A method for enzymatic asymmetric reduction of citral to improve the optical purity of (r)-citronellal

A technology of optical purity and citral, applied in fermentation and other fields, can solve the problems of expensive catalyst and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

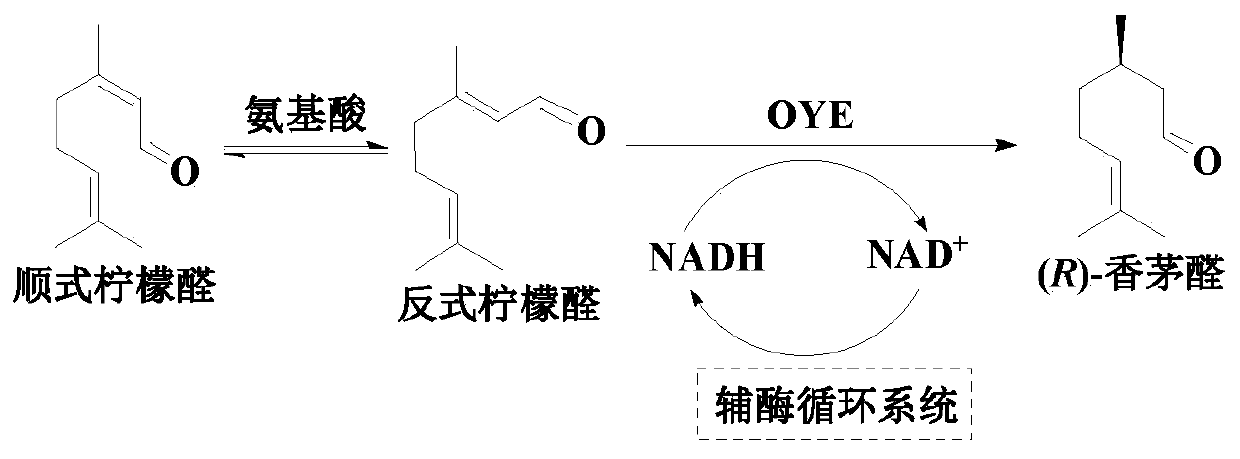

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

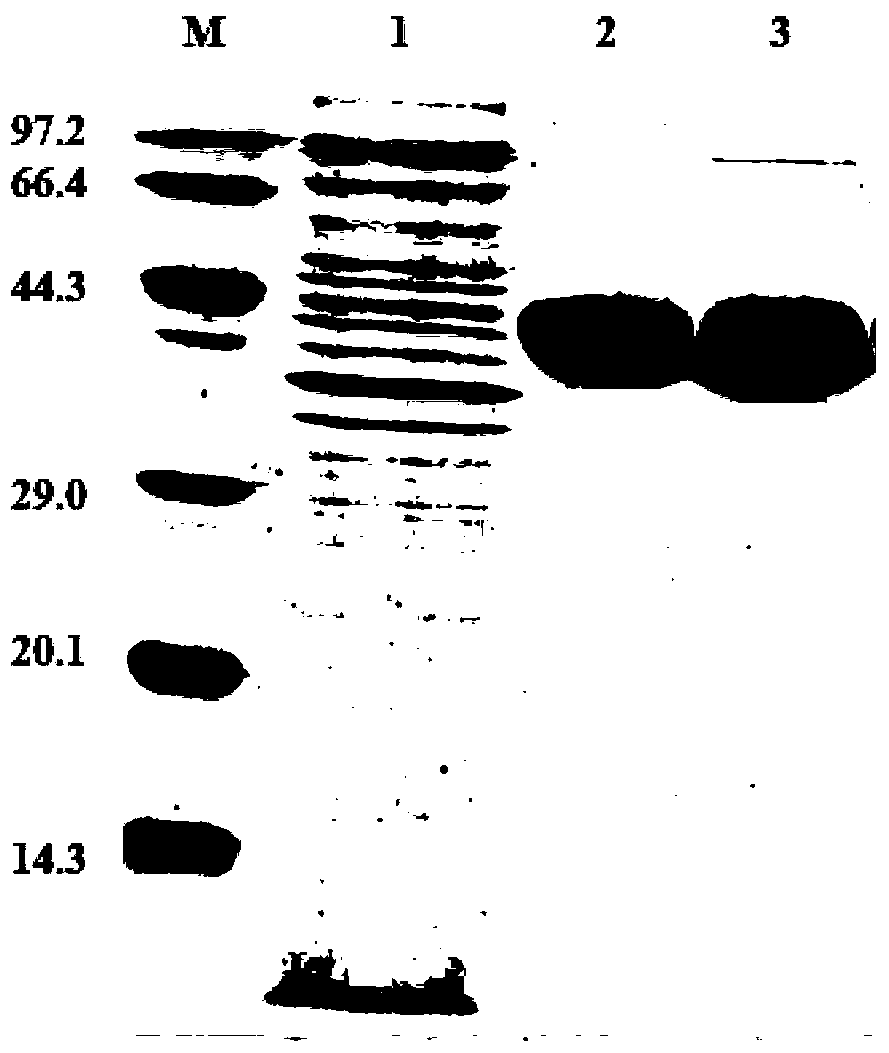

[0033] Example 1: Expression and purification of Saccharomyces cerevisiae enol reductase OYE1 and formate dehydrogenase FDHCB from Candida boidinii

[0034] (1) Construction and induced expression of Saccharomyces cerevisiae enol reductase OYE1 Escherichia coli genetically engineered bacteria

[0035] Saccharomyces cerevisiae enol reductase OYE1 gene oye1 was amplified by PCR with the designed primers F1 and R1 using Saccharomyces cerevisiae CICC 1002 genomic DNA purchased from China Industrial Microorganism Culture Collection Management Center. Table 1 shows.

[0036] Table 1 PCR amplification reaction system

[0037]

[0038] The primers are as follows: F1, 5'-ATGCCATTTGTTAAGGACTTTA-3'; R1, 5'-TTAATTTTTGTCCCAACCGA-3'. The PCR reaction process is as follows: pre-denaturation at 94°C for 5 minutes; then, a cycle of denaturation at 94°C for 30 s, renaturation at 57°C for 30 s, and holding at 72°C for 1 min, repeating this cycle 35 times; finally, holding at 72°C for 10 min...

Embodiment 2

[0045] Embodiment 2: the enzyme activity assay of Saccharomyces cerevisiae enol reductase OYE1

[0046] The standard enzyme activity assay system (2mL) contains 0.4mM NADH, 100μg / mL Saccharomyces cerevisiae enol reductase OYE1, 20mM citral (citral is added in the form of a 1M substrate solution prepared with octanol, and the amount of substrate solution added Based on the amount of citral, the final concentration in the reaction system is 20 mM), and 50 mM PIPES buffer (pH 7.0) is used as the reaction medium; the concentrations all refer to the final concentration in the assay system. The reaction was carried out at 30°C, and NADH was added last, and the enzyme activity was determined by detecting the change of the absorbance value of the reaction system at 340 nm per minute (the molar coefficient of NADH ε 340 =6.3mM -1 cm -1 ). Activity unit (U) was defined as the amount of enzyme required to consume 1 μmol NADH per minute.

Embodiment 3

[0047] Example 3: Characterization of catalytic properties of Saccharomyces cerevisiae enol reductase OYE1

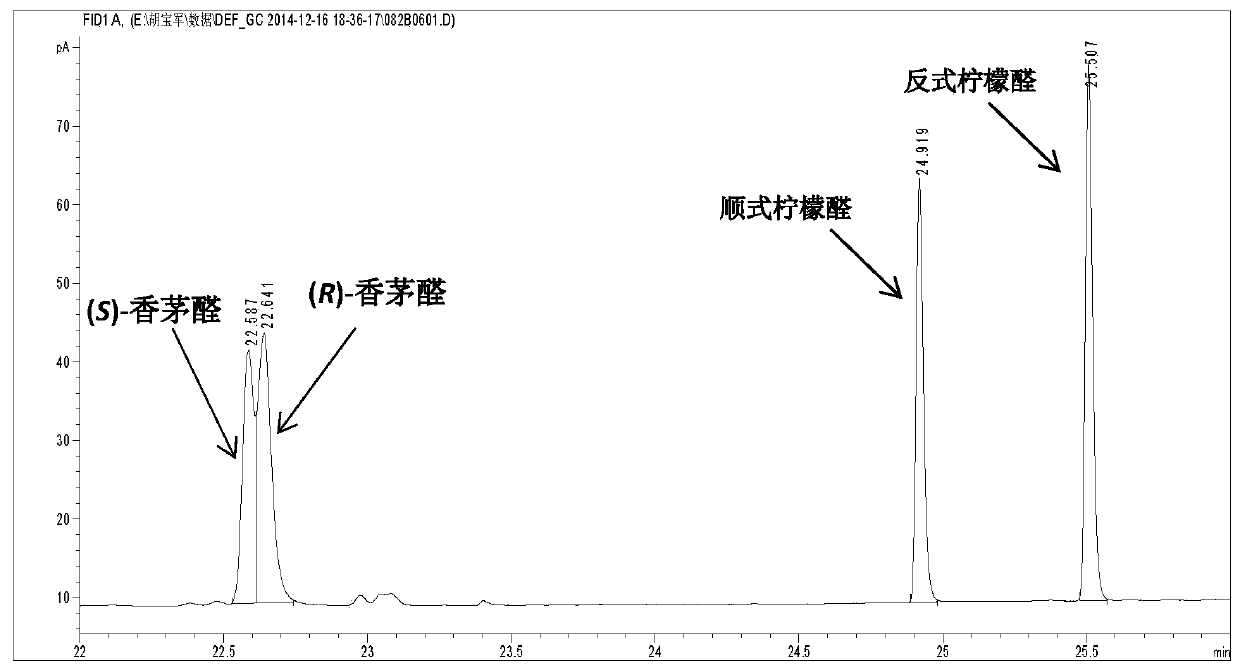

[0048] The total volume of the standard catalytic system is 10mL, including 20mM citral respectively (citral is added in the form of a 1M substrate solution prepared with octanol, the amount of substrate solution added is based on the amount of citral, and the final concentration in the reaction system is 20mM) , 0.25mM NAD+ , 100mM sodium formate, 0.3U / mL OYE1, 0.5U / mL FDHCB, with 50mM PIPES buffer (pH 7.0) as the reaction medium. The condition optimization of the asymmetric reduction reaction was carried out on a water-bath shaker with a rotation speed of 200rpm. The reaction solution was extracted with ethyl acetate, and the obtained organic phase was dried over anhydrous sodium sulfate, and the substrate citral and the product (R)-citronellal were quantitatively determined by gas chromatography.

[0049] The gas chromatography (Agilent 6890N) detection conditions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com