Alkali-free aluminoborosilicate glass and application thereof

A technology of borosilicate glass and alkali aluminum, applied in the field of alkali-free alumino borosilicate glass and its application, to achieve the effect of facilitating float production, increasing difficulty and cost, and adjusting thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

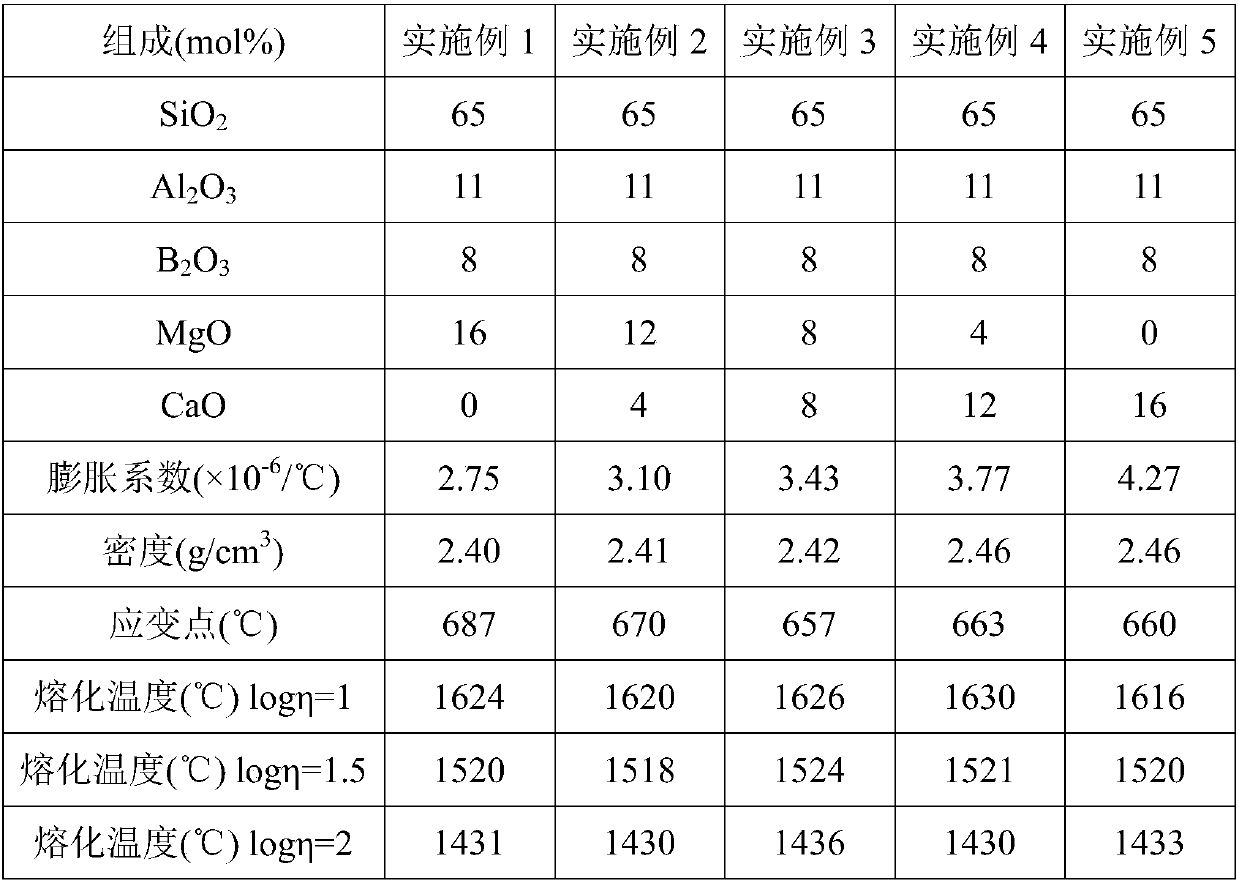

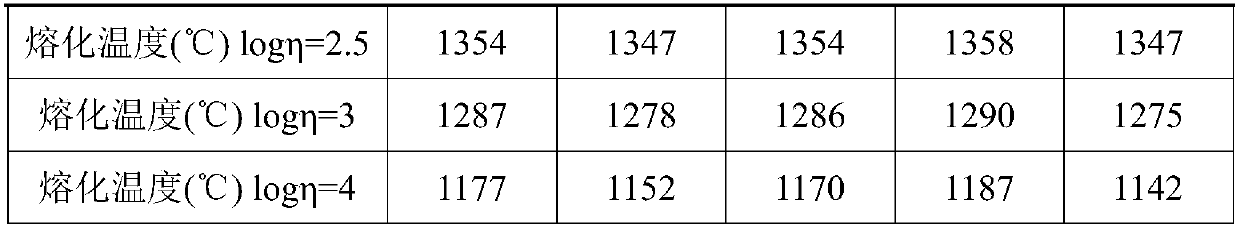

[0023] The chemical composition (each component is measured in mole percent) and performance index of the alkali-free aluminoborosilicate glass respectively provided in Examples 1-5 are shown in Table 1, and the alkaline earth metal oxides are MgO and CaO.

[0024] Table 1. Glass compositions with different MgO-CaO ratios

[0025]

[0026]

Embodiment 6-10

[0028] The chemical composition (each component is measured in mole percent) and performance indexes of the alkali-free aluminoborosilicate glass respectively provided in Examples 6-10 are shown in Table 2. The alkaline earth metal oxides are CaO and SrO.

[0029] Table 2. Glass compositions with different CaO-SrO ratios

[0030] Composition (mol%)

Embodiment 11-15

[0032] The chemical composition (each component is measured in mole percent) and performance indexes of the alkali-free aluminoborosilicate glass respectively provided in Examples 11-15 are shown in Table 3, and the alkaline earth metal oxides are MgO and SrO.

[0033] Table 3. Glass compositions with different MgO-SrO ratios

[0034]

[0035]

[0036] As can be seen from Table 1, when MgO+CaO=16mol%, adjusting the MgO / CaO ratio regulates the thermal expansion coefficient of the glass, especially when 0.253 , the strain point is above 650°C, and the corresponding temperature of logη=1 is less than 1630°C.

[0037] It can be seen from Table 2 that when CaO+SrO=16mol%, adjusting the ratio of CaO / SrO regulates the thermal expansion coefficient of the glass, especially when CaO / (CaO+SrO)=0.5, Example 8 can make the thermal expansion coefficient close to the optimal range , the density is less than 2.60g / cm 3 , the strain point is above 650°C, and logη=1 corresponds to a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com