RTCP calibration and compensation method for five-axis NC machine tool of double-pendulum-head structure

A compensation method, a technology of CNC machine tools, applied in the direction of program control, computer control, general control system, etc., can solve the problem that the five-axis calibration data and the corresponding relationship between parameters cannot be accurately understood, and the highest point position of the ball end stick cannot be guaranteed to be the same. Increase the work intensity of debugging and maintenance personnel to achieve the effect of improving rapidity and accuracy, solving uncertainty, and improving RTCP accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is applicable to a type of five-axis numerical control machine tool with a double swing head structure. For the numerical control machine tool, the numerical value of eccentricity and the vector direction of the axis of the rotation axis need to be set, but the spatial position of the machine tool itself cannot be calculated and five-axis linkage processing is required.

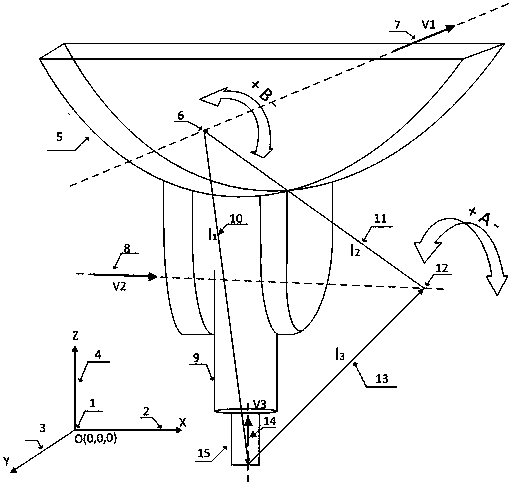

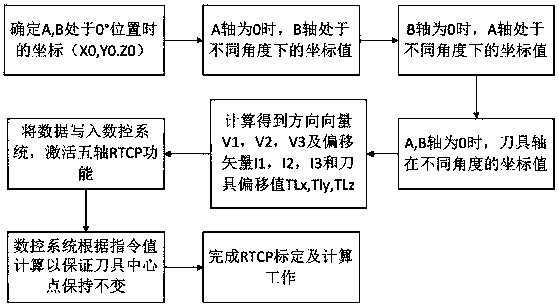

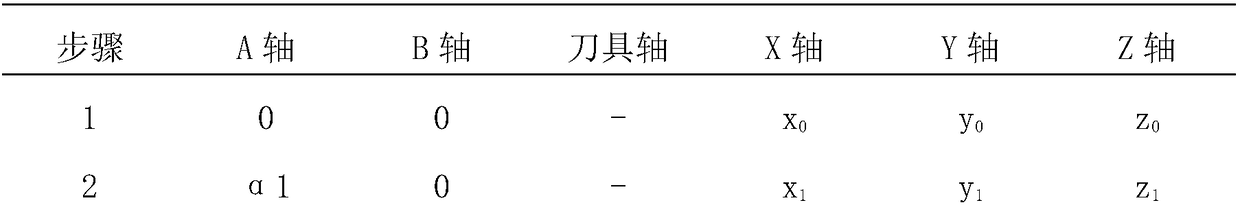

[0025] see figure 1 . In order to complete the calibration and compensation of the RTCP function of the five-axis vertical machining center point of the double swing head structure, it is necessary to calibrate the tool center point (16) in the machine tool coordinate system (0) and the B axis (5) in the machine tool coordinate system ), A-axis (9) at different angles in the X-axis (2), Y-axis (3), Z-axis (4) three directions of coordinate values, and through the algorithm to obtain the B-axis center line vector direction V1 ( 7), A-axis axis vector direction V2 (8), tool axis ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com