Middle-low temperature sintered fine bone china and production method thereof

A technology of low-temperature sintering and refined bone china, which is applied in the production of ceramic materials, other household utensils, and applications. It can solve the problems of high thermal expansion coefficient of bone china, easy softening and deformation of products, and high cost. The effect of less amount, improved strength and thermal stability, and improved high temperature deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

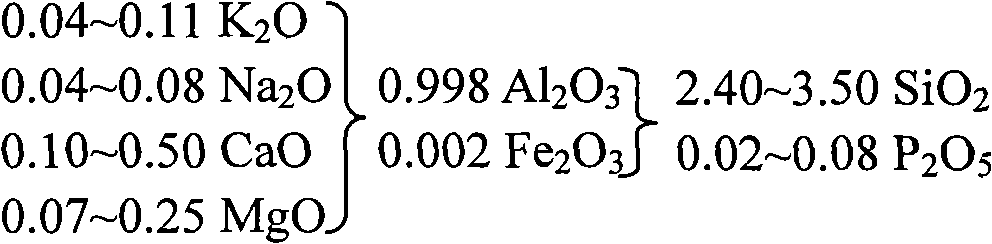

Method used

Image

Examples

Embodiment 1

[0018] Weigh various raw materials according to the billet formula: bone ash 3%, kaolin 43%, alumina powder 17%, frit 37%, the chemical composition of the billet is: SiO 2 53.69%, Al 2 o 3 37.07%, Fe 2 o 3 0.13%, CaO3.29%, MgO1.12%, K 2 O 2.40%, Na 2 O 1.03%, P 2 o 5 1.27%, the chemical composition of the frit is: SiO 2 79.41%, Al 2 o 3 8.10%, CaO 3.87%, MgO 2.64%, K 2 O 3.33%, Na 2 O2.57%. Put the above raw materials into the ball mill, mix and ball mill to the required fineness (the required fineness of plastic clay is <10μm, accounting for 75-80%, and the required fineness of grouting mud is <10μm, accounting for about 75%). Then, sieve, remove iron, press filter, smelt, stale, and shape in sequence, and then bisque-fired at 1200°C-1250°C. ℃ glaze firing, and finally fine bone china is obtained. If the one-time firing process is adopted, the raw material glaze is applied after the green body is formed, and then fired at a temperature of 1200 ° C to 1250 ° C. ...

Embodiment 2

[0020] Weigh various raw materials according to the billet formula: 5% ashes, 40% kaolin, 13% alumina powder, and 42% frit. The chemical composition of the billet is: SiO 2 56.48%, Al 2 o 3 31.06%, Fe 2 o 3 0.12%, CaO5.44%, MgO1.93%, K 2 O 1.96%, Na 2 O 0.87%, P 2 o 5 2.13%, the chemical composition of the frit is: SiO 2 80.65%, Al 2 o 3 5.29%, CaO 5.69%, MgO 4.27%, K 2 O 2.10%, Na 2 O1.92%. The firing temperature is 1190°C to 1220°C, and the other production processes are the same as in Example 1.

Embodiment 3

[0022] Weigh various raw materials according to the billet formula: 7% ashes, 35% kaolin, 11% aluminum oxide powder, and 47% frit. The chemical composition of the billet is: SiO 2 56.14%, Al 2 o 3 28.00%, Fe 2 o 3 0.12%, CaO 7.12%, MgO 2.33%, K 2 O 2.15%, Na 2 O 1.14%, P 2 o 5 2.99%, the chemical composition of the frit is: SiO 2 77.42%, Al 2 o 3 6.74%, CaO 6.15%, MgO 4.72%, K 2 O 2.57%, Na 2 O 2.31%. The firing temperature is 1170°C to 1200°C, and the other production processes are the same as in Example 1.

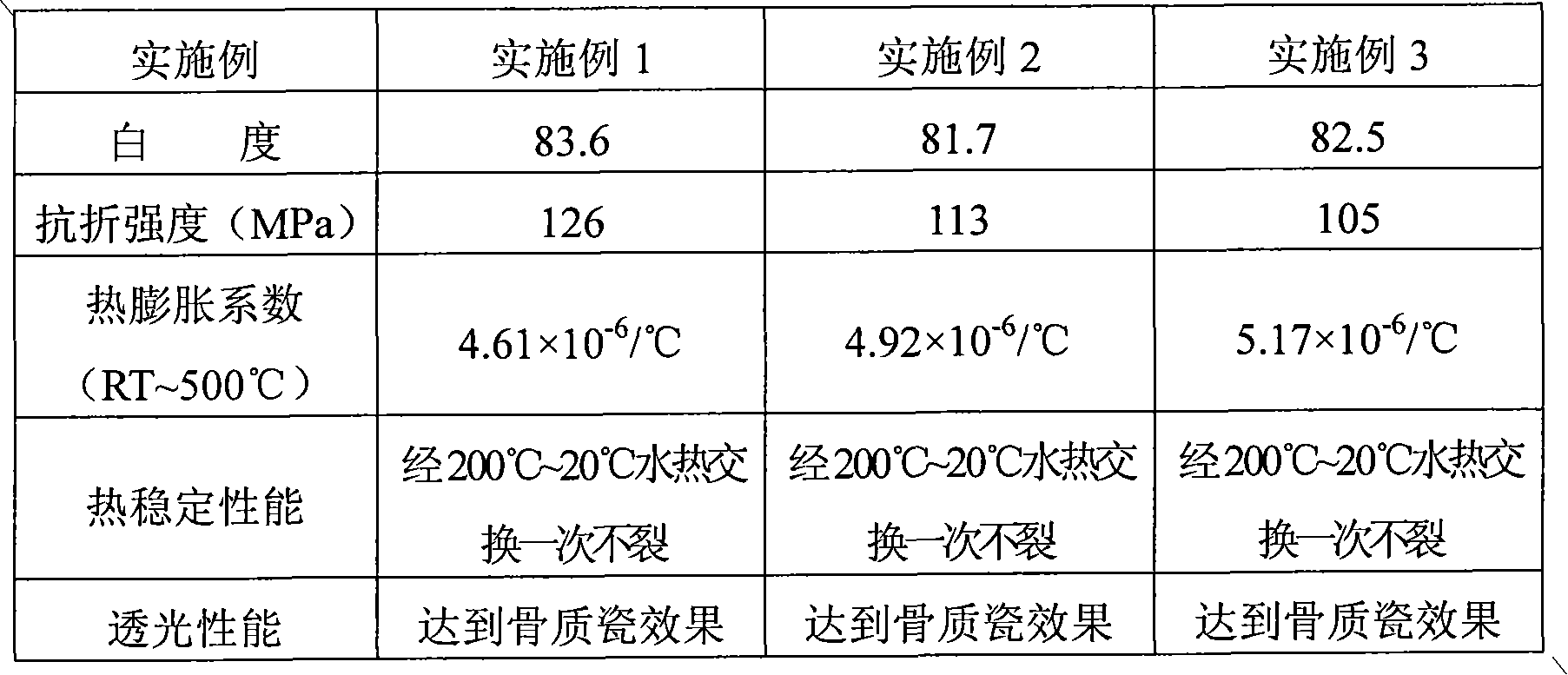

[0023] The performance of fine bone china made by each of the above-mentioned embodiments is as follows:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com