Patents

Literature

480results about How to "Reduced thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

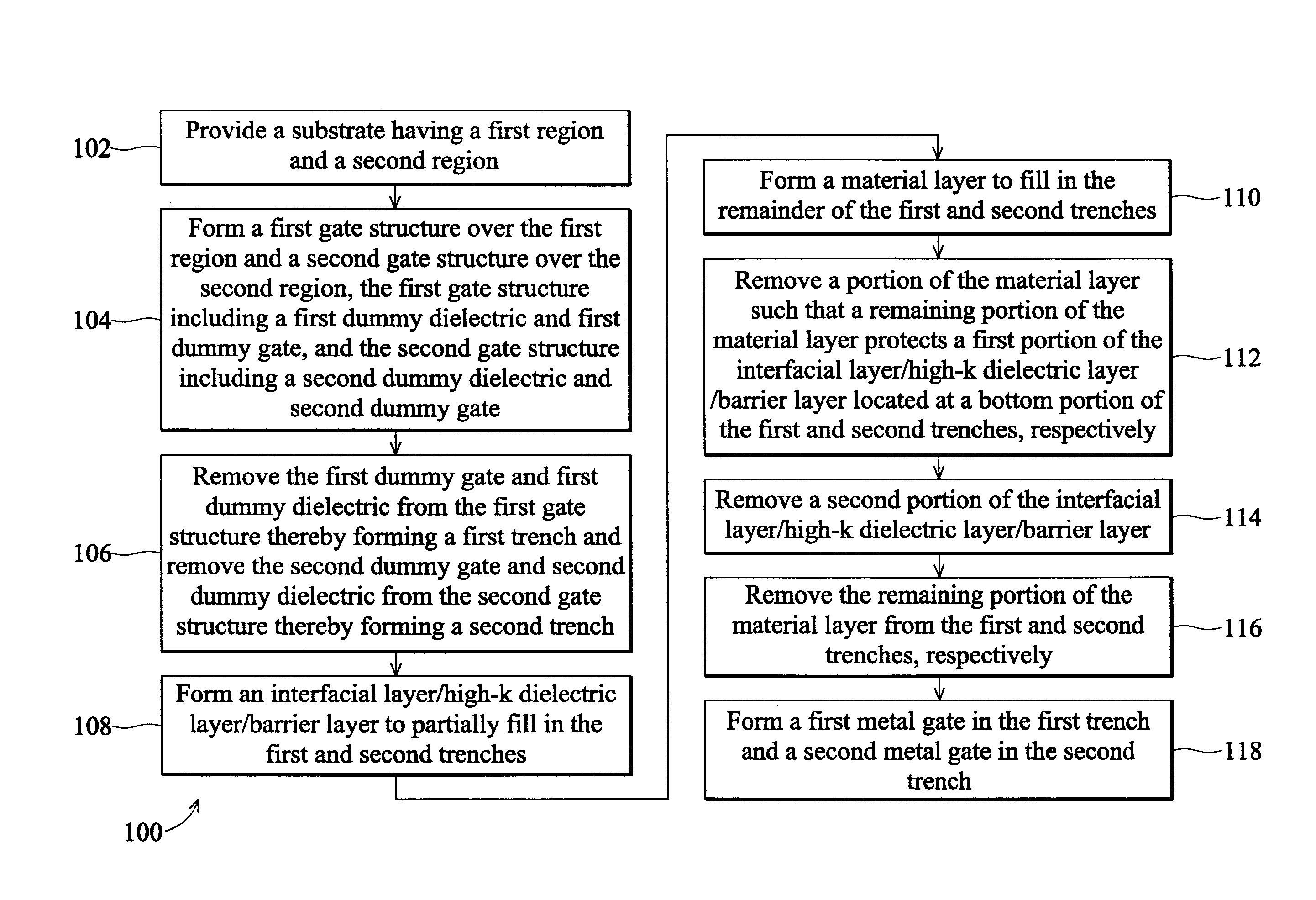

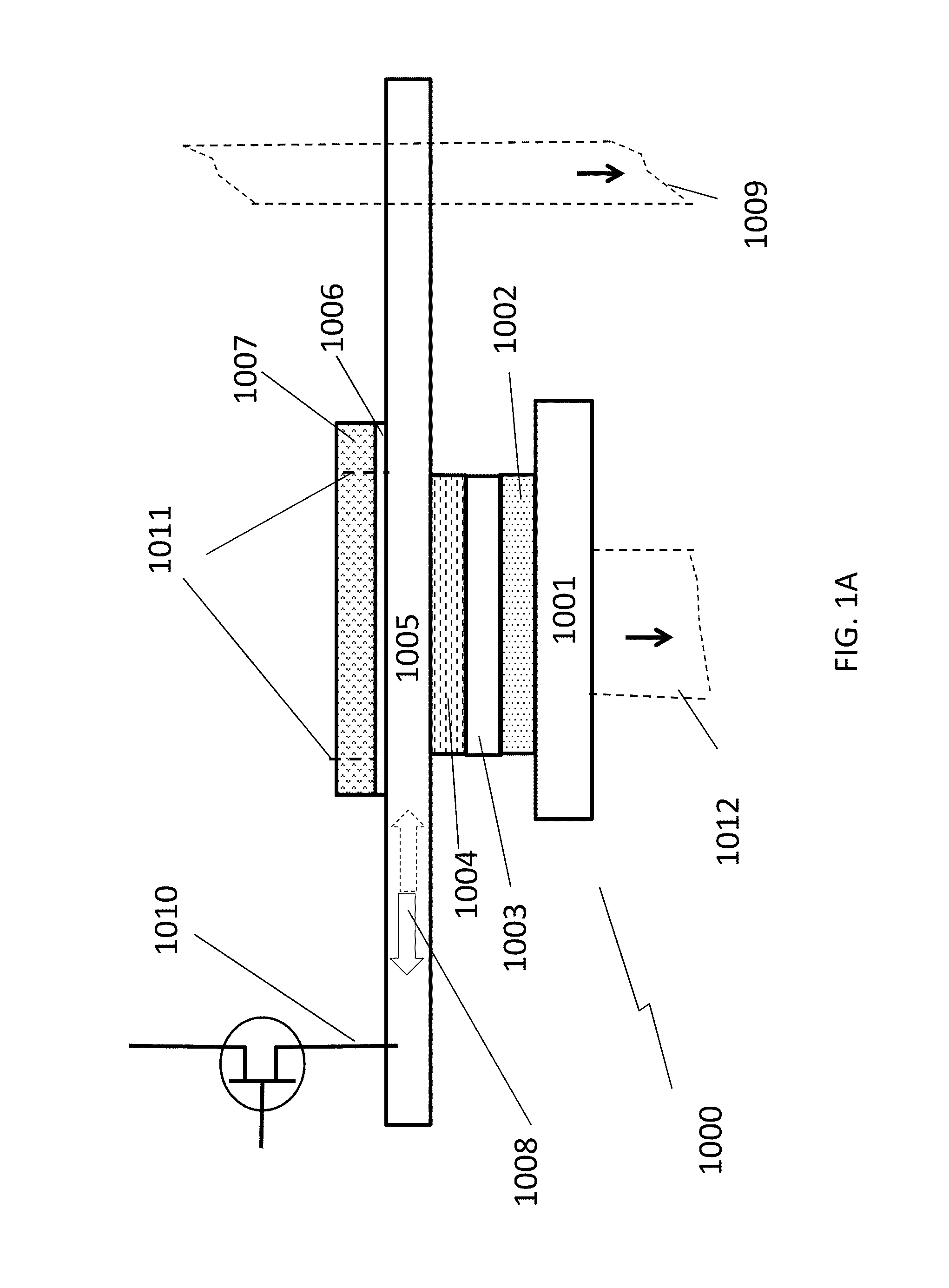

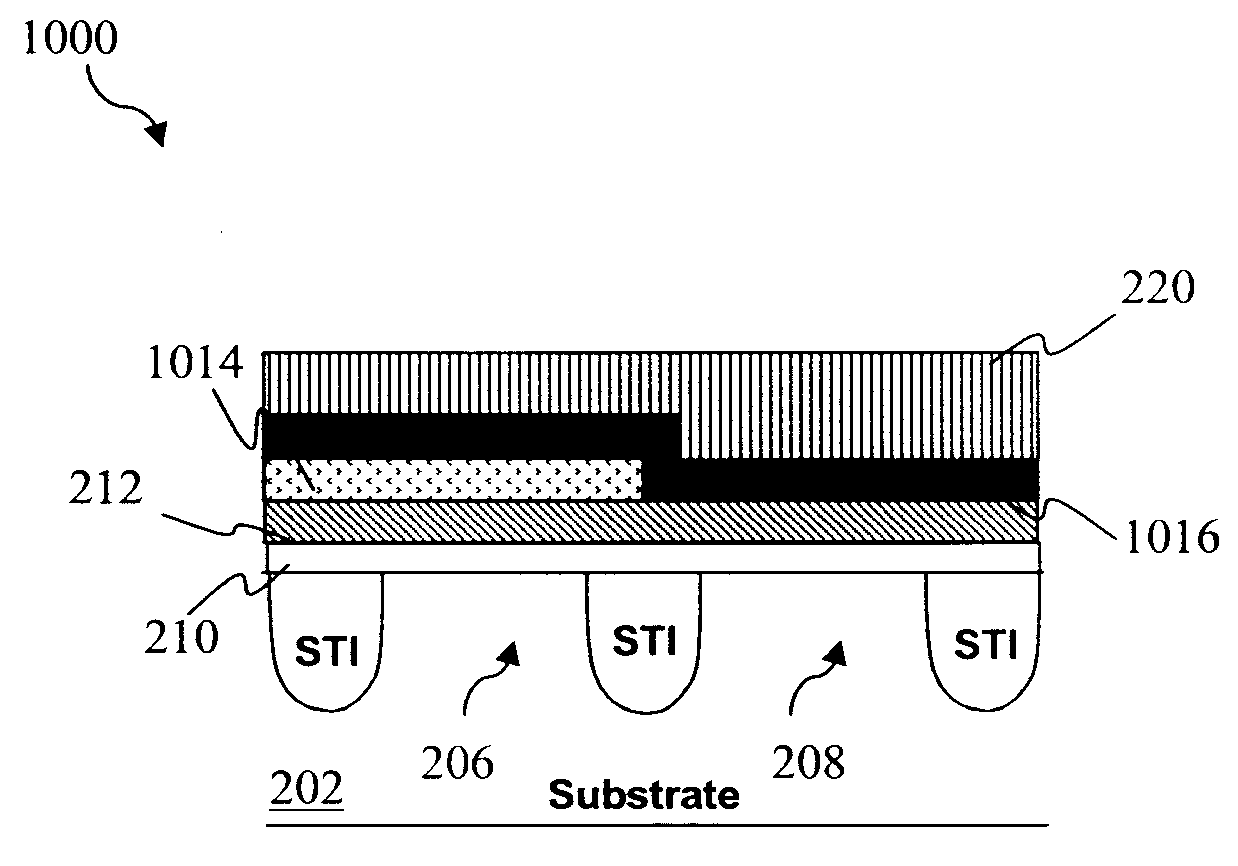

Fabricating high-k/metal gate devices in a gate last process

ActiveUS20100124818A1Reduced thermal stabilityIncrease productivitySemiconductor/solid-state device manufacturingSemiconductor devicesDielectricMetal

The present disclosure provides a method that includes forming first and second gate structures over first and second regions, respectively, removing a first dummy gate and first dummy dielectric from the first gate structure thereby forming a first trench and removing a second dummy gate and second dummy dielectric from the second gate structure thereby forming a second trench, forming a gate layer to partially fill the first and second trenches, forming a material layer to fill the remainder of the first and second trenches, removing a portion of the material layer such that a remaining portion of the material layer protects a first portion of the gate layer located at a bottom portion of the first and second trenches, removing a second portion of the gate layer, removing the remaining portion of the material layer from the first and second trenches.

Owner:TAIWAN SEMICON MFG CO LTD

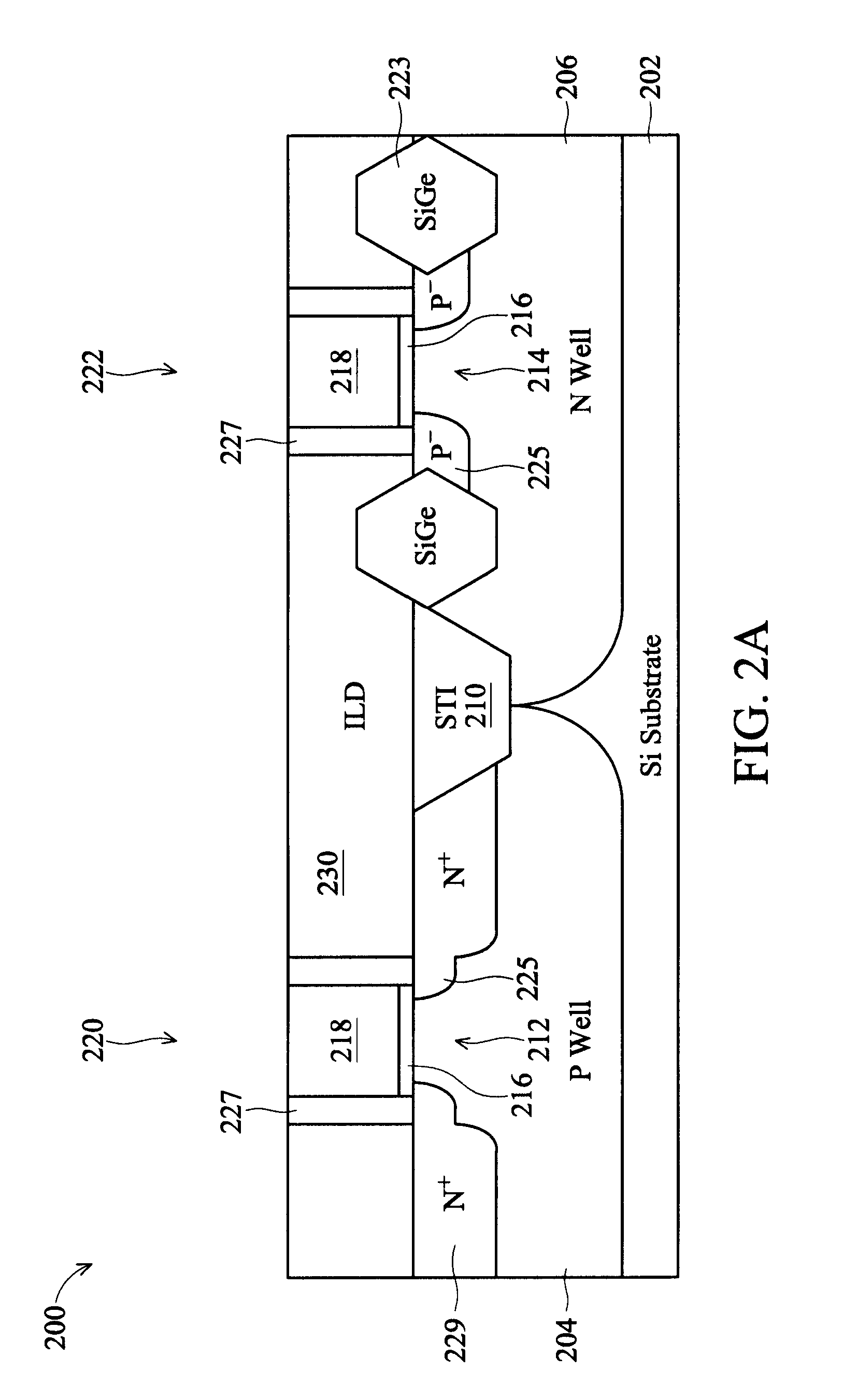

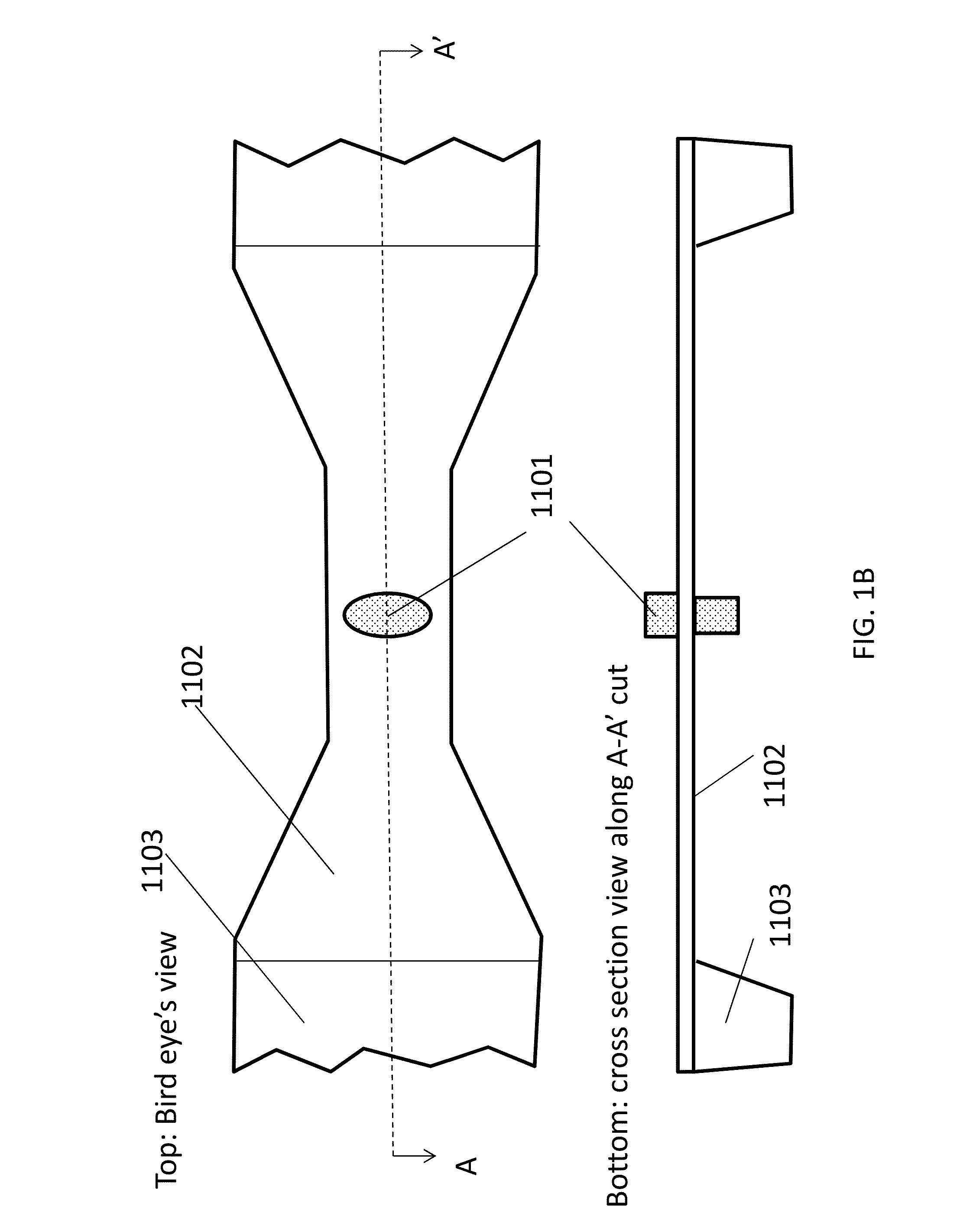

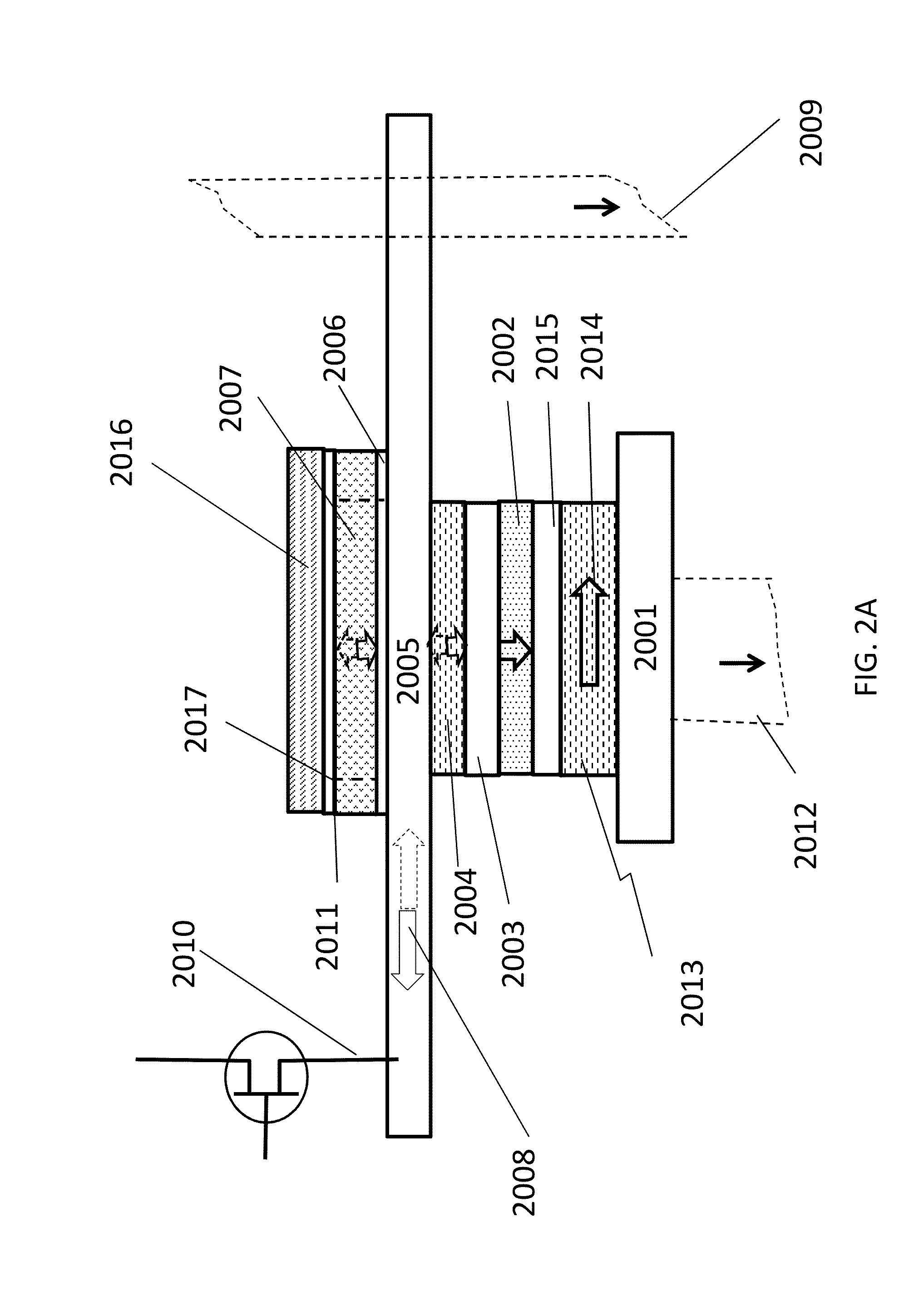

Magnetoresistive random access memory cell and 3D memory cell array

ActiveUS9218864B1Easy to implementImprove thermal stabilityDigital storageMagnetic stabilizationMagnetic reluctance

A novel three-terminal SOT-MRAM memory cell with a unique magnetic stabilization layer or structure is proposed. A complementary magnetic footprint of the data storage layer for the memory cell is able to be created within the magnetic stabilization layer or structure by the magnetic field from the storage layer to enhance the magnetic and thermal stability of the memory cell. Several designs for both perpendicular and in-plane SOT-MRAM memory cell have been invented. With proper wire connection and sensing arrangement, the proposed memory cell is capable of forming not only the 2D array but also 3D array.

Owner:GE YI +1

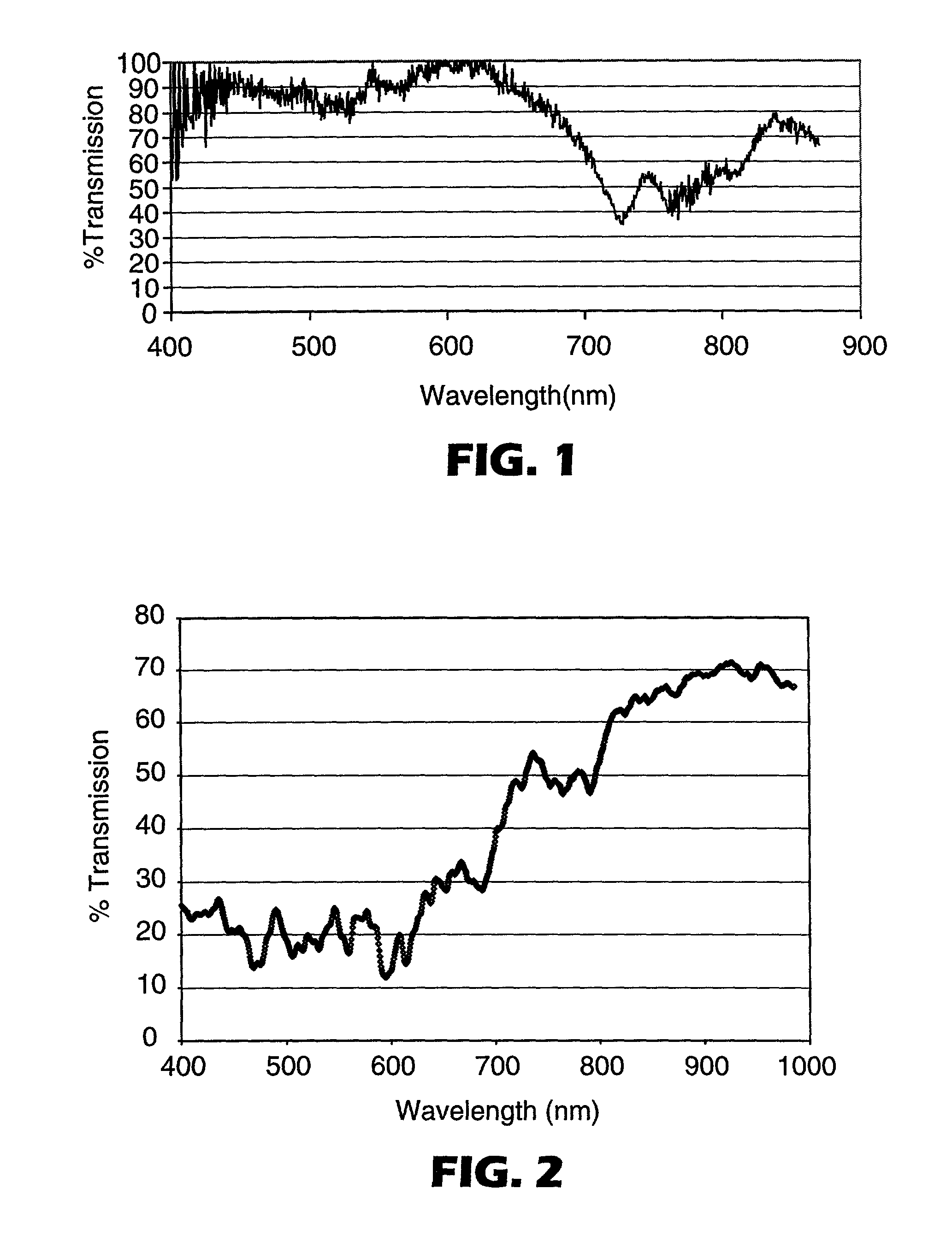

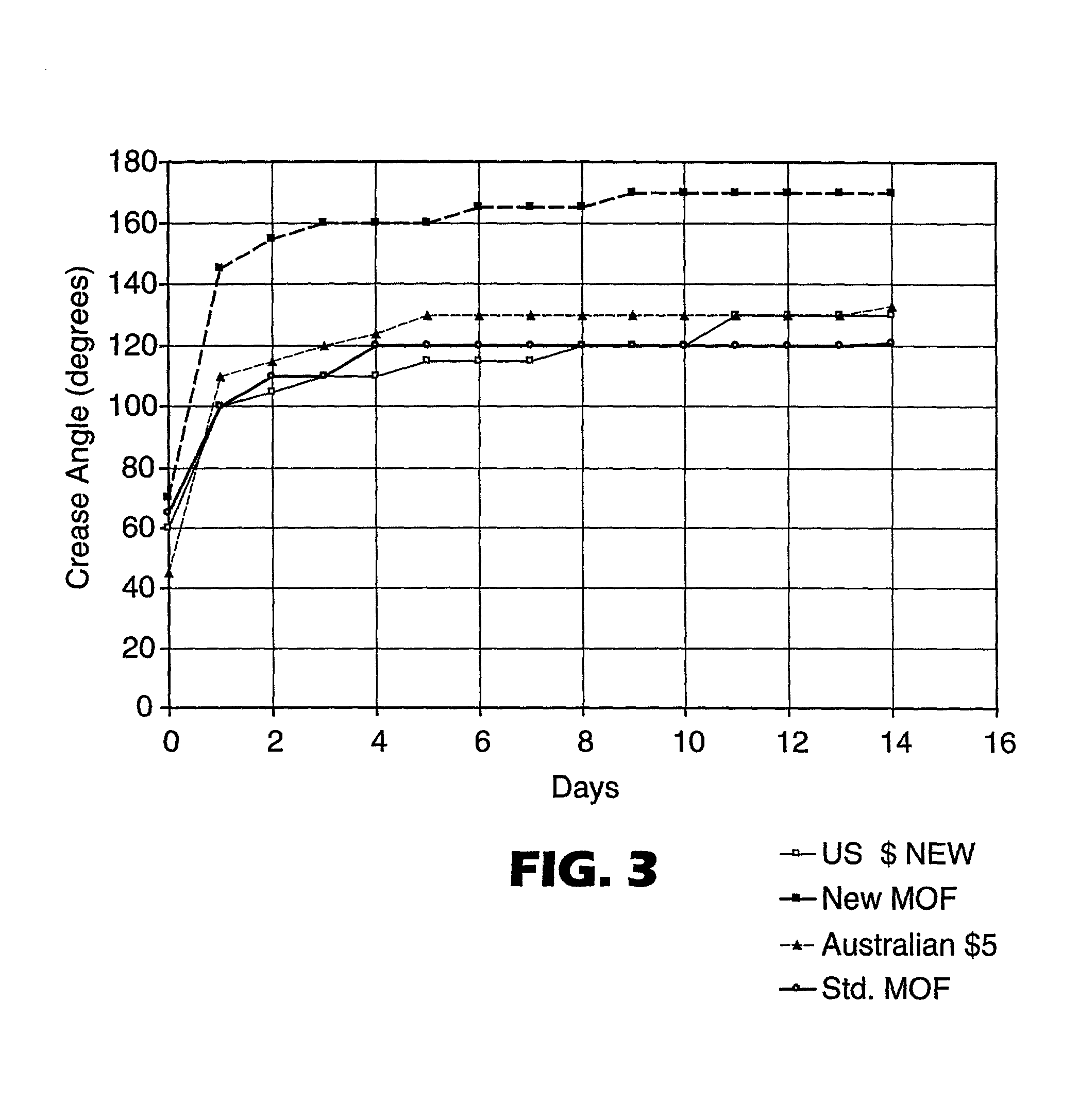

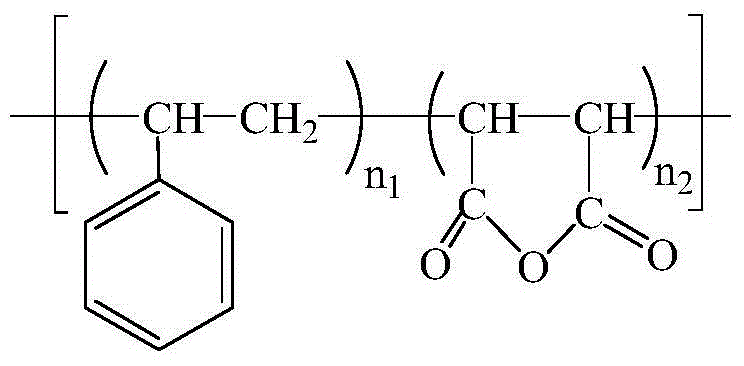

Low Tg multilayer optical films

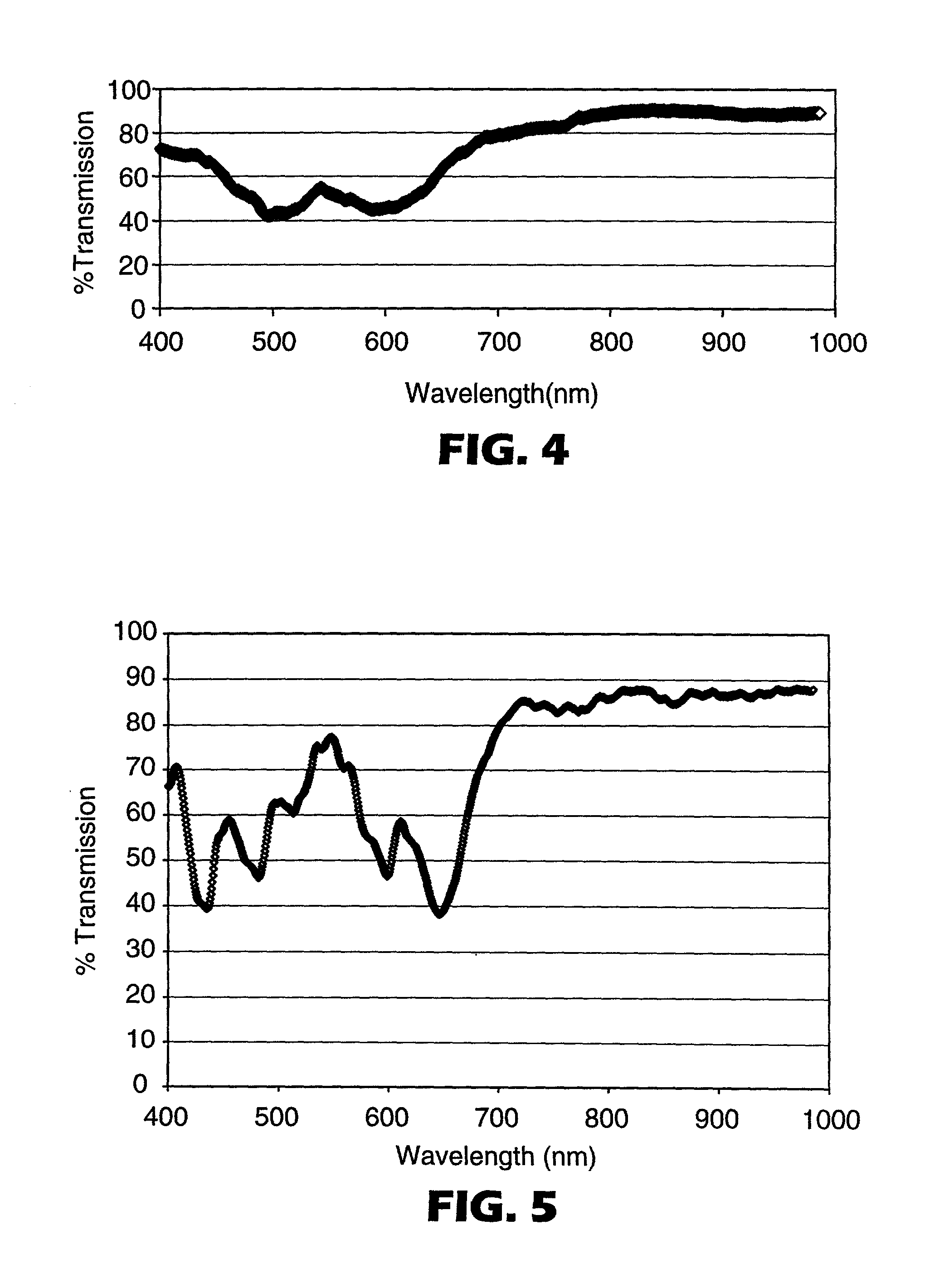

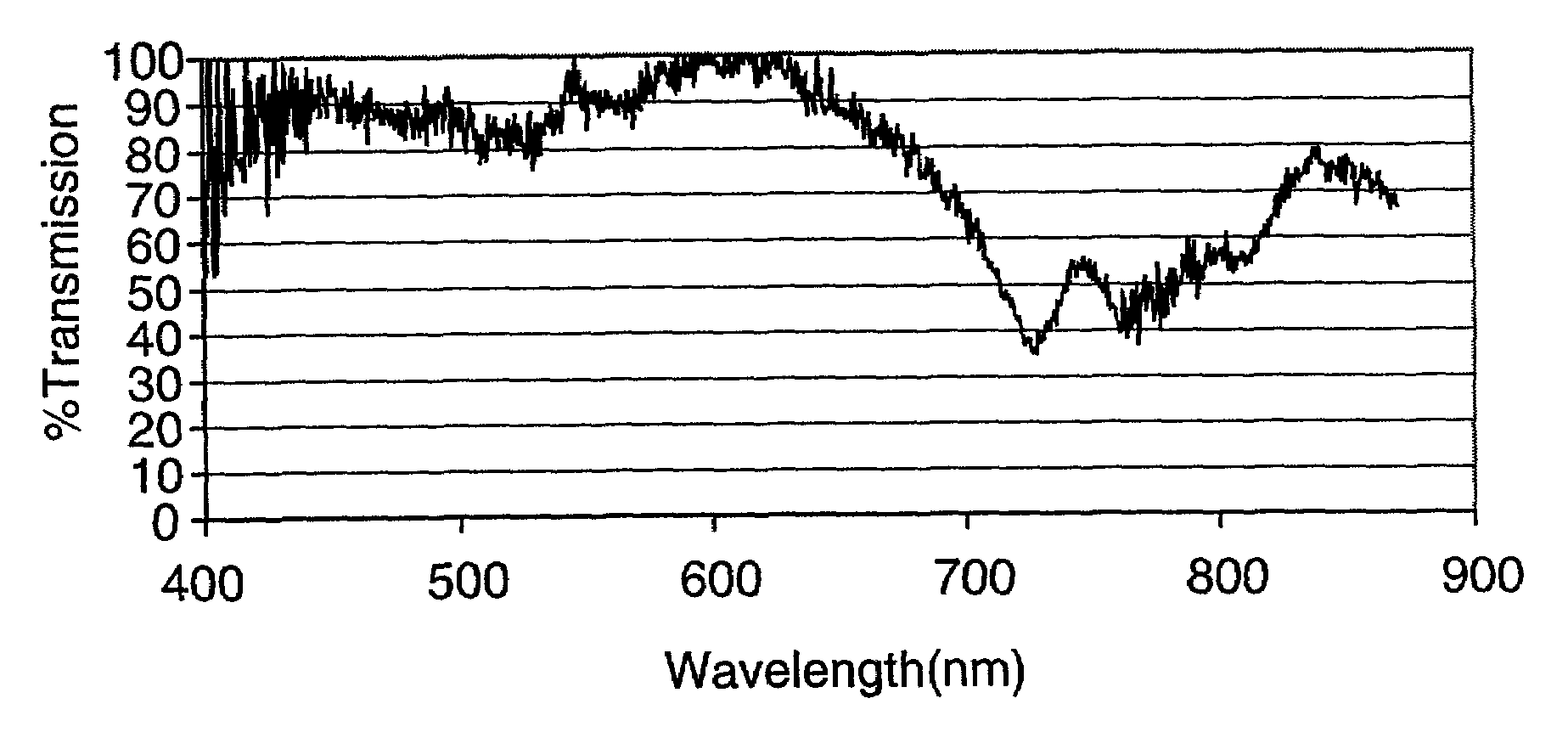

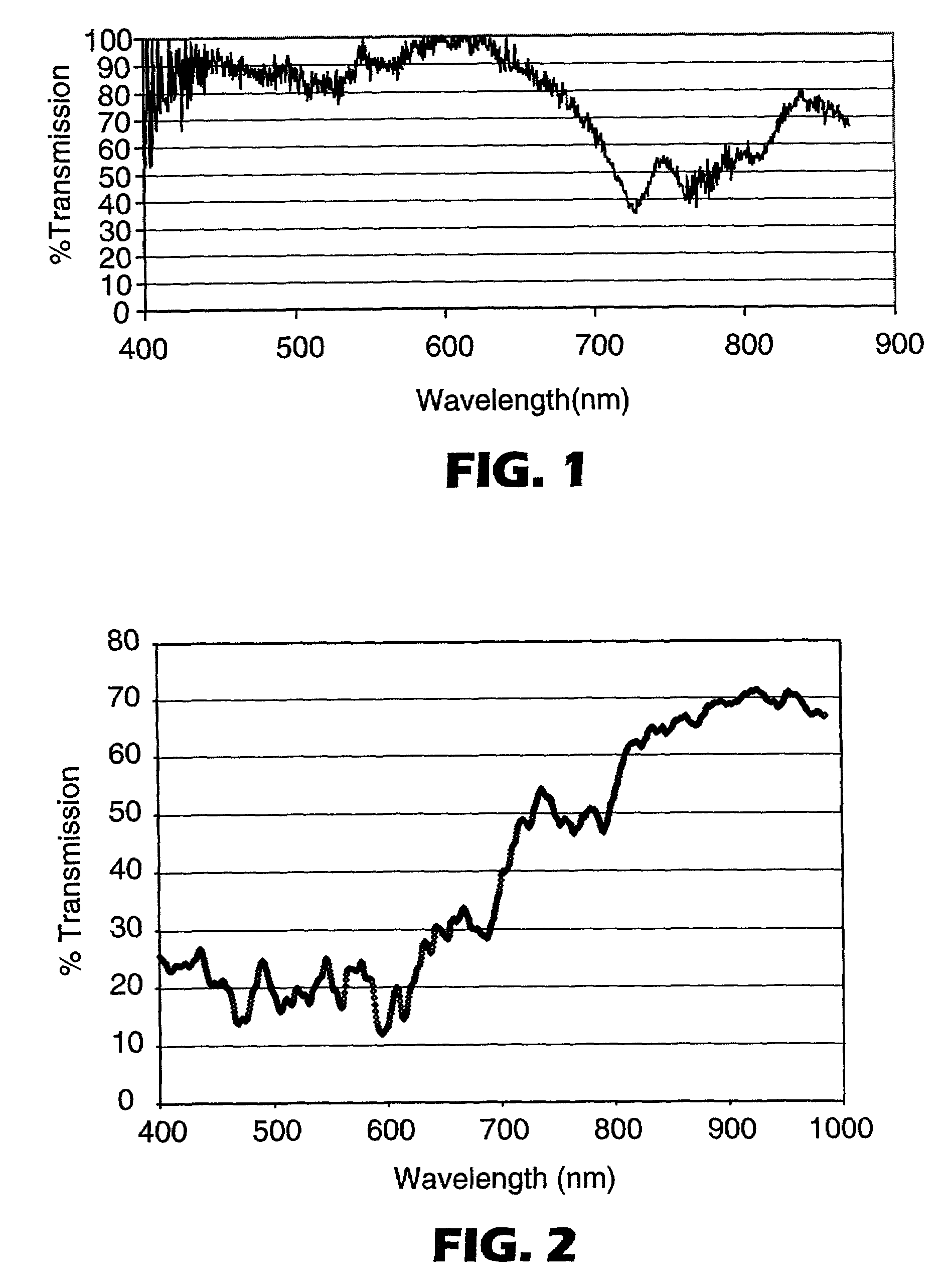

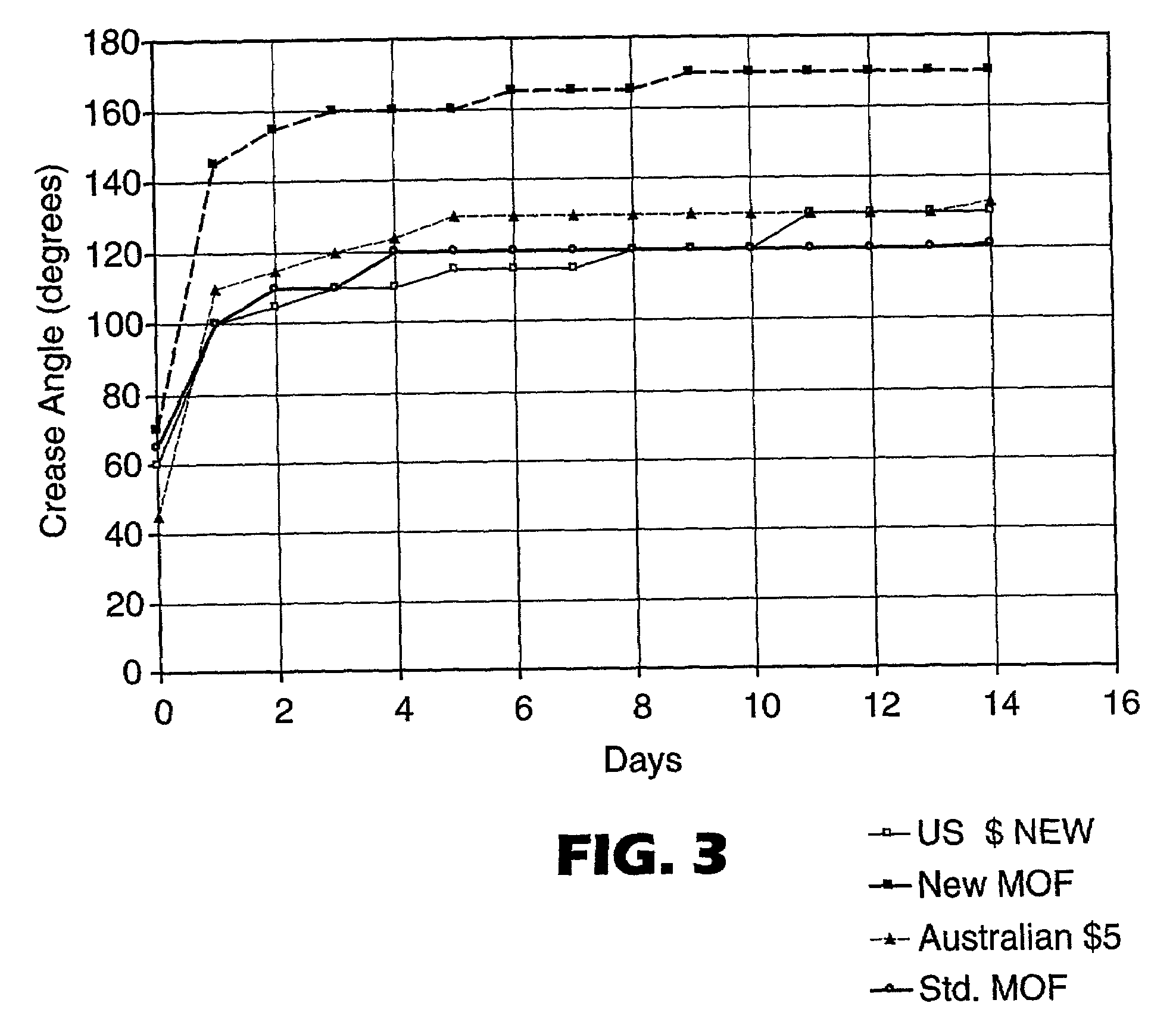

InactiveUS20030072931A1Fine creaseExcellent crumple recoveryLayered productsPolarising elementsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

Low Tg multilayer optical films

InactiveUS7052762B2Excellent crease and crumple recoveryHigh refractive indexOther printing matterLayered productsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

Lithium-ion batteries and cathode materials thereof

InactiveUS20130260231A1Increase energy densityImprove cycle performanceElectrode carriers/collectorsSecondary cellsPhosphateOptoelectronics

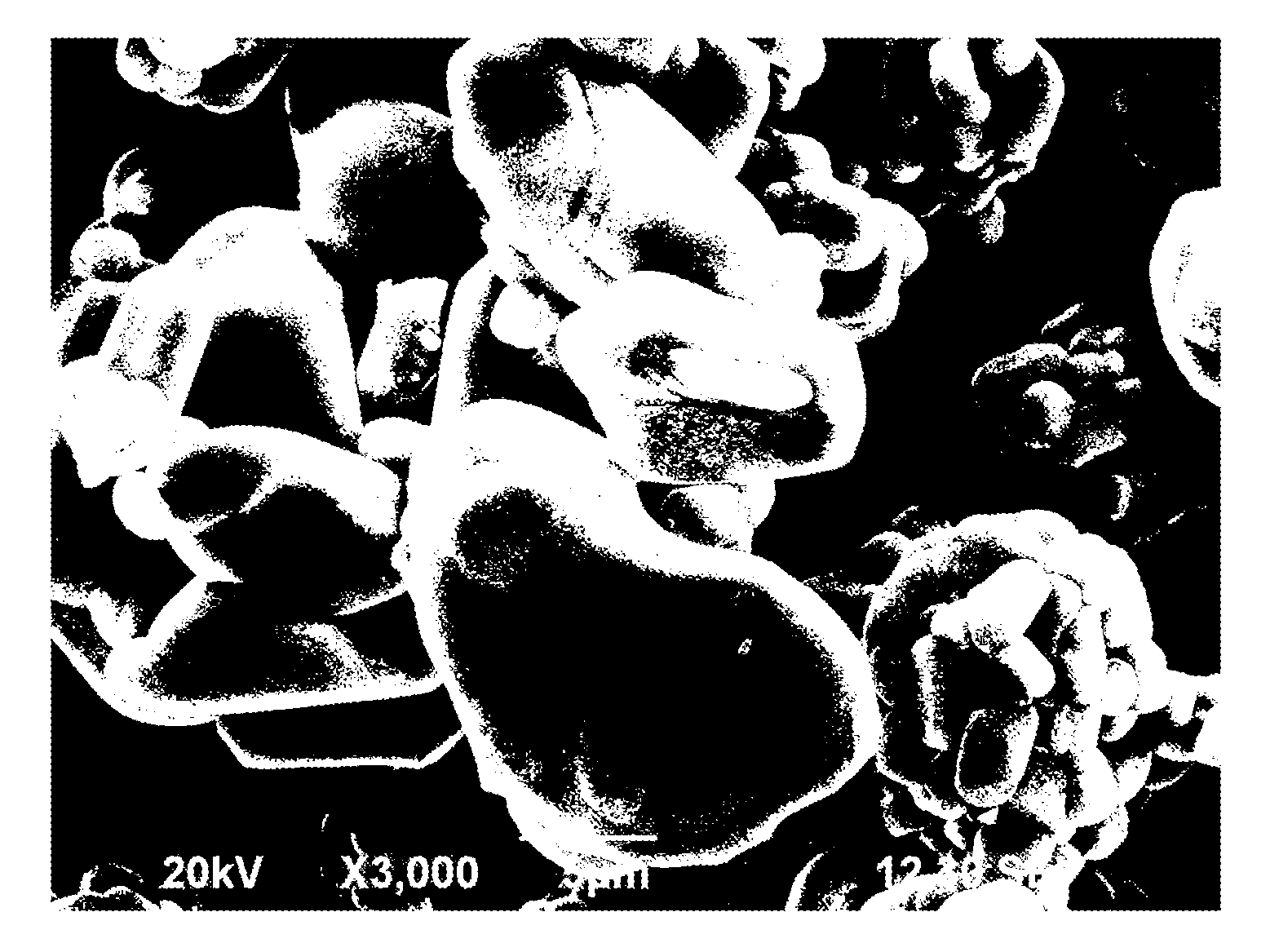

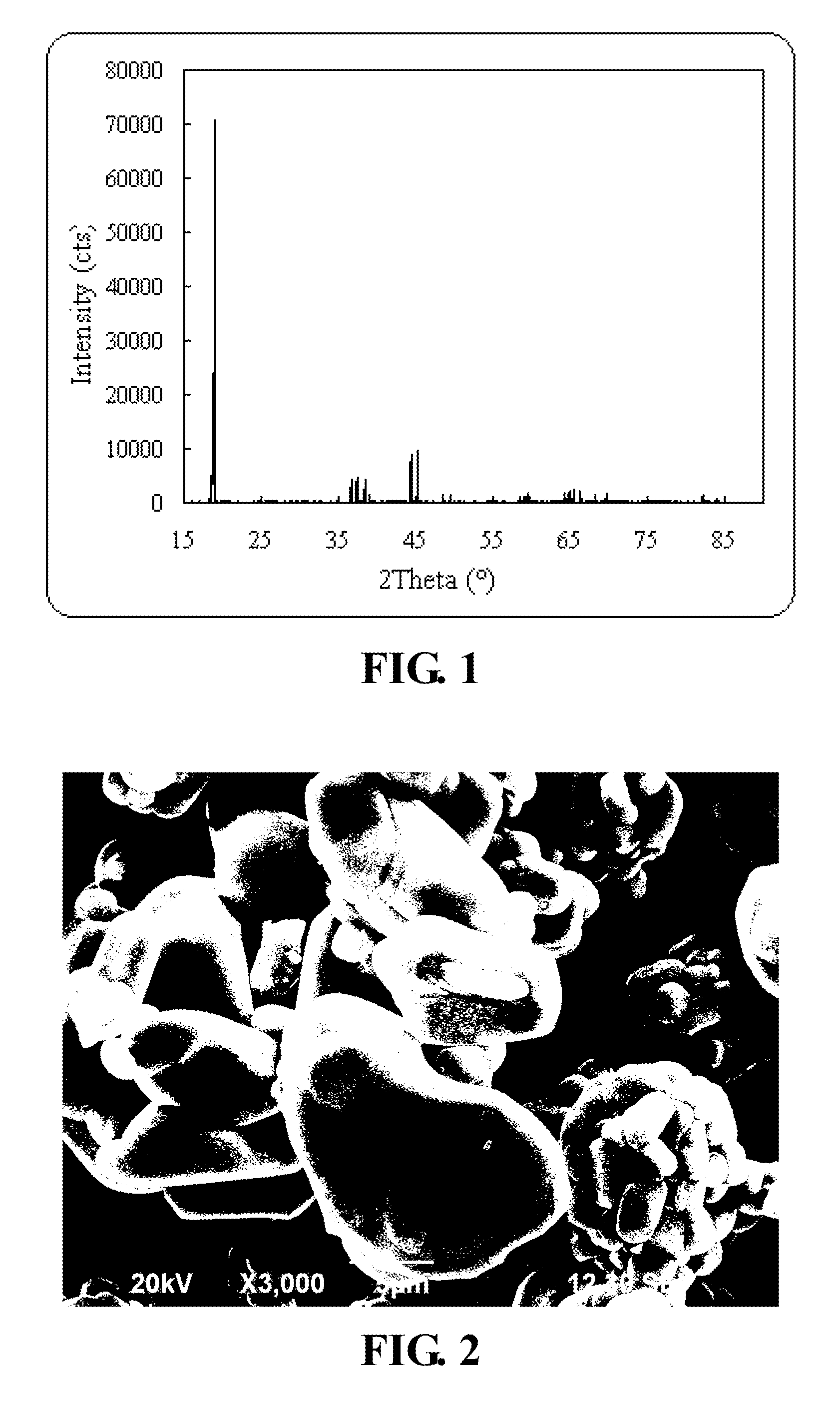

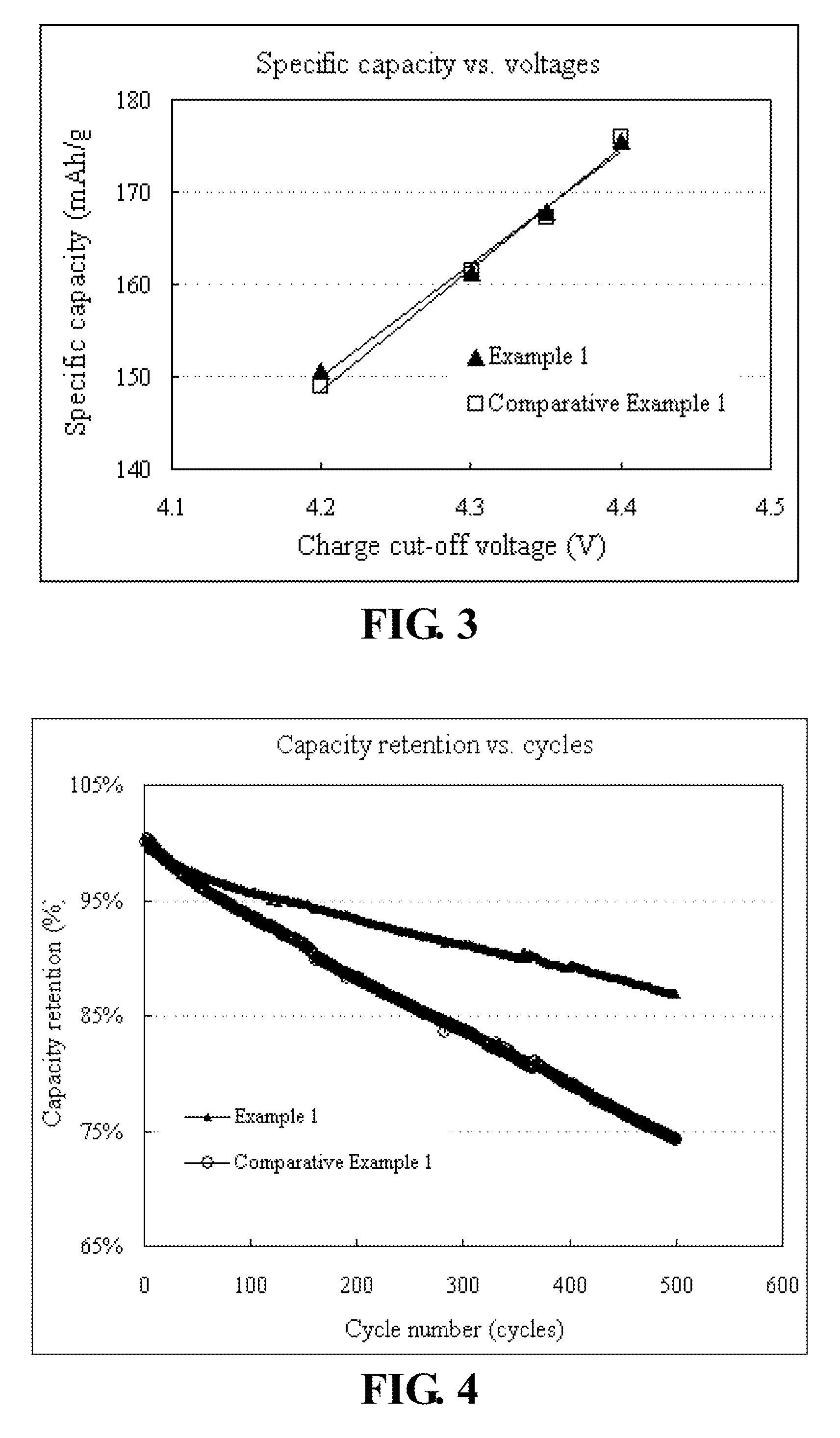

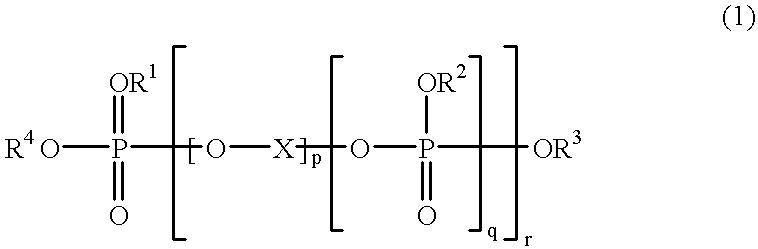

The invention provides a type of lithium-ion battery cathode materials applicable to a high charge cut-off voltage. The cathode materials comprises two active substances of LiCoO2 and Li (NixCoyMn1-x-y)O2, where 0.3≦x≦0.8, 0.1≦y≦0.4, and 0.6≦x+y≦0.9. Both LiCoO2 and Li(NixCoyMn1-x-y)O2 are doped with element M and then treated by surface coating with the oxide, sulfide, fluoride of element M′ or phosphate. The element M is at least one of the Mg, Ti, Al, Zr, B, La, Ce, Y, P, S, N or F while the element M′ is at least one of the Al, Ti, Mg, Zr, B, Si, Fe, La, Ce or Y. The cathode materials provided herein, having the advantages of excellent cycling performance and low cell swelling against high temperature, can help to remarkably increase the energy density of lithium-ion batteries. The invention also discloses a lithium-ion battery containing such cathode materials.

Owner:NINGDE AMPEREX TECH

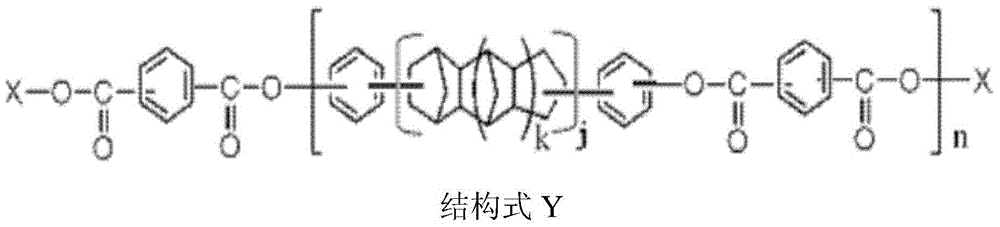

Flame-retardant polycarbonate resin composition and its moldings

InactiveUS6197857B1Poor impact resistanceReduced thermal stabilityPlastic/resin/waxes insulatorsSkin carePhosphateShell molding

An object of the invention is to provide a flame-retardant polycarbonate resin composition which can provide a sliding property of a molding product formed of a flame-retardant resin composition obtained by blending a polycarbonate resin and a styrene resin with a phosphate ester compound and having a good flowability without decreasing an appearance of a molding product. The invention relates to a flame-retardant polycarbonate resin composition including 100 parts by weight of a resin composed of (A) from 60 to 99% by weight of a polycarbonate resin and (B) from 40 to 1% by weight of a styrene resin, (C) from 1 to 30 parts by weight of a phosphate ester compound and (D) from 0.3 to 3 parts by weight of a silicone oil having a viscosity of from 1,000 to 20,000 cs.

Owner:IDEMITSU KOSAN CO LTD

Deposition precursors for semiconductor applications

InactiveUS20080248648A1Improve responseHigh crystallinityCobalt organic compoundsSemiconductor/solid-state device manufacturingElectron donorGas phase

This invention relates to organometallic compounds comprising at least one metal or metalloid and at least one substituted anionic 6 electron donor ligand having sufficient substitution (i) to impart decreased carbon concentration in a film or coating produced by decomposing said compound, (ii) to impart decreased resistivity in a film or coating produced by decomposing said compound, or (iii) to impart increased crystallinity in a film or coating produced by decomposing said compound. The organometallic compounds are useful in semiconductor applications as chemical vapor or atomic layer deposition precursors for film depositions.

Owner:PRAXAIR TECH INC

Metal delivery system for nanoparticle manufacture

ActiveUS20060229197A1Improve productivityWell mixedRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidMetallacarboxylic acid

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

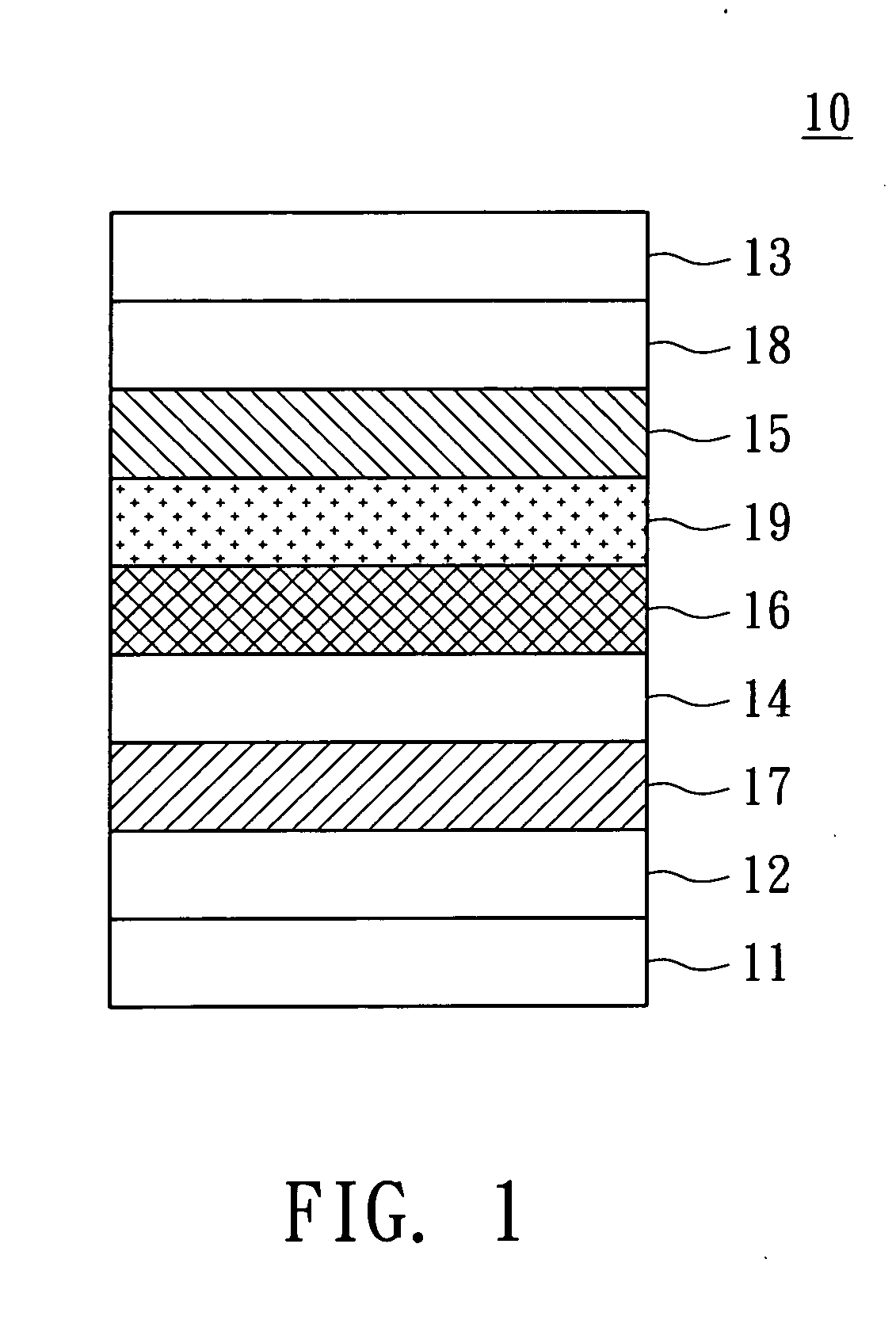

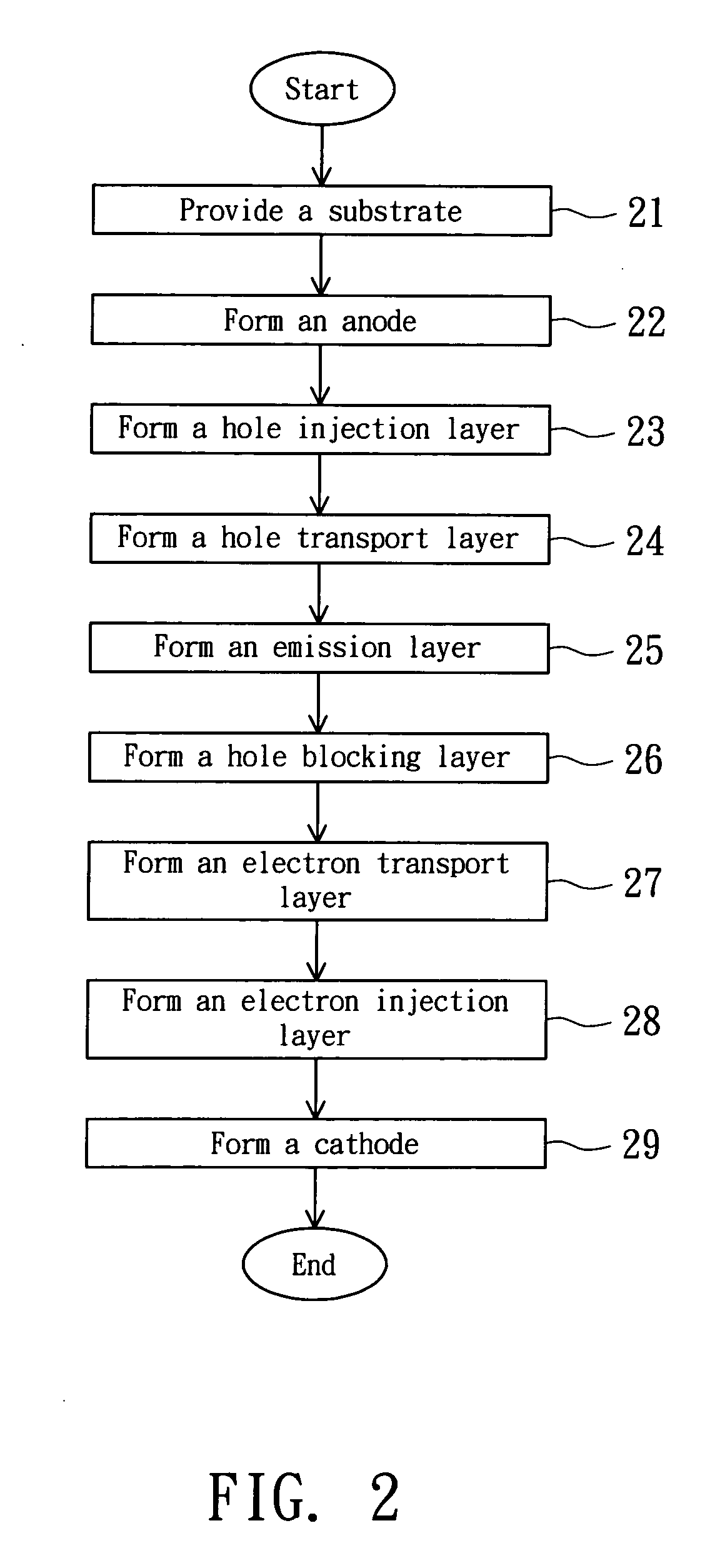

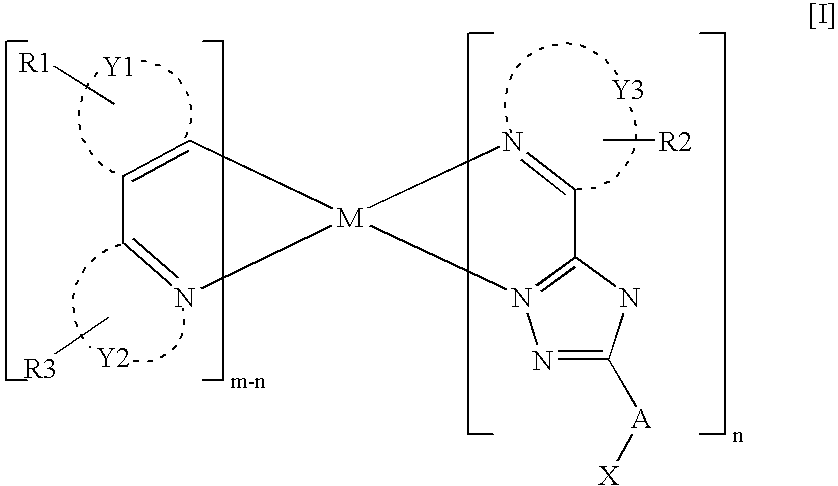

Light emission material and organic electroluminescent device using the same

ActiveUS20060286404A1Easy sublimationQuick responseDischarge tube luminescnet screensGroup 8/9/10/18 element organic compoundsPhysicsOrganic electroluminescence

An organic electroluminescent device including a substrate, an anode, a cathode, a hole transport layer, an electron transport layer and an emission layer is provided. The anode and the cathode are disposed on the substrate. The hole transport layer is disposed between the anode and the cathode. The electron transport layer is disposed between the hole transport layer and the cathode. The emission layer is disposed between the hole transport layer and the electron transport layer. The chemical structure of the dopant is represented by formula [I]: “M” represents a metal atom, m is smaller than or equal to the ligand number of “M”, n is smaller than m. “Y1” is selected from aryl or heteroaryl. “Y2” and “Y3” are respectively selected from nitro-containing heterocyclic ring. “X”, “R1”, “R2” and “R3” are respectively selected from any substituent group or hydrogen. “A” is selected from aryl, heteroaryl or nitro-containing heterocyclic group.

Owner:TESCOM CORP

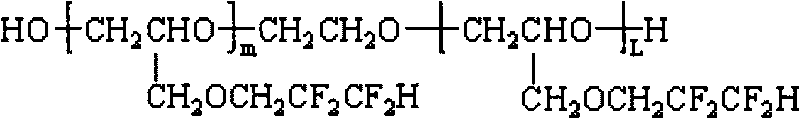

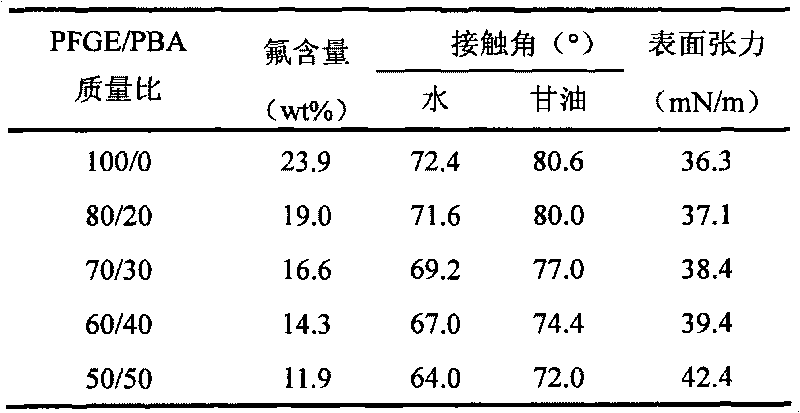

Method for preparing high-toughness thermoplastic fluorine-containing polyurethane elastomer

ActiveCN101717485AKeep the elastomer perfectly linearLower surface energyPolyurethane elastomerThermoplastic

The invention discloses a method for preparing a high-toughness thermoplastic fluorine-containing polyurethane elastomer, which is characterized in that a bulk polymerization two-step method is adopted to synthesize the fluorine-containing polyurethane elastomer, the isocyanate index is 0.98, and the hard segment content is between 20 and 40 weight percent. The method comprises the following steps of: weighing 6 to 40 parts of non-fluorine macromolecular polylol and / or 30 to 80 parts of fluorine-containing polyether diol in a reactor, performing vacuum dehydration on the mixture for 2h at thetemperature of 120 DEG C, cooling the mixture to be between 70 and 100 DEG C, adding 16 to 33 parts of polyisocyanate into the mixture, stirring the mixture to react for 3h, heating the mixture to bebetween 120 and 140 DEG C, adding 0.1 to 15 parts of low molecular (fluorine-containing) diol chain extender into the mixture, uniformly stirring the mixture, then dumping the mixture into a preheated container, and performing vacuum baking for 20 hours at the temperature of between 120 and 140 DEG C to obtain the high-toughness thermoplastic fluorine-containing polyurethane elastomer.

Owner:SICHUAN UNIV

Lithium secondary battery

InactiveUS20020018926A1Avoid emissionsLarge capacityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsOrganic solventDecomposition

A lithium secondary battery exhibiting very high safety, which is ensured by restraining both the generation of flammable gas caused by the decomposition of an electrolyte, and the emission of oxygen from a positive active material even during overcharging. The lithium secondary battery includes a positive electrode of which an active material is a lithium transition metal composite oxide, a negative electrode of which an active material is a carbon material, and a nonaqueous electrolyte containing an organic solvent in which a lithium salt is dissolved. The nonaqueous electrolyte contains at least one kind of conductive polymer-forming monomers which have an alkyl group and is electrochemically polymerizable on the positive electrode within a battery operation voltage, and at least one kind of film-forming agents which electrochemically decompose within the battery operation voltage to form films on a surface of the negative electrode.

Owner:TOYOTA CENT RES & DEV LAB INC

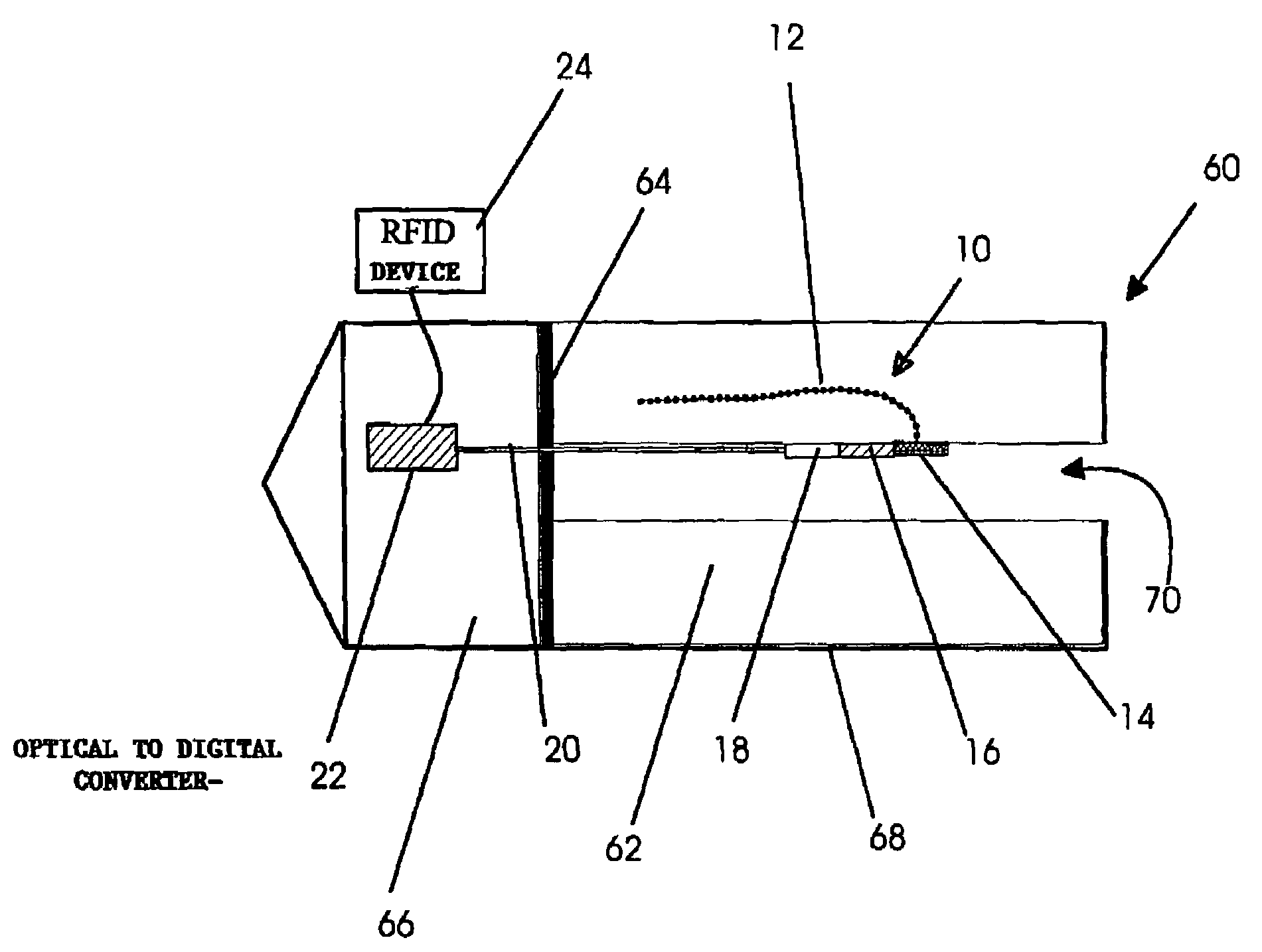

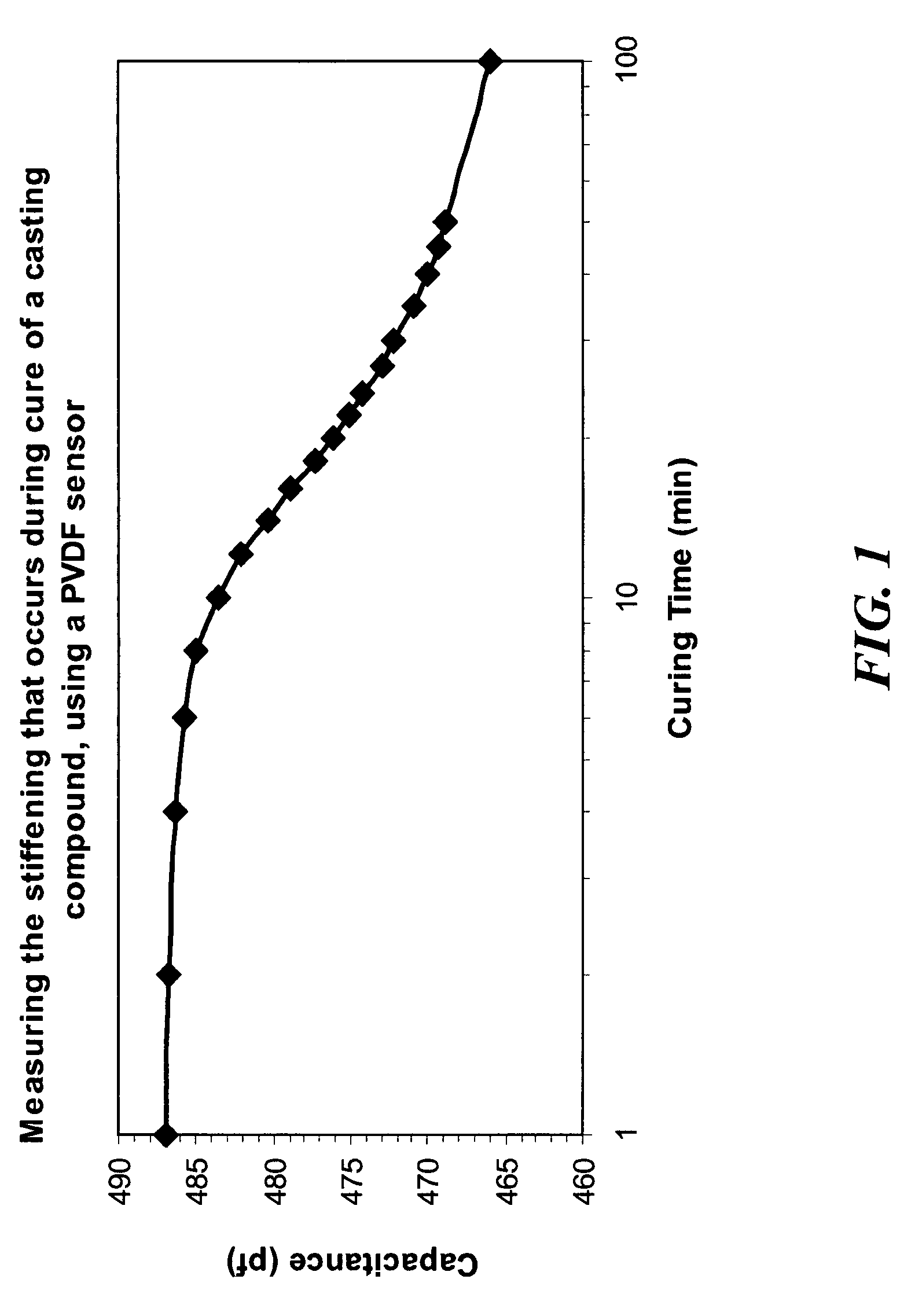

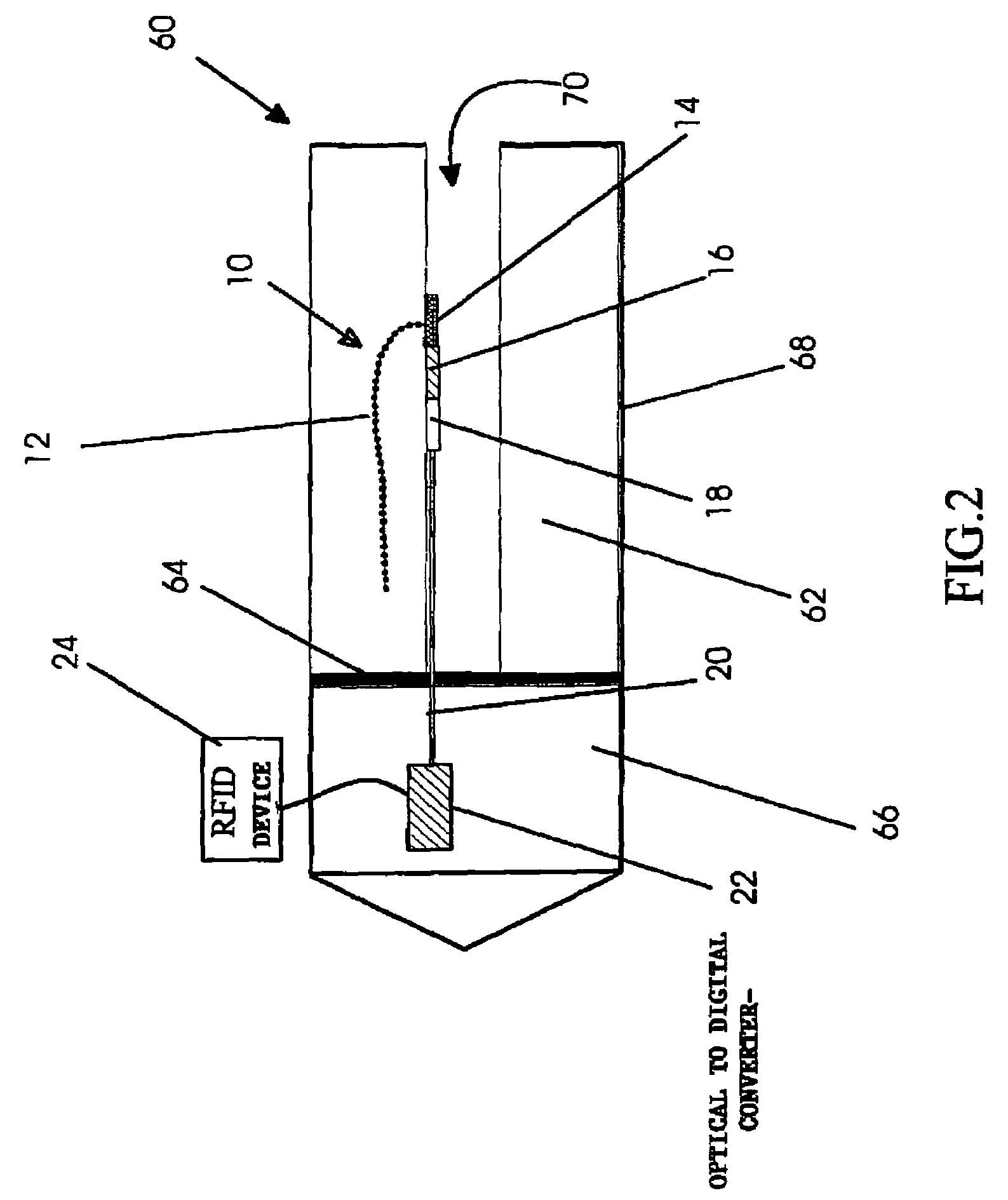

Method for measuring the health of solid rocket propellant using an embedded sensor

InactiveUS7652488B1Reduce capacitancePoor impedance matchingResistance/reactance/impedenceForce measurementElectricityShear modulus

The invented method for measuring the health of a solid rocket propellant includes embedding at least one piezoelectric capacitance sensor in the propellant, where the capacitance of the sensor is a function of a modulus of the propellant, and where the position is selected to measure manifestations of stress failure as a consequence of changes in the shear modulus. The capacitance of the sensor is measured at a predetermined frequency. The capacitance of the piezoelectric capacitance sensor is converted into a digital representation which is then converted into the digital representation of a modulus (or gradient modulus). In subsequent analysis, the modulus (or gradient of the modulus) is correlated to the health of the solid rocket propellant.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

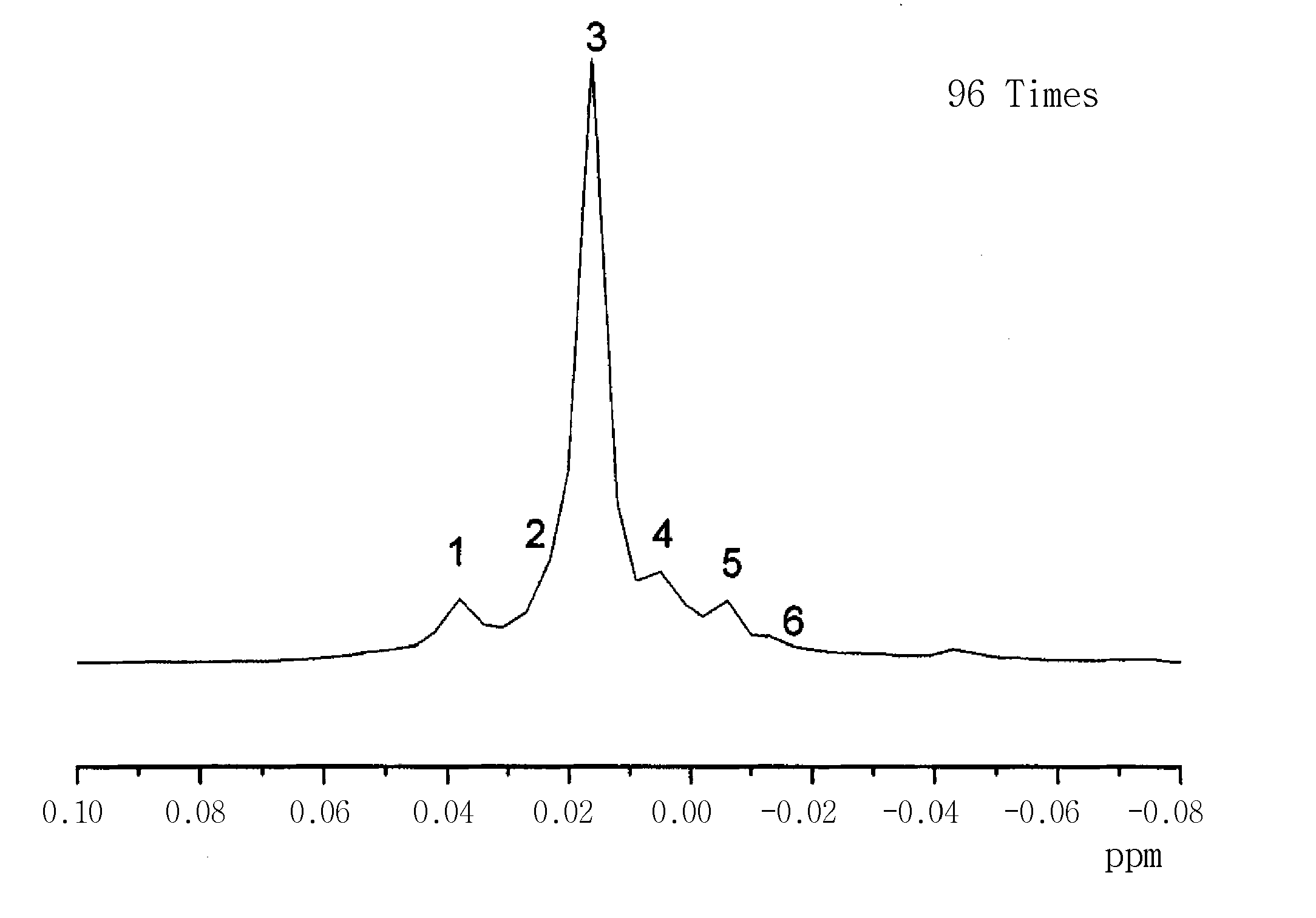

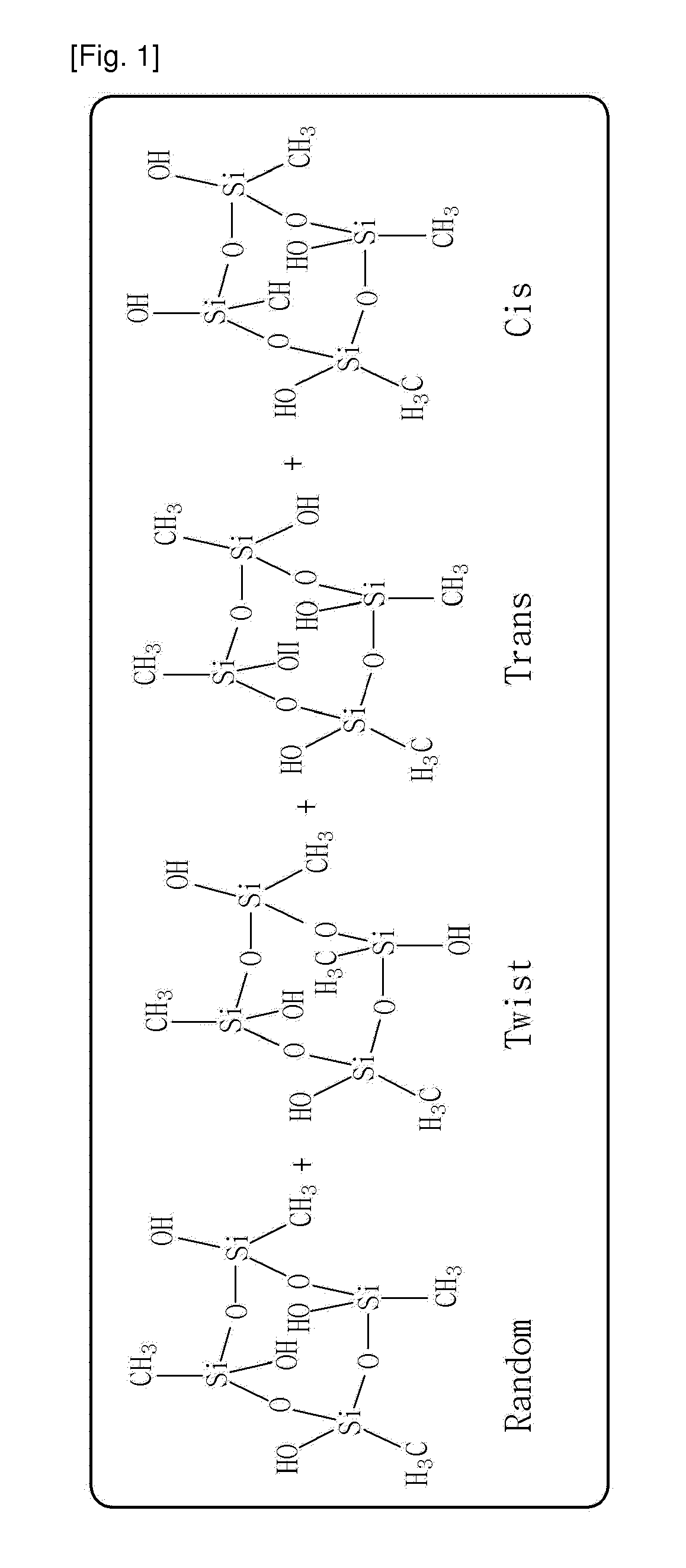

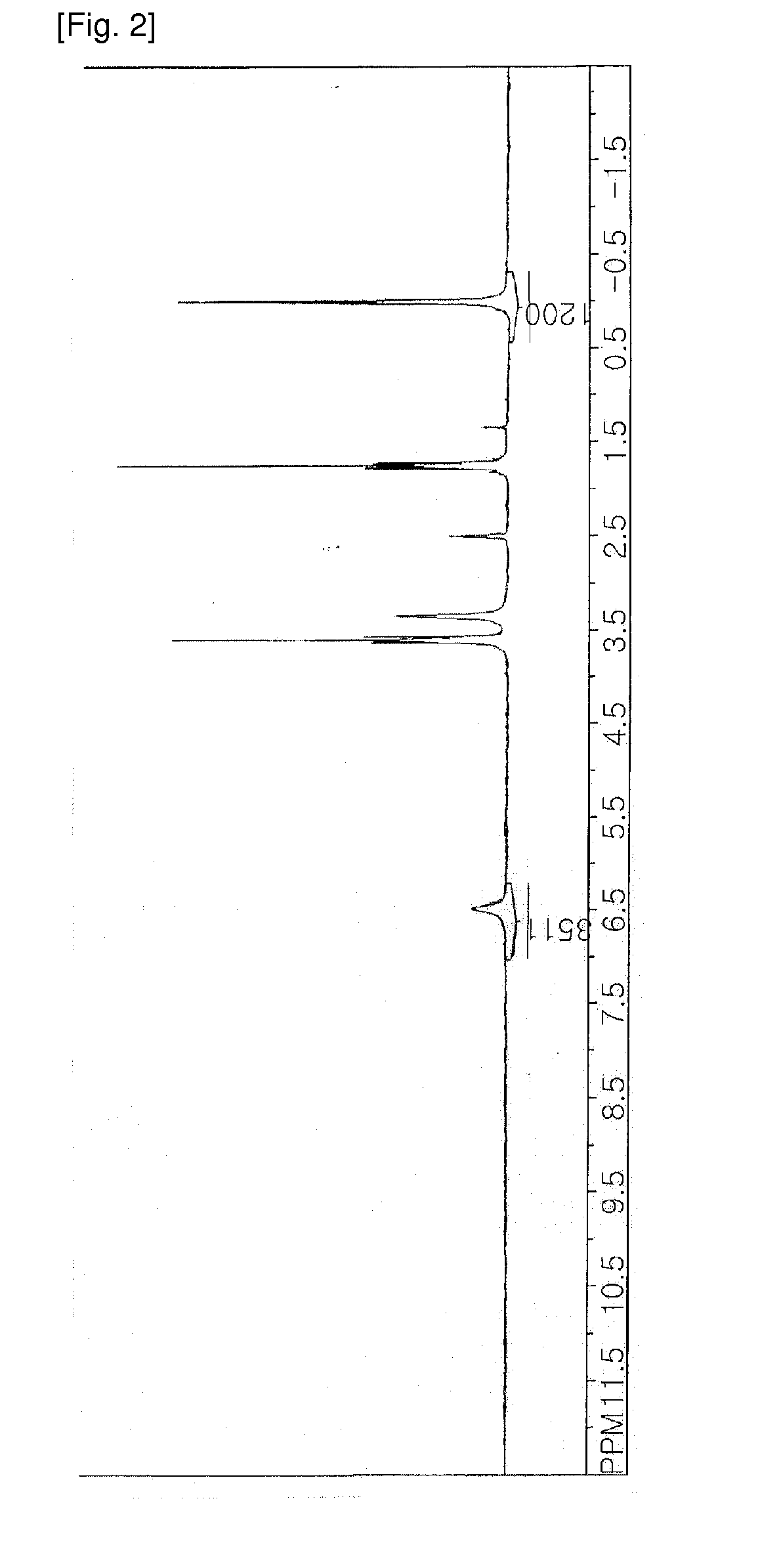

Composition comprising a monomer for polymerizing branch-type silsesquioxane polymer, branch-type silsesquioxane polymer synthesized from the same and a method for synthesizing the same

InactiveUS20130165617A1Improve responseReduced thermal stabilitySilicon organic compoundsMonomer compositionPolymer science

A monomer composition for polymerizing a branch-type silsesquioxane polymer is disclosed. The monomer composition includes hydroxy-substituted cyclic siloxane in a solvent, and the hydroxy-substituted cyclic siloxane includes stereoisomers of cyclic siloxane of cis, trans, random and twist structures at controlled ratios. Also disclosed are a branch-type silsesquioxane polymer synthesized by polymerizing the monomer composition for polymerizing a branch-type silsesquioxane polymer, and a method for synthesizing the same. In accordance with the disclosure, the isomers can be isolated stably at desired ratios. The isolated isomers may be polymerized into polymers of various types. Since the polymers exhibit low dielectric property, they may be utilized as low dielectric materials.

Owner:KOREA INST OF SCI & TECH

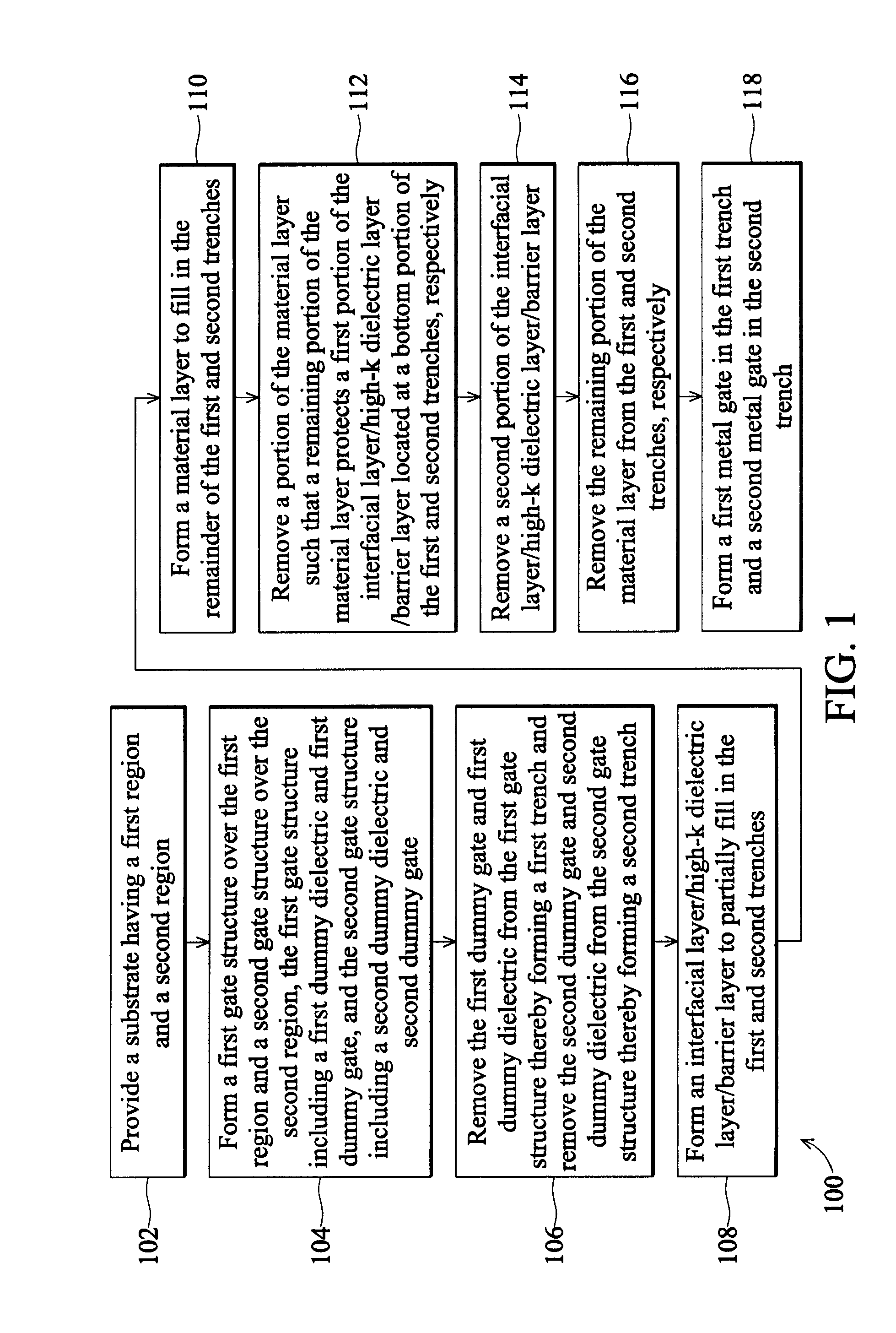

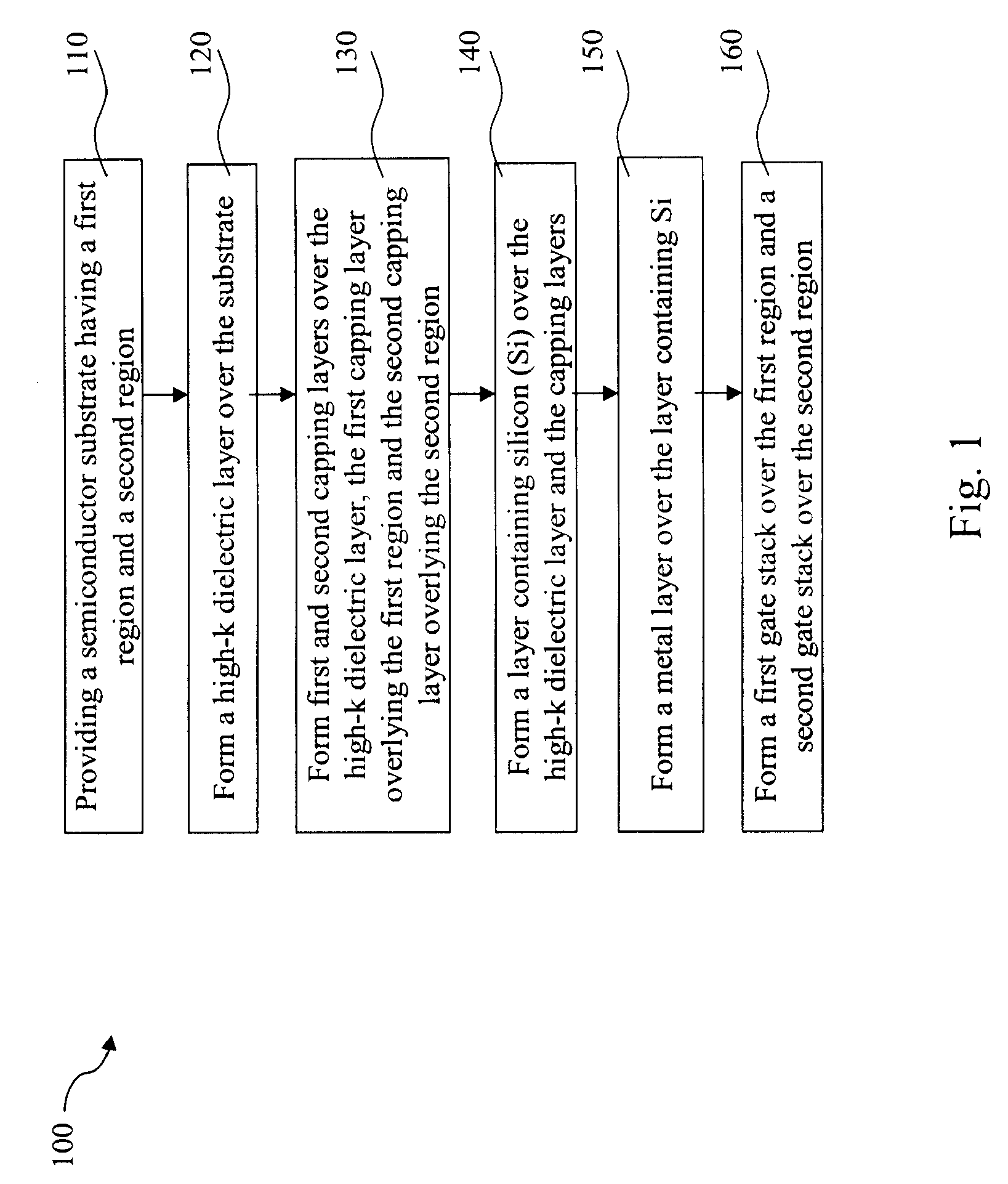

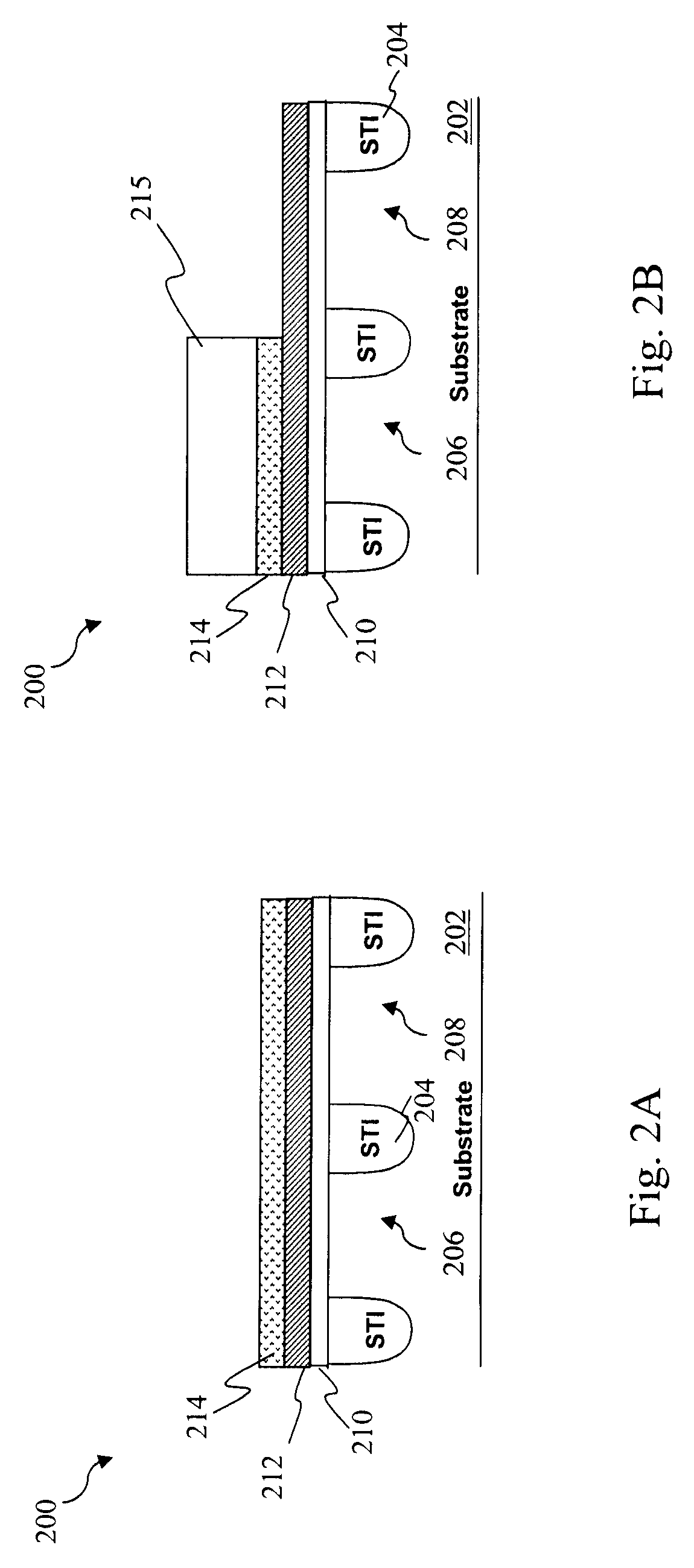

Method to improve dielectric quality in high-k metal gate technology

ActiveUS20100052063A1Reduced thermal stabilityIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialGate stack

The present disclosure provides a method of fabricating a semiconductor device. The method includes providing a semiconductor substrate having a first active region and a second active region, providing a semiconductor substrate having a first region and a second region, forming a high-k dielectric layer over the semiconductor substrate, forming a first capping layer and a second capping layer over the high-k dielectric layer, the first capping layer overlying the first region and the second capping layer overlying the second region, forming a layer containing silicon (Si) over the first and second capping layers, forming a metal layer over the layer containing Si, and forming a first gate stack over the first region and a second gate stack over the second active region. The first gate stack includes the high-k dielectric layer, the first capping layer, the layer containing Si, and the metal layer and the second gate stack includes the high-k dielectric layer, the second capping layer, the layer containing Si, and the metal layer.

Owner:TAIWAN SEMICON MFG CO LTD

A kind of biodegradable composition and preparation method thereof

InactiveCN102295825AImproved hydrolysis resistance and thermal oxygen resistanceFast biodegradationConjugated synthetic polymer artificial filamentsArtifical filament manufactureCopolyesterPolymer chemistry

The invention discloses a biodegradable composition and a preparation method thereof, which consist of a biodegradable homopolyester (A), a biodegradable copolyester (B) and a chain extender (C), the total weight of which is 100 parts by mass Calculated, containing (A+B) is 95.0~99.9 parts and containing C is 0.1~5.0 parts, wherein the ratio of A:B is in the range of 1:9~9:1. The present invention finds that the compounding of biodegradable homopolyester with faster biodegradation rate and biodegradable copolyester with better processability in different proportions can not only endow the composition with proper biodegradation rate, but also improve the composition The physical properties and processing performance can be properly adjusted according to the requirements of different processing and application fields; we also found that by introducing a chain extender with long chain characteristics into the biodegradable resin composition, the combination after chain extension can be avoided It can prevent unnecessary gel phenomenon during processing and improve the heat resistance and stability of the material.

Owner:KINGFA SCI & TECH CO LTD +2

Preparation method and application of multifunctional polyamine amide for oil field

The invention relates to a preparation method of multifunctional polyamine amide for an oil field. The preparation method comprises the steps of: firstly dissolving long-chain fatty acyl polyamine prepared from long-chain fatty acid and polyethylene polyamine in an organic solvent in a container, adding a cross-linking agent to the container under stirring, stirring and heating reactants in the container, and cooling to room temperature to finally obtain a light yellow solution, namely a polyamine amide solution in the container; or evaporating the organic solvent from the light yellow solution obtained in the container to obtain light yellow waxy solid, namely polyamine amide. In application, polyamine amide is dissolved in an organic solvent to prepare a solution, the solution is added to crude oil to obtain a mixture, when the solidifying point of the crude oil is reduced by 5-25 DEG C and the viscosity of the crude oil is reduced by 30-80%, the mixture is prepared into an aqueous solution with mass concentration of 100-10000 ppm, and the corrosion inhibition of the aqueous solution is measured to obtain that the corrosion inhibition rate of the aqueous solution to the steel sheets in different concentrations of hydrochloric acid is 40-90%.

Owner:西安利奇材料科技有限公司

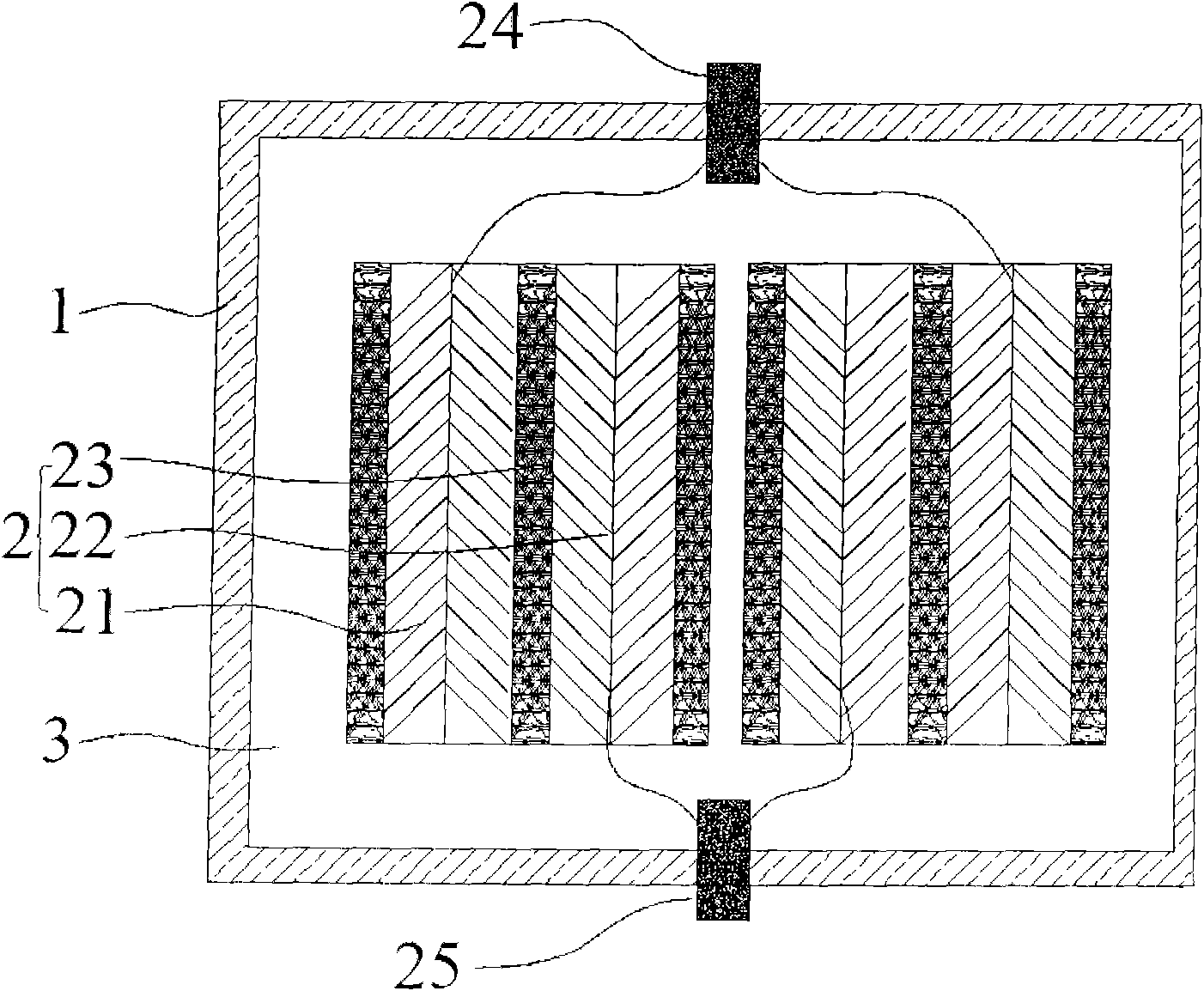

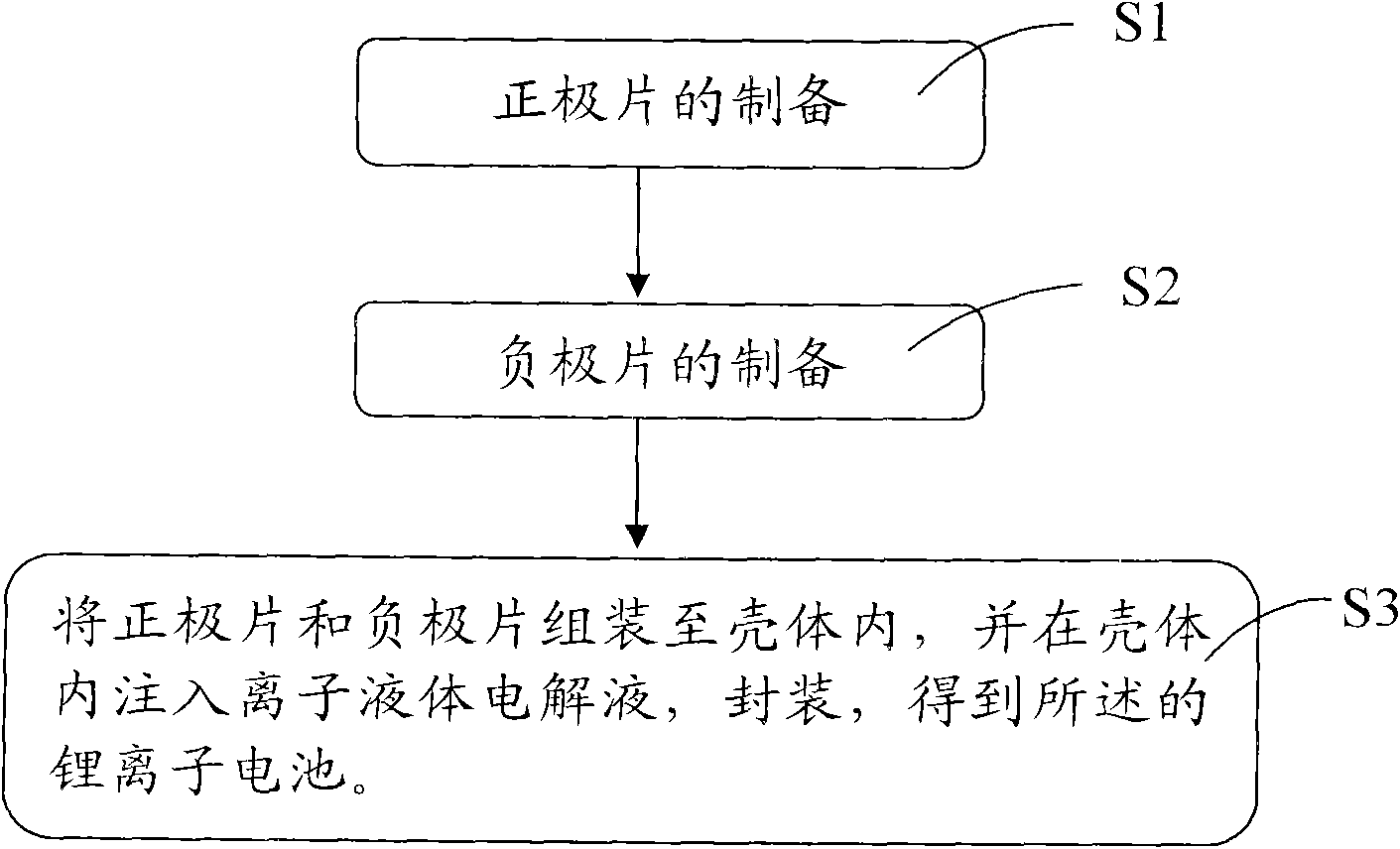

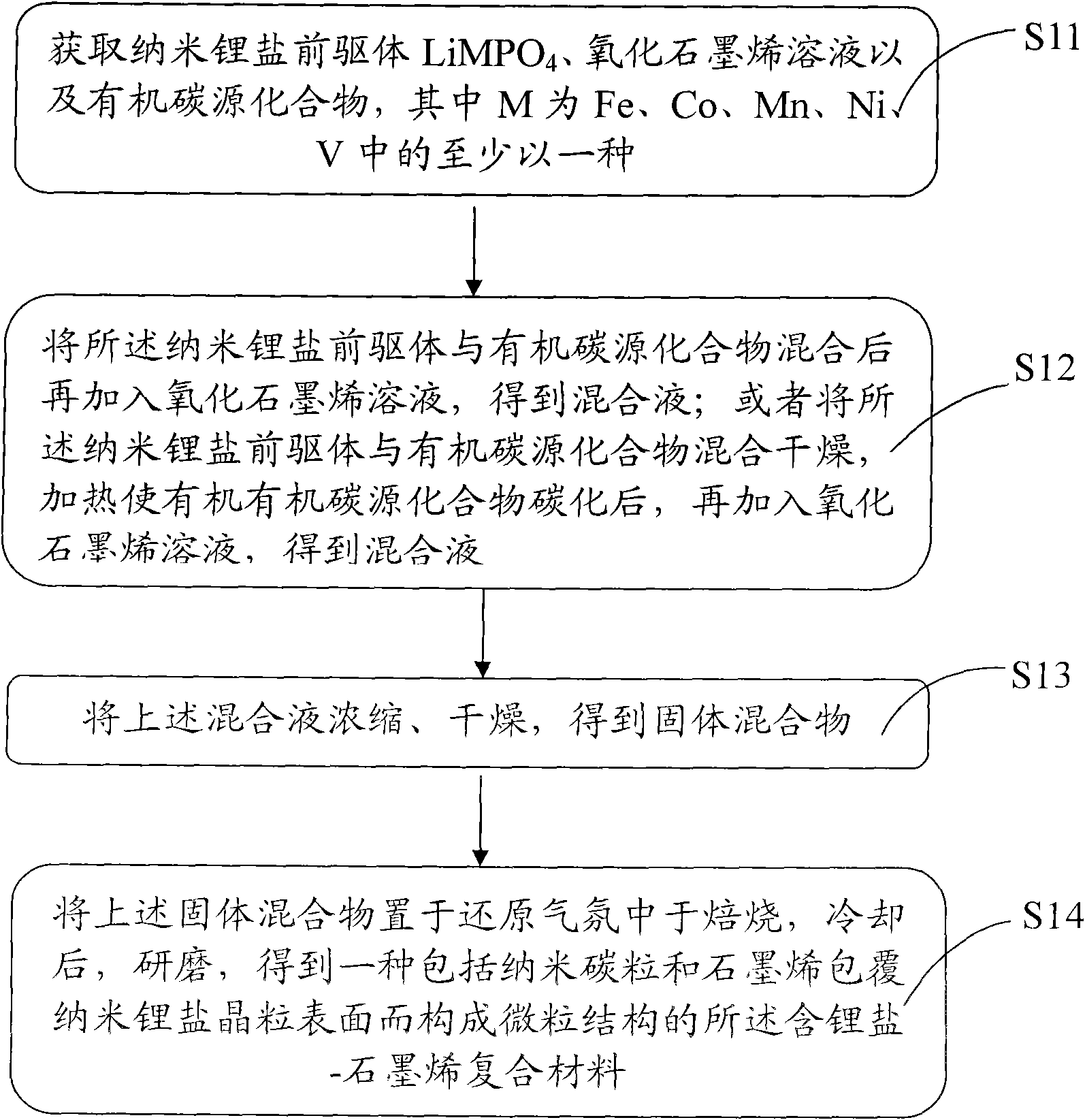

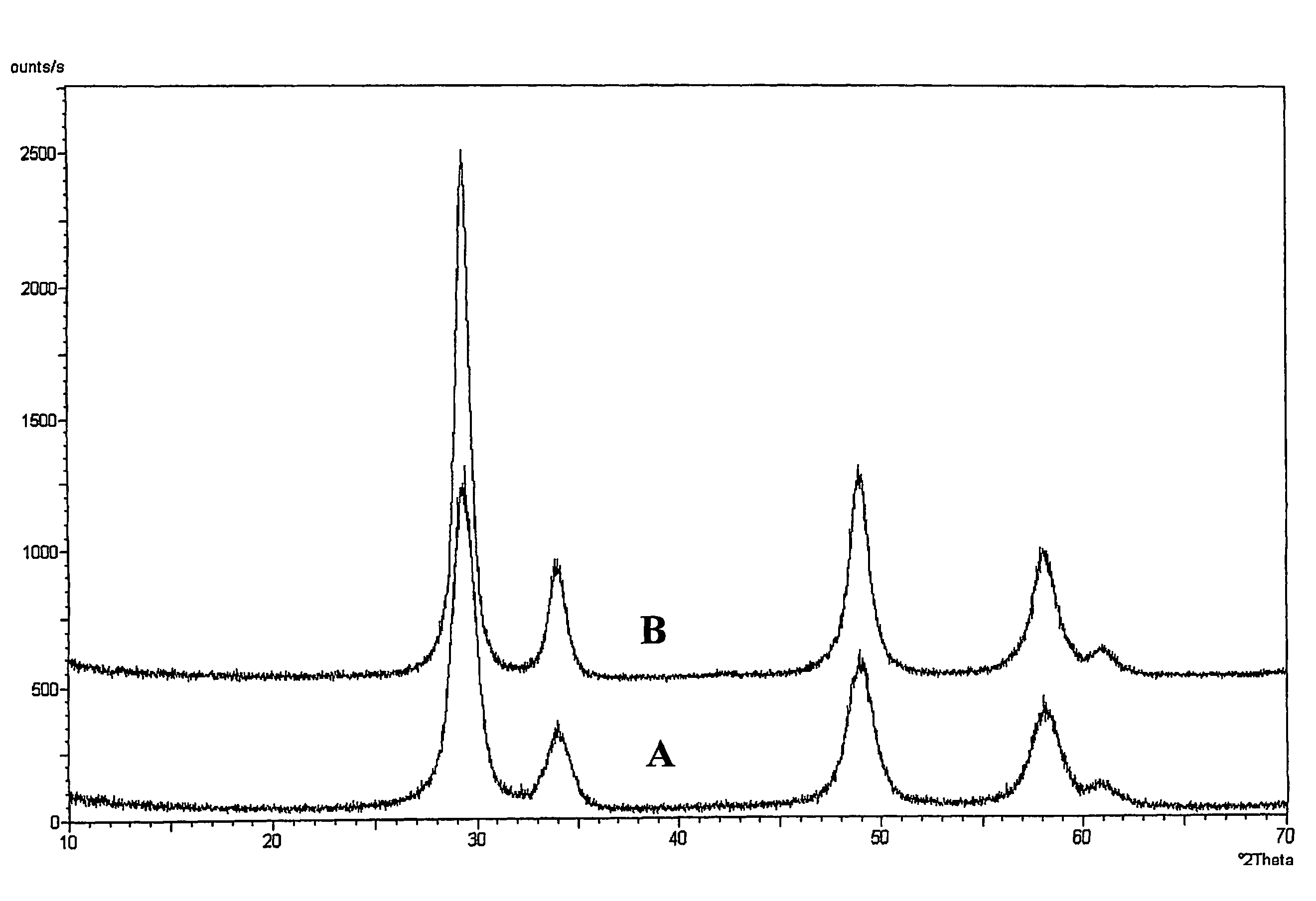

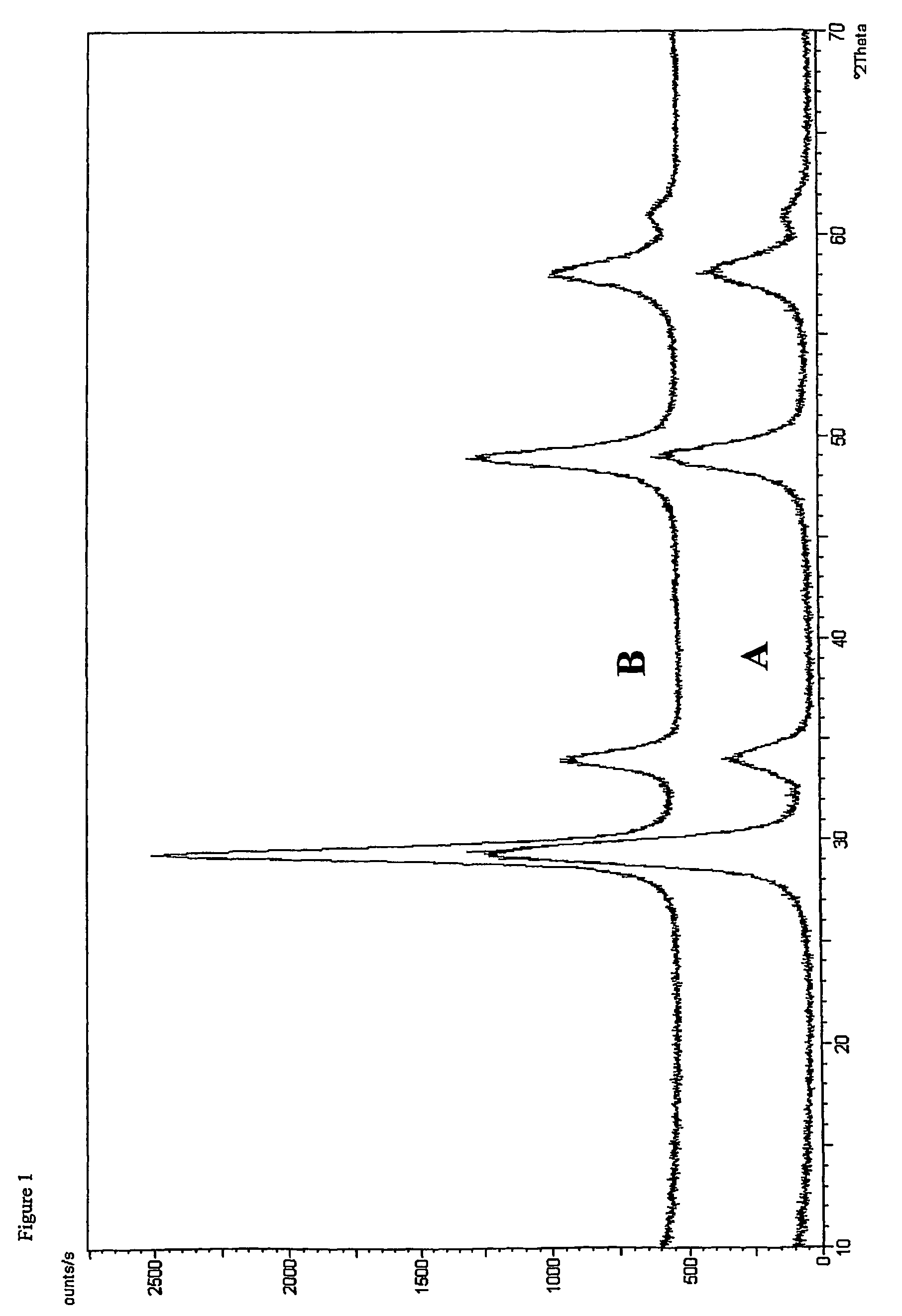

Lithium ion battery and preparation method thereof

ActiveCN102468515APromote circulationImprove performanceFinal product manufactureNon-aqueous electrolyte accumulator electrodesHigh energyPhysical chemistry

The invention discloses a lithium ion battery and a preparation method thereof. The lithium ion battery comprises a shell, ionic liquid electrolyte, positive plates, negative plates and diaphragms, wherein the ionic liquid electrolyte, the positive plates, the negative plates and the diaphragms are coated in the shell; the diaphragms are used for dividing the positive plates from the negative plates; each positive plate comprises a positive substrate and a positive coating which is combined on the surface of the positive substrate; the positive coating comprises a LiMPO4-graphene composite, wherein M is at least one of Fe, Co, Mn, Ni and V; each negative plate comprises a negative substrate and a negative coating which is combined on the surface of the negative substrate; and the negative coating comprises a Li4Ti5O12-graphene composite. The invention also discloses a preparation method for the Li4Ti5O12-graphene composite. The lithium ion battery has high energy density, high power density, better circulation performance and stable performance. The preparation method for the Li4Ti5O12-graphene composite is a simple in process and has high production efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of nano-conducting attapulgite material

InactiveCN101000809AReduce manufacturing costEasy to prepareNanostructure manufactureConductive materialNanometreCoprecipitation

A method for preparing conductive concave-clay nanomaterial includes scattering concave-clay aggregate to be concave-clay bar nanocrystal, using concave-clay bar nanocrystal as core to clad a layer of conductive compound precursor on surface of said nanocrystal by utilizing chemical coprecipitation technique and using high temperature doping to form new one-dimensional conductive concave-clay nanomaterial.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Process for preparing zirconium-cerium-based mixed oxides

ActiveUS7431910B2Reduced thermal stabilityEasy to controlCatalyst carriersOxygen/ozone/oxide/hydroxideMixed oxideSulphate Ion

Owner:MAGNESIUM ELETRON LTD

Rubber material formula of car tires and production method thereof

The invention relates to a formula of tire rubber, in particular to a rubber material formula of car tires. The rubber material formula of car tires, provided by the invention, is composed of following components in parts by weight: 110-140 parts of crude rubber material, 60-110 parts of reinforcing agent, 10-15 parts of environment-friendly aromatic hydrocarbon oil, 2-3 parts of activating agent, 2-4 parts of anti-aging agent, 1-2 parts of microcrystal wax, 2-5 parts of accelerator and 2-2.5 parts of vulcanizing agent. The tires prepared by the rubber material formula disclosed by the invention have greatly improved safety and reduced oil consumption; and the design meets the requirements for environment protection, safety and energy saving of the car tires.

Owner:克劳斯玛菲股份有限公司

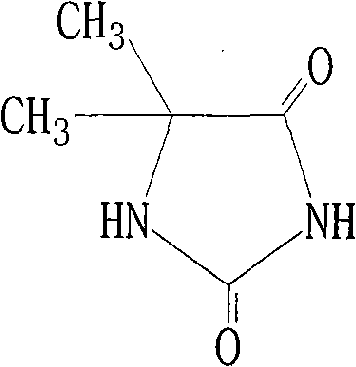

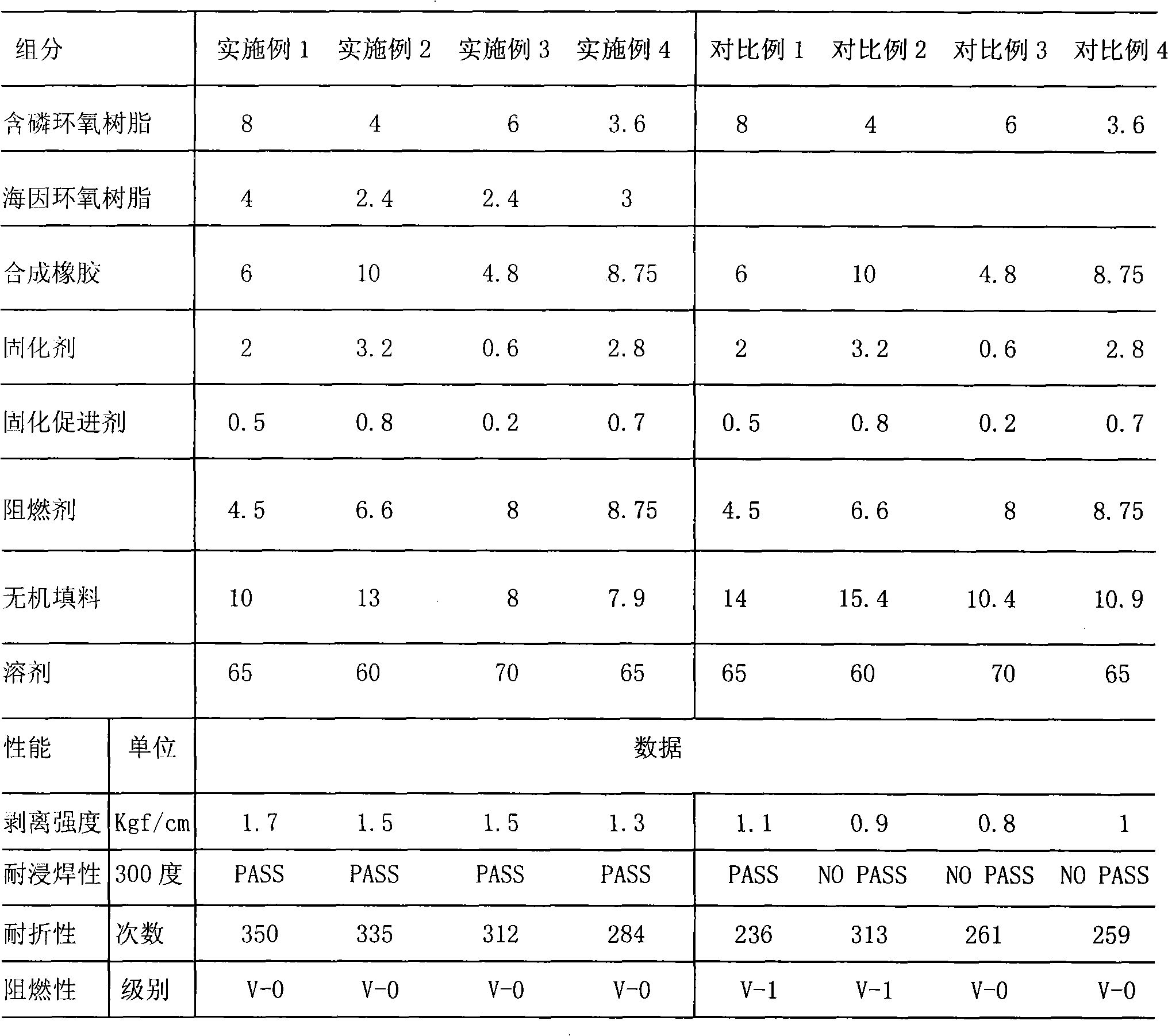

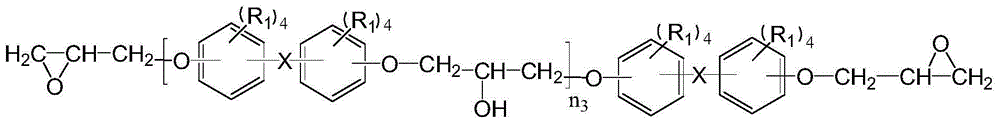

Halogen-free flame retardant epoxy resin composite and flexible copper clad laminate prepared with same

ActiveCN101633770ALow viscosityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentWeather resistanceChemistry

The invention discloses a halogen-free flame retardant epoxy resin composite and a flexible copper clad laminate prepared from same. The invention is characterized that hydantoin epoxy resin is added in the existing composite and the hydantoin epoxy resin has the advantage that the viscosity is low, the manufacturability is good; the thermal stability is good, the thermostability is high; the weather resistance is good, the hydantoin epoxy resin can be shined by sunlight and ultraviolet light without yellowing and chalking; the hydantoin epoxy resin can be is resistant to salt fog, the corrosion resistance is outstanding, the product has low toxicity and good flame retardant and the like. Therefore the hydantoin epoxy resin is very applicable to being used to prepare the halogen-free flame retardant epoxy resin composite. In addition, the invention also provides a polyimide copper clad laminate prepared by adopting the composite as adhesive, and the prepared copper clad laminate has the advantage of good flame retardant performance, high peel strength, good folding endurance and the like and can increase the electrical property of the copper clad laminate.

Owner:PANYU NANSHA YAN TIN CHEM

Polymer and method for producing the same

ActiveCN102190779AEfficient manufacturingReduced thermal stabilityMetal freeRing-opening polymerization

Owner:RICOH KK

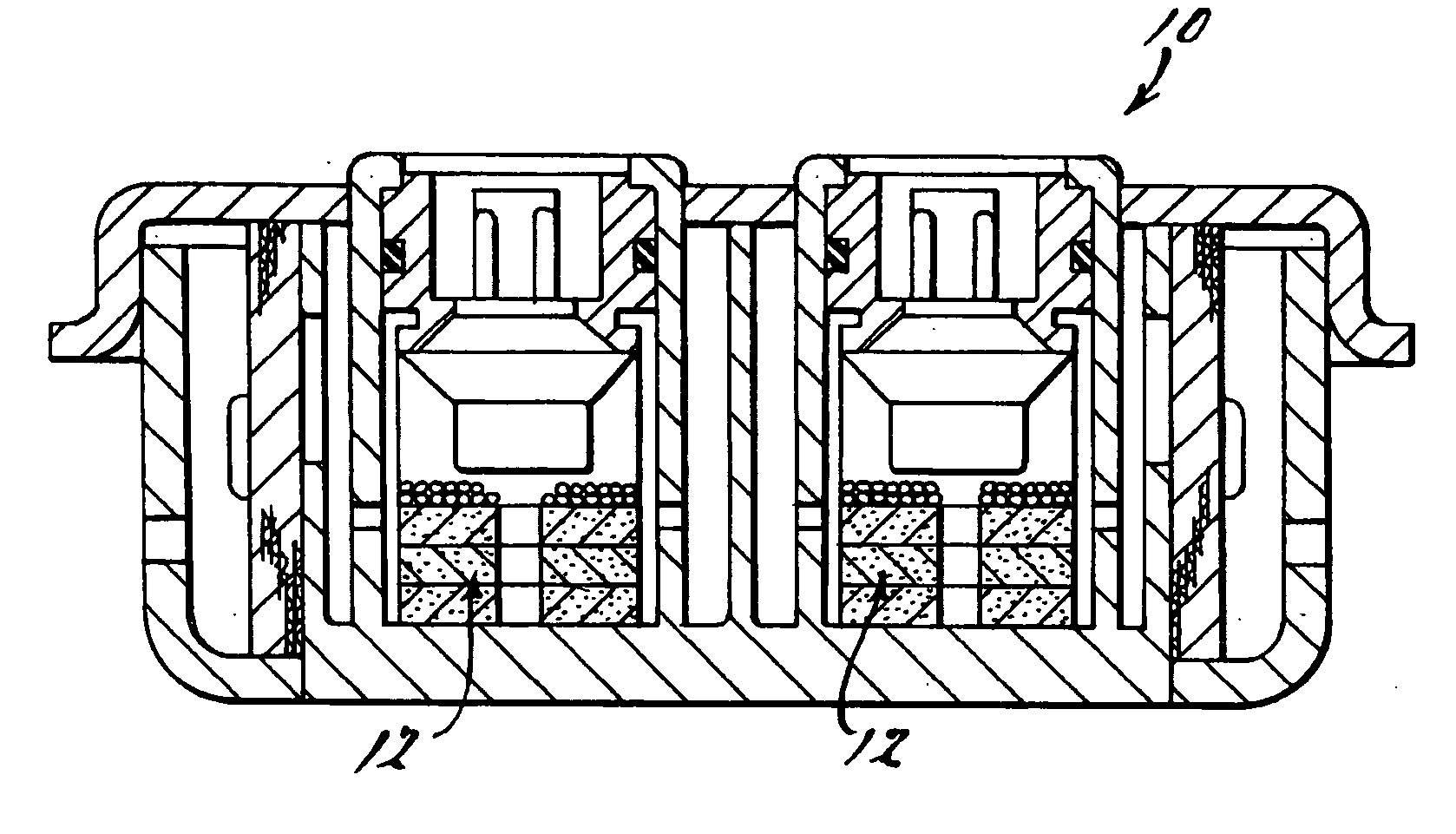

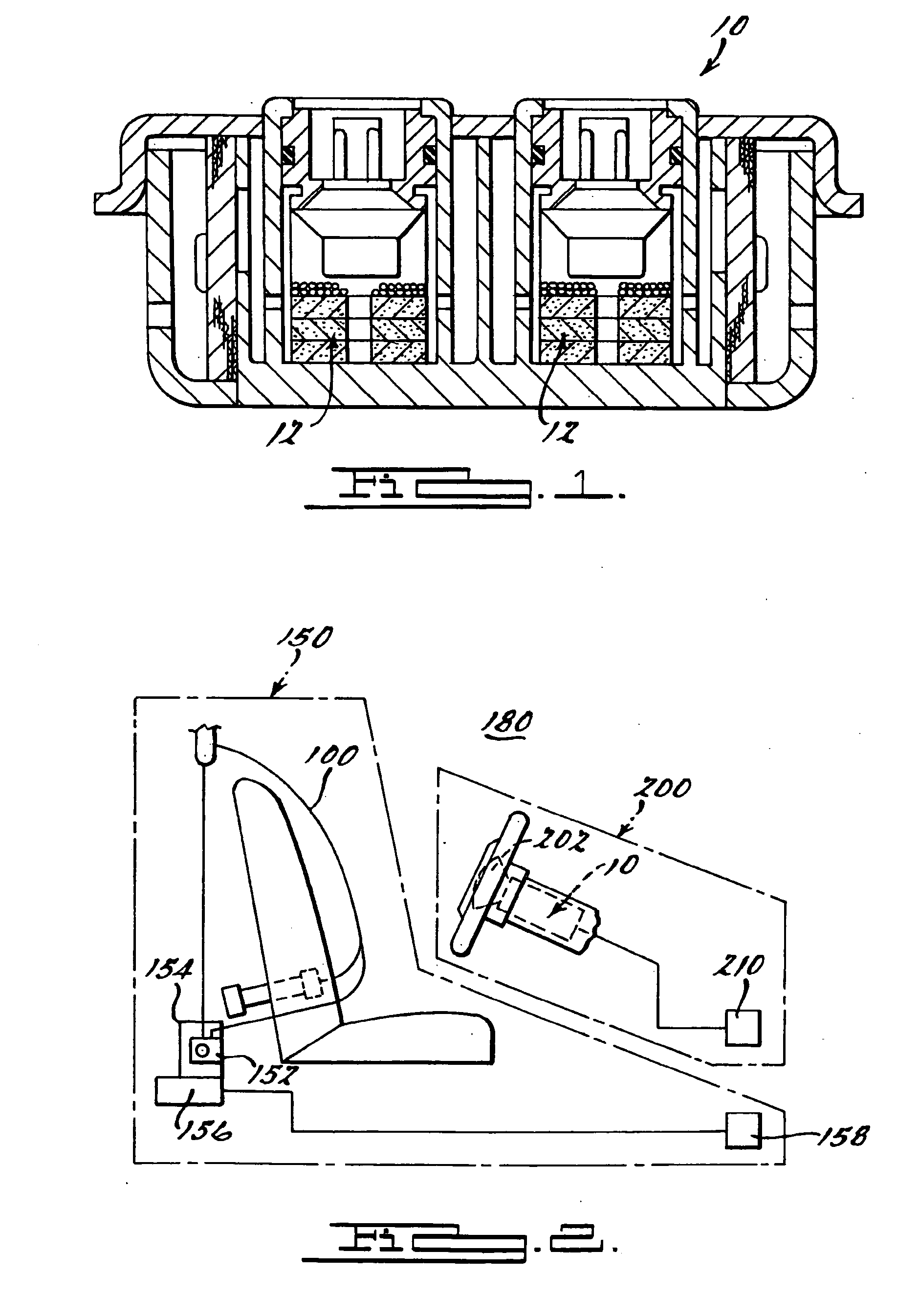

Gas generating system

InactiveUS20050263223A1Promote productionMinimize solid combustion productExplosivesPressure gas generationProtection systemChemistry

The present invention generally relates to gas generant compositions for inflators of occupant restraint systems, for example. A gas generating composition 12 formed in accordance with the present invention includes a carboxyl alkyl cellulosic binder. A vehicle occupant protection system 180, and other gas generating systems, incorporate the compositions of the present invention.

Owner:AUTOMOTIVE SYST LAB

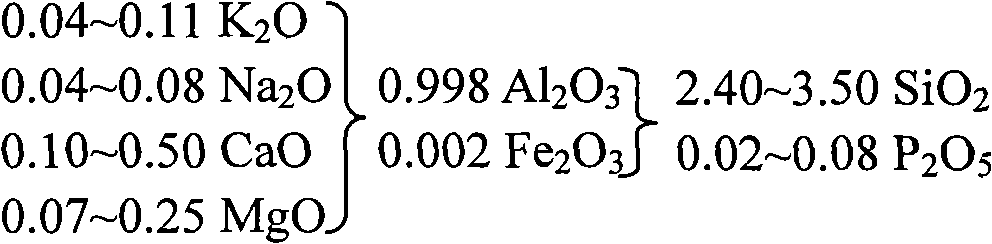

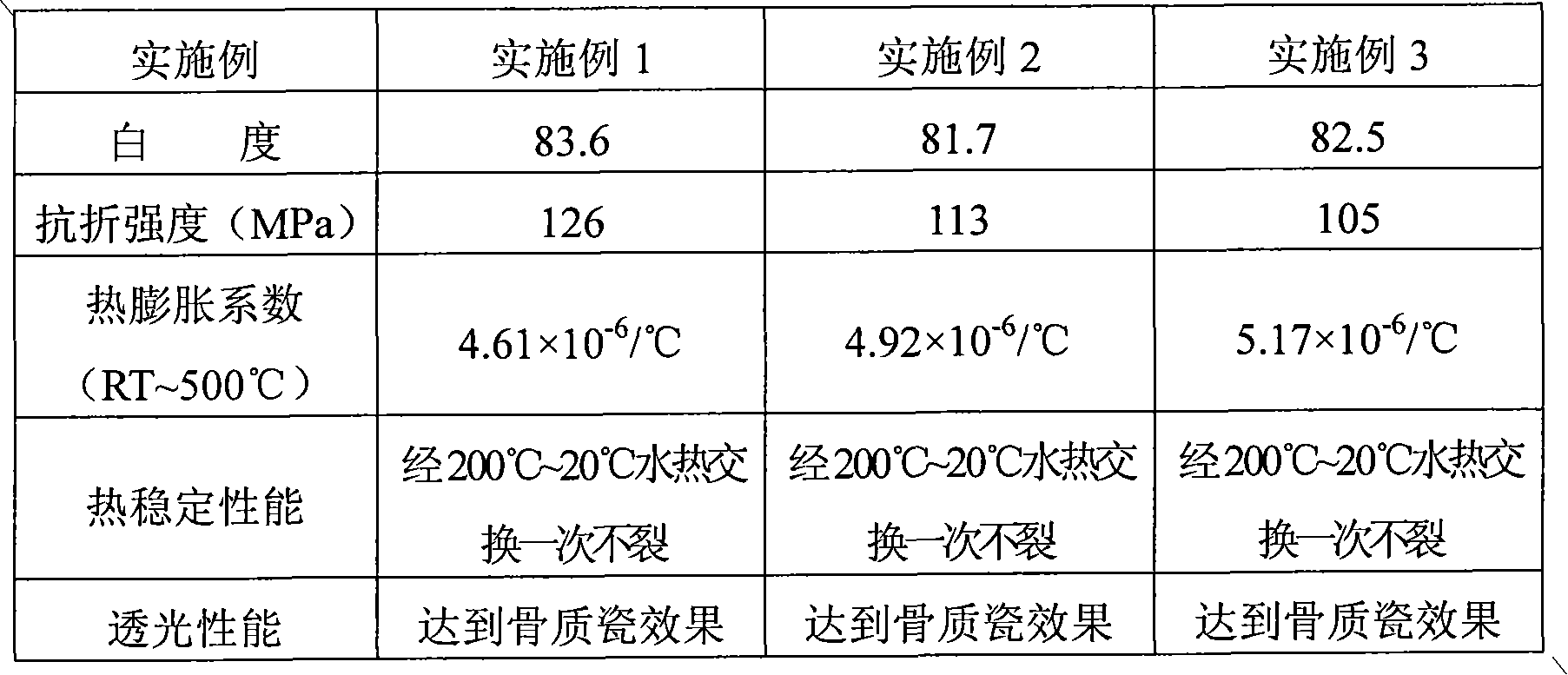

Middle-low temperature sintered fine bone china and production method thereof

ActiveCN101891455AReduced thermal stabilityImprove thermal stabilityCeramic materials productionClaywaresCoalBone china

The invention relates to a middle-low temperature sintered fine bone china and a production method thereof. The china comprises the following chemical components in percentage by weight: 52 to 60 percent of SiO2, 28 to 37 percent of Al2O3, 1 to 4 percent of K2O, 1 to 2 percent of Na2O, 3 to 8 percent of CaO, 1 to 3 percent of MgO and 1 to 3 percent of P2O5; a used formula comprises the following raw materials in percentage by weight: 3 to 8 percent of bone ash, 32 to 45 percent of kaolin, 10 to 20 percent of aluminum oxide and 35 to 50 percent of fusion cake; the sintering temperature is between 1,170 and 1,250 DEG C; and not only a double-firing process of 'high-temperature biscuit firing and low-temperature glazed firing' or 'low-temperature biscuit firing and high-temperature glazed firing' can be adopted, but also a high-temperature single firing process can be applied. The fine bone china has an appearance effect of the conventional bone china, has physical and chemical properties superior to those of the bone china, has the significant advantages of low bone coal consumption and low sintering temperature, and is favorable for reducing the production cost and the energy consumption.

Owner:JINGDEZHEN CERAMIC UNIV

Thermosetting resin composition and application thereof

InactiveCN104892902ALow dielectric constantLow water absorptionSynthetic resin layered productsPrinted circuit aspectsEpoxyDielectric loss

The present invention discloses a thermosetting resin composition, which comprises epoxy resin with 2 or more than 2 epoxy groups in each resin molecule; and active ester containing styrene structure. The thermosetting resin composition is used to prepare resin sheet, resin composite metal copper foil, prepreg, laminate, copper clad laminate, printed circuit board and the like. The thermosetting resin composition significantly reduces the probability of delamination in PCB substrate, and the obtained resin composition has excellent thermal stability and moisture-heat resistance, low dielectric constant and dielectric loss angle tangent, and excellent flame retardancy.

Owner:GUANGDONG SHENGYI SCI TECH

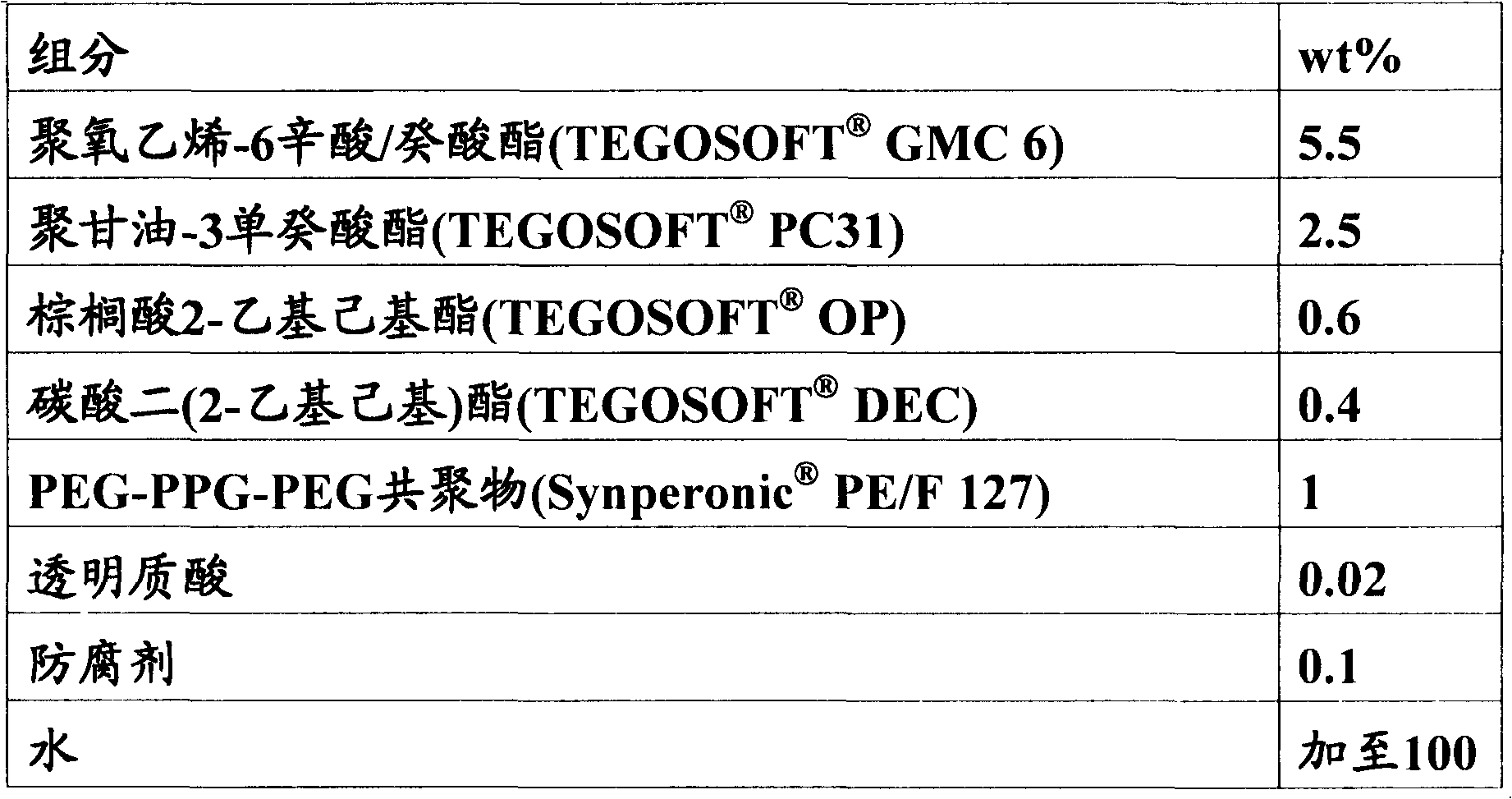

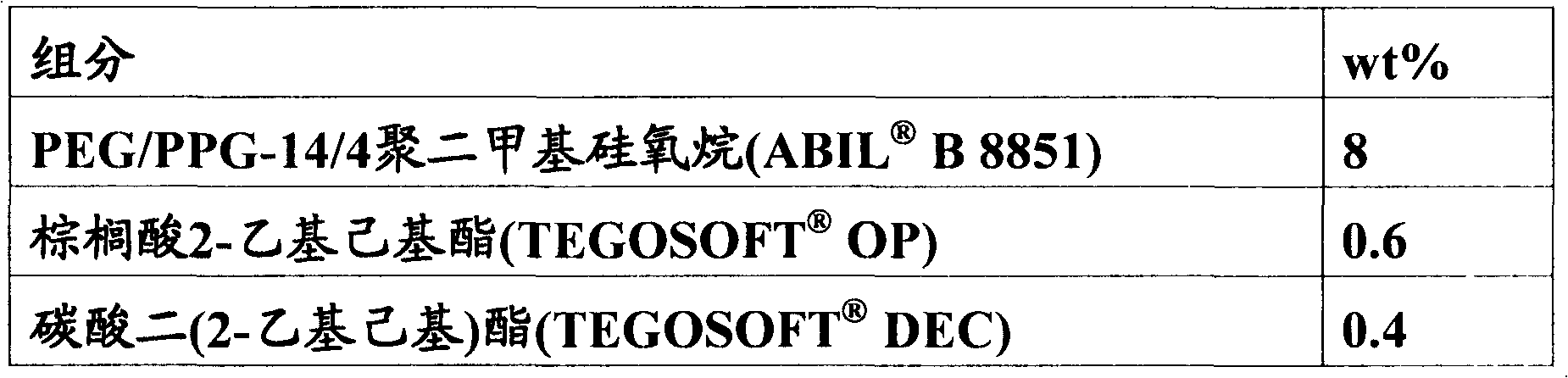

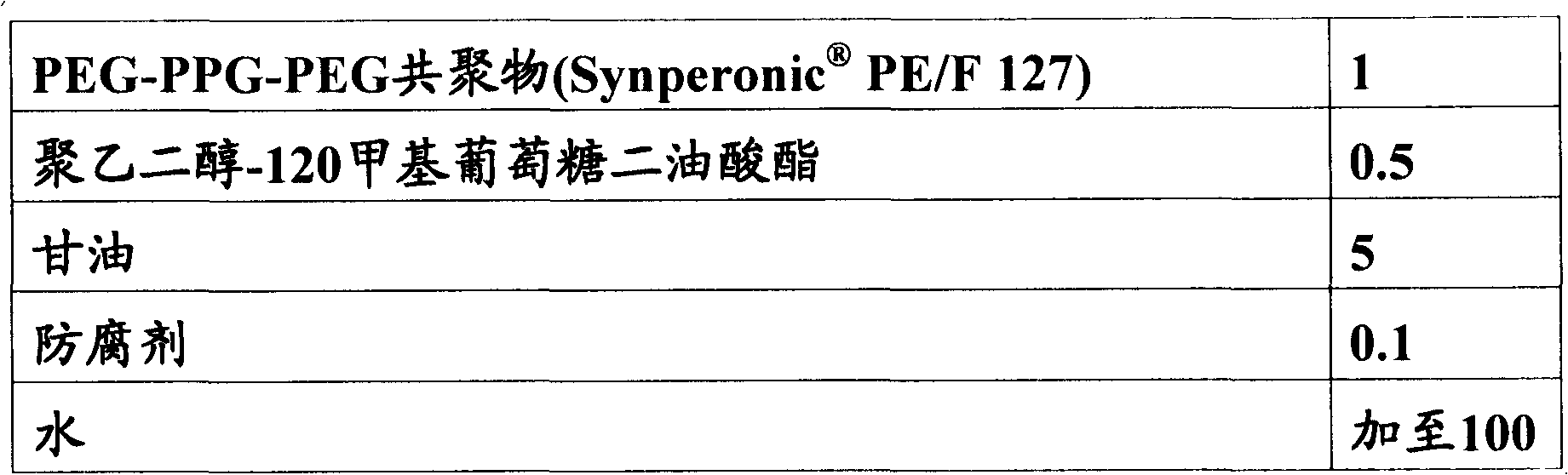

Thermally stable oil-in-water microemulsion

InactiveCN101987069AImprove thermal stabilityReduced thermal stabilityCosmetic preparationsMake-upTurbidityOil phase

The invention relates to oil-in-water microemulsion. The oil-in-water microemulsion comprises the following components based on the total weight: A) 75 to 94 weight percent of aqueous phase, B) 0.5 to 5 weight percent of oil phase, C) 2 to 20 weight percent of oil-in-water nonionic emulsifier serving as a surfactant, and D) 0.2 to 2 weight percent of auxiliary nonionic surfactant or auxiliary zwitterionic surfactant with the hydrophile-lipophile balance (HLB) value more than or equal to 17, wherein the weight ratio of the component C to the component D is 5 to 20. The oil-in-water microemulsion of the invention has thermal stability, can maintain the transparent property of the oil-in-water microemulsion at room temperature in the condition of high temperature, and has no phenomenon of turbidity, emulsion breaking or demixing; moreover, the microemulsion has a simple formula and is easy to prepare; in addition, the microemulsion can remove cosmetics rapidly, has a cleaning effect of being washed easily, also can be used as a resident product, and provides a moisture feeling different from a common water aqua product.

Owner:EVONIK DEGUSSA GMBH

Chopped glass fiber enhanced polyformaldehyde material

The invention discloses a chopped glass fiber enhanced polyformaldehyde material. The chopped glass fiber enhanced polyformaldehyde material is prepared from the following raw materials in part by weight: 50 to 80 parts of copolyoxymethylene resin, 10 to 30 parts of chopped glass fiber, 1 to 10 parts of aldehyde absorption agent, 0.1 to 5 parts of glass fiber leakage prevention agent, 0.1 to 5 parts of coupling agent, and 0.1 to 5 parts of antioxidant. The polyformaldehyde is used as a matrix resin, and the high-strength polyformaldehyde material is prepared by enhancement of the chopped glass fiber; the tensile strength of the polyformaldehyde material can reach 125 MPa, flexural strength can reach 180 MPa, notch impact strength can reach 7.5kj / m<2>, and the polyformaldehyde material is good in comprehensive performance, and the polyformaldehyde material can meet the application requirements of the polyformaldehyde in automobile industry, electronic and electrical industry, precision machinery industry and other industry.

Owner:KAIFENG LONGYU CHEM

Self-aligning metal oxide thin film transistor and manufacturing method thereof

InactiveCN103311128AImprove mobilityLow resistivityTransistorSemiconductor/solid-state device manufacturingDopantGate dielectric

The invention provides a self-aligning metal oxide thin film transistor and a manufacturing method thereof. The method includes depositing a metal oxide semiconductor layer, a gate dielectric layer and a conducting thin film on a substrate and photoetching for imaging, spin-coating a dopant layer on the surface of a device, performing heat treatment to enable doping atoms in the spin-coated dopant layer to be diffused into a lower-layer material. The graphical gate electrode and the graphic gate dielectric exist, so that the doping atoms can only be diffused into metal oxide semiconductor areas on two sides of a channel area, doping of the metal oxide semiconductor on two sides of a channel is realized, resistivity of the metal oxide semiconductor is greatly lowered, and a self-aligned source-drain area is formed. The spin-coated dopant layer can also serve as a passivating layer of the device and is combined with subsequent processes like photoetching of contact holes and leading-out of electrodes and a wiring layer to manufacture a complete TFT (thin film transistor) device. The metal oxide thin film transistor prepared by the method has a self-aligning structure and is simple in process and compatible with large-area substrate process.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

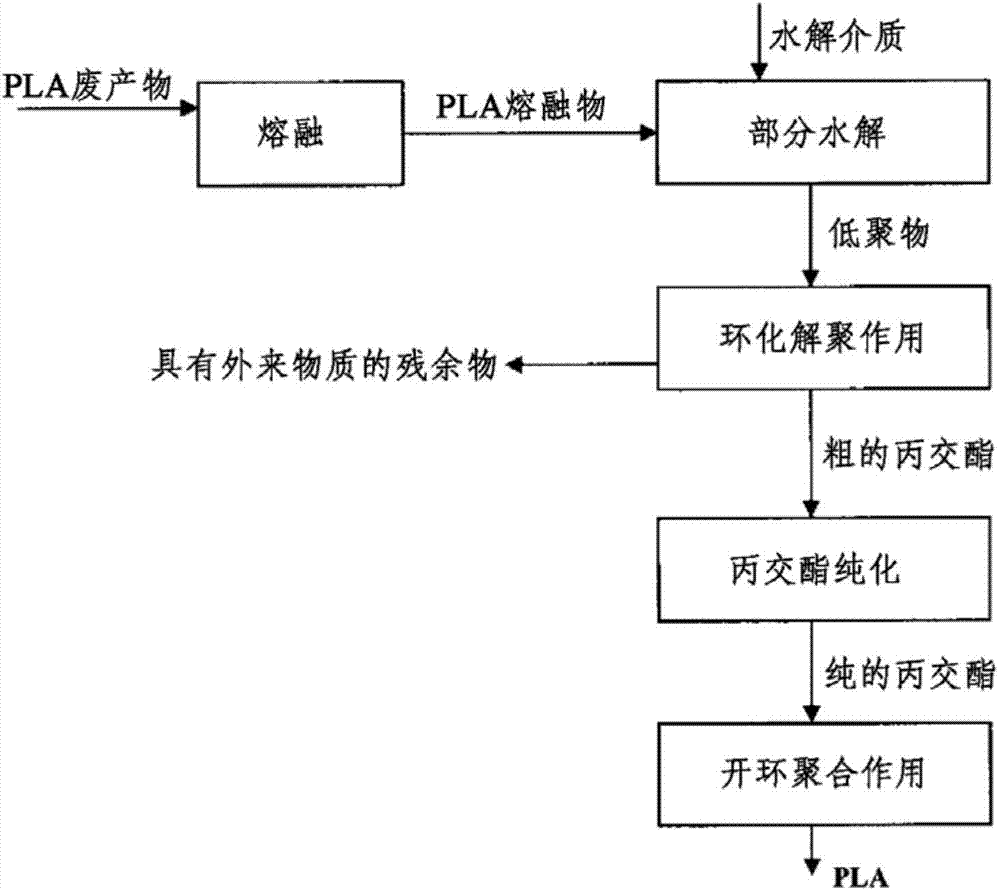

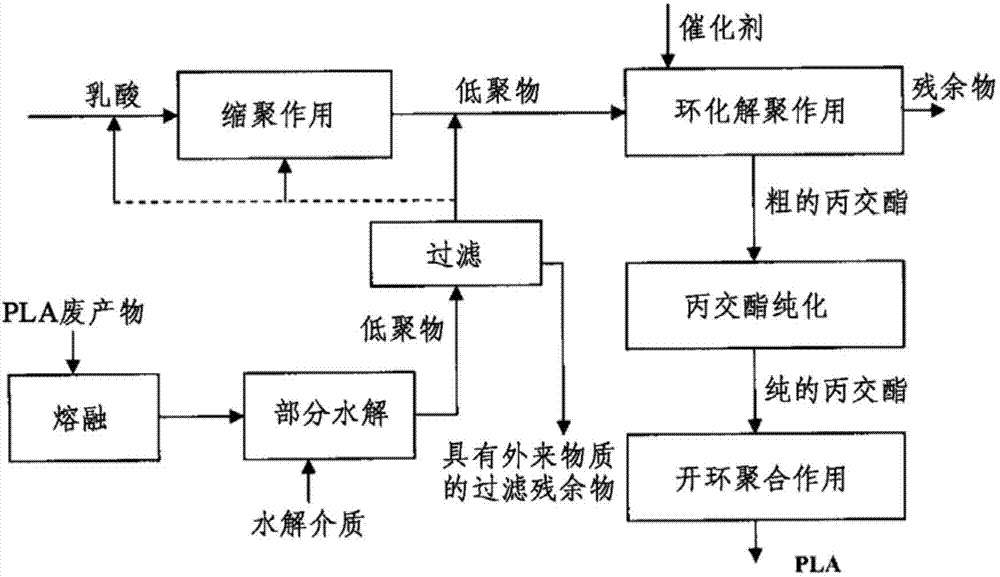

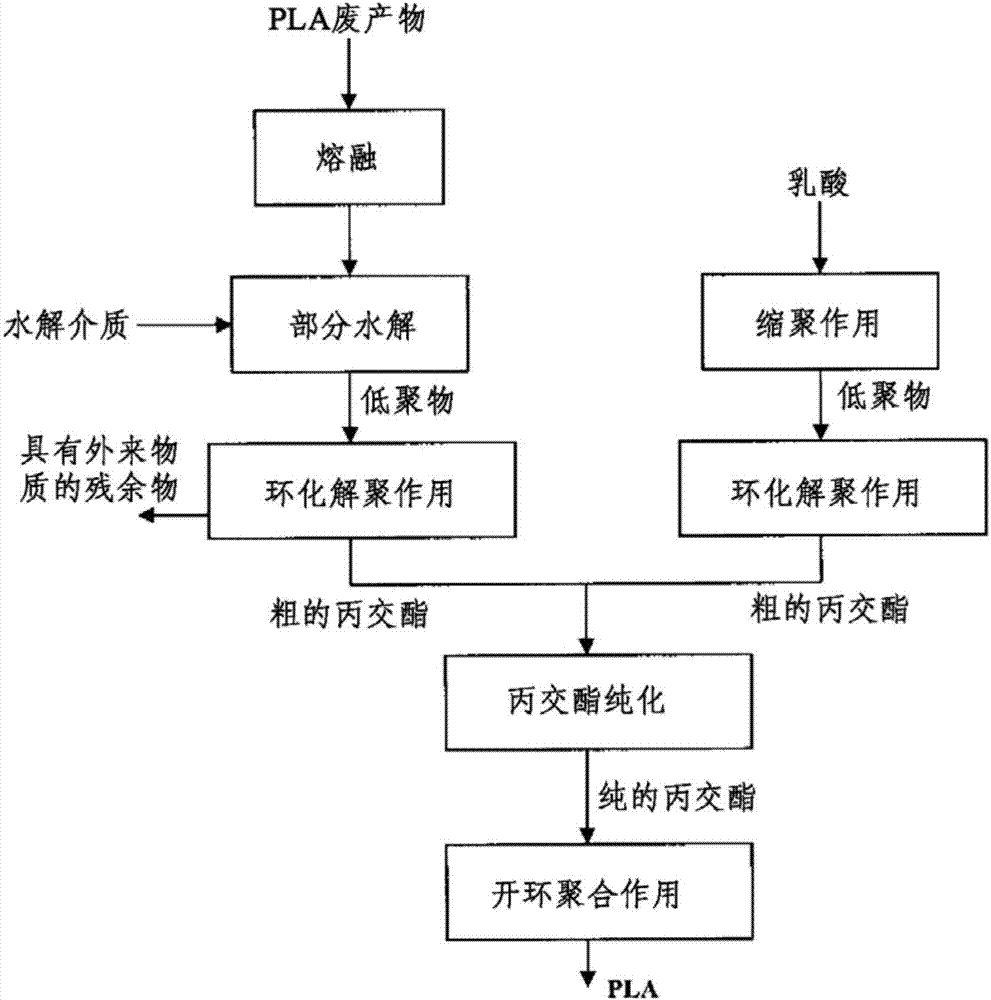

Process and apparatus for recovering lactide from polylactide or glycolide from polyglycolide

ActiveCN103781833ASave energySaverPlastic recyclingPreparation from carboxylic acid esters/lactonesPartial hydrolysisOligomer

The present invention relates to a process for recovering lactide from polylactide (PLA) or glycolide from polyglycolide (PGA), in which, in a first step, PLA or PGA is contacted with a hydrolysing medium and hydrolytically degraded to oligomers. In a further step, a cyclising depolymerisation of the oligomers obtained in the first step is effected to give lactide or glycolide. In addition, the present invention relates to an apparatus based on the combination of a hydrolysis apparatus with a depolymerisation reactor, with which the above-described process can be performed. The core of the process according to the invention is a partial hydrolysis of the polymeric materials originally used in combination with a cyclising depolymerisation.

Owner:UHDE INVENTA FISCHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com