Device and method for calibrating and detecting sensor and AD convertor of multiple devices

A sensor and converter technology, applied in measurement devices, analog/digital conversion calibration/testing, instruments, etc., can solve the problems of wasting manpower, material resources and time, unable to ensure the correctness of the sensor, unable to solve the problem of rated value detection, etc. The effect of improving detection efficiency, small human error, and reducing labor and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

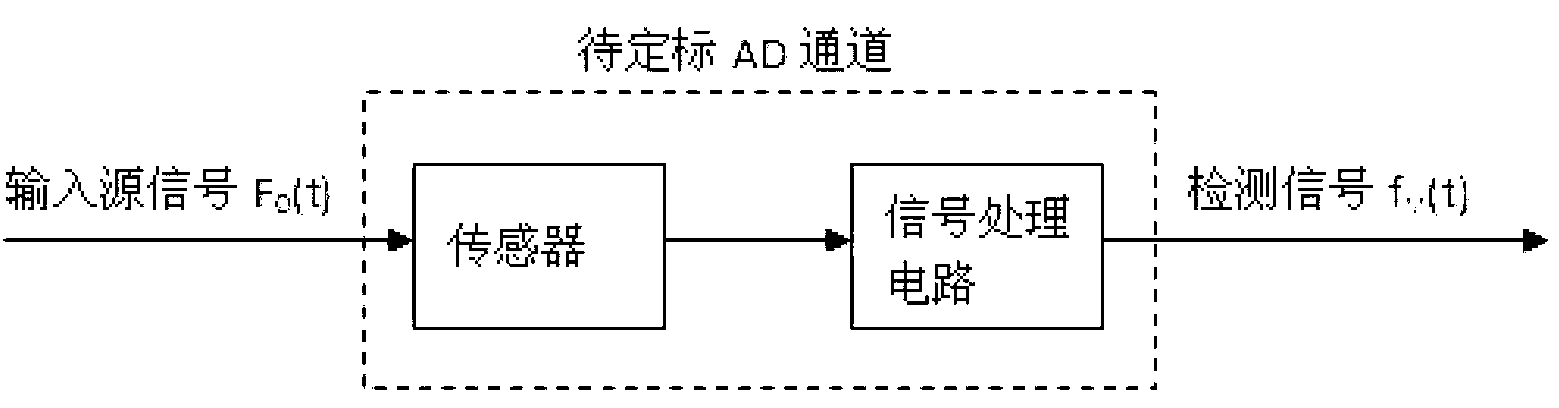

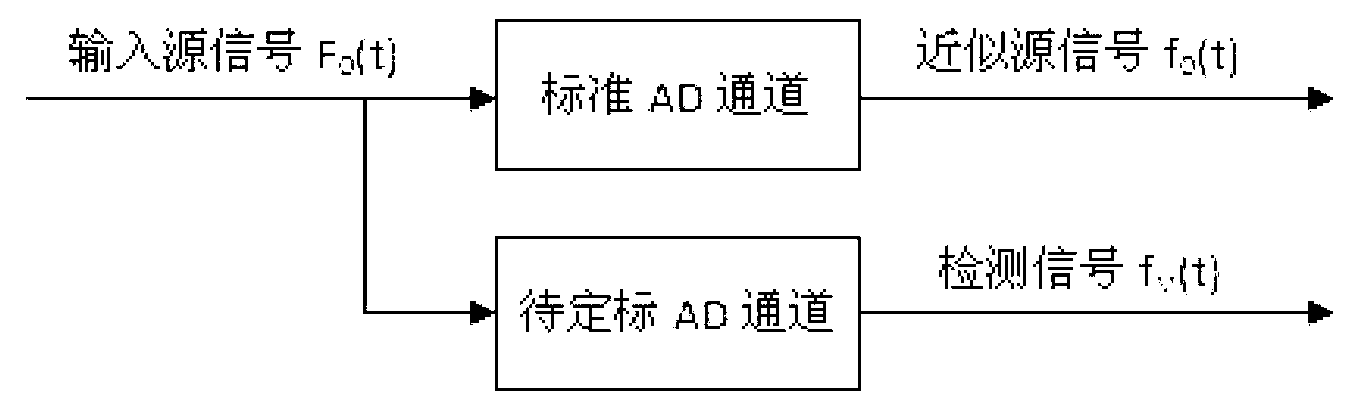

[0024] Such as figure 1 As shown, during the operation of the inverter, the input source signal F 0 (t) After being processed by the sensor and signal processing circuit, the detection signal f is finally obtained M (t), and f M (t) Transmission to computer to participate in control. In this process, the signal usually undergoes linear changes such as stretching or offset, so that the detection signal f M (t) and the input source signal F 0 (t) produces a linear deviation. In order to ensure that the detection signal participating in the control accurately reflects the characteristics of the input source signal, it is necessary to perform linear compensation on the detection signal, so that the compensated detection signal is consistent with the source signal. The process of obtaining the compensation-related parameters of the detection signal is calibration.

[0025] Since the signal deviation is linear, the signal compensation is also linear.

[0026] Let the scaling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com