Ceramic inner wall brick for construction produced by using alkaline land deposition soil and technique for producing the same

A technology for saline-alkali land and construction, which is applied in the field of ceramic interior wall tiles for construction and its production process, and achieves the effects of good thermal stability, low water absorption, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Get 40 kilograms of saline-alkali sedimentary soil, 15 kilograms of wollastonite, 20 kilograms of kaolin, 15 kilograms of diopside, 5 kilograms of Jilin soil, 5 kilograms of talc, 0.4 kilograms of sodium tripolyphosphate and 50 kilograms of water; Ball mill, use high-alumina balls to grind the mixed ingredients to form mud slurry, until the particle size is 250 mesh sieve and 1.5% mud slurry; dry to 5% water content with spray dryer, and granulate at the same time, the average diameter of the particle size is 600 Microns.

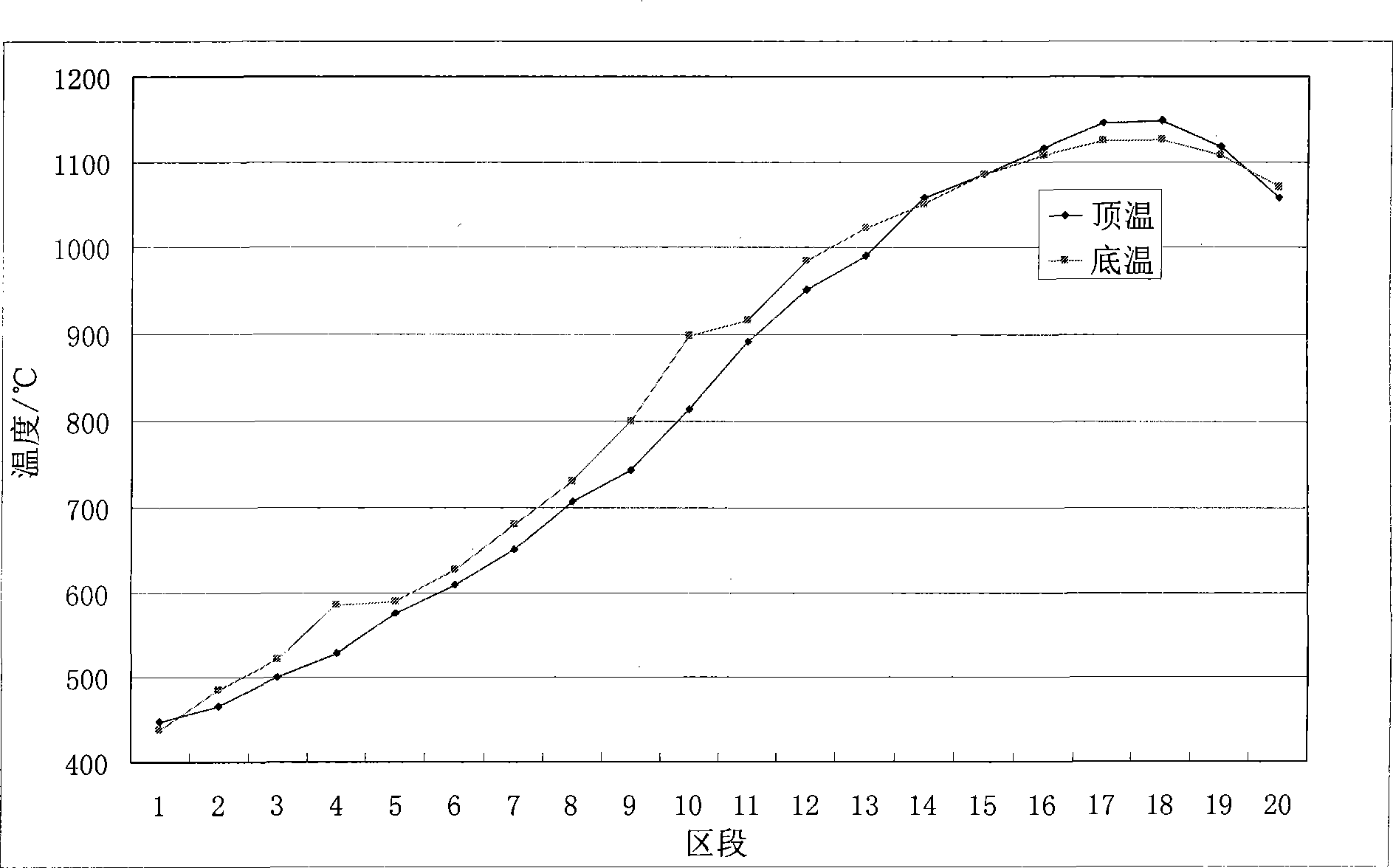

[0049] Press the granulated material to 200 MPa with a molding industrial air press, burn it in a roller kiln according to the above-mentioned firing curve for 40 minutes, and cool it naturally. Tested by Harbin Product Quality Supervision and Inspection Institute of Heilongjiang Province: water absorption rate is 17%, breaking strength is 650, thermal shock resistance does not appear cracks or cracks after 10 tests, and rupture modulus is 16.5. All ...

Embodiment 2

[0051] Get 51 kilograms of saline-alkali deposit soil, 17 kilograms of wollastonite, 26 kilograms of kaolin, 16 kilograms of diopside, 6 kilograms of Jilin soil, 4 kilograms of talc, 0.6 kilogram of sodium tripolyphosphate and 48 kilograms of water; Ball mill, use high alumina balls to grind the mixed ingredients to form mud slurry, until the particle size is 250 mesh sieve and 2% mud slurry; dry to 6% water content with spray dryer, and granulate at the same time, the average diameter of the particle size is 800 Microns.

[0052] Press the granulated material to 240MPa with a molding industrial air press, burn it in a roller kiln according to the above-mentioned firing curve for 38 minutes, and cool it naturally. Tested by Harbin Product Quality Supervision and Inspection Institute of Heilongjiang Province: water absorption rate 17.5%, breaking strength 620, thermal shock resistance after 10 tests without bursting or cracking, modulus of rupture 17.0, all indicators meet the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com