Polymer and method for producing the same

A technology of polymers and compounds, applied in the field of polymers, can solve the problem of no monomers capable of ring-opening polymerization, and achieve the effect of reducing formability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

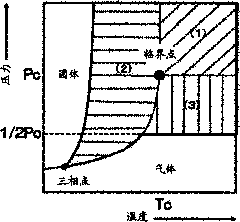

[0167] Lactide (90 parts by mass) of L-lactic acid, lactide (10 parts by mass) of D-lactic acid, and 3.00 mol% of lauryl alcohol relative to 100 mol% of monomers (acting as an initiator) were placed in a pressure vessel. agent) and 4-pyrrolidinylpyridine (PPY) (3.3 parts by mass), and then heated to 60°C.

[0168] Subsequently, supercritical carbon dioxide (60°C, 10 MPa) was added thereto, followed by reaction at 60°C for 12 hours.

[0169] After the reaction was completed, the flow rate at the outlet of the back pressure valve was adjusted to 5.0 L / min using a pressure pump and a back pressure valve. Then, supercritical carbon dioxide was flowed for 30 minutes, and PPY and residual monomer (lactide) were removed.

[0170] Thereafter, the reaction system was gradually returned to normal temperature and pressure. After three hours, the polymer (polylactic acid) contained in the container was taken out.

[0171] Using the above method, the physical properties (Mn, Mw / Mn, poly...

Embodiment 1-2 to 1-4

[0173] The procedure of Example 1-1 was repeated except that the amount of the initiator was changed as shown in each column of Examples 1-2 to 1-4 in Table 1-1, thereby obtaining a polymer.

[0174] Using the above method, the physical properties of the obtained polymer were measured, as shown in Table 1-1.

Embodiment 1-5 to 1-7

[0176] The procedure of Example 1-1 was repeated except that the reaction temperature was changed as shown in each column of Examples 1-5 to 1-7 in Table 1-1, thereby obtaining a polymer.

[0177] Using the above method, the physical properties of the obtained polymer were measured, as shown in Table 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com