Antioxidant acne-removing repair essence and preparation method thereof

An anti-oxidation and essence technology, applied in the field of anti-acne repair essence and its preparation, in the field of anti-oxidation, can solve the problems of inability to dissolve and disperse, difficult for skin absorption and utilization, easy recrystallization and precipitation of cannabidiol, etc., and achieves the effect of moisturizing and moisturizing Good, increase transdermal absorption effect and bioavailability, clear and transparent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

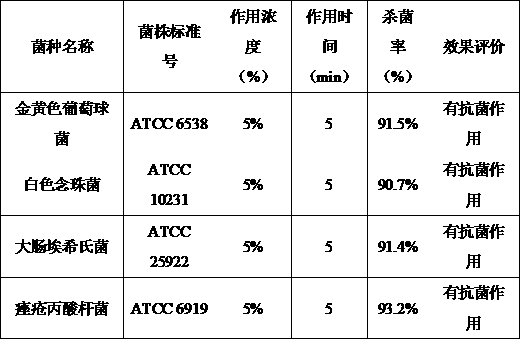

Image

Examples

Embodiment 1

[0036] (1) The preparation of cannabidiol nanoliposomes comprises the following steps:

[0037] ①Preparation of the organic phase: Accurately weigh 10 mg of cannabidiol, 300 mg of phospholipids and 100 mg of cholesterol and add them to ethanol, heat and stir to dissolve them fully to obtain an organic phase.

[0038] ② Film production: Evaporate the organic phase obtained in step ① on a rotary evaporator to remove the solvent, so that the residue forms a phospholipid film on the inner wall of the container. The rotary evaporation temperature is 50 ° C and the vacuum degree is 0.1 MPa.

[0039] ③Hydration: Slowly add 20ml of 0.02mol / L phosphate buffer (pH 8.0) into the phospholipid film container, and continue rotary steaming for 3 hours to make the phospholipid film fall off to obtain cannabidiol liposome suspension.

[0040]④ Homogenization: inject the suspension into a high-pressure homogenizer for 3 times for homogenization, the homogenization pressure is 40MPa, after homog...

Embodiment 2

[0046] (1) Preparation of cannabidiol nanoliposomes, the steps are as follows:

[0047] ①Preparation of the organic phase: Accurately weigh 10 mg of cannabidiol, 200 mg of phospholipids and 50 mg of cholesterol and add them to ethanol, heat and stir to fully dissolve to obtain an organic phase.

[0048] ② Film production: Evaporate the organic phase obtained in step ① to remove the solvent on a rotary evaporator, so that the residue forms a phospholipid film on the inner wall of the container. The rotary evaporation temperature is 40 ° C and the vacuum degree is 0.2 MPa.

[0049] ③Hydration: Slowly add 15ml of 0.01mol / L phosphate buffer (pH7.0) into the phospholipid film container, and continue rotary steaming for 2 hours to make the phospholipid film fall off to obtain cannabidiol liposome suspension.

[0050] ④ Homogenization: Inject the above suspension into a high-pressure homogenizer for 2 times for homogenization, the homogenization pressure is 20MPa, after homogenizatio...

Embodiment 3

[0056] (1) The preparation of cannabidiol nanoliposomes comprises the following steps:

[0057] ①Preparation of the organic phase: Accurately weigh 10 mg of cannabidiol, 100 mg of phospholipid and 20 mg of cholesterol and add them to ethanol, heat and stir to fully dissolve to obtain the organic phase.

[0058] ② Film production: Evaporate the organic phase obtained in step ① on a rotary evaporator to remove the solvent, so that the residue forms a phospholipid film on the inner wall of the container. The rotary evaporation temperature is 40 ° C and the vacuum degree is 0.1 MPa.

[0059] ③Hydration: Slowly add 10ml of 0.01mol / L phosphate buffer (pH6.5) into the phospholipid film container, and continue rotary steaming for 1 hour to make the phospholipid film fall off to obtain cannabidiol liposome suspension.

[0060] ④ Homogenization: inject the above suspension into a high-pressure homogenizer for 3 times for homogenization, the homogenization pressure is 30MPa, after homoge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com