Multi-period corner small straight-line segment interpolation method based on S curve acceleration/deceleration control

A small straight line, acceleration and deceleration technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as reducing calculation efficiency, discontinuous acceleration change, and prolonging calculation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation process and performance analysis of the present invention will be further described in detail below in conjunction with the accompanying drawings and simulation examples.

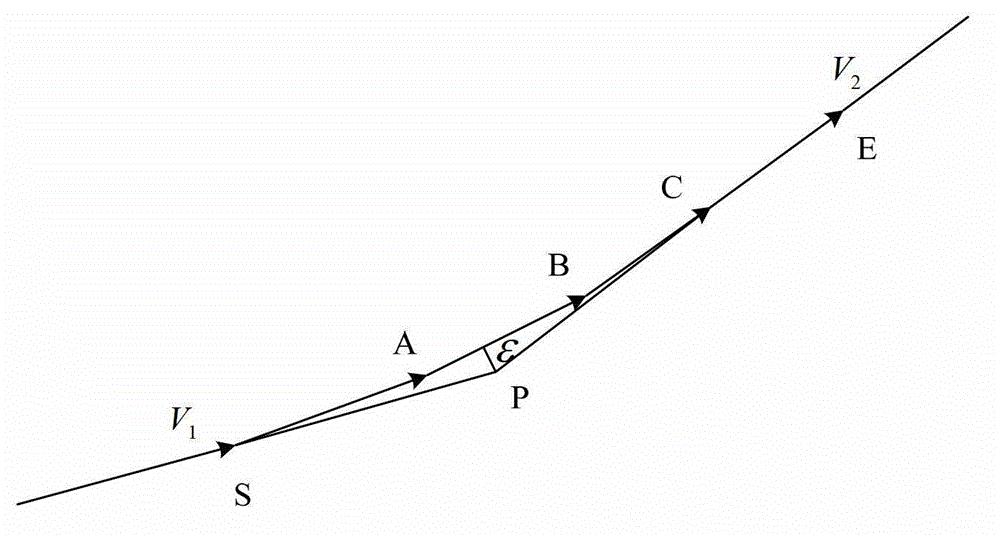

[0056] see figure 1 , first specifically introduce several terms and concepts related to multi-cycle corner transition in the present invention:

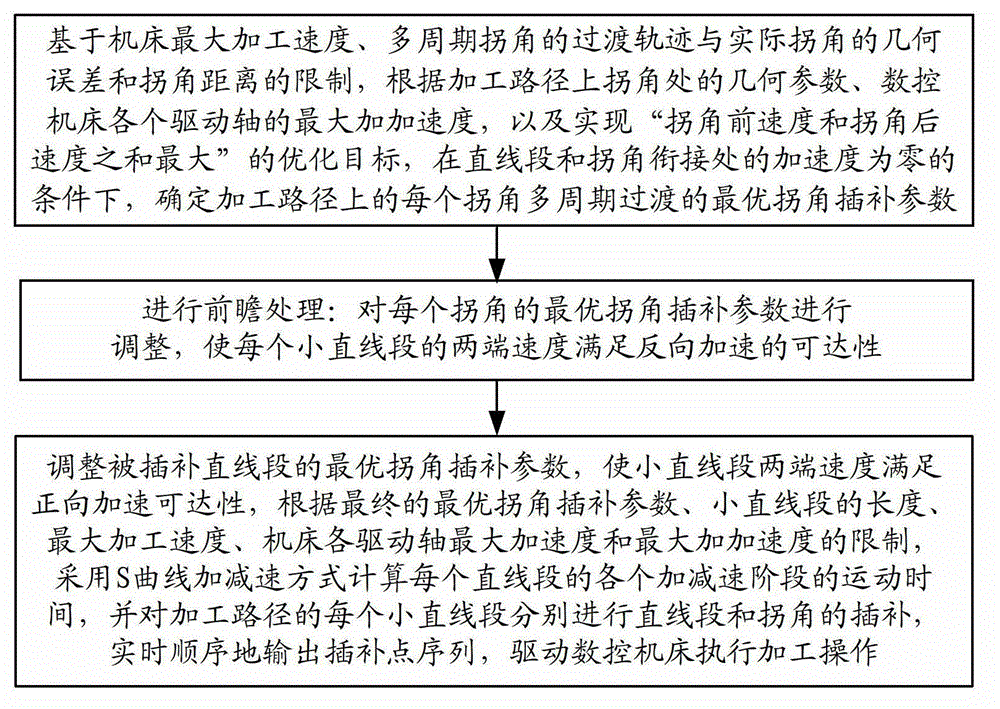

[0057] The idea of multi-period optimal corner transition proposed by the present invention is to disperse the change of the processing speed direction at the corner which was originally completed in one interpolation cycle into a processing method which is gradually changed in multiple interpolation cycles, which is used to improve the corner The corner machining speed is limited by the geometric parameters at the corner of the machined path. The corner here is the connection point of two adjacent small straight segments that are not on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com