Patents

Literature

137results about How to "Simplify computational problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional face modeling method and device

ActiveCN104376594ASimplify the collection processEasy to operate3D modellingComputer graphics (images)Data acquisition

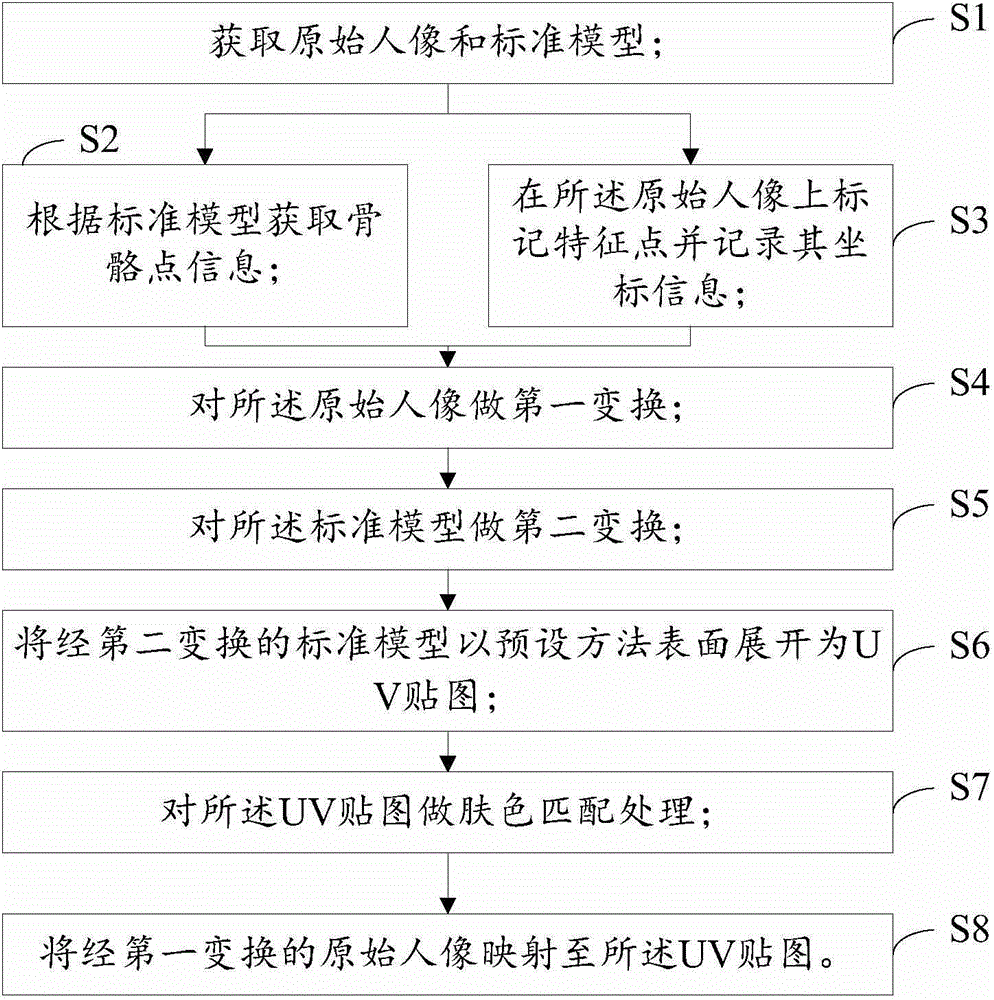

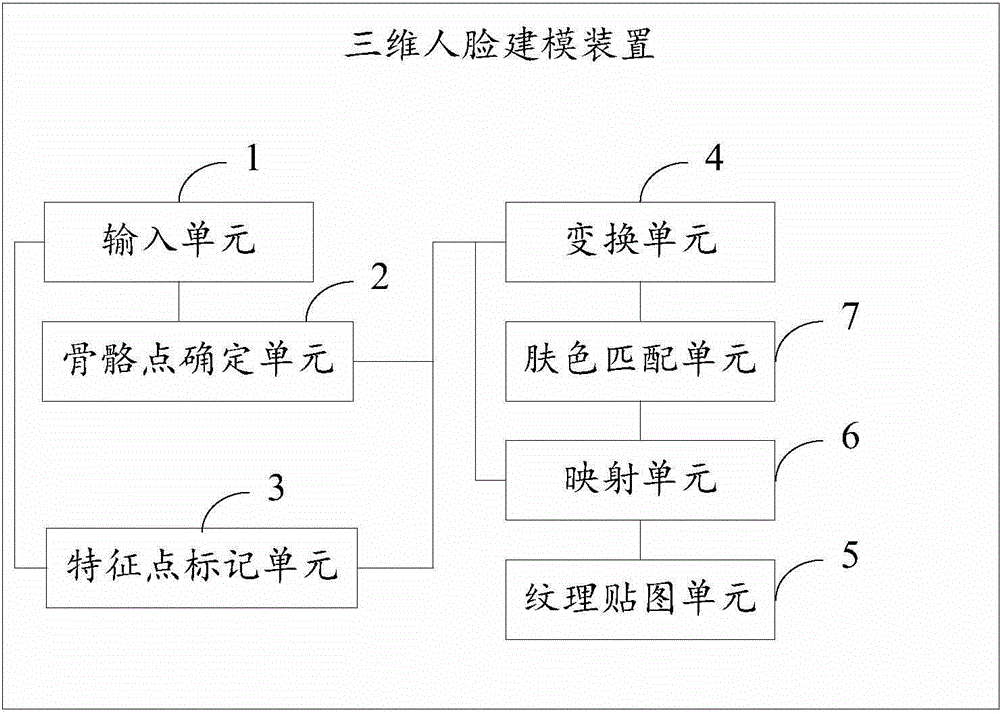

The invention provides a three-dimensional face modeling method to achieve efficient three-dimensional face modeling. The method includes the steps that an original image and a standard model are obtained; the bone point information is obtained according to the standard model; a feature point is marked on the original portrait and the coordinate information of the feature point is recorded; first conversion is conducted on the original portrait; second conversion is conducted on the standard model; the surface of the standard model generated after the second conversion is conducted is unfolded according to the preset method to form a texture image; the original portrait generated after the first conversion is conducted is mapped to the texture image. The invention further provides a corresponding three-dimensional face modeling device for implementing the three-dimensional face modeling method. According to the technical scheme, the three-dimensional face modeling method and device are simple in operation mode, good in fitting effect and high in degree of reduction; meanwhile, the method and device are higher in implementation speed and higher in efficiency, the processes of implementation and calculation are simplified, the data collection process is simplified, practicability and adaptability of a system are improved, and the method and device have great advantages in situations of low requirement for the face depth information.

Owner:FUJIAN TQ DIGITAL

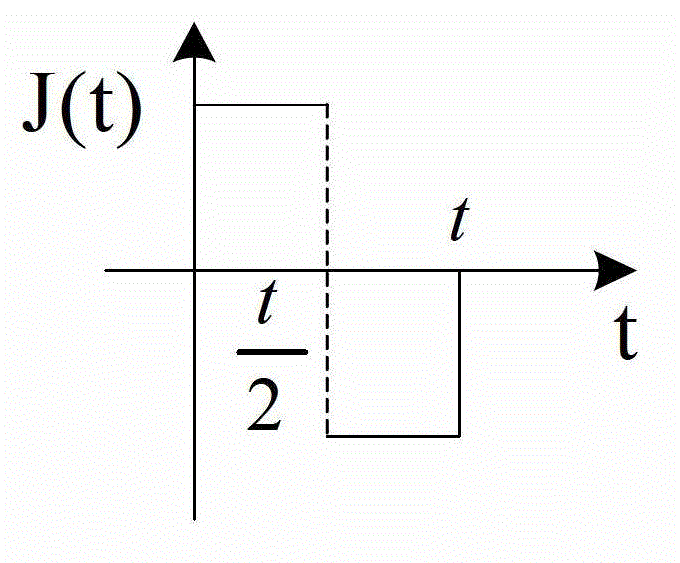

Multi-period corner small straight-line segment interpolation method based on S curve acceleration/deceleration control

InactiveCN102722140ACalculation speedSimplify calculation stepsProgramme controlComputer controlControl mannerPoint sequence

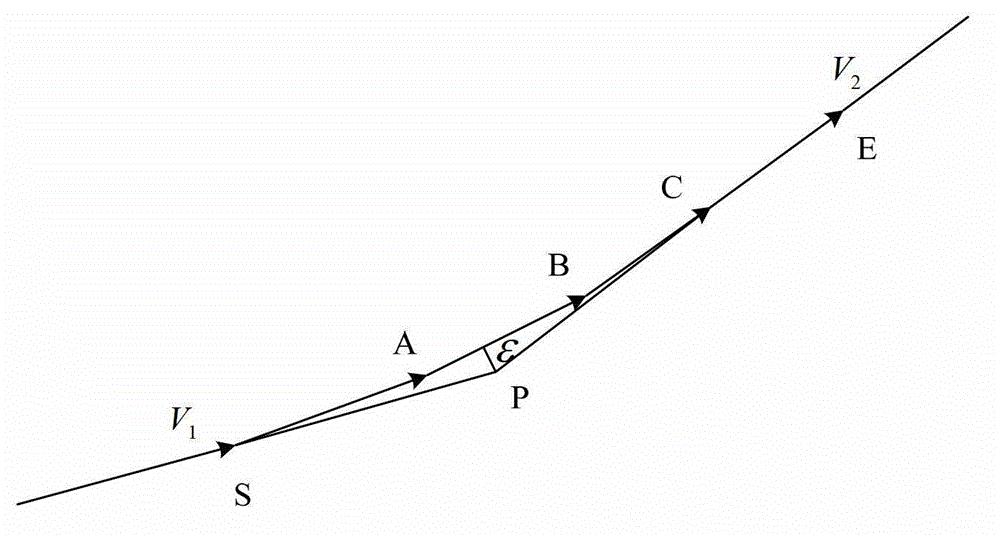

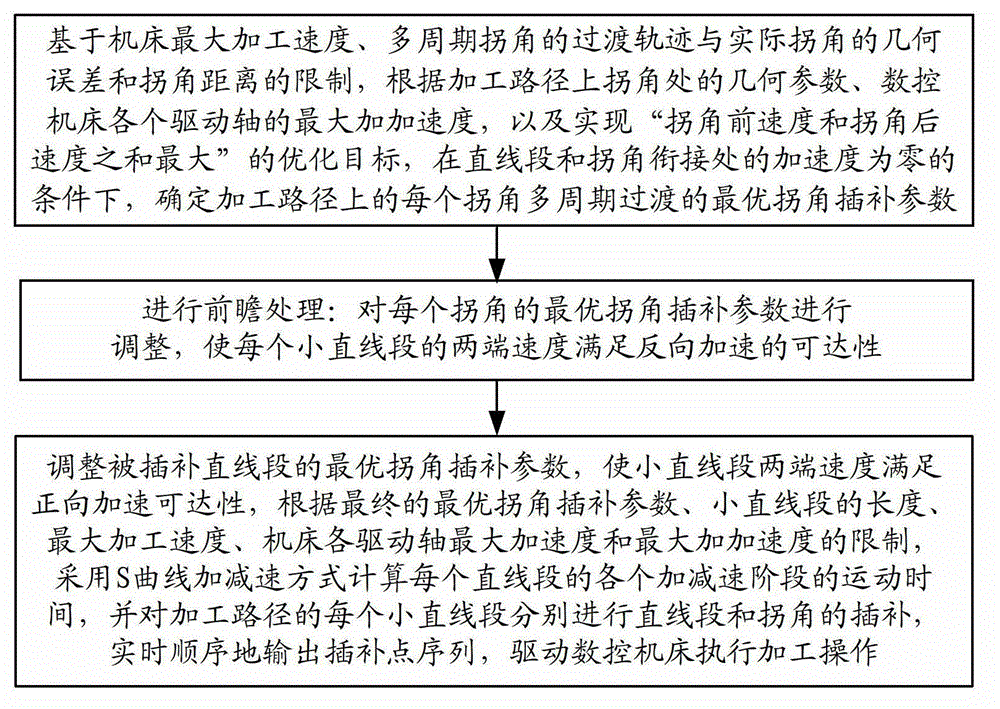

The invention discloses a multi-period optimal corner small straight-line segment interpolation method based on S curve acceleration / deceleration control in a numerical control system. The method comprises the following steps of: based on the limitations of the machining precision of a machine tool and the maximum machining speed of each driving shaft, setting the acceleration speed at the joint of the corner and the straight-line segment to be zero according to geometrical parameters of each corner on a machining path, the maximum machining acceleration speed of each driving shaft and an optimization target, and determining and adjusting the optimized corner interpolation parameters in multi-period transition at each corner, so that the acceleration speed at two ends of each small straight-line segment meets the reachability requirement of the S curve acceleration / deceleration control mode; and calculating the time at each acceleration / deceleration stage of each straight-line segment according to the S curve acceleration / deceleration mode, respectively performing straight-line segment and corner interpolation on each small straight-line segment, sequentially outputting interpolation point sequences in real time, and driving a numerical control machine tool to execute the machining operation. By the method, the vibration of the machine tool is reduced, the quality of the surface of a workpiece is improved, the calculation speed is high, the real-time machining requirements can be met, and the method is suitable for different models of three-axis, four-axis or five-axis numerical control machine tools.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

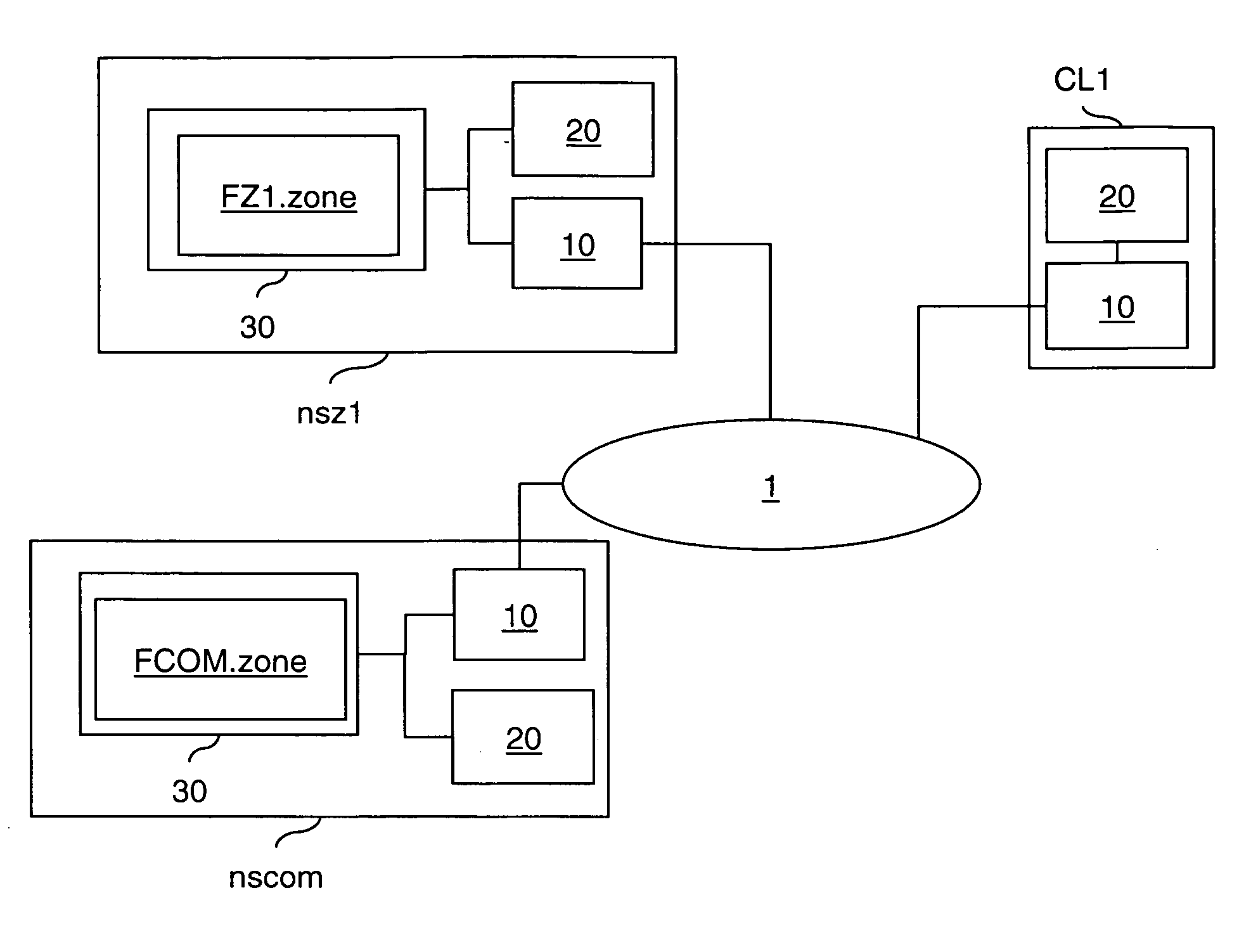

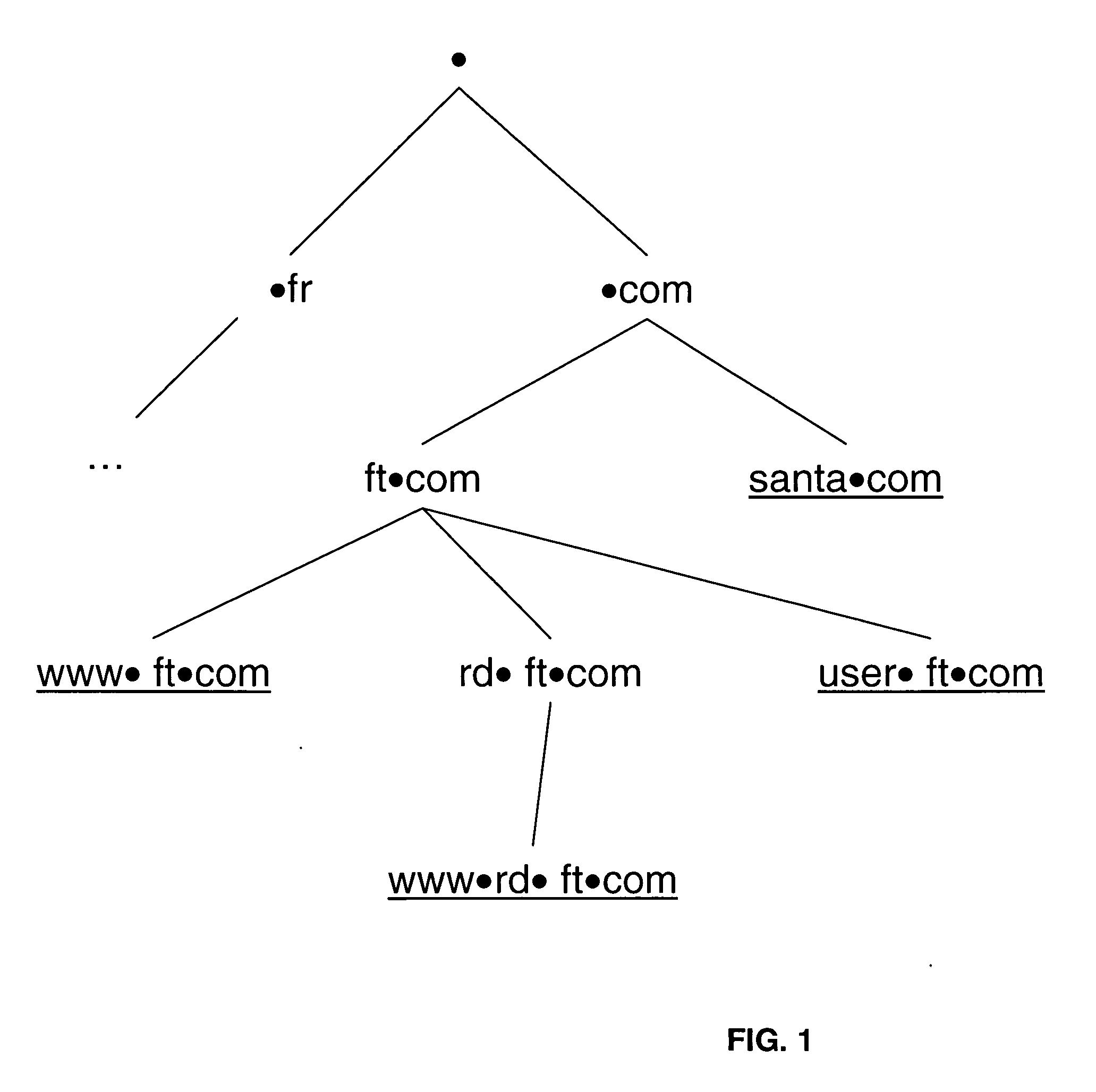

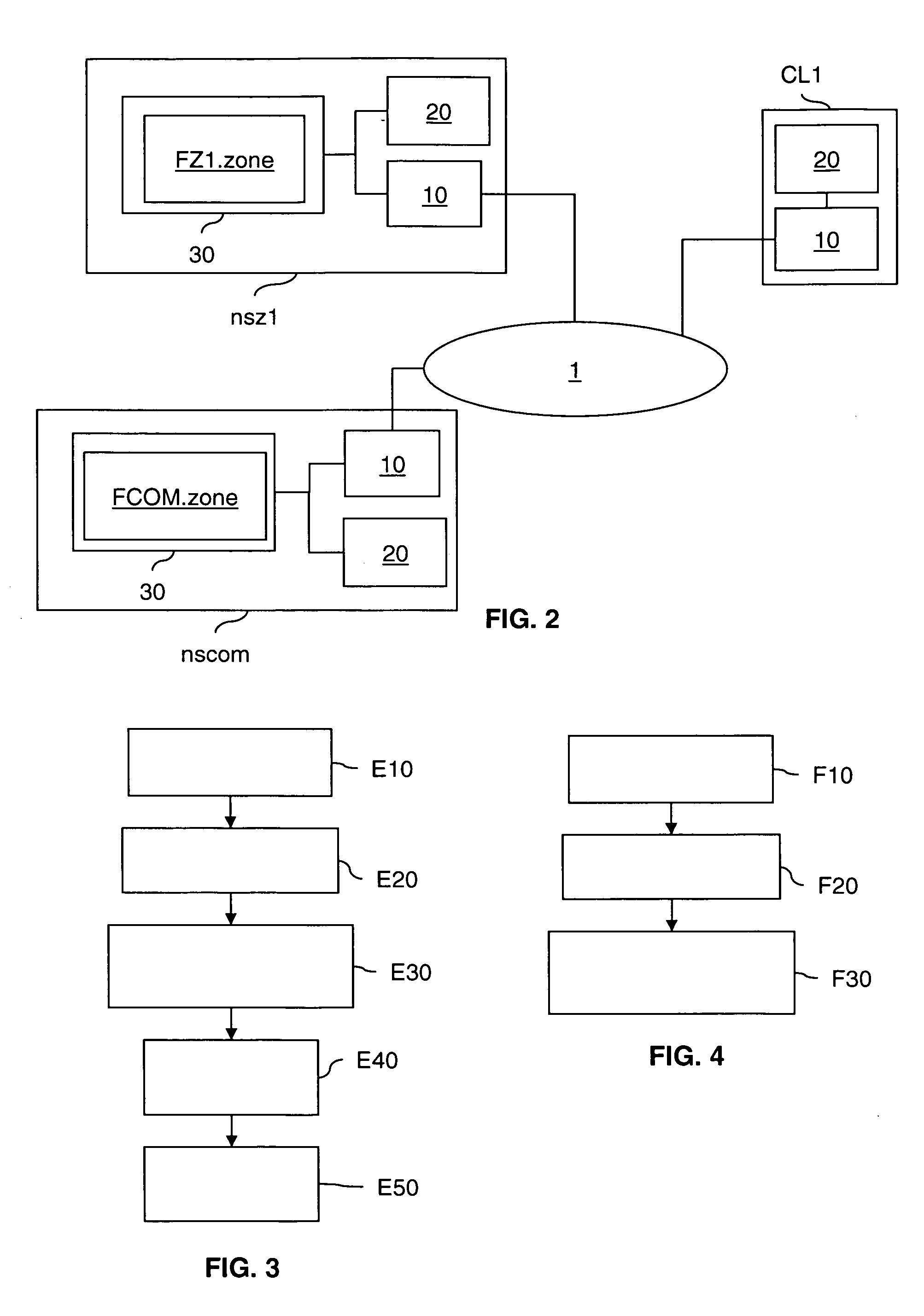

Server and Method for Managing DNSSEC Requests

InactiveUS20090187649A1Simplify computational problemsIncrease computation timeDigital computer detailsTransmissionZone fileClient-side

A domain server that comprises: means (10) for receiving a query transmitted from a client device (CL1) for obtaining DNS data; a zone file (FZ1, zone) comprising one or more distribution rules defining a partitioning of the domain into sub-zones, DNS data of said sub-zones being associated with a pair of partition keys specific to said sub-zone; means (20) for obtaining from said zone file a useful piece of information sufficient for identifying the pair of the partition keys associated with the required DNS data; and means (10) for transmitting to the client device (CL1): the required DNS data, the value of the signature of said data produced by means of the private component (ZSK2[pr]) of the pair of partition keys; and the useful piece of information.

Owner:FRANCE TELECOM SA

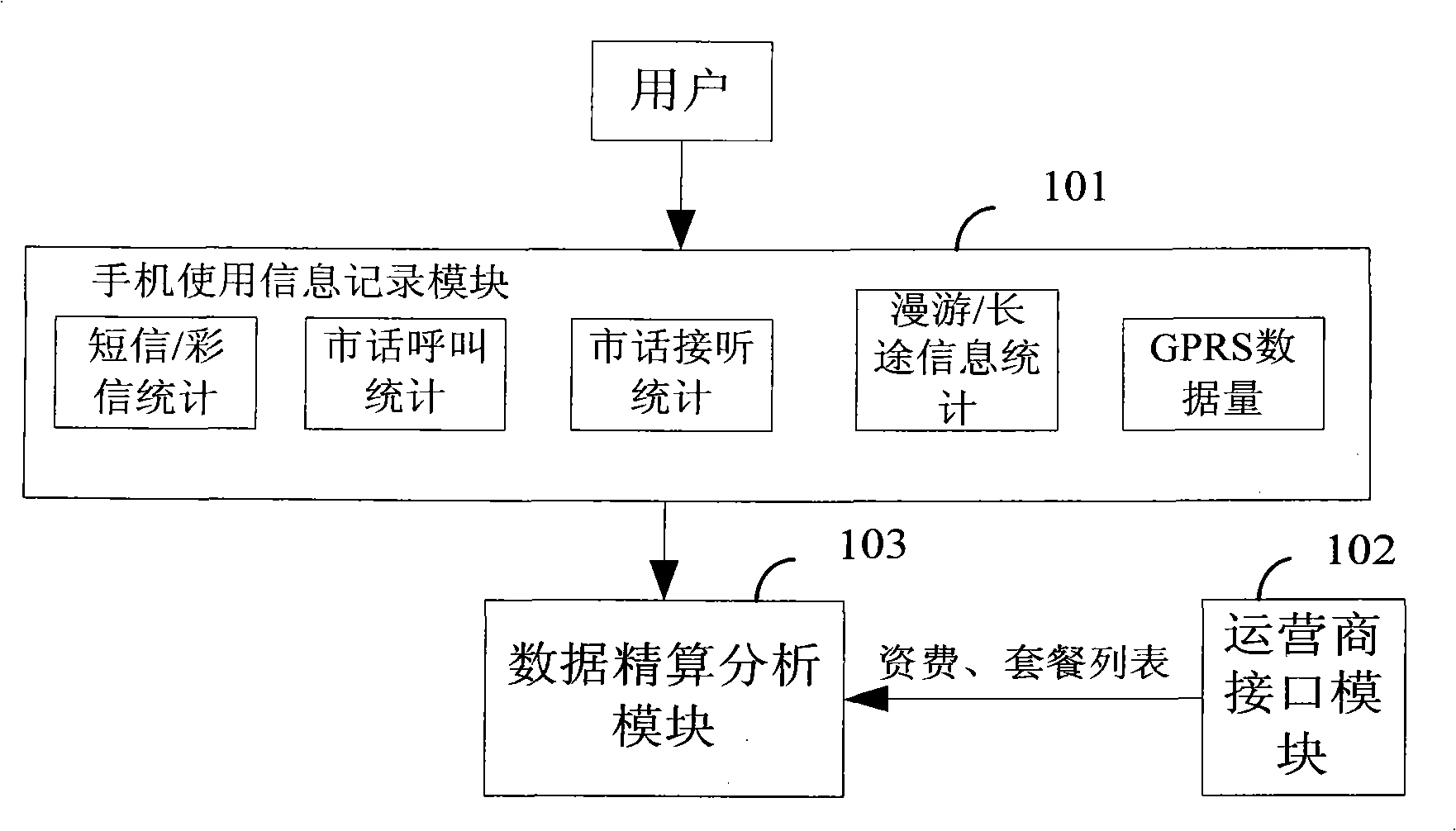

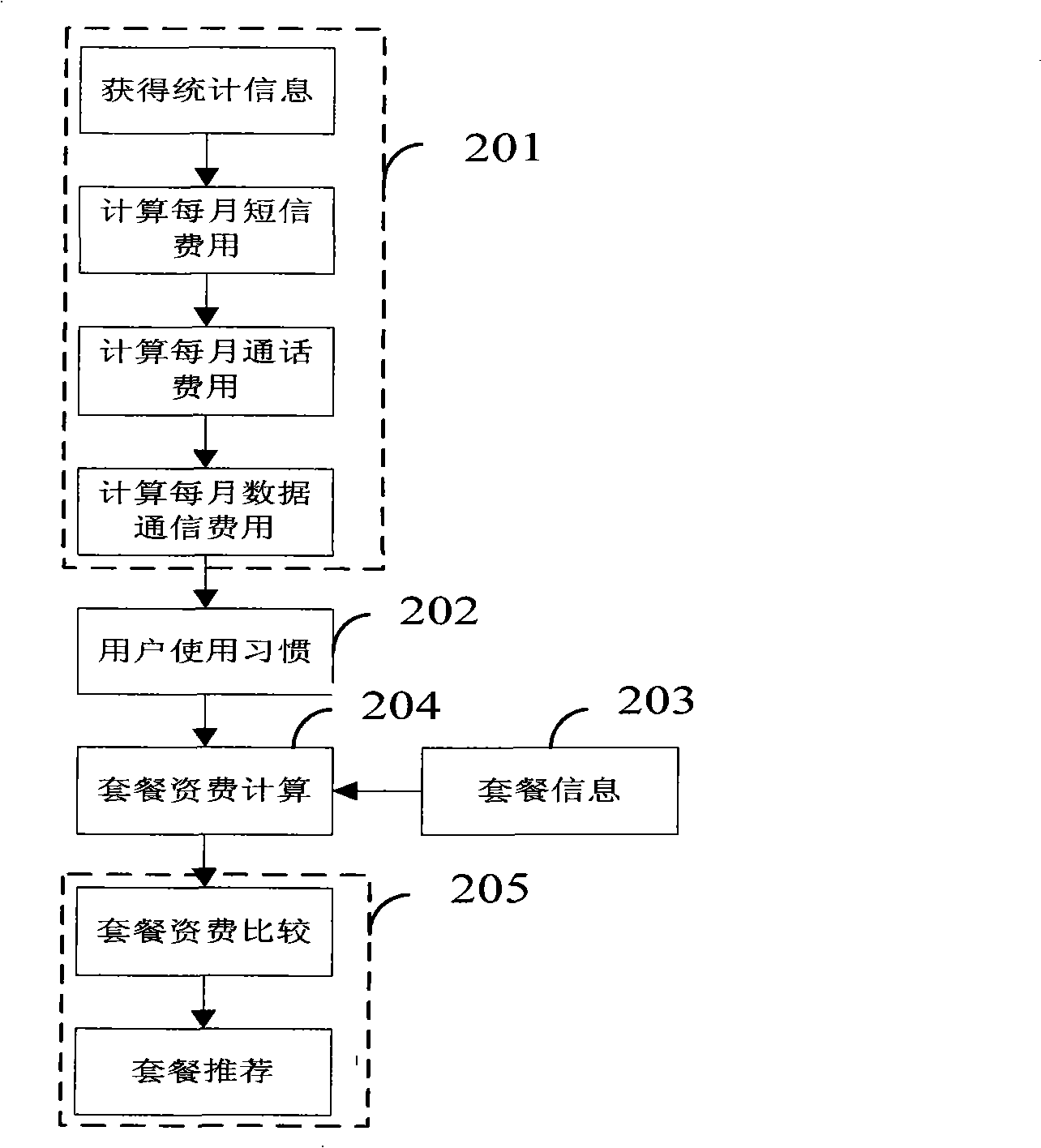

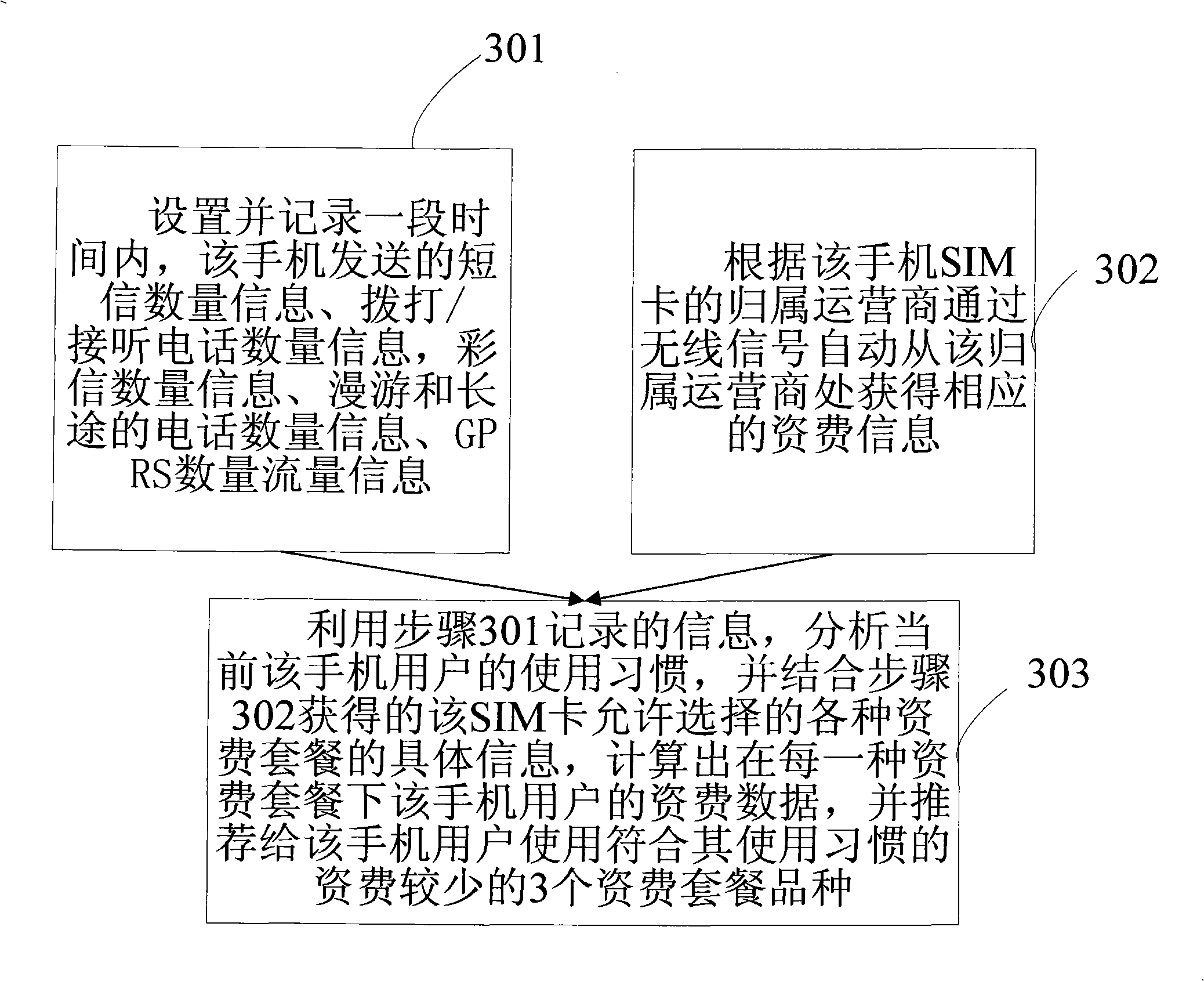

A system and method for selecting fee suite of a mobile phone

InactiveCN101262676AEasy to useSimplify computational problemsRadio/inductive link selection arrangementsHabitComplex calculation

The invention discloses a system and a method for selecting mobile tariff package schemes. The method of the invention comprises the steps of (1) setting and recording the quantity information of the short messages sent by the cell phone and that of dialing / answering phone call in a period of time; (2) obtaining corresponding fees and billings information from the corresponding operator through wireless signals according to the operator the SIM card of the mobile belongs to; (3) analyzing the current use habits of the user according to the information recorded in the step (1) and calculating and recommending the most economical tariff package scheme for the mobile user by combining the fees and billings information obtained in the step (2). The system and the method of the invention can analyze the actual mobile using conditions of the user, automatically calculate a better tariff package scheme and recommends the tariff package scheme to the user, meanwhile, simplify the processes of complex calculation and inquiry, thereby being convenient for the usage of users.

Owner:ZTE CORP

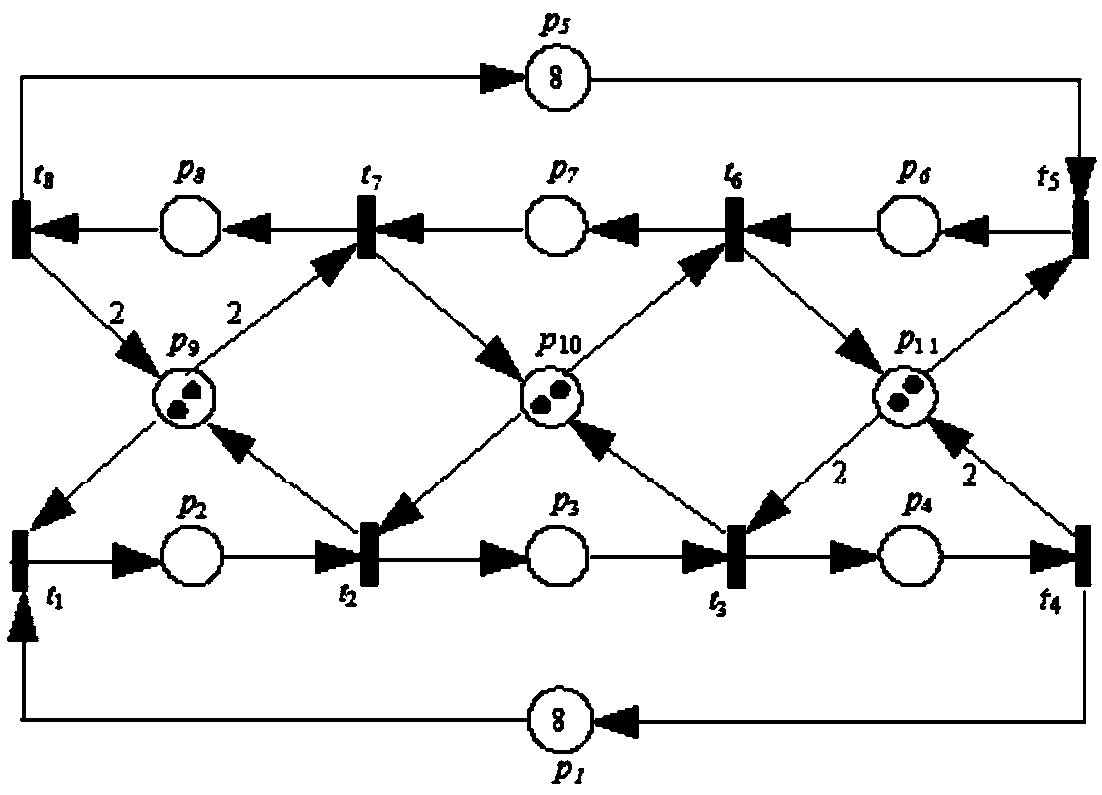

Robustness control method of automatic manufacture system based on Petri network

ActiveCN106200575AAvoid deadlockSolve the blockageTotal factory controlProgramme total factory controlReal-time computingDevice Sensor

The invention relates to a robustness control method of an automatic manufacture system based on a Petri network. The robustness control method firstly detects all enabled transitions under an achievable state M, detects a transition set guaranteeing that a system has no deadlock from all enabled transitions, detects transitions guaranteeing the system to be robust from all transitions having no deadlocks, detects biggest concurrency allowable transitions from all robust transitions, chooses a transition to emit from the biggest concurrency allowable transition, wherein every time one transition is emitted, a new state is obtained, and executes the above steps in a new state. So repeatedly, a transition sequence which can guarantee system is robust and can operate without deadlock can be obtained, the that transition is emitted according to the sequence cannot only guarantee that the system has not deadlock, but also guarantee that the system has not blockage. The robustness control method uses a Petri network as a mathematic tool and performs modeling on an automatic manufacture system so as to realize a fact that the system can continuously and smoothly process.

Owner:XIDIAN UNIV

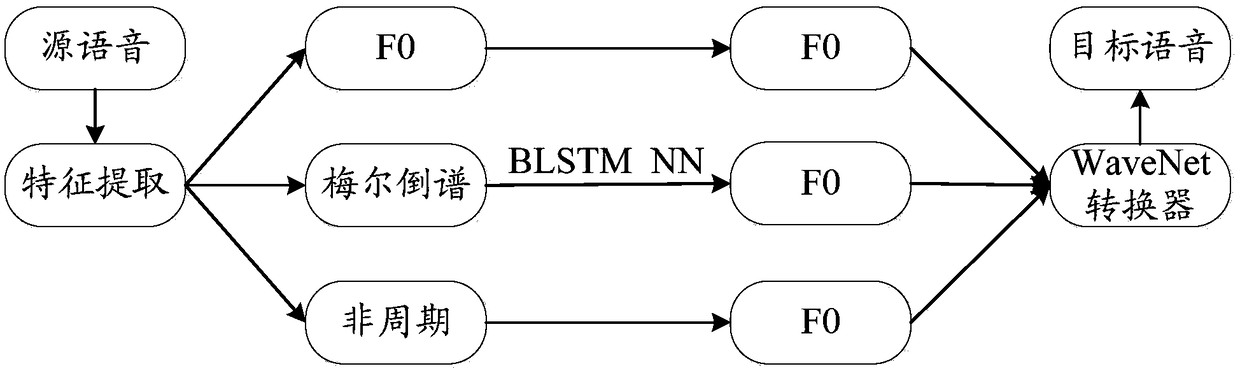

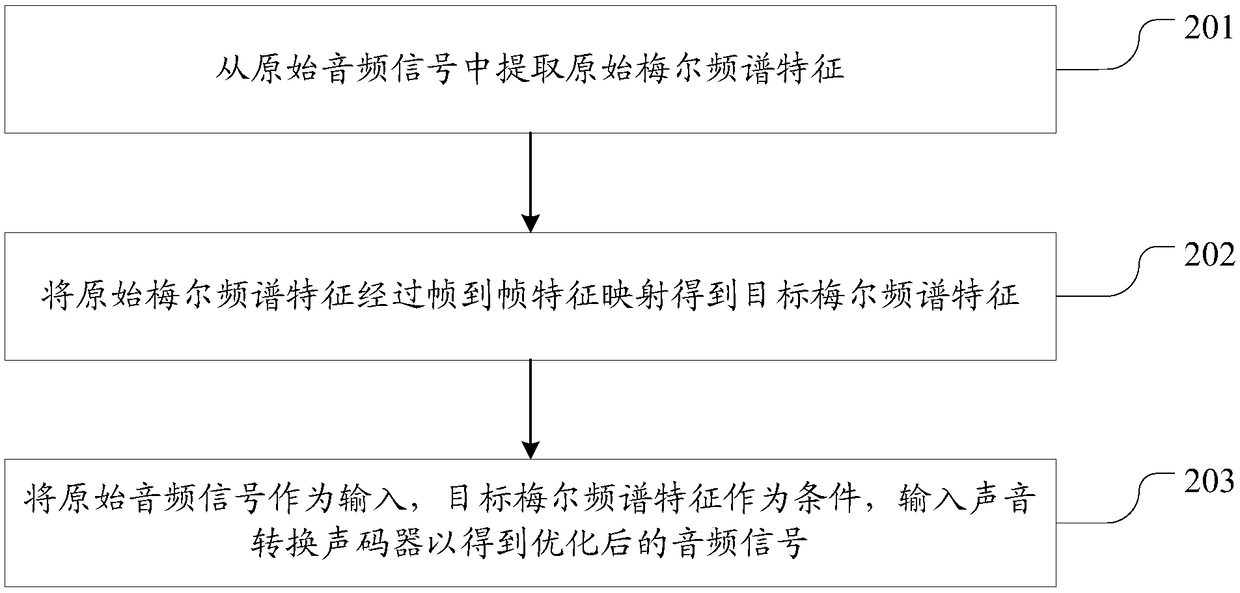

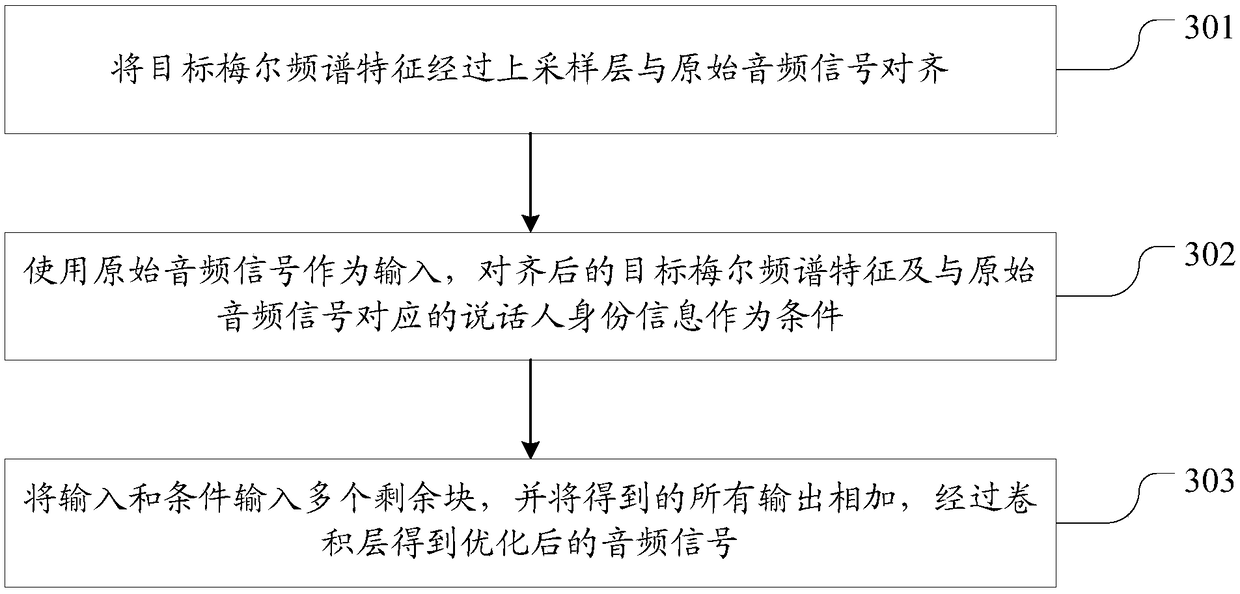

Sound conversion optimization method and system

ActiveCN108847249ASimple structureSimplify computational problemsSpeech analysisAudio signalFundamental frequency

The invention discloses a sound conversion optimization method and system. The method comprises steps that original Mel-spectrum features are extracted from an original audio signal; the original Mel-spectrum features are mapped through frame-to-frame features to obtain target Mel-spectrum features; the original audio signal is taken as input, the target Mel-spectrum features are taken as the condition, and the original audio signal is inputted to a sound conversion vocoder to obtain an optimized audio signal. The method is advantaged in that the high quality audio conversion structure is proposed, a Mel cepstral coefficient and the fundamental frequency F0 commonly used in acoustic features are discarded, instead, a very low level of the Mel spectrum is used as an acoustic feature, the sound is more natural compared with the sound converted in the prior art while the structure and calculation are simplified.

Owner:AISPEECH CO LTD

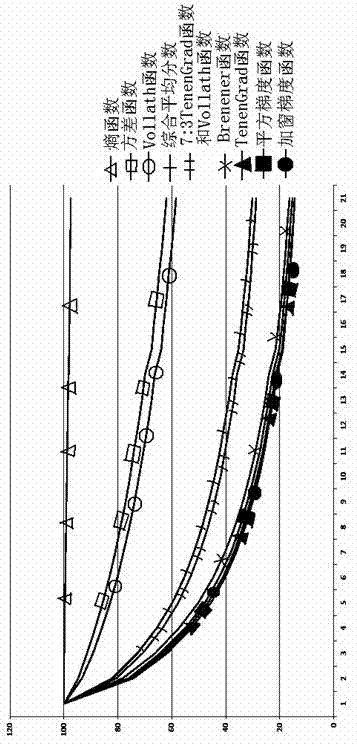

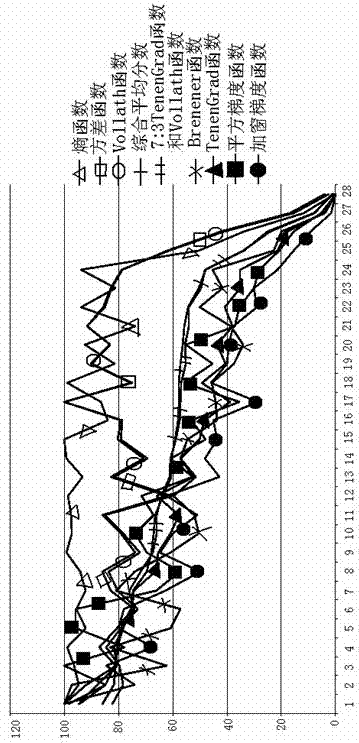

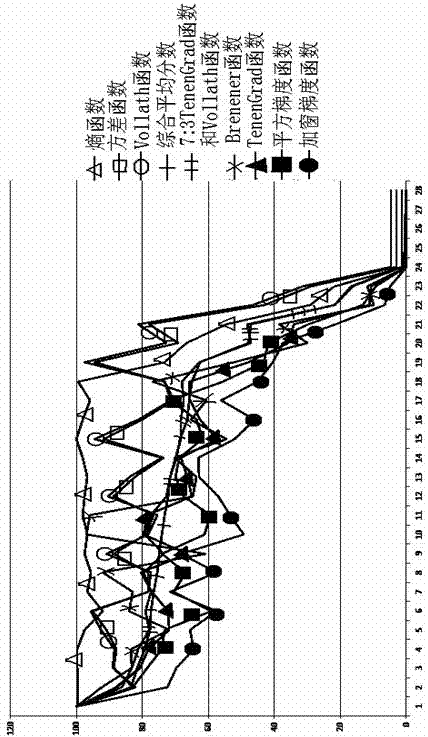

Image definition evaluation method

ActiveCN102968800ASimplify computational problemsEase of evaluationImage analysisEvaluation resultImage evaluation

The invention provides an image definition evaluation method comprising the following steps of: 1, carrying out data calculation on images by using image evaluation functions; 2, integrating all the calculated values of data of all the image evaluation functions; and 3, evaluating the definitions of the images by integrating the calculated values. The image definition evaluation method provided by the invention is more accurate than a single value through integrating the data of all the evaluation functions; and furthermore, the combined TenenGrad function and Vollath function are applied so that the calculation process is simplified and convenience is brought for evaluation. The image definition evaluation method is convenient, fast and efficient and capable of ensuring that an evaluation result is consistent with a result observed through human eyes.

Owner:KONFOONG BIOTECH INT

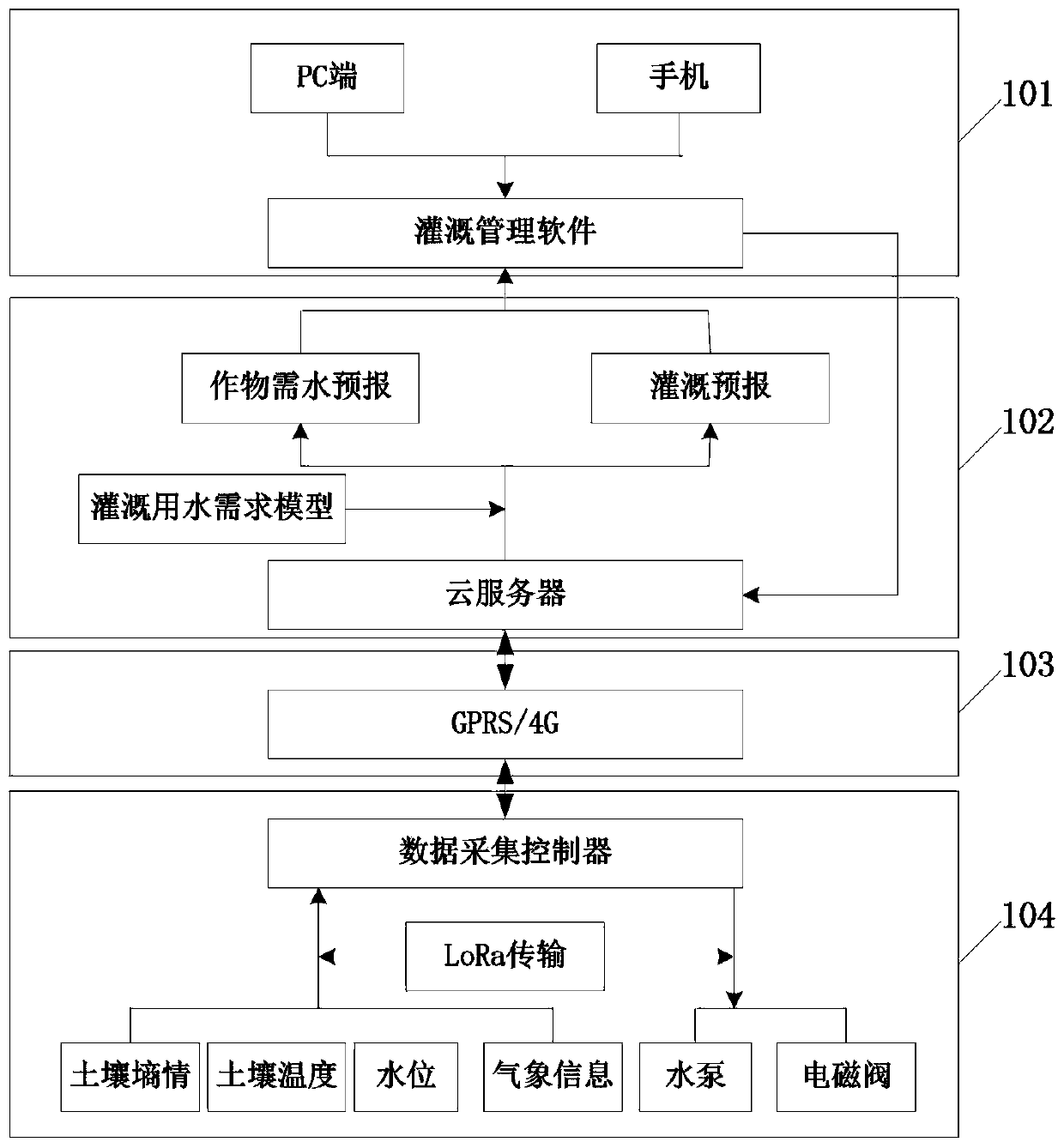

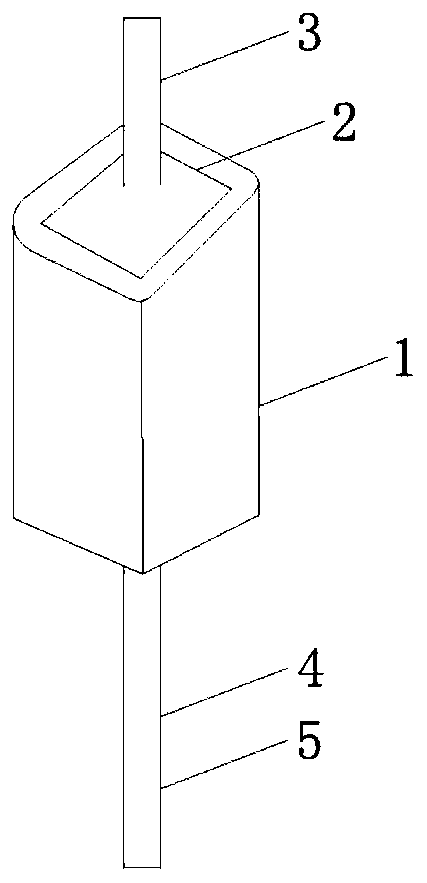

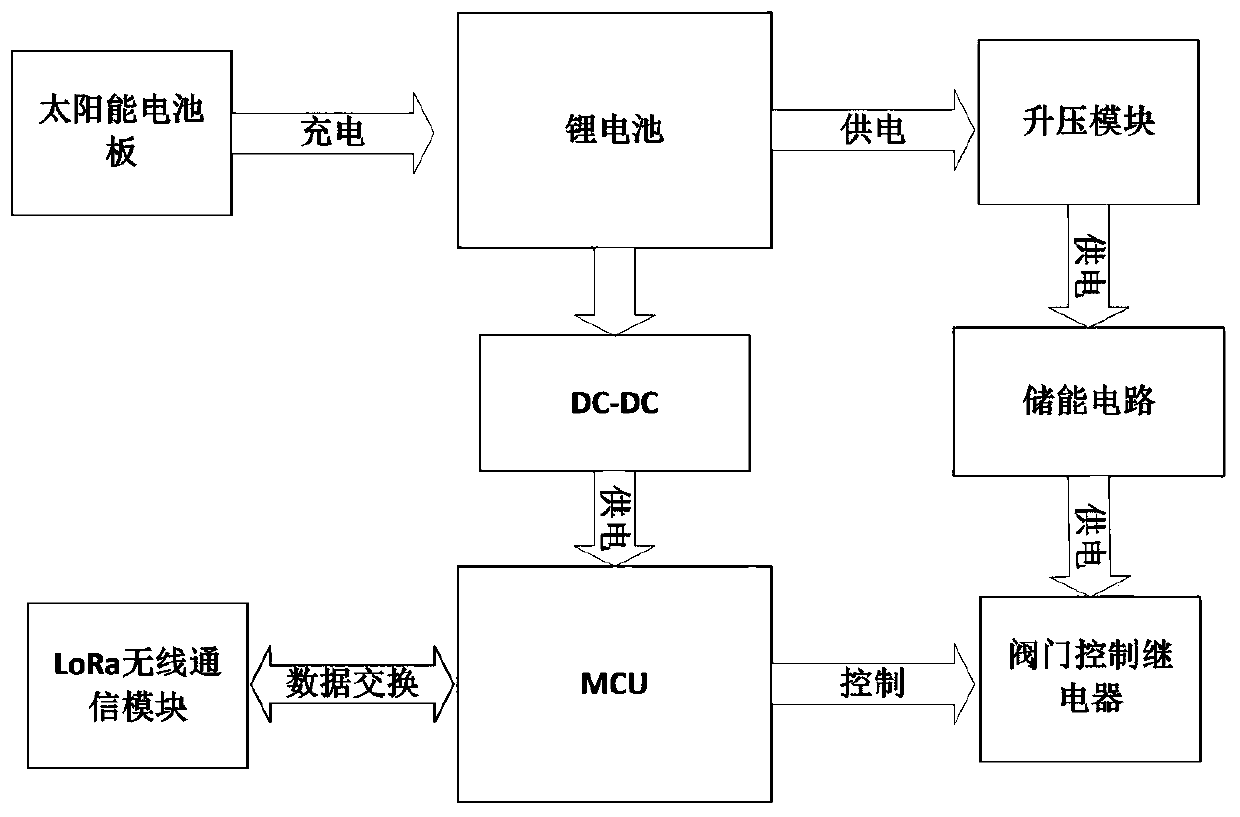

Intelligent irrigation management system

PendingCN110050673AEase of accessThere are many types of reliefWatering devicesCultivating equipmentsData acquisitionEngineering

The invention provides an intelligent irrigation management system, comprising an application management platform, a cloud data center, a wireless transmission platform and an intelligent sensing platform; the application management platform comprises an intelligent terminal and irrigation management software; the intelligent sensing platform comprises a data acquisition controller, a LoRa transmission module, a soil moisture sensor, a soil temperature sensor, a water level sensor, a meteorological environment sensor, a water pump and an electromagnetic valve; the cloud data center comprises acloud server; the cloud data center receives the information, collected by the intelligent sensing platform, by means of the wireless transmission platform, generates crop water demand forecast and irrigation forecast according to the collected information and a preset irrigation water demand model, and transmits the generated crop water demand forecast and irrigation forecast to the irrigation management software; the irrigation management software generates a corresponding irrigation strategy. The intelligent irrigation management system provided by the invention can avoid the problems in the prior art, and can set different irrigation strategies according to the different requirements of the crops for watering, thus realizing personalized watering.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

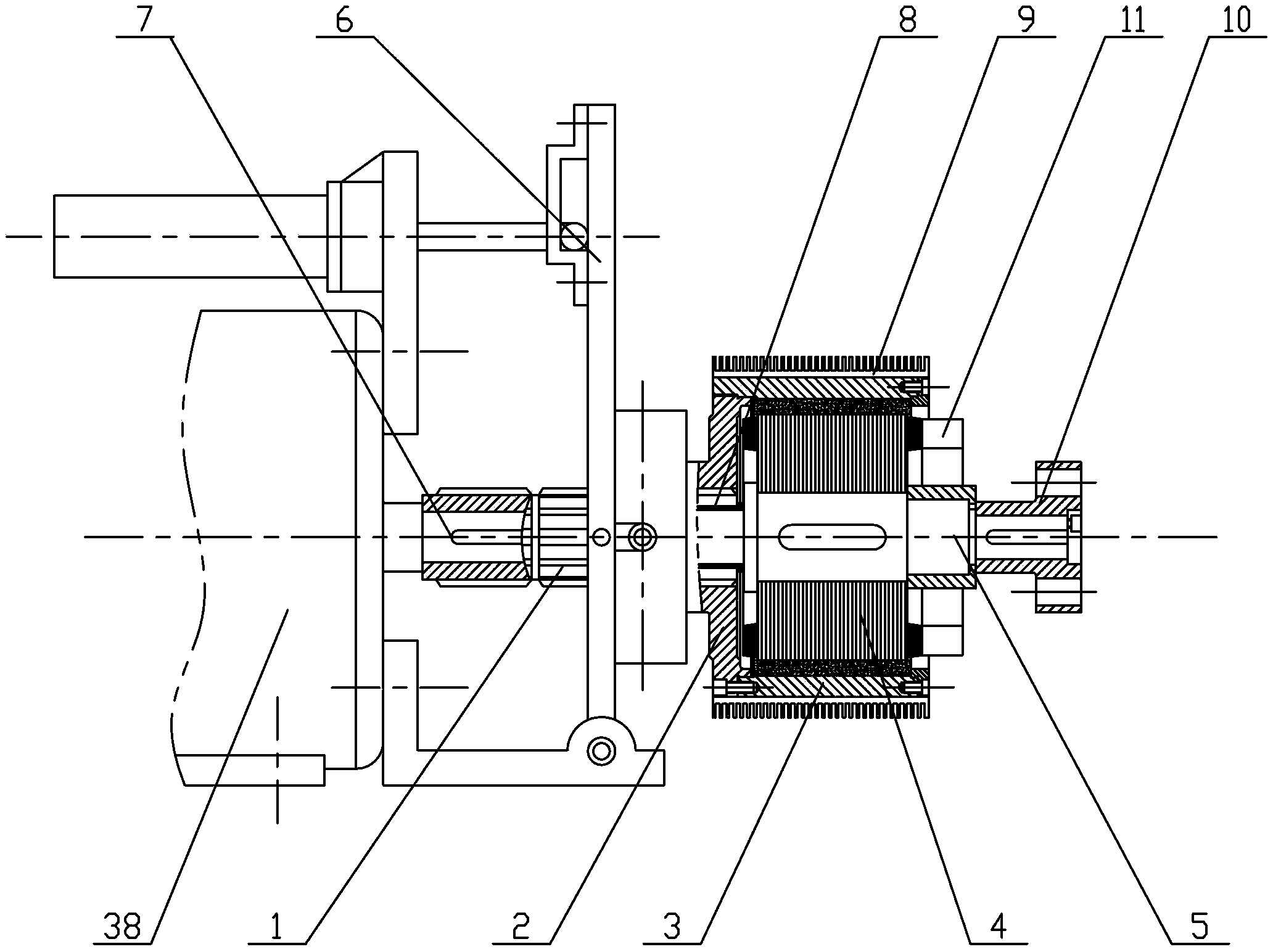

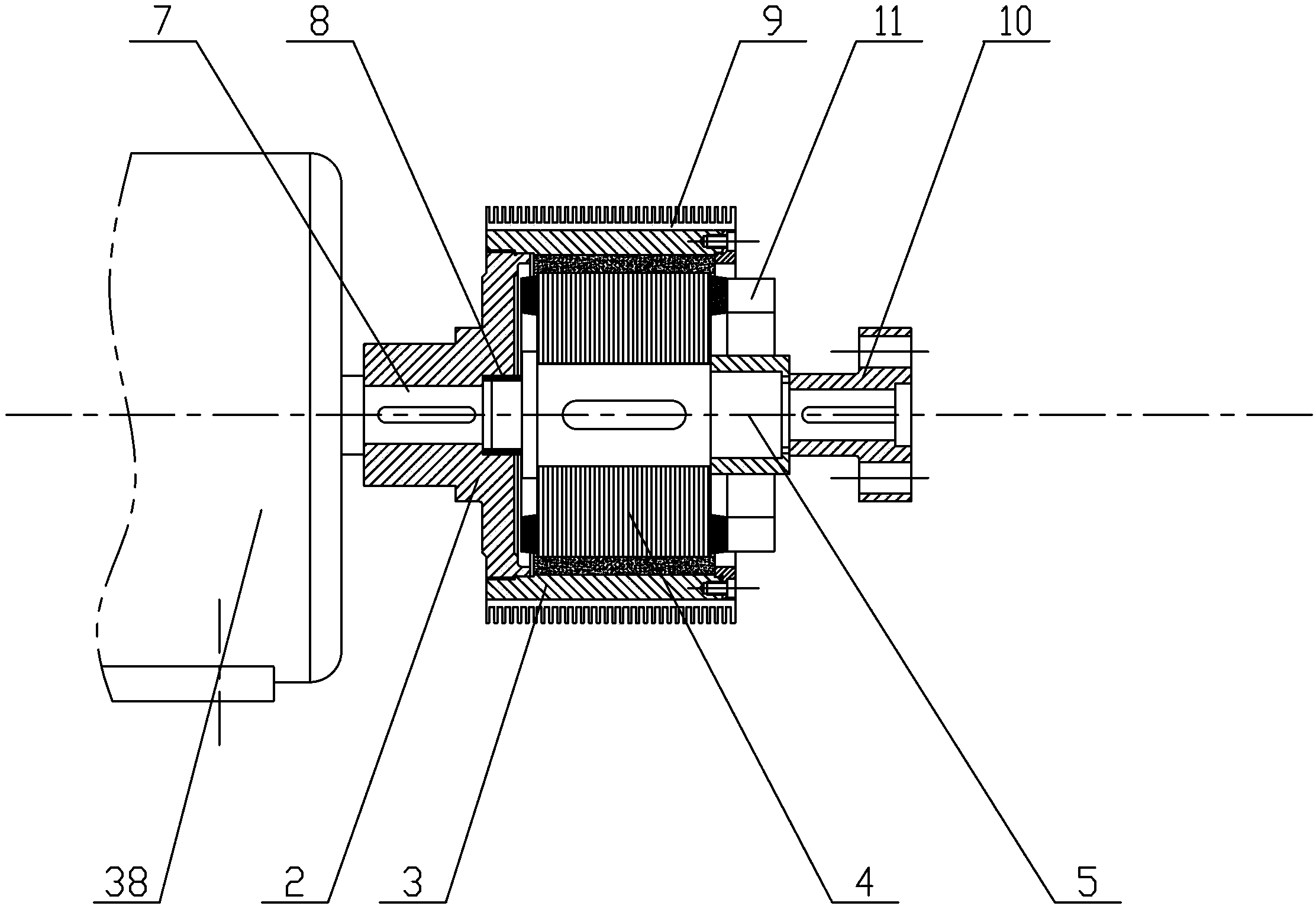

Magnetic coupler

ActiveCN103401398ASmall moment of inertiaImprove reliabilityDynamo-electric gearsElectric machineControl theory

The invention discloses a magnetic coupler which comprises a power input shaft, connecting flanges, permanent magnet outer rotor assemblies, cage type inner rotors, a power output shaft and a mechanical speed adjustment device, wherein the permanent magnet outer rotor assemblies have hollow cup-shaped structures, are sleeved outside the cage-type inner rotors and realize transmission of torque under the coupling action of an air gap magnetic field between the permanent magnet outer rotor assemblies and the cage-type inner rotors; the mechanical speed adjustment device can change axial air gap areas between the permanent magnet outer rotor assemblies and the cage-type inner rotors according to a lever theory, thus realizing stepless speed variation for load rotating speed. According to the magnetic coupler, a method for designing the number of pole pairs of the permanent magnet outer rotor assemblies is provided on the basis of a minimum torque ripple rule, so that the thickness of yokes and the rotating inertia of the coupler are reduced. The cage-type inner rotors can adopt structures which are the same as or similar to that of the conventional motor cage rotor iron core. The magnetic coupler disclosed by the invention can be coaxially connected with a load and can be used as a belt wheel adapter matched with a belt wheel.

Owner:DALIAN JIAOTONG UNIVERSITY

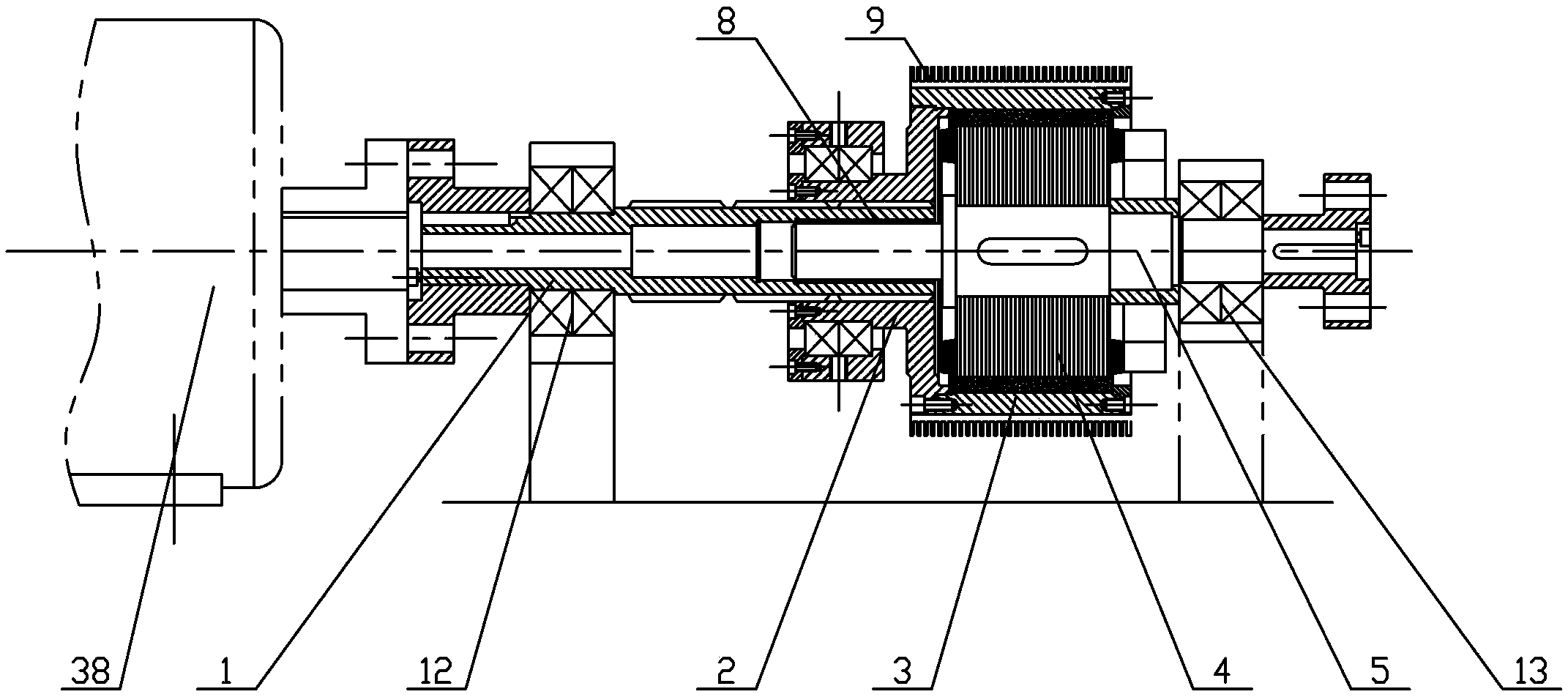

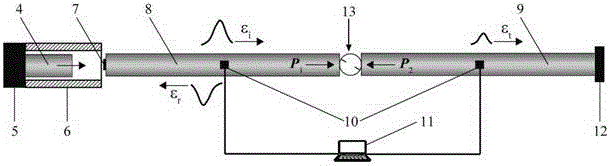

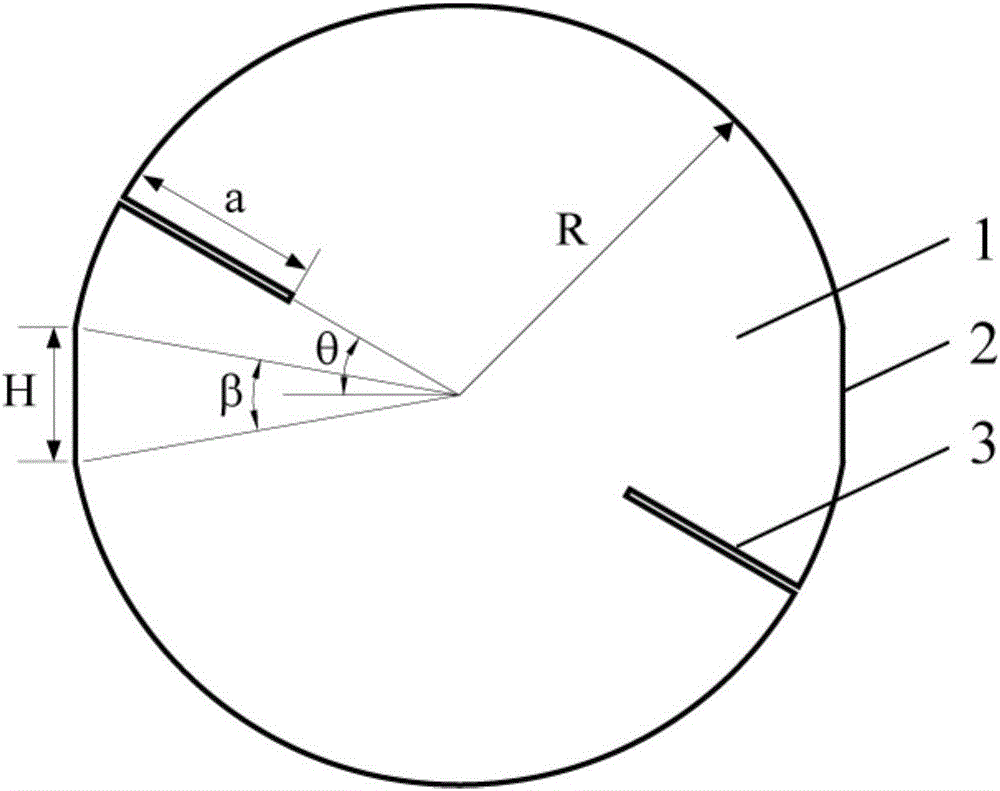

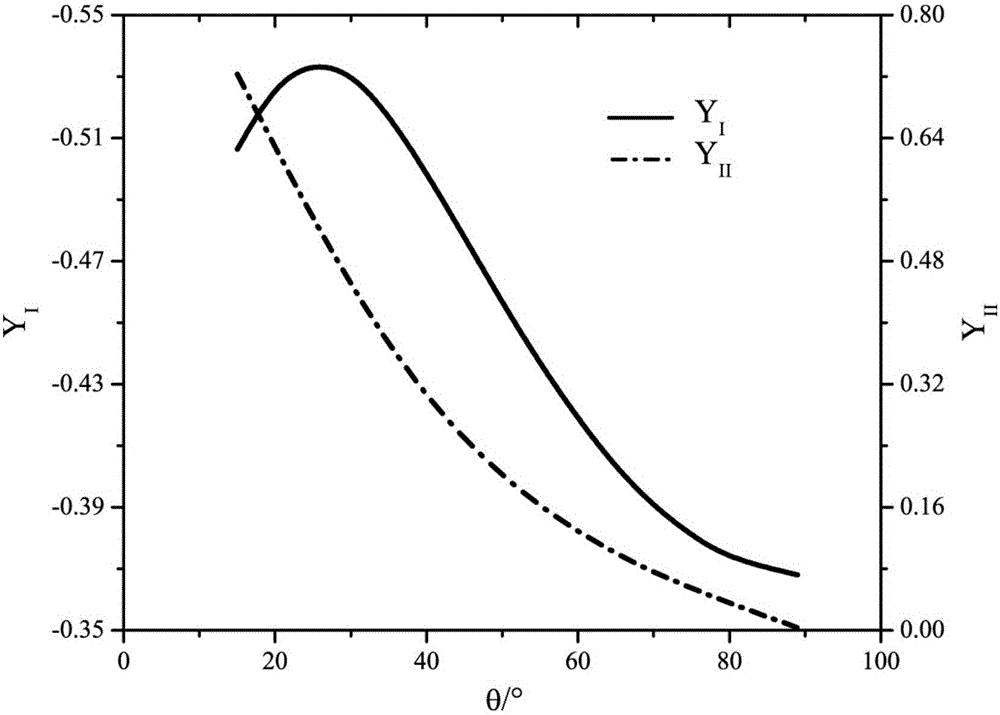

Test piece for testing rock II-type dynamic fracture toughness and testing method

InactiveCN106404562ASimple structureSmall amount of cuttingPreparing sample for investigationMaterial strength using single impulsive forceStress waveStrain gauge

The invention discloses a test piece for testing rock II-type dynamic fracture toughness and a testing method. The test piece is a disc-shaped test piece with two cutting grooves, two rectangular mounting planes identical in shape and size and perpendicular to a diameter are processed at positions, symmetric according to a same diameter, of a test piece body, the cutting grooves which are identical in shape and size are positioned on a same diameter of the test piece body, cutting groove faces are along side face thickness direction and diameter direction of the test piece, and openings of the cutting grooves extend into the test piece and penetrate upper and lower disc plate faces of the test piece. The testing method includes: mounting the test piece between an incidence rod and a transmission rod of a Hopkinson press rod testing device; utilizing an impact rod to impact the front end face of the incidence rod, wherein generated stress waves are shaped by a waveform shaping piece arranged on the front end face of the incidence rod and then act on the test piece through the incidence rod; collecting incidence strain, reflection strain and transmission strain in the whole process from impact starting to failing of the test piece by strain pieces arranged on the incidence rod and the transmission rod, and calculating to acquire rock II-type dynamic fracture toughness.

Owner:SICHUAN UNIV

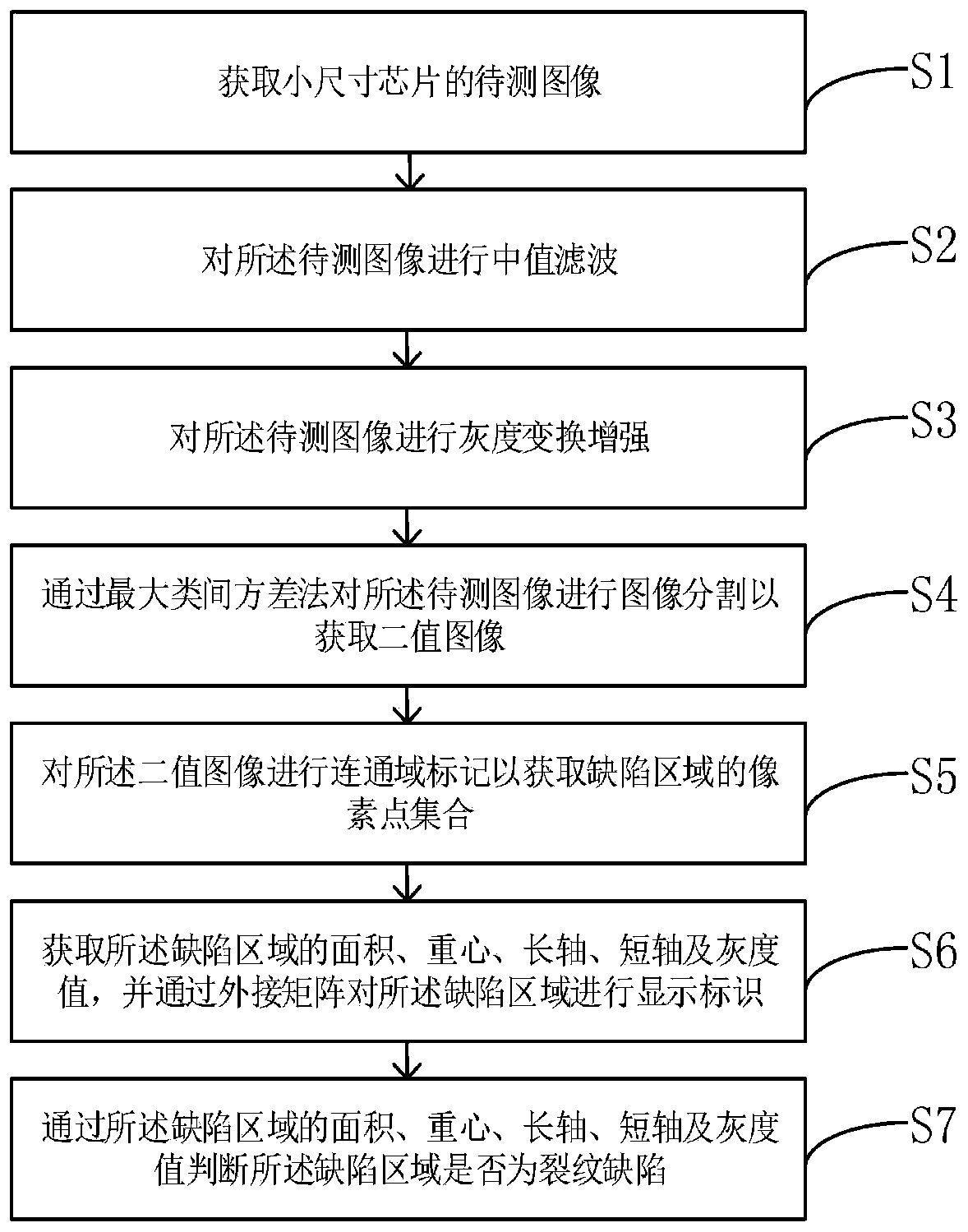

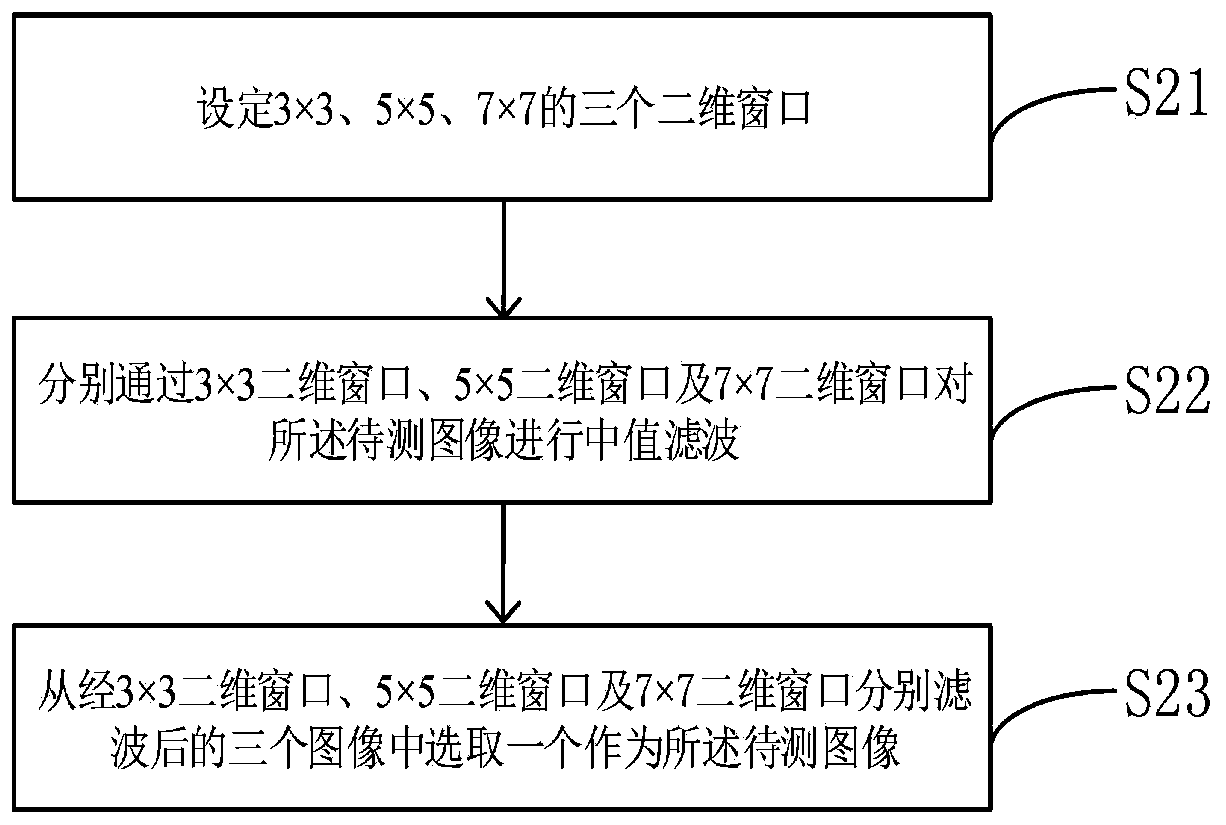

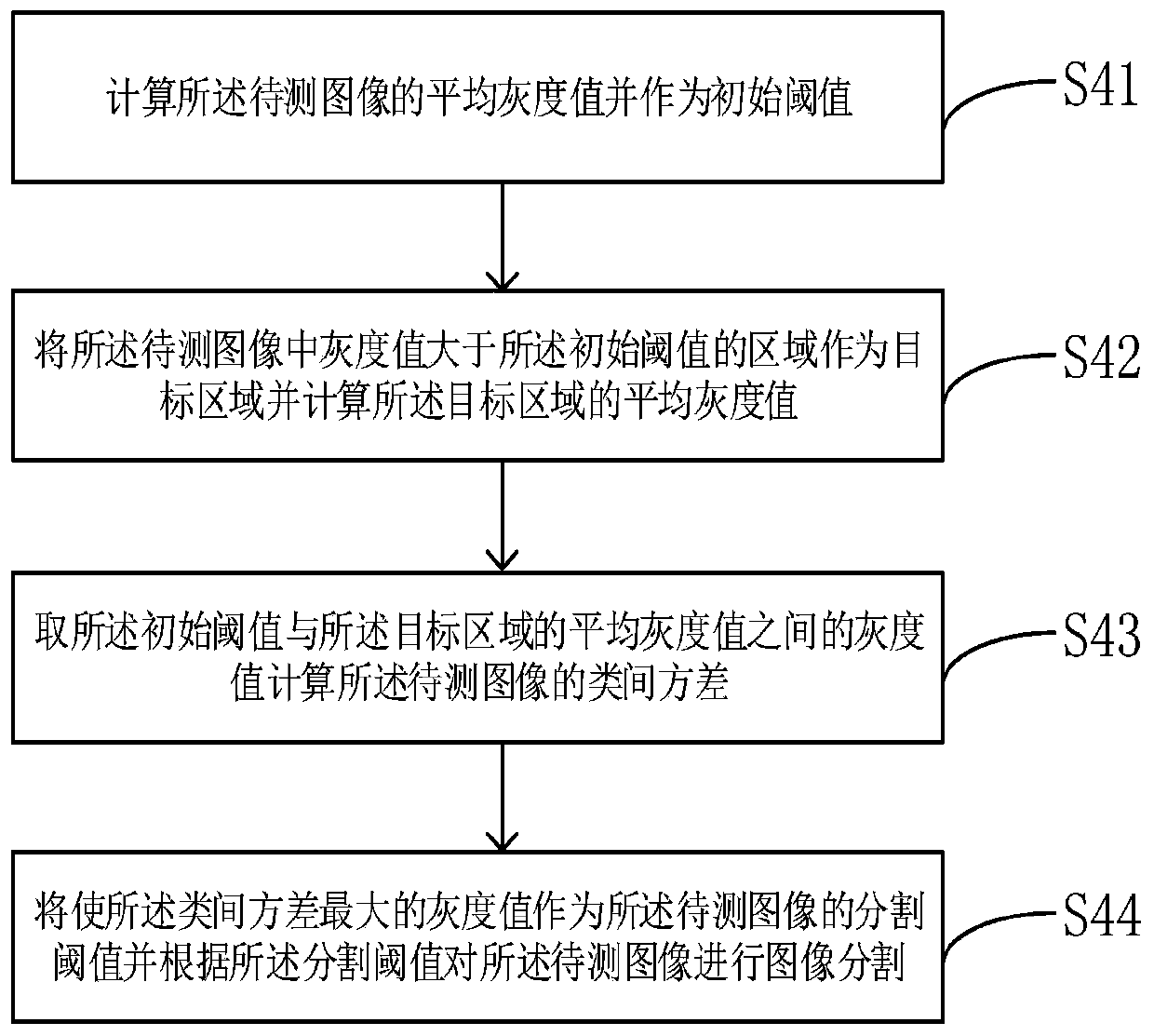

Small-size chip crack detection method and system based on computer vision

PendingCN111179243AImprove reliabilitySimplify computational problemsImage enhancementImage analysisImage segmentationEngineering

The invention provides a small-size chip crack detection method and system based on computer vision. The method comprises the steps that a to-be-detected image of a small-size chip is acquired; performing median filtering on the to-be-detected image; gray scale transformation enhancement is carried out on the to-be-detected image; performing image segmentation on the to-be-detected image through amaximum between-cluster variance method to obtain a binary image; connected domain marking is carried out on the binary image to acquire a pixel point set of the defect area; and judging whether thedefect area is a crack defect or not according to the area, the gravity center, the long axis, the short axis and the gray value of the defect area. Whether the defect area is a crack or not is judgeddirectly through the area, the gravity center, the long axis, the short axis and the gray value of the defect area; according to the method, registration and position correction of the to-be-detectedimage and the standard image are not needed, crack defects in various defects do not need to be further recognized, the calculation process and the calculation amount are greatly simplified, introduced noise interference is reduced, and the reliability of the detection result is improved.

Owner:武汉昕竺科技服务有限公司

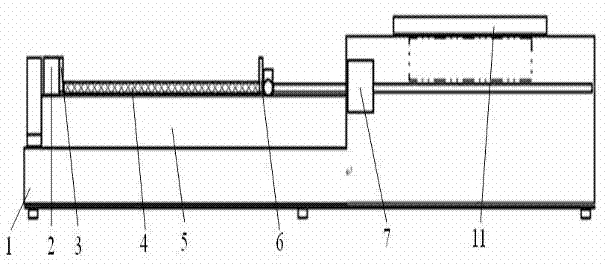

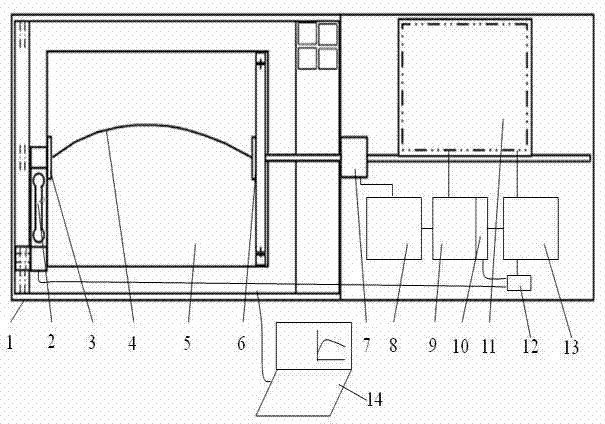

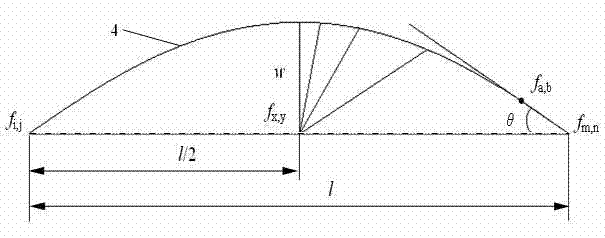

Method and apparatus for simultaneous determination of post-buckling deformation parameters and elastic moduli of elastomeric material

InactiveCN102818732ARealize simultaneous measurementMiniaturizationMaterial strength using steady bending forcesImaging processingMiniaturization

The invention discloses a method and an apparatus for simultaneous determination of post-buckling deformation parameters and elastic moduli of an elastomeric material. The method is as follows: a PLC controller controls a linear stepping motor through a driver, a movable supporting baffle plate is pushed by the linear stepping motor so as to allow a sample to undergo post-buckling deformation, a scanner acquires a post-buckling deformation image of the sample and transfers the image to a notebook computer, and image processing analysis software is used to process the sample so as to obtain the skeleton of the post-buckling deformation image; a coordinate of a point at a leftmost end of the sample and a coordinate of a point at a rightmost end of the sample are determined according to the skeleton of the post-buckling deformation image, a coordinate of the midpoint of chord length between the leftmost end point coordinate and the rightmost end point coordinate is calculated, and then flexibility of the midpoint, corners at the ends and elastic moduli are calculated. According to the invention, synchronous determination of the elastic moduli in a pressure bar post-buckling method and the post-buckling deformation parameters of the pressure bar are realized, which enables the processes of determination and calculation of the elastic moduli to be simplified; test operation is simple, determination precision is improved, and miniaturization, intelligentization and automation of the apparatus are realized.

Owner:JIANGSU UNIV

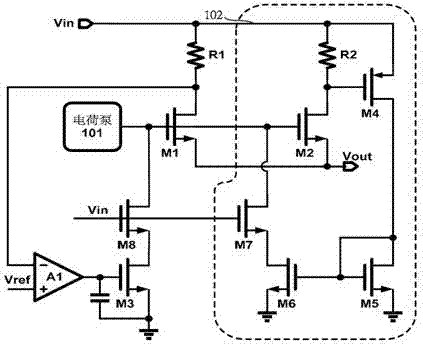

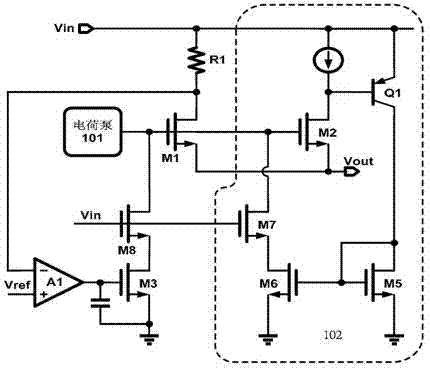

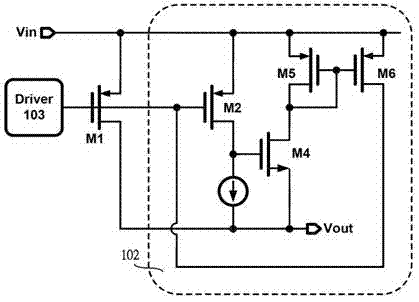

Quick-response current-limiting protection circuit

ActiveCN102769281AShort response timeEasy to implementEmergency protective arrangements for limiting excess voltage/currentSlow-startCurrent limiting

A quick-response current-limiting protection circuit can quickly response the change of the output current of the power switch tube and timely limit the output current to a safe range, and wait for a precise current-limiting circuit having slow start and high precision and consisting of a monitoring resistor, a comparator and an MOS (Metal Oxide Semiconductor) tube to further precisely adjust the output current, thus realizing the combination of the quick current limitation and precise current limitation. The quick-response current-limiting protection circuit is characterized by comprising a second MOS tube, namely a current induction MOS tube, which is connected with the first MOS tube, namely the grid electrode of the power switch tube, wherein the source electrode of the current induction MOS tube is directly connected with the source electrode of the power switch tube; and the drainage electrode of the current induction MOS tube is connected with a bleeder circuit which is connected with a quick-response current-limiting switch circuit.

Owner:SG MICRO

Method for correcting measurement vibration of deformation video of multi-constrained wind tunnel test model

ActiveCN103697863AFlexible choiceFacilitate iterative optimization solution calculation processAerodynamic testingPhotogrammetry/videogrammetryPoint projectionComputer science

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

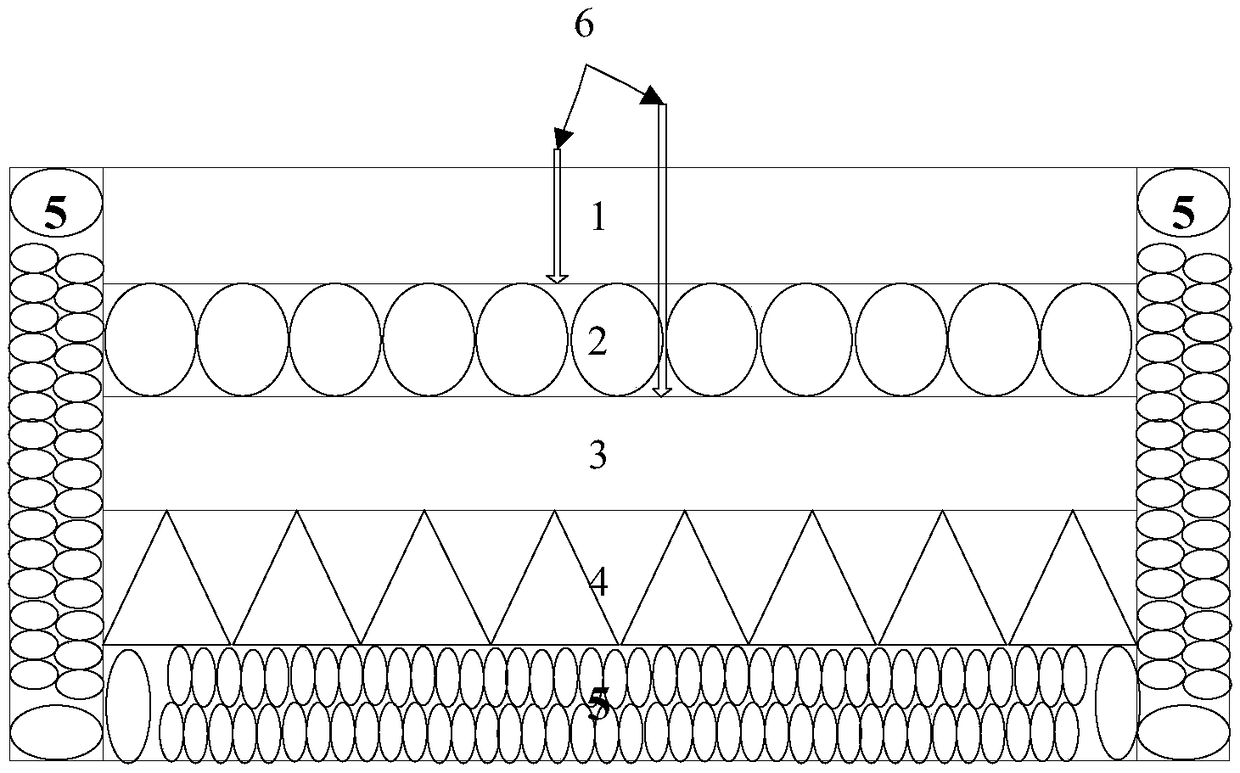

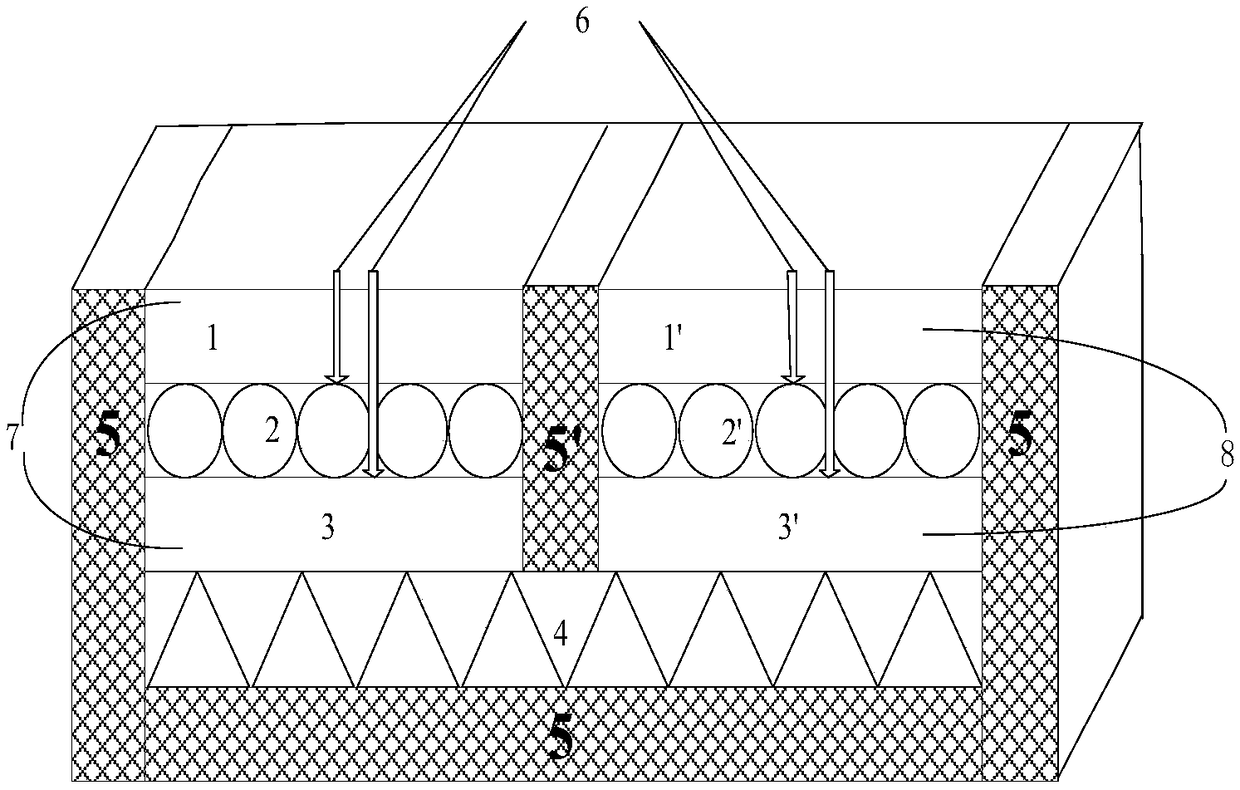

Heat transfer coefficient test apparatus and heat transfer coefficient measuring method

InactiveCN109490355AAvoid errorsEasy to operateMaterial heat developmentEngineeringHeat transfer coefficient

The application discloses a heat transfer coefficient test apparatus and a heat transfer coefficient measuring method. The heat transfer coefficient test apparatus comprises: a protective component including a first portion in U shape and a second portion inside the first portion; a heating component arranged at the bottom of the first portion, wherein the second portion divides a receiving spaceformed by the first portion into two receiving spaces to receive a comparison reference component and a component under test; the comparison reference component and the component under test which respectively include a heating plate, a standard test piece, a piece under test and a heat-dissipating plate which are arranged in stacked manner; temperature measuring components arranged on the upper and lower surfaces of the standard piece and the piece under test in order to monitor changes in the surface temperatures of the standard piece and the piece under test. The apparatus and method disclosed herein help solve the technical problems that measurement of heat transfer coefficient in the prior art is highly difficult and equipment of the prior art is highly complex.

Owner:DATANG MOBILE COMM EQUIP CO LTD

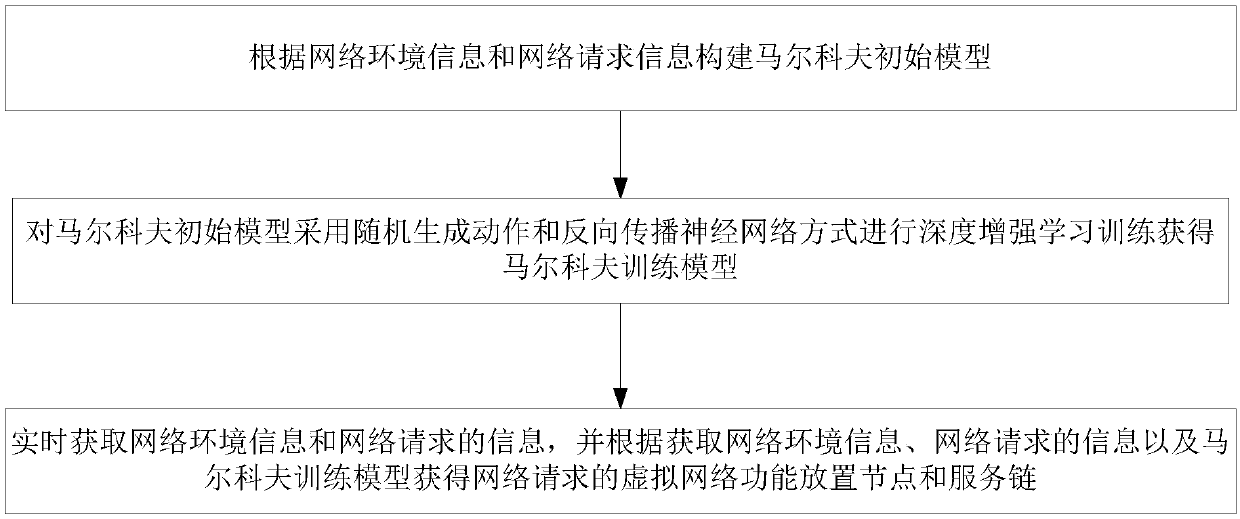

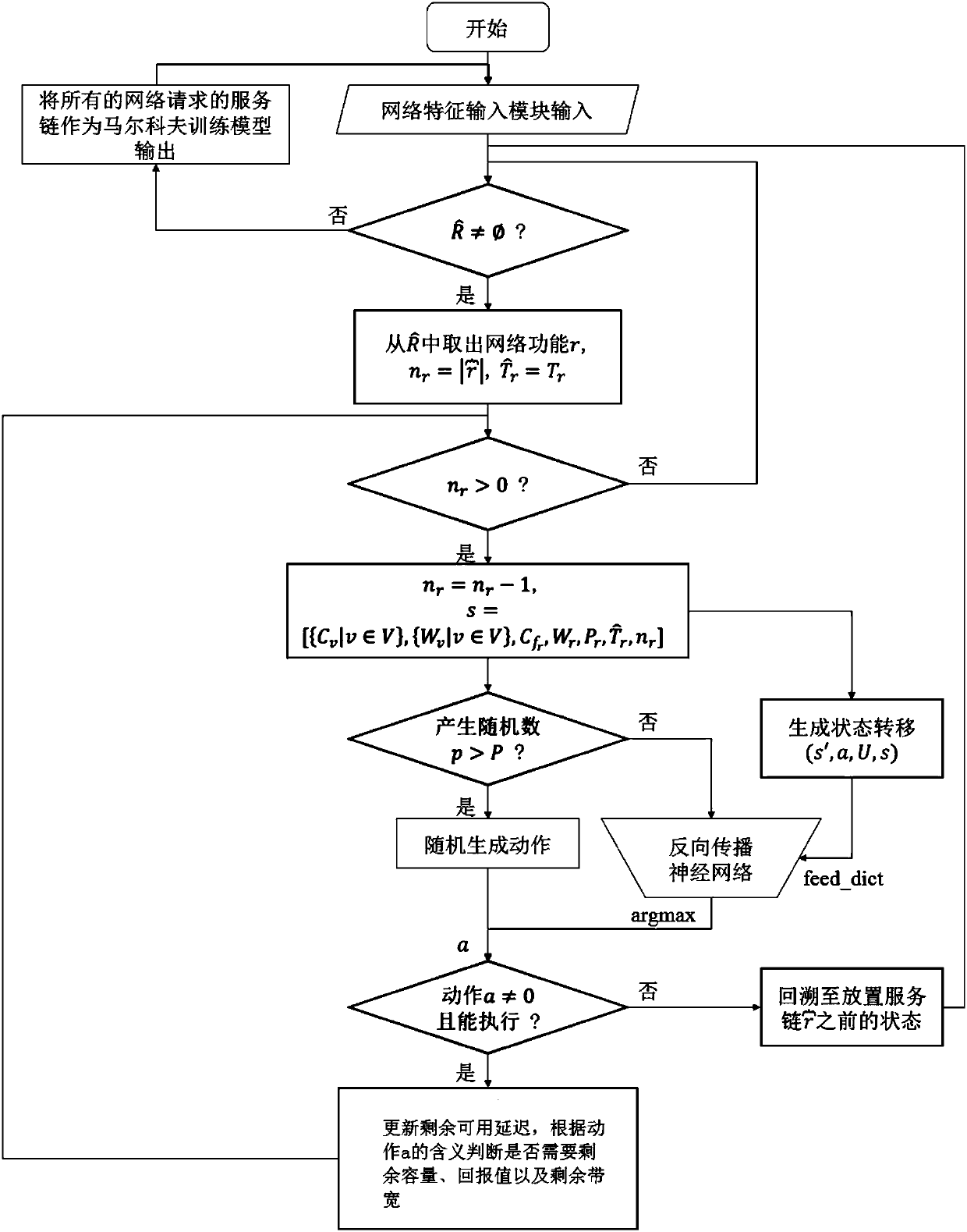

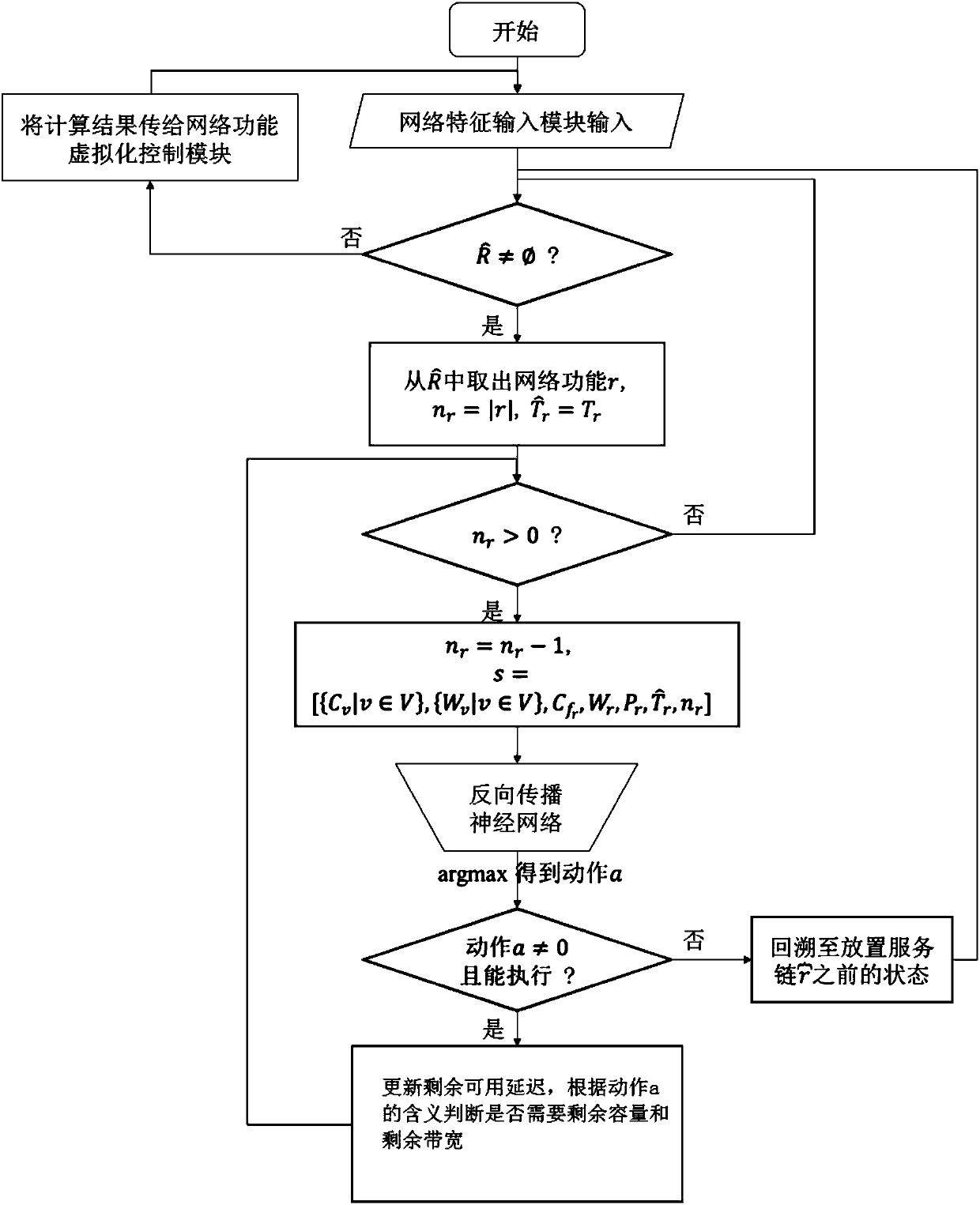

Method and system of scheduling and linking virtual network functions

ActiveCN108111335ASimplify computational problemsEasy to trainData switching networksTotal delayVirtual network

The present invention discloses a method and system of scheduling and linking virtual network functions. The method comprises the following steps of constructing a Markov initial model according to the network environment information and the network request information; carrying out the deep reinforcement learning training on the Markov initial model to obtain a Markov training model by the randomgeneration action and in a back-propagation neural network manner; real-timely obtaining the network environment information and the network request information, and obtaining the virtual network function placement nodes and the service chains of the network requests according to the obtained network environment information, the network request information and the Markov training model. Accordingto the present invention, by carrying out the deep reinforcement learning training on the Markov initial model to obtain the Markov training model via the random generation action and in the back-propagation neural network manner, the optimal deployment of the network functions and the service chains can be realized furthest, and the purposes of reducing the total delay of the network requests and improving the network resource utilization rate are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

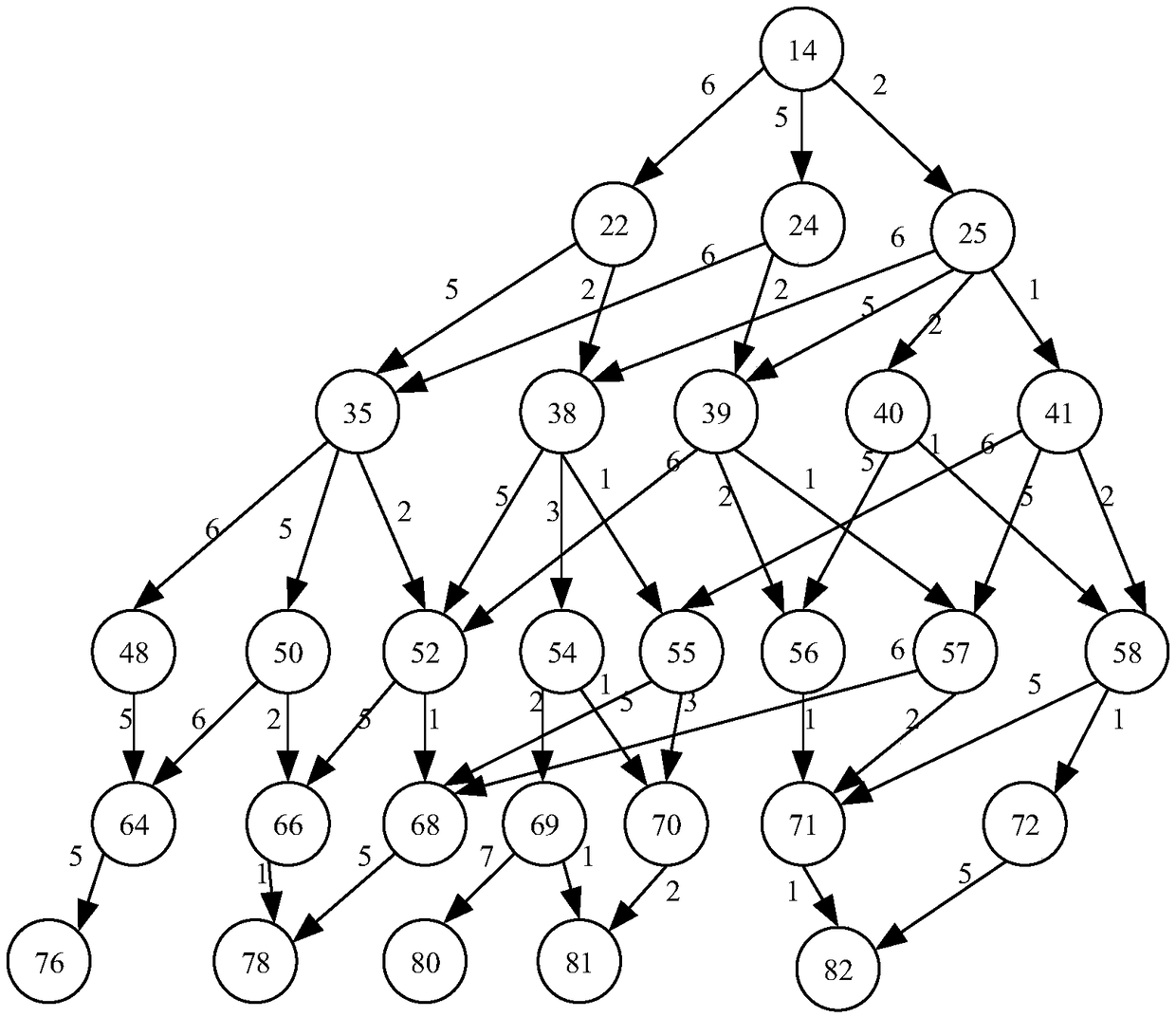

Deadlock-free control method for an automated manufacturing system containing uncontrollable events

ActiveCN108762221AAvoid exhaustionSimplify computational problemsTotal factory controlProgramme total factory controlDeadlock freeDesign control

A deadlock-free control method for an automated manufacturing system containing uncontrollable events is disclosed. The deadlock-free control method includes: acquiring a feasible step size of an automated manufacturing system containing uncontrollable events through a feasible step size online generation algorithm of a partially controllable and fully considerable automated manufacturing system;acquiring an optimal step size of the automated manufacturing system containing the uncontrollable events through the optimal step size online generation algorithm of the partially controllable and fully considerable automated manufacturing system, and performing prediction on the optimal step size of the automated manufacturing system containing the uncontrollable events in the current state so as to avoid deadlocks. The invention adopts the real-time online operation policy of synchronous prediction and control, and does not need to design a controller in advance. According to the state predicted in the current state, analysis and determination are performed, the determination result is timely fed back to the controller, and the controller makes an appropriate control decision to determine the transition needing to be transmitted in the current state, thereby avoiding deadlocks during processing.

Owner:XIDIAN UNIV

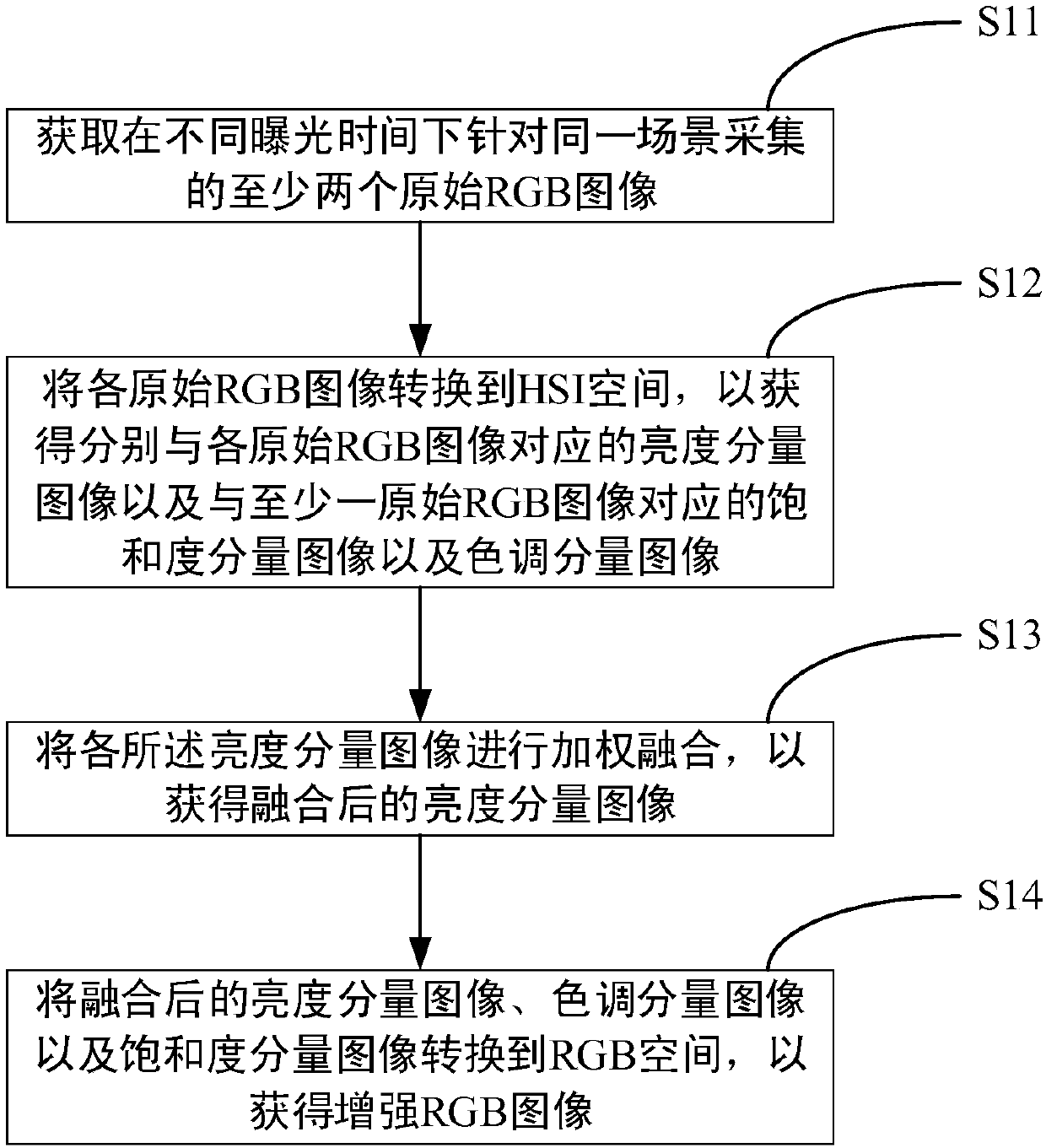

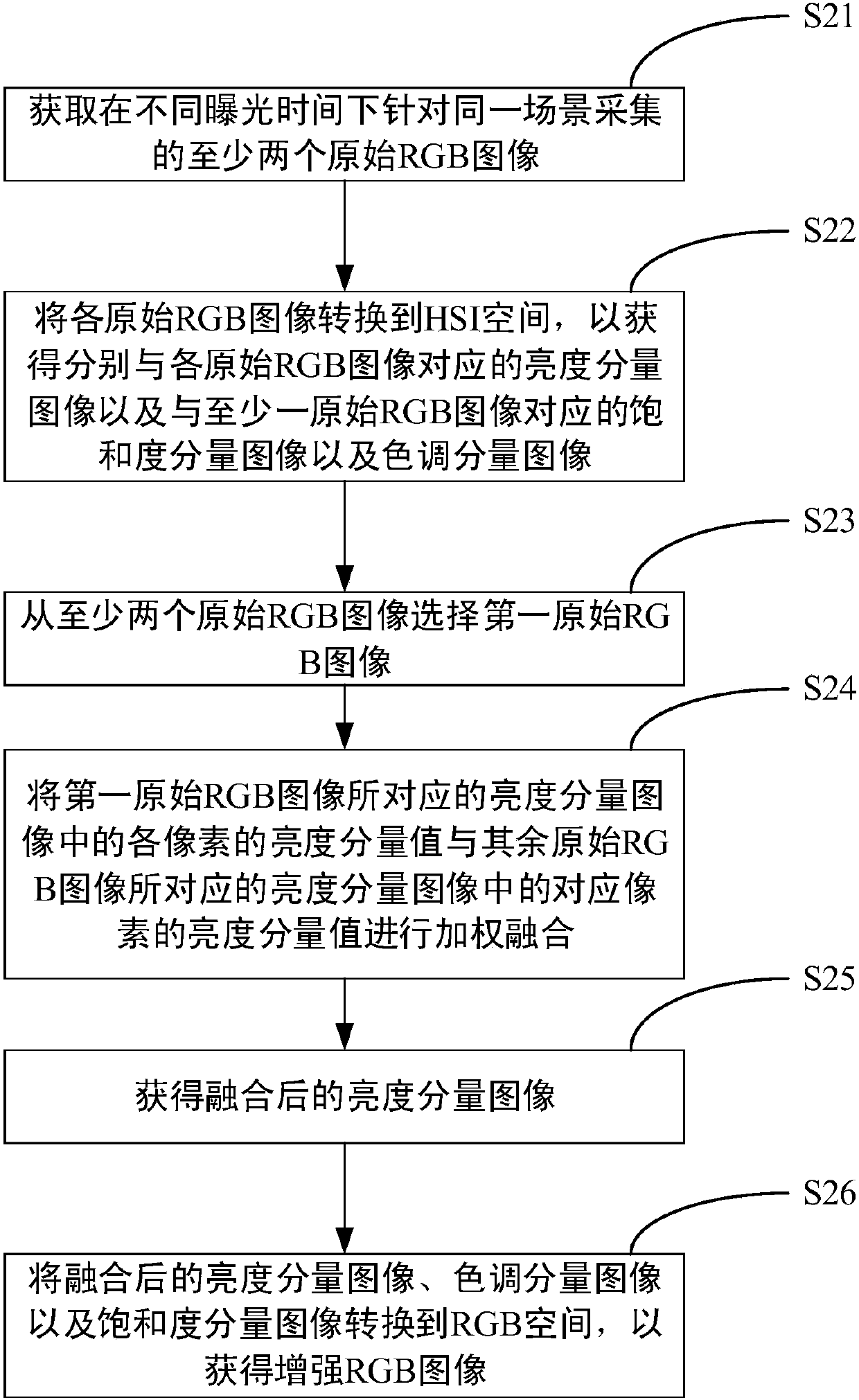

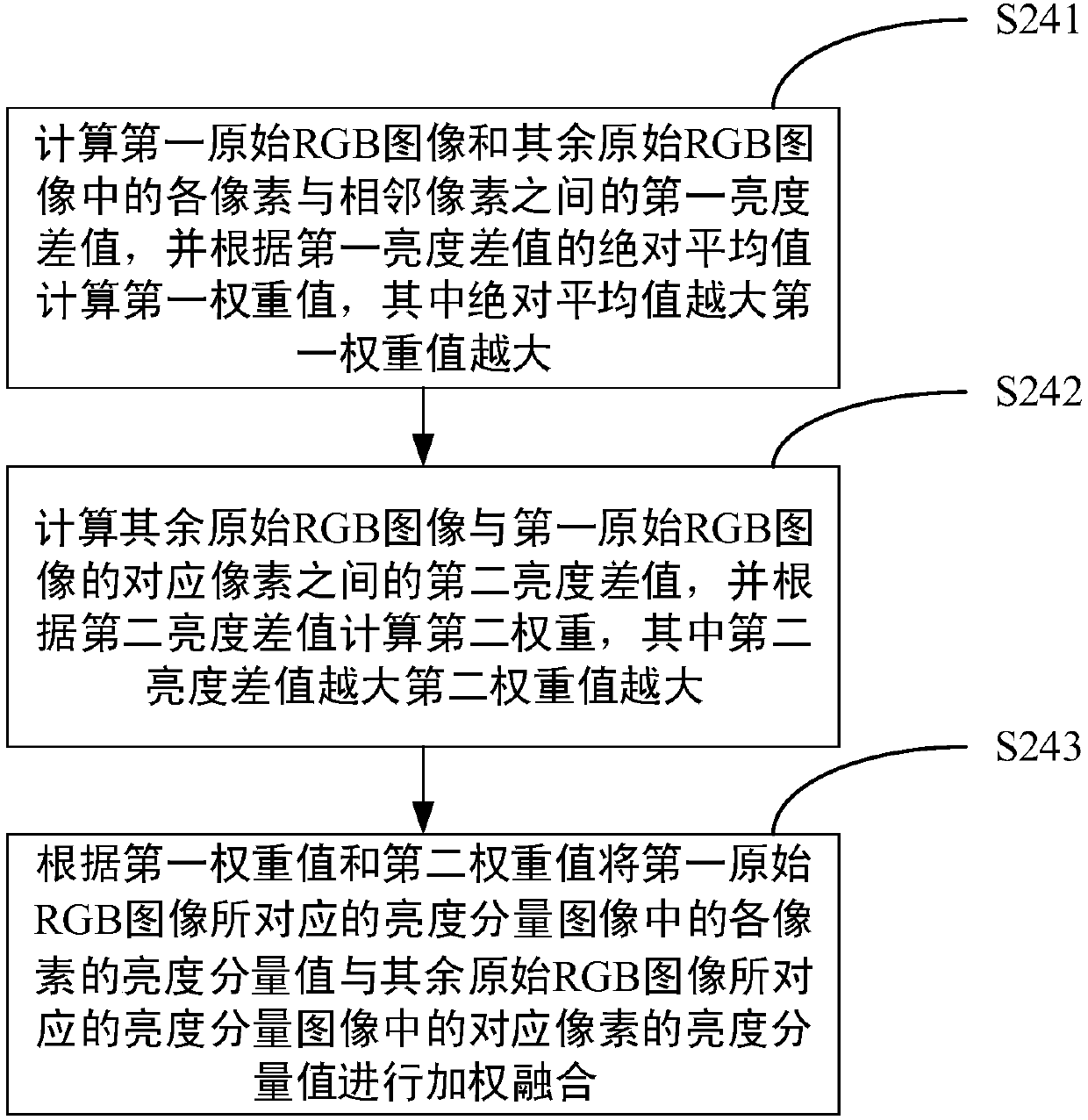

Image enhancement method and image processing device

ActiveCN107590791ASimplify the calculation process and calculation amountReduce the computational complexity of makingImage enhancementImage analysisColor toneImage enhancement

The invention discloses an image enhancement method and an image processing device. The image enhancement method comprises the steps of acquiring at least two original RGB images which is acquired foraiming at the same scene at different exposure time points; transferring each original RGB image to an HSI space for obtaining a brightness component image, a saturation component image and a tone component image; performing weighing fusion on each brightness component image, thereby obtaining a fused brightness component image; and transferring the fused brightness component image, the tone component image and the saturation component image to an RGB space for obtaining an enhanced RGB image. Through the image enhancement method and the image processing device, only the brightness componentis calculated and weighted fusion is performed, thereby simplifying a computing process, reducing calculation amount, reducing computing complexity in manufacturing a high dynamic comparing image.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Dynamic compensation method of abrasion of grinding wheel of numerical control horizontal shaft surface grinding machine

InactiveCN104476398AImprove processing efficiencySimplify computational problemsGrinding drivesGrinding feed controlSurface grindingNumerical control system

The invention provides a dynamic compensation method of the abrasion of a grinding wheel of a numerical control horizontal shaft surface grinding machine and relates to the technical field of numerical control grinding machines, particularly to a dynamic compensation technology of the abrasion of the grinding wheel of the numerical control horizontal shaft surface grinding machine. The active power of a main shaft or grinding head motor and for grinding is measured to indirectly calculate the abrasion of the grinding wheel and implement the dynamic compensation of the abrasion of the grinding wheel of the numerical control horizontal shaft surface grinding machine. The invention also provides a calculation method of the dynamic compensation of the abrasion of the grinding wheel of the numerical control horizontal shaft surface grinding machine. According to the dynamic compensation method of the abrasion of the grinding wheel of the numerical control horizontal shaft surface grinding machine, the dynamic compensation method is not affected by the shape of workpieces and limitations are avoided; only a main shaft motor active power transducer and a digital transmission device need to be added to a numerical control system and accordingly the cost of the added hardware is low; the machining efficiency of the numerical control surface grinding machine can be greatly improved.

Owner:GUILIN XINQUAN NUMERICAL CONTROL

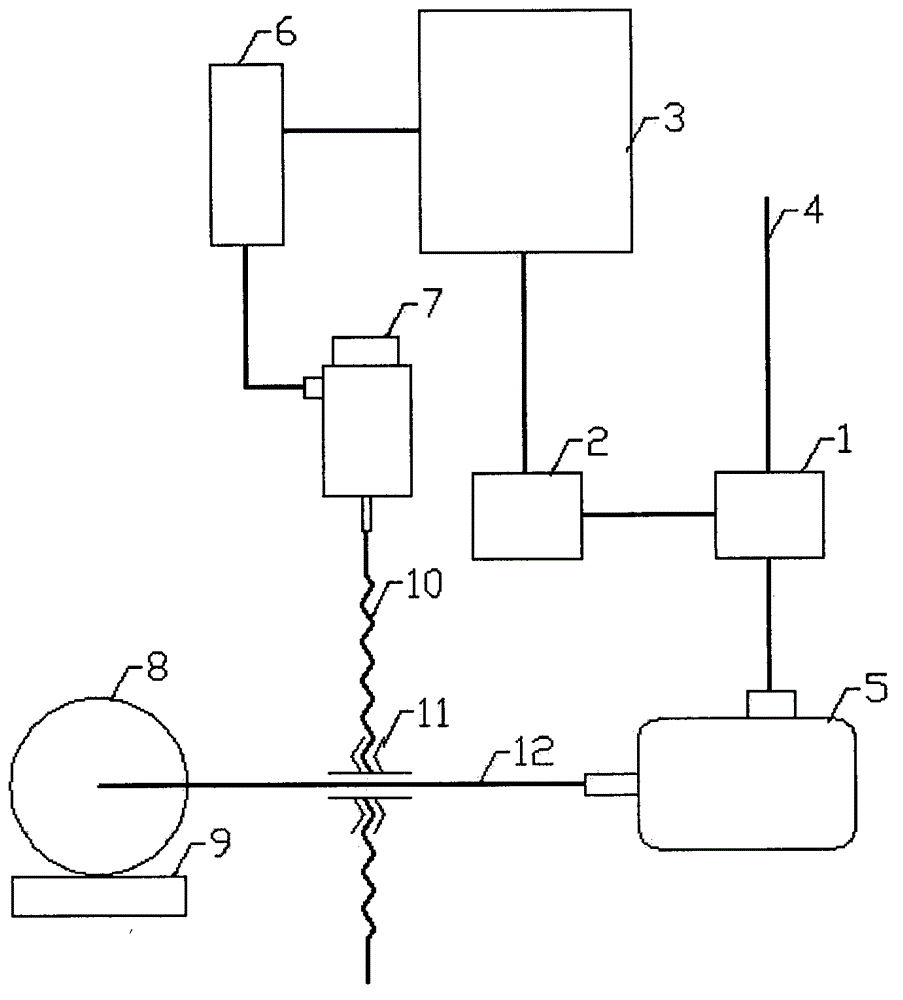

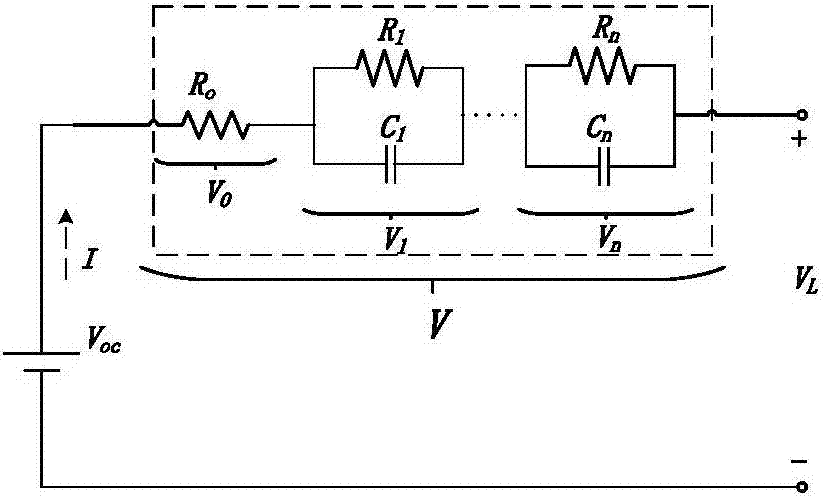

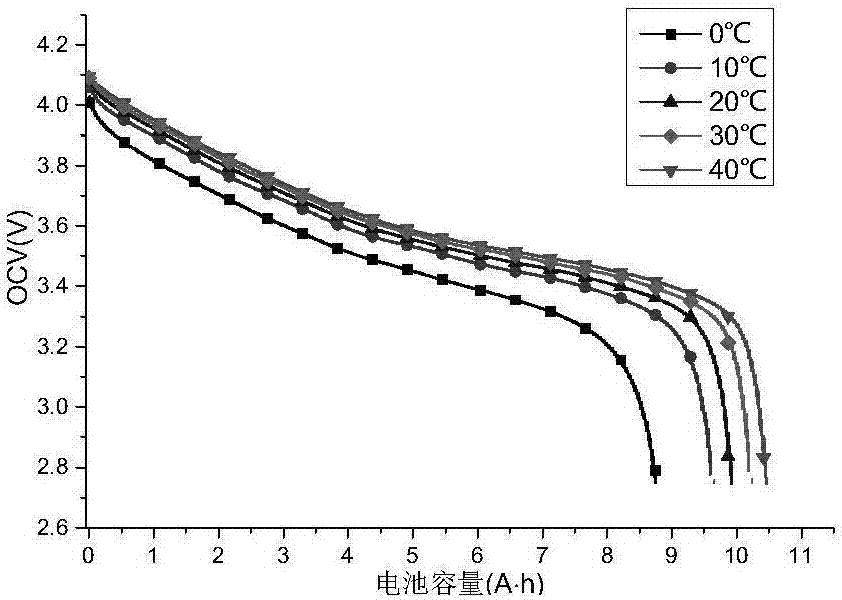

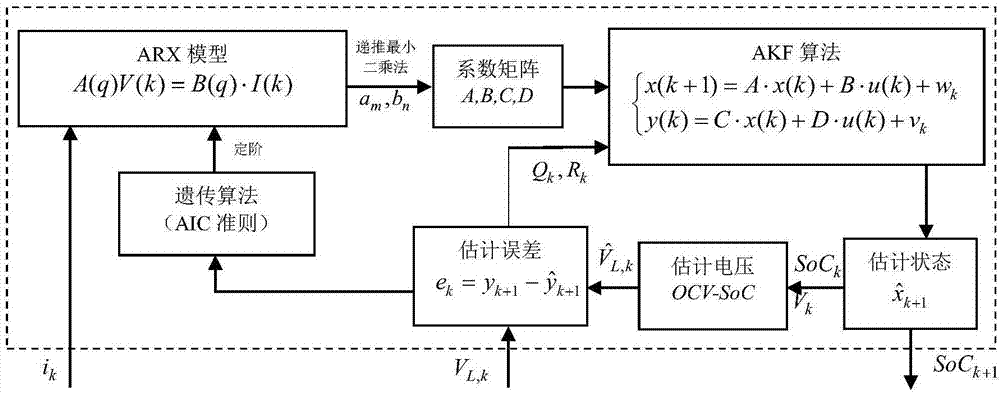

New method for estimating SoC of power lithium battery

InactiveCN107957555ASimplify formula derivation and calculation processAvoid calculationElectrical testingGenetic algorithmsTransfer matrixLeast squares

The invention discloses a new method for estimating a SoC of a power lithium battery. The method comprises the steps of: adopting an autoregressive exogenous (ARX) model to establish a lithium batteryequivalent model, then adopting a genetic algorithm based on an AIC criterion to determine order of the lithium battery equivalent model, and calculating model coefficients by utilizing a recursive least-squares method after determining the model order; establishing a spatial state equation required by Kalman filtering according to the acquired ARX model coefficients and a lithium battery state equation; and finally realizing estimation of the SoC of the lithium battery by utilizing a Kalman prediction iterative equation. The method just needs to determine the order and coefficients of the ARX model without calculating specific equivalent circuit parameter values, simplifies the tedious formula derivation and calculation process so as to avoid the subsequent calculation of e indexes of aKalman filtering state transfer matrix and an input control matrix, and reduces the error introduced because the equivalent circuit parameters are affected by complicated operating conditions of the lithium battery.

Owner:CHONGQING THREE GORGES UNIV

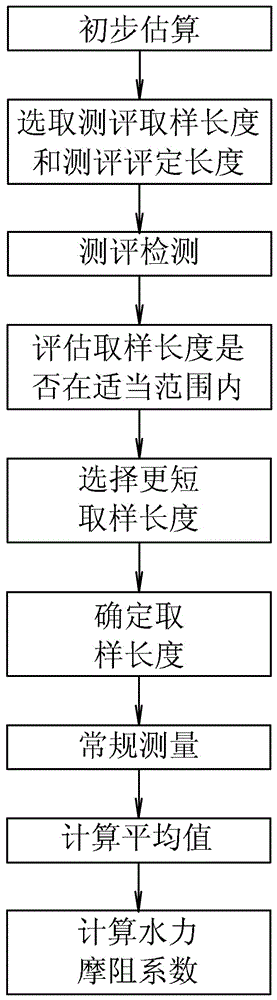

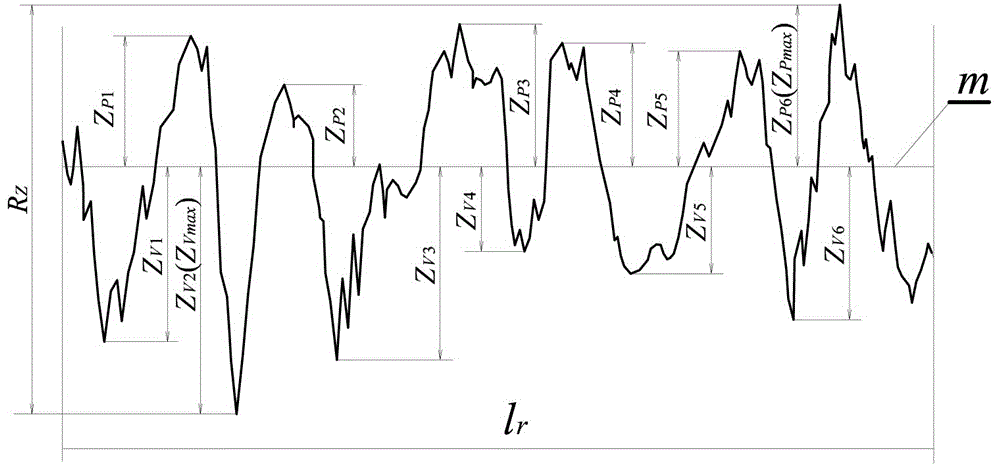

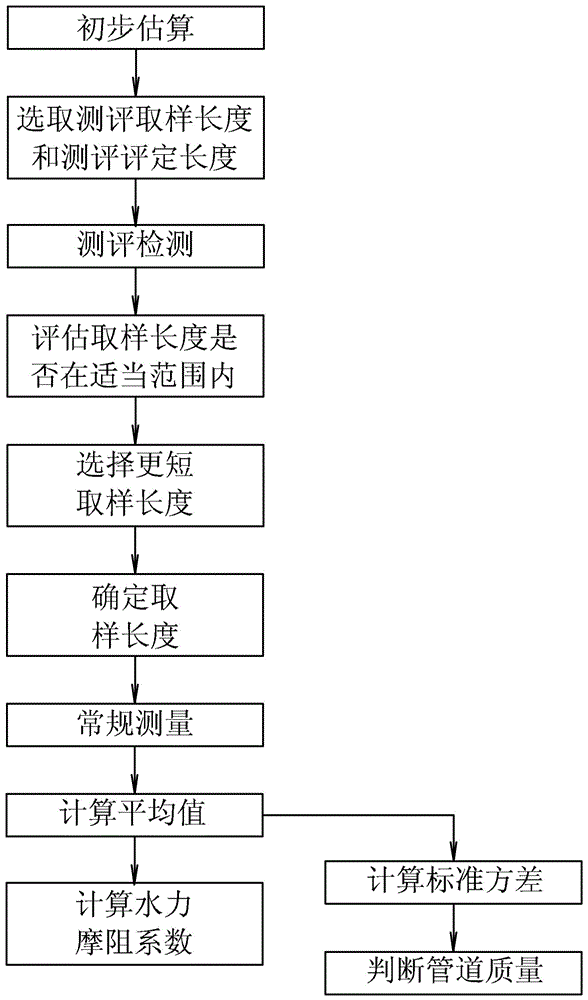

Rapid evaluation method for hydraulic friction resistance of pipelines

InactiveCN106777830AEasy to measureEasy to calculateDesign optimisation/simulationSpecial data processing applicationsMeasuring instrumentSurface roughness

The invention relates to a rapid evaluation method for hydraulic friction resistance of pipelines. The rapid evaluation method comprises the steps of preliminary estimating; selecting an evaluation sampling length and an evaluation rated length; evaluation detecting; evaluating whether or not the sampling length is in a proper range; selecting a shorter sampling length; determining the sampling length; regular measuring; calculating the average value; calculating a coefficient of the hydraulic friction resistance. According to the method, a measuring instrument for surface roughness in existing machining is used for repeatedly adjusting measuring length, and the maximum height of a surface roughness profile (i)R( / i)(i)z( / i) can be used as an equivalent roughness (i)k( / i), which is taken into Colebrook - White equation to calculate the coefficient of the hydraulic friction resistance (i) lambda ( / i). The rapid evaluation method for the hydraulic friction resistance of pipes makes the measurement and calculation of the coefficient of the hydraulic friction resistance more convenient, faster, and simpler, improves the quality of pipeline construction, and reduces the operation cost of pipeline projects.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

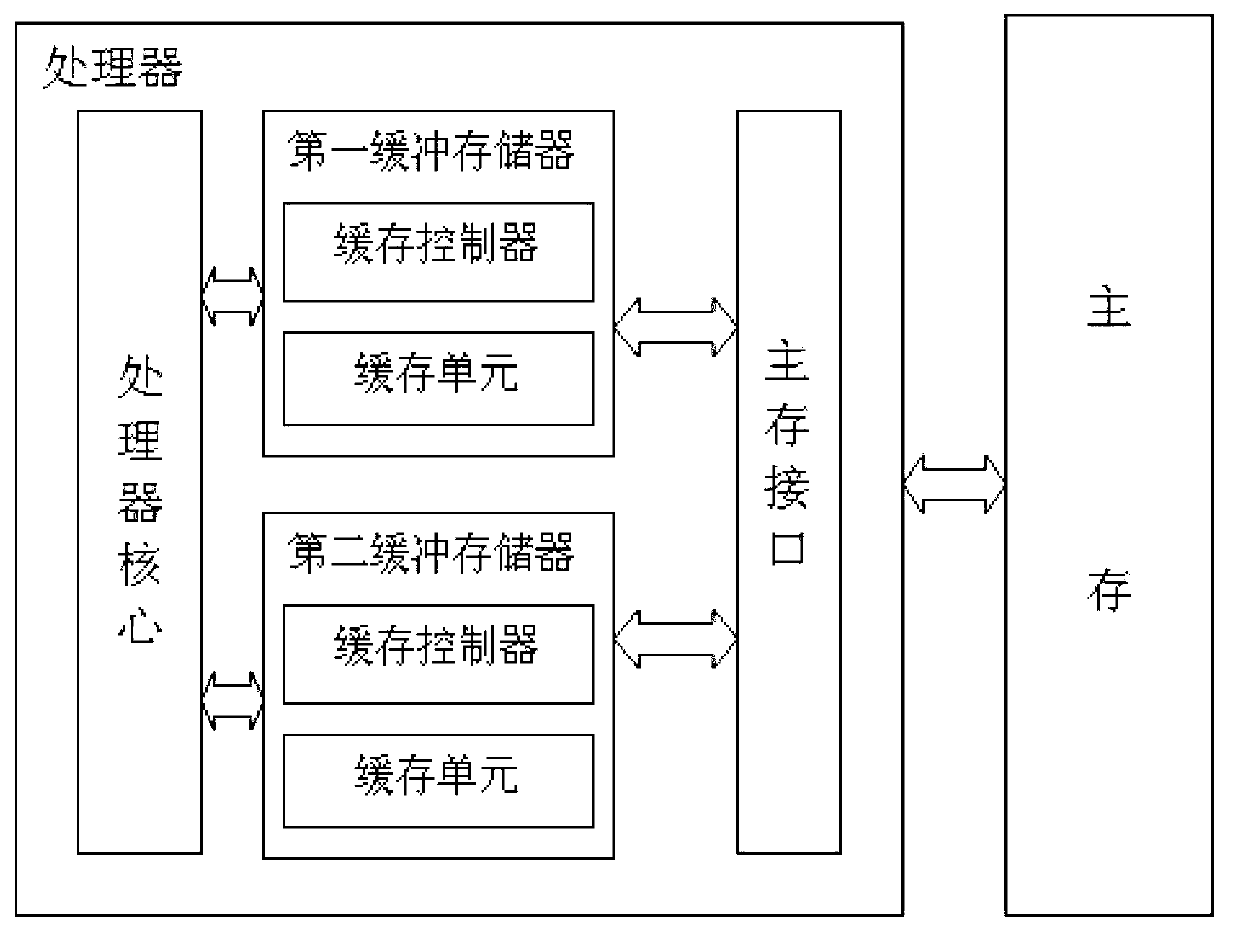

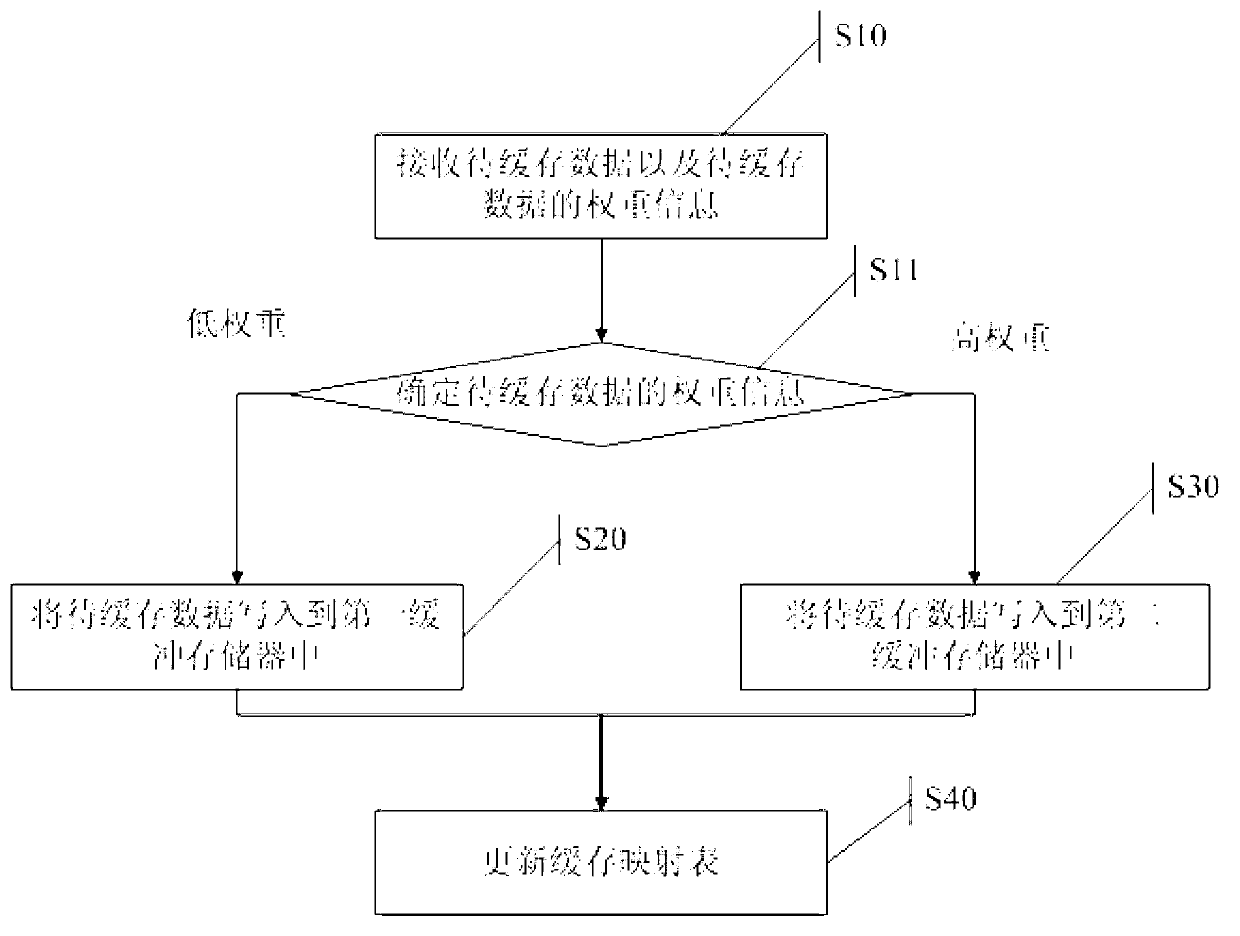

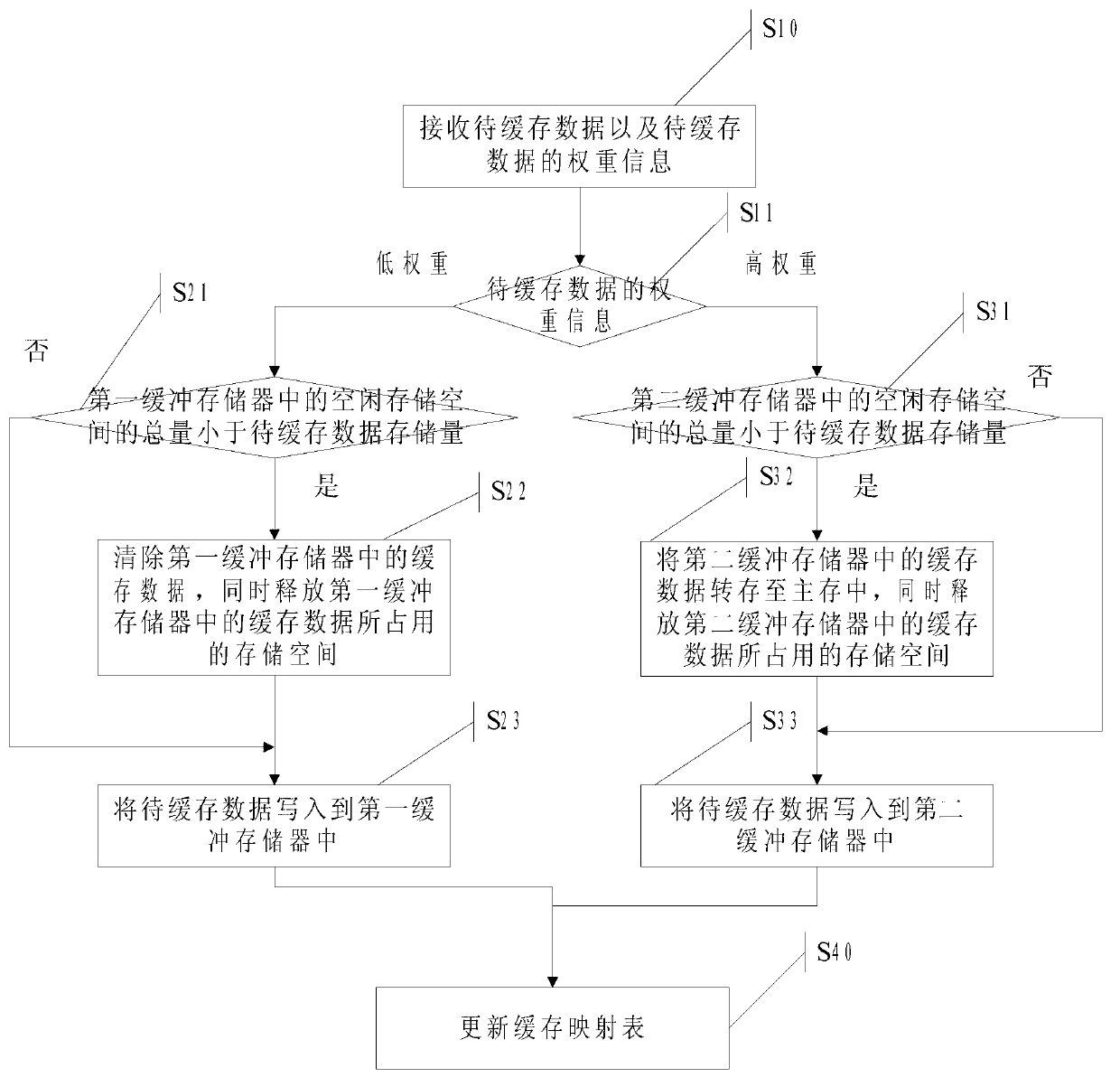

Data caching method in multiple buffer storages according to weight information

ActiveCN103345452ASimplify calculation and query algorithmsImprove hit rateMemory adressing/allocation/relocationOperating system

Owner:FUJIAN RUIJU INFORMATION TECHNOLOGY CO LTD

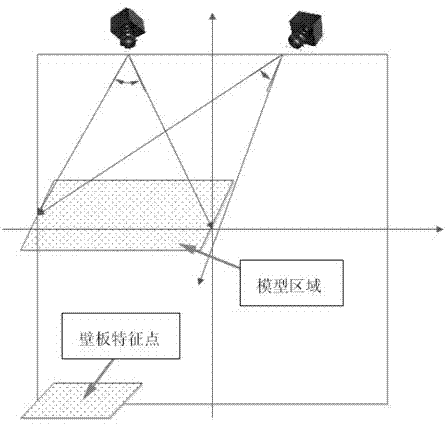

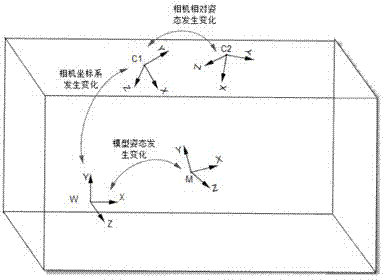

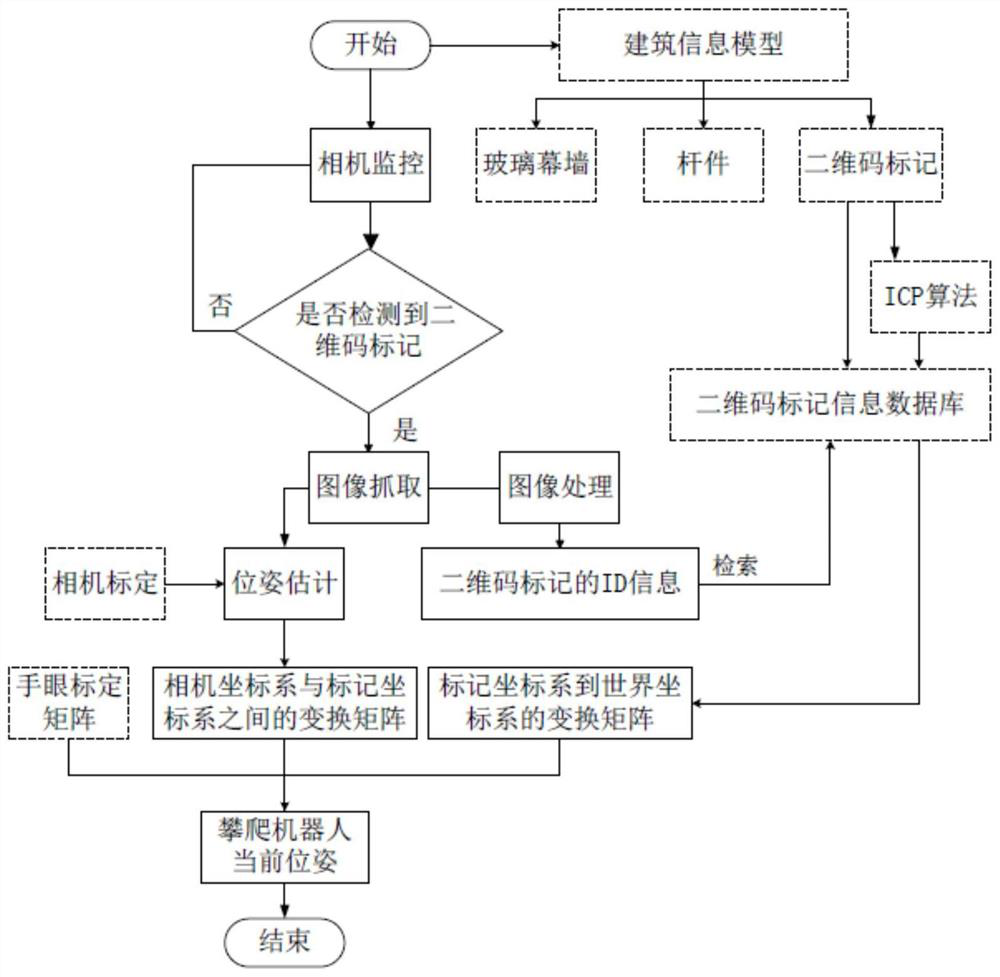

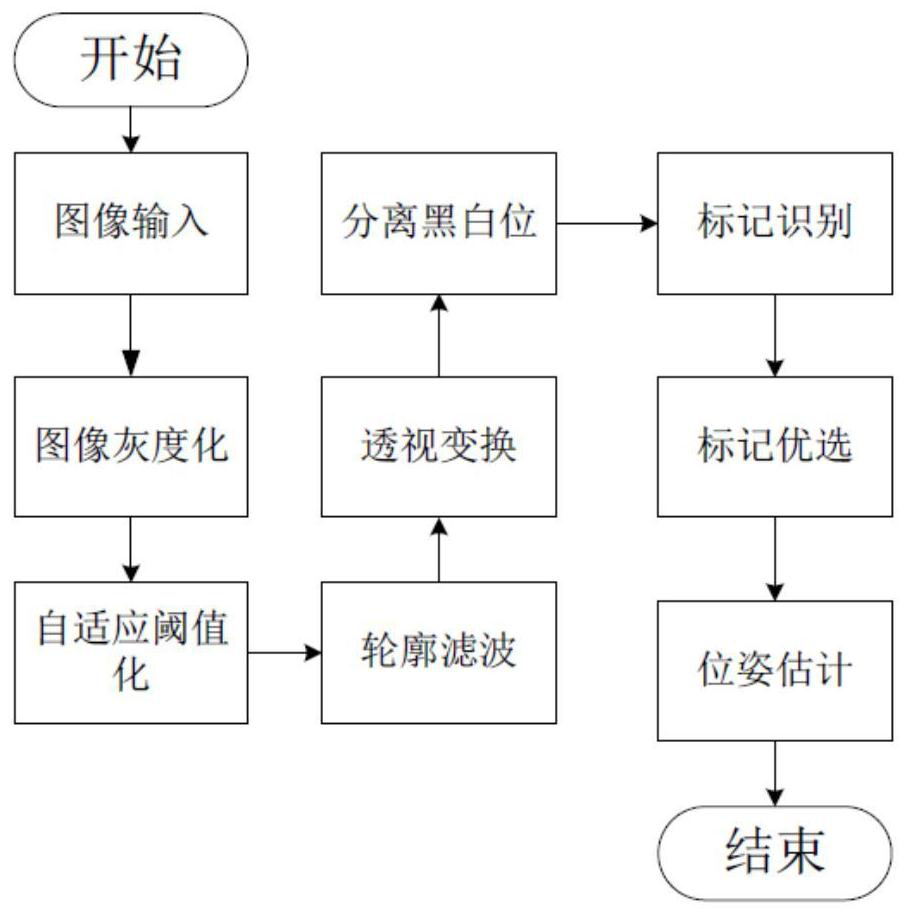

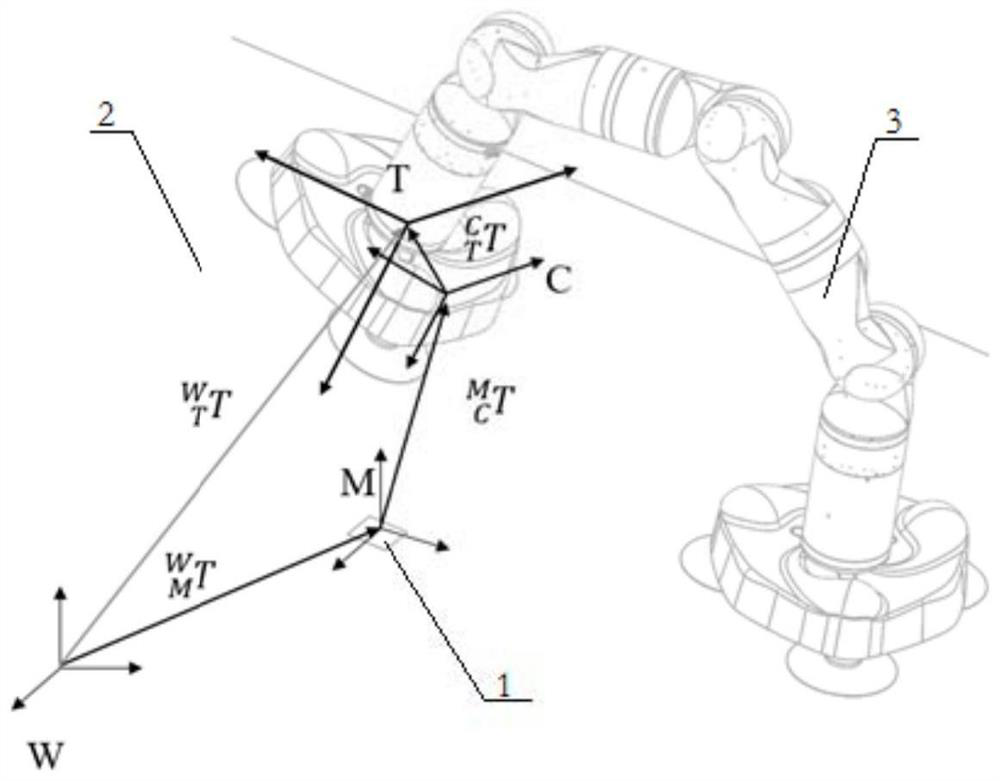

Spatial positioning method and spatial positioning system for climbing robot

ActiveCN113276106AReduce usageStable and effective spatial positioningProgramme-controlled manipulatorImage analysisVideo monitoringComputation process

The invention relates to the technical field of visual positioning of robots, in particular to a space positioning method and a space positioning system for a climbing robot. The space positioning system comprises an offline operation module and an online operation module. Offline operation comprises the steps of performing information extraction and operation on a building information model, solving a transformation matrix of a mark coordinate system and a world coordinate system, generating a manual mark information database, performing camera calibration, performing hand-eye calibration and the like; and online operation comprises the steps of performing real-time video monitoring and image capture, performing mark detection and pose estimation, performing two-dimensional code mark information database retrieval, performing absolute pose solving of the climbing robot and the like. The offline operation and the online operation are combined, so that the use of sensors is reduced and the algorithm calculation process is simplified; and each two-dimensional code mark has unique ID information, and a single two-dimensional code mark can provide enough corresponding points, so that remote space positioning in the climbing process of the climbing robot is realized and the positioning precision is improved.

Owner:GUANGDONG UNIV OF TECH

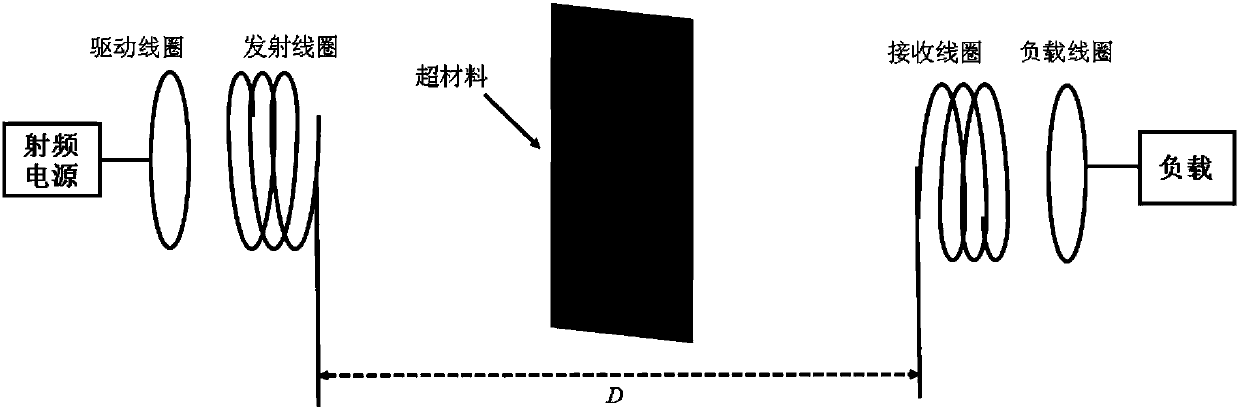

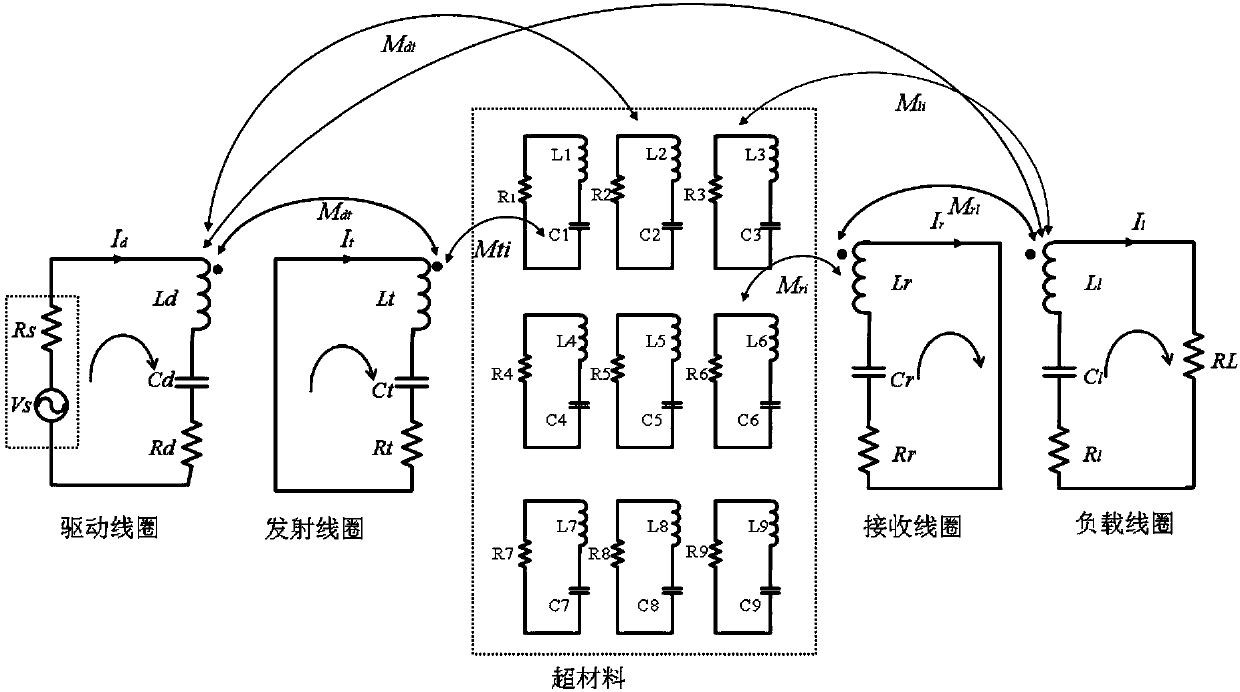

Analysis method of metamaterial equivalent circuit for wireless electric energy transmission system

InactiveCN108494112AAnalyzing the effect of transfer efficiencyClear guidanceCircuit arrangementsCapacitanceResonance

The invention discloses an analysis method of a metamaterial equivalent circuit for a wireless electric energy transmission system. The method comprises: each metamaterial unit is equivalent to an RLCresonance circuit including a resonance coil, an additional capacitor and a dielectric substrate; the RLC resonance circuits are adjusted and thus when the resonant frequency of each metamaterial unit is the operating frequency of the system, the equivalent magnetic permeability is -1; the N metamaterial units are arranged and combined according to the periodic structure of the array to obtain ametamaterial; the metamaterial is loaded between a transmitting coil and a receiving coil and mutual inductance values between the modules are calculated; a circuit matrix equation of the system is established to solve circuit parameters, and then the transmission efficiency of the system is calculated; and then the distance between the metamaterial and the transmitting coil is changed to obtain an optimal intervention position. Therefore, the acting rule and coupling mechanism of metamaterial loading to the wireless electric energy transmission system are analyzed deeply and accurately; and the analysis process is simplified.

Owner:HUAZHONG UNIV OF SCI & TECH +3

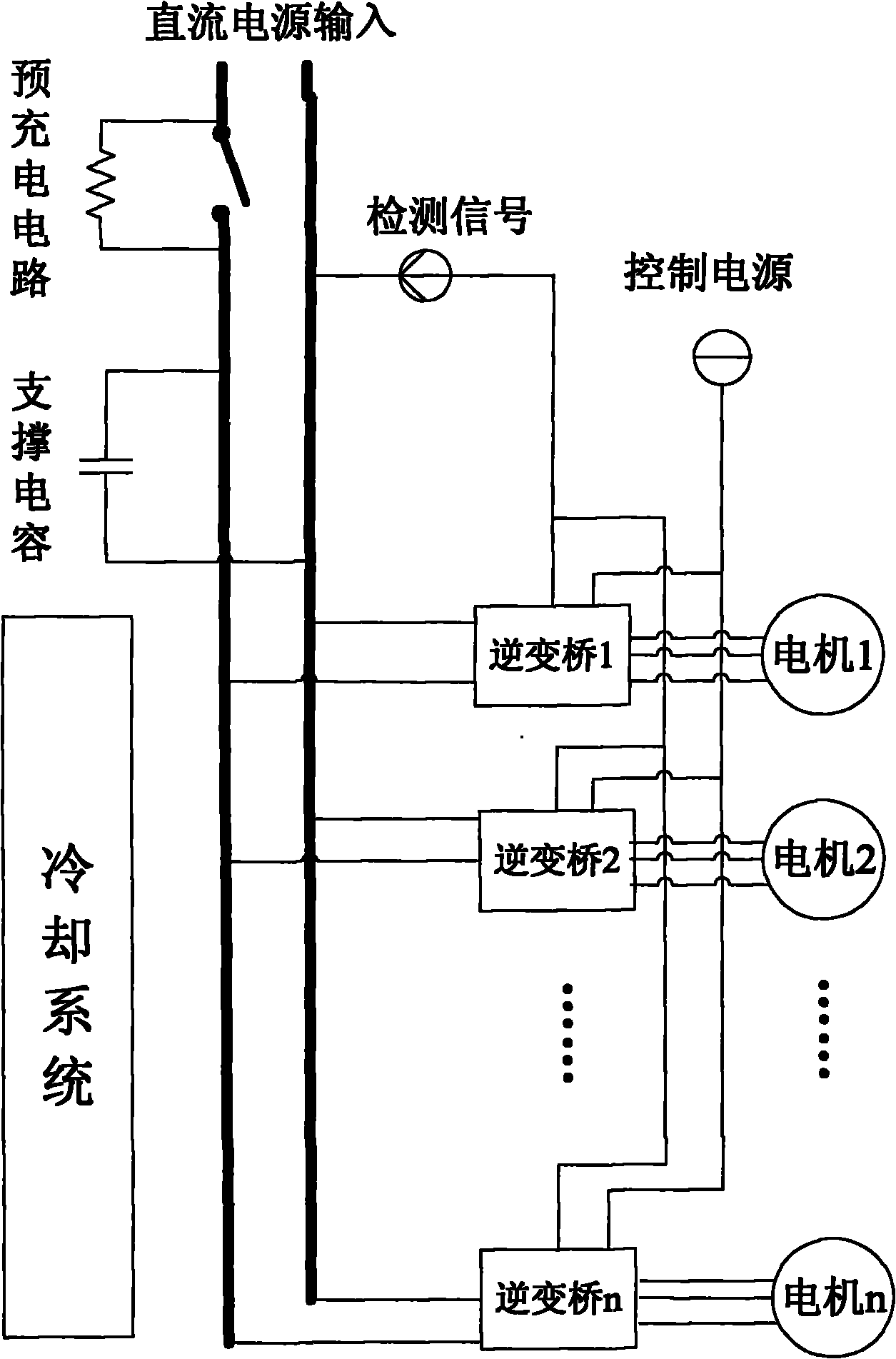

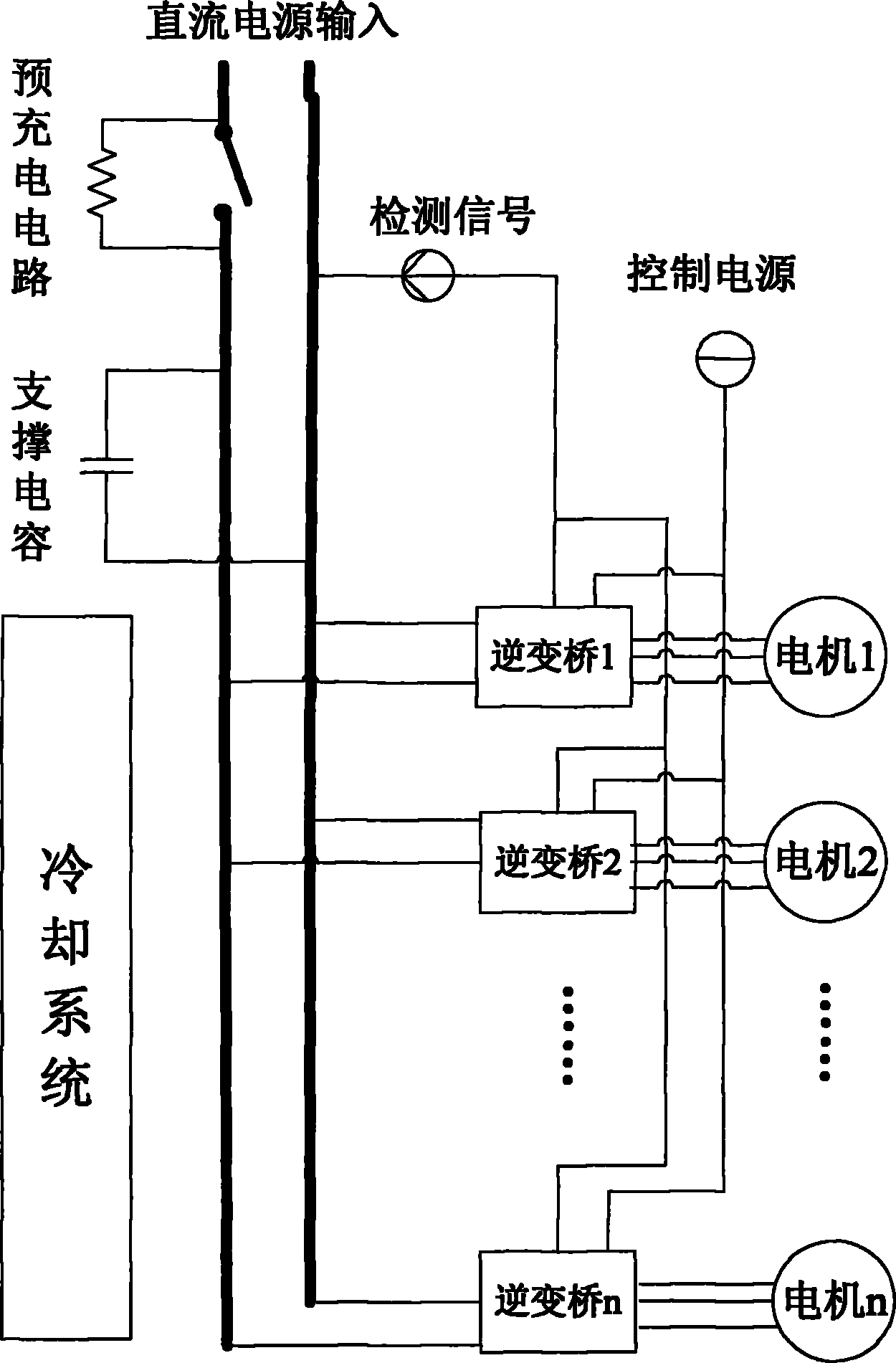

Multi-motor synchronous/asynchronous driving system of electric vehicle

InactiveCN102136817ASimplify computational problemsSimplify the design processMultiple ac dynamo-electric motors controlControl powerMotor drive

The invention provides a multi-motor synchronous / asynchronous driving system of an electric vehicle, which can reduce the cost of the system and output multiple mutually independent motor driving system loops. The synchronous / asynchronous driving system comprises a plurality of inverter bridges, and a direct-current bus, a pre-charging circuit, a supporting capacitor, a cooling system, a detection signal and a control power supply shared by the inverter bridges; and all the parts except the cooling system are electrically connected together, and the cooling system is mechanically connected. The outputs of all the motor inverter bridge driving loops are independent without influencing the work of one another, and even when one path or multiple paths of the loops do not work or fails temporarily, other loops can continue to work.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

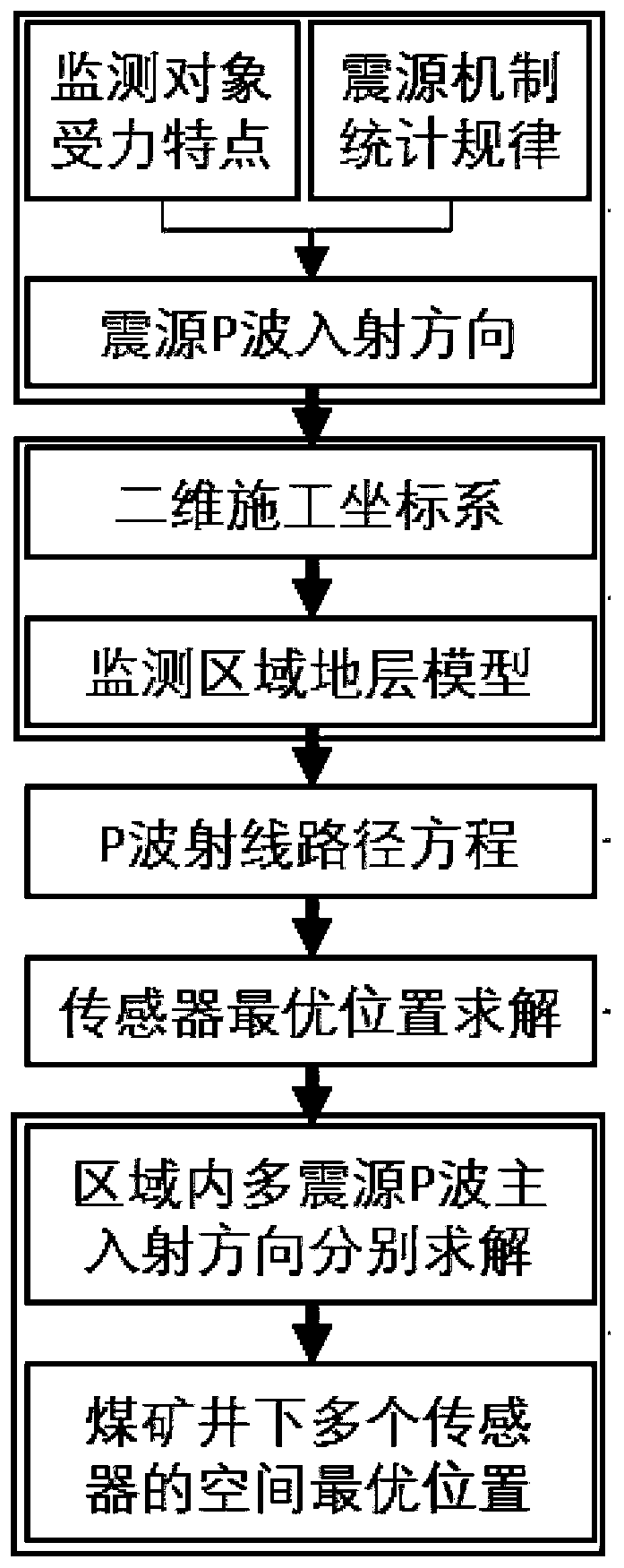

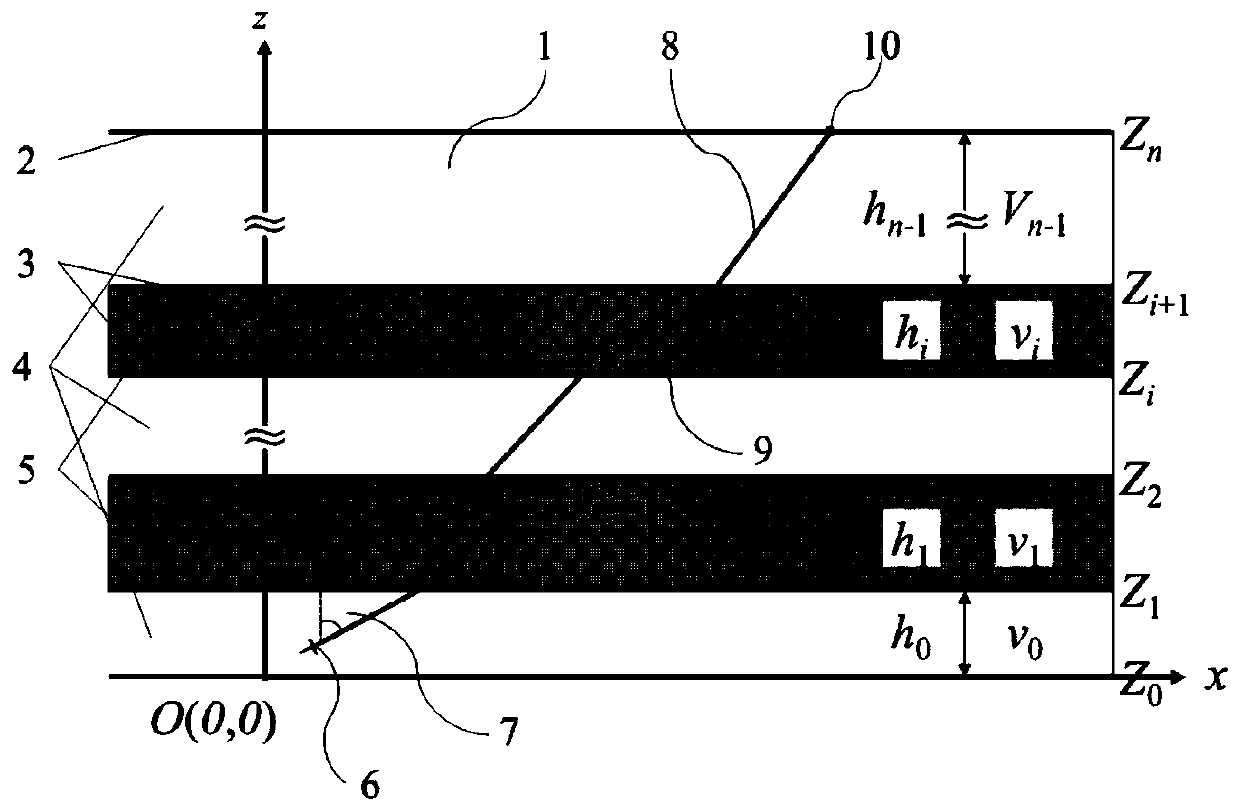

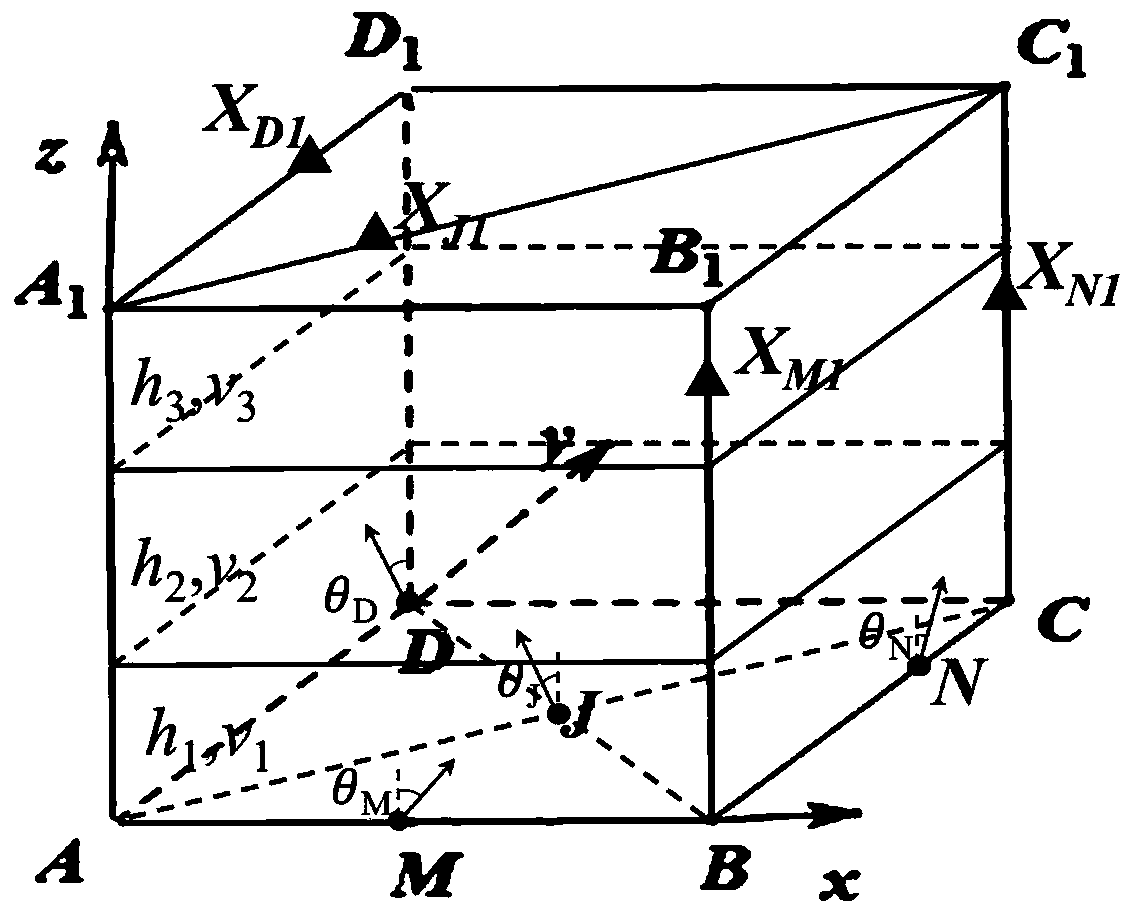

Coal mine underground micro-seismic monitoring sensor arrangement method based on P-wave incident direction

ActiveCN111308559AEasy constructionMeet the project siteMining devicesSeismology for water-loggingEngineeringMechanical engineering

The invention provides a coal mine underground micro-seismic monitoring sensor arrangement method based on a P-wave incident direction, and belongs to the technical field of coal mine underground safety monitoring. The method comprises the following steps: determining a P-wave main incident direction of a micro-seismic event in a monitoring area according to a stress characteristic of a monitoringobject and a seismic source mechanism characteristic statistical law in the monitoring area; then establishing a two-dimensional area construction coordinate system and a layered stratum model conforming to geological characteristics of the monitoring area, and further establishing a ray path equation of P waves; substituting ray parameters, stratum parameters, wave velocity parameters and the like into a ray equation in sequence to obtain the optimal position of sensor arrangement in a coal seam medium; and finally, sequentially solving the sensor positions corresponding to other main incident directions of the P waves of all seismic sources in the monitoring area, and using the sensor positions as the optimal arrangement positions of the sensors in the three-dimensional monitoring area.The method is simple in calculation and accurate in result, and can be suitable for the design of the optimal position of the micro-seismic monitoring sensor of horizontal layered medium undergroundengineering such as coal mines.

Owner:SOUTHWEST UNIVERSITY

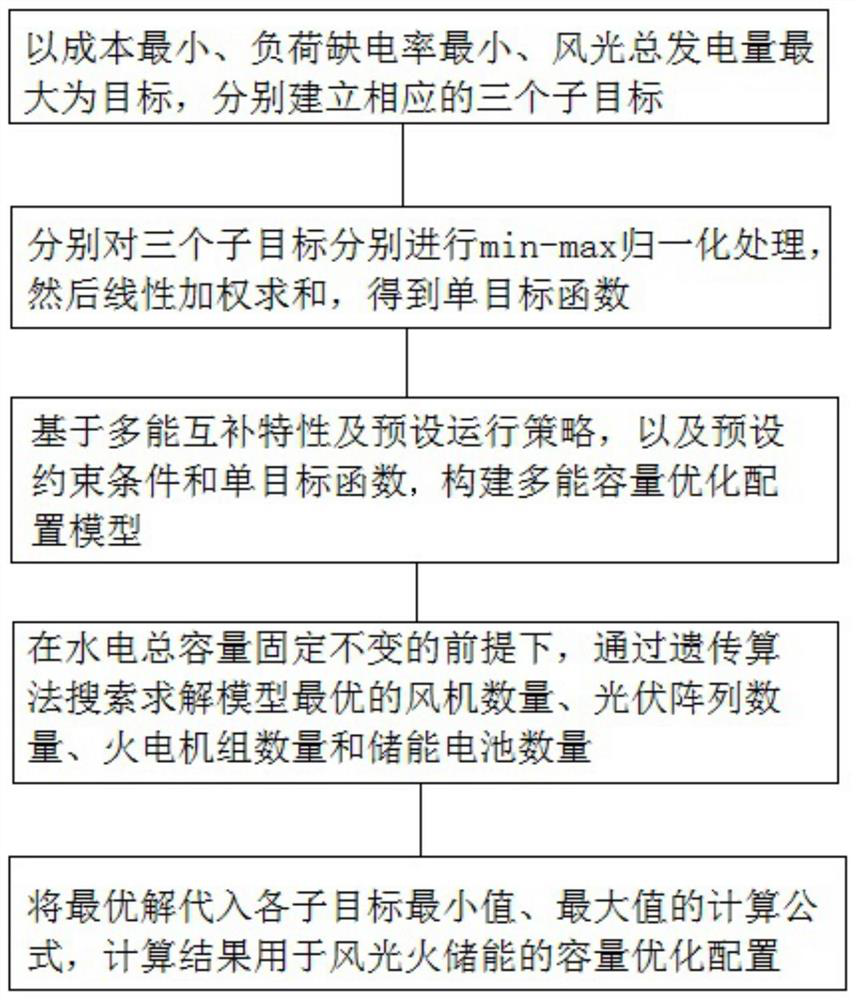

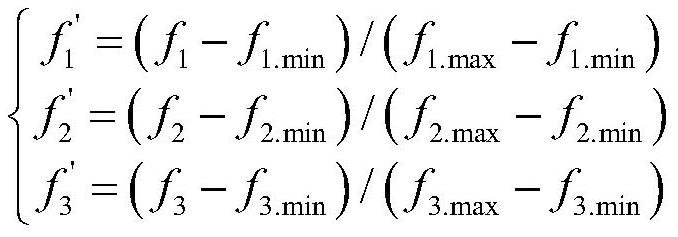

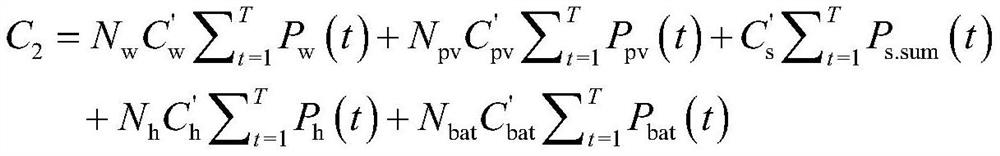

Multi-energy capacity optimal configuration method of wind, light, water and fire storage system

ActiveCN113394817ASimplify the analysis processSimplify computational problemsSingle network parallel feeding arrangementsPhotovoltaic energy generationElectrical batteryPhotovoltaic arrays

The invention relates to a multi-energy capacity optimal configuration method for a wind-solar-water-fire storage system, and the method comprises the steps: taking the minimum cost, the minimum load power shortage rate and the maximum total wind-solar power generation as targets, and building three corresponding sub-targets respectively; respectively carrying out min-max normalization processing on the three sub-targets, and then carrying out linear weighted summation to obtain a single target function; based on the multi-energy complementary characteristics, a preset operation strategy, a preset constraint condition and a single objective function, constructing a multi-energy capacity optimal configuration model; and on the premise that the total hydroelectric capacity is fixed, searching and solving the optimal number of fans, the optimal number of photovoltaic arrays, the optimal number of thermal power generating units and the optimal number of energy storage batteries through a genetic algorithm to be used for calculating the minimum value and the maximum value of each sub-target. According to the method, more types of power supplies are involved, more targets are comprehensively considered, the analysis and calculation of the maximum value and the minimum value of each sub-target are simplified by utilizing the genetic algorithm, and the calculation efficiency of the whole optimal configuration process is improved.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +3

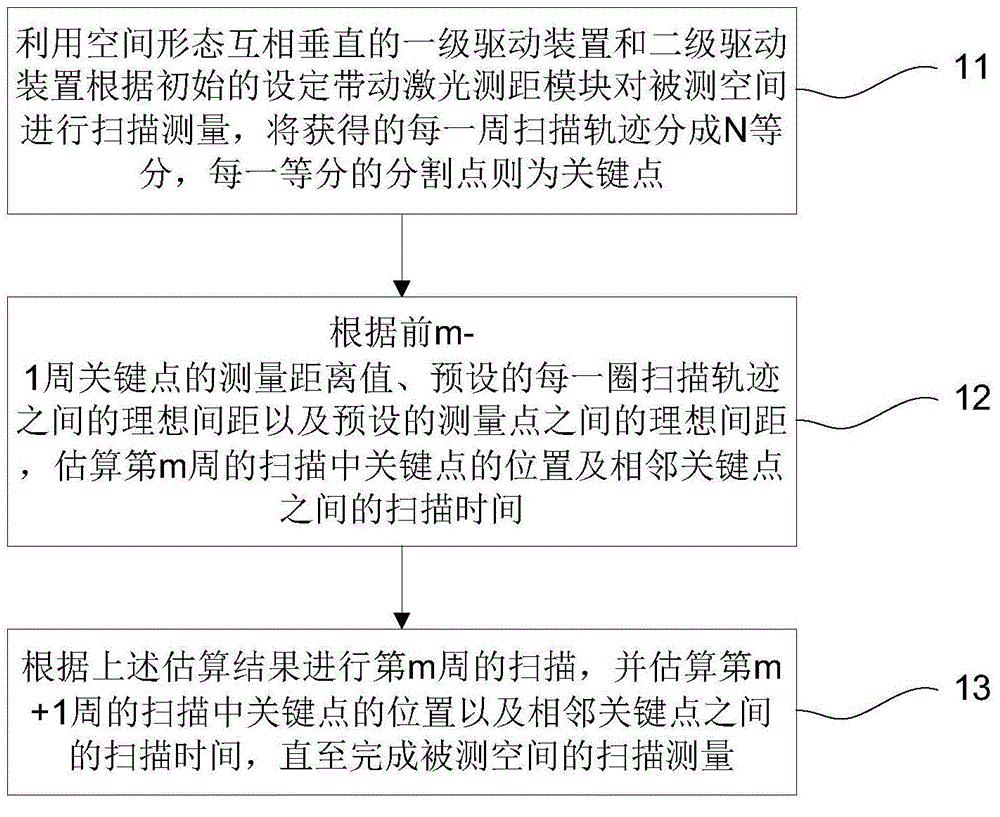

Three-dimensional laser scanning space resolution reinforcing method

ActiveCN104613896AHigh-resolutionImprove scanning efficiencyUsing optical meansImage resolutionLaser scanning

The invention discloses a three-dimensional laser scanning space resolution reinforcing method. The three-dimensional laser scanning space resolution reinforcing method uses two stages of drive devices to run synchronously, and the scanning efficiency can be effectively improved; a scanning space is divided into meridian and parallel grids, and key points are set to effectively simplify the calculation and control process; for any measured space environment, a three-dimensional laser scanner is capable of regulating according to real-time environment, and the three-dimensional laser scanning space resolution is greatly reinforced through regulating gaps between scanning tracks and the scanning time of the adjacent key points.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

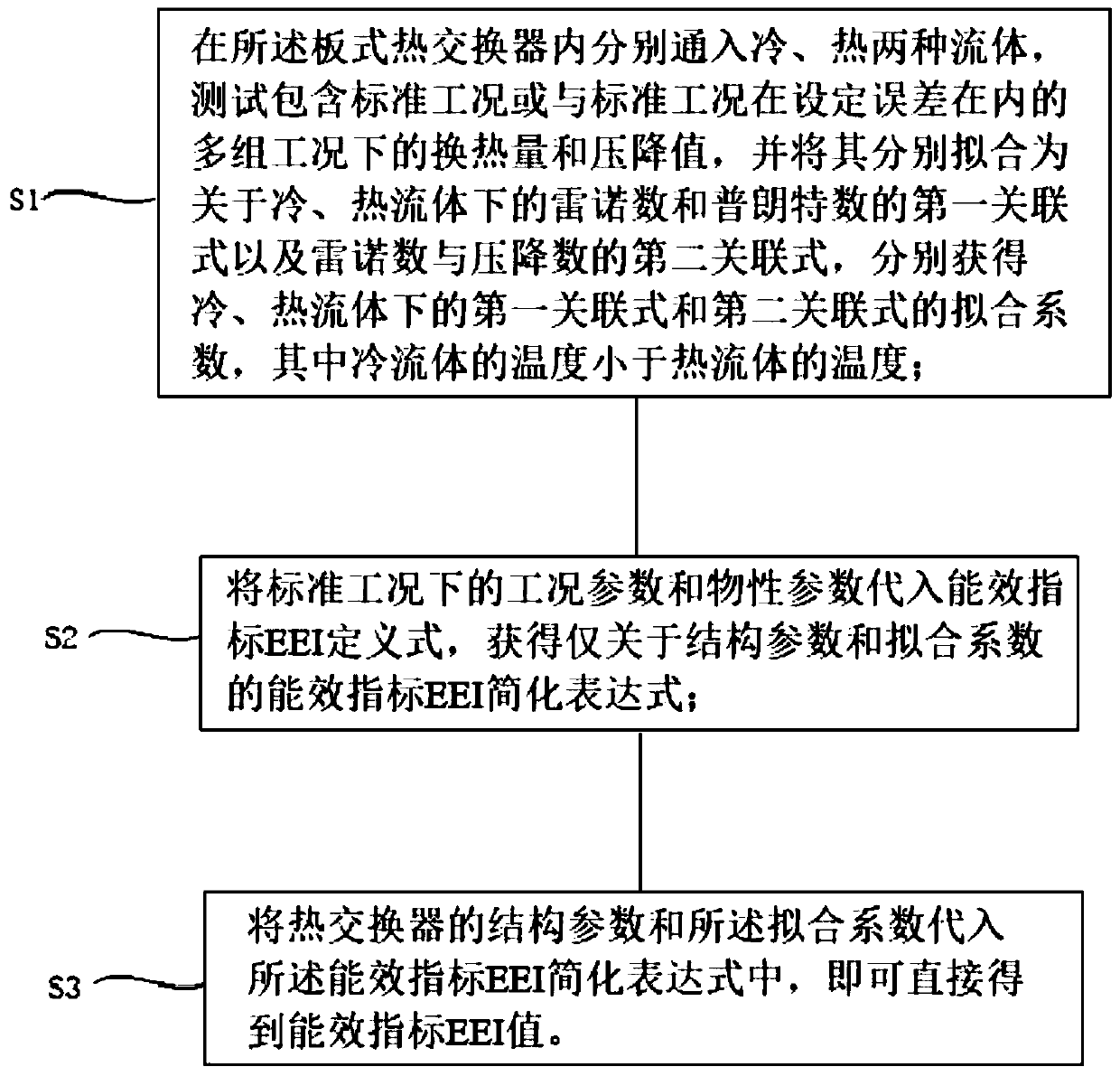

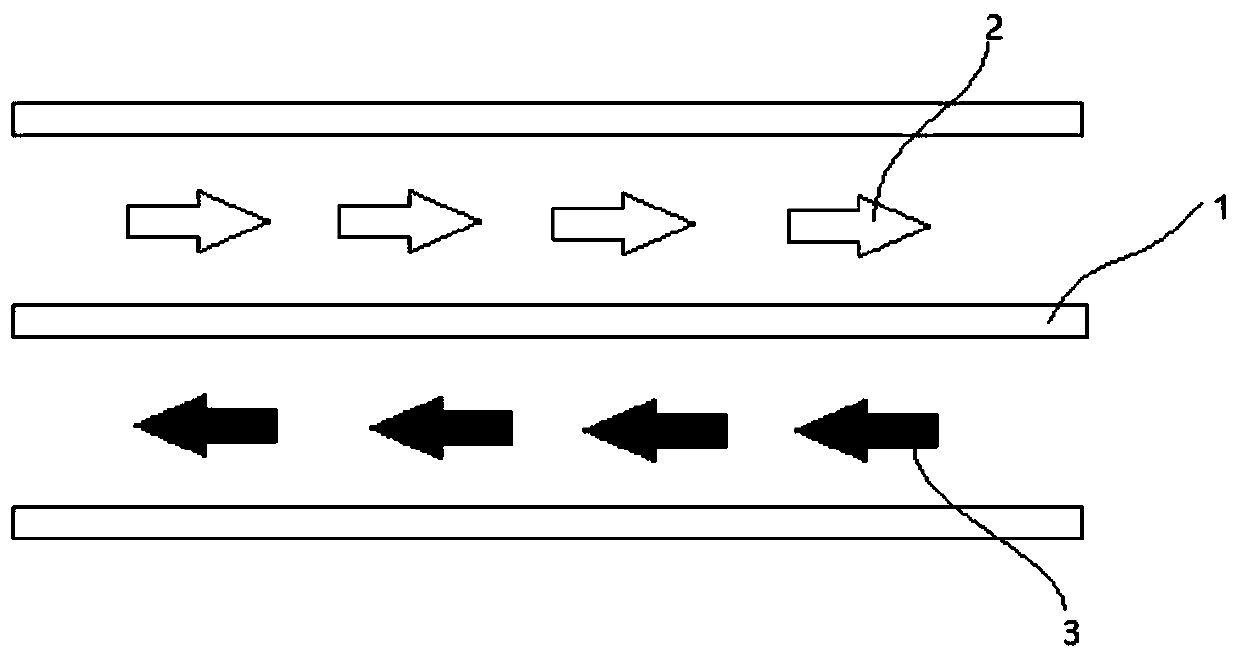

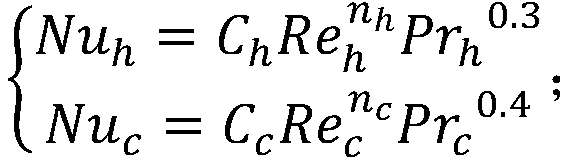

Simplified calculation method for energy efficiency index EEI of plate heat exchanger

ActiveCN110489706ASolving energy efficiency (EEI) calculation problemsSimplify computational problemsComplex mathematical operationsComputational problemEngineering

The invention provides a simplified calculation method for an energy efficiency index EEI of a plate heat exchanger. According to the method, the intermediate processes of solving the heat exchange amount Q, the total heat transfer coefficient k and the like in sequence can be omitted, the calculation process and the tedious degree are greatly simplified, and the precision problem deviating from the standard working condition and the energy efficiency (EEI) calculation problem of the old plate heat exchanger are solved.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES +1

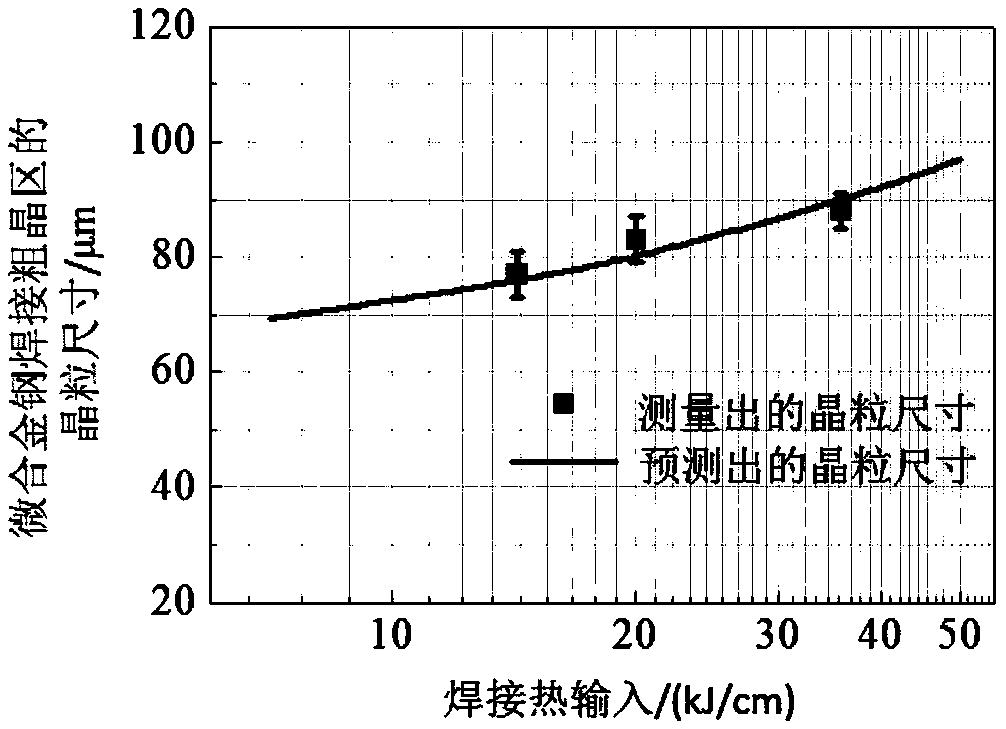

Method for predicting grain size of micro-alloy steel welding coarse grained region

ActiveCN109147873AImprove thermal stabilityReduced thermal stabilityChemical property predictionAustenite grainFinite difference method

The invention relates to a method for predicting the grain size of a micro-alloy steel welding coarse grained region and belongs to the field of physical measurement. The method comprises the steps that firstly, through heat simulation, information of the original austenite grain size of the micro-alloy steel welding coarse grained region under three or more different kinds of heat input is obtained; secondly, the grain growth dynamics formula which is shown in the description is set, wherein M0 and PZ are unknown constants, other parameters are known parameters, corresponding reasonable values are obtained by looking up literature, then the values of the original austenite grain size of the coarse grained region under three different kinds of heat input and the grain growth dynamics formula are fitted (through numerical integration and a finite difference method), and the values of M0 and PZ are obtained through an optimal fitting result; finally, through the grain growth dynamics formula and the fitted values of M0 and PZ, the grain size of the micro-alloy steel welding coarse grained region under different kinds of welding heat input is calculated, and the grain size of the micro-alloy steel welding coarse grained region is predicted. According to the method, the fitting and calculation process is simplified, and importance basis is provided for controlling the grain size ofthe micro-alloy steel welding coarse grained region.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com