Folic acid preparation and preparation method thereof

A technology of folic acid and preparations, which is applied in the direction of pill delivery, pharmaceutical formulations, and medical preparations of non-active ingredients. It can solve the problems of poor solubility, folic acid sensitivity to oxygen and temperature, and folic acid instability, so as to achieve high safety and improve Absorption speed and bioavailability, effects of improving water solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention relates to the preparation method of the above-mentioned folic acid preparation, and the preparation method includes the following steps: taking the components, mixing and molding.

[0040] In one example, the forming method is freeze-vacuum drying. The formula is prepared into a solution by freeze-drying, which is more accurate than the traditional oral solid preparation method, and the dosage is accurate without considering the problem of dosage uniformity. The orally disintegrating tablets prepared by freeze-drying do not need water to be taken, there is no obvious gritty feeling in the mouth, and they disintegrate rapidly in the oral cavity within 5 seconds, which has obvious therapeutic advantages for patients who are not suitable for oral administration. over-effect.

[0041] In one example, the freeze-vacuum drying process includes: placing the mixed mixture at -40°C to -60°C for 2h to 4h, sublimation with a vacuum of 10Pa...

Embodiment 1

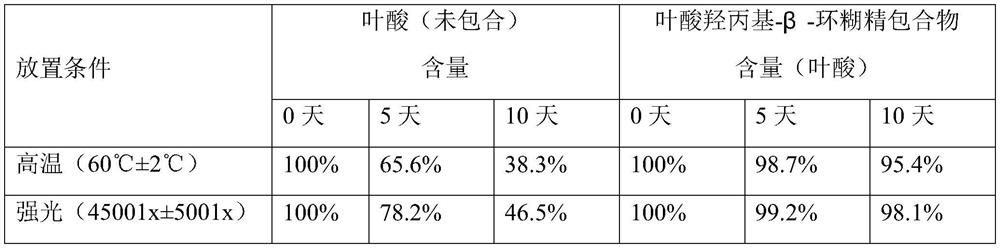

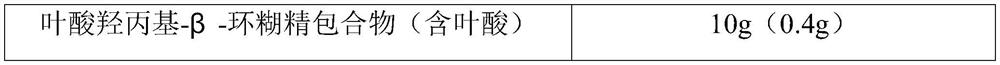

[0060] The formula composition of folic acid freeze-dried orally disintegrating tablets is shown in the following table:

[0061] Table 2

[0062]

[0063]

[0064] The preparation method of folic acid freeze-dried orally disintegrating tablet comprises the following steps:

[0065] (1) Mixing: Add the hydroxypropyl folic acid-β-cyclodextrin inclusion complex, lactose, polyethylene glycol 15-hydroxystearate, sucralose, and sweet orange flavor in 500ml of purified water in sequence , stirring and dissolving to obtain a clear liquid medicine;

[0066] (2) Injection molding: accurately inject the liquid medicine into the mold by 0.5ml / tablet;

[0067] (3) Freeze-drying process: cool down the shelf of the freeze-dryer to -40°C, place the mold filled with the liquid medicine in the freeze-dryer, and keep it warm for 3 hours; cool down the water-catching condenser of the freeze-dryer to below -40°C, Turn on the vacuum pump to evacuate, and sublimation begins at a vacuum deg...

Embodiment 2

[0071] The formula composition of folic acid freeze-dried orally disintegrating tablets is shown in the following table:

[0072] table 3

[0073]

[0074]

[0075] The preparation method of folic acid freeze-dried orally disintegrating tablet comprises the following steps:

[0076] (1) Mixing: add folic acid hydroxypropyl-β-cyclodextrin inclusion compound, mannitol, Tween 80, cyclamate, and lemon flavor in 500ml of purified water in sequence, stir and dissolve to obtain a clear medicinal solution ;

[0077] (2) Injection molding: accurately inject the liquid medicine into the mold by 0.5ml / tablet;

[0078] (3) Freeze-drying process: cool down the shelf of the freeze-dryer to -50°C, place the mold filled with the liquid medicine in the freeze-dryer, and keep it warm for 2 hours; cool down the water-catching condenser of the freeze-dryer to below -40°C, Turn on the vacuum pump to evacuate, and sublimation begins at a vacuum degree of 20Pa; raise the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com