Alumina ceramic material and preparation method thereof

A technology for alumina ceramics and raw materials, applied in the field of preparation of alumina ceramic materials, can solve the problems of high sintering temperature, high energy consumption, high material cost, etc., and achieve the effects of low sintering temperature, less dosage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

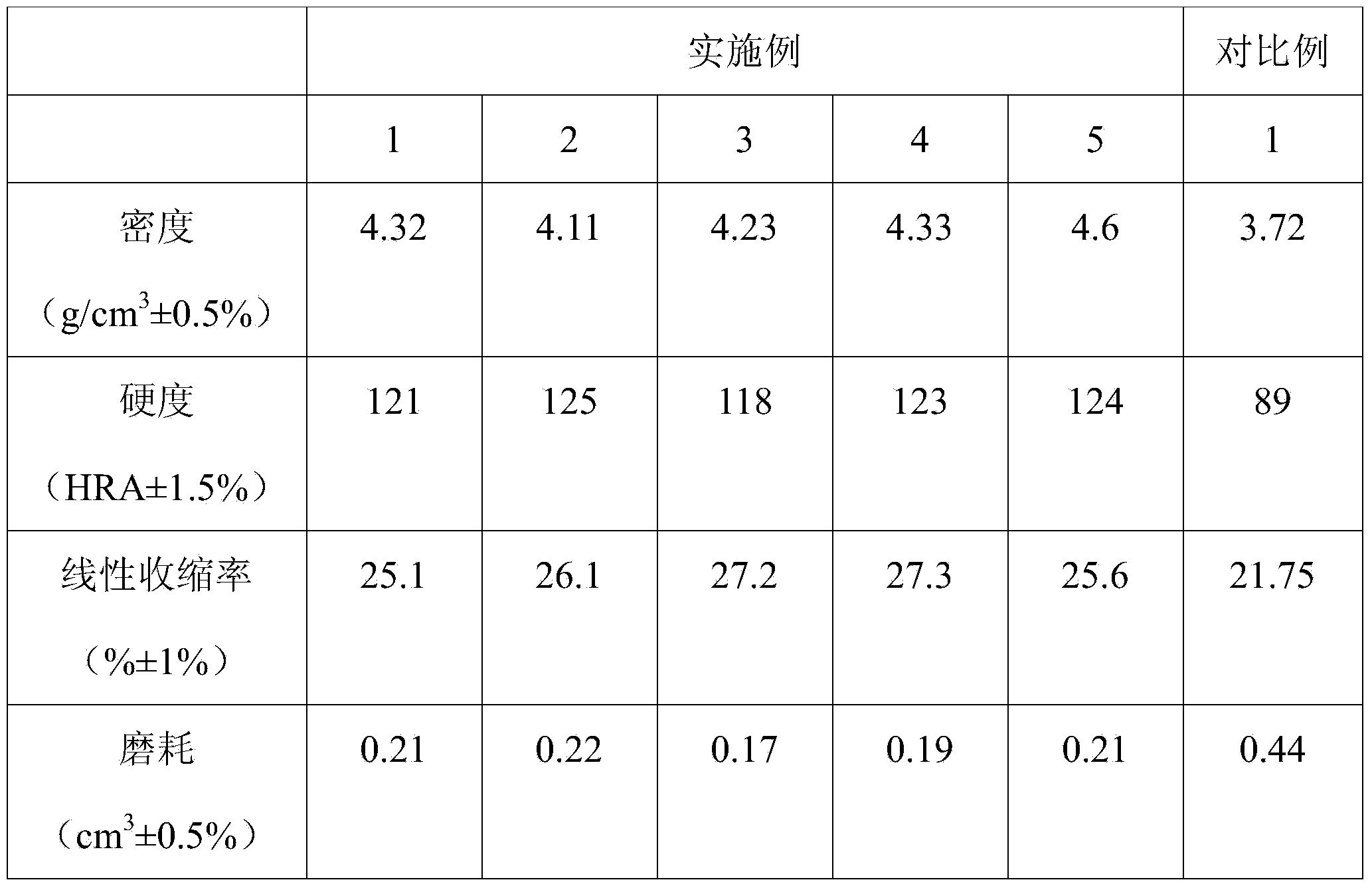

Examples

Embodiment 1

[0061] Pre-desilication reaction: put high-aluminum fly ash in 20% sodium hydroxide solution, the liquid-solid ratio is 3:1, heat up to 100°C, and stir at 450r / min for 5h to react.

[0062] Acid activation reaction: filter the fly ash after the pre-desiliconization reaction, wash it with water, put it in 10% hydrochloric acid solution, the liquid-solid ratio is 3:1, raise the temperature to 95°C, stir at 750r / min for 0.5h to react and then filter ,dry.

[0063] Weigh 9446kg of pretreated fly ash, 157kg of light calcium carbonate, 397kg of magnesium carbonate, and 3kg of ISOBAM-110 respectively, place them in a polyurethane ball mill tank, add 7780kg of deionized water as the dispersion medium, and ball mill for 38 hours; then add 3kg of ISOBAM-104 , ball milled again for 7 hours to obtain the slurry; when the particle size of the slurry reaches D50 of 1.31 μm and D90 of 1.87 μm, it is dried at a temperature of 75°C for 20 hours and ground for 1 hour, and then passed through a ...

Embodiment 2

[0067] Pre-desilication reaction: put high-alumina fly ash in 15% sodium hydroxide solution, the liquid-solid ratio is 0.5:1, heat up to 120°C, and stir at 750r / min for 5h to react.

[0068] Acid activation reaction: filter the fly ash after the pre-desiliconization reaction, wash it with water, put it in 5% hydrochloric acid solution, the liquid-solid ratio is 1:1, raise the temperature to 60°C, stir at 750r / min for 2h to react, then filter, dry.

[0069] Weigh 9745kg of pretreated fly ash, 13kg of light calcium carbonate, 242kg of magnesium carbonate, and 2kg of ISOBAM-110 respectively, place them in a polyurethane ball mill tank, add 8000kg of deionized water as the dispersion medium, and ball mill for 40 hours; then add 2kg of ISOBAM-104 , ball milled again for 8 hours to obtain the slurry; when the particle size of the slurry reached D50 to 1.45 μm and D90 to 2.14 μm, it was dried at 80°C for 24 hours and ground for 2 hours, then passed through a 200-mesh sieve to remove ...

Embodiment 3

[0073] Pre-desilication reaction: put high-alumina fly ash in 17% potassium hydroxide solution, the liquid-solid ratio is 2:1, heat up to 90°C, and stir at 650r / min for 2h to react.

[0074] Acid activation reaction: filter the fly ash after the pre-desiliconization reaction, wash it with water, put it in 20% hydrochloric acid solution, the liquid-solid ratio is 2:1, raise the temperature to 75°C, stir at 650r / min for 2h to react, then filter, dry.

[0075] Weigh 9665kg of pretreated fly ash, 90kg of light calcium carbonate, 324kg of magnesium carbonate, and 1kg of ISOBAM-110 respectively, place them in a polyurethane ball mill tank, add 8180kg of deionized water as the dispersion medium, and ball mill for 42 hours; then add 1kg of ISOBAM-104 , ball milled again for 9 hours to obtain the slurry; when the particle size of the slurry reached D50 to 1.42 μm and D90 to 2.03 μm, it was dried at 85°C for 28 hours and ground for 1.5 hours, then passed through a 200-mesh sieve to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com