Patents

Literature

57 results about "Cryphonectric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular sieve based catalysts, preparation method and application thereof in crylic acid preparation by lactic acid dehydration

InactiveCN101602010AExtended service lifeReduce energy consumptionMolecular sieve catalystsOrganic compound preparationPhosphateAcid preparations

The invention discloses a molecular sieve based catalyst, a preparation method and an application thereof in crylic acid preparation by lactic acid dehydration. The method comprises the following steps: processing the ZSM-5 molecular sieve in aqueous alkali, or adopting an impregnation method to support phosphate, drying, roasting and finally obtaining the modified molecular sieve based catalyst. The catalyst realizes the reaction of crylic acid preparation by lactic acid dehydration in low temperature and has the advantages of high lactic acid conversion rate and crylic acid selectivity, and long-life of catalyst, the conversion rate of lactic acid dehydration reaction is 100%, and crylic acid selectivity can reach as high as 83.9%, thus having good industrial application prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

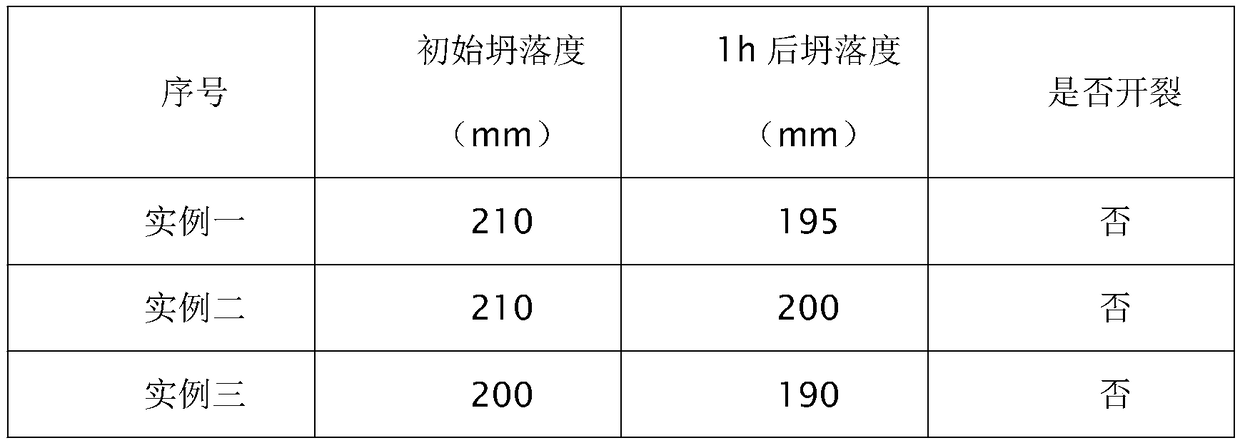

Polycarboxylate superplasticizer with improved workability and encapsulation and preparation method thereof

ActiveCN106116226AImprove workabilitySimple production processSodium Hypophosphite MonohydrateHydrogen

The invention relates to preparation of polycarboxylate superplasticizer, in particular to polycarboxylate superplasticizer with improved workability and encapsulation and a preparation method thereof. An effective dose of monomers, polysaccharide with the molecule side chain containing rhamnose, hydroxide radical and carboxyl, sodium hypophosphite, sodium bisulfoxylate formaldehyde powder, vitamin C, sodium hydrogen sulfite, crylic acid, hydrogen peroxide and sodium hydroxide are dissolved in water and then subjected to blending, fed-batch blending and other steps, and then the polycarboxylate superplasticizer is obtained. The technical problems that in the prior art, during using, the process operation is complex are solved. The polycarboxylate superplasticizer has the advantages that the preparation process and a use method are simple, the polycarboxylate superplasticizer meets national standard requirements, and after being used, the polycarboxylate superplasticizer is good in workability and does not separate or bleed.

Owner:石家庄协耦化学科技有限公司

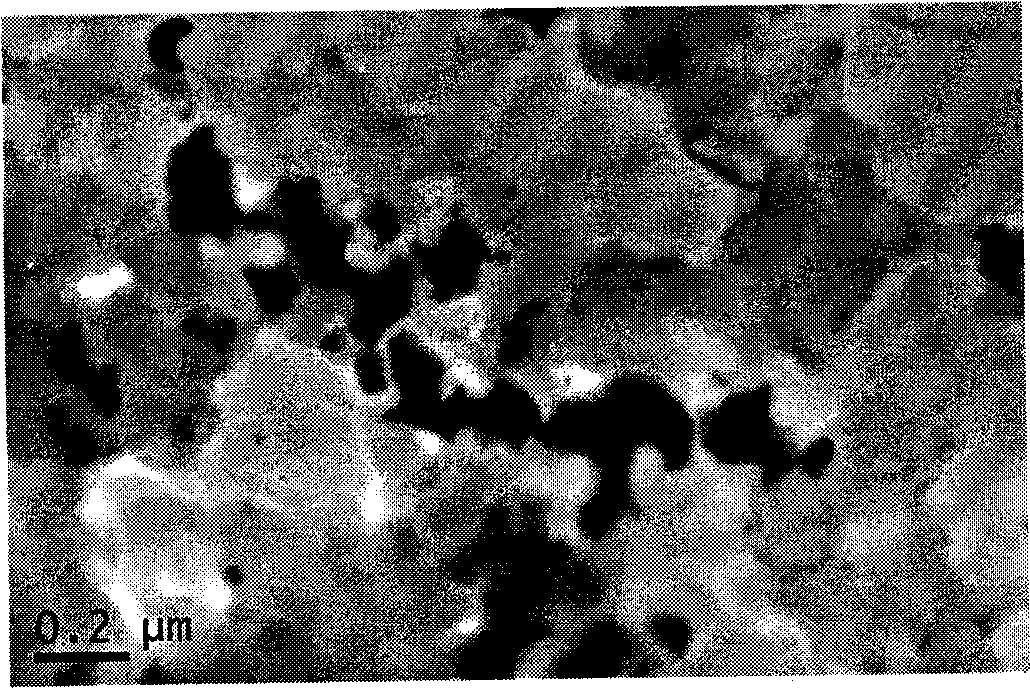

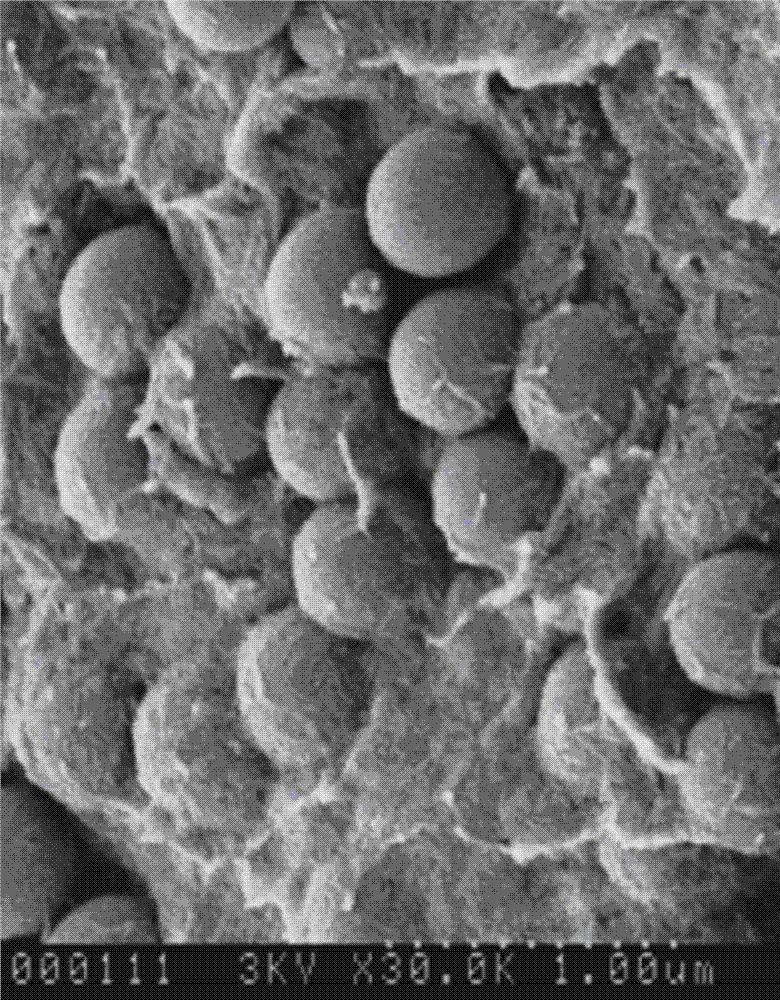

Composite cationic ion-exchange resin supporting iron-series duplex metal nano granules as well as preparation method and use thereof

InactiveCN101497051ASolve the problem of large head lossIncreased pre-enrichment capacityCation exchanger materialsOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeIon

The invention discloses a supported ferric bimetallic nanometer composite cation exchange resin, a preparation method and application thereof, which belong to the field of nanometer composite resin. A carrier of the resin is an ionic exchange and adsorption resin with an acidic functional group; a resin frame is styrene series or crylic acid series, and contains a sulfonic group, a carboxylic group or a phosphonic acid group; and a solid supported inorganic material is nanometer iron series bimetallic particles. The preparation method uses the ion exchange and adsorption resin with the acidic functional group as the carrier to be solidly loaded by Fe or Fe, is reduced by a NaBH4 or KBH4 solution, and is immersed in a salt solution of the second metal so as to produce the supported ferric bimetallic nanometer composite cation exchange resin. The supported ferric bimetallic nanometer composite cation exchange resin, the preparation method and the application thereof combine Donnan preenrichment effect and high-efficiency catalysis degradation effect into a whole, and improve the degradation speed of the material on a target pollutant while overcoming the deficiencies of easily agglomerated pure nanometer nulvalent iron, unstable chemical property, small particles, large hydraulic loss and the like, thereby having degradation characteristics of high efficiency, fast speed and low cost on an environment micro-pollutant.

Owner:NANJING UNIV

Medical antibacterial adhesive and preparation method thereof

InactiveCN104434542AImprove adhesionImprove antibacterial propertiesImpression capsDentistry preparationsEpoxyCellulose

The invention relates to a medical antibacterial adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The medical antibacterial adhesive comprises the following constituents in parts by weight: 16 to 20 parts of epoxy resin, 2 to 10 parts of crylic acid, 4 to 10 parts of editic acid, 12 to 18 parts of polyurethane, 2 to 5 parts of polyvinyl alcohol, 2 to 8 parts of methylol cellulose, 1 to 3 parts of citric acid, 3 to 9 parts of nanometer silicon micro powder, 10 to 14 parts of titanium dioxide, and 20 to 30 parts of glycol. The medical antibacterial adhesive has good bonding property, and can rapidly realize bonding even at low temperature; the medical antibacterial adhesive has excellent antibacterial property; the preparation method is simple, convenient to carry out, and suitable for large-scale promotion and application.

Owner:SUZHOU BEC BIOLOGICAL TECH

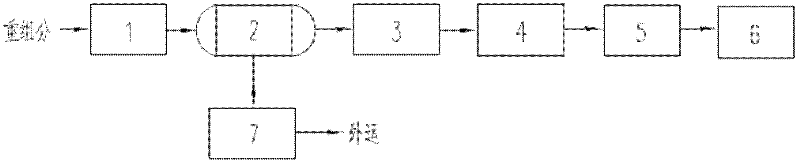

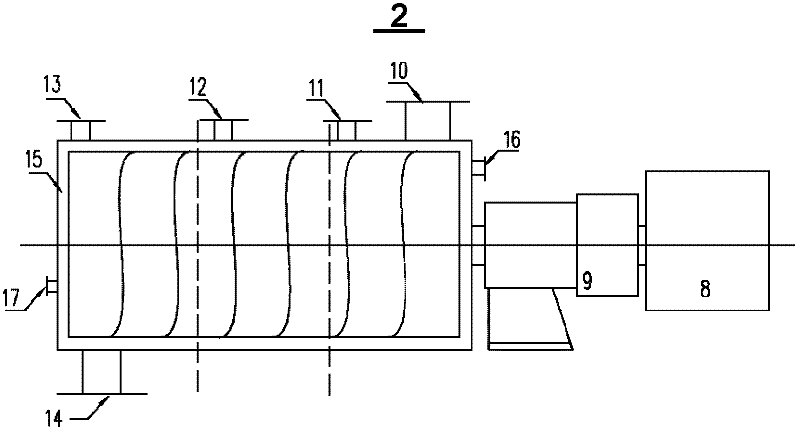

Processing method and processing device of crylic acid and ester heavy components

InactiveCN102516061AHigh recovery rateHigh purityOrganic compound preparationPreparation from carboxylic acid esters/lactonesDistillationProcess engineering

A processing method of crylic acid and ester heavy components includes the following steps: A) conducting distillation splitting on the crylic acid or the ester heavy components to enable the crylic acid or the ester heavy components to be converted into crylic acid steam; B) condensing and collecting the crylic acid steam; and C) purifying the collected crylic acid. The processing method is simple in process flow, high in recycle rate, high in purity, stable in long-term operation, capable of bringing high economical and environment benefits to society and worth popularizing in the market.

Owner:李开明

Water-soluble no-clean soldering flux

InactiveCN102049634ADifficulties in exempting protectionReduce consumptionWelding/cutting media/materialsSoldering mediaSolventInsulation resistance

The invention relates to a water-soluble no-clean soldering flux which comprises the following components in percentage by weight: 2.0-3.7% of crylic acid activator, 0.1-0.5% of surfactant, 1.5-5.0% of ester wetting agent, 2.0-15.0% of ester cosolvent, 0.05-1.0% of antioxidant, 0.03-0.5% of antifoaming agent, and the balance of deionized water. The soldering flux provided by the invention is scientifically designed and reasonably prepared, and has the advantages of good solderability and high insulation resistance, does not contain halogen or VOC (volatile organic compound) substance or need to be cleaned, is environment-friendly soldering liquid, has less possibility of combustion, and does not explode; and in the water-soluble no-clean soldering flux, the deionized water is utilized as solvent.

Owner:广东剑鑫科技股份有限公司

External wall putty

The invention relates to external wall putty, which comprises two components of A and B according to following weight percentage: component A comprises 30-40 percent of heavy calcium carbonate, 5-15 percent of talcum powder, 25-35 percent of quartz sand, 25-30 percent of Portland, 42.5 of cement, 1-3 percent of subdividable latex powder, 0.2-0.5 percent of ethoxyl methyl cellulose ether, and 0.02-0.1 percent of modified starch ether; component B is 5-12 percent of crylic acid latex; assorting ratio of component A and B is 100:5-12. The external wall putty has the advantages that cracks and pores can be padded; after hard drying, the product is characterized by strong adhesion force, good water resistance and corrosion resistance, smooth surface layer, crack control, and good impact resistance; after tested, 0.8 MPa is reached under a standard state in terms of bond strength; after five times of freeze-thaw cycles, bond strength of the putty reaches 1.03 MPa; the putty can be extensively applied to alteration and face lifting of external walls, which provides smooth underside base material for applying dope.

Owner:广福建材(蕉岭)精化有限公司

Method for restoring heavy metal contaminated soil

InactiveCN103894404AWide variety of sourcesUnique in natureContaminated soil reclamationCryphonectric acidEnvironmental chemistry

Owner:SOUTH CHINA UNIV OF TECH

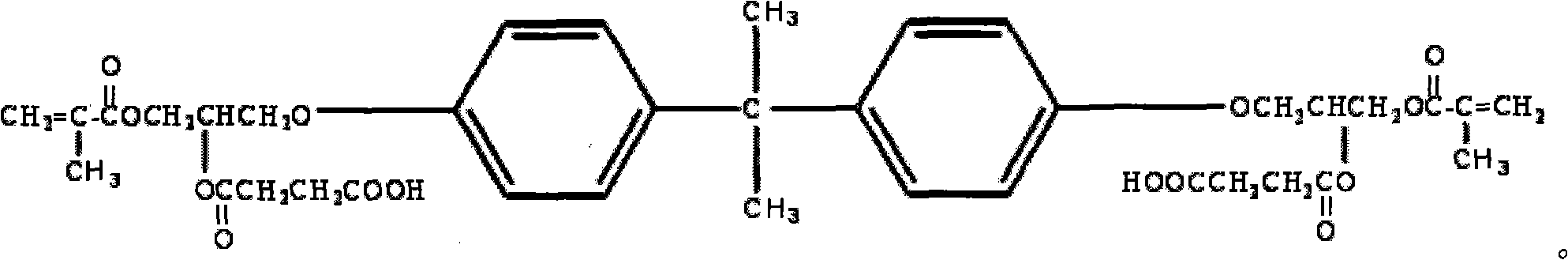

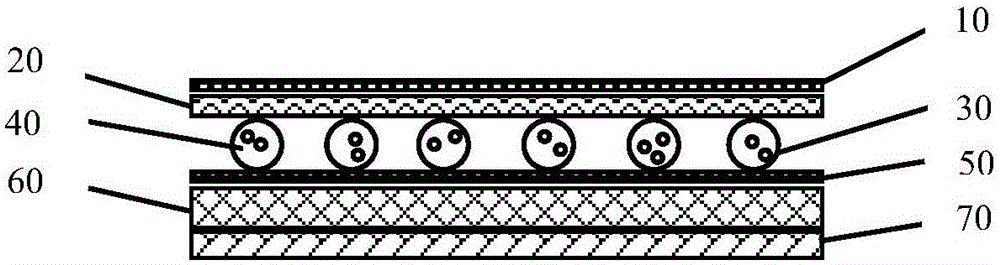

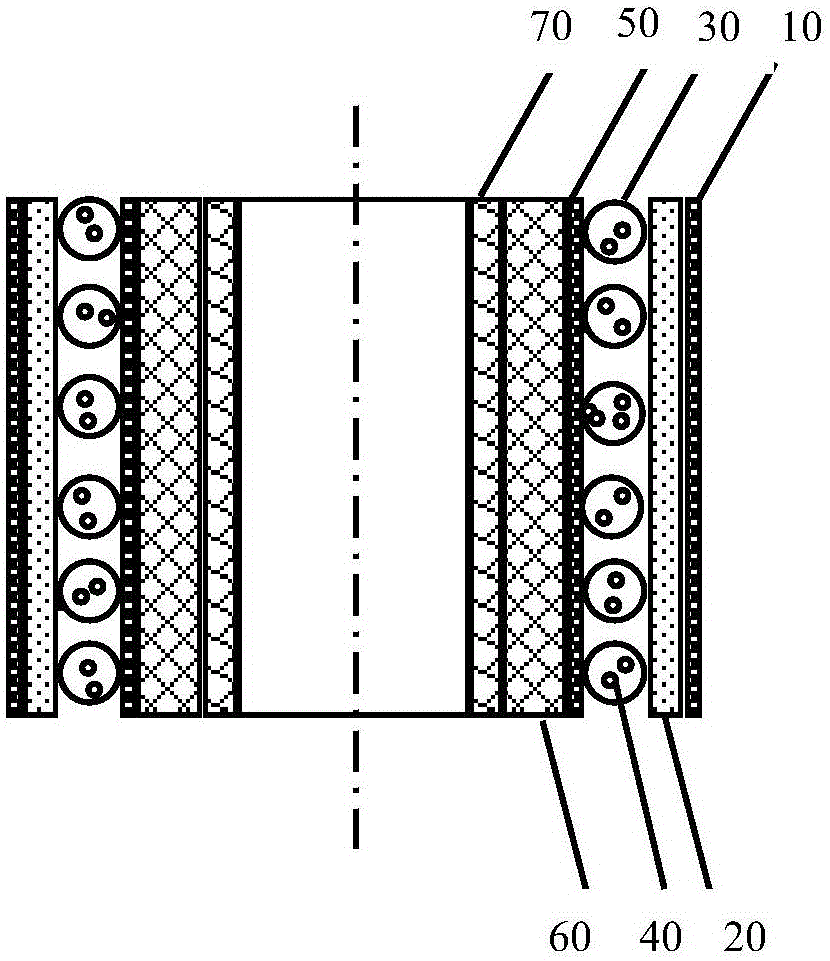

Novel flame retardant, heat insulation and heat preservation material structure

InactiveCN105040841AImprove safety cushioningNot easy to convect heatThermal insulationClimate change adaptationPhysical chemistryHeat conservation

A novel flame retardant, heat insulation and heat preservation material structure is characterized by comprising a first aluminum foil layer, a weaved cloth layer, cystic bubbles, a second aluminum foil layer, melamine foam and an aerogel felt; the cystic bubbles are filled with flame retardant inert gas; nanometer flame retardant particles are added in the bubble layer, the height of the bubbles ranges from 2 to 16 mm, and the width of the bubbles ranges from 3 to 30 mm; the thickness of the melamine foam ranges from 2 to 10 mm, and the gas hole ratio of the foam ranges from 90% to 97%; the thickness of the aerogel felt ranges from 8-15 mm; the first aluminum foil layer, the weaved cloth layer, the cystic bubbles and the second aluminum foil layer are bonded through polyurethanes binding agents, and the thickness ranges from 30 to 50 mm; the second foil layer and the melamine foam are bonded through PA-80 binding agents, and the thickness ranges from 30 to 55 mm; the melamine foam and the aerogel felt are bonded through crylic acid binding agents, and the thickness ranges from 35 to 65 mm. The heat preservation material can be applied horizontally or made into pipes for use, the flame retardant property is good, the damping effect is good, the weight is low, and the heat preservation and energy conservation effects are ideal.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

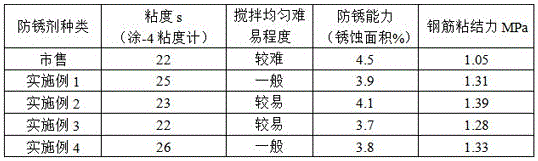

Micro-nano reinforcing steel bar anti-rusting agent for autoclaved aerated concrete slab and preparation method of micro-nano reinforcing steel bar anti-rusting agent

The invention discloses a micro-nano reinforcing steel bar anti-rusting agent for an autoclaved aerated concrete slab. The micro-nano reinforcing steel bar anti-rusting agent is prepared from the following raw materials in percentage by mass: 15-25% of organosilicone modified crylic acid emulsion, 15-20% of silicon sol emulsion, 8-12% of lime, 8-12% of silicon ash, 8-12% of cement, 8-12% of light calcium carbonate, 3-8% of a coalescing agent, 0.2-3% of a tackifier, 0.1-0.7% of a defoaming agent, 0.1-0.5% of a dispersing agent and the balance of water. The micro-nano reinforcing steel bar anti-rusting agent is relatively easy to stir uniformly, so that the dip-coating quality stability can be ensured, the bonding force of a reinforcing steel bar can be greatly increased, the anti-rusting property of the reinforcing steel bar is further improved, tests show that various indexes are all superior to those required in GB 15762-2008 and JC / T 855-1999, and meanwhile the micro-nano reinforcing steel bar anti-rusting agent has the advantages of stable quality, environment-friendliness and the like. The invention further discloses a preparation method of the micro-nano reinforcing steel bar anti-rusting agent.

Owner:广东省建筑材料研究院有限公司 +1

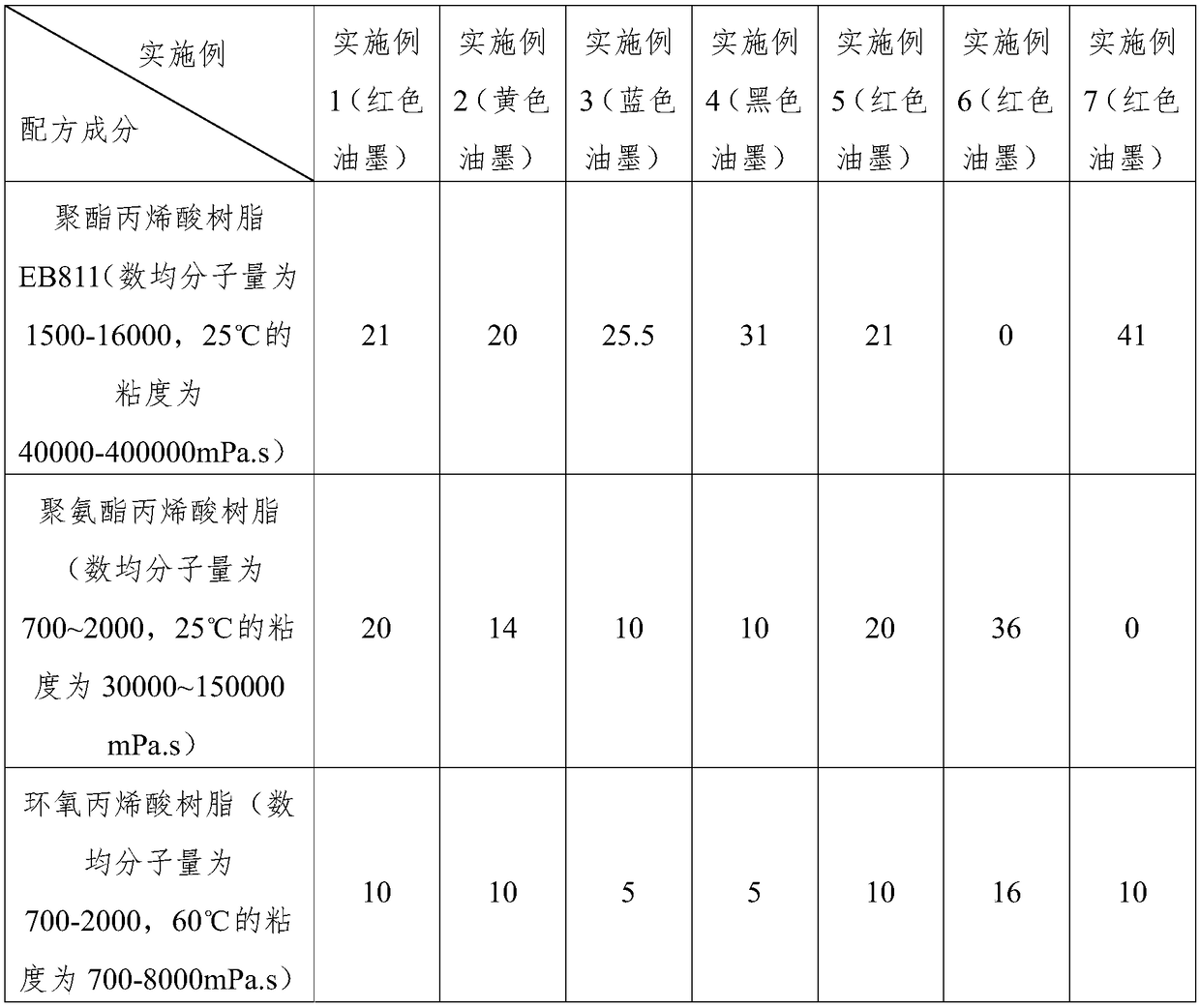

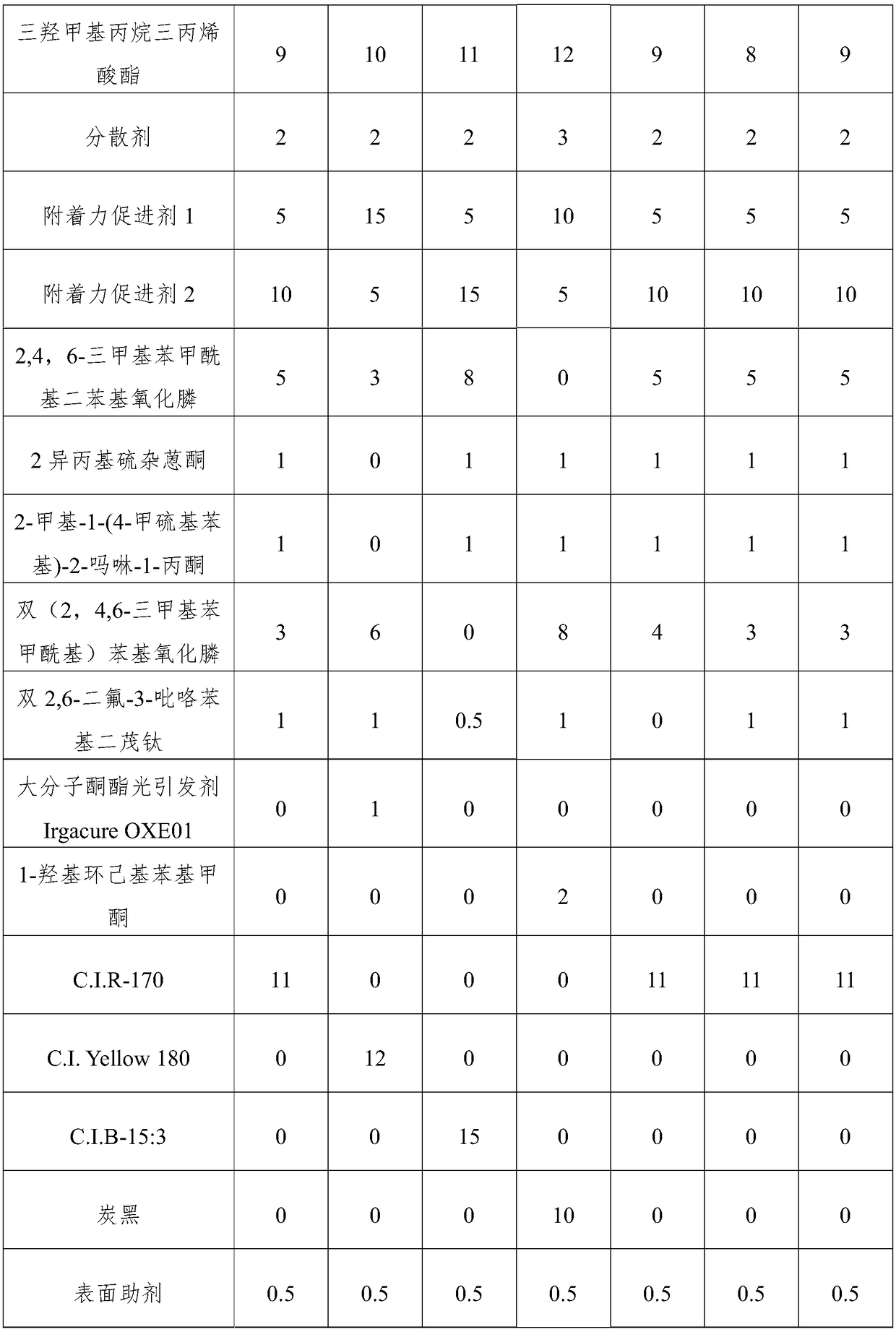

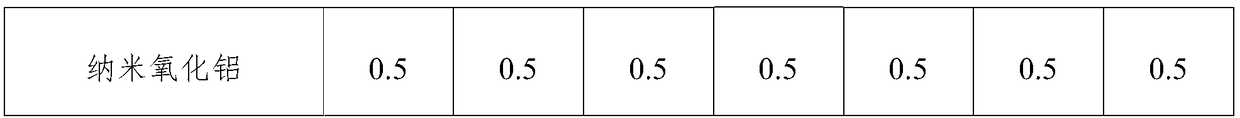

UV-LED curing transfer printing ink and preparation method and application

The invention provides UV-LED curing transfer printing ink in order to solving the problem that existing transfer printing ink is poor in adhesive force. The UV-LED curing transfer printing ink is prepared from, by mass, 40-60 parts of crylic acid prepolymer, 5-25 parts of adhesion promoter, 5-15 parts of monomers, 5-15 parts of photoinitiator, 5-25 parts of pigment and 0.3-3 parts of surface aid.Meanwhile, the invention discloses a preparation method and application of the UV-LED curing transfer printing ink. The adhesive force of the UV-LED curing transfer printing ink on all kinds of basematerials is good, the alcohol resistance and boiling water resistance are excellent, the durability at high temperature and high humidity is good, the scratch resistance is prominent, and the workingtime is short.

Owner:清远慧谷新材料技术有限公司

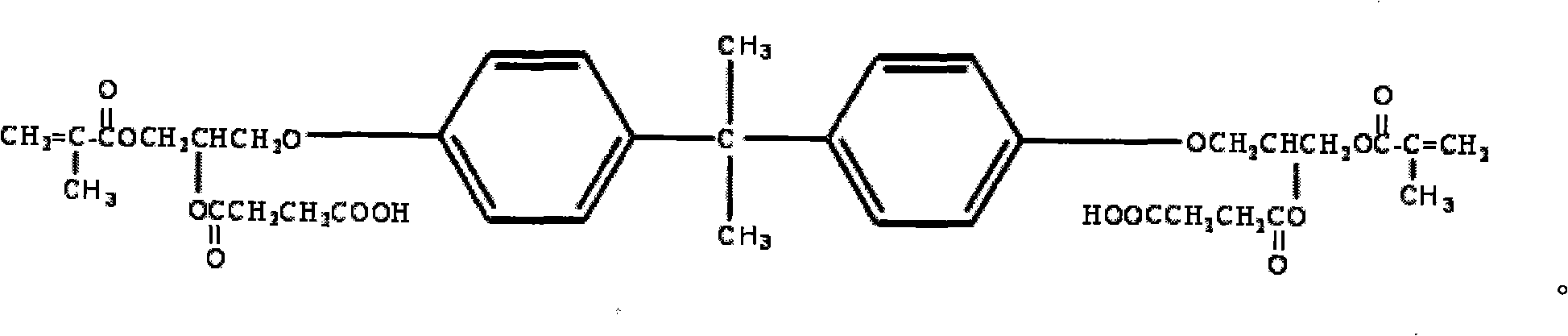

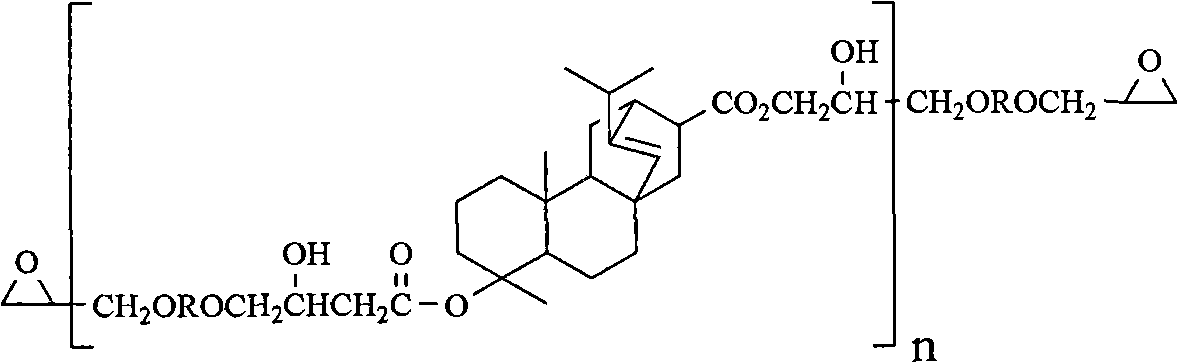

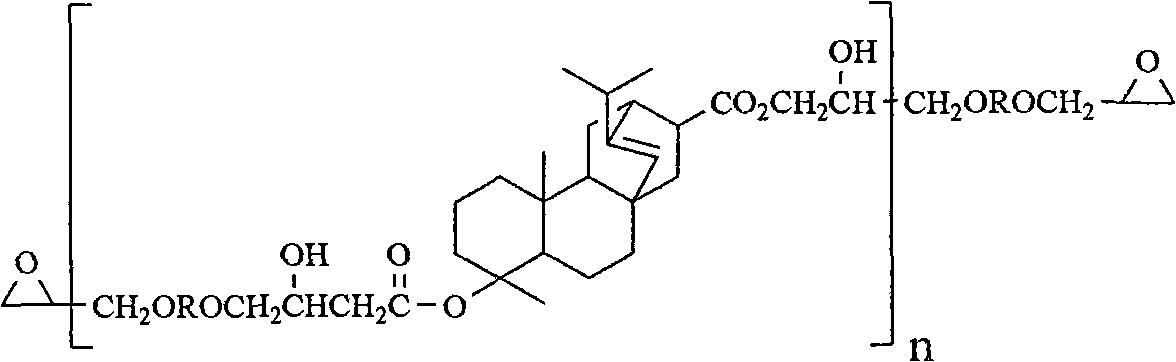

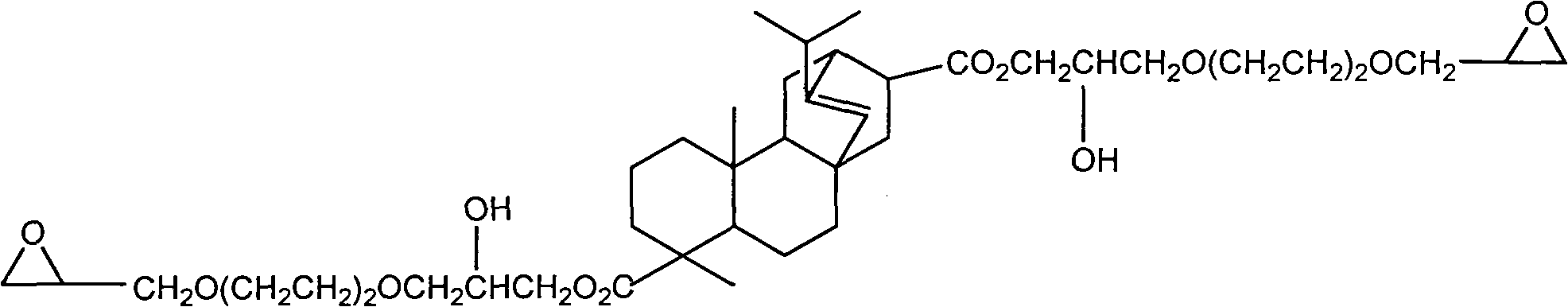

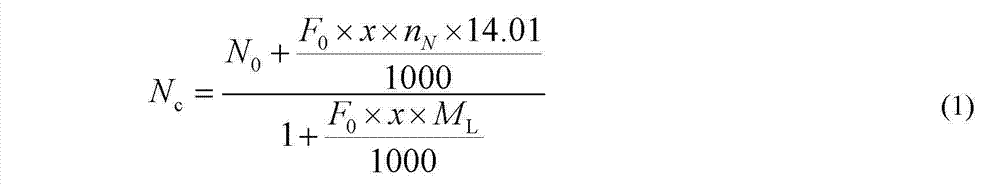

Crylic acid rosin epoxy resin, curing method and application thereof

InactiveCN101638473AGood flexibilityLower glass transition temperaturePlastic/resin/waxes insulatorsEpoxy resin adhesivesPrepolymerRosin

The invention discloses crylic acid rosin epoxy resin, a curing method and application thereof. The curing method comprises the following steps: uniformly blending crylic acid rosin epoxy resin prepolymer, dodecyl succinic anhydride and catalyst which are cured to obtain crylic acid rosin epoxy resin; or dissolving crylic acid rosin by using acetone and then uniformly blending the dissolved crylicacid rosin and dodecyl succinic anhydride, and finally volatilizing and removing the acetone; adding aliphatic glycidol ether and catalyst, uniformly blending and curing to obtain crylic acid rosin epoxy resin. The cured product provided by the invention has good flexility, low glass transition temperature, excellent mechanical property and uvioresistant performance, is particularly suitable formanufacturing outdoor weather resistance electrician insulation material, also can be used as weather resistance epoxy adhesive, epoxy resin-based paint and water-borne epoxy resin paint, etc.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

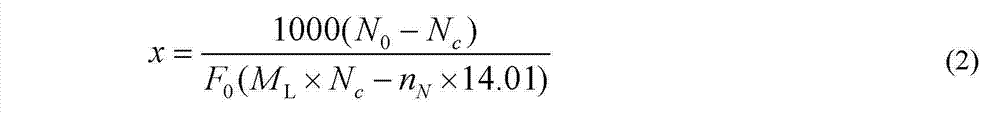

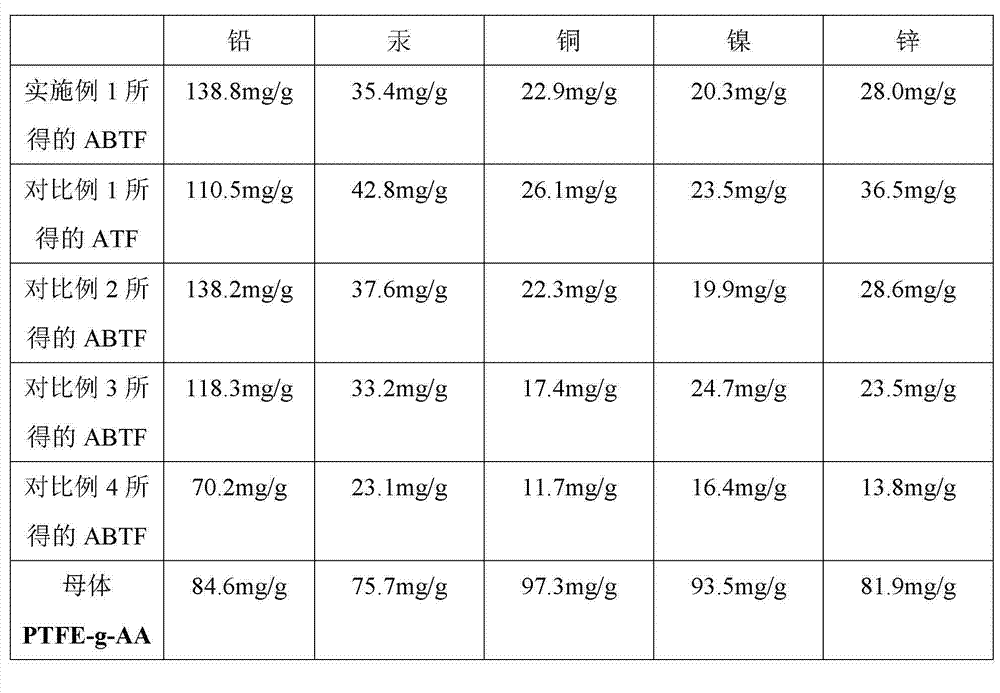

Chelate fiber ABTF and synthetic method thereof

InactiveCN103301817AExtensive sources of raw materialsLow priceOther chemical processesFibre typesFiberToluene

The invention discloses a synthetic method of chelate fiber ABTF. The method comprises the following steps of: firstly, soaking crylic acid modified polytetrafluoroethylene fiber into methylbenzene for 7 hours to 9 hours with the crylic acid modified polytetrafluoroethylene fiber as a parent; secondly, adding ligand into material obtained in the first step, stirring and reacting for 12 hours to 16 hours at 60 to 80 DEG C, wherein 2-aminobenzothiazole is taken as the ligand, and the mole ratio of the parent to the ligand is (0.9-1.1):3; thirdly, filtering material obtained in the second step, washing a filter cake obtained, and drying to constant weight so as to obtain the chelate fiber ABTF. The chelate fiber ABTF obtained through the synthetic method has selective adsorption to lead ions, thereby overcoming the disadvantage that an original parent is poor in selective adsorption.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Biodegradable polylactic acid-PBS-wood fiber compound foam material and preparation method thereof

InactiveCN107057389AImprove bindingBio-packagingContainers to prevent mechanical damageFiberSodium bicarbonate

The invention discloses a biodegradable polylactic acid-PBS-wood fiber compound foam material and a preparation technology thereof. The preparation technology is characterized by taking polylactic acid, PBS, poplar wood powder, sodium bicarbonate, dicumyl peroxide, nanometer calcium carbonate, KH550, ammonium polyphosphate, melamine, expansible graphite, coating red phosphorus and a crylic acid solution as raw materials. The crylic acid solution and KH550 / ethanol solution are used for soaking the poplar wood powder, so that the modified wood fiber has excellent dispersibility in matrix and is high in compatibility and the binding property with the interface of the matrix is improved; the tensile strength, bending strength and impact toughness of the composite material are promoted; the mechanical properties and heat resistance of the composite material are promoted; after ammonium polyphosphate is activated and modified with melamine, the ammonium polyphosphate is mixed and milled with the expansible graphite and coating red phosphorus; the components have a synergistic effect; and the acquired composite flame retardant is used for promoting the flame retardant property of the composite material.

Owner:JMINDUSTRIES GRP +1

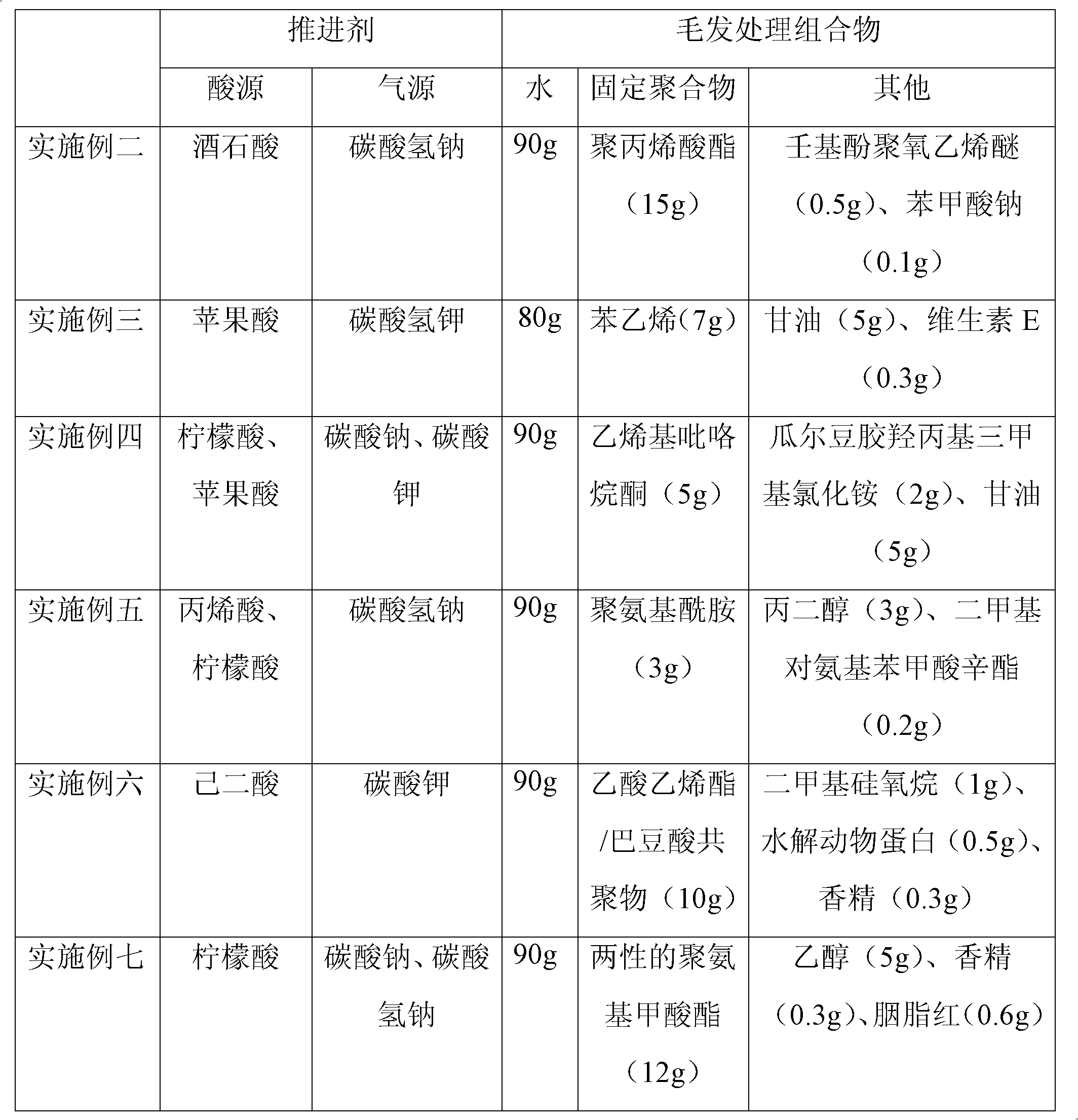

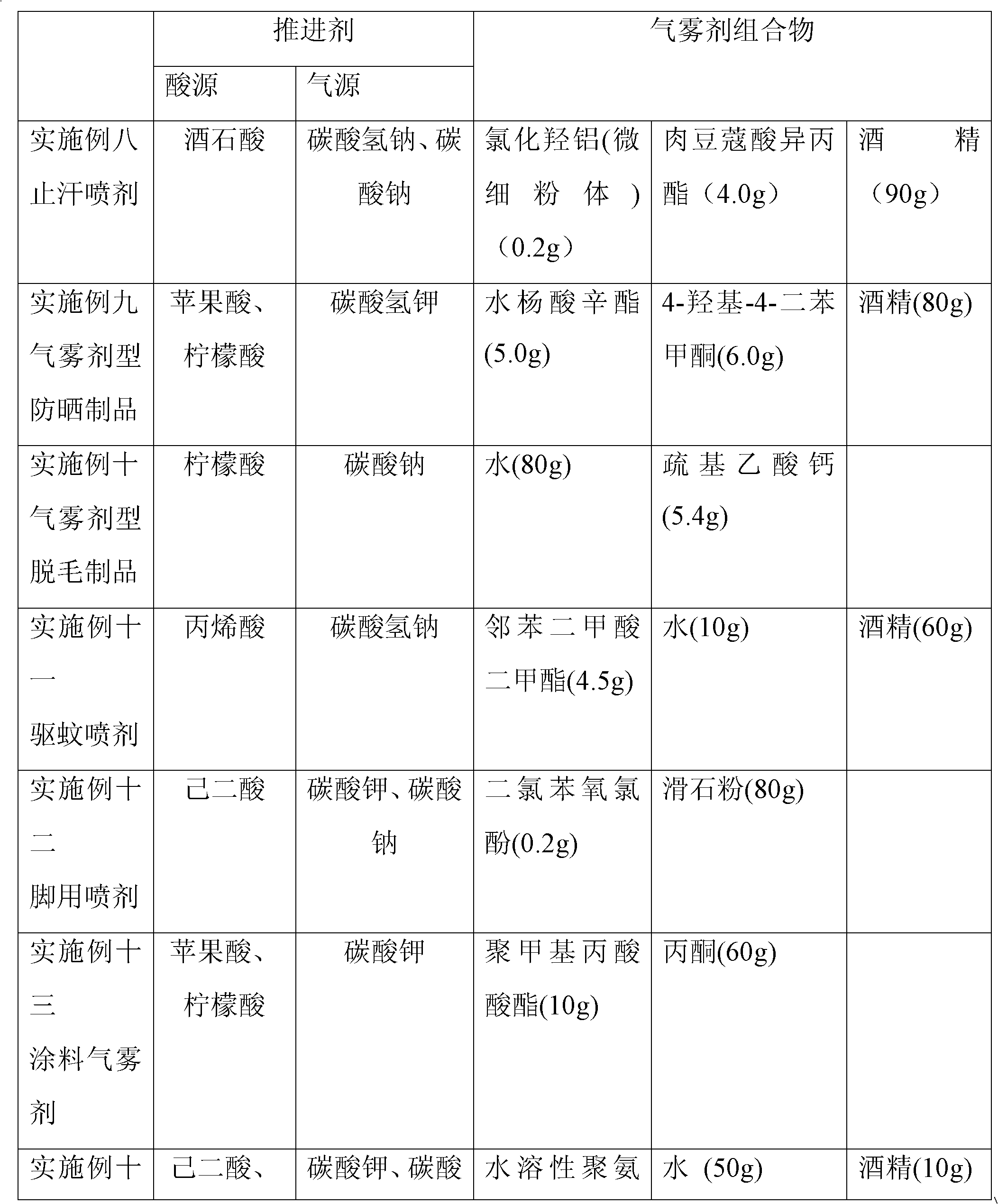

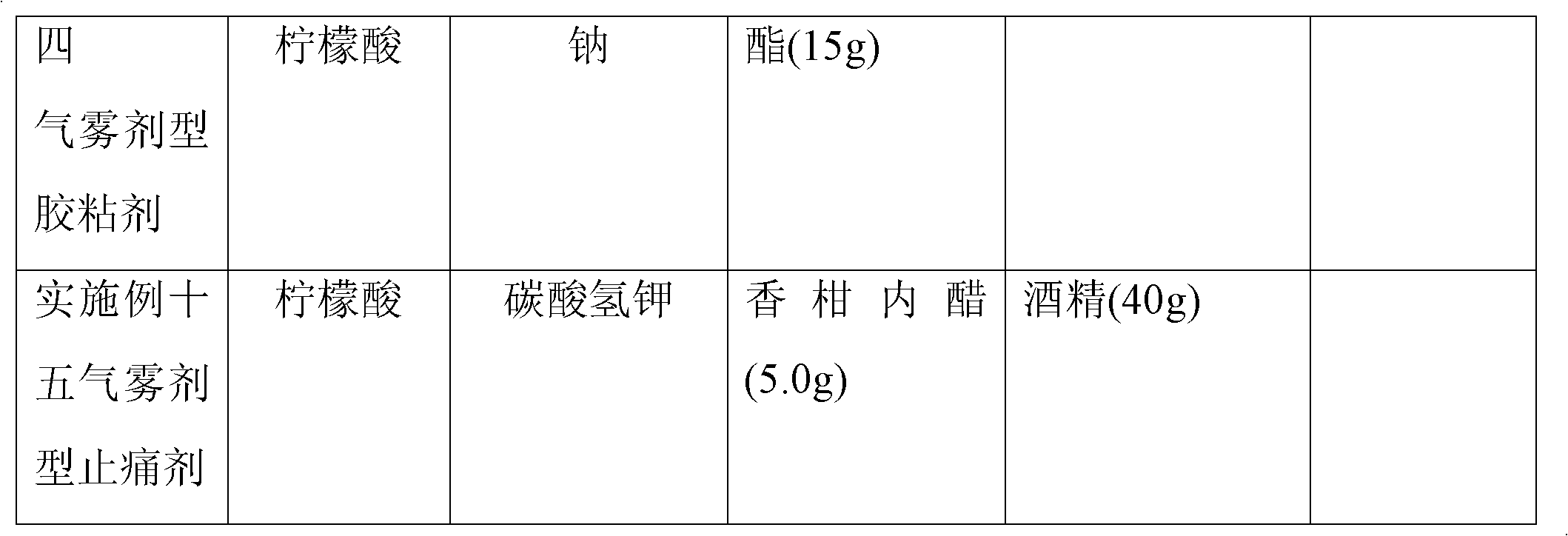

Low-pressure type propellant and application thereof

InactiveCN102058488AReduce energy consumptionReduce pollutionCosmetic preparationsHair removalSodium bicarbonateAdipic acid

The invention discloses a low-pressure type propellant which is formed by separated acid source and gas source, wherein the acid source is one or more of citric acid, crylic acid, tartaric acid, fumaric acid, adipic acid and malic acid, and the gas source is one or more of sodium carbonate, sodium bicarbonate, potassium bicarbonate and calcium carbonate. The application of the low-pressure type propellant can be used for daily chemicals comprising mousse, hair spray, unhairing articles, mosquitoes-dispelling articles, aerosol-type sunscreen articles, hidroschesis spray, aerosol-type shaving foam and foot spray. The invention also discloses a low-pressure mousse comprising a low-pressure type propellant and a hair processing composition. The invention broadens the service range and reduces the energy consumption of the aerosol-type product, reduces air pollution and improves the efficiency of the aerosol-type product.

Owner:广州好迪集团有限公司

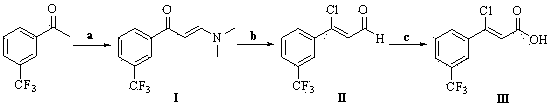

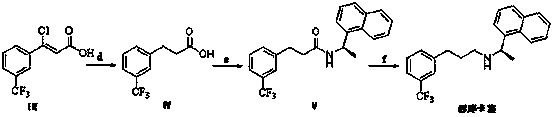

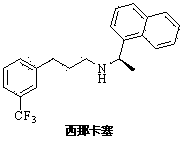

Preparation method of cinacalcet intermediate

ActiveCN103664577AHigh yieldEasy to purifyOrganic compound preparationPreparation from carboxylic acid esters/lactonesCombinatorial chemistryCinacalcet

The invention relates to a preparation method of a cinacalcet intermediate (Z)-3-chlorine-3-[3-(trifluoromethyl)phenyl]-2-crylic acid. The preparation method comprises the following steps: condensing 3-(trifluoromethyl) acetophenone used as a starting material; reducing and performing other reactions to obtain the intermediate. The invention also relates to two methods for preparing cinacalcet by utilizing intermediate.

Owner:BEIJING WINSUNNY PHARMA CO LTD

Tanshinon IIA crylic acid or sodium salt thereof, preparation method and application thereof

ActiveCN101974068AGood water solubilityImprove bioavailabilityOrganic active ingredientsSenses disorderSodium saltStereochemistry

The invention discloses a tanshinon IIA crylic acid or sodium salt thereof, a preparation method and application thereof. The tanshinon IIA crylic acid or sodium salt thereof has the following structure described in the specification. The tanshinon IIA crylic acid or sodium salt thereof provides a reliable path for the clinical application of the tanshinon IIA, and makes up the defects of hyperacidity and large stimulation of a sodium tanshinon II asilate injection as a clinical medicament.

Owner:JIANGSU CAREFREE PHARM CO LTD

Ultrathin nano radiating film material and preparation method thereof

ActiveCN105188322AEasy to useGreat cooling effectNon-macromolecular adhesive additivesFilm/foil adhesivesParticulatesColloid

The invention discloses a method for preparing an ultrathin nano radiating film material. The ultrathin nano radiating film material includes a nano coating, a matrix layer and a colloid layer, the nano coating comprises 80 to 90wt% of solvent type resin ink and 10 to 20 wt% of nanoscale inorganic particulate auxiliaries, the colloid layer comprises 30 to 90wt% of crylic acid glue and 10 to 70wt% of nanoscale inorganic particulate auxiliaries, and under certain temperature the nano coating and the colloid layer are coated on an electrolytic surface or smooth surface of the matrix layer for full solidification, thereby obtaining the ultrathin nano radiating film material. The ultrathin nano radiating film material obtained by the method has an excellent radiating effect, is safe and reliable, is easy to assemble and attach, is convenient to use, and can be widely applied to parts that need heat radiation of a mobile phone, a smartphone, a computer, communication equipment and other electronic products.

Owner:昆山秉德电子科技有限公司

Conductive gel tablet for defibrillator

InactiveCN104667425AEffective infiltrationImprove conductivityHeart defibrillatorsExternal electrodesNetwork structureAqueous solution

The invention provides a conductive gel tablet for a defibrillator. Conductive particles are dispersed in aqueous solution of crylic acid according to a scale for preparing the water-absorbing conductive gel tablet, and the conductive gel tablet used for the defibrillator is prepared after aggregating polyaniline. An interactive network structure is formed due to interconnection between the conductive particle in a PAA network and a polyaniline chain, so that a conductive channel is formed, and the conductivity of the prepared conductive gel tablet is 9.3*10<-3>S.cm<-1>.

Owner:QIANFOSHAN HOSPITAL OF SHANDONG

Preparation method and application of anti-blocking agent

InactiveCN102659554ANot easy to agglomerateImprove playbackCarboxylic compound separation/purificationPolythylene glycolSODIUM NAPHTHALENESULFONATE

The invention discloses an anti-blocking agent, which comprises, by mass ratio, 3 parts to 25 parts of polyethylene glycol (400), 5 parts to 30 parts of dodecanol polyoxyethylene (3) phosphomonoester, 5 parts to 55 parts of crylic acid- malefic anhydride with solid content of 30% to 100%, and 1 part to 35 parts of disodium methylene dinaphthalenesulfonate. The anti-blocking agent is good in performance and little in dosage. Under the normal condition, the anti-blocking agent is added to potassium formate, the potassium formate can keep loose for 3 to 6 months, and The anti-blocking agent can not cause negtive effects on the quality and usage of the potassium formate after addition.The invention also discloses a preparation method and a usage method of the anti-blocking agent.

Owner:四川鸿康科技股份有限公司

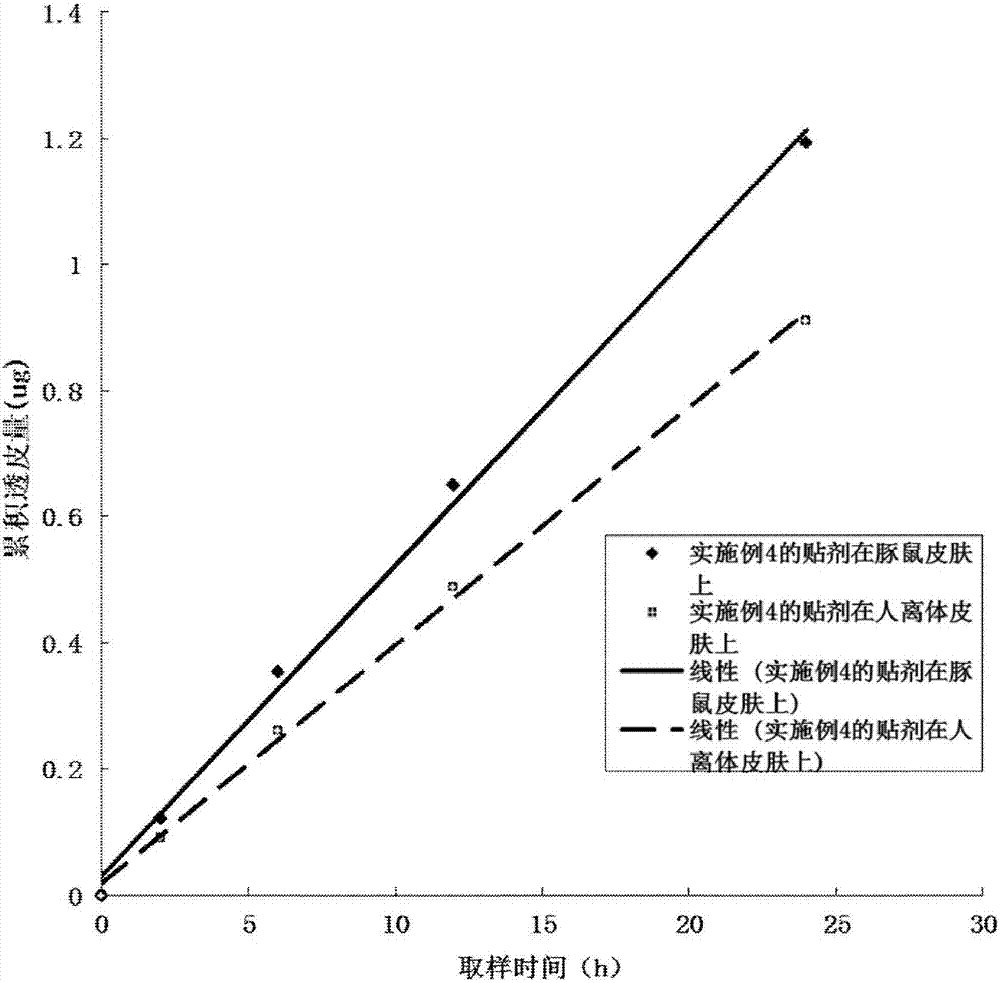

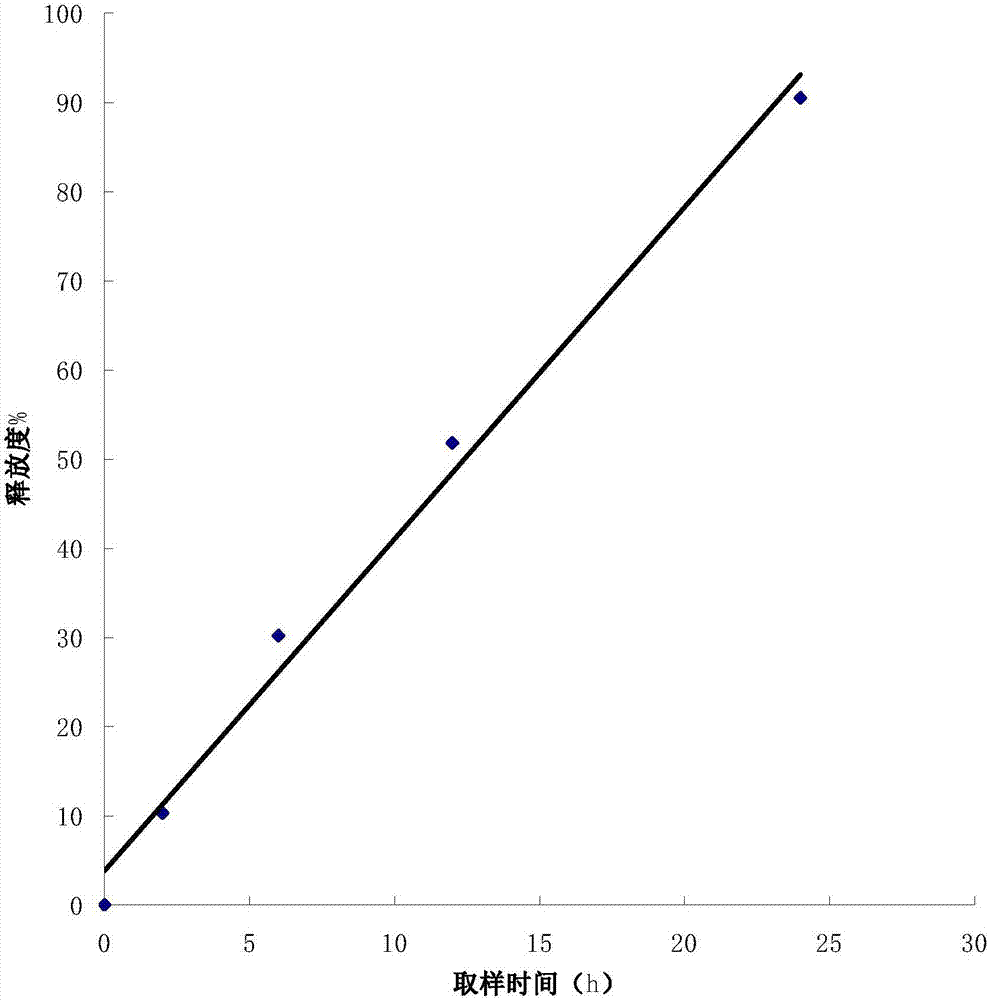

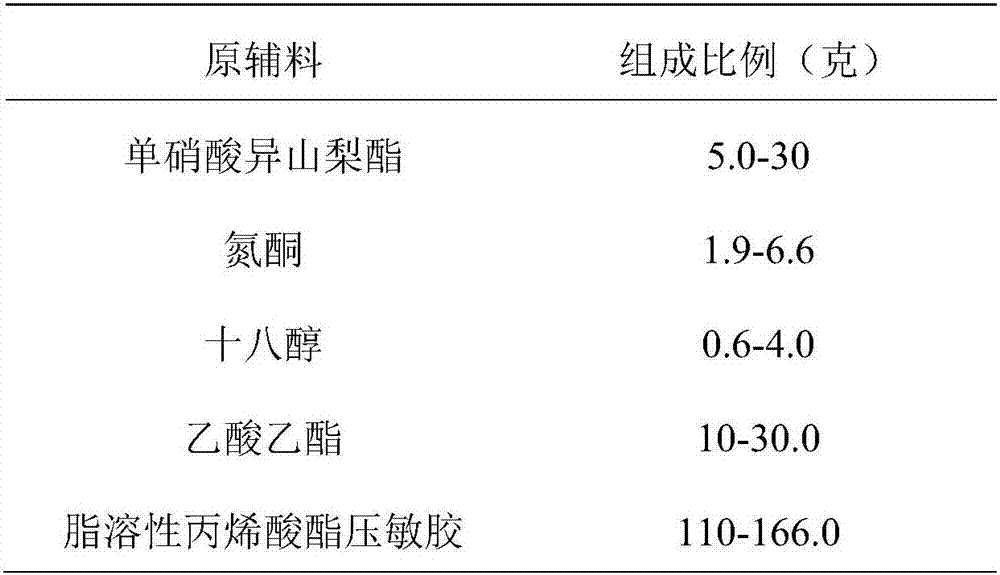

Slow-release transdermal patch containing isosorbide mononitrate and application thereof

InactiveCN107320463AGuaranteed stabilitySmall toxicityPharmaceutical non-active ingredientsSheet deliveryTransdermal patchOleic Acid Triglyceride

The invention relates to a slow-release transdermal patch containing isosorbide mononitrate and an application thereof. The slow-release transdermal patch is composed of a backing layer, a drug-containing storage layer and an anti-sticking protecting layer; the drug-containing storage layer is prepared according to a preparation method which comprises the following steps: uniformly mixing isosorbide mononitrate with macromolecule adhesive material or pressure-sensitive adhesive, coating on the backing layer, heating and drying, thereby acquiring the drug-containing storage layer; the macromolecule adhesive material or pressure-sensitive adhesive is selected from water-soluble crylic acid pressure-sensitive adhesive, fat-soluble crylic acid pressure-sensitive adhesive, organosilicone pressure-sensitive adhesive and polyisobutene pressure-sensitive adhesive; the drug-containing storage layer contains a transdermal accelerant and is selected from azone, oleic acid, glyceryl triacetate and isopropyl myristate; the drug-containing storage layer contains crystallization inhibitor octadecanol.

Owner:徐静

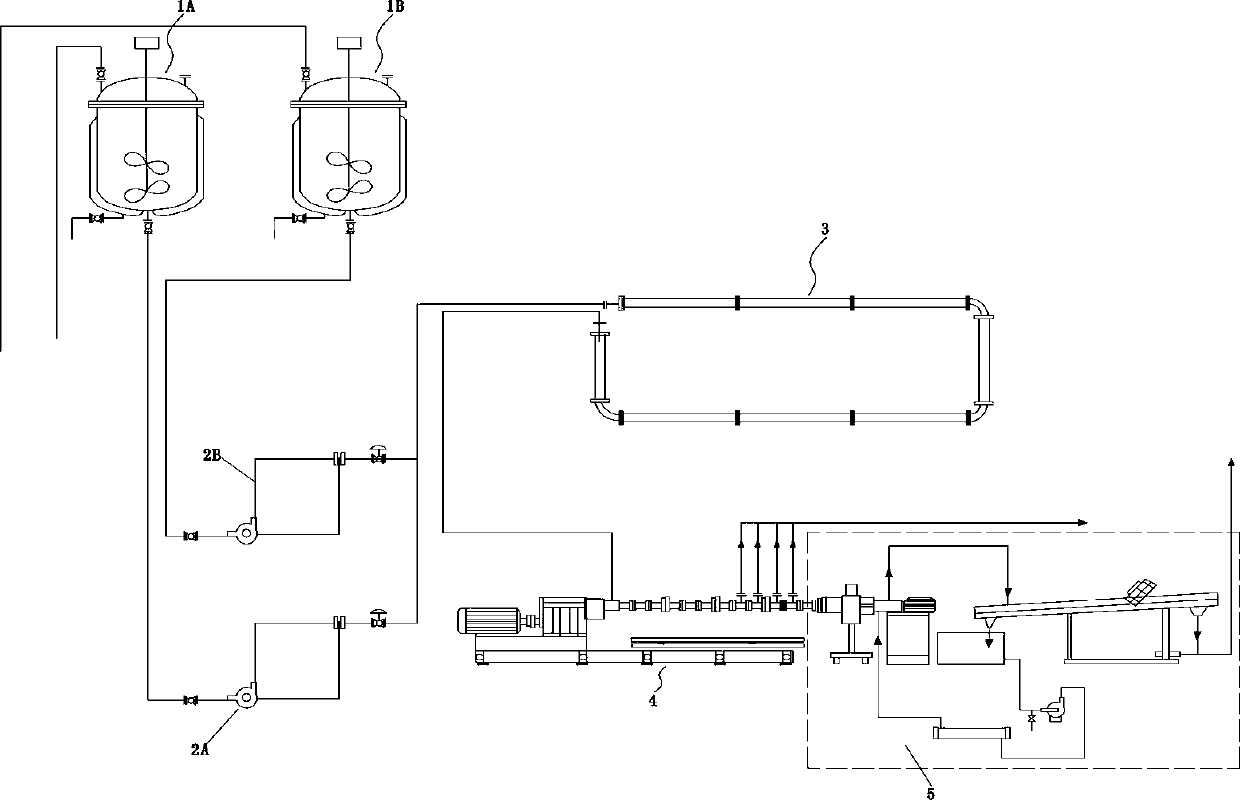

Method for preparing water-based crylic acid resin by continuous extruding process and production equipment for realizing method

The invention provides a method for preparing water-based crylic acid resin by a continuous extruding process and production equipment for realizing the method. The method is characterized in that anannular pipe type reactor and a twin-screw extrusion reactor are connected in series to be used as a continuous reactor; firstly, monomers, initiating agents and optional molecular weight modifiers are sucked into a mixed raw material preparation tank from each raw material barrel under the negative pressure; then, the materials in the preparation tank are conveyed to the annular pipe type reactorwith the temperature being 120 DEG C by a material conveying pump at the speed of 50 to 150kg / h; the detention time of the materials in the annular pipe type reactor is 15 minutes; after the materials enter the twin-screw extrusion reactor, the screw rotating speed is controlled to be 20 to 50 turns / min; a devolatilization section valve is opened so that the materials are subjected to vacuum devolatilization at the third stage; the product after devolatilization is subjected to underwater pelleting and drying at the temperature being 30 DEG C or below, and then passes through a cyclone separator; next, packaging is performed. The crylic acid resin prepared by the method has the characteristics that the quality stability is good; the molecular weight is great; the distribution is narrow. The invention also provides the production equipment for realizing the method.

Owner:广东龙湖科技股份有限公司

Water treatment ternary copolymerization bactericide and preparation method thereof

InactiveCN104396956AImprove the bactericidal effectThe synthesis method is simpleBiocideFungicidesBiotechnologySodium phosphates

The invention discloses a water treatment ternary copolymerization bactericide and a preparation method thereof. The preparation method comprises the following steps: weighing glutaraldehyde, AMPS, crylic acid, isopropanol, water, sodium hydroxide, a polymerization inhibitor, sodium hypophosphite, maleic anhydride, ammonium persulfate, a dispersing agent, phosphorus trichloride, N,N-dimethylformamide, L-aspartic acid and glutamic acid according to parts by weight, and uniformly mixing the materials to prepare the bactericide. The scale inhibiting ratio of the bactericide is 85.5-98.5%; the density is 1.15-1.35 g / cm<2>; after the bactericide is stored at 50-60 DEG C for one month, the bactericidal rate is 98.5-99.5%; after the bactericide is stored at 40-50 DEG C for half a year, the bactericidal rate is 97-99%; after the bactericide is stored at the room temperature for 1-2 years, the bactericidal rate is 96-98%; when the bactericide is applied to escherichia coli, staphylococcus aureus, streptococcus albus, gonococcus, penicillium, aspergillus, saprophytic bacteria and salmonella, the bactericidal rate is 98.8-99.8%.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Piezoelectric material and manufacturing method thereof

InactiveCN103700763AExcellent piezoelectric propertiesSimple preparation stepsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionEthylene oxidePhysical chemistry

The invention provides a piezoelectric material, which comprises 20 to 25g of copper powder, 10 to 13g of resin, 0.2 to 0.6g of ethylene oxide, 8 to 19g of crylic acid, 2 to 6g of lead powder, 8 to 12g of silver nitrate, 5 to 9.55g of liquid crystal materials, 12 to 19g of ultraviolet coating, 9 to 12g of titanium dioxide and 0.2 to 0.6g of lead cerium. A manufacturing method of the piezoelectric material comprises the following steps that 20 to 25g of copper powder, 10 to 13g of resin, 0.2 to 0.6g of ethylene oxide, 8 to 19g of crylic acid, 2 to 6g of lead powder, 8 to 12g of silver nitrate, 5 to 9.55g of liquid crystal materials, 12 to 19g of ultraviolet coating, 9 to 12g of titanium dioxide and 0.2 to 0.6g of lead cerium are uniformly mixed, the reaction lasts 20 to 30 hours at the temperature being 100 to 200 DEG C, the cooling is carried out, and the material is obtained. The method provided by the invention has the advantages that the manufacturing steps are simple, the piezoelectric effect of the obtained material is good, and in addition, the material and the method are suitable for mass production.

Owner:苑振贵

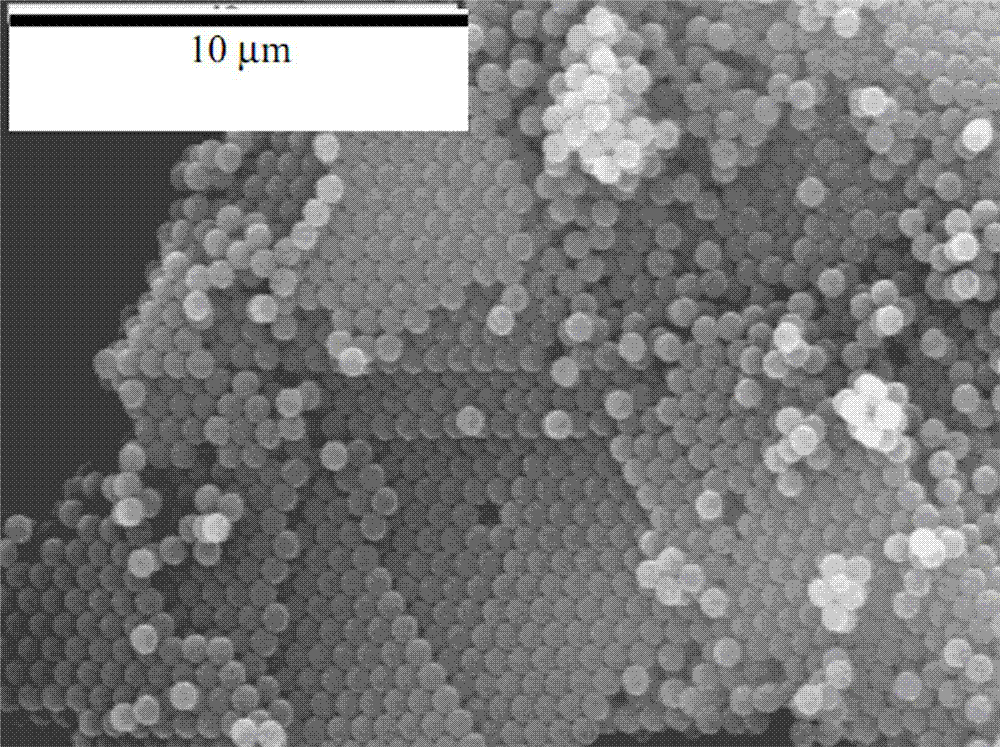

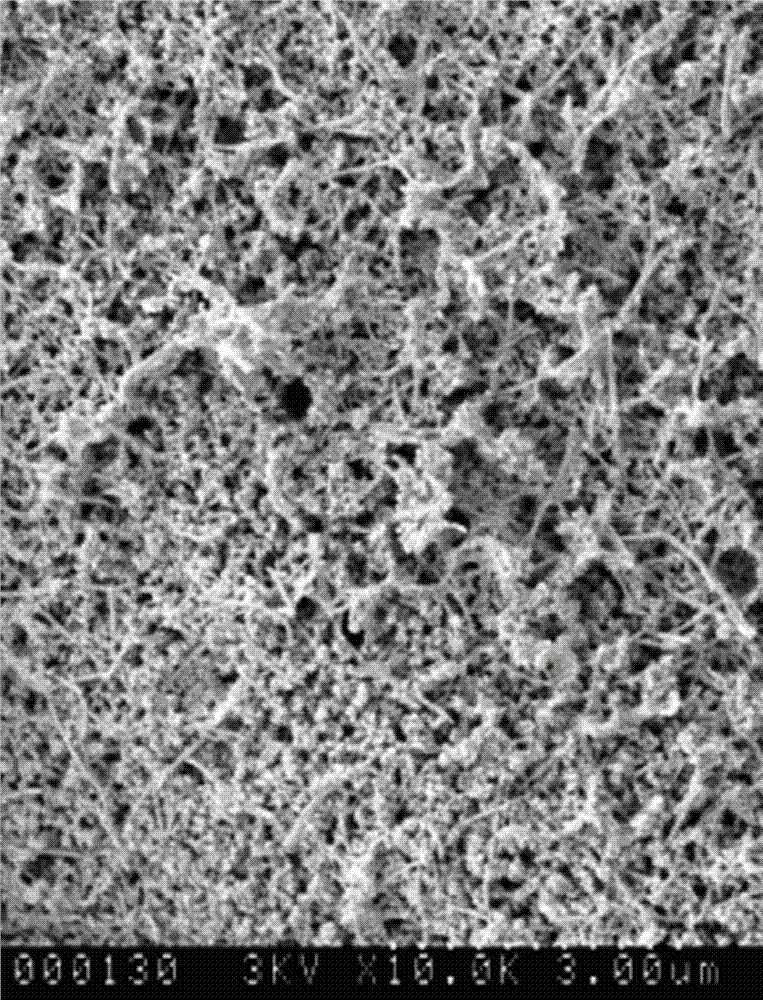

Catalyst for preparing crylic acid from propane through selective oxidation and preparation method thereof

ActiveCN102179261BImprove controllabilityHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationPtru catalystPropane

The invention relates to a compound metal oxide type catalyst for preparing crylic acid from propane through selective oxidation and a preparation method thereof. The general formula of the catalyst is MoVTeNbO, wherein Mo, V, Te and Nb are active ingredients, and an atomic molar ratio of the four metal elements and oxygen thereof is 1:(0.1-1.0):(0.2-1.0):(0.2-0.9):(20-60). When the catalyst is adopted for preparing the crylic acid, the conversion rate of the propane and the once through yield of the crylic acid are high, and a template synthesis method for preparing the compound metal oxide type catalyst with a periodically arranged ordered structure from the propane through selective oxidation is provided; and the catalyst prepared by the method has good controllability, the size, appearance, structure, arrangement and the like of the compound catalyst material can be controlled by the space limiting effect of the catalyst and the debugging effect of a template agent, and the catalyst has small particles and high catalytic activity.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Special polycarboxylic water reducer for high mud content system super-long slump loss resistant concrete

The invention discloses a special polycarboxylic water reducer for a high mud content system super-long slump loss resistant concrete. The special polycarboxylic water reducer comprises the followingraw materials by weight: 15-20 parts of itaconic acid, 20-35 parts of crylic acid, 15-25 parts of maleic anhydride, 5-12 parts of ammonium persulfate, 4-9 parts of sodium sulfite, 4-11 parts of retarder, 8-12 parts of TPEG, 2-5 parts of initiator, 3-6 parts of chain transfer agent, and 1-3 parts of corrosion remover. The design principle of the molecular structure is used, itaconic acid, maleic anhydride and crylic acid are taken as polymerization monomers to react with the retarder, the TPEG, the ammonium persulfate and the sodium sulfite under the action of the initiator and the chain transfer agent, the free radical is polymerized, the polycarboxylic water reducer is obtained, the cost of the water reducer is low, the slump loss resistant performance is excellent, the slump loss of theconcrete is basically not changed for 1 hour, the water reducer is green and environmentally friendly and is excellently adaptive to the cement, the performance is obviously better than that of the like product, and the water reducer is worthy of extensive promotion.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Modified multi-amino macroporous resin, preparation method and crylic acid production waste gas treatment method

ActiveCN109134733AHigh affinityImprove adsorption capacityGas treatmentDispersed particle separationEconomic benefitsAcrolein

The invention discloses modified multi-amino macroporous resin, a preparation method and a crylic acid production waste gas treatment method. The modified resin is the amino modified macroporous resin, and compared with common macroporous resin, the modified multi-amino macroporous resin has the better adsorbing effect on acrolein due to the special acting force between amino molecules and carbonyl hydrogen molecules and is easy to desorb and regenerate and stable in performance under the alkaline condition. Recovery of methylbenzene in crylic acid waste gas can be achieved by adopting the resin, the methylbenzene is reused in a crylic acid refining process to serve as an entrainer for cyclic use, and resourceful waste gas utilization is achieved. In addition, the waste gas obtained afteradsorption treatment meets the requirement of the national discharge index, waste gas incineration disposal is decreased, the energy consumption is further reduced, and great environmental protectionand obvious economic benefit are produced.

Owner:WANHUA CHEM GRP CO LTD

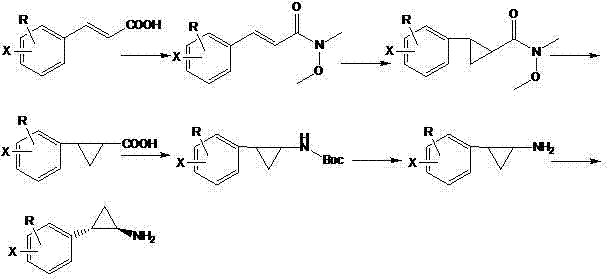

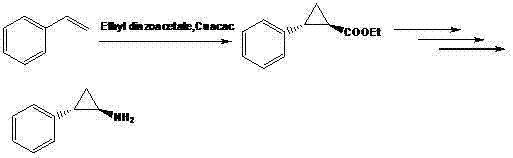

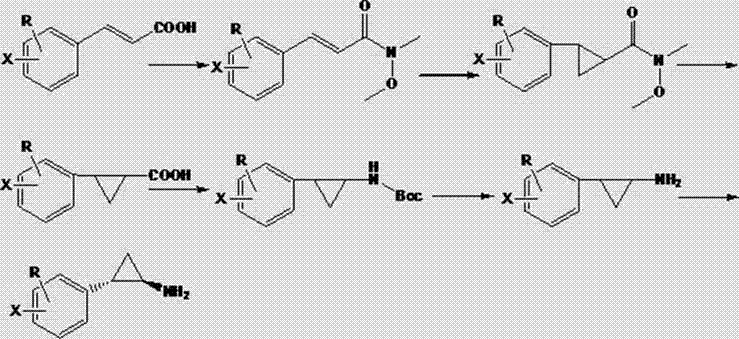

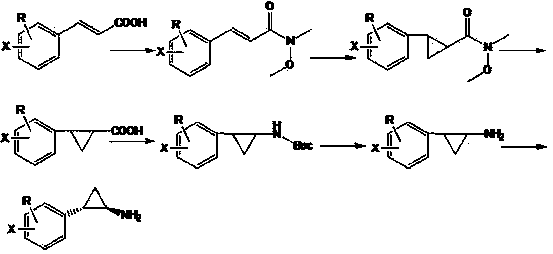

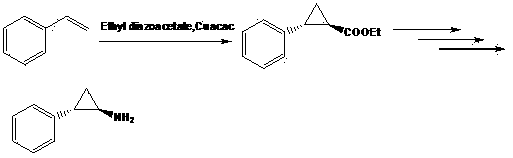

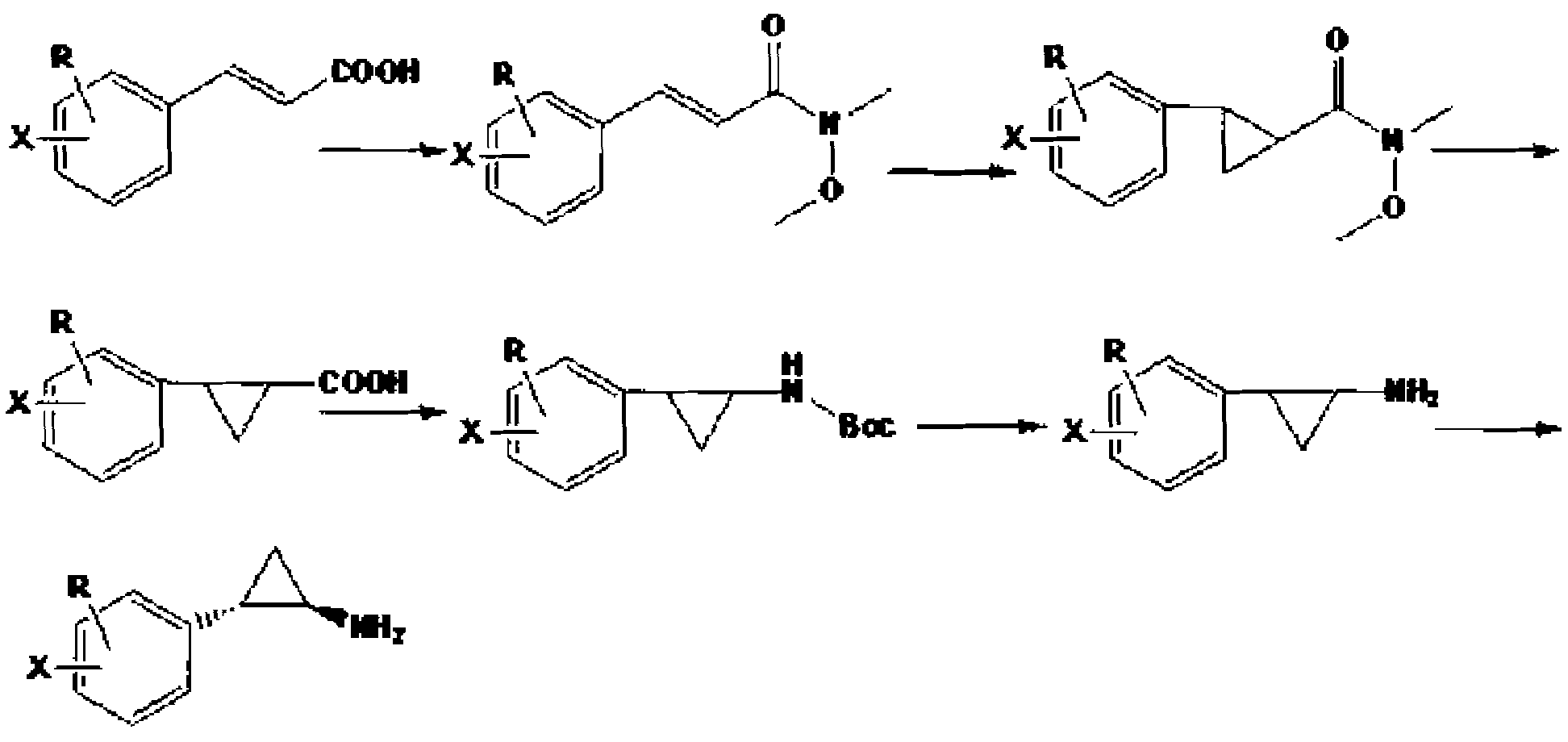

Chemical synthesis method of (1R, 2S)-2-aryl cyclopropylamine derivative

InactiveCN102863341AImprove e.e. valueAvoid the risk of racemization inAmino compound purification/separationOrganic compound preparationChemical synthesisHydroxylamine

The invention relates to a chemical synthesis method of a (1R, 2S)-2-aryl cyclopropylamine derivative. 3-aryl crylic acid serves as a raw material, the raw material and N,O-dimethyl hydroxy amine hydrochloride are subjected reaction to prepare a corresponding amide intermediate, cyclization reaction is conducted, 2- aryl cyclopropylamine is obtained; and finally D-mandelic acid serves as a resolving agent to obtain the (1R, 2S)-2-aryl cyclopropylamine derivative. The method has the advantages of being high in yield and high in e.e. value.

Owner:NANTONG UNIVERSITY

Sound absorbing paint for lowering noise of electrical equipment

InactiveCN105238193AImprove sound absorption and noise reduction effectCoatingsTransformerElectric power equipment

The invention discloses sound absorbing paint for lowering noise of electrical equipment. The sound absorbing paint is prepared through the following steps that 1, by weight, clay powder, sepiolite, methyl sulfonic acid ester and crylic acid are added into a mixing and stirring machine for being evenly stirred and mixed, and a mixed material is obtained; 2, the mixed material is added to a reaction kettle, azo dimethyl valeronitrile and glass fibers are added and heated to 60 DEG C, stirring is conducted for 15 minutes, then the temperature is raised to 75 DEG C under the protection of nitrogen gas, stirring is continued for 18 minutes, the mixture is lowered to the room temperature, and a first intermedium is obtained; 3, the first intermedium is heated to 50 DEG C at normal pressure and stirred for 25 minutes, and a second intermedium is obtained; 4, ethyl acetate and barium stearate are added to the second intermedium for being evenly mixed, and the sound absorbing paint is obtained. The sound absorbing paint is sprayed on a firewall of a converter transformer, the sound absorption and noise reduction effects are greatly improved, and it is proved by tests that the noise reduction rate of a noise reduction device sprayed with the sound absorbing paint reaches over 90%.

Owner:孟红琳

Chemical synthesis method of (1R, 2S)-2-aryl cyclopropylamine derivative

InactiveCN102863341BImprove e.e. valueAvoid the risk of racemization inAmino compound purification/separationOrganic compound preparationChemical synthesisHydroxylamine

The invention relates to a chemical synthesis method of a (1R, 2S)-2-aryl cyclopropylamine derivative. 3-aryl crylic acid serves as a raw material, the raw material and N,O-dimethyl hydroxy amine hydrochloride are subjected reaction to prepare a corresponding amide intermediate, cyclization reaction is conducted, 2- aryl cyclopropylamine is obtained; and finally D-mandelic acid serves as a resolving agent to obtain the (1R, 2S)-2-aryl cyclopropylamine derivative. The method has the advantages of being high in yield and high in e.e. value.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com