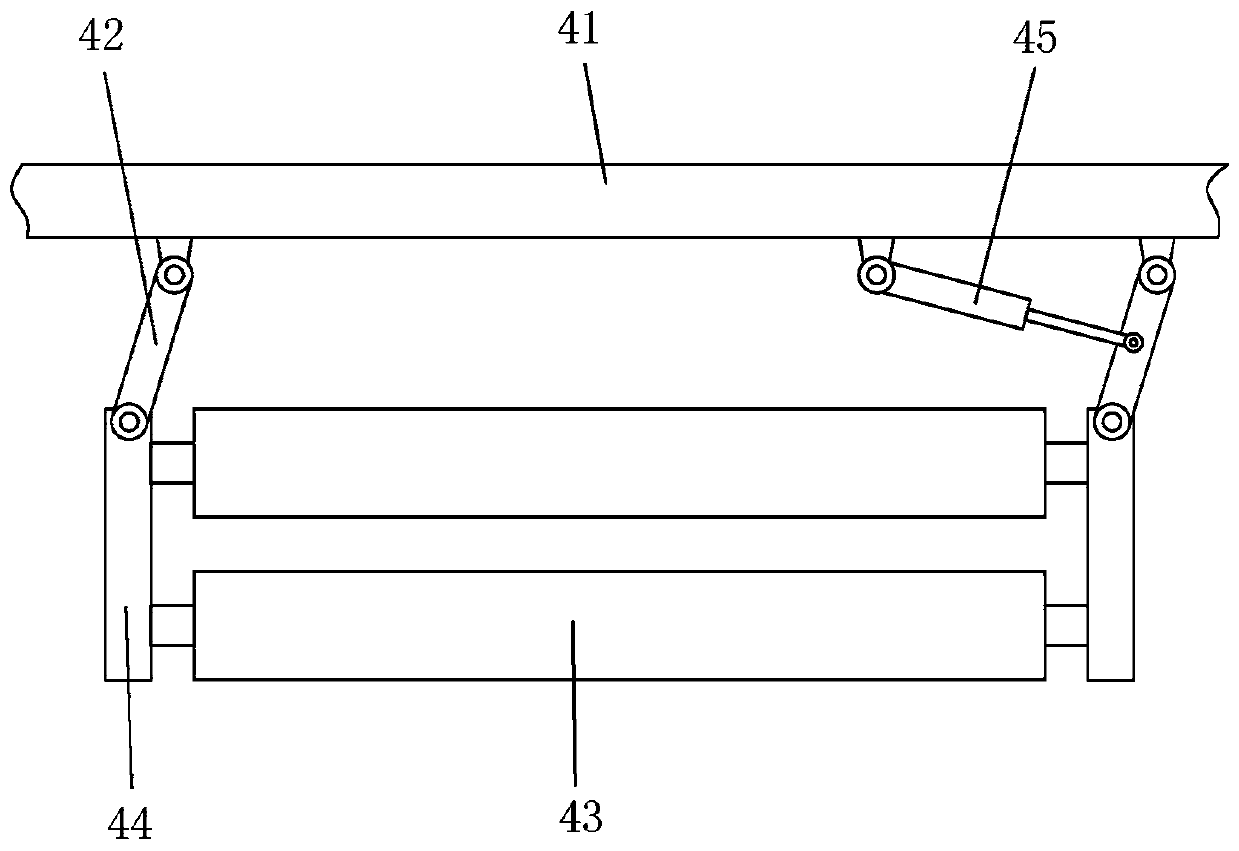

Intelligent adjusting system and method for pinch roll before shear

PendingCN112518017AReduce dependenceEliminate manual inspectionMetal working apparatusMetal rolling arrangementsControl engineeringStress sensors

The invention discloses an intelligent adjusting system and method for a pinch roll before a shear, and belongs to the field of machineries. The vertical distance, required to be adjusted, of the pinch roll is obtained by arranging a pressure sensor on a supporting device of a pinch roll shaft and comparing the detection values of the pressure sensor, and finally, a servo motor is controlled by acontroller for executing. By means of the intelligent adjusting system and method for the pinch roll before the shear, the technical problems that existing pinch roll adjustment depends on subjectiveexperience or measurement is needed through a special instrument after adjustment, the adjusting work is tedious, no accurate adjusting parameters can be followed, and consequently the clamping forceof the pinch roll is too large or too small, and the production efficiency and the product quality are influenced are solved; and the application effect is good, and the practicability is high.

Owner:HUATIAN NANJING ENG & TECH CORP MCC +1

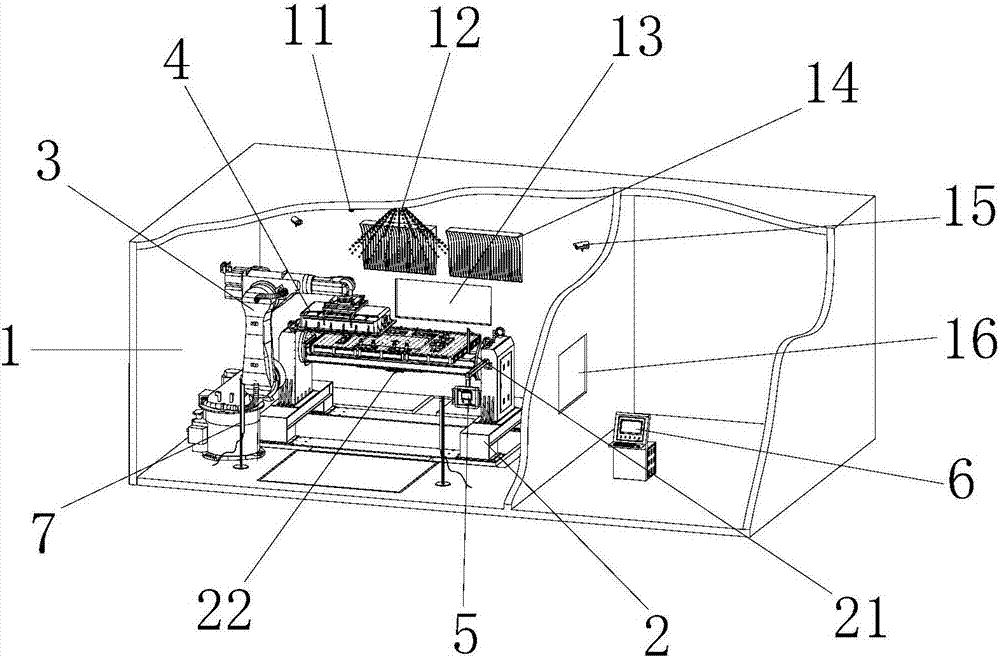

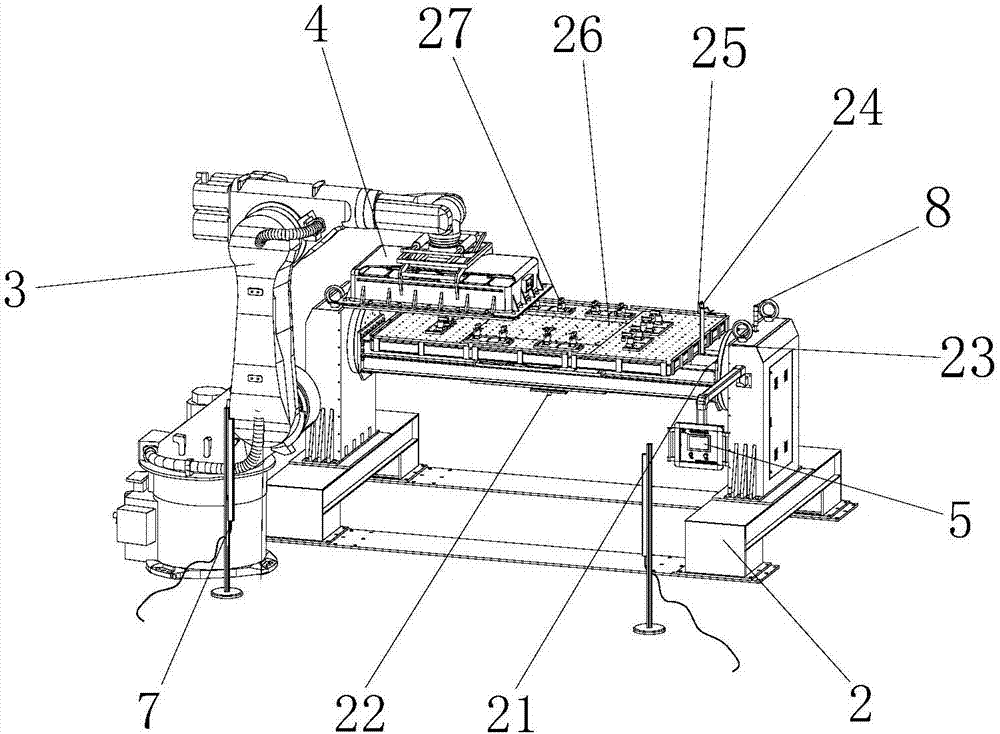

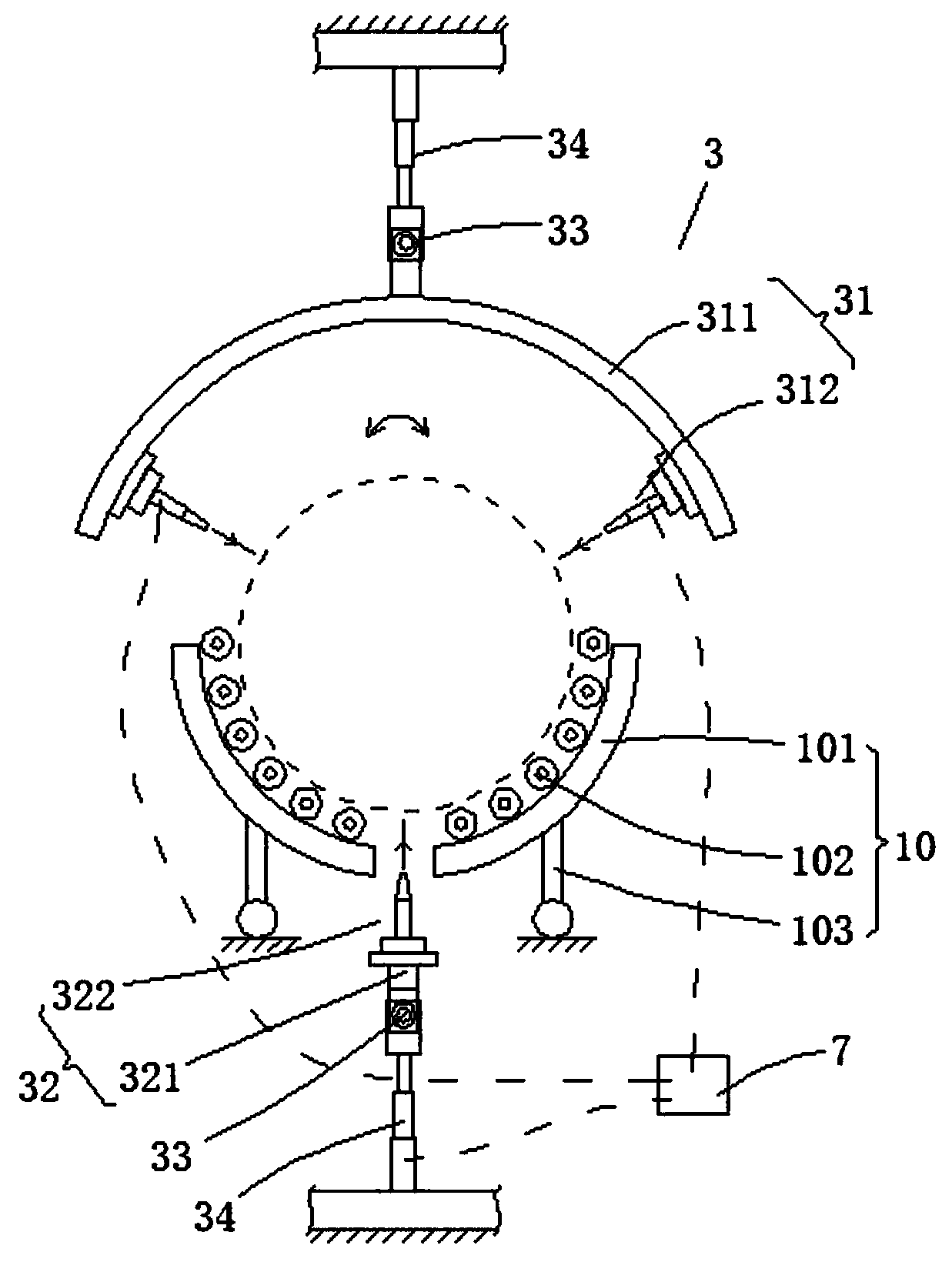

Battery bag overturning test device

PendingCN106950506AEliminate manual inspectionEnsure safetyElectrical testingRemote patient monitoringVideo transmission

The invention relates to the technical field of power battery manufacturing, and particularly relates to a battery bag overturning test device. A protective wall is provided with a smoke alarm, a spray extinguishing device, a pressure release port, a smoke exhaust kitchen, a video monitor, and a monitoring window, an overturning test platform is provided with a three-color alarm, an infrared temperature sensor, an infrared object sensor, an X-axis cross beam rotating assembly, a Y-axis platform rotating assembly, and an installing table, and a tab pneumatic clamp is arranged on the installing table, the clamping and detachment of the battery can be completed by an automatic charging and discharging robot arm, the overturning table for testing the battery adopts the power device with servo motor transmission and single-turbine and double-worm rotation transmission to carry out the automatic detection, and through the cooperation with a whole set of monitoring and protection system, the detection data and the video of the detection site are transmitted to a remote monitoring computer, the remote and real-time monitoring is carried out, the artificial detection is completely not needed, moreover, the safety during battery detection and the data accuracy are guaranteed, problems can be better found and solved during the detection, and the product design can be optimized and the product quality is improved.

Owner:广东贝尔试验设备有限公司

A fabric double-sided raising machine

Owner:ZHEJIANG CADY IND

System and method for maintaining condition of relay protection

InactiveCN102064612BReduce manual inspection itemsEliminate manual inspectionCircuit arrangementsCircuit interrupters testingReal-time dataElectric power system

The invention relates to a system and method for maintaining the condition of relay protection, belonging to the technical field of condition maintenance of relay protection of power systems. The system comprises a relay protection, measurement and control device, a real time data recording system, a relay protection monitoring server and a remote condition monitoring center, wherein the relay protection, measurement and control device is connected into a station level network via a cable; the relay protection monitoring server receives data sent by the relay protection, measurement and control device via the station level network; the real time data recording system is connected with the relay protection monitoring server via a cable; and the relay protection monitoring server is in communication connection with the remote condition monitoring center via a network. The system and the method have the beneficial effects of effectively reducing the items which are periodically maintained manually, even dispensing with manual inspection, reducing the power outage time due to maintenance of equipment and improving the reliability and the working efficiency.

Owner:XJ ELECTRIC +2

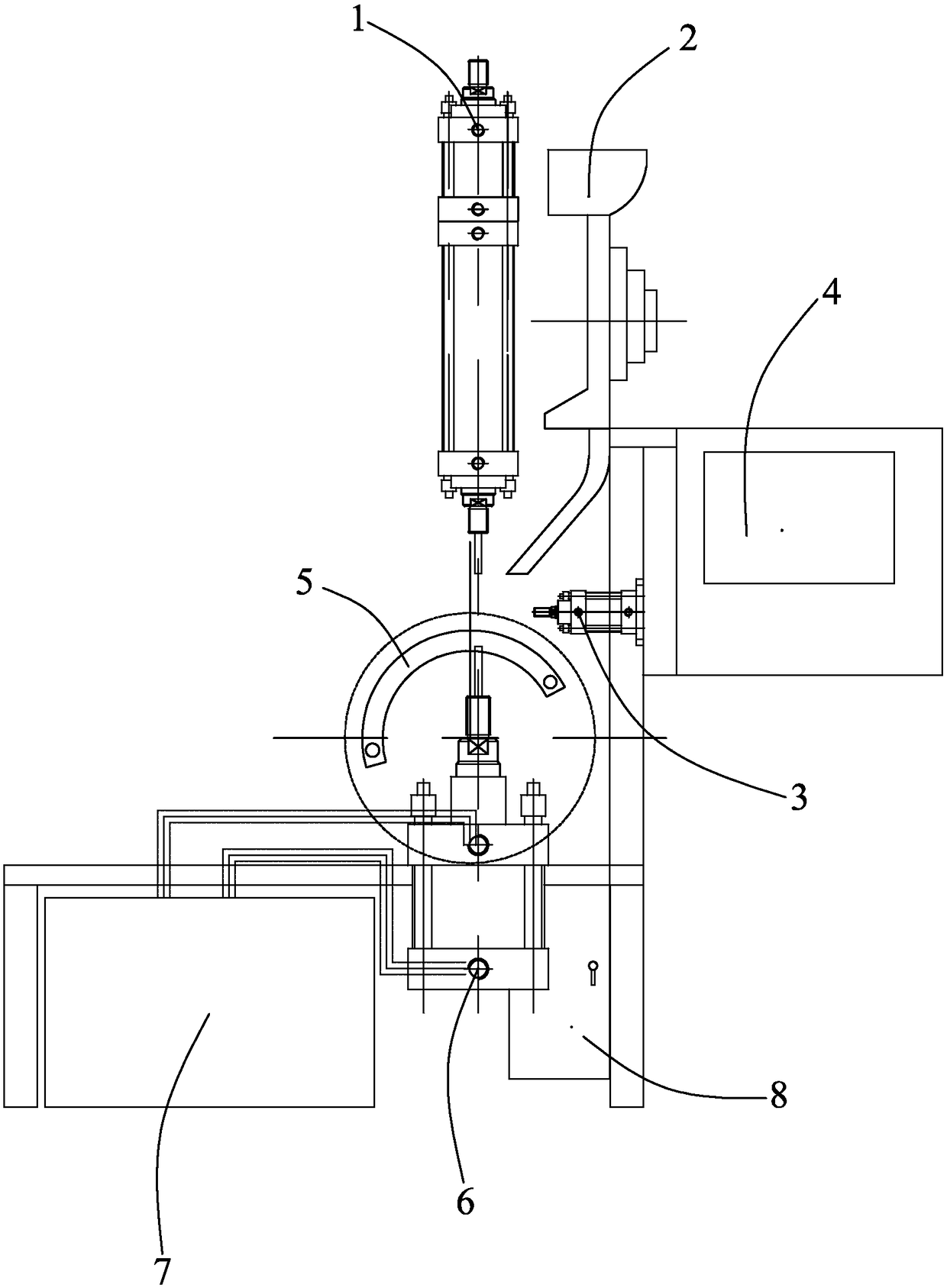

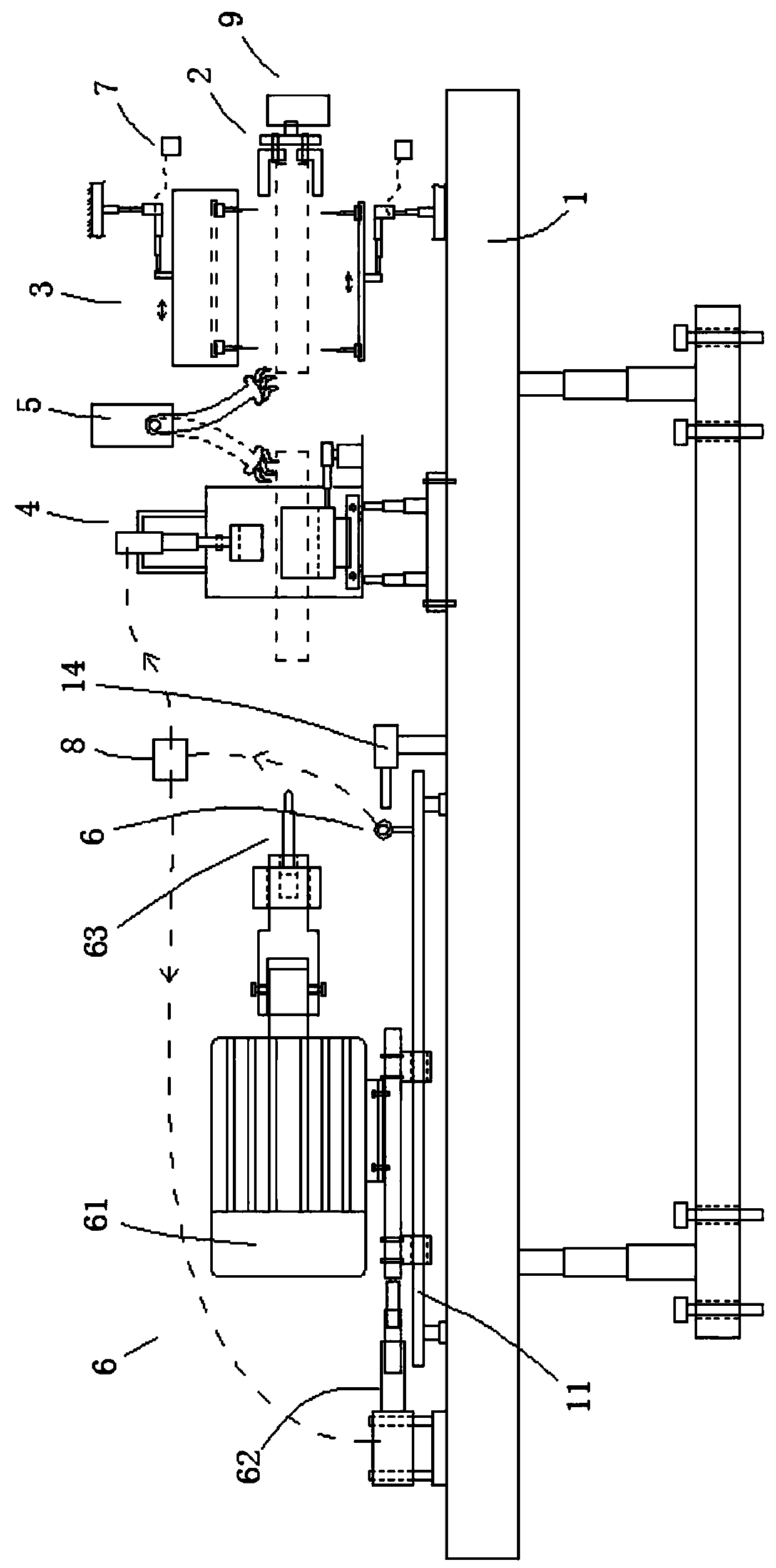

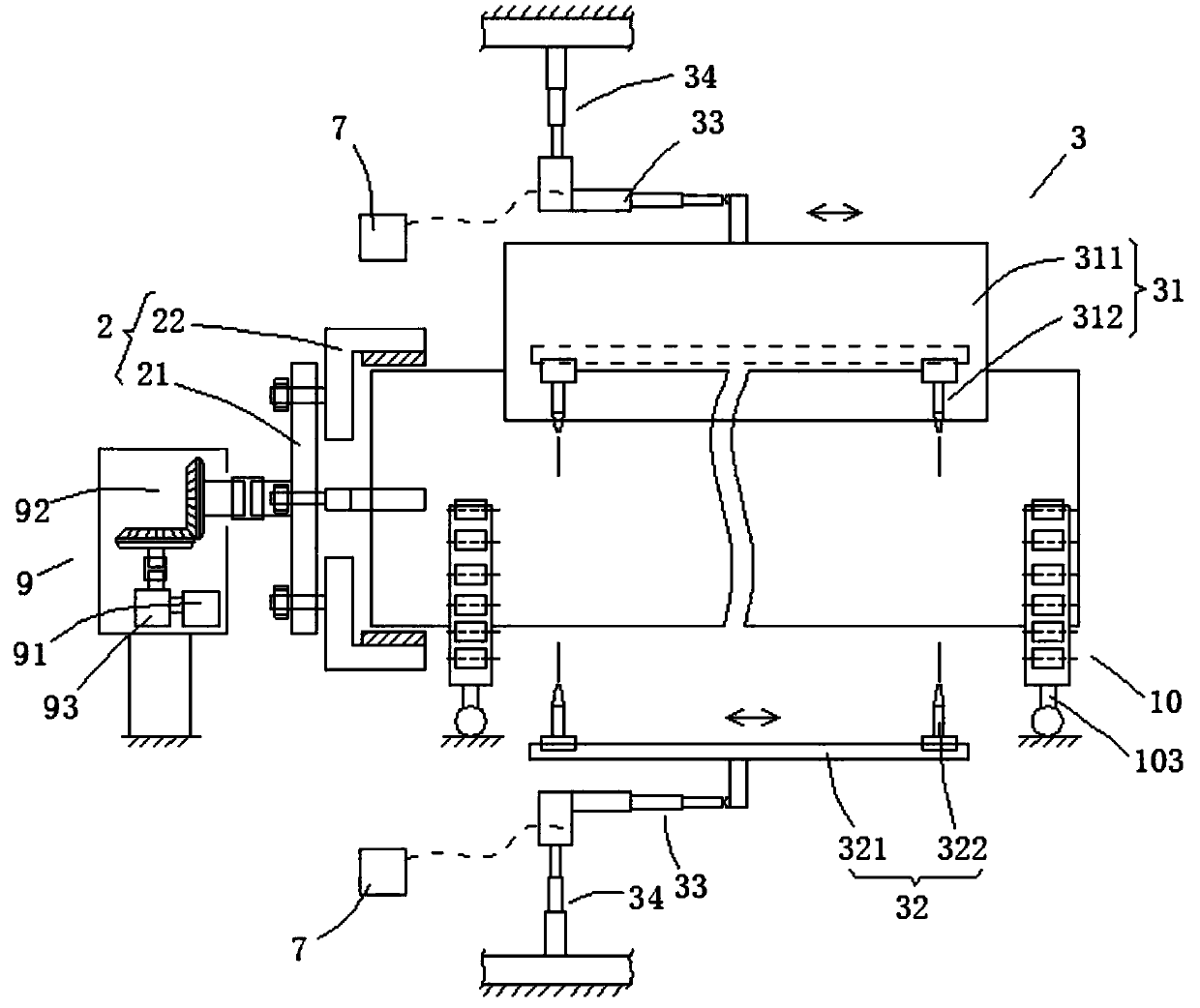

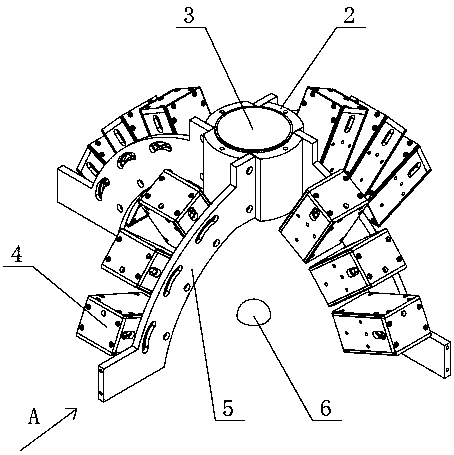

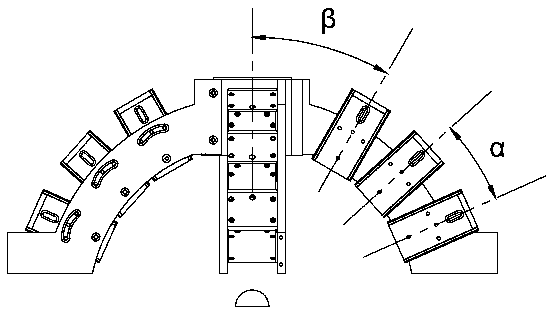

Flange connecting piece visual detection and center hole perforating device

ActiveCN111571310AReduce labor intensitySolve the technical problem of inconvenient punching operationMeasurement/indication equipmentsBoring/drilling componentsWell drillingEngineering

The invention provides a flange connecting piece visual detection and center hole perforating device, and belongs to the technical field of well drilling connecting piece production. The flange connecting piece visual detection and center hole perforating device comprises a base, a rotating mechanism, a detection mechanism, a clamping mechanism, a mechanical arm, a perforating mechanism, a first control mechanism and a second control mechanism. A connecting piece is arranged on the rotating mechanism, the detection mechanism detects outer wall quality defects of the connecting piece, the connecting piece has no defects after detection, the mechanical arm transfers the connecting piece to the clamping mechanism, the clamping position is adjusted through the clamping mechanism, and the perforating depth to the connecting piece and the clamping action to the connecting piece are adjusted through the second control mechanism. The flange connecting piece visual detection and center hole perforating device has the technical effects that the visual detection speed for the connecting piece is high, manual detection is eliminated, the labor strength is small, the perforating depth is controllable, the perforating is convenient, simple and easy to operate, the connecting pieces with different depths can be perforated, the clamping is stable, and the perforating efficiency is high.

Owner:京鸿石油钻采工程技术有限公司

Detection method for image defect of receiver product and detection light source thereof

The invention relates to the technical field of image defect detection, in particular to a detection method for an image defect of a receiver product and a detection light source thereof. The detection method for the image defect of the receiver product is to detect the image defect of the receiver product by using the detection light source, and the detection method comprises the following stepsof (1) debugging the light source; (2) setting light source parameters; (3), collecting images; (4), image processing; and (5), dividing a warehouse for the product. In the invention, the collected image is subjected to image processing by a photometric stereo vision algorithm, so that the gentle slope pit defect is detected, and the image forming mode displays the height information, so the dirtydefect is not presented in the image, and the pit defect rather than the dirty defect can be detected only; the influence of the dirty defect is avoided; the pit defect of the receiver product can beautomatically detected in batches, the manual inspection process is eliminated, and the detection efficiency is improved and the detection cost is saved.

Owner:BEIJING FOCUSIGHT TECH

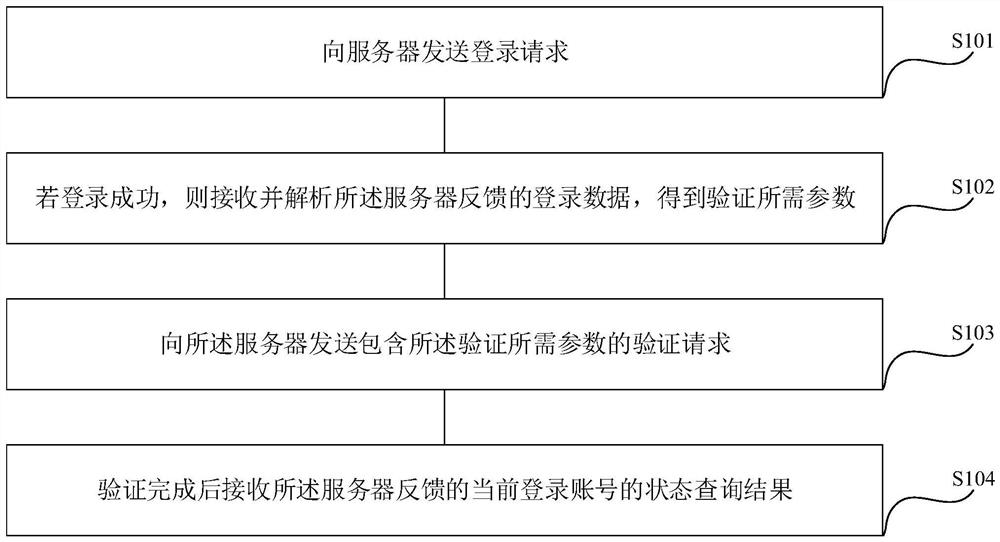

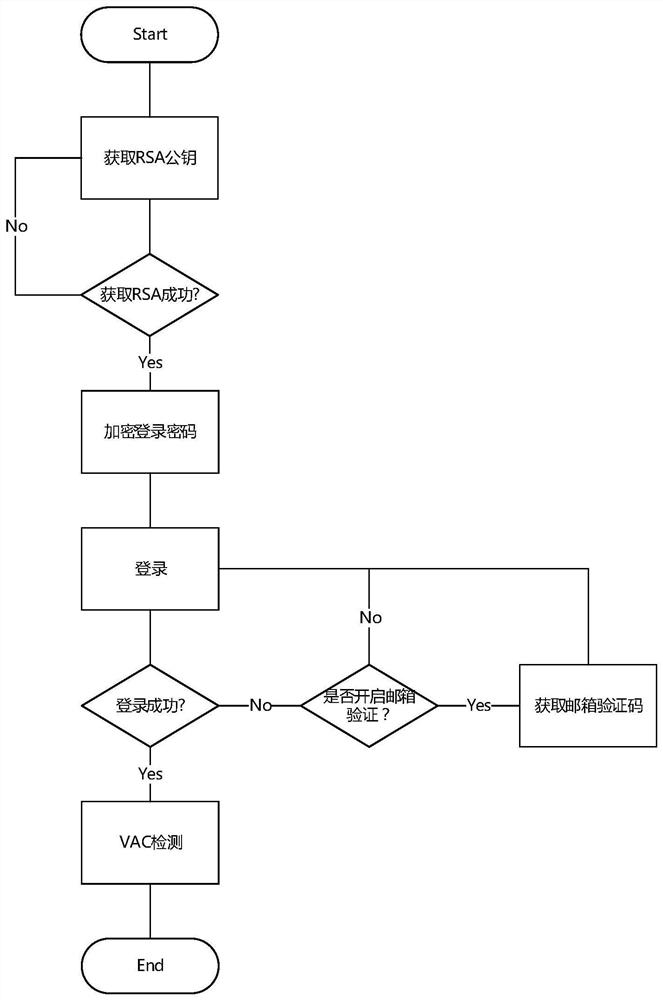

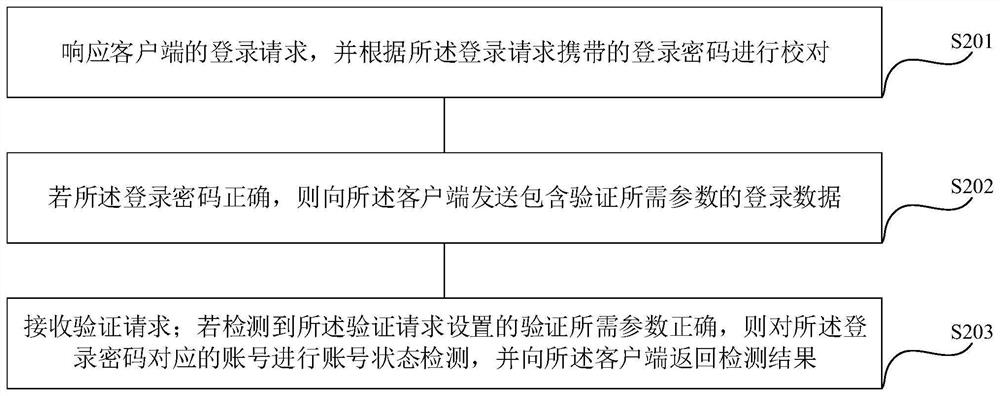

Steam platform account state detection method and system

ActiveCN112054999AEliminate manual inspectionImprove detection efficiencyTransmissionPasswordReliability engineering

The invention discloses a Steam platform account state detection system. The system comprises a client and a server. The client sends a login request containing a login password to the server; if thelogin is successful, the server feeds back login data to the client; the client analyzes the login data to obtain parameters required for verification, and accesses an account state detection interface of the server by inputting the parameters required for verification; and the server performs account state detection on an account corresponding to the login password, and sends a detection result to the client. The invention provides a Steam platform account state detection method and system. The state of a Steam platform account is automatically and rapidly detected.

Owner:广州点云科技有限公司

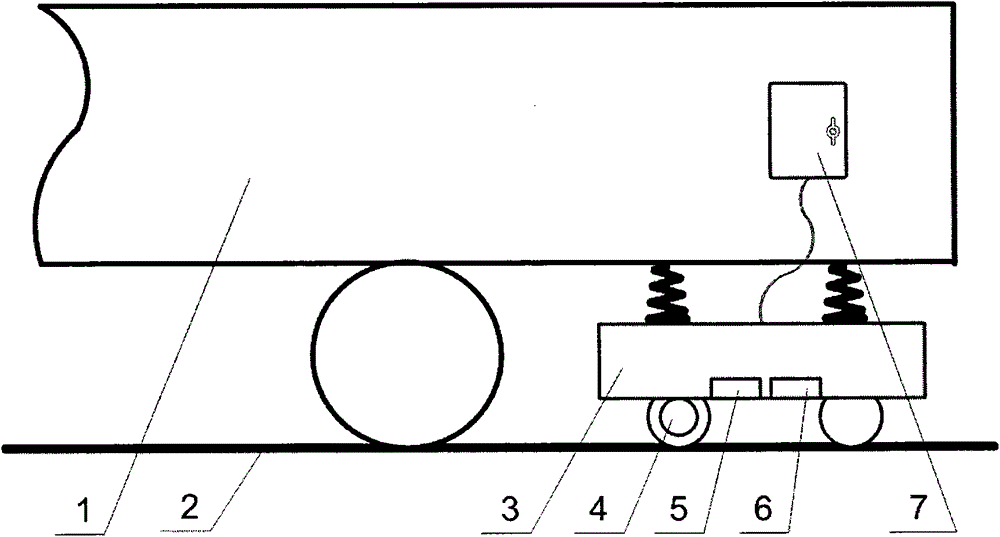

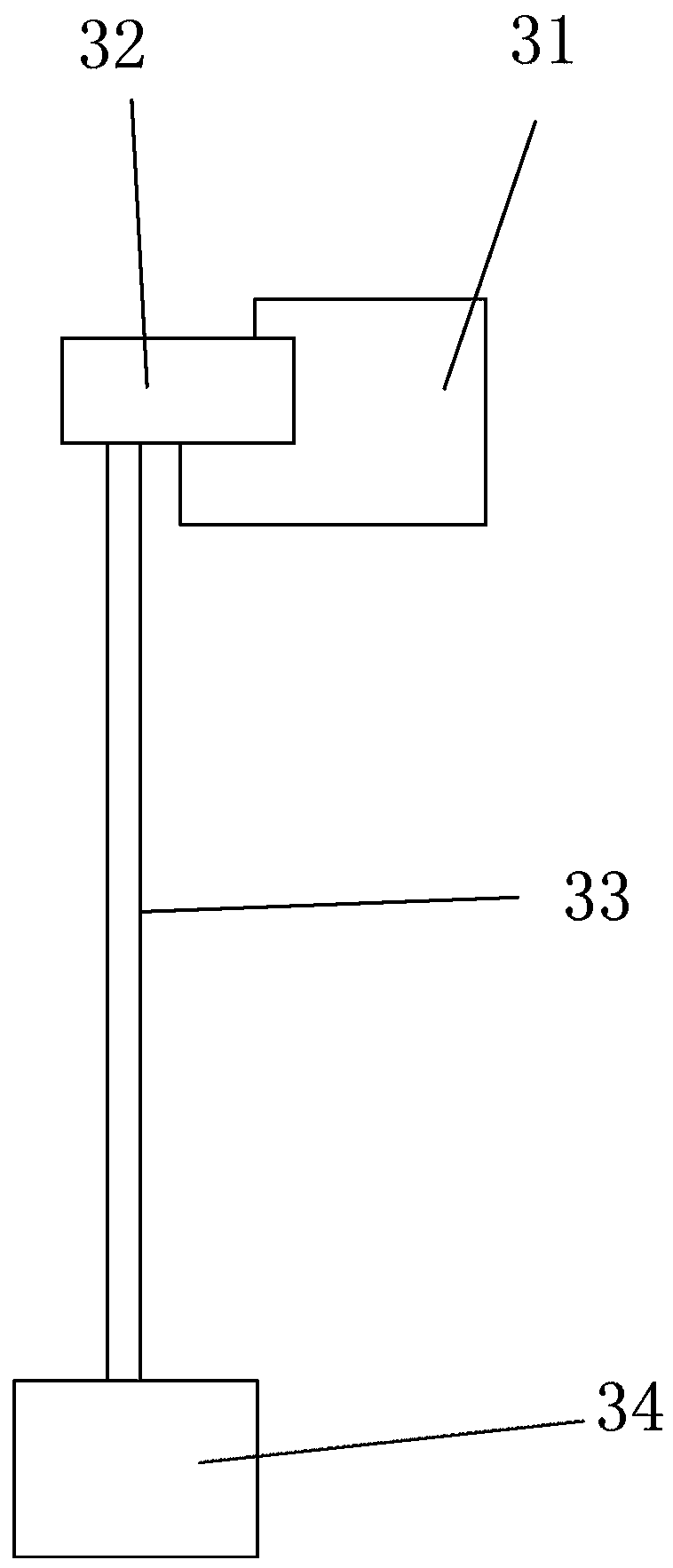

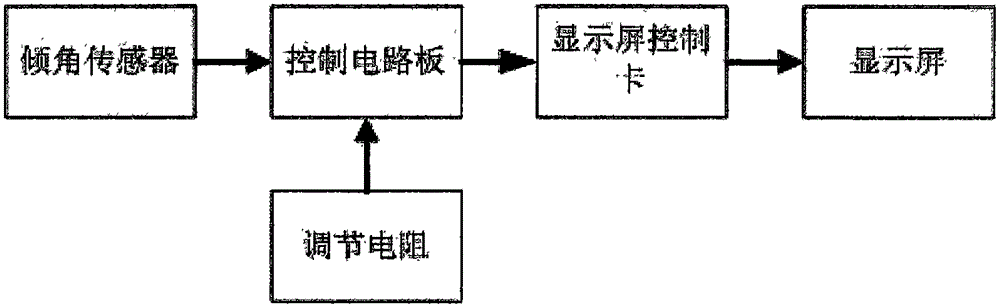

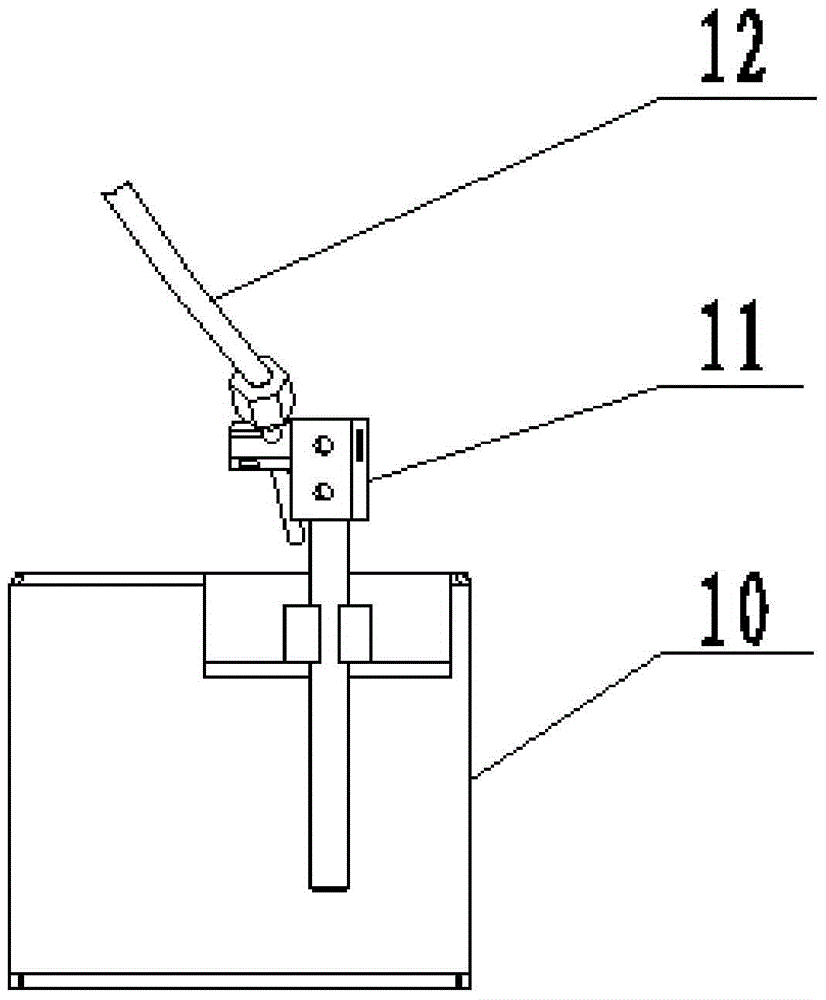

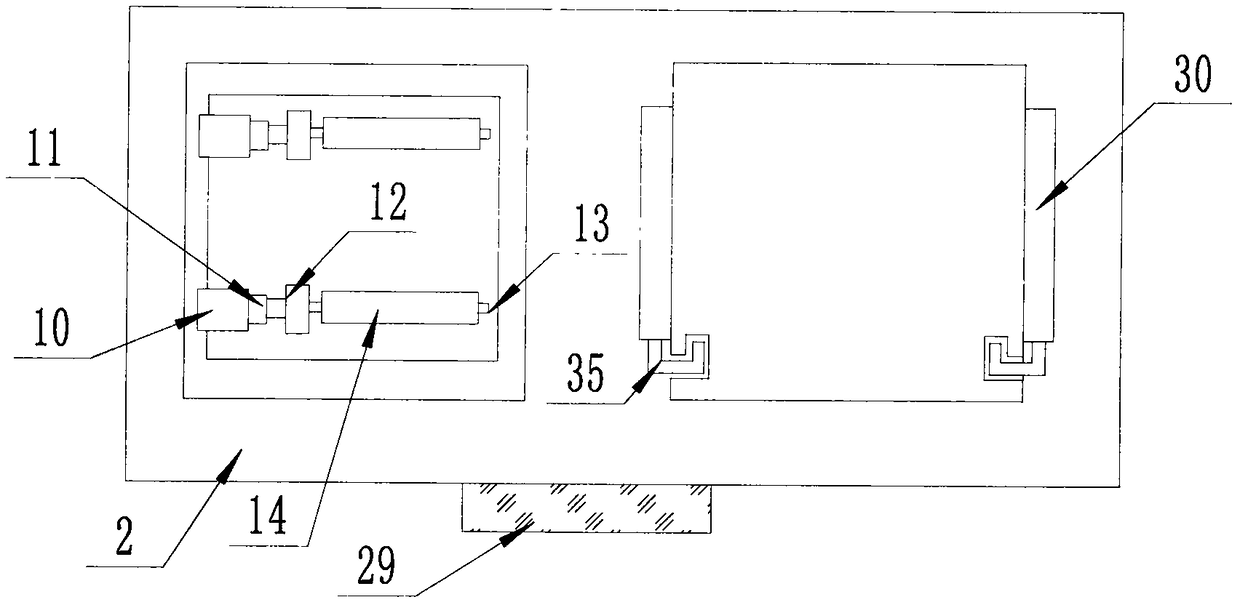

Device for detecting after-operation line level parameters of tamping car

InactiveCN105484116AEliminate manual inspectionReduce labor intensityTrack superstructureMeasuring apparatusEngineeringData processing

The invention relates to a device for detecting after-operation line level parameters of a tamping car. The detection device is installed on a B measuring trolley and a tailstock of the tamping car and mainly comprises an electrical cabinet 1 and a case 2. The electrical cabinet 1 fixedly provided with an inclination sensor is fixed on the B measuring trolley of the tamping car; a control circuit board in the case 2 acquires level parameters detected by the electrical cabinet 1 through a 4-core cable; after data processing, the data is transmitted to a display screen control card through an RS232 communication protocol and is then displayed through a display screen; and the position of a triangular symbol below the display screen explains that a left part is over-high or a right part is over-high. The device provided by the invention can quickly detect the after-operation level parameters of the tamping car in real time, omit detection links, reduce detection labor intensity as well as improve detection efficiency, thereby providing guarantee for efficient operation of the tamping car.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

A method for detecting solder joints and performing soldering on a complete electronic product

ActiveCN104668695BEasy to detectEasy to operateMetal working apparatusWelding apparatusEngineeringData memory

The invention provides a method for detecting soldering points of electronic product complete machines and performing tin soldering on the electronic product complete machines. The method is implemented by the aid of an automatic tin soldering machine with a CPU (central processing unit). The automatic tin soldering machine structurally comprises a workbench, an X-axis, a Y-axis, a Z-axis and a four-axis numerical control system, wherein the four-axis numerical control system is formed around a rotating shaft of the Z-axis. A soldering head is fixed on the Z-axis which is fixedly provided with an industrial camera. The method includes that standard image information of various kinds of qualified electronic product complete machines is stored in a data storage unit of the CPU, the industrial camera acquires an image of a to-be-detected electronic product complete machine, the image is stored in the data storage unit and is transmitted to a data processor, the data processor compares to-be-detected image information with the standard information in the data storage unit, if the image information is identical to the standard information, tin soldering points of the to-be-detected complete machine are qualified, or otherwise, the tin soldering points are unqualified, the data storage unit displays differences of the to-be-detected image on a display screen in a partial enlarged manner, repair soldering is performed, and if the soldering points are still unqualified, manual detection is performed.

Owner:河北科瑞达仪器科技股份有限公司

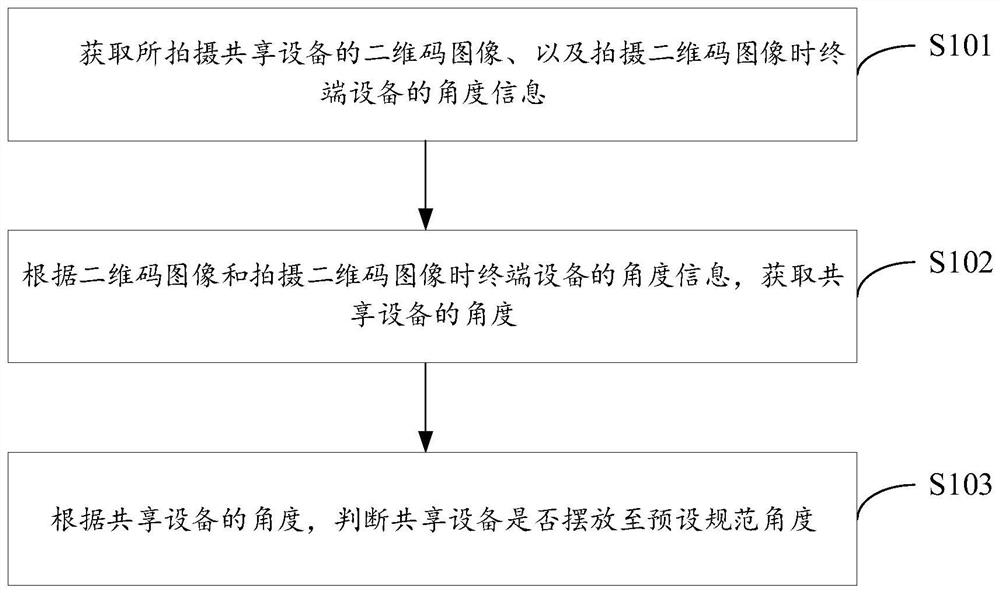

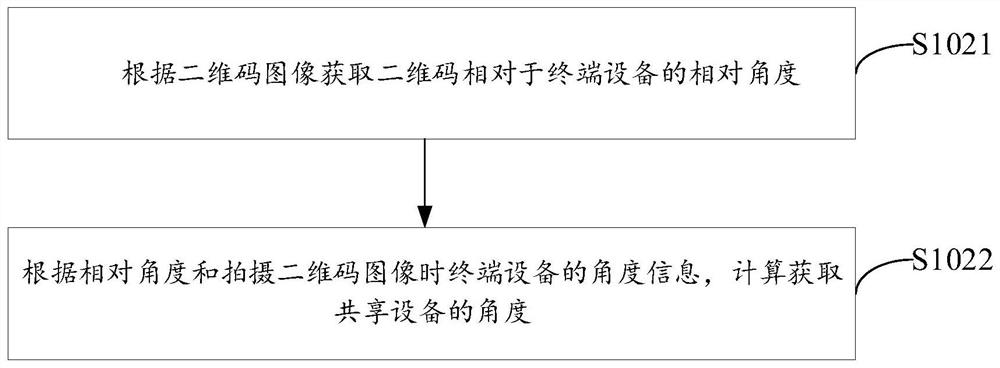

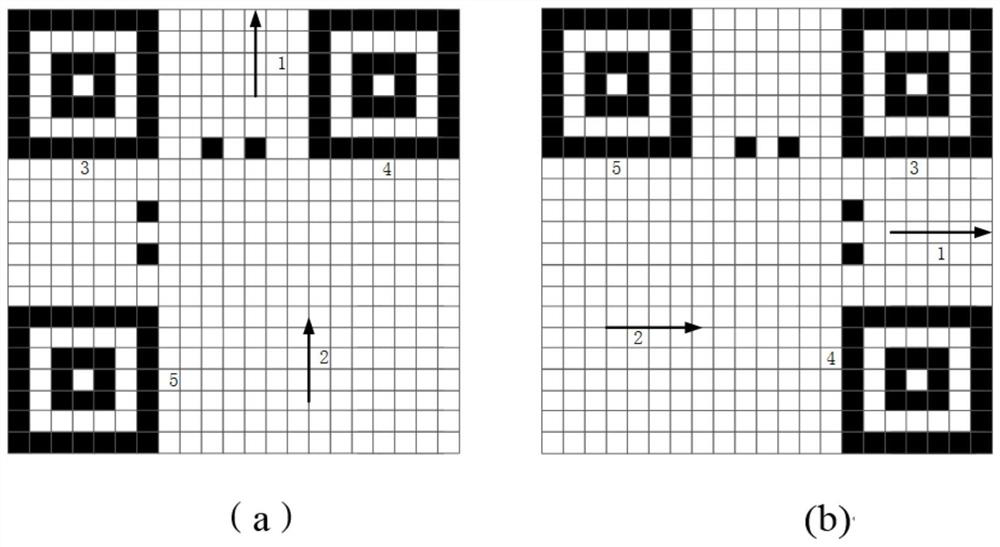

Shared equipment detection method and device and storage medium

ActiveCN111784763AImprove timelinessImprove user experienceImage analysisComputer hardwareTerminal equipment

The invention provides a shared device detection method and device and a storage medium, and relates to the technical field of the Internet. Obtaining a two-dimensional code image of the shot shared device and angle information of the terminal device when the two-dimensional code image is shot; obtaining the angle of the shared device according to the two-dimensional code image and the angle information of the terminal device when the two-dimensional code image is shot; and judging whether the shared equipment is placed to a preset standard angle or not according to the angle of the shared equipment. According to the embodiment of the invention, the placement angle of the shared device is finally obtained by obtaining the shot two-dimensional code image and the angle information of the terminal device when the two-dimensional code image is shot, so that the intermediate manual inspection link is omitted, the timeliness of standard parking detection of the shared device is improved, andthe user experience is improved.

Owner:浙江小遛信息科技有限公司

Tool for preventing carbon brush from direction error in installation

ActiveCN104868662AAssembling the product is quick and easyReduce movementManufacturing dynamo-electric machinesLight-emitting diodeAlarm device

The invention discloses a tool for preventing a carbon brush from direction error in installation. The tool comprises a regulator, a carbon brush length control block, a PCB trigger plate and an alarm device; and the carbon brush is mounted on the regulator. The tool is characterized in that the carbon brush length control block is mounted on the regulator, the PCB trigger plate is mounted on the carbon brush length control block, the alarm device is arranged at the right end of the regulator and internally provided with an LED, a piezoelectric active buzzer and a battery, and the PCB trigger plate is connected with the LED and the piezoelectric active buzzer via leads. The tool has the advantages that the alarm device is triggered no matter which position of the PCB trigger plate is pressed when the carbon brush is mounted reversely, pseudo-connection does not occur, and during use, the tool is sensitive for triggering, safe and reliable.

Owner:JIANGSU YUNYI ELECTRIC

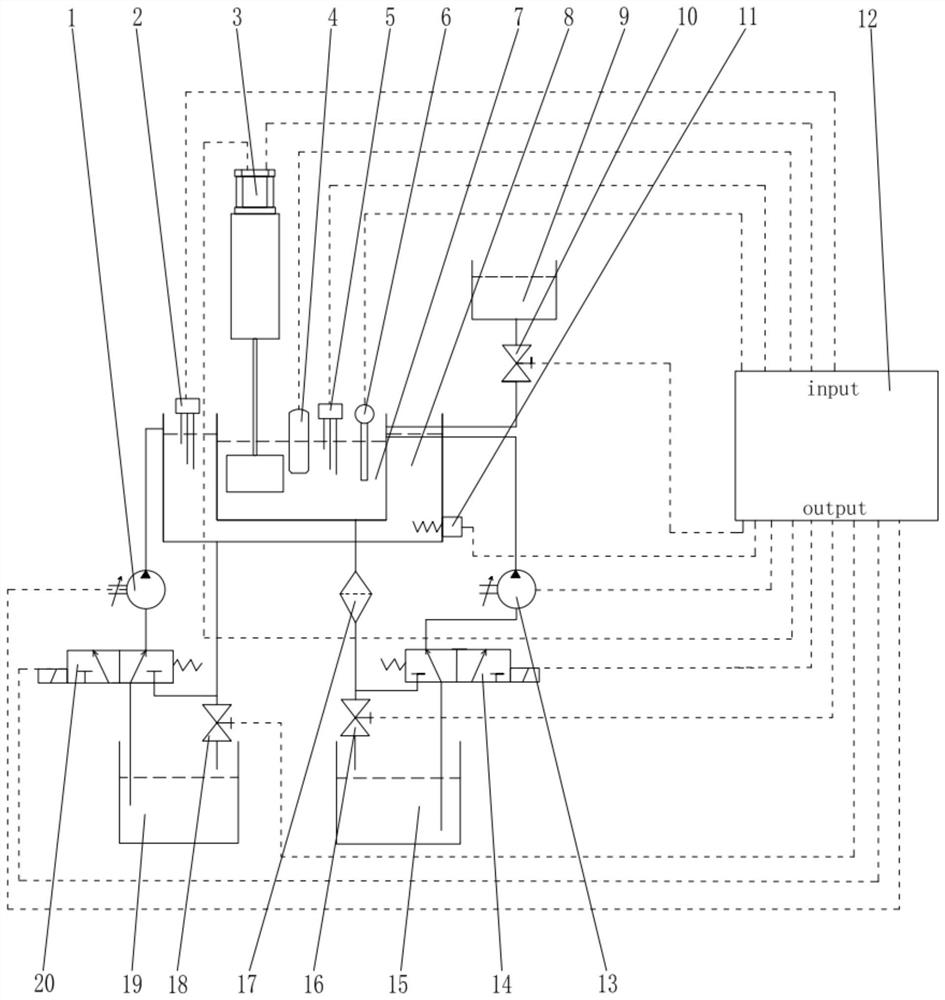

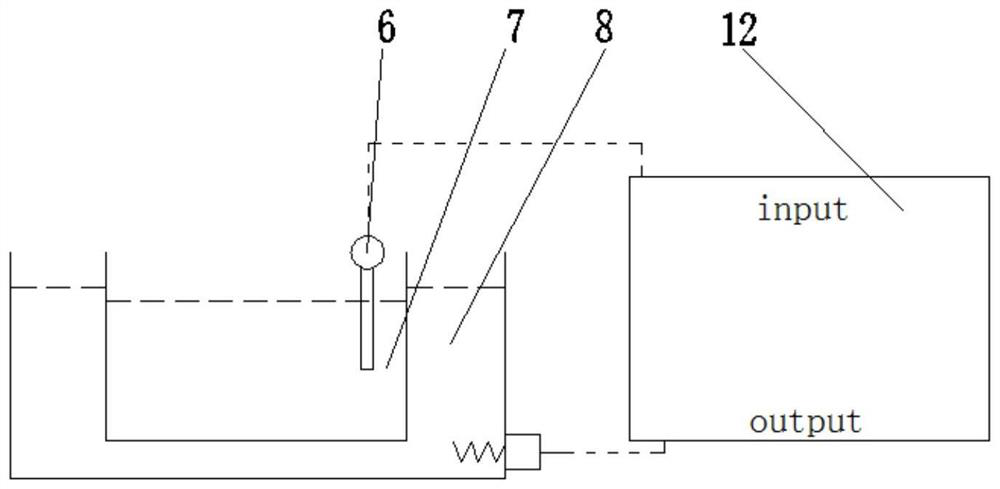

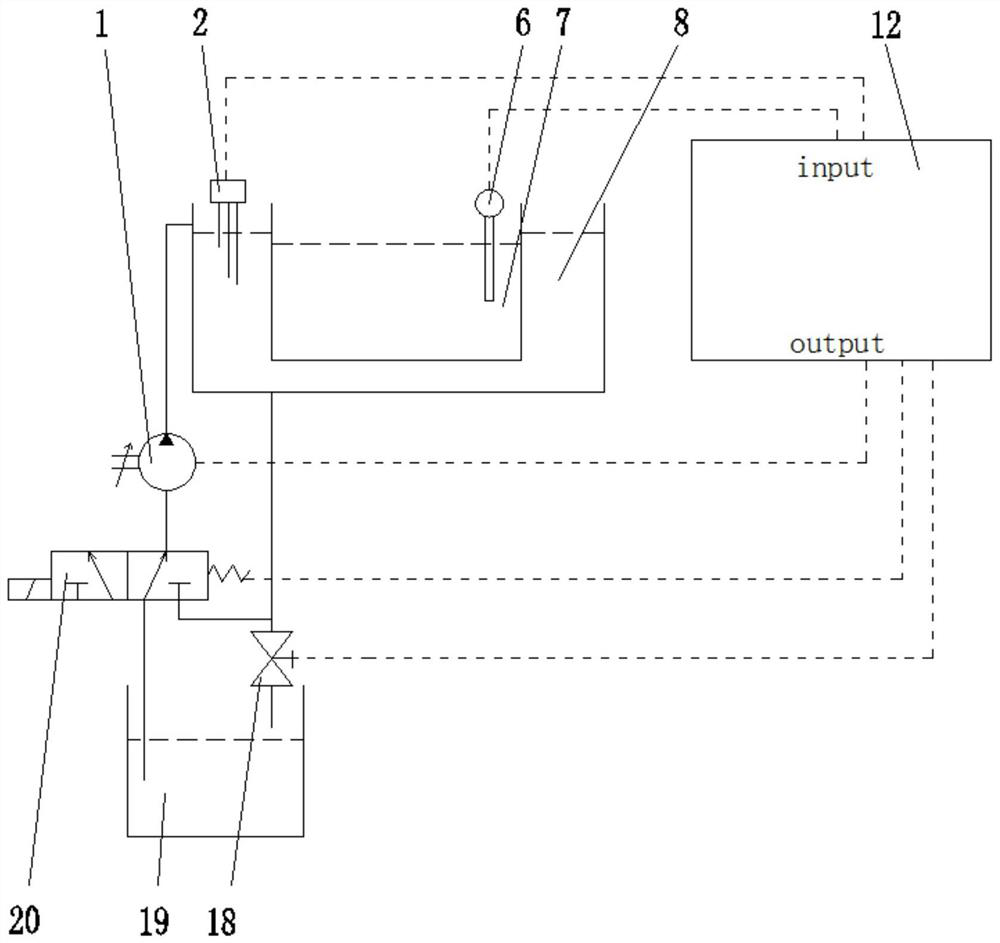

Precision electroforming system and control method

ActiveCN112030196AHigh control precisionIncrease the level of automationElectroforming processesSimultaneous control of multiple variablesWater bathsTemperature control

The invention discloses a precision electroforming system and a control method. The precision electroforming system comprises an electroforming liquid temperature control module, a water bath water level control module, an electroforming liquid pH value control module, an electroforming tank liquid level control module and a control system. A modular automatic control method is mainly adopted, corresponding parameters are accurately controlled by designing different modules, and the problems that an electroforming device is low in automation level and poor in parameter control accuracy are solved; meanwhile, through a coordination method among different modules, the problems that the temperature of electroforming liquid is not uniformly heated and the control precision is poor are finallysolved; and the problem that the pH value control precision of the electroforming liquid is poor is solved. Mutual influence between control parameters is considered, closed-loop automatic control isformed, the control precision of technological parameters of precision electroforming equipment and the stability of the equipment can be effectively improved, the forming quality of a workpiece can be improved, the automation level of the electroforming equipment can be improved, manual detection and operation links are omitted, the labor cost is effectively reduced, and workpiece machining is simpler and more convenient.

Owner:CENT SOUTH UNIV

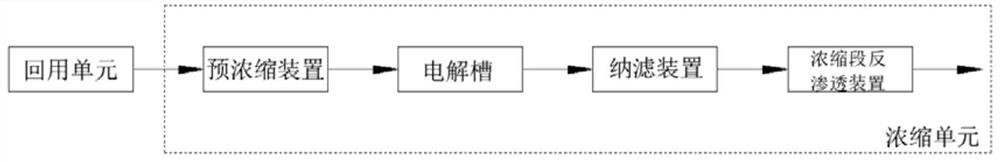

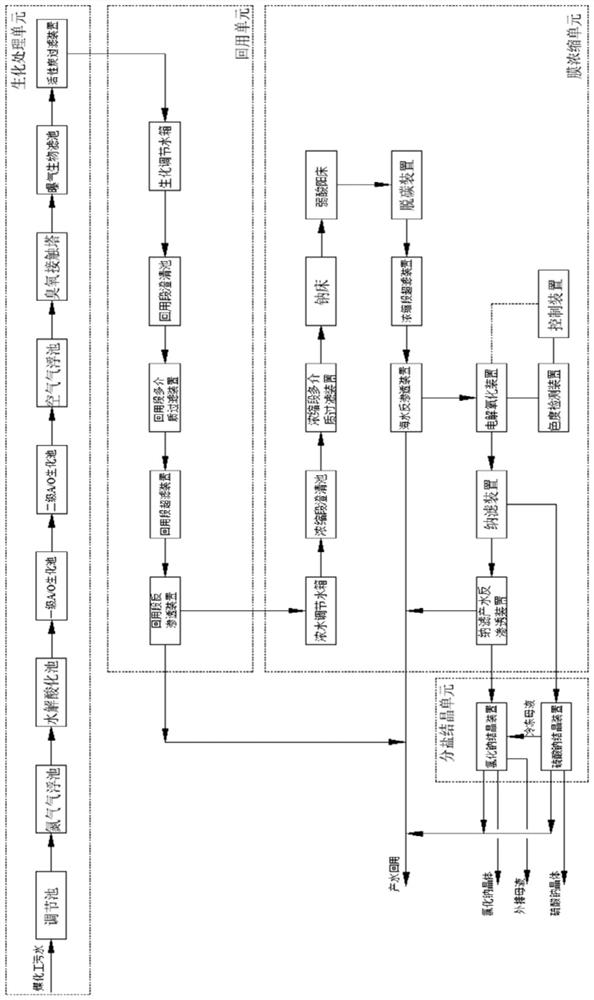

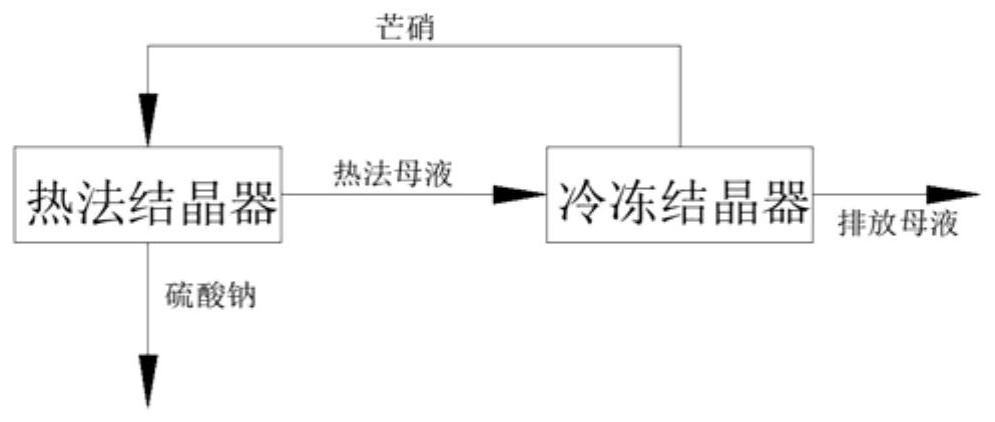

A system and method for zero-discharge treatment of coal chemical wastewater with electrolytic oxidation and salt separation and crystallization

ActiveCN109942148BClosely connectedEliminate manual inspectionWater contaminantsMultistage water/sewage treatmentChemistryNanofiltration

The invention provides a system and method for zero-discharge treatment of coal chemical industry sewage with electrolytic oxidation and salt separation and crystallization. The system includes a sequentially connected recycling unit and a membrane concentration unit; wherein, the membrane concentration unit includes sequential A pre-concentration device, an electrolytic oxidation device, a nanofiltration device and a nanofiltration product water reverse osmosis device are connected secondaryly; the electrolytic oxidation device includes an electrode with a working voltage of 4.3V. On the one hand, the present invention installs an electrolytic oxidation device in the middle of the membrane concentration unit, electrolytically oxidizes the concentrated water entering the nanofiltration device of the salt separation crystallization unit, and obtains electrolytic oxidation product water for salt separation by adjusting appropriate electrolytic oxidation working parameters , providing the water quality basis for the subsequent salt division. On the other hand, the present invention provides a whole set of zero discharge system for coal chemical industry sewage, which adjusts each unit in the existing sewage treatment system from the perspective of the whole process for coal chemical sewage with poor water quality, and properly handles each unit. Pollution-like impact factors make the connection between the upstream and downstream units closer.

Owner:中海油山西能源投资有限责任公司

The Determination Method of Minimum Cutting Thickness of Workpiece Material

InactiveCN104128646BImprove processing qualityEasy to measureMilling equipment detailsDepth of fieldAnalysis method

The invention relates to a minimum cutting thickness determination method of a workpiece material. At present, a theoretical analysis method during the processing of obtaining the minimum cutting thickness value of a workpiece material is tedious and has poor applicability, and a calculation result obtained is not accurate enough. The method comprises the following steps: milling trace of a workpiece material is observed under a super field-depth microscope, the surface is divided into a cutting area, a ploughing area and a rubbing area, and the total length l of the ploughing area-the rubbing area is measured; an intersection A of an interface of the ploughing area-the cutting area and a boundary line between a first cutter tooth and the surface of the workpiece is taken, central positions of the first cutter tooth and a second cutter tooth of the cutter starting to cut into the workpiece material are taken as points O1 and O2, a coordinate system is established with the point O1 as the origin of coordinates, a cutting cross section perpendicular to XO1Y is made by crossing the point O2 and the point A, and a projection point O1' of the point O1 on the section is obtained; a vertical line of XO1Y is made by crossing the point A, an intersection of the vertical line and the outline of the lower end of the cutting cross section is a point B, an intersection of O2B and the outline of the upper end of the cutting cross section is a point C, and hD=R-|O2C| is calculated in a triangle O2CO1' by the cosine law. The method is used for determining the minimum cutting thickness of a workpiece material during processing of a cutter.

Owner:HARBIN UNIV OF SCI & TECH

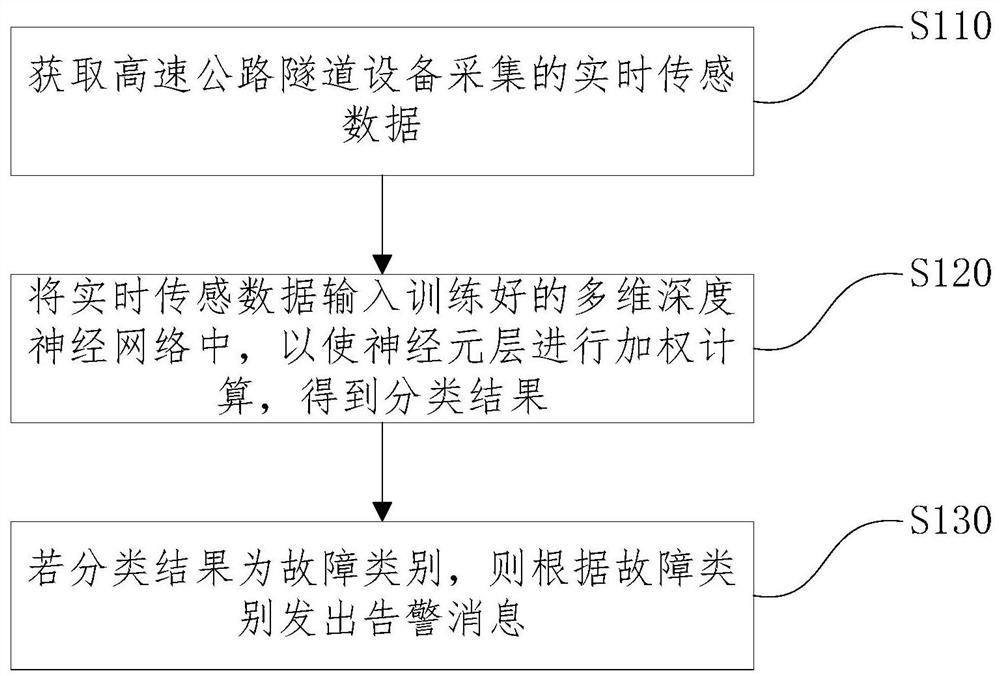

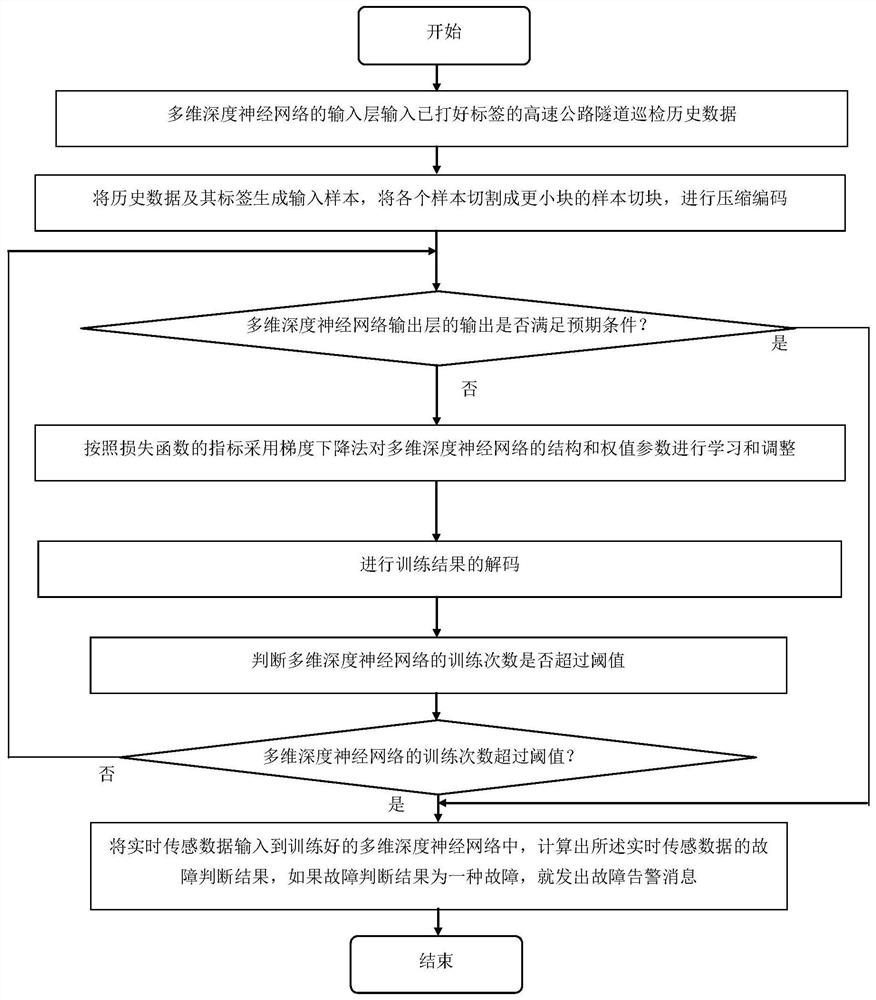

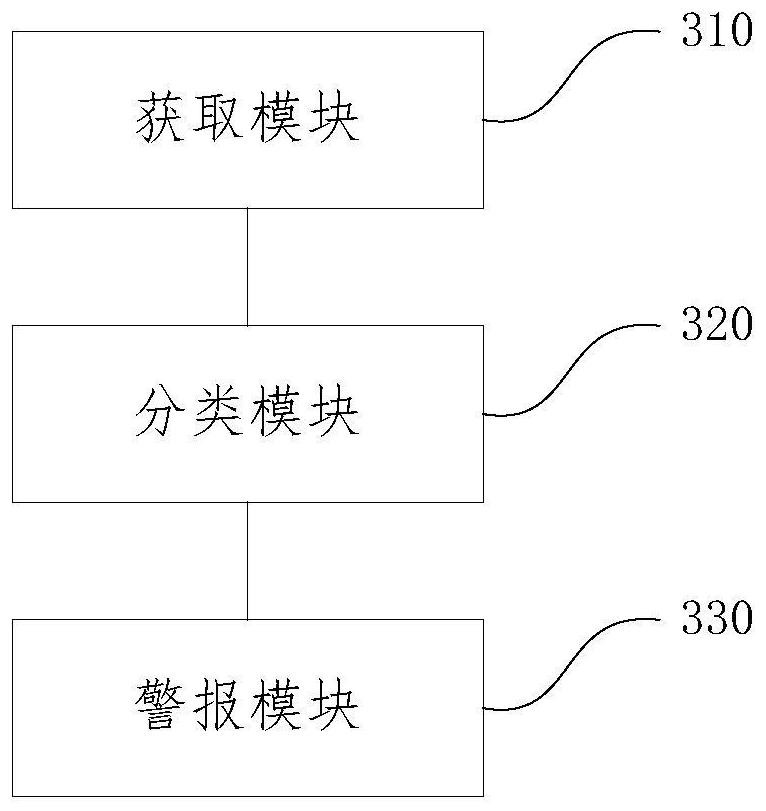

Expressway tunnel equipment fault processing method and device and electronic equipment

PendingCN113920720AGuaranteed uptimeEliminate manual inspectionDetection of traffic movementAnti-collision systemsSensing dataAlarm message

The invention discloses an expressway tunnel equipment fault processing method and device and electronic equipment, and belongs to the technical field of expressway tunnel equipment maintaining. The expressway tunnel equipment fault processing method comprises the steps: acquiring real-time sensing data collected by expressway tunnel equipment; inputting the real-time sensing data into the trained multi-dimensional deep neural network to enable a neuron layer to perform weighted calculation to obtain a classification result; and if the classification result is a fault category, sending an alarm message according to the fault category. According to the method, manual inspection is avoided, the fault equipment can be quickly analyzed and determined, the normal operation of the expressway tunnel equipment is ensured, and the occurrence of expressway tunnel traffic accidents is reduced.

Owner:SHANGHAI TUSHAN INTELLIGENT TECH CO LTD

An online peel strength detection device and working method of a hook cutting machine for hook and loop fasteners

ActiveCN106370450BSave human effortSave moneyStructural/machines measurementTraction systemControl system

Owner:WUXI PAIHO TEXTILES CO LTD

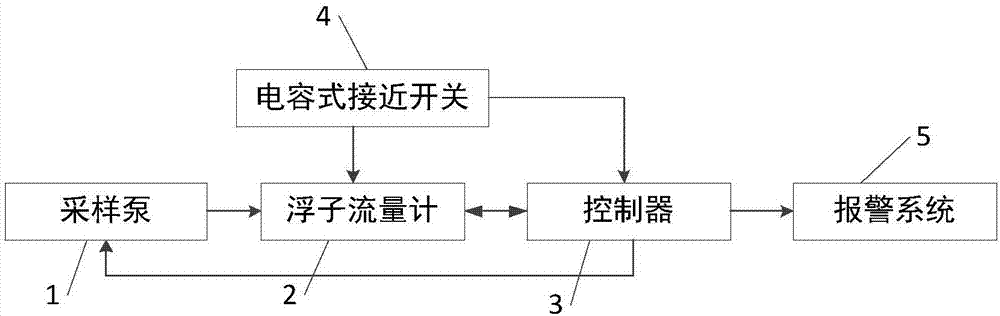

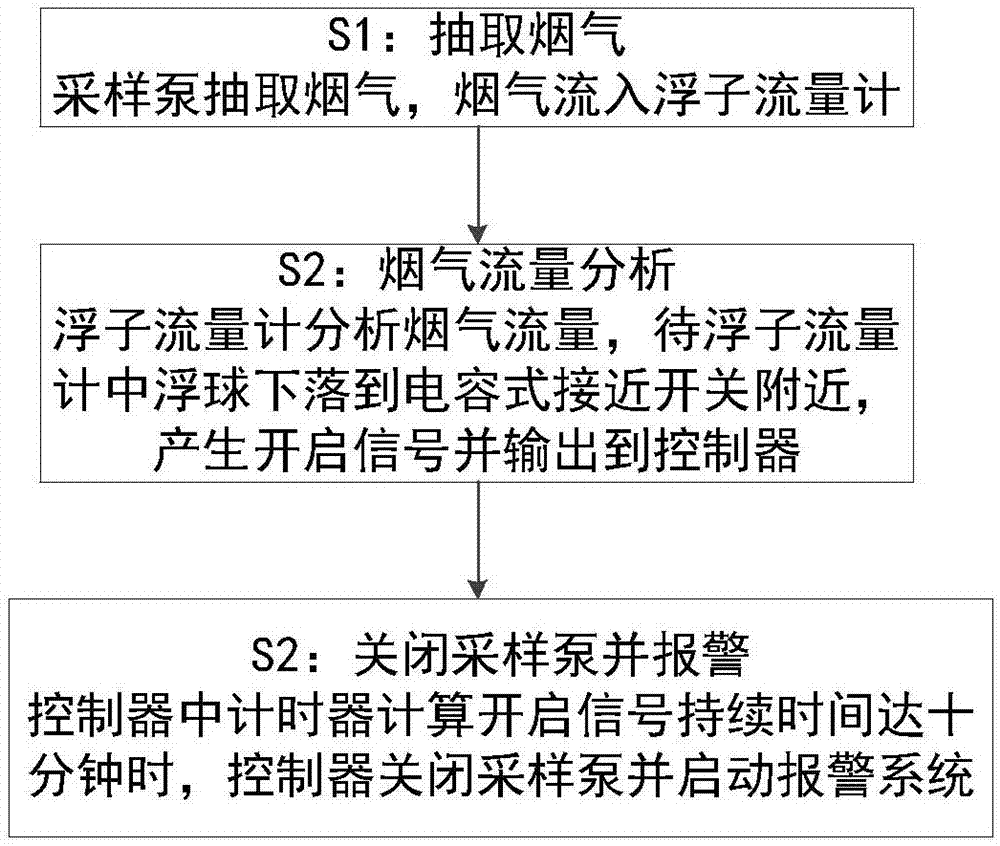

Automatic fume monitoring system with flow alarm control and method of automatic fume monitoring system

The invention provides an automatic fume monitoring system with flow alarm control and a method of the automatic fume monitoring system. The automatic fume monitoring system comprises a sampling pump, a floater flowmeter and a controller, wherein the floater flowmeter is connected with the output end of the sampling pump; the floater flowmeter and the sampling pump are connected with the controller; the controller is used for controlling opening and closure of the sampling pump and the floater flowmeter; and a capacitive approach switch is arranged on the floater flowmeter. By adopting the automatic fume monitoring system, the flow of fume inside a sampling pump outlet flue is monitored in real time, and an alarm system can be powered on and the sampling pump can be switched off if the fume flow is too small, that is, the sampling pump is blocked by granules and dust for a certain time, and thus the sampling pump can be prevented from being damaged because of blocking.

Owner:ANHUI BISHUI ELECTRONICS TECH

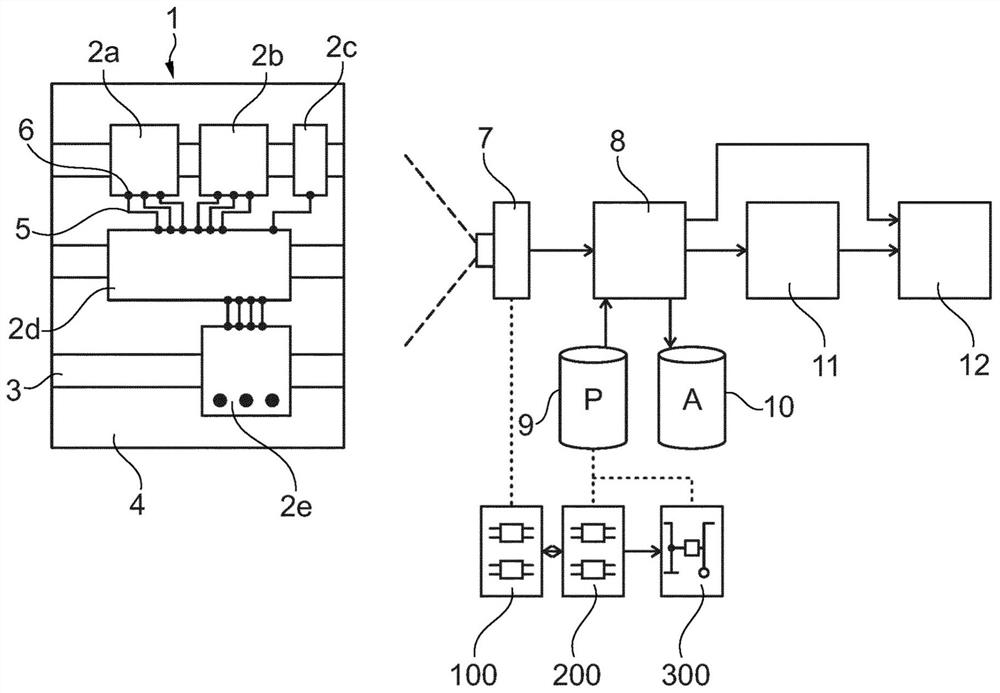

Device and method for testing the contents of a switchgear cabinet following installation according to a plan

PendingCN112534664AEliminate manual inspectionReduce failure factorsProgramme controlImage enhancementImage basedImage capture

The invention relates to a device for testing the contents of a switchgear cabinet following installation of equipment components (2a-2e) according to a plan and the wiring thereof via terminals (6) provided therefor by means of designated electrical cables (5), comprising: - a camera unit (7) for the at least two-dimensional image capture of the components (2a-2e) fully installed and wired on aninstallation board (4) of a switchgear cabinet (1); - an evaluation unit (8) for carrying out a comparison between an imaged layout (100), on the basis of the image capture, of the actual state with aprovided plan layout (200) of the target state, at least with regard to: a) the completeness and position of the installed components (2a-2e), b) the allocation of electrical terminals (6), c) the routing of the electrical cables (5); - an output unit (11) for providing the test result on the structural consistency of the switchgear cabinet (1) for an assessment with regard to delivery approval or fault rectification.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

A flexible circuit board re-inspection equipment

ActiveCN113777114BReduce labor intensityEliminate manual inspectionMaterial analysis by optical meansWebs handlingFlexible circuitsEngineering

Owner:佛山市坦斯盯科技有限公司

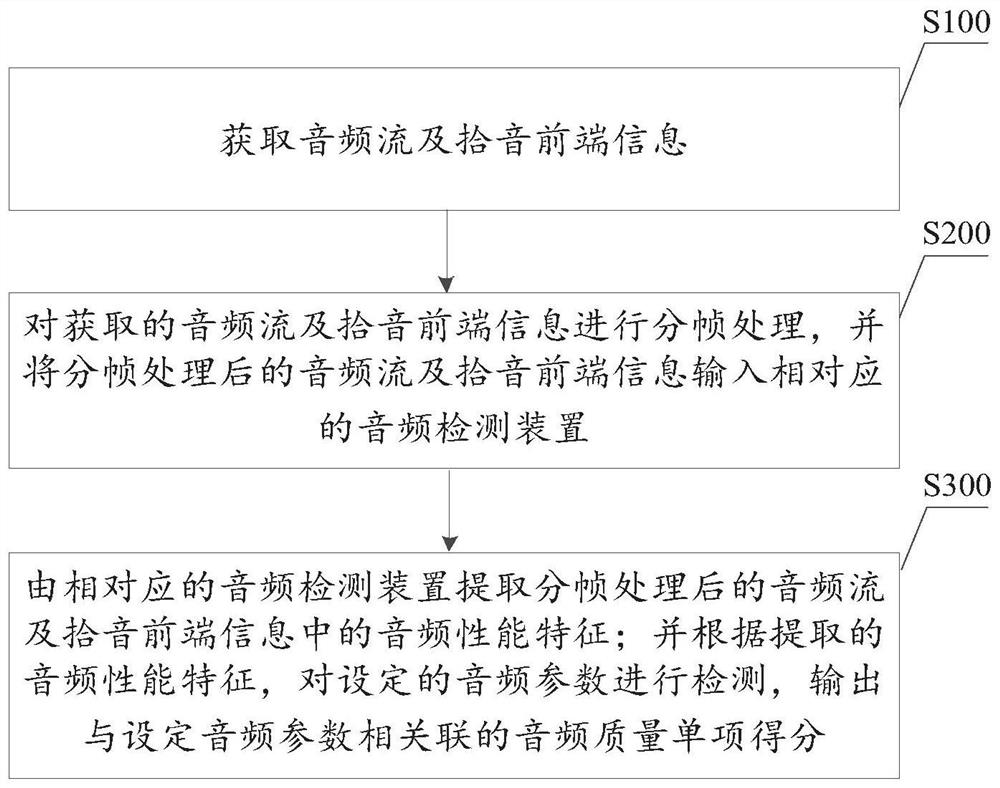

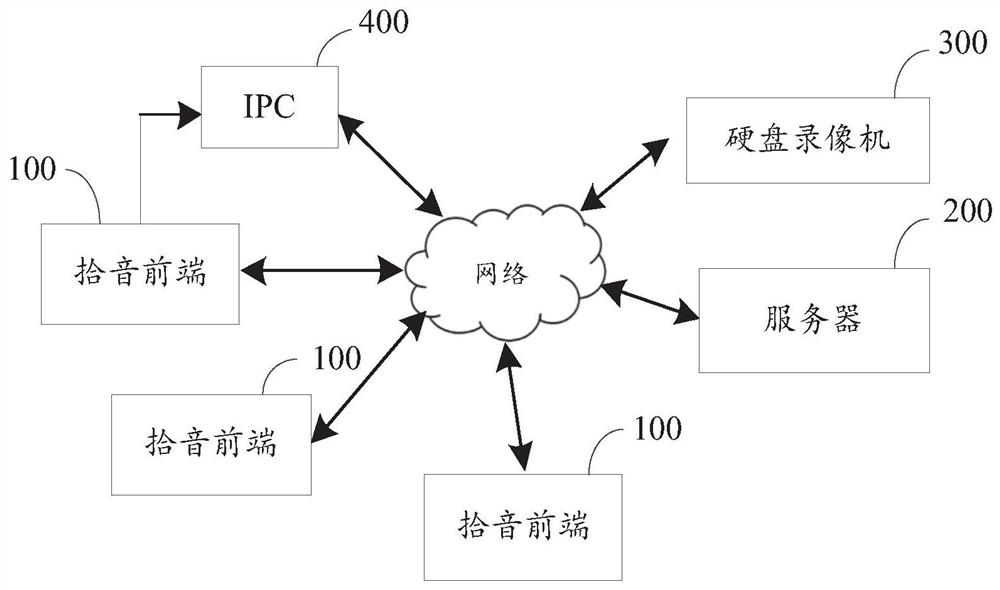

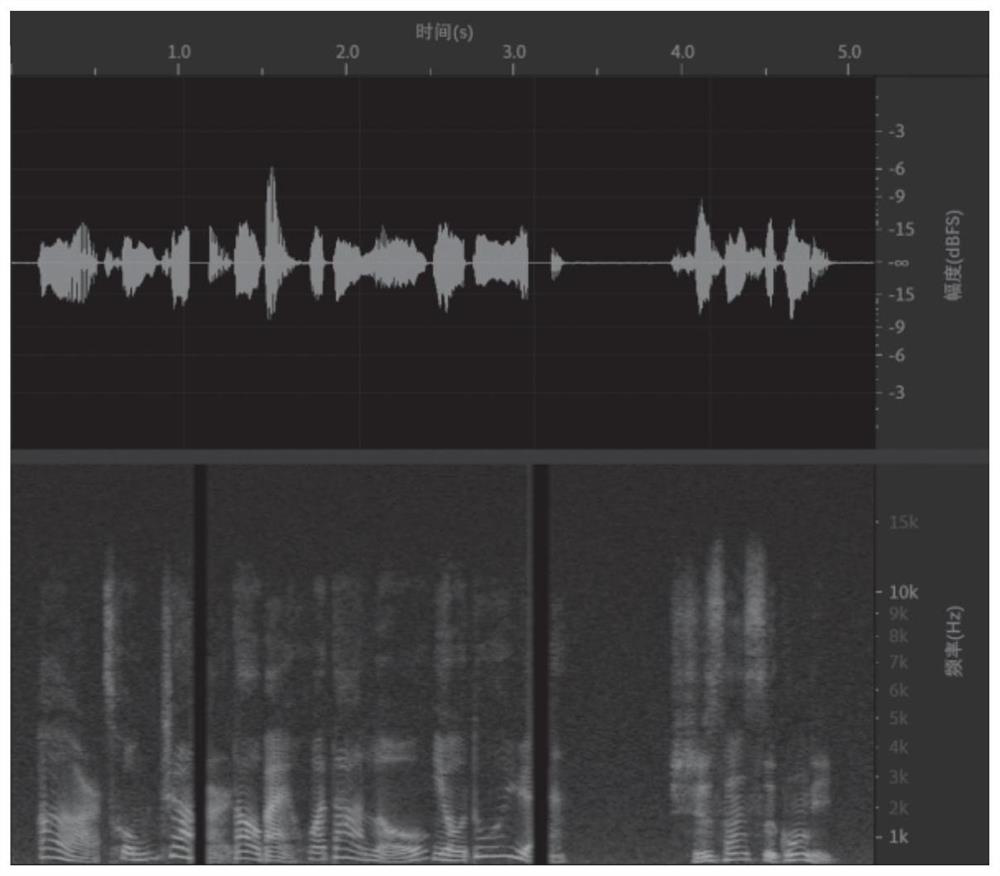

Audio detection method and system thereof

PendingCN112542179AImprove reliabilityEliminate manual inspectionSpeech recognitionEngineeringPickup

The invention discloses an audio detection method and a system. The method comprises the following steps: acquiring an audio stream and pickup front-end information; framing the acquired audio streamand pickup front-end information, and inputting the framed audio stream and pickup front-end information into a corresponding audio detection device; extracting audio performance characteristics in the framed audio stream and the pickup front-end information by a corresponding audio detection device; and detecting the set audio parameters according to the extracted audio performance characteristics, and outputting audio quality single scores associated with the set audio parameters. According to the audio detection method and system provided by the invention, the defect that the audio problemof the sound pickup system can be found only through manual real-time monitoring or after-event backtracking is avoided, and the reliability and stability of the whole security monitoring system are greatly improved; and corresponding channel audio quality information can be provided, so that maintenance personnel can carry out related maintenance conveniently.

Owner:世邦通信股份有限公司

An article qualified rate testing equipment

ActiveCN106768004BImprove practicalityEasy to operateMeasurement devicesEngineeringInfrared detector

The invention discloses a device for detecting percent of pass of an article. The device comprises a rectangular base, wherein the upper surface of the rectangular base is fixedly connected with a rectangular box body 1#; the interior of the rectangular box body 1# is of a hollow structure; the upper surface of the rectangular box body 1# is provided with a push mechanism; a safety detection mechanism is arranged on the upper surface of the rectangular box body 1# and is further located on the push mechanism; an infrared detector is connected with an optical imaging objective lens through a data line; two side surfaces of a rectangular through hole are both connected with rectangular baffling doors through hinges. The device has the beneficial effects that the practicality is high; the operation is convenient; the detection is convenient; meanwhile, the observation whether the article is qualified or not is facilitated; meanwhile, the percent of pass is calculated; the manual detection is omitted; the device is more time-saving and labor-saving.

Owner:徐佩登

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com