Test piece for testing rock II-type dynamic fracture toughness and testing method

A fracture toughness and specimen technology, which is applied in the field of rock type II dynamic fracture toughness test and specimen field of rock type II dynamic fracture toughness test, can solve problems such as complex structure, achieve simple loading operation and low processing difficulty , to avoid the effect of secondary fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

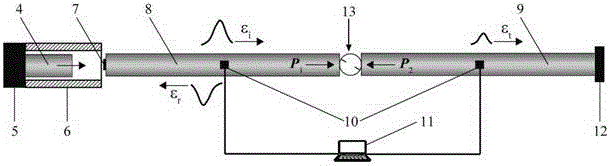

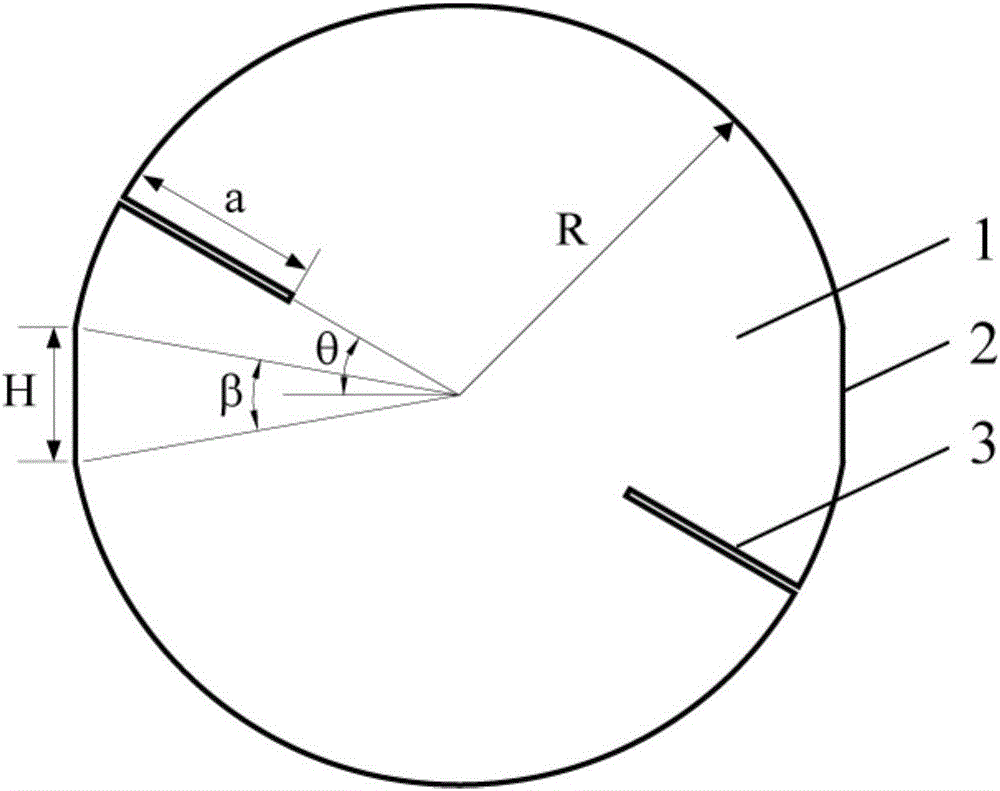

[0045] In the present embodiment, the structural schematic diagram of the specimen used for rock type II dynamic fracture toughness test is as follows figure 1 As shown, the test piece is made by cutting the cylindrical core drilled on the construction site through a diamond slicer.

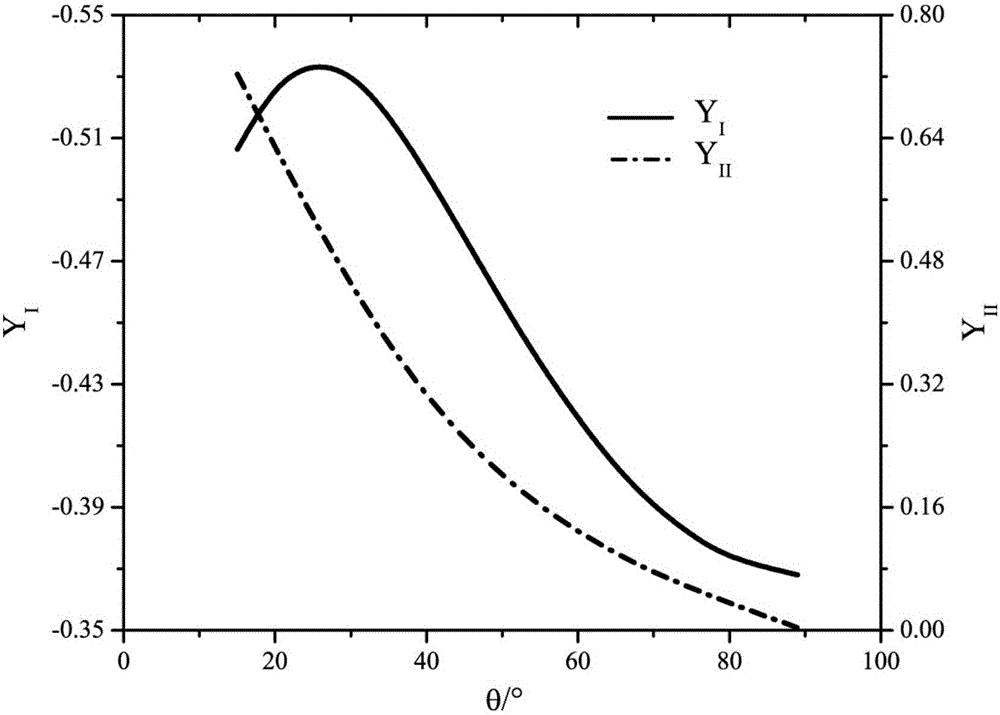

[0046] The test piece used for rock type II dynamic fracture toughness test, the test piece includes a disc-shaped test piece body 1, the radius R=25mm, thickness B=20mm of the disc-shaped test piece body, two Two slots 3, two rectangular mounting planes 2 with the same shape and size are processed on the disc-shaped test piece body 1, the two mounting planes are formed by removing part of the disc-shaped test piece body, perpendicular to the disc-shaped test piece body The same diameter and through the upper and lower disc surfaces of the test piece body, the ratio of the width H of the installation plane to the radius R of the disc-shaped test piece body is 0.35, the central angle β correspondi...

Embodiment 2

[0048] In the present embodiment, the structural schematic diagram of the specimen used for rock type II dynamic fracture toughness test is as follows figure 1 As shown, the test piece is made by cutting the cylindrical core drilled on the construction site through a diamond slicer.

[0049] The test piece used for rock type II dynamic fracture toughness test, the test piece includes a disc-shaped test piece body 1, the radius R=50mm, thickness B=30mm of the disc-shaped test piece body, two Two slots 3, two rectangular mounting planes 2 with the same shape and size are processed on the disc-shaped test piece body 1, the two mounting planes are formed by removing part of the disc-shaped test piece body, perpendicular to the disc-shaped test piece body The same diameter and through the upper and lower disc surfaces of the test piece body, the ratio of the width H of the installation plane to the radius R of the disc-shaped test piece body is 0.52, that is, the width H of the ins...

Embodiment 3

[0051] In the present embodiment, the structural schematic diagram of the specimen used for rock type II dynamic fracture toughness test is as follows figure 1 As shown, the test piece is made by cutting the cylindrical core drilled on the construction site through a diamond slicer.

[0052] The test piece used for rock type II dynamic fracture toughness test, the test piece includes a disc-shaped test piece body 1, the radius R=25mm, thickness B=25mm of the disc-shaped test piece body, two Two slots 3, two rectangular mounting planes 2 with the same shape and size are processed on the disc-shaped test piece body 1, the two mounting planes are formed by removing part of the disc-shaped test piece body, perpendicular to the disc-shaped test piece body The same diameter and through the upper and lower disc surfaces of the test piece body, the ratio of the width H of the installation plane to the radius R of the disc-shaped test piece body is 0.4, that is, the width H of the inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Rod diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com