High-purity lactide and preparation method thereof

A lactide, high-purity technology, applied in the direction of organic chemistry, can solve the problems of low optical purity of L-lactide, harsh preparation conditions, high production cost, etc., achieve wide practical application value, simple preparation method, no The effect of three waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

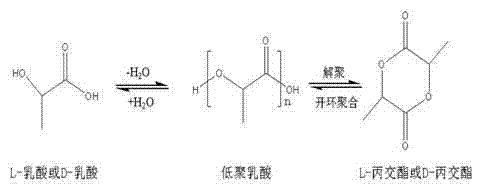

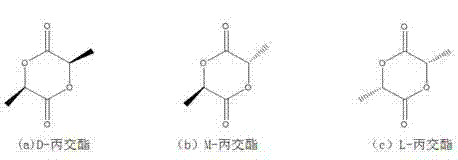

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of high-purity L-lactide, comprising the following steps:

[0032] a. Add raw materials

[0033] Add 0.5g of zinc oxide and 0.5g of stannous oxide to 50g of 92% L-lactic acid, and add it to a 250mL round bottom flask;

[0034] b. In addition to free water

[0035] At a temperature of 80°C and a vacuum of -0.08MPa, remove free water for 2 hours;

[0036] c. Polycondensation

[0037] Raise the temperature to 140°C, carry out polycondensation under the condition of stirring at a vacuum degree of -0.095MPa, decondense the water for 3.5 hours, and generate oligomeric lactic acid;

[0038] d. Depolymerization

[0039] Then rapidly raise the temperature to 220°C, carry out depolymerization under the condition of vacuum degree -0.098MPa and stirring until no L-lactide is evaporated, and crude L-lactide is obtained;

[0040] e. Distillation

[0041] The crude L-lactide is transferred to the rectification device, and the bottom temperature is 180°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com