Chemical synthesis method of (1R, 2S)-2-aryl cyclopropylamine derivative

An arylcyclopropylamine, a technology for chemical synthesis, applied in chemical instruments and methods, purification/separation of amino compounds, organic chemistry, etc., and can solve problems such as low stereoselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

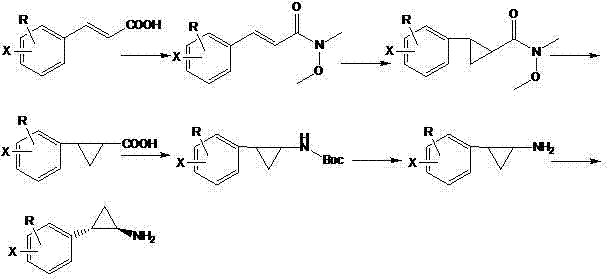

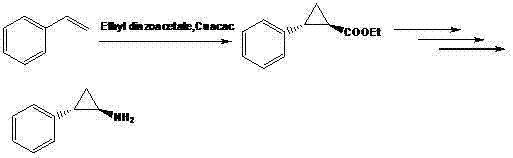

Method used

Image

Examples

Embodiment 1

[0019] Synthesis of 2-phenyl-cyclopropylcarboxylic acid: Add 10.0 g NaH and 250 ml dimethyl sulfoxide into a three-necked flask under nitrogen protection, and add N-methoxy-N methyl-3-phenylpropene in batches amide 27.4 g, stirred and dissolved for 30 min, then added dropwise 42.0 g trimethylsulfoxide iodide, and reacted at room temperature. After adding water to quench and extract with methyl tert-butyl ether, the organic phase was washed with water three times, dried and concentrated to obtain 25.0 g of light yellow liquid with a yield of 85.0%. Transfer the yellow product to a single-necked bottle, add 200 ml of methanol and 100 ml of water, stir to dissolve, then add 10.0 g of sodium hydroxide, and stir to react overnight. After the reaction was completed, water was added to adjust the pH to 3-4, extracted with dichloromethane, and concentrated to obtain 17.8 g of white 2-phenyl-cyclopropyl formic acid solid with a yield of 90.1%.

[0020] Synthesis of N-Boc-2-phenylcyclo...

Embodiment 2

[0024] Synthesis of 2-(4'-methoxyphenyl)-cyclopropanecarboxylic acid: Add 10.0 g NaH and 300 ml dimethyl sulfoxide into a three-necked flask under nitrogen protection, and add N-methoxy-N 31.7 g of methyl-3-(4'-methoxyphenyl)acrylamide was stirred and dissolved for 30 min, then 42.0 g of trimethylsulfoxide iodide was added dropwise, and reacted at room temperature. It was quenched by adding water, extracted with methyl tert-butyl ether, washed with water three times, dried and concentrated to obtain 30.0 g of yellow liquid with a yield of 89.0%. Transfer the yellow product to a single-necked bottle, add 250 ml of methanol and 125 ml of water, stir to dissolve, then add 10.0 g of sodium hydroxide, and stir to react overnight. After the reaction was completed, water was added to adjust the pH to 3-4, extracted with dichloromethane, and concentrated to obtain 22.3 g of light yellow 2-(4'-methoxyphenyl)cyclopropanecarboxylic acid solid, with a yield of 91.0%.

[0025] Synthesis o...

Embodiment 3

[0029]Synthesis of 2-(4'-bromophenyl)-cyclopropanecarboxylic acid: Add 10.0 g NaH and 350 ml dimethyl sulfoxide into a three-necked flask under nitrogen protection, and add N-methoxy-N methyl - 38.7 g of 3-(4'-bromophenyl) acrylamide, stirred and dissolved for 30 min, then added dropwise 42.0 g of trimethylsulfoxide iodide, and reacted at room temperature. It was quenched by adding water, extracted with methyl tert-butyl ether, washed three times with water, dried and concentrated to obtain 32.3 g of yellow liquid with a yield of 79.3%. Transfer the yellow product to a single-necked bottle, add 300 ml of methanol and 150 ml of water, stir to dissolve, then add 10.0 g of sodium hydroxide, and stir to react overnight. After the reaction was completed, adjust the pH to 3-4, extract with dichloromethane, and concentrate to obtain 24.3 g of light yellow 2-(4'-bromophenyl)cyclopropyl formic acid solid, with a yield of 88.6%.

[0030] Synthesis of N-Boc-2-(4'-bromophenyl)cyclopropyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com