Patents

Literature

2524results about How to "Reduce human error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

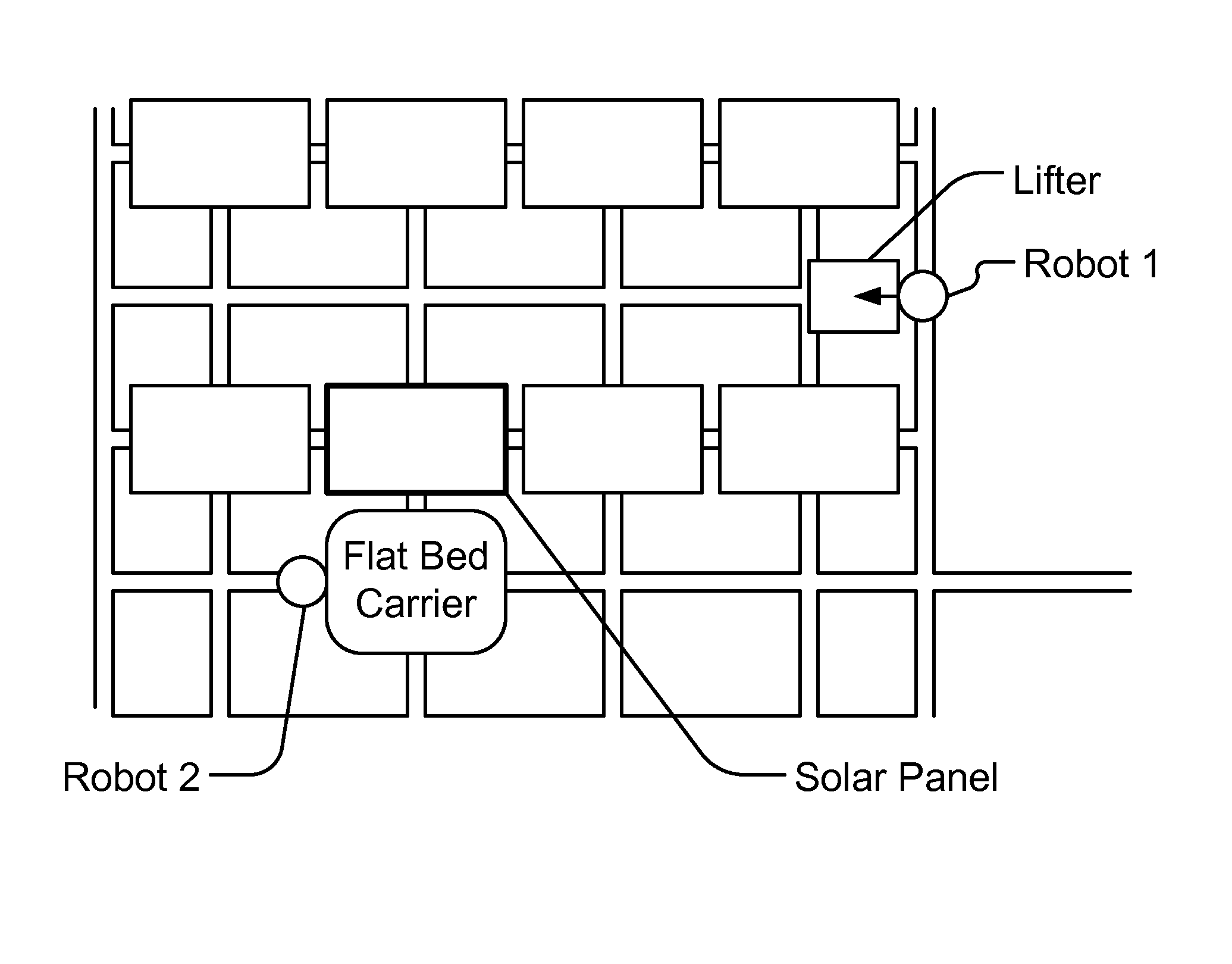

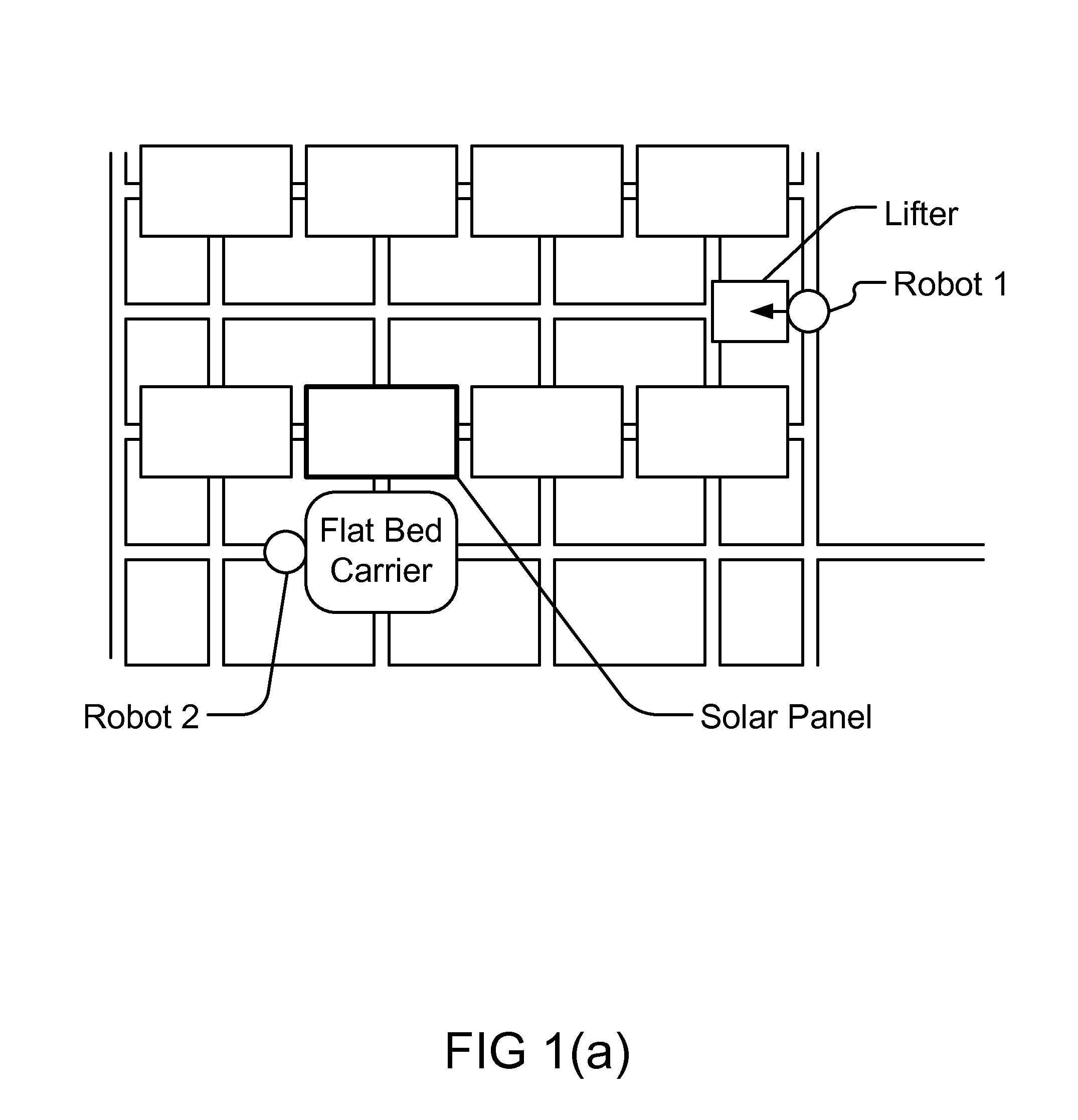

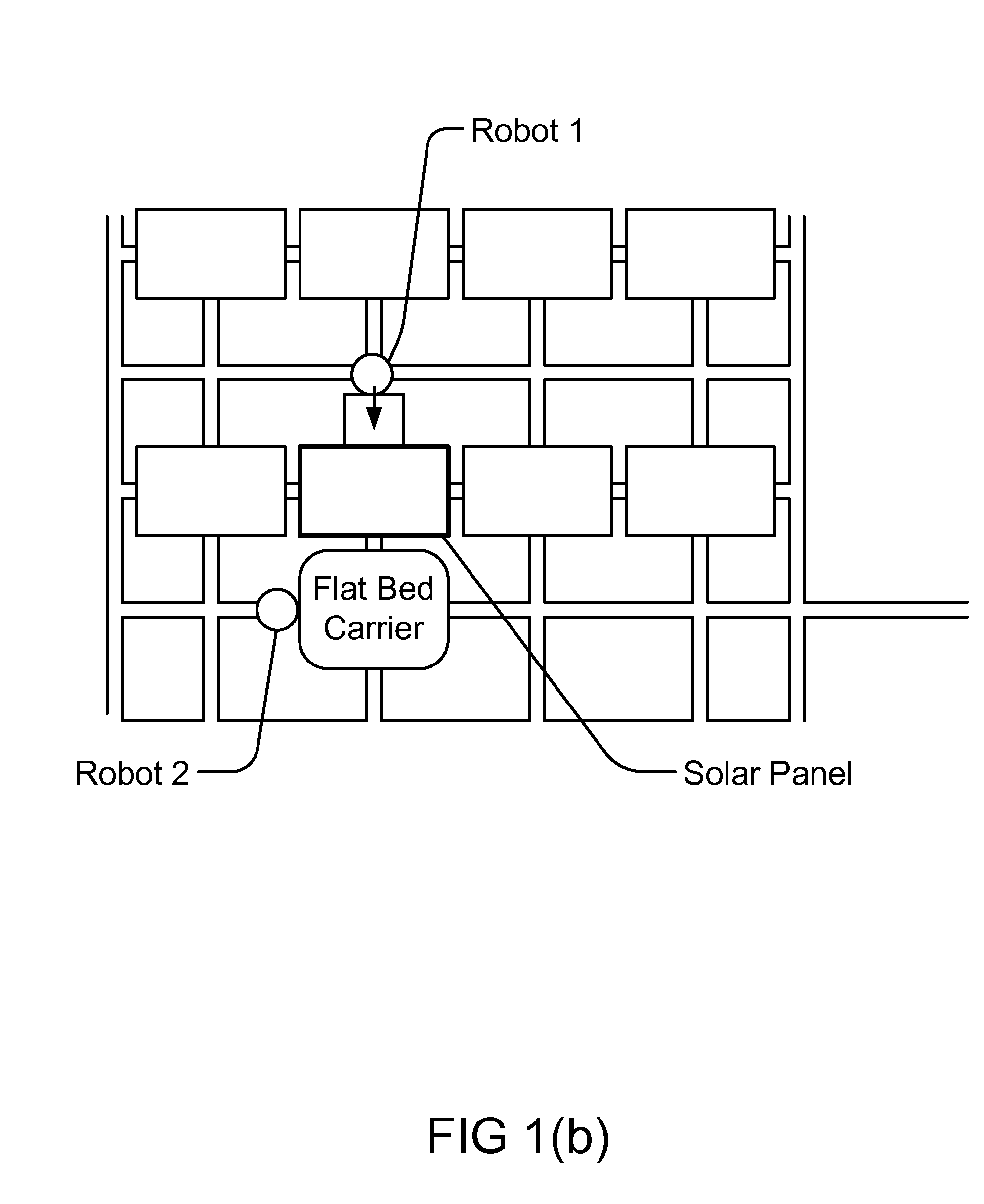

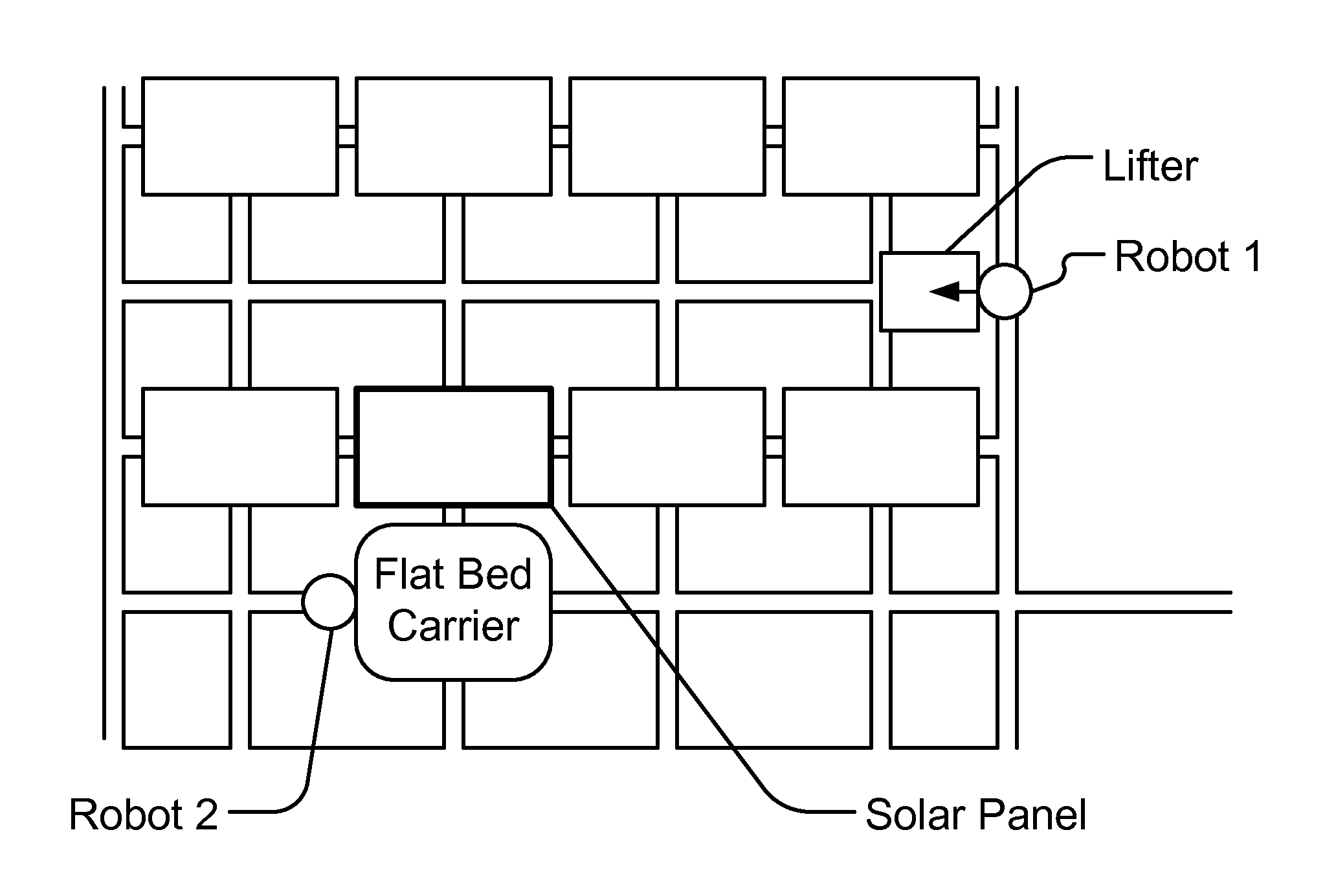

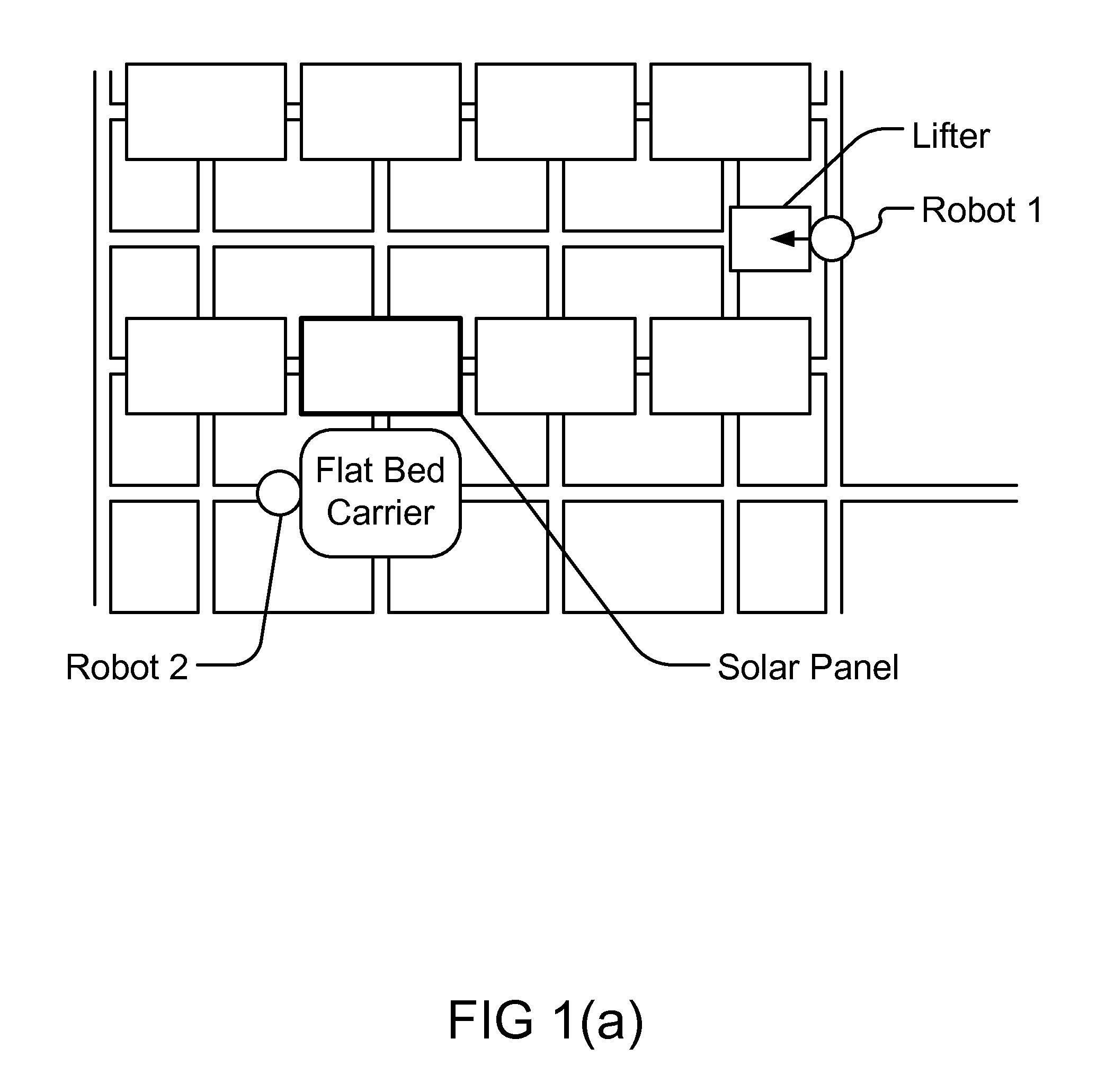

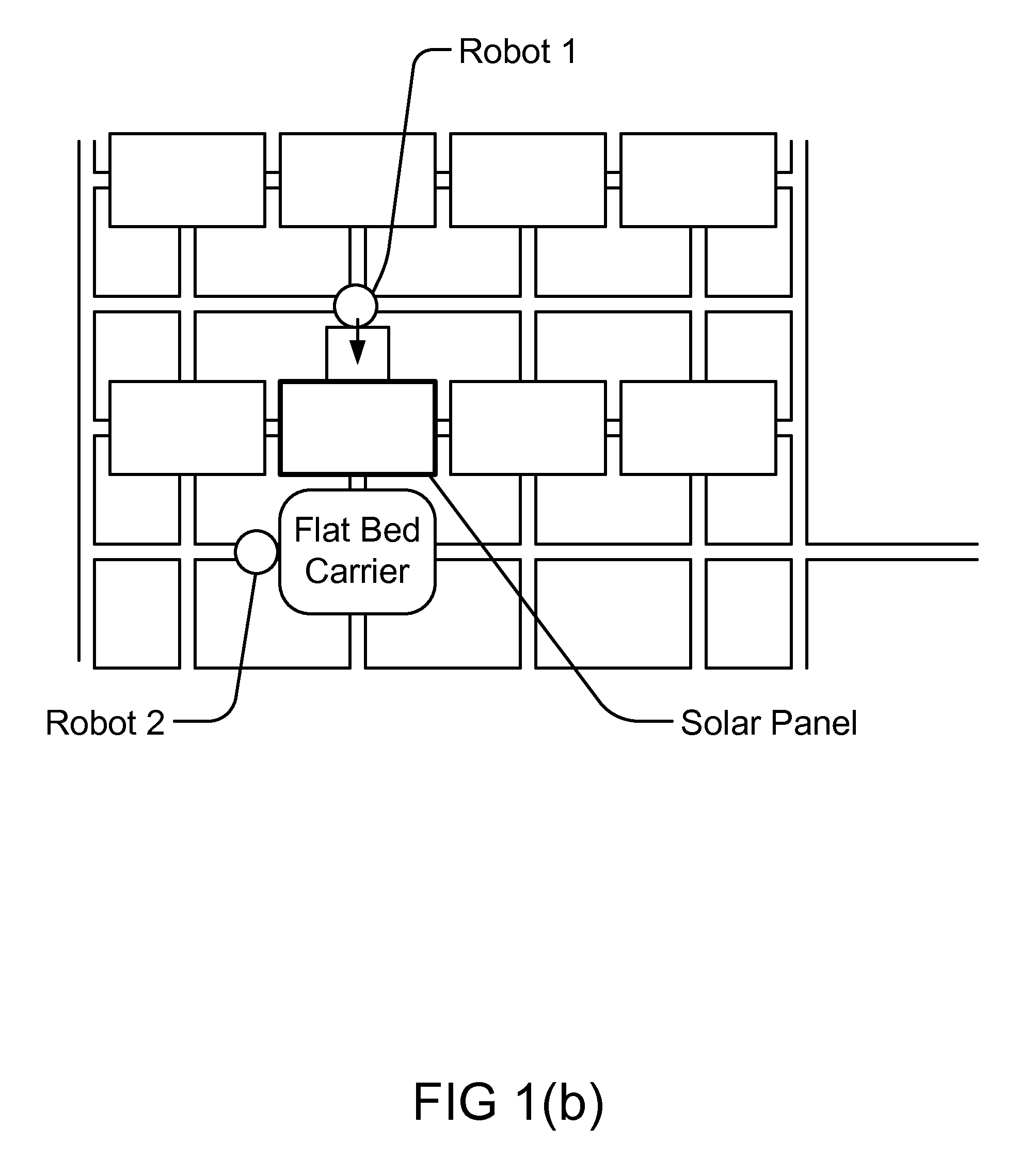

Robot for Solar Farms

ActiveUS20120152877A1Easy to operateMaintenanceSolar heating energySolar heat simulation/predictionEnvironment of AlbaniaEngineering

The solar energy and solar farms are used to generate energy and reduce dependence on oil (or for environmental purposes). The maintenance and repairs in big farms become very difficult, expensive, and inefficient, using human technicians. Thus, here, we teach using the robots with various functions and components, in various settings, for various purposes, to improve operations in big (or hard-to-access) farms, to automate, save money, reduce human mistakes, increase efficiency, or scale the solutions to very large scales or areas.

Owner:BTPATENT

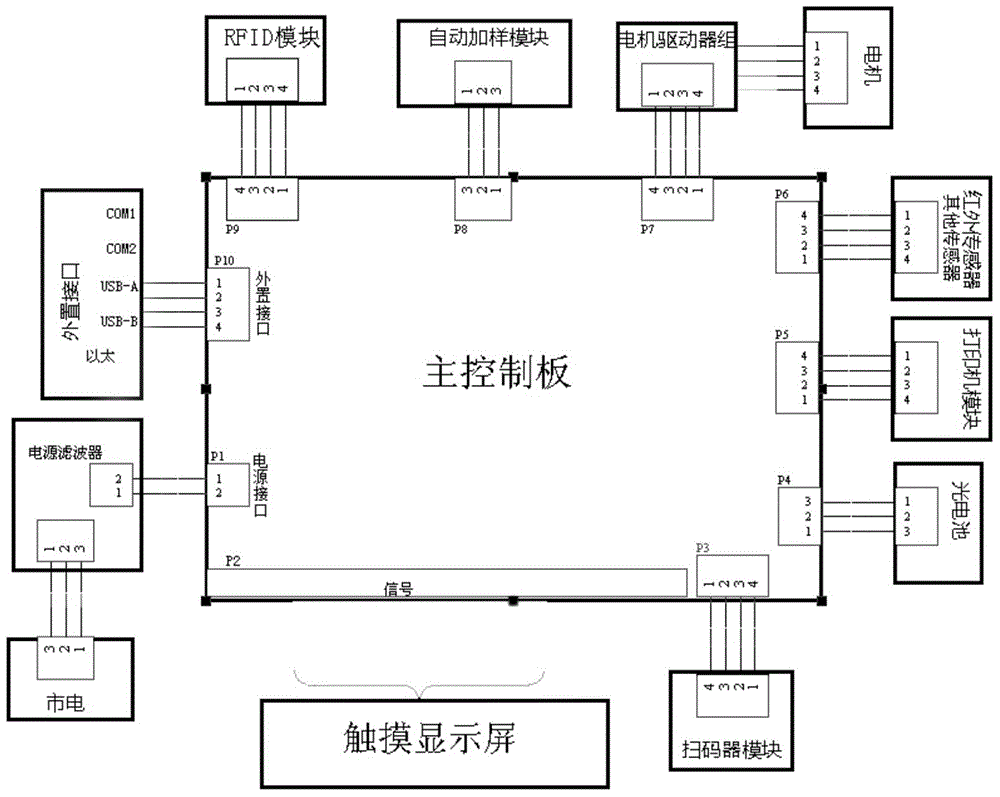

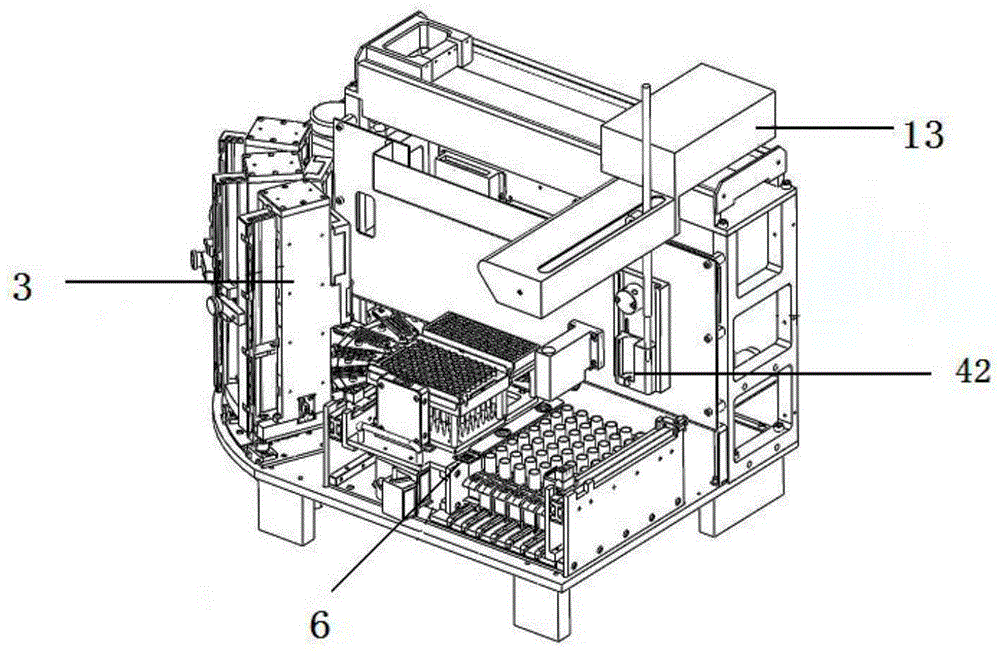

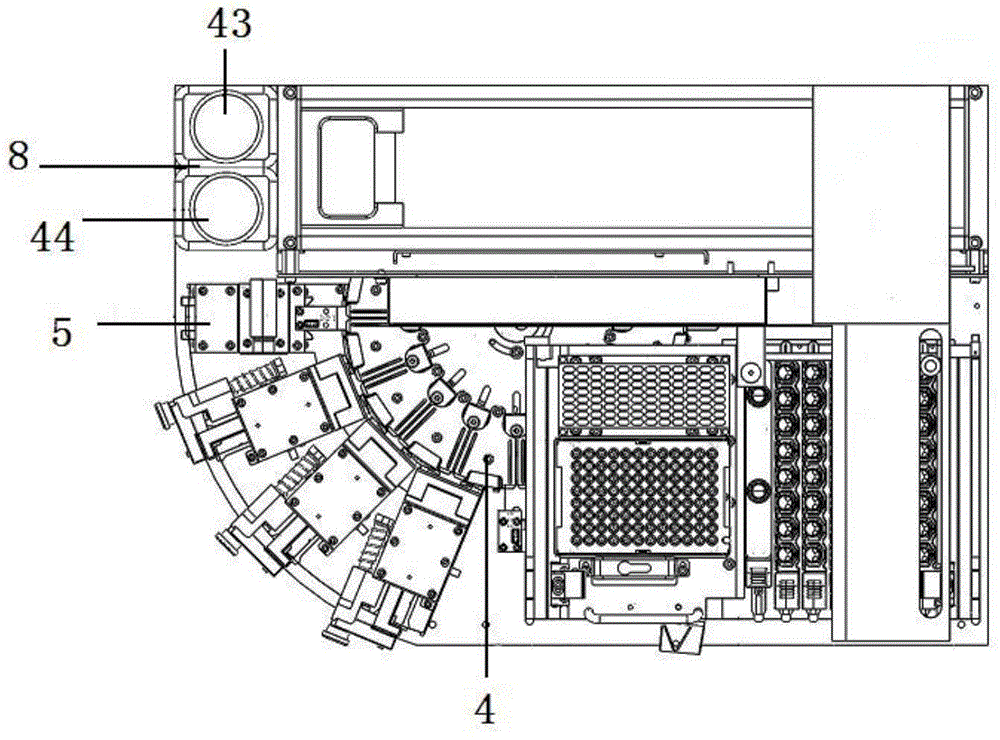

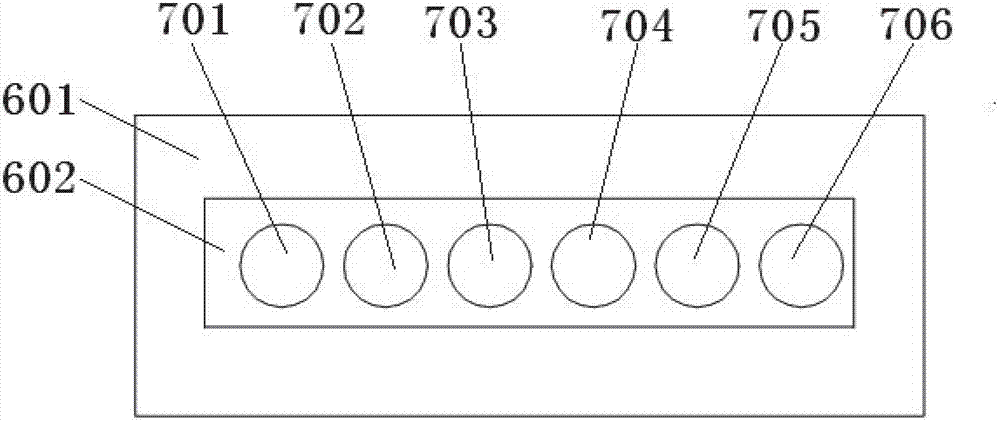

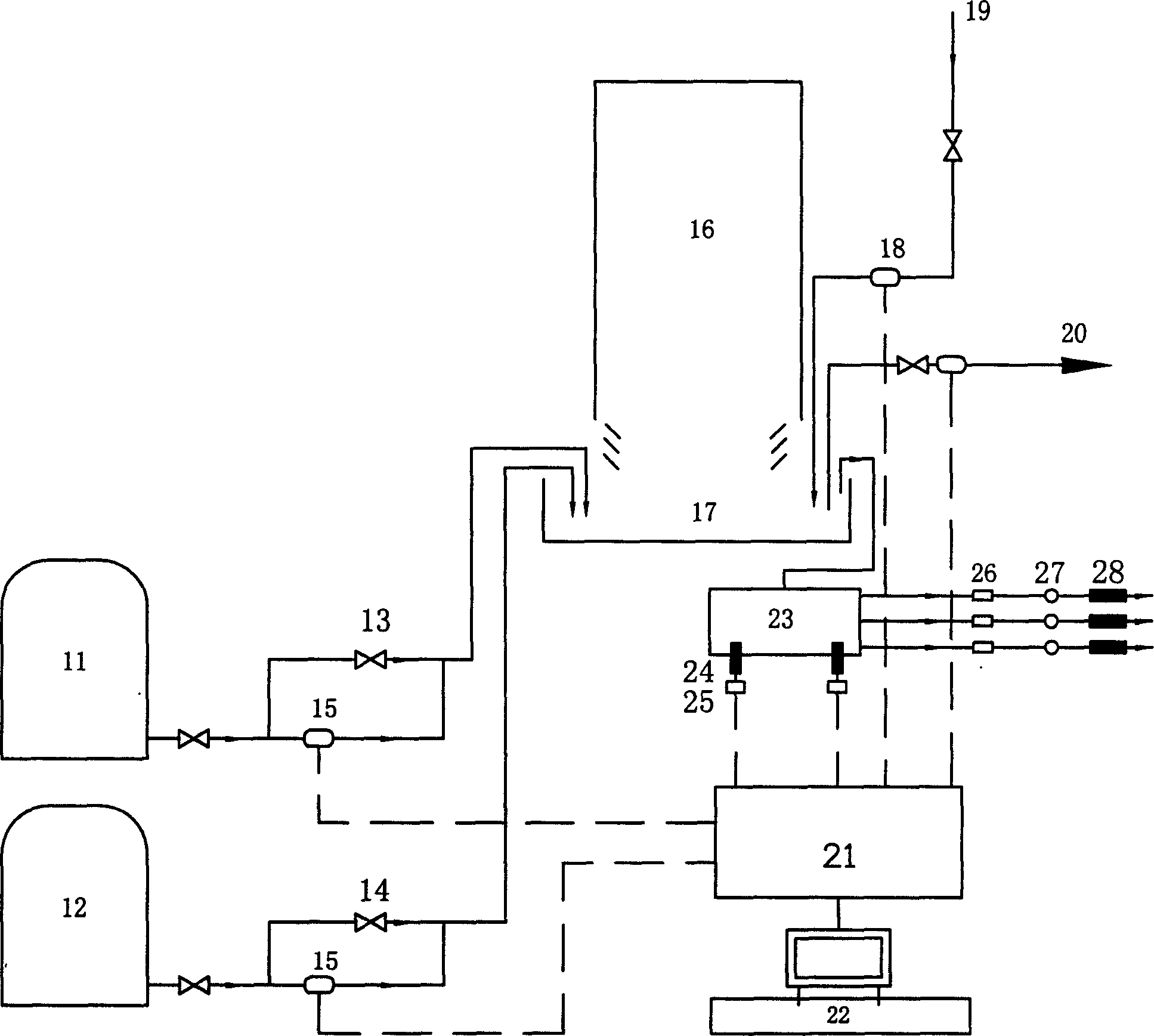

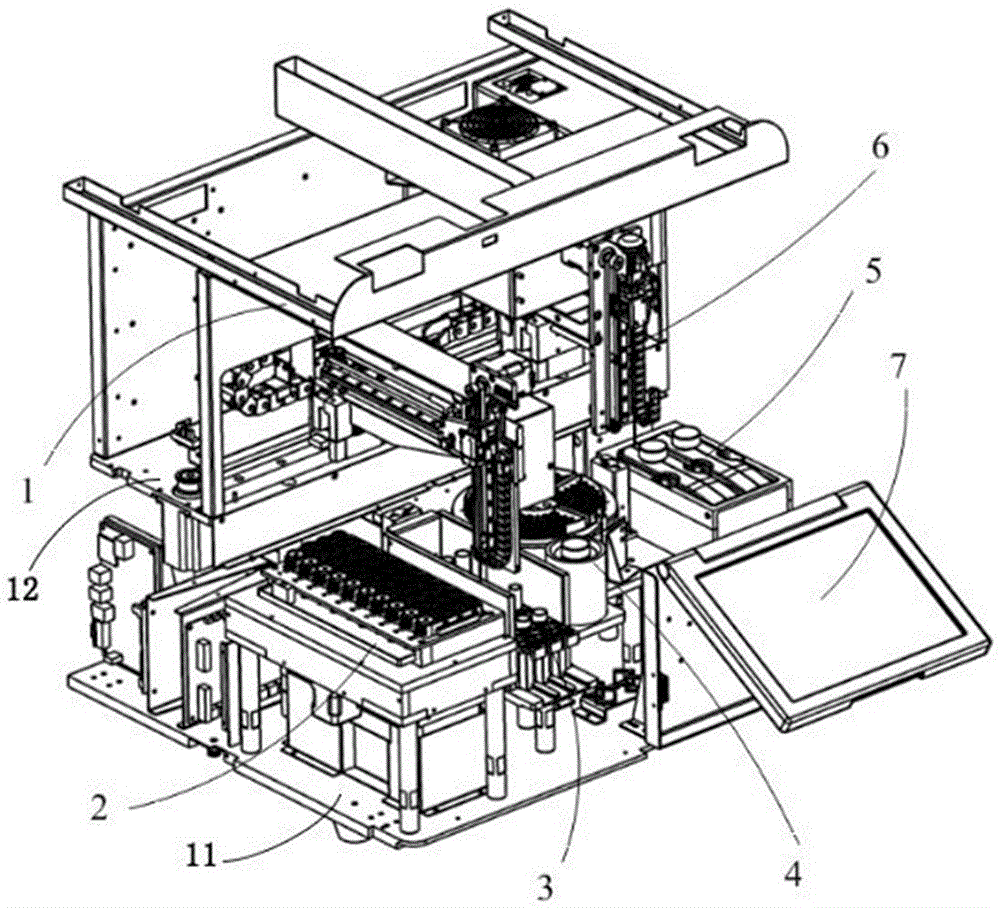

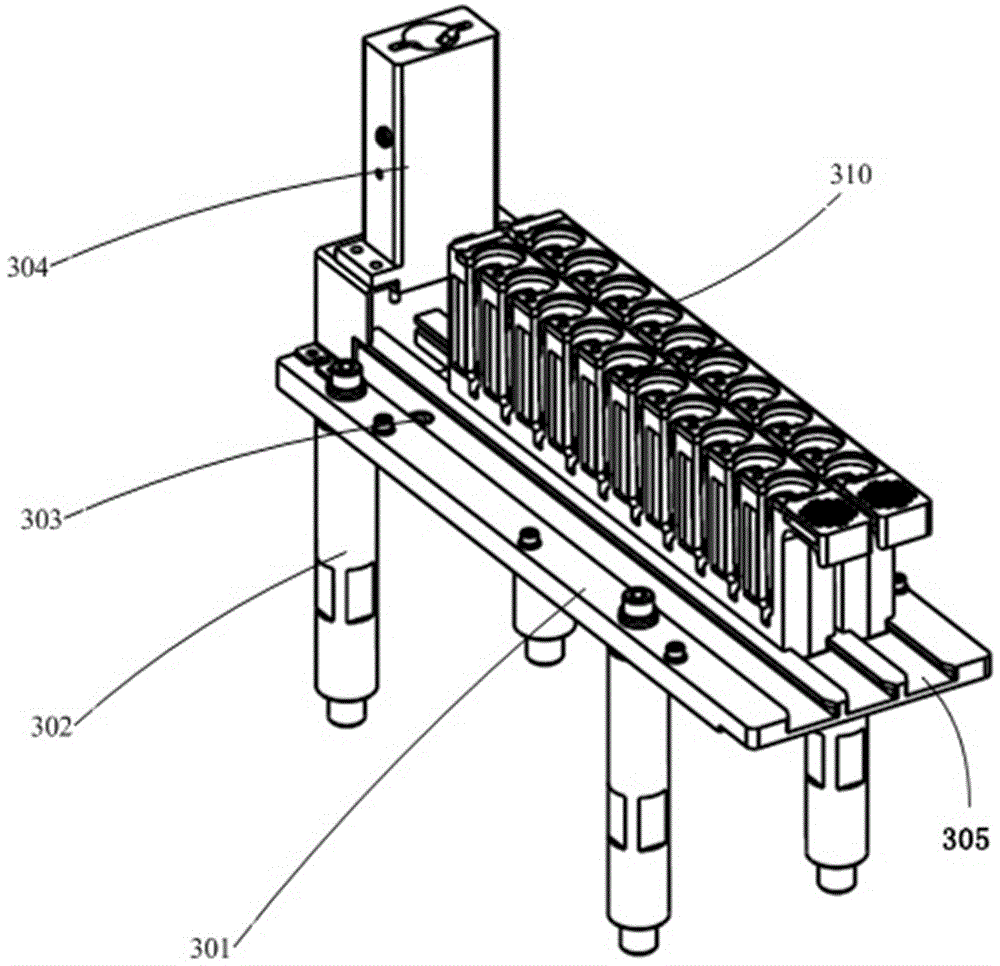

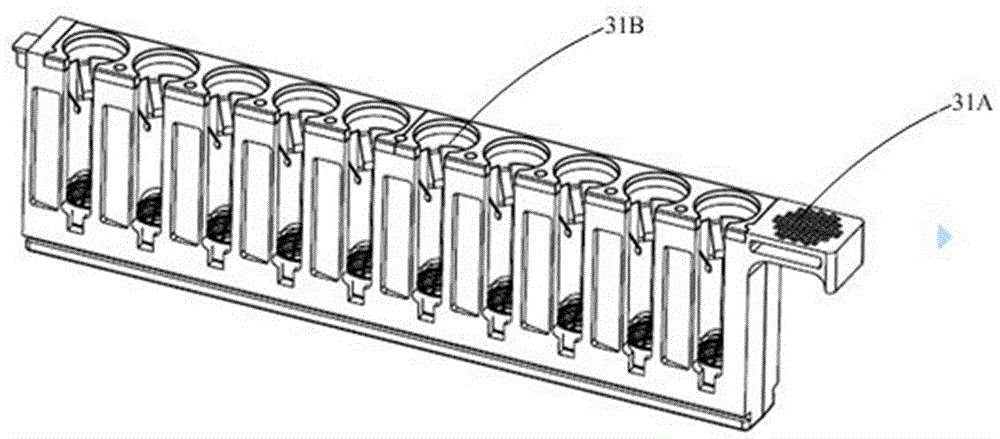

Full-automatic immuno-fluorescence quantitative analysis device and implementation method

ActiveCN104535782ASolving hard-to-automate challengesImprove repeatability and test accuracyMaterial analysisReagent stripControl system

The invention discloses a full-automatic immuno-fluorescence quantitative analysis device and an implementation method, belonging to the field of quantitative immuno-fluorescence analysis and detection. The full-automatic immuno-fluorescence quantitative analysis device comprises a supporting bottom plate, a reagentstrip storage and automatic loading module, a reactiondisc module, a detection module, a sample module, a sample adding module, a washing module and a control system, wherein the reagentstrip storage and automatic loading module, the reactiondisc module, the detection module, the sample module, the sample adding module and the washing module are arranged on the supporting bottom plate in sequence; the reagentstrip storage and automatic loading module provides a reagent strip for the reactiondisc module; the sample adding module is used for adding samples in the sample module into the reactiondisc module to carry out reaction, and after reaction is finished, the samples enter the detection module to be detected. The full-automatic immuno-fluorescence quantitative analysis device and the implementation method disclosed by the invention have the advantages that the difficulty that automation is hard to implement for an in-vitro diagnosis product is solved, the artificial error is reduced, the testing accuracy is improved and the detection efficiency is improved.

Owner:GETEIN BIOTECH

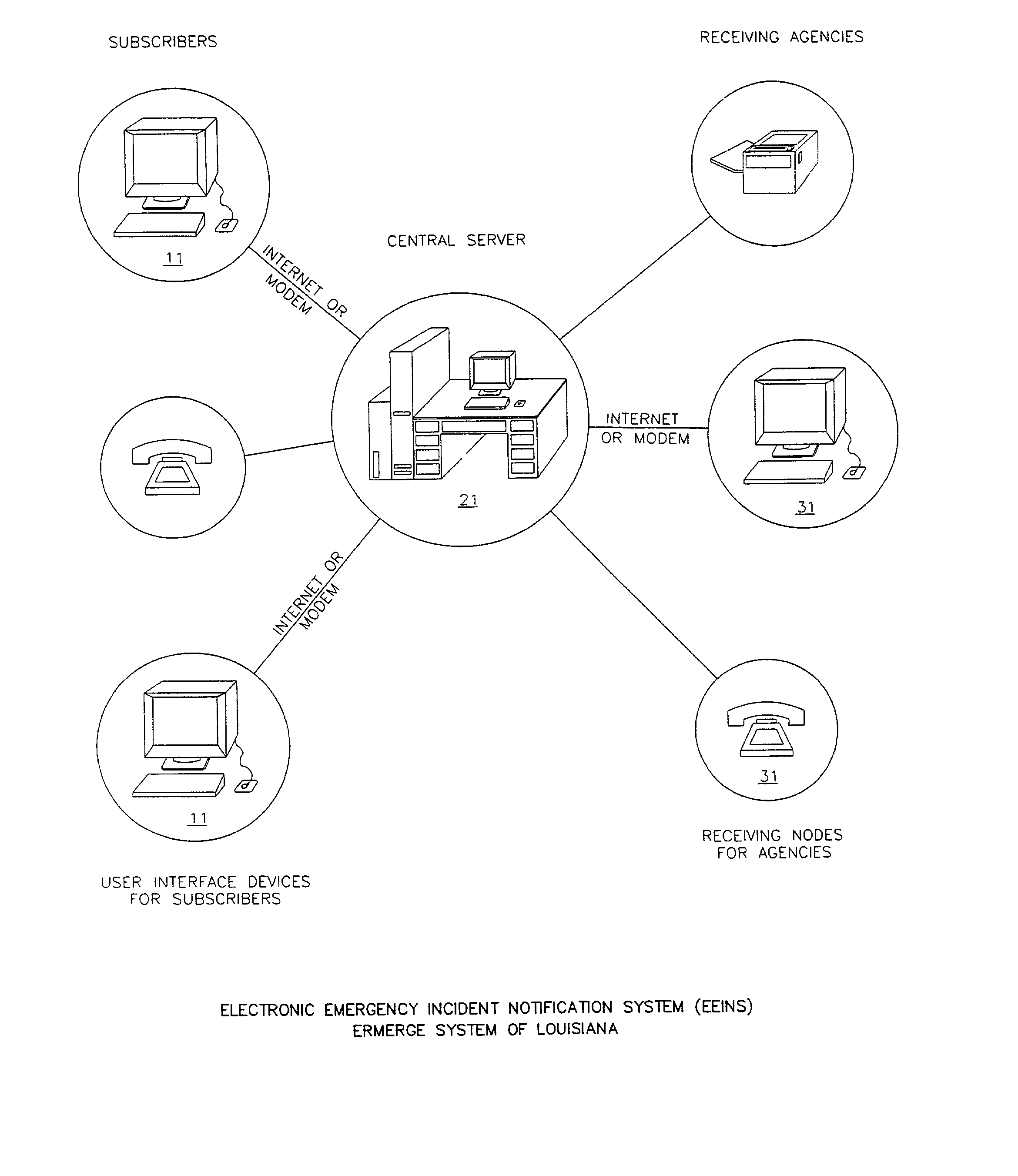

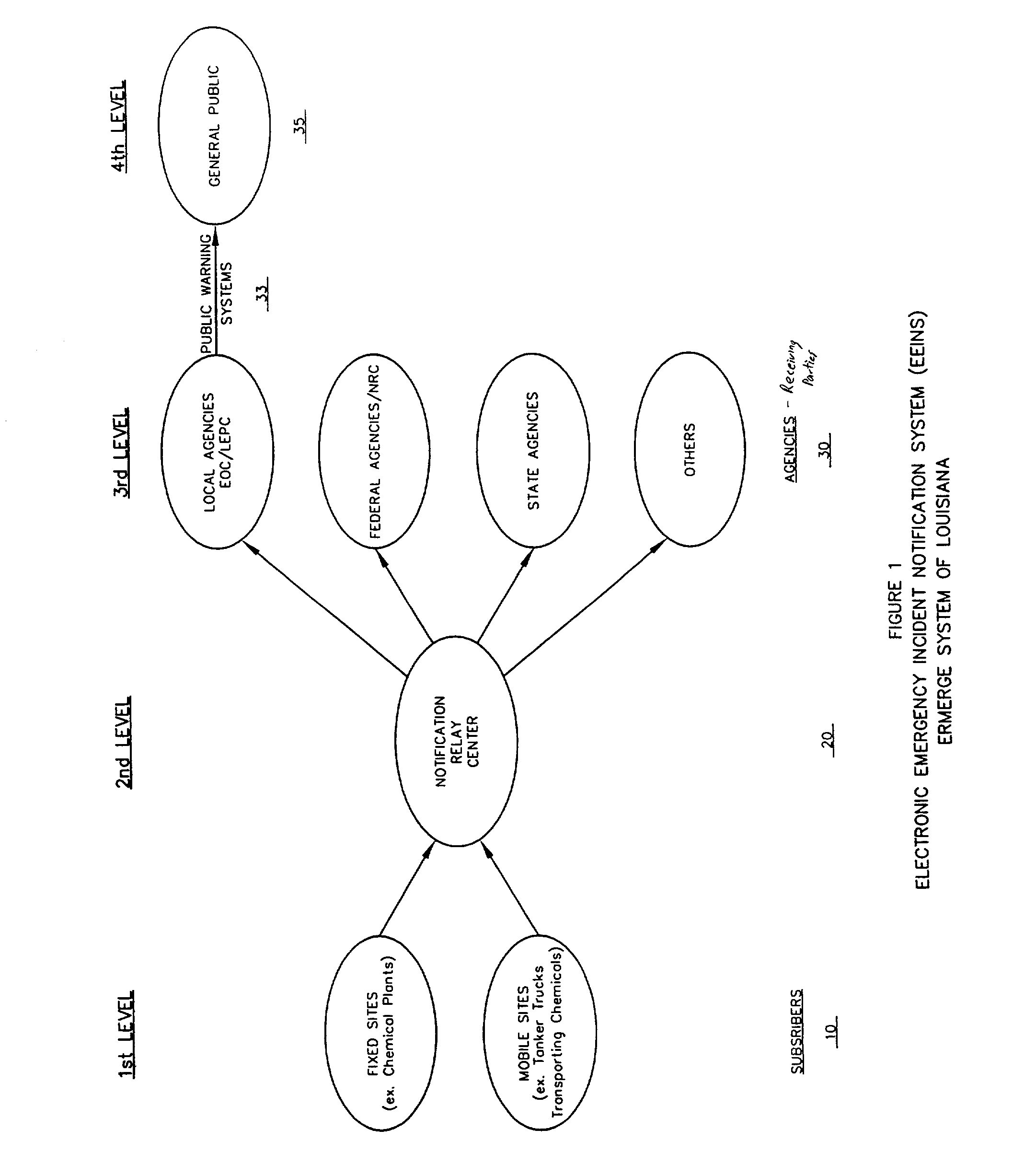

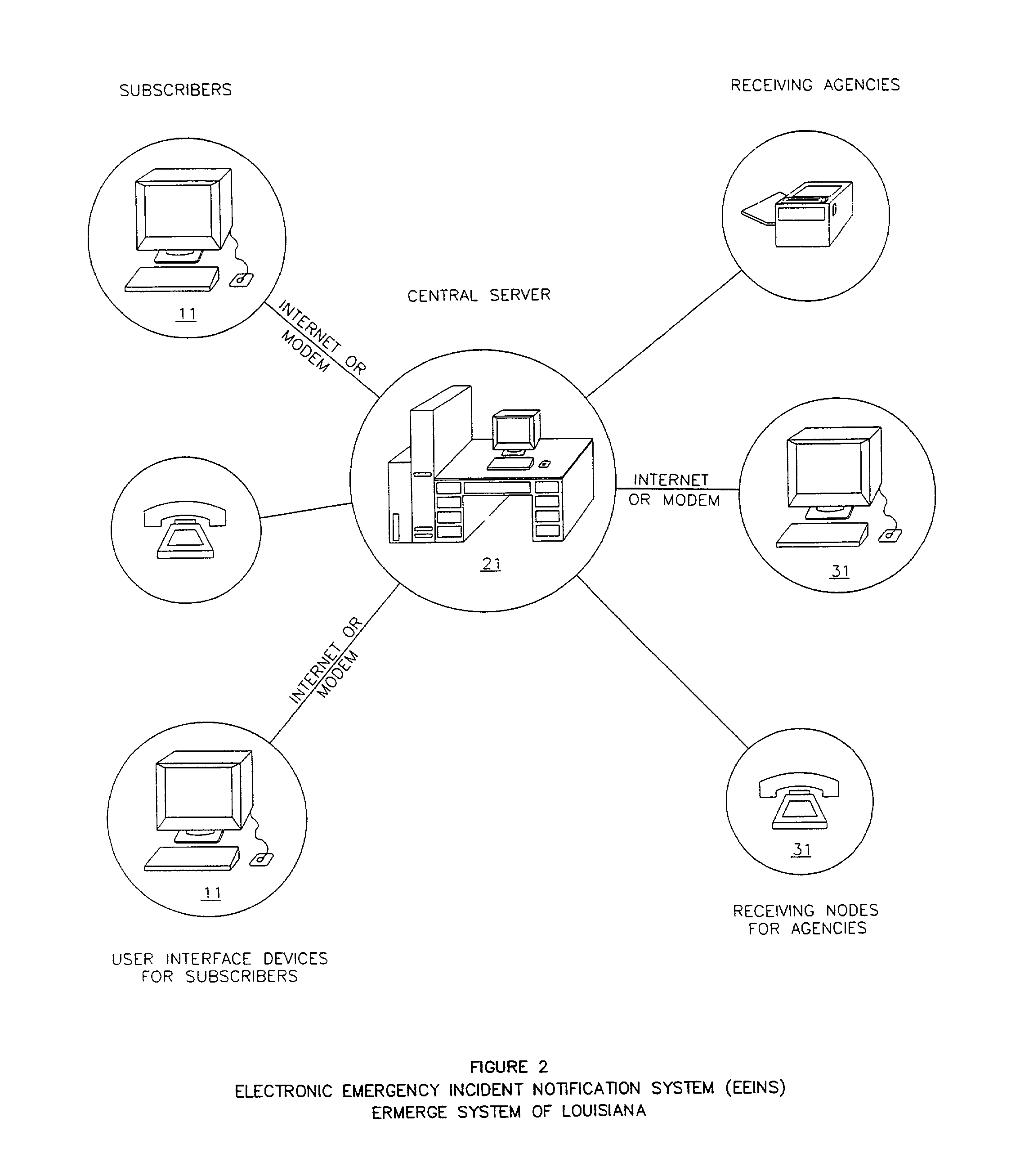

Electronic emergency incident notification system

InactiveUS20030141971A1Reduce human errorSpeedy and accurate notificationFrequency-division multiplex detailsTelephonic communicationIncident reportThe Internet

The present invention is an electronic emergency incident notification system ("EEINS") which allows subscribers to transmit notification of a nuclear / chemical / biological release to a central server for transmittal to the appropriate governmental agencies. In the preferred embodiment, a subscriber would utilize a user interface device to transmit spatial data and an incident report to the central server, typically using the Internet. The central server would map the spatial data onto a GIS database to determine which agencies require notification, and would then transmit the incident report to the receiving nodes at the appropriate agencies. At the local level, the receiving node may include software to automatically activate the appropriate public warning systems. The EEINS is sufficiently flexible to service both fixed and mobile sites.

Owner:HEIKEN EDWARD DANIEL JR

Robot for solar farms

ActiveUS9020636B2Easy to operateMaintenanceSolar heating energySolar heat simulation/predictionEnvironment of AlbaniaEngineering

The solar energy and solar farms are used to generate energy and reduce dependence on oil (or for environmental purposes). The maintenance and repairs in big farms become very difficult, expensive, and inefficient, using human technicians. Thus, here, we teach using the robots with various functions and components, in various settings, for various purposes, to improve operations in big (or hard-to-access) farms, to automate, save money, reduce human mistakes, increase efficiency, or scale the solutions to very large scales or areas.

Owner:BTPATENT

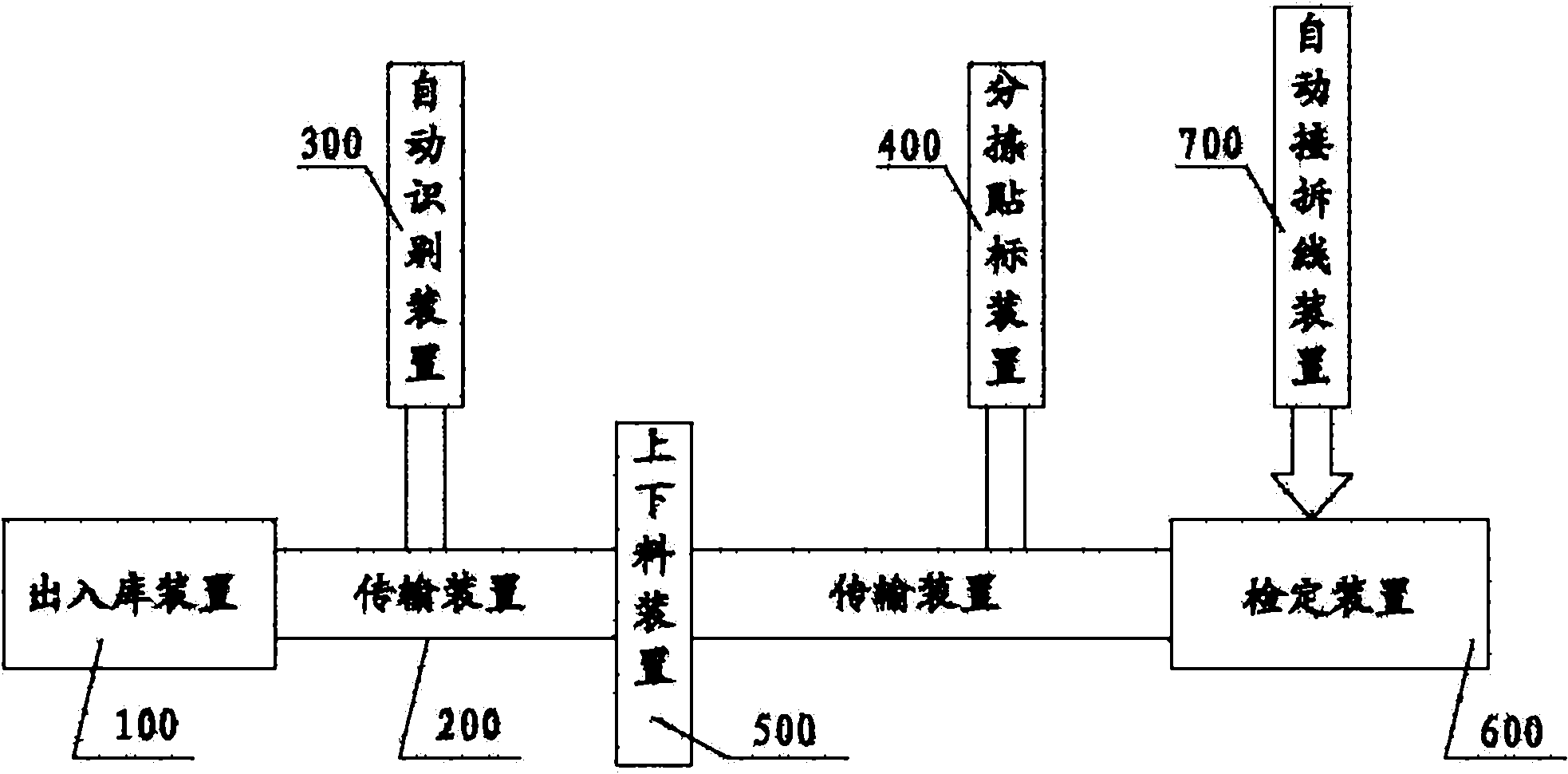

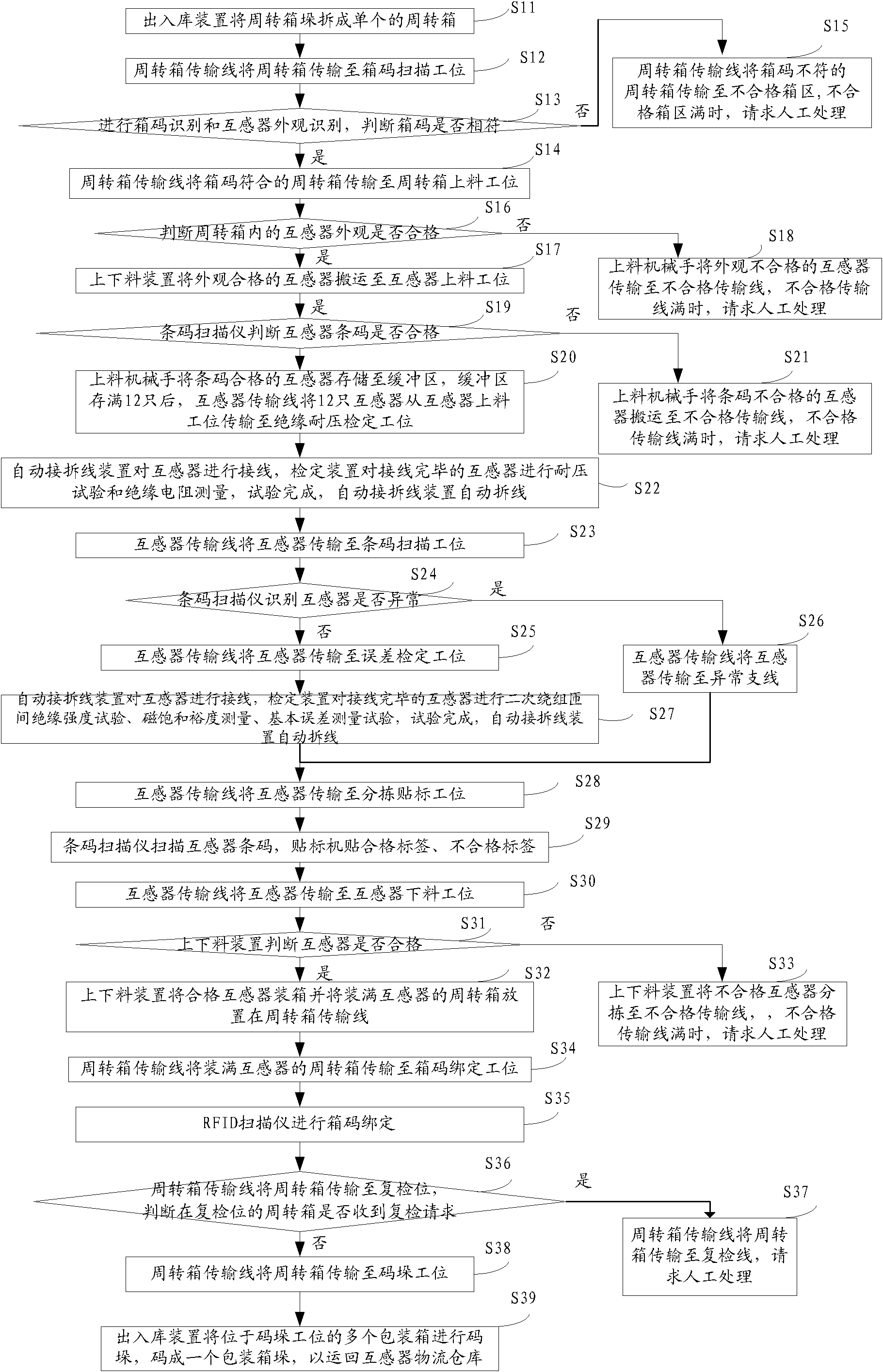

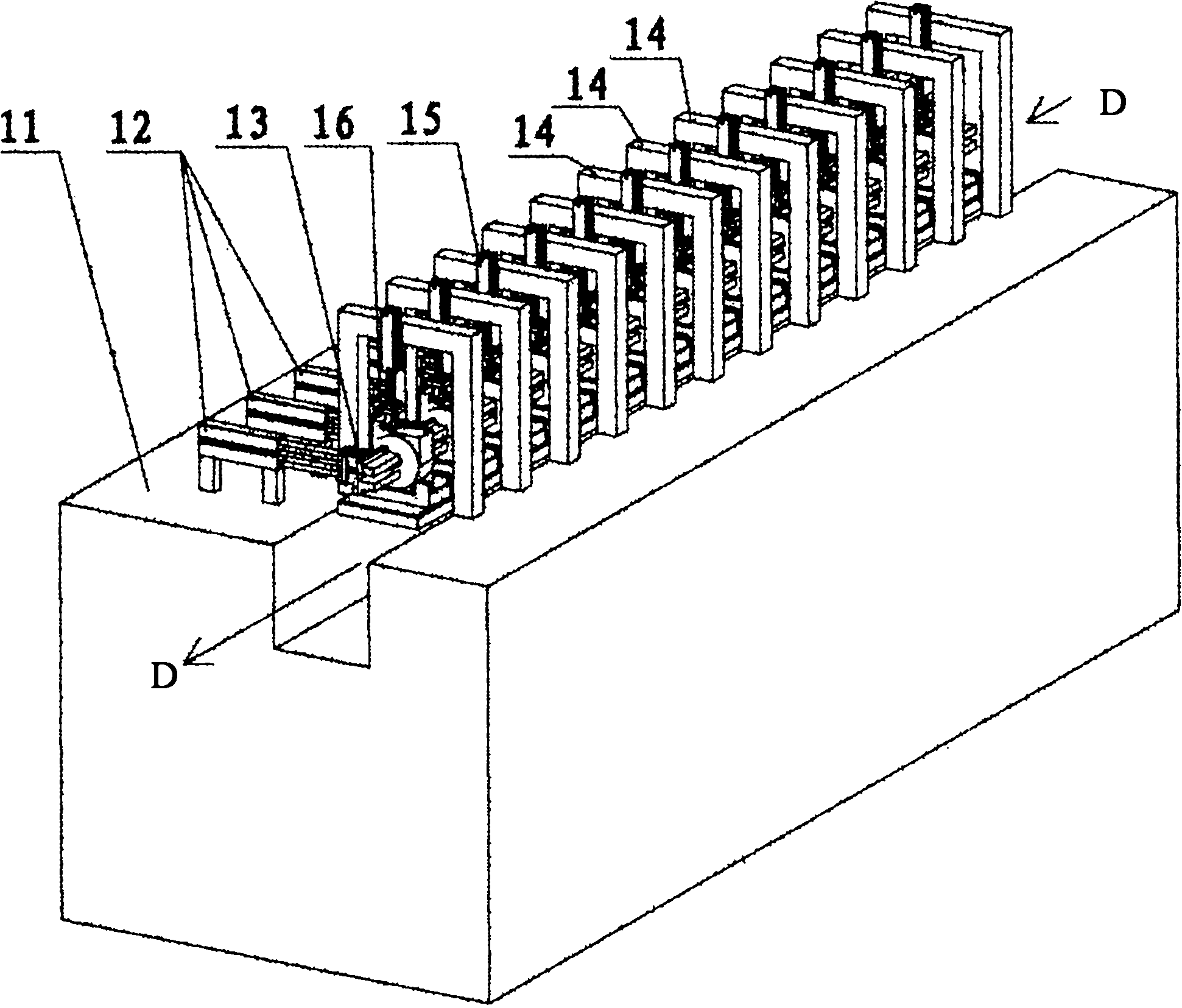

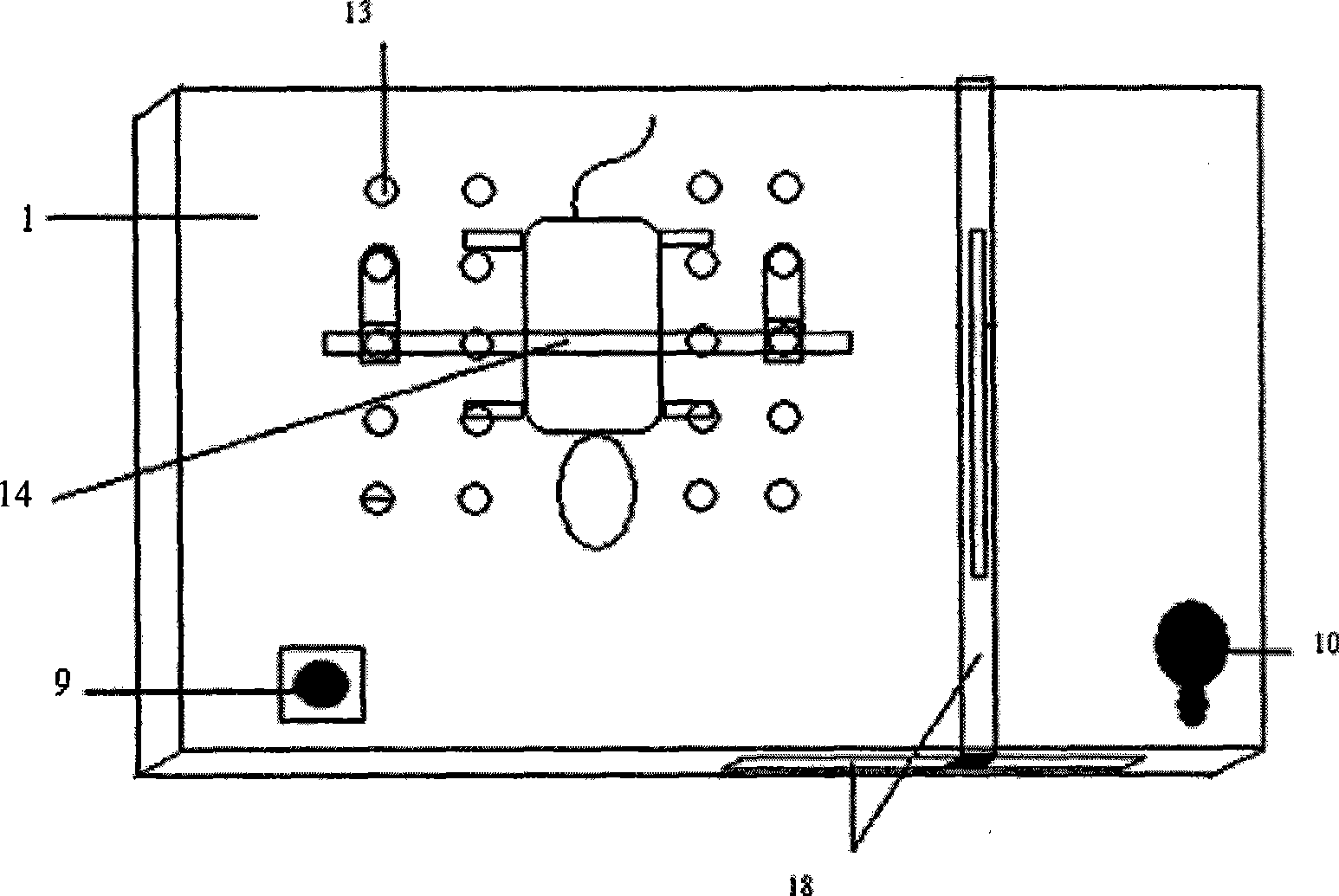

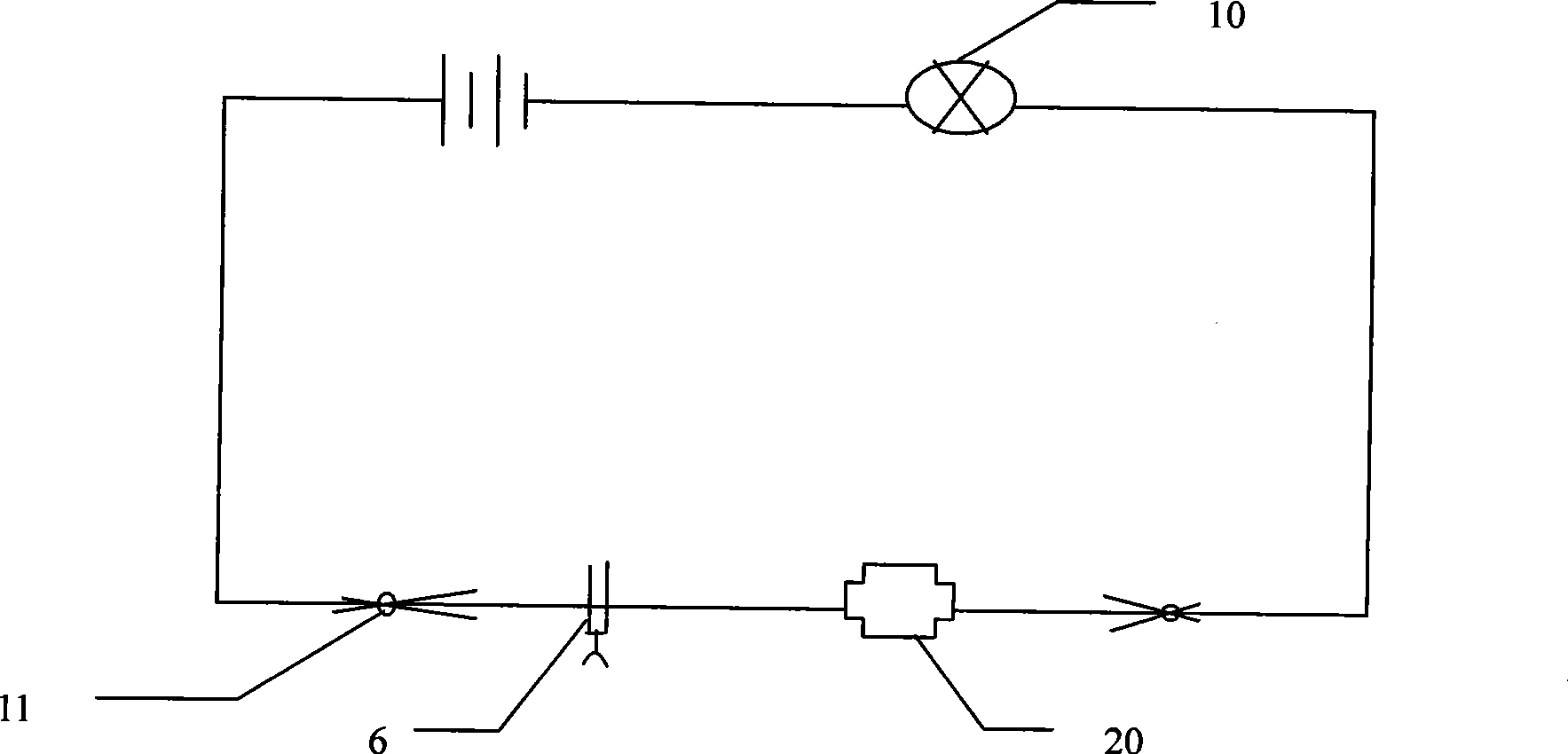

Automatic calibration line and method for intelligent type low-tension current transformers

ActiveCN102135607AImprove test efficiencyReduce human errorElectrical measurementsEngineeringIdentification device

The invention discloses an automatic calibration line for intelligent type low-tension current transformers, comprising a warehouse in-out device, a loading and unloading device, an automatic identification device, a transmission device, an automatic line connecting and disconnecting device, a calibration device and a sorting and labeling device, wherein the warehouse in-out device realizes the automatic warehouse in-out of the intelligent type low-tension current transformers; the material loading and unloading device realizes the automatic loading and unloading of the intelligent type low-tension current transformers; the automatic identification device realizes the automatic identification of the intelligent type low-tension current transformers; the transmission device realizes the automatic transmission of the intelligent type low-tension current transformers; the automatic line connecting and disconnecting device realizes the automatic line connection of the intelligent type low-tension current transformers for the calibration by the calibration device and also realizes the automatic line disconnection of the intelligent type low-tension current transformers; and the sortingand labeling device realizes the automatic sorting of the intelligent type low-tension current transformers. The automatic calibration line is free from manually carrying out the warehouse in-out, the transmission, the identification, the sorting, the loading and unloading and the line connection and disconnection on the intelligent type low-tension current transformer when calibrating the intelligent type low-tension current transformer, and has the advantages of no personal error, high calibration efficiency, good automation degree and capability of automatically measuring multiple transformers. The invention also discloses an automatic calibration method of the intelligent type low-tension current transformer.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +2

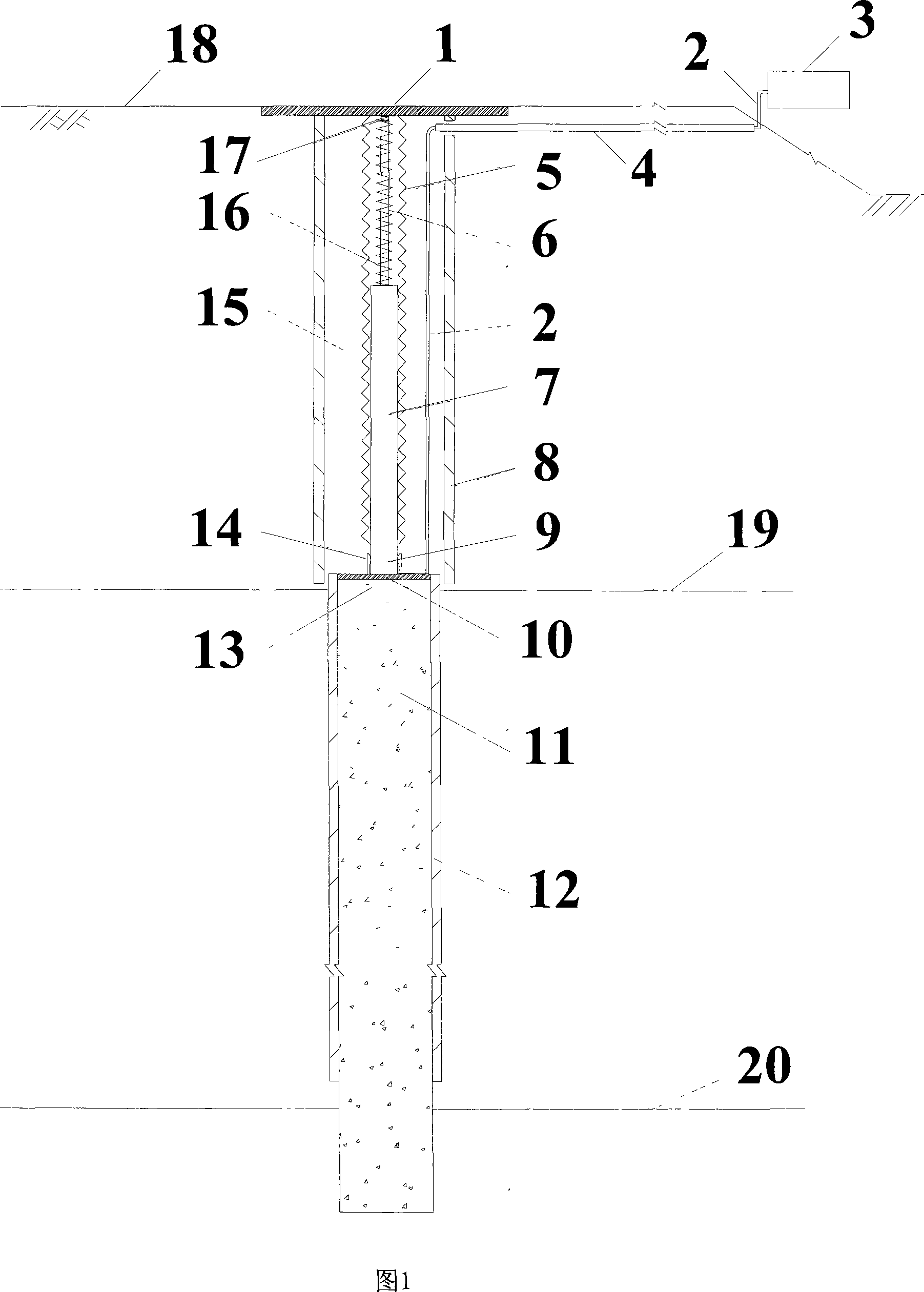

Soft soil roadbed settlement monitoring method and device

InactiveCN101078220ASimple and reliable measurement methodReduce datum point error and manual errorFoundation testingSteel platesEngineering

The invention discloses a monitoring method for sedimentation of soft soil foundation and the device. Procedures are that firstly, working reference pile is buried; secondly displacement sensor is installed; thirdly cable is connected; fourthly sedimentation steel plate is set; fifthly displacement is monitored and data are read; sixthly data is processed. Cement sand pile is connected with lower-layer PVC pipe and pre-buried steel plate is embedded at the top of pile. Four clip springs are welt on the pre-buried steel plate. The foundation of displacement sensor is fixed on the pre-buried steel plate tightly by clip springs. The foundation is connected with pull rod. The pull rod mated with spring is connected ball head. The ball head is connected with sedimentation steel plate. Shell, foundation, pull rod, spring and ball head are covered by bellows. The sedimentation steel plate is connected with upper-layer PVC pipe and the foundation of sensor is connected with the cable. After the cable passes through the hole and it is connected with digital display instrument through the cable protective pipe. The invention can not be constrained by construction and weather conditions and can realize quick, accurate, continuous and easy measurement for sedimentation value of soft soil foundation. The measuring accuracy is high and foundation sedimentation after opening for traffic can be monitored for a long time.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

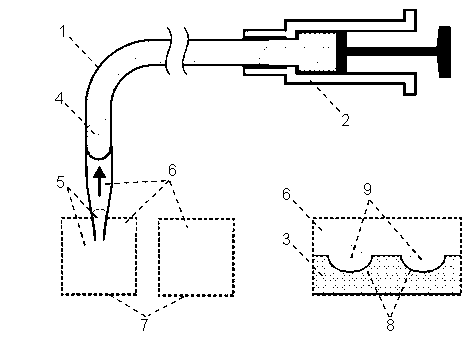

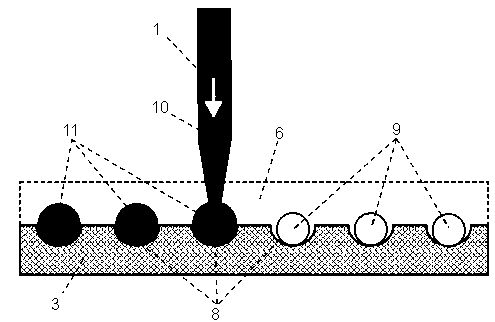

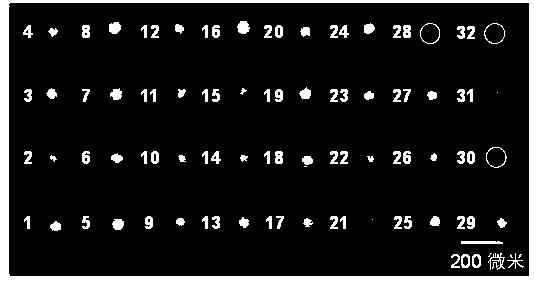

Automatic micro-droplet array screening system using method with pico-liter-scale precision

ActiveCN103008037AReduce adsorptionReduced activityLaboratory glasswaresMaterial analysisPhysical chemistryCapillary Tubing

The invention relates to the field of high-throughput screening and particularly relates to an automatic micro-droplet array screening system using method with pico-liter-scale precision. The using method provided by the invention comprises the following steps of: firstly, using liquid with a low thermal expansion coefficient and filled in a liquid driving system and a capillary tube as carrier liquid, and entirely emptying bubbles inside the capillary tube; secondly, soaking a sampling end of the capillary tube in an oil phase sample immiscible with a water phase sample, extracting a section of oil phase sample into the capillary tube, so as to isolate the water phase sample and the carrier liquid; thirdly, soaking the sampling end of the capillary tube into a sample / reagent storage tube and extracting a certain volume of the water phase sample solution into the capillary tube; and finally, moving the sampling end of the capillary tube into the oil phase sample above micro-pores of a micro-porous array chip, and pushing the sample solution in the capillary tube into the micro-pores, so as to form sample droplets. With the adoption of the using method provided by the invention, the liquid is quantitatively measured, and the generated droplets have the pico-liter-scale volume precision, so that the consumption of the samples / reagents in the high-throughput screening can be effectively reduced, and the experiment cost can be saved.

Owner:ZHEJIANG UNIV

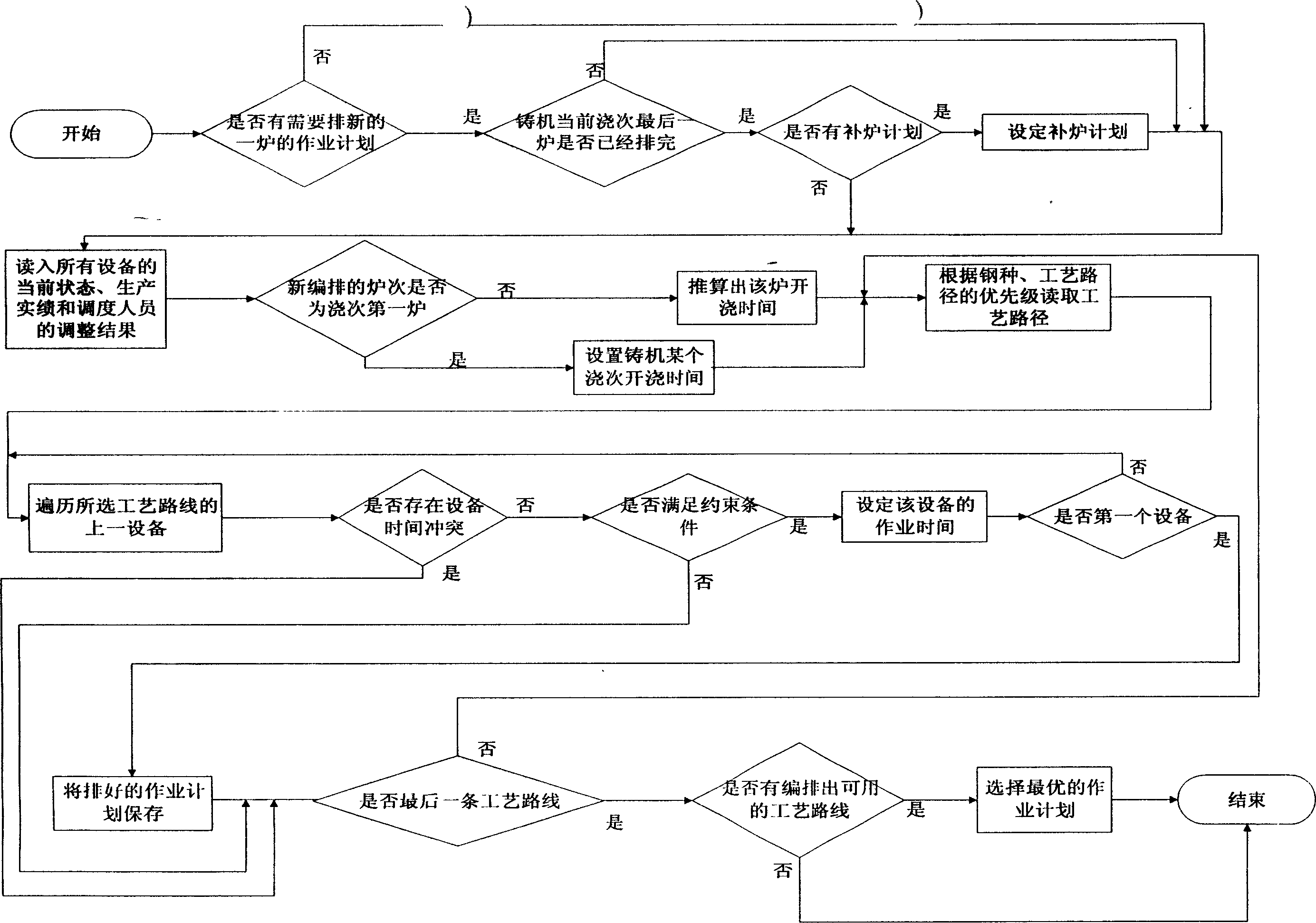

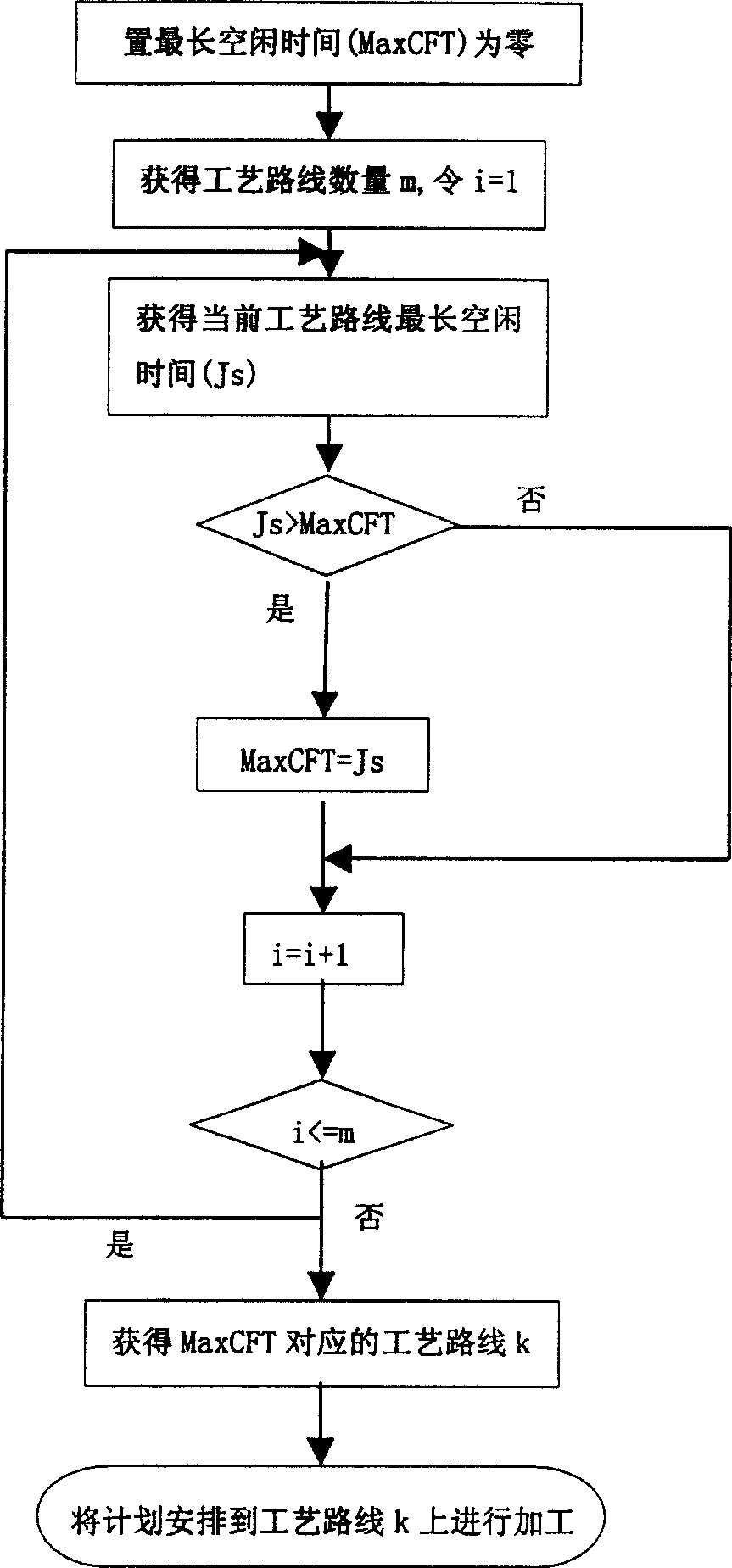

On-line dynamic dispatching method for continuous steel casting production

InactiveCN1614618AReduce cumulative time errorEasy production organizationSpecial data processing applicationsComputerized systemWorkstation

An on-line dynamic dispatching method for continuous production of steel making includes applying distributed computer system; working out a dynamic operation plan suitable for current production state by collecting data from site process and equipment, combining the set of dispatcher and using roll search mode; following the plan to carry out operation by operation station and feeding back regulation request to dispatching room for used as basis of next dispatch.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

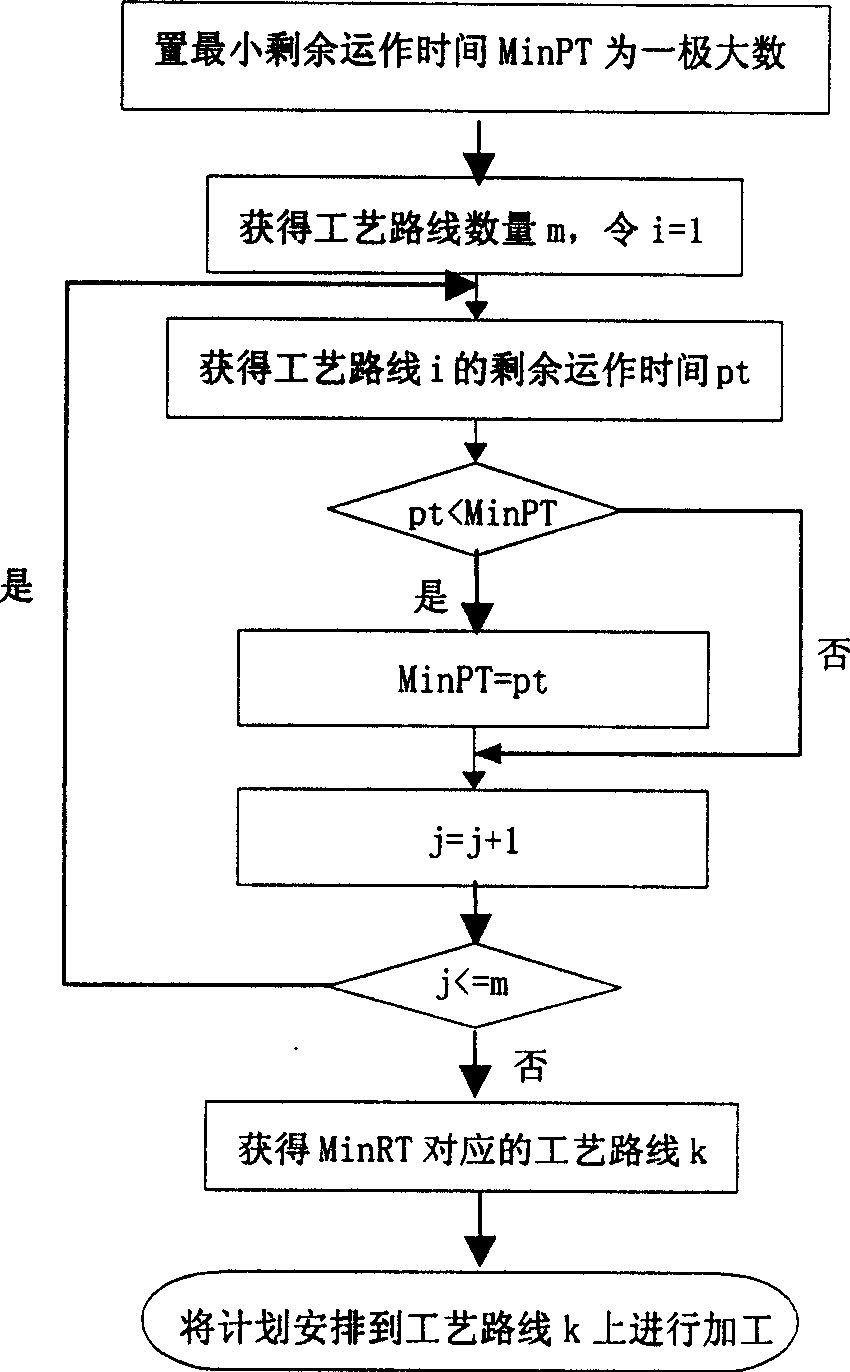

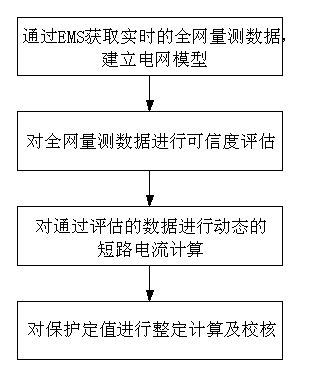

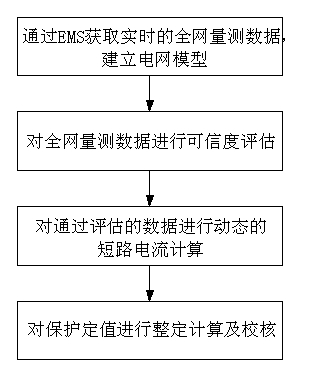

Online examination method of relay protection setting value based on dynamic short-circuit current

InactiveCN102074939ASafe and stable operationThe calculation result is accurateEmergency protective circuit arrangementsPower gridComputer science

The present invention discloses an online examination method of relay protection setting value based on dynamic short-circuit current, which includes the following steps of: (1) obtaining real-time network-wide measurement data through EMS to establish an electrical network model; (2) carrying out a credibility assessment to the network-wide measurement data and to obtain the data which passes the assessment; (3) carrying out a dynamic short-circuit current calculation to the data passing the credibility assessment; (4) carrying out a setting calculation and examination of the protection setting value. The method enhances the accuracy of the short-circuit calculation result, realizes the online examination and real-time early warning of the relay protection setting value, and improves the automation degree of the protection setting value work.

Owner:NORTH CHINA GRID +1

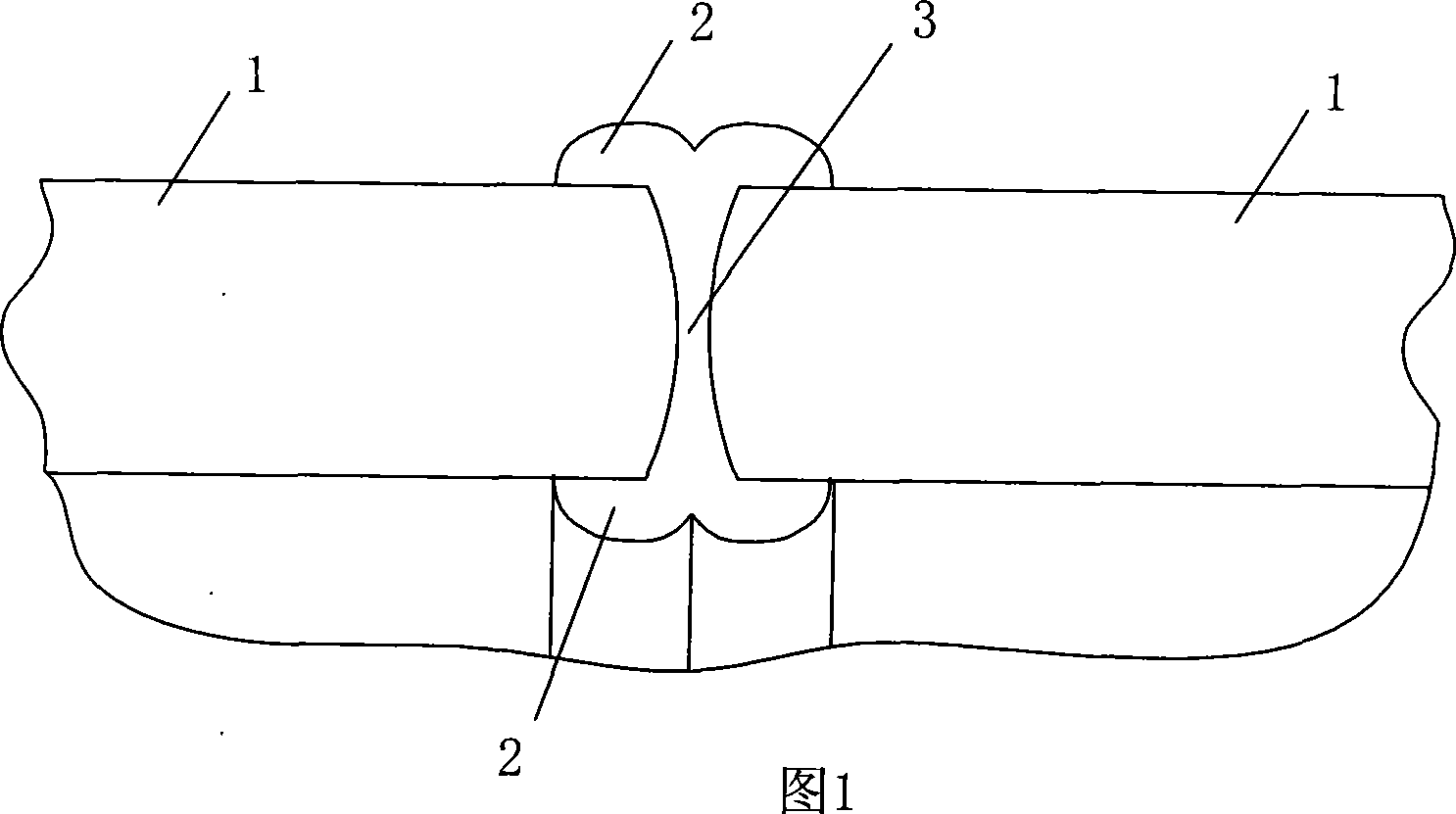

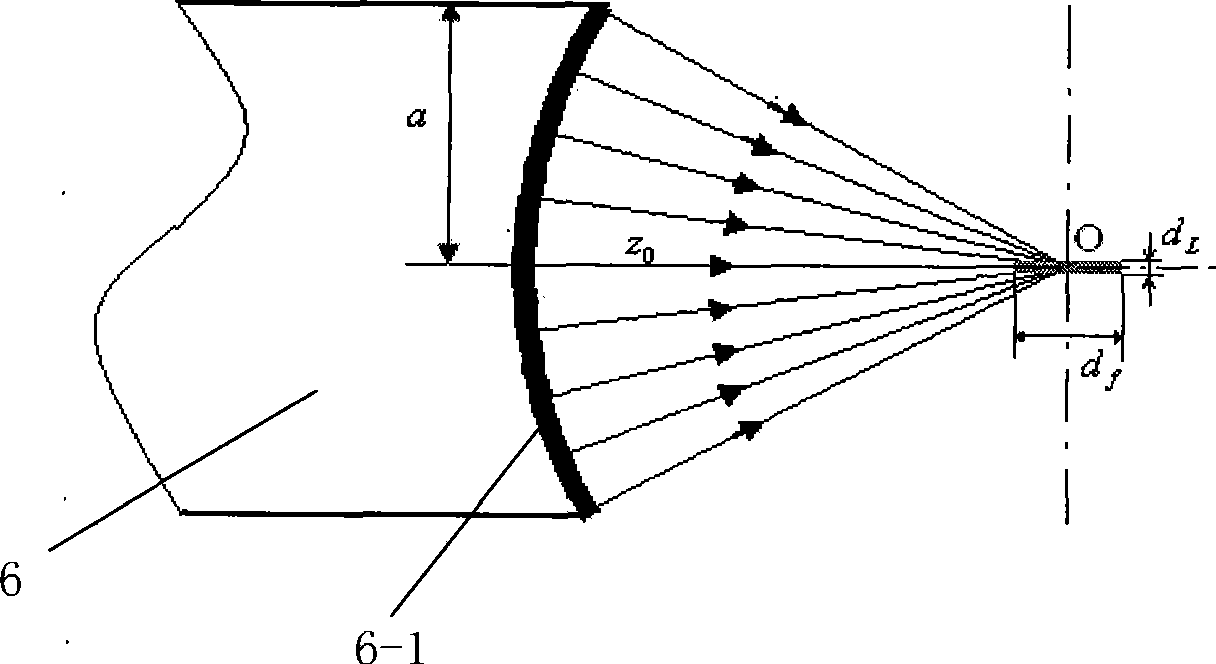

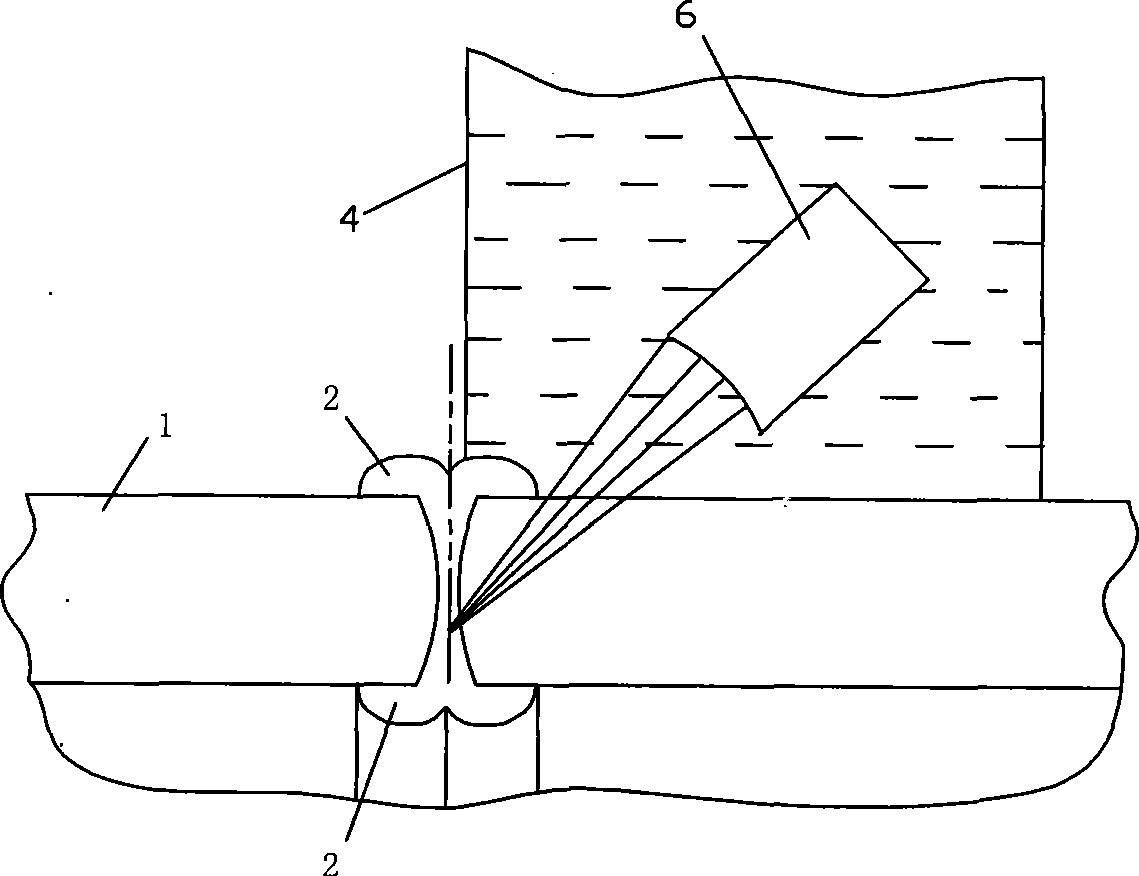

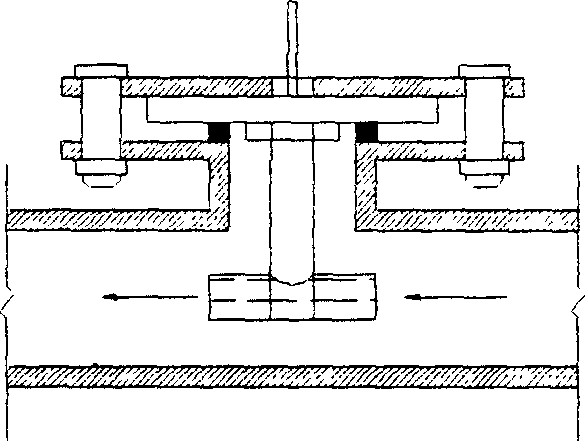

Coupling and focusing ultrasonic detection method and detection device for polyethylene pipe hot melt butt joint

ActiveCN101393170AHigh detection sensitivityImprove detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesMiddle lineSonication

The invention relates to a method for detecting the welding quality of a hot-melt even joint of a polyethylene pipeline and a detection device thereof. The aim of the invention is that the provided detection method and the detection device have the characteristics of high sensitivity, high detection precision, high reliability, high detection efficiency and low misoperation rate. The technical proposal is a method for the coupling focusing ultrasonic detection of the hot-melt even joint of the polyethylene pipeline, which comprises the following steps: (1) a coupling agent liquid is positioned on the outer surface of a pipeline joint fusion region; (2) an ultrasonic probe adopting a spherical curved wafer is immersed into the coupling agent liquid in order that the focus is positioned in the centerline of the pipeline joint fusion region; and (3) the ultrasonic probe does linear scanning motion along the diameter direction of the pipeline and does uniform scanning motion along the circumferential direction of the pipeline; and obtained signal data is processed by a computer to form a C scanning picture. The ultrasonic detection device comprises a coupling receiving device, the ultrasonic probe adopting the spherical curved wafer, a mechanical scanning device, a signal processing and controlling system, and the computer.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST +1

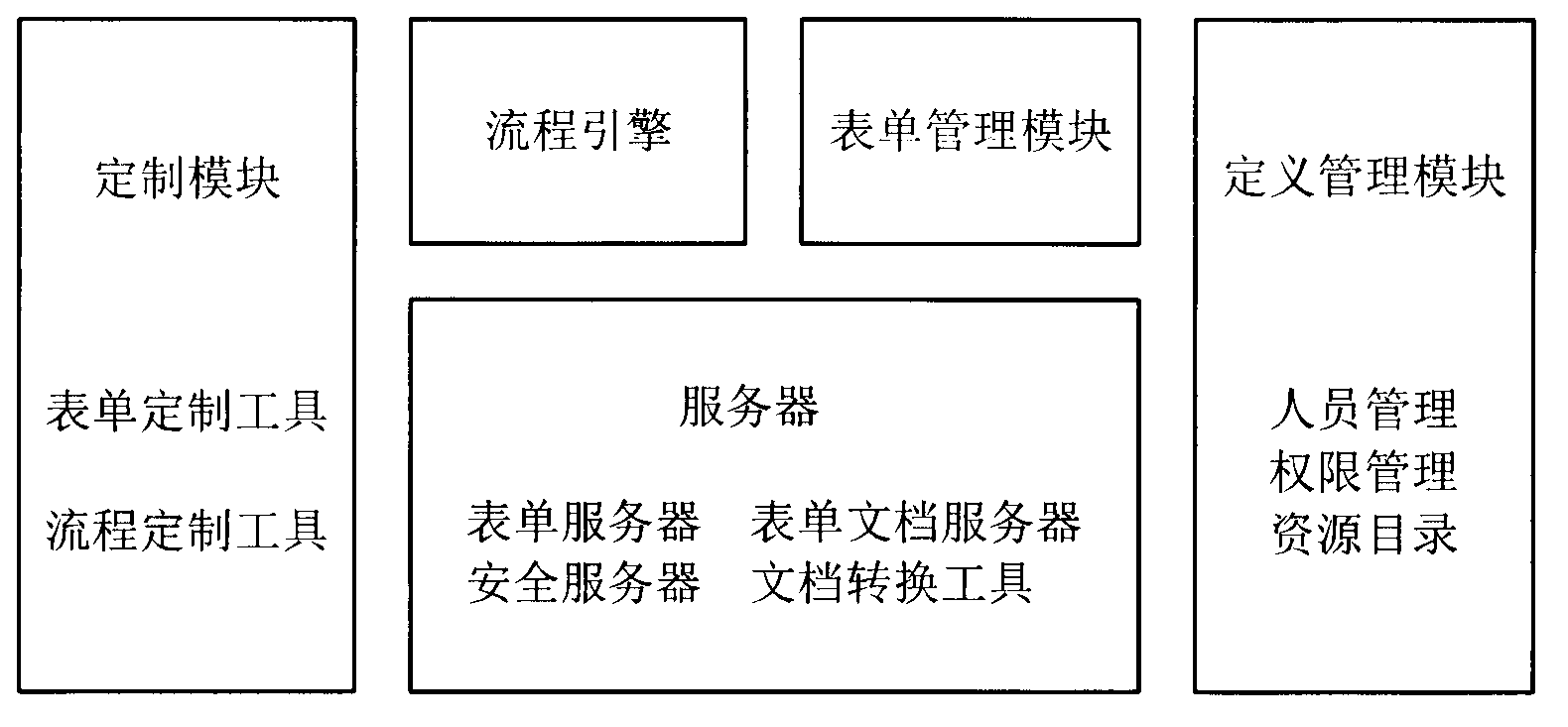

Flexible management information system with process and form customization function

InactiveCN103838706APromote reconstructionImplement triggerSpecial data processing applicationsPersonalizationBusiness Personnel

The invention discloses a flexible management information system with the process and form customization function. The flexible management information system comprises a customization module, a server, a process engine, a form management module and a definition management module, wherein the customization module is used for customizing the needed form style and the needed business process, the server is used for storing data, converting formats and ensuring safety, the process engine is used for analyzing and executing the business process designed by a designer, the form management module is used for managing various resources, such as form templates and process templates, in various application systems in a unified mode, and having control over the versions and the authority of the templates, and the definition management module is used for managing staff, the authority, the resource catalogues and the like. Real business personnel can customize the business process and the business forms according to the business requirements so as to configure the specific application system, then, operation is carried out according to the customized process through driving of the process engine, data are displayed according to customized forms, the capacity of management software for meeting the individual requirements of enterprises and supporting business process reengineering is greatly improved, the success rate of execution of the software is increased, and the degree of satisfaction of a client for the flexible management information system is improved.

Owner:JIANGSU MODERN SHIPBUILDING TECH

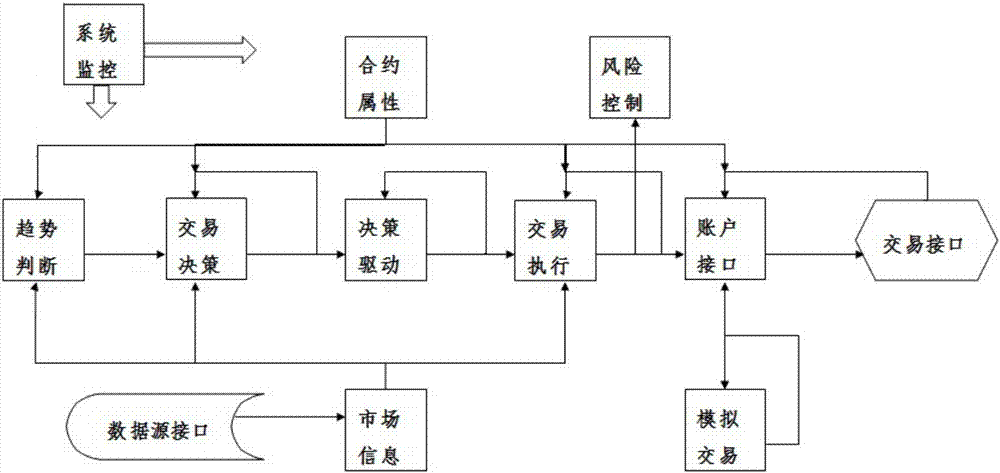

Multi-module automatic trading system based on network distributed computing

InactiveCN106934716AReduce human errorSimplify Quantitative Modeling ProceduresFinanceRisk ControlTransaction management

The invention discloses a multi-module automatic trading system based on network distributed computing. The system comprises a historical and real-time market data processing module, a real-time market probability distribution prediction module, a trading strategy design and development module, a trading strategy history backtracking and evaluating module, a trading strategy market access and transaction management module, a system monitoring and risk control module, and a transaction report and quantitative analysis module. The automatic trading system can face various types of quantitative traders, a quantitative modeling program is simplified, a quantitative trading threshold is reduced, the quantitative strategy test and evaluation efficiency is improved, and the transaction security is guaranteed. The automatic trading system can automatically and intelligently analyze market and trading trends, provide real-time price probability distribution prediction for market main transaction products, provide a transaction signal with low delay and a high success rate for a transaction strategy and thus generate a timely and accurate trading signal, an efficient tool and comprehensive and accurate data are provided to construct the strategy of a user, and back testing and optimization are carried out.

Owner:燧石科技(武汉)有限公司

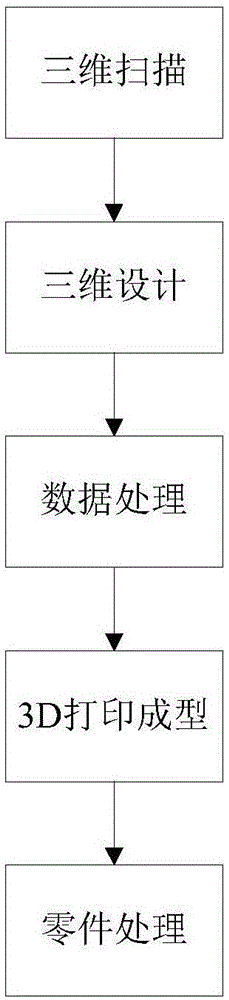

3D printing forming method for metal dental restoration

InactiveCN106361455AHigh precisionShort manufacturing cycleArtificial teeth3D printingMicron scaleLaser scanning

The invention relates to a 3D printing forming method for a metal dental restoration. The method includes the steps of three-dimensional scanning, wherein three-dimensional data of an oral cavity of a patient is obtained; three-dimensional designing, wherein the appearance of the restoration is designed and derived according to the three-dimensional data; data processing, wherein a derived restoration model is at least subjected to data checking and repairing, position arranging, support adding, slicing and scanning strategy planning to obtain data suitable for 3D printing; 3D printing forming, wherein through a metal 3D printing device for selective laser welding, with micron-scale spherical metal powder as the material, the metal powder of each layer of section region of a forming substrate is melted through the laser scanning of the 3D printing device, and then a metal part is obtained through layer-by-layer overlapping; part processing, wherein the metal restoration is obtained through later-period processing. Lots of labor is saved, personal errors are reduced, the restoration is high in forming precision and good in fitting degree, and the manufacturing cycle of the restoration is greatly shortened.

Owner:OPTIMAL MATERIAL TECH CO LTD

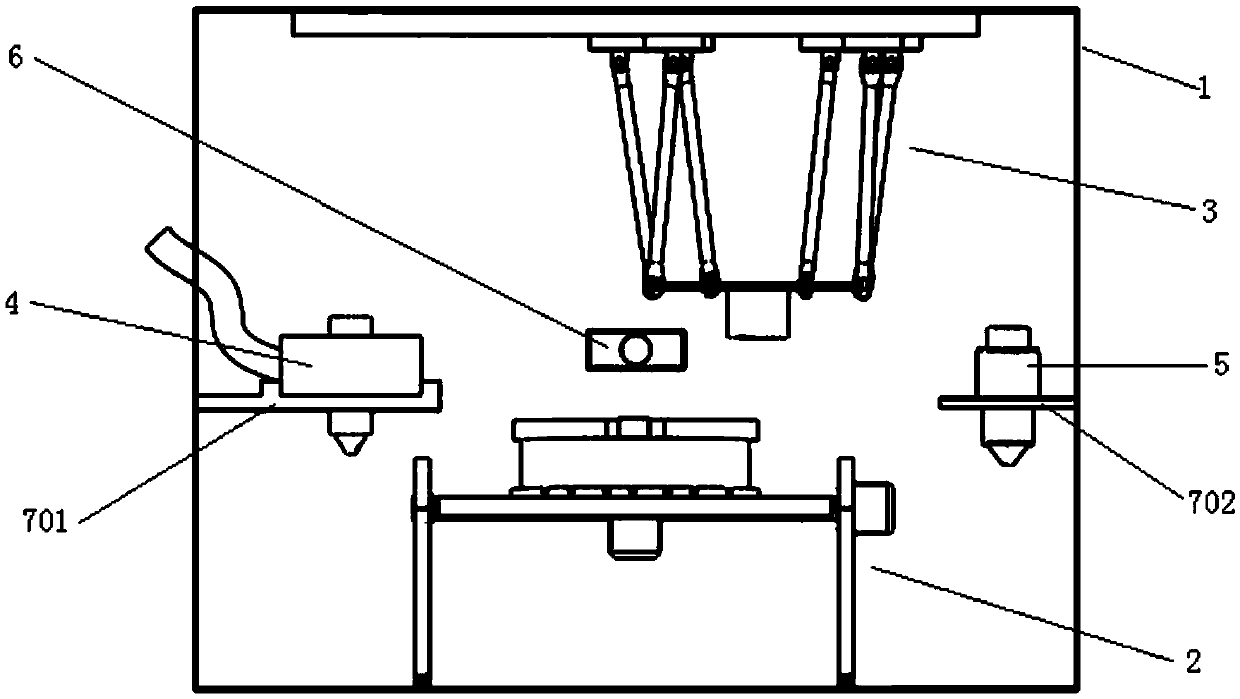

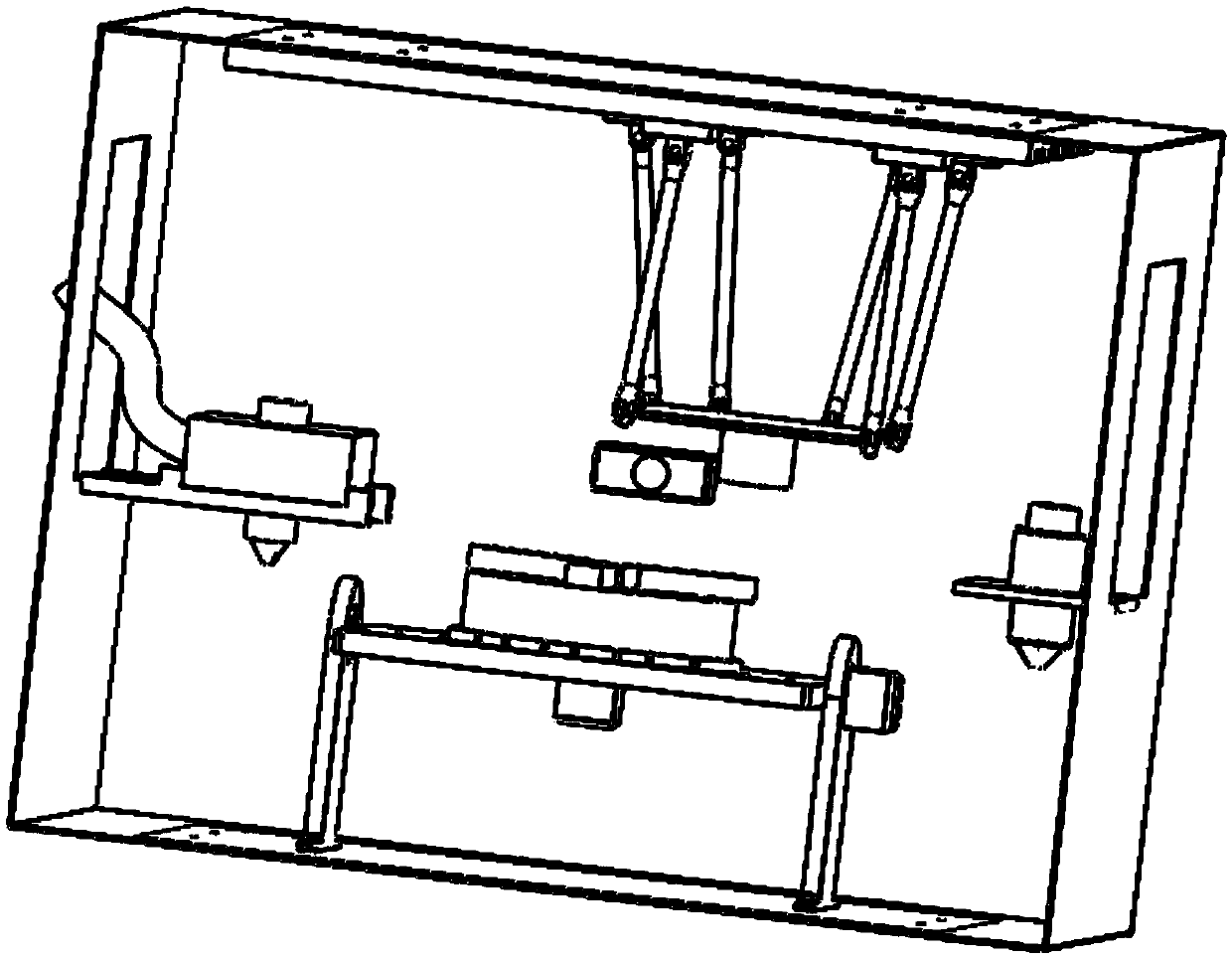

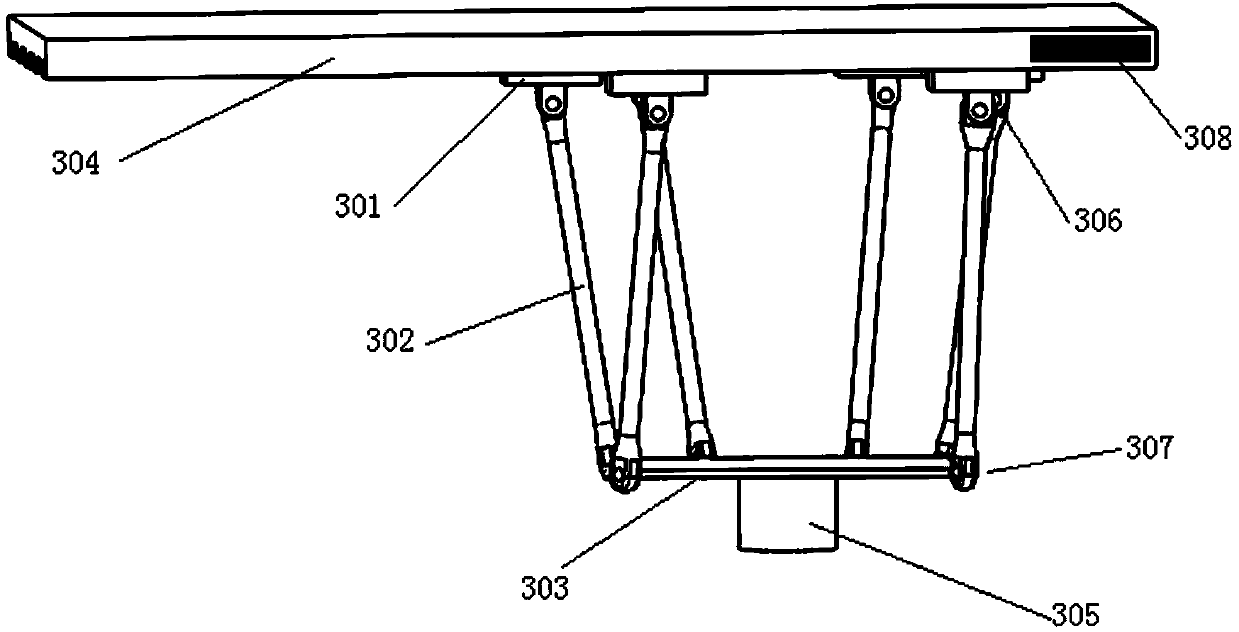

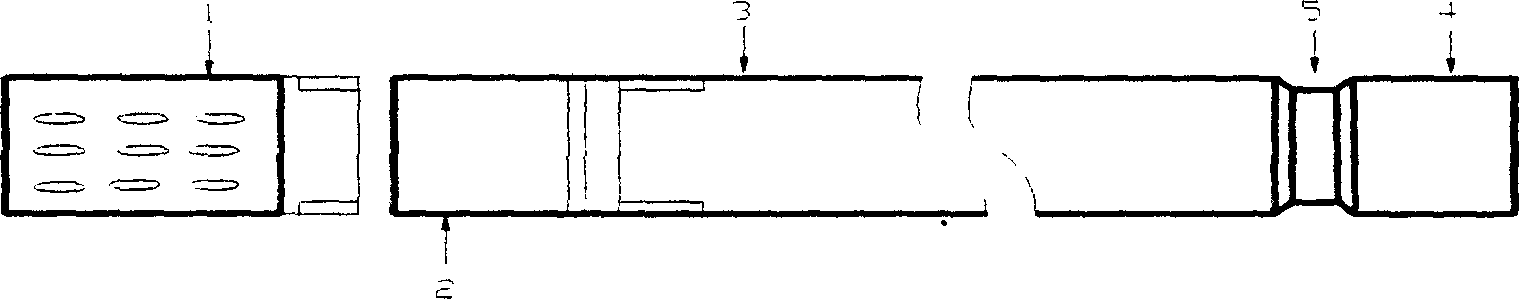

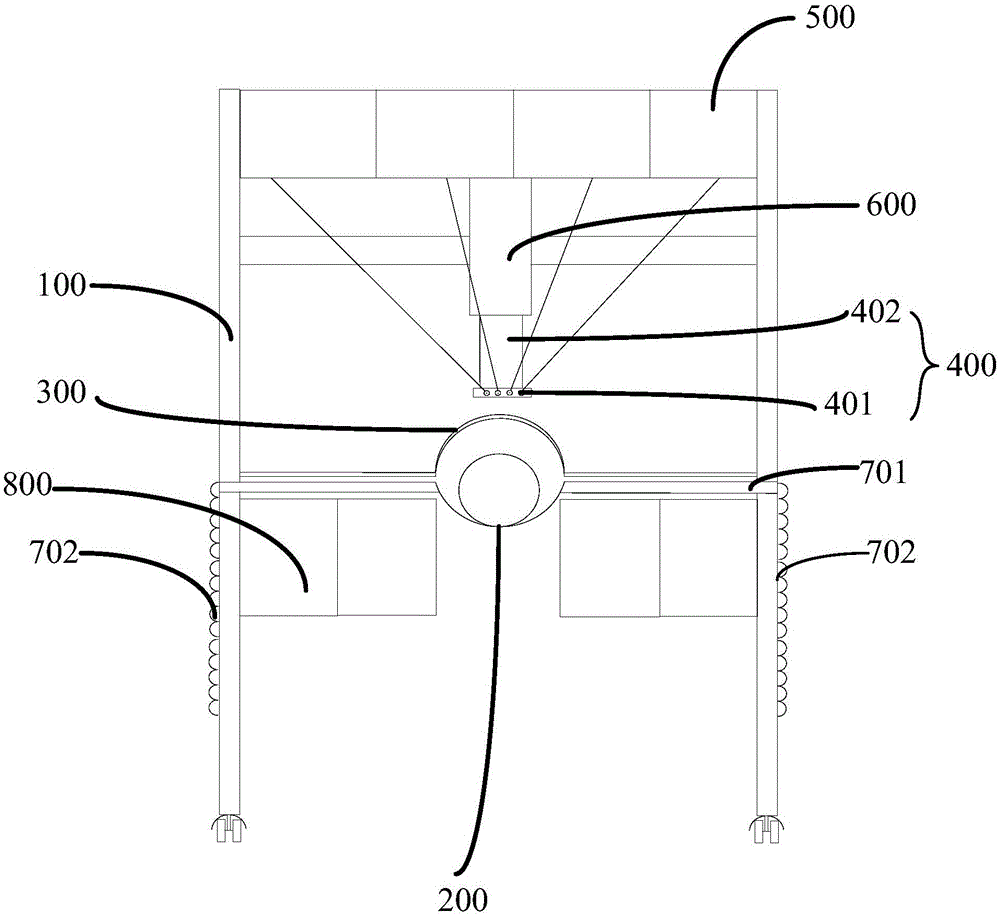

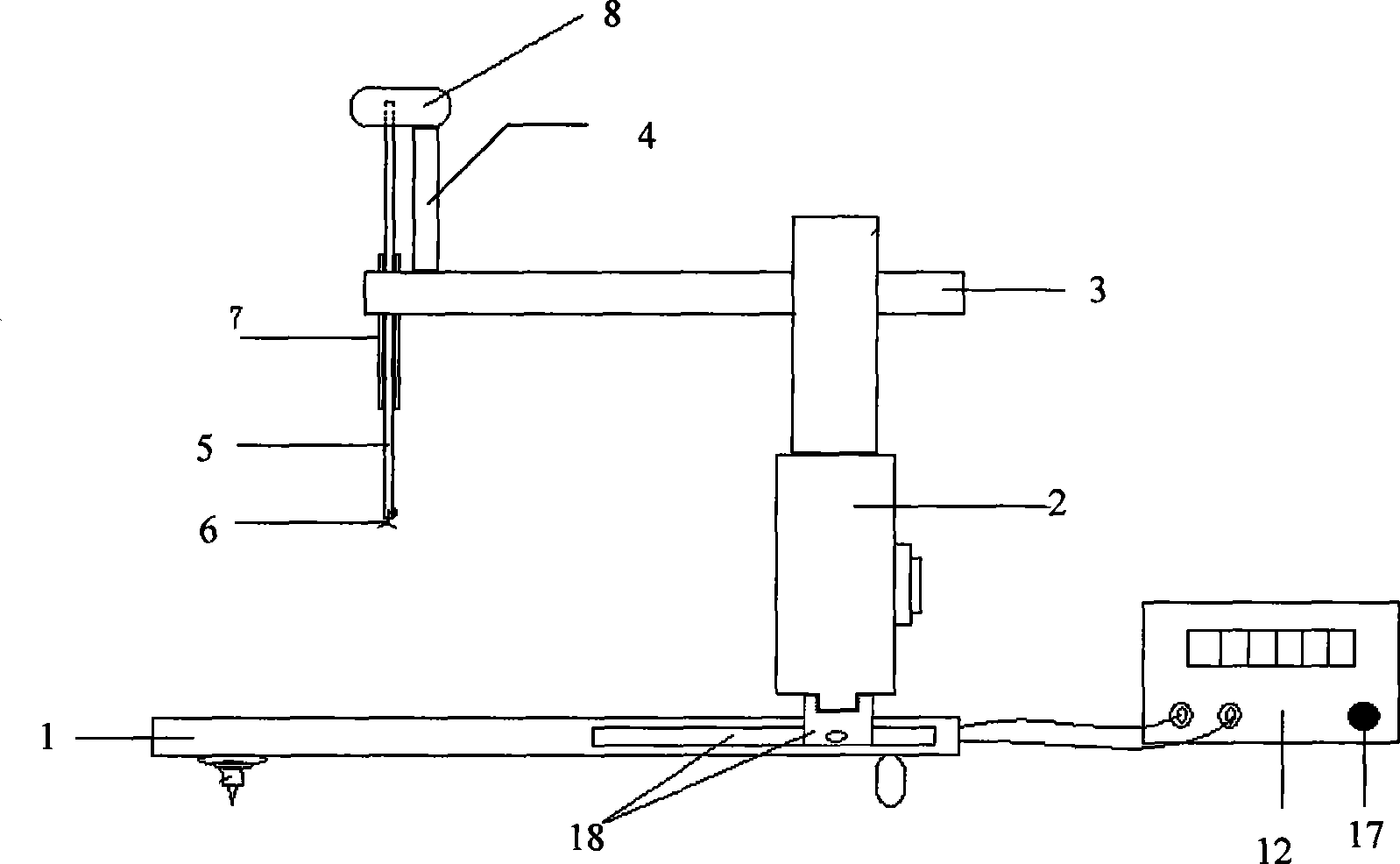

Part repairing device based on additive and decreasing manufacturing and application method of part repairing device

ActiveCN105499904AQuality improvementQuick fixLaser beam welding apparatusEngineeringMechanical engineering

The invention provides a part repairing device based on additive and decreasing manufacturing. The part repairing device comprises a lathe bed (1) and a worktable (2), and is characterized in that a parallel clamping device (3) is arranged at the upper part of the lathe bed (1); a three-dimensional scanner (6), an additive manufacturing module fixing mechanism (701) and a decreasing machining module fixing mechanism (702) are arranged at the side part of the lathe bed (1); an additive manufacturing module (4) is arranged on the additive manufacturing module fixing mechanism (701); a decreasing machining module (5) is arranged on the decreasing machining module fixing mechanism (702); and the worktable (2) is located under the parallel clamping device (3). With the adoption of the part repairing device, after model three-dimensional data is obtained, a regular surface is obtained by using a decreasing machining manner, and then an additive manufacturing repairing process is carried out; finally, surface machining also can be carried out to obtain a part with relatively good surface quality; and in a whole process, the part only needs to be clamped and positioned once, manual errors are reduced, and a repairing effect is relatively reliable.

Owner:XIANGTAN UNIV

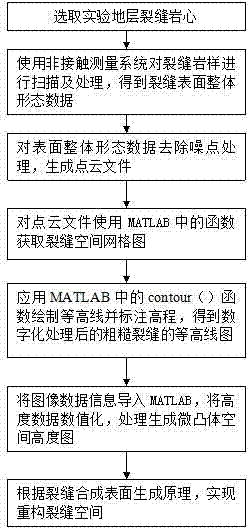

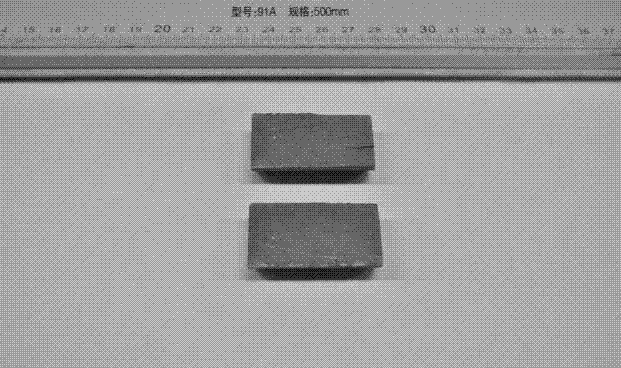

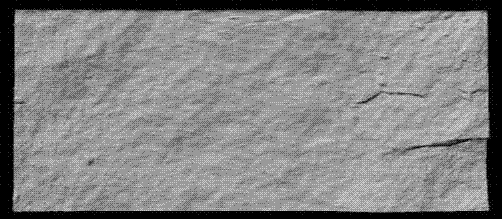

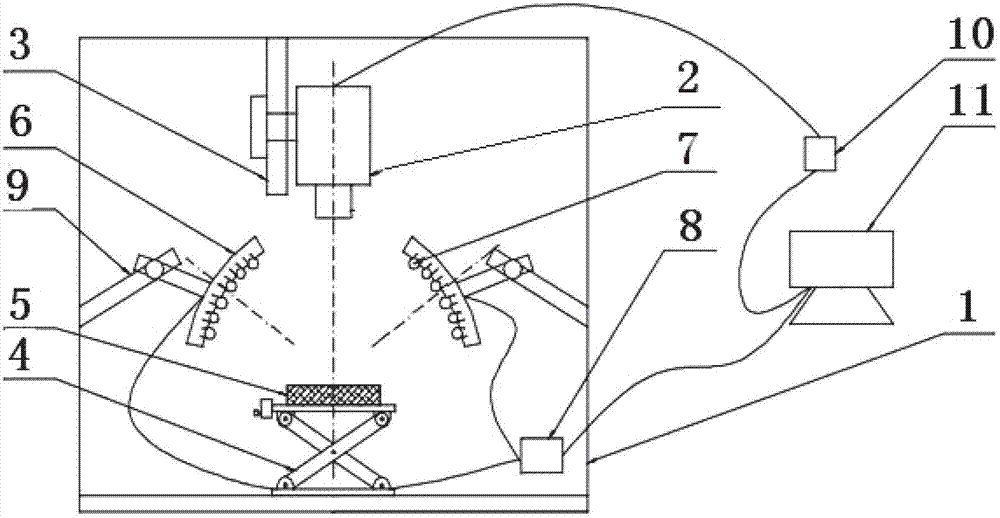

Formation fracture space reconstruction method based on rock core measure

InactiveCN103114848APracticalReduce human errorBorehole/well accessoriesReconstruction methodRock sample

The invention discloses a formation fracture space reconstruction method based on rock core measure. The formation fracture space reconstruction method based on the rock core measure comprises the following steps: step 1 of selecting fracture rock core, step 2 of scanning and processing a fracture rock sample through non-contact type measure system and obtaining a surface chart, step 3 of acquiring form data through a three-dimensional point cloud data reverse engineering software, step 4 of exporting the form data, generating a point cloud file, step 5 of generating the point cloud file to a fracture space grid chart by using a matrix laboratory ( MATLAB), step 6 of drawing contour lines, step 7 of processing and generating a space height map, and step 8 of conducting necessary rotation and move to the space height map, and obtaining a reconstruction fracture space model. The formation fracture space reconstruction method based on the rock core measure has the advantages that the height of the reconstruction fracture space model acquired through reconstruction is the same as an actual fracture form, precision is improved significantly, feasibility and practicability are achieved, digital simulation research of mesomechanics can be well satisfied, and necessary reference for further research of reservoir network fracture plane, output volume prediction and pressure sensitivity test is served.

Owner:SOUTHWEST PETROLEUM UNIV

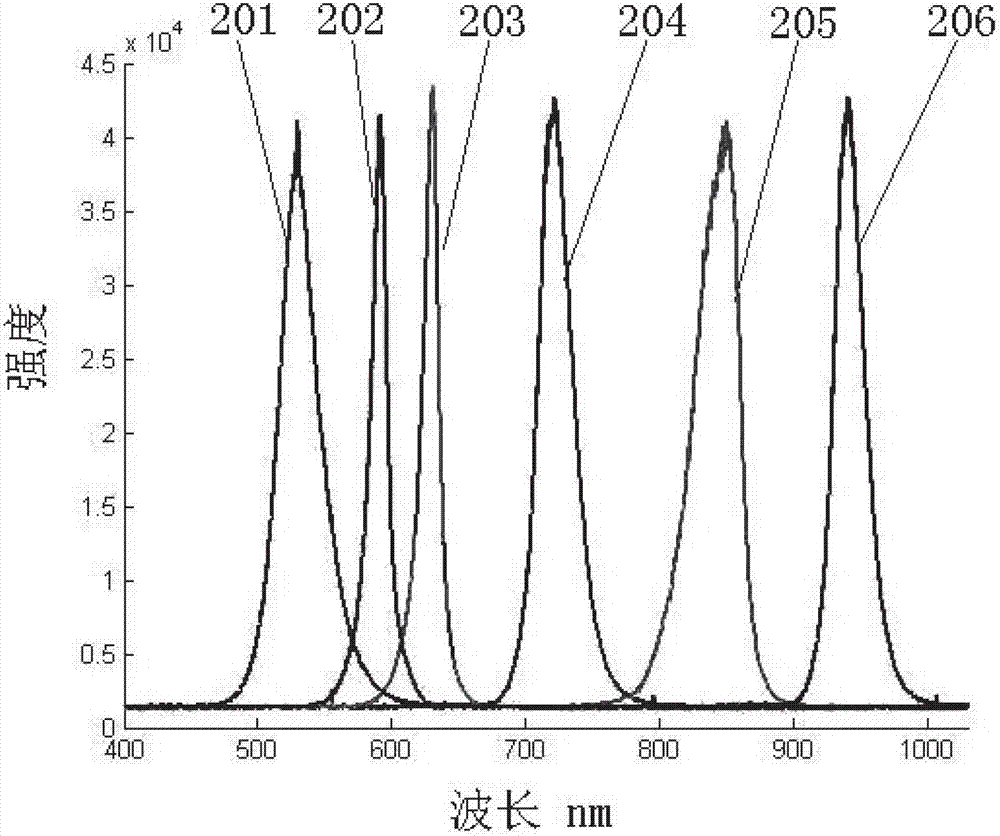

Detection and grading system for tenderness of fresh beef based on multispectral imagery

InactiveCN102854148AEasy to detectAchieve ratingColor/spectral properties measurementsCamera lensLean meat

The invention relates to a detection and grading system for tenderness of fresh beef based on multispectral imagery, which belongs to the technical field of detection of food quality. In a dark box, the lens of a CCD industrial camera is aligned with the center of a table board of a height-adjustable objective table, two multispectral light source assemblies are symmetrically arranged at a left sidewall and a right sidewall of the dark box respectively through two light source fixing supports, and a large power LED array on each of multispectral light source assemblies is composed of LEDs of 6 kinds of wave bands; during detection, a sample to be detected is put on the table board of the height-adjustable objective table, the LEDs of 6 kinds of wave bands alternately radiate in order, the CCD industrial camera acquires multispectral images of the sample to be detected, a multispectral beef sample reflection image in an interested area of a lean meat part is extracted through computer image processing, and therefore, marbling of beef is extracted, and evaluation and grading of content of marbling of the beef are carried out, and tenderness of the beef is predicted. The detection and grading system provided by the invention is applicable to companies dealing with cutting, marketing, processing and import and export of fresh beef and to market supervision by quality and technical supervision departments.

Owner:CHINA AGRI UNIV

Circulating cooling water quality monitoring system and equipment

InactiveCN1514248AEmission reductionReduce processingMaterial analysisAutomatic controlMonitoring system

A system uses PLC programmable controller as a core with nine attachment units as pH on line detection unit, electric conductivity on line detection unit, flow rate on line detection unit, hardness on line detection unit, corrosion resistance on line detection unit, C1 concentration on line detection unit, automatic control unit for proportionally adding medicine, water supplementing automatic control unit and pollution discharging automatic control unit so that automatic control for adding medicine, automatic discharging of concentrated water and automatic supplementing of fresh water can be realized.

Owner:UNIV OF SCI & TECH BEIJING

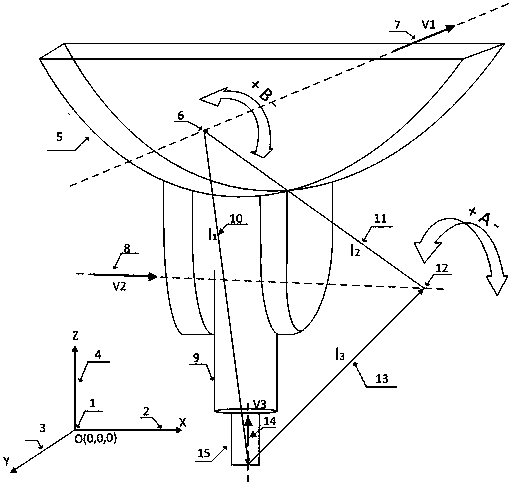

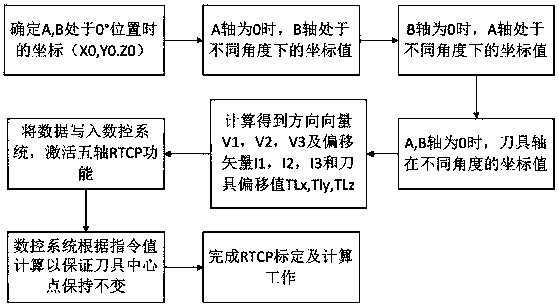

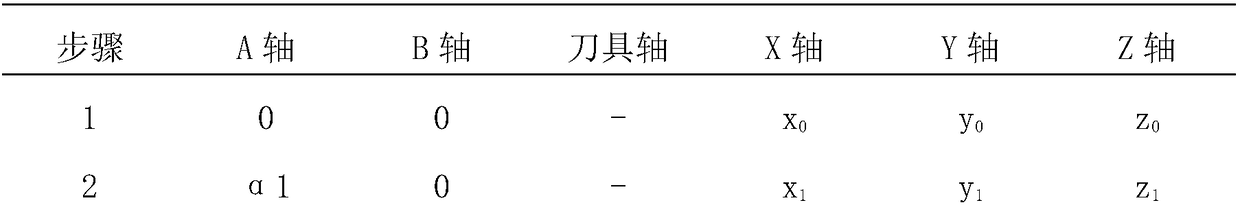

RTCP calibration and compensation method for five-axis NC machine tool of double-pendulum-head structure

ActiveCN108334030AHigh precisionReduce the error valueProgramme controlComputer controlEngineeringMachine tool

The invention discloses an RTCP calibration and compensation method for a five-axis NC machine tool of a double-pendulum-head structure. The method comprises the steps of recording the calibrated coordinate values of each rotating shaft at different angle positions, and calculating to obtain the offset vector of each rotating shaft and the vector data of each rotating shaft in the axis direction;writing the data into corresponding machine tool parameters of a numerical control system; and activating the five-axis linkage function of the numerical control system. In this way, the problems thatthe characteristic data of the five-axis machine tool cannot be directly acquired and the precision of a traditional method is low can be effectively solved. The accuracy of calibrated data is guaranteed, and the rapidity and the accuracy of the five-axis RTCP calibration are improved. As a result, the adjustment time is shortened, and the introduction of human errors is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

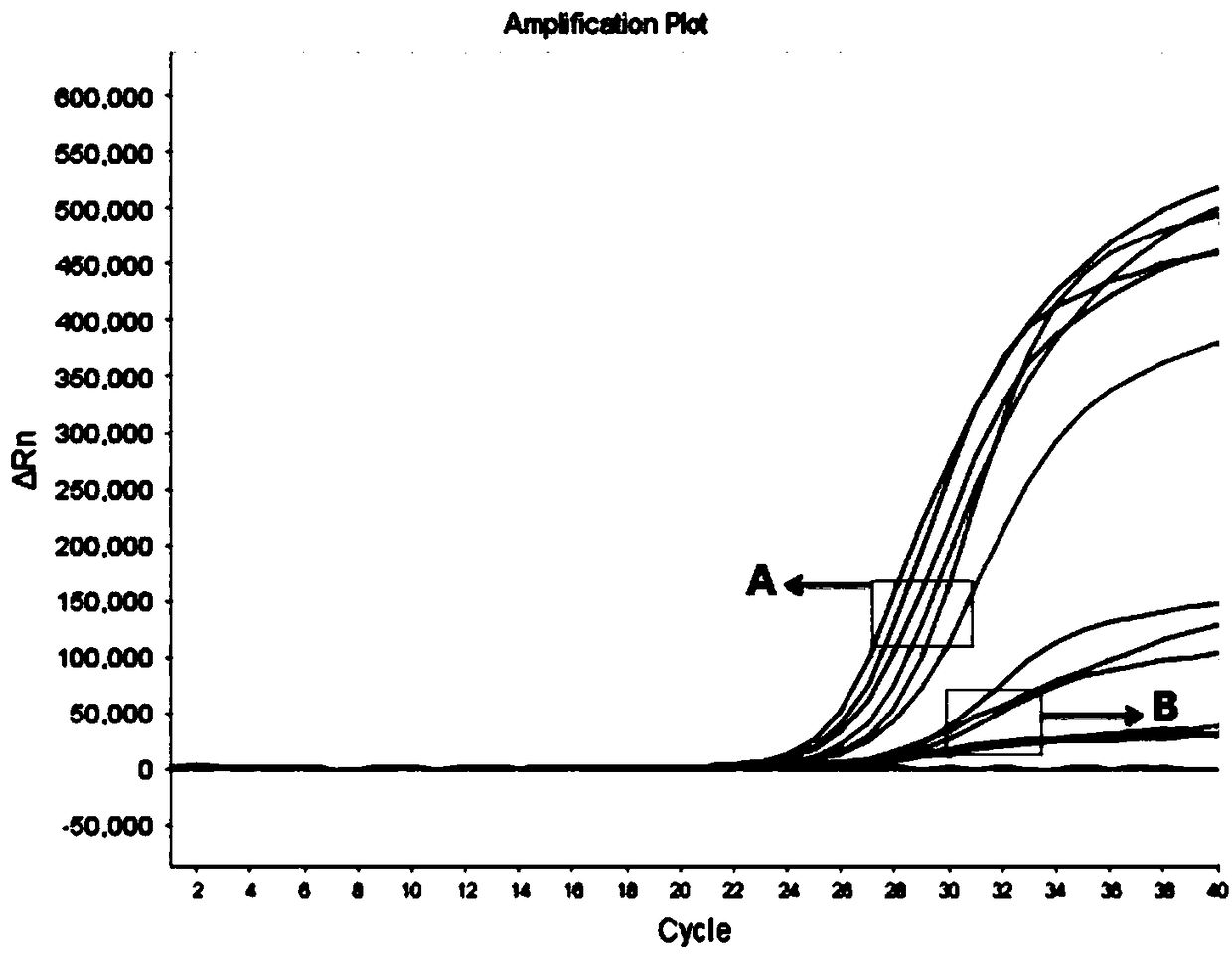

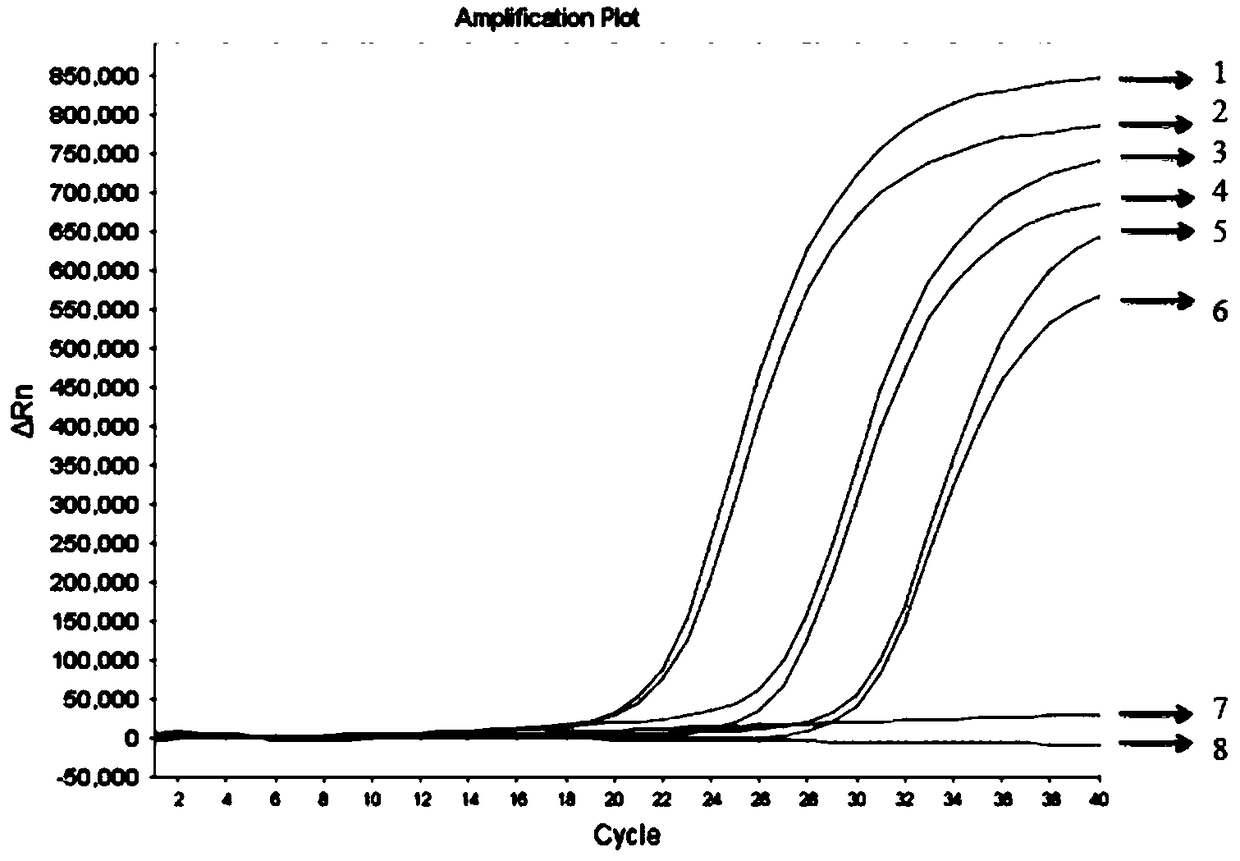

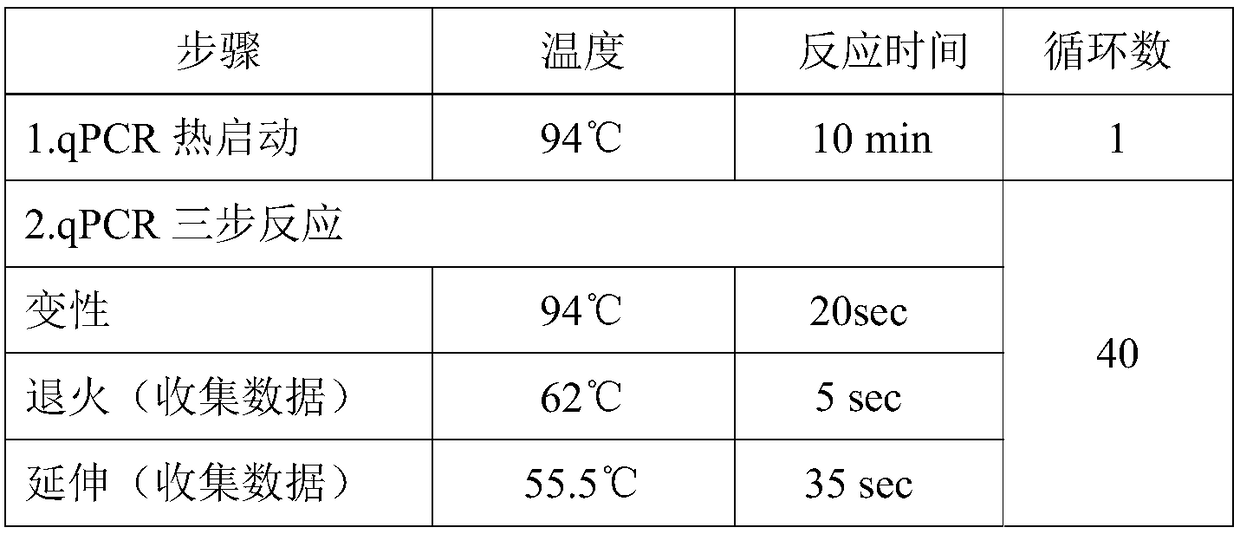

Magnetic bead process nucleic acid extraction and transformation kit, and using method thereof

InactiveCN109022417AAvoid wastingHigh purityMicrobiological testing/measurementDNA preparationLysisMagnetic bead

The invention provides a magnetic bead process nucleic acid extraction and transformation kit, and a using method thereof. The kit includes a lysate, a protease K, a magnetic bead solution, a transforamtion reagent, a nucleic acid protection agent, a binding solution, a washing solution I, a washing solution II and an eluent. The using method of the kit includes the following steps: (1) lysis; (2)transformation; (3) layering; (4) binding; (5) primary washing; (6) secondary washing; (7) drying; and 8) elution. The kit and the using method thereby can complete the transformation while achievingautomatic extraction of nucleic acid from a sample. The sample is lysed, releases the nucleic acid, and then begins to transform, the nucleic acid is separated from proteins by the binding solution after the transformation is completed, the methylated nucleic acid is purified by a magnetic bead process, and a pre-denaturation step in subsequent qPCR detection of the sample is used to replace a previously omitted sulfo group removal step, so a purification process in the original nucleic acid extraction step is omitted in the entire extraction and transformation process.

Owner:SUREXAM BIO TECH

Automatic needle inserting device

ActiveCN105056351AReduce human errorIncrease the speed of injectionUltrasonic/sonic/infrasonic diagnosticsAutomatic syringesBiomedical engineeringEngineering

The invention provides an automatic needle inserting device which comprises a frame, a bearing mechanism, an acquiring mechanism, a needle inserting mechanism and a first control mechanism. The bearing mechanism is arranged on the frame and is used for bearing positions where needles are required to be inserted; the acquiring mechanism is arranged on the frame and is used for acquiring blood vessel information of the positions where the needles are required to be inserted; the needle inserting mechanism is arranged on the frame and is used for executing needle inserting and pulling operation on the positions where the needles are required to be inserted; the first control mechanism is connected with the needle inserting mechanism and the acquiring mechanism and is used for controlling working states of the needle inserting mechanism according to the blood vessel information acquired by the acquiring mechanism. The automatic needle inserting device which is an automatic injecting device has the advantages that the information of the positions, the depths and the like of the blood vessels is acquired, then injection can be automatically carried out, accordingly, errors due to manual operation can be reduced, and the injection speeds can be increased.

Owner:BOE TECH GRP CO LTD +1

Intelligent supermarket cashier system and method based on mobile payment and IOT (Internet of Things)

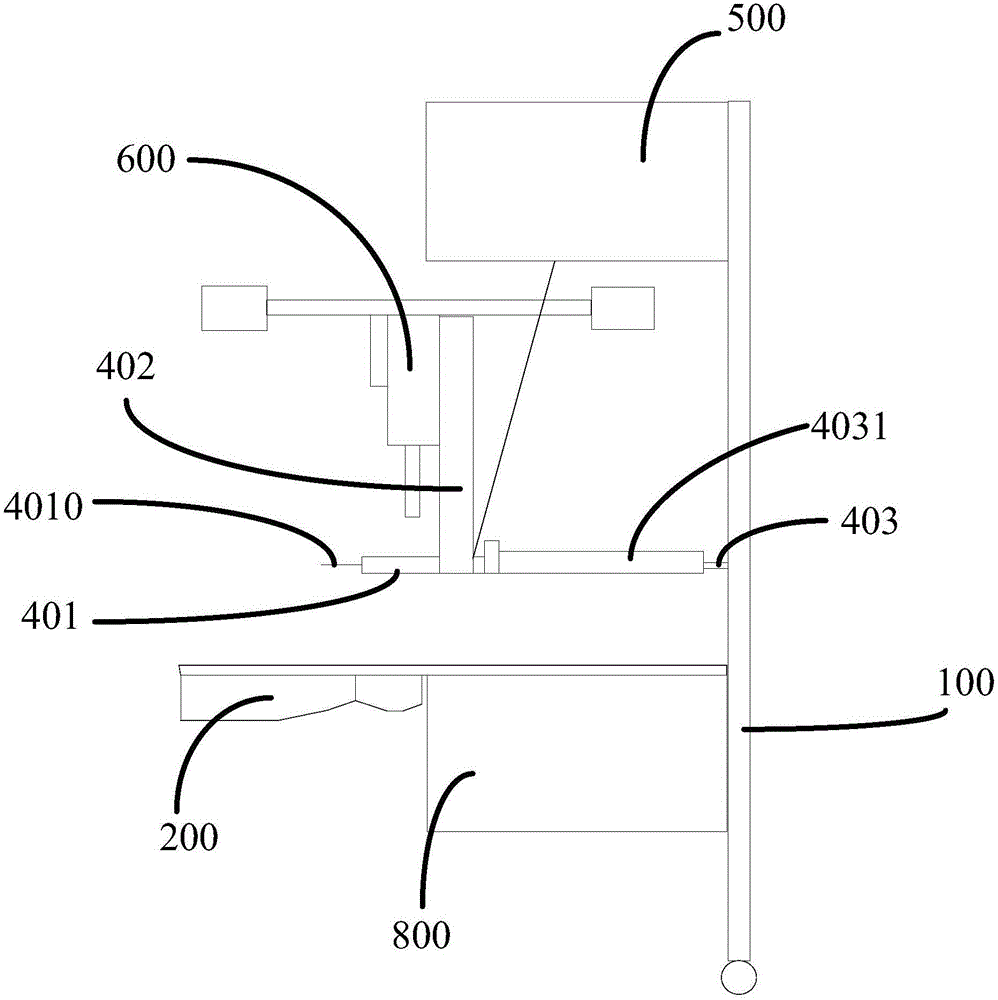

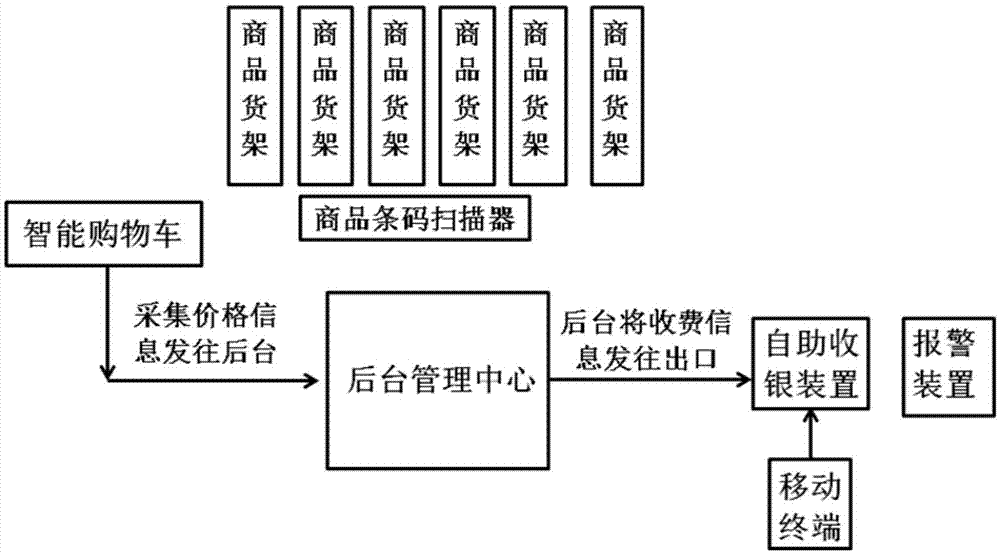

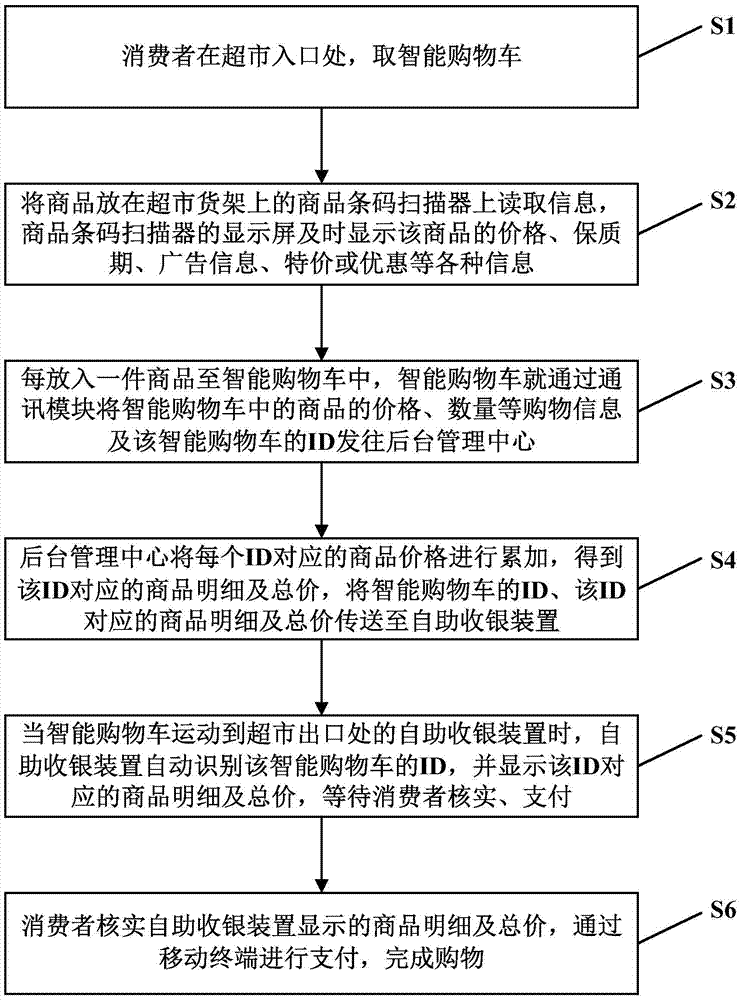

InactiveCN105448006AReduce waiting time in lineShorten the timeCash registersPayment architectureComputer terminalSmart city

The invention discloses an intelligent supermarket cashier system and method based on mobile payment and the IOT (Internet of Things), and relates to the field of smart city application. The system comprises a plurality of commodity bar code scanners, a plurality of intelligent shopping carts, a background management center, a plurality of self-service cashier devices, an alarm device, and a wireless network covering a whole supermarket. The intelligent shopping carts are provided with price recognition modules and communication modules, so as to recognize the price and number of commodities in the shopping carts and transmit the price and number of commodities and the IDs of the shopping carts to the background management center. The background management center calculates the total prices corresponding to the IDs. The self-service cashier devices automatically recognize the IDs of the shopping carts, and display the details and total prices of corresponding commodities. A consumer can finish payment through a mobile terminal. The system can achieve the self-service shopping and payment, saves the time in searching the commodities, saves the time of a cashier in scanning the price of each commodity, reduces the waiting time of the consumer, is convenient and quick, and can remarkably improve the user experience.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

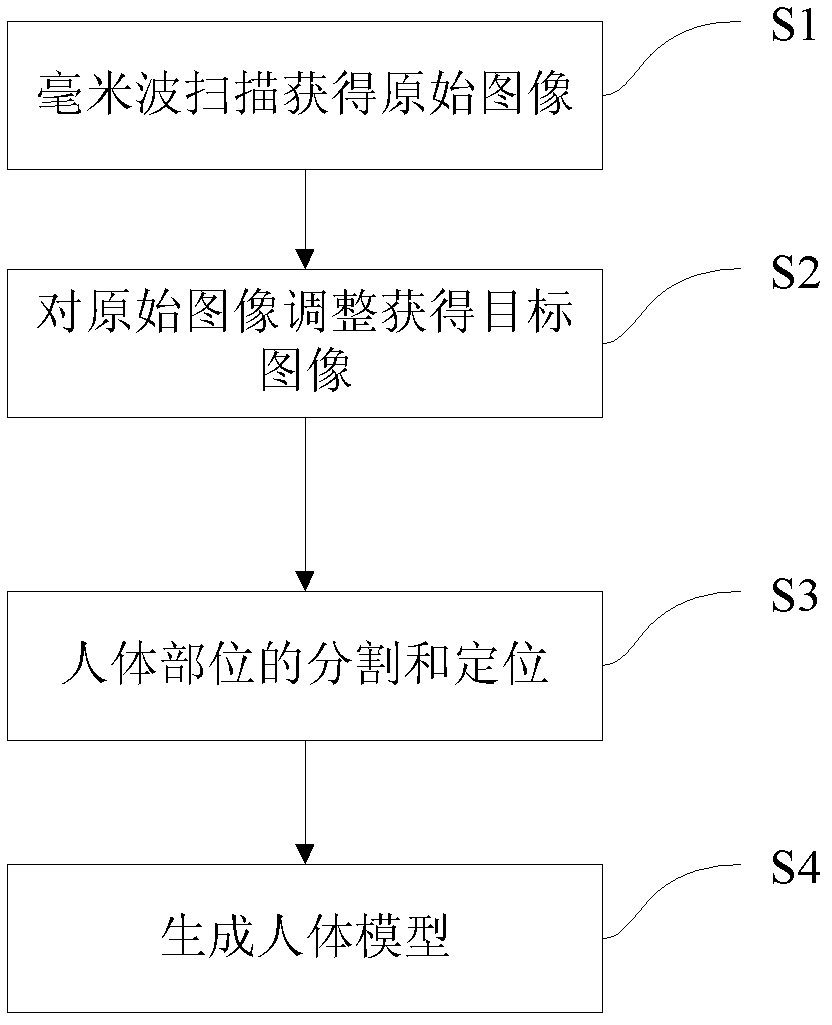

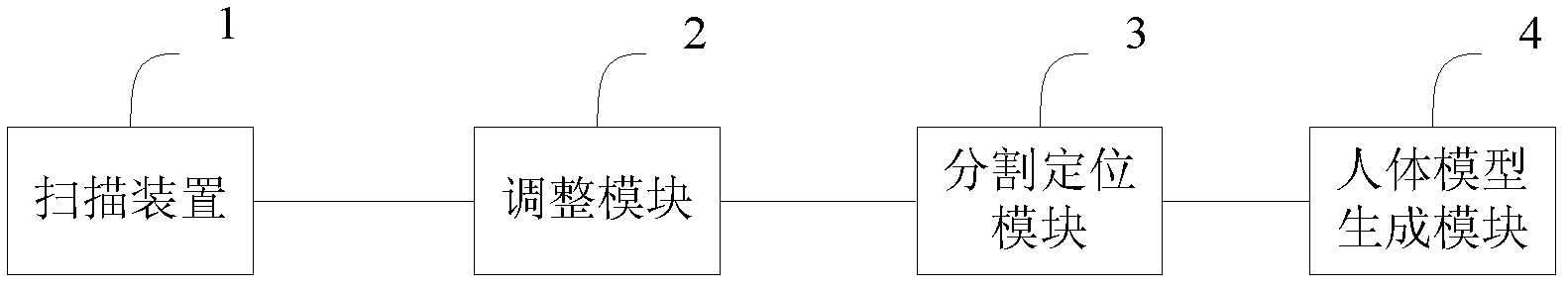

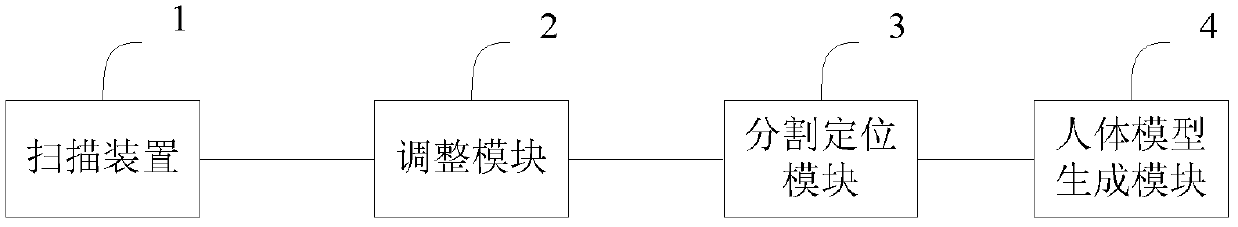

Automatic detection and identification apparatus of concealed object

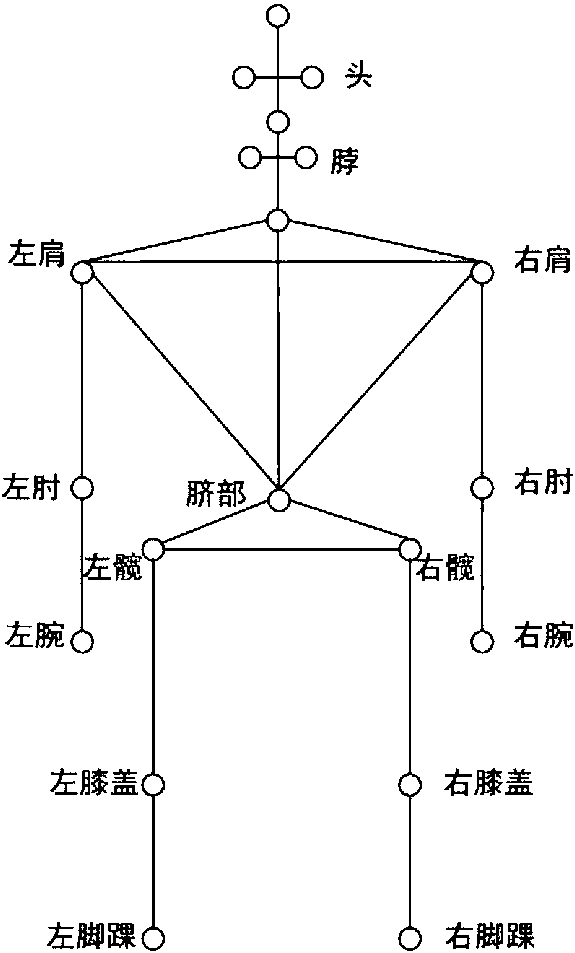

ActiveCN102629315AAchieving identifiabilityAchieving processing powerCharacter and pattern recognitionCategory recognitionComputer module

The invention discloses an automatic detection and identification apparatus of a concealed object. The apparatus comprises a scanning device, an adjusting module, a segmentation positioning module, a bar and rod combination model generation module, a non-human-body object preliminary detection module, a non-human-body object distribution module and a category recognition module. By using the automatic detection and identification apparatus of the concealed object, the detection and the identification of the concealed object are turned to be automatic from manual, which reduce a usage requirement of personnel, decrease a personal error and shorten detection interpretation time.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Small electrochemical luminescence immunoassay analyzer and analysis method thereof

ActiveCN106018784AHigh degree of automationImprove accuracyBiological testingDisplay deviceSmall footprint

The invention discloses a small electrochemical luminescence immunoassay analyzer which comprises a machine frame with a platform at the bottom. The platform is provided with a special reagent unit, a sample bin unit, an incubation unit and a general reagent unit. An upper platform is arranged above the rear portion of the machine frame and provided with a mechanical arm unit. The mechanical arm unit comprises a first mechanical arm provided with a sampling needle and a second mechanical arm provided with a rear processing needle. The machine frame is further provided with a measurement and analysis unit, a liquid path unit, a displayer unit and a board card control unit, wherein the measurement and analysis unit is used for measuring and analyzing an incubated reaction sample, the liquid path unit is used for controlling the sample, the reagent and the waste liquid flow direction, the displayer unit is used for human-computer interaction, and the board card control unit is used for carrying out circuit control over the units. The small electrochemical luminescence immunoassay analyzer has the advantages that the structure is compact, the occupied area is small, the reagent can be preserved for a long time, the whole incubation process and measurement and analysis process are high in automation degree, human assistance is not needed, manual errors are reduced, the measurement precision is excellent, measurement is easy and convenient, and working efficiency is greatly improved.

Owner:SHENZHEN LIFOTRONIC TECH

Method for coal blending coking through utilizing Gieseler fluidity index

The invention relates to a coal blending coking method, and especially relates to a method for coal blending coking through utilizing a Gieseler fluidity index to mainly solve technical problems of heavy workload, long test period and the like existing in the application of multiple index coal blending which simultaneously relates to many independent variables. The method comprises the following steps: 1, carrying out coal blending according to the following mass percentages: 10-15% of 1 / 3 coking coal, 22-30% of gas coal, 20-25% of rich coal, 30-38% of coking coal and 0-5% of lean coal; 2, combining with coal quality control to make the combined coal ash percentage be 9-10%, the sulfur percentage be 0.8-0.9%, the logarithm value of the largest fluidity be 2.2-3.0 and the largest fluidity temperature of the Gieseler fluidity be 437-442DEG C; 3, fragmenting the obtained mixed coal: fragmenting the mixed coal obtained after the coal combination in step 2; 4, coking: sending the fragmented mixed coal to a coal coking furnace, and coking for 17-21h according to a coke cake center temperature of 950-1050DEG C; and 5, cooling after coke discharging, and carrying out coke quality detection.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Large visual drawing test device for geosynthetics

ActiveCN104198276AReduce mistakesCalculation results are in line with realityMaterial strength using tensile/compressive forcesTest chamberGeosynthetics

The invention relates to a large visual drawing test device for geosynthetics. The large visual drawing test device for the geosynthetics comprises a test box for placing a sample, a vertical loading system and a horizontal loading system, wherein the test box is filled with a filler; the vertical loading system is mounted above the test box; the horizontal loading system comprises a horizontal load applying device and a drawing clamp; the drawing clamp is connected with the horizontal load applying device by virtue of a telescopic rod; a displacement sensor I is mounted between the horizontal load applying device and the drawing clamp; armored glass is arranged on the test box; a digital photographing and recording device used for photographing and recording a change process of the sample in the test box is mounted on the front surface of the armored glass; a displacement sensor II is mounted on one side with a through hole of the test box; one end of the sample in the test box is connected with the drawing clamp and the other end is connected with the displacement sensor II during drawing. By virtue of the large visual drawing test device for the geosynthetics, the error generated when data is read, recorded and processed during testing is reduced, so that the data is more accurate.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

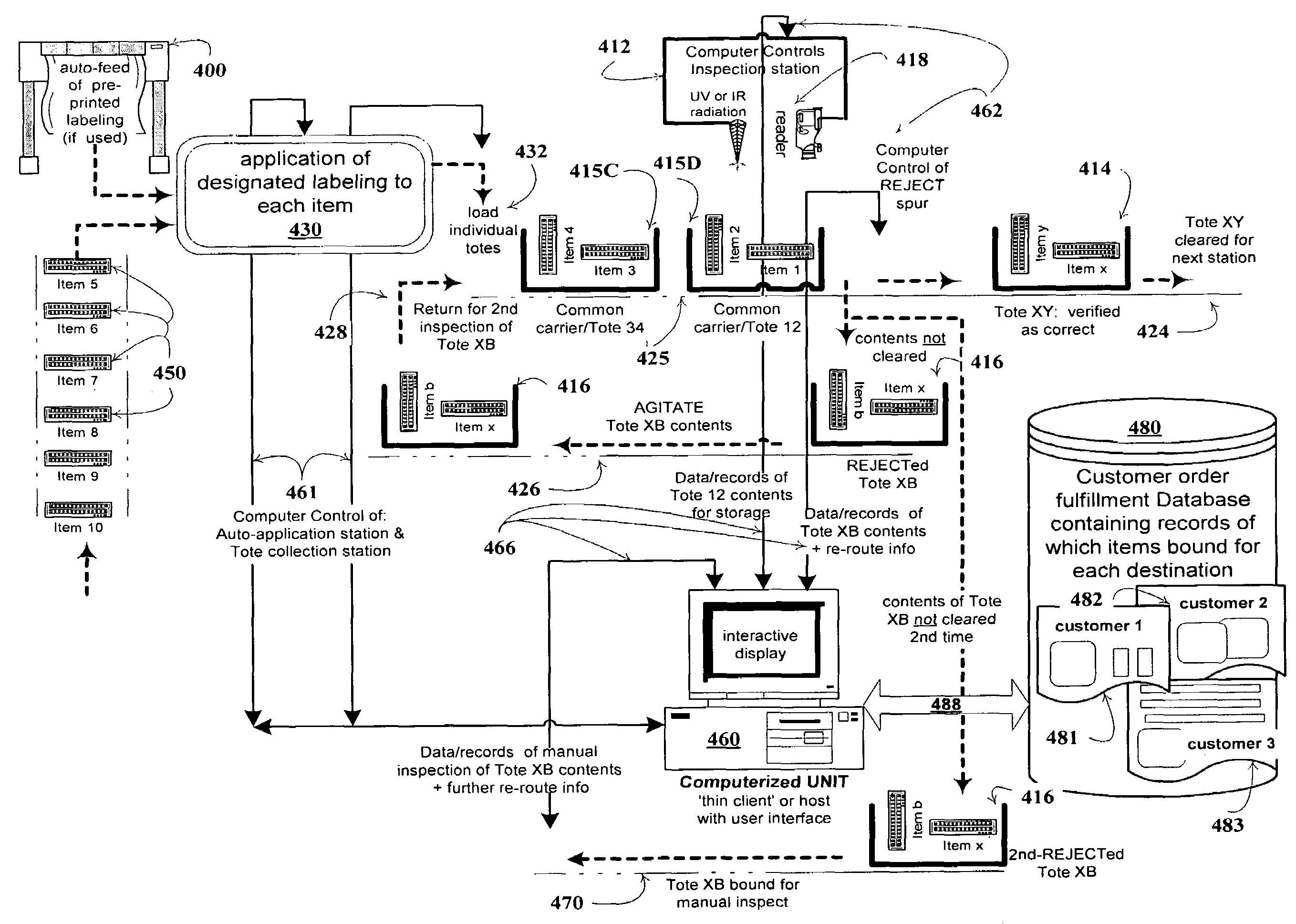

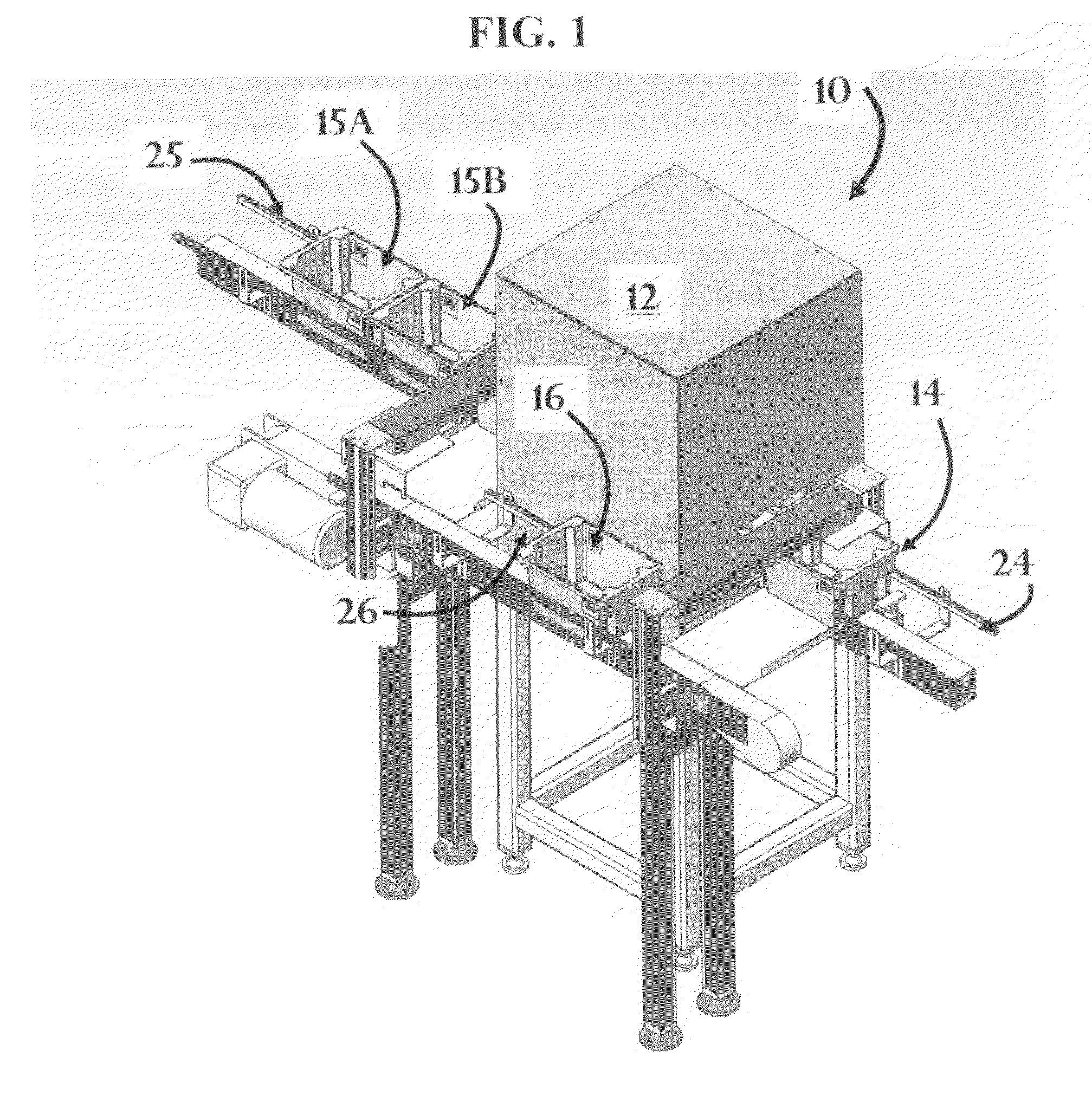

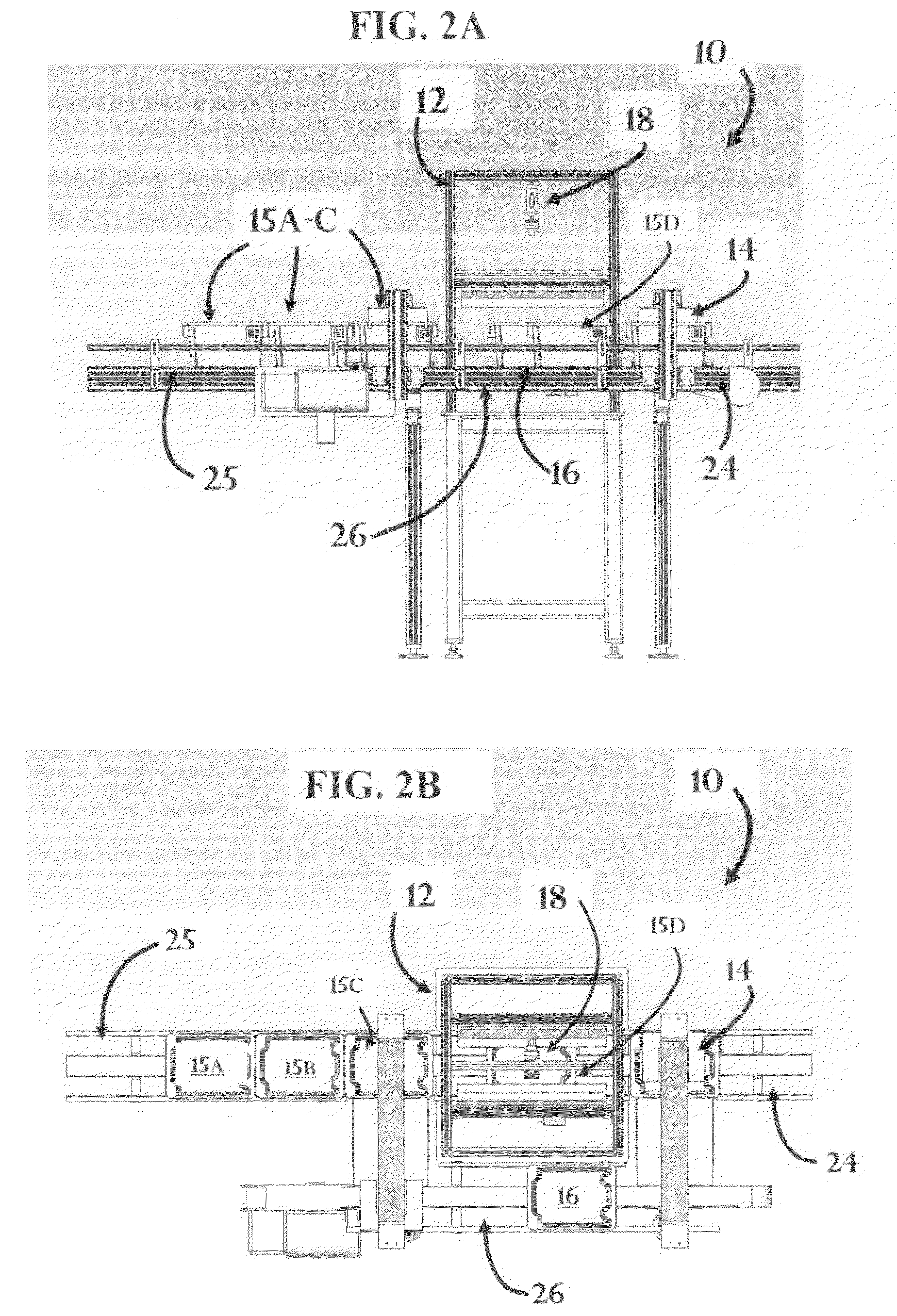

Item labeling, inspection and verification system for use in manufacturing, packaging, product shipment-fulfillment, distribution, or on-site operations

ActiveUS7918402B2Reduce labor costsImproper operationElectric signal transmission systemsDigital data processing detailsAssembly lineIrradiation

An item contents verification system, and associated method, for use in an assembly line of carrier-totes (if used) each containing at least one of a plurality of items having a labeling. Also, a labeling for use with a computerized inspection apparatus for verification of items, and associated method. The system includes: (a) the labeling comprising a luminescent marking and a human-visible indicia; (b) the luminescent marking comprises a coded-indicia generally invisible to a human eye without an irradiation, each of these coded-indicia contains item-information about the item to which the labeling is applied, multiple such coded-indicia will be substantively identical; (c) an inspection apparatus adapted for automatically collecting item-information from luminescent coded-indicia oriented outwardly from items passing in proximity to the inspection apparatus; (d) in communication with the inspection apparatus is a processor unit used for comparing an order of selected items against the item-information collected about all items; if the item-information collected matches the order of selected items, that carrier-tote contents is deemed verified. A reject spur is included to which any respective carrier-tote, or any respective item not matched to an order, is routed if the contents of the carrier-tote is not deemed verified.

Owner:TENSION INT

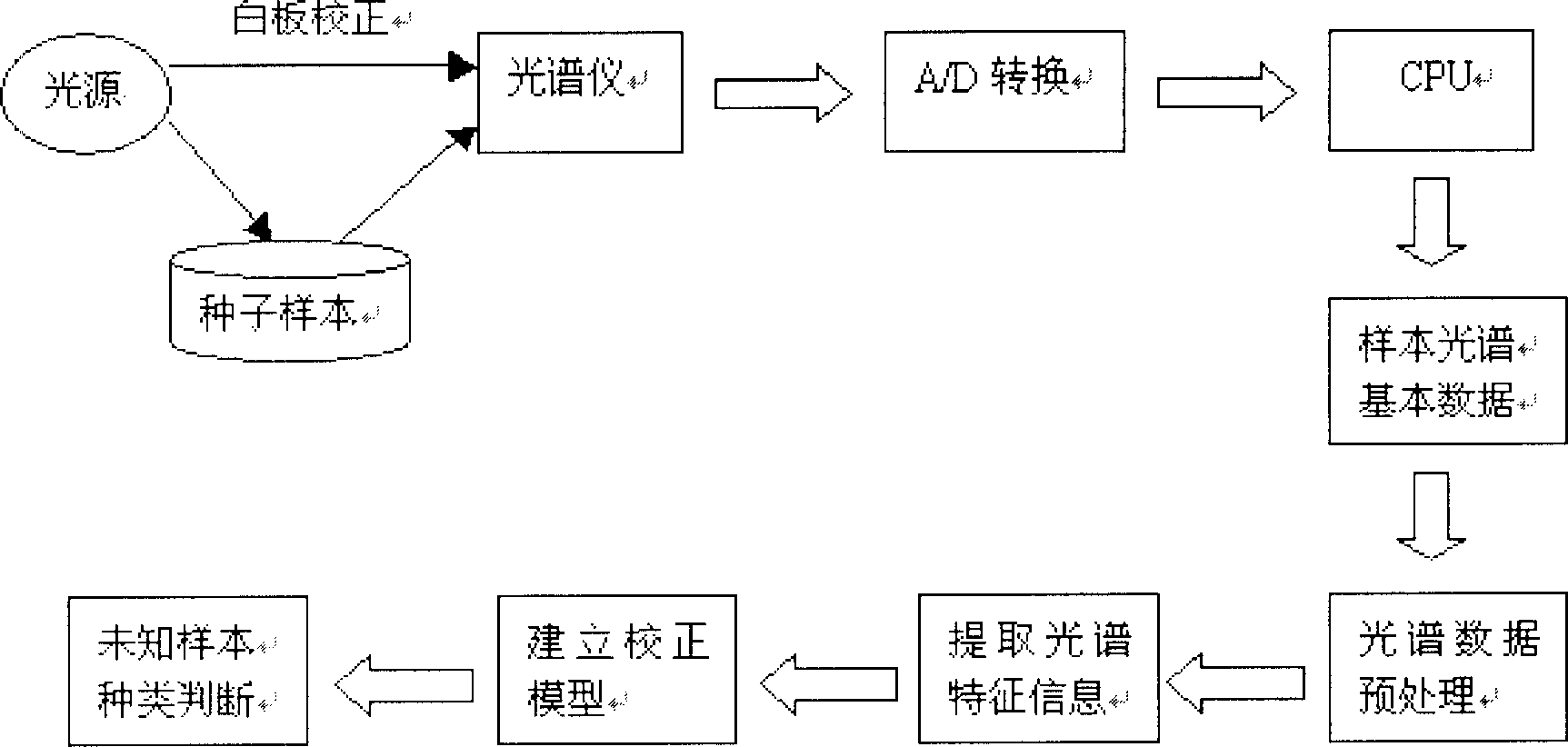

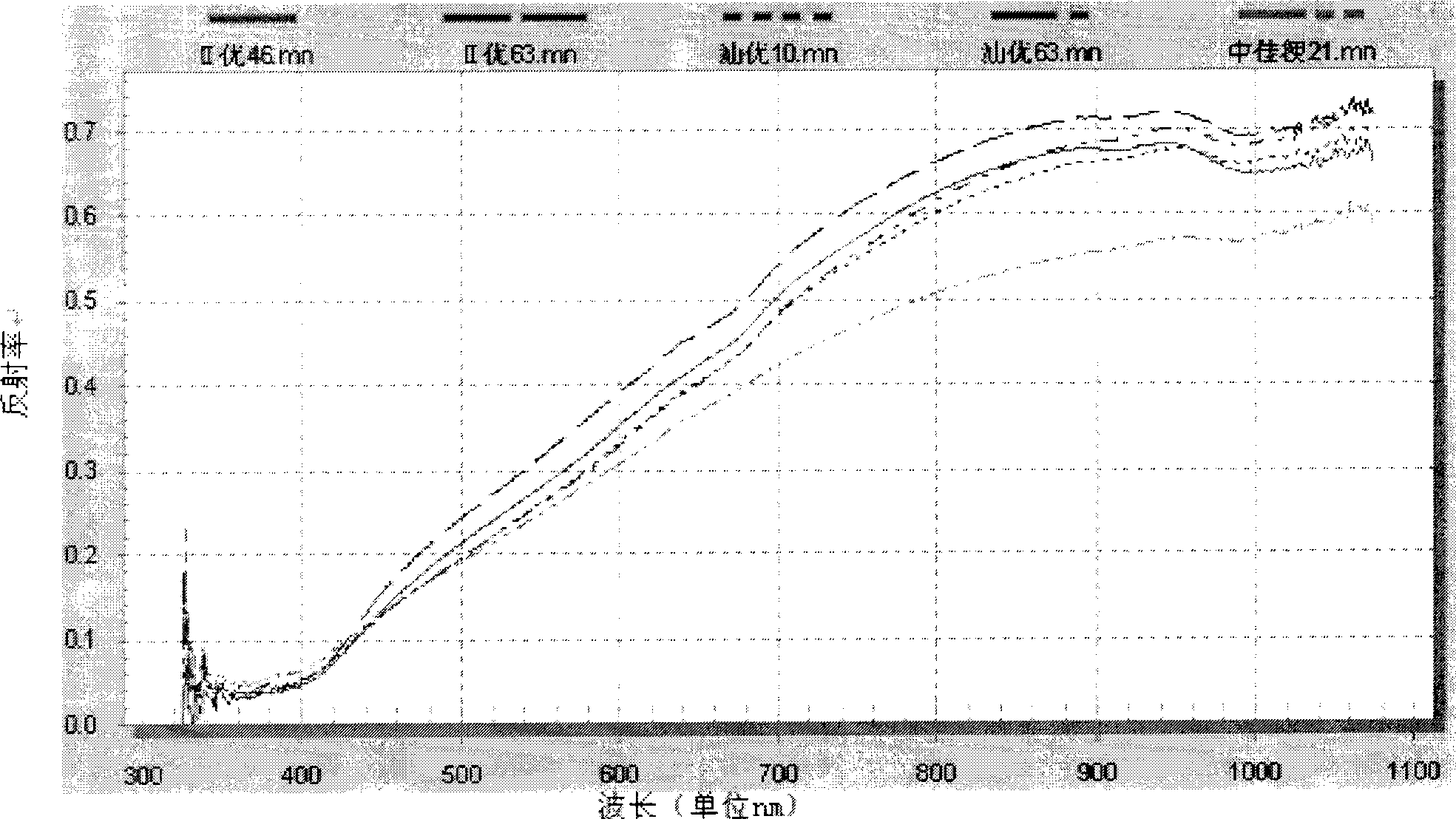

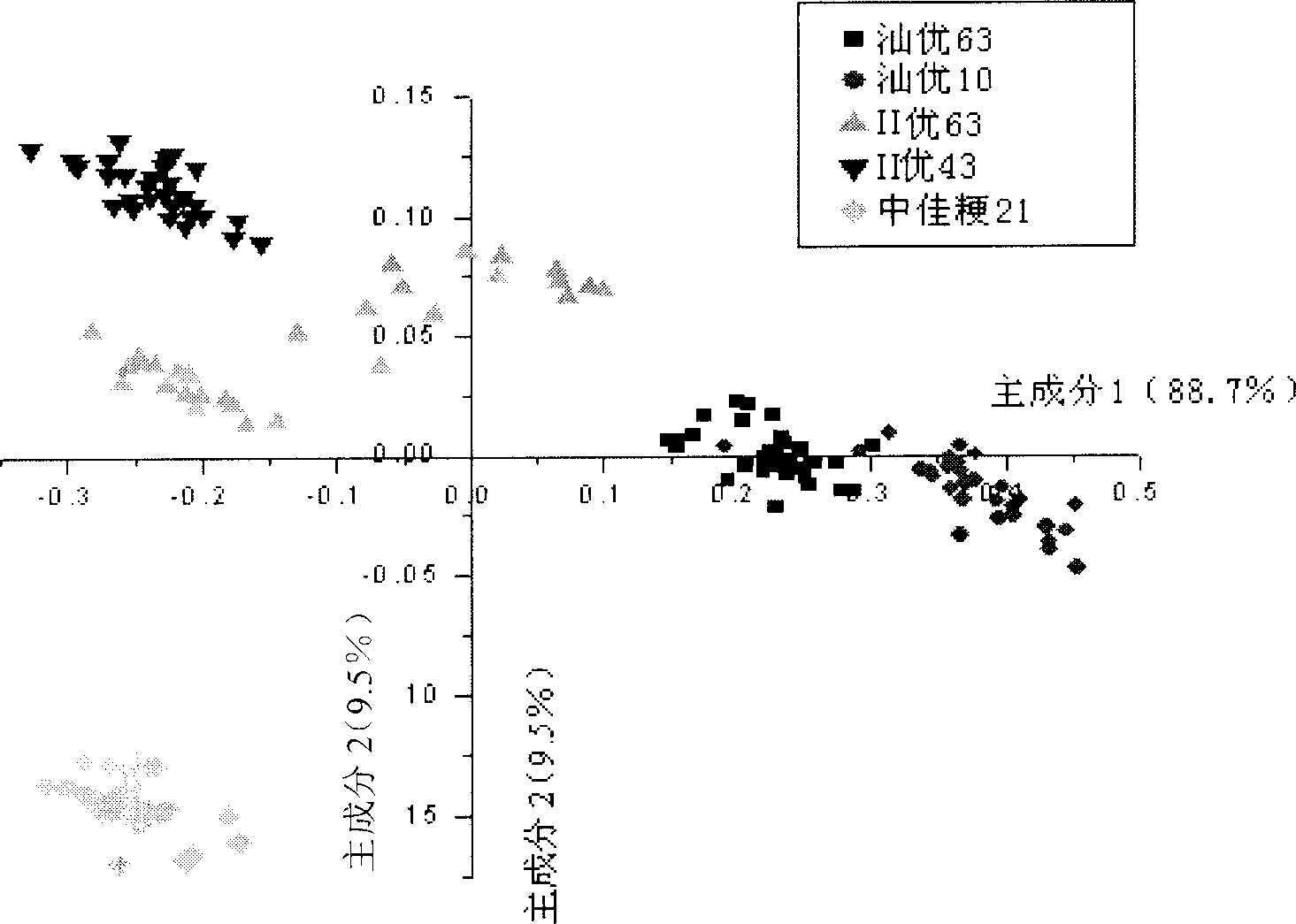

Method for nondistructive discriminating crop seed variety using visible light and near-infrared spectrum technology

InactiveCN1831515AFast analysisNo pollutionMicrobiological testing/measurementColor/spectral properties measurementsTest sampleAC power

A method of using visual light and near infrared spectrum to identify variety of crop seed nondestructively includes fixing halogen lamp on A - frame, using power supply wire to provide 220V AC power to spectrograph and light source as well as computer, connecting spectrograph to computer through data line for transmitting collected data of sample spectrum to computer, carrying out process and analysis on collected data by spectrum special software ASD View Spec ProV 2.14 and Unscramble V9.2 then feeding analyzed data back to information platform for displaying variety of tested sample.

Owner:ZHEJIANG UNIV

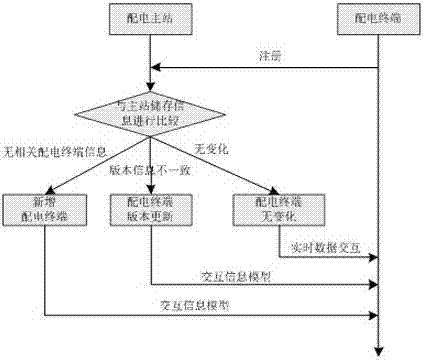

Power distribution terminal system based on IEC 61850 and realizing plug and play mechanism

InactiveCN104269924AEasy to install on siteEasy to debugCircuit arrangementsPlug and playEngineering

The invention discloses a power distribution terminal system based on the IEC 61850 and realizing a plug and play mechanism. The power distribution terminal system is realized through the following steps that (1) a power distribution terminal is connected with a power distribution master station, and automatically sends registration information to the power distribution master station; (2) information contrast is conducted on the power distribution terminal and the power distribution master station; (3) a plug and play self-describing modeling module is run between the power distribution terminal and the power distribution master station; (4), the power distribution master station receives information collected by the power distribution terminal and controls power distribution network equipment. According to the power distribution terminal system, the plug and play function of the power distribution terminal is realized by the self-describing modeling module based on the IEC 61850 standard through plug and play information interaction, the automatic on-line function of the power distribution terminal at the power distribution master station system is achieved during on-site deployment, the power distribution terminal can be installed, debugged, operated and maintained conveniently on site, in this way, the time of conducting spotting and other debugging operations on the master station and an FDU and a DTU of the power distribution terminal can be greatly shortened, human errors can be reduced, and reliability is improved. The power distribution terminal system has important significance in debugging and maintenance of a power distribution automation system with a large number of power distribution terminal systems distributed quite dispersively.

Owner:STATE GRID CORP OF CHINA +3

Automatic detection and identification method for hidden articles

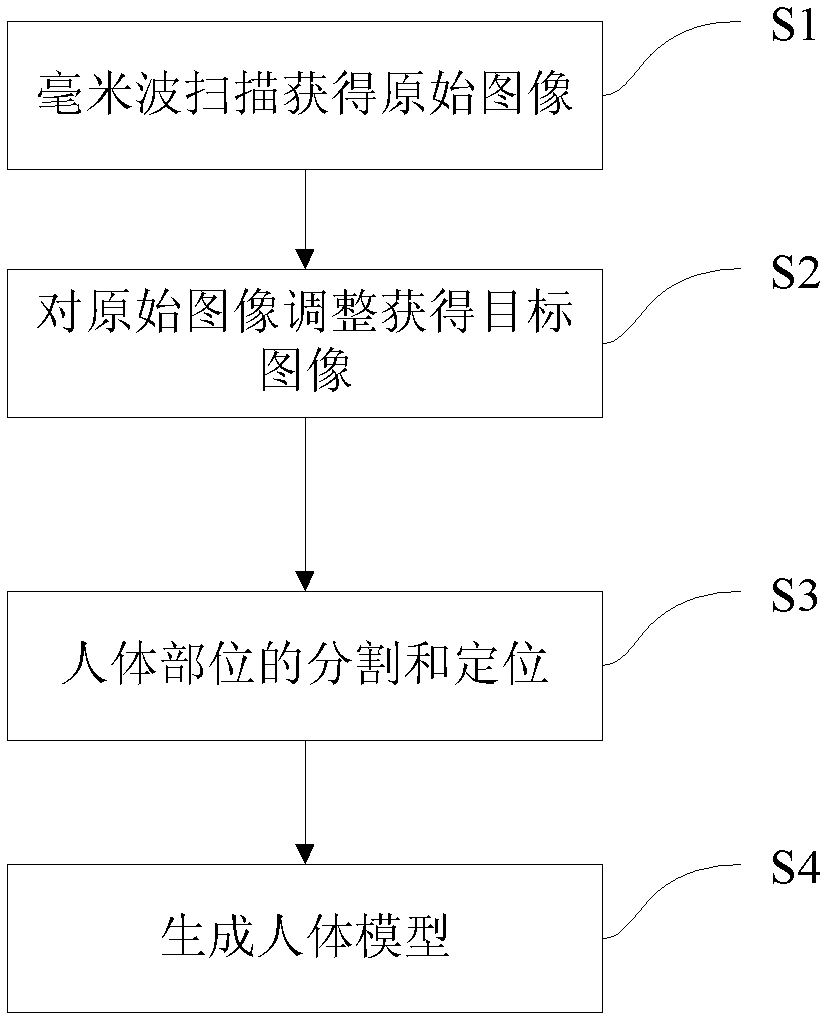

ActiveCN102708372AAchieving identifiabilityAchieving processing powerImage analysisCharacter and pattern recognitionPattern recognitionHuman body

The invention discloses an automatic detection and identification method for hidden articles. The method comprises the following steps of: performing millimeter-wave scanning on a detected person to obtain an original image; regulating the original image to obtain a target image; segmenting and locating parts of a human body according to the target image; generating a bar combination model; detecting a non-human body target according to the original image to obtain a non-human body target distribution original image; obtaining position distribution information of the non-human body target distribution original image relative to the human body through the bar combination model; and identifying the type of the non-human body target and displaying the position distribution information of the hidden articles relative to the human body. By the automatic detection and identification method for hidden articles provided by the invention, a manual mode of detection and identification for the hidden articles is changed to an automatic mode, demands on staff is lowered, human error is reduced, and the detection and judging time is shortened.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Device for causing injury of laboratory animal

The invention provides a device for causing damage to an experimental animal, which comprises a platform and an altitude controller arranged on the platform, and further comprises a striking component, a horizontal bracket and a vertical bracket; the striking component comprises a striking bar, a striking head, a guiding pipe, an electromagnet, a power and a switch; the guiding pipe, which is an open-ended through-tube, is fixed on the horizontal bracket; a cover of the striking bar is arranged in clearance fit with the guiding pipe; one end of the striking bar is connected with the striking head, and the other end of the striking bar is made of ferromagnetic materials and arranged in the magnetic field produced by the electromagnet; the electromagnet and the power are electrically connected with the switch; the altitude controller and the vertical bracket are vertically connected with the horizontal bracket; and the electromagnet is fixed on the vertical bracket. The device causes fixed-point and fixed-amount damage to animal tissue such as spinal cord, reduces artificial errors through mechanized operation, and enhances the repeatability of an experiment.

Owner:BEIHANG UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com