Patents

Literature

52results about How to "Fine porcelain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Middle-low temperature sintered fine bone china and production method thereof

ActiveCN101891455AReduced thermal stabilityImprove thermal stabilityCeramic materials productionClaywaresCoalBone china

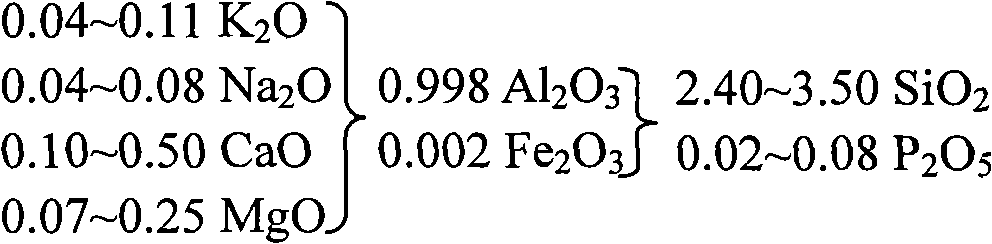

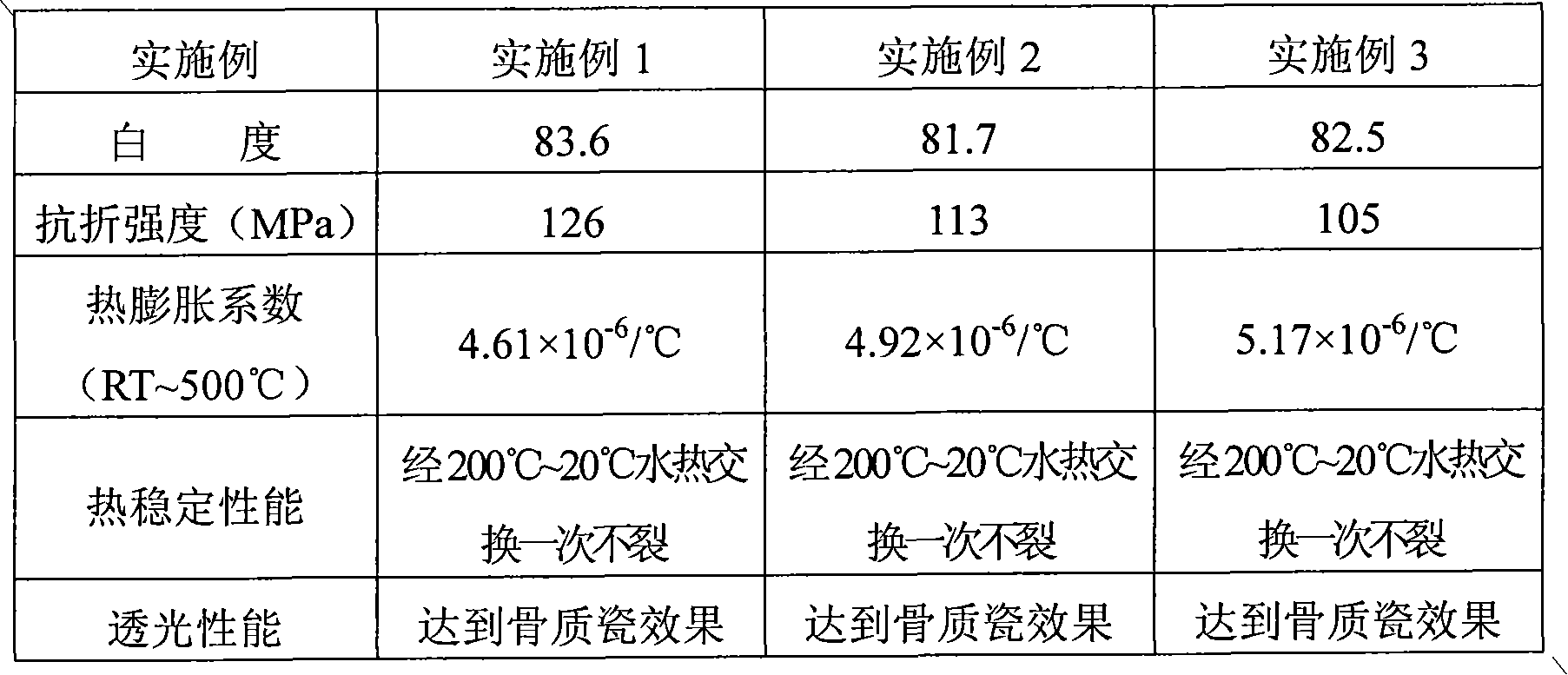

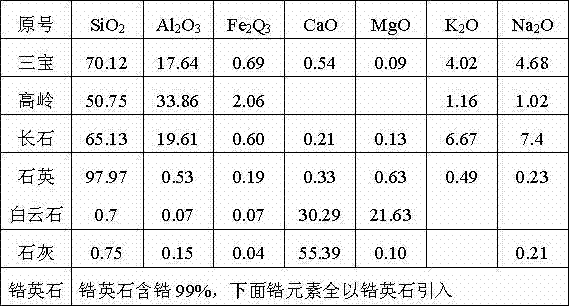

The invention relates to a middle-low temperature sintered fine bone china and a production method thereof. The china comprises the following chemical components in percentage by weight: 52 to 60 percent of SiO2, 28 to 37 percent of Al2O3, 1 to 4 percent of K2O, 1 to 2 percent of Na2O, 3 to 8 percent of CaO, 1 to 3 percent of MgO and 1 to 3 percent of P2O5; a used formula comprises the following raw materials in percentage by weight: 3 to 8 percent of bone ash, 32 to 45 percent of kaolin, 10 to 20 percent of aluminum oxide and 35 to 50 percent of fusion cake; the sintering temperature is between 1,170 and 1,250 DEG C; and not only a double-firing process of 'high-temperature biscuit firing and low-temperature glazed firing' or 'low-temperature biscuit firing and high-temperature glazed firing' can be adopted, but also a high-temperature single firing process can be applied. The fine bone china has an appearance effect of the conventional bone china, has physical and chemical properties superior to those of the bone china, has the significant advantages of low bone coal consumption and low sintering temperature, and is favorable for reducing the production cost and the energy consumption.

Owner:JINGDEZHEN CERAMIC UNIV

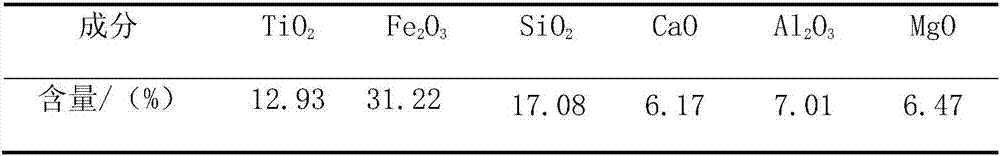

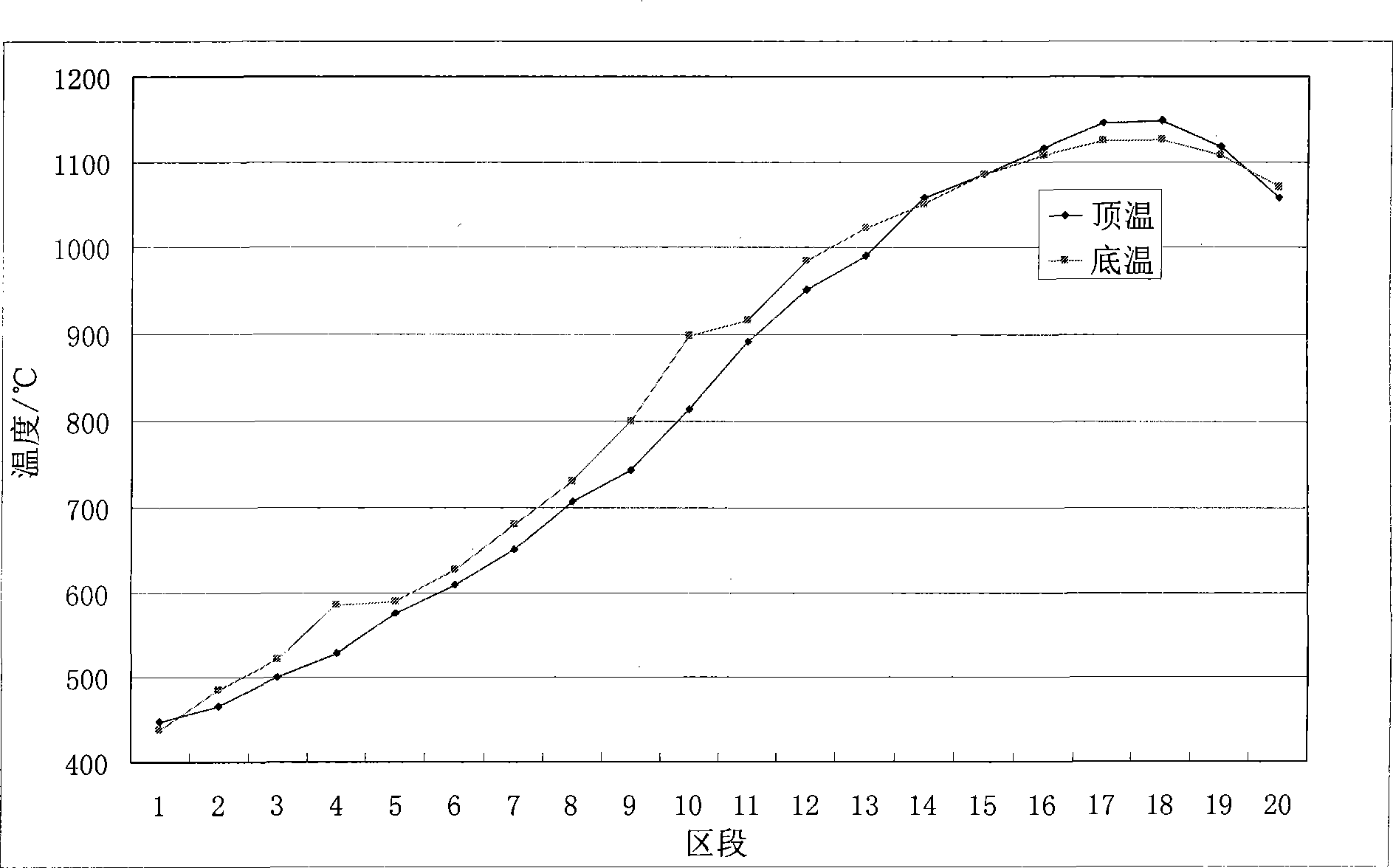

Anti-oxidation decarburized coating in process of billet rolling and preparation method thereof

InactiveCN101857452AGood porcelainReduce oxidation rate and carbon lossOxidation rateMetallic materials

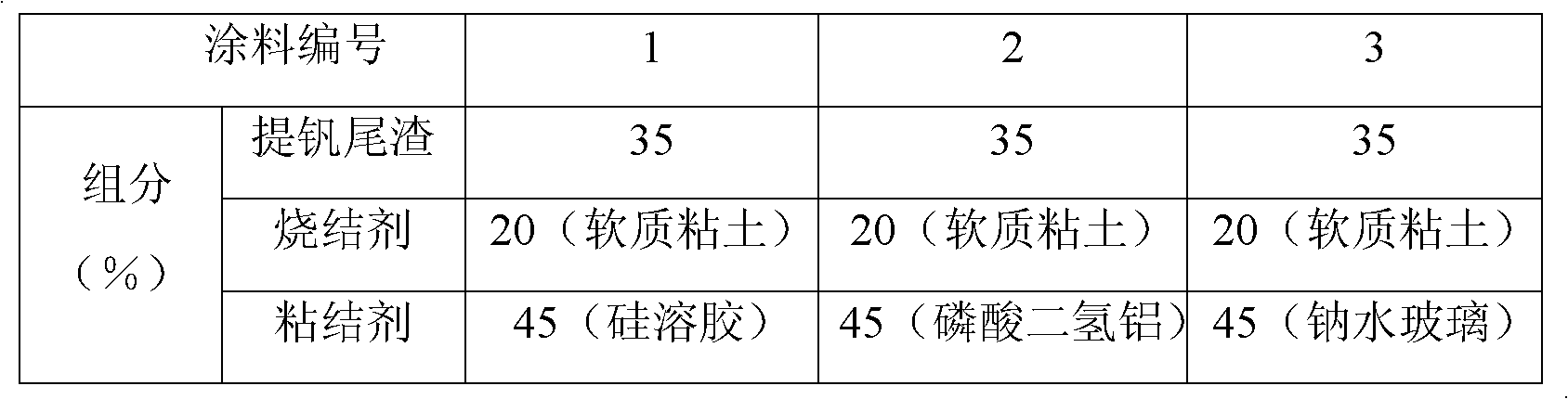

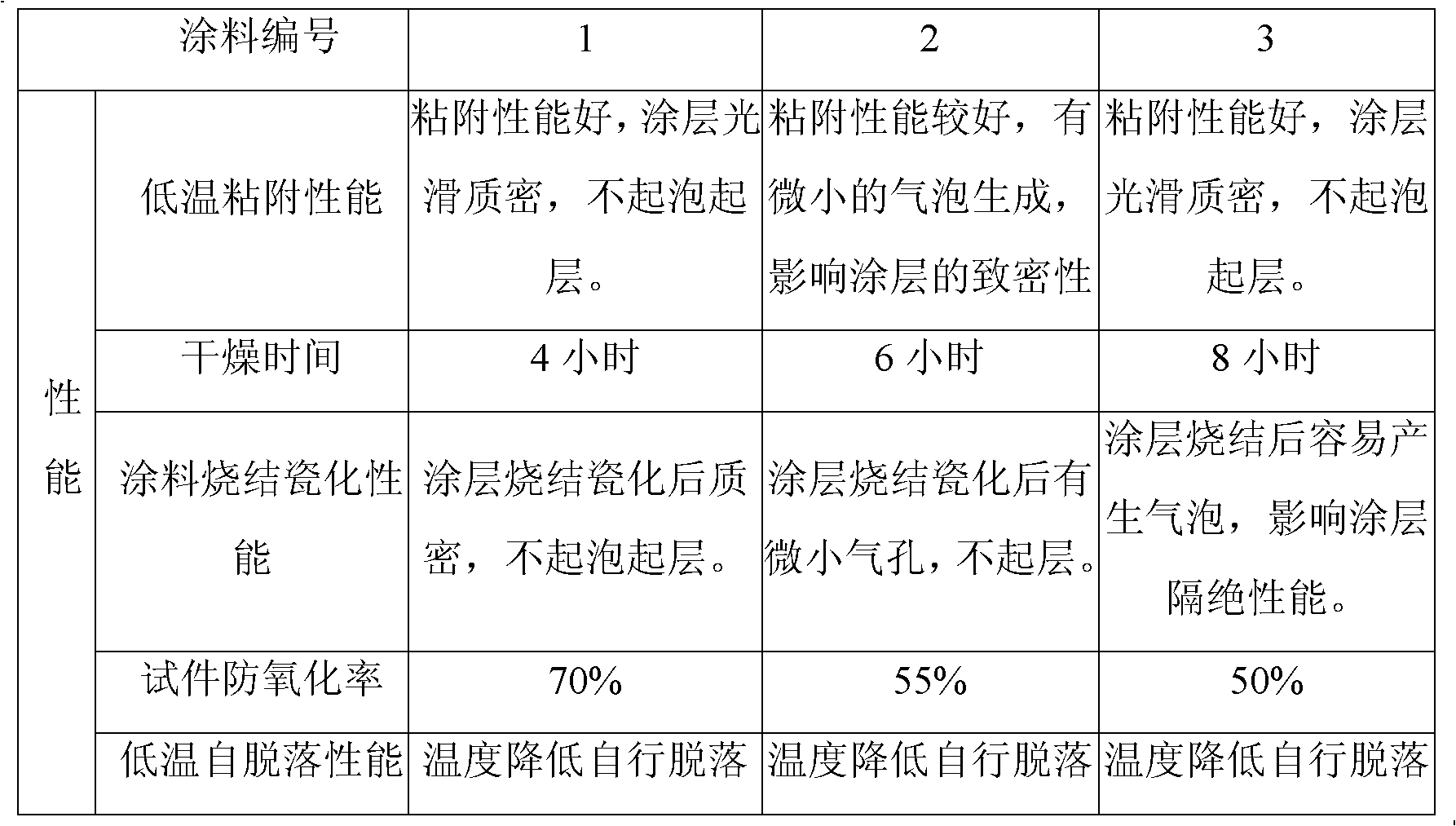

The invention belongs to the technical field of inorganic non-metal materials, and in particular relates to an anti-oxidation decarburized coating in the process of billet rolling and a preparation method thereof. The invention provides a low-cost and good-performance anti-oxidation decarburized coating in the process of billet rolling, which comprises the following raw materials in parts by weight: 20-60 parts of vanadium extraction tailings, 0-40 parts of agglutinant and 30-60 parts of binding agent. The coating is used in the process of billet rolling, can effectively reduce the oxidation rate and carbon loss of billets and can improve the heating efficiency of a heating furnace for the billets. The preparation method is a solution to the problem of pollution of vanadium extraction tailings, and can reduce the production cost of the anti-oxidation decarburized coating by changing the tailings into valuables.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Daily used reinforced ceramic and its preparation process

InactiveCN1724459ARegular shapeReduce production complexityClaywaresHeat stabilityUltimate tensile strength

A strengthened ceramic for daily purpose is proportionally prepared from albite, talc and clay. Its preparing process features sintering twice respectively at 1250-1350 deg. C and at 1100-1200 deg. C. Its advantages are fine quality, high whiteness, and high strength and thermal stability.

Owner:QINGDAO UNIV OF SCI & TECH

Ternary-system chip negative temperature coefficient thermal resistor

InactiveCN101719404ALow costImprove yieldNegative temperature coefficient thermistorsEpoxyReaction temperature

The invention relates to a ternary-system chip negative temperature coefficient thermal resistor, which uses manganese nitrate, nickel nitrate and cobalt nitrate as raw materials and ammonium bicarbonate as precipitator, is prepared by a liquid-phase co-precipitation method, and comprises the following steps: improving the agglomeration phenomenon of the precipitated particles by controlling the molar ratio of nitrate to precipitator ammonium bicarbonate, the reaction temperature and the pH value, washing out the impurities in the product by modes of water washing and alcohol washing to obtain superfine and uniform thermal resistor powder, drying, calcining to obtain evenly dispersed mixed oxide powder of Mn, Ni and Co, briquetting and moulding the powder, isopressing, sintering under high temperature, slicing by a semiconductor to obtain a thermal resistor chip, and encapsulating with epoxy resin to obtain the ternary-system chip negative temperature coefficient thermal resistor with high performance which has the characteristics of good uniformity, high stability, capability of repeatability and interconversion, and is suitable for temperature measurement, control and line compensation in the household appliance field such as refrigerators, air conditioners and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Raw material for low-temperature firing of Longquan celadon and firing method

The invention relates to a firing technology for low-temperature firing of celadon and aims to provide a raw material for low-temperature firing of Longquan celadon and a firing method. According to the invention, as for a blank body and glaze, a raw mineral material and a chemical raw material which are generally used by the Longquan celadon are adopted for matching, and nano calcium carbonate and zinc borosilicate glass powder are also contained; the nano particle high-specific external surface activity and various additives are combined with a cooling down mechanism, so as to allow the Longquan celadon to be fired under 1,150-11,800 DEG C, and the problems that the Longquan celadon is high in sintering temperature and high in energy consumption are solved. The product has the characteristics of high finished product ratio, good porcelain quality, high strength and the like, and has a wide application prospect.

Owner:ZHEJIANG TIANFENG CERAMIC

Ceramic fire-resistant functional filling material as well as preparation method and purpose thereof

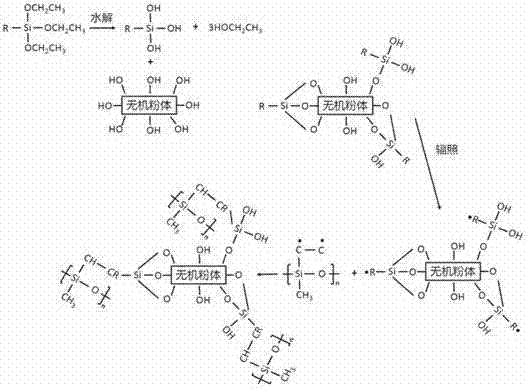

InactiveCN107501946AIncrease filling volumeEvenly dispersedNon-macromolecular adhesive additivesOther chemical processesGraft reactionHigh energy

The invention belongs to the technical field of a ceramic organic silicon fire-resistant material, and concretely discloses a ceramic fire-resistant functional filling material as well as a preparation method and a purpose thereof. The filling material is prepared from 80 to 120 parts of ceramic forming powder, 1 to 5 parts of silane coupling agents, 10 to 20 parts of diluting agents, 0.01 to 0.03 part of pH regulators, 2 to 6 parts of ethenyl polysiloxane and 2 to 10 parts of ceramic auxiliary agents. The ceramic forming powder is subjected to surface treatment through the silane coupling agents; grafting reaction is performed with polysiloxane in high-energy rays, so that good compatibility is achieved with organic silicon materials, so that the ceramic conversion rate can be improved. The method is applicable to the preparation of the ceramic fire-resistant material using the organic silicon materials as substrates. The filling material has excellent fire-resistant performance, good processing performance, low cost and convenient and fast production; meanwhile, the dispersion performance of the powder body is excellent; the ceramic forming effects of the prepared material in the flame combustion process is greatly promoted; the formed ceramic body is hard; good fire-resistant and heat-insulation functions are realized.

Owner:成都众一高材科技有限公司

Daily-use ceramic and preparation method thereof

The invention discloses a daily ceramics and preparing method, which is characterized by the following: adopting once sintering technology to prepare similar bone-ceramics; adding mineralizer based on common materials; allocating.

Owner:HUAIREN JIAMING CERAMICS

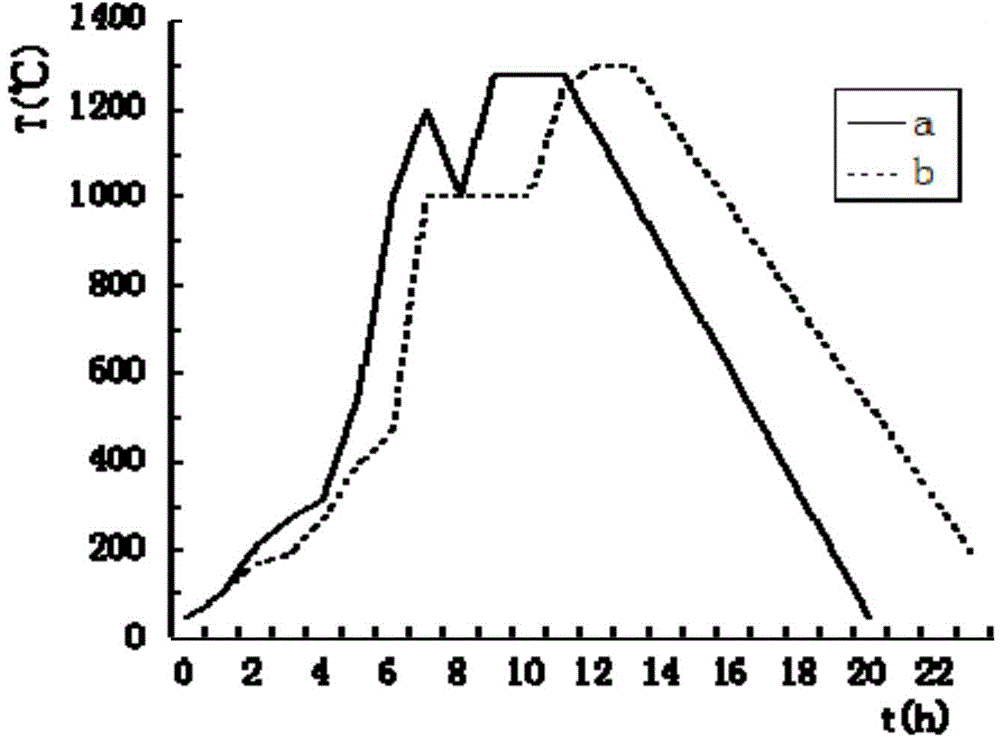

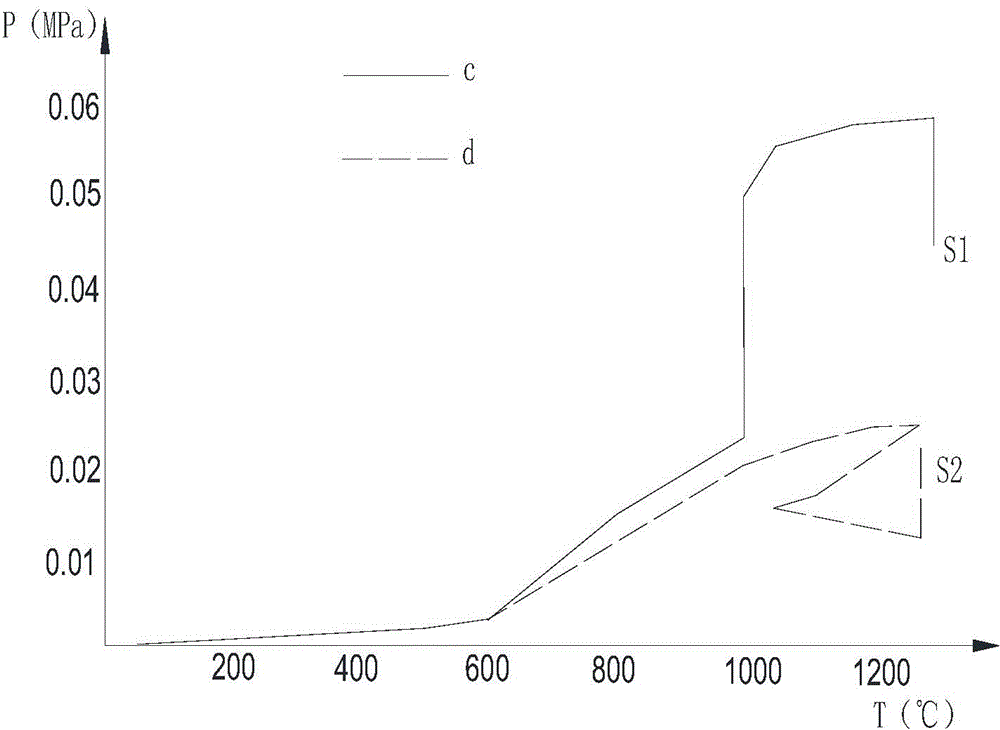

Method for manufacturing official kiln imitated crackle glaze ceramic product

The invention discloses a formula of an official kiln imitated crackle glaze material, wherein a small deal of zirconite is introduced to the formula, and through the reasonable matching ratio of all components, the glaze material is wide in adaptability, good in heat stability as well as gentle and jade-like in glazing color. The invention also discloses a method for manufacturing an official kiln imitated crackle glaze ceramic product by using the official kiln imitated crackle glaze material, wherein the ball milling fineness of the glaze material is mastered, and the ceramic blank biscuit firing and glaze firing times, temperature and glaze applying thickness are controlled, so that large official kiln crackle pieces appear after a glazing surface is subjected to thermal expansion and cold shrinkage. The method has the characteristics of science, reasonability, easiness for implementation, high rate of finished products, good ceramic quality, clear, simple, unsophisticated and elegant crackle pieces and uniform glaze layer crackles and can form the visual artistic effect that the jade-like stone is as thick as accumulated fat.

Owner:汤秋影

Celadon and preparation method thereof

The invention discloses celadon and a preparation method thereof and belongs to the field of manufacturing of porcelain. The preparation method of the celadon comprises the following steps: processing kaolin, processing marble and diorite, preparing green body soil, preparing glaze, moulding and biscuiting a green body, applying glaze on the green body, and firing, wherein the kaolin is processed by the following steps: drying kaolin, spreading and blowing with strong breeze, distributing materials, scouring with water flow, precipitating, reclaiming layer by layer, screening out a kaolin raw material used for preparing the green body soil and the glaze, then firing by combining unique firing atmosphere and a warming curve to obtain the celadon which is steadier and more implicit in colour and lustre and semi-transparent in glazing colour and is provided with a grey or dark brown green body. The preparation method of the celadon is not fettered by a historic skill, body and glaze can be fine and smooth and also can be rough, glaze light is milder, the glazing colour is not pure, but differential regional characteristic is formed.

Owner:SHENZHEN POLYTECHNIC

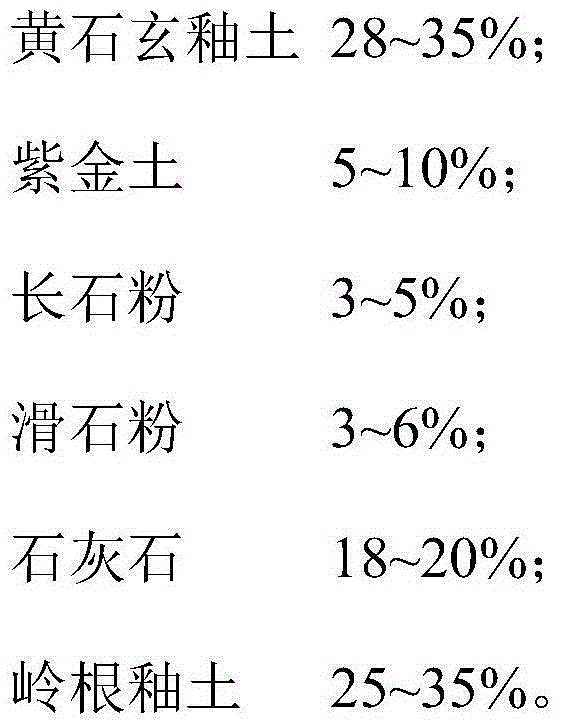

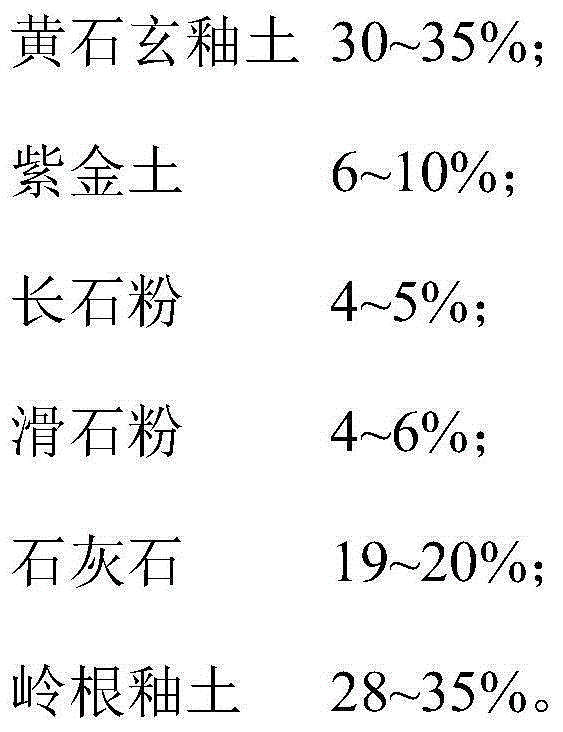

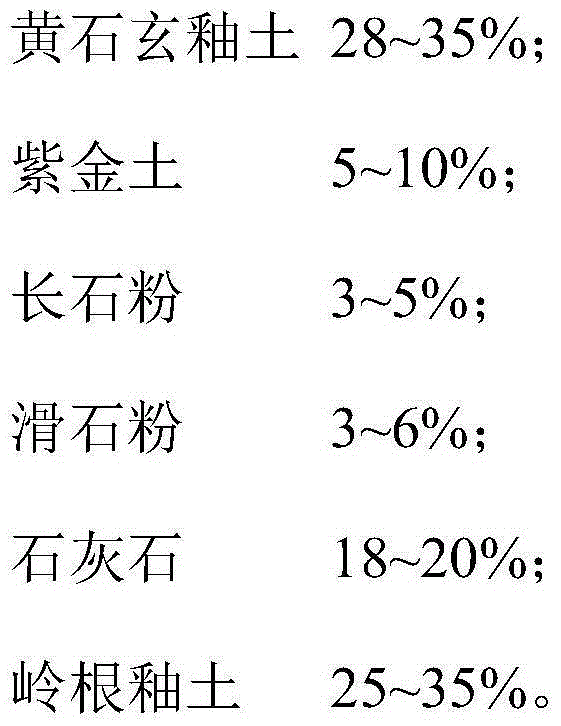

Preparation method and glaze material of celadon secret color glaze

The present invention provides a preparation method and a glaze material of a celadon secret color glaze. According to the present invention, Huangshixuan glaze soil, purple-gold soil, feldspar powder, talc powder, limestone and Ling'gen glaze soil are adopted as raw materials, air in the glaze can not float out of the glaze surface during the glaze firing process while a lot of small gas bubbles are formed, a certain number of undissolved quartz particles are remained in the glaze when the temperature of the porcelain forming stage is 1280-1310 DEG C, a large amount of anorthite crystals are formed, light entering the glaze layer produces the scattering due to the formed small gas bubbles, the formed quartz particles and the formed anorthite crystals so as to make the glaze layer have the transparent jade texture, and after the thermal expansion and contraction, the glaze layer cracks so as to form the stereoscopic vision effect of the smooth and rich jade; the prepared celadon secret color glaze has characteristics of green, mild and moist glaze color, good thermal stability and wide adaptability; and the preparation method is scientific and rational, and is easy to perform, and the obtained celadon secret color glaze product has characteristics of high yield and good product porcelain quality.

Owner:郑峰

Ceramic underglaze five-color silk screen transfer printing method

The invention relates to a ceramic underglaze five-color silk screen transfer printing method which comprises the following steps: carrying out ball milling on a ceramic raw material and screening to prepare a slurry, and carrying out mold injection molding into the required shape to obtain a billet; glazing, and firing to obtain a glaze billet; brushing a water-containing adhesive on the surface of the glaze billet; attaching a silk screen prepared according to the required pattern to the surface of the glaze billet by silk screen transfer printing, spreading the prepared pigments in the pattern formed by the silk screen on the glaze billet, peeling off the silk screen to form the required pattern outline, dipping the underglaze five-color pigments with a painting device, carrying out painting decoration on the pattern outline to obtain a color billet, and carrying out color treatment to spread a glaze layer on the surface of the color billet; and firing the color billet coated with the transparent glaze in a kiln at high temperature to obtain the underglaze five-color ceramic article.

Owner:HUNAN NEW CENTURY CERAMICS

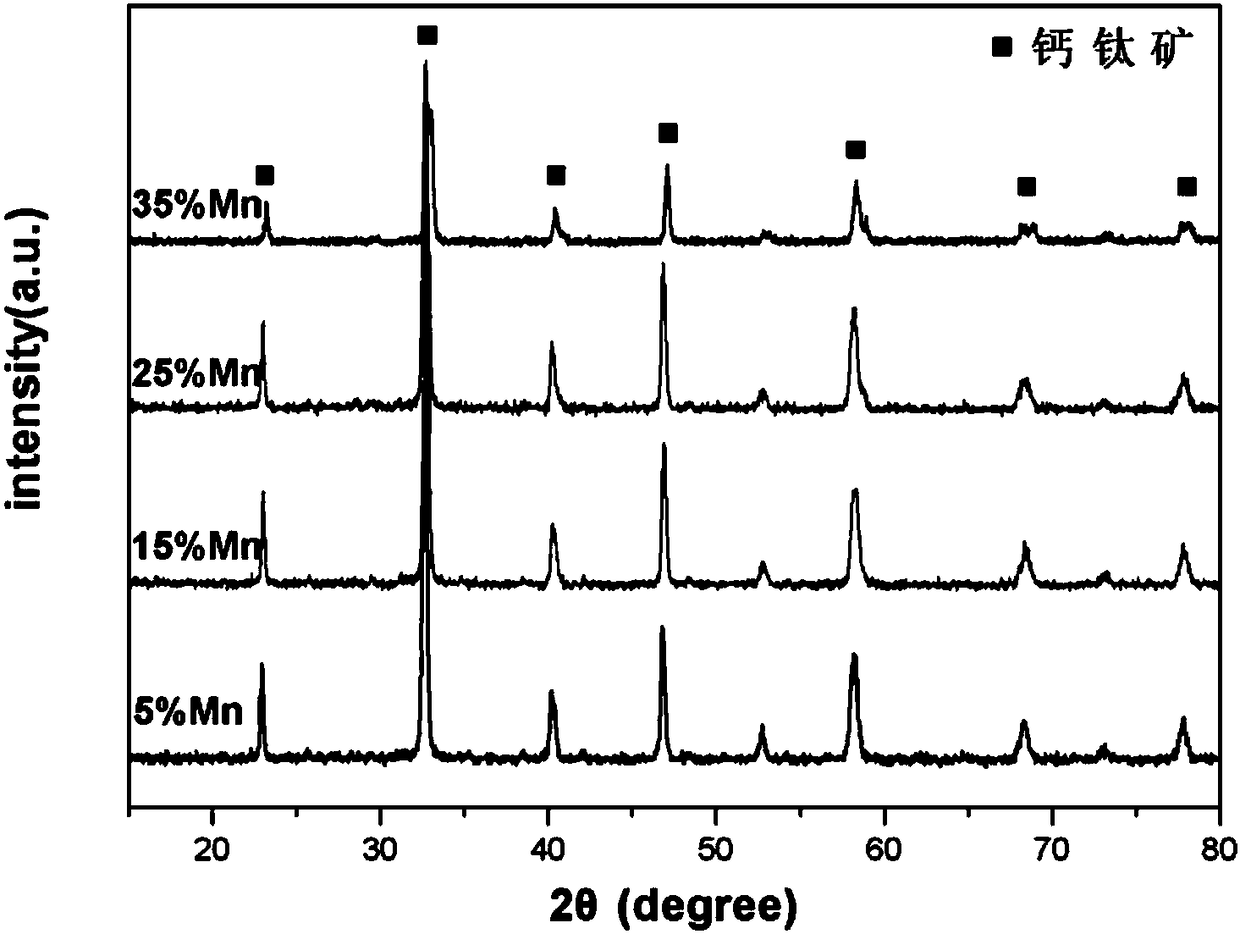

Chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material

InactiveCN108585794AUniform particle sizeImprove ball milling activityNegative temperature coefficient thermistorsHigh resistanceManganese

The invention provides a preparation method of a chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material. The method comprises the following step: weighing the following raw materials: 20-55% by atom of La, 5-75% by atom of Cr and 5-40% by atom of Mn; performing wet milling to obtain slurry; drying and grinding the slurry to obtain powder; roasting to obtain perovskite-phase La(CrMn)O3 powder; preparing the powder into block materials; performing two-step sintering method; cooling with the furnace to obtain the chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material. The chromium and manganese co-doped perovskite type negative temperature coefficient heat-sensitive ceramic material prepared according to the method has the advantages that electrical parameters are that rho25 DEG C=15.2 omega.cm-13823.2 ohm.cm+ / -2%, B25 / 50=2688-3942K+ / -1.5%; the material has the characteristics that the high-resistance, low-B and low-resistance and high-B parameter combination is realized; the consistency is high; the stability is high; the material is recyclable; the material is applicable to measuring and controlling of temperature in wide temperature range, circuit compensating and inhibiting of surge current.

Owner:UNIV OF JINAN

Te-hua ivory white porcelain and preparation process thereof

The invention belongs to the field of ceramic products, and in particular relates to a Dehua ivory white porcelain and a preparation process thereof. The Dehua ivory white porcelain prepared by the present invention includes lard white body and lard white glaze, and the lard white body is made of Dehua kaolin, low-temperature clay, low-temperature stone, Dehua quartz, and pyrophyllite 18-25%. Made by comparison, the lard white glaze is made of low-temperature stone, pyrophyllite, Dehua Yangshan limestone, quartz, and Dehua kaolin. The Dehua ivory white porcelain provided by the present invention selects raw materials with large reserves and low prices as raw materials for lard white body and lard white glaze, and strictly controls the chemical components of the raw materials. Introducing trace amounts of rare earth elements cerium and praseodymium into the raw materials of the glaze can make the body and glaze appear milky yellow lard color, making the porcelain fine, dense, moist, lard color, soft in color, firm in white, and as white as fat , slightly yellow, has the closest artistic effect to traditional Dehua ivory white porcelain.

Owner:CERAMICS SCI & TECH RES INST QUANZHOU +1

Manufacture method of square bricks

ActiveCN107473713AHigh strengthReduce manufacturing costCeramic materials productionClaywaresFerrosiliconBuilding material

The invention relates to the technical field of building materials and particularly relates to a manufacture method of square bricks. The manufacture method comprises the following steps: 1) preparing raw materials, and uniformly mixing the raw materials to obtain a first material mixture, wherein the raw materials comprise the following components in percentage by mass: 58%-65% of vanadium extracting tailings, 1%-3% of aluminate cement, 18%-22% of clay, 3%-10% of ferrosilicon ash, 6%-10% of aluminium oxide powder and 4%-8% of coal ash; 2) adding a certain amount of water into the first material mixture, and uniformly mixing the mixture with the water to obtain a second material mixture; 3) pouring the second material mixture into a mold, and performing hitting forming to obtain square brick semi-products; and 4) calcining the square brick semi-products at a high temperature to obtain square brick products. The method can be used for manufacturing square bricks with low cost.

Owner:PANZHIHUA UNIV

High-grade ceramic underglaze color manufacturing and decorating method

The invention discloses a high-grade ceramic underglaze color manufacturing and decorating method. The underglaze color is manufactured in a three-time firing mode. The method comprises the following steps: performing biscuit firing on the green body, performing colored firing, and finally performing glaze firing; the method is characterized in that according to the three-time firing mode, the underglaze color ceramics are manufactured by virtue of a three-times firing method comprising high-temperature biscuit firing, high-temperature colored firing and low-temperature glaze firing, wherein the high-temperature biscuit firing is performed under the temperature condition of 1150-1250 DEG C; the high-temperature colored firing is performed under the temperature condition of 1000-1250 DEG C; and the low-temperature glaze firing is performed under the temperature condition of 1000-1140 DEG C.

Owner:HUNAN NEW CENTURY CERAMICS

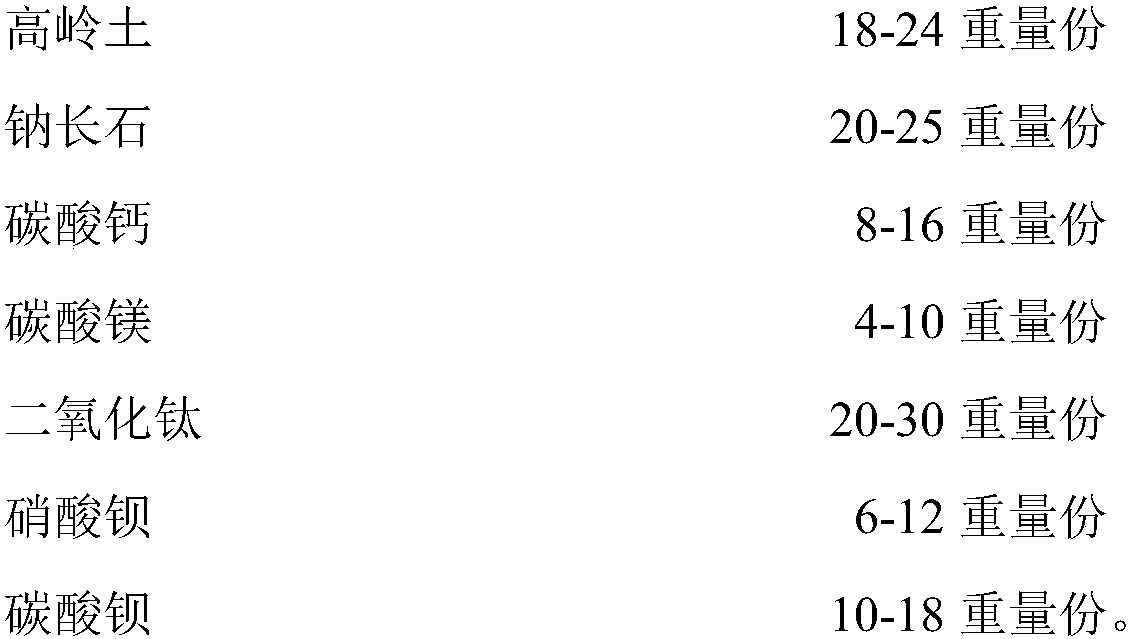

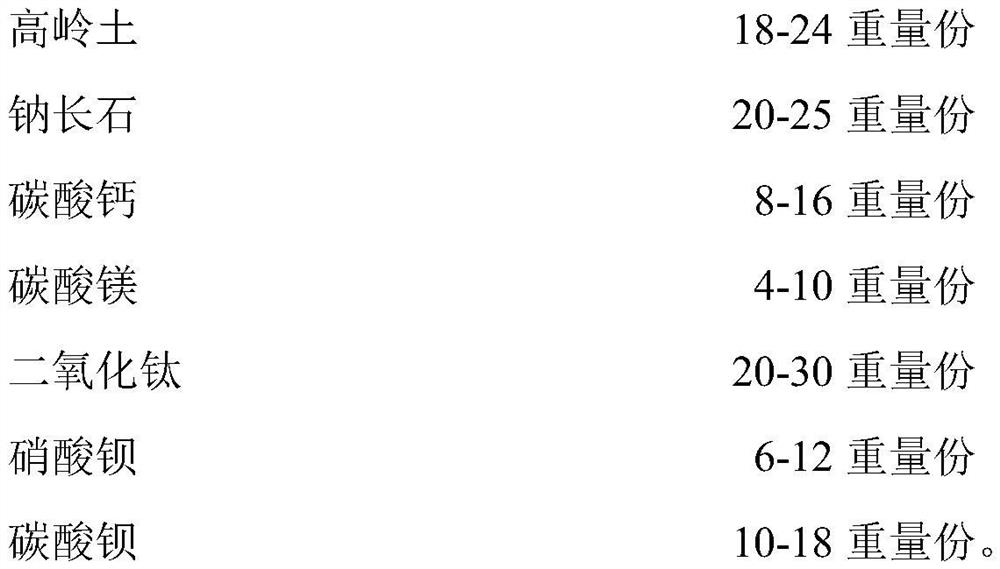

High-brightness ivory white ceramic product and making process thereof

ActiveCN108249887AHigh whitenessGood adhesionCeramic materials productionClaywaresBarium nitrateGlaze

The invention relates to the technical field of ceramics, in particular to a high-brightness ivory white ceramic product and a making process thereof. The ceramic product comprises a green body and aglaze layer applied on the surface of the green body; the green body consists of the following components: 25-30 weight parts of kaolin, 12-15 weight parts of quartz, 8-12 weight parts of a fluxing agent and 5-15 weight parts of a ceramic micro-powder; the glaze layer consists of the following components: 18-24 weight parts of kaolin, 20-25 weight parts of albite, 8-16 weight parts of calcium carbonate, 4-10 weight parts of magnesium carbonate, 20-30 weight parts of titanium dioxide, 6-12 weight parts of barium nitrate and 10-18 weight parts of barium carbonate. The making process comprises the following steps: S1, raw material preparation; S2, green body making; S3, glaze water making; S4, glazing and firing. The ceramic product manufactured by the raw materials provided by the inventionand the making process has the characteristics of high glaze brightness, good glossiness and exquisite ceramic quality.

Owner:福建省德化县中国白陶瓷有限责任公司

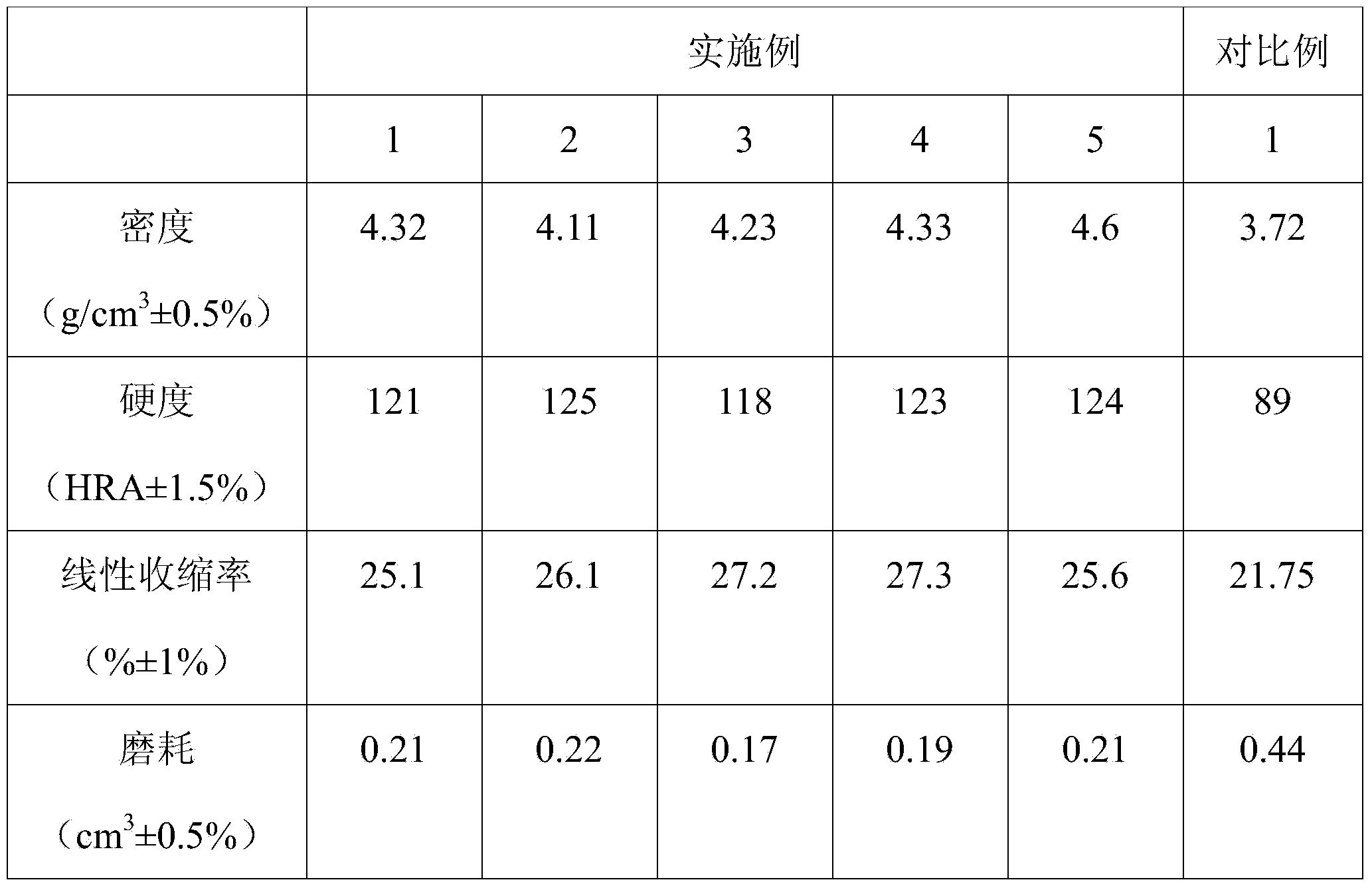

Alumina ceramic material and preparation method thereof

The invention provides an alumina ceramic material which uses high-alumina fly ash, light calcium carbonate and magnesium carbonate as raw materials. The preparation method comprises the following steps: firstly, performing pre-desilicification and acid activation pretreatment on the high-alumina fly ash to improve the alumina content in the high-alumina fly ash; then, ball-milling the high-alumina fly ash, the light calcium carbonate, the magnesium carbonate, water, a dispersing agent and a binding agent, drying, and grinding, so as to obtain powder; sieving and deironing the powder, adding a release agent, uniformly mixing, then pressing into a green body, and performing pressurization high-temperature sintering on the green body, so as to obtain the alumina ceramic material. According to the method, no other additional aluminium sources are needed, and the sintering temperature is obviously reduced during the preparation process, so that the cost is reduced; moreover, the method is high in parameter controllability and high in repeatability, and the prepared products are good in consistency, high in abrasion resistance and high in stability.

Owner:江苏龙欧新型建材科技有限公司

Silicone rubber for wires and cables

InactiveCN105566832AImprove mechanical propertiesGood flame retardantRubber insulatorsInsulated cablesHydroxideSilicone oil

Silicone rubber for wires and cables is prepared from methyl vinyl silica gel, fumed silica, wollastonite, crylic acid, sodium stearate, aluminum hydroxide, an initiator, an anti-ageing agent, a flame retardant and hydroxyl silicone oil. Methyl vinyl silica gel, fumed silica, wollastonite, crylic acid, sodium stearate, aluminum hydroxide, the initiator, the anti-ageing agent, the flame retardant and hydroxyl silicone oil are adopted by the accurate weight part to manufacture the silicon rubber through rigorous process steps, the mechanical property of the silicon rubber is greatly improved, and the silicon rubber has excellent flame retardant and ceramic forming effects.

Owner:SUZHOU CHENGSHENG INFORMATION TECH

Ceramic inner wall brick for construction produced by using alkaline land deposition soil and technique for producing the same

The invention provides a ceramic interior wall tile for construction produced by alkaline land luvial soil and a production process thereof, using the alkaline land luvial soil as a main raw material. The ceramic interior wall tile comprises the following compositions in percentage by mass: 40 to 48 percent of luvial soil, 12 to 15 percent of aedelforsite, 18 to 22 percent of kaolinite, 12 to 15 percent of diopside, 3 to 7 percent of Jilin soil, and 3 to 9 percent of talc. The ceramic interior wall tile prepared by the compositions has large mechanical strength, good thermal stability and low water absorption rate, has each technical index in accordance with national standard, and opens a new path in comprehensively developing and treating the alkaline land.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

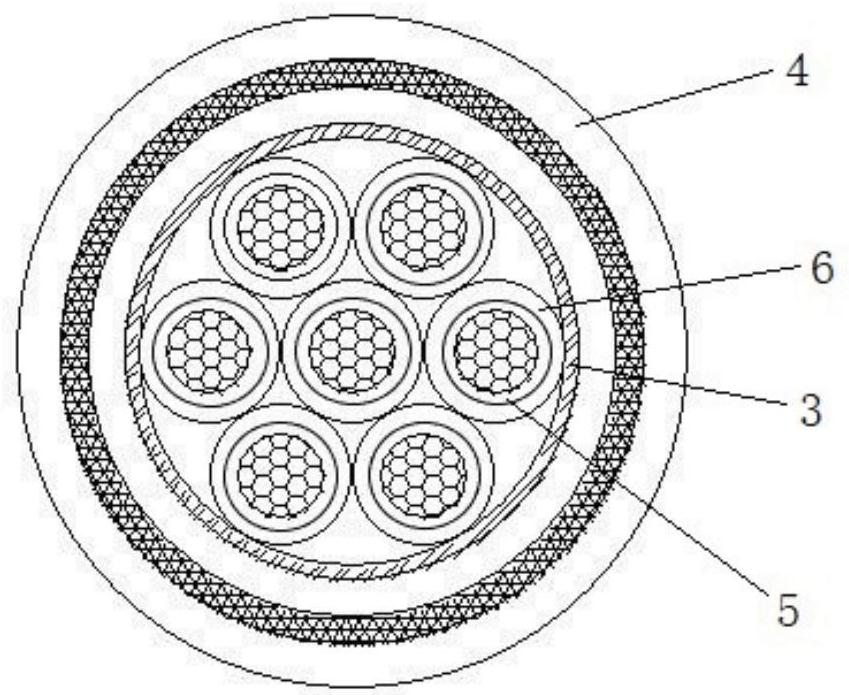

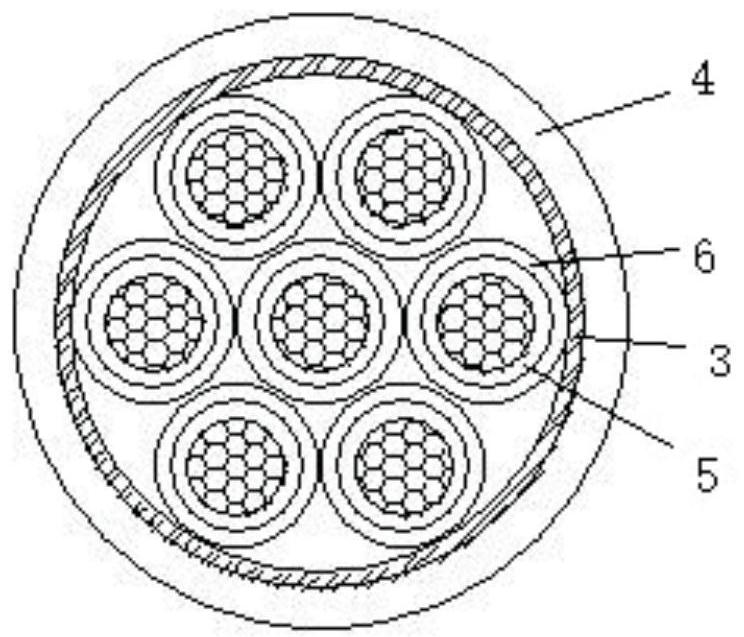

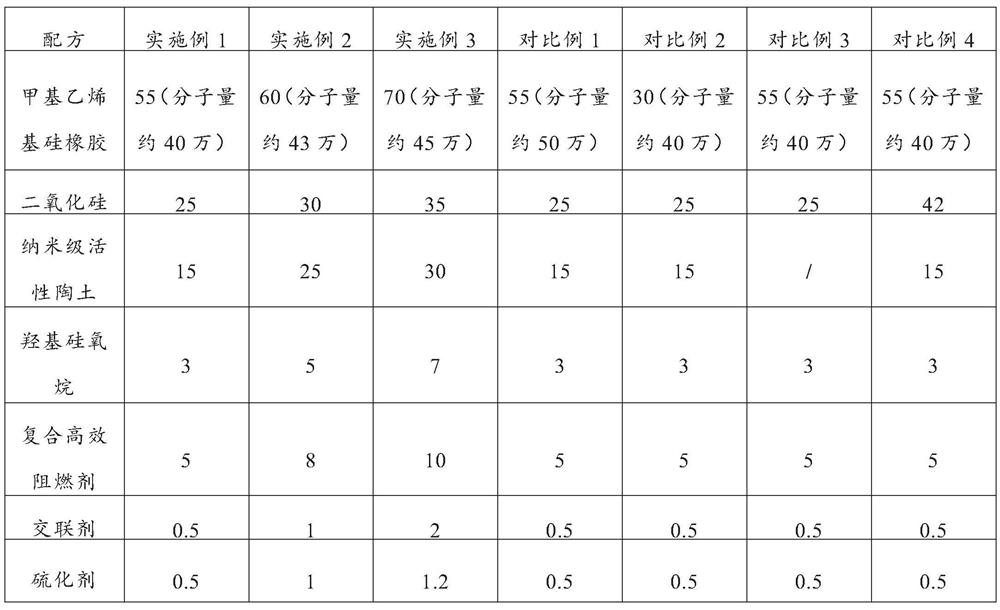

Tensile flame-retardant silicone rubber composition, flame-retardant B1-level silicone rubber insulation polyolefin sheath control cable and preparation method thereof

ActiveCN113652091AHigh strengthEnhanced tensile tear strengthPlastic/resin/waxes insulatorsClimate change adaptationPolymer sciencePolyolefin

The invention provides a tensile flame-retardant silicone rubber composition, a flame-retardant B1-grade silicone rubber insulation polyolefin sheath control cable and a preparation method thereof. The tensile flame-retardant silicone rubber composition comprises the following components by weight: 45-75 parts of methyl vinyl silicone rubber; 20-40 parts of silicon dioxide; 10-35 parts of nano-scale active pottery clay; 3-10 parts of hydroxyl siloxane; 5-10 parts of a composite efficient flame retardant; 0.5-3 parts of a cross-linking agent; and 0.5-2 parts of a vulcanizing agent. The tensile flame-retardant silicone rubber composition has the advantages of high temperature resistance, favorable ceramic forming property, B1-level flame retardancy, overload incombustibility, fire resistance and no toxicity.

Owner:GUANGZHOU METRO DESIGN & RES INST +1

Halogen-free low-smoke cable material

InactiveCN105367888AImprove mechanical propertiesExcellent halogen-free and low-smokePlastic/resin/waxes insulatorsZinc borateAluminium hydroxide

The invention relates to a halogen-free low-smoke cable material which comprises, by weight, 50-80 parts of EVA40, 10-30 parts of POE, 10-20 parts of PPR, 40-60 parts of aluminium hydroxide, 30-60 parts of magnesium hydroxide, 10-30 parts of low temperature glass powder, 5-15 parts of ZB zinc borate, 1-3 parts of a coupling agent A172, 1-3 parts of dimethyl silicone oil, 3-8 parts of polyethylene wax, 3-8 parts of melamine phosphate, and 5-10 parts of a 8112 environment-friendly fire retardant. A preparation method of the cable material comprises steps of mixing and granulation. According to the invention, mechanical property is enhanced, and the cable material has excellent halogen-free, low-smoke, flame-retardant and porcelain-forming effects.

Owner:WUXI HUAMEI CABLE

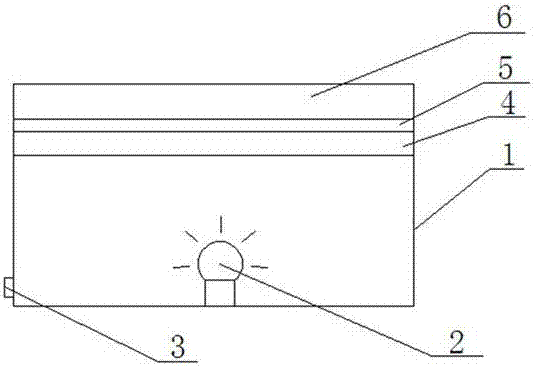

Crystalline light transmitting porcelain plate painting showing structure and preparation process thereof

InactiveCN107336556AGood light transmissionImprove the decorative effectGlass shaping apparatusSpecial artistic techniquesEngineeringGlass sheet

The invention relates to a crystalline light transmitting porcelain plate painting showing structure and a preparation process thereof. The showing structure comprises a lamp box with an opening in the upper portion; a light source is arranged in the lamp box; a power source switch is arranged on the outer side of the lamp box; a glass plate layer for closing is fixedly arranged on the lamp box opening, and a porcelain plate painting adheres to the glass plate layer through a light transmitting shadowless glue layer; and the lower surface of the glass plate layer is subjected to etching and multi-angle polishing to form refracting faces different in curvature so that light ray can be irradiated to the refracting faces to form different refracting paths, and then the light source is projected to the porcelain plate painting through the glass plate layer and the shadowless glue layer at multiple angle to achieve different light transmitting effects, wherein the refracting faces are formed by combining curved surfaces and inclined surfaces. According to the crystalline light transmitting porcelain plate painting showing structure and the preparation process thereof, by arranging the lamp box and adhering the porcelain plate painting to a glass plate above the lamp box through shadowless glue, the showing structure is fine and smooth in porcelain, a bone porcelain plate blank is thin, weight is small, good light transmitting performance is achieved, a foggy feeling is achieved, and very high artistic quality is achieved.

Owner:李梦娟

Overglaze color art porcelain based on Dehua white porcelain body and preparation process thereof

ActiveCN110963786AGlossyFine porcelainPigmenting treatmentCeramic materials productionPolymer sciencePolymer chemistry

The invention relates to the field of ceramic artwork making, in particular to a overglaze color art porcelain based on a Dehua white porcelain body and a preparation process thereof. According to theoverglaze color art porcelain based on a Dehua white porcelain body, the improved Dehua white porcelain has the original characteristics, also the hydrophobicity of the surface of a white porcelain matrix can be reduced, thus facilitating the adhesion of a color material layer, and the color material layer is brighter after coloring the improved Dehua white porcelain; the prepared color materialis strong in tinting strength and easy to disperse, and can be tightly combined with the surface of the Dehua white porcelain matrix. The overglaze color art porcelain based on the Dehua white porcelain body has pug, color material and pigment superposed decorative material, so that various decorative processes and technologies are mutually reflected, and the color material layer and the white porcelain layer are mutually reflected to show beauty, thus forming a delightful comprehensive artistic effect and interesting artistic charm, and the overglaze color art porcelain is particularly suitable for making artistic artware with fine patterns, like sculptures of figures, fine lines and Buddha statues.

Owner:福建省德化县山花陶瓷有限公司

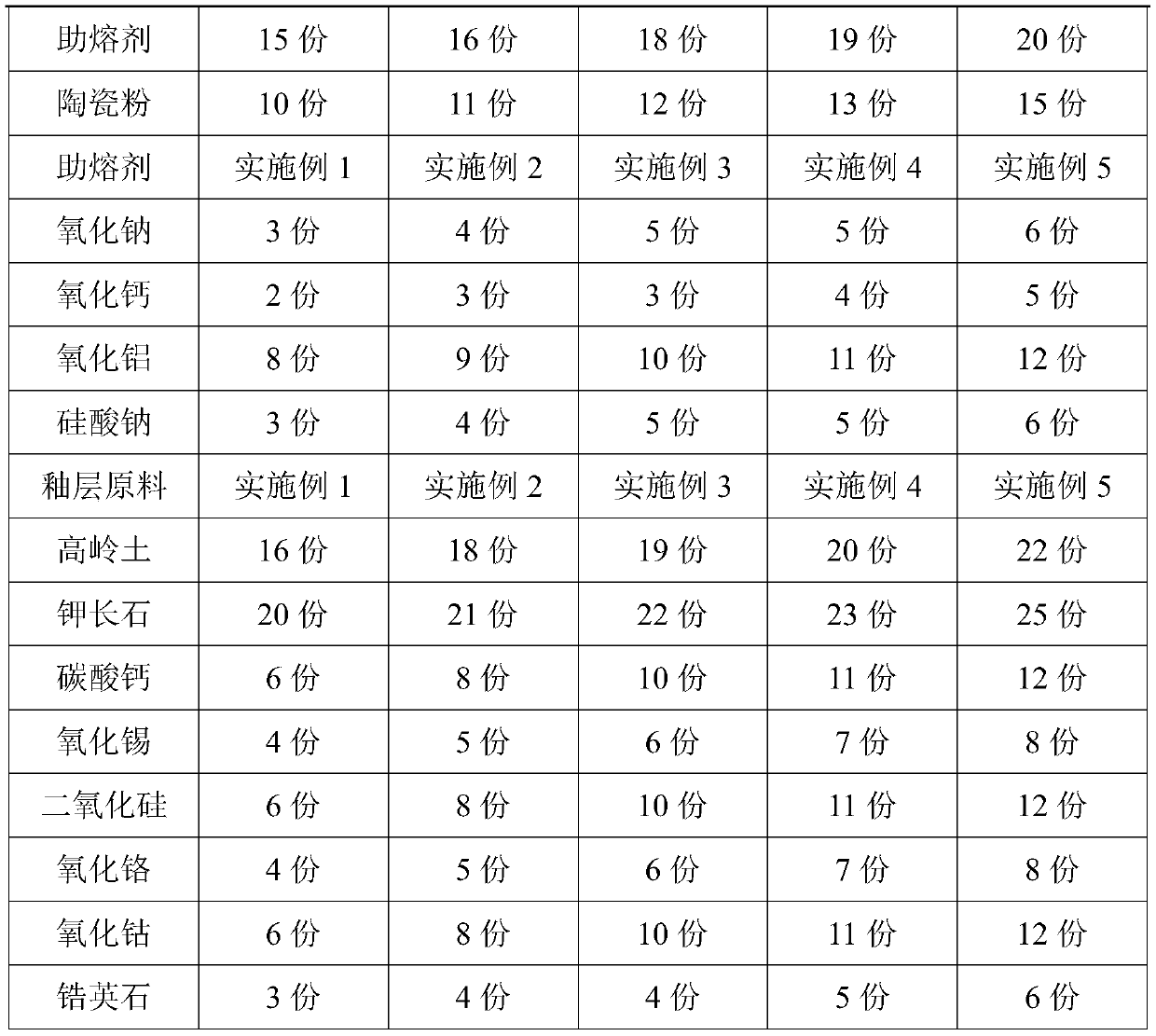

High-strength red glaze daily ceramic and preparation method thereof

The invention relates to high-strength red glaze daily ceramic and a preparation method thereof, and belongs to the technical field of ceramics. The ceramic product comprises a blank body and a glazelayer, wherein the blank body comprises the following components in parts by mass: 30-35 parts by weight of kaolin, 20-25 parts by weight of quartz, 15-20 parts by weight of a fluxing agent and 10-15parts by weight of ceramic micropowder; and the glaze layer comprises the following components in parts by mass: 16-22 parts of kaolin, 20-25 parts of potassium feldspar, 6-12 parts of calcium carbonate, 4-8 parts of tin oxide, 6-12 parts of silicon dioxide, 4-8 parts of chromium oxide, 6-12 parts of cobalt oxide and 3-6 parts of zircon. The preparation method comprises raw material preparation, blank body preparation, glaze water preparation and glazing and firing. The ceramic product prepared by the invention has bright glaze, beautiful agate red or red grape color, soft luster and fine porcelain quality, and also has the characteristics of high strength, firmness, durability, easy cleaning and non-friability.

Owner:福建省德化县合和陶瓷技术开发有限公司

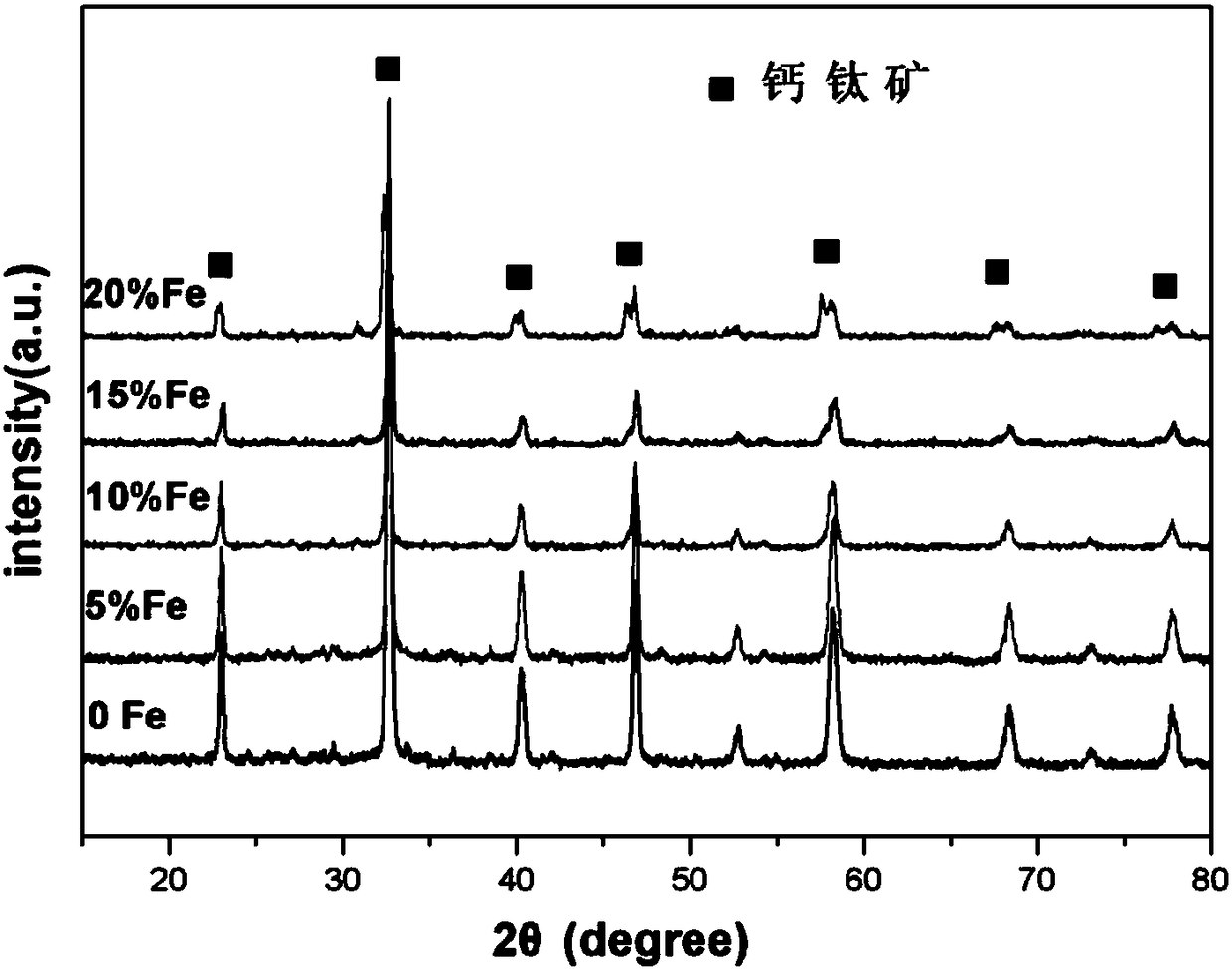

Iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material and preparation thereof

ActiveCN108585854AUniform particle sizeImprove ball milling activityGrain boundary migrationNegative temperature

The invention provides a preparation method of an iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material. The method comprises the following steps: weighing rawmaterials according to a La-Cr-Fe atomic percent of 30-55 to 10-65 to 5-35), and performing wet grinding to obtain slurry; drying the slurry, and grinding to obtain a powder; calcining to obtain a perovskite phase (LaCrFe)2O3 powder; preparing a bulk material from the powder, adopting a two-step sintering method, and performing furnace cooling, so as to obtain the iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material. According to the preparation method disclosed by the invention, the two-step sintering method is adopted, grain boundary diffusion is positioned in an active state while inhibiting grain boundary migration, and the aim of completing sintering on premise of not growing grains is achieved; the finally prepared ceramic material is smallin grain size, uniform in distribution, high in resistance, wide in adjustable range, small in value B change, high in stability and excellent in consistency.

Owner:UNIV OF JINAN

Daily used reinforced ceramic and its preparation process

InactiveCN1330603CRegular shapeReduce production complexityClaywaresHeat stabilityUltimate tensile strength

A strengthened ceramic for daily purpose is proportionally prepared from albite, talc and clay. Its preparing process features sintering twice respectively at 1250-1350 deg. C and at 1100-1200 deg. C. Its advantages are fine quality, high whiteness, and high strength and thermal stability.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of viviparus shell vase

InactiveCN108610012AFine porcelainHigh whitenessCeramic materials productionClaywaresViviparusMaterials science

The invention discloses a preparation method of a viviparus shell vase. The method comprises the following steps of screening, mixing, blank making, drying, glazing, firing and the like. The viviparusshell vase is fine in porcelain, high in whiteness, good in semi-transparency and bright in picture and has dual value of application and art.

Owner:刘春环

Self-luminous glaze and preparation method thereof

The invention discloses a self-luminous glaze and a preparation method thereof. The self-luminous glaze is prepared from the following raw materials in percentage: 10-90% of noctilucent powder, 10-70% of kaolin, 40-45% of chinastone, 15-35% of Zijin clay, 5-25% of feldspar and 5-15% of talc. The self-luminous glaze has the beneficial effects that the prepared celadon takes the high-temperature celeste glaze as a primary color, the noctilucent powder layer is fused to achieve the noctilucent and jade texture effects, and the celadon is good in thermal stability and wide in adaptability. In addition, the preparation method provided by the invention is scientific, reasonable and easy to implement, and the obtained celadon self-luminous glaze product is high in yield and good in porcelain quality.

Owner:刘梁锋

A kind of high-brightness ivory white ceramic product and its manufacturing process

ActiveCN108249887BHigh whitenessHigh densityCeramic materials productionClaywaresBarium nitrateGlaze

The invention relates to the technical field of ceramics, in particular to a high-brightness ivory white ceramic product and a making process thereof. The ceramic product comprises a green body and aglaze layer applied on the surface of the green body; the green body consists of the following components: 25-30 weight parts of kaolin, 12-15 weight parts of quartz, 8-12 weight parts of a fluxing agent and 5-15 weight parts of a ceramic micro-powder; the glaze layer consists of the following components: 18-24 weight parts of kaolin, 20-25 weight parts of albite, 8-16 weight parts of calcium carbonate, 4-10 weight parts of magnesium carbonate, 20-30 weight parts of titanium dioxide, 6-12 weight parts of barium nitrate and 10-18 weight parts of barium carbonate. The making process comprises the following steps: S1, raw material preparation; S2, green body making; S3, glaze water making; S4, glazing and firing. The ceramic product manufactured by the raw materials provided by the inventionand the making process has the characteristics of high glaze brightness, good glossiness and exquisite ceramic quality.

Owner:福建省德化县中国白陶瓷有限责任公司

Congealed fat jelly glaze and preparation method thereof

The invention discloses a congealed fat jelly glaze. The congealed fat jelly glaze is composed of a unitary glaze and a binary glaze, the unitary glaze comprises the following raw materials: 40-45% of chinastone, 10-15% of dolomite, 7-10% of calcite, 10-15% of Xikou black stone, 10-18% of feldspar, 6-8% of agalmatolite, and 0-0.5% of plant ash containing titanium and magnesium; the binary glaze comprises the following raw materials: 35-40% of chinastone, 13-18% of dolomite, 7-10% of calcite, 16-20% of Longquan stone, 6-10% of feldspar, 6-8% of agalmatolite, 5-8% of titanium oxide and 5-10% of zinc oxide. The celadon prepared by the method is fine, smooth, mild and moist in glaze color, good in thermal stability and wide in adaptability, in addition, a preparation method provided by the invention is scientific, reasonable and easy to implement, and the obtained celadon congealed fat jelly glaze product is high in yield and good in porcelain quality.

Owner:谢明东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com