Patents

Literature

401results about How to "Good water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

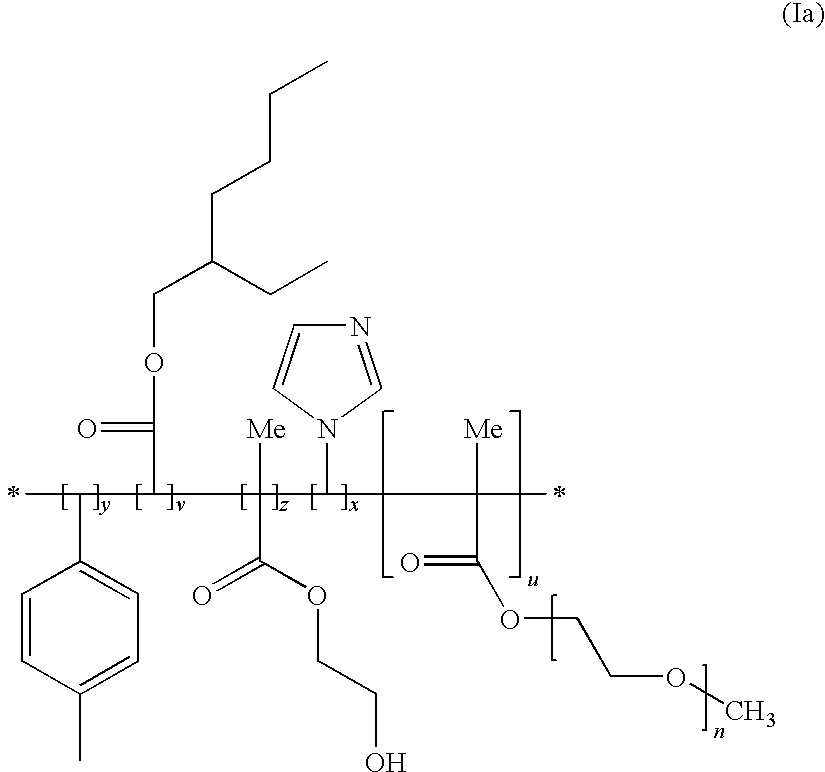

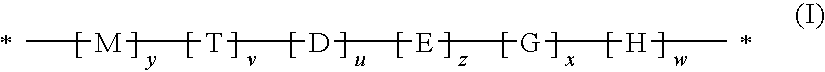

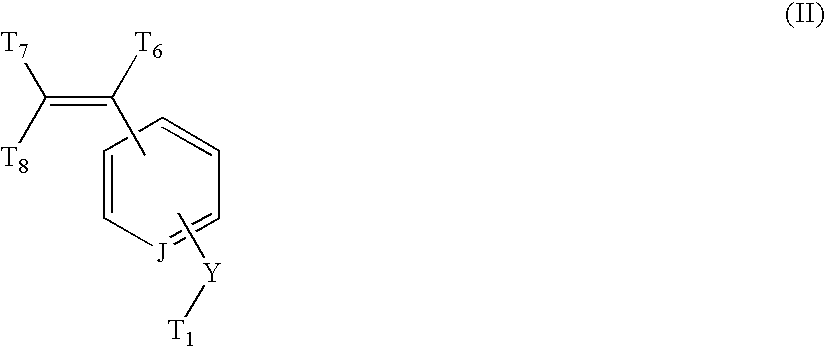

Sunscreen and personal care compositions comprising a random terpolymer

InactiveUS20100129303A1Improve stabilityGood water-resistanceCosmetic preparationsToilet preparationsPersonal careAdditive ingredient

Topically applicable, water-resistant cosmetic or dermatological compositions well suited for the UV-photoprotection of human skin and / or hair comprising an effective UV-photoprotecting amount of: (a) at least one UV screening agent from various classes and particularly effect mixtures thereof; and, (b) at least one random terpolymer; and, optionally, (c) other cosmetically acceptable ingredients. The various classes of UV-protecting compounds or UV sunscreens of special interest are selected from the groups b1 sparingly soluble micronized organic UV absorber, b2 Bis-Ethylhexyloxyphenol Methoxyphenyl Triazine, b3 at least one oil soluble organic UV absorber, b4 at least one inorganic UV absorber and b5 at least one water soluble UV absorber further defined herein.The present invention also relates to personal care compositions comprising at least one random terpolymer and other cosmetically acceptable ingredients.

Owner:BASF AG

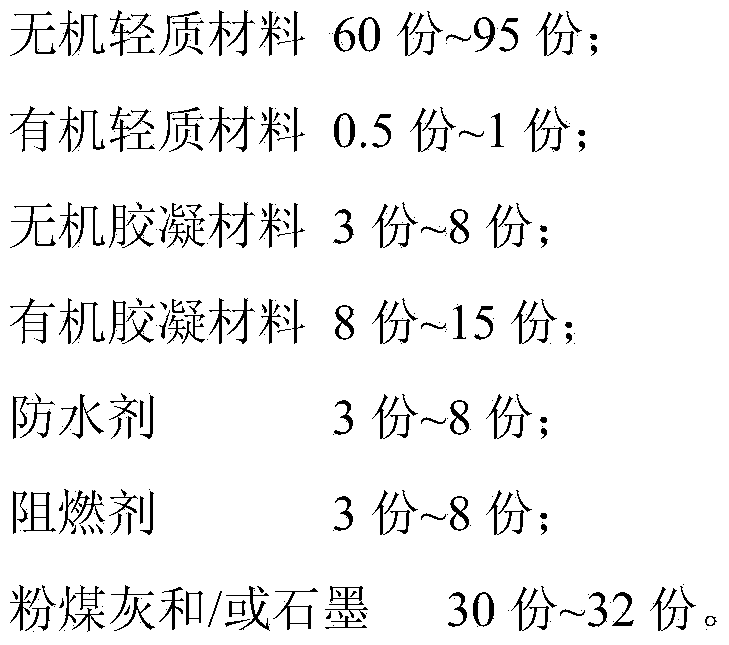

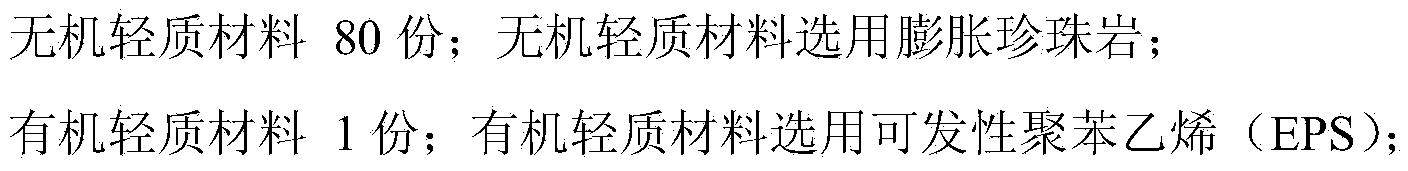

Inorganic modified heat insulation plate and preparation process thereof

The invention discloses an inorganic modified heat insulation plate and a preparation process thereof. The inorganic modified heat insulation plate has the following components in parts by weight: 60-95 parts of inorganic light-weight material, 0.5-1 part of organic light-weight material, 3-8 parts of inorganic cementing material, 8-15 parts of organic cementing material, 3-8 parts of waterproofing agent, 3-8 parts of flame retardant and 30-32 parts of fly ash and / or graphite. The heat insulation plate has the nonflammability under the conditions of fire-protection rating A (A2) GB8624-2012, not only has lower thermal conductivity but also has excellent water resistant strength and good resistance against tension and compression, so that good weatherability is guaranteed.

Owner:常州高能新型建材有限公司

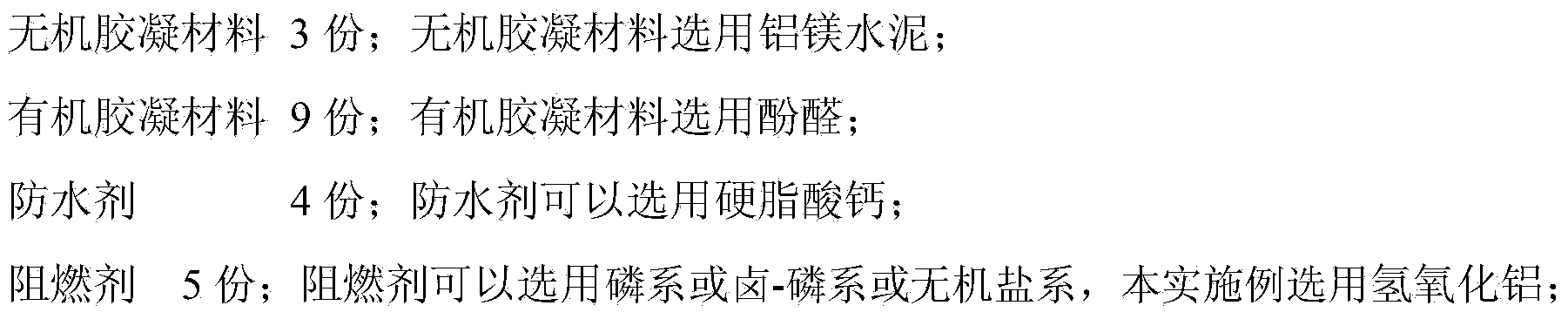

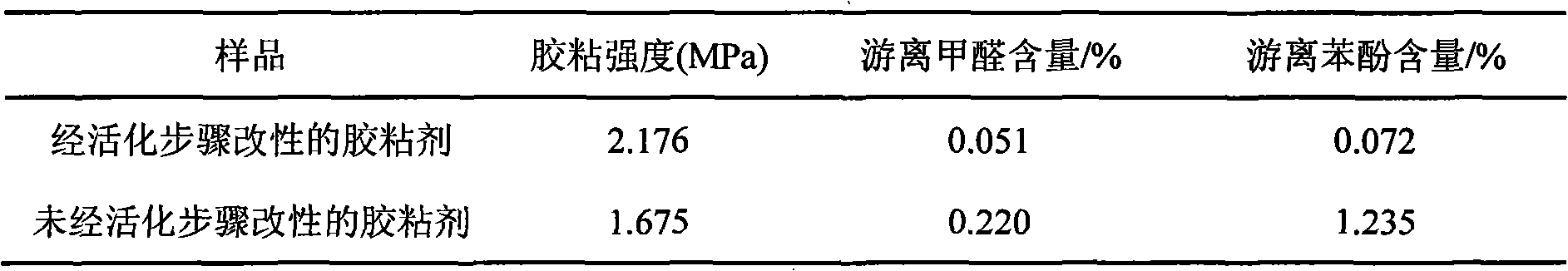

Environment-friendly type alkali lignin modified phenolic resin adhesive and preparation method thereof

InactiveCN101358120AGood water resistanceLess phenolAldehyde/ketone condensation polymer adhesivesProduct propertyPhenols

The present invention relates to an environment-friendly alkali-lignin-modified phenolic resin adhesive and a preparation method thereof. The method includes the following steps: water is added into alkali lignin powder, acid is then added, and under a temperature between 100 DEG C and 120 DEG C, acidolysis lasts for one to three hours; desugarized alkali lignin is obtained; the desugarized alkali lignin powder, sodium hydroxide and water are uniformly mixed, oxidant and 2-naphthol are added for reaction, the temperature is reduced to 45 DEG C to 50 DEG C, formaldehyde and phenol are added so that polycondensation reaction occurs, and the environment-friendly alkali-lignin-modified phenolic resin adhesive is prepared. The method adopts acidolysis desugarization to reduce a great deal of alcoholic hydroxyl content in the alkali lignin and modifies the alkali lignin by alkaline hydrolysis, degradation and nucleophilic addition reaction, thus greatly increasing the chemical reaction activity of the alkali lignin, the amount of toxic phenol required in the technique of preparing modified phenolic resin is little, and the residual phenol and formaldehyde are less, so the environment-friendly alkali-lignin-modified phenolic resin adhesive has the advantages of green production technique and product properties.

Owner:SOUTH CHINA UNIV OF TECH

Process for preparing water soluble epoxy resin grouting agent

The invention relates to a process for preparing water soluble epoxy resin grouting agent which consists of, introducing carboxyl radicals onto the molecular matrix of the epoxy resin, preparing water-based epoxy resin by neutralizing with neutralization agent, introducing double bonds to both ends of the molecular chain, employing water-soluble redox initiation system to produce water non-soluble gel through radical polymerization reaction. The invention can be applied to realize epoxide aquosity.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material and preparation method thereof

ActiveCN104727150AImprove mechanical propertiesGood water resistanceVegetal fibresChemistrySilane coupling

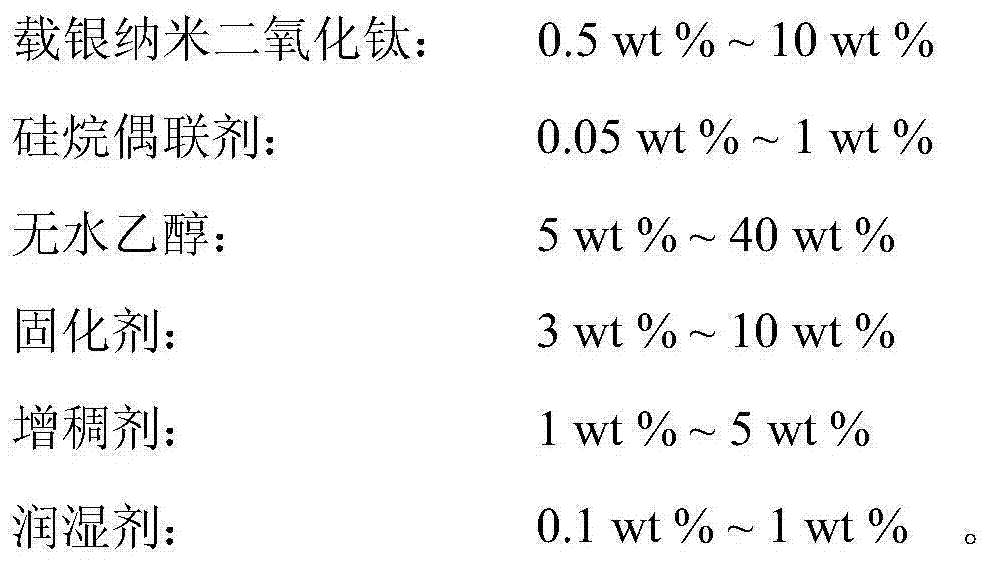

The invention provides a waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material for dry method coating finishing of cotton and terylene textiles and a preparation method of the waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material. The material is obtained by blending waterproof moisture-penetrable waterborne polyurethane resin with silver-loaded nano titanium dioxide accounting for 0.5wt%-10wt% of the resin, a silane coupling agent accounting for 0.05wt%-1wt% of the resin, anhydrous ethanol accounting for 5wt%-40wt% of the resin, a curing agent accounting for 3wt%-10wt% of the resin, a thickening agent accounting for 1wt%-5wt% of the resin and a wetting agent accounting for 0.1wt%-1wt% of the resin. The highly moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material provided by the invention is finished into a textile, and an obtained coated textile is good in waterproof moisture-penetrability and has antibacterial, anti-ultraviolet and other functions at the same time.

Owner:SOUTHEAST UNIV

Preparation method for low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin

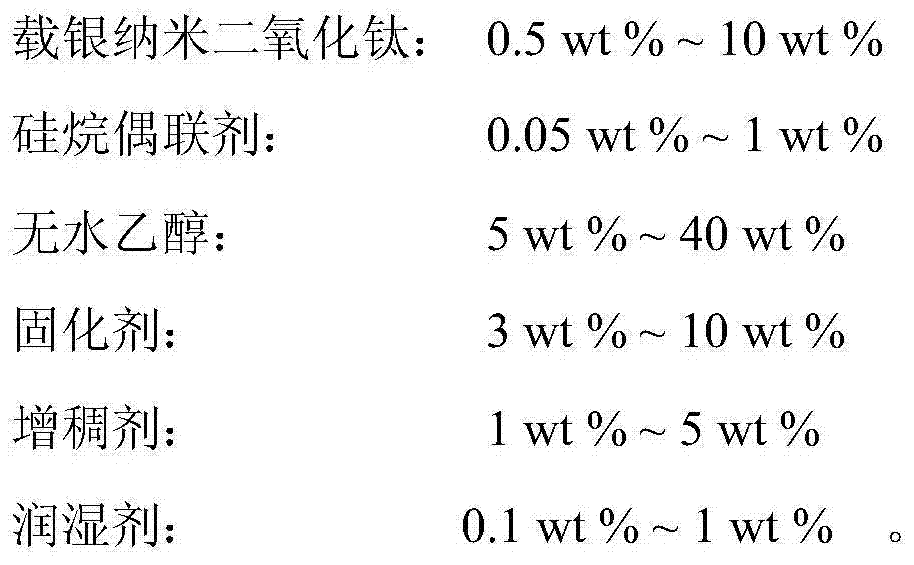

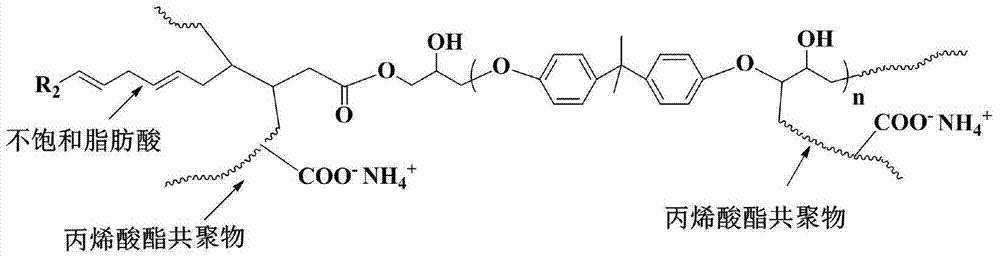

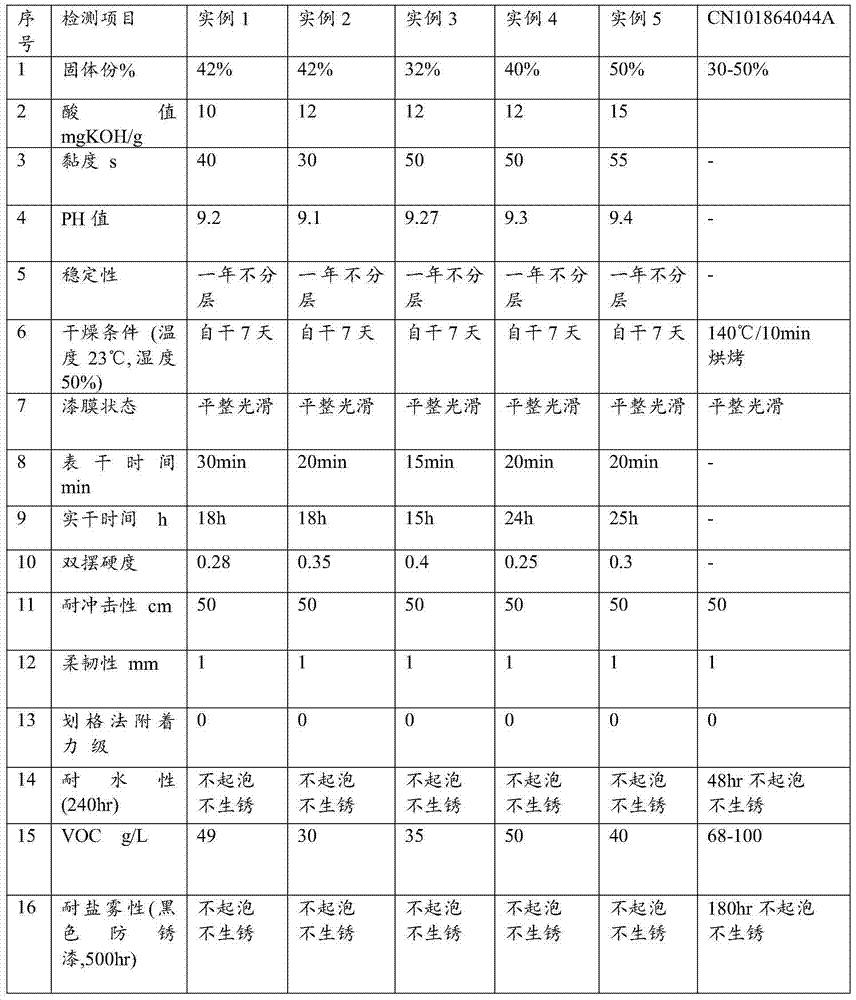

Belonging to the paint field, the invention relates to a preparation method for a low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin. The method includes: firstly modifying epoxy resin with fatty acid, then conducting modification with acrylic acid and acrylate monomer under the action of an initiator, then adding a neutralizer and a drier, adding water to perform emulsification, and reducing pressure to remove the solvent, thus obtaining a low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin emulsion, which has an acid value of 10-15mgKOH / g, a solid content of 30-50%, and a VOC content of less than 7%. Due to a low acid value, the obtained resin has excellent water resistance, and because of the extremely low VOC content, the emission of pollutants is greatly reduced, and the harm to the human is lowered. In addition, due to high unsaturated fatty acid content and epoxy resin content and adding of the drier, the resin itself can have the characteristics of natural drying at room temperature, excellent anti-rust performance and the like.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Solvent-free environment-friendly polyurethane automobile leather foamed layer resin, and preparation method and application thereof

ActiveCN104072715AGood toughnessGood water resistanceSynthetic resin layered productsTextiles and paperPolymer scienceAlcohol

The invention provides a solvent-free environment-friendly polyurethane automobile leather foamed layer resin which is formed by mixing a component A and a component B. The component A is composed of 50.0-85.0% of polyether dibasic alcohol, 10.0-37.5% of polyether tribasic alcohol, 1.5-5.5% of liquid chain extender, 0.5-2.0% of solid chain extender, 0.1-0.8% of deionized water, 0.8-1.2% of catalyst, 0.5-1.0% of light / heat stabilizer, 0.2-1.0% of foam stabilizer and 0.5-1.0% of solvent-free color paste. The component B is composed of 30.0-50.0% of polyether dibasic alcohol, 10.0-30.0% of polyether tribasic alcohol, 35.0-55.0% of aliphatic isocyanate, 0.05-0.1% of catalyst and 0.1-0.2% of H3PO4. The invention also provides a preparation method and application of the resin. The low-temperature bending strength of the resin can reach 0.1 million times at -25 DEG C.

Owner:XUCHUAN CHEM SUZHOU

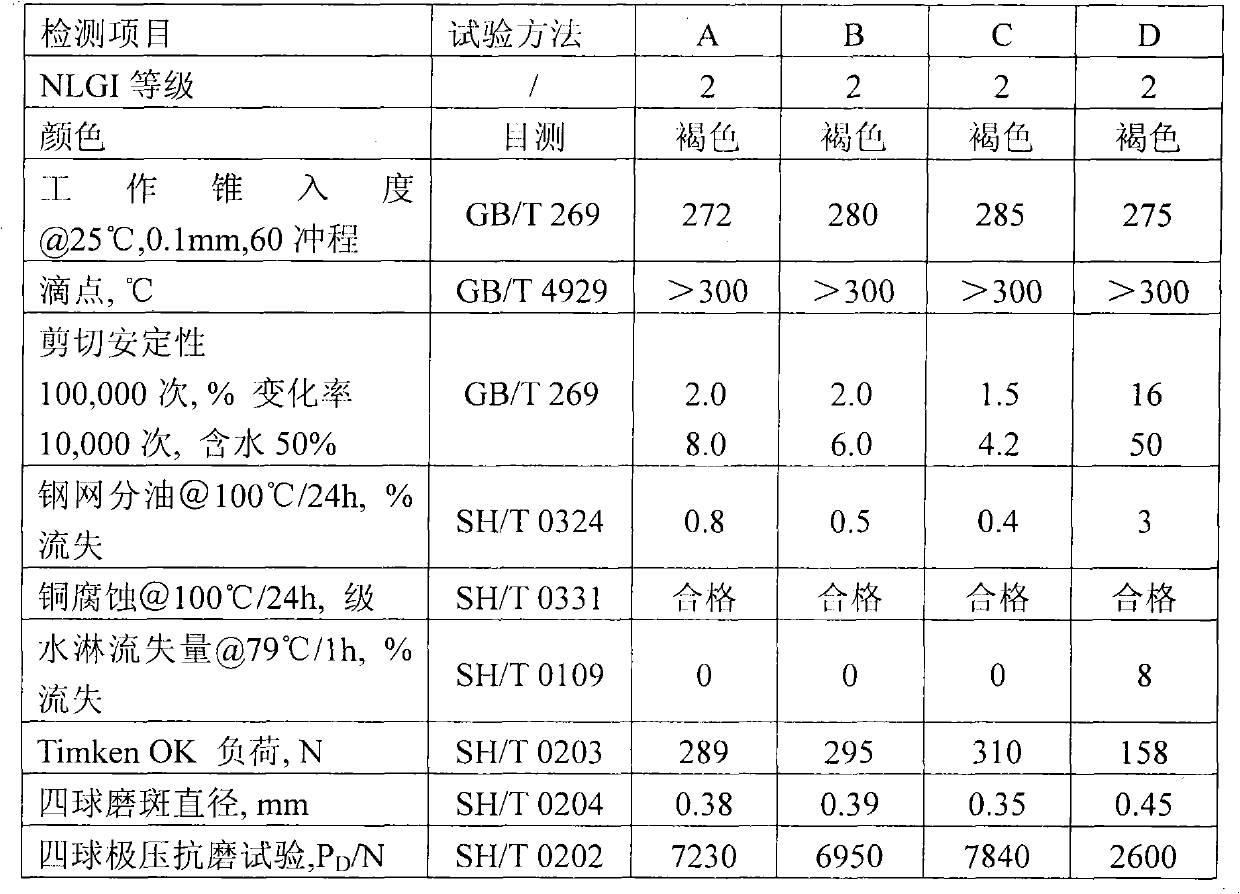

Synthetic high-temperature lubricating grease and preparation method thereof

ActiveCN101921653AGood high temperature performanceSmall oil separationLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to synthetic high-temperature lubricating grease and a preparation method thereof, in particular to lubricating grease generated by taking high-base number compound calcium sulfonate as a thickening agent and high-viscosity synthetic oil as base oil. The synthetic high-temperature lubricating grease comprises the following components in percentage by mass: 30%-80% of the synthetic base oil, 15%-30% of high-base number compound calcium sulfonate, 2%-10% of 12-hydroxyl stearic acid, 1%-5% of boric acid, 1%-4% of acetic acid, 0.5%-2% of water, 1%-3% of calcium hydroxide and0.1%-0.5% of antioxidants. The produced high-temperature lubricating grease has the advantages of excellent high temperature and water spraying resistance, very well extreme pressure abrasion resistance, cutting safety, rust protection, and the like and is very suitable for the production parts of steel mills, cement plants, power plants, and the like, which have high temperature, heavy loads andlarge quantities of cooling water.

Owner:北京奥力助兴石化科技有限公司

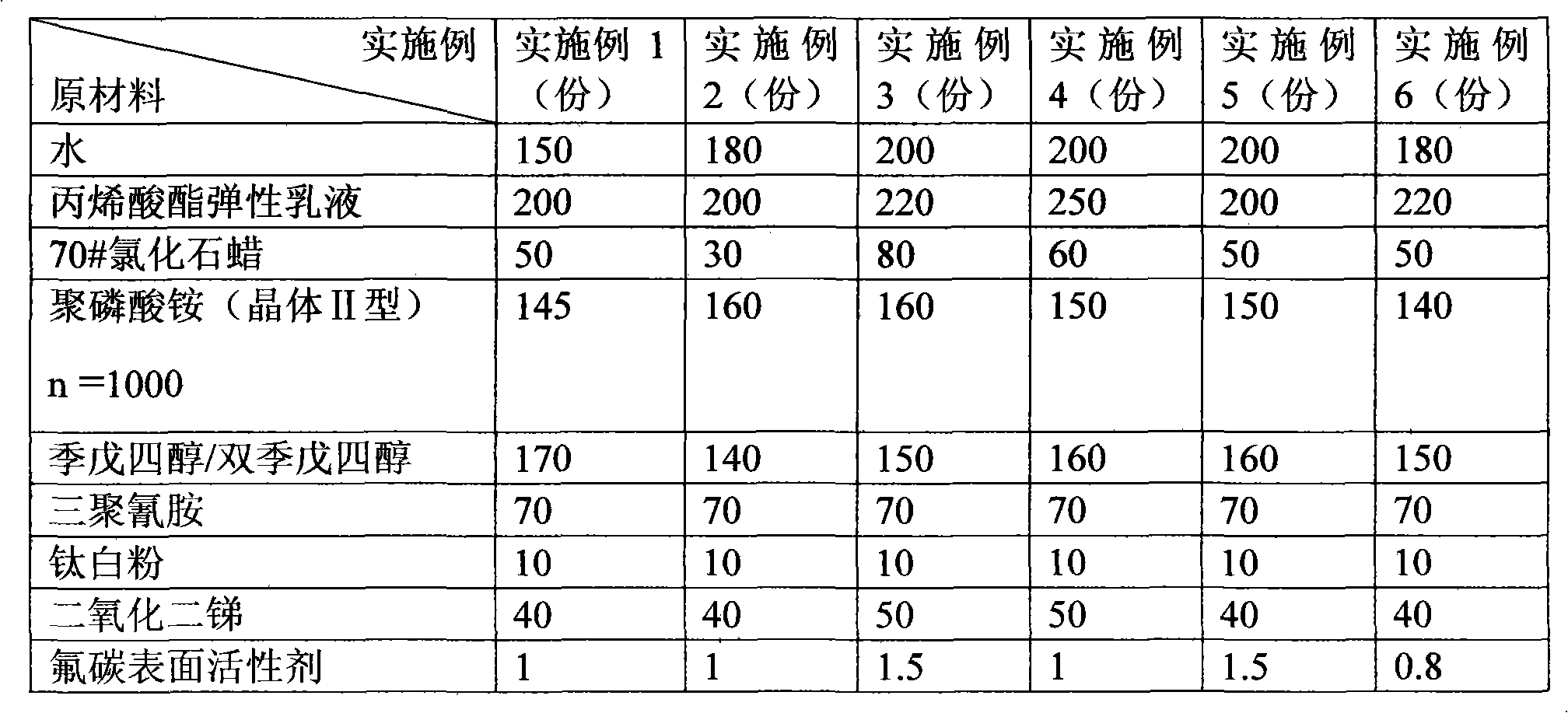

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

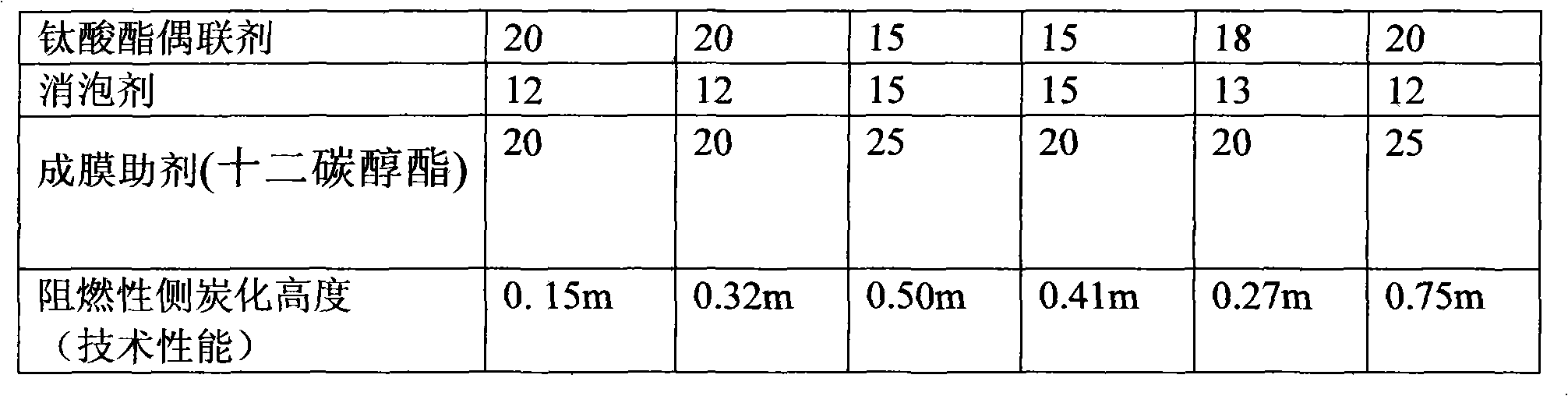

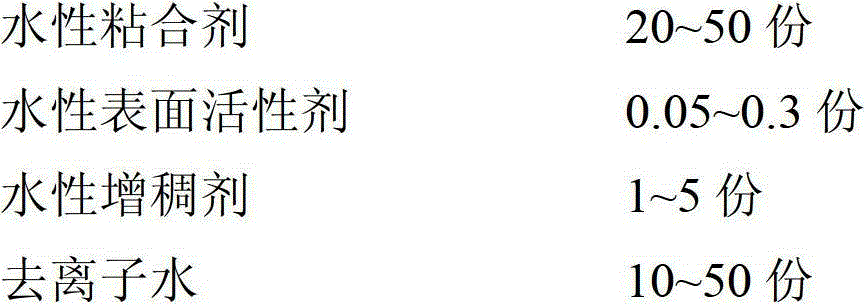

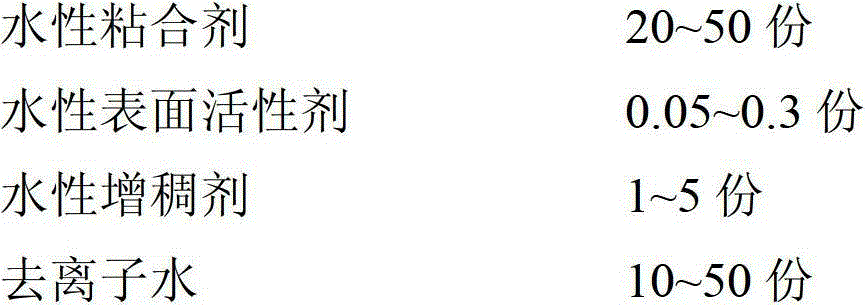

Medical hydrophilic lubrication coating of water system and preparation method thereof

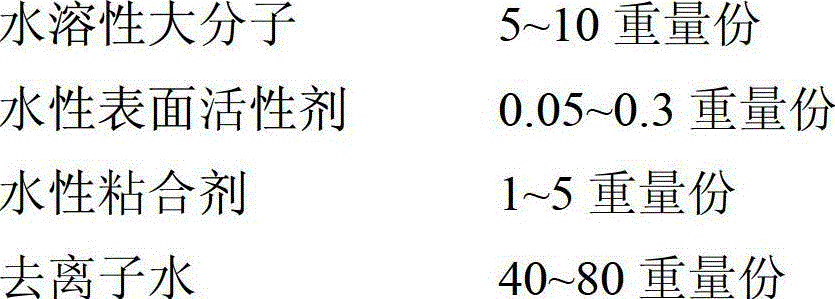

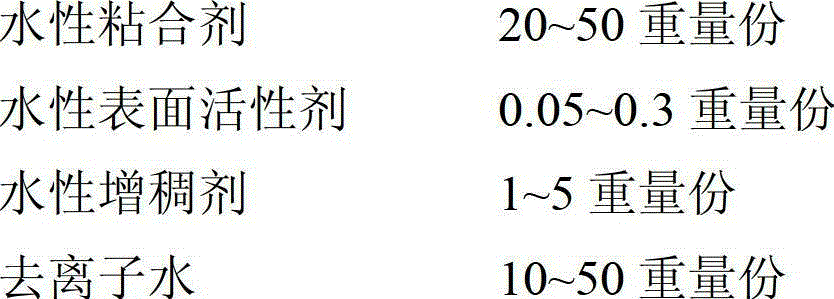

The invention relates to a medical hydrophilic lubrication coating of a water system. The coating is characterized by comprising a bottom coating adhered to the surface of an instrument, and a lubricating coating adhered to the bottom coating, wherein the bottom coating comprises the components as shown in the specification in parts by weight: 20-50 parts of aqueous binder, 0.05-0.3 part of aqueous surfactant, 1-5 parts of aqueous thickener; and 10-50 parts of deion water; and the lubricating coating comprises the components as shown in the specification in parts by weight: 5-10 parts of aqueous macromolecule; 0.05-0.3 part of the aqueous surfactant; 1-5 parts of the aqueous binder and 40-80 parts of the deion water. Compared with the prior art, the medical hydrophilic lubrication coating does not need volatile solvents, and can be used for effectively reducing the surface friction resistance.

Owner:宁波保税区安杰脉德医疗器械有限公司

Recording medium

InactiveUS6945646B2Good water resistanceCrack is causedPattern printingTypewritersBoehmiteCrystallite

A recording medium includes a substrate and an ink-receiving layer provided on the substrate, wherein the ink—receiving layer includes an alumina hydrate having a boehmite structure, an average particle thickness of 2.0 to 6.0 nm and a crystallite size of 5.0 to 8.0 nm in a direction of a (020) plane, and the recording medium has a degree of parallelization of 30 to 1,000.

Owner:CANON KK

Sodium aluminate soap grease for ship

InactiveCN102021068AGood water resistanceReduce mechanical noiseLubricant compositionPropellerChemistry

The invention relates to a mechanical lubricating grease, in particular to a sodium aluminate soap grease for a ship. The sodium aluminate soap grease comprises the following components in parts by weight: 4-12 parts of stearic acid, 3-9 parts of hardened oil, 5-15 parts of oleic acid, 3-15 parts of white alum, 1-5 parts of NaOH, 1-5 parts of 50# machine oil and 80-90 parts of 60# cylinder mixed oil. The sodium aluminate soap grease for the ship is suitable for a ship propeller, a floating crane and a dredge boat, the dropping point is above 75 DEG C, the sodium aluminate soap grease has good water resistance, protective property and anti-corrosive performance, the sodium aluminate soap grease not only has the function of proper lubrication, but also has the anti-corrosion performance, and has the function of reducing the mechanical noise.

Owner:俞磊

Polyuria-acrylate emulsion and aqueous gravure ink prepared from same

The invention discloses a preparation method of a polyuria-acrylate emulsion and application thereof. The polyuria-acrylate emulsion is prepared by employing a seed emulsion polymerization method and organically combining polyurea and acrylate ester, has the advantages of excellent flexibility and wear resistance of polyurea and good water resistance and high mechanical strength of acrylate ester and overcomes the disadvantages of the two components; and aqueous gravure ink prepared from the emulsion is substantially improved in performances. The prepared aqueous gravure ink is nontoxic, odorless, strong in adhesive force to PP base material, good in flexibility and excellent in heat resistance and water resistance, and is applicable to furniture production, interior decoration and the like, such as printing of surfaces of decorative plates, grainy paper and plastic cement.

Owner:汕头市东和机械有限公司 +1

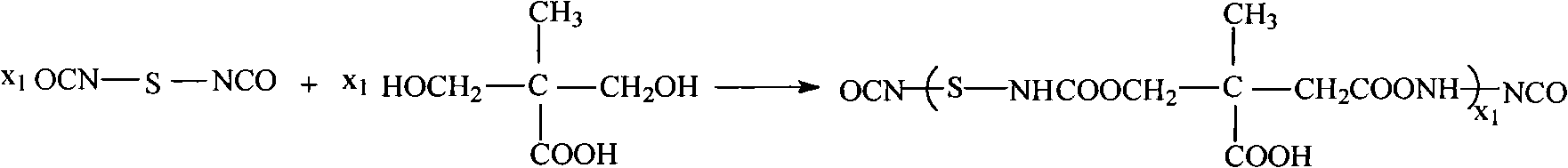

Room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and preparation method thereof

InactiveCN101792592AGood water resistanceAnti-pollution mechanical propertiesPolyurea/polyurethane coatingsPrepolymerChemistry

The invention discloses a room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and a preparation method thereof. The preparation method comprises following steps: vacuum-dehydrating polyether glycol containing fluorine, and reacting with polyisocyanate to obtain FPU prepolymer containing -NCO end groups; chain-extending with dimethylolpropionic acid to obtain FPU prepolymer containing carboxyl groups; neutralizing with triethylamine to obtain hydrophilic FPU prepolymer, adding water, stirring, and dispersing at high speed to obtain an emulsion; adding a water solution containing a chain extender ADH to obtain chain-extended FPU; orderly adding diacetone acrylamide and vinyl monomer, and initiating by stirring to obtain the PUA copolymerized emulsion; and finally, uniformly mixing the chain-extended FPU with the PUA copolymerized emulsion, coating the mixture on a teflon plate, and drying and crosslinking at room temperature to form the film. The invention can be widely used for surface protection for plastics, rubber, leather, fabrics, ceramics, glass, high-rise building external walls, solar batteries and other materials and devices.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

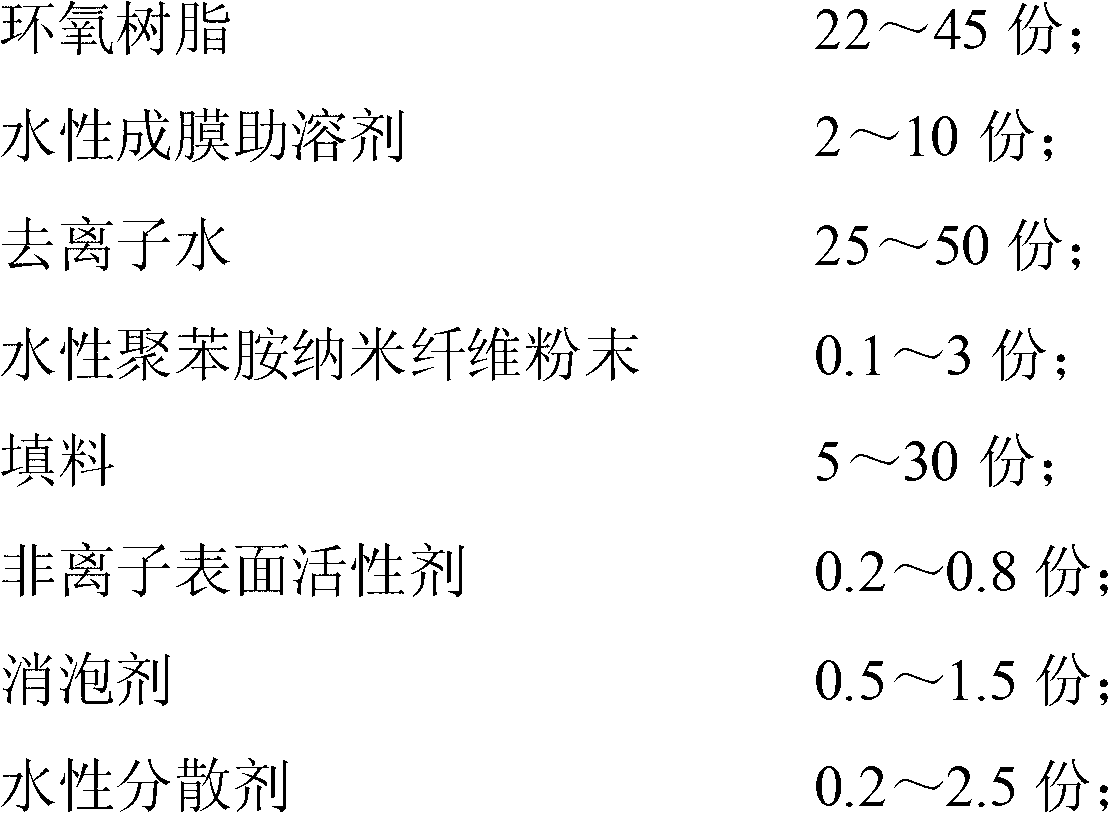

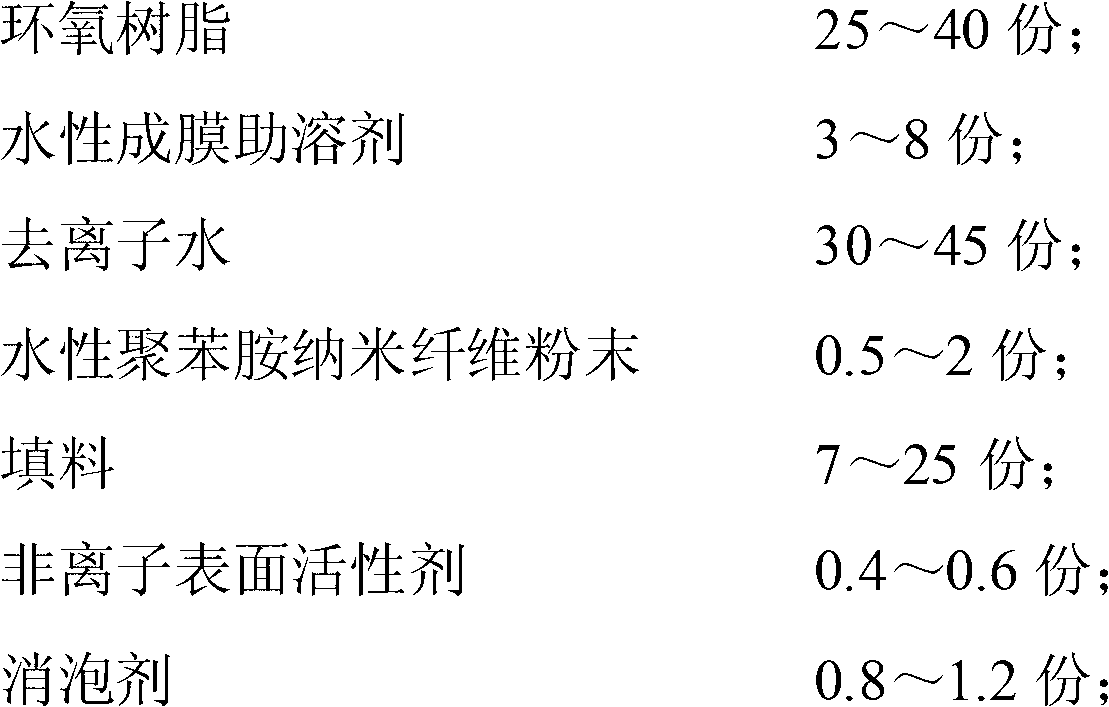

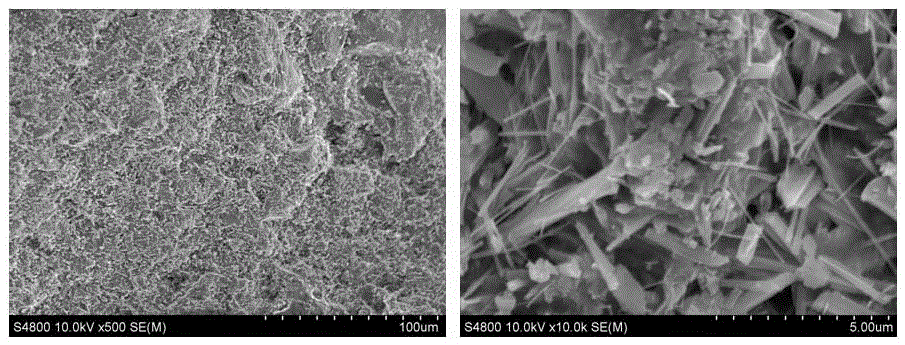

Aqueous polyaniline anti-corrosive paint and preparation method thereof

ActiveCN102702920AGood anti-corrosion effectGood water resistanceAnti-corrosive paintsEpoxy resin coatingsSolventIon

The invention provides an aqueous polyaniline anti-corrosive paint and a preparation method thereof, belongs to the technical field of paint, and is used for solving the problem that the traditional polyaniline anti-corrosive paint causes pollution to the environment and harms the human body. The paint comprises a component A and a component B, wherein the component A comprises 22-45 parts by weight of epoxy resin, 2-10 parts by weight of aqueous film-forming cosolvent, 25-50 parts by weight of deionized water, 0.1-3 parts by weight of aqueous polyaniline nano fiber powder, 5-30 parts by weight of filler, 0.2-0.8 part by weight of non-ionic surfactant, 0.5-1.5 parts by weight of defoaming agent, 0.2-2.5 parts by weight of aqueous dispersant; and the component B comprises 35-65 parts by weight of aqueous curing agent, 28-62 parts by weight of deionized water and 0.2-5 parts by weight of leveling agent. The aqueous polyaniline anti-corrosive paint is a green and environment-friendly type anti-corrosive paint and has an excellent anti-corrosive property.

Owner:HUNAN BENAN YADA NEW MATERIALS

Method for preparing porous adsorption material by using microwave low-temperature pore-forming activated granular red mud

InactiveCN102908983AGood water resistanceWon't breakOther chemical processesAlkali metal oxides/hydroxidesPorosityMicrowave

The invention provides a method for preparing a porous adsorption material by using microwave low-temperature pore-forming activated granular red mud. The method comprises the following steps: taking a bonding agent which is 2-10 percent of mass of the red mud, uniformly mixing red mud wastes and the bonding agent, kneading into grains by using a granulator or by a hand and activating the red mud grains for 5-30 minutes at an activation temperature of 80-500 DEG C by utilizing microwaves to obtain the porous adsorption material. The red mud is activated by utilizing the selective heating and resonant sintering effects of the microwaves on iron and other matters in the red mud. The porous adsorption material prepared by the method has a pore volume of more than 0.0826 ml / g and a specific surface area of 18.62-24.25 m2 / g, and the grain size can be different as required. The produced porous adsorption material has the characteristics of fine grain, high porosity, large surface area, strong hydroscopicity, good temperature-resistant stability and low cost and has the great advantage in aspect of wastewater adsorption and treatment.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing building material from metallurgy slag

The invention relates to a method for preparing building material from metallurgy slag. The method comprises the following steps; preparing a dry blend from the metallurgy slag, gypsum or industrial byproduct gypsum, a calcium gel material and aggregates, adding water or excitant-dissolved water to prepare a wet blend, allowing the wet blend to stand, carrying out static pressure molding, and carrying out natural or steam curing to prepare the ultrahigh strength material. The method solves the problems of low activity and difficult utilization of low-grade metallurgy slag, the metallurgy slag is coupled with a large amount of gypsum or the industrial byproduct gypsum to prepare the ultrahigh strength building material with the compressive strength of 60-200 MPa. The ultrahigh strength material undergoes variation molding die methods to produce high-strength building bricks, high-strength road bricks, high-strength permeable bricks, curb stones, various decoration plates and other various high-strength and high-durability products.

Owner:韩涛

Low-wear environment-friendly shield tail sealing grease and preparation method thereof

The invention discloses low-wear environment-friendly shield tail sealing grease and a preparation method thereof. The shield tail sealing grease is mainly prepared from 10-15% of base oil, 15-35% of powder filler, 7-15% of thickener, 3-10% of tackifier, 1-5% of second dispersant, 10-30% of water-resistant sealing material, 2-8% of anti-static material, 0.2-2% of preservative and 1-5% of toner. The prepared shield tail sealing grease is applied to shield tail sealing of shield machines in tunnel engineering. The shield tail sealing grease has the advantages of low wear, excellent pumping performance, good compression resistance sealing performance, strong adhesion, good lubricity, oxidation resistance, environmental friendliness, simple preparation technology and the like.

Owner:苏州瀚固新材料科技有限公司

Compound calcium sulfonate base lubricating grease and preparation method thereof

The invention discloses compound calcium sulfonate base lubricating grease and a preparation method thereof. The key points of the technical scheme of the invention lie in that the compound calcium sulfonate base lubricating grease is prepared by adding calcium sulfonate in an inorganic substance and an organic substance compound calcium soap and thickening base oil, and an arylamine antioxidant is added in a thickening procedure. The high-performance compound calcium sulfonate base lubricating grease is prepared and acquired in a certain raw material ratio and operation condition. By using the compound calcium sulfonate base lubricating grease and the preparation method, the cost of a user is reduced; a product has favorable water resistance, lubricating property and high temperature resistance, cannot be emulsified and degreased, and is not easy to run off; the service life of mechanical equipment is prolonged; the maintenance time of the equipment is decreased; the production efficiency of the equipment is improved; a raw material formula is reasonable; the cost is low; the emission of three wastes does not exist in a production procedure; the compound calcium sulfonate base lubricating grease and the preparation method are environment-friendly while an industrial requirement is met; and the preparation method is a green production process.

Owner:XINXIANG HENGXING TECH CO LTD

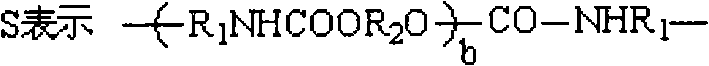

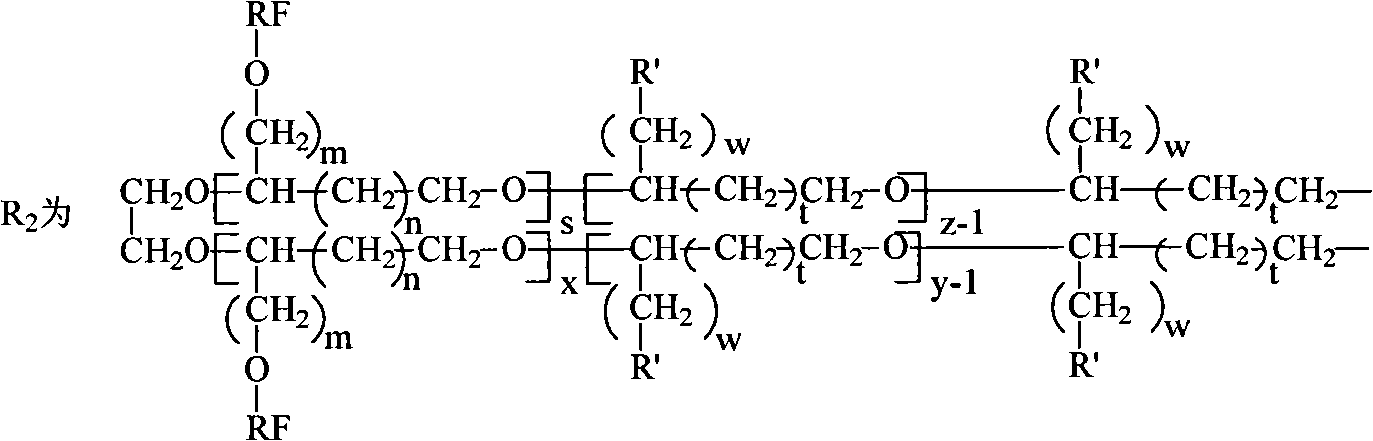

Combination of modified polyurethane and aqueous polyurethane adhesive

ActiveCN101948564AGood water resistanceHigh bonding strengthPolyureas/polyurethane adhesivesIsophoroneSolvent

The invention provides a compound with a structure shown as formula (I), wherein R1 is an isophorone group, hexyl, methyl cyclohexyl, dicyclohexyl methyl or methylphenyl, R2 is polyester group, R3 is a tertiary amine group, and m is the polymerization degree and is no less than 0 and no more than 12. The invention also provides an aqueous polyurethane adhesive combination, comprising the following compositions in parts by weight: 43-78 parts of modified polyurethane with a structure shown as the formula (I), 0.8-2 parts of waterborne wetting agent, 1-3 parts of waterborne flow agent, 1.3-3.5 parts of waterborne defoaming agent, 13-21 parts of waterborne cosolvent and 20-47 parts of crosslinking agent. The aqueous polyurethane adhesive combination has the advantages of good water resistance, strong bond strength, strong initial adhesive strength and strong peel strength and can be used as an adhesive for an interior decorating piece of a vehicle.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

One-component deoximation type room-temperature vulcanized silicone rubber sealant and preparation method thereof

InactiveCN104610907AImprove bonding performanceGood water resistanceNon-macromolecular adhesive additivesMethyl siliconeAluminium alloy

The invention discloses a one-component deoximation type room-temperature vulcanized silicone rubber sealant and a preparation method thereof. The sealant is prepared through the following steps: mixing alpha,omega-dyhydroxylpolydimethylsiloxane and a silane coupling agent at a high temperature, terminating alpha,omega-dyhydroxylpolydimethylsiloxane with the silane coupling agent, and then adding dimethyl silicone oil, a de-ketoxime type cross-linking agent, a filling material and a catalyst. Compared with a traditional deoximation type sealant, the sealant has excellent adhesive properties for stainless steel, aluminium alloy, magnesium alloy, PPO, PC, PVC, PMMA, ABS, PET and the like, and can be used for adhesion and sealing in the industries of electronics, automobiles, household appliances, photovoltaic modules and the like. Besides, the sealant has excellent water resistance and especially has a high strength retention rate under high-temperature and high-humidity conditions.

Owner:TONSAN ADHESIVES INC

Flame retardant waterborne polyurethane and preparation method thereof

The invention discloses flame retardant waterborne polyurethane which is prepared from the following raw materials: toluene diisocyanate, 2, 2-dimethylolpropionic acid, polyether diol, a catalyst, triethylamine, a silane coupling agent, deionized water, a defoamer and a dispersed nano-silicon sol. According to the flame retardant waterborne polyurethane disclosed by the invention, a polyurethane emulsion is modified by using the silane coupling agent, so that polyurethane has excellent waterproofness, polyurethane, mechanical property and the like, and moreover, the dispersed nano-silicon sol is introduced by using an ultrasonic dispersion method to prepare the flame retardant waterborne polyurethane. As SiO2 has reinforcing and flame-retarding effects, a SiO2 covering matter is formed when the polyurethane is combusted so as to have dual functions of shielding and insulating heat, alleviating burning rate and inhibiting combustion reaction, so that the flame retardant effect is improved, and moreover, the preparation method is good in operability and has a good application prospect.

Owner:济南永昌利化工有限公司

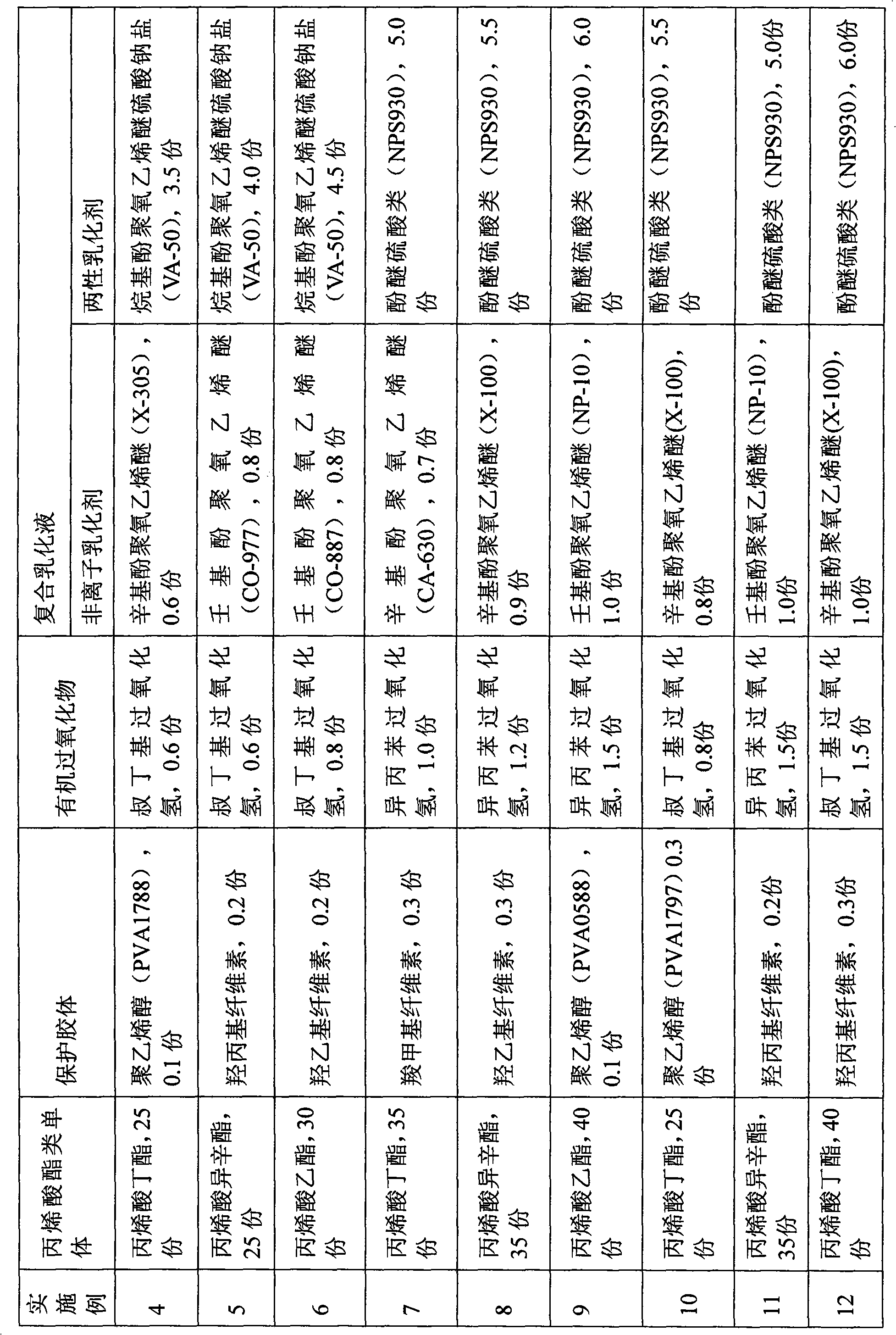

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood water resistanceStrong adhesionMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsSurface energyWaterproofing

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

UV cured strippable water-based coating and preparing method thereof

InactiveCN105219252AHigh gloss water resistanceGood water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPhotoinitiatorAntifoam agent

The invention relates to a UV cured strippable water-based coating. The UV cured strippable water-based coating is prepared from, by weight, 60-70 parts of UV cured water-based polyurethane resin, 0.05-0.1 part of flatting agent, 1-10 parts of wetting agents, 1-3 parts of thickening agents, 0.2-1 part of antifoaming agent, 2-5 parts of film coalescing agents, 3-6 parts of photoinitiator, 3-8 parts of rust-proof resist, 0.10-0.30 part of mould-proof antibacterial agent, 10-20 parts of functional filler and 10-20 parts of water-based stripping agents. The invention further provides a preparing method of the coating. The preparing method includes the steps that a part of the wetting agents, the antifoaming agent, the rust-proof resist and deionized water are added into a high-speed dispersion machine and dispersed through stirring, the functional filler is added and dispersed through stirring, and the UV cured water-based polyurethane resin, the remaining antifoaming agent, the remaining wetting agents, the flatting agent, the film coalescing agents, the water-based stripping agents, the photoinitiator and the mould-proof antibacterial agents are added and uniformly stirred, continue to be dispersed and are filtered after being mixed to obtain the UV cured strippable water-based coating.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Preparation method of vinyl acetate-acrylate copolymerization emulsion

The invention discloses a preparation method of vinyl acetate-acrylate copolymerization emulsion, comprising the steps of adding 55-65 parts of water by weight, 0.01-4 parts of surfactant by weight, 0.5-2 parts of pH stabilizer by weight and 0.1-1 part of alkyl alcohol by weight into a reaction kettle with an agitator, a thermometer, a nitrogen tube and a reflux condenser, adding part of mixed monomers of mixed chain transfer agents, adequately emulsifying, raising temperature to a reaction temperature, adding part of initiators, reacting for 0.5 hour, and obtaining the seed emulsion when the emulsion has blue lights; dripping the rest mixed monomers into the reaction kettle with the seed emulsion, finishing dripping within 3 hours, synchronously supplementing the rest initiators, after finishing feeding, keeping the reaction temperature, reacting for 3 hours, raising temperature to 85 DEG C, continuously reacting for 0.5 hour so as to reduce the content of residual monomers, and then adding a neutralizing agent, adjusting the pH value of the emulsion to be neutral, cooling down and discharging material, and filtering to obtain the nanometer-sized emulsion. The obtained emulsion has a particle diameter smaller than 100nm and has excellent storage stability and other comprehensive performances.

Owner:SICHUAN UNIV

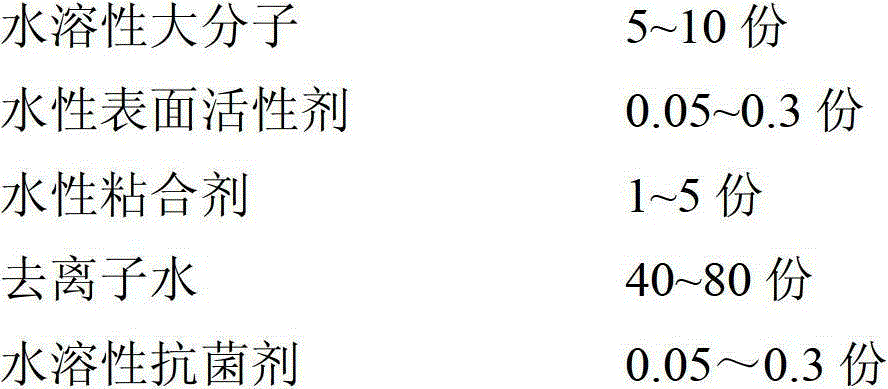

Antimicrobial coat on surface of water system, and its preparation method

ActiveCN103143067ASimple preparation stepsGood water resistanceCatheterCoatingsAntimicrobial effectAdhesive

The invention relates to an antimicrobial coat on the surface of a water system, and its preparation method. The antimicrobial coat is characterized in that the antimicrobial coat comprises a primer coat attached to the surface of a medical apparatus matrix, and a surface coat attached to the primer coat, wherein the primer coat is composed of 20-50 parts by weight of an aqueous adhesive, 0.05-0.3 parts by weight of an aqueous surfactant, 1-5 parts by weight of an aqueous thickening agent, and 10-50 parts by weight of deionized water; and the surface coat is composed of 5-10 parts by weight of an aqueous macromolecule, 0.05-0.3 parts by weight of the aqueous surfactant, 1-5 parts by weight of the aqueous adhesive, 40-80 parts by weight of deionized water, and 0.05-0.3 parts by weight of an aqueous antimicrobial agent. Compared with coats in the prior art, the antimicrobial coat provided by the invention has the advantages of environmental protection, effective reduction of the surface friction resistance, and good antimicrobial effect.

Owner:宁波保税区安杰脉德医疗器械有限公司

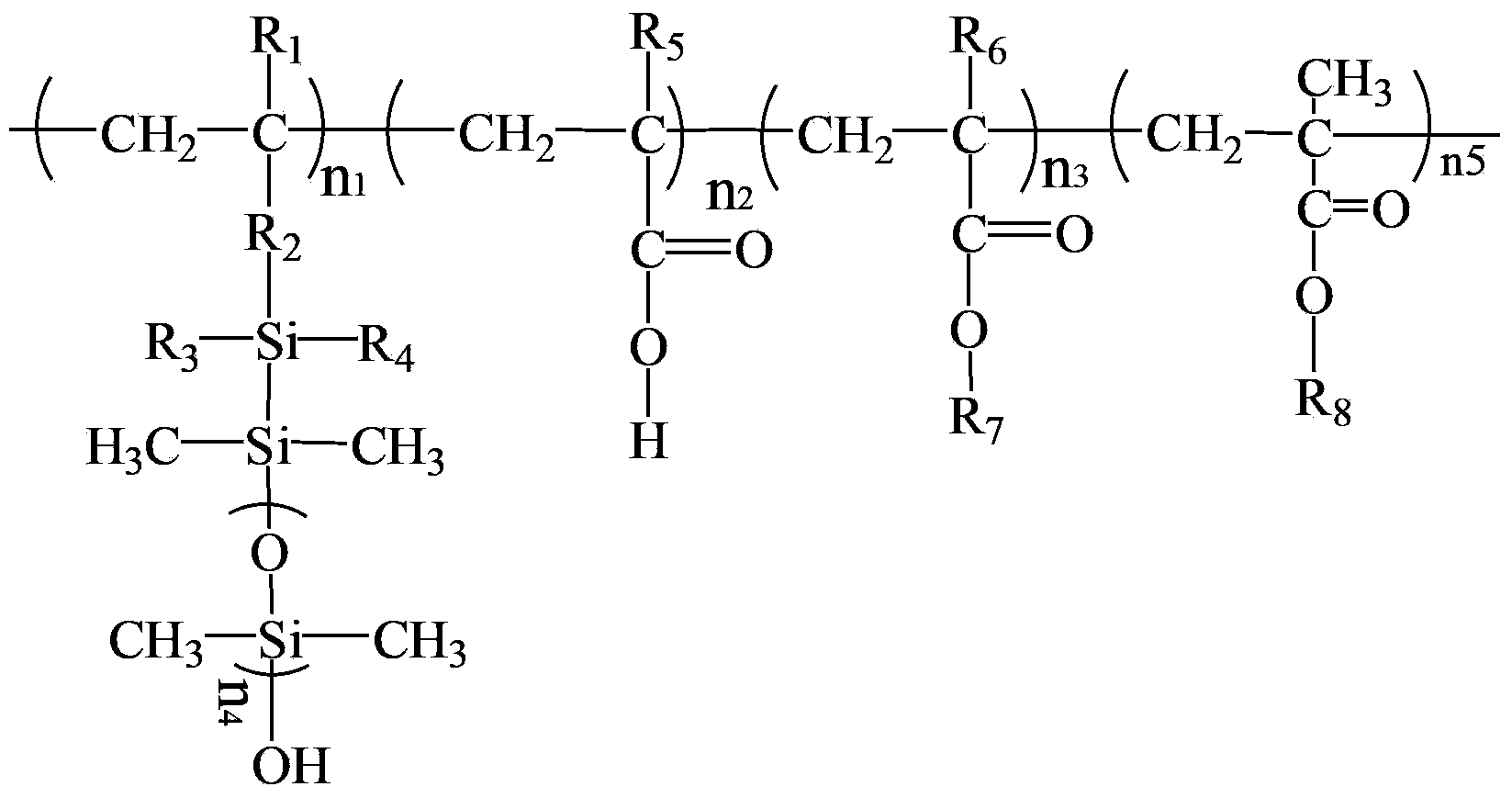

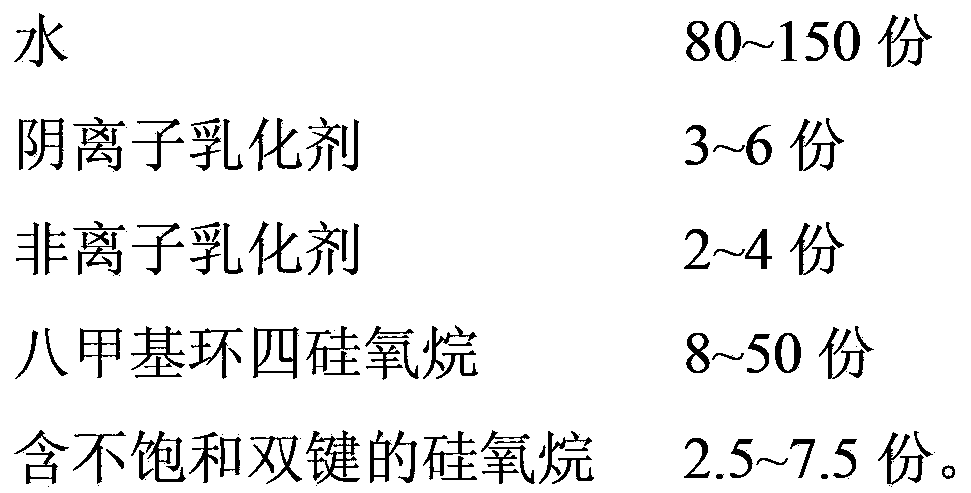

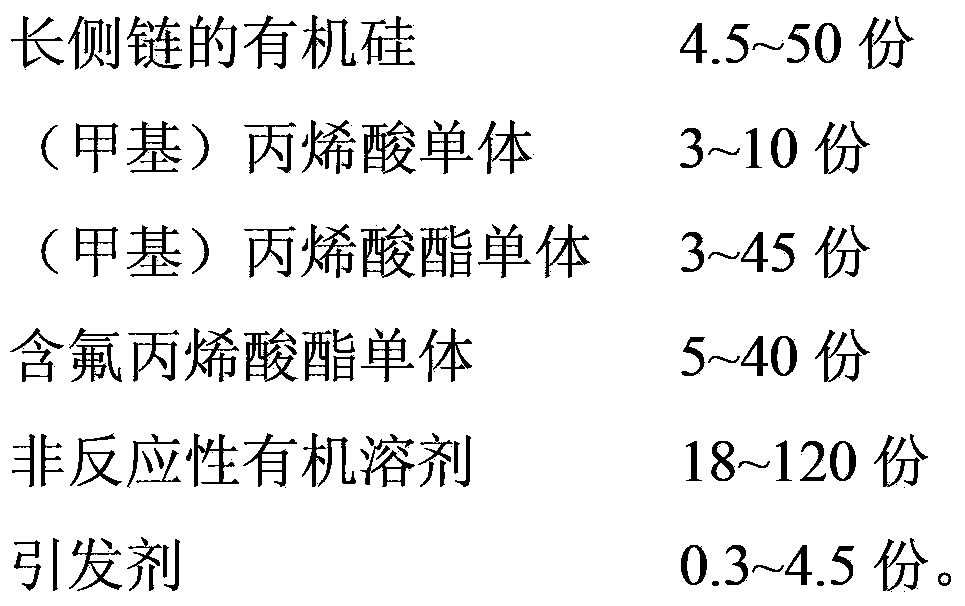

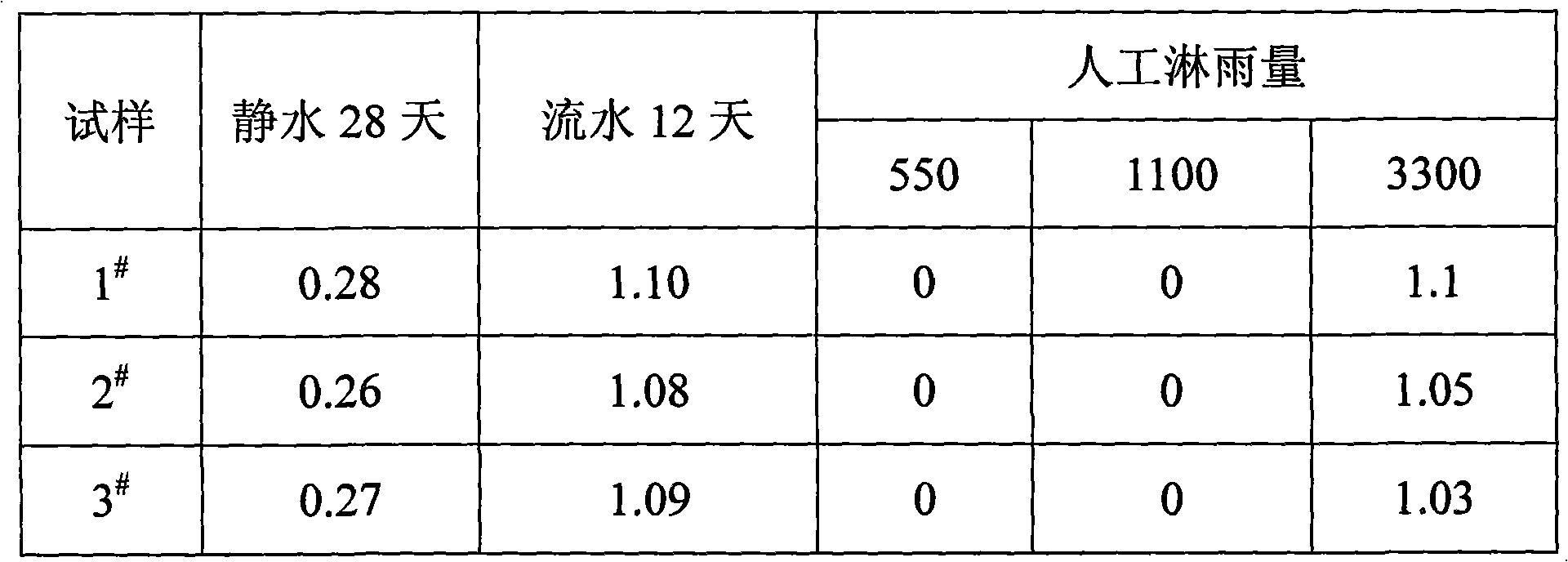

Organosilicone modified fluorine-containing (methyl) acrylic resin with long side chain

The invention belongs to the technical field of acrylic resin modification and discloses an organosilicone modified fluorine-containing (methyl) acrylic resin with a long side chain. The invention further discloses a preparation method. The preparation method comprises the following steps: mixing water, an anionic emulsifier and a nonionic emulsifier with octamethylcyclotetrasiloxane, and reacting at 70-90 DEG C for 3-9h under nitrogen protection; adding siloxane containing unsaturated double bonds, and reacting at 75-90 DEG C for 3-9h; dropwise adding reaction liquid into ethanol of which the volume is 2-4 times as large as that of the reaction liquid, performing ultrasonic treatment, outwelling the supernatant to obtain organosilicone with a long side chain; and (2) mixing the organosilicone with a long side chain prepared in the step (1) with a (methyl) acrylic acid monomer, a (methyl) acrylate monomer, a fluorine-containing acrylate monomer, a non-reactive organic solvent and an initiator, and reacting at 60-75 DEG C for 2-6h under nitrogen protection to obtain the organosilicone modified fluorine-containing (methyl) acrylic resin with a long side chain, and the resin has better water resistance and stain resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Waterproof and mildew-proof gypsum board

The invention discloses a waterproof and mildew-proof gypsum board. The waterproof and mildew-proof gypsum board is prepared from, by mass, 50-55 parts of gypsum powder, 8-14 parts of fine sand, 12-16 parts of wood fiber, 7-10 parts of fiber glass filaments, 5-9 parts of acrylic emulsion, 15-20 parts of an inorganic aluminum salt waterproof agent, 5-7 parts of aluminum oxide clay, 3-5 parts of magnesium oxide, 9-11 parts of a nano-zinc oxide fungus-proof agent, 4-8 parts of polyamide resin and 35-40 parts of water. The waterproof and mildew-proof gypsum board is good in water resistance, high in strength and fungus-proof capability and capable of preventing mildewing and blackening caused by inlet water.

Owner:青岛燕园海洋生物科技有限公司

Interface mortar

The present invention discloses interface sand pulp, the constitutional materials of which comprises inorganic cementing compound, organic cementing compound tylose ether MC and hydrophobe redispersionable rubber powder, skeletal material and solidification setting accelerator; the ingredients with the following weight percent: 40 to 50 percent of inorganic cementing compound, 0.05 to 1.0 percent of tylose ether MC, 1.0 to 2.5 percent of hydrophobe redispersionable rubber powder, 48 to 60 percent of skeletal material, and 0 to 6 percent of solidification setting accelerator. The interface sand pulp of the present invention has strong adhesive strength, good water-resistant performance, small modulus and good climate-resistant performance, and is free from aging and is free from shrinking during the hardening, and has good flexibility, and is free from producing the interface stress. The interface sand pulp is particularly suitable to be used as the processing agent for the surface of the aeroconcrete and the smooth concrete, and is also applicable to be used as the transitional layer between the substrate and the coating layer, and can also be used for bonding the ceramic tile.

Owner:长沙归一新材料科技股份有限公司

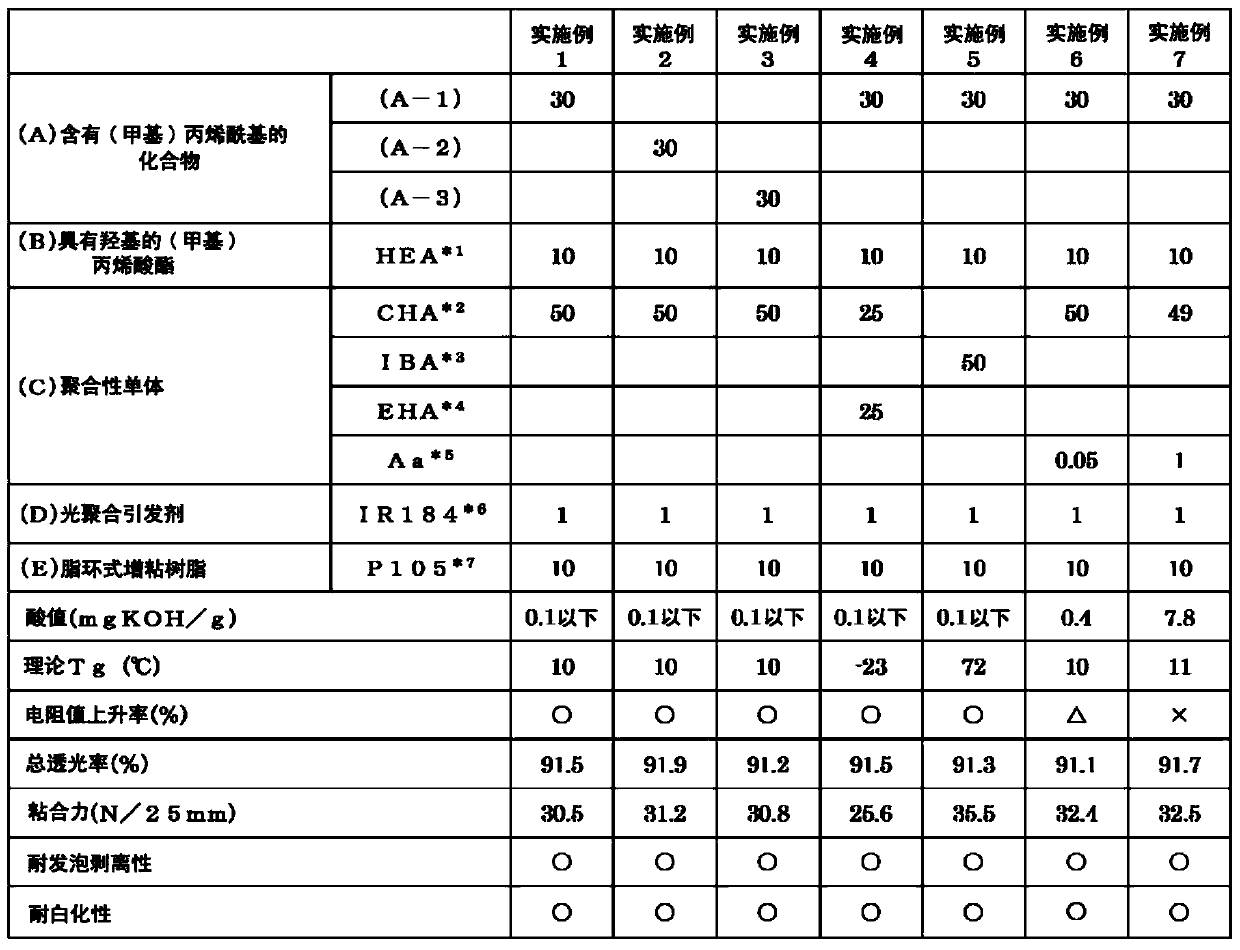

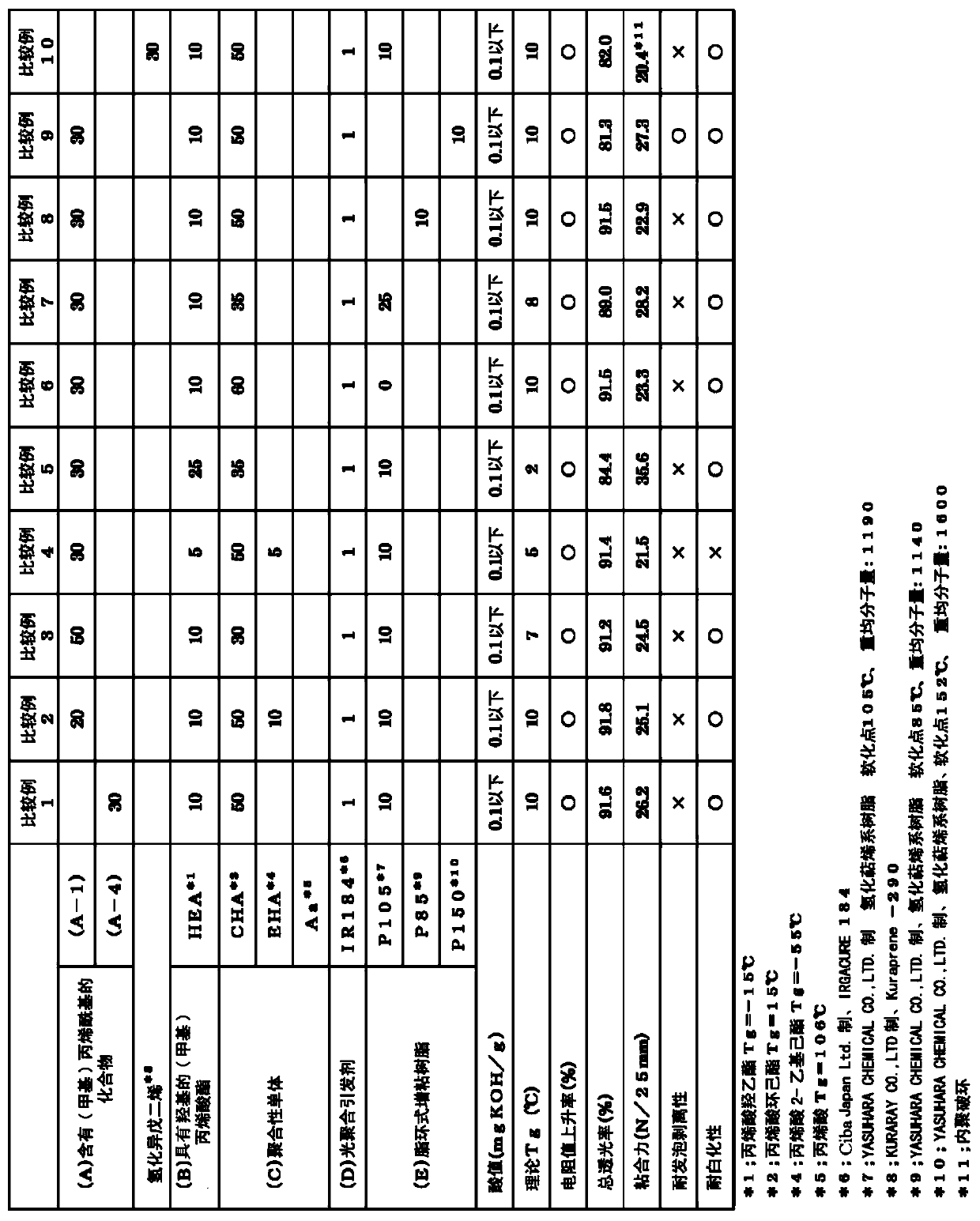

Photocurable translucent composition for adhesive sheet, and optical adhesive sheet

ActiveCN104093800AExcellent moisture permeability resistanceGood water resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolycarbonateChemistry

The purpose of the present invention is to provide a photocurable translucent composition for an adhesive sheet which will not corrode the electroconductive layer of a translucent electroconductive film even when bonded directly onto the surface of the electroconductive layer, and which offers excellent whitening resistance and foaming resistance in a high-temperature, high-humidity environment when used to bond a translucent resin sheet such as an acrylic sheet or a polycarbonate sheet, as well as to provide an adhesive sheet. The present invention pertains to a photocurable translucent composition for an adhesive sheet, the composition being of high molecular weight, having (meth)acryloyl groups introduced thereto, and being a formulation of a hydrogenated 1,2-polybutadiene-based acrylate compound or hydrogenated isoprene-based compound, a (meth)acrylic acid ester having a hydroxyl group, a polymerizable monomer other than the (meth)acrylic acid ester having a hydroxyl group, an alicyclic tackifying resin having a softening point in a specific range, and a photopolymerization initiator.

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com