Patents

Literature

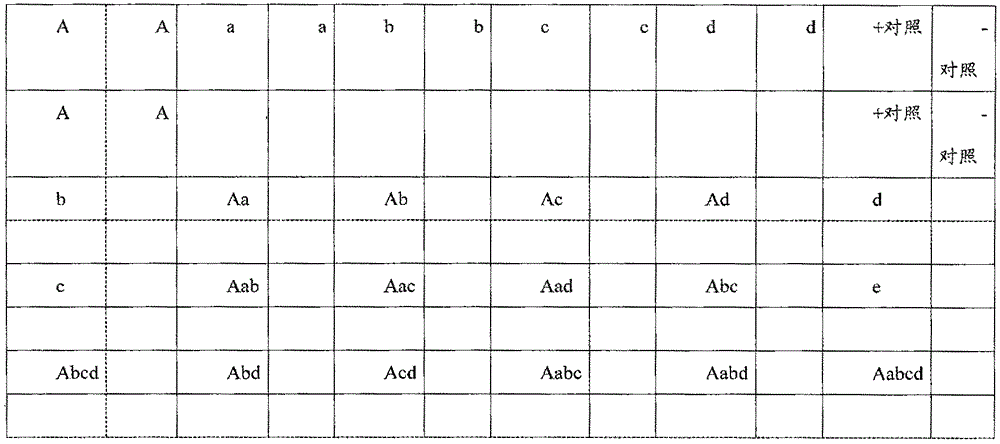

375 results about "Acid preparations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular sieve based catalysts, preparation method and application thereof in crylic acid preparation by lactic acid dehydration

InactiveCN101602010AExtended service lifeReduce energy consumptionMolecular sieve catalystsOrganic compound preparationPhosphateAcid preparations

The invention discloses a molecular sieve based catalyst, a preparation method and an application thereof in crylic acid preparation by lactic acid dehydration. The method comprises the following steps: processing the ZSM-5 molecular sieve in aqueous alkali, or adopting an impregnation method to support phosphate, drying, roasting and finally obtaining the modified molecular sieve based catalyst. The catalyst realizes the reaction of crylic acid preparation by lactic acid dehydration in low temperature and has the advantages of high lactic acid conversion rate and crylic acid selectivity, and long-life of catalyst, the conversion rate of lactic acid dehydration reaction is 100%, and crylic acid selectivity can reach as high as 83.9%, thus having good industrial application prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

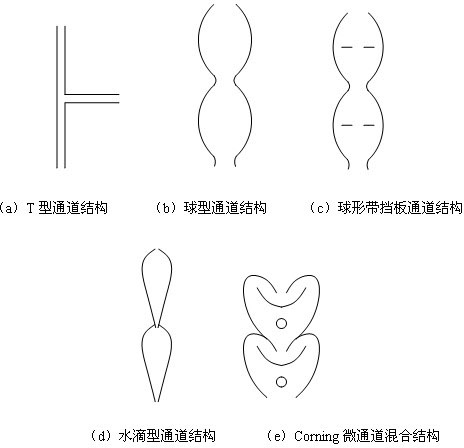

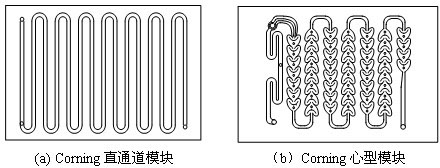

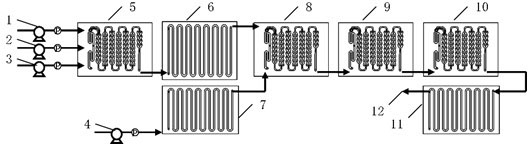

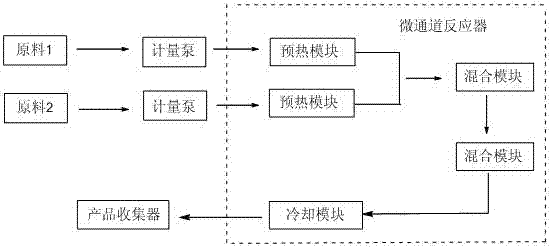

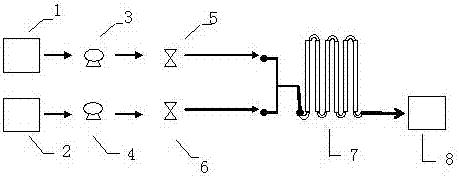

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

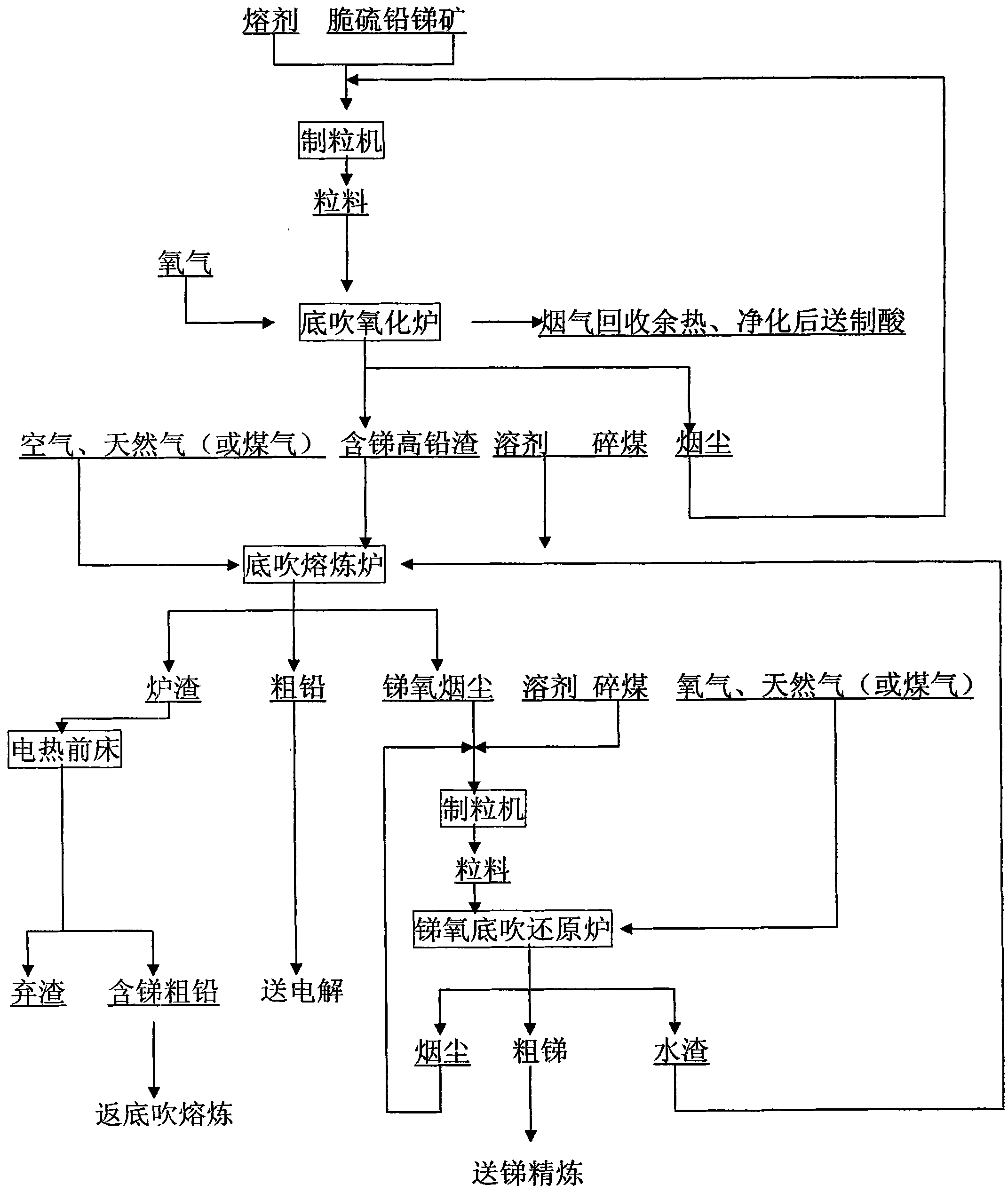

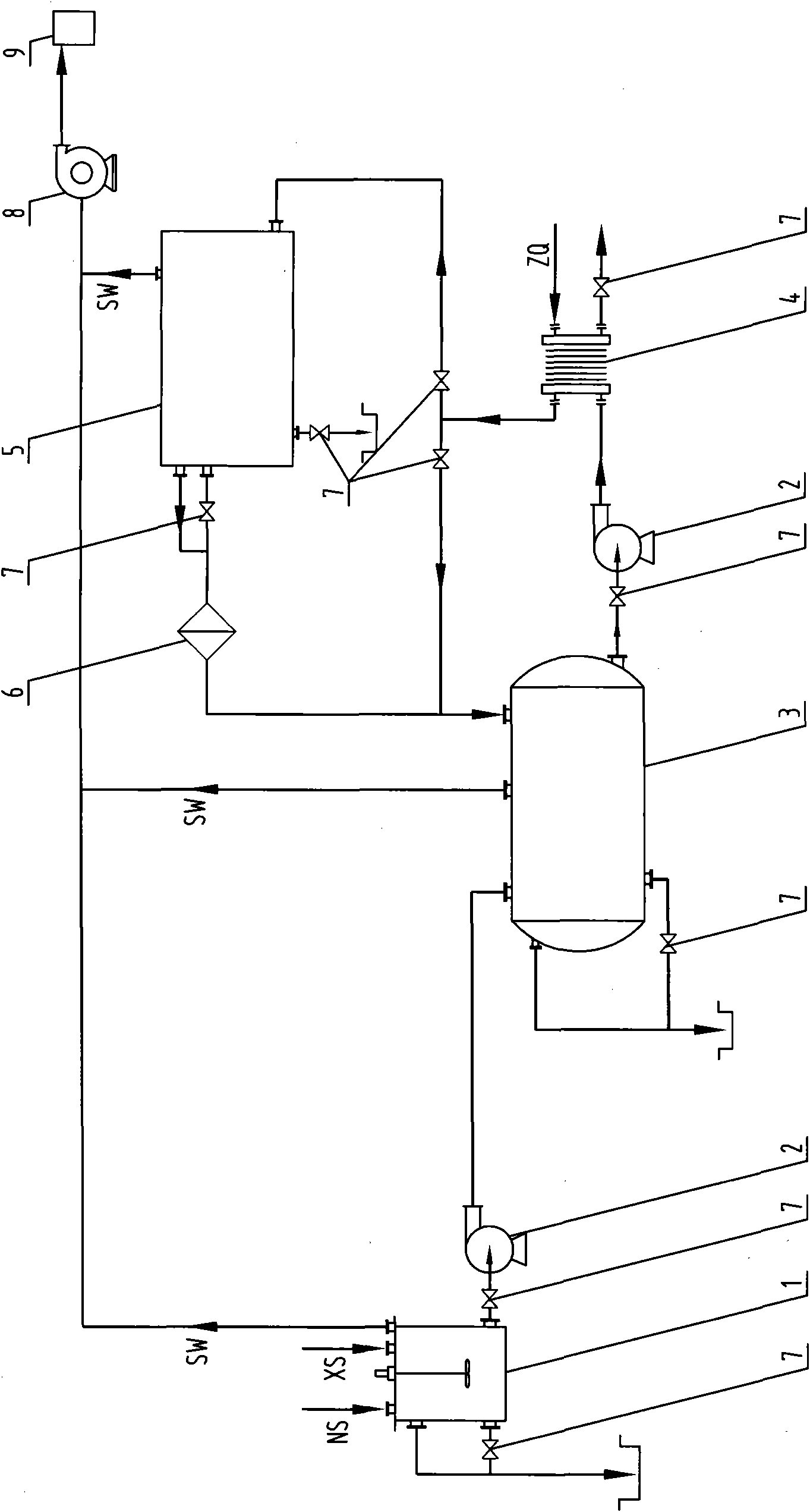

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

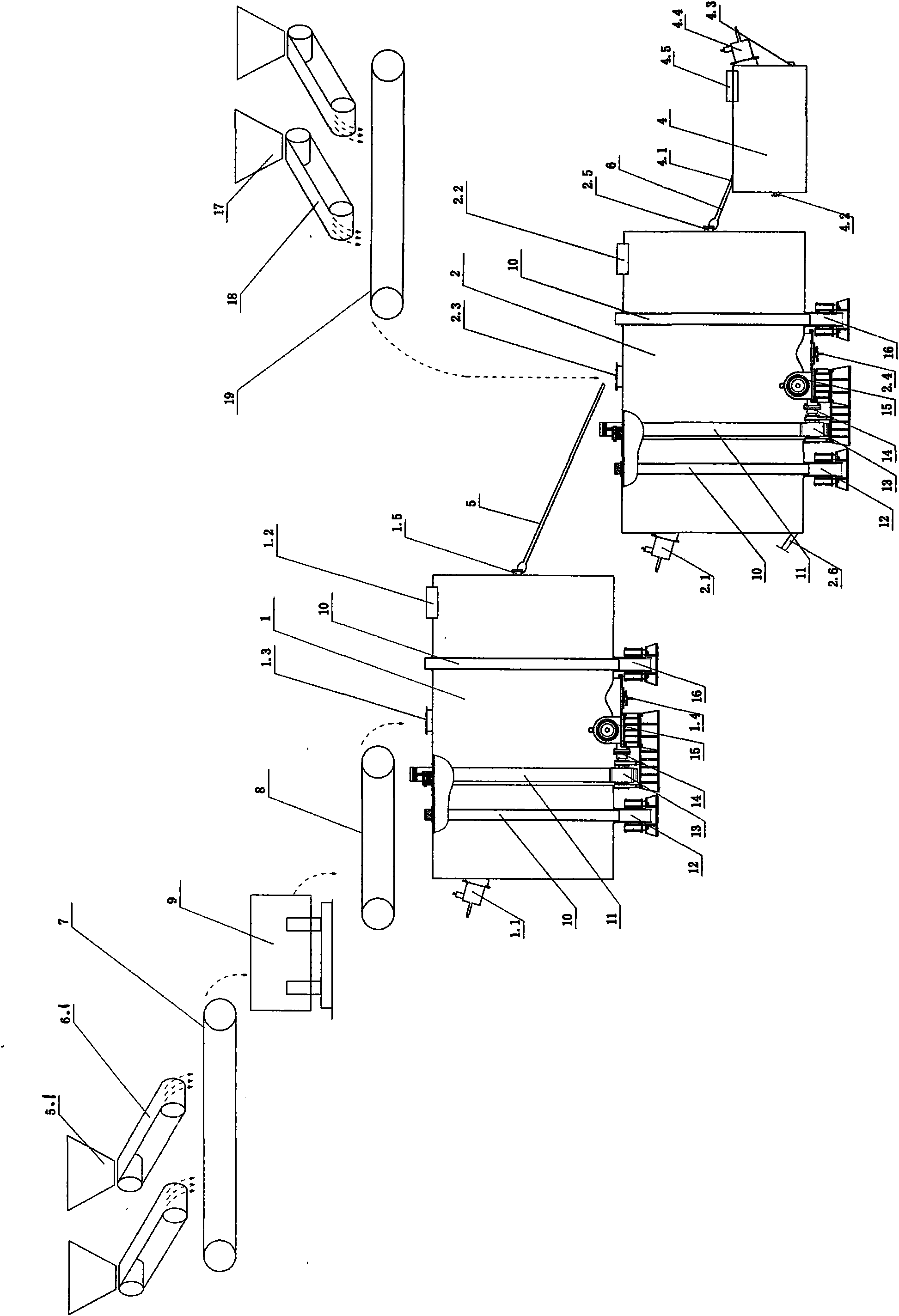

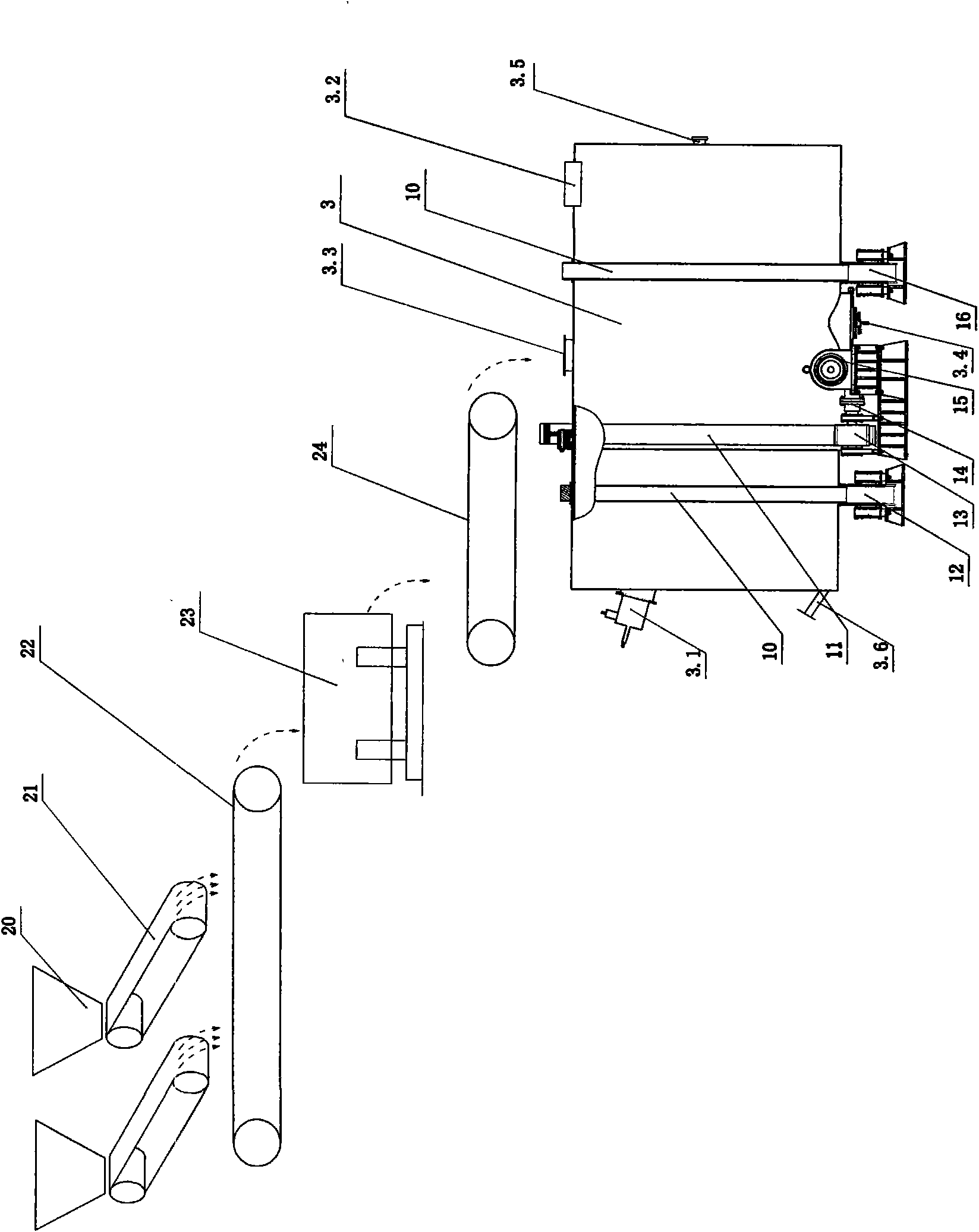

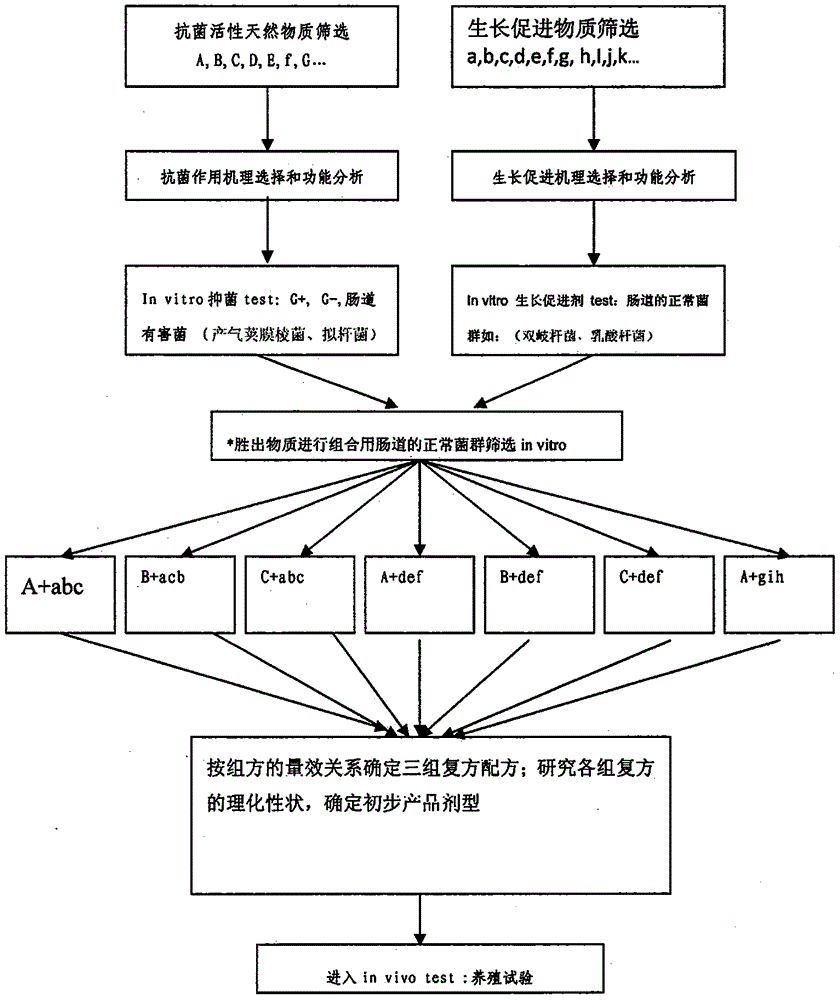

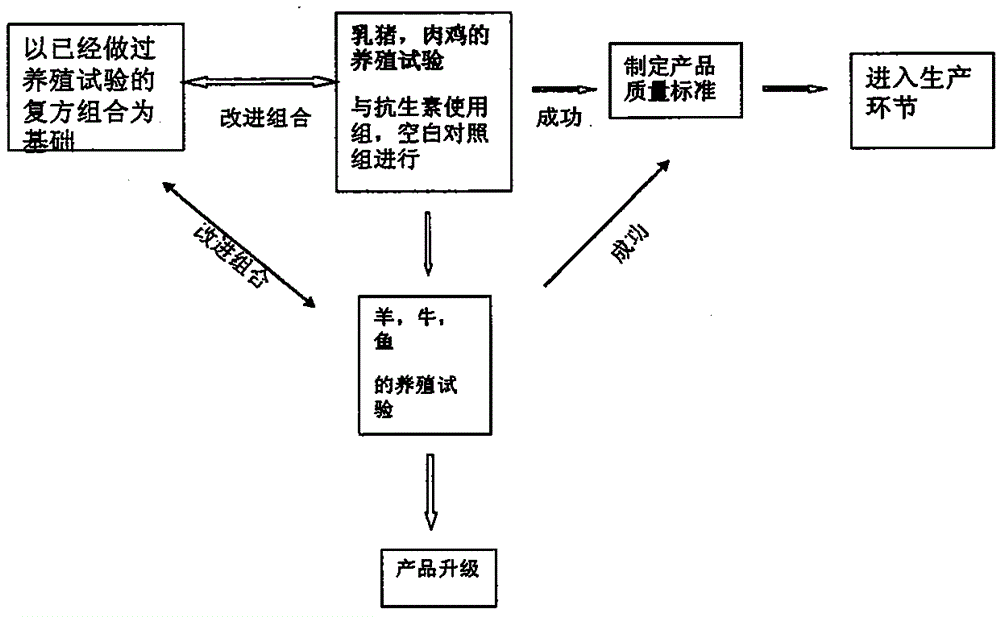

Antibiotic substitute feed additive, its formula, feed with antibiotic substitute feed additive and production method of feed with antibiotic substitute feed additive

InactiveCN105901305AWide range of functionsAdaptableAntibacterial agentsOrganic active ingredientsBiotechnologyTrace element

The invention relates to an antibiotic substitute feed additive, a formula of the antibiotic substitute feed additive, feed with the antibiotic substitute feed additive and a production method of the feed with the antibiotic substitute feed additive. The antibiotic substitute feed additive is a natural antibiotic component. The formula of the antibiotic substitute feed additive comprises a natural antibiotic component, trace elements, a compound enzyme, probiotics, prebiotics and an acid preparation. The invention also relates to the production method of the feed with the antibiotic substitute feed additive.

Owner:张兴龙 +1

Recovery processing method for cyanogen golden mine tailing

InactiveCN101403042AImprove the level of comprehensive utilizationEmission reductionProcess efficiency improvementSulfurSludge

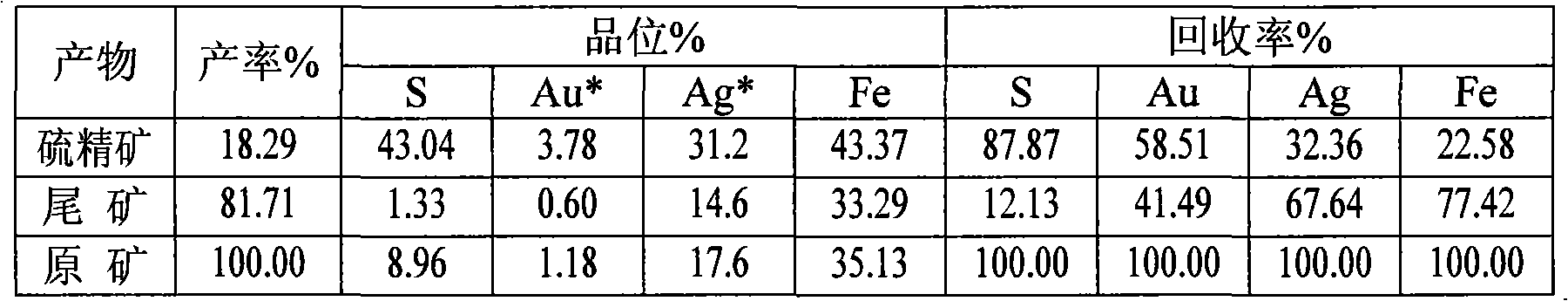

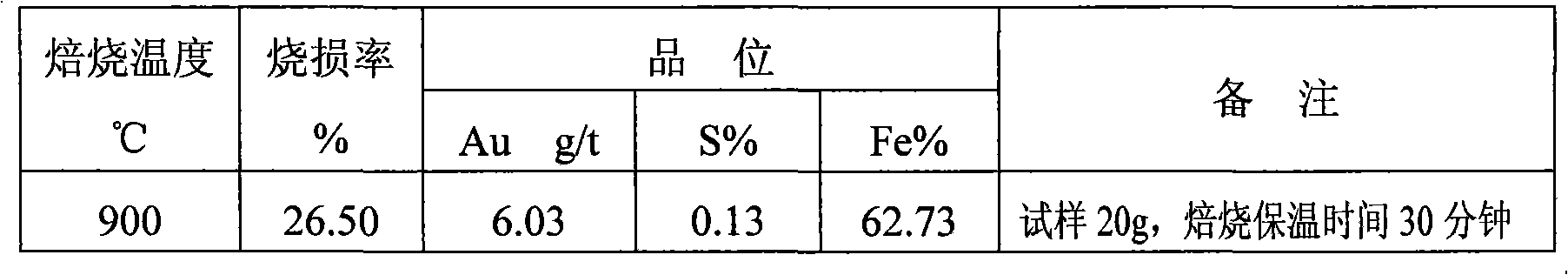

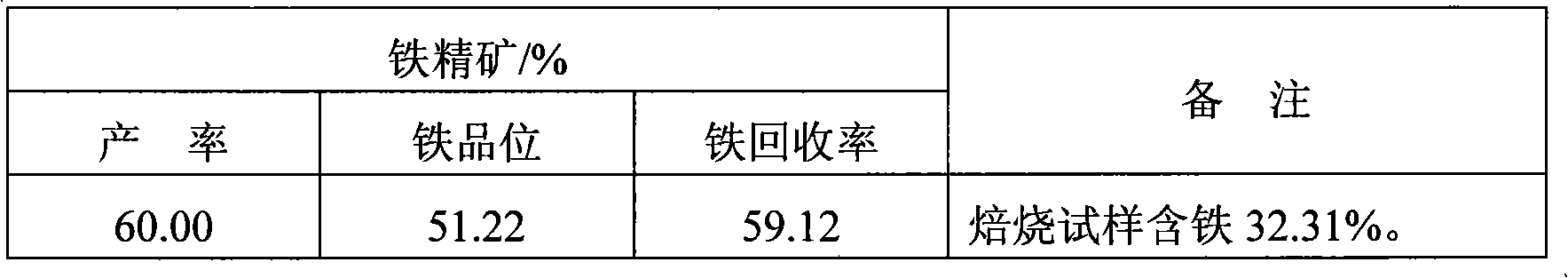

The invention relates to the recycle of tailings of oxidized ore containing gold with high content of sulfur and iron after cyaniding and gold extraction, in particular to a recycling and processing method of gold-cyaniding tailings. The invention uses the technology of flotation of sulfur, acid preparation with sulphur ore concentrate and gold extraction and iron obtaining by cyaniding acid sludge, magnetizing roasting and magnetic separation for obtaining iron and of selection sulfur tailings after dehydration as additive in cement to realize recycling of the gold-cyaniding tailings, realize single separation and final no-tail of gold mineral and provide the route of proper technique for recycling the gold-cyaniding tailings. The invention has the advantages of low processing cost and wide application range and is a recycling technique of the gold-cyaniding tailings, which is economic, simple and applicable and has good processing effect.

Owner:罗仙平

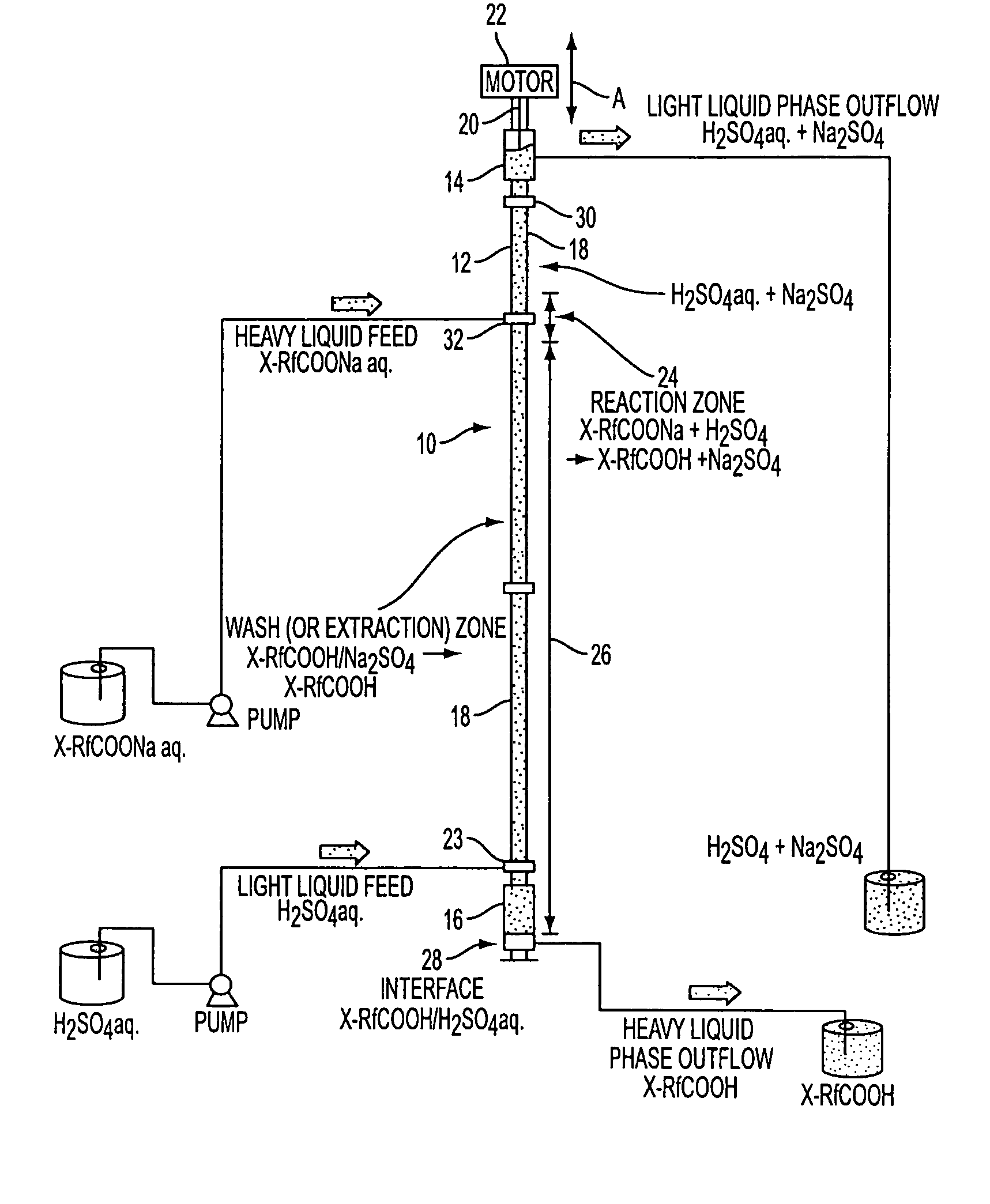

Process for preparing fluorocarboxylic acids

InactiveUS7126016B2Minimize releaseReduce lossesPreparation from carboxylic acid saltsOrganic compound preparationSulfateCarboxylic acid

A fluorocarboxylic acid preparation process continuously carries out acidification reaction treatment and washing treatment, and includes subjecting a fluorocarboxylate-containing aqueous solution to acidification reaction treatment in the presence of sulfuric acid so as to form a sulfate-containing fluorocarboxylic acid phase; and subjecting the fluorocarboxylic acid phase to washing treatment using an aqueous sulfuric acid solution.

Owner:DAIKIN IND LTD +1

Method for extracting soluble dietary fiber

The invention discloses a method for extracting soluble dietary fiber, which comprises the following steps of: A, processing dietary fiber raw materials by adopting a carbon dioxide blasting, extruding and puffing method to obtain modified dietary fiber raw materials; B, carrying out microbial fermentation processing on the modified dietary fiber raw materials obtained in the step A by using mixed microbial bacterial solution to obtain a fermented mixture; and C, carrying out extraction filtration on the fermented mixture, drying filter residues obtained through extraction filtration after washing the filter residues to be neutral, thereby obtaining the soluble dietary fiber. Compared with the current acid preparation process, alkaline preparation process or microbial extraction process, by adopting the dietary fiber modification method, the content of the soluble dietary fiber in the product is up to 28.69+ / -0.9%.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

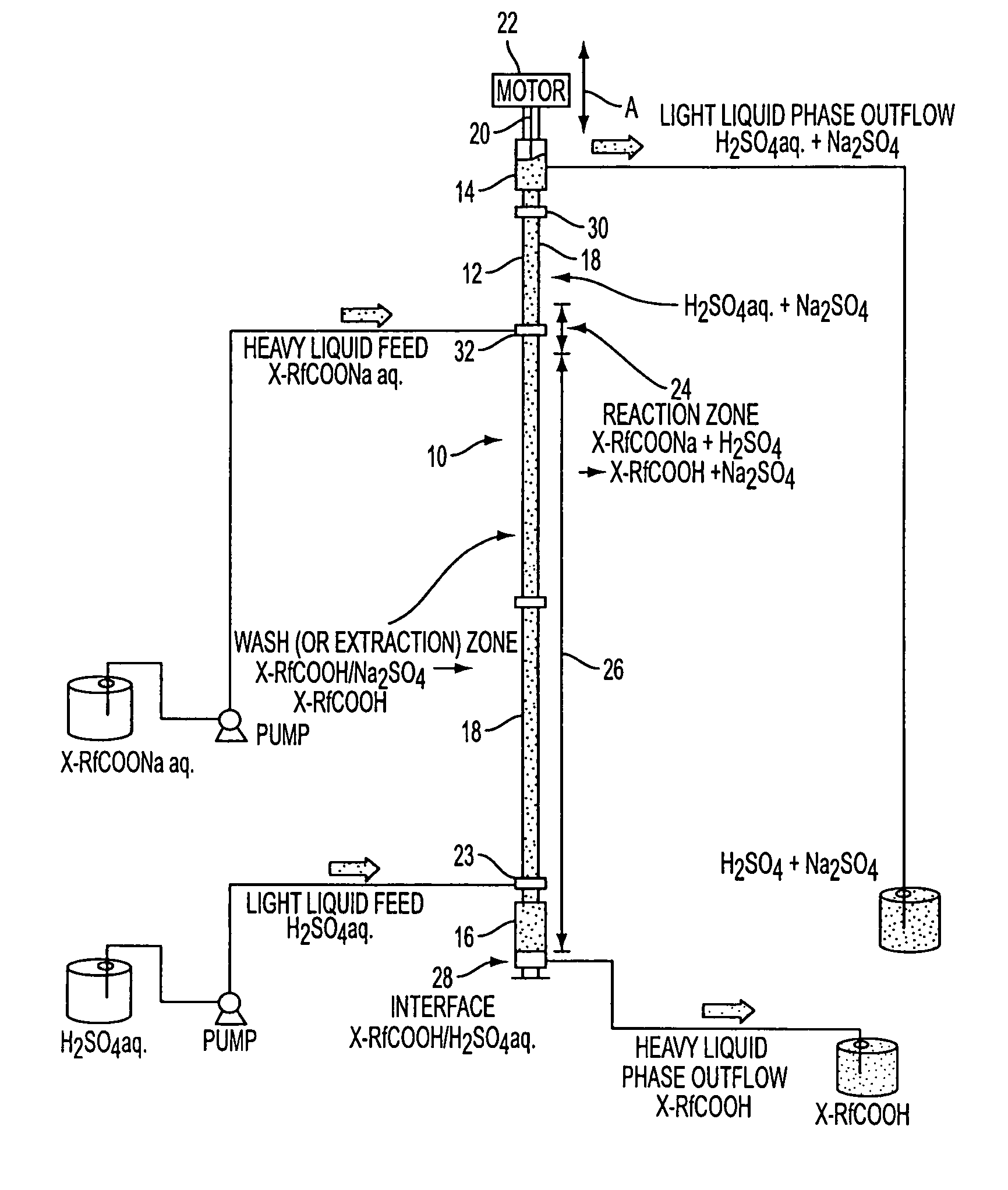

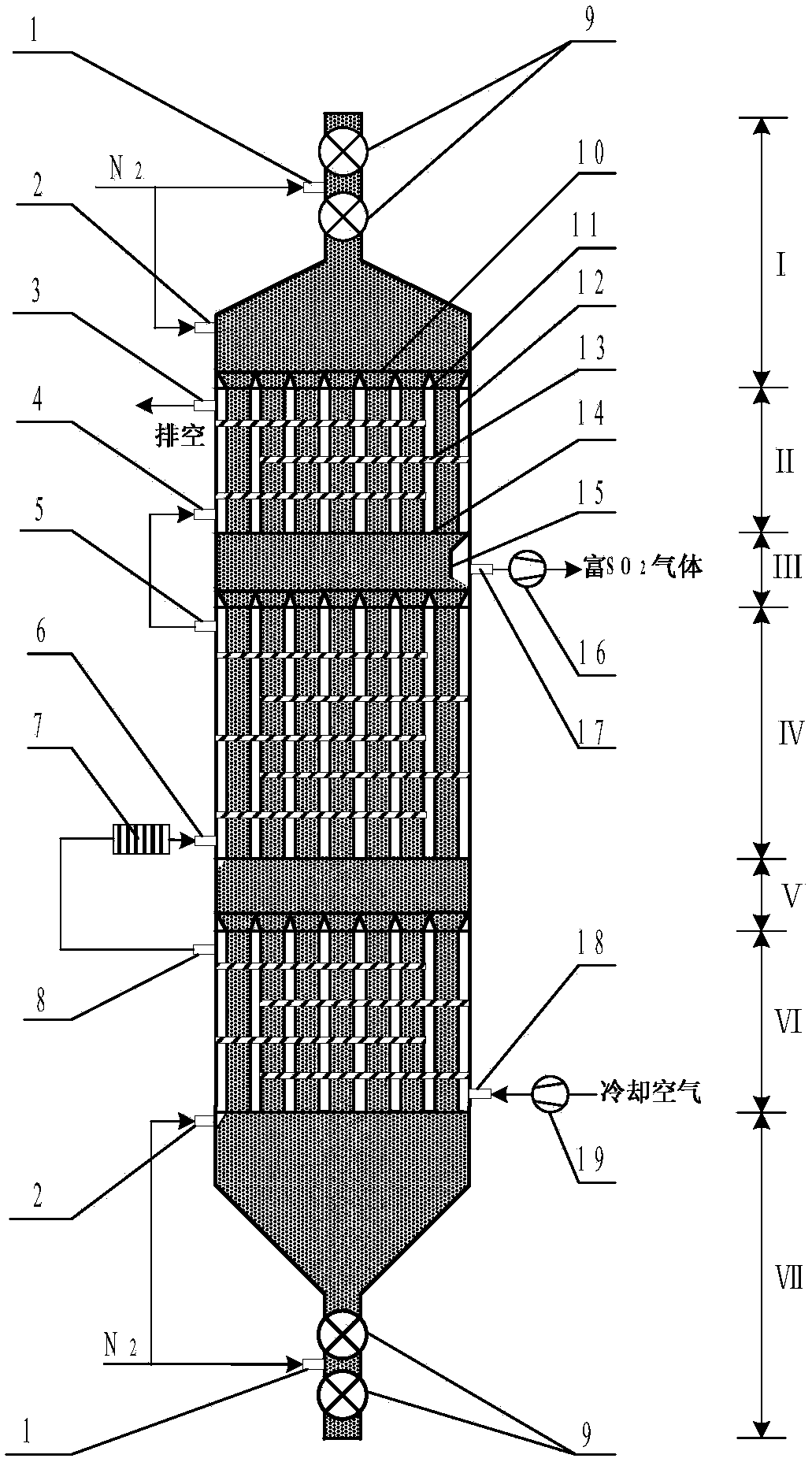

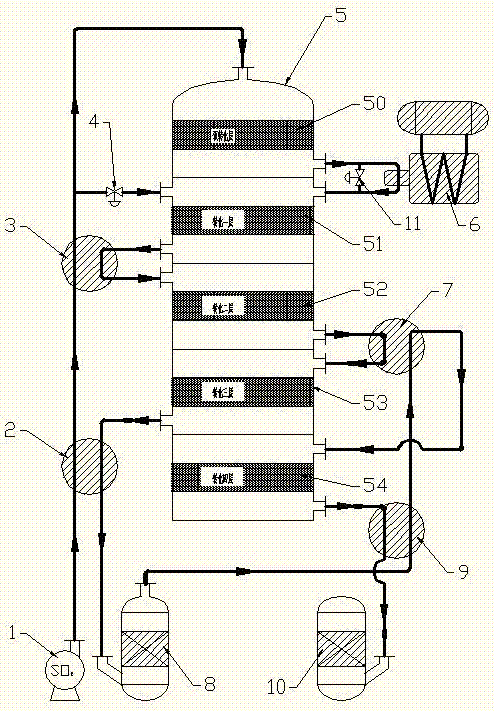

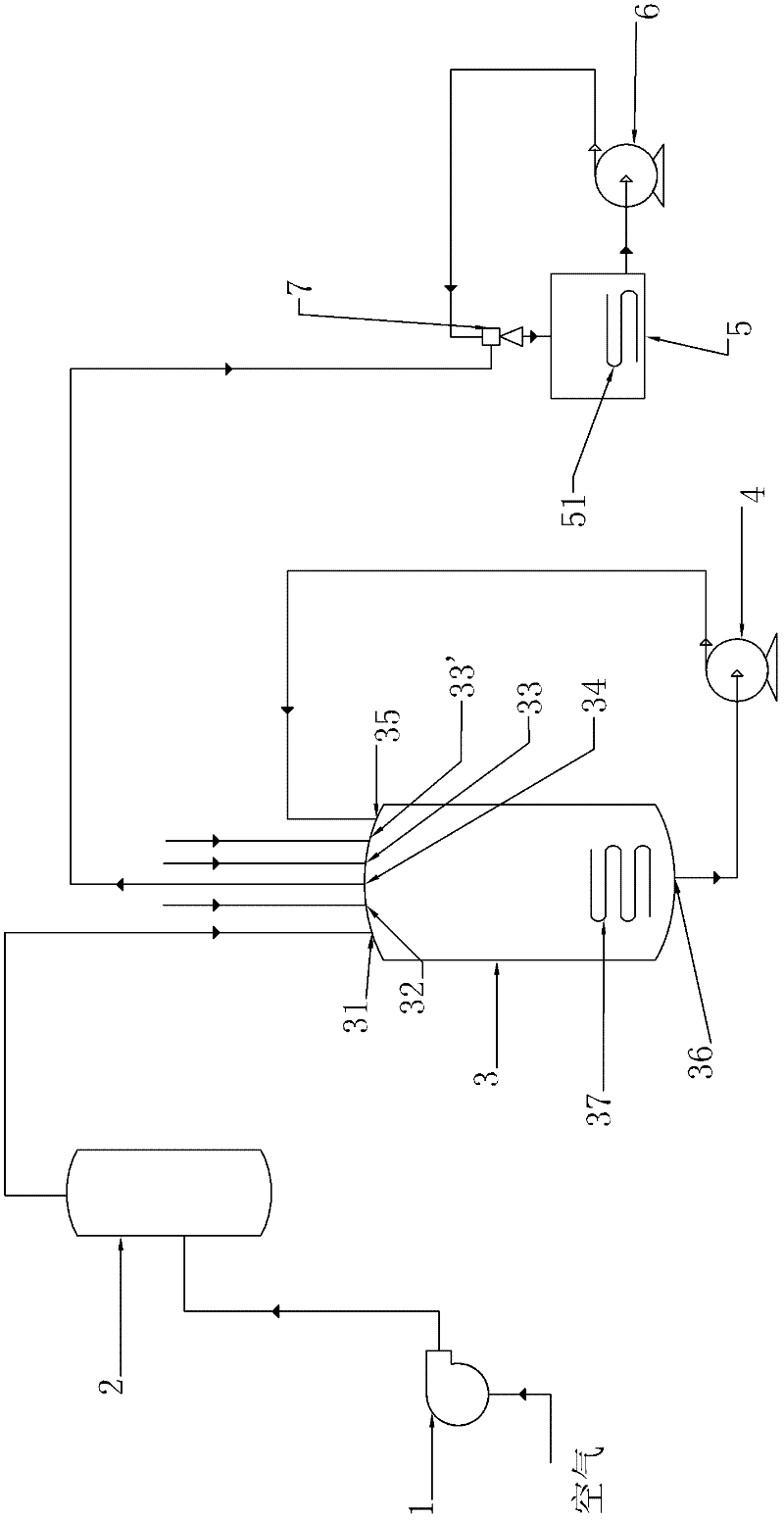

High-efficiency desulfurized active coke analysis tower and analysis method

ActiveCN104209107AGuaranteed heat exchange effectNo disturbanceChemical industrySulfur compoundsHigh concentrationSulfur

The invention discloses a high-efficiency desulfurized active coke analysis tower and an analysis method. The analysis tower comprises a material feeding section, a preheating section, a first buffering section, an analysis section, a second buffering section, a cooling section and a material discharging section which are communicated with one another in sequence from top to bottom, wherein the preheating section, the analysis section and the cooling section are all of tube-shell type heat exchange structures; a cooling section gas inlet is formed in the lower part of the cooling section, and a cooling section gas outlet is formed in the upper part of the cooling section and is communicated with an analysis section gas inlet formed in the lower part of the analysis section; an analysis section gas outlet formed in the upper part of the analysis section is communicated with a preheating section gas inlet formed in the lower part of the preheating section; a preheating section gas outlet formed in the upper part of the preheating section is emptied; the first buffering section is provided with a material distribution and gas guide structure and an analysis gas outlet; the analysis gas outlet is connected with an acid preparation system through a fan. The invention also provides an analysis method of the analysis tower. The analysis tower is simple in structure, high in heat exchange efficiency and low in energy consumption; regeneration of desulfurized active coke is realized; furthermore, high-concentration SO2 can be obtained, and recycling of sulfur is realized.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +2

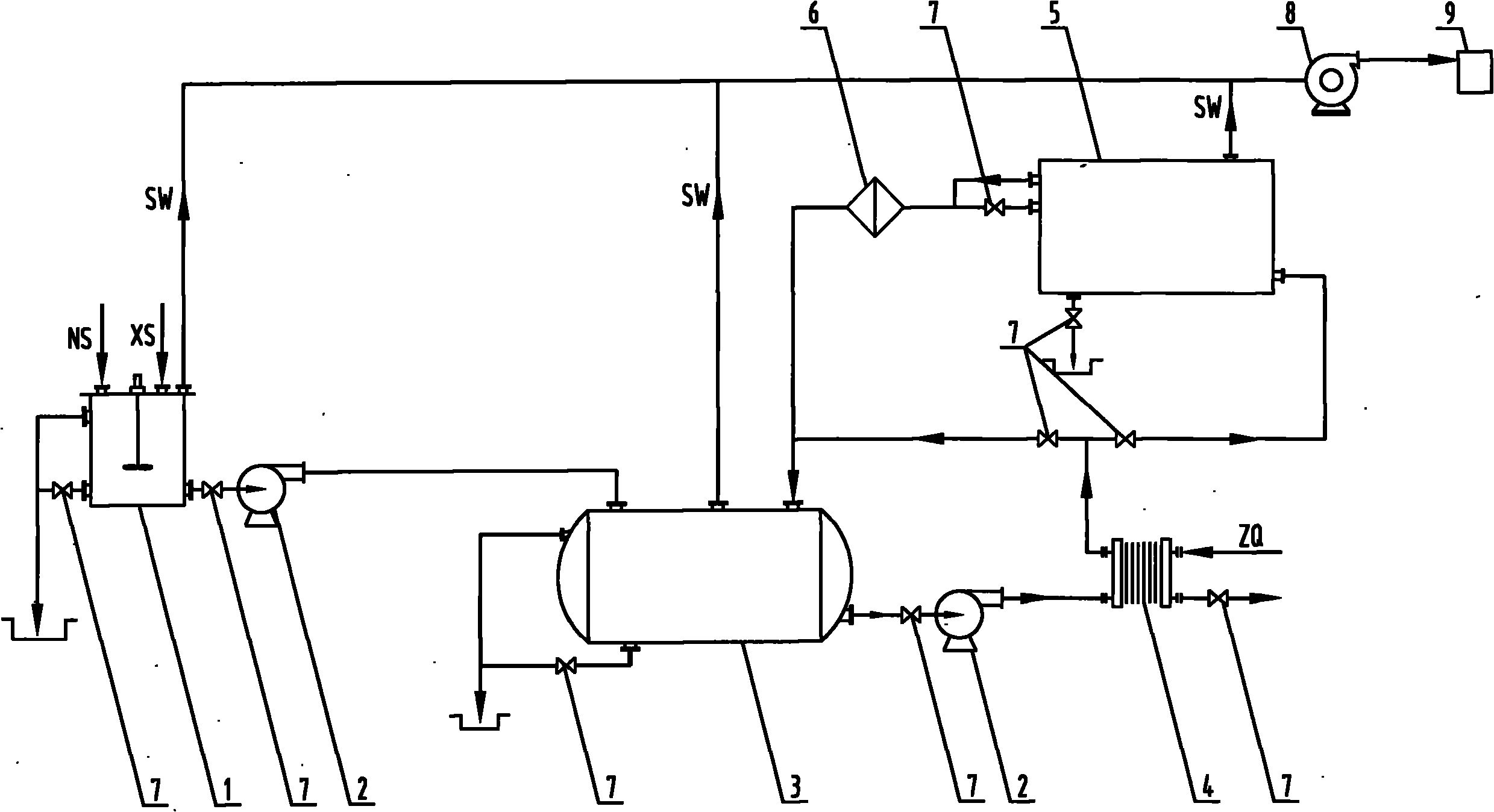

Forced circulation pickling method of copper and copper alloy tubes, rods and wires

The invention discloses a forced circulation pickling method process of copper and copper alloy tubes, rods and wires, comprising the following steps: preparing pickling liquor in an acid preparation tank, stirring the pickling liquor in a mechanical or circular flow manner and sending the pickling liquor to a circulation tank after stirring; firstly heating the pickling liquor in the circulation tank by a heat exchanger and then circulating the pickling liquor under the action of a circulation pump, and transferring the pickling liquor to a pickling tank after the temperature uniformity meets the use requirement of the process; and forming turbulent flow by forcing the pickling liquor to flow circularly between the circulation tank and the pickling tank to realize relative movement of the pickling liquor and the copper products so as to ensure the pickling liquor to be fully contacted with the surfaces of the copper products to the greatest extent and achieve the effects of uniform pickling and acceleration of pickling, wherein the pickling tank is provided with a movable cover to ensure the copper products to under pickling in relatively sealed space. Acid preparation, circulation and pickling are all carried out in the relatively sealed space, thus the acid mist no longer diffuses toward the workshop but is sent to an acid mist purification tower through an air duct to be subjected to neutralization treatment, thereby effectively protecting the environment.

Owner:CHINA NERIN ENG

Preparations with deodorizing action comprising the zinc salt of ricinoleic acid and at least one amino functional amine acid

ActiveUS7226584B2Good water solubilityImprove solubilityCosmetic preparationsOrganic detergent compounding agentsOrganic acidSolubility

Preparations with deodorizing action are provided. The preparations include the zinc salt of ricinoleic acid; amino-functional amino acids; solubility promoters; organic and / or inorganic acids; and, optionally, water.

Owner:EVONIK DEGUSSA GMBH

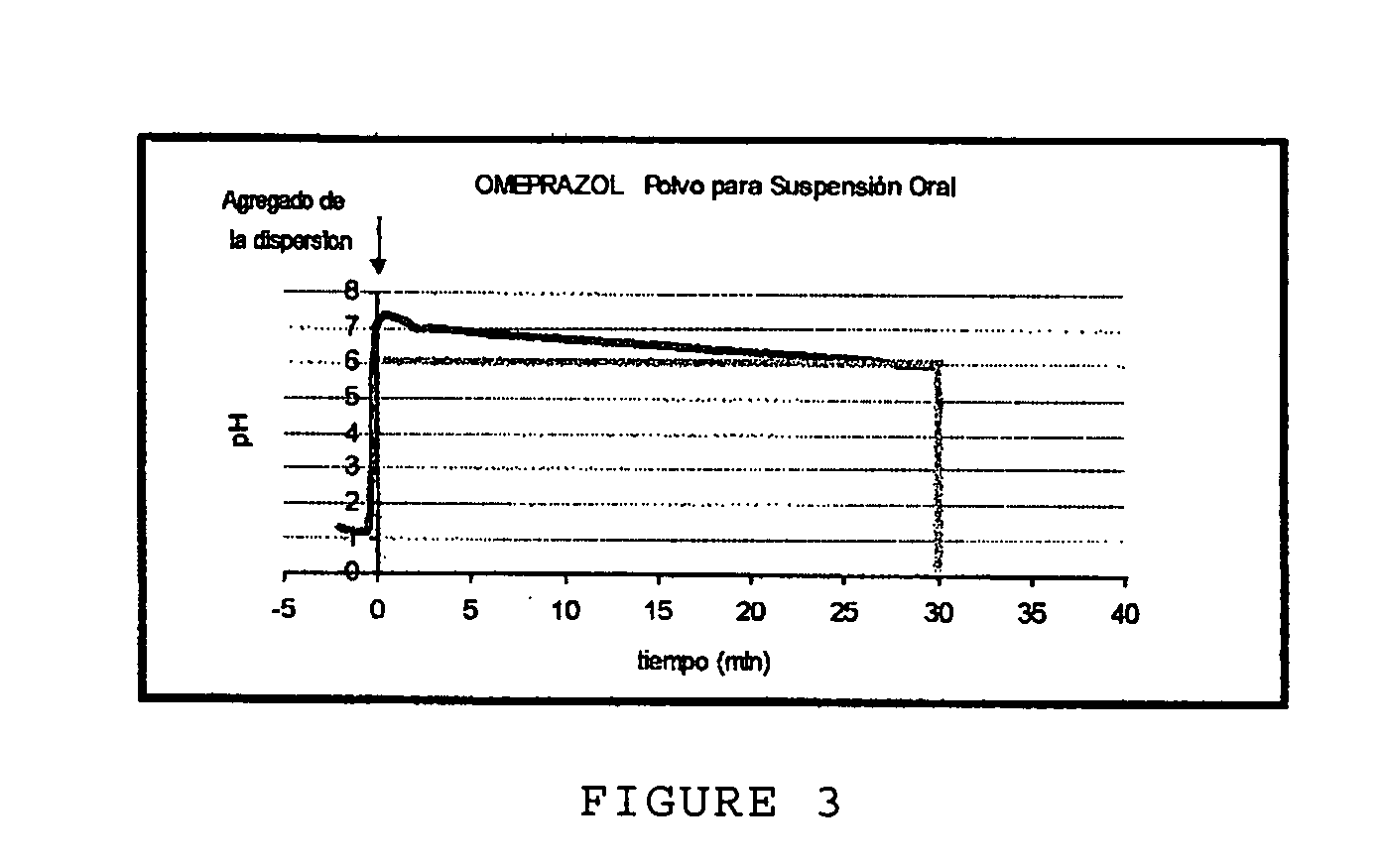

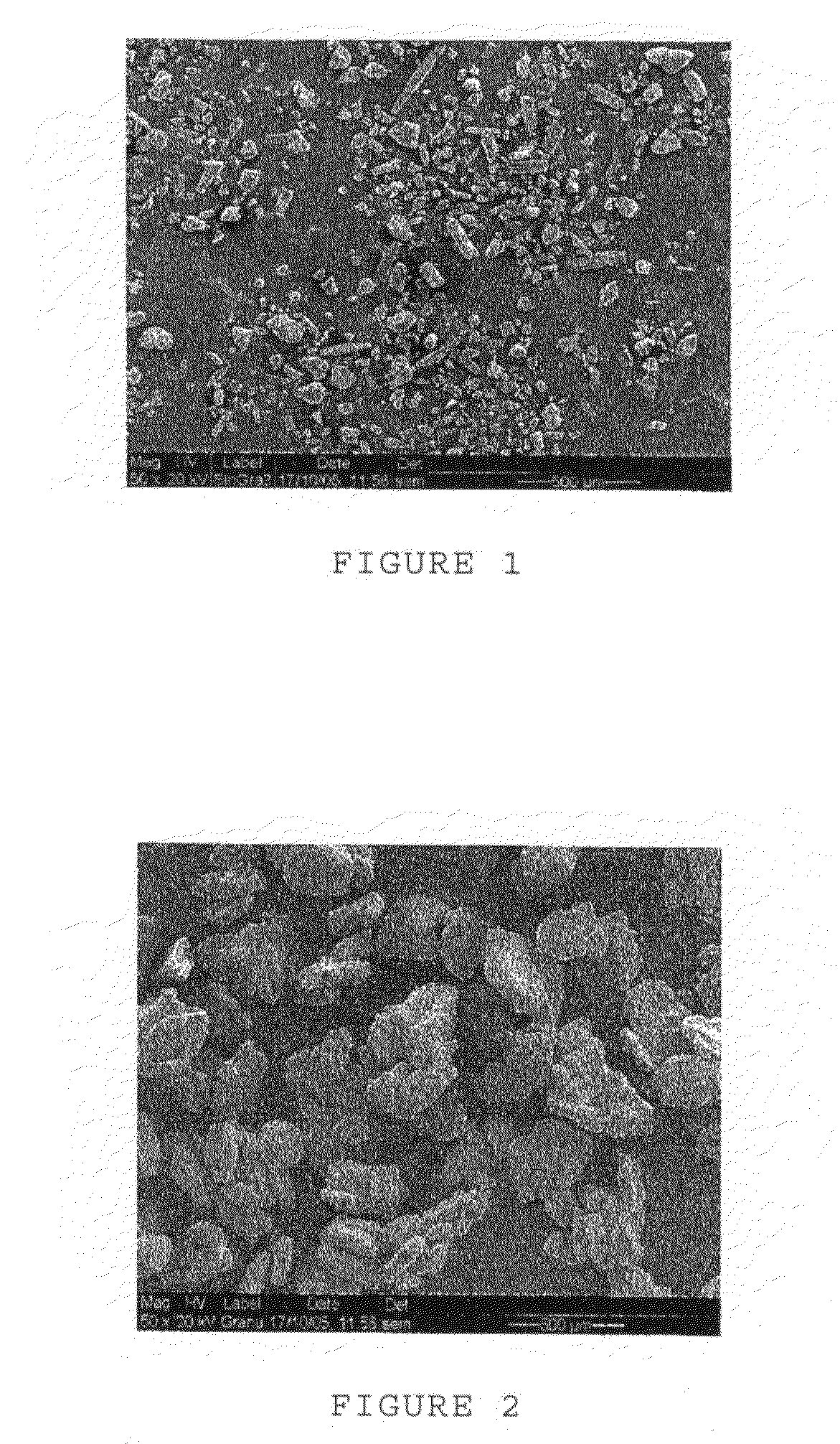

Anti-acid pharmaceutical composition in powder form and process for making it

ActiveUS20070281015A1Easy to controlImprove stabilityBiocideDispersion deliveryDrugs solutionDiluent

An anti-acid pharmaceutical composition for the rapid and prolonged neutralization of gastric acidity with mucosa-protecting activity in powder form to prepare, by dispersion in water, a pharmaceutical solution or suspension for oral use characterized in that the composition includes sodium alginate; an anti-acid soluble agent or a combination of anti-acids; an inhibitor of proton pump; diluent and sweetening agents, wherein a) at least 30% of sodium alginate present in the formulation along with the total of the inhibitor of proton pump are homogeneously distributed over the surface of the total soluble anti-acid agent or of the combination of anti-acids of the composition; and b) the rest, about 70%, of sodium alginate present in the formulation contains a percentage of humidity of less than 2%.

Owner:LAB BAGO

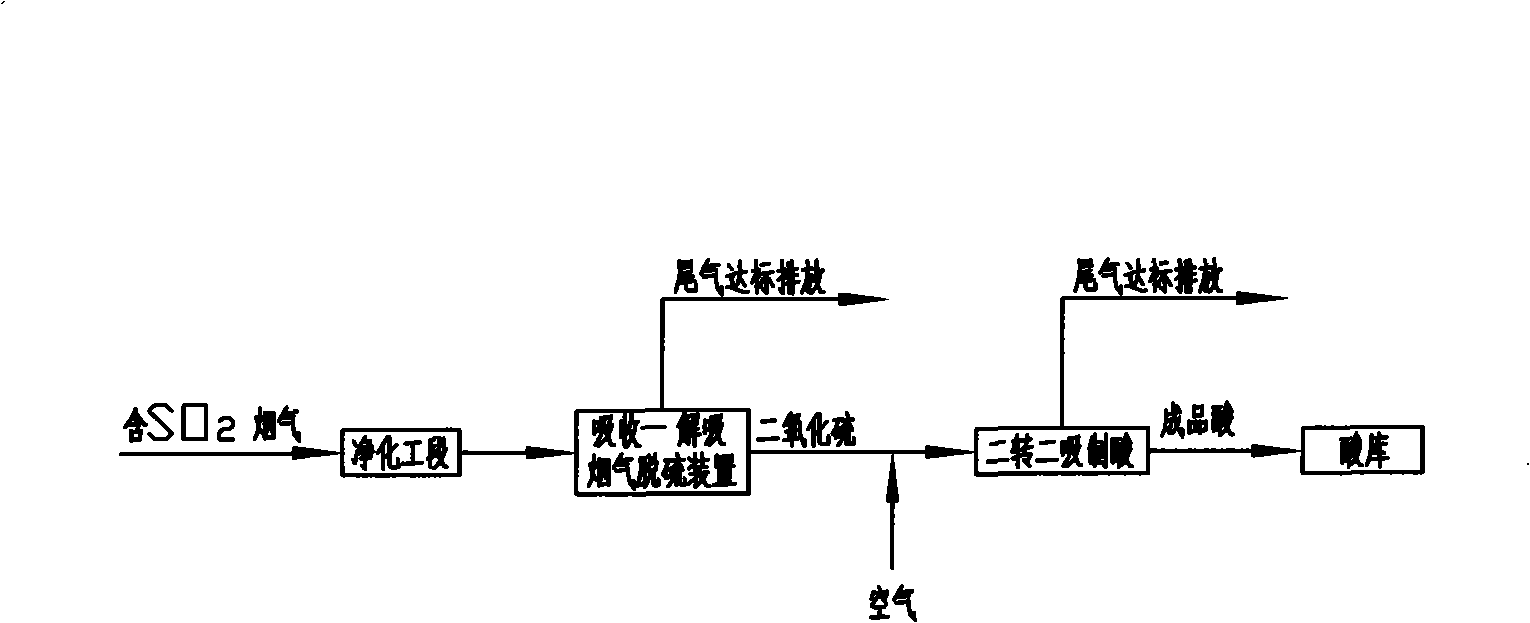

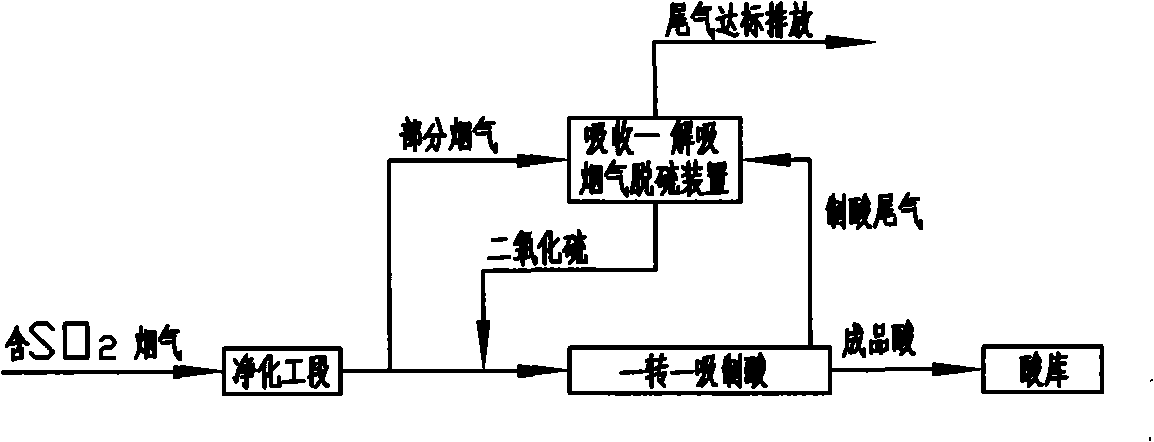

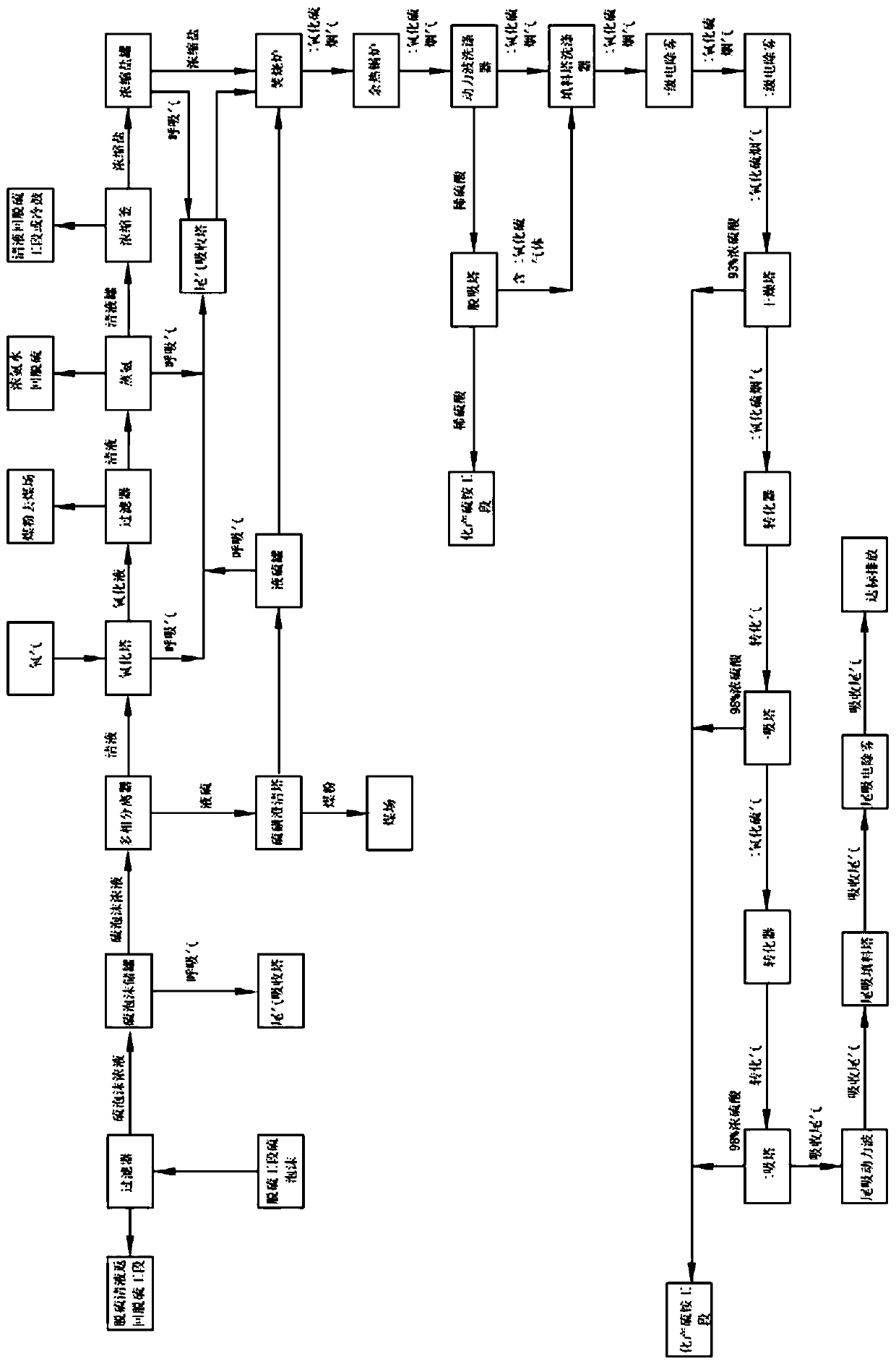

Method for economically recycling sulphur dioxide from low-concentration or non-continuity flue gas to produce sulphuric acid

ActiveCN101492154AMaximum recoveryReduce energy consumptionDispersed particle separationSulfur compoundsDesorptionEmission standard

The invention discloses a method for preparing sulphuric acid by economically recovering sulfur dioxide in low-concentration or noncontinuous flue gas, which comprises that: the flue gas containing the sulfur dioxide is subjected to purification, dust and impurity removal, temperature reduction, and acid mist removal, and then divided into two paths; one path of the flue gas is sent to a desulfurization working section, high-purity SO2 gas generated after absorption and desorption of the flue gas is evenly mixed into the other path of flue gas which is not subjected to desulfurization, the SO2 concentration of the mixed flue gas is improved to be more than 5 percent, and the mixed flue gas enters a single-conversion single-absorption acid preparation working section; and tail gas after acid preparation enters the desulfurization working section again for desulfurization, and is discharged after the SO2 content is far lower than the discharge standard. The process changes smelter off-gas which cannot meet the requirement of preparing acid by a contact method originally into the flue gas which can prepare the acid normally, and does not need desulfurizing all the flue gas, so the method greatly reduces energy consumption, running cost and investment, and the discharge amount of SO2 is far lower than that of a conventional flow so as to solve a difficult environmental protection problem for partial non-ferrous metallurgical plants and accord with the policy of national energy saving, energy consumption and pollution reduction.

Owner:CHINA NERIN ENG

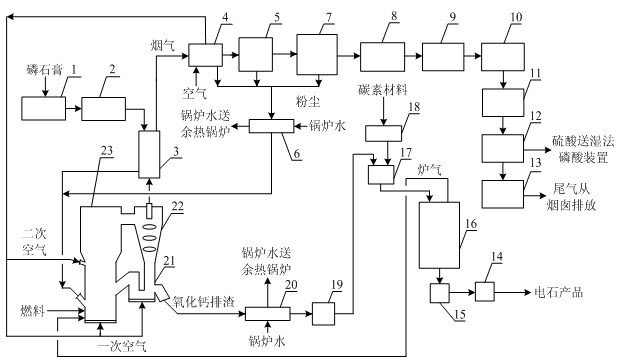

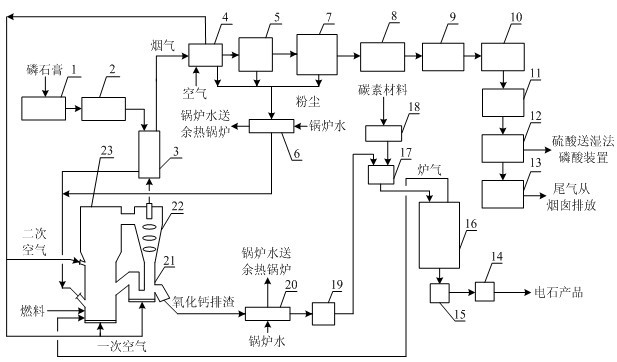

Method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum

ActiveCN102442650ASolve the problem of difficult resource utilizationAchieve recyclingSulfur compoundsEnergy inputCycloneDecomposition

The invention relates to a method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum, and belongs to the technical field of environmental protection. According to the method, phosphogypsum is subjected to a water washing and purification pretreatment by a multi-stage cyclone; then the pretreated phosphogypsum is dried and dewatered; the dewatered phosphogypsum enters a multi-stage suspension heat exchanger to carry out preheating; the hot state gypsum enters a circulating fluidized bed decomposing furnace, then primary air and secondary air are respectively introduced to carry out decompositions; high temperature sulfur dioxide-containing flue gas discharged from the top of the circulating fluidized bed decomposing furnace enters the multi-stage suspension heat exchanger to carry out heat exchanging and cooling with the cold state gypsum; dust in the cooled hot flue gas is removed by a multi-stage dust removing device; the dust-removed flue gas enters an acid washing and purification system to further remove the dust and the gaseous impurities in the flue gas; the purified and cleaned flue gas is conveyed into an acid preparation system to produce the sulfuric acid product; the hot state calcium oxide discharged from the bottom of the circulating fluidized bed decomposing furnace is cooled, and conveyed into a sealed calcium carbide furnace to carry out an electrical arc reaction with a carbon material to generate the calcium carbide product; the high temperature furnace gas discharged from the top of the sealed calcium carbide furnace is directly conveyed into the decomposing furnace, wherein the high temperature furnace gas is adopted as a fuel and a reducing agent. The method of the present invention has good environmental protection benefits and strong economic advantages.

Owner:CHINA PETROCHEMICAL CORP +1

Oxygen-enriched molten pool antimony refining production process

InactiveCN106521189AAdaptablePrevent escapeProcess efficiency improvementOxygen enrichmentAcid preparations

The invention discloses an oxygen-enriched molten pool antimony refining production process, and belongs to the field of smelting of nonferrous metal. The process comprises the following steps: 1) batching: raw materials are uniformly mixed according to a mass ratio to obtain a mixture; 2) granulation: the uniformly mixed mixture is prepared as spherulites; 3) the prepared spherulites are fed in an oxygen-enriched oxidation furnace for oxidation smelting to prepare a primary high-temperature melt and liquid-state high-antimony ore slag; 4) reduction smelting: the liquid-state high-antimony ore slag flows in an oxygen-enriched reducing furnace for reduction smelting to prepare a secondary high-temperature melt and reducing furnace slag; 5) metal recovery: the reducing furnace slag flows in a fuming furnace through a slag chute; and recovery includes valuable metal; and 6) the smoke is recovered. The process effectively increases the SO2 concentration in smelted smoke to achieve conventional acid preparation system requirements, reduces the pollution, meanwhile, increases the yield, and reduces the energy consumption.

Owner:河池市生富冶炼有限责任公司

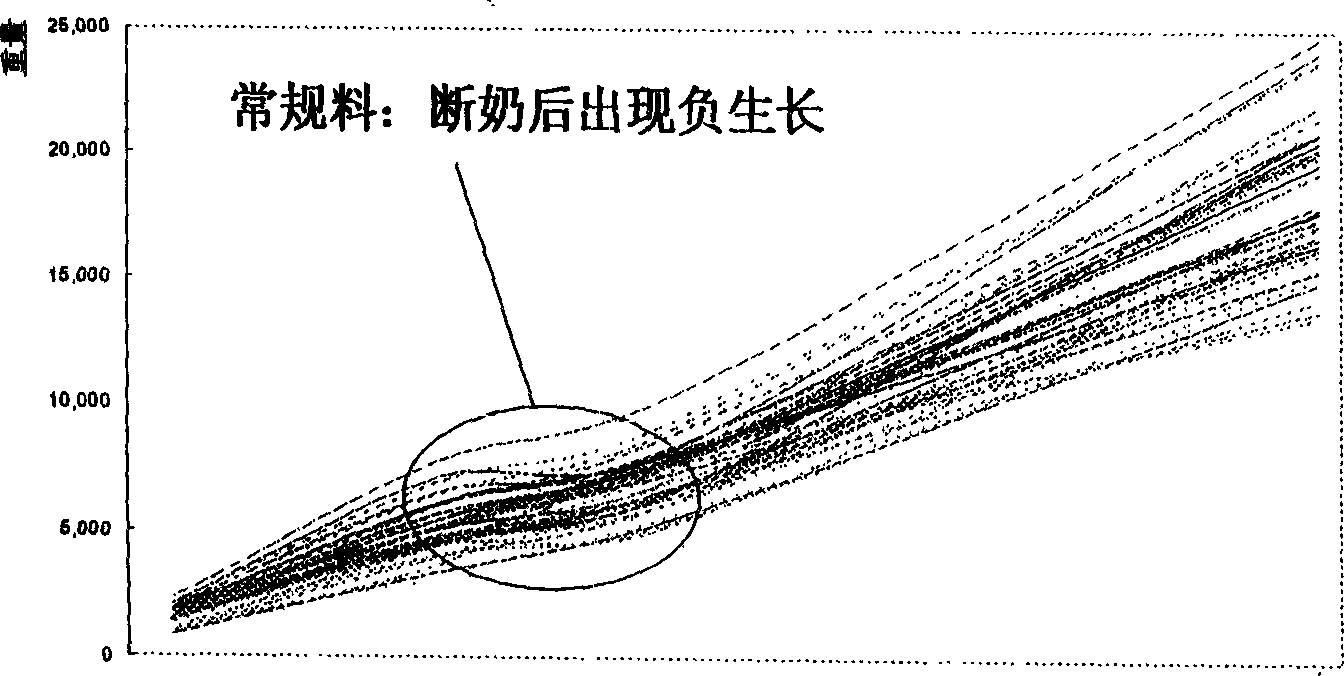

Feed for weaned piglet

ActiveCN1810147AMaintain nutritional balanceNutritional balance meetsAnimal feeding stuffAccessory food factorsAntioxidantFodder

The feed for weaned piglet contains vitamin additive 0.2-3 weight portions, trace mineral element additive 2-20 weight portions, enzyme preparation 0.2-5 weight portions, antioxidant 1-3 weight portions, amino acid additive 5-70 weight portions, growth promoter 1-20 weight portions, acid preparation 10-100, seasoning 5-60 weight portions, enzymolyzed protein 50-700 weight portions and feed carrier 80-150 weight portions. It is puffed to form puffed feed. It is superior to available feed for weaned piglet, which results in diarrhea and weight loss of weaned piglet, and is environment friendly.

Owner:北京劲能生物科技股份公司

System for preparing sulfuric acid from sulfur foam and desulfurization waste liquid by semi-dry method and acid preparation method

ActiveCN111285335AReduce the impactGuarantee continuous and stable operationSulfur compoundsEnergy inputEnvironmental engineeringAcid preparations

The invention discloses a system for preparing sulfuric acid from sulfur foam and desulfurization waste liquid by a semi-dry method and an acid preparation method. The system is formed by sequentiallyconnecting a separation unit, an incineration unit, a purification unit, a dry absorption unit and a tail absorption unit. Sulfur is extracted from sulfur foam, mixed with salt and sent to an incinerator to be incinerated for acid making, and dissolved clear liquid obtained after the sulfur is extracted and mixed with salt meets the requirement for returning to a desulfurization section to be recycled or entering a cold drum section.

Owner:江苏康茂环保工程有限公司

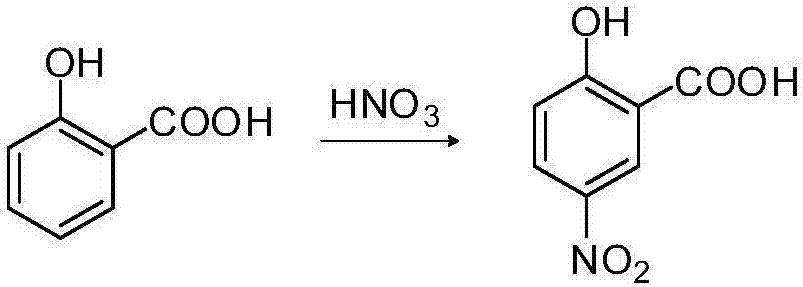

5-nitrosalicylic acid preparation process adopting microchannel continuous flow reactor

InactiveCN107353208AReduce generationSimple preparation processChemical industryChemical/physical/physico-chemical microreactorsIce waterRetention time

The invention relates to a novel 5-nitrosalicylic acid preparation process adopting a microchannel continuous flow reactor and belongs to the technical field of organic synthesis. According to the process, salicylic acid is taken as a raw material, concentrated nitric acid or a mixture of concentrated nitric acid and glacial acetic acid is taken as a nitrification reagent, the raw material and the nitrification reagent are injected into a reaction module of the microchannel reactor by a metering pump respectively, a material discharged from the reactor is directly injected into ice water, solids are separated out, and 5-nitrosalicylic acid is obtained through water washing. Continuous, efficient, safe and energy-saving industrial production is realized with the microchannel continuous flow process, the preparation process is simple, conditions are mild, retention time is short, product quality is stable, consumed acid content is reduced, yield is high and reaches 75% or higher, and industrial popularization and application are greatly facilitated.

Owner:PUYANG VOCATIONAL & TECHN COLLEGE

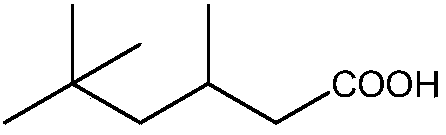

Method for preparing isooctanoic acid

InactiveCN101125810AReasonable recyclingShort reaction timeOrganic compound preparationCarboxylic compound preparationIsooctyl alcoholHydrogen

The invention relates to an isooctyl acid preparation method: isooctyl alcohol and sodium hydroxide are positioned in an inert atmosphere for reaction, with zinc acetate being the catalyst and the temperature being 250-260 DEG C and the pressure being 2.8-3.2 MPa, until no hydrogen is produced, after which the reaction continues under the same pressure for 30-50min, then the reaction product is acidized at normal pressure and at a temperature of 65-80 DEG C, thereby acquiring the crude isooctyl acid which is finely distilled and purified to produce the fine isooctyl acid. The reaction time of the method is short, and the production cycle is essentially confined to 8-10 hours; the method has high purity, as much as 99.5 percent, high yield, fundamentally non-pollution and reasonably recyclable by-products.

Owner:河南庆安化工高科技股份有限公司

Processing process for gold products

InactiveCN102660748AAdded brightness processing stepAvoid bad colorPotassium nitrateHydrofluoric acid

The invention provides processing process for gold products, which comprises the steps of gold melting, mould reversing, polishing, mould grasping, press finishing and embrotheridery, and is characterized by further comprising the step of brightness treatment, the step is performed after the step of embrotheridery, and the step of brightness treatment comprises the followings: (1), hot acid preparation: pouring sulfuric acid, phosphoric acid, nitric acid and potassium nitrate according to priority into a container for uniform stirring, and heating until boiling, so as to form the hot acid; (2), cold acid preparation: mixing hydrofluoric acid, hydrochloric acid and dairy salt together for uniform stirring so as to from mixed solution, and then pouring salt water heated into the mixed solution for uniform stirring, so as to form the cold acid; and (3), placing gold products treated through embrotheridery into hot acid for soaking and then taking out, then placing into the cold acid for soaking and then taking out, and finally washing the gold products clean by using water, wherein the hot acid is kept to be under a boiling state.

Owner:莆田市金伯爵珠宝首饰有限公司

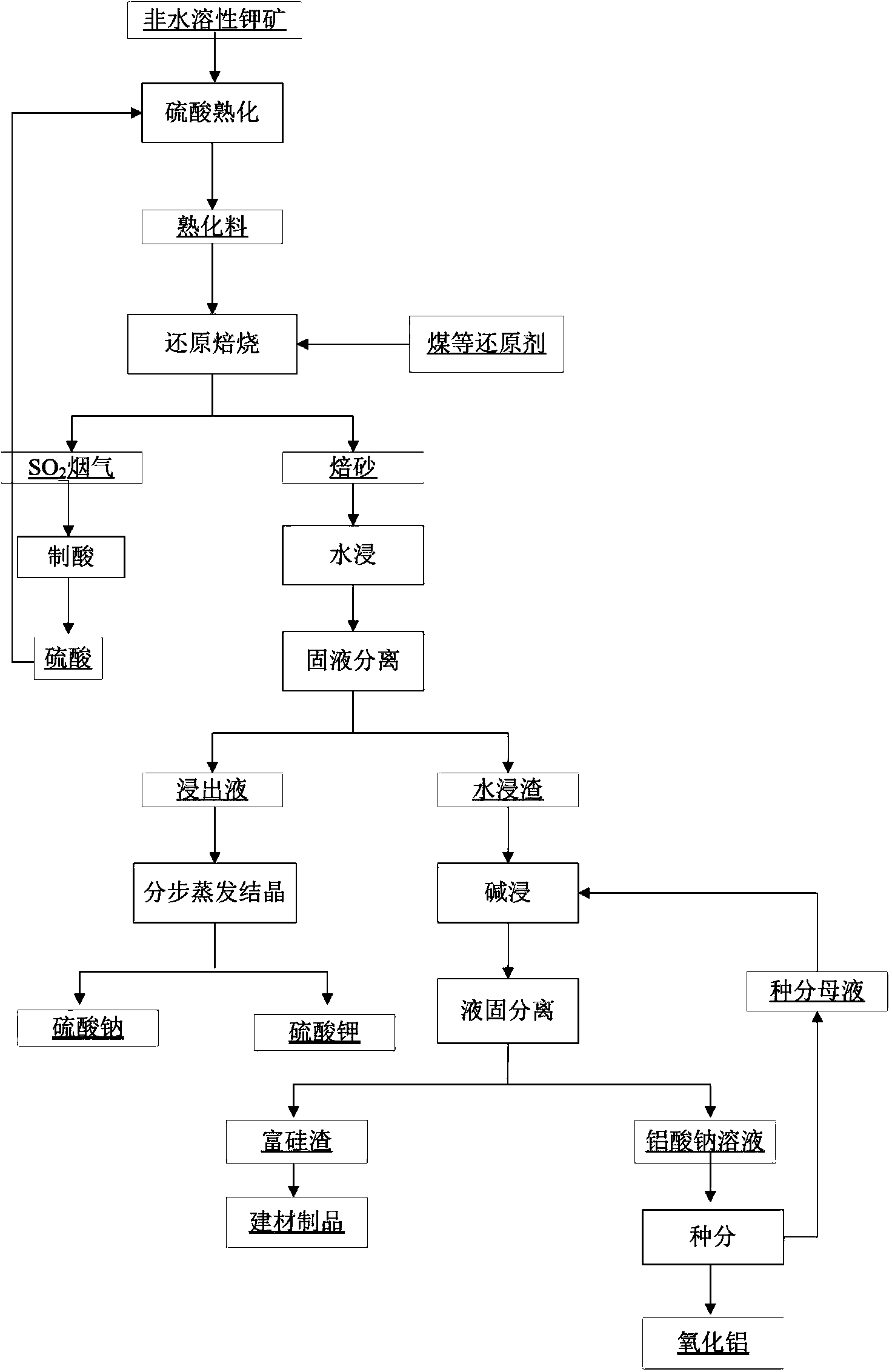

Method applied to acid-base combined extraction of aluminum, potassium and sodium from water-insoluble potassium ore

ActiveCN104388668AAchieve dissolutionKeep aliveProcess efficiency improvementAluminium recyclingFlue gas

The invention discloses a method applied to acid-base combined extraction of aluminum, potassium and sodium from water-insoluble potassium ore resource such as nepheline, potassium feldspar and the like. The method comprises the following steps: uniformly mixing finely-ground water-insoluble potassium ore with a proper amount of concentrated sulfuric acid, curing, and carrying out rapid high-temperature reduction roasting desulfurization at a certain temperature by a reducing agent, wherein the sulfur-containing flue gas is used for acid preparation to achieve regeneration and cyclic utilization of sulfuric acid; extracting potassium and sodium by water from the reduced calcine, and preparing aluminum oxide by alkaline leaching. By virtue of the method, the decomposition of aluminosilicate-containing material phase in the water-insoluble potassium ore resource such as nepheline, potassium feldspar and the like is enhanced by high-temperature reaction of concentrated sulfuric acid; the cyclic utilization of sulfuric acid is realized. The method can be used for comprehensively recycling aluminum, potassium and sodium resources; the recycling rate of aluminum oxide is high; the energy consumption is low; the corrosion to equipment is small; the large-scale industrialization is easy to implement.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Dinitrodiazophenol waste water processing method

InactiveCN101693572ASimple processReduce processing costsWater contaminantsMultistage water/sewage treatmentElectrochemical responseActivated carbon

The invention relates to a dinitrodiazophenol waste water processing method, which relates to a waste water processing method. The invention aims at providing the dinitrodiazophenol waste water processing method which utilizes iron casting iron chips and the electrical bridge function of active carbon to process dinitrodiazophenol waste water. The technical solution is that acid waste water and alkali waste water are firstly mixed during the manufacturing process of dinitrodiazophenol, then iron chips and active carbon are fed into an electrolyzation tower for standby application after being uniformly mixed, waste water firstly enters into an acidifying tank, after the pH value is adjusted to 2 - through acid preparation, precipitator is added under the stirring condition, the electrochemical reaction is carried out through an electrolyzation tower, the waste water processed by the electrochemical reaction enters into a neutralization reaction tank for the neutralization reaction after filtration, alkalescnce preparation is added, and coagulant aid is added when a great deal of fine crystals generate, the granule of sedimentary is bigger, clear liquid on the upper portion is pumped to enter active carbon for adsorption after the neutralization reaction and the waste settlement. The method is mainly used for purifying dinitrodiazophenol waste water which is initiating agent of domestic blasting machines.

Owner:YAHUA GROUP MIANYANG INDAL

Binary adjustable pre-converting method for preparing sulfuric acid from high concentration sulfur dioxide flue gas

ActiveCN107010607ALess investmentLow running costSulfur compoundsEnergy inputHigh concentrationFlue gas

The invention discloses a binary adjustable pre-converting method for preparing sulfuric acid from high concentration sulfur dioxide flue gas. The method comprises the following steps: a. high concentration SO2 flue gas successively subjected to twice heat exchange reaches the initiation temperature of a catalyst; and b, all (when the concentration is 14.5-20%) or part (when the concentration is 11-14.5%) of the high concentration SO2 flue gas enters a pre-converting catalyst layer of a converter for a converting reaction, the temperature is raised in reaction, and the flue gas leaves the pre-converting catalyst layer and enters a conventional #1 catalyst layer before the glue gas reaches the SO2 equilibrium conversion or is mixed with residual part of high concentration SO2 flue gas to enter the conventional #1 catalyst layer for a conventional '31-42'3+1 double-conversion and double-absorption normal flow for acid preparation. According to the method disclosed by the invention, SO2 concentration in flue gas entering the converting system fluctuates between 11% and 20%, the flue gas amount for preparing acid is decreased by 20-35%, the equipment investment is reduced by 20%, and the operating cost is lowered by 20%.

Owner:双盾环境科技有限公司

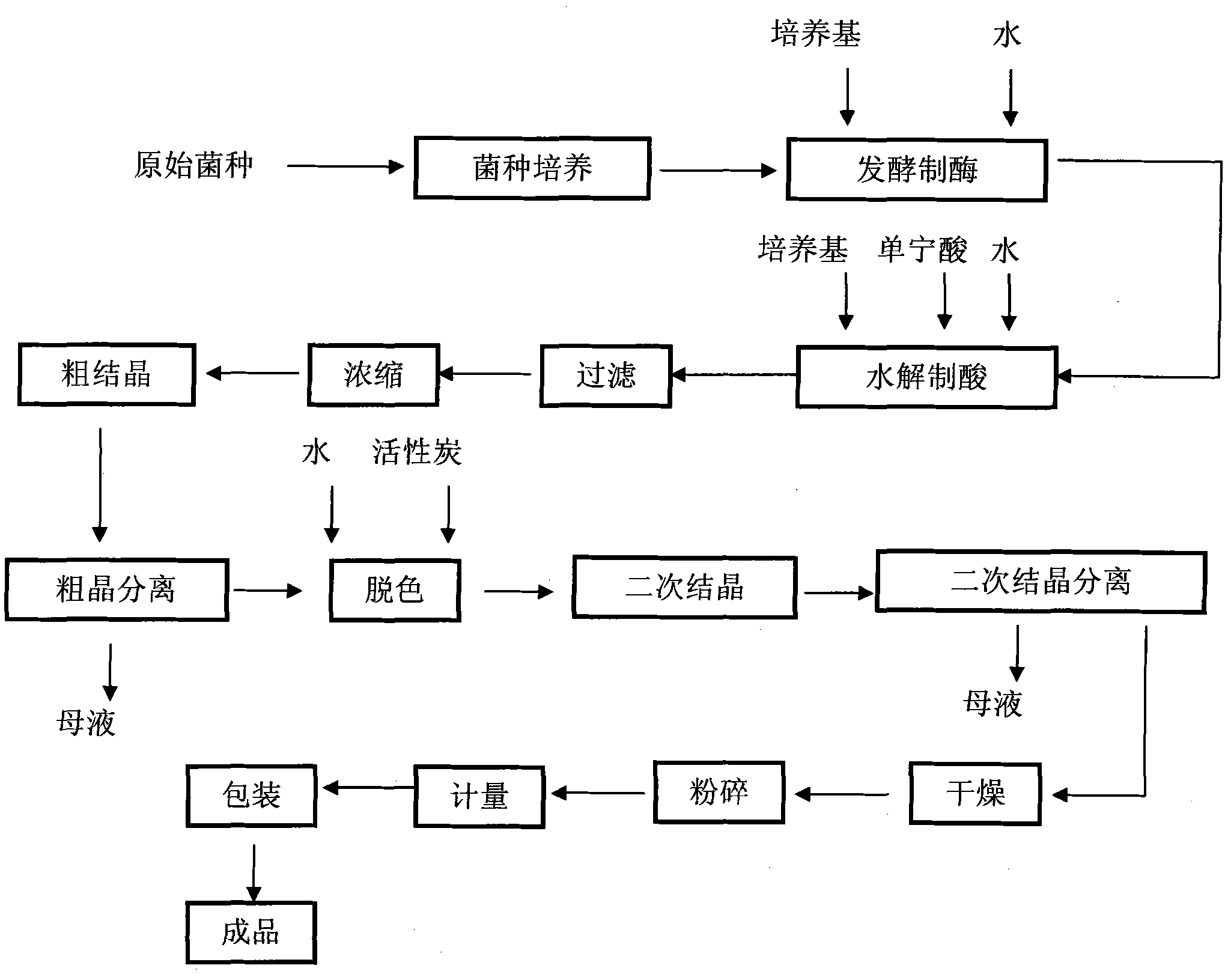

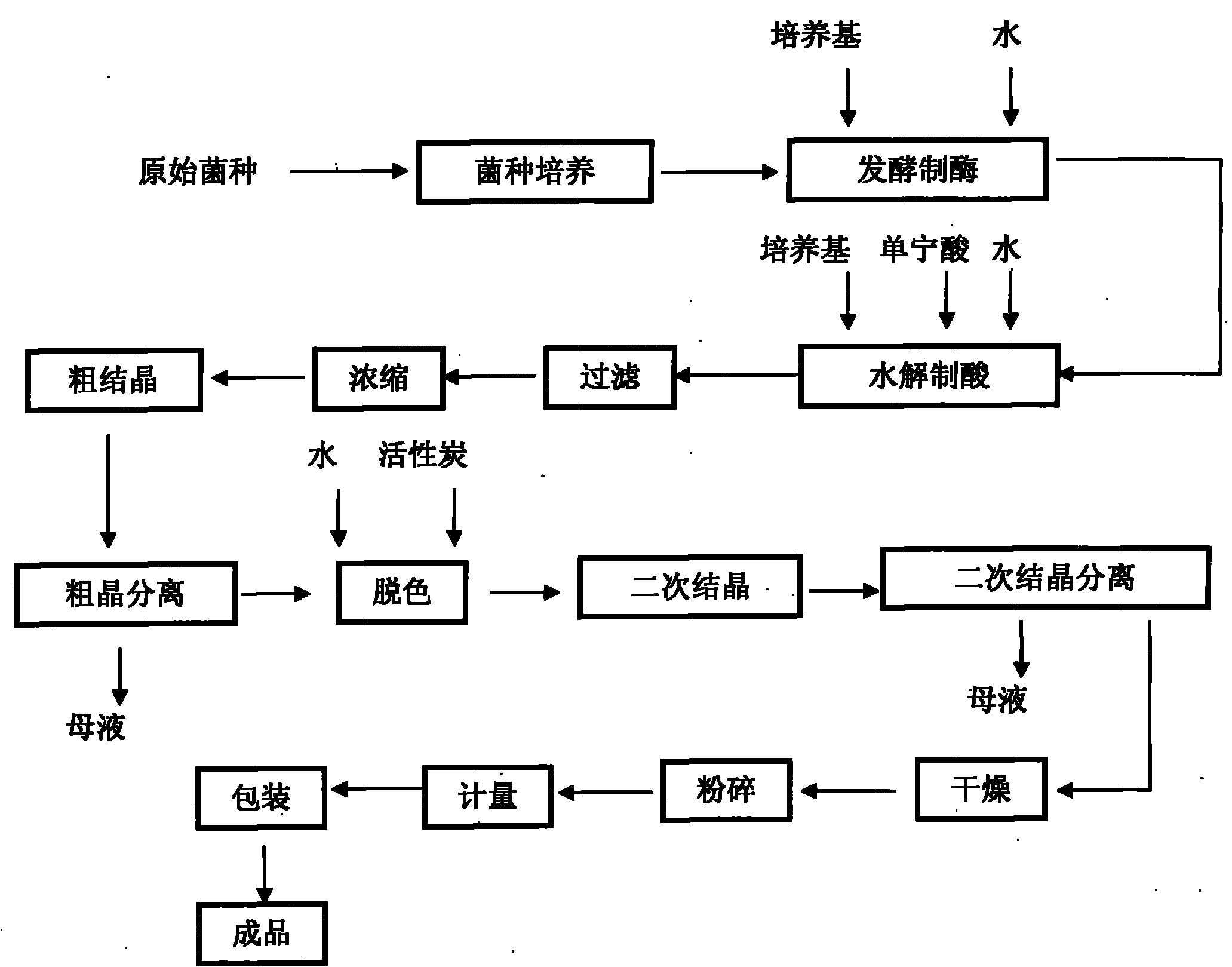

Method for preparing gallic acid

InactiveCN101864459AEasy to separateLow viscosityMicroorganism based processesFermentationMicroorganismSal ammoniac

The invention discloses a method for preparing gallic acid. In the method, enzyme preparation and acid preparation processes are performed in two different containers by stages; and NaOH solution is used for adjusting pH value in both the enzyme preparation and acid preparation processes. The invention aims to provide a method for preparing gallic acid, which reduces reaction time and raw and auxiliary material consumption, overcomes the drawbacks of strong smell, effumability and easy environmental pollution of the ammonia water due to the fact that the pH value is adjusted not by ammonia water and reduces environmental pollution. And as microorganism growing and enzyme production processes are still performed in the acid production period, the method is advantageous over a common enzyme method in hydrolysis safety, and product purity and yield and can create great social and economic benefits.

Owner:遵义市倍缘化工有限责任公司

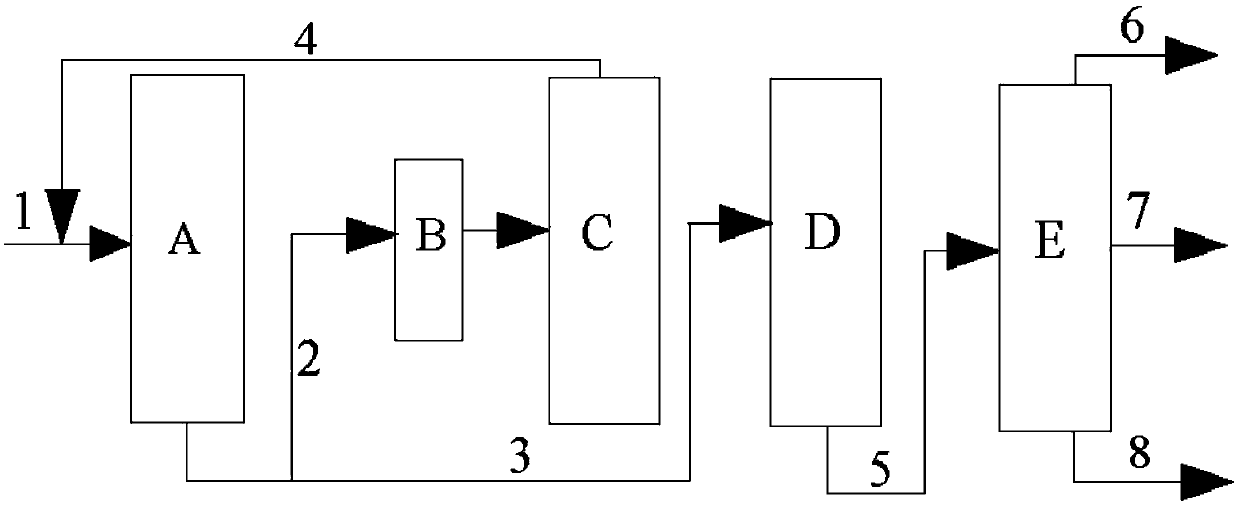

System and method for preparing isononanoic acid and method for preparing metal organic skeletal catalyst

ActiveCN108047027AHigh selectivityPromote decompositionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionMetal-organic framework

The invention provides a system and method for preparing isononanoic acid and a method for preparing a metal organic skeletal catalyst. The system includes an oxidation reactor used for oxidizing isononylaldehyde to isononanoic acid; a cooler used for cooling a part of material flow that flows out of the oxidation reactor; a metal ion separator used for separating excessive metal ions from the material flow that flows out of the cooler; a peroxide decomposition reactor used for decomposing a peroxide in the other part of the material flow that flows out of the oxidation reactor; and a rectification apparatus used for separating the material flow that flows out of the peroxide decomposition reactor to obtain the isononanoic acid product, wherein the material outlet of the metal ion separator is connected to the material inlet of the oxidation reactor. The invention further provides an isononanoic acid preparation method that is good in selectivity and safety and high in yield.

Owner:WANHUA CHEM GRP CO LTD

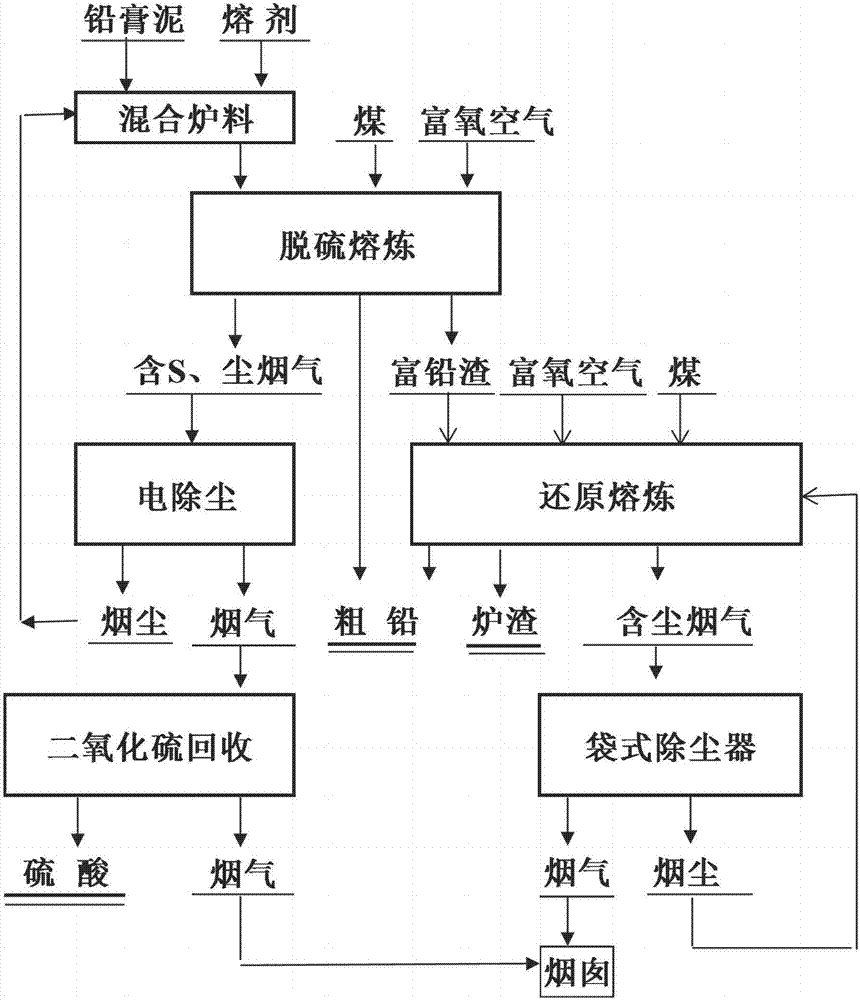

Waste lead-acid battery lead plaster molten bath smelting treatment method

ActiveCN107083488AAvoid pollutionLess investmentSulfur compoundsEnergy inputHigh concentrationElectrolysis

The invention discloses a waste lead-acid battery lead plaster molten bath smelting treatment method. Waste lead-acid battery lead plaster is treated by adopting an oxygen-enrichment molten bath smelting technology which replaces an existing production technology. The method is suitable for industrialized and large industrial production, and has the characteristics of being small in investment, high in efficiency and environmentally friendly and saving energy. Produced lead is returned to storage battery manufacturing after being subjected to pyrogenic or electrolytic refining, and circular economy is formed. Sulfuric acid can be prepared from produced high-concentration sulfur dioxide through a standard acid preparation process, the problem that environmental pollution is caused by low-concentration sulfur dioxide can be effectively solved, the lead content in produced slag does not exceed 2%, and the slag contains no ingredient which is dissolved in water and affects environment and does not need to be subjected to hazardous waste treatment.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD +1

Method for treating salt-bearing waste sulfuric acid

InactiveCN106629630AGuaranteed resolutionPromote atomizationEnergy inputSulfur-trioxide/sulfuric-acidWater vaporNitrogen gas

The invention relates to a cracking technology for recovering and treating salt-bearing waste sulfuric acid. The cracking technology includes feeding the salt-bearing waste sulfuric acid, air and fuel for providing heat required by cracking into a cracking furnace, enabling the waste sulfuric acid to undergo cracking reaction in the cracking furnace to generate mixed furnace gas containing sulfur dioxide, molten salt droplets, sulfur trioxide, carbon dioxide, water vapor, nitrogen and smoke dust, removing part of the molten salt droplets in the furnace gas through the trapping effect of a retaining wall in the furnace, removing another part of the molten salt droplets in the furnace gas through phase change after a heat exchanger is cooled, and enabling desalted furnace gas to enter a subsequent acid preparation system after heat exchange so as to obtain a sulfuric acid finished product. According to the cracking technology, the cracking rate of the waste sulfuric acid is near 100%, and the salt separation recovery rate is near 100%. The method has good economic and social benefits.

Owner:JIANGSU KERUI ENG DESIGN CO LTD

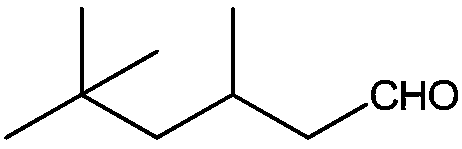

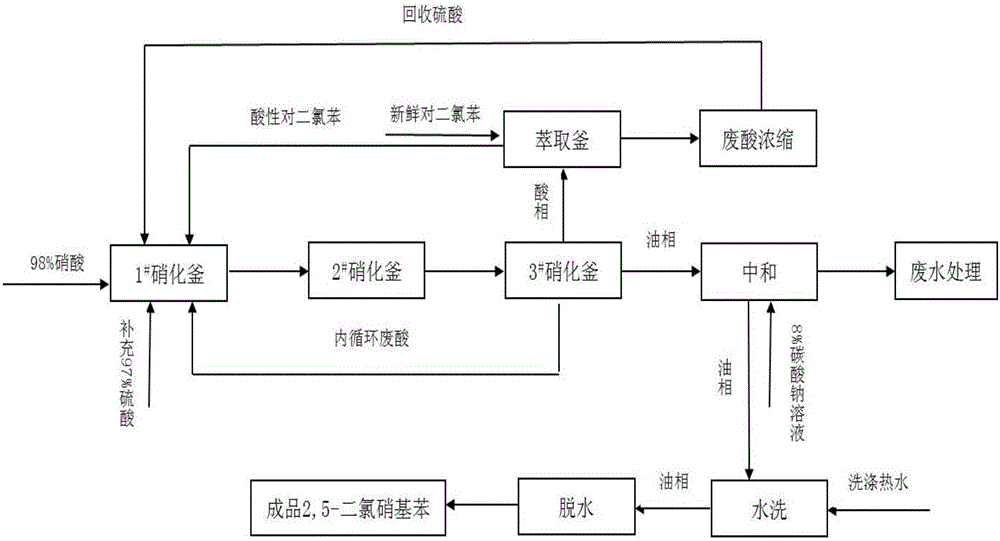

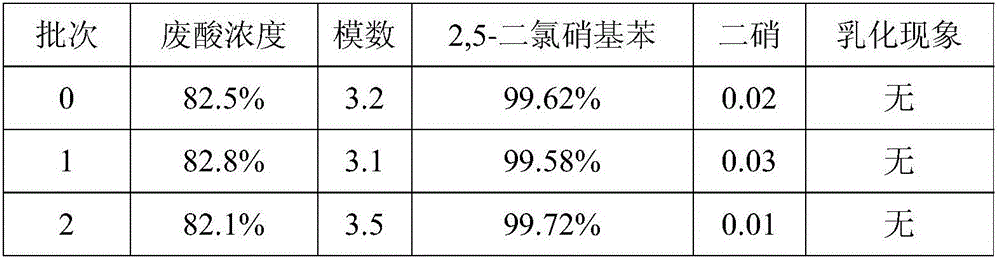

Method for preparation of 2, 5-dichloronitrobenzene by continuous nitration

ActiveCN106083596AOptimize process flowWith automatic separation functionNitro compound preparationNitrationOil phase

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

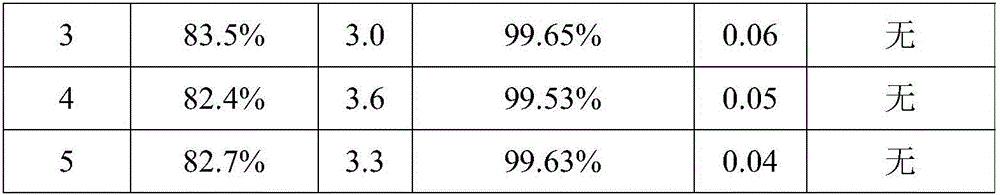

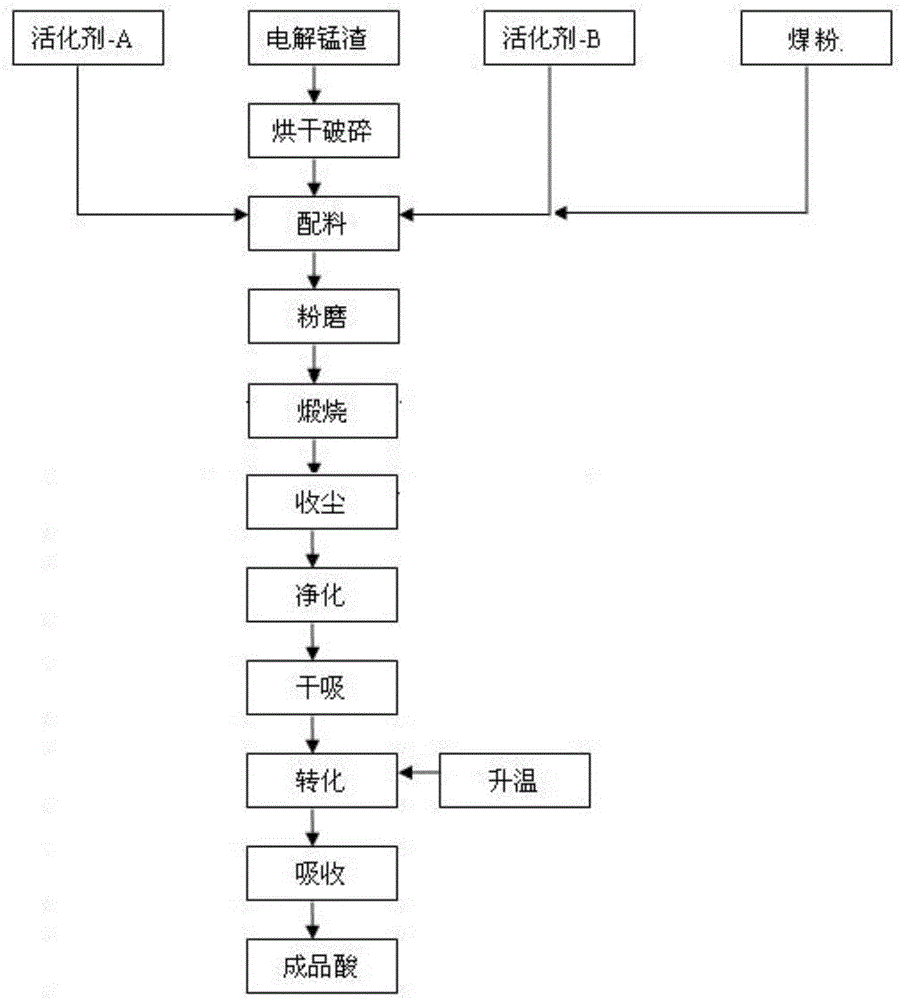

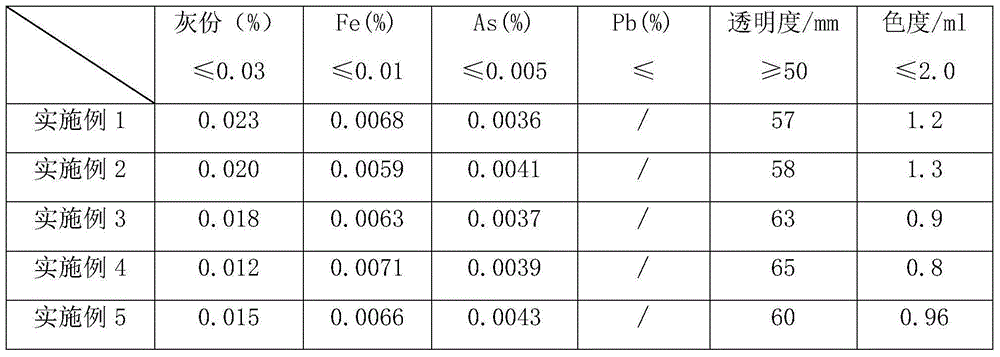

Method for preparing sulfuric acid by utilizing enriched flue gas through high-temperature desulphurization of electrolytic manganese residue

The invention discloses a method for preparing sulfuric acid by utilizing enriched flue gas through high-temperature desulphurization of an electrolytic manganese residue. The method comprises: adding an activating agent and a reducing agent according to a certain ratio into the electrolytic manganese residue; performing uniform grinding; and feeding the obtained product to a rotary kiln after metering for high-temperature calcination desulphurization. The desulphurization rate of the acid leaching residue can be improved to more than 85%; the concentration of SO2 in the enriched flue gas can be improved to more than 5.5%; and an acid preparation process by means of one conversion and one absorption is adopted to produce 93% or 98% of industrial sulfuric acid. According to the method, the electrolytic manganese residue is utilized to prepare sulfuric acid; reuse of waste resource is realized, that is, the electrolytic manganese residue is recycled; and environmental pollution is reduced. The method has a wide industrial application.

Owner:湘西蒙成科技有限责任公司

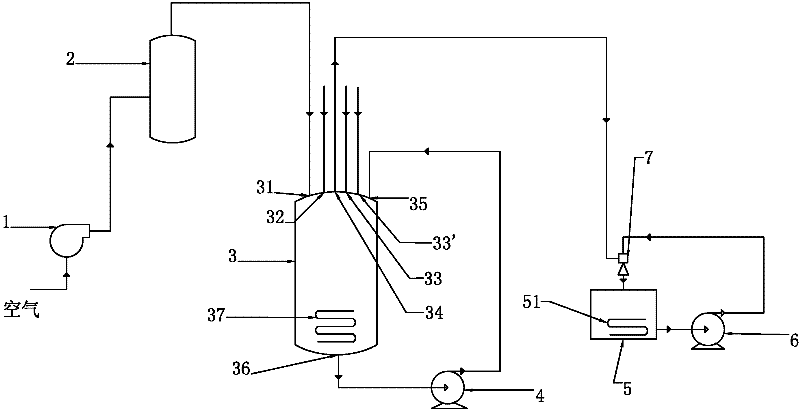

Equipment for preparing nitric acid aqueous solution

The invention provides equipment for preparing a nitric acid aqueous solution, relating to universal dilution equipment in the chemical or physical field. The equipment has the following advantages that the equipment can be used for preparing a nitric acid aqueous solution at any concentration; and in the preparation process, NO2 gas can not be exhausted into the environment and is reused by reacting with water to generate nitric acid. The equipment comprises a blower, a gas-liquid separator, an acid preparation tank, a dilute acid storage tank, a dilute acid circulating pump and an ejector, wherein the acid preparation tank is provided with an air inlet and a gas outlet; the outlet of the blower is connected with the gas-liquid mixture inlet of the gas-liquid separator; the gas outlet of the gas-liquid separator is connected with the air inlet of the acid preparation tank; the gas outlet of the acid preparation tank is connected with the pumped medium inlet of the ejector; the outlet of the ejector is connected with the inlet of the dilute acid storage tank; the outlet of the dilute acid storage tank is connected with the inlet of the dilute acid circulating pump; and the outlet of the dilute acid circulating pump is connected with the working medium inlet of the ejector.

Owner:ANHUI HUAIHUA

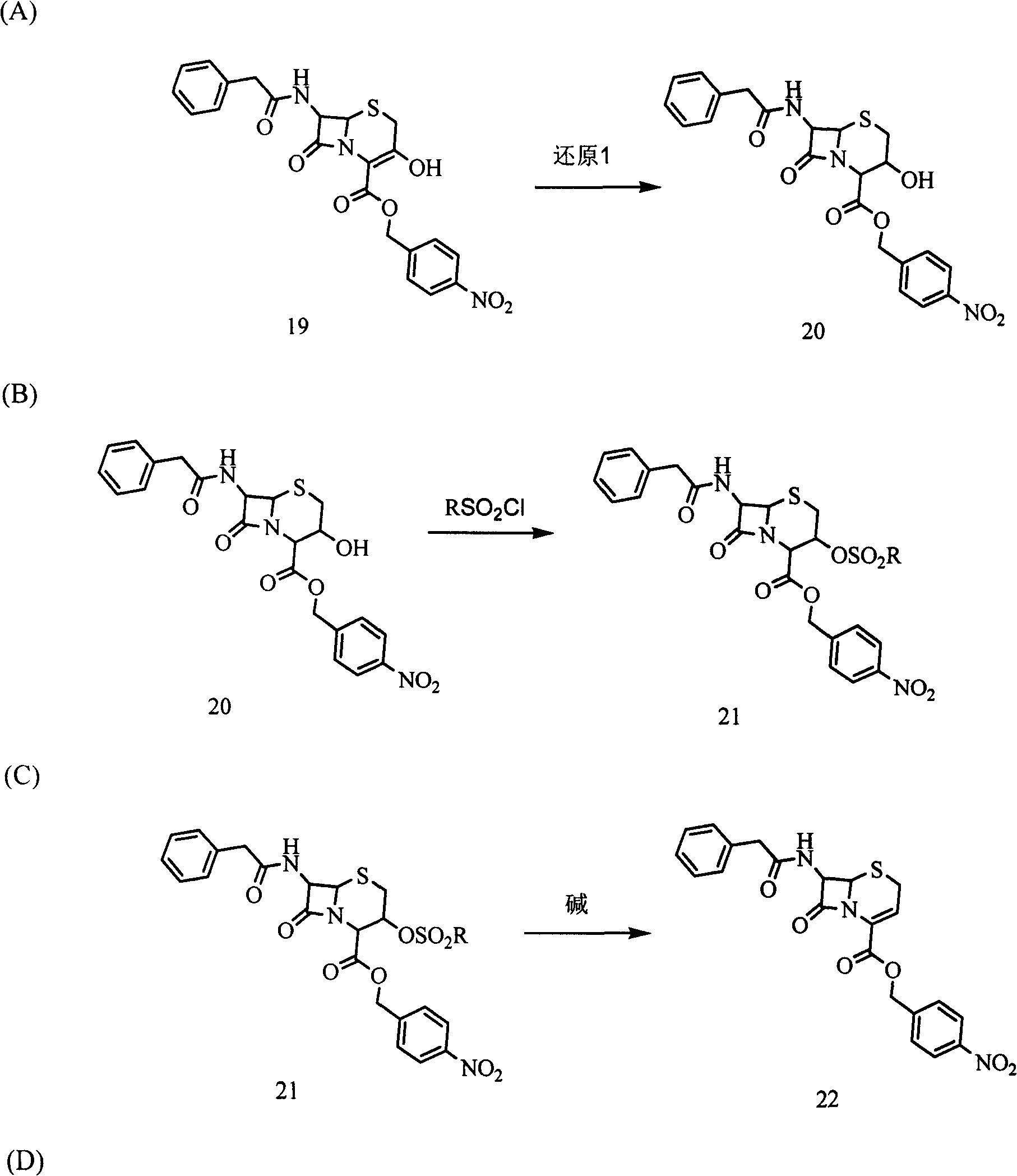

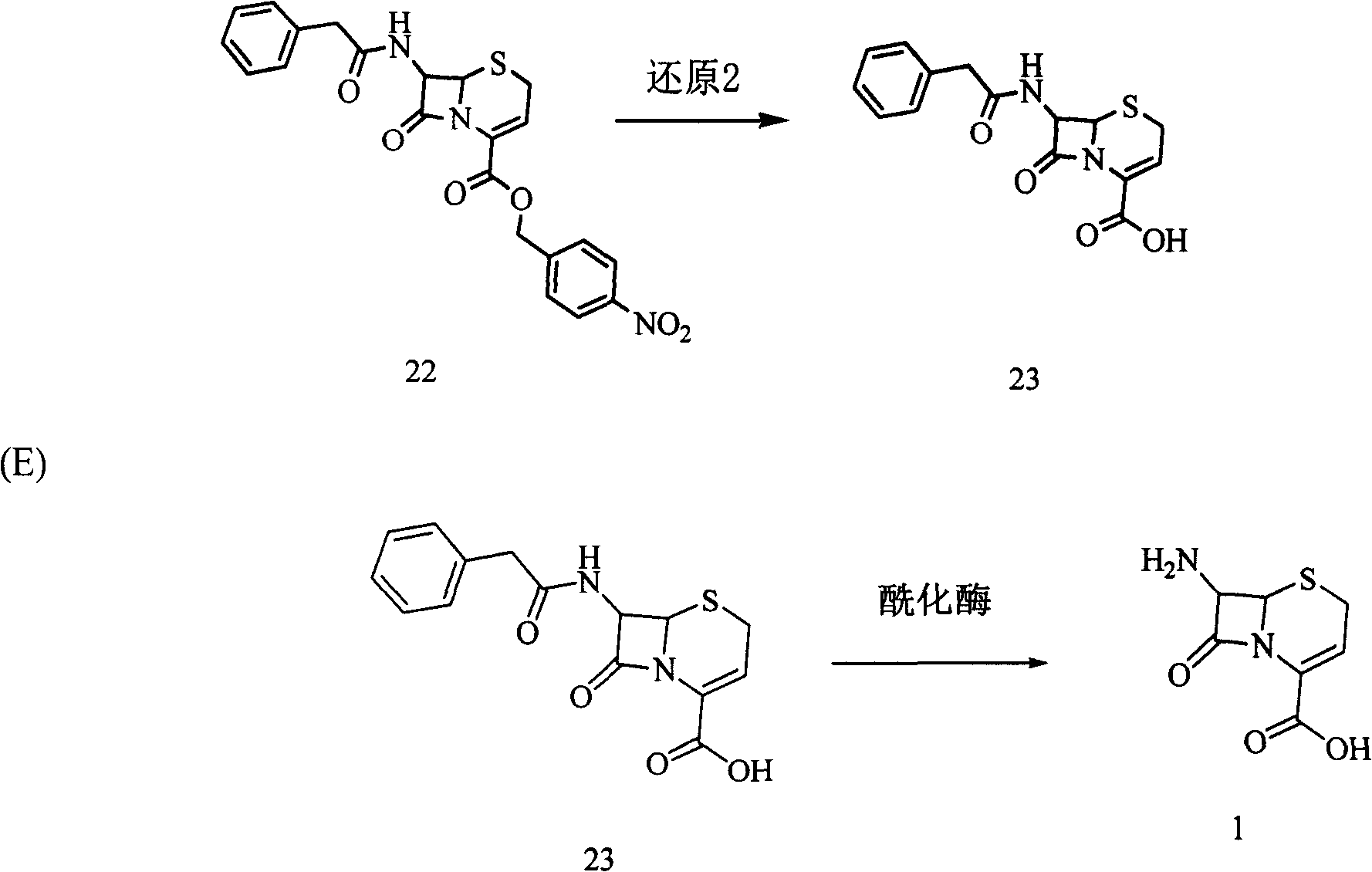

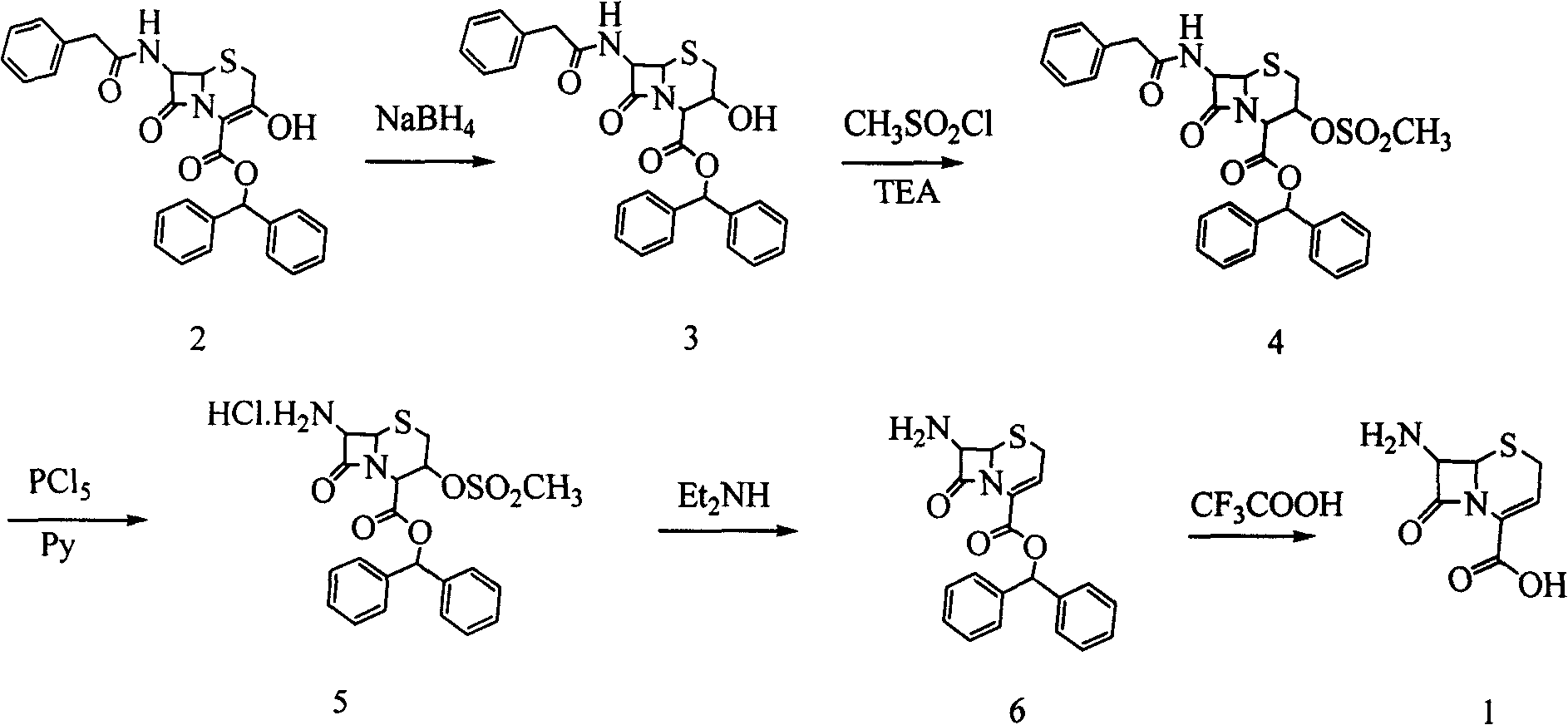

7-amino-3-non-3-cephalosporin-4-carbosylic acid preparation method

InactiveCN101357927AAvoid pollutionReduce pollutionOrganic chemistryBulk chemical productionDouble bondCarboxylic acid

The invention provides a preparation method of 7-amino-3-non-cephem-4-carboxylic acid which is 7-ANCA for short. The preparing procedures are as follows: 7-phenyl acetamide-3-hydroxy-3-cephem-4-carboxylic acid-p-nitrobenzyl ester is taken as raw material; firstly, metal borohydride is used to reduce the double bonds between the 3-parental nucleus and the 4-parental nucleus; sulfuryl etheride is used to esterify the 3-hydroxy, then alkali is used to remove the 3-methanesulfonic acid ester group to restore the double bonds between the 3-parental nucleus and the 4-parental nucleus; finally, a catalytic hydrogenation method is used to remove the protecting group on the 4-carboxyl of the parental nucleus, an enzyme method is used to remove the protecting group on the 7-amino of the parental nucleus, thus obtaining the product 7-ANCA. The invention has the advantages of being simple and feasible technology, improving production quality, reducing production cost and reducing environment pollution.

Owner:ZHEJIANG APELOA TOSPO PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com