Inorganic modified heat insulation plate and preparation process thereof

A technology of inorganic modification and thermal insulation board, which is applied in the field of inorganic modified thermal insulation board and its preparation process, fire protection and thermal insulation of equipment, and industrial pipelines. It can solve the problems of low water resistance, looseness and damage, and unusability, and achieve good weather resistance. , good compression resistance, excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

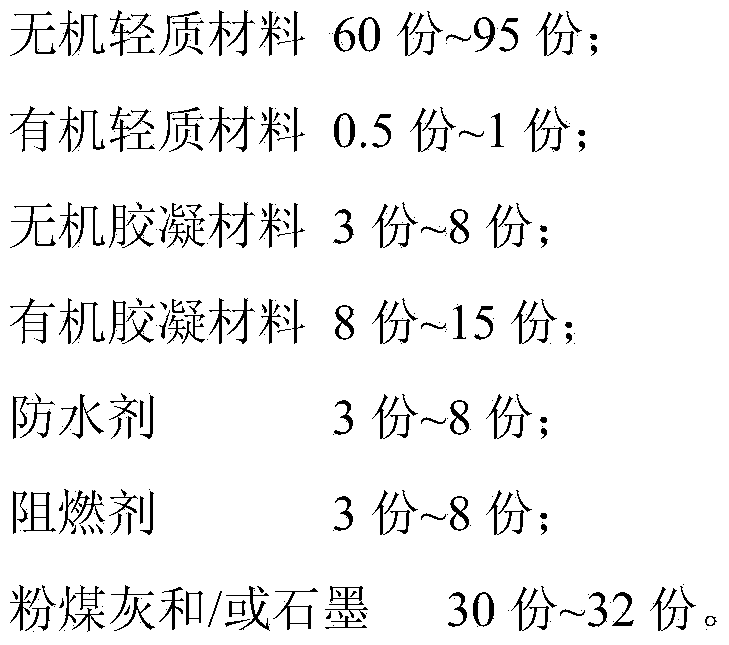

[0026] An inorganic modified insulation board, its components and the mass parts of each component are as follows:

[0027]

[0028]

[0029] Choose one of 32 parts from fly ash or graphite.

[0030] The steps of the preparation process of the inorganic modified insulation board are as follows:

[0031] (a) Prepare materials according to the above components and the mass parts of each component;

[0032] (b) Mix and pre-mix the solid materials in the components to obtain the mixture A;

[0033] (c) Mix and pre-mix the liquid materials in the components to obtain the mixture B;

[0034] (d) After the mixture A is mixed, continue to mix, and at the same time, spray the mixture B evenly in the mixture A;

[0035] (e) After the mixture A and the mixture B are evenly mixed, the material is discharged, enters the insulation board mold, is extruded, and is controlled

[0036] Preserve at a suitable temperature for 12 hours, and obtain the inorganic modified insulation board...

Embodiment 2

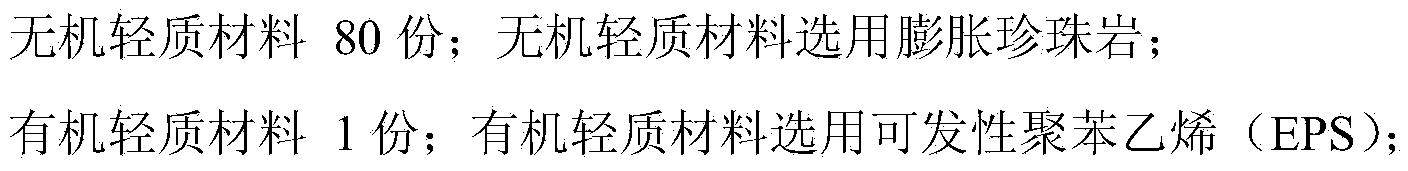

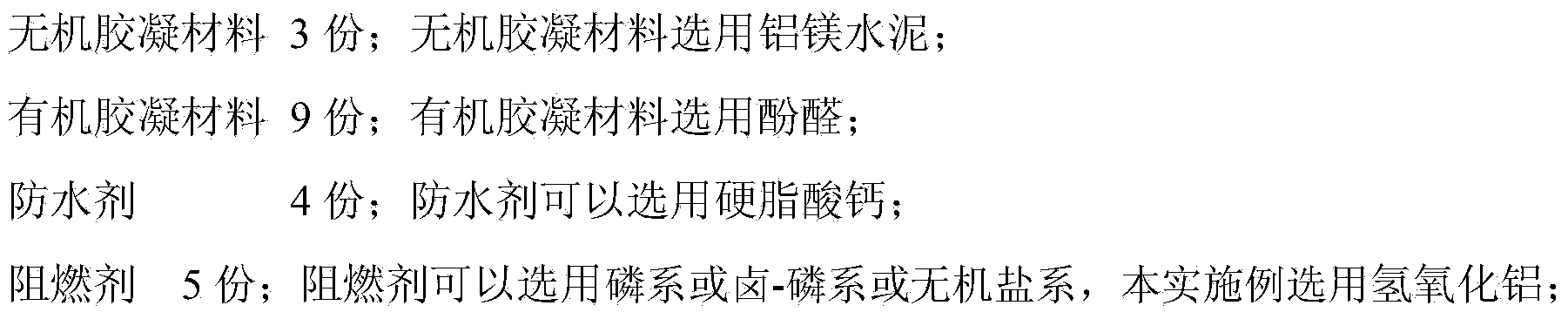

[0039] An inorganic modified insulation board, its components and the mass parts of each component are as follows:

[0040] 60 parts of inorganic light materials; the inorganic light materials are selected from the mixture of expanded perlite, expanded vermiculite, foamed cement particles and expanded ceramic particles;

[0041]

[0042] The flame retardant can be phosphorus-based or halogen-phosphorus-based or inorganic salt-based, for example, aluminum hydroxide or magnesium hydroxide or ammonium polyphosphate or red phosphorus can be selected.

[0043] The waterproofing agent can be calcium stearate, but not limited thereto.

[0044] The steps of the preparation process of the inorganic modified insulation board are as follows:

[0045] (a) Prepare materials according to the above components and the mass parts of each component;

[0046] (b) Mix and pre-mix the solid materials in the components to obtain the mixture A;

[0047] (c) Mix and pre-mix the liquid materials...

Embodiment 3

[0053] An inorganic modified insulation board, its components and the mass parts of each component are as follows:

[0054] 95 parts of inorganic light materials; the inorganic light materials are selected from diatomite light particles or vitrified microbead particles;

[0055] 1 part of organic lightweight material; the organic gelling material is any one of polyurethane or modified polyurethane or phenolic or polyurea or polyurea modified particles;

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com