Ceramic fire-resistant functional filling material as well as preparation method and purpose thereof

A ceramization and filler technology, applied in chemical instruments and methods, other chemical processes, binder additives, etc., to achieve the effect of increasing the amount of filling, increasing the conversion rate of ceramics, and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

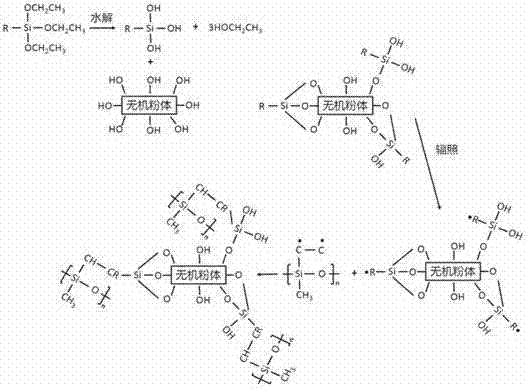

Method used

Image

Examples

Embodiment 1

[0049] The composition of raw materials by weight is:

[0050] Porcelain powder: 85 parts of calcium carbonate, 10 parts of aluminum hydroxide;

[0051] Silane coupling agent: 5 parts of vinyltriethoxysilane;

[0052] Diluent: 10 parts of a solution prepared by ethanol and distilled water in a weight ratio of 8:1;

[0053] pH regulator: 0.01 part of acetic acid;

[0054] Vinyl polysiloxane: 5 parts of vinyl-terminated polydimethylsiloxane (Vi-PDMS);

[0055] Ceramic aid: 5 parts of boric acid;

[0056] A. First dissolve the silane coupling agent in the diluent, adjust the pH value to 3 for hydrolysis with a pH regulator, and obtain a hydrolyzate until the solution is clear and transparent; 10 parts of alumina), ceramizing additives were added into the gravity-free mixer, mixed for 40 minutes, then discharged, dried at 120°C for 2 hours, and the diluent (ethanol and water) was removed to obtain a modified coupling agent Porcelain powder;

[0057] B. Add the coupling agent...

Embodiment 2

[0065] The composition of raw materials by weight is:

[0066] Porcelain powder: 20 parts of calcium carbonate, 5 parts of magnesium oxide, 5 parts of magnesium hydroxide, 20 parts of wollastonite powder, 30 parts of alumina, 10 parts of mica powder, and 10 parts of low-temperature glass powder;

[0067] Silane coupling agent: 3 parts of n-dodecyltriethoxysilane;

[0068] Diluent: 10 parts of a solution prepared by methanol and distilled water in a weight ratio of 10:1;

[0069] pH regulator: 0.03 parts of citric acid;

[0070] Vinyl polysiloxane: 5 parts of vinyl-terminated polymethyl vinyl siloxane (viscosity 300mPa∙s);

[0071] Ceramic additive: 10 parts of low-temperature glass powder;

[0072] A. Dissolve n-dodecyltriethoxysilane in the diluent first, add citric acid to adjust the pH value to 4 for hydrolysis until the solution is clear and transparent to obtain a hydrolyzate; 20 parts of calcium, 5 parts of magnesium oxide, 5 parts of magnesium hydroxide, 20 parts of...

Embodiment 3

[0082] The composition of raw materials by weight is:

[0083] Porcelain powder: 50 parts of mica powder, 10 parts of aluminum hydroxide, 15 parts of wollastonite powder, 5 parts of silicon dioxide, 10 parts of kaolin powder;

[0084] Silane coupling agent: 1 part of vinyltrimethoxysilane;

[0085] Diluent: 20 parts of a solution prepared by methanol and distilled water at a weight ratio of 9:1;

[0086] pH regulator: 0.02 parts of hydrochloric acid with a concentration of 0.01mol / L;

[0087] Vinyl polysiloxane: 6 parts of vinyl-terminated polydimethylsiloxane (Vi-PDMS);

[0088] Ceramic additives: 2 parts of borax, 2 parts of glass fiber powder;

[0089] A. Dissolve vinyltrimethoxysilane in the diluent first, adjust the pH value to 3-4 with hydrochloric acid with a concentration of 0.01mol / L for hydrolysis, until the solution is clear and transparent to obtain a hydrolyzate; then use the hydrolyzate to form porcelain powder Body (50 parts of mica powder, 10 parts of alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com