Patents

Literature

3923 results about "Numerical control system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerical control, (NC), Control of a system or device by direct input of data in the form of numbers, letters, symbols, words, or a combination of these forms. It is a principal element of computer-integrated manufacturing, particularly for controlling the operation of machine tools.

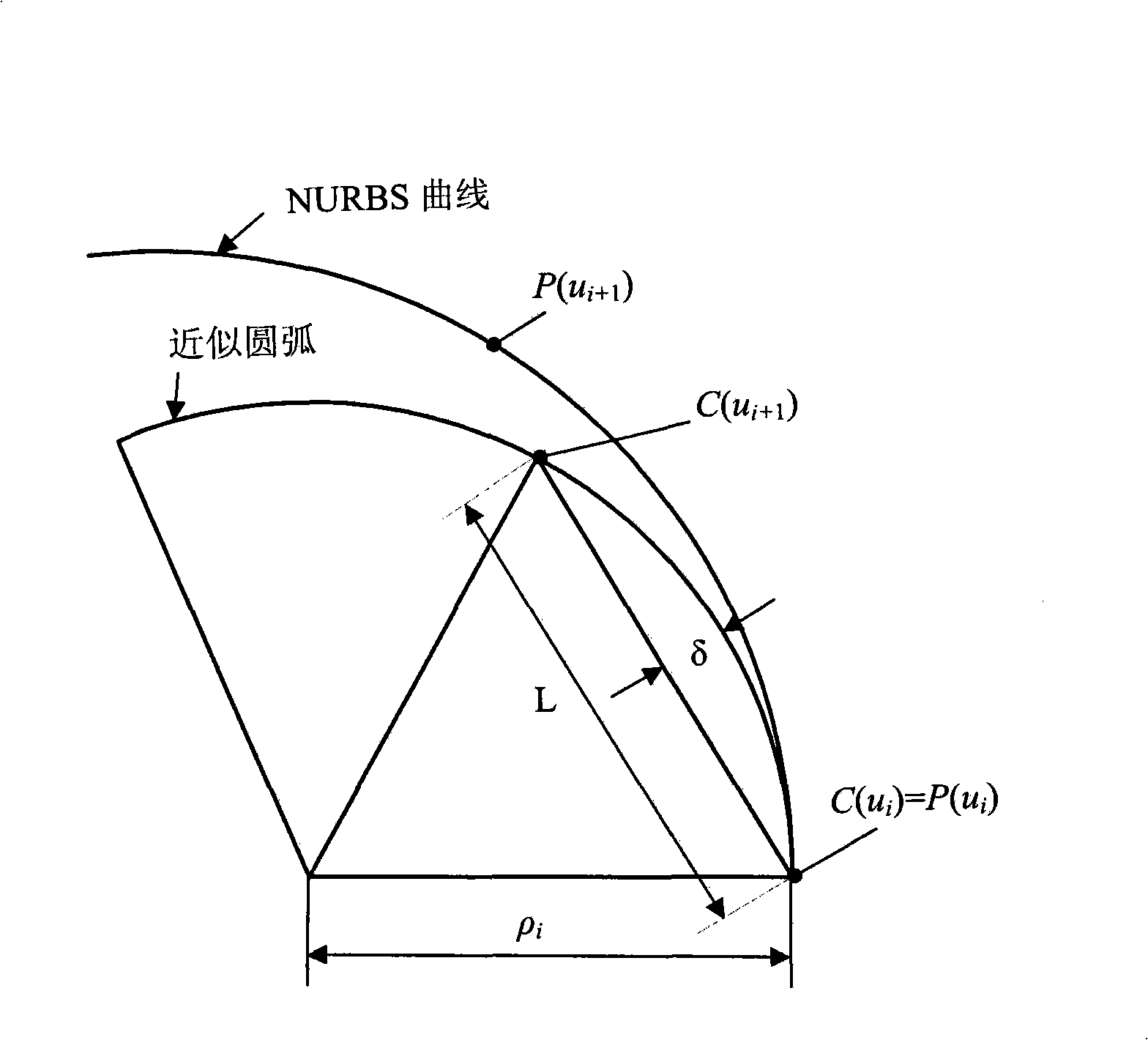

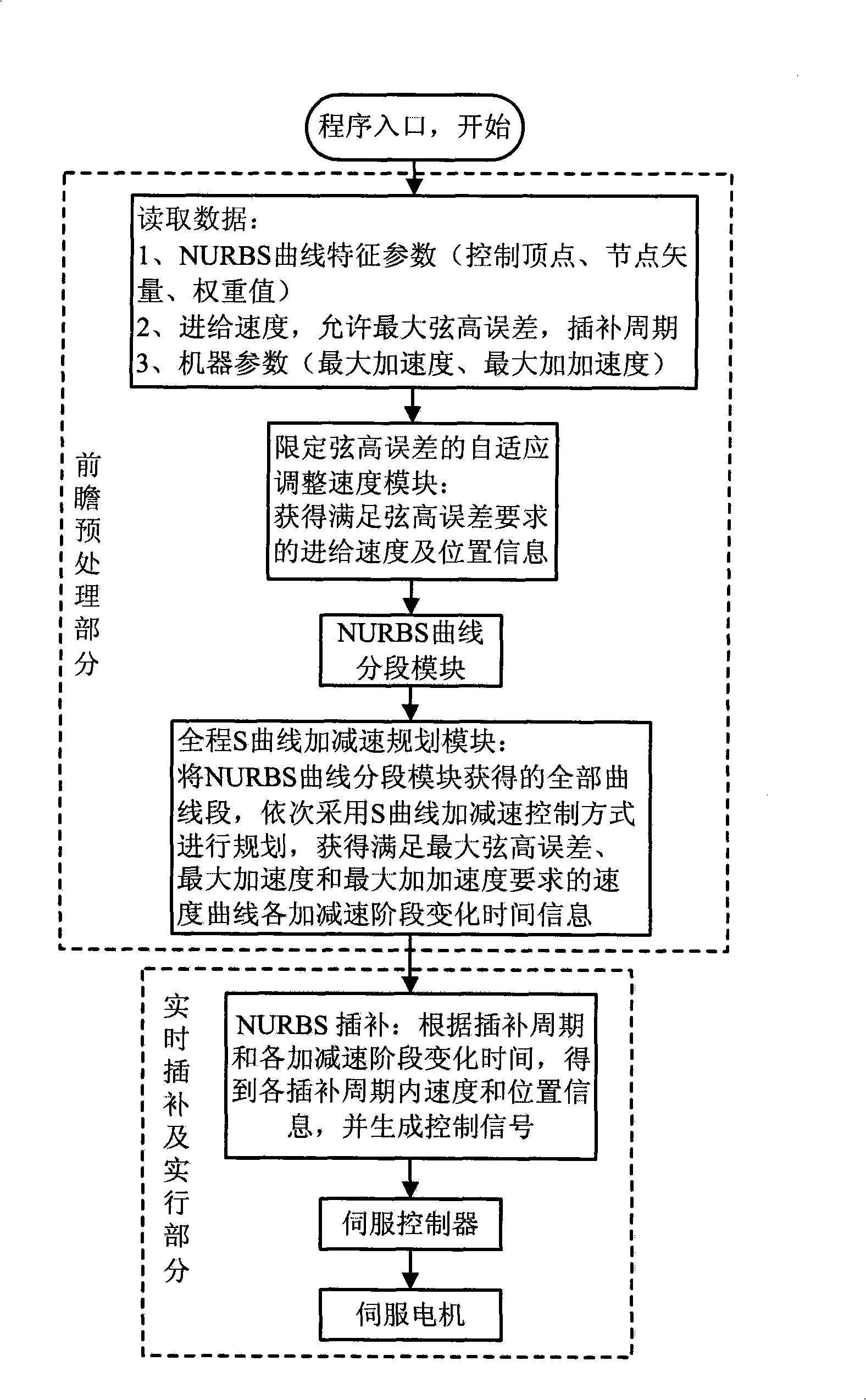

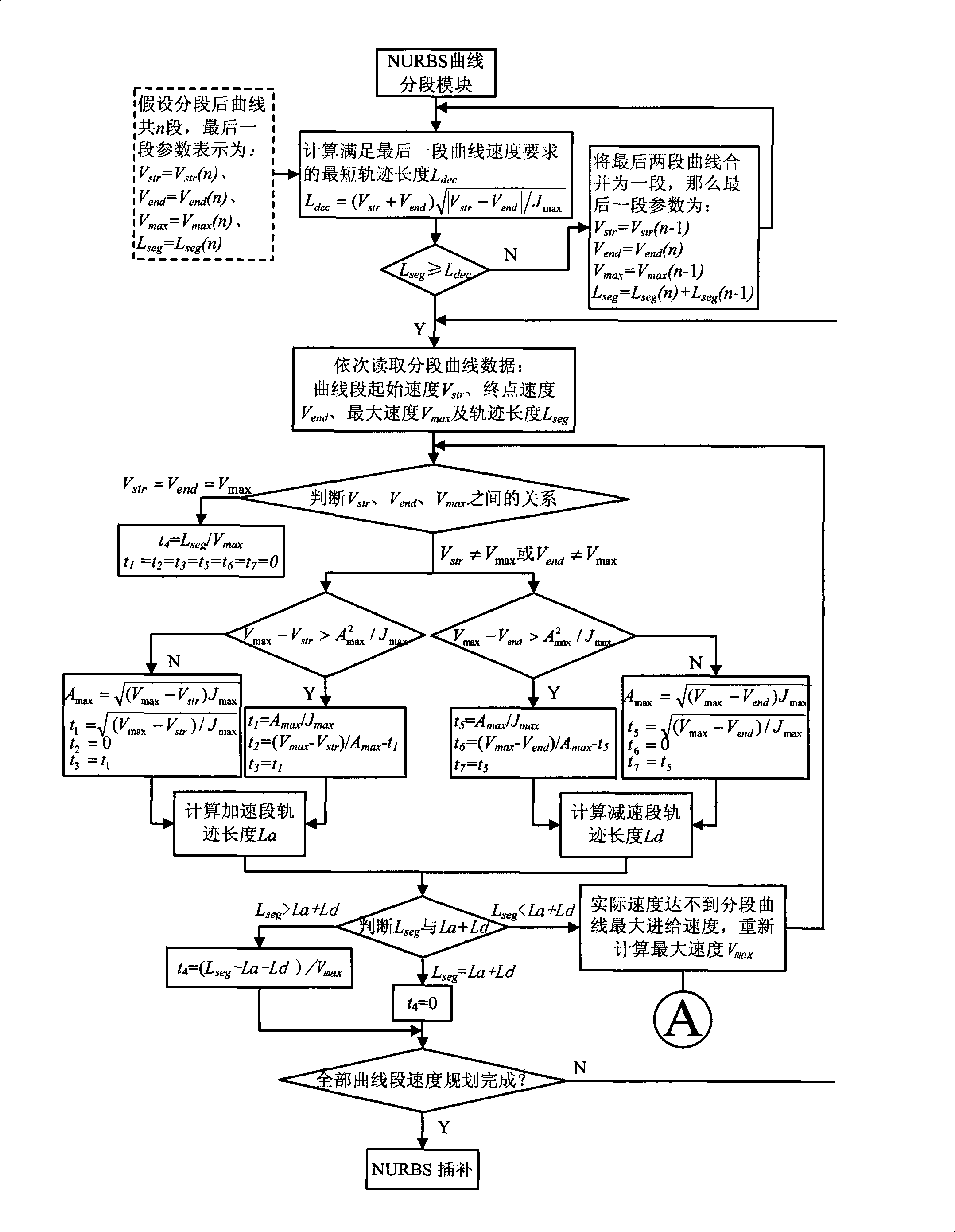

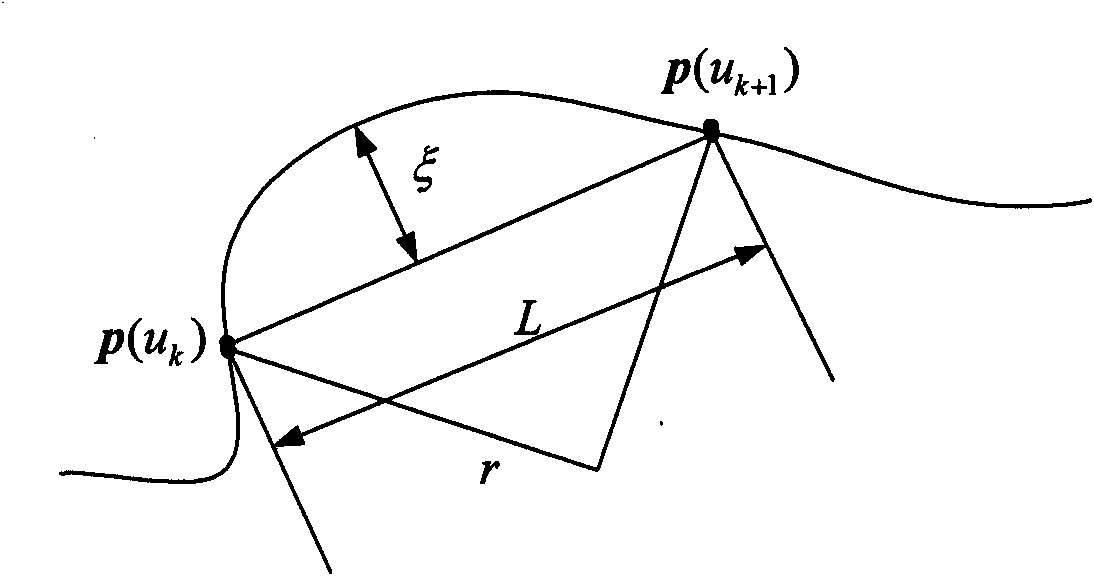

Real time forward looking whole-process acceleration and deceleration controlled NURBS curve self-adapting subsection interpolation method

InactiveCN101493687AImprove motion smoothnessSmooth speed changeNumerical controlControl signalForward looking

The invention discloses a method for self-adaptive subsection interpolation of NURBS curve under the real-time look-ahead whole-process accelerated and decelerated control. The NURBS curve is presented by a matrix form and is pre-processed; the self-adaptive speed adjusting arithmetic is adopted for the NURBS curve, thus obtaining the parameters meeting the interpolation precision requirement such as feeding speed and the like; the curve is segmented at all maximum curvatures of the curve; speed planning is carried out on all the segmented curves by an S-curve accelerated and decelerated control method, thus obtaining the changing time of the speed curve at all accelerated and decelerated stage; according to the interpolation period and the changing time of all accelerated and decelerated stage, the feeding speed of all interpolation periods and coordinates of corresponding interpolation points are obtained; and according to the coordinates of the interpolation points and the feeding speed, the control signal given value is generated. The invention can realize the look-ahead processing of the NURBS curve during the whole interpolation process, leads the real-time interpolation process to be quick and effective, leads the whole interpolation movement process to be smooth and stable, has wide applicable range and has important significance to the development of the high-speed high-precision numerical control system.

Owner:GUANGXI UNIV

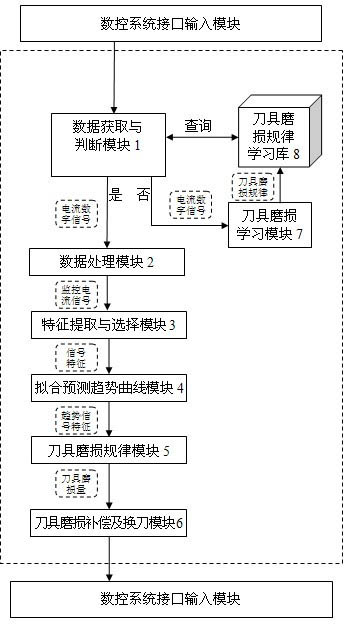

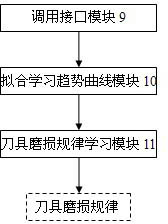

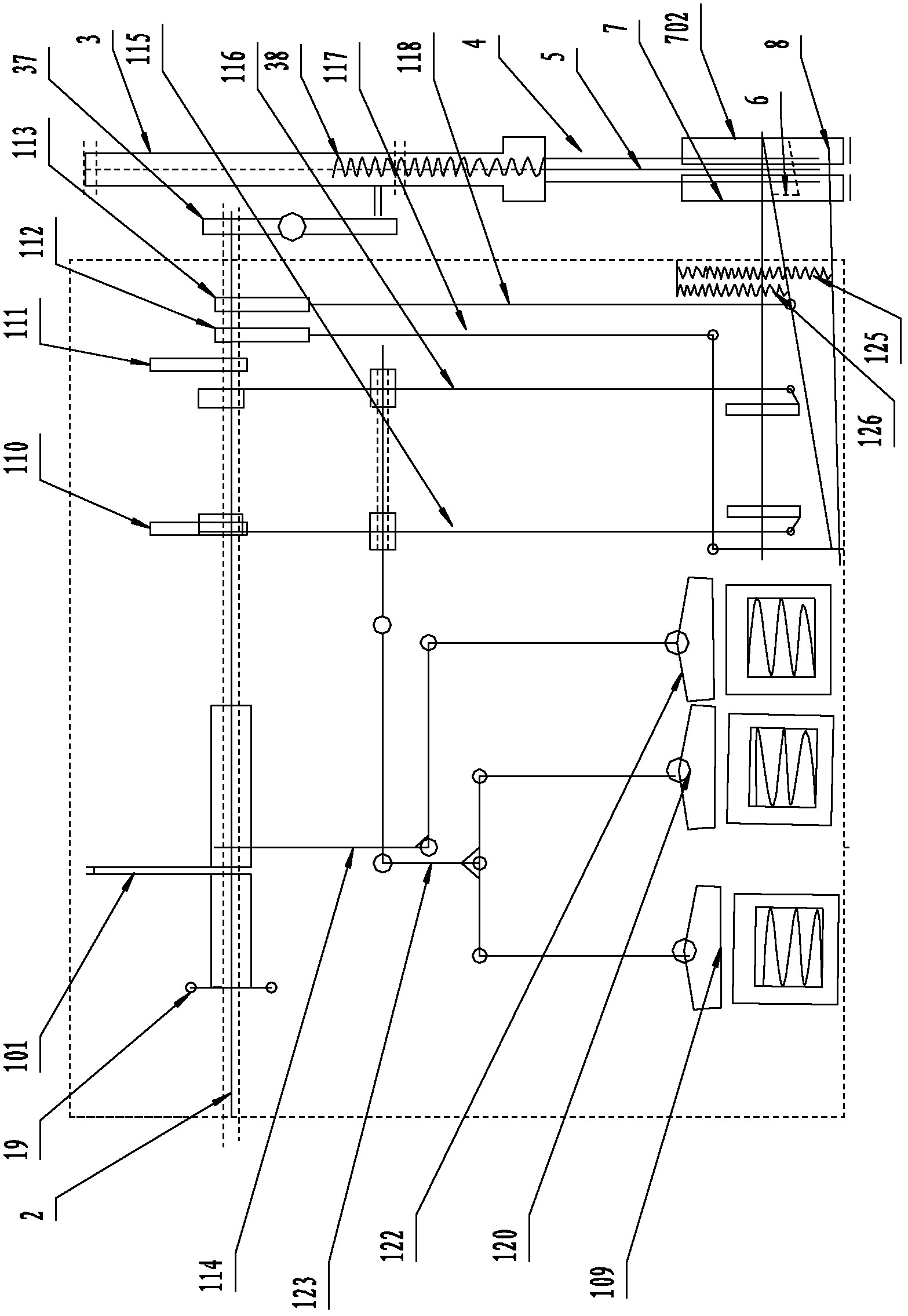

Tool wear monitoring system capable of realizing self-learning in numerical control machining state

InactiveCN102073300ACutting Condition MonitoringReal-time monitoring of cutting statusProgramme controlComputer controlData acquisitionEngineering

The invention discloses a tool wear monitoring system capable of realizing self-learning in a numerical control machining state. The structure of the system is that: a tool wear rule learning library stores learned tool wear rules; a data acquisition and judgment module provides a servo drive current digital signal for a data processing module to perform format conversion and store the signal as a monitoring current signal; a characteristic extraction and selection module selects signal characteristics strongly correlated with tool wear; a fitted predicted trend curve module establishes a signal characteristic-tool machining service life relationship curve; a tool wear rule module obtains the learned tool wear rules from the tool wear rule learning library, and substitutes the trend signal characteristics into the learned tool wear rules to obtain a tool wear extent; and a tool wear compensation and tool replacement module makes a tool wear compensation and tool replacement decision according to the tool wear extent, and provides the tool wear compensation and tool replacement decision for a numerical control system interface input module. The system is applied to the condition offluctuating cutting parameters in mass production, and can achieve relatively higher accuracy under the condition of constant cutting parameters.

Owner:HUAZHONG UNIV OF SCI & TECH +1

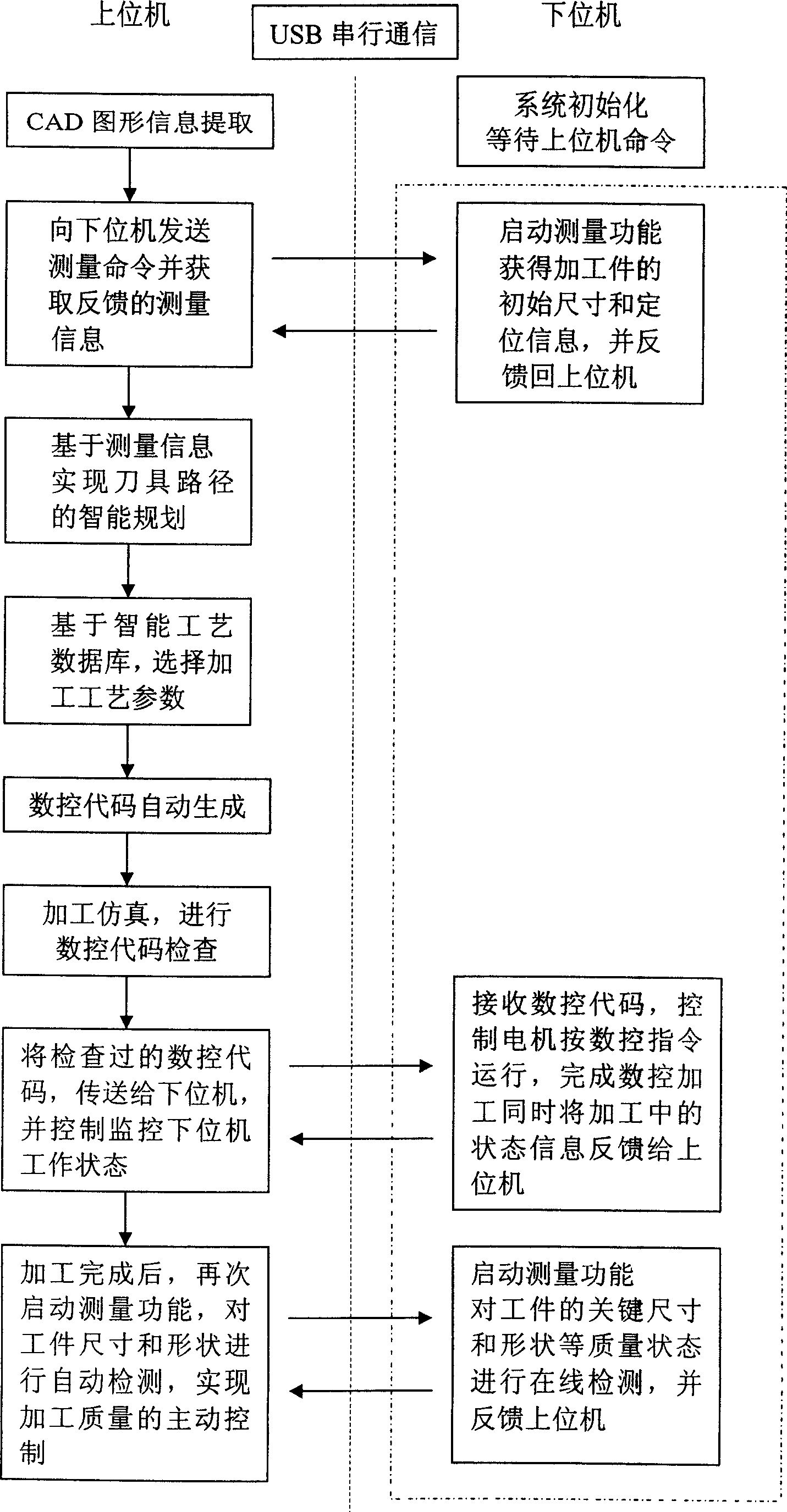

Intelligent control system for digital control machine tool and control method thereof

InactiveCN1740932ARealize real-time controlEasy to detectComputer controlSimulator controlUSBDigital control

The intelligent control system of NC machine tool is formed from NC machine tool, upper position machine and lower position machine. The upper position machine and lower position machine are formed into open control system, between upper position machine and lower position machine it utilizes USB to make serial communication, on the NC machine tool a photoelectric detection device is mounted and connected with lower position machine. Said system can implement on-line detection.

Owner:SHANDONG UNIV

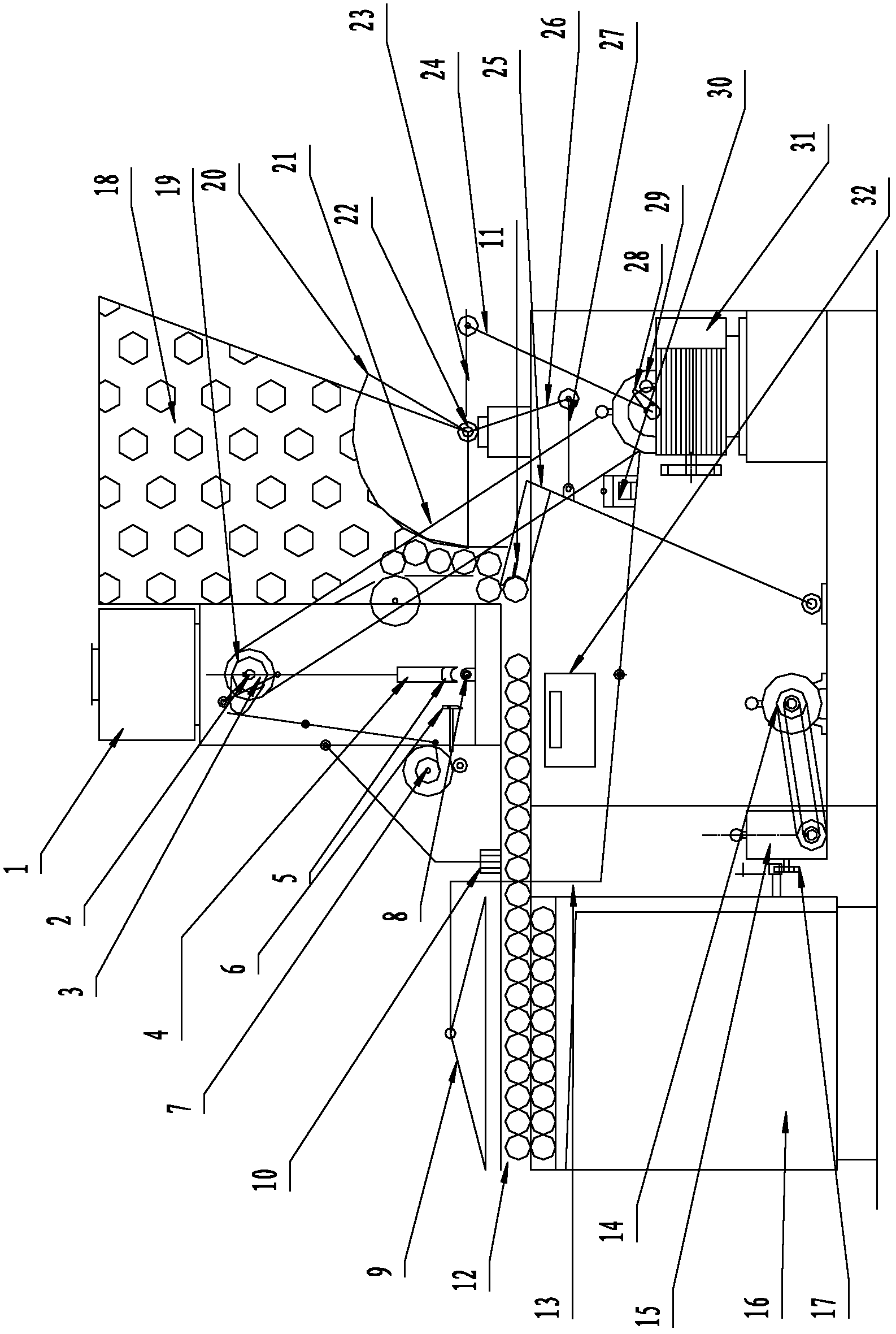

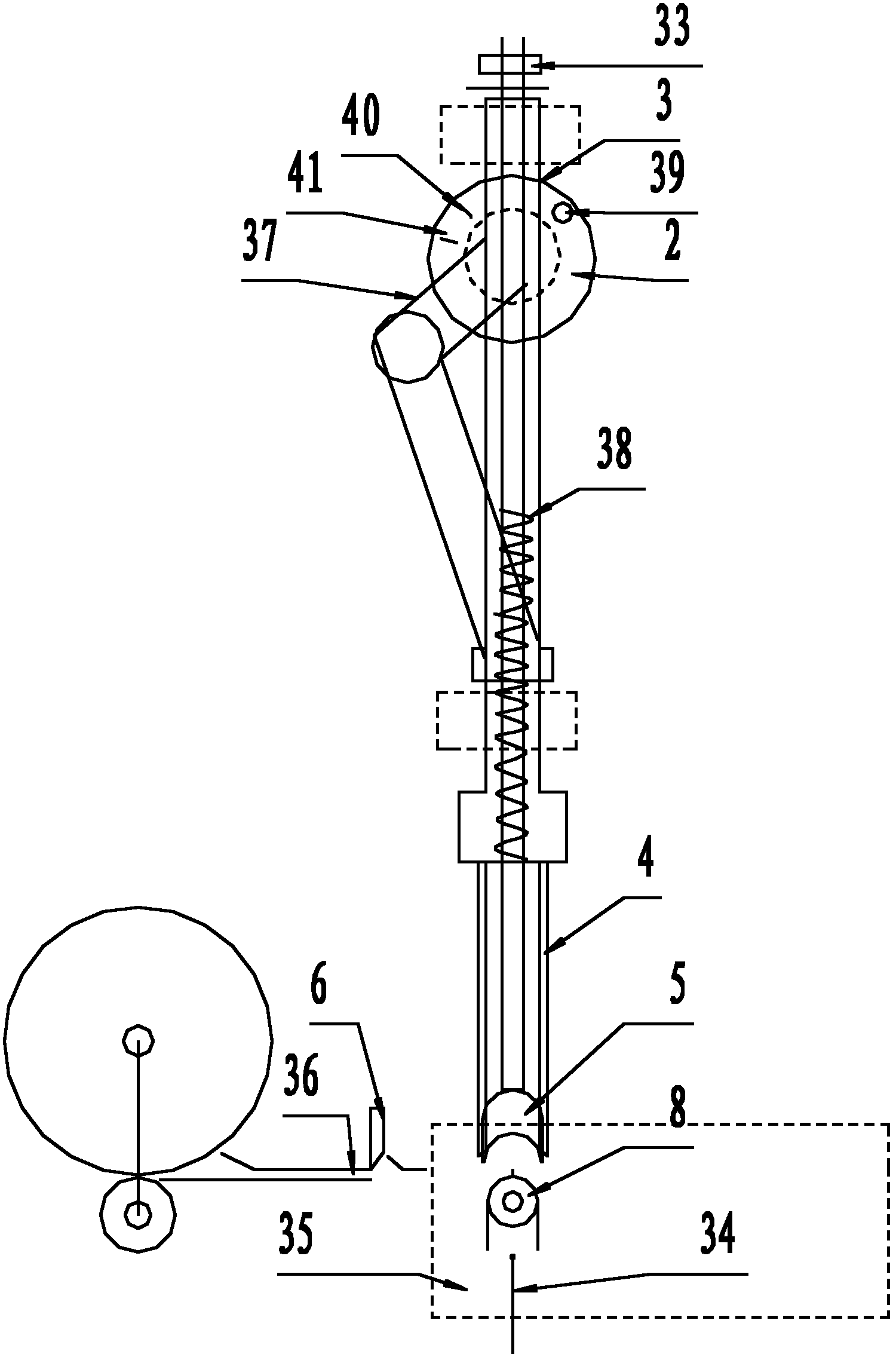

Drilling and lead inserting system for assembling firework

The invention discloses a drilling and lead inserting system for assembling a firework. The system comprises a needle bar, a lead feeding device, a numerical control system and a driving and transmission system, wherein the needle bar can move upwards and downwards in a reciprocating way; the lower end of the needle bar is provided with an n-shaped drilling and lead inserting device which consists of two parallel drilling needles; a large movable tongue and a small movable tongue are arranged between the two drilling needles; the lead feeding device consists of at least one lead supply wheel and a lead guide groove; and the driving and transmission system comprises at least one driving motor and a plurality of transmission devices, is connected with an electromagnet of the numerical control system and is used for driving and controlling every component of the drilling and lead inserting system to run synchronously. The drilling and lead inserting system is arranged above a firecrackerbarrel conveying passageway, can be used for accurately finishing a series of works such as lead supply, lead cutting, lead inserting and the like, has high degree of automation, high working efficiency and working reliability; and drilling and lead inserting are finished synchronously, and the lead inserting quality of is effectively ensured.

Owner:宋俊钦

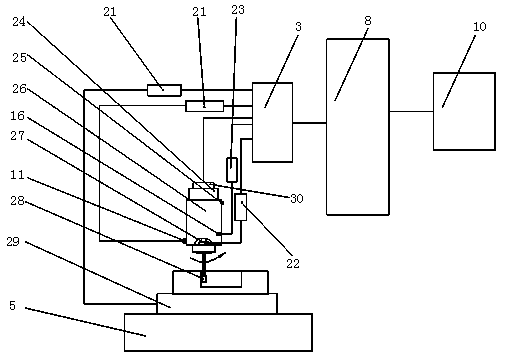

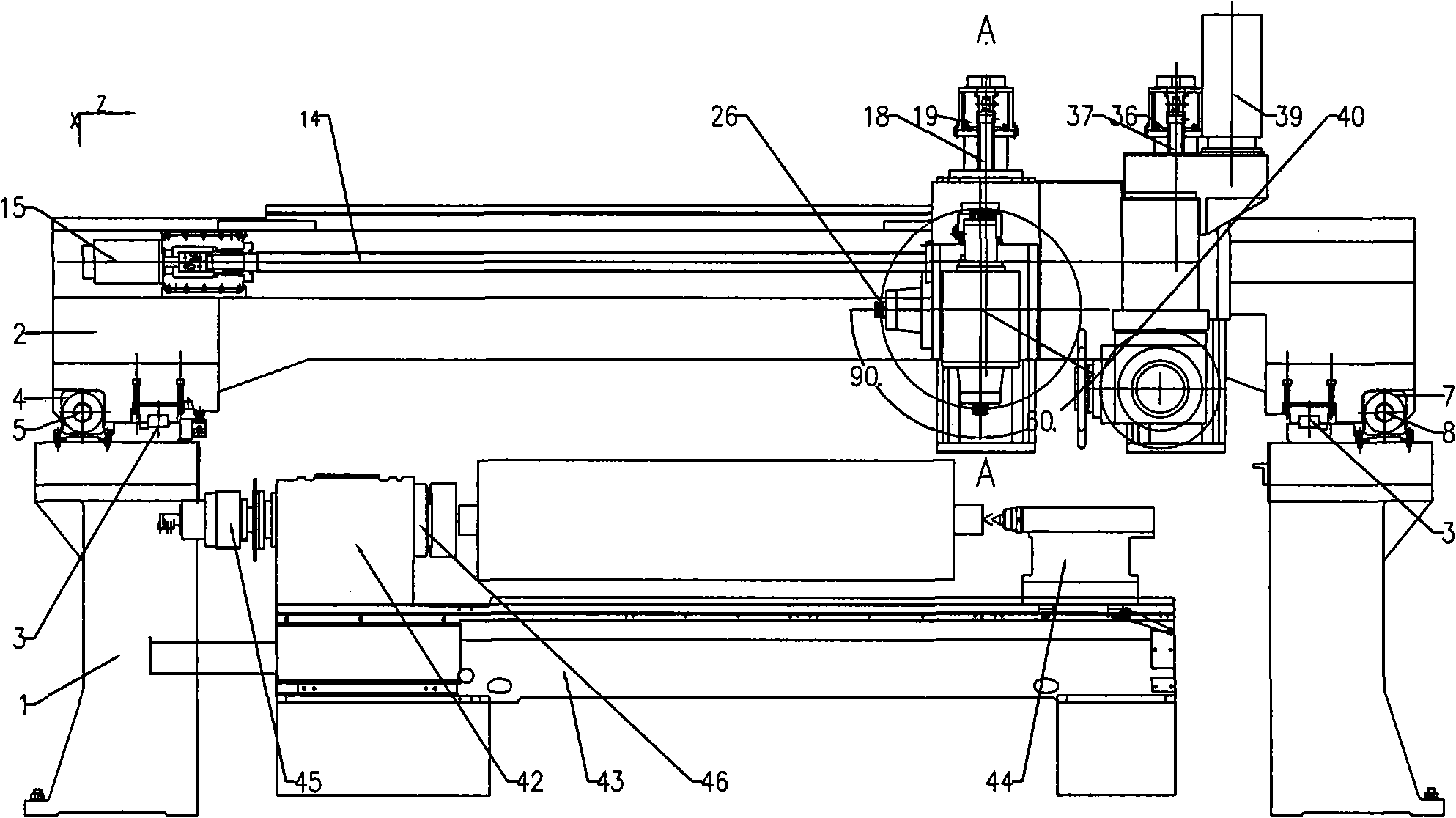

Combined additive and subtractive manufacturing machine tool

ActiveCN104384936AGuaranteed complexityGuaranteed processing effectOther manufacturing equipments/toolsUltrasonic vibrationMachining process

The invention belongs to the field of machine tool design, and relates to a combined additive and subtractive manufacturing machine tool, which comprises a body, a workbench, a main shaft, a numerical control system, a subtractive machining module and an additive manufacturing module. According to the combined additive and subtractive manufacturing machine tool, the additive manufacturing module is controlled by the numerical control system to form a basic structure of a required part on the workbench, then the subtractive machining module is controlled by the numerical control system to perform subtractive machining on the basic structure obtained by additive manufacturing, a function of applying ultrasonic vibration to a cutter and a gas cooling function are realized in a subtractive machining process, and the whole combined additive / subtractive manufacturing process is finally implemented. The combined additive and subtractive manufacturing machine tool can be used for realizing the efficient and precise combined additive and subtractive manufacturing of the component, the manufacturability of a complex part is improved, the production cycle is shortened, and the manufacturing accuracy of the complex part is ensured.

Owner:DALIAN UNIV OF TECH

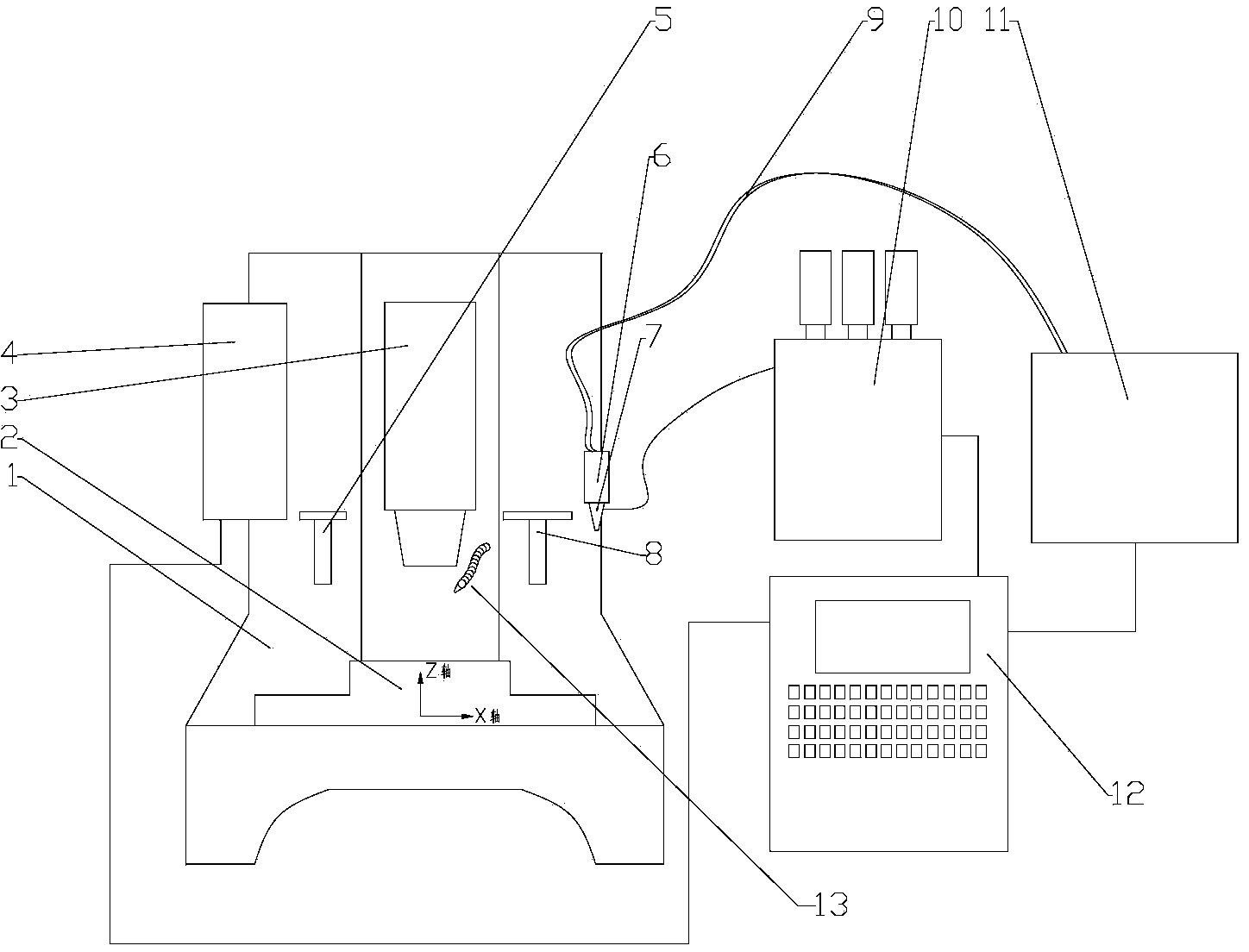

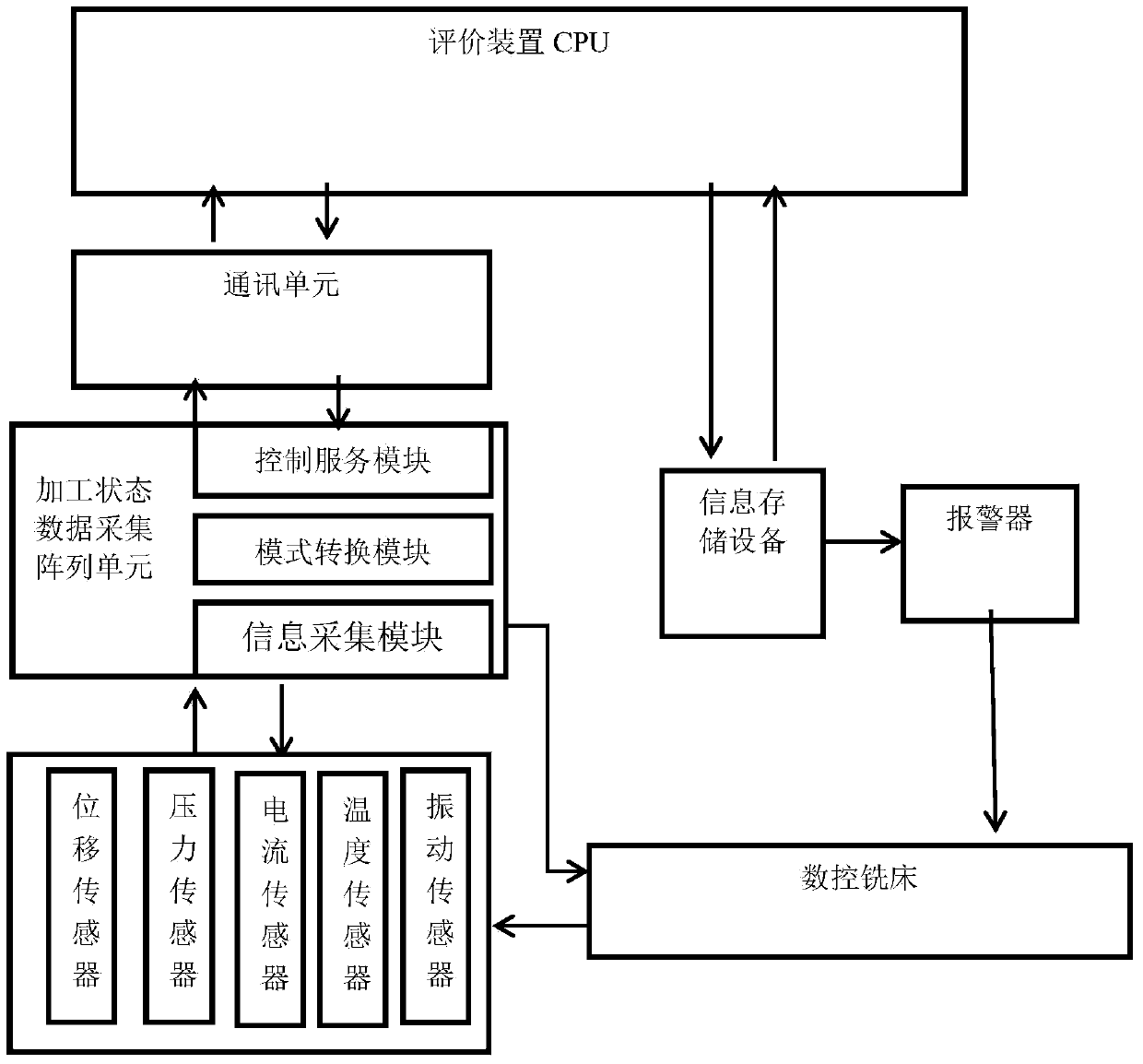

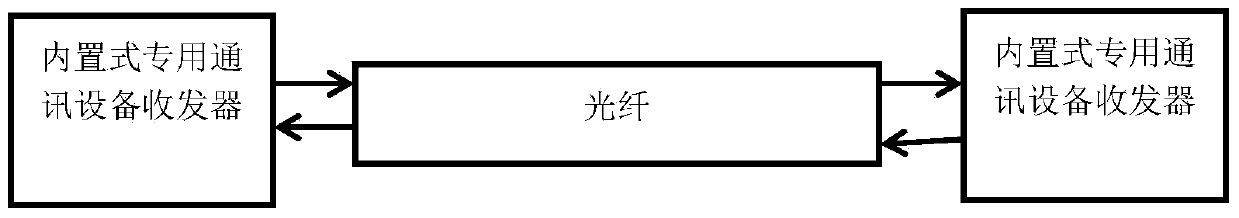

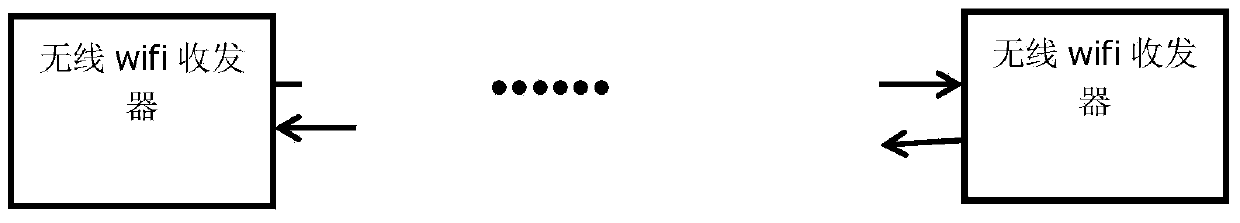

Evaluation device of state information of machining process of numerical control milling machine

InactiveCN103760820AImprove processing qualityImprove efficiencyProgramme controlComputer controlMaterial defectCommunication unit

The invention discloses an evaluation device of state information of the machining process of a numerical control milling machine. A machining state data collecting array device, an information storage device, a numerical control system and the like on a machine tool are connected into a semi-closed-loop control circuit through the evaluation device MCU. A machining state data collecting array collects state data of main shaft currents, feed currents, vibration, machining temperatures and the like in the machining process of the numerical control machine tool and can intelligently identify abnormal states of abrasion and breakage of a cutter, material defects of workpiece blank and the like. A communication unit can achieve real-time connection between the machining state information collecting array and the evaluation device MCU. The evaluation device MCU checks and analyzes collected machining state parameters according to a certain algorithm, generates a check report and guides the information storage device to update the optimal parameter record. Meanwhile, the evaluation device has the prejudgment function, submits alarming when meeting with problems which cannot be dealt with and meanwhile analyzes corresponding error reasons and provides proper solutions. According to the evaluation device of the state information of the machining process of the numerical control milling machine, the machining parameters of the milling machine and the state information of the machining process are checked.

Owner:HUAZHONG UNIV OF SCI & TECH

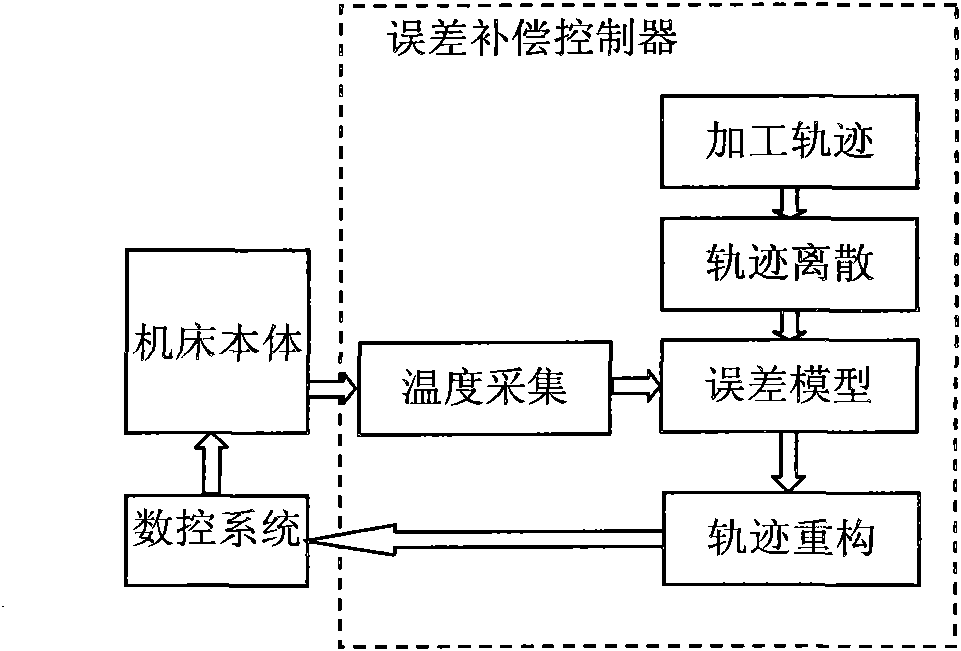

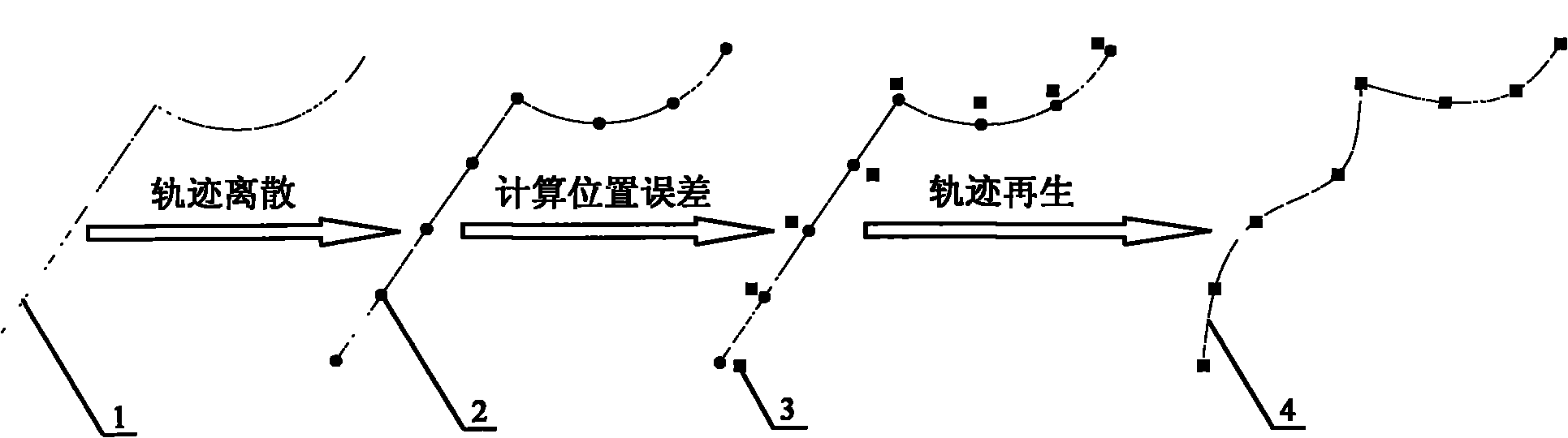

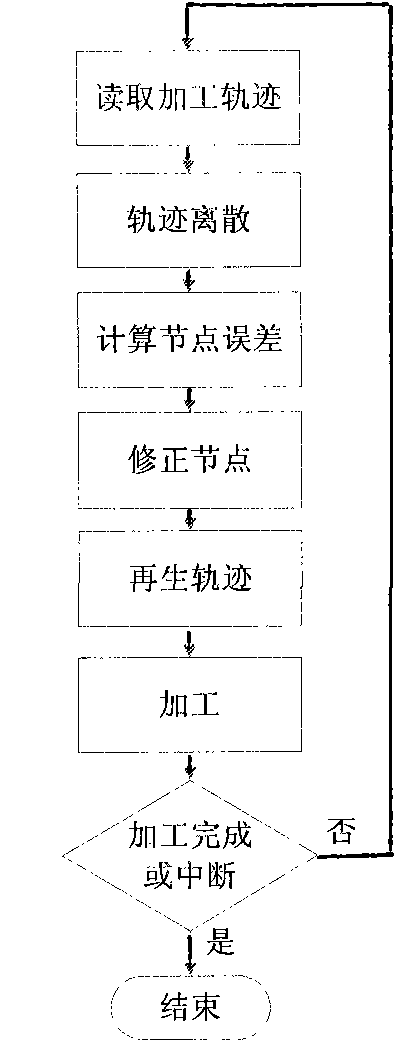

Trajectory regeneration compensation method of numerical control machine error

InactiveCN101943896AImprove machining accuracySimple structureProgramme controlComputer controlEngineeringControl theory

The invention discloses a trajectory regeneration compensation method of numerical control machine error. The method comprises the steps that: at first, a temperature sensor is arranged on a numerical control machine to measure geometrical error and thermal error of the machine, and then a machine error model is established; second, an error compensation controller diverges a numerical control trajectory to be processed and reads data from the temperature sensor; afterwards, the error compensation controller substitutes a node coordinate subsequent to divergence and temperature data in the machine error model to obtain an error to which the coordinate is corresponding, the error is then superposed on the coordinate of the node, and the numerical trajectory is reconstructed according to the corrected coordinate; and finally, the error compensation controller transfers the reconstructed trajectory to numerical control system for being processed, so as to realize the compensation for numerical control machine error. Compared with other compensation methods, the method according to the invention has the advantages of great flexibility and convenience, strong adaptability and no need of changing numerical control system, etc.

Owner:ZHEJIANG UNIV

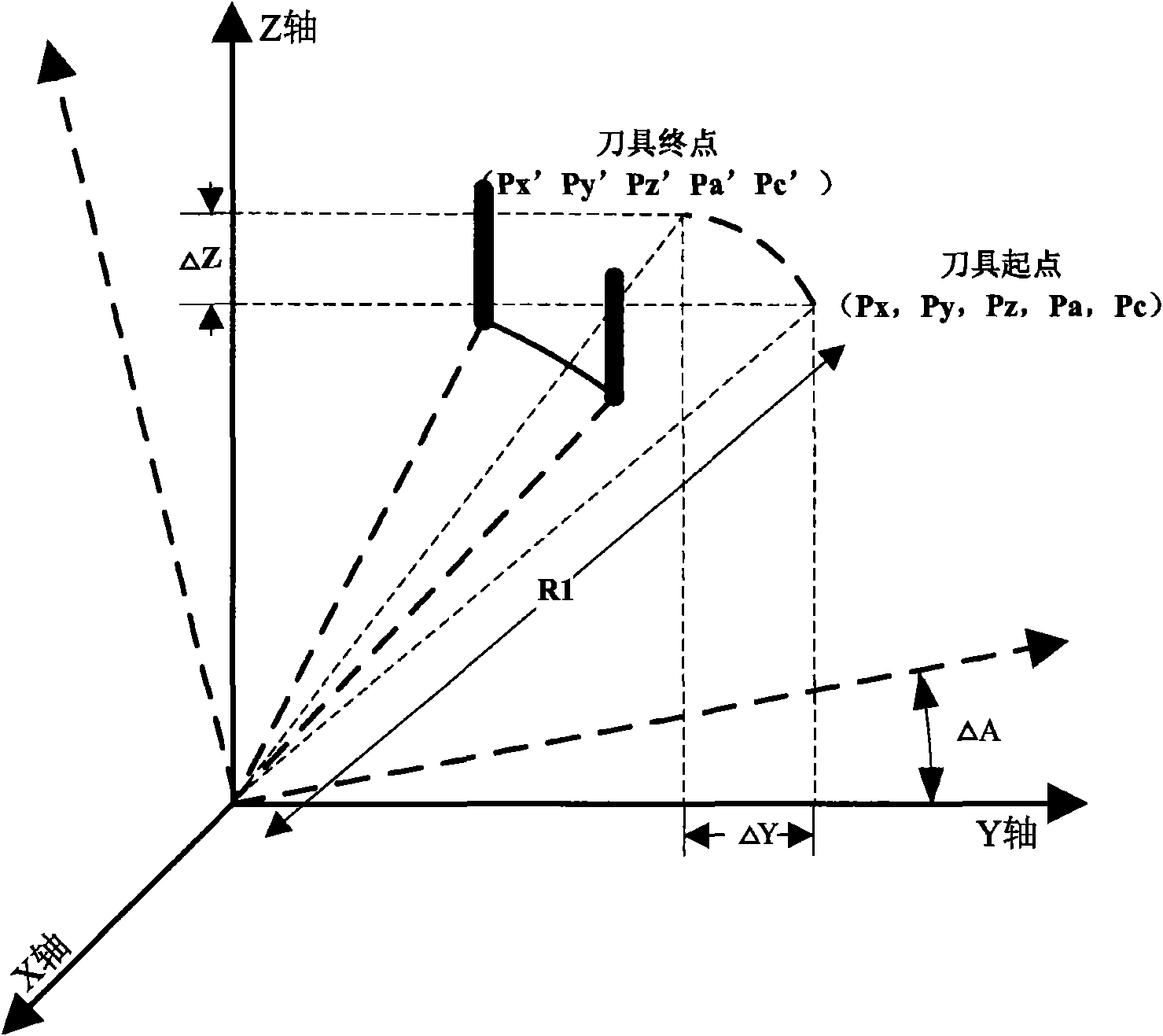

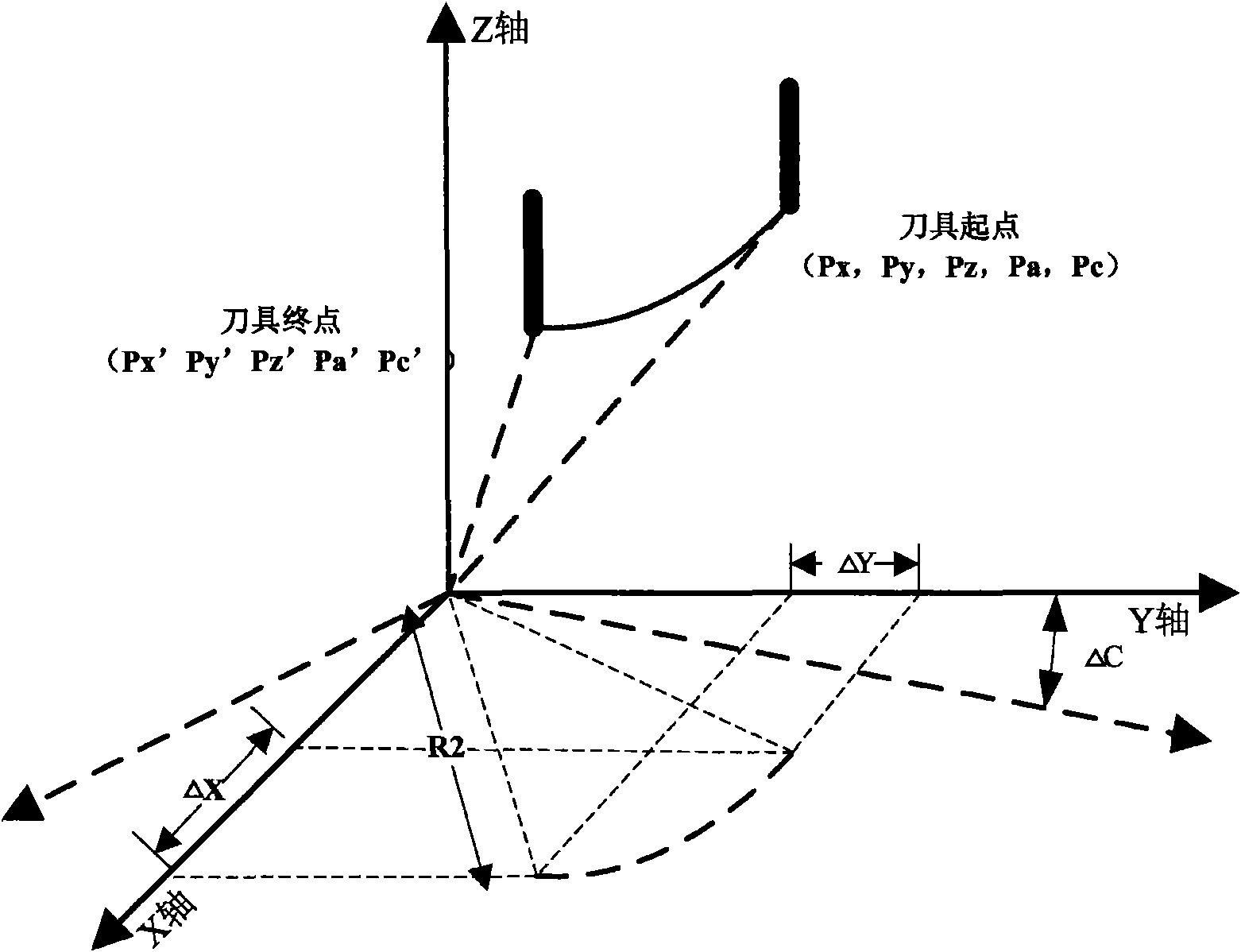

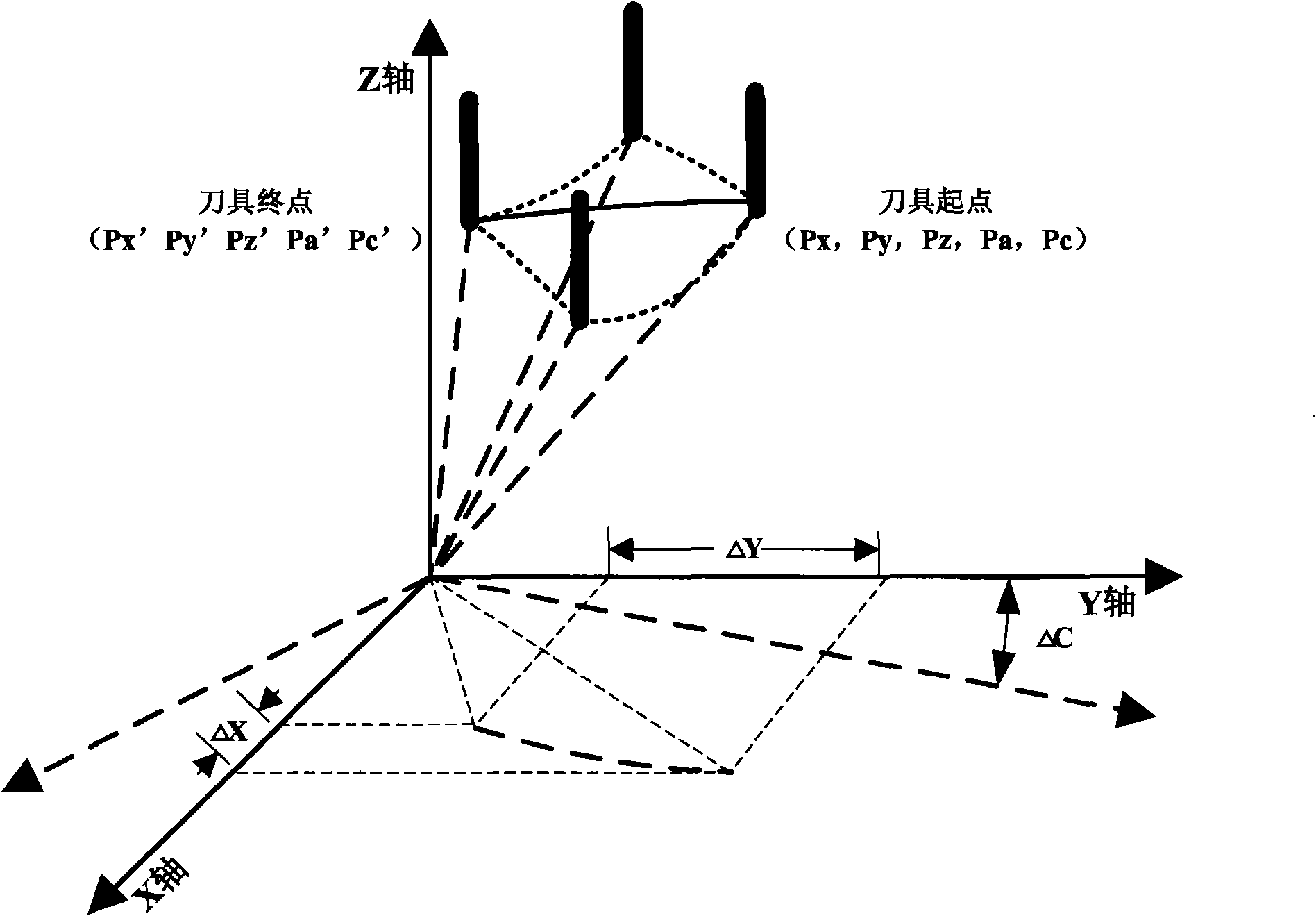

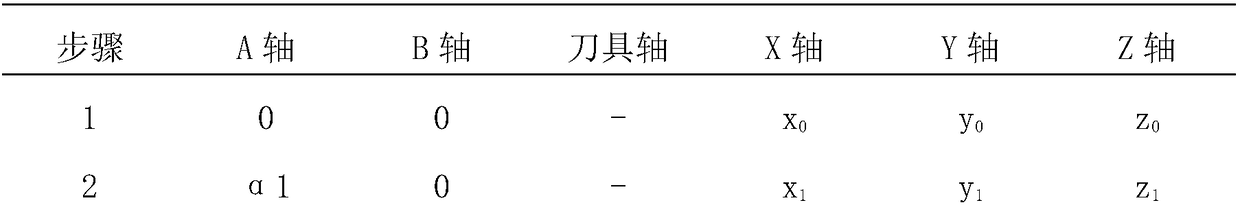

Method for compensating central point of double-turntable five-axis linked numerical control machining rotary tool

InactiveCN101980091ASolve the problem of nonlinear motion errorImprove performanceProgramme controlComputer controlLinear motionNonlinear motion

The invention discloses a method for compensating a central point of a double-turntable five-axis linked numerical control machining rotary tool. The method is characterized by comprising the following steps of: when a tool trace of a double-turntable five-axis linked numerical control system which machines a spatial complex curved surface is a straight line, discretely approximating the movement trace of the central point of the tool through line interpolation, starting a real time control protocol (RTCP) module, obtaining a normal plane compensation vector and performing projection to obtain a central point compensation vector and output displacement by using the RTCP module, and inputting a number axis center distance parameter to realize the compensation of a nonlinear movement error during the machining of the double-turntable five-axis linked numerical control system. The method can well inhibit the nonlinear movement error, so that the running efficiency of the numerical control machining equipment is improved, the numerical control equipment can perform high-precision and high-efficiency machining, the machining quality of parts can be remarkably improved, and the method has excellent application prospect in the field of mechanical engineering.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

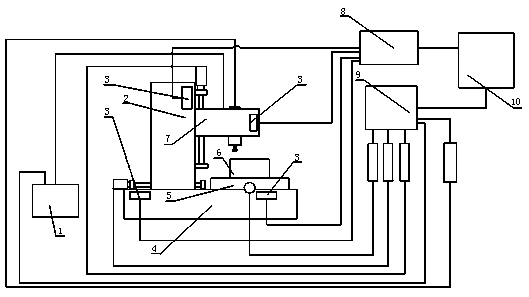

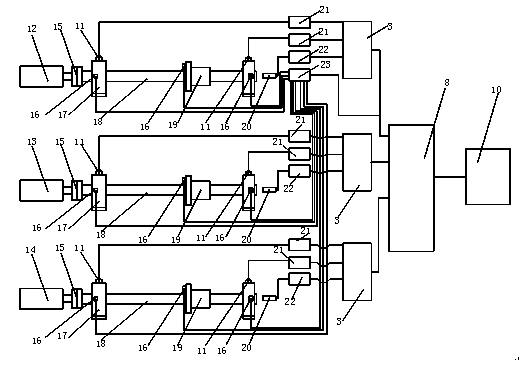

Numerical machine tool machining state multi-parameter online active monitoring system and implement method thereof

ActiveCN103823409AImprove processing qualityImprove processing efficiencyProgramme controlComputer controlActive monitoringState parameter

The invention discloses a numerical machine tool machining state multi-parameter online active monitoring system and an implement method thereof. The system and the method mainly solve the problems that state detection performance indexes of an existing numerical control machine tool are not comprehensive, and closed-loop control during the machining process can not be achieved. The numerical machine tool machining state multi-parameter online active monitoring system comprises a first sensor assembly arranged on a numerical control machine tool servo feeding unit, a second sensor assembly arranged on a main shaft unit, a third sensor assembly disposed on a cooling liquid circulating unit and a multi-channel synchronous data collecting PXI box used for receiving information of collected data. The multi-channel synchronous data collecting PXI box sends related collected state signals to a monitoring computer in real time for analysis, calculation, display and storage, the monitoring computer generates related control instructions according to abnormal or optimized machining state parameters, transmits the related control instructions to a numerical control system of the numerical control machine tool through an Ethernet bus and executes related active control instruments, and accordingly real-time adjustment and control of numerical control machining process states are finished.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

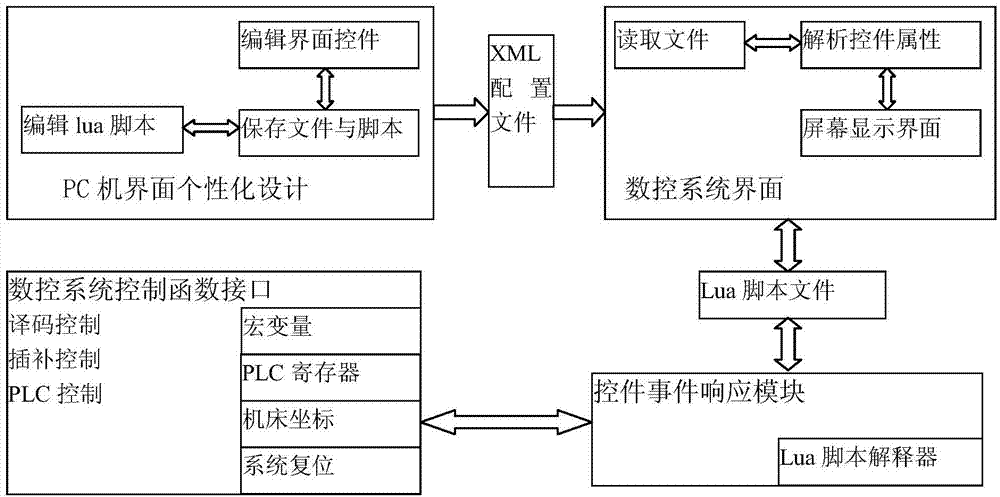

Human-machine interface customizable configuration design method for open type numerical control system

ActiveCN104731584AImprove portabilityReduce development costsSpecific program execution arrangementsPersonalizationHuman–machine interface

The invention discloses a human-machine interface customizable configuration design method for an open type numerical control system. A programming method oriented to an object is adopted, a self-drawing control operating function is derived out of an LUA interface, a control tree structure is organized and managed in a combined mode, personalized interface design and customization are conducted, and a personalized interface is stored in an XML file. An internal variable and an operating interface in the numerical control system are derived out and correlated with an LUA function in response to a control event, an LUA script file can be directly called, the requirements for human-machine interface and control flow customization of the numerical control system are met, interface display and numerical control software can be independently compiled and debugged, transplantability is high, and development cost is reduced.

Owner:WUHAN AIKEWEI AUTOMATION TECH CO LTD

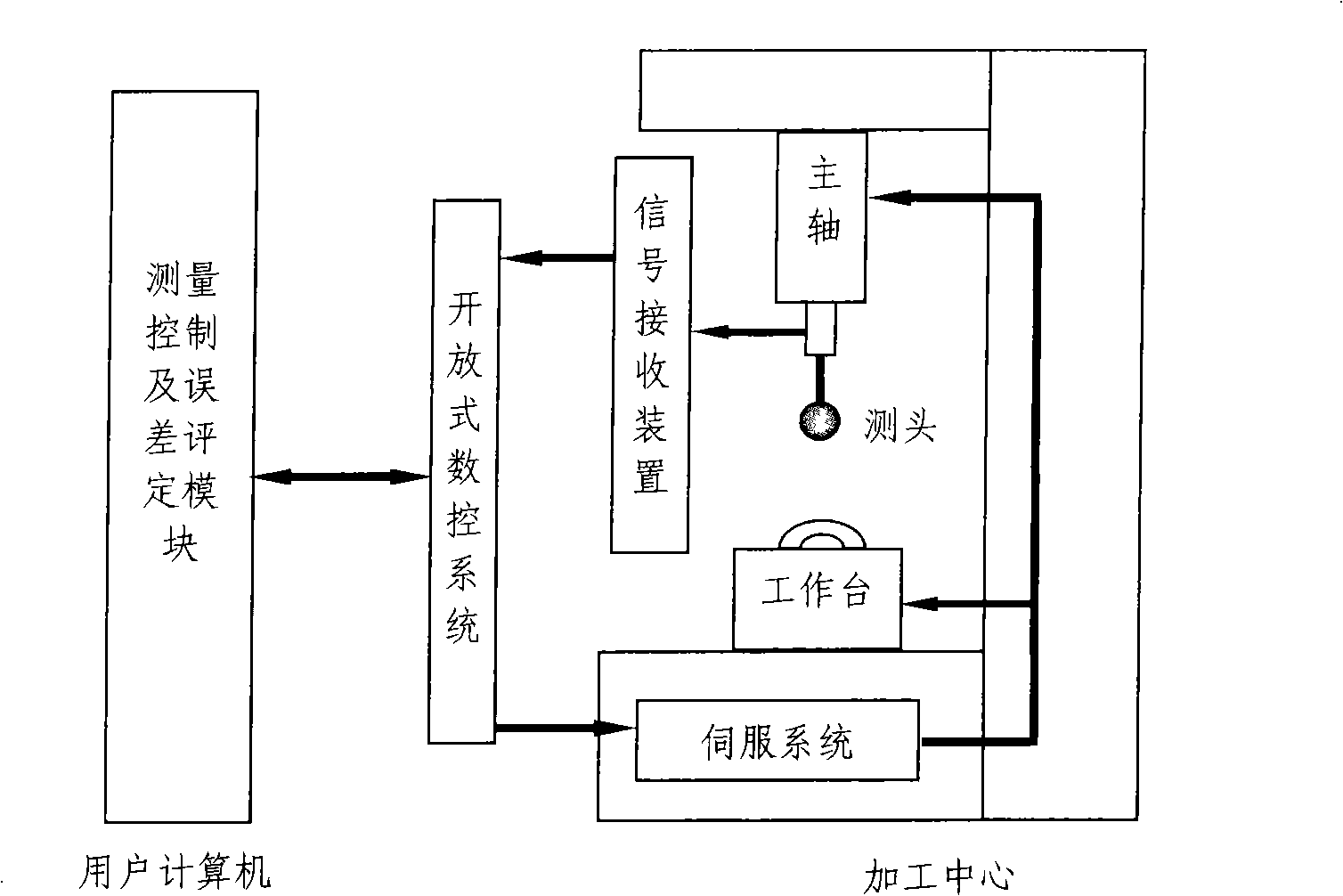

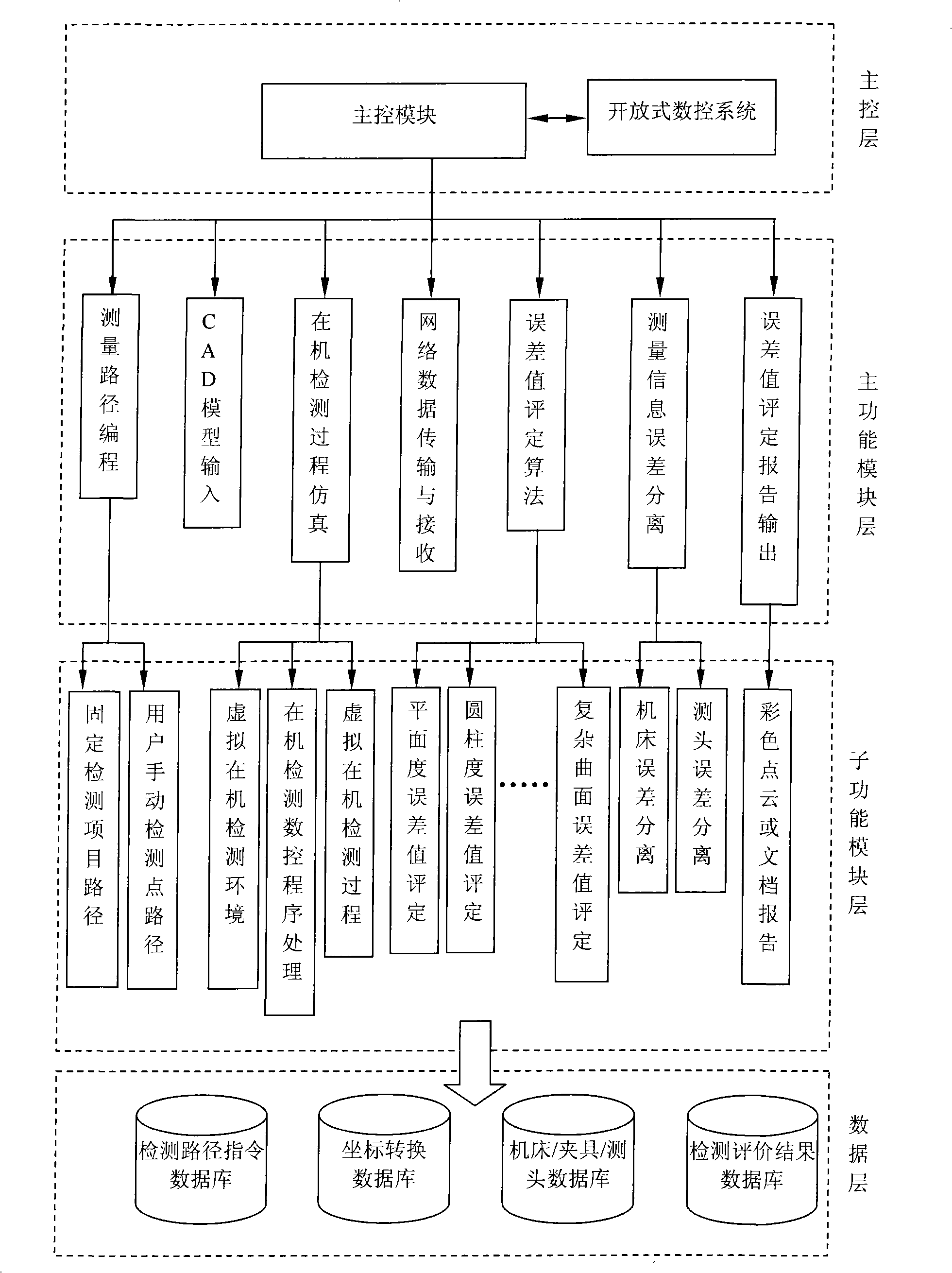

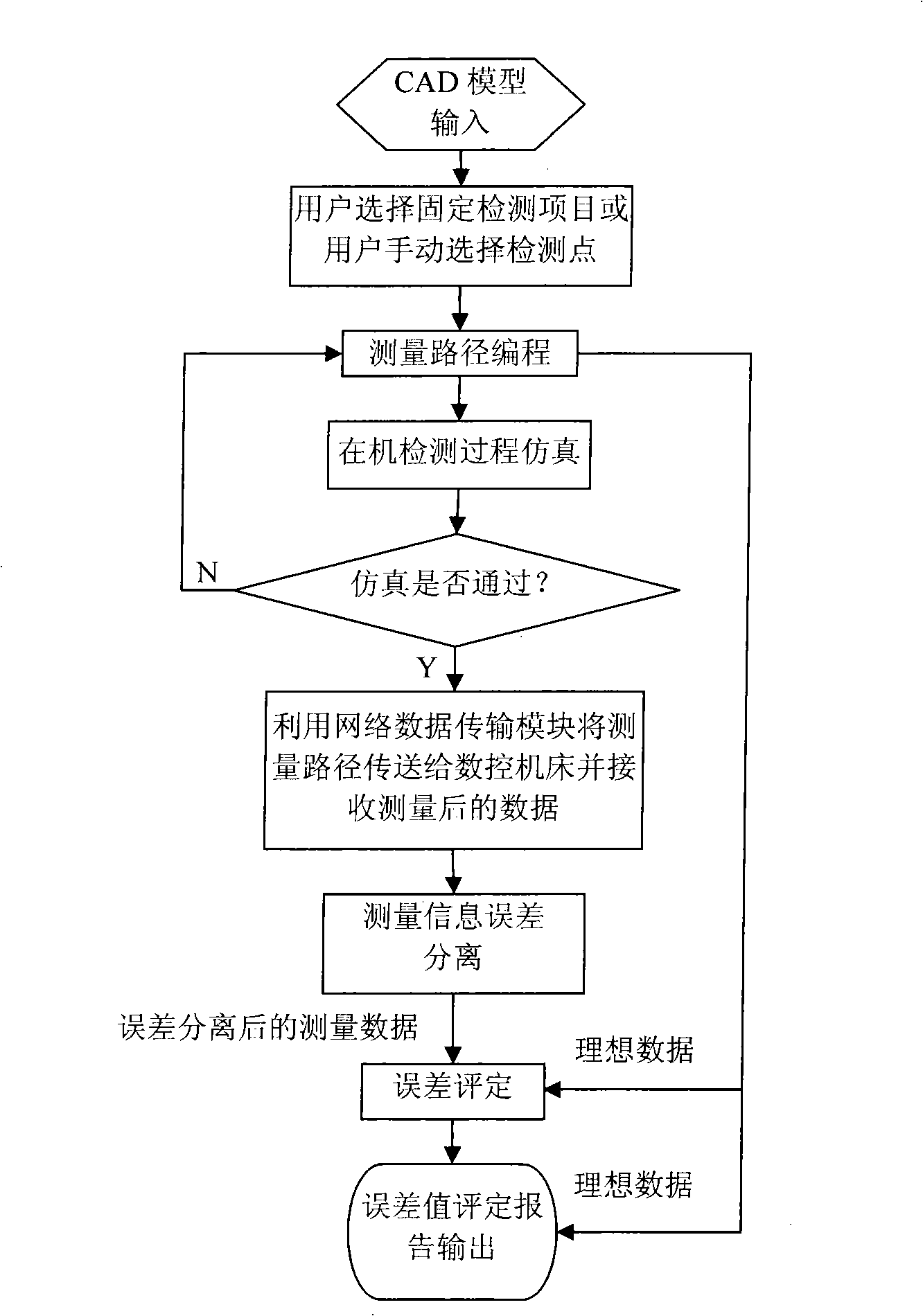

On-machine quality detecting system for complex space type surface

ActiveCN101342664AGuaranteed machining accuracyIncrease productivityProgramme controlComputer controlCommunications systemData exchange

The invention discloses a complex space surface on-machine quality test system, comprising a processing center, three coordinate probes and a measuring signal receiver. The processing center is used to process parts and is equipped with an open numerical control system. The probes are controlled by the numerical control system of a numerically controlled machine tool, and are used to obtain the geometrical measurement value of the discrete points on the surface of the workpiece which has been processed. The measuring signal receiver is used to receive the infrared signals sent by the probes, and transmits the signals to the numerical control system. The numerical control system transmits the measurement value signals to the computer of the user through a communication system, and controls the main shaft of the numerically controlled machine tool to stop moving at the same time. The computer of the user which is provided with a measurement control and error evaluation module is used to exchange data with the numerical control system through the communication system, and evaluates the error and gives an evaluation result based on the ideal value and measurement value of measuring points through the measurement control and error evaluation module. The complex space surface on-machine quality test system can inspect the quality of the workpiece at any moment during processing, guarantees the processing precision of the workpiece, and saves time.

Owner:TIANJIN UNIV

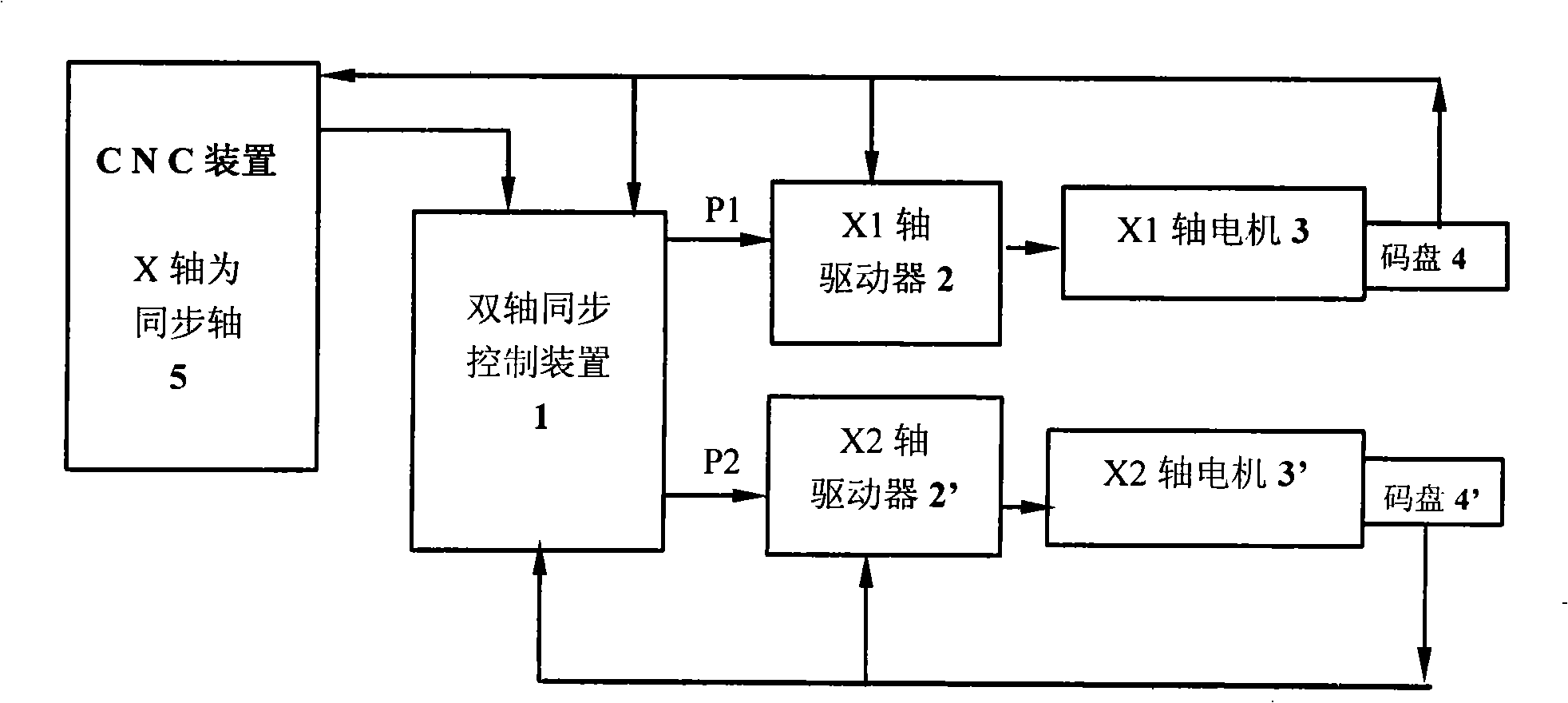

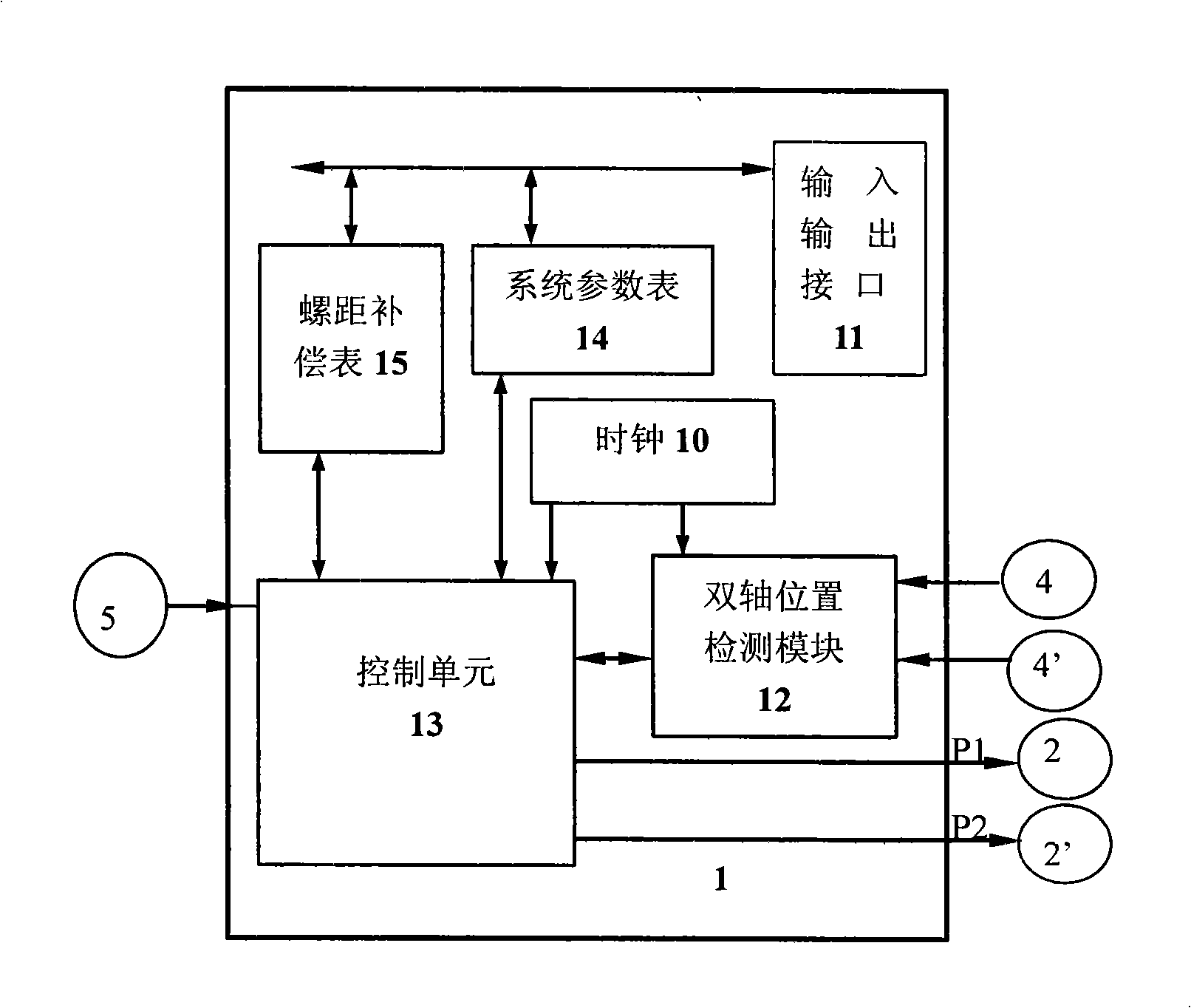

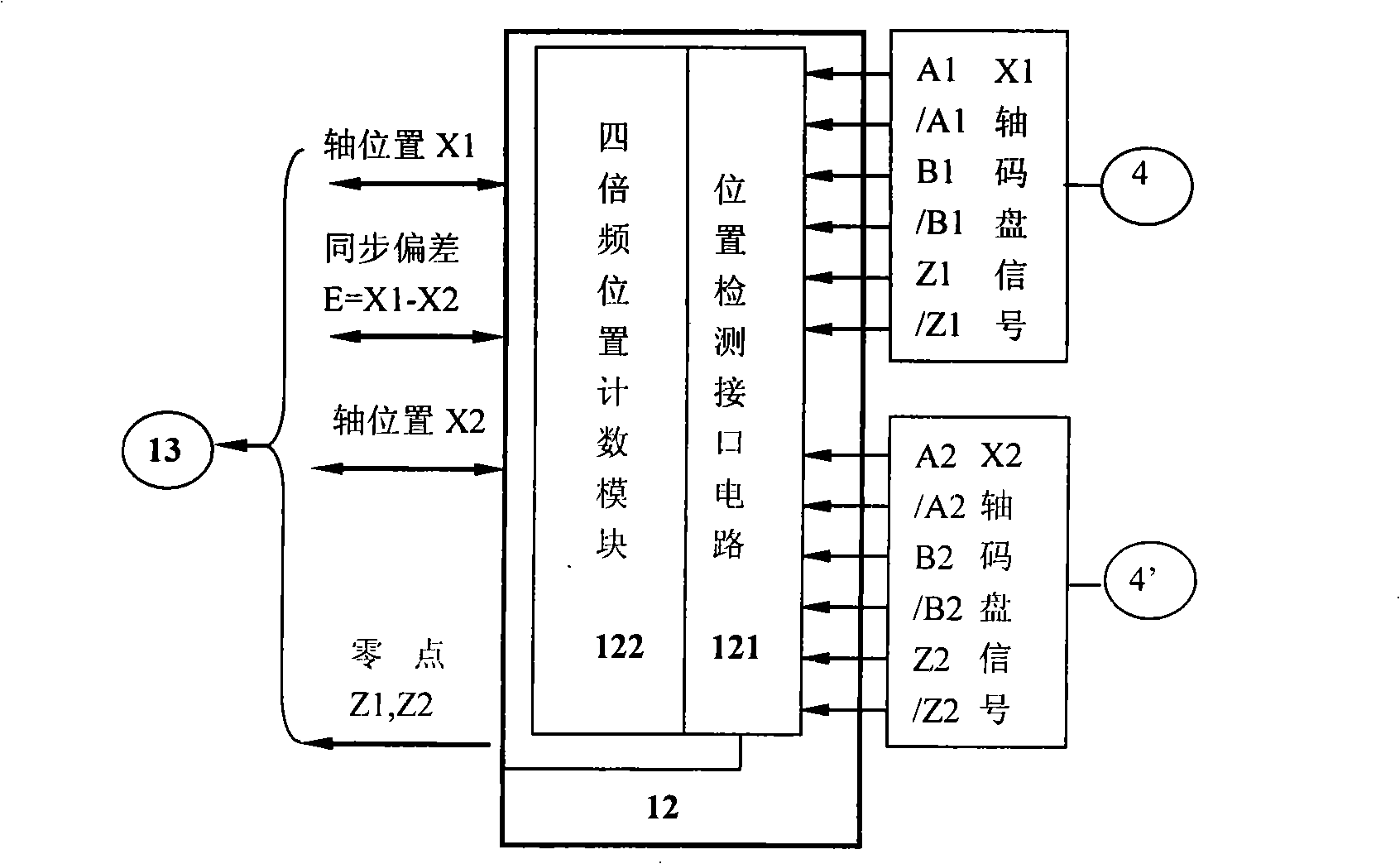

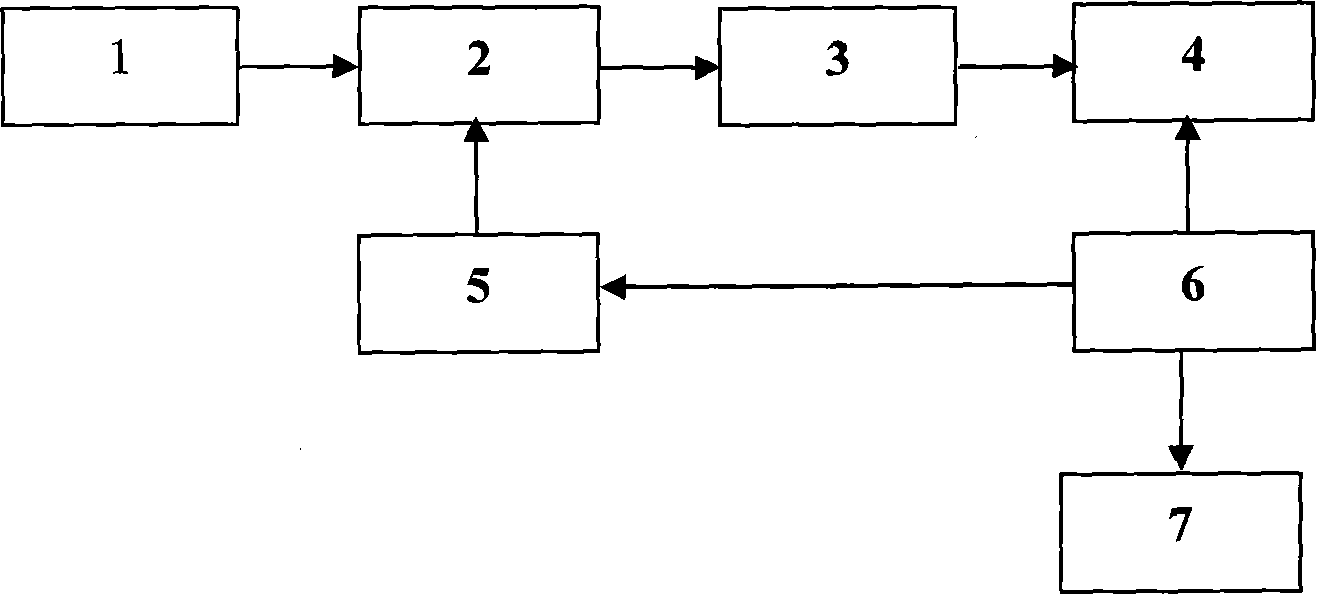

Numerical control machine tool double-shaft synchronization controller

InactiveCN101349910AAvoid wear and tearSolve the problem that synchronous control cannot be realizedProgramme controlComputer controlError checkSynchronous motor

The invention discloses a digit control machine double-shaft synchronization control device, comprising a clock, an input and output interface, a double-shaft position check module, a control unit, a system parameter list and a pitch compensation list, wherein the double-shaft position check module processes position and synchronization error check for two synchronous shaft motor encoders and provides the check information to the control unit, the control unit selects a working mode corresponding to the parameters of the system parameter list, according to the position and error information of the two synchronous shafts provided with the double-shaft position check module and the process corresponding to the selected working mode, the control on the two synchronous shafts can be realized. The invention resolves the problem of the common digit control system which can not realize synchronous control, realizes the real-time character between transfer and adjustment, avoids the profile error of processed elements caused by delayed transfer time, and avoids the serious dynamic synchronous error caused by long adjustment.

Owner:HUAZHONG UNIV OF SCI & TECH

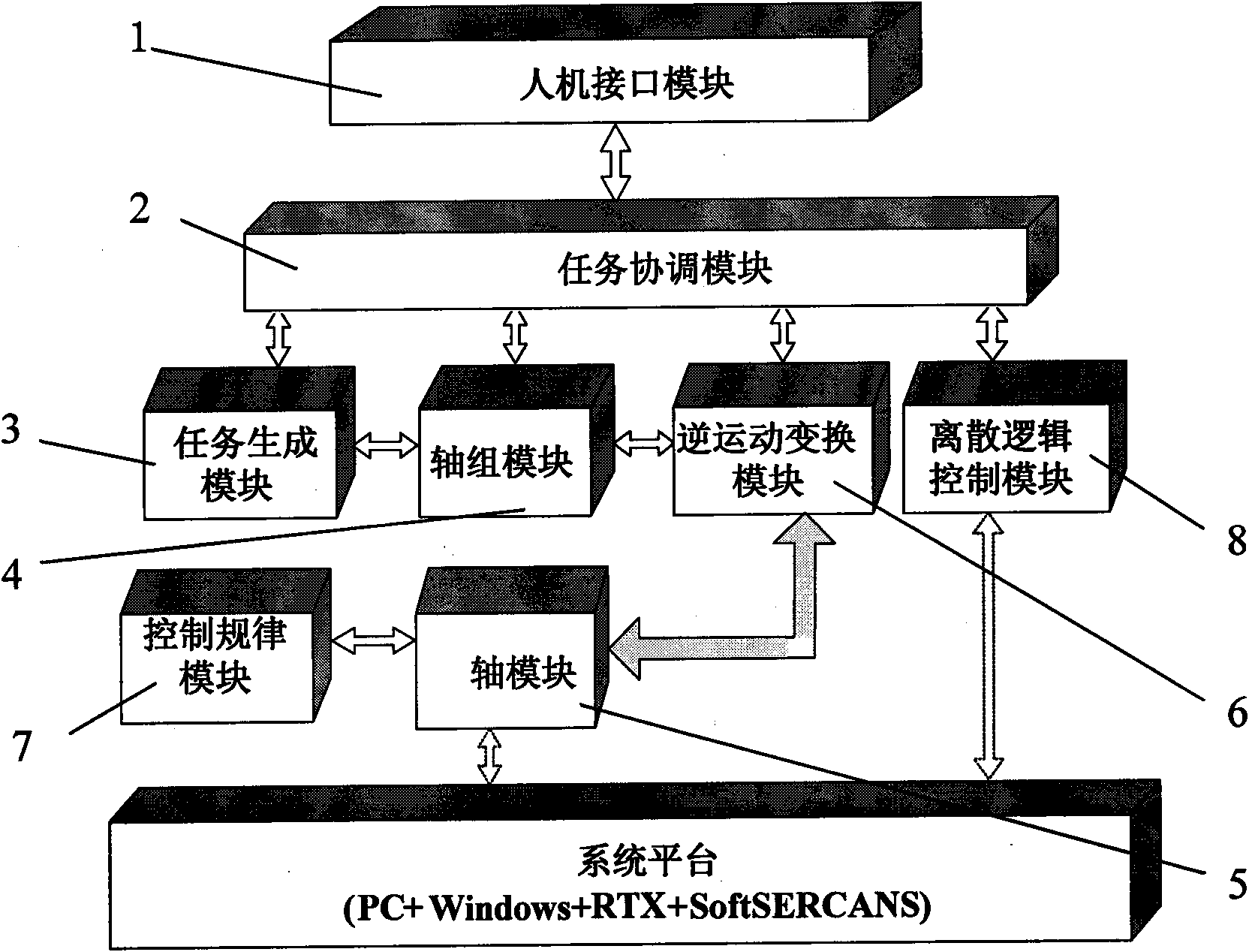

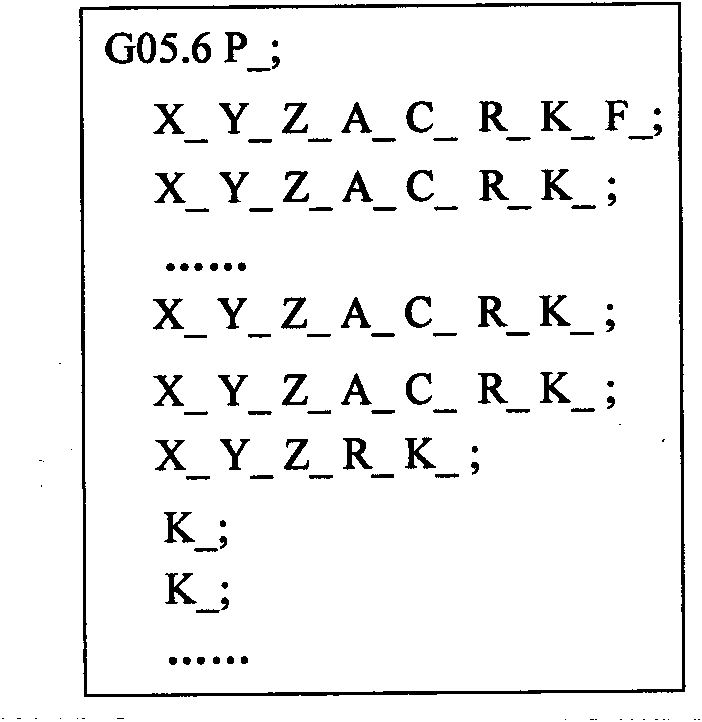

Five-coordination numerical control machine tool motion controller with NURBS interpolation function

The invention discloses a five-coordination numerical control machine tool motion controller with an interpolation function, and relates to a numerical control machine tool motion controller. The purpose of the invention is to solve the problems that the functions of the controller can not be easy to be expanded and modified, which is caused by the poor openness and flexibility of the existing numerical control machine tool motion controller, and the requirements of a configurable motion controller can not be met, and NC program size is seriously limited, which is caused by the multiplication of information amount in the controller by adopting a type value point direct interpolation method. The motion controller comprises a man-machine interface module, a task coordination module, a task generation module, an axis group module, an axis module, a reverse motion transformation module, a control rule module and a discrete logic control module. When the NURBS interpolation method of the invention is adopted to carry out NC machining, the NC program is reduced substantially; meanwhile, the machining error is more greatly reduced than the linear interpolation error. By adopting a modularized systematic structure, the requirements of the configurable motion controller can be met, the openness of the numerical control system can be enhanced, and the function expansion and modification of the controller can be carried out on the specific modules.

Owner:HARBIN INST OF TECH

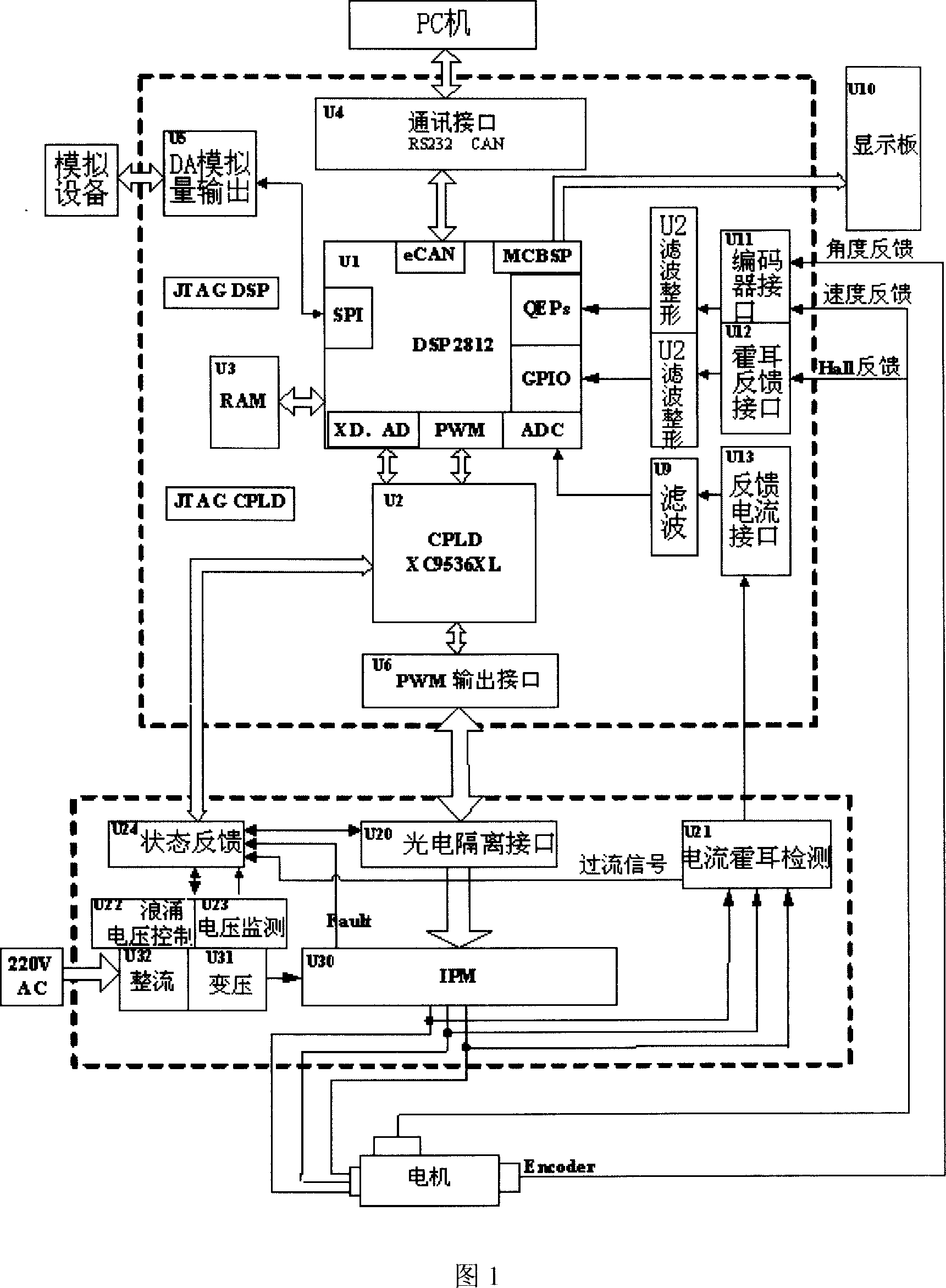

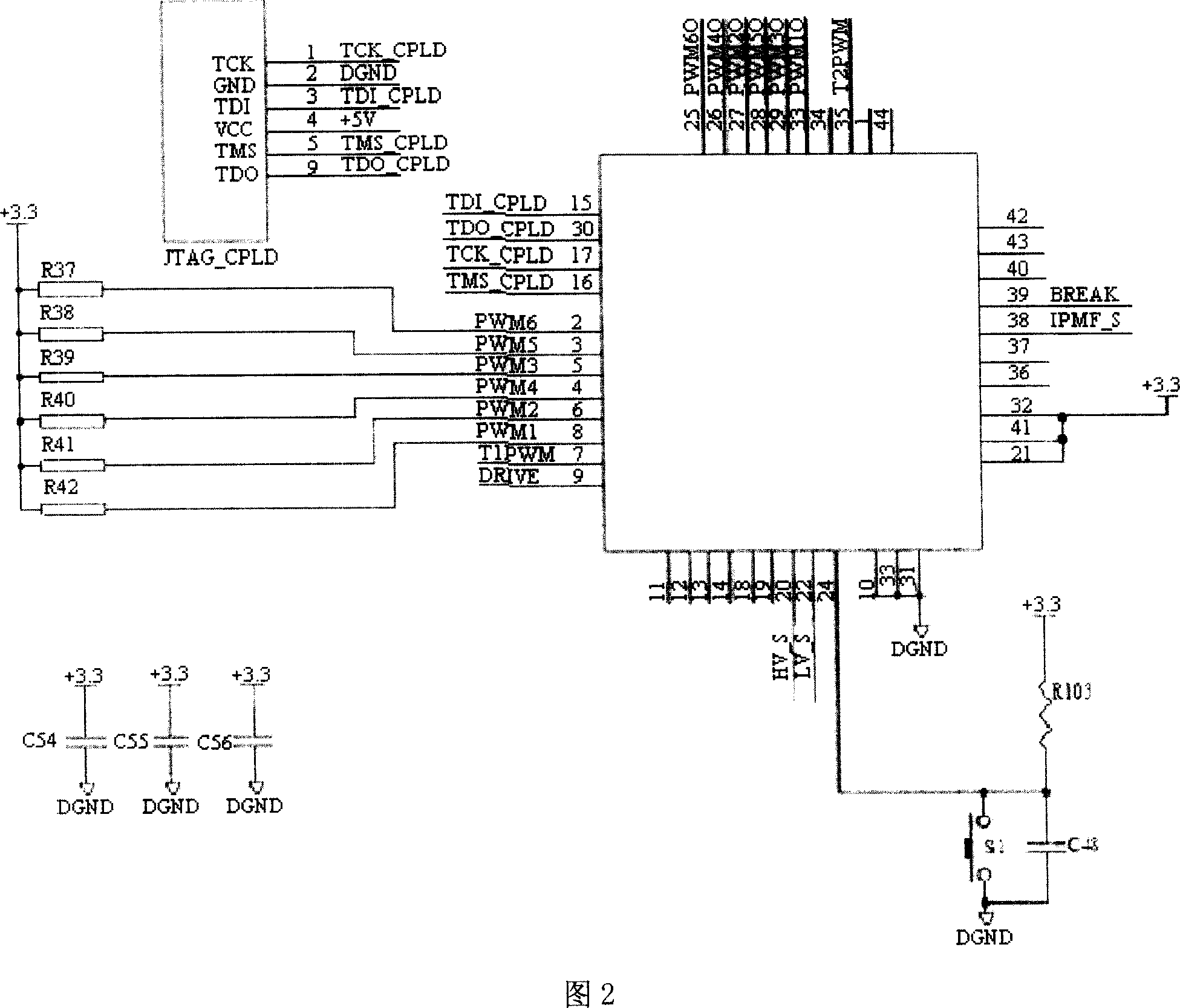

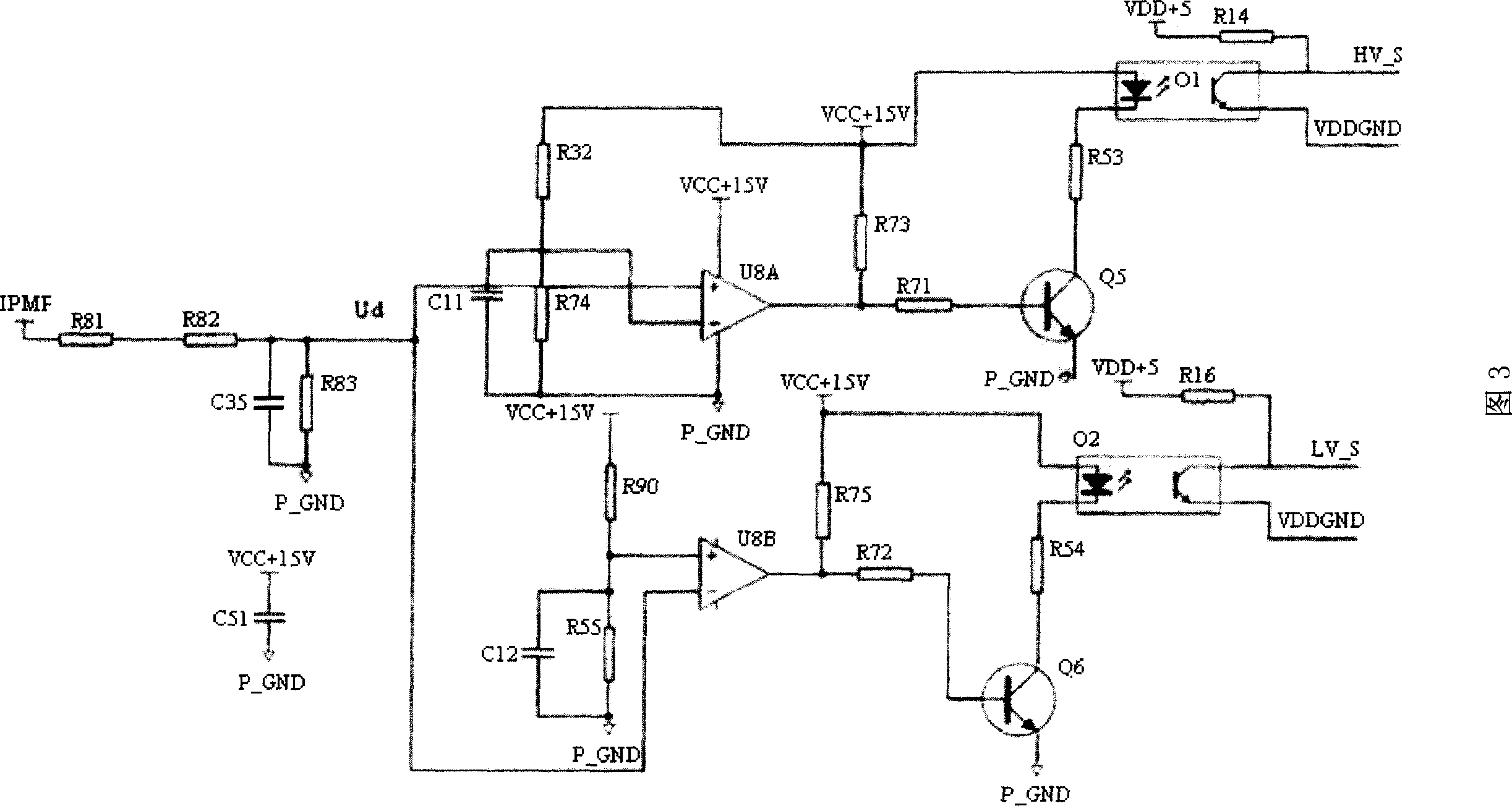

DSP-based electric machine position servo device

InactiveCN1955868ARealize closed-loop servo controlImprove reliabilitySingle motor speed/torque controlControl using feedbackProgrammable logic deviceElectric machine

A servo device of motor position based on DSP consists of brushless DC motor being used as servo motor as its servo device being suitably set on digital control system requiring position control response quickly, control circuit being designed independently by DSP and programming logic component for realizing closed loop servo control of current loop and speed loop as well as position loop.

Owner:HARBIN ENG UNIV

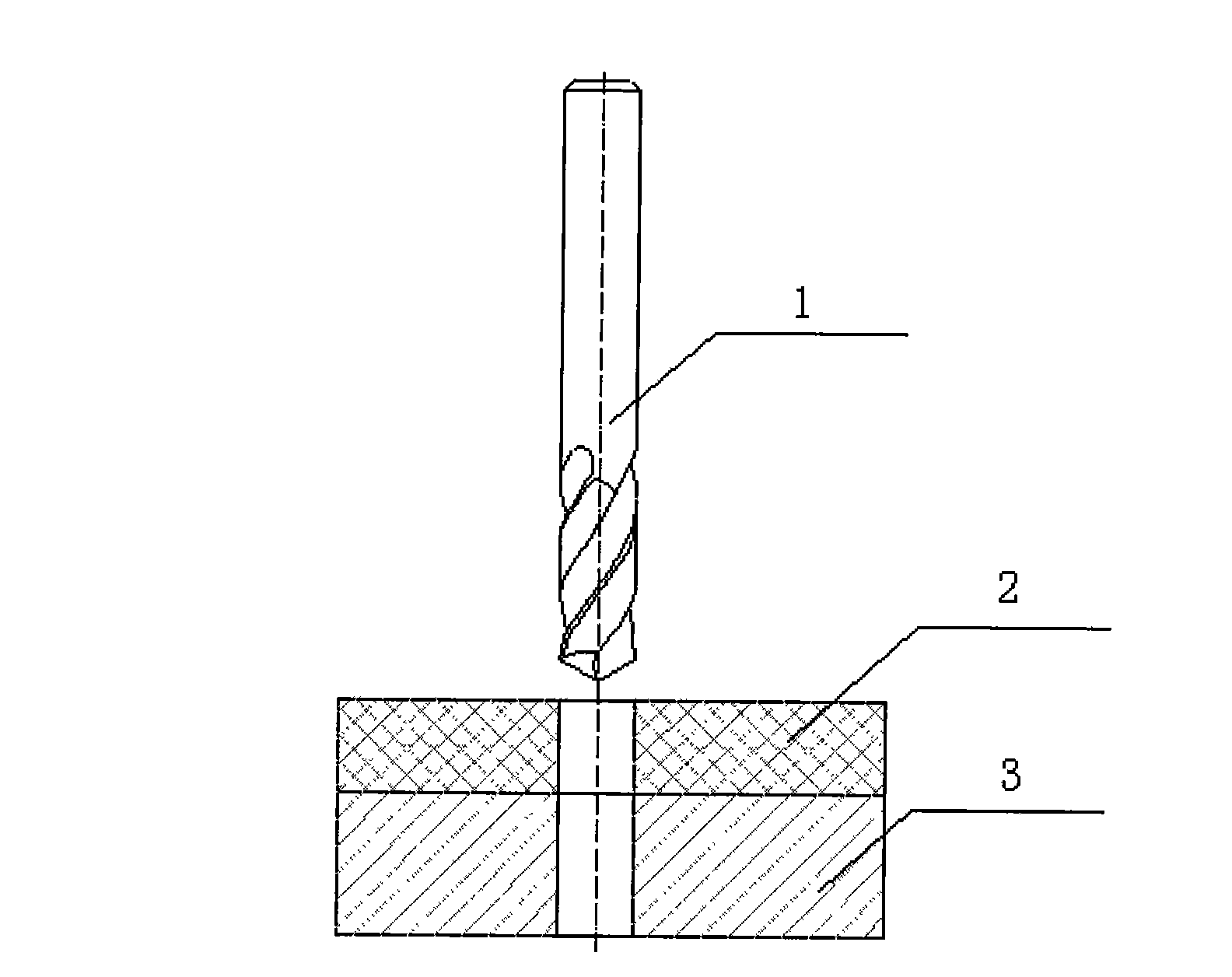

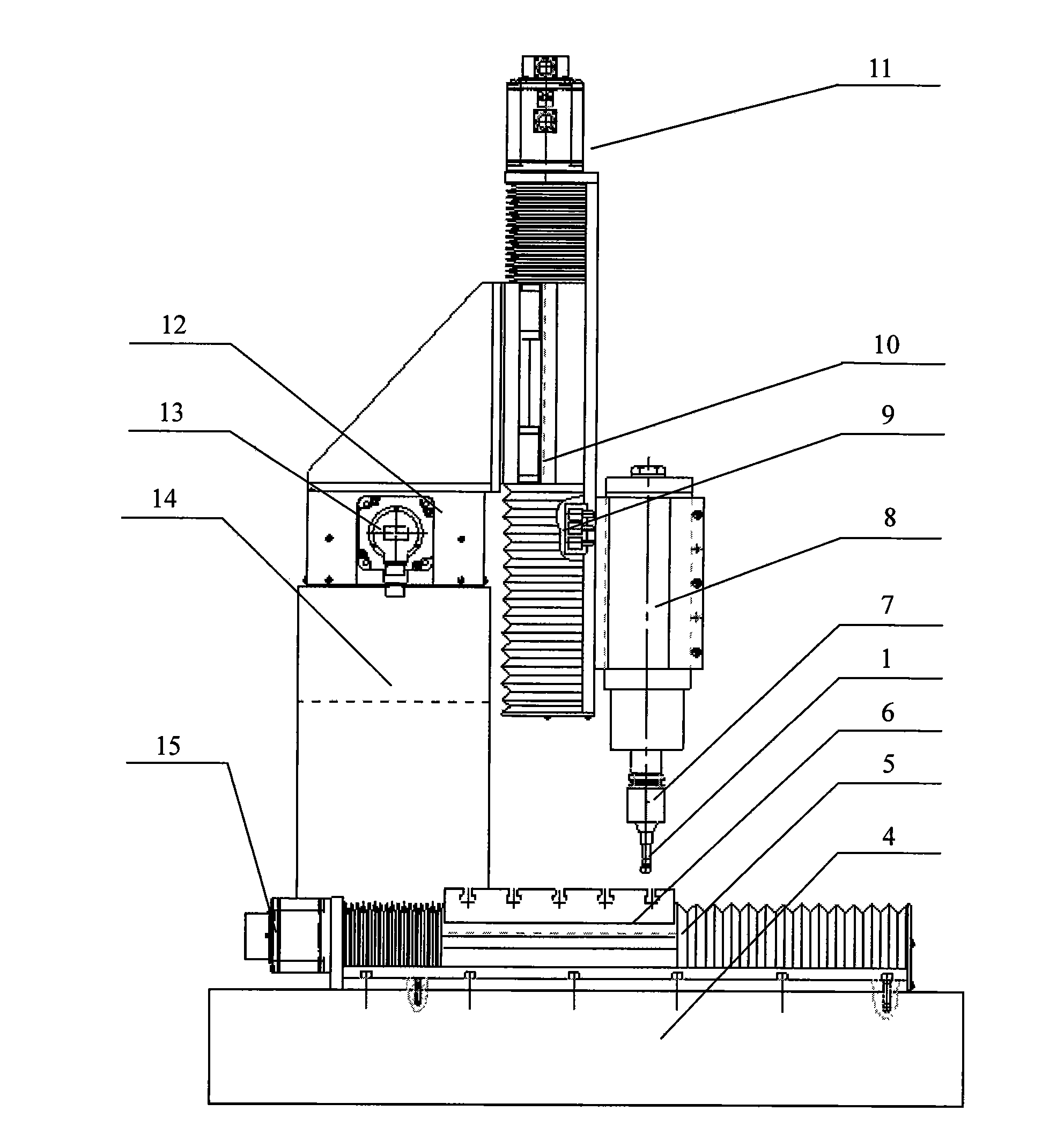

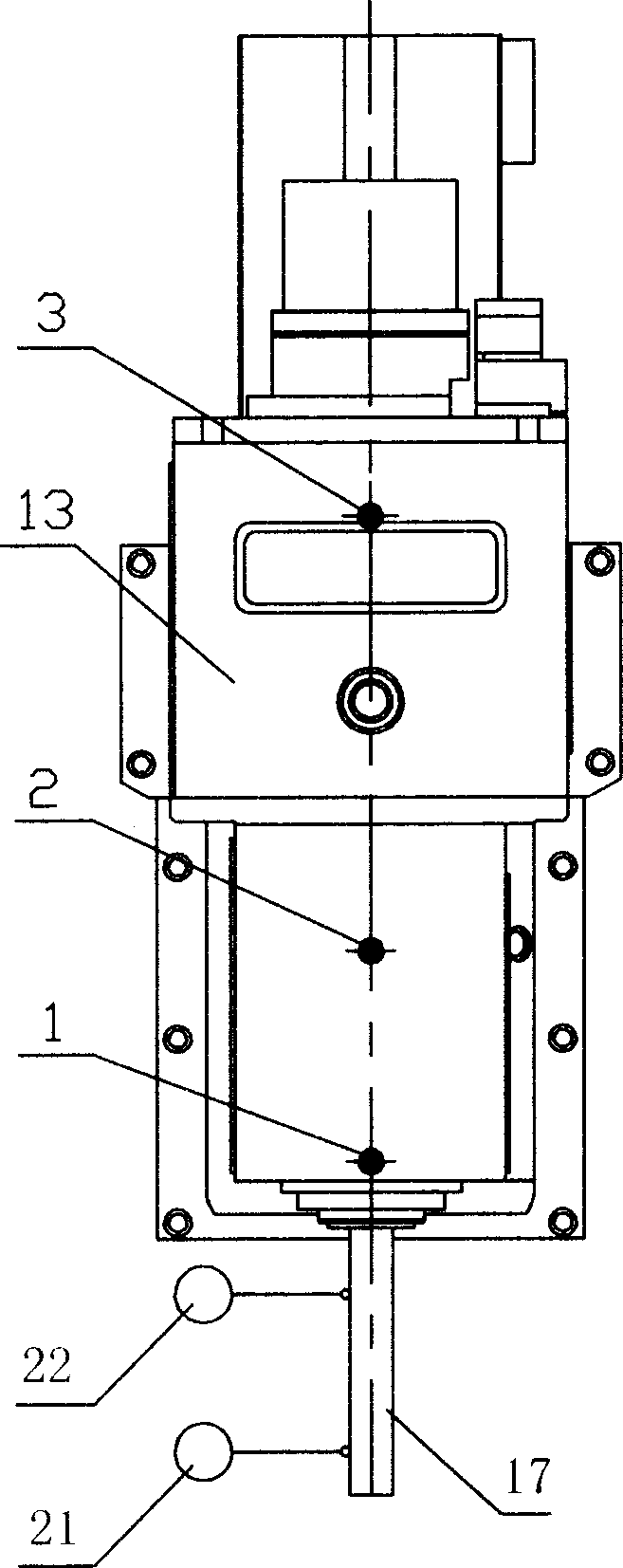

Method and device of disposing holes on carbon fiber composite material and meal material which are overlapped

InactiveCN101670448AHigh degree of automationGuaranteed stabilityAutomatic control devicesTransportation and packagingManufacturing technologyControl manner

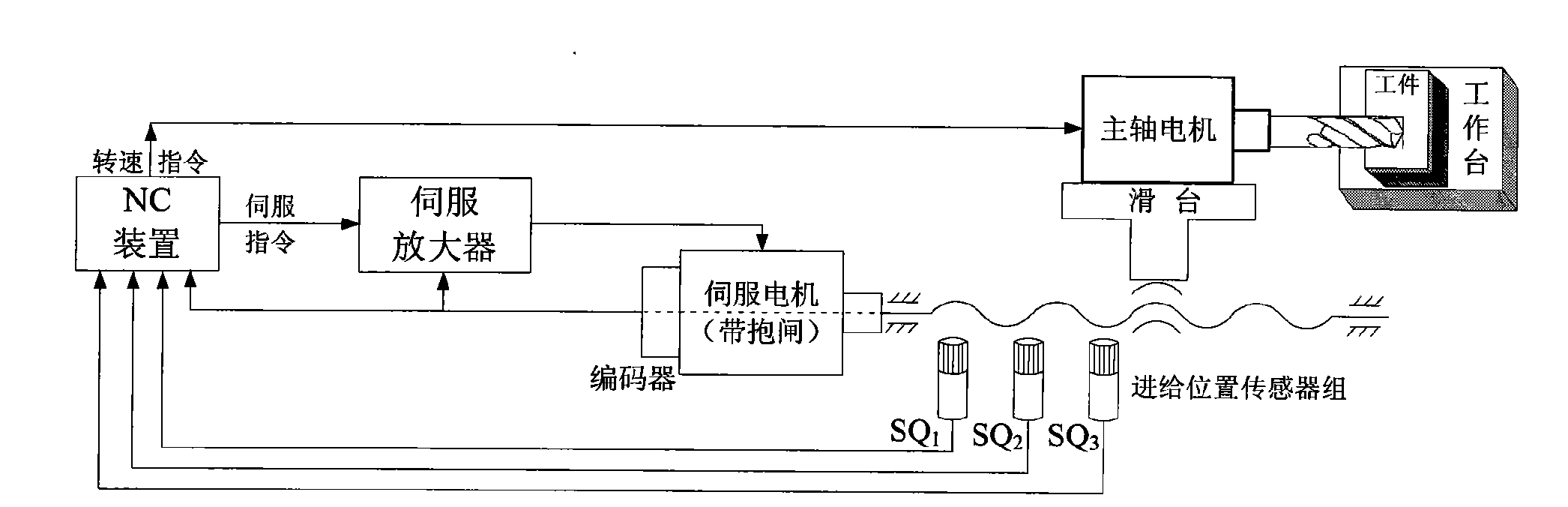

The invention relates to a method and device of disposing high-quality holes on carbon fiber composite material and meal material which are overlapped, belonging to the field of the mechanical processing and manufacturing technology. The method of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized in that in the process of disposing holes on the carbon fiber composite material and the meal material which are overlapped by a device of disposing holes, such as a polycrystalline diamond (PCD), a coating, a cemented carbide bit and a diamond grinding rod, the rotating speed and the feeding speed of a cutter are automatically changed according to the materials on which holes are to be disposed by the hardware triggering or software numerical-control programming control mode of a feeding position sensor set so that the cutter can be in the optical process parameter state. The device of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized by comprising a body, the cutter the handle of the cutter, an electric main shaft, the feeding position sensor set, a vertical feeding sliding-platform, a main shaft variable-frequency speed-regulating system and a hole disposing device numerical control system. The invention realizes the adaptive continuous processing, obviously improves the quality and the processing efficiency of holes disposed integrally on different overlapped materials and lowers the production cost.

Owner:DALIAN UNIV OF TECH

Laser-induction hybrid melting direct forming method and device

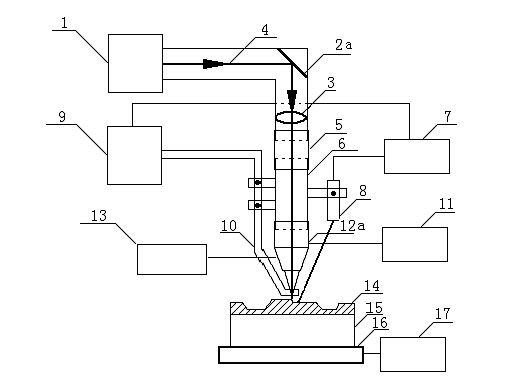

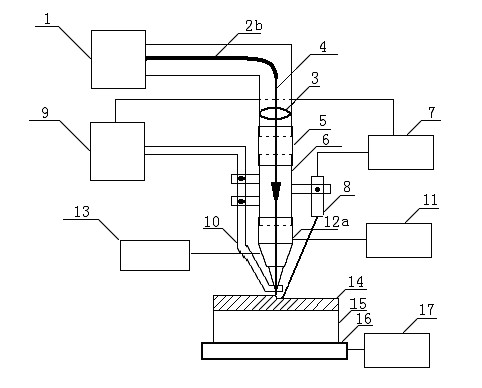

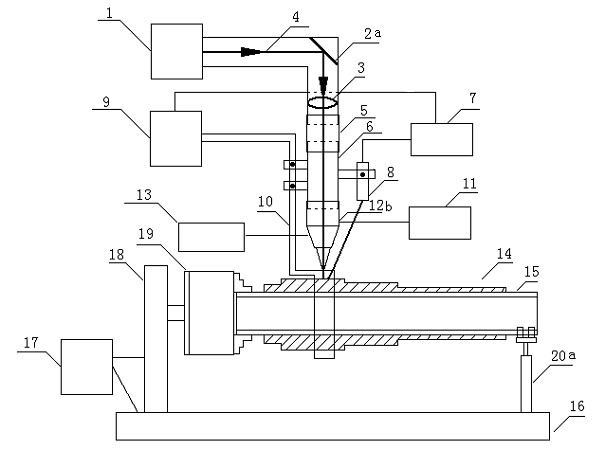

The invention discloses a laser-induction hybrid melting direct forming method and device. The laser-induction hybrid melting direct forming method comprises the following steps of: generating a three-dimensional model of a part through CAD (Computer-Aided Design) software, and then slicing the three-dimensional model and generating a G code to drive a numerical control system and a base body to move; and melting synchronously fed metal or metal / ceramic hybrid powder through a high-power laser beam and an induction heat source, and depositing the three-dimensional part in a designed shape layer by layer, wherein a temperature controller is used for monitoring and controlling the temperature of the base body in the processing process. The device for realizing the laser-induction hybrid melting direct forming method comprises a laser, a light path system, an induction heating and temperature control system, a powder feed system and the numerical control system. The device can be used for directly generating large and medium size three-dimensional parts on various metal base bodies, has the advantages of high processing efficiency, compact part structure, fine crystalline grain, excellent mechanical property, less residual stress without deformation or cracking phenomenon, high processing flexibility without tools and moulds, high material utilization ratio, cleanness without pollution and capability of designing the components of a metal-ceramic hybrid layer as required and even changing the components in a gradient manner.

Owner:HUAZHONG UNIV OF SCI & TECH

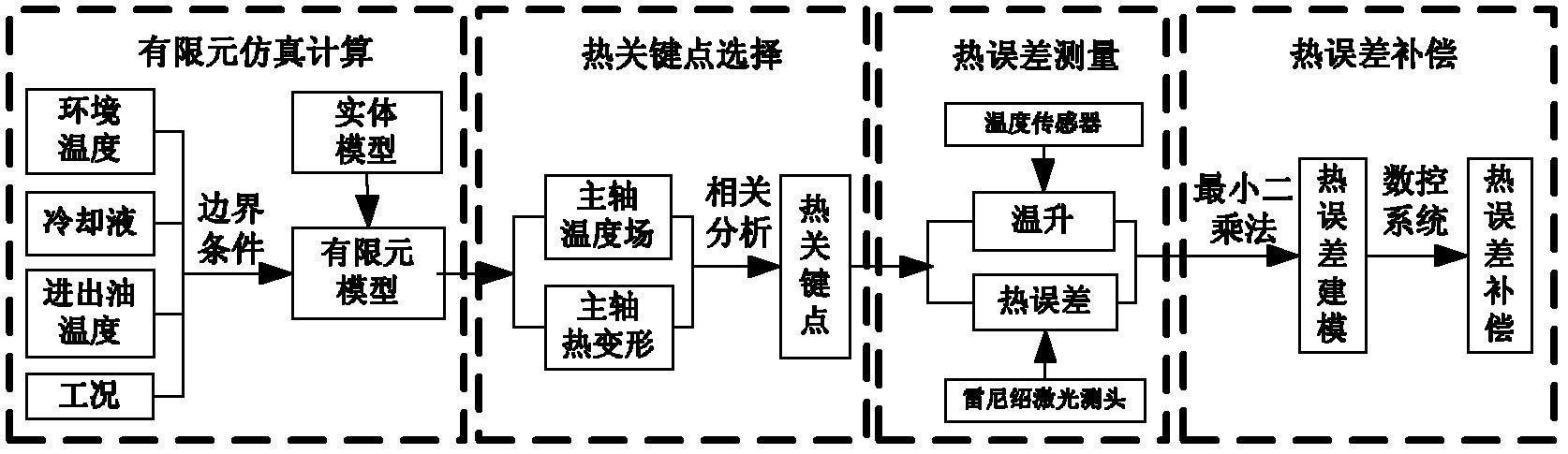

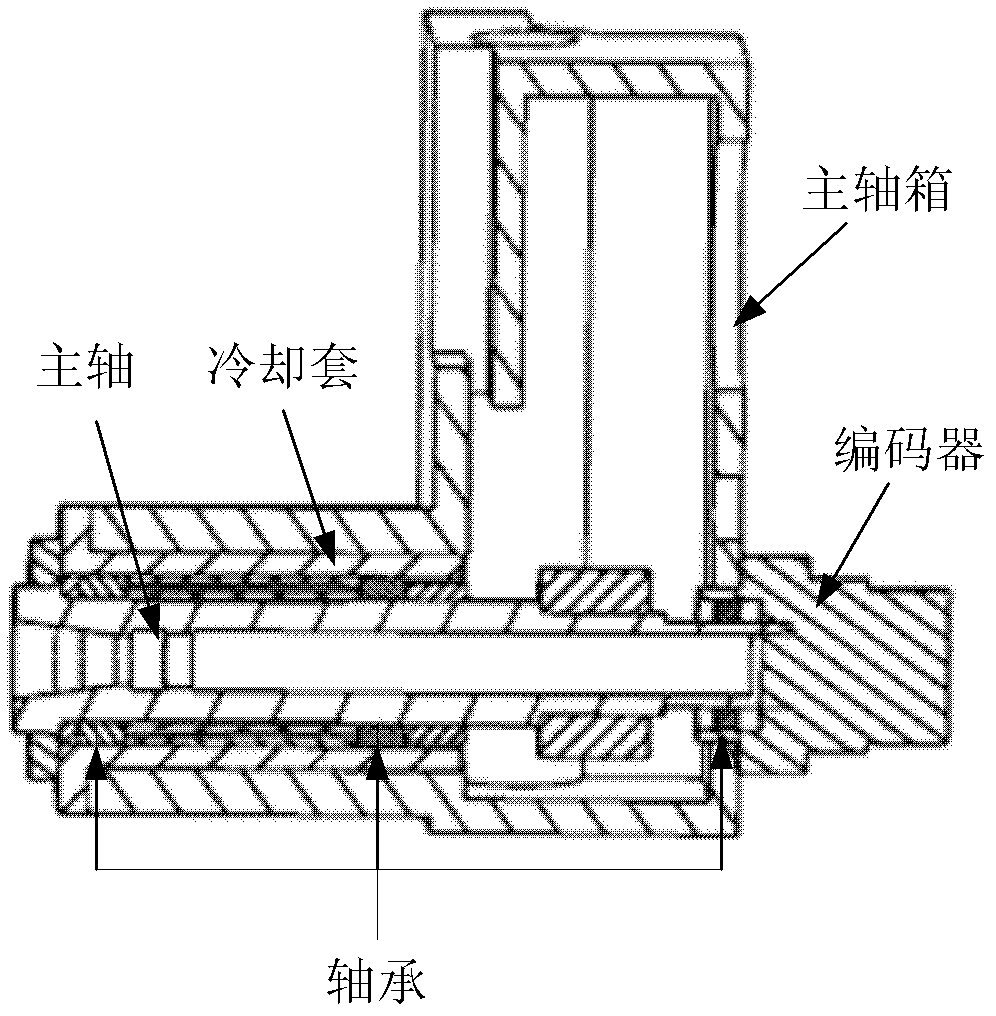

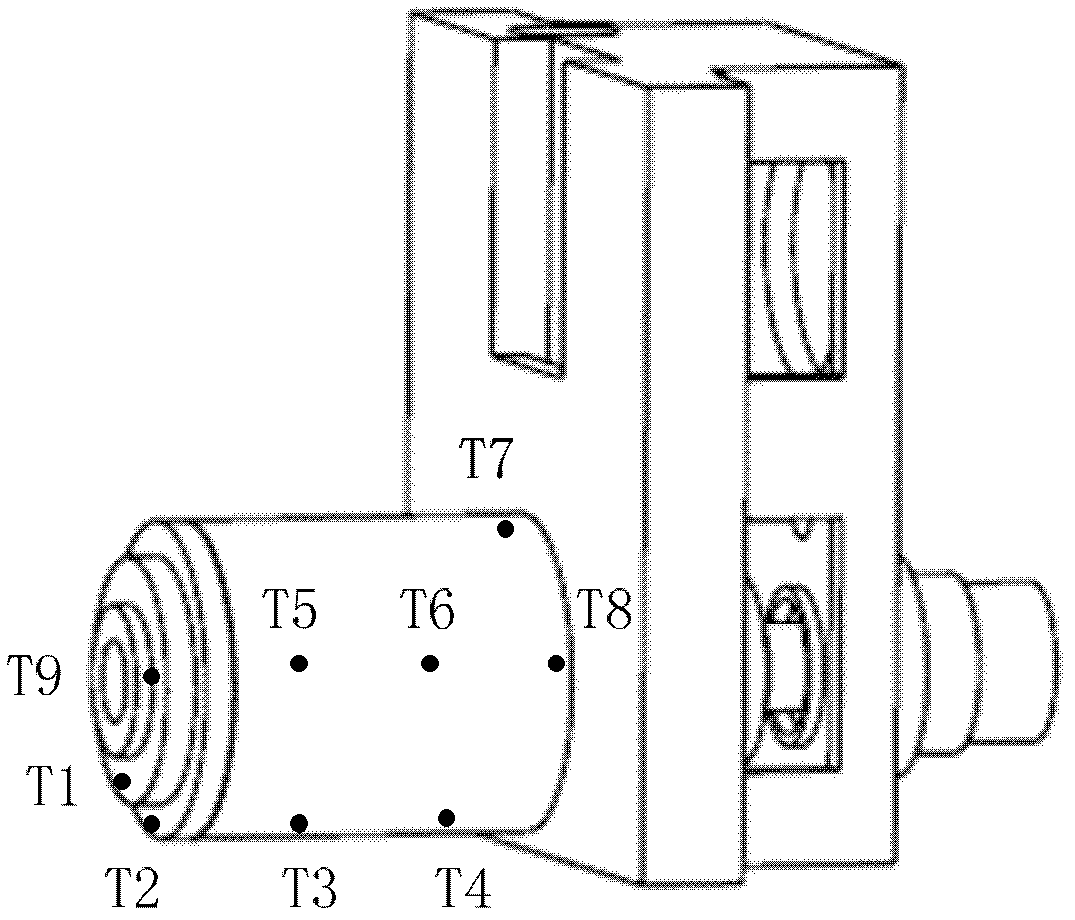

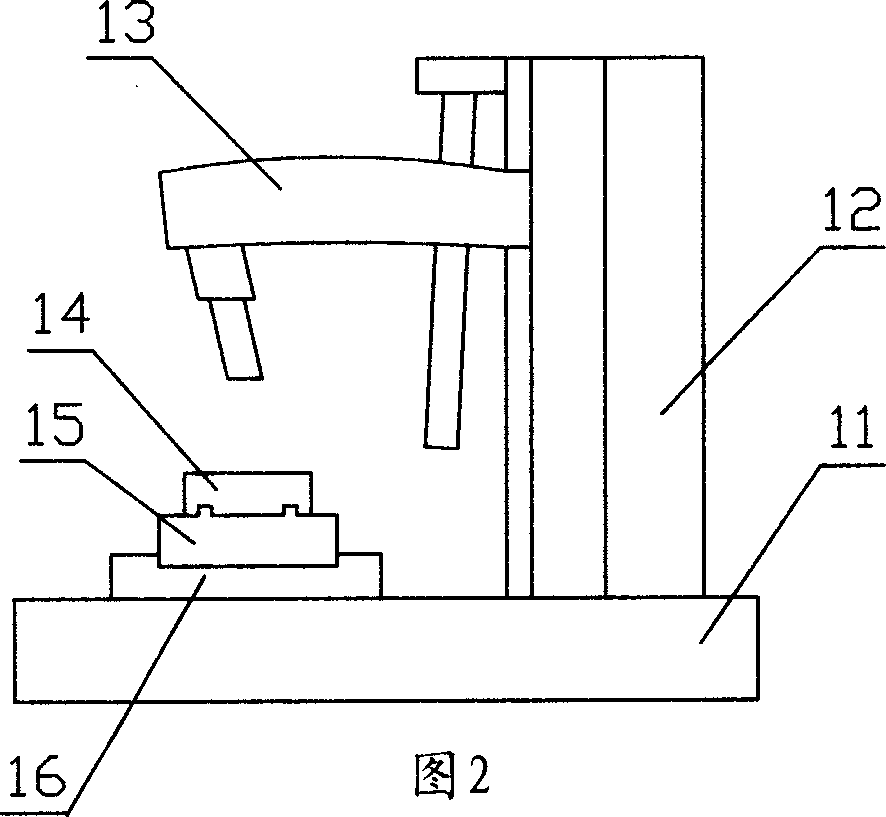

Spindle thermal distortion compensation method for precision horizontal machining center

InactiveCN102658499AReduce thermal errorsMeasurement/indication equipmentsMaintainance and safety accessoriesElement modelEngineering

A spindle thermal distortion compensation method for a precision horizontal machining center comprises the steps as follows: a spindle model of a machine tool is simplified structurally; an ANSYS (finite element analysis software)-Workbench is utilized to perform mesh generation on a spindle entity model that is simplified, so as to obtain a spindle finite element model; and boundary conditions are calculated by combining with the practical spindle rotational speed, the environmental temperature, the coolant velocity, the flow rate, the inlet and outlet oil temperature and the like, and configuration is performed. Thermodynamics analysis and statics analysis are carried out in the ANSYS-Workbench to obtain more accurate spindle temperature field distribution and thermal deformation. Based on a finite element emulation result, the spindle temperatures in different positions and the spindle thermal deformations are analyzed at different rotational speeds by utilizing the Spearman rank correlation analysis, and spindle thermal key points are found out, so that references are provided to spindle thermal error tests and thermal error compensation. Finally, a thermal error compensation model is built up by utilizing a least squares method according to the key point temperature of the spindle and the thermal errors in the practical tests. Based on the thermal error compensation model, the spindle thermal error compensation is carried out by combining with thermal error compensation strategies of a numerical control system of the machine tool.

Owner:XI AN JIAOTONG UNIV +1

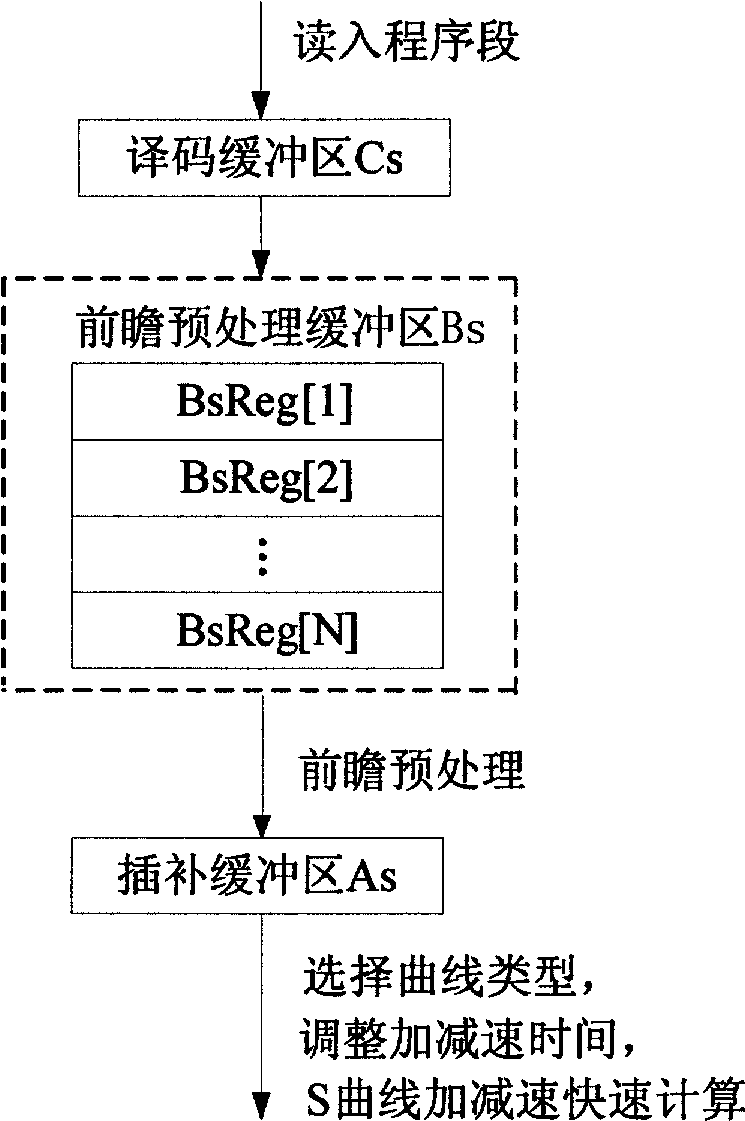

Forward looking self-adapting speed controlling method for high-speed processing tiny line segment

InactiveCN101510087AImprove practicalityMeet the requirements of high precision CNC systemNumerical controlProgram segmentSelf adaptive

The invention discloses a forward-looking self-adaptive speed control method of high-speed numerical control equipment. The numerical control system of the method conducts a plurality of layers of pre-reading decoding processing, uses pre-reading program segment information for pre-calculation to the terminal speed of a segment to be processed, adjusts a speed acceleration and deceleration time constant according to the calculation result, selects a speed acceleration and deceleration curve type, and then conducts a fast speed acceleration and deceleration calculation to an S curve so as to lead the numerical control equipment to process the micro-segments with high speed and smooth operation. The forward-looking self-adaptive speed control method comprises the following steps of: the pre-calculation of the terminal speed of the segment to be processed, the self-adaptive selecting strategy of the speed acceleration and deceleration time constant, and the speed acceleration and deceleration curve type; and the fast speed acceleration and deceleration calculation of the S curve. The invention provides a self-adaptive speed acceleration and deceleration control method for the high-speed numerical control equipment, leads the numerical control equipment to have the capacity of processing the micro-segments with high speed and smooth operation, and satisfies the speed control requirements of high-speed high-precision numerical control equipment.

Owner:XI AN JIAOTONG UNIV

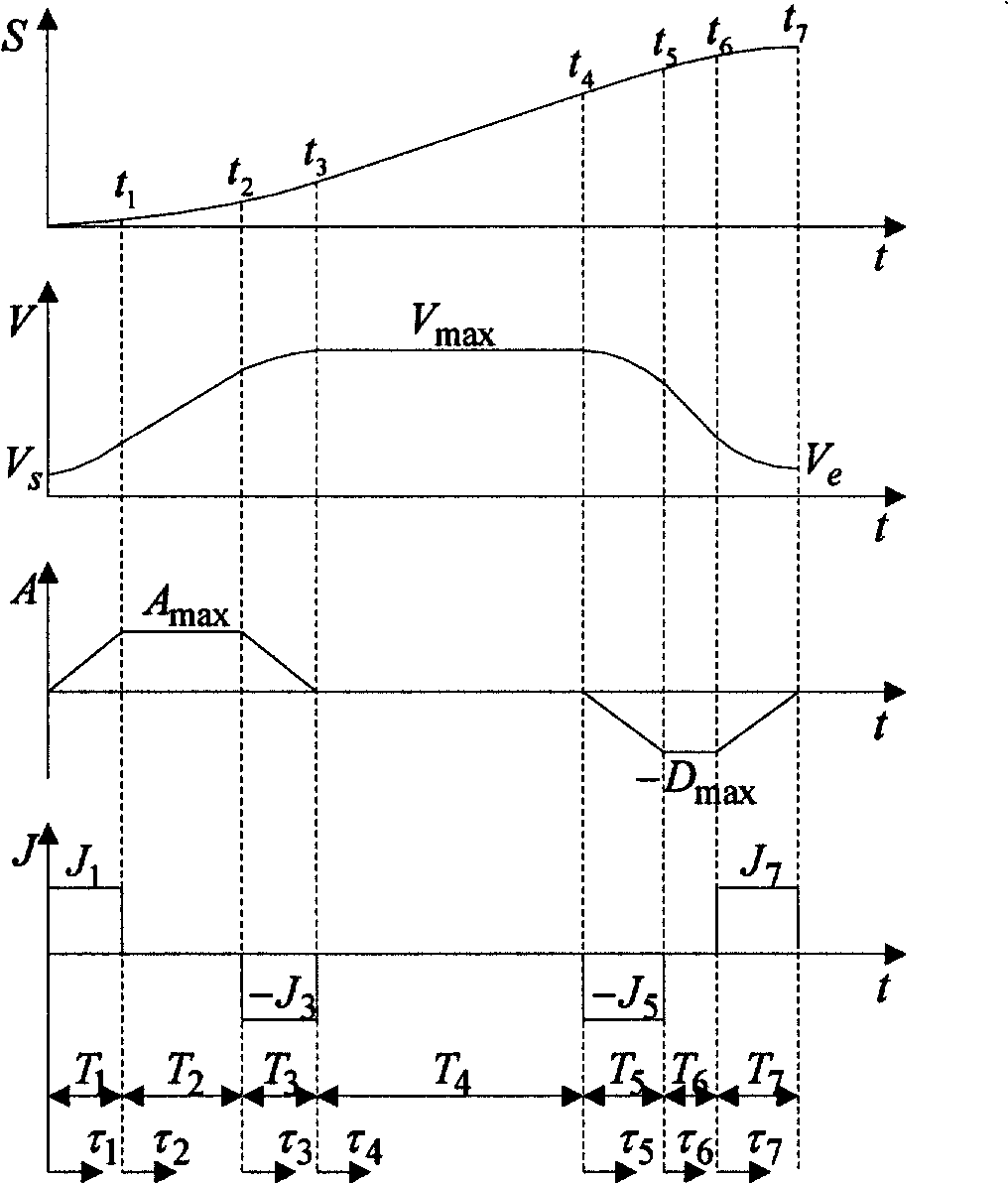

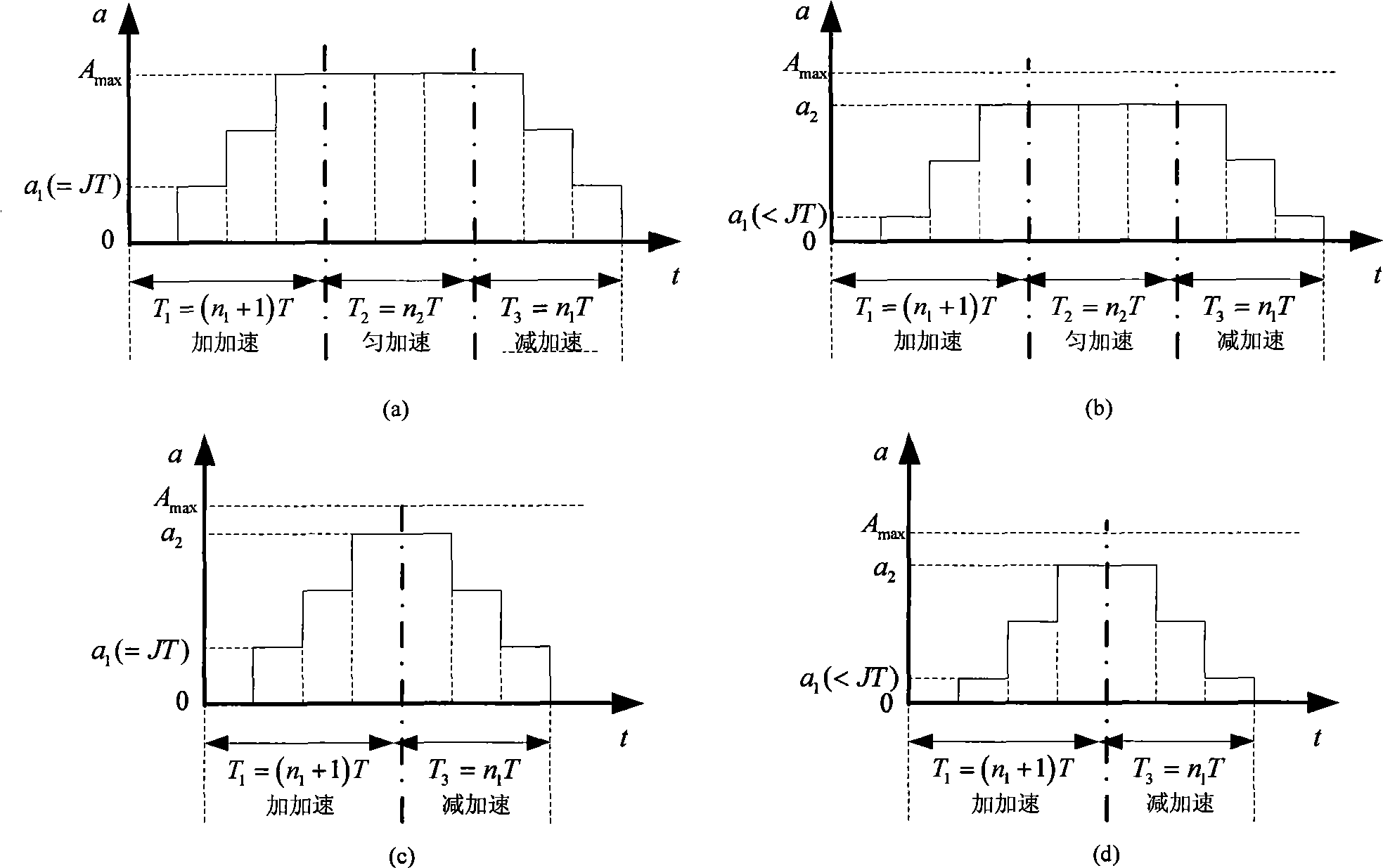

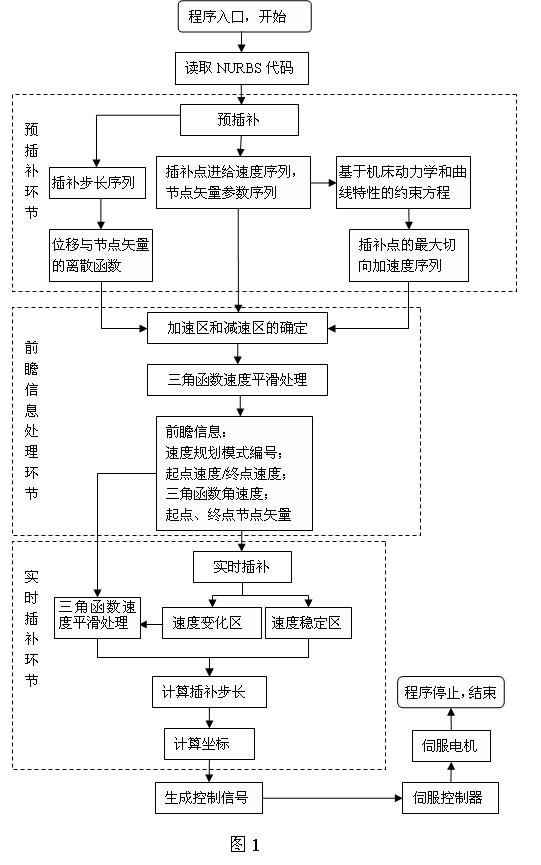

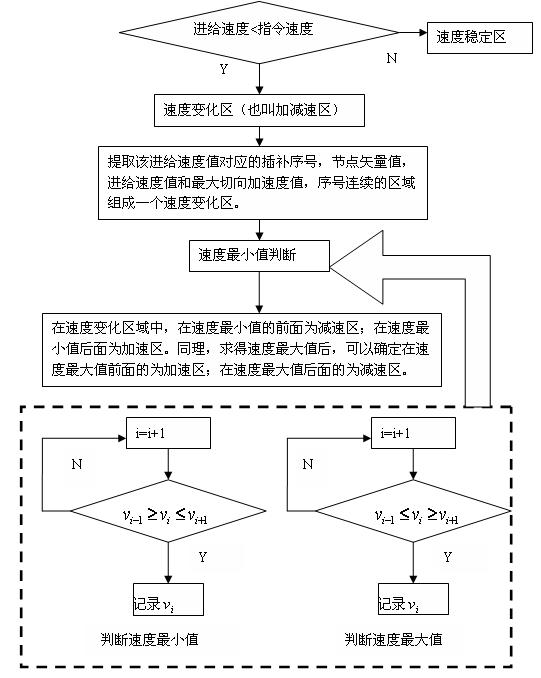

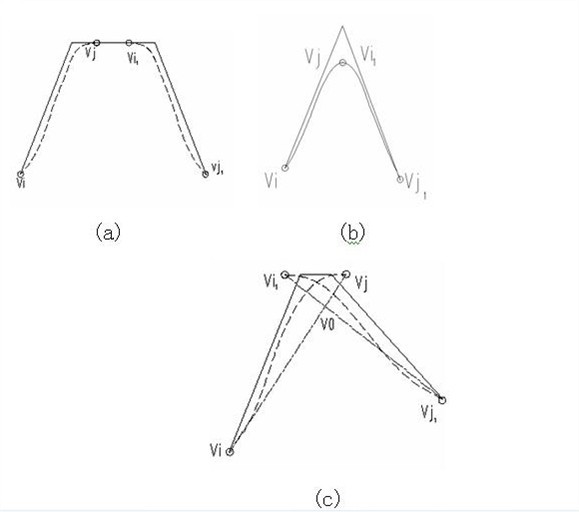

NURBS (Non-Uniform Rational B-Spline) interpolation method based on machine tool dynamics and curve characteristics

ActiveCN101976060AThe interpolation movement process is smooth and stableContinuous speedNumerical controlInformation processingAcceleration deceleration

The invention discloses an NURBS (Non-Uniform Rational B-Spline) interpolation method based on machine tool dynamics and curve characteristics, which adopts a constraint equation ZHYS considering integrative factors of machine tooling for controlling the feeding speed and the acceleration of the interpolation algorithm. The method consists of three links: pre-interpolation, prospective information processing and real-time interpolation, and comprises the following steps of: carrying out trigonometric function speed smoothing processing according to the corresponding speed mode; storing corresponding data after the trigonometric function speed smoothing processing; adopting the trigonometric function speed smoothing processing according to prospective information if entering an acceleration-deceleration region; and adopting a speed self-adapting method for calculation if not entering the acceleration-deceleration region, thus finally obtaining the coordinates and the feeding speed of interpolation points. The method of the invention has the advantages that the interpolation is always in the safe range of a machine tool, the whole interpolation movement process is smooth and stable through the trigonometric function speed smoothing processing, in addition, the tangential acceleration and the continuity of the tangential acceleration in the speed change region can be ensured, and the NURBS interpolation method has the important significance on the development of a high-speed and high-precision numerical control system.

Owner:成都天佑创软科技有限公司

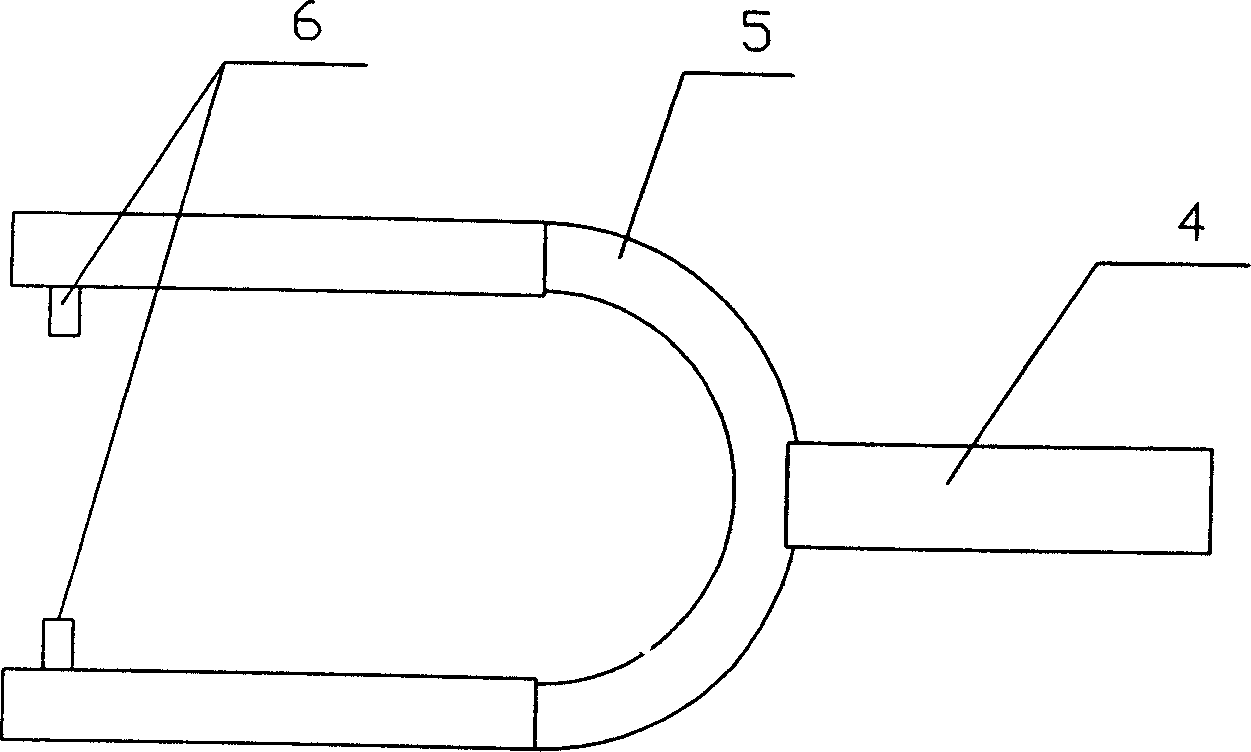

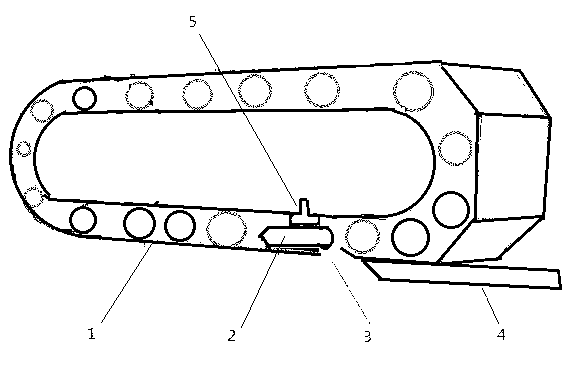

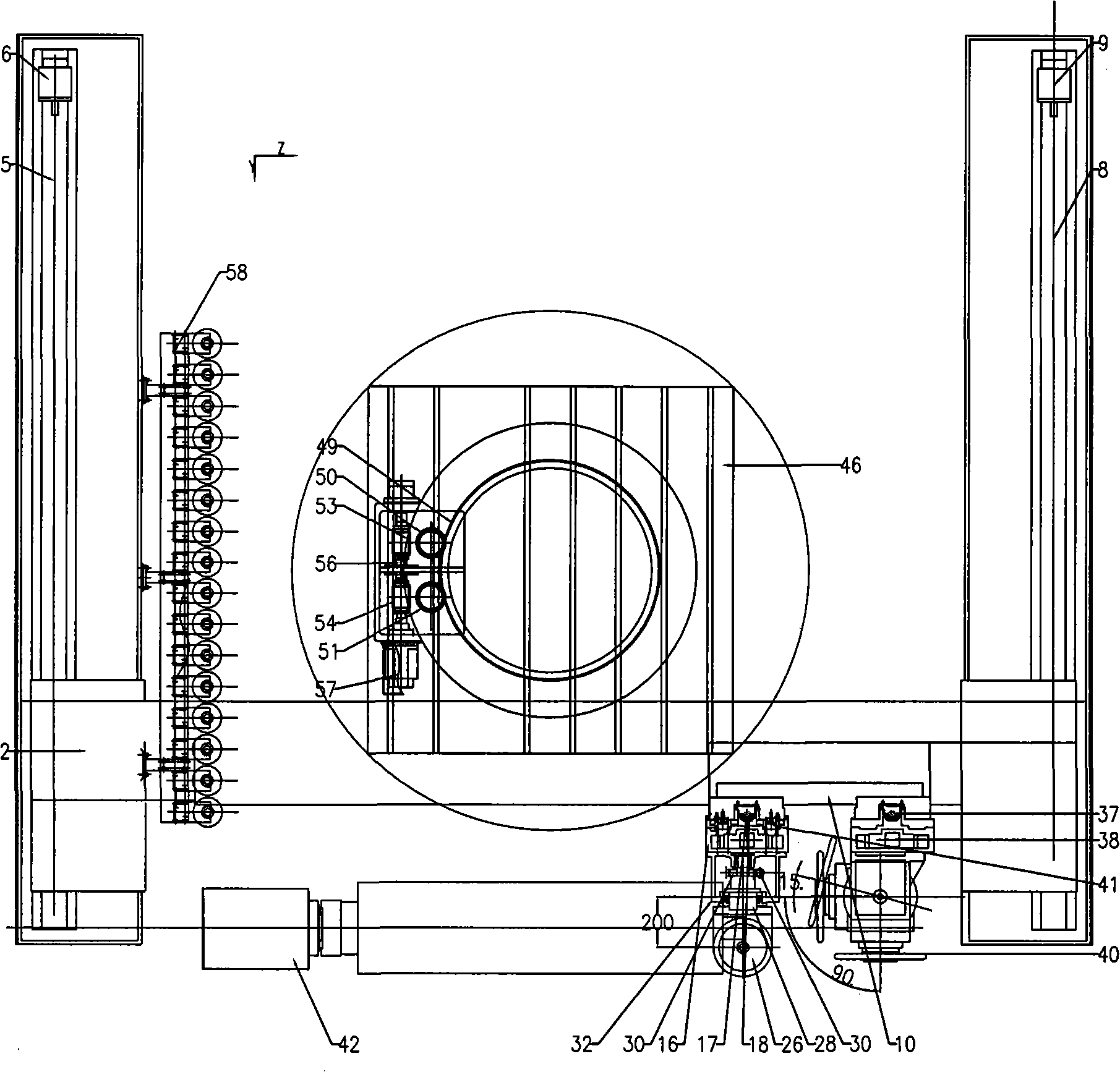

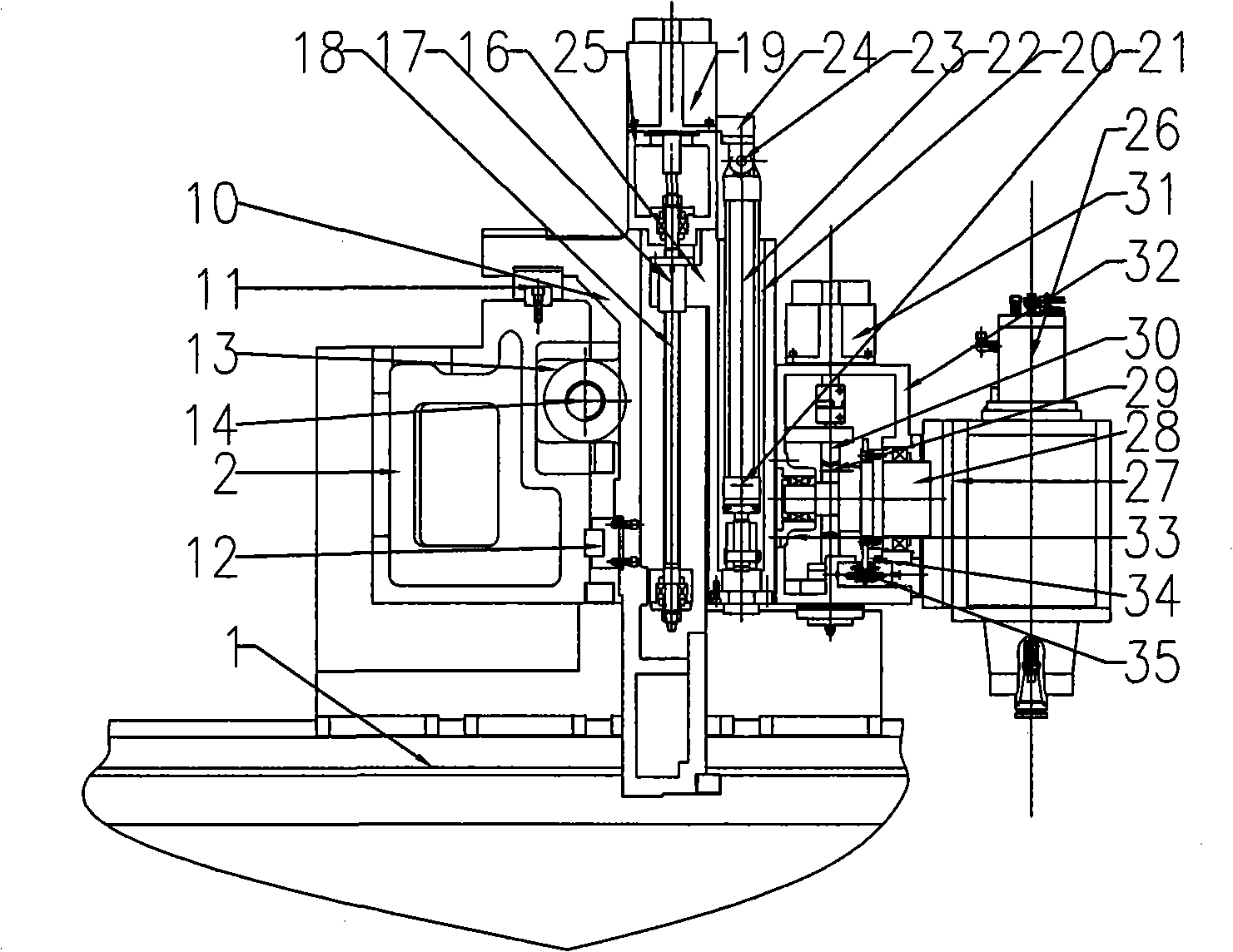

Numerical control abrasive belt grinding machine with six-axis linkage

ActiveCN101559574AImprove processing efficiencyHigh dimensional accuracyGrinding carriagesBelt grinding machinesMachine controlForm liner

The invention discloses a numerical control abrasive belt grinding machine with six-axis linkage. An upright post component and a worktable are arranged on the grinding machine body in a sliding way, and the relative sliding between the two of the upright post component and the worktable and the grinding machine body respectively forms liner motion of X-axis direction and Y-axis direction; an A-axis component is arranged above the worktable and used for clamping a workpiece to rotate around the axial line thereof so as to form rotary motion of the A-axis; a cantilever on the upright post component is provided with a grinding seat which is connected with the upright post component through a box body in a sliding way so as to form liner motion of Z-axis direction; a turntable is arranged on the box body in a rotating way, and the relative rotation between the turntable and the box body forms rotary motion of B-axis direction; an abrasive belt machine is arranged inside the grinding seat, and the relative rotation between the abrasive belt machine and the grinding seat forms swivel motion of C-axis direction; and the grinding machine controls the motion of each axis direction by a numerical control system. The numerical control abrasive belt grinding machine can greatly enhance grinding efficiency, and can effectively improve the grinding precision and surface quality of the workpiece.

Owner:北京胜为弘技数控装备有限公司

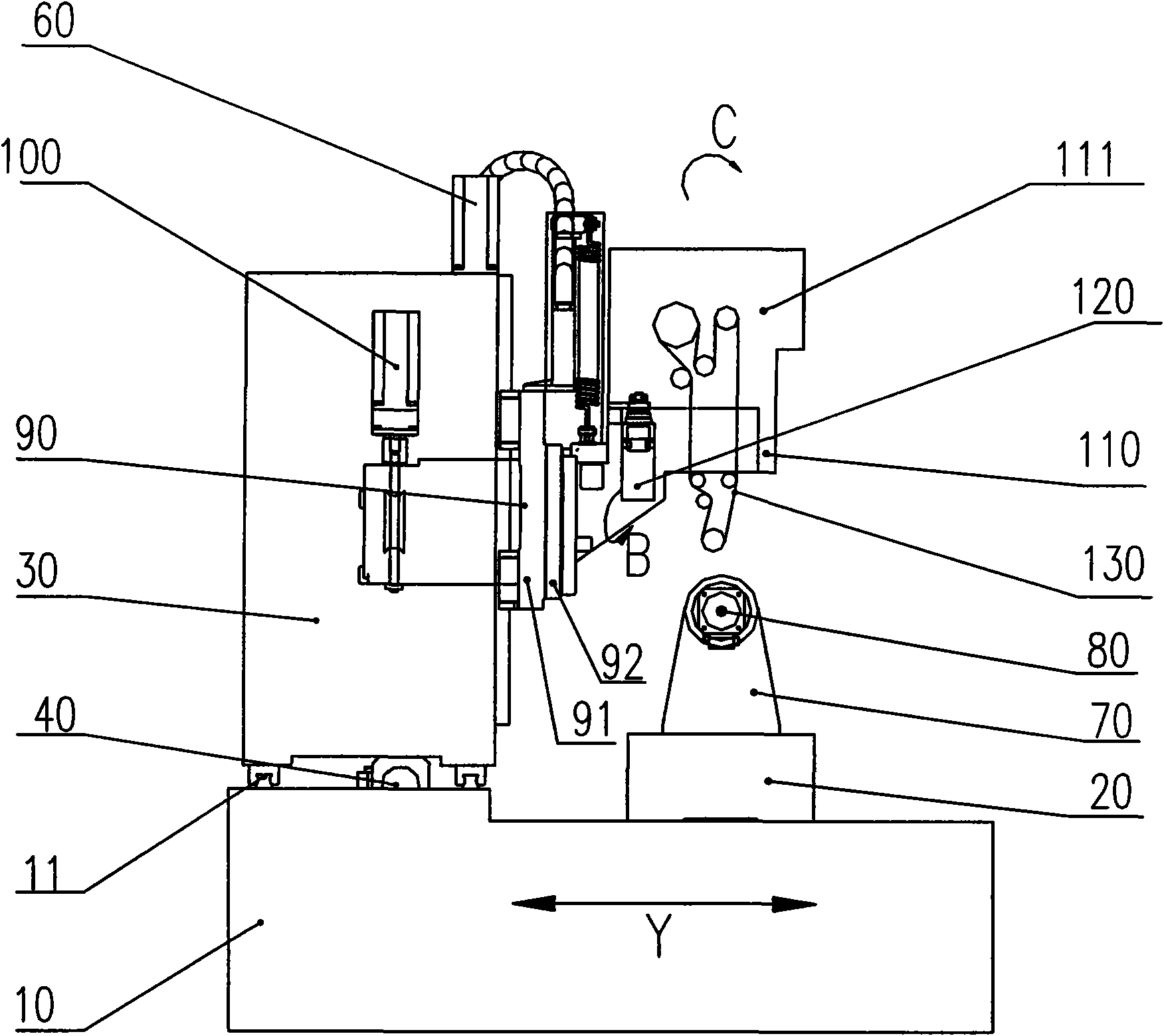

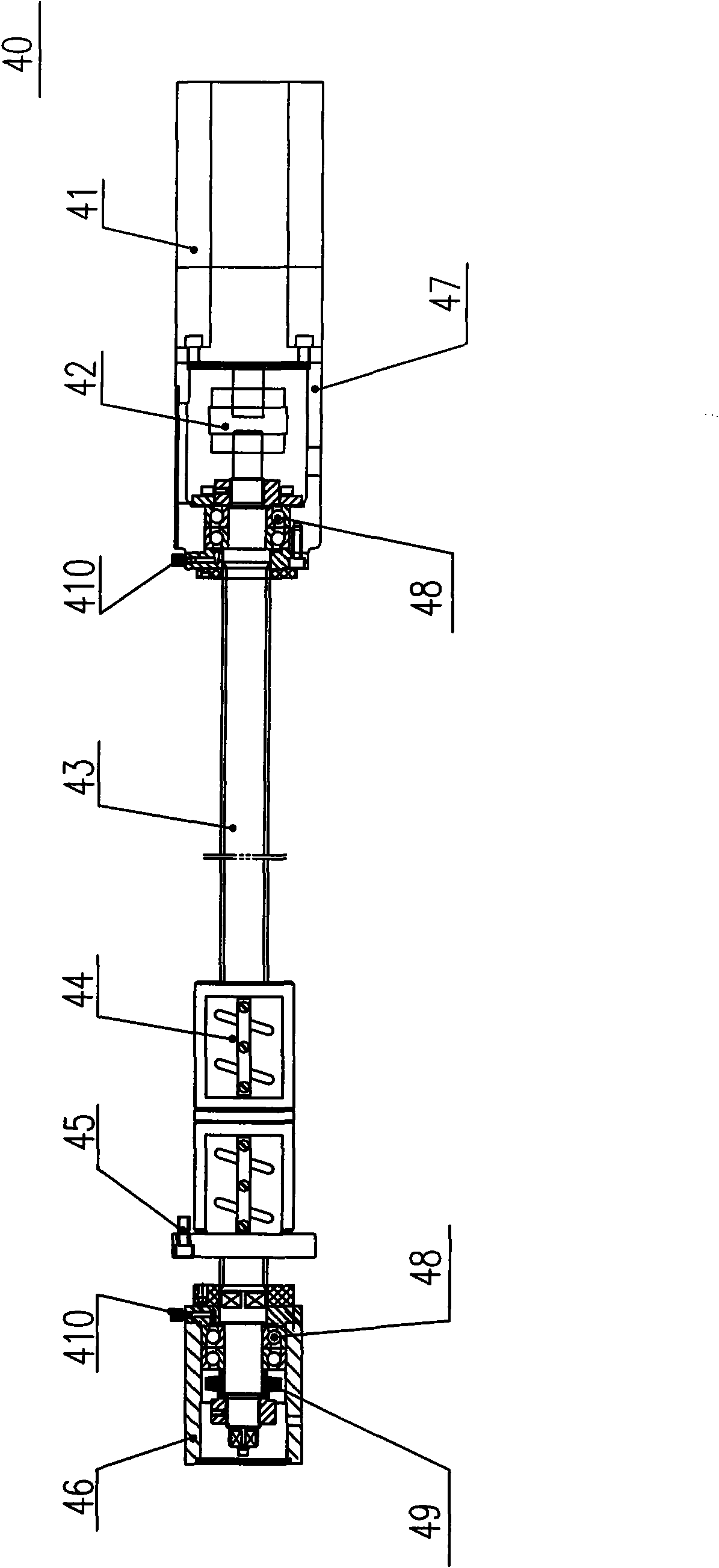

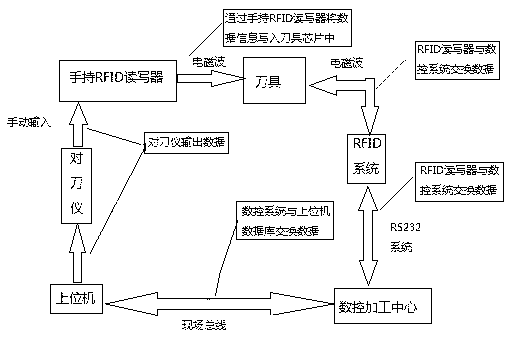

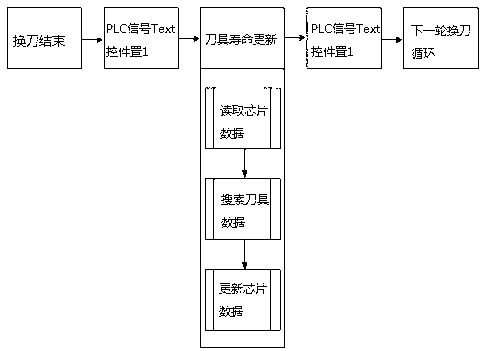

RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of Siemens 840D numerical control system

InactiveCN103076764AImprove entry efficiencyImprove accuracyProgramme controlComputer controlTerra firmaReader writer

The invention belongs to the technical field of machine tools and particularly relates to an RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of a Siemens 840D numerical control system. Through research on an RFID automatic identification technology and integration with a numerical control system, a tool in a machining center is automatically identified. An RFID reader-writer selected by the invention is a BIS-C-600 type reader-writer produced by Germany BALLUFF company, an automatic tool identification technology is integrated in a numerical control system, tool information is automatically identified and tool key data is read and input to the numerical control system of the machining center, and thus the accuracy and efficiency of tool information entry are effectively improved; and life monitoring data in the numerical control system is written an RFID chip, thus a tool which is discarded or approaches the life limit is effectively prevented from being misused, and the risks that the machining quality of products is reduced and even the production safety accidents are caused are avoided. The firm foundation is laid for further realizing the tool network-based management of the whole workshop.

Owner:TONGJI UNIV

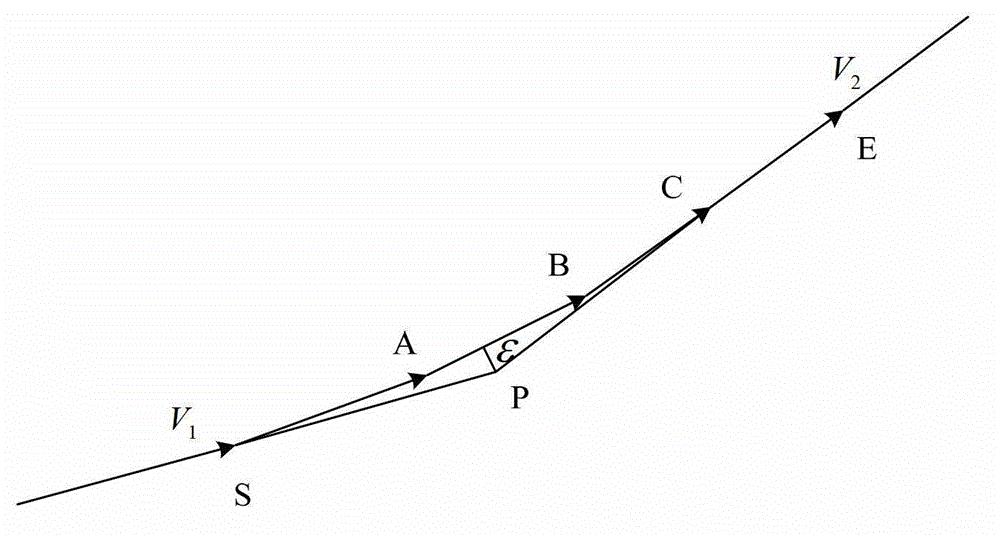

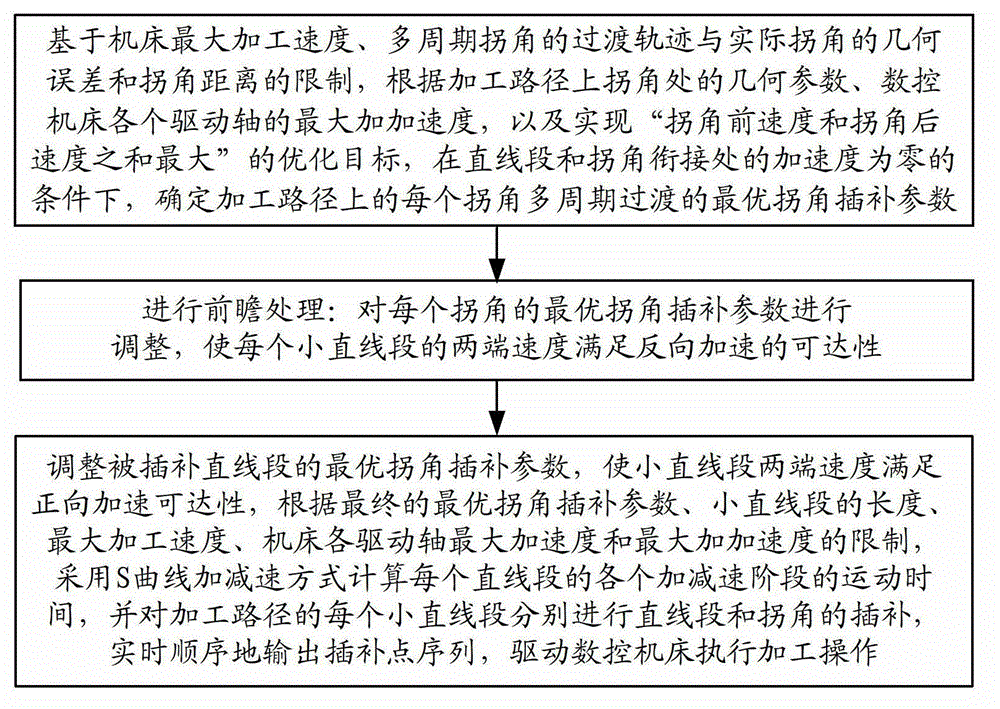

Multi-period corner small straight-line segment interpolation method based on S curve acceleration/deceleration control

InactiveCN102722140ACalculation speedSimplify calculation stepsProgramme controlComputer controlControl mannerPoint sequence

The invention discloses a multi-period optimal corner small straight-line segment interpolation method based on S curve acceleration / deceleration control in a numerical control system. The method comprises the following steps of: based on the limitations of the machining precision of a machine tool and the maximum machining speed of each driving shaft, setting the acceleration speed at the joint of the corner and the straight-line segment to be zero according to geometrical parameters of each corner on a machining path, the maximum machining acceleration speed of each driving shaft and an optimization target, and determining and adjusting the optimized corner interpolation parameters in multi-period transition at each corner, so that the acceleration speed at two ends of each small straight-line segment meets the reachability requirement of the S curve acceleration / deceleration control mode; and calculating the time at each acceleration / deceleration stage of each straight-line segment according to the S curve acceleration / deceleration mode, respectively performing straight-line segment and corner interpolation on each small straight-line segment, sequentially outputting interpolation point sequences in real time, and driving a numerical control machine tool to execute the machining operation. By the method, the vibration of the machine tool is reduced, the quality of the surface of a workpiece is improved, the calculation speed is high, the real-time machining requirements can be met, and the method is suitable for different models of three-axis, four-axis or five-axis numerical control machine tools.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

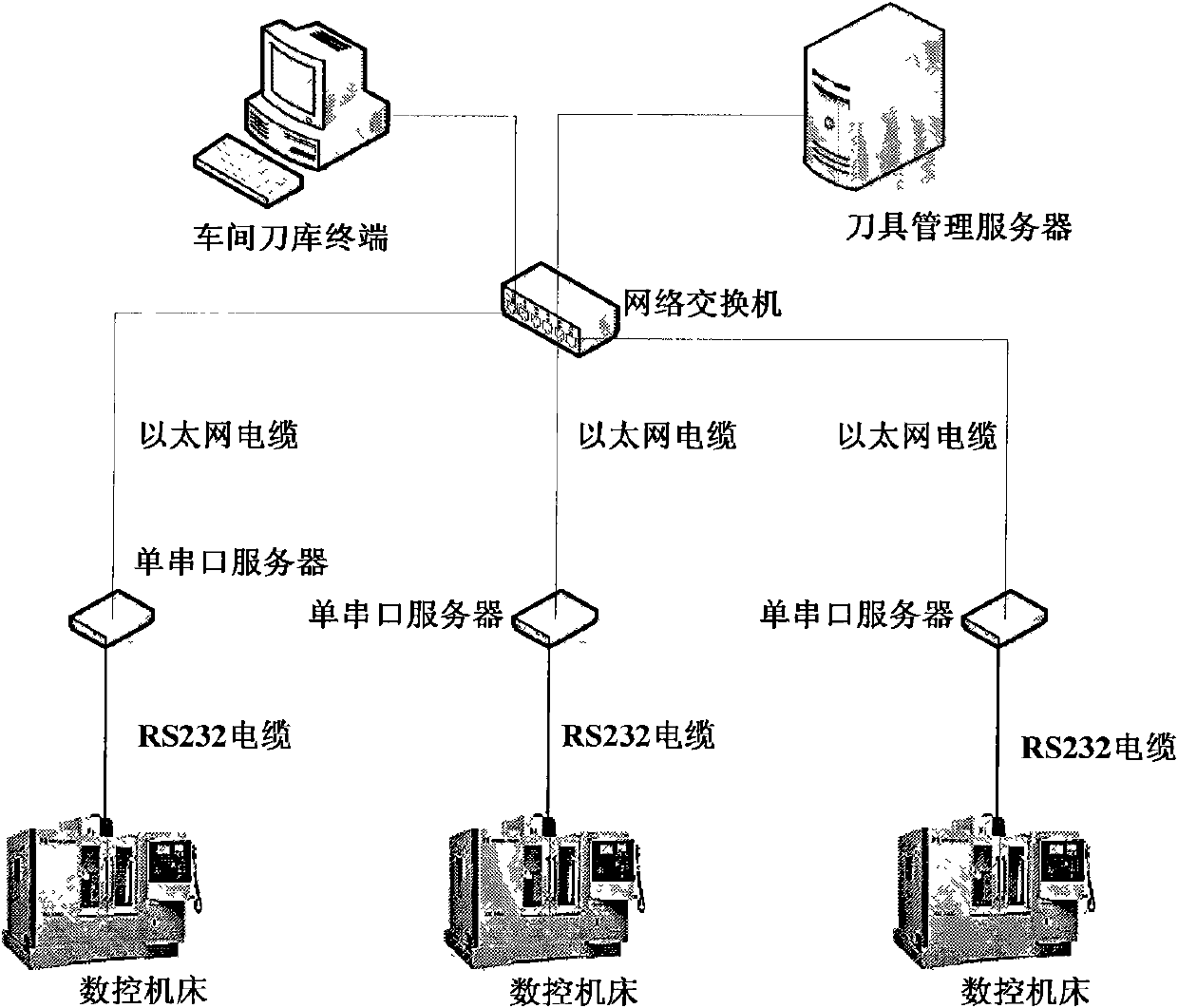

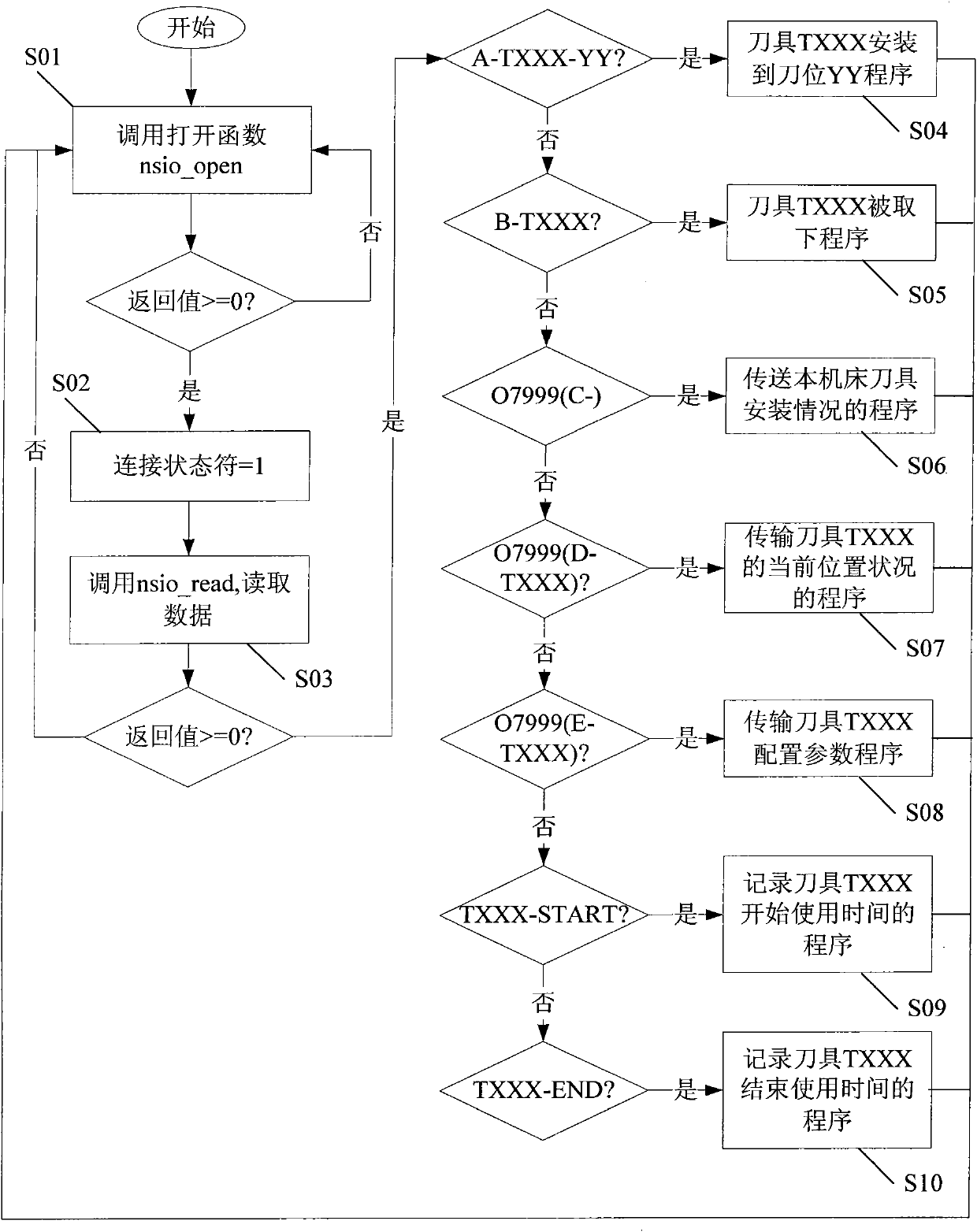

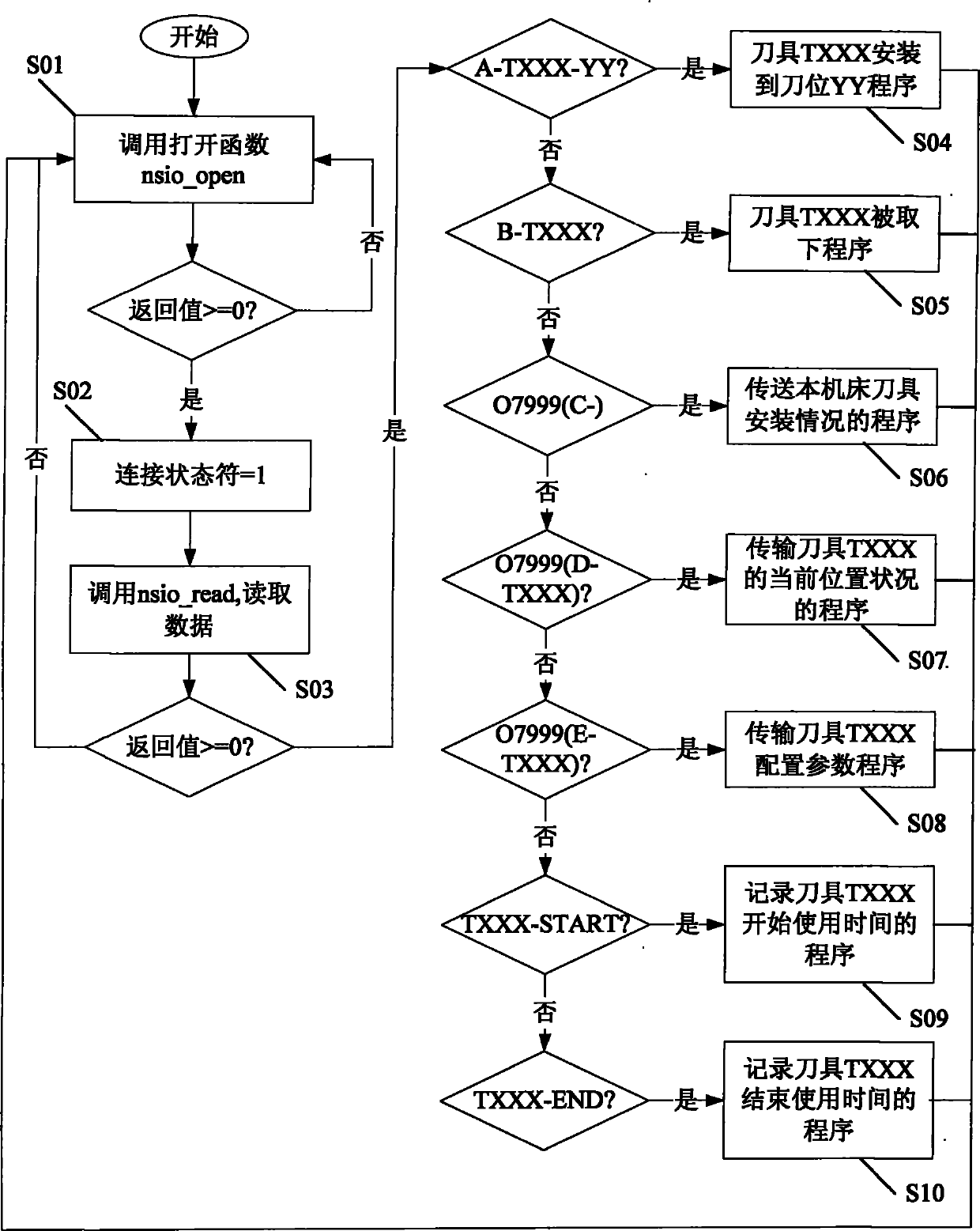

Method for online managing cutting tool of numerically controlled lathe

InactiveCN101770222AAccurately record usage timePredict remaining lifeNumerical controlComputer scienceMachine tool

The invention discloses a method for online managing a cutting tool of a numerically controlled lathe, which comprises the following steps: firstly, setting up a device for online managing the cutting tool of the numerically controlled lathe, establishing a database on a cutting tool management server and developing a corresponding functional module interface on a lathe tool magazine terminal; formulating a subprogram on the numerically controlled lathe according to programming rules adopted by the numerical control system; and by using the cutting tool management server, receiving and transmitting information between the lathe and the cutting tool management server by calling a function in a serial port server, processing read program data, modifying or querying the database and transmitting the queried information to the corresponding numerically controlled lathe. Through the method, the information about the cutting tool is accurately recorded and queried by networking all machining centers and lathe tool magazine terminals so as to shorten cutting tool replacing time, make full use of the residual life of the cutting tool, save human resources and improve production efficiency.

Owner:JIANGNAN UNIV

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

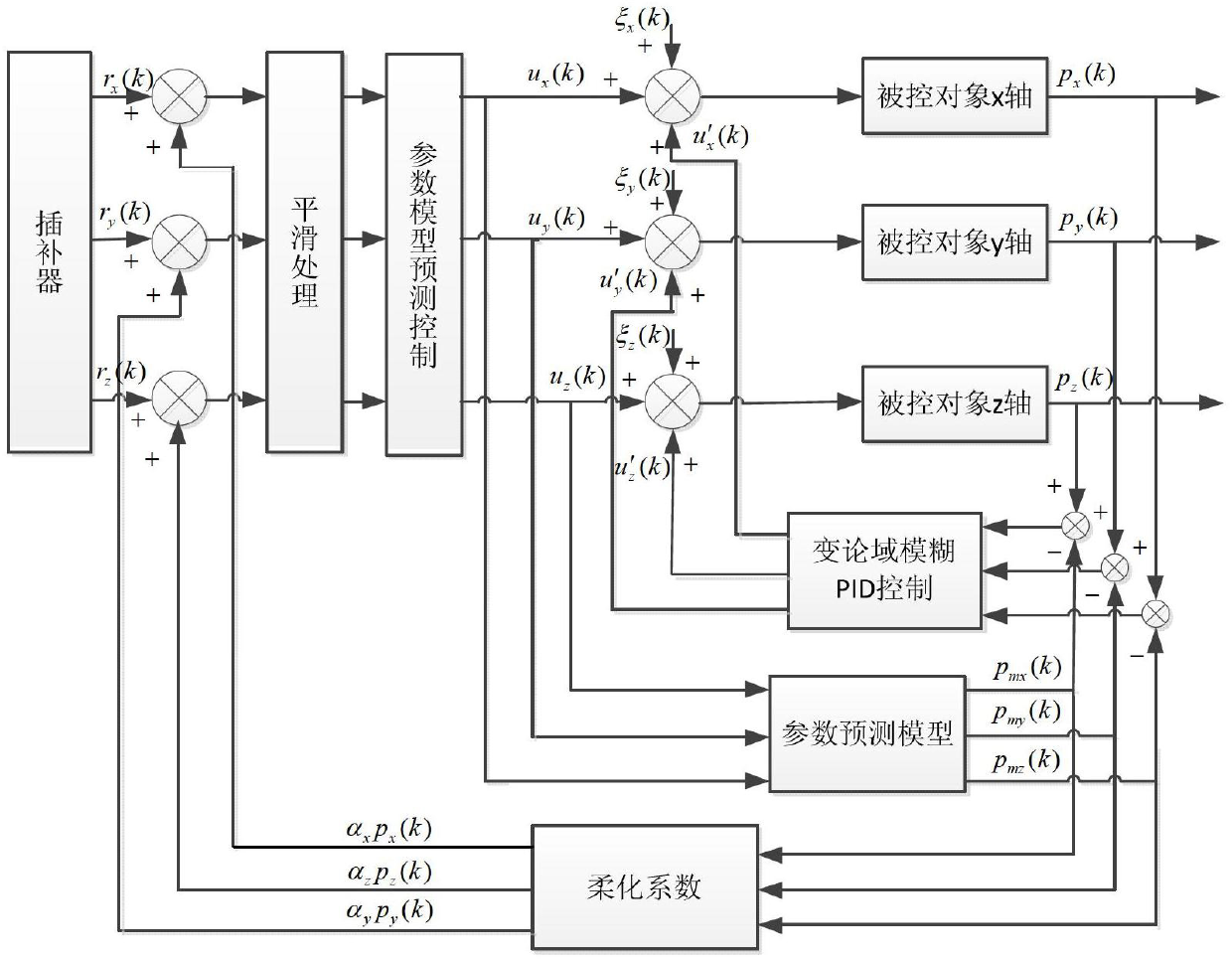

Control method for motion stability and outline machining precision of multi-shaft linkage numerical control system

ActiveCN102681489AAchieve smooth motionRealization errorNumerical controlFuzzy pid controlControl system

The invention discloses a control method for motion stability and outline machining precision of a multi-shaft linkage numerical control system. The control method achieves control on the motion stability and outline machining errors of the multi-shaft linkage numerical control system by using a compound control mode of multi-shaft parameter module predictive control and non-linear self-adaptive fuzzy proportional-integral-derivative (PID) control. Simultaneously, error module calculating efficiency is improved by building an outline error module, a speed error module and an acceleration error module. By means of performance optimization indexes, tracking errors, outline errors, speed errors and acceleration errors of the system are minimum, and control performance of a multi-shaft servo control system is improved. Multi-shaft parameter module predicative control increment is solved through a simplified calculating module so as to meet real-time requirements of the control system. Robust property of the multi-shaft linkage numerical control system is improved by adopting the non-linear self-adaptive fuzzy PID control method. The control method effectively improves the motion stability and outline machining precision of the multi-shaft linkage numerical control system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

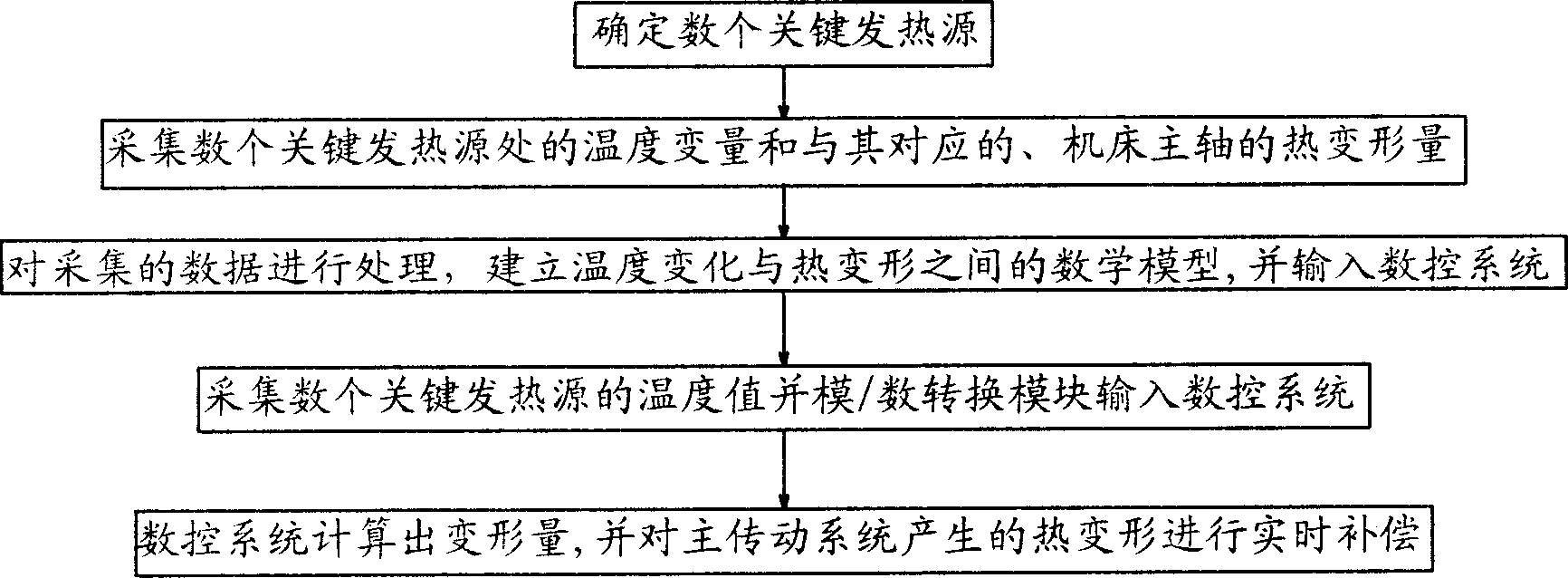

Heat distortion compensation method of digial controlled machine tool main driving system

InactiveCN1868666AHigh precisionImprove stabilityAutomatic control devicesFeeding apparatusControl systemMathematical model

A thermal deformation compensating method for the main drive system of numeral controlled machine-tool includes such steps as determining several important heat generating sources of numeral controlled machine-tool, acquiring their temp variables and relative thermal deformations of mainshaft, processing them to obtain a mathematical model between temp variation and thermal deformation of mainshaft, inputting it to the numeral control system, acquiring the temp values of several important heat sources, inputting them to the numeral control system, calculating the thermal deformation of mainshaft, and real-time compensation by driving the transmission part.

Owner:四川长征机床集团有限公司

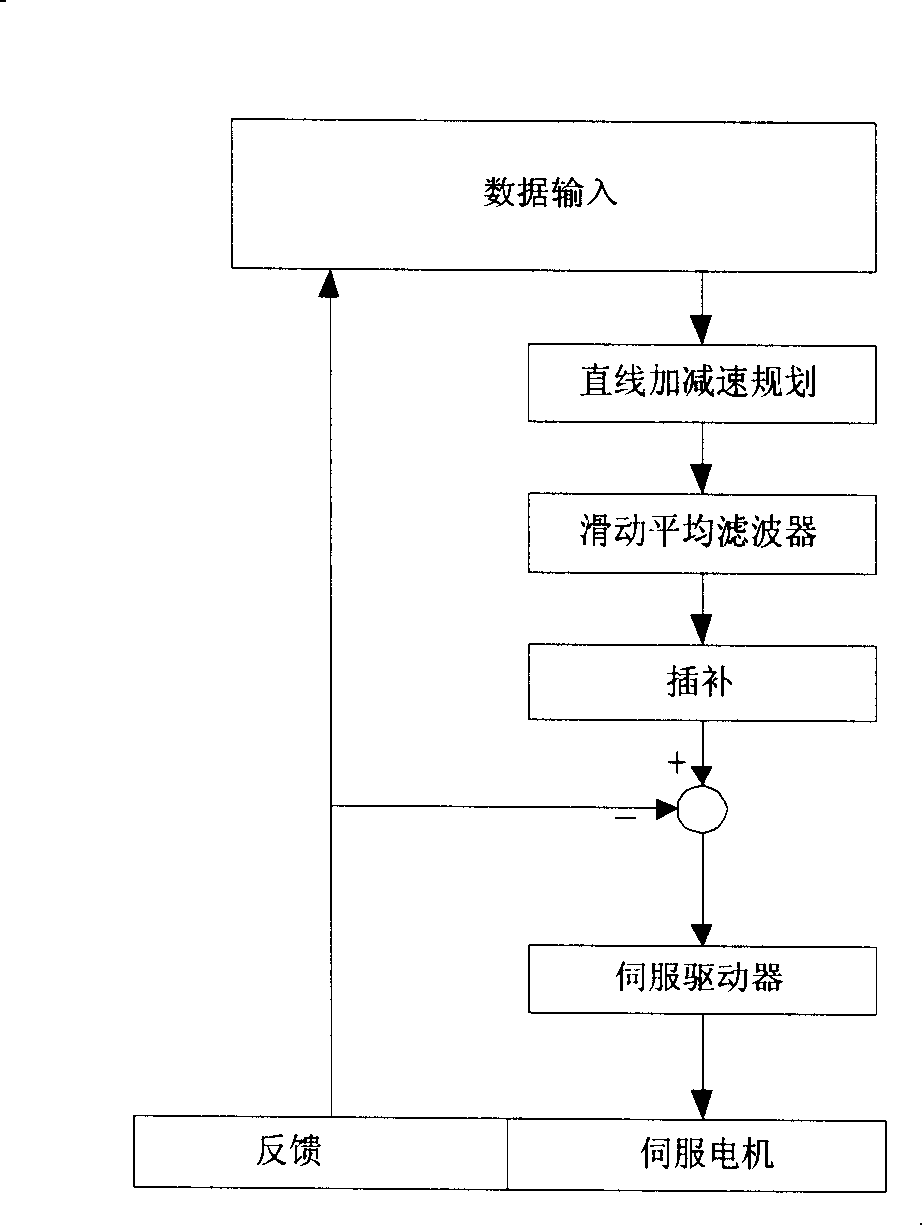

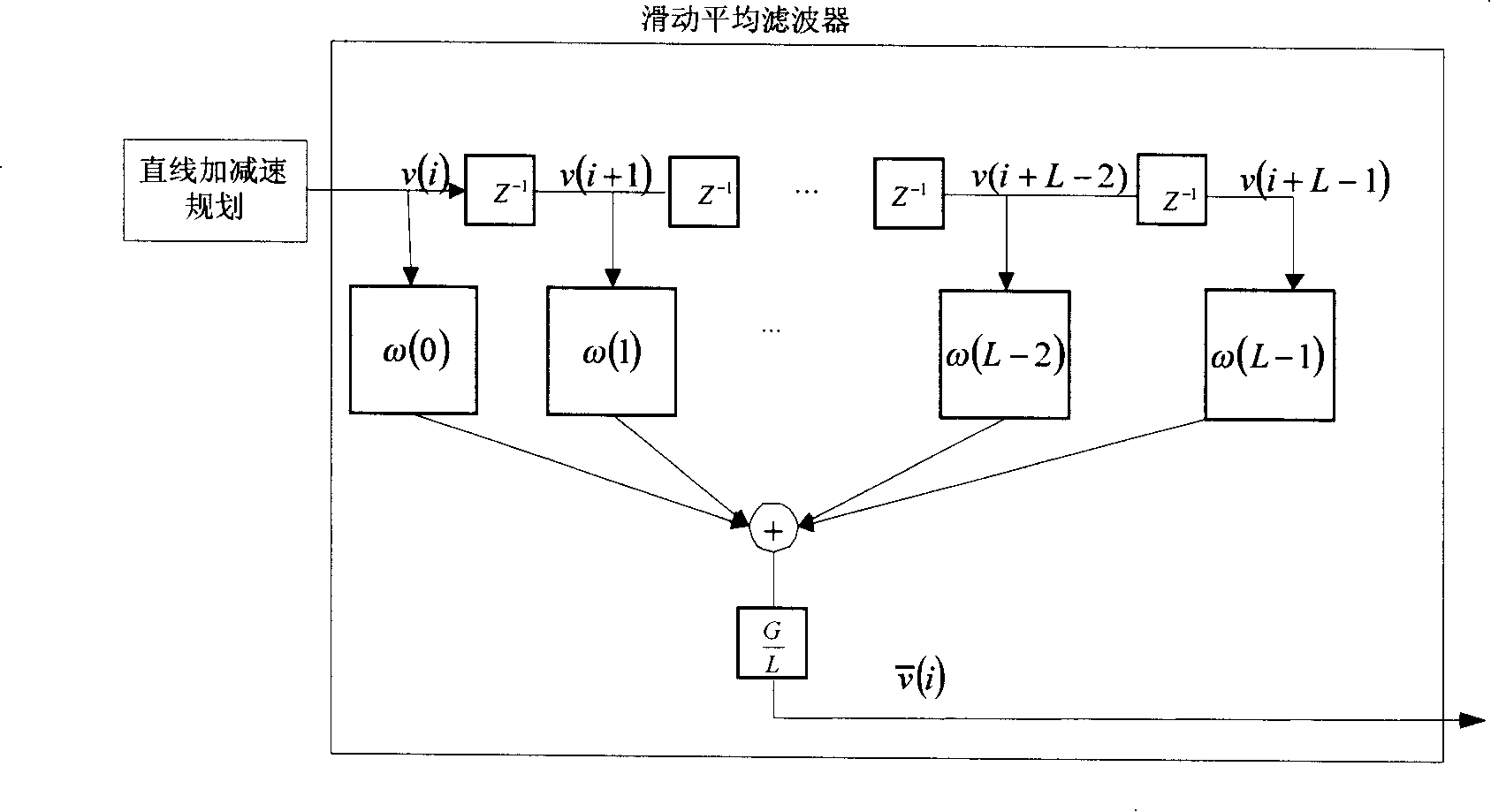

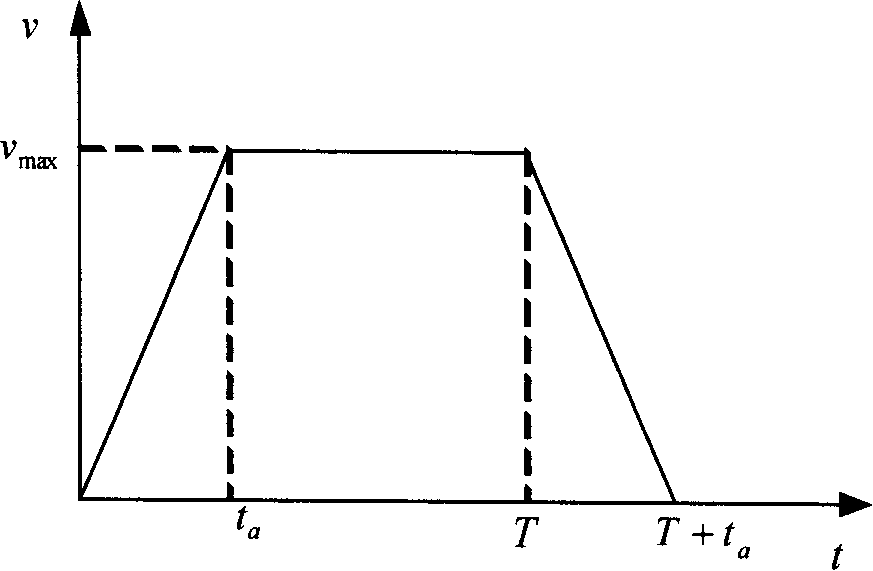

Filter technique based numerical control system acceleration and deceleration control method

ActiveCN101211177ASolve Vibration ProblemsReduce vibrationDigital technique networkNumerical controlMoving averageAverage filter

The invention relates to an acceleration or deceleration control method of numerical control system based on filter technique, which comprises the following steps: planning straight acceleration or deceleration by using the inputted workpiece program data; performing moving average filtering and filter compensation on the planned speed of the straight acceleration or deceleration to obtain a new planned speed value and a position value; performing interpolation on the position value; transmitting the interpolated position value to a servo driver in order to control a servomotor; wherein the moving average filtering of the planned speed of the straight acceleration or deceleration is implemented by adding a moving average filter after planning the straight acceleration or deceleration to control sudden changes of an accelerated speed, particularly comprising the following steps: calculating the speed with a method of planning the moving average filtering speed; changing the smooth degree of the straight acceleration or deceleration by selecting filter length (i.e. controlling the magnitude and the shape of the accelerated speed); and calculating a planned position according to the speed after filtering. The invention solves the vibration problem of a numerically-controlled machine tool during movement, and has the advantages of easy implementation, good compatibility and good flexibility.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Photoelectric detector amplitude versus frequency character test method for optical fiber peg-top

InactiveCN101126784AAccurate Frequency CharacteristicsAccurately obtain frequency characteristicsSagnac effect gyrometersContactless testingGyroscopePhotodetector

The utility model discloses a method for testing the frequency properties of the photoelectric detector used for fiber optic gyroscopes. A signal generator produces sinusoidal signals and adds the signal to a light intensity modulator to carry out sinusoidal modulation on the optical power of the optical signal from the fiber source in order to produce an optical signal with sinusoidal components. The measured photodetector converts the modulated optical signal into an electrical signal and samples the electric signal by means of high-speed data acquisition card, then conducts narrowband filter and signal processing over the collected samples and calculates the corresponding frequency response. The frequency sequence pre-selected by a numerical control system changes the frequency at which the sine wave generator (NC) system sends out signals , tests a series of frequency point responses, which can be combined into an amplitude frequency response curve of the measured photodetector, and the curve is transmitted to the terminal computer for displaying and storage. By controlling all the test processes by numerical control system, the utility model has the advantages of automatic measurement, fast testing speed, high testing precision, and therefore is suitable for carefully weighing the photodetector frequency performance in the whole operating frequency range.

Owner:ZHEJIANG UNIV

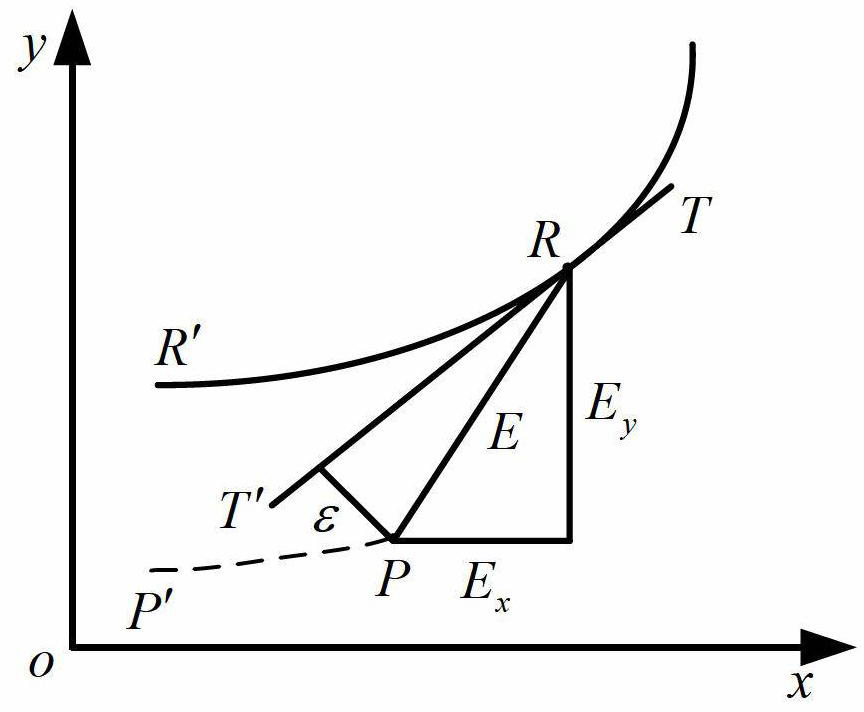

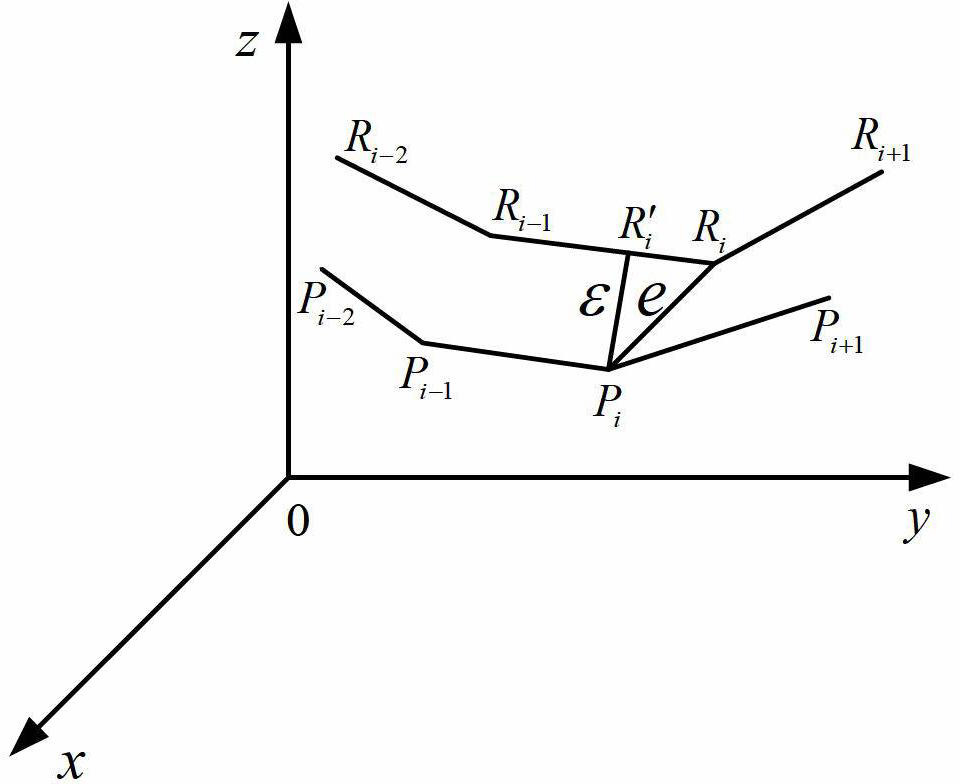

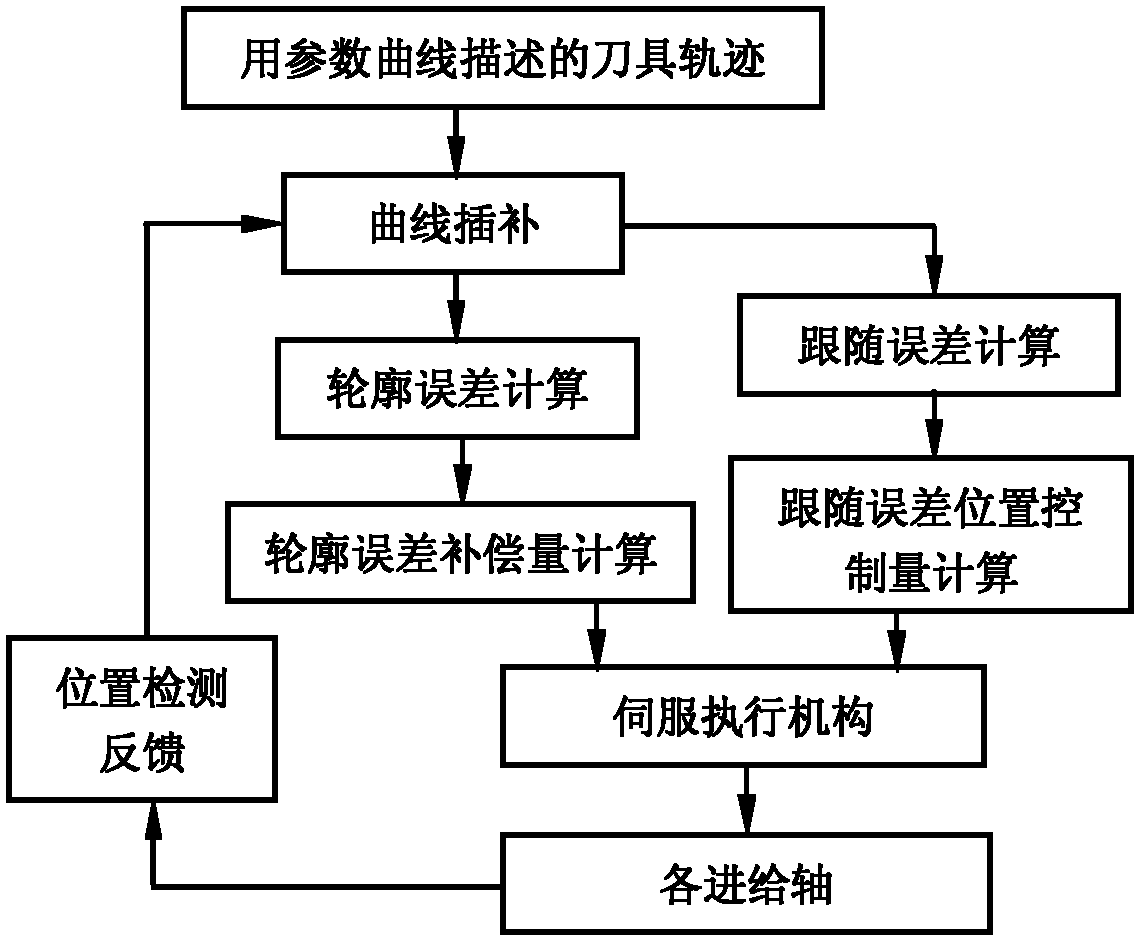

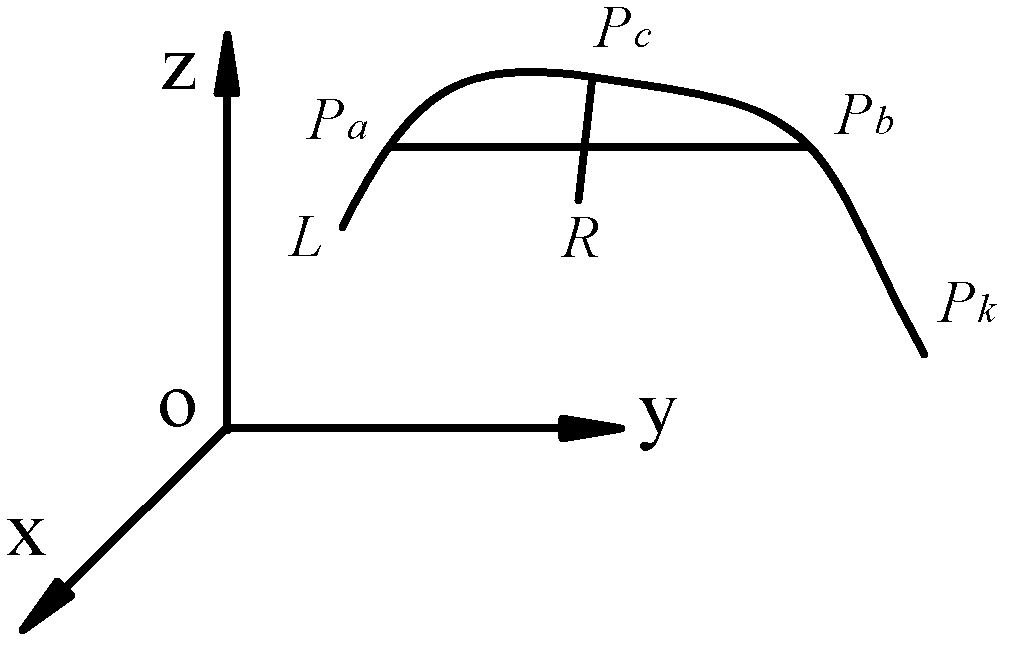

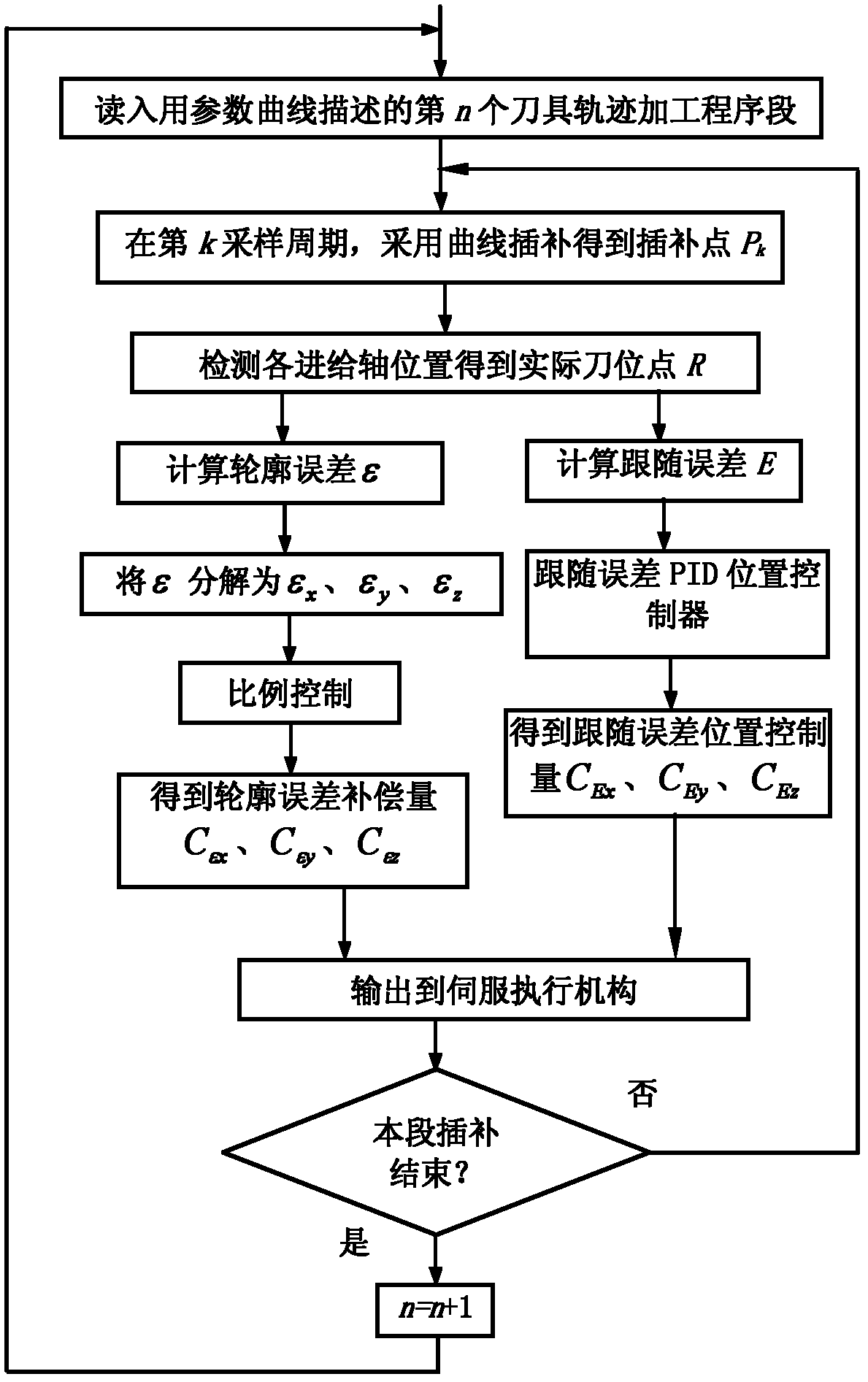

Parameter curve cutter path oriented numerical control system contour error control method

InactiveCN102591257ACalculation method is simpleImprove calculation accuracyProgramme controlComputer controlProportional controlCutter location

The invention provides a parameter curve cutter path oriented numerical control system contour error control method which comprises the following steps of: 1) calculation of the contour error; 2) calculation and control of the contour error compensation quantity, and is characterized in that: in the step 1), in each sampling period for performing curve interpolation on the parameter curve cutter path, the contour error epsilon is calculated according to the current actual cutter location point and the interpolation point on the tracked parameter curve cutter path, namely the shortest distancefrom the current actual cutter location point to the tracked parameter curve cutter path is calculated; in the step 2), the components of the contour error epsilon along the X axis, Y axis and Z axisare calculated, and the contour error compensation quantities are obtained by proportional control and superposed with the location control quantities for the following error on the X axis, Y axis and Z axis respectively; and then the result is output to a servo execution mechanism to perform contour error compensation control. The method provided by the invention has the advantages that: the contour error calculation precision is high, the contour error compensation method is simple and effective, and the contour precision can be obviously improved.

Owner:SHANDONG UNIV OF TECH

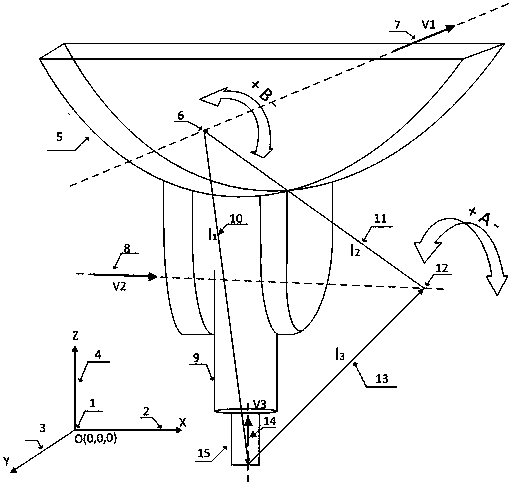

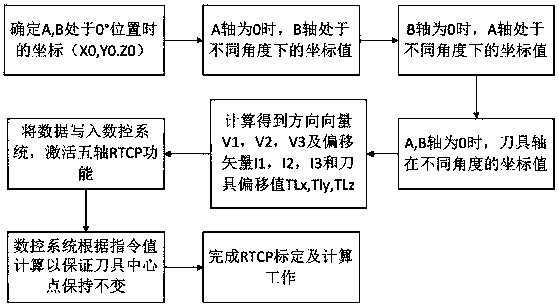

RTCP calibration and compensation method for five-axis NC machine tool of double-pendulum-head structure

ActiveCN108334030AHigh precisionReduce the error valueProgramme controlComputer controlEngineeringMachine tool

The invention discloses an RTCP calibration and compensation method for a five-axis NC machine tool of a double-pendulum-head structure. The method comprises the steps of recording the calibrated coordinate values of each rotating shaft at different angle positions, and calculating to obtain the offset vector of each rotating shaft and the vector data of each rotating shaft in the axis direction;writing the data into corresponding machine tool parameters of a numerical control system; and activating the five-axis linkage function of the numerical control system. In this way, the problems thatthe characteristic data of the five-axis machine tool cannot be directly acquired and the precision of a traditional method is low can be effectively solved. The accuracy of calibrated data is guaranteed, and the rapidity and the accuracy of the five-axis RTCP calibration are improved. As a result, the adjustment time is shortened, and the introduction of human errors is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com