Patents

Literature

69results about How to "Good thermal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

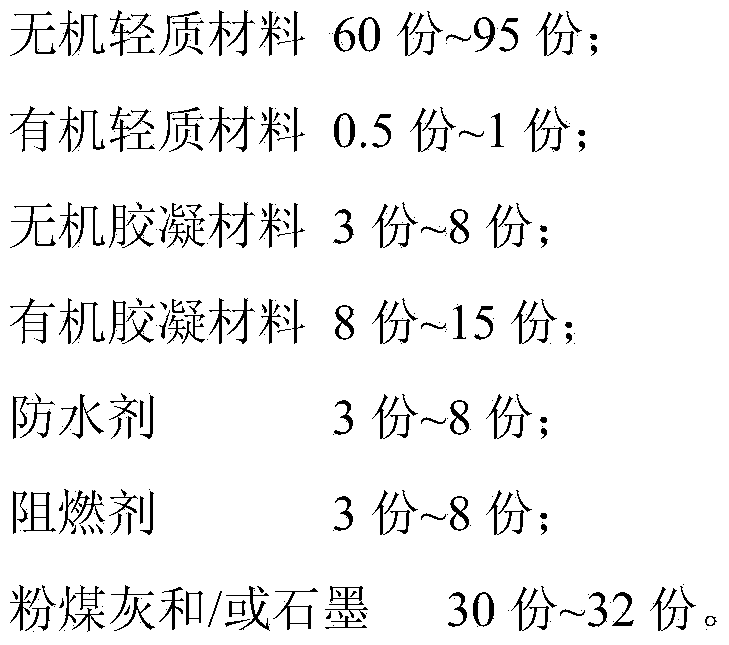

Inorganic modified heat insulation plate and preparation process thereof

The invention discloses an inorganic modified heat insulation plate and a preparation process thereof. The inorganic modified heat insulation plate has the following components in parts by weight: 60-95 parts of inorganic light-weight material, 0.5-1 part of organic light-weight material, 3-8 parts of inorganic cementing material, 8-15 parts of organic cementing material, 3-8 parts of waterproofing agent, 3-8 parts of flame retardant and 30-32 parts of fly ash and / or graphite. The heat insulation plate has the nonflammability under the conditions of fire-protection rating A (A2) GB8624-2012, not only has lower thermal conductivity but also has excellent water resistant strength and good resistance against tension and compression, so that good weatherability is guaranteed.

Owner:常州高能新型建材有限公司

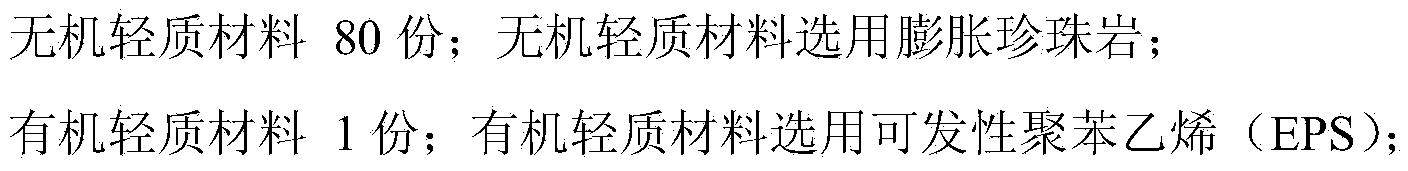

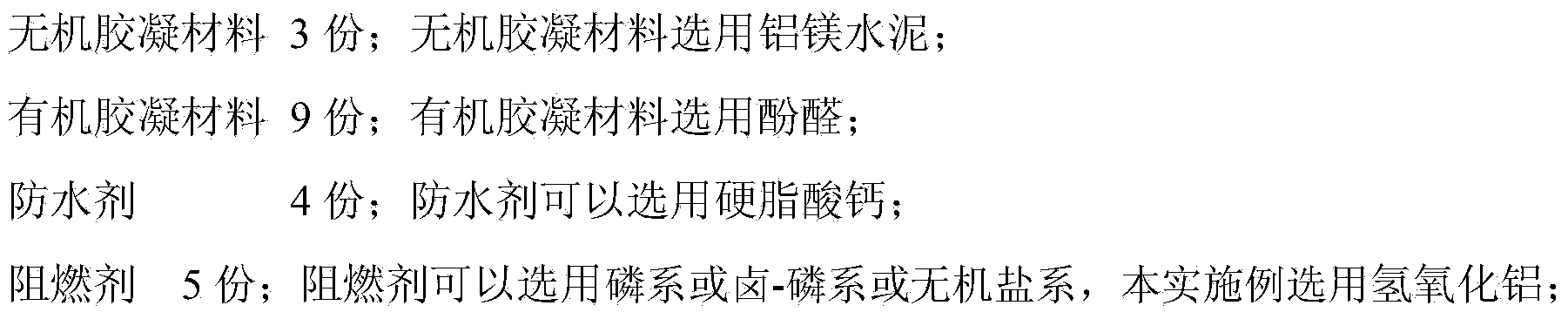

Method for brickmaking by comprehensive utilization of desiccated sludge

ActiveCN102381877AReduce moisture contentCrushed fullySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentBrickSolar drying

The invention discloses a method for brickmaking by comprehensive utilization of desiccated sludge; sludge is desiccated and is used as a raw material for brickmaking; the method comprises the following steps: firstly transporting municipal sludge with water content of 80-85% to a sludge warehouse for sealing storage, grabbing the sludge in the sludge warehouse by controlling a grab bucket traveling boom through a PLC system, transferring the sludge to a feed hopper of a sludge feeding device, adding a curing agent into the feed hopper, fully stirring, transporting the sludge to a desiccationchamber of a desiccation device, performing desiccation in the desiccation chamber by solar energy and waste heat of a tunnel furnace so as to obtain sludge which is used as a material for brickmaking. The invention performs desiccation by using brickkiln waste heat and solar energy; the physical heat at a brick-baking tail part of the tunnel furnace is made full use of, which increases self heat, and saves a lot of energy; sludge is added into various raw materials, and no clay is used; with respect to baked brick production by using municipal sludge with a high mixing amount, the highest mixing amount of municipal sludge is up to 50%.

Owner:南京鑫翔环保产业有限公司

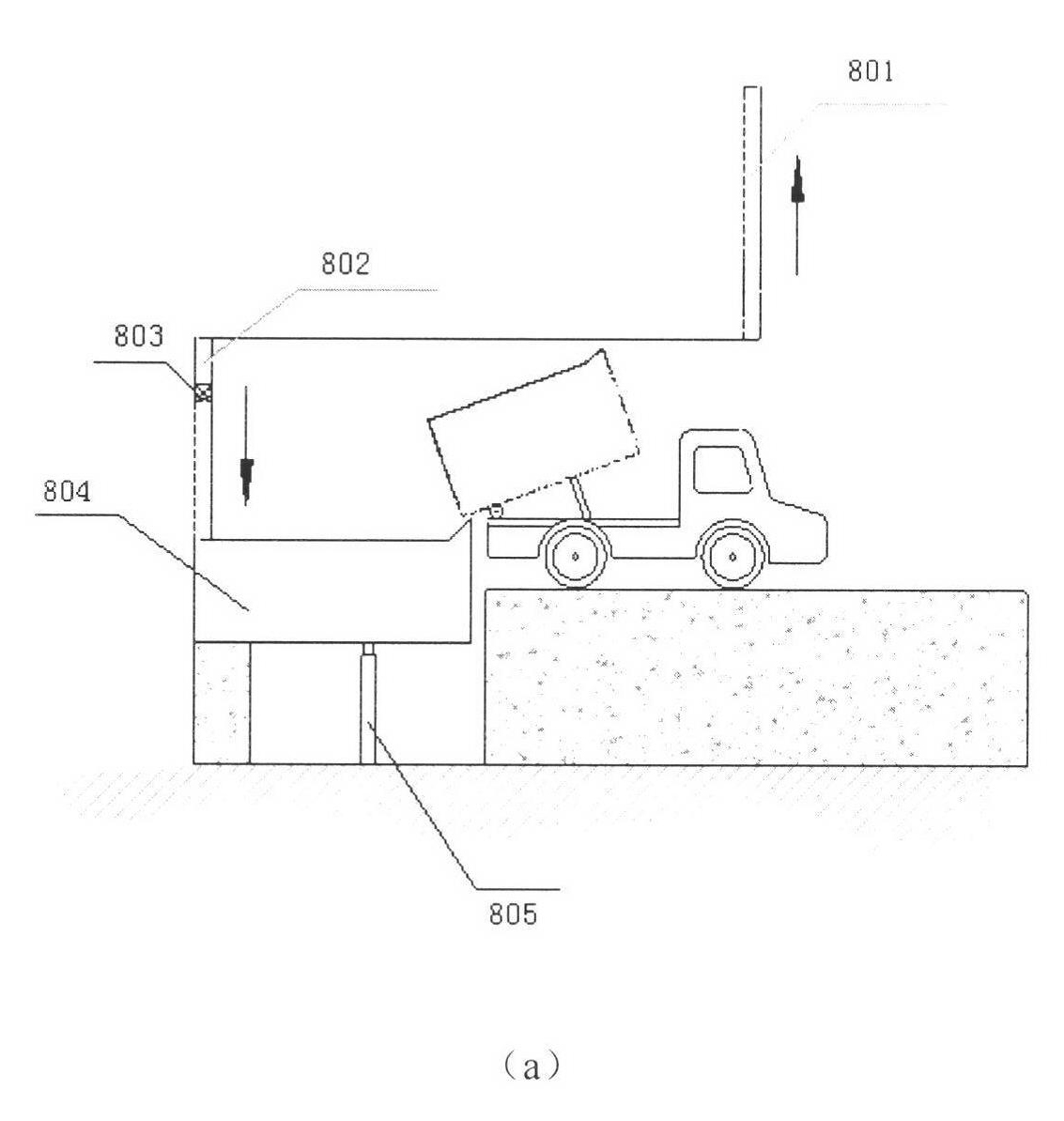

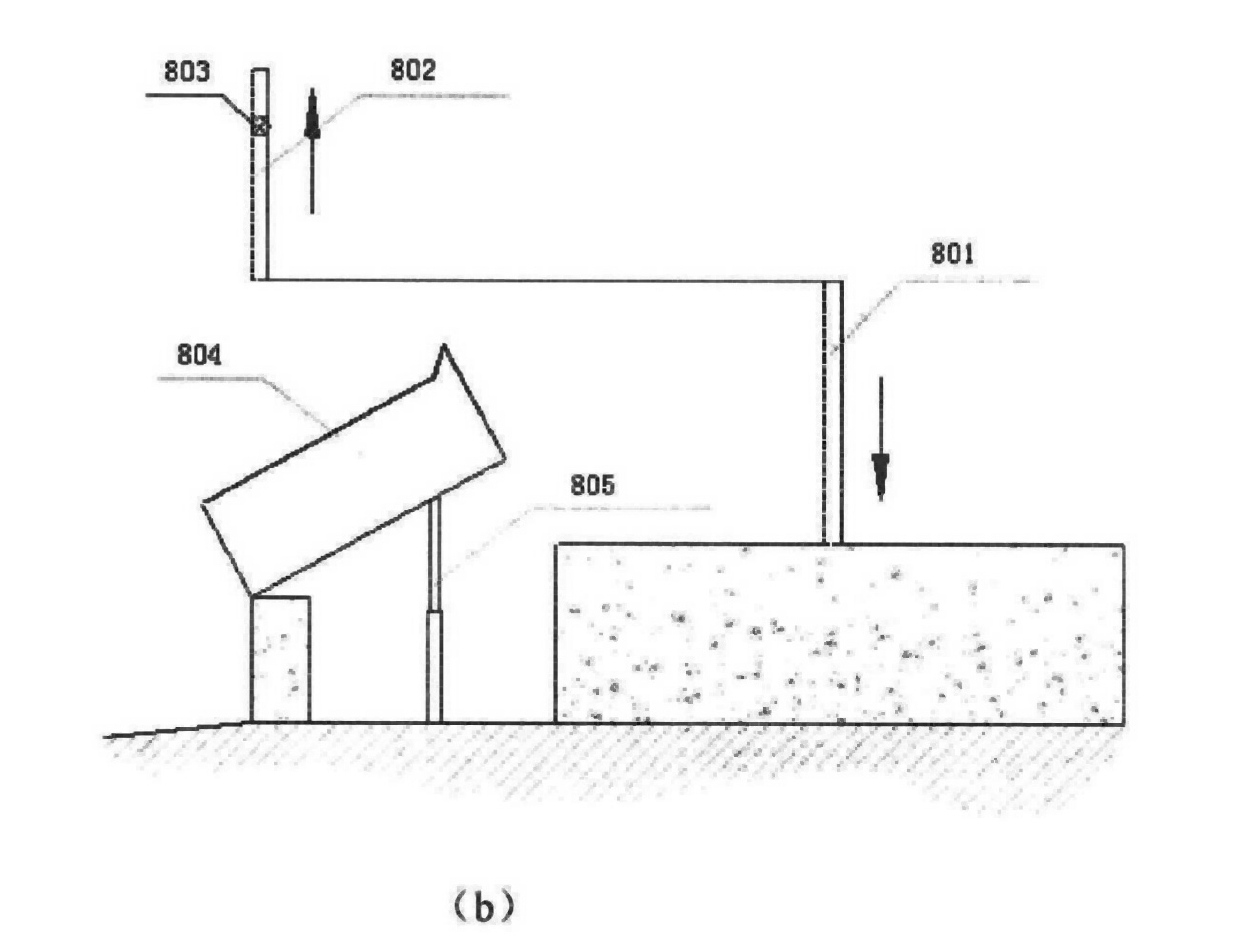

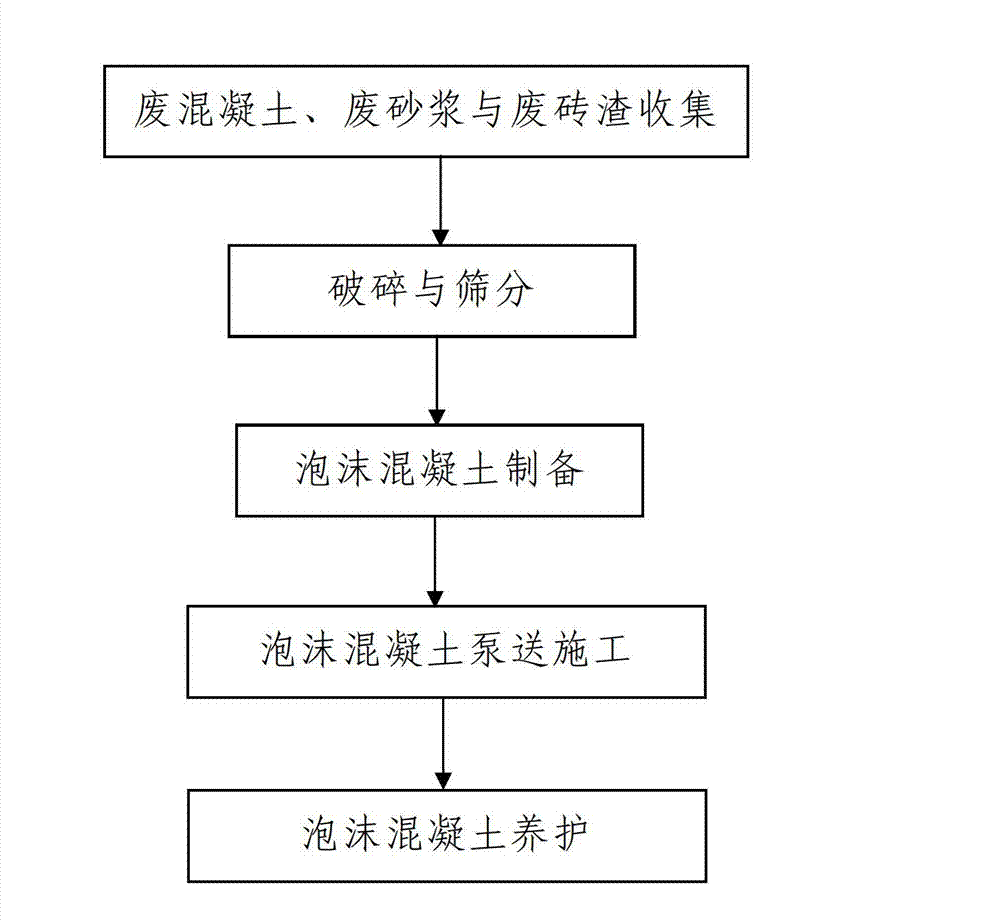

Construction waste recycling and reusing process

InactiveCN102815964AThe method steps are simpleReasonable designSolid waste managementBuilding material handlingFoam concreteBrick

The invention discloses a construction waste recycling and reusing process, which comprises the following steps of: 1, collecting waste concrete, waste mortar and waste brick slag; 2, smashing and screening, namely smashing and screening the collected waste concrete, the collected waste mortar and the collected waste brick slag to obtain regenerative rough aggregates and regenerative fine aggregates; and 3, preparing foam concrete, namely firstly preparing cement slurry, namely uniformly stirring concrete, water, the regenerative rough aggregates and the regenerative fine aggregates to obtain the cement slurry, and secondly adding a foam dilution solution, namely adding the foam dilution solution formed by uniformly mixing a foaming agent and water into the cement slurry, and uniformly stirring to obtain the foam concrete. The steps of the process are simple; the investment cost is low; the process is simple, feasible and high in operability; the waste concrete, the waste mortar and the waste brick slag can be effectively reused; the economical benefit is outstanding; the produced foam concrete material is high in heat preservation performance; and the problems that the construction waste is abandoned and stacked randomly and occupies the land, the waste of resources is severe, and the environment pollution is severe are solved.

Owner:陕西建工集团有限公司

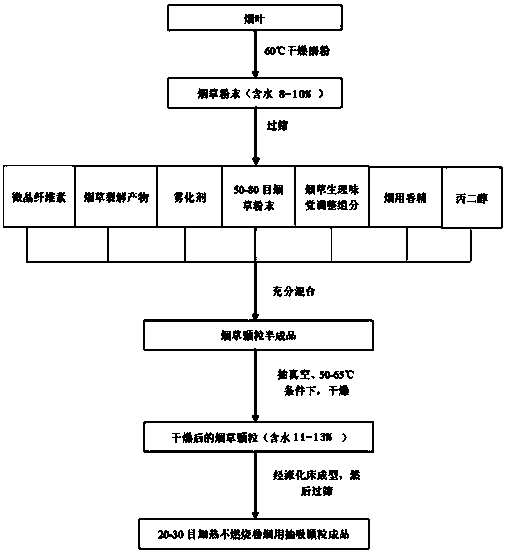

Sucking particles for heat-not-burn cigarettes and manufacturing method

ActiveCN108077992AGood thermal performanceFoggy quicklyTobacco preparationTobacco treatmentPropylene glycolIsopropylene glycol

The invention discloses sucking particles for heat-not-burn cigarettes. The particles are prepared from, by weight, 8-20 parts of microcrystalline cellulose, 50-80 parts of cigarette powder, 0.5-2 parts of split products of cigarettes, 1 part of physiological taste adjusting components of cigarettes, 8-30 parts of atomizer, 0.1-2 parts of tobacco essence and 1-10 parts of propylene glycol. The invention further provides a manufacturing method of the sucking particles. The sucking particles have high heated performance, when a heating sheet is utilized to heat the sucking particles at 250-310 DEG C, the particles generate smoke quickly, heating is complete, and the smoke volume is large; meanwhile, the sucking particles have fragrance and smell of cigarettes and physiological satisfaction similar to traditional cigarettes, and the required process difficulty is small.

Owner:GUANGDONG WONDERFUL INT BIOTECH CO LTD

Environment protection energy-saving type insulating block

InactiveCN101177962AGood thermal performanceImprove thermal performanceSolid waste managementClimate change adaptationSlagPolystyrene

The invention relates to the technical field of preparing hollow insulation building blocks with environmental light aggregate concrete, in particular to light aggregate concrete building blocks prepared with industrial waste materials such as polystyrene granules, slag, pulverized fuel ash, etc., which can well make use of local resources and lead industrial waste materials such as slag, pulverized fuel ash, etc. to be profitable. The volume density of the environmental insulation building blocks is 700 - 750kg / m<3> and the compressive strength of the building blocks reaches to 1.5MPa to 2.5MPa or more; moisture content is 1.7 percent and water absorption rate is 9.3 percent; relative moisture content is 28.8 percent and the resistance of heat transfer of a wall body with the thickness of 190mm is 0.53m<2>.K / W. The dynamic, physical and thermal properties are all relatively good under the condition of guaranteeing light weight.

Owner:SHENZHEN JINXIN GREEN CONSTR LTD BY SHARE LTD

Energy-saving heat-insulating masonry mortar and method for making same

InactiveCN101139188AOvercoming the "Cold Bridge" PhenomenonCompliance with thermal insulationSolid waste managementBrickUltimate tensile strength

The present invention relates to an energy-saving and heat-preservation masonry mortar. The component materials and the weight ratio for the masonry mortar are that: 17-23 percent of cement, 15-55 percent of powder coal ash, 10-55 percent of hearth residue, 0-25 percent of glass micro pearl, 0.7-1.2 percent of additive agent and 0.05-0.10 percent of natrium water reducing agent. The mixture material after being mixed is added into a mixer and then is mixed for 3-4 minutes for well-proportioned matching. And then the clear water with the thickness for mortar 70-90mm is added and is mixed for 3-5 minutes. So the finished products can be obtained. The present invention has the advantages that: if being used together with the energy-saving and heat-preservation brick or the heat-preservation and light brick, the present invention can overcome the problem that when using the common masonry mortar, the heat conductivity coefficients in both materials are much more different, so the whole brick body will be in cold bridge effect. The present invention accords to the requirements of heat insulation and heat preservation for the energy-saving building materials. The present invention is with much better workability and construction performance, much better heat-working performance, much higher intension and much lower cost. So the present invention can be widely applied and popularized.

Owner:YANCHENG INST OF TECH

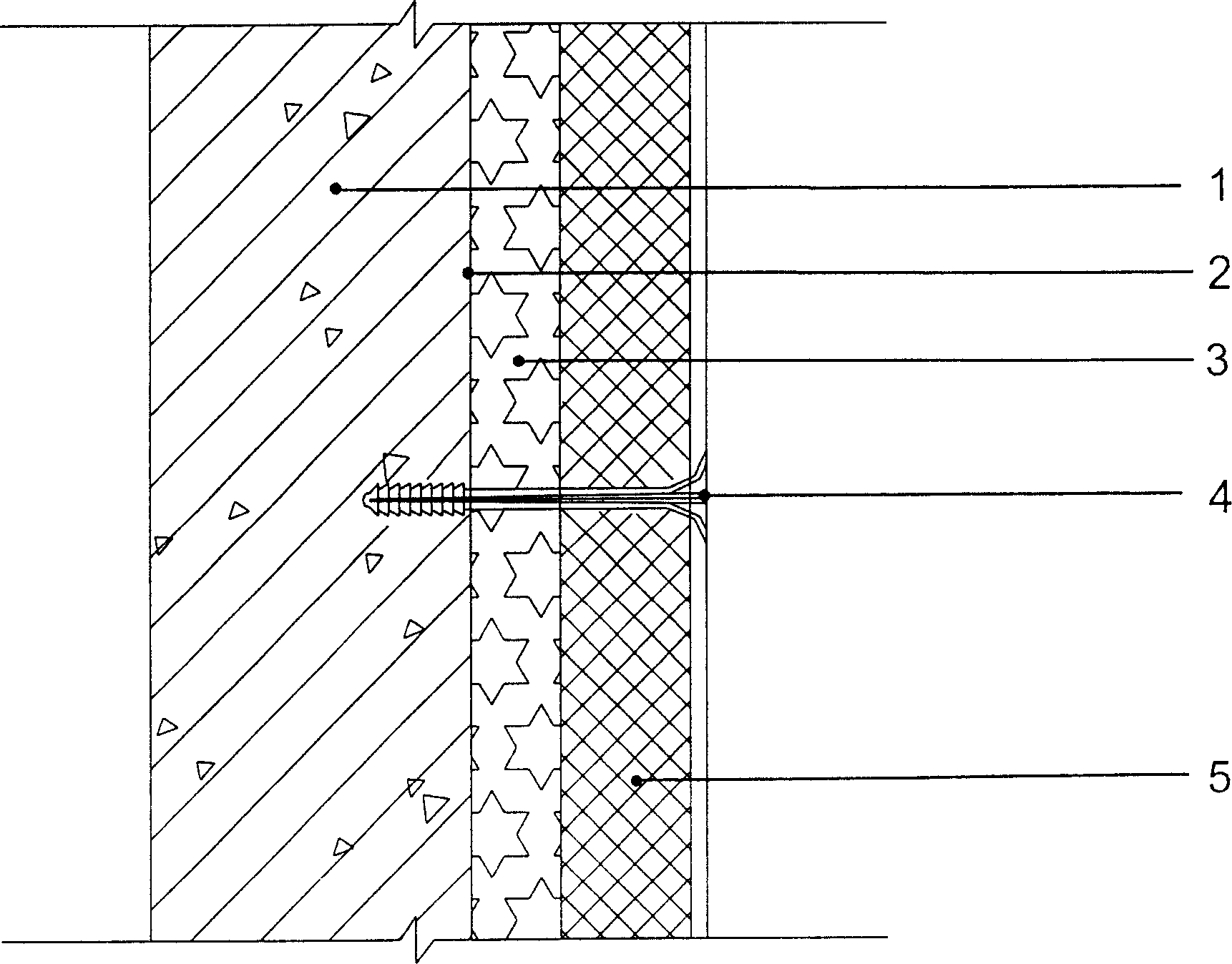

Outer heat preservation system of composite decorative board of rigid polyurethane for pouring in site, and construction technique

InactiveCN1916307ALow costRealize production prefabricationCovering/liningsWallsPolystyreneFluorocarbon

The present invention relates to a cast-in-place hard polyurethane composite decorative plate exterior heat-insulating system and its construction process. It is characterized by that said process includes the following steps: utilizing a special composition technique to make polystyrene or hard polyurethane foam plate and fluorocarbon aluminium alloy plate or fluorocarbon inorganic plate into a kind of misplaced heat-insulating decorative plate; fixing said heat-insulating decorative plate on wall body base layer in the field by adopting three-dimensinal positioning method and invisible plastic expansion stay bolt, and forming a cavity between said heat-insulating decorative plate and wall body base layer, pouring hard polyurethane foam into said cavity so as to form adhesive heat-insulating layer; finally caulking the periphery of said misplaced composite decorative plate.

Owner:武汉德丽宝建筑节能技术有限公司

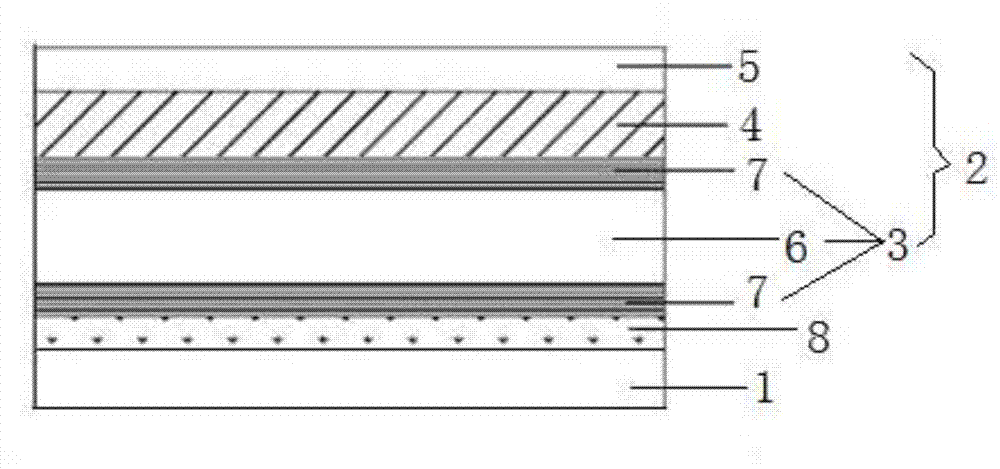

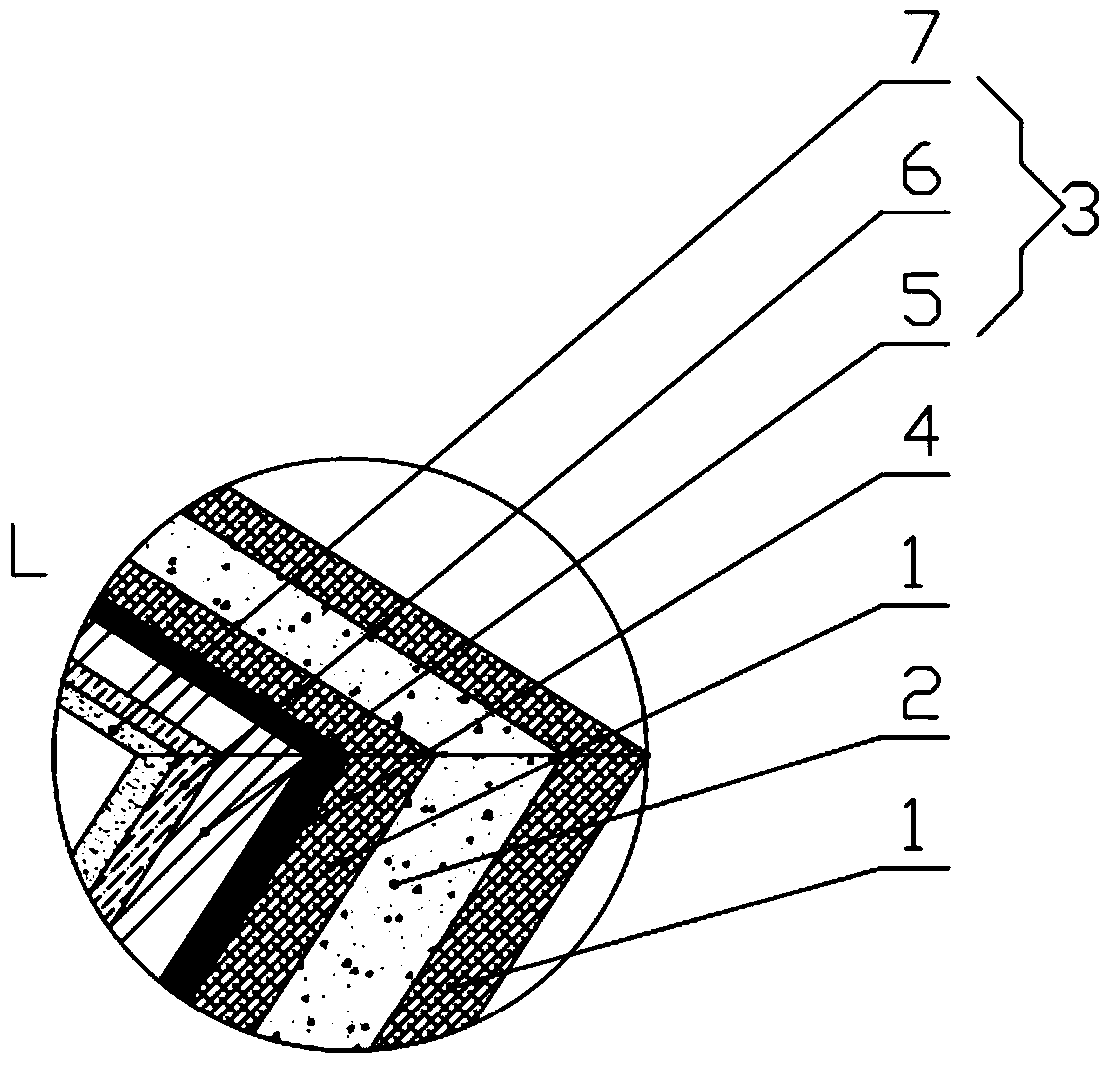

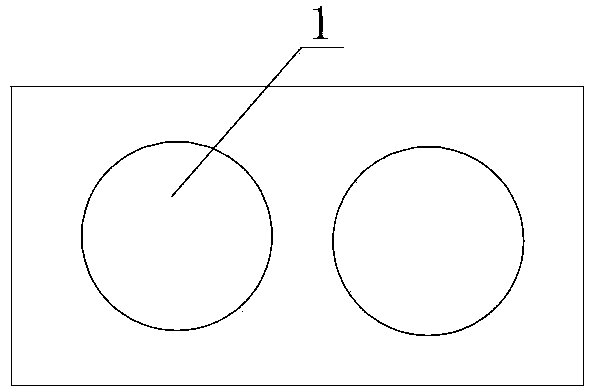

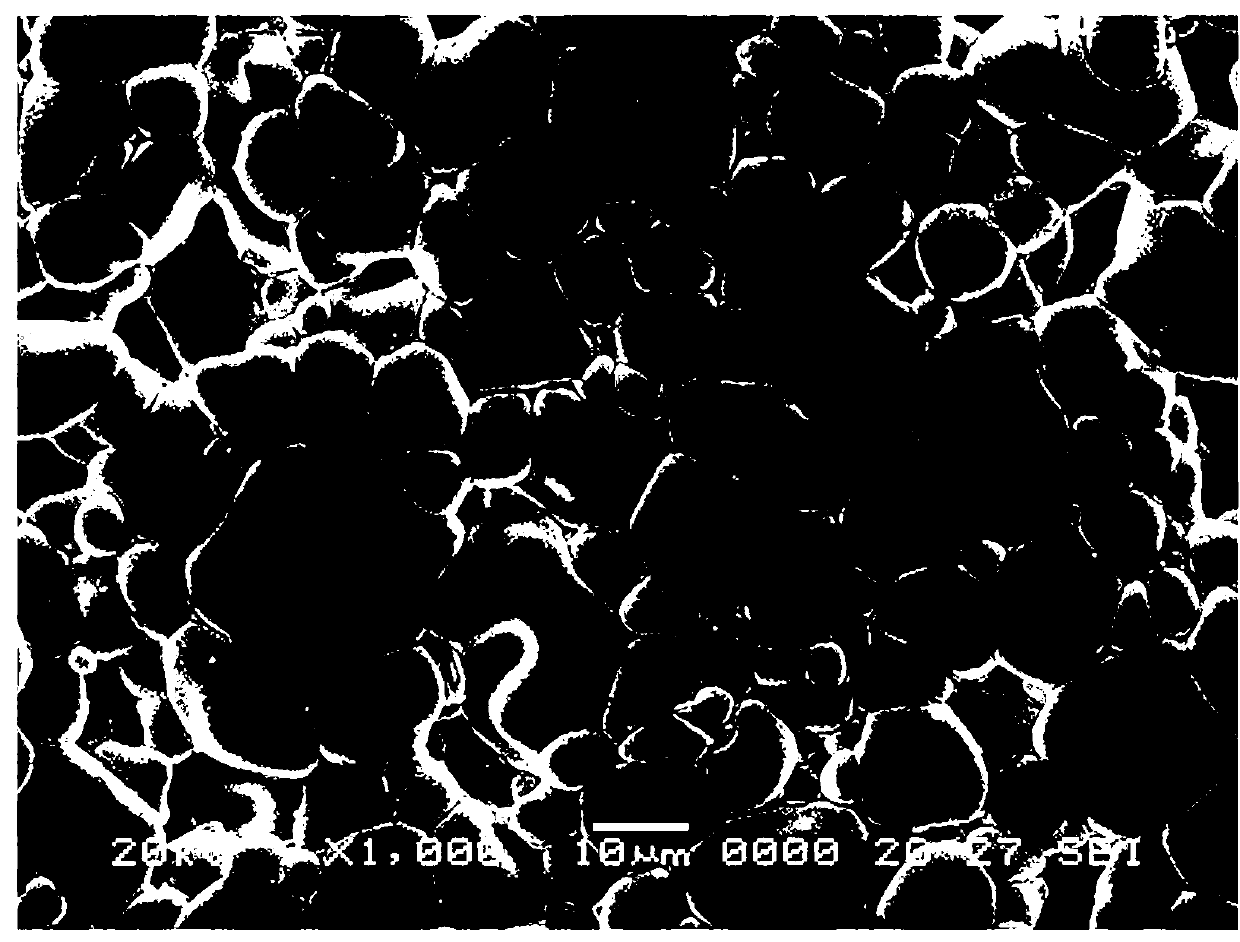

Microcrystalline foamed ceramic thermal insulation decoration composite plate and manufacturing method thereof

InactiveCN103938820AEnvironmentally friendlyLow thermal conductivityCovering/liningsCeramic layered productsPolymer modifiedThermal insulation

The invention discloses a microcrystalline foamed ceramic thermal insulation decoration composite plate which comprises a thermal insulation layer (1) and a decoration layer (2), wherein the decoration layer (2) is fixed onto the thermal insulation layer (1) by the adoption of an anti-flaming binder (8). The thermal insulation layer (1) is a microcrystalline foamed ceramic thermal insulation plate, the decoration layer (2) is a flexible facing clad material, and the decoration layer (2) sequentially comprises a flexible composite material sheet (3), color facing mortar (4) and a finishing coat (5) from bottom to top, wherein the anti-flaming binder (8) is a polymer modified cement mortar adhesive. Through the mode that the microcrystalline foamed ceramic thermal insulation plate with a fireproof function is combined with the flexible facing clad material through the anti-flaming binder, the microcrystalline foamed ceramic thermal insulation decoration composite plate has the advantages of factory component industrialization, construction assembly, fire hazard high-temperature anti-flaming fire prevention, thermal insulation, sound insulation and decoration composition.

Owner:山东鲁蒙低碳技术研究有限公司

Ceramsite recycled concrete as well as hollow block masonry and preparation method thereof

InactiveCN104150821AEnergy-saving and waste-savingGreenSolid waste managementExpanded clay aggregateHollow core

The invention discloses ceramsite recycled concrete, a hollow block masonry and a preparation method of the hollow block masonry. The ceramsite recycled concrete consists of the following raw materials in parts by weight: 360-440 parts of ceramsite, 660-860 parts of a recycled fine aggregate, 400-520 parts of cement and 150-200 parts of water. The ceramsite recycled concrete disclosed by the invention adopts the ceramsite as a light-weight coarse aggregate, adopts waste concrete as the recycled fine aggregate, integrates the characteristics of a lightweight aggregate and recycled aggregate concrete, and ensures that the ceramsite recycled concrete has the advantages of energy conservation, waste utilization, environmental protection, light weight, heat preservation, heat insulation and the like. A hollow block manufactured by adopting the ceramsite recycled concrete disclosed by the invention is a green wall material which has the performances of light weight, environmental protection, heat preservation and heat insulation, and has good physical, mechanical and thermotechnical performances.

Owner:GUANGXI UNIV

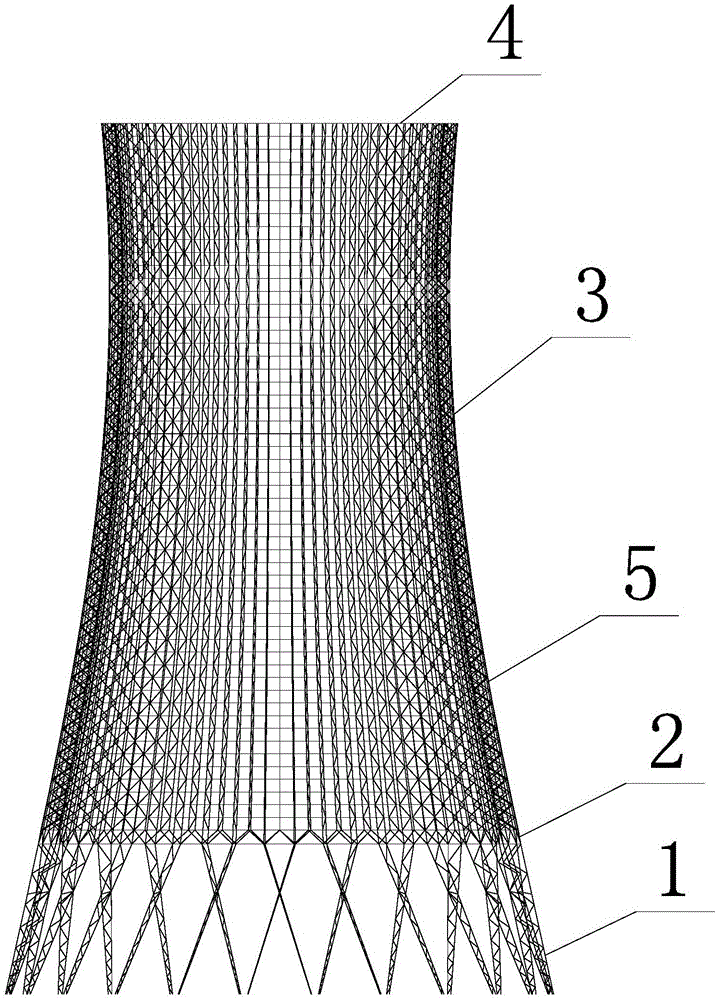

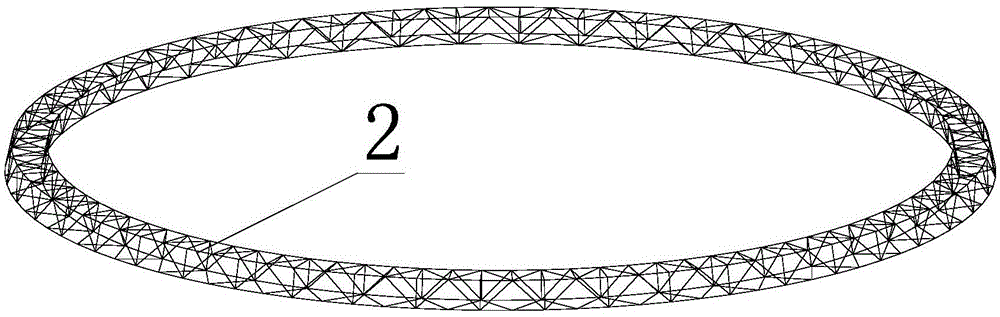

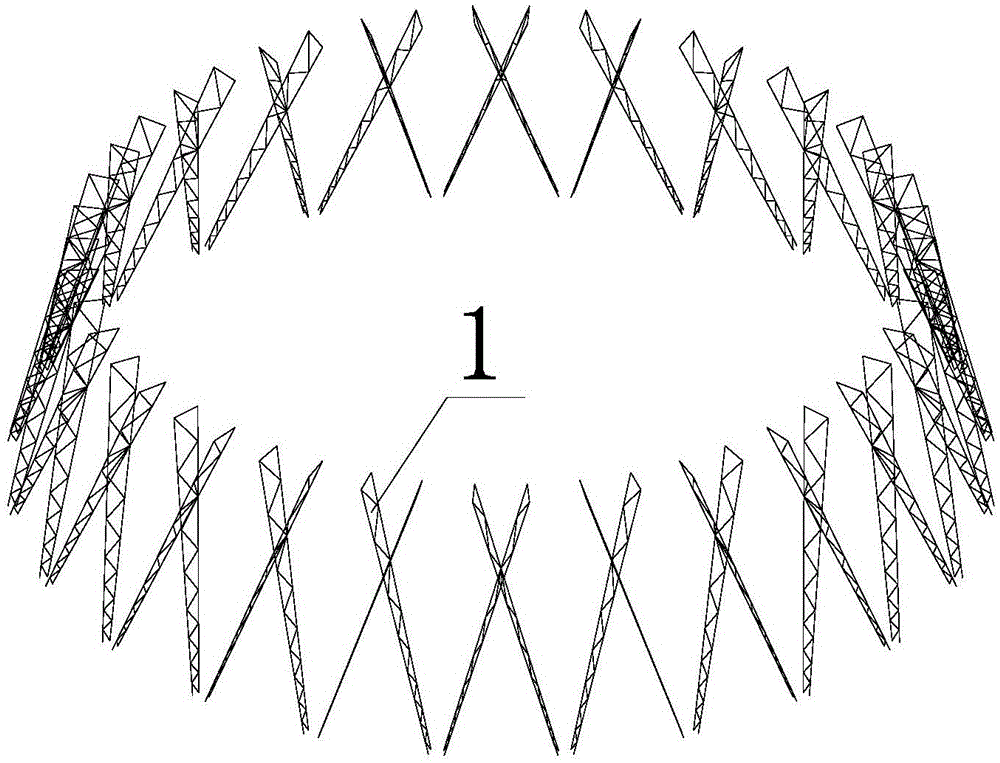

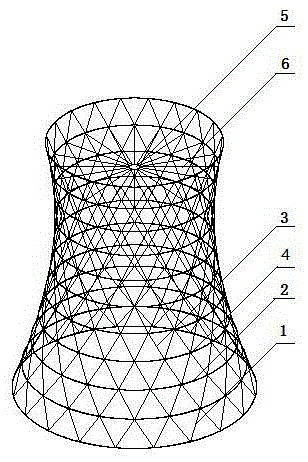

Hyperbolic double-layer reticulated shell steel structure cooling tower

The invention discloses a hyperbolic double-layer reticulated shell steel structure cooling tower, which comprises a bottom latticed column, a transfer truss and an upper tower tube, wherein the transfer truss is arranged at the upper part of the bottom latticed column; and the upper tower tube is arranged at the upper part of the transfer truss and is of a double-layer reticulated shell structure. The cooling tower adopts a hyperbolic appearance, so that the thermotechnical performance is good. Compared with a concrete thin shell tower, the cooling tower provided by the invention has the advantages that the dead weight is light; the foundation treatment is simple; and the construction is convenient and fast. Compared with a single-layer reticulated shell steel tower, the cooling tower provided by the invention has the advantages that a structure component mainly receives pulling and pressing stress; the strength of materials is fully used; the steel consumption is low; the structure rigidity is high under the condition of the same steel consumption; through the reasonable connection node design, the component field assembly can be realized; the construction is simple; the speed is high; and the anti-seismic performance and the wind-resistant performance are good.

Owner:CHINA WUZHOU ENG GRP +1

Foam glass insulation and photovoltaic decoration integrated panel and preparation method thereof

ActiveCN103410289ALow thermal conductivityGood thermal performanceRoof covering using slabs/sheetsRoof covering using tiles/slatesThermal insulationGreen building

The invention discloses a foam glass insulation and photovoltaic decoration integrated panel and a preparation method thereof. The integrated panel comprises an insulation layer and a photovoltaic decoration layer, the insulation layer is a foam glass insulation board and is wrapped by a waterproof rolling material in a sealing way, and the photovoltaic decoration layer comprises a flexible film battery component, a film layer and a coating layer in sequence from inside to outside. The integrated panel has fire resistance, flame-retardant performance and good durability, thermal insulation and photovoltaic power generation can be realized, and the integrated panel complies with green building concepts such as energy conservation, emission reduction and zero power consumption.

Owner:湖北亚细亚陶瓷有限公司 +1

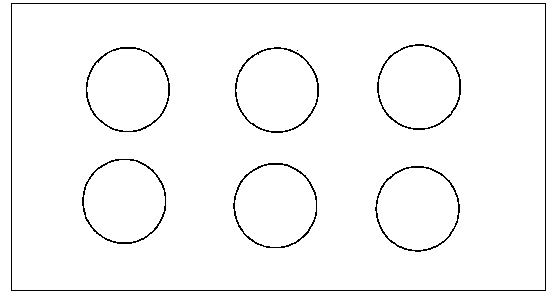

Energy-saving type heat preservation building block

The invention relates to a concrete building block, in particular relates to an energy-saving type heat preservation building block, and specifically a light aggregate concrete building block which is made of industrial waste materials such as polyphenyl grains, slag and coal ash, belonging to the technical field of building material machining. The energy-saving type heat preservation building block is a light aggregate concrete small-sized hollow building block which is made of industrial waste materials such as polyphenyl grains, slag and coal ash, and local resources can be well utilized, so that industrial waste materials such as slag, coal ash and the like are turned into wealth.

Owner:吕燕

Interface agent, as well as preparation method and application thereof

ActiveCN104650302AHigh bonding strengthImprove application durabilityBuilding componentsWater-setting substance layered productEpoxySodium bicarbonate

The invention relates to an interface agent. The interface agent is prepared from the following components by mass percent: 5-8.5% of n-butyl acrylate, 3-10.2% of methyl methacrylate, 0-1.2% of acrylic acid, 0-0.2% of initiator, 0.2-1.5% of composite emulsifier, 0-8% of epoxy resin, 61-78% of water, 4-8.2% of styrene, 0.3-1.5% of propylene glycol, and 0-0.3% of sodium bicarbonate. The interface agent has the advantages of excellent construction performance, interface tensile adhesive strength and aging resistance, and long storage life; when the interface agent is applied to interface areas, such as building heat-preservation composite outer templates and heat-preservation decorative sheets, the defects that the adhesion strength of the traditional interface agent with a heat-preservation material and mortar is low, the heat-preservation material is easy to hollow and crack and the like can be overcome.

Owner:江苏丰彩建材(集团)有限公司 +2

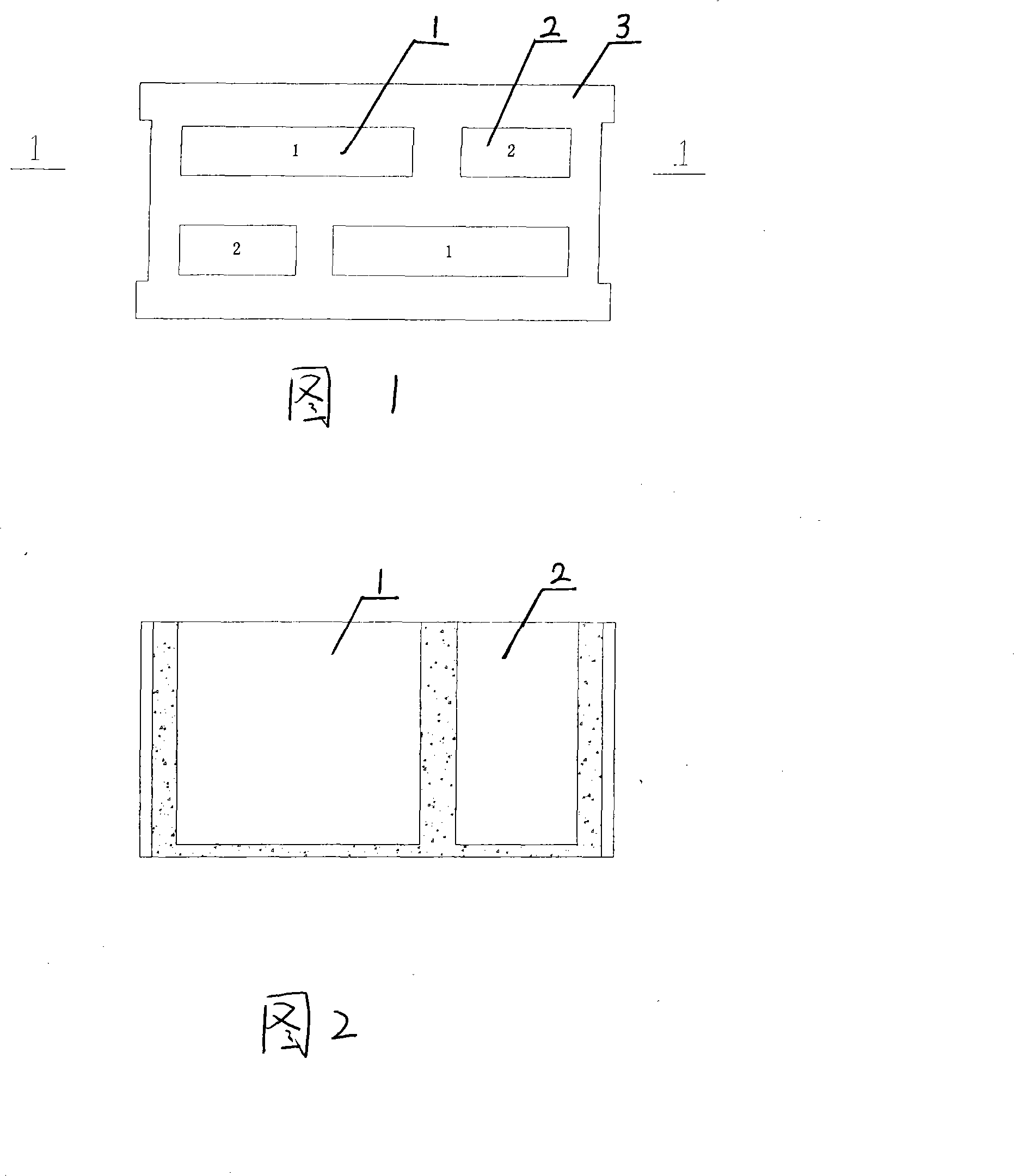

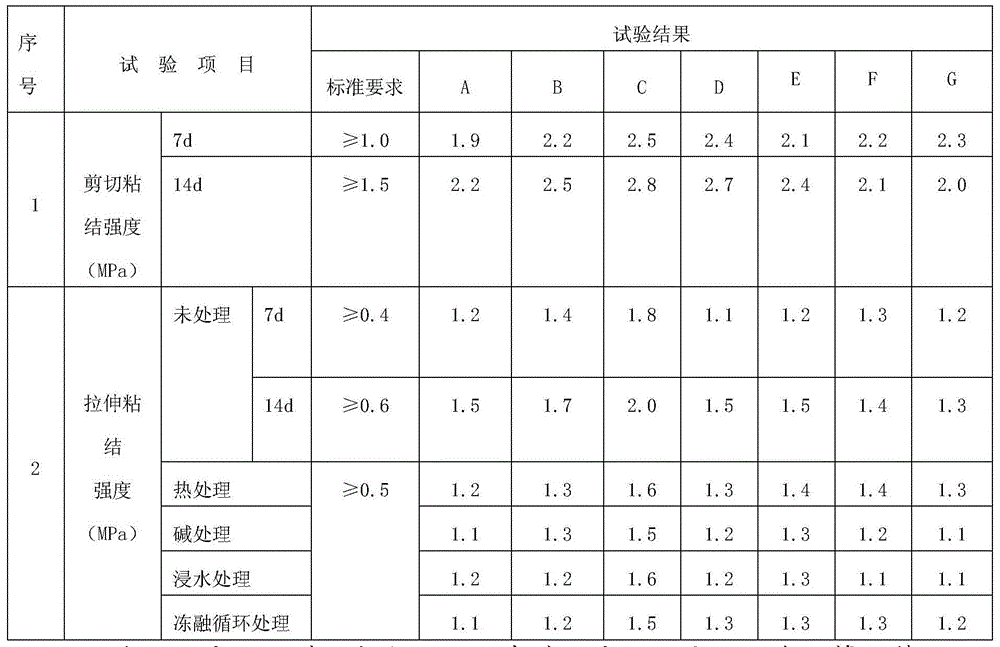

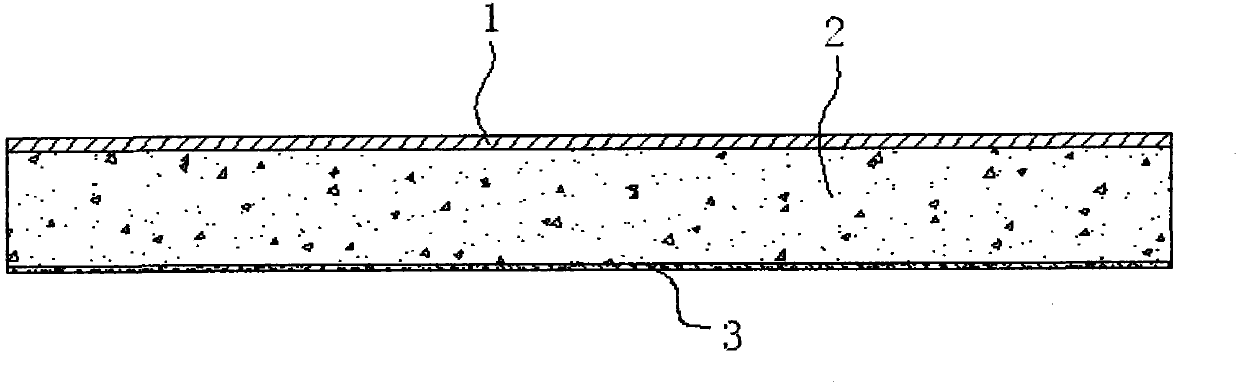

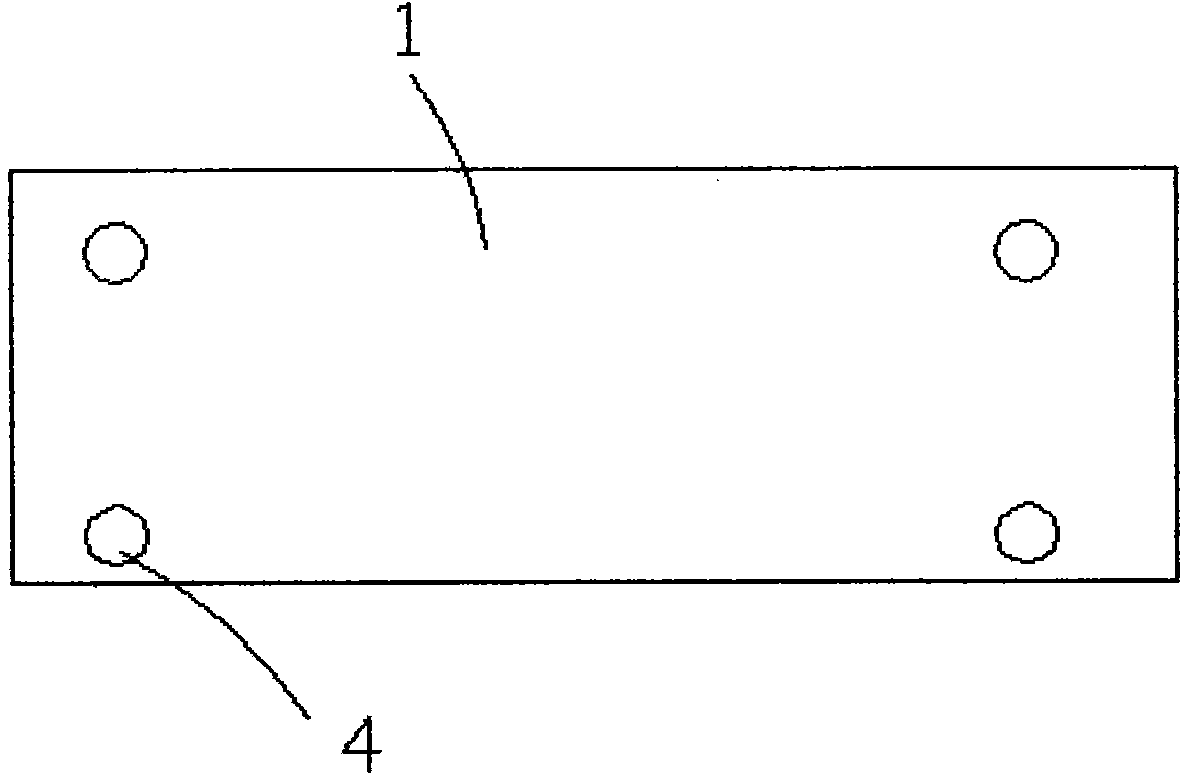

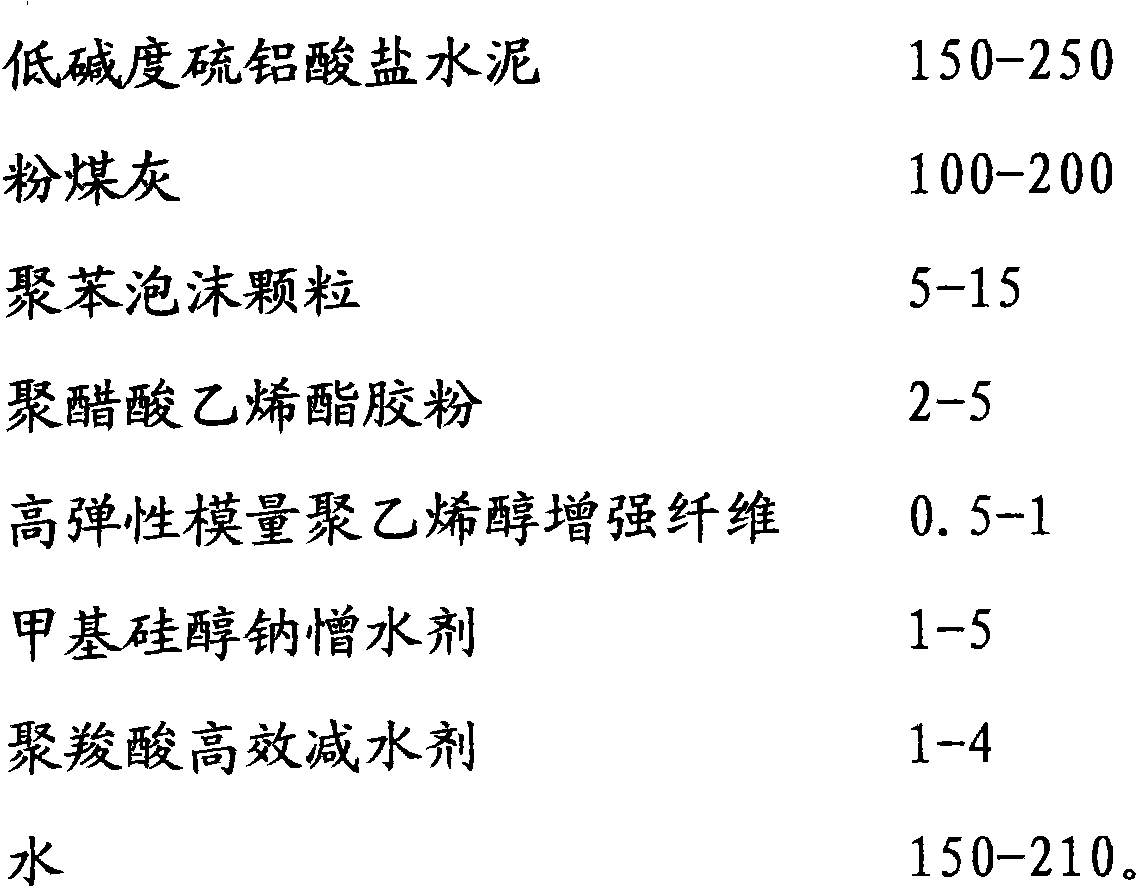

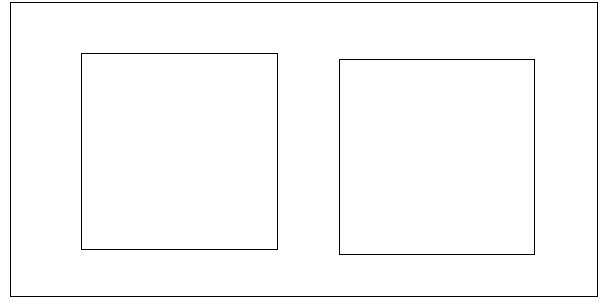

Composite insulation board and production method thereof

InactiveCN104863277AGood thermal performanceRealize integrationSolid waste managementHeat proofingCalcium silicateFiber

The invention discloses a composite insulation board and a production method thereof. The composite insulation board is formed by compositing a calcium silicate panel, glass fiber gridding cloth and lightweight concrete. The production method of the composite insulation board comprises steps as follows: the alkali-resistant glass fiber gridding cloth is fixed on an inner parathion of a vertical mold, and the calcium silicate panel with bonding holes leans in the mold; fly ash, polyphenyl foam particles, low-alkalinity sulphoaluminate cement, polyvinyl acetate glue powder, polyvinyl alcohol reinforced fibers with high modulus of elasticity, a sodium methylsilanolate water repellent, an efficient polycarboxylic acid water reducer and water are sequentially added to a stirrer in proportion and evenly stirred to form slurry; the slurry is pumped into a vertical mold through a high-pressure slurry pump; the slurry is demolded after curing and hardening and subjected to film winding, packaging and curing. The composite insulation board is high in strength and good in thermal insulation and fire prevention; the production method is simple and easy to implement due to adoption of ingredient stirring and pouring molding by the vertical mold. During usage, the construction technology is simple, the speed is high, time and labor are saved, and the economic benefit is significant.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Aerated concrete block and preparation method thereof

InactiveCN107162628AEasy to prepareSuitable for industrial productionCeramicwareGlass fiberHigh intensity

The invention discloses an aerated concrete block. The aerated concrete block is prepared from, by weight, 40-60 parts of coal ash, 30-40 parts of levigated quartz powder, 20-30 parts of desulfurized gypsum, 10-30 parts of talc powder, 10-20 parts of sepiolite powder, 5-15 parts of activated silicon material, 15-25 parts of lime, 5-10 parts of mica powder, 2-8 parts of lightweight ceramsite, 5-15 parts of quartz sand, 3-8 parts of gypsum, 5-15 parts of asbestos powder, 4-10 parts of glass fibers, 3-10 parts of aluminum powder, 2-6 parts of an air entraining agent, 1-5 parts of a foam stabilizer, 3-8 parts of a foam homogenizing agent and 60-80 parts of deionized water. The aerated concrete block meets requirements on heat insulation, energy saving and high strength, and a preparation method of the aerated concrete block is simple, convenient and suitable for industrial production.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

High-titanium type blast furnace slag concrete hollow brick

The invention discloses a high-titanium type blast furnace slag concrete hollow brick which gives consideration on both mechanical property and thermal performance, belonging to the field of concrete. The hollow brick is manufactured by casting concrete grout, and comprises the following raw material components according to the amount of the concrete grout of each cubic meter: 300-420kg of cement, 1,150-1,300kg of high-titanium type blast furnace slag sand with a particle size of 4.75-10mm, 680-800kg of high-titanium type blast furnace slag sand with a particle size of 0.16-4.75mm and 180-210kg of water. The high-titanium type blast furnace slag concrete hollow brick is produced by taking the high-titanium type blast furnace slag as a raw material, the production cost is saved, good economic benefits and social benefits are achieved, the requirements on compression resistance and shearing strength in the Brick Structure Design Specification GB50003-2001 are met, and the brick can be used as a wall material in construction engineering.

Owner:PANZHIHUA UNIV

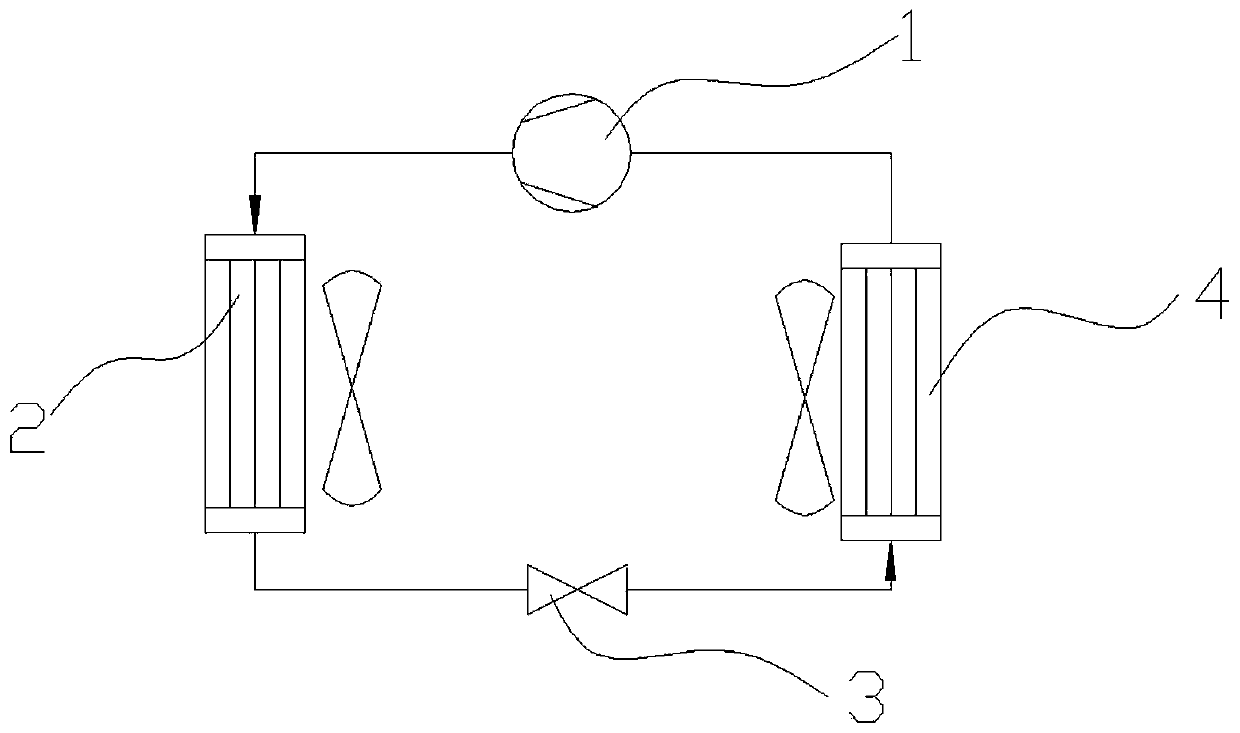

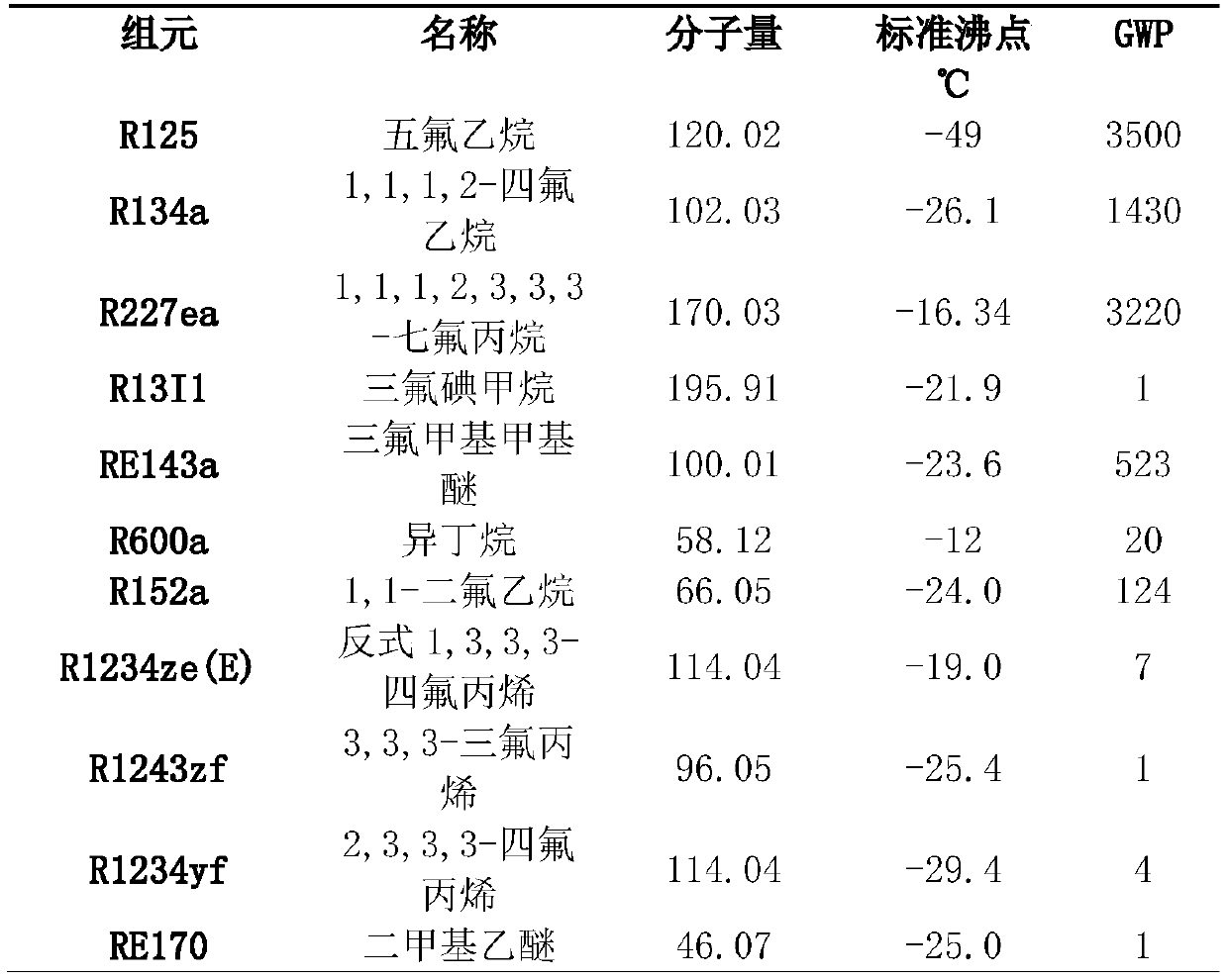

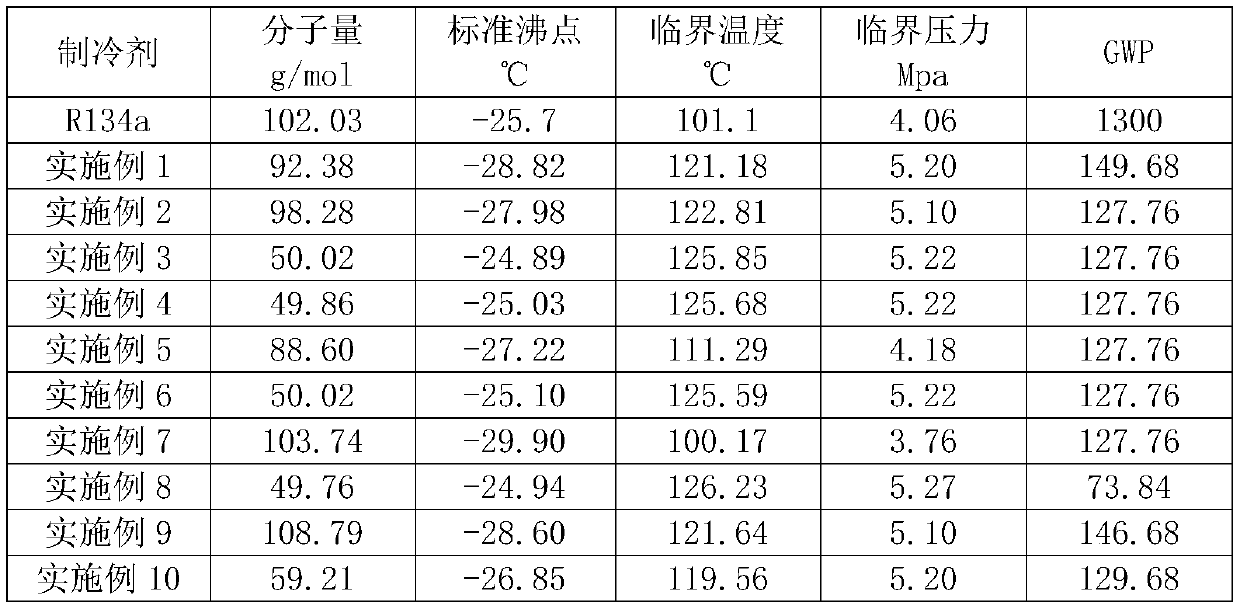

Car air-conditioning heat pump system adopting environment-friendly refrigerant

ActiveCN110843457AGood thermal performanceAvoid heat transfer efficiency reductionAir-treating devicesHeat pumpsAutomotive engineeringRefrigerant

The invention provides a car air-conditioning heat pump system adopting an environment-friendly refrigerant. The car air-conditioning heat pump system further comprises a compressor, an indoor side heat exchanger, a throttle valve and an outdoor side heat exchanger which are sequentially connected to form a closed loop, and the environment-friendly refrigerant adopted by the car air-conditioning heat pump system is prepared from four components in percentage by mass: 4%-8% of the first component, 4%-80% of the second component, 4%-88% of the third component and 4%-88% of the fourth component.GWP of the adopted refrigerant is less than or equal to 150, environment-friendly performance is good, and requirements of environment-friendly regulations in all global regions are met. Thermal performance of the car air-conditioning heat pump system is equivalent to or more superior to a refrigeration system heat pump system using R134a, and thus the car air-conditioning heat pump system adopting the environment-friendly refrigerant is used for replacing a car air-conditioning heat pump system adopting an R134a refrigerant.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

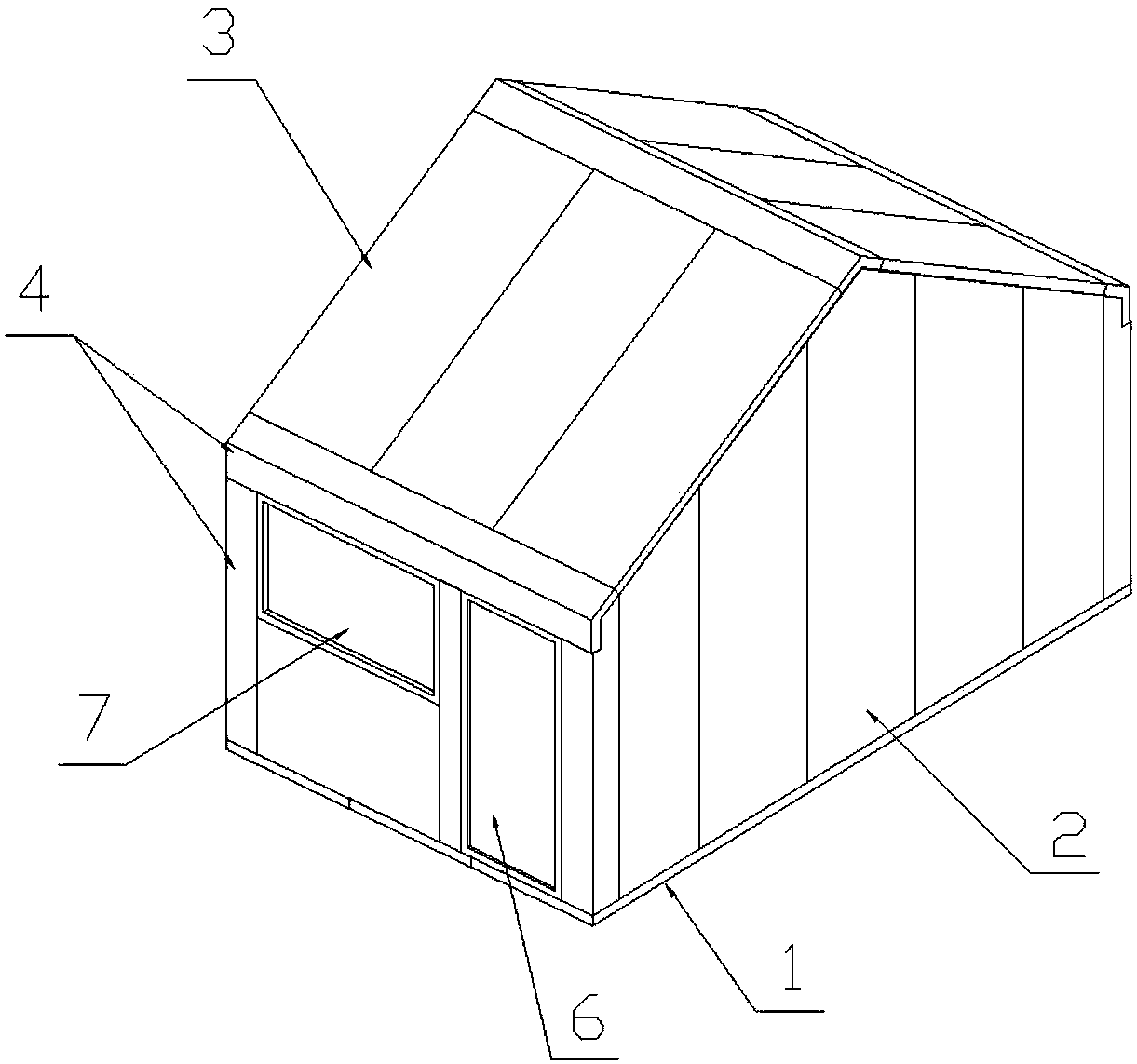

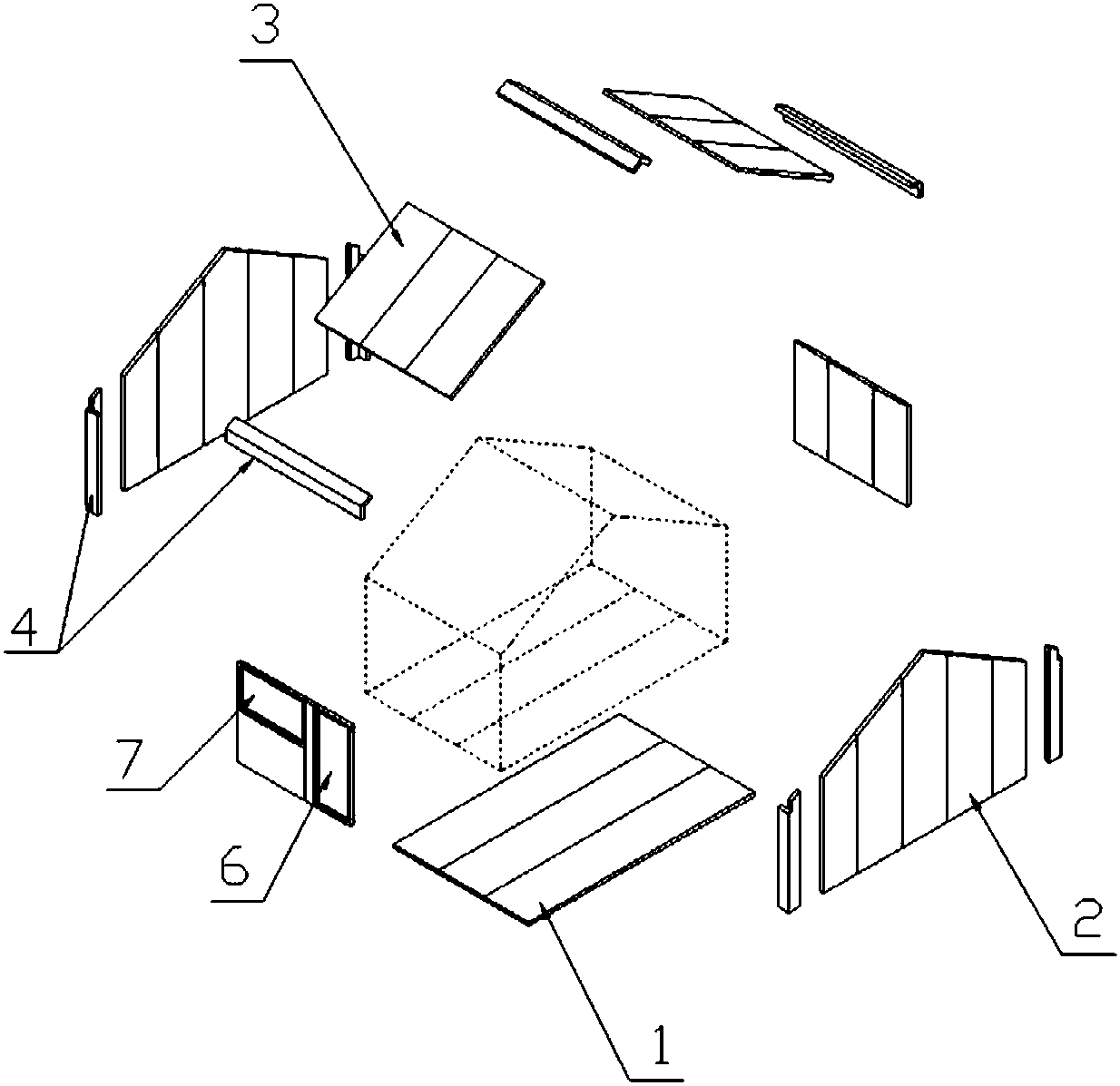

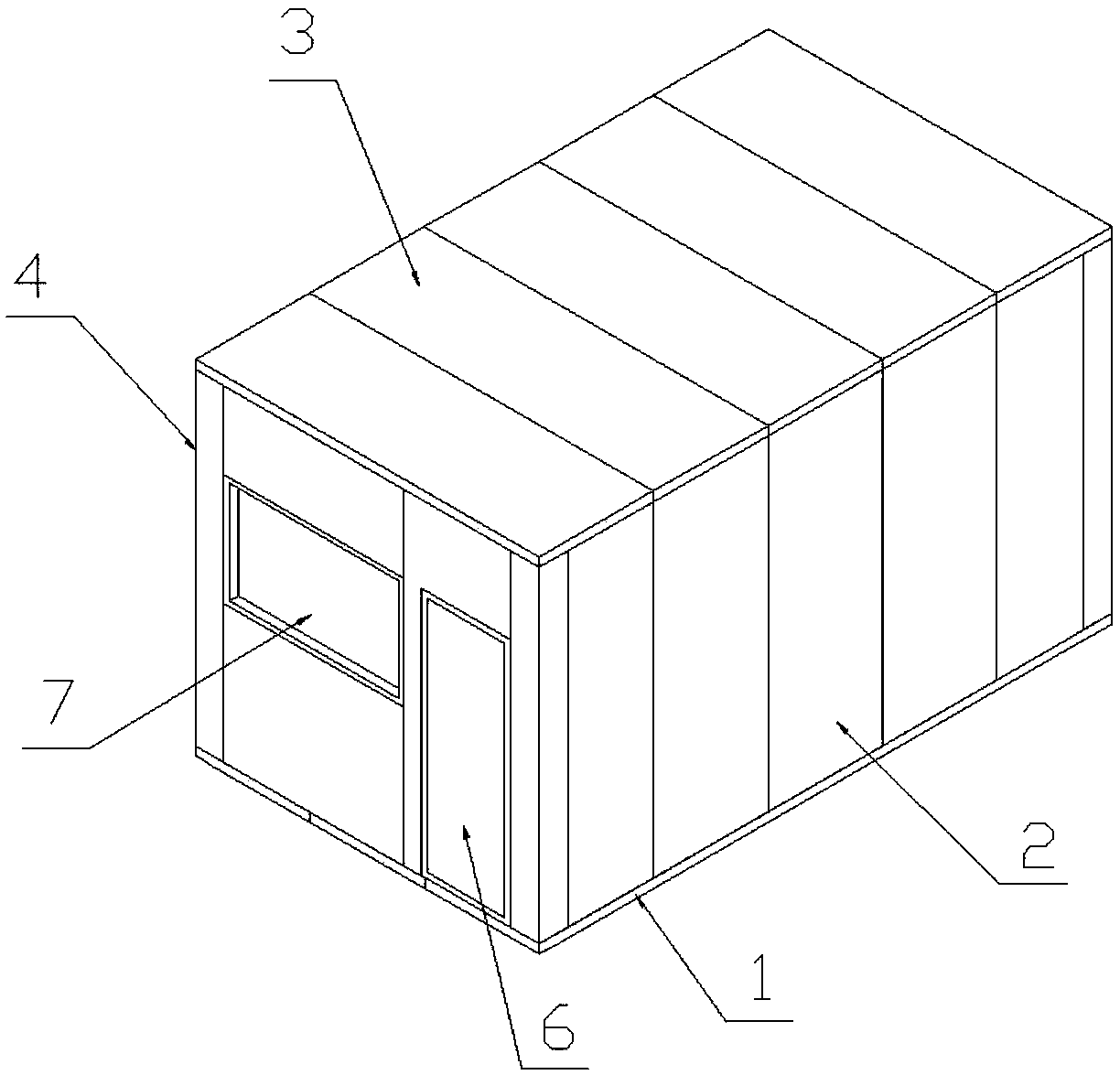

Fabricated house capable of being quickly assembled and disassembled

PendingCN108331173AFast installationSimple and fast constructionBuilding constructionsEngineeringWrench

The invention relates to a fabricated house capable of being quickly assembled and disassembled. The fabricated house comprises a floor panel, a wall panel and a roof panel, wherein the roof panel isinstalled horizontally or with a certain slope. The floor panel is composed of a plurality of modularized floor panel bodies, the wall panel is composed of a plurality of modularized wall panel bodies, and the roof panel is composed of a plurality of modularized roof panel bodies. The modularized floor panel bodies, the modularized wall panel bodies and the modularized roof panel bodies are prefabricated plates in advance, and eccentric hook lock catches are embedded in the modularized floor panel bodies, the modularized wall panel bodies and the modularized roof panel bodies to realized quickassembling and disassembling only through a hexagonal wrench. The fabricated house capable of being quickly assembled and disassembled can be embedded in old houses, and can also be directly used forbuilding outdoor houses, the process is simple, the installation speed is fast, the heat preservation and the sealing performance are good, the fabricated house can be disassembled and reused for multiple times, and the cost is reduced.

Owner:众造建筑设计咨询(北京)有限公司

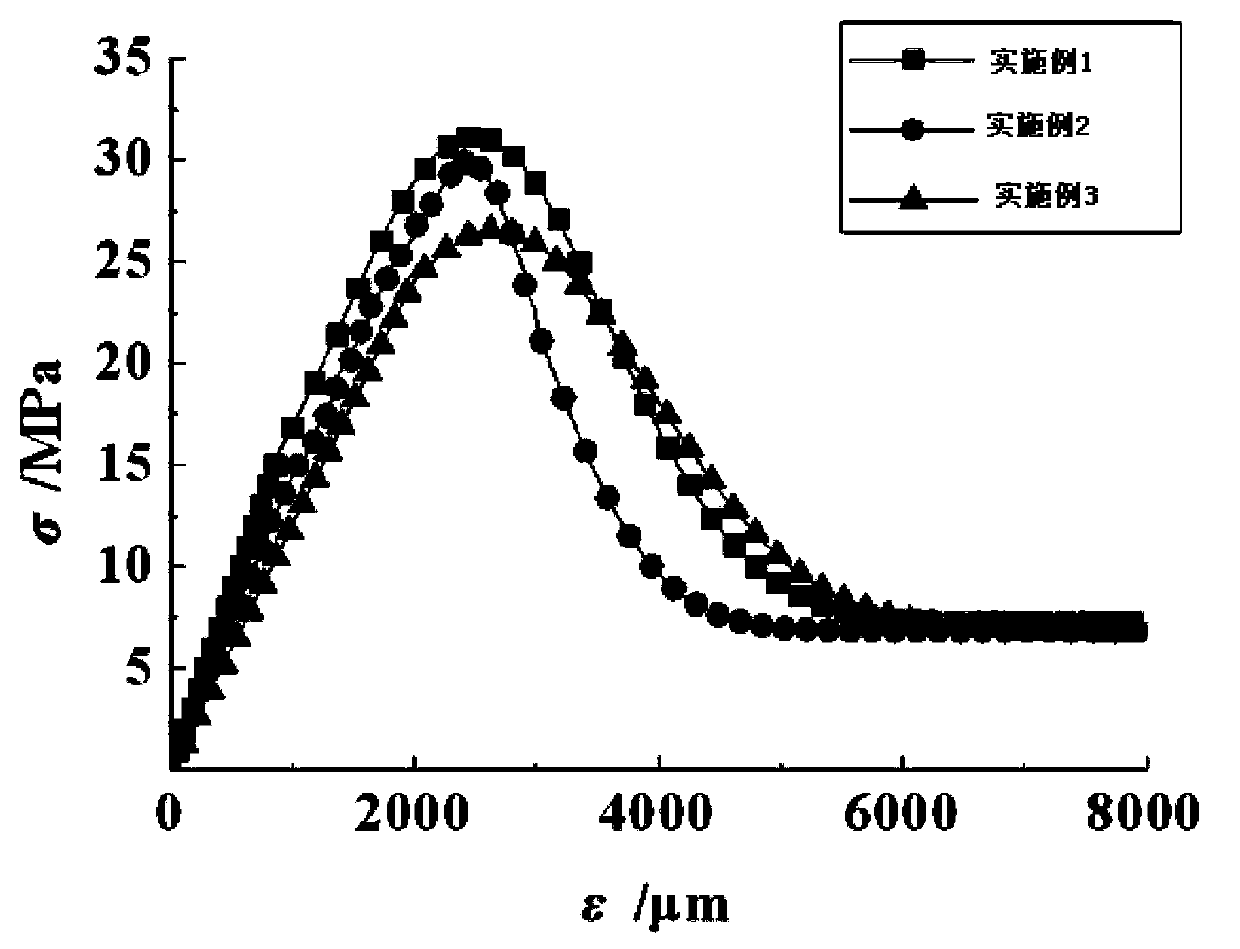

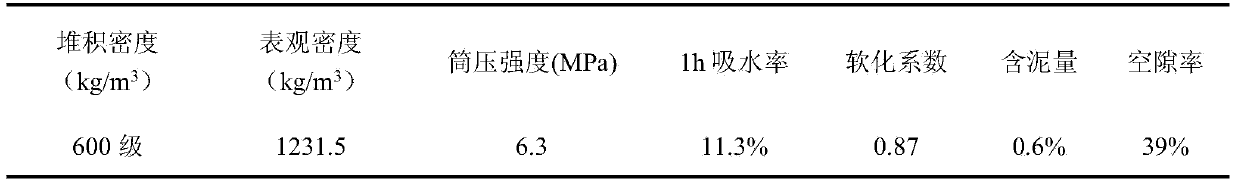

Light aggregate assembly type sheet material and production technology thereof

InactiveCN106946525ALow thermal conductivityGood thermal performanceBuilding material handlingCeramicwareThermal insulationThermal conductivity

The invention relates to a light aggregate assembly type sheet material and a production technology thereof. The sheet material is prepared from the following raw materials in parts by weight: 200 to 400 parts of cement, 100 to 200 parts of water, 350 to 460 parts of ceramsite, 0.2 to 0.4 part of foaming agent, 0.1 to 0.4 part of porcelainizing agent, 0 to 0.2 part of thickening and water retaining agent, 0 to 2 parts of water reducer, and 0 to 2 parts of plasticizer. The preparation method comprises the following steps: preparing raw materials according to the formula mentioned above, evenly mixing water, cement, a thickening and water retaining agent, a water reducer, a plasticizer, and a porcelainizing agent to obtain slurry, adding a foaming agent into the slurry to carry out foaming, then adding ceramsite, evenly mixing, pouring the mixture into a mould, carrying out curing for 24 hours, cutting, and performing maintenance. The provided light aggregate assembly type sheet material has the advantages of little thermal conductivity, good thermal performance, good soundproof and thermal insulation effect, low water absorption, high compression strength, and large hanging force, meets the requirements on wall strength, and integrates the advantages of foam concrete and light aggregate.

Owner:河南华泰新材科技股份有限公司

Self-insulating building block containing aerated concrete building waste

InactiveCN106495662ALarge thermal resistanceGood thermal performanceCeramic materials productionClaywaresPolyvinyl alcoholAbsorption rate

The invention discloses a self-insulating building block containing aerated concrete building waste. The self-insulating building block is prepared from the following raw materials in parts by mass: 5 to 9 parts of attapulgite, 60 to 80 parts of aerated concrete building waste, 3 to 5 parts of nano polytetrafluoroethylene, 0.5 to 0.9 part of nano nickel, 0.7 to 1.1 parts of tantalum carbide, 0.4 to 0.9 part of vanadium carbide, 0.9 to 1.1 parts of tungsten carbide, 1.2 to 1.5 parts of glass micro-beads, 30 to 45 parts of mixed solution I, an additive I accounting for 2 to 3 percent of the weight of the mixed solution I and an additive II accounting for 0.03 to 0.04 percent of the weight of the mixed solution I, wherein the mixed solution I comprises acrylic acid, polyvinyl alcohol, modified wheat straw and water. The self-insulating building block containing the aerated concrete building waste has the beneficial effects that the thermal performance is excellent, the weight is light, the strength is high, the early strength is high, the insulating performance is excellent, the product water absorption rate is low, no secondary byproduct is produced, the waste is used, the environmental protection is realized, and the delivery cycle of the building block is greatly shortened.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

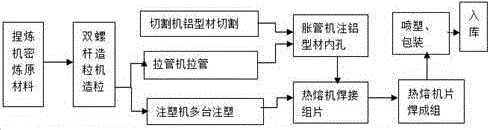

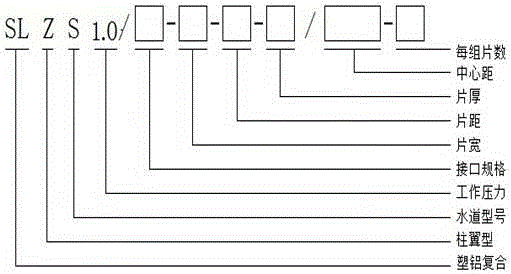

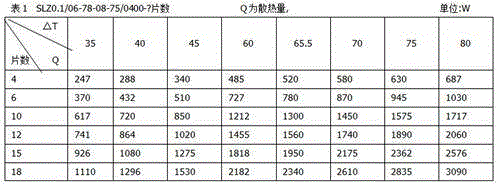

Thermal conductive plastic alloy, radiator based on alloy and preparation method

InactiveCN105175907AGood frost and heat resistanceStable molecular structureHeat exchange apparatusFiberAlloy

The invention discloses a thermal conductive plastic alloy used for a radiator, a radiator and a preparation method. The thermal conductive plastic alloy comprises polybutene or polyisobutene, polyethylene, graphite powder, carbon fiber, thermal conductive carbon black, a thermal conductive reinforcing agent, a titanate coupling agent and stearic acid. The thermal conductive plastic alloy is subjected to granulation, then pipe drawing and injection molding are carried out, an inner water channel pipe and a connecting piece of an radiator are prepared, the inner water channel pipe is expanded into an inner hole of an aluminum wing pipe of the radiator to obtain a radiator column material or sheet material, the column material or the sheet material and the connecting piece are subjected to sweat soldering to prepare a radiator single sheet, and finally the radiator single sheets are subjected to sweat soldering to compose a radiator. The thermal conductive plastic alloy and the radiator are advantaged by good environmental protection and excellent heat radiation performance, are stable and durable, and have protruding characteristics of no fouling, no rusting, no corrosion, no cracking, no pollution, no deformation, no abnormal sound and no aging.

Owner:徐继煌

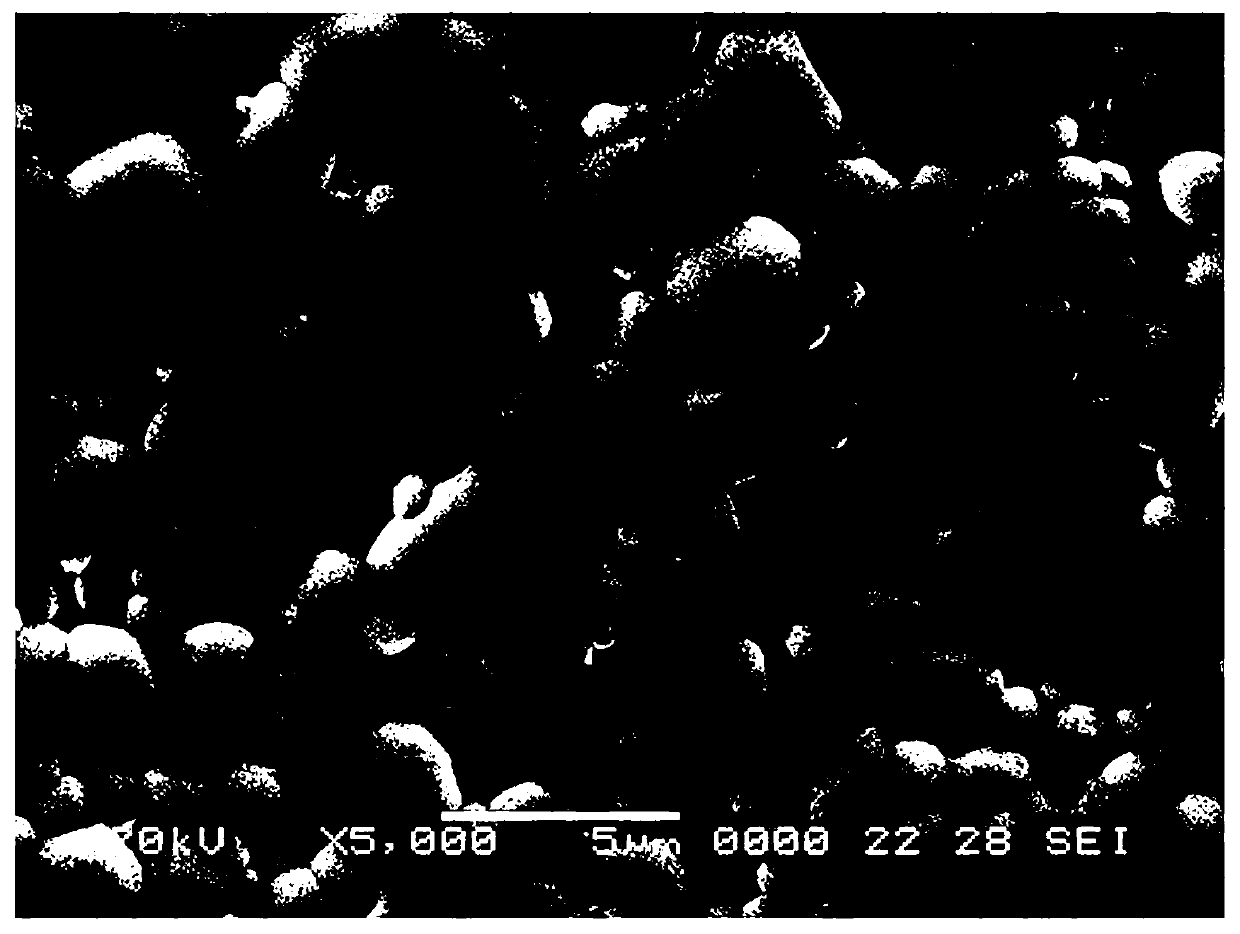

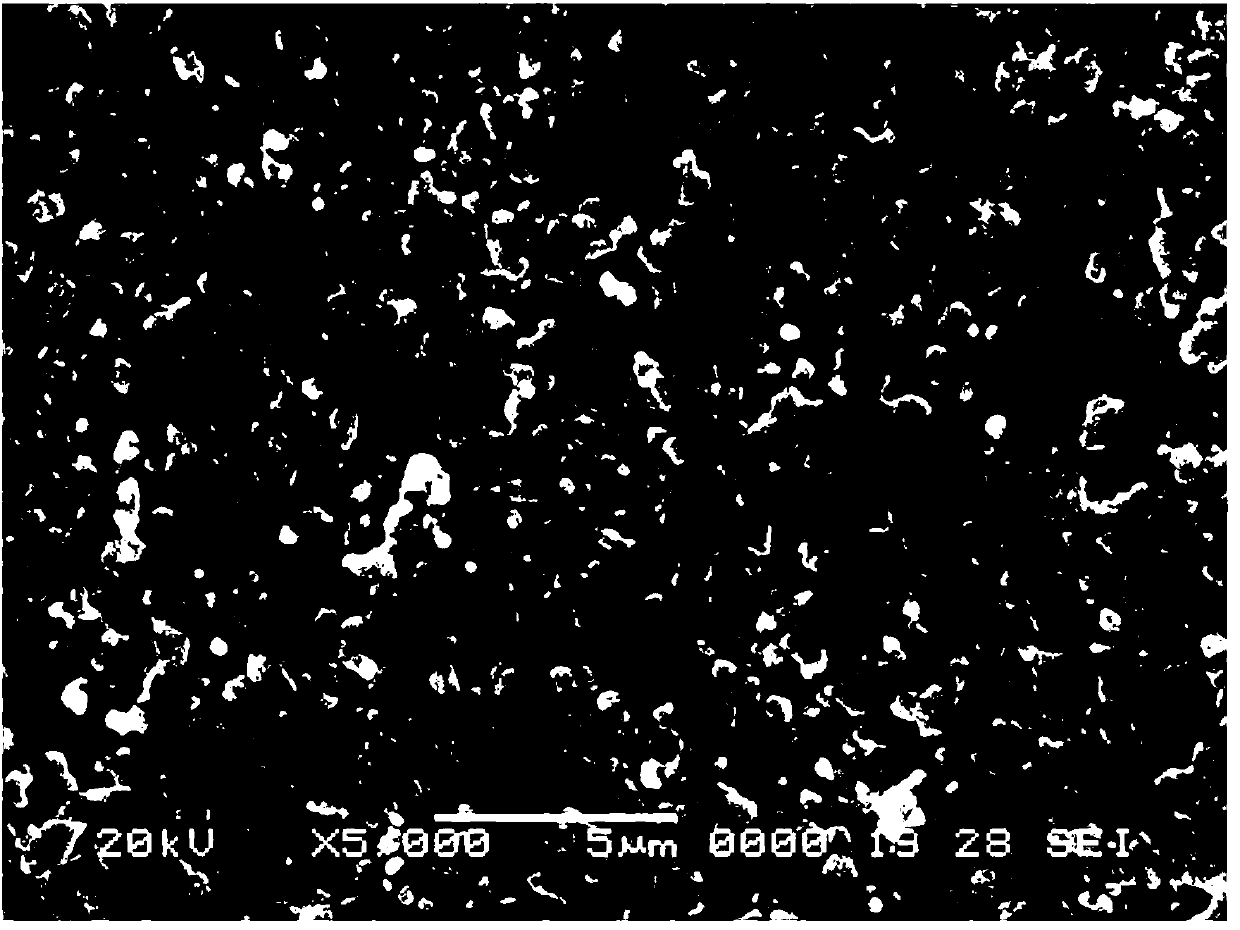

Low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material and preparation method thereof

The invention discloses a low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material and a preparation method thereof. According to the preparation method, (1-x)BiFeO3-xMeMO3 powder is firstly synthesized, no SiO2 or a small amount of SiO2 is doped, and the SiO2-doped (1-x)BiFeO3-xMeMO3 thermosensitive ceramic material is formed through compression molding and sintering. According to the low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material prepared by the preparation method, the sintering temperature is lower than 95 DEG C, the performance is stable, and shown by property tests, the following better comprehensive thermosensitive properties can be obtained: the thermosensitive constant beta25 / 85 is higher than 5,000 K, the room-temperature resistivity rho25 is lower than 1,000,000 ohm.cm, and the aging rate eta is lower than 5%. According to the preparation method, a traditional ceramic solid phase sintering preparation process is adopted, and the adopted process is relatively simple and stable, so that the preparation method has higher practicality and popularization and application prospects.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Thermal-insulation healthy clothes shell fabric

InactiveCN103526400AGood thermal performanceGood warmth retentionWeft knittingSynthetic resin layered productsThermal insulationPolyester

The invention discloses a thermal-insulation healthy clothes shell fabric. The thermal-insulation healthy clothes shell fabric comprises an outer layer shell fabric body, a middle windproof layer shell fabric body and an inner layer thermal-insulation shell fabric body which are sequentially arranged from outside to inside. The outer layer shell fabric body is formed by weaving tencel fibers and cotton fibers, the middle windproof layer shell fabric body is formed by weaving polyester yarns and nylon yarns, and the inner layer thermal-insulation shell fabric body comprises kapok fibers, bamboo carbon fibers, coffee carbon fibers and cashmere wool fibers. By means of the method, the thermal-insulation healthy clothes shell fabric is excellent in thermal insulation and further has anti-bacterium and health-care functions.

Owner:JIANGSU HAODA

Steaming-free aerated brick prepared by utilizing construction waste and preparation method thereof

InactiveCN106187281ALow densityGuaranteed uniformity and stabilitySolid waste managementCeramicwareBrickShock resistance

The invention discloses a steaming-free aerated brick prepared by utilizing construction waste. The steaming-free aerated brick is prepared from the following components in parts by weight: 20 to 30 parts of the construction waste, 30 to 60 parts of pulverized fuel ash, 30 to 50 parts of cement, 5 to 10 parts of desulfurized dihydrate gypsum, 3 to 8 parts of quicklime, 0.5 to 1 part of aluminum powder paste, 4 to 6 parts of ultra-light ceramic particle, 1 to 5 parts of silica aerogel, 1 to 2 parts of naphthyl sulfonate formaldehyde condensate, 2 to 5 parts of retarding agent and 30 to 50 parts of water. The invention also discloses a preparation method of the steaming-free aerated brick. The steaming-free aerated brick made by using the method is light in weight, good in heat preservation performance and heat insulation performance, high in shock resistance ability and excellent in compression resistance performance, and has certain high temperature resistance performance, good sound insulation performance and high adaptability; further, the preparation method is simple; the production cost is low.

Owner:绍兴职业技术学院

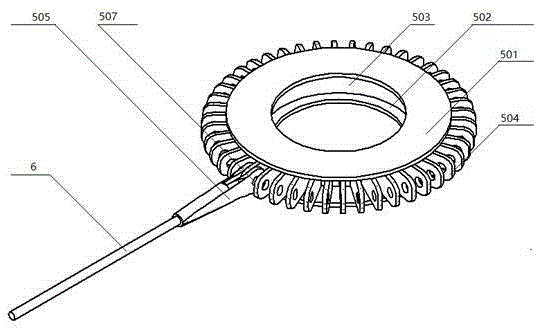

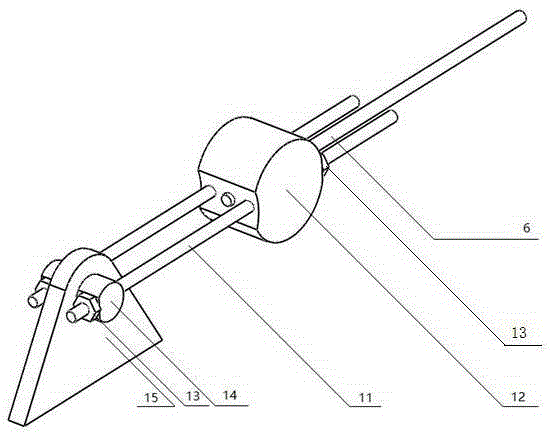

Steel-structure hyperbolic air cooling tower

Provided is a steel-structure hyperbolic air cooling tower. The outer contour of a steel netty supporting structure is a single-leaf hyperbolic rotating surface, a barrel formed by aluminum skin is installed in the steel netty supporting structure, the outer contour of the barrel is also a single-blade hyperbolic rotating surface, and multiple layers of radial tension steel cables are installed in the hyperbolic barrel. Each radial tension steel cable is composed of a center tension ring, steel cables, first steel cables and pins; each center tension ring is an annular component and comprises an upper tension annular plate and a lower tension annular plate, an annular web is fixedly connected between each upper tension annular plate and the corresponding lower tension annular plate, and the peripheral cylindrical surface of each annular web is fixedly connected with pulling plates at equal angles; one end of each steel cable is fixedly connected with the corresponding first steel cable, each first steel cable is hinged to the corresponding pulling plate through a pin, the other end of each steel cable is fixedly connected with a second steel cable, and the second steel cables are connected to the steel netty supporting structure. According to the steel-structure hyperbolic air cooling tower, the problems that for an ultra-large type hyperbolic air cooling tower, vibration resistance is weak, the tower height is limited, and the heat exchange performance is poor are solved.

Owner:哈博林技术公司 +1

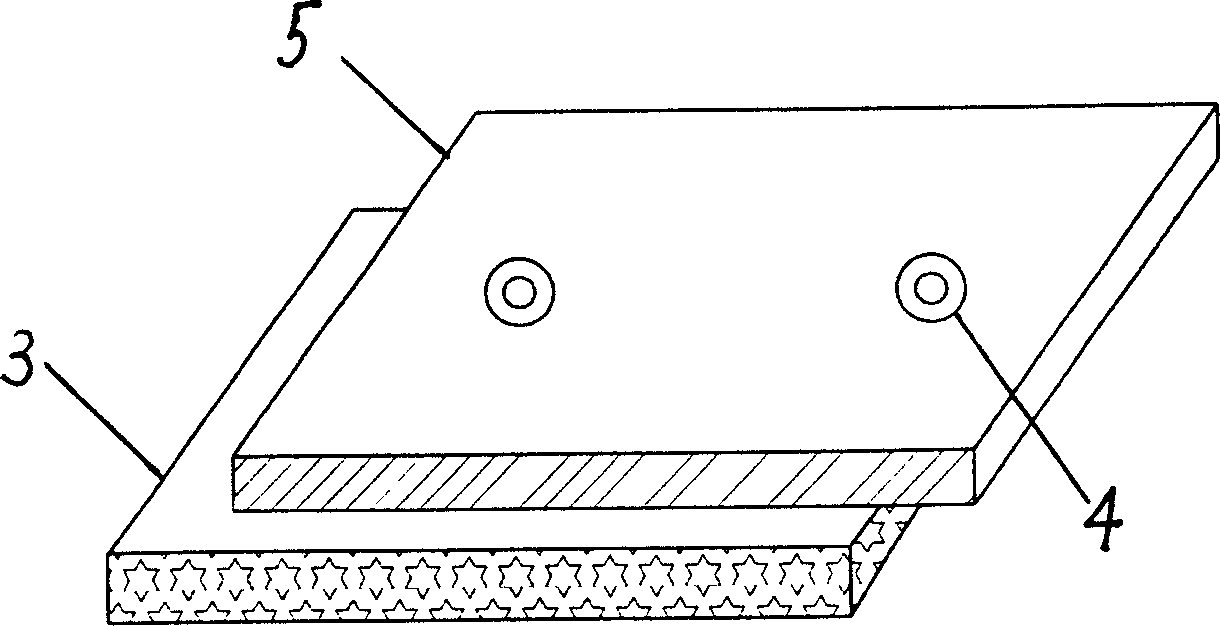

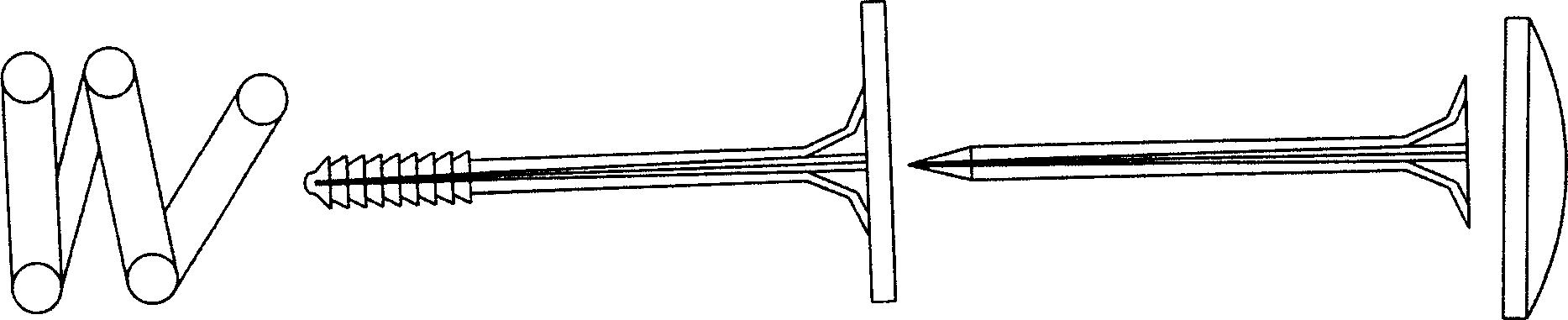

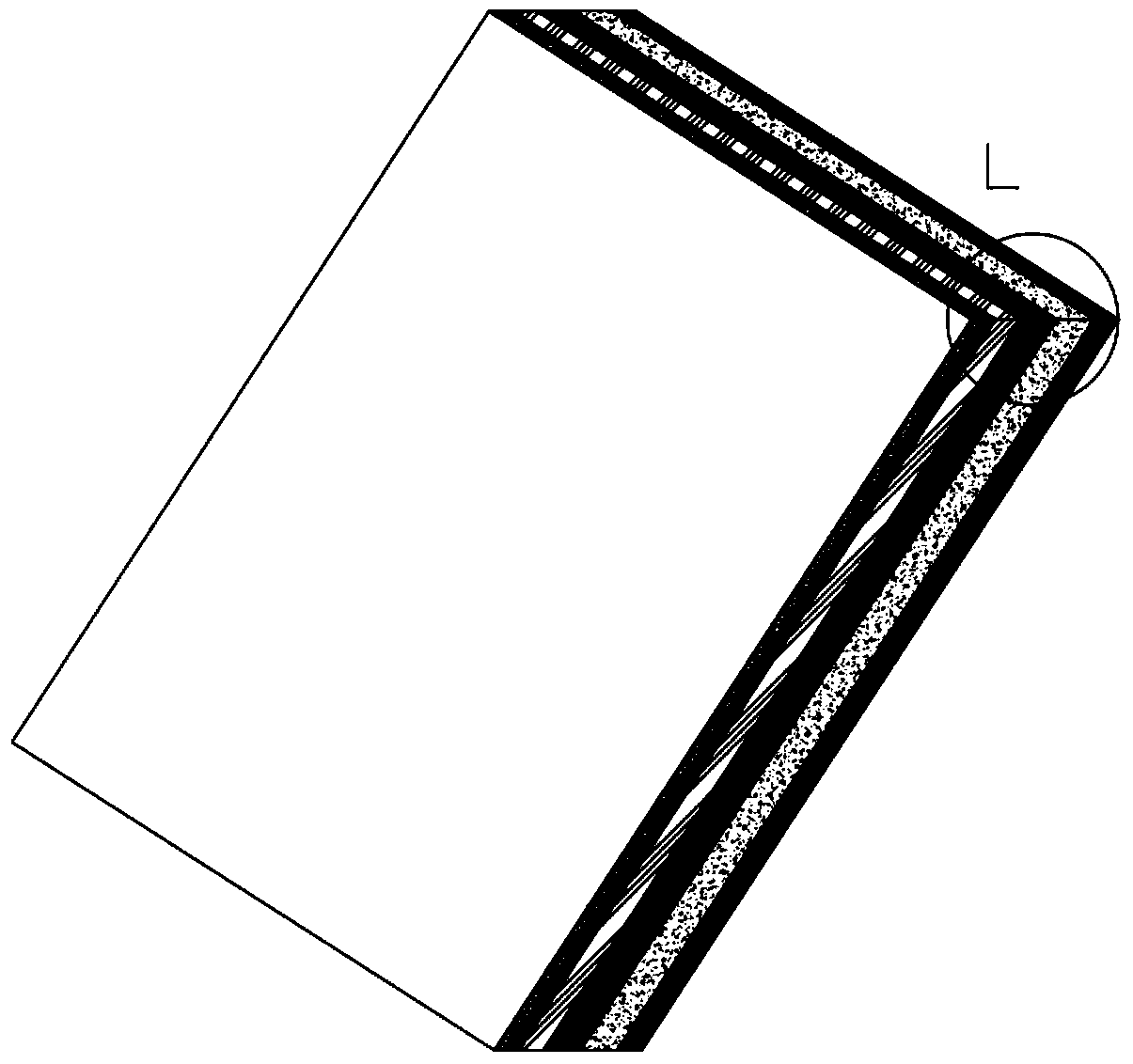

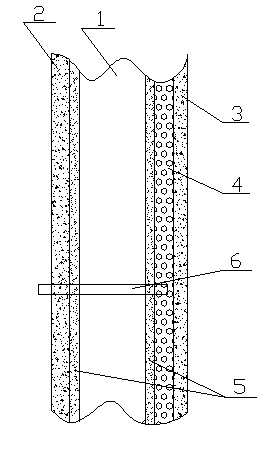

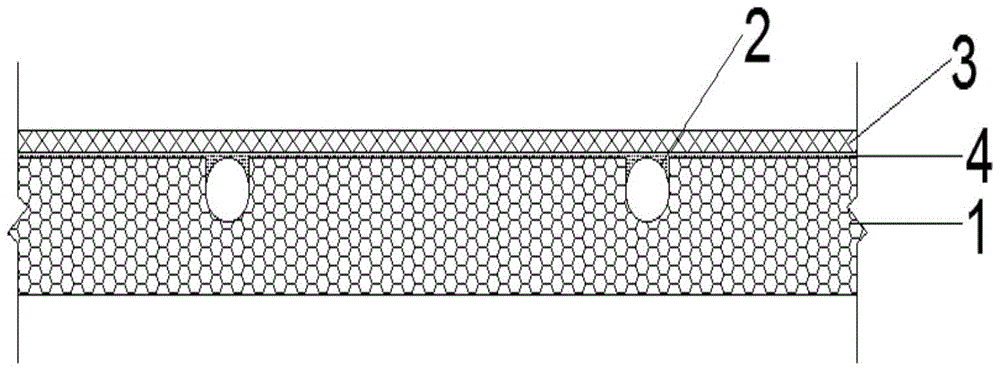

Reinforced composite thermal insulation template

InactiveCN103015703AEasy to produceGood thermal performanceForming/stuttering elementsThermal insulationMechanical engineering

The invention relates to the technical field of the wall body thermal insulation used for buildings, in particular to a reinforced composite thermal insulation template. The invention aims to provide the reinforced composite thermal insulation template, which has the advantages of low manufacture cost and good thermotechnical performance, and the phenomenon that an outer side cement base and other adhesive layers are fallen after a thermal insulation template body is molten by the high temperature of big fire is avoided. The purpose of the reinforced composite thermal insulation template is realized by the following technical scheme that the reinforced composite thermal insulation template comprises a thermal insulation template body, wherein the inner side of the thermal insulation template body is provided with a reinforcement layer, and the outer side of the thermal insulation template body is provided with an outer side reinforcement layer. The reinforced composite thermal insulation template is characterized in that the inner side reinforcement layer is connected with the outer side reinforcement layer by a connection piece made of noncombustible or fire-retardant materials. The reinforced composite thermal insulation template has the beneficial effects that a rock wool or foam thermal insulation template is molten by the high temperature of the big fire when the composite thermal insulation template is burnt in the big fire, the outer side cement base and other adhesive layers can not collapse or fall because the outer side cement base, an inner side cement base and a cast-in-place concrete wall body are connected by the connection piece made of noncombustible or fire-retardant materials, and potential safety hazards are eliminated.

Owner:SHANDONG HUIXING TECH DEV

Rigid polyurethane foam culture stone and production method thereof

InactiveCN101649674ASmall adjustment rangeHigh closed cell rateCovering/liningsThermal insulationEngineering

The invention aims at the shortcomings that the current culture stones are heavy in weight, high in cost or poor in thermal insulation properties and have poor bondability with the building blocks, masonries and the like, are easily spalled, have short service lives and the like, and provides a rigid polyurethane foam (RPUF) culture stone and a production method thereof. The RPUF product with goodbondability, good thermal insulation property, light materials and long service life is obtained by improving the culture stone raw materials, production steps and technological conditions, which issuitable for the indoor and outdoor decoration in various environments.

Owner:宿迁特力新材料有限公司

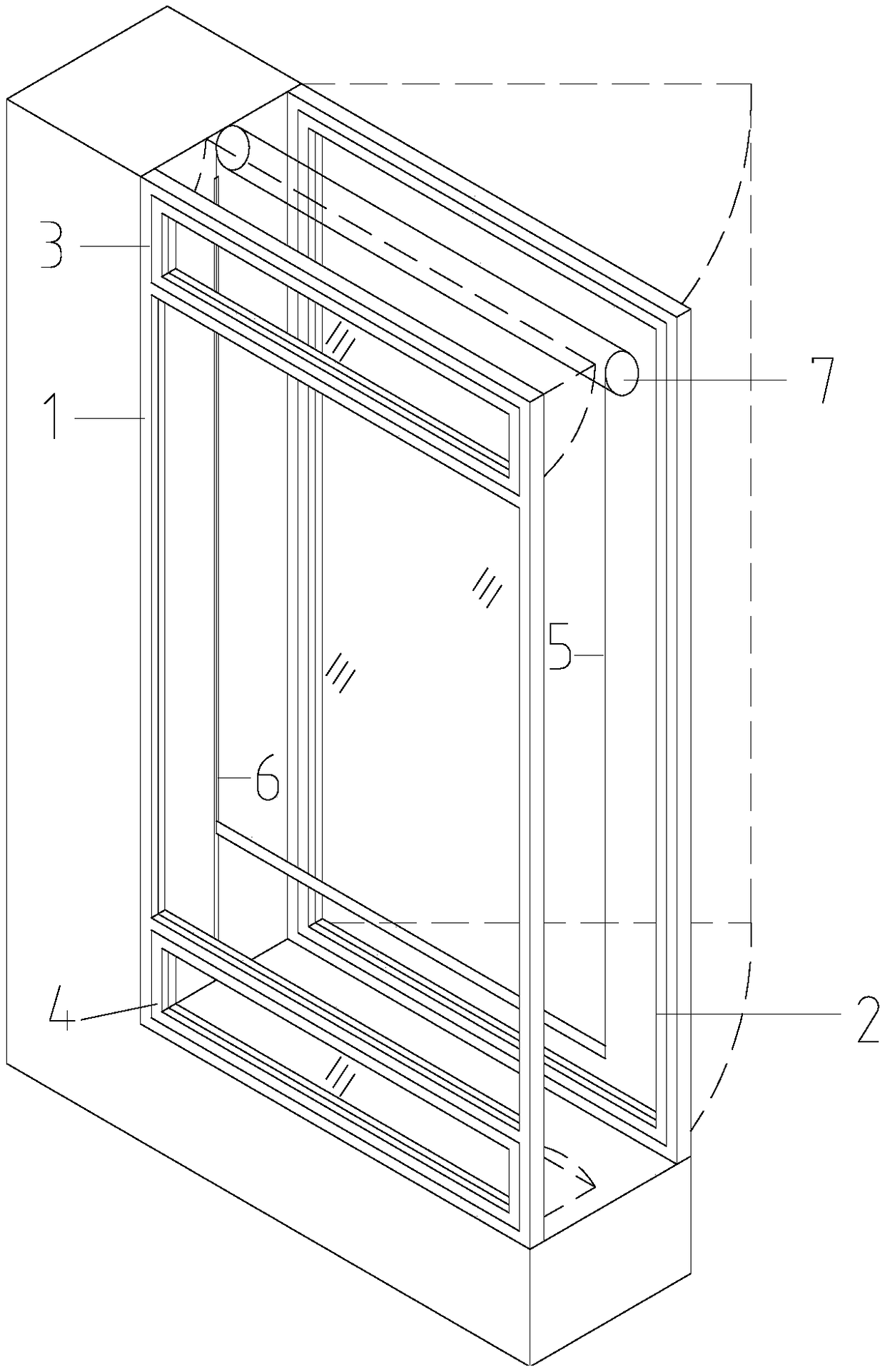

Central external sunshade system

The invention discloses a central external sunshade system. The central external sunshade system comprises an inner layer open glass window sash, an outer layer fixed glass window, and a sunshade curtain arranged between the inner layer open glass window sash and the outer layer fixed glass window. The inner layer open glass window sash, the outer layer fixed glass window and the sunshade curtainare mounted on a window frame. Inwards-opening sealing window sashes are arranged at the upper end and the lower end of the outer layer fixed glass window. The central external sunshade system is convenient to mount. Daily use and maintenance are convenient. The central external sunshade system is excellent in thermal performance. In summer, the central external sunshade system has the best effectof building external shading and can prevent conduction of thermal radiation into a room. In winter, full heat energy absorption is achieved in sunlight, and full heat preservation and energy savingare achieved without sunlight. The energy-saving requirements of green buildings are more reasonably and dynamically met. The sunshade, heat dissipation, heat absorption and thermal insulation properties of existing glass curtain walls and external windows are improved, and thermal performance of energy-saving buildings in China are enhanced and supplemented.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

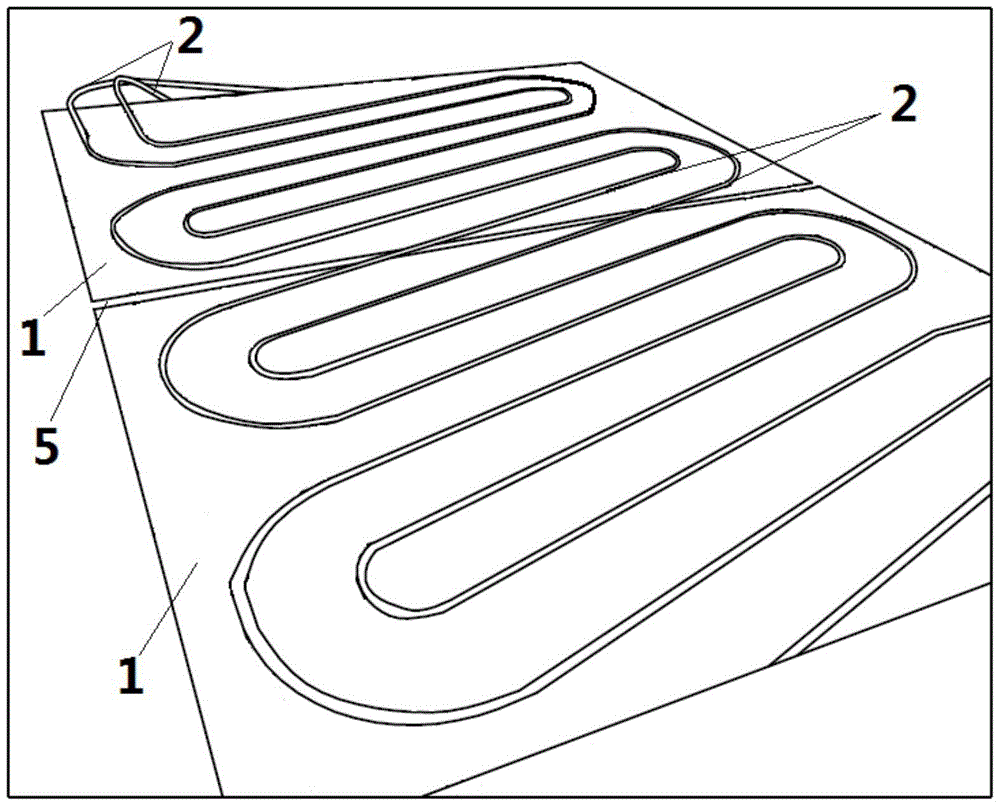

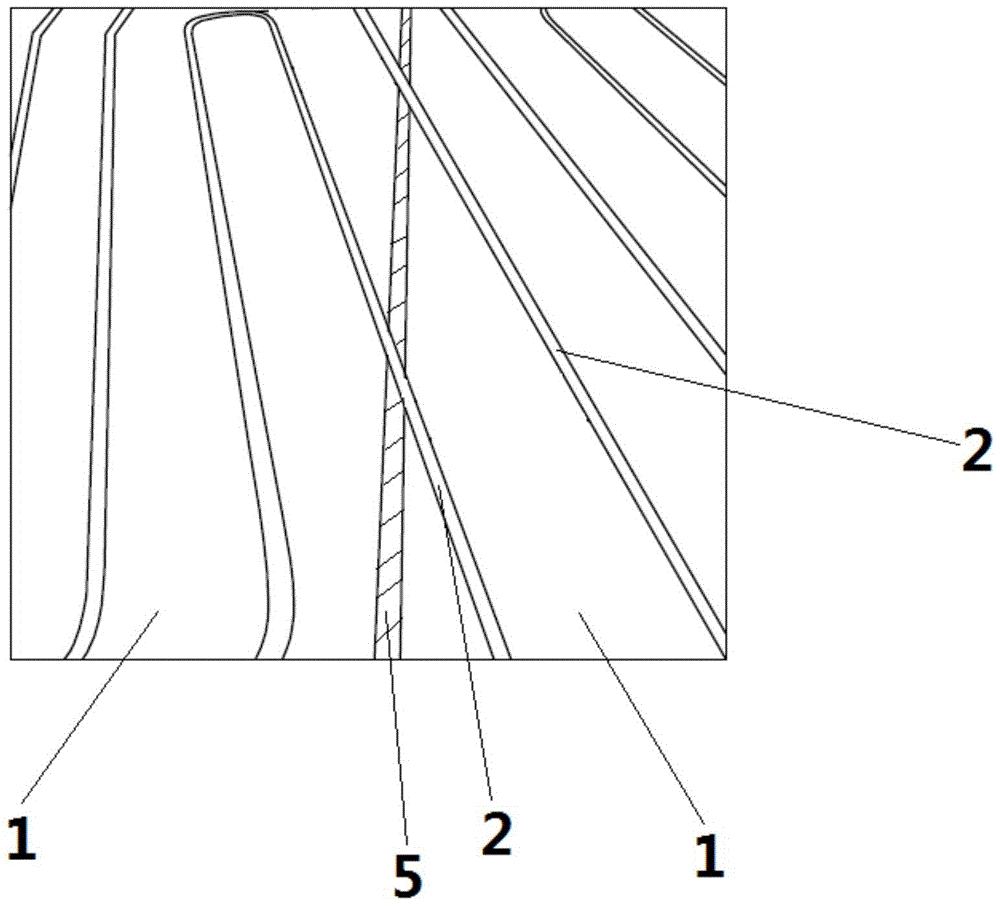

High-strength foldable prefabricated floor heating plate and manufacturing method thereof

InactiveCN105672609AImprove structural strengthGood thermal performanceLighting and heating apparatusFlooringPolystyreneCement board

The invention provides a high-strength foldable prefabricated floor heating plate and a manufacturing method thereof. A cement plate, a polystyrene board and a heating pipe serve as main materials, and the manufactured high-strength foldable prefabricated floor heating plate is good in integral thermal performance, high in structural strength, long in service life, foldable, convenient to transport and simple and convenient to install on the site. The method is simple, and specifications and a heating pipe laying mode can be selected according to actual demand and design; gaps and the heating pipe are adopted to be matched with the included angle of the side edge of the foldable prefabricated floor heating plate; when the obtained foldable prefabricated floor heating plates are folded with each other, heating water pipes arranged in the foldable prefabricated floor heating plates have small rotation and deformation and do not damage easily, and thus the foldable prefabricated floor heating plates can be folded through 180 degrees; and the foldable prefabricated floor heating plates folded through 180 degrees have a small occupied space and are convenient to transport. The method for manufacturing the high-strength foldable prefabricated floor heating plate is suitable for large-scale batch assembly production.

Owner:RHEIN TECH BEIJING ENERGY EFFICIENCY TECH CO LTD

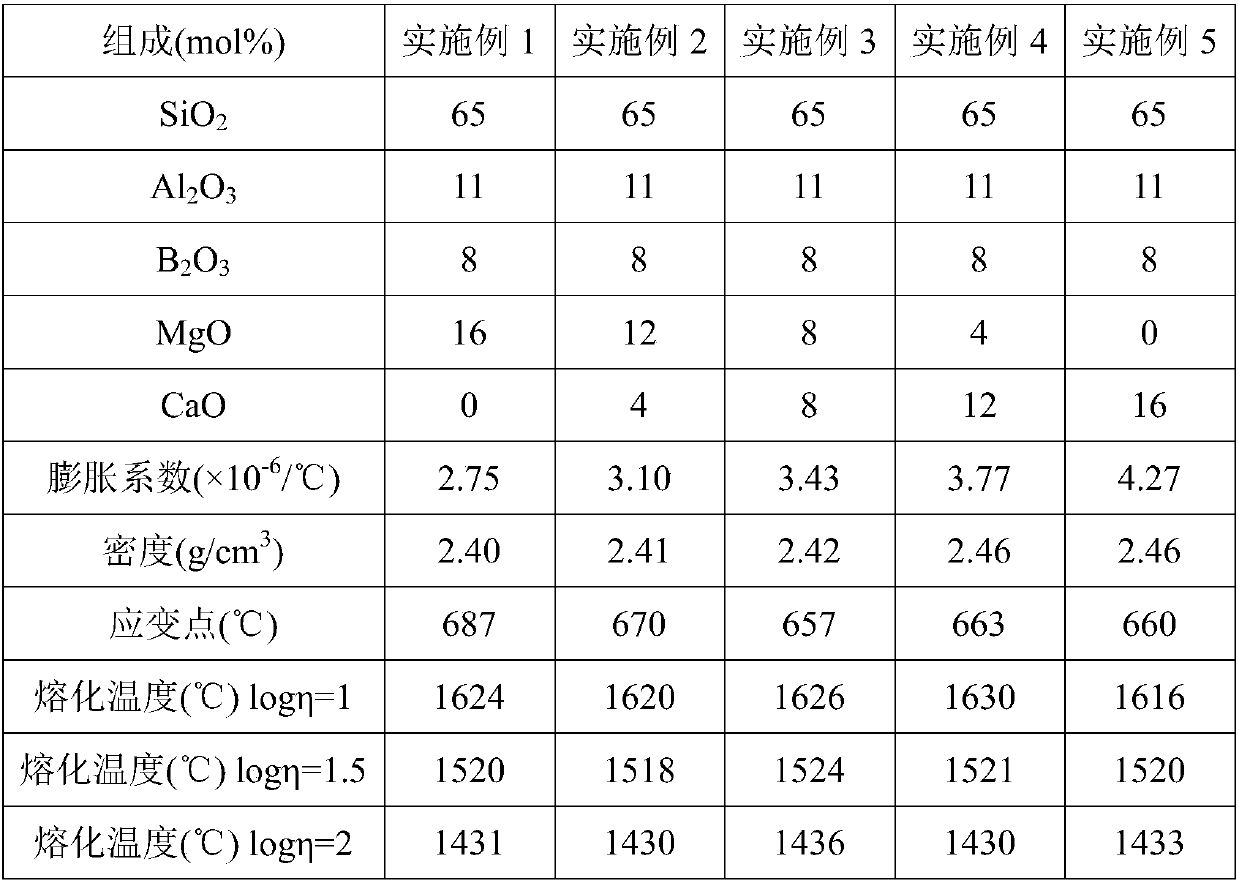

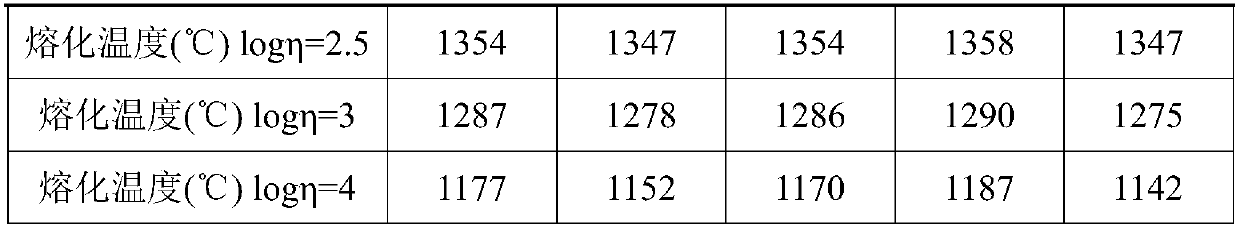

Alkali-free aluminoborosilicate glass and application thereof

InactiveCN109608039ANo crystallizationGreatly adjusted coefficient of thermal expansionAlkali freeLiquid-crystal display

The invention relates to alkali-free aluminoborosilicate glass. The glass is prepared from, by molar ratio, 61.00-65.00% of SiO2, 11.00-12.00% of Al2O3, 6.00-8.00% of B2O3, (16.00-x)% of R1O, and x% of R2O (X=0-16), wherein R1O and R2O are selected from one of the alkaline earth metal oxides such as MgO, SrO and CaO, and R1O and R2O are different. The optimum ratio of the linear expansion coefficients of alkaline earth metal oxides is 0.25 <MgO / (MgO+CaO)<0.5, CaO / (CaO+SrO)=0.5, and MgO / (MgO+SrO) = 0.5. The alkali-free aluminoborosilicate glass has the advantages of being low in density, high in strain point, suitable for the float production process, and capable of being applied to a thin film transistor liquid crystal displayer.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com