Patents

Literature

530results about How to "High chemical purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

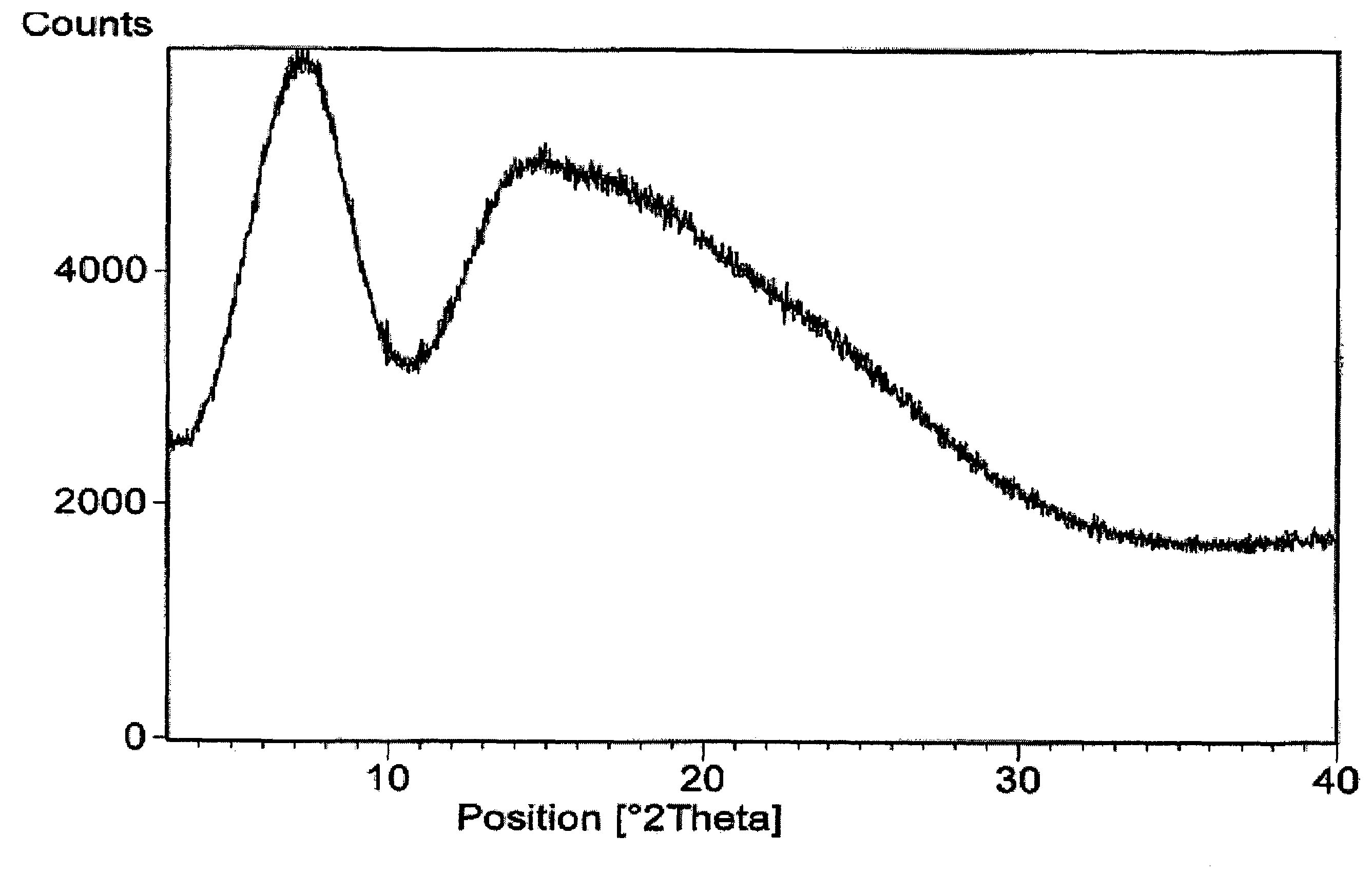

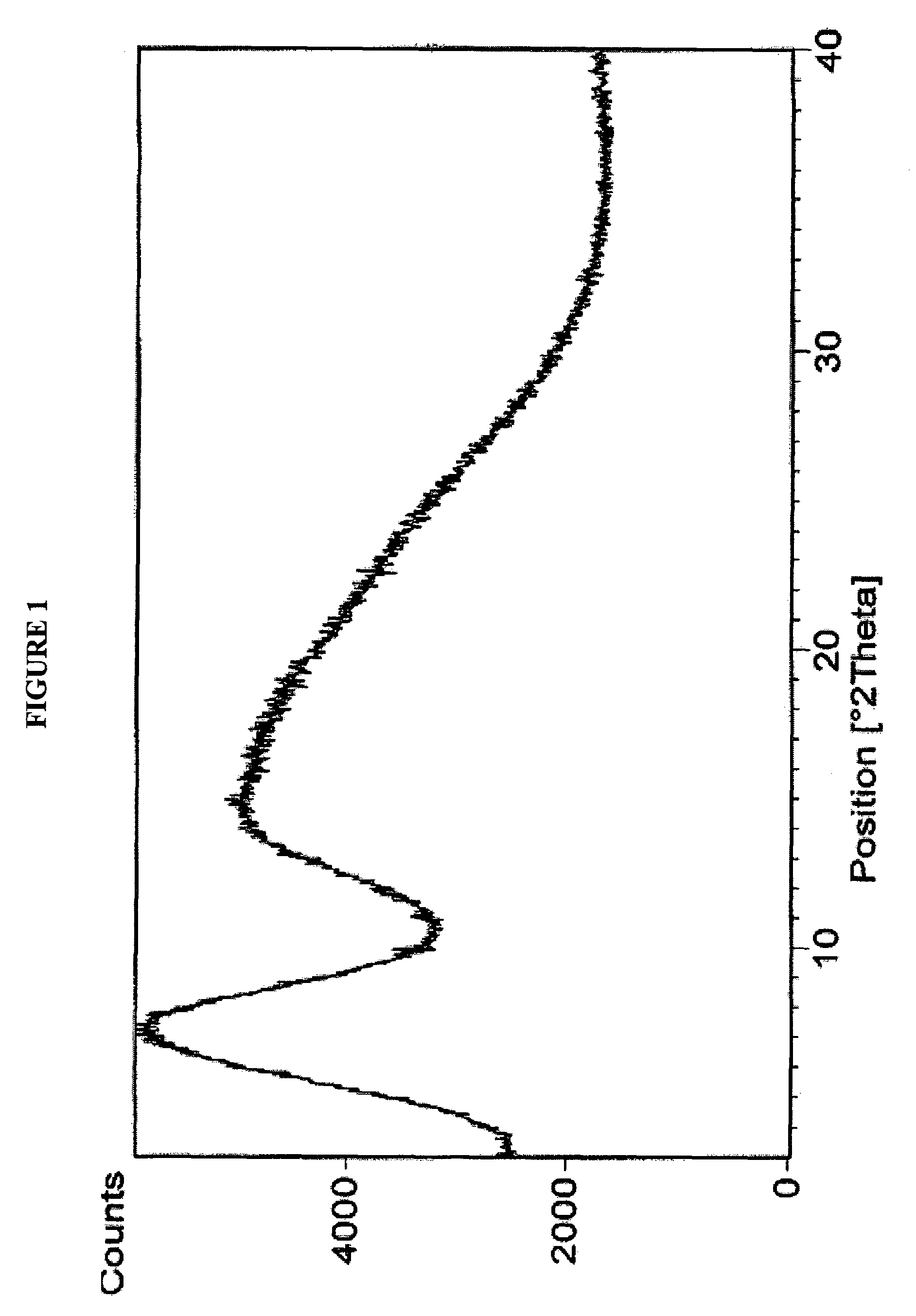

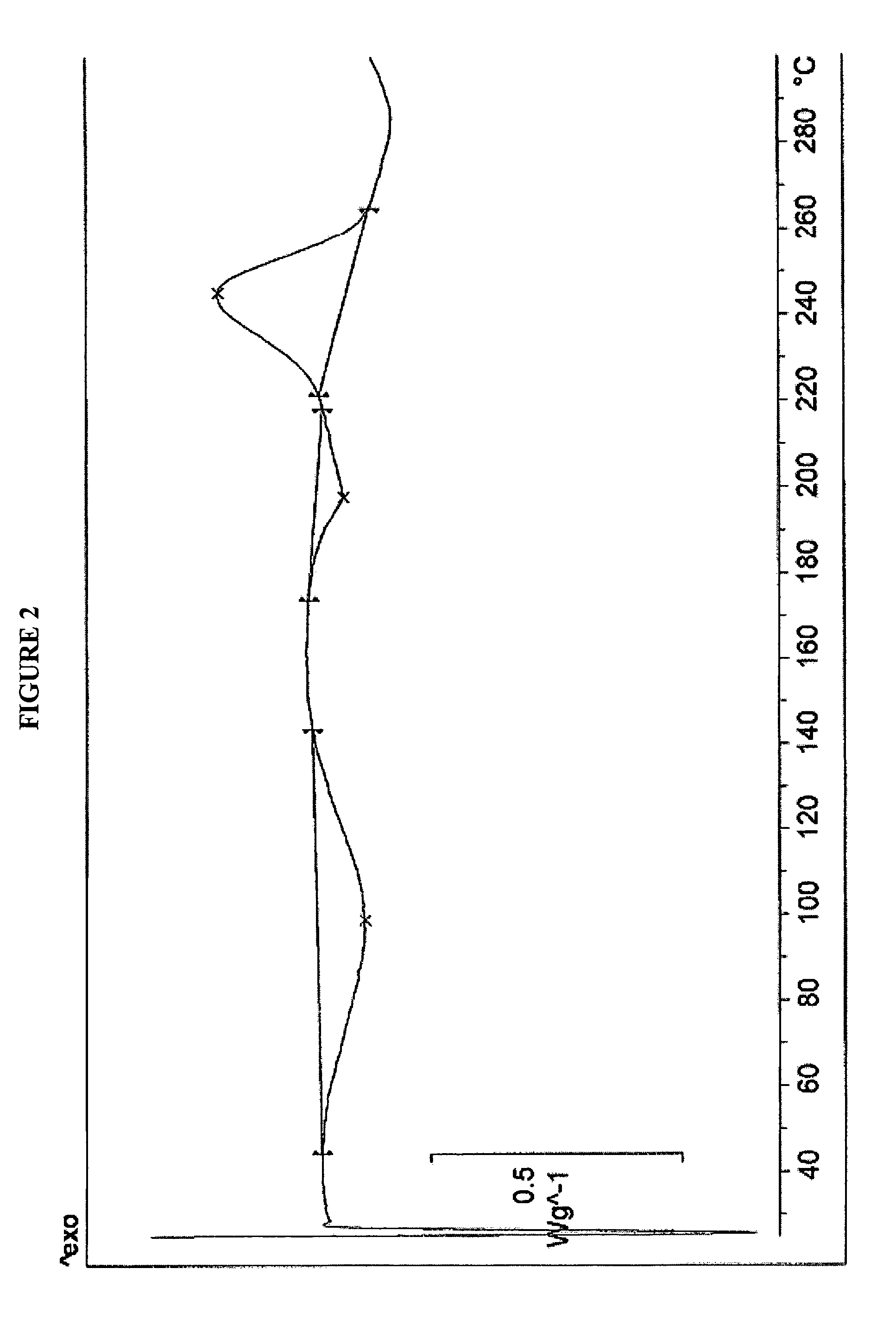

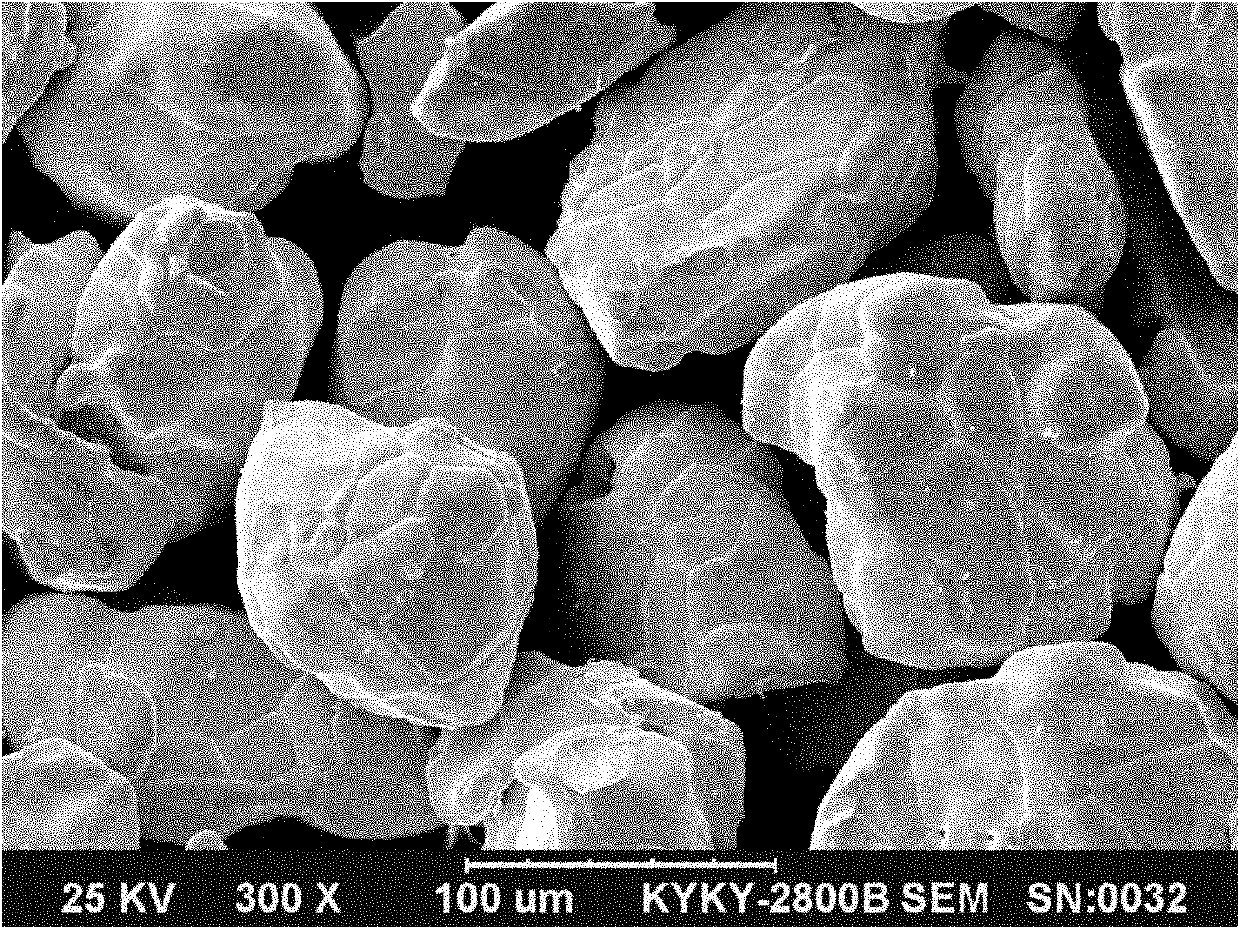

Amorphous form of rifaximin and processes for its preparation

A stable amorphous form of rifaximin is disclosed. This form is chemically and polymorphically stable on storage and can be prepared by dissolving rifaximin in a solvent to form a solution, which is precipitated by adding an anti-solvent and isolating of the precipitated amorphous rifaximin as an end product.

Owner:SALIX PHARMA INC

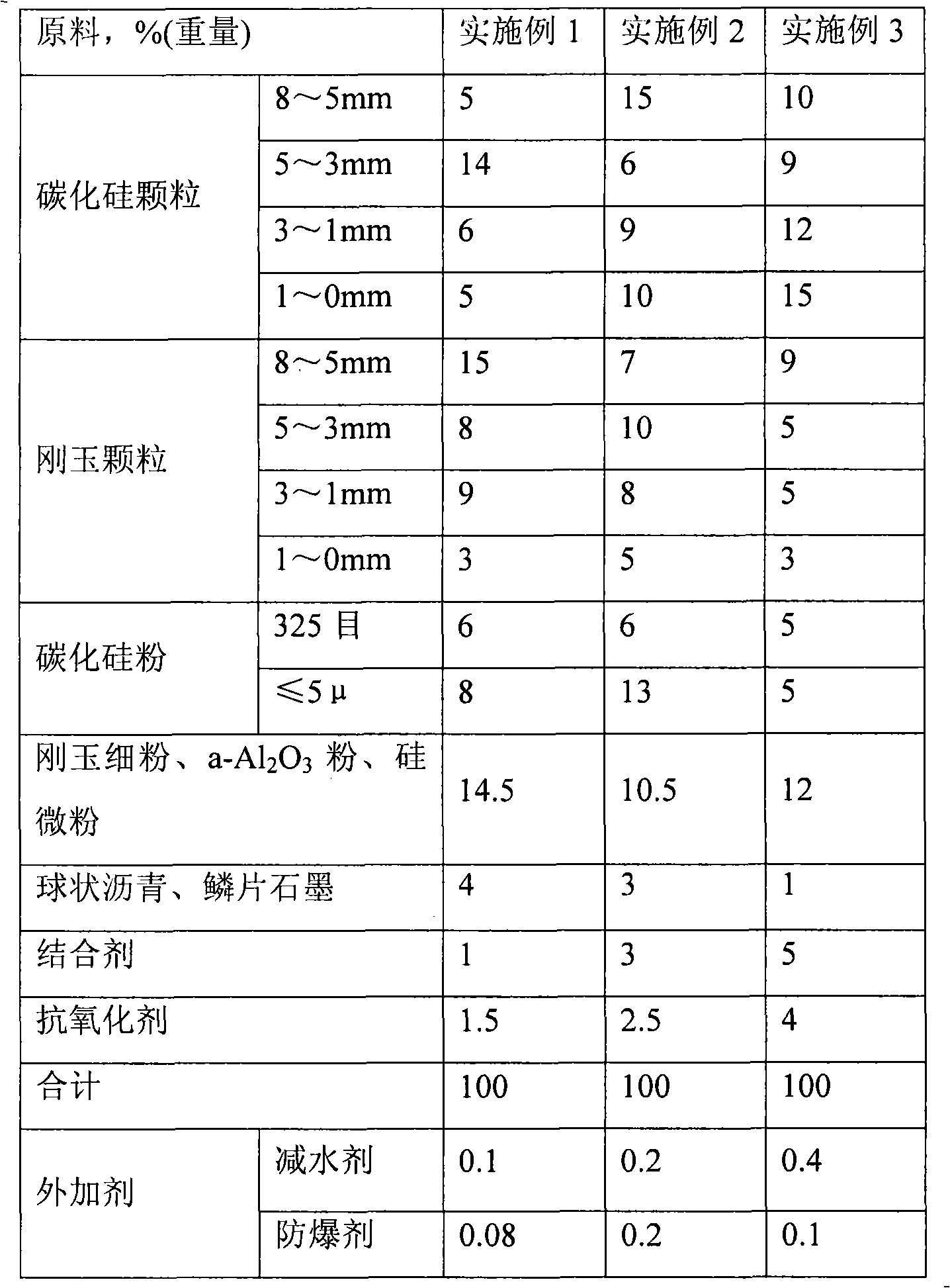

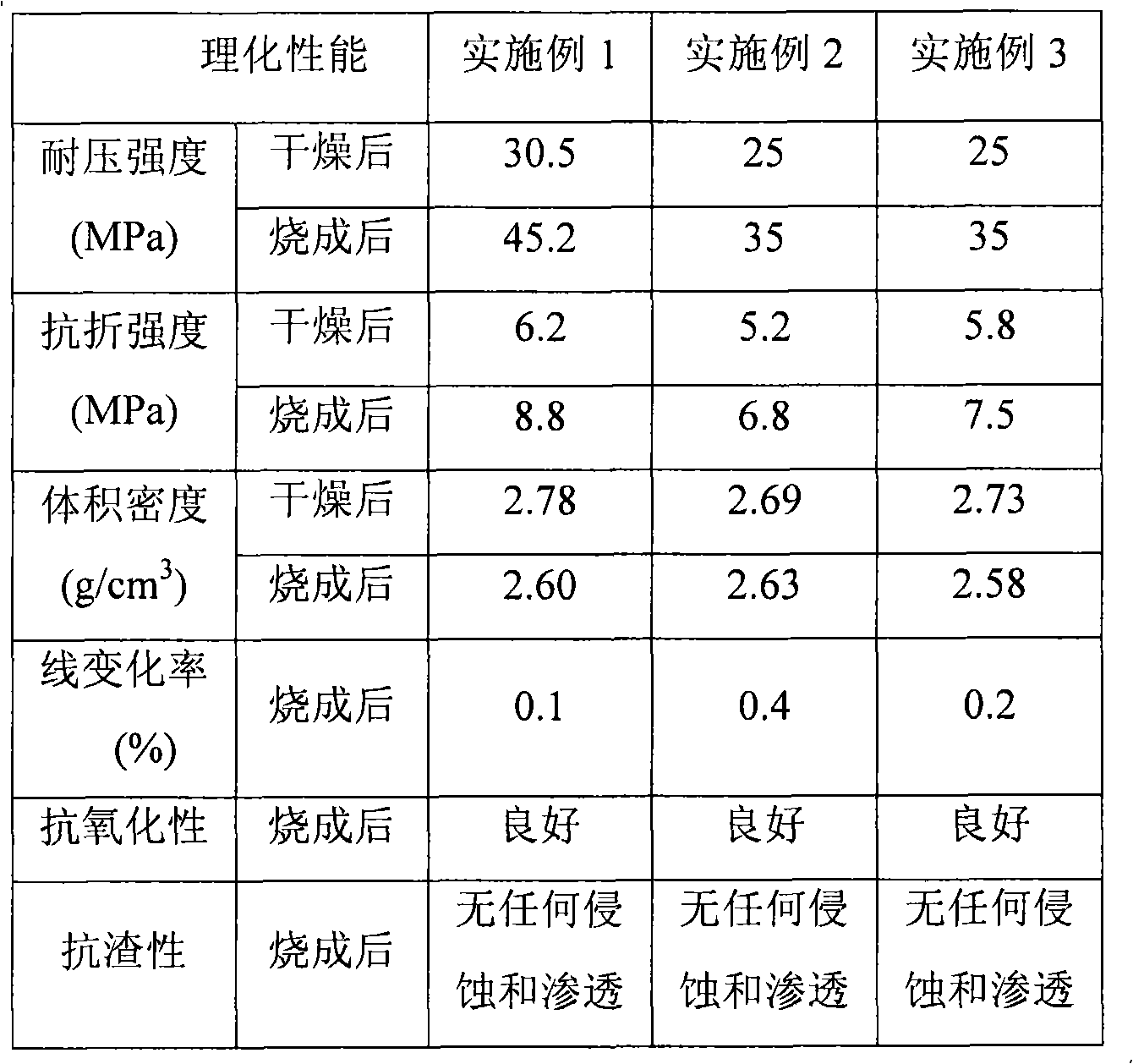

Preparation method of Al2O3-SiC-C castable material for slag line of main trough of blast furnace

The invention relates to an Al2O3-SiC-C castable material for a slag line of a main trough of a large blast furnace and a preparation method thereof. The castable material comprises an aggregate, a matrix, a bonding agent, an antioxidant and an admixture; wherein, the aggregate comprises corundum grains and carborundum grains; the matrix comprises ball pitch, flake graphite, corundum fine powder, a-Al2O3 ultrafine powder, silicon powder and carborundum ultrafine powder; the bonding agent is aluminate cement; the antioxidant is a compound of aluminium powder and silicon powder; the admixture comprises a water reducing agent and a detonation suppressor. The castable material is prepared by the steps of mixing various raw materials evenly, adding water, stirring, casting molding, maintaining and drying. The castable material has strong anti-slag corrosion and anti-scour capabilities, good high temperature resistance, abrasion resistance and thermal shock resistance, slight reheating change and long service life.

Owner:BEIJING TONGDA REFRACTORY TECH CO LTD

Organic silicon lubricating grease and preparation method thereof

ActiveCN101870905AImprove the lubrication effectNo dielectric constantThickenersAdditivesBase oilThermal stability

The invention relates to the technical field of lubricating grease, in particular to organic silicon lubricating grease and a preparation method thereof. The organic silicon lubricating grease comprises the following components in percentage by mass: 10 to 80 percent of base oil, 1 to 30 percent of modifier and 5 to 25 percent of thickening agent. The organic silicon lubricating grease has the advantages of wide application range, excellent dielectric property, insulating property, sealing property, thermal stability, shockproof property and lubricating property, and obvious improvement on lubricating property and thermal stability particularly.

Owner:东莞太平洋博高润滑油有限公司

Lightweight insulated calcium hexaluminate castable

The invention relates to a lightweight insulated calcium hexaluminate castable prepared from the following raw materials by weight percent: 25-35% of super lightweight calcium hexaluminate of which the grain size is 3-6mm, 10-15% of super lightweight calcium hexaluminate of which the grain size is 1-3mm, 15-20% of super lightweight calcium hexaluminate of which the grain size is 0.088-1mm, 0-25% of super lightweight calcium hexaluminate of which the grain size is smaller than 88mu m, 0-25% of corundum fine powder of which the grain size is smaller than 88 mu m, 0-10% of alpha-Al2O3 micro-powder and 5-20% of pure calcium aluminate cement, and in addition, a water reducer which is 0.12-0.18% of total weight of the raw materials. The lightweight insulated calcium hexaluminate castable disclosed by the invention has the advantages of small volume density, good thermal insulating properties, high strength, low impurity content, high refractoriness and strong anti-erosion capability.

Owner:河南竹林庆州耐火材料有限公司

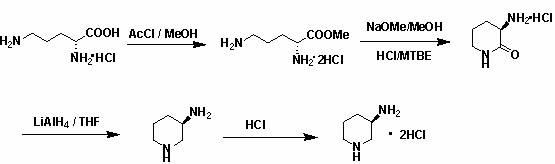

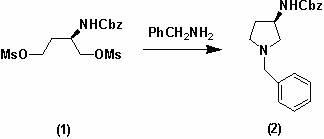

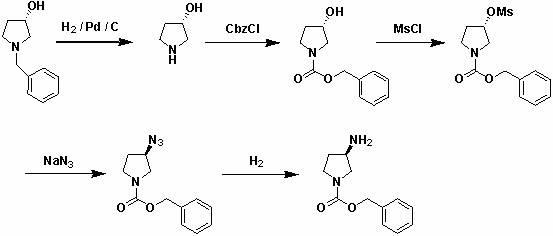

General preparation method of optical-activity 3-aminopyrrolidine, 3-alkyl amino piperidine and derivatives thereof

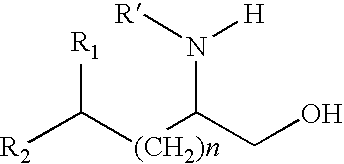

InactiveCN101955457AHigh chemical purityLow costOrganic chemistryBulk chemical productionChemical compoundPharmaceutical drug

The invention relates to a general preparation method of optical-activity 3-aminopyrrolidine, 3-alkyl amino piperidine and derivatives thereof by using compounds with optical activity as an initial raw material. The compounds can be simply expressed in the following molecular structure shown in the specification, wherein n is 1, 2 or 3, R1 or R2 can independently present a hydrogenous or amino-group protection group, and * presents a chiral centre with optical activity and can be R configuration or S configuration. The 3-aminopyrrolidine, 3-alkyl amino piperidine and derivatives thereof, which have optical activity, are generally used for synthesizing chiral medicaments or pesticides in the development and the production of medicaments. The invention has the advantages of cheap and easily obtainable raw materials, simple and convenient process operation, high safety, low cost and little environmental pollution and is suitable for industrial production.

Owner:WISDOM PHARM CO LTD

Preparation method of high purity aluminium oxide powder

InactiveCN1903728AHigh chemical purityReduce sodiumAluminium oxide/hydroxide preparationWater bathsAluminium hydroxide

The present invention relates to a preparation method of high-purity aluminium oxide powder body. It is characterized by that it adopts aluminium sheet whose purity is 99.9999% and organic alkal; and makes them be mutually reacted in hot water bath to obtain the precipitate of aluminium hydroxide, then the precipitate is calcined at 1100-1200deg.C and ground so as to obtain high-purity ultrafine aluminium oxide powder body. The described organic alkal; includes any one of choline, hexamethohydrotetramine and dopamine.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

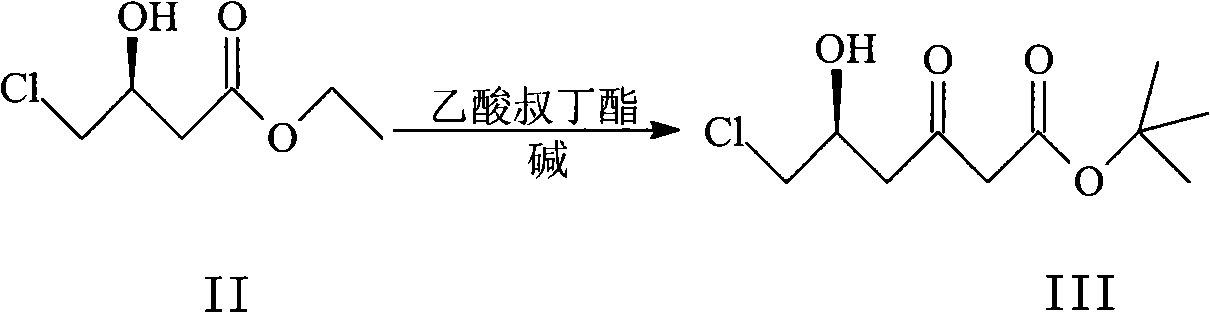

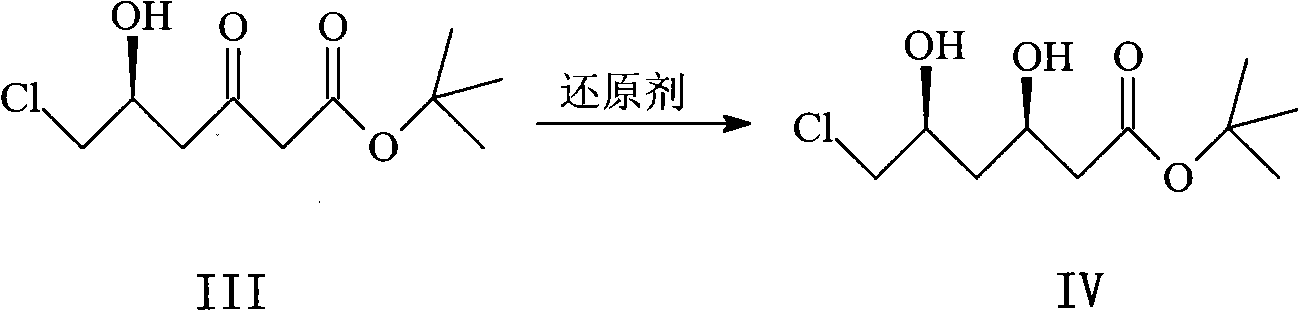

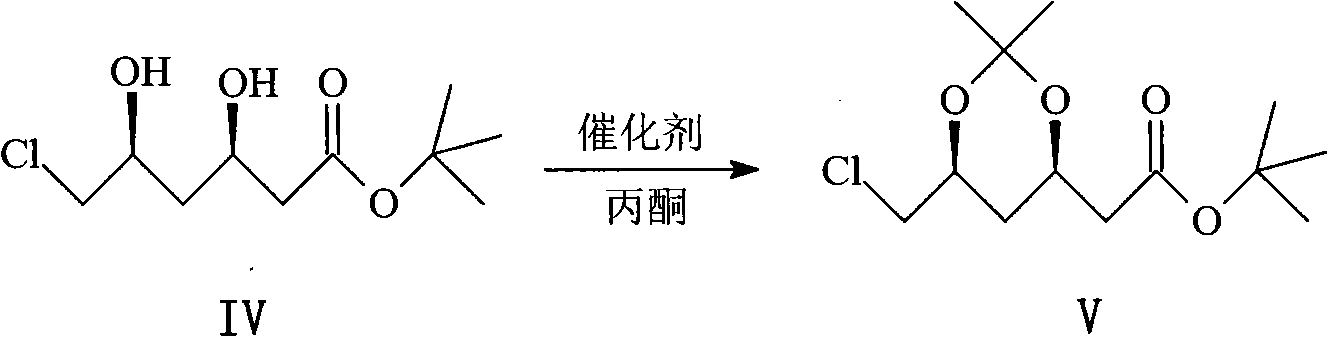

Preparation method of key intermediate of rosuvastatin calcium side chain

ActiveCN101624390AEase of industrial productionSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationSide chainRosuvastatin Calcium

The invention provides a preparation method of a key intermediate of a rosuvastatin calcium side chain, comprising the following steps: using (S)-4-chlorine-3-hydroxybutanoate as an initial raw material; and preparing the key intermediate through four-step reactions of condensation, reduction, hydroxy group protection and condensation. The reaction process is simple to operate, the products in each step are easy to separate and purify, the purification and separation step is carried out without a silicagel column, and the yield is more than 80 percent, therefore, the intermediate with higher chemical purity and optical purity can be obtained. The GC determination shows that the chemical purity is more than or equal to 99.5 percent and the optical purity is more than or equal to 99.2 percent ee.

Owner:LUNAN PHARMA GROUP CORPORATION

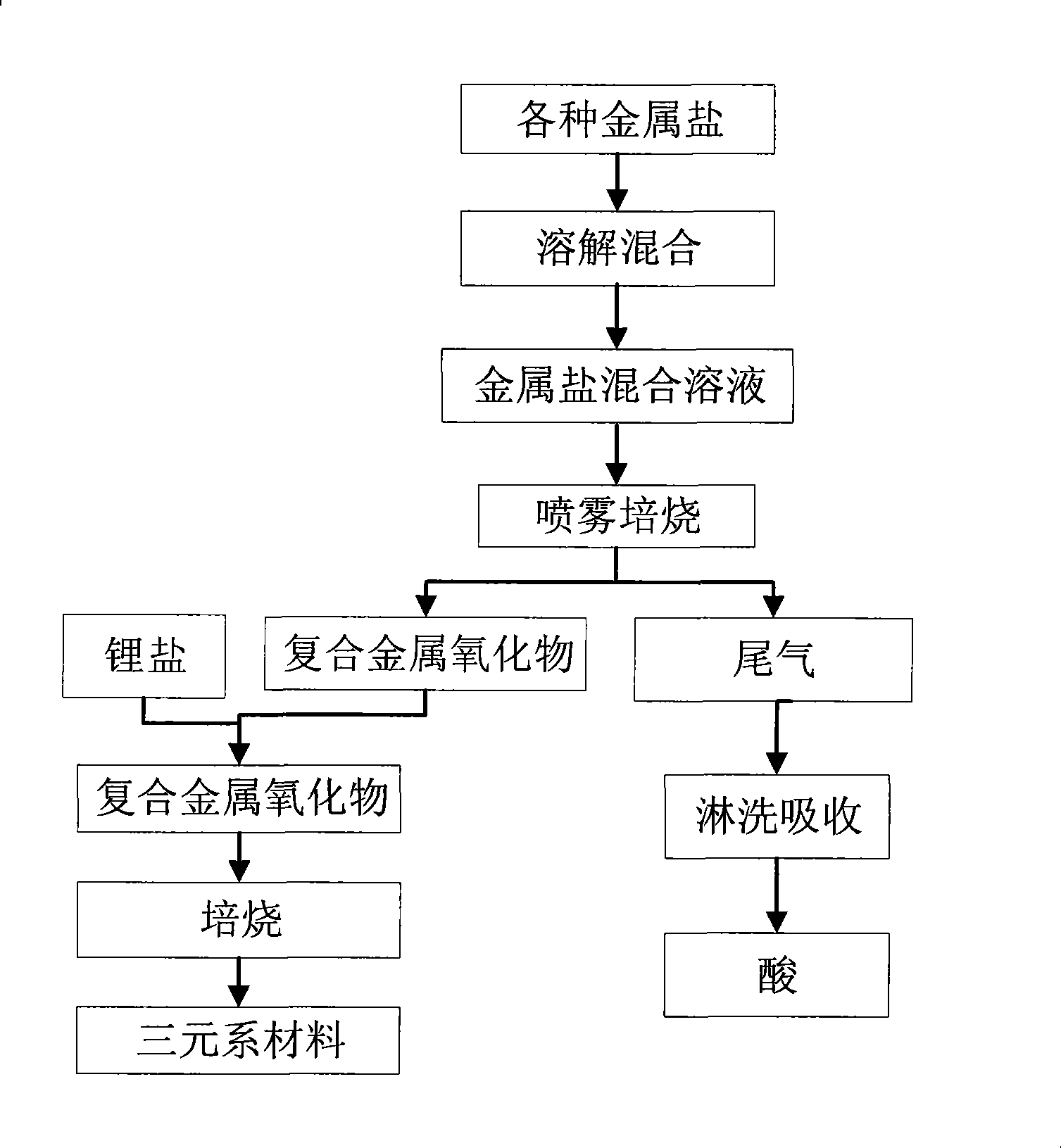

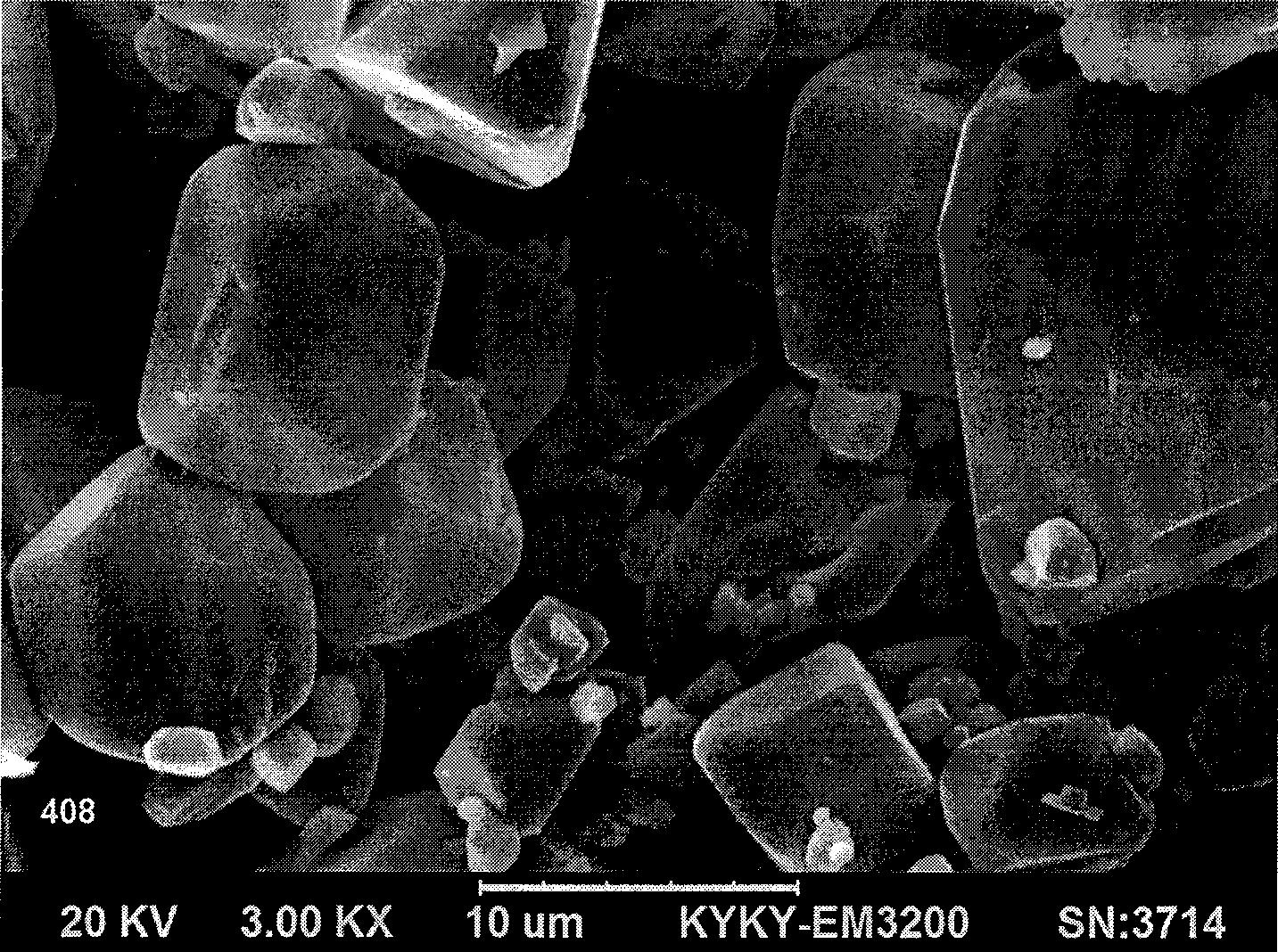

Novel method for preparing lithium ion battery anode ternary material LiCoxNiyMn2O2

InactiveCN101369651AGood fluidity of powderUniform particle sizeElectrode manufacturing processesCrystallinityManganese oxide

The invention relates to a preparation method of ternary system material, in particular to a preparation method of lithium cobalt nickel manganese oxide ternary system material for lithium ion batteries. The invention applies ensured ternary system material salt as raw material. After needed matching weight, by means of eve dissolving and mixing, a composite metal oxide prepared by a spray-roasting method is used as a fore body. The fore body is mixed with a lithium-source compound according to the substance amount of 1:1-1.5, and then roasting is carried out at the temperature of 700 to 1000 degrees centigrade to obtain the ternary system material. The tail gases, such as vapor, acidic gas, generated in the spray-roasting process are absorbed by a washing tower to obtain acid. The invention has the advantages of advanced technique, stable production, low cost, no waste water discharge, environmental protection, high product purity, even granularity, high crystallinity, etc.

Owner:ZHEJIANG HUAYOU COBALT

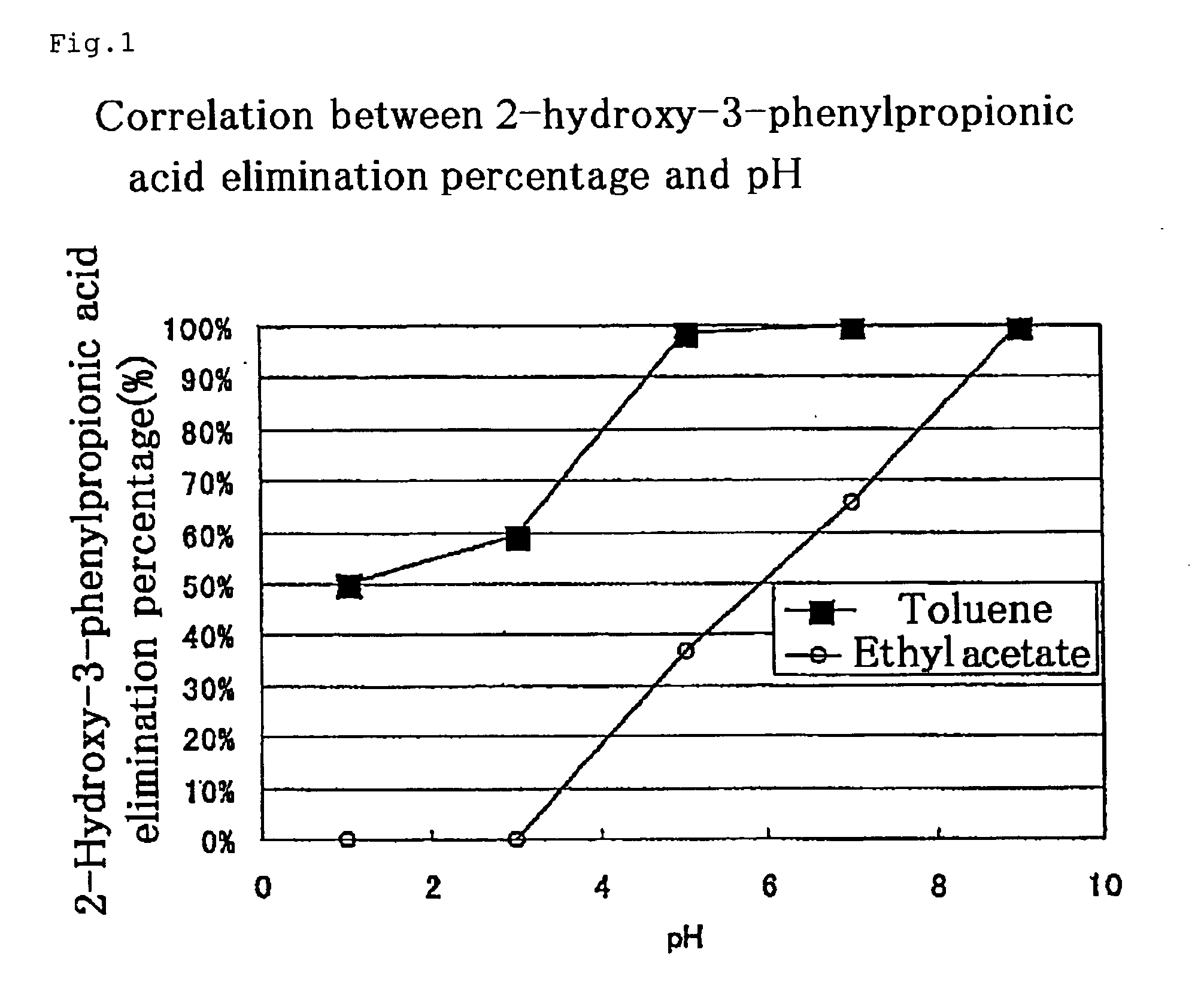

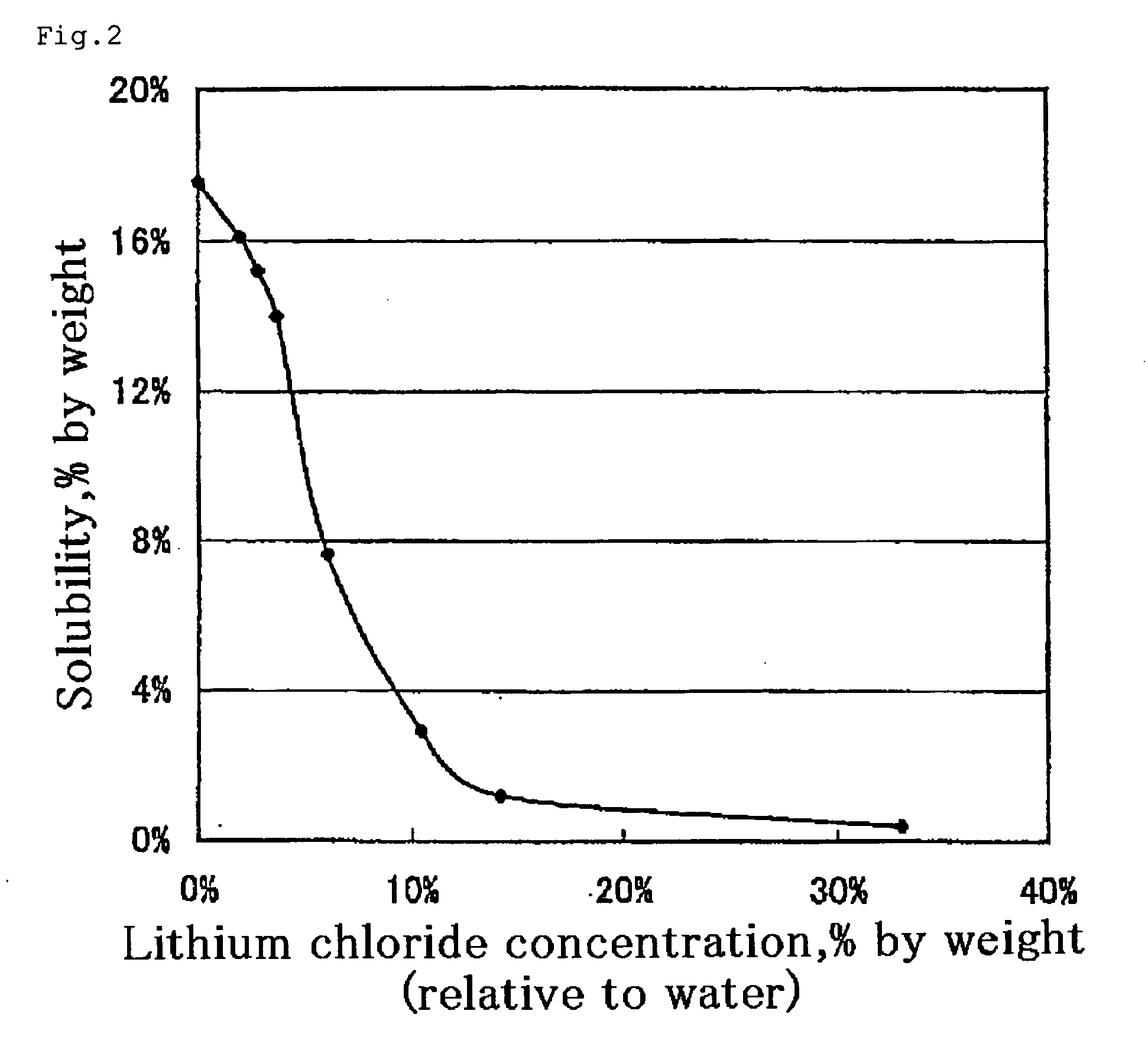

Process for producing optically active 2-substituted carboxylic acid

InactiveUS20050245764A1High optical purityHigh chemical purityOrganic compound preparationOrganic chemistry methodsMedicinal chemistrySubstituted carboxylic acid

The present invention relates to a process for efficiently producing an optically active 2-bromocarboylic acid and an optically active 2-sulfonyloxycarboxylic acid, which are important in the production of medicinal compounds and so forth. An optically active 2-sulfonyloxycarboxylic acid ester is subjected to deprotection under acid conditions to obtain an optically active 2-sulfonyloxycarboxylic acid. A metal bromide is caused to act on the acid to brominate it with configuration inversion at position 2 to thereby produce an optically active 2-bromocarboxylic acid. The resultant optically active 2-bromocarboxylic acid is isolated / purified by subjecting it to a step in which the acid is crystallized and separated as a salt with a base. Thus, an optically active 2-bromocarboxylic acid having a high chemical purity and high optical purity can be produced.

Owner:KANEKA CORP

Preparation method of high-stability high-purity extra-coarse tungsten carbide powder

InactiveCN102557028ANarrow particle size distributionImprove stabilityTungsten/molybdenum carbideGranularityCarbonization

A preparation method of a high-stability high-purity extra-coarse tungsten carbide powder contains the following steps of: (1) grinding a high-purity extra-coarse tungsten carbide powdered raw material with its chemical purity being greater than or equal to 99.98 wt%, and carrying out size grading to obtain the required average granularity and a high-purity extra-coarse tungsten powder according to the particle size distribution; (2) carrying out carbon addition by the use of carbon black according to the total carbon content of the obtained tungsten carbide powder being 6.13+ / -0.05%, followed by ball milling and mixing to obtain a ball-milling mixture; (3) filling the obtained ball-milling mixture into a graphite boat and a carbide furnace, and carrying out high-temperature carbonization at 1600-2500 DEGC for the carbonization time of 1-10 hours; and (4) carrying out coarse crushing on the obtained carbonized material, followed by grinding and crushing, and carrying out size grading to obtain the high-purity extra-coarse tungsten carbide powder. The method provided by the invention can be adopted to produce the high-purity extra-coarse tungsten carbide powder with good crush resistance, morphology and structure and excellent thermal stability. The high-purity extra-coarse tungsten carbide powder is used to prepare an extra-coarse crystal cemented carbide product with high performance.

Owner:江西耀升钨业股份有限公司 +1

Resource recycling method of industrial phosphogypsum waste residues

ActiveCN104211099AResource conservationHigh chemical puritySulfate/bisulfate preparationCalcium/strontium/barium oxides/hydroxidesHydrogen SulfateSilicic acid

The invention discloses a resource recycling method of industrial phosphogypsum waste residues and relates to the technical field of inorganic chemical industry. The method comprises the following steps: carrying out a reaction on gypsum calcium sulfate and concentrated sulfuric acid to generate calcium hydrogen sulfate; carrying out a reaction on calcium hydrogen sulfate which is 1 time and a sodium hydroxide NaOH or potassium hydroxide KOH aqueous solution which is 4 times; filtering or precipitating and separating to recover calcium hydroxide, limonite, silicic acid and calcium fluoride and CaHPO4; and obtaining sodium sulfate / potassium sulfate, sodium aluminate or potassium aluminate and calcium acetate Ca(CH3COO)2. The method is mainly applied to resource recycling of industrial phosphogypsum waste residues.

Owner:济宁理工思源商务服务有限公司

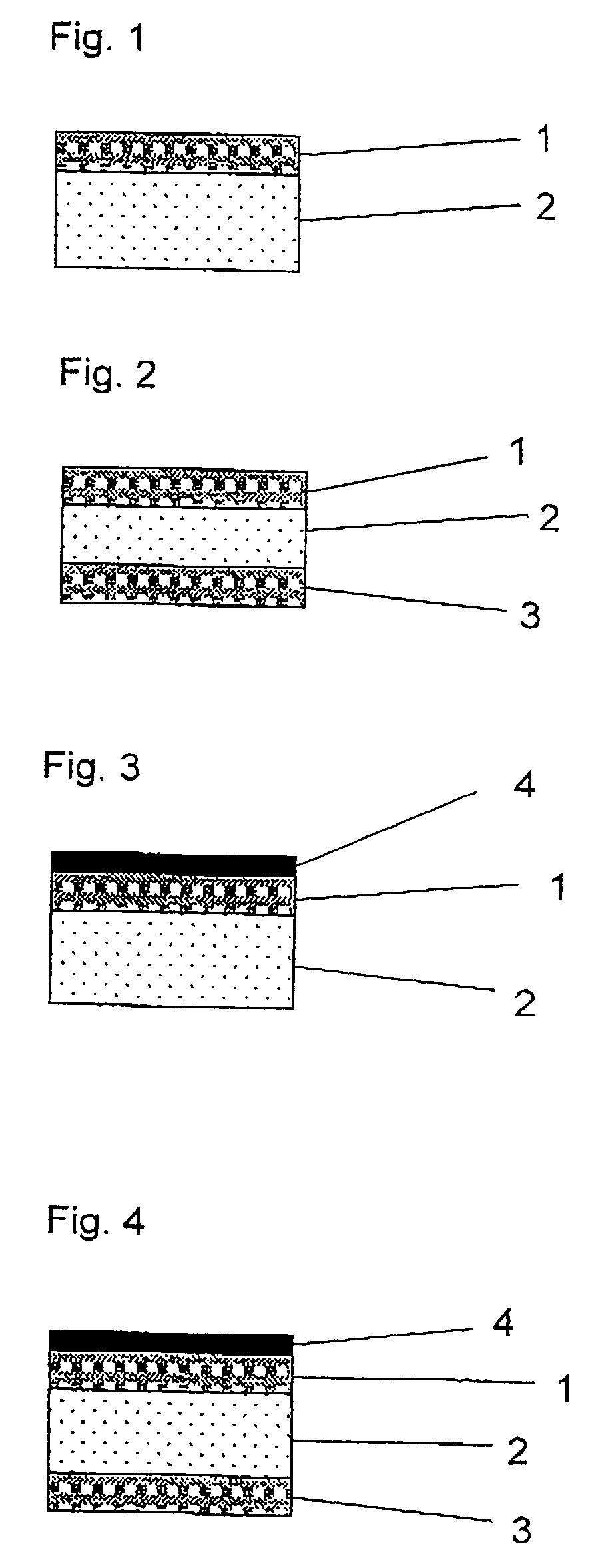

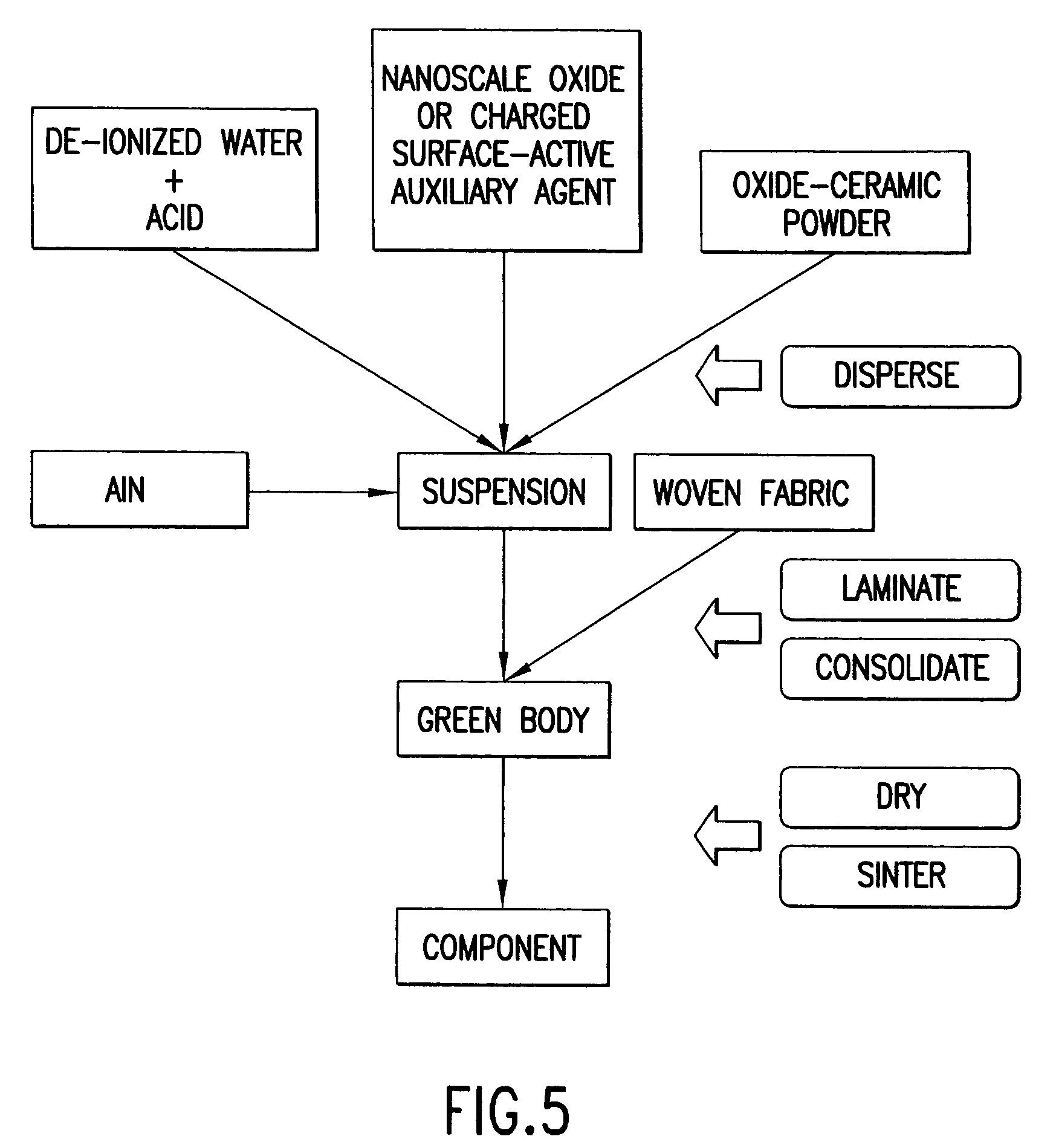

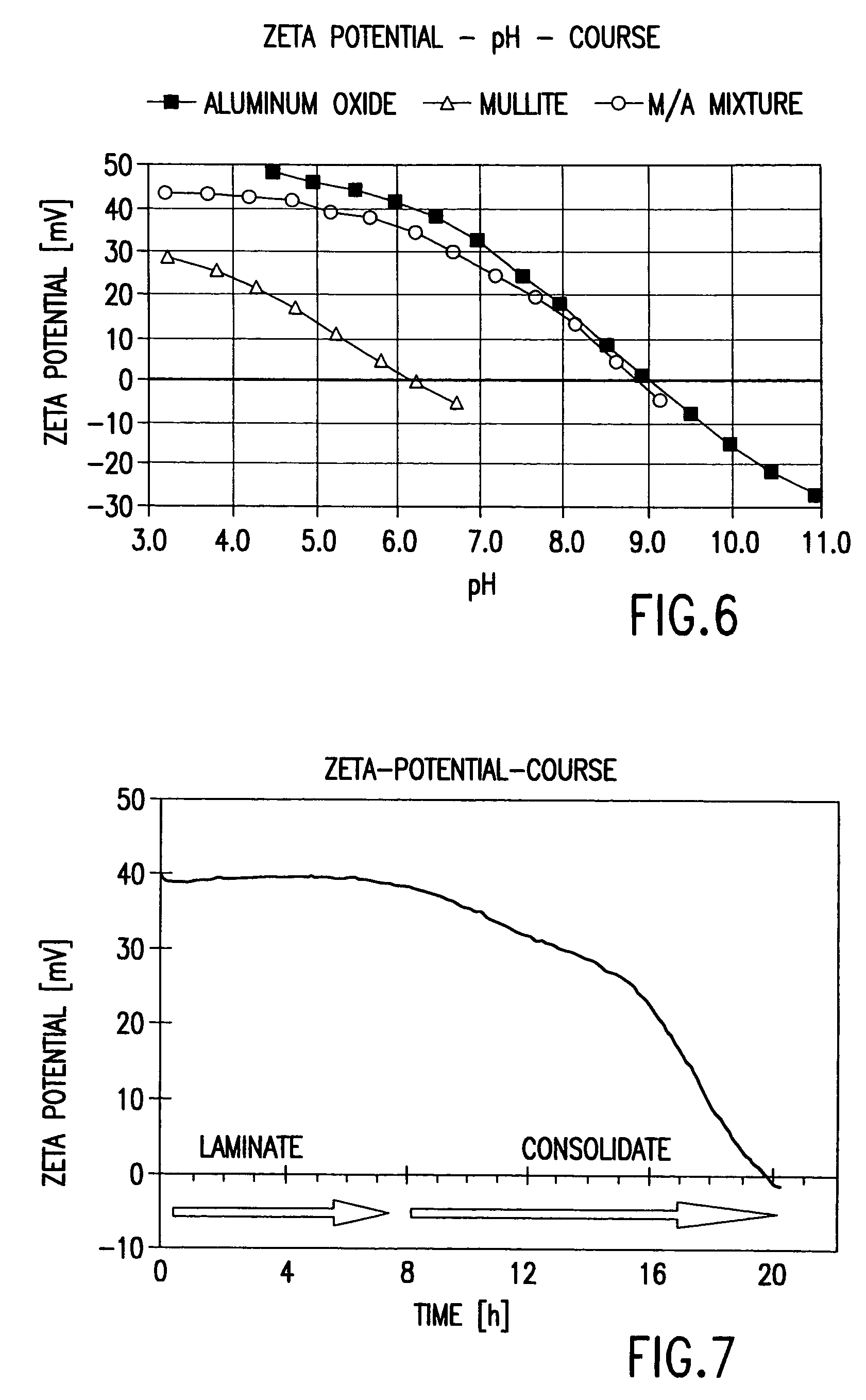

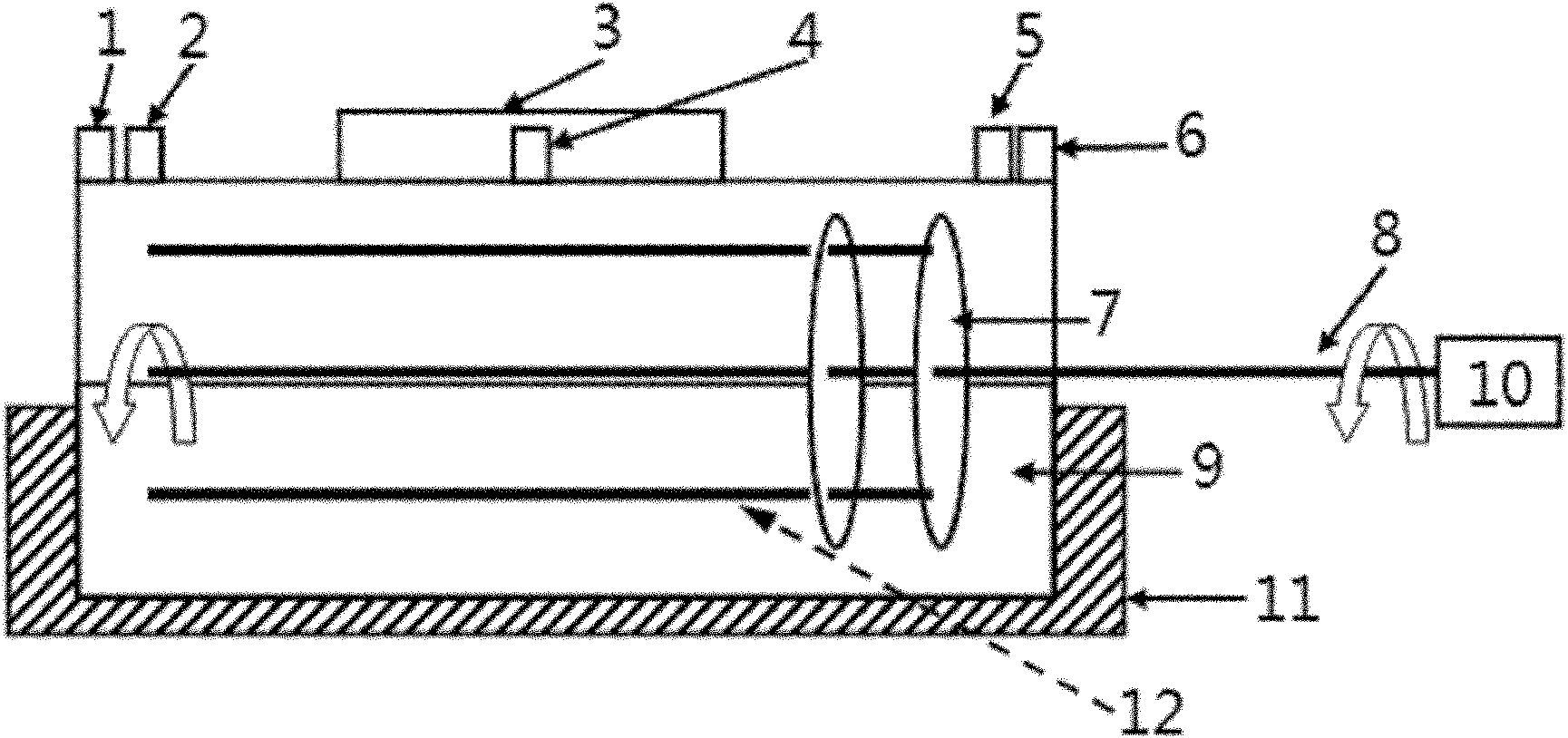

Multi-layer ceramic composite material with a thermal-protective effect

InactiveUS7118802B2Increasing the thicknessSufficient effectCombination devicesCosmonautic thermal protectionOxide ceramicsCeramic composite

A two-layer ceramic composite material, wherein the first predominantly load-bearing layer is an oxidic, carbon-free fiber-reinforced ceramic layer which is made by a colloidal process. The second predominantly thermally insulating layer is an oxide-ceramic foam. The colloidal process produces carbon-free oxide ceramics which, because of their high purity, have low dielectric losses in the entire usage temperature range. In addition, the colloidal process provides a simple and cost-effective production method.

Owner:LFK LENKLUGKOERPERSYST

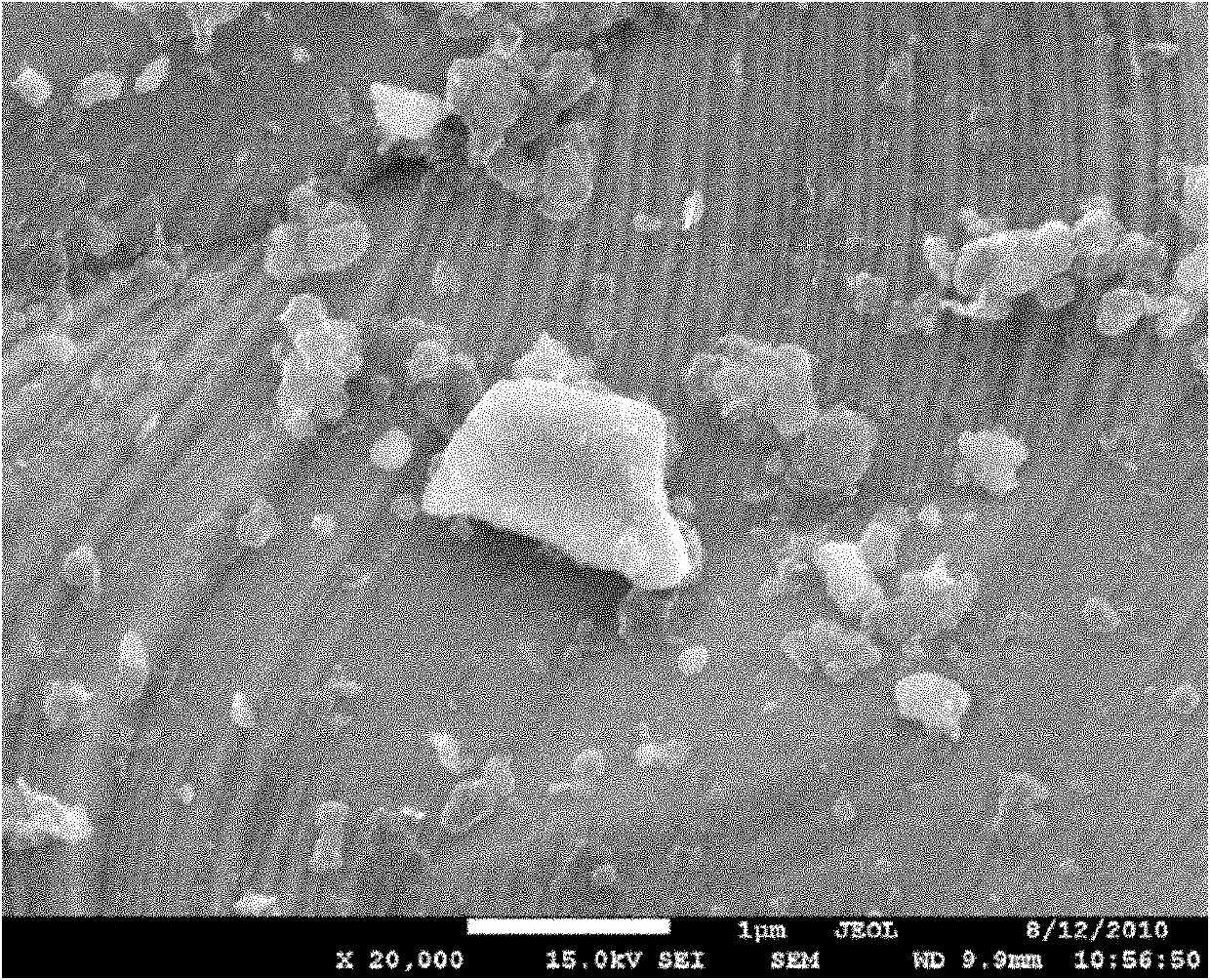

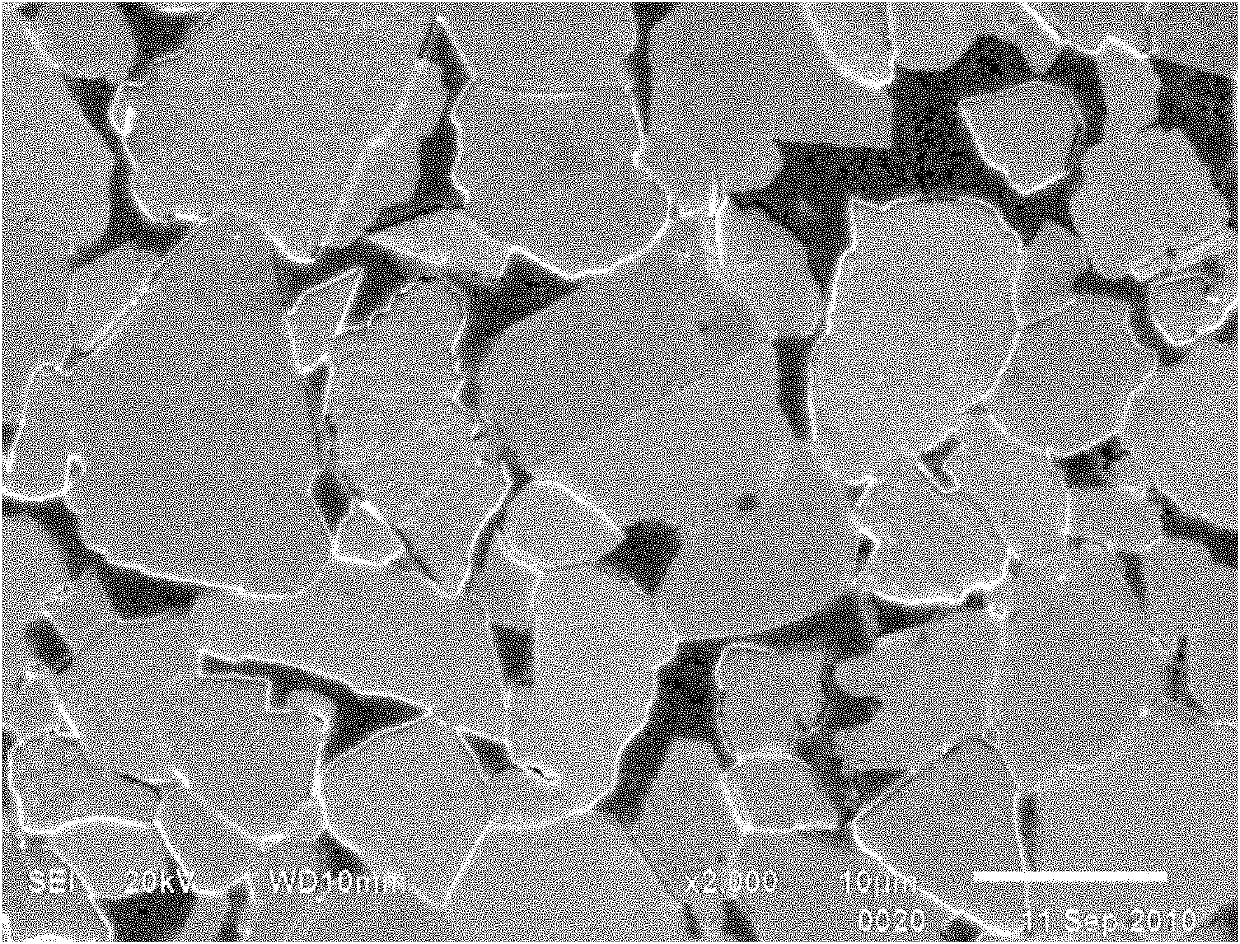

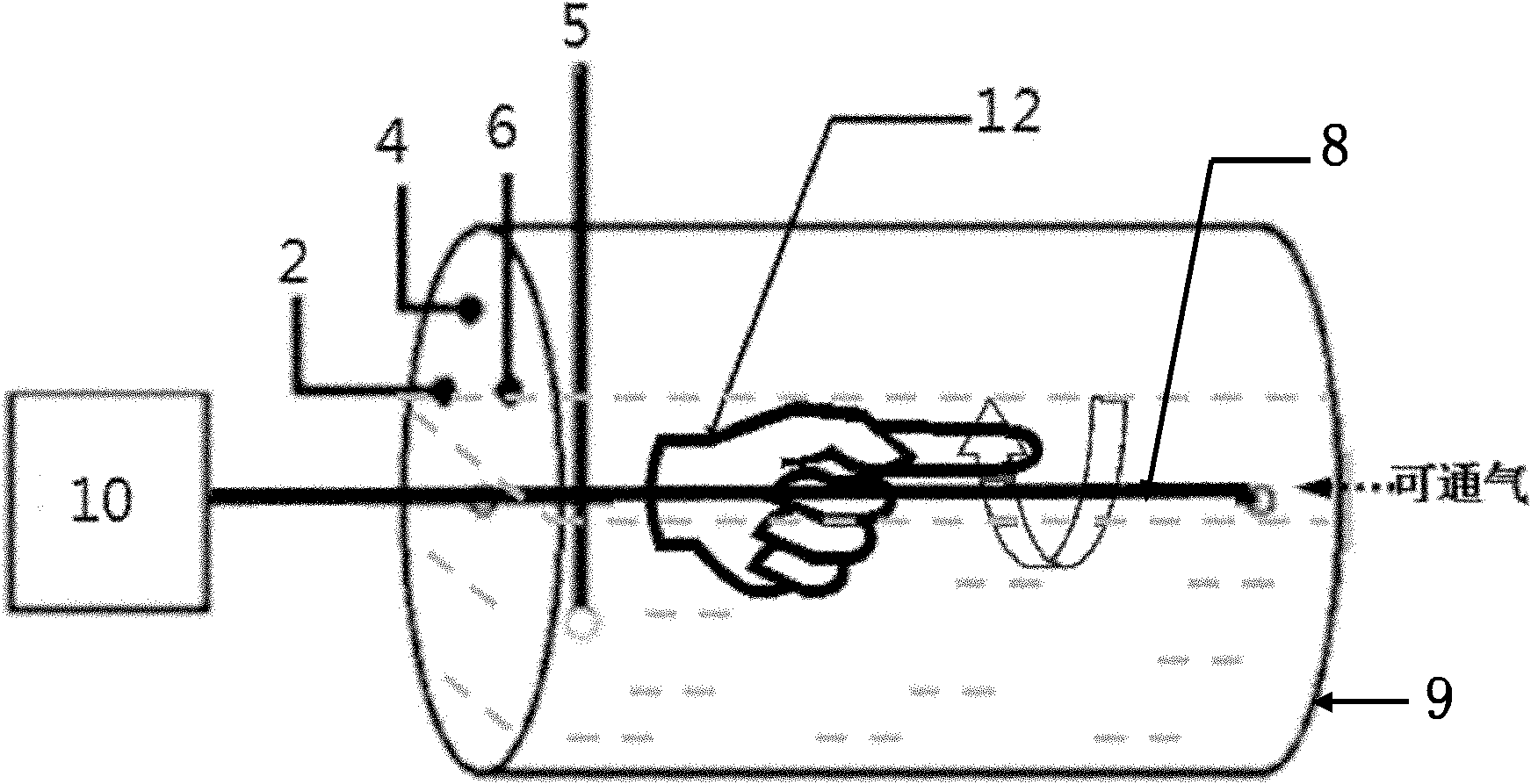

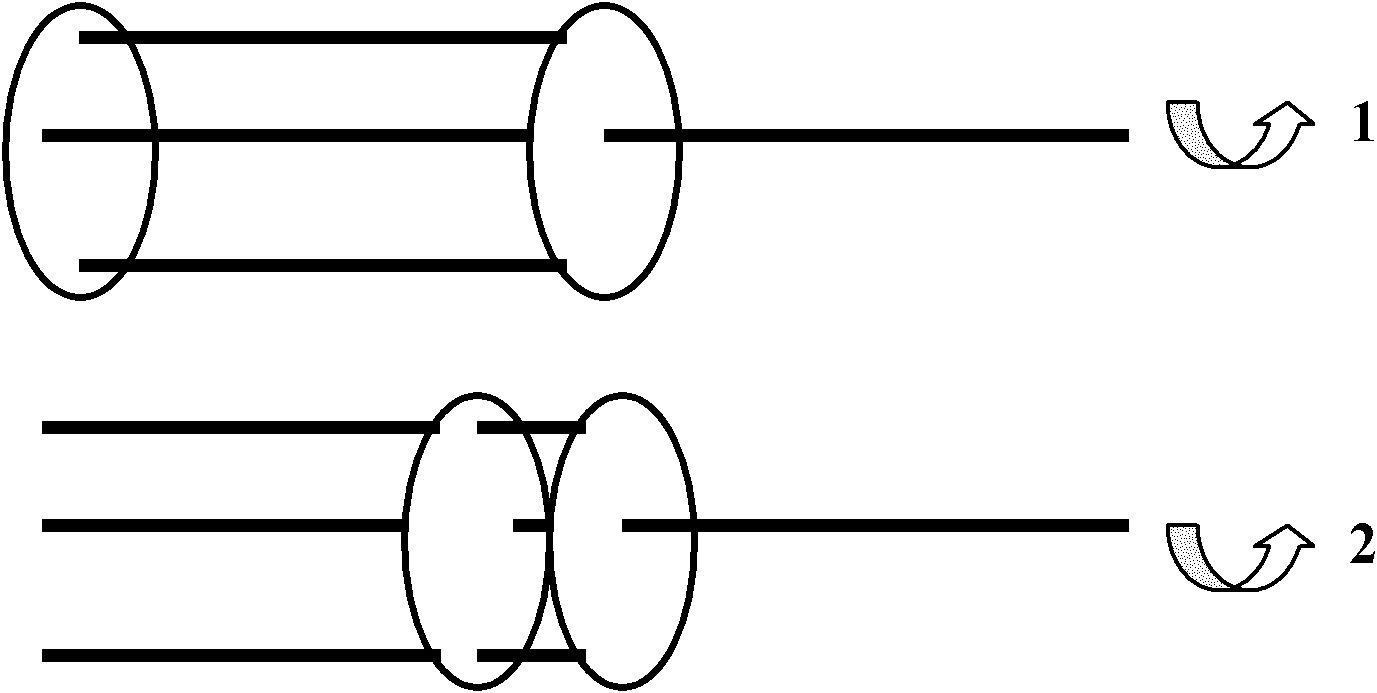

Device and method for dynamically preparing heterocavity bacterium cellulose materials

ActiveCN101914434AUnique three-dimensional network nanostructureHigh chemical purityBioreactor/fermenter combinationsBiological substance pretreatmentsFiberNerve fiber bundle

The invention relates to a device and a method for dynamically preparing heterocavity bacterium cellulose materials. The device comprises a thermometer hole, an acid liquor and alkali liquor adding hole, a handle, a venting hole, a pH meter hole, a nutrition supplement hole, a rotating shaft, a fermentation tank, a motor, a water bath device and a mould. The preparation method comprises the following steps of: inoculating bacterium cellulose strains into a fluid nutrient medium to be propagated and then transferring to a fermentation device provided with specific shape moulds for later dynamic disturbance cultivation, and then obtaining the heterocavity cellulose materials after the cultivation step. The size and the shape of the heterocavity BC (Bacterium Cellulose) materials prepared by utilizing the invention are controllable, and the moulds of the fermentation device can be detached to be reused. The preparation method has the advantages of simple and convenient implementation, low cost and high production efficiency, and is suitable for industrialization production. The heterocavity BC materials can be widely applied to cavity organ succedaneums of artificial vessels, nerve fiber conduits and the like, and can be used as food packing materials, such as meat sausage wrappers, jelly wrappers and the like.

Owner:DONGHUA UNIV

Radiation crosslinked polyethylene pipe and its preparation method

ActiveCN1282699CImproved chemical purityAvoid cross-linking reactionsTubular articlesPolymer scienceCross linker

The invention relates to a radiation crosslinked polyethylene pipe, which has a three-dimensional network crosslinked molecular structure, and the pipe is made of a certain proportion of mixed polyethylene resin, antioxidant and stearate lubricant. The raw material is extruded into a tube by a tube extruder at a temperature below 235°C, and then irradiated by electron rays; the ratio of each component in the raw material is: polyethylene resin 98.5-99.0%wt, antioxidant 0.1 ~0.6%wt, stearate lubricant 0.5~1.0%wt; molecular crosslinking degree inside the pipe ≥60%. The invention provides a radiation cross-linked polyethylene pipe material which does not need to add a cross-linking agent, has low raw material cost, high extrusion production efficiency and high chemical purity of the product.

Owner:FSPG HI TECH

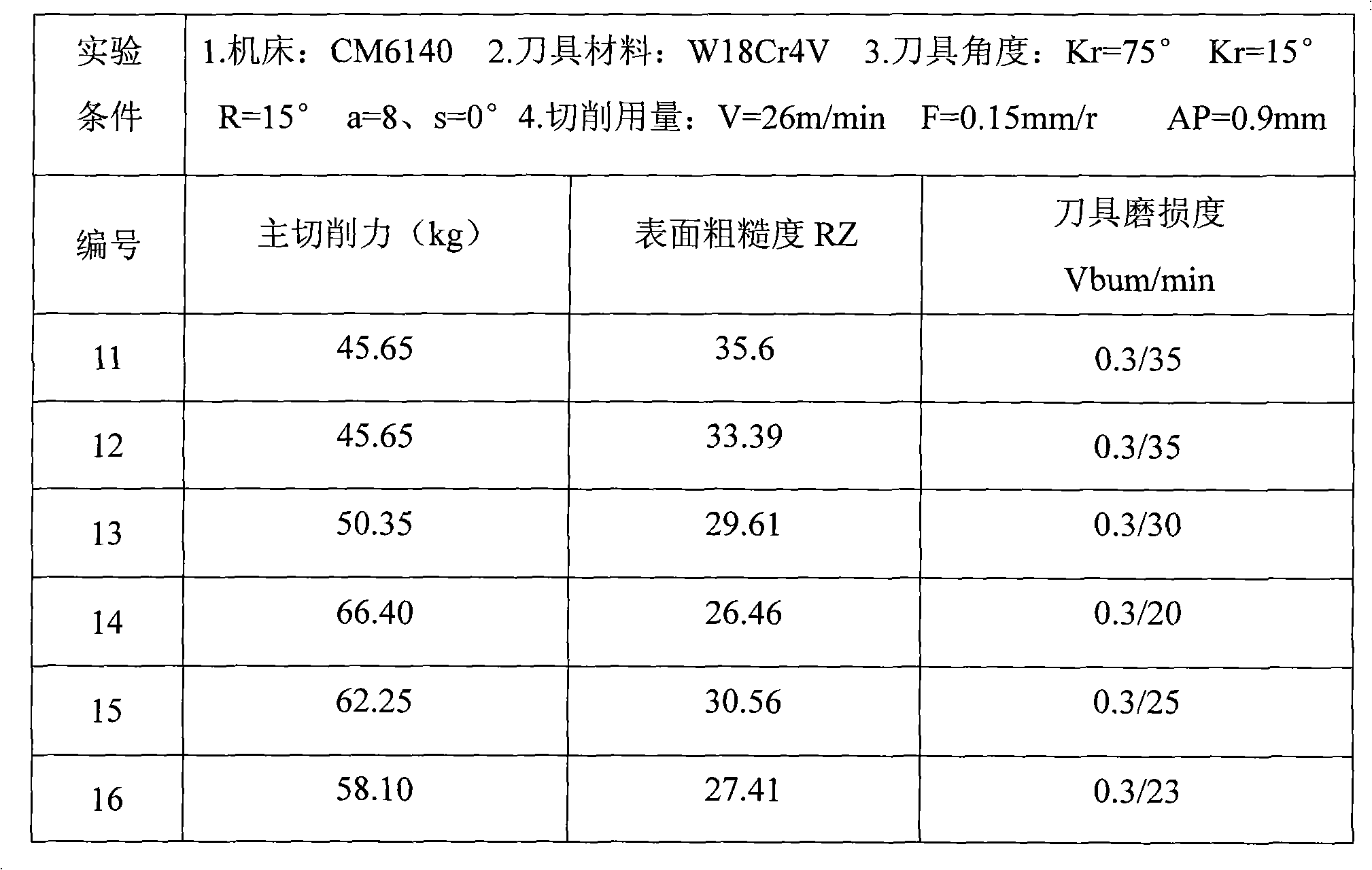

Free-cutting water-atomized steel powder and preparation method thereof

ActiveCN102049523AIngredient control and stabilityHigh chemical purityProcess efficiency improvementElectric furnacePowder metallurgyScrap

The invention belongs to the powder metallurgy field and particularly relates to a preparation method of free-cutting water-atomized steel powder. The method comprises the following steps of smelting, water atomization and reduction. The method provided by the invention is characterized in that the S content in the steel powder is controlled by adding high sulfur iron alloy. The method comprises the following operation steps: 1) smelting; 2) performing the water atomization technology; and 3) reducing. The free-cutting water-atomized steel powder prepared by the method comprises the following chemical components in percentage by weight: 0.10-0.20% of C, 0.20-0.35% of Si, 0.10-0.30% of Mn, 0-0.01% of P, 0.30-0.45% of S, 1.1-1.5ppm of [o] and balance of Fe and inevitable impurities. The water-atomized steel powder has the following beneficial effects: the used steel scrap raw material has low cost, the cutting property can be effectively improved, the service life of the cutting tool can be increased, and the steel powder is suitable for large-scale powder metallurgical products.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

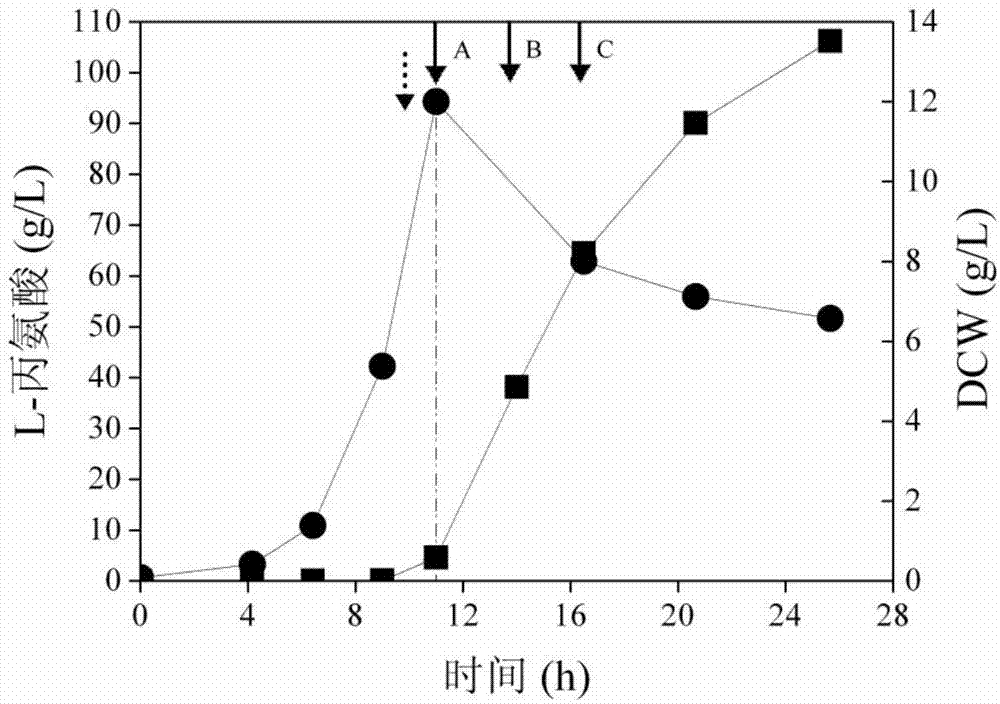

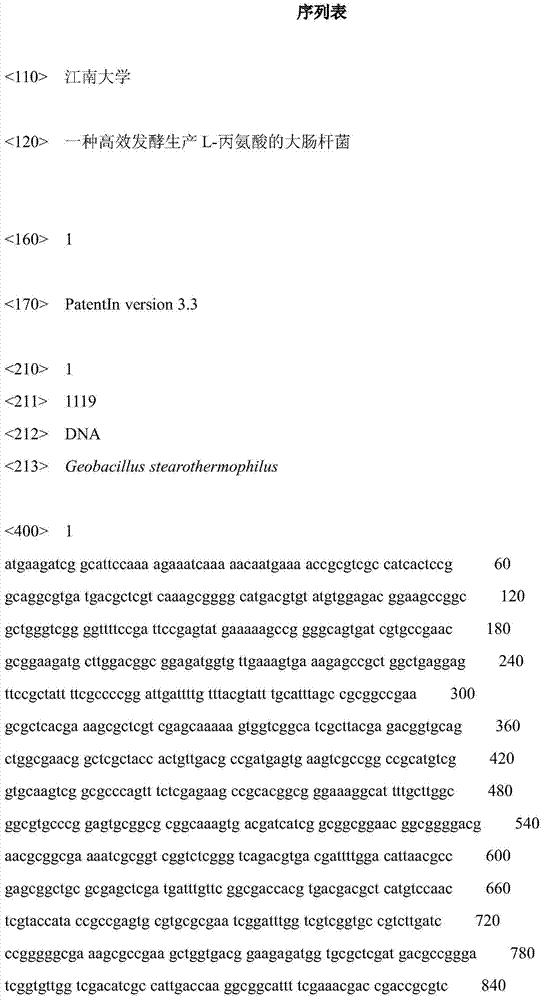

Escherichia coli for efficiently producing L-alanine by fermentation

ActiveCN104774790AAbility to produce high L-alanineHigh chemical purityBacteriaMicroorganism based processesEscherichia coliSuccinic acid

The invention discloses escherichia coli for efficiently producing L-alanine by fermentation, and belongs to the technical field of microbial metabolic engineering. Coding genes for a synthesis route for byproducts acetic acid, formic acid, alcohol, succinic acid and lactic acid on a chromosome of escherichia coli CGMCC No.10628 provided by the invention are deleted, and the chromosome dadX gene is replaced as an alanine dehydrogenase gene, wherein the coding genes comprise ackA-pta, pflB, adhE, frdA and idhA. The recombinant bacterium is fermented for 26 hours to produce 106g / L or more than 106g / L L-alanine with high optical purity and high chemical purity at 28-45 DEG C; and in the whole fermentation process, the production strength reaches 4.27g / L.h or more.

Owner:JIANGNAN UNIV

Preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber

InactiveCN103184586ALow priceWide variety of sourcesFibre chemical featuresCarbon fibersCellulose fiber

The invention relates to a preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber. According to the invention, a bacterial cellulose wet film is adopted as a substrate raw material. The prepared nano-grade carbon fiber is a product obtained after pyrolytic carbonization and graphitization of ultrafine bacterial cellulose fiber processed through an acupuncture carding refining treatment. The bacterial-cellulose-fiber-based nano-grade carbon fiber preparation method provided by the invention is safe, simple, and highly efficient, and has the advantages of wide raw material source, low price, and environment-friendly processing method. The bacterial-cellulose-fiber-based nano-grade carbon fiber obtained by processing has wide application field and great potential economic benefit.

Owner:ZHONGYUAN ENGINEERING COLLEGE

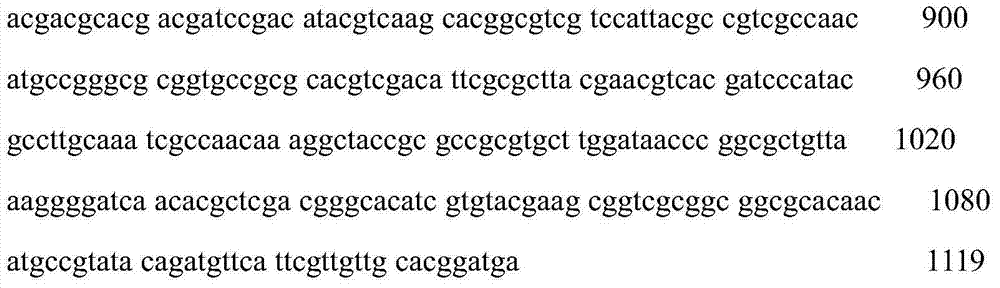

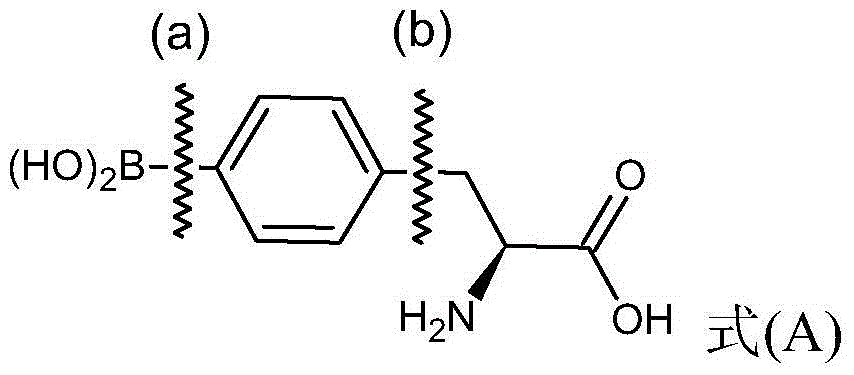

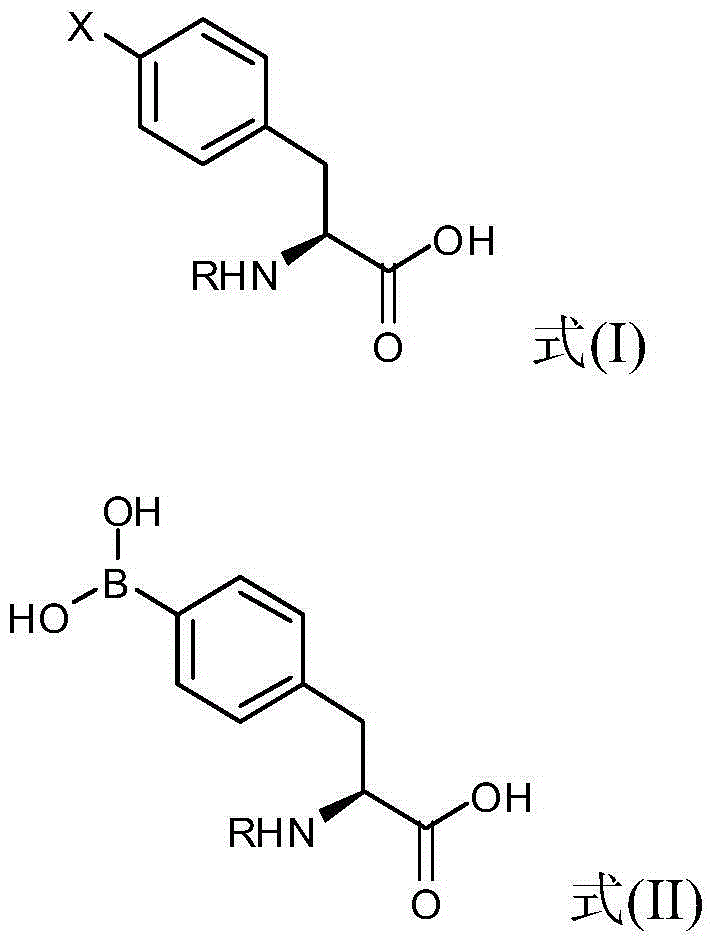

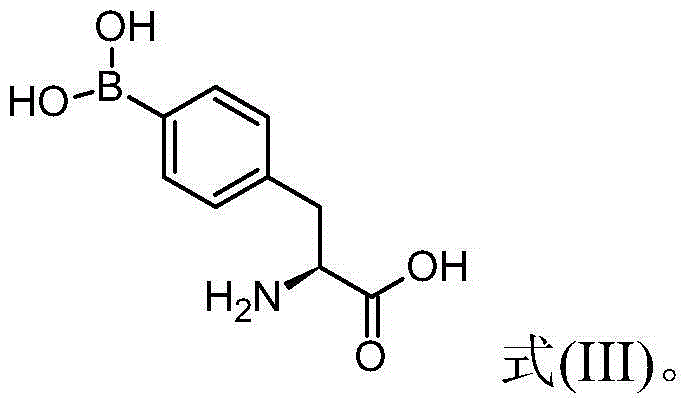

4 - dihydroxy boryl - l-phenylalanine preparation method

InactiveCN104447823AReduce processHigh chemical purityGroup 3/13 element organic compoundsBulk chemical production4-dihydroxyborylphenylalanineBoriding

The invention provides a 4 - dihydroxy boryl - L-phenylalanine preparation method which is as follows: reacting amino terminal-protected (S) - 4 -halogeno phenylalanine shown as the formula (I) with a boriding agent and an organic lithium compound to obtain a reaction mixture containing amino terminal-protected (S) - 4 - dihydroxy boryl phenylalanine shown as the formula (II) with R being a protective group; separating the reaction mixture to obtain the amino terminal-protected (S) - 4 - dihydroxy boryl phenylalanine; and de-protecting the amino terminal-protected (S) - 4 - dihydroxy boryl phenylalanine to obtain 4 - dihydroxy boryl - L-phenylalanine.

Owner:TAIWAN BIOTECH

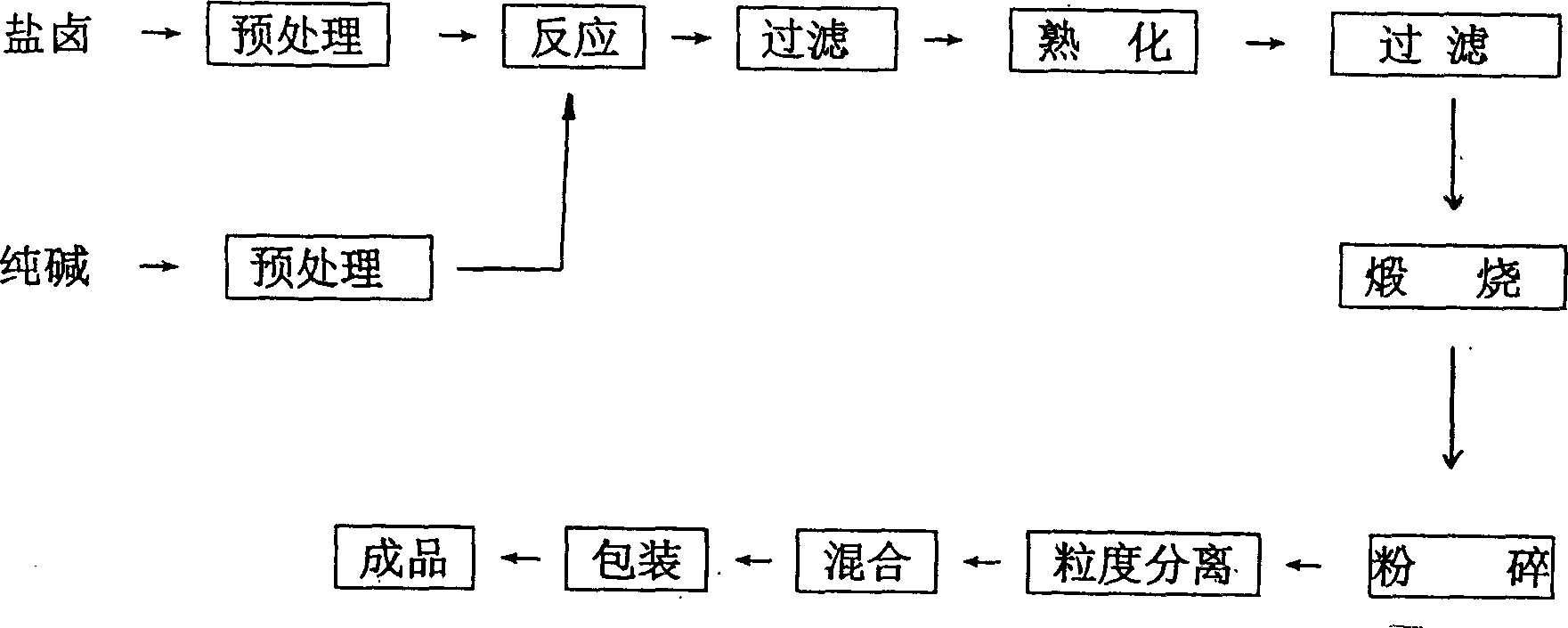

Prepn process of magnesia for silicon steel

The present invention relates to preparation process of magnesium compound, and is especially preparation process of magnesia for silicon steel. The present invention produces silicon steel level magnesia through a bittern-sodium carbonate process, which includes reaction of refined magnesium chloride solution and refined sodium carbonate solution at 65-85 deg.c for 5-15 min to produce basic magnesium carbonate, curing, filtering and calcining at 1100+ / -50 deg.c for 2.0+ / -0.5 hr. Thus produced silicon steel level magnesia has high purity, small average grain size, good coating performance, high adhesivity and other features, and the preparation process is simple and low in cost.

Owner:山西银海锋源新材料有限公司

Radiation crosslinked polyethylene pipe and its preparation method

ActiveCN1670068AImprove chemical purityImprove pipe extrusion efficiencyTubular articlesCross-linkPolymer science

The invention relates to a radiation crosslinked polyethylene tube, which has a stereoscopic netted cross-linking molecular structure, and the process comprises: extruding the mixture in a finite proportion of polyvinyl resin, anti-oxidizing agents and stearic acid salt lubricating agents as raw materials in the temperature of less than 235 Deg. C to get the tubes by a tube extruder, then radiating by electron-beams to get the product. The components of the said raw materials is with a proportion of polyvinyl resin of 98.5-99.0 wt%, anti-oxidizing agents of 0.1-0.6 wt% and stearic acid salt lubricating agents of 0.5-1.0 wt%, and the degree of molecular crosslinking in the inner of the said tubes is more than 60 %.

Owner:FSPG HI TECH

Method for hydrolyzing chitosan and chitin

InactiveCN101723989ALow costFast hydrolysisSugar derivativesOligosaccharidesChitin formationReaction speed

The invention relates to a method for hydrolyzing chitosan and chitin to prepare monosaccharide and oligosaccharide by using ionic liquid as a reaction medium and using protonic acid as a catalyst under the condition of heating. Particularly, the method comprises the following steps: dissolving the chitosan or the chitin into the ionic liquid, adding acid and water into the solution, and heating the solution to perform reaction so as to obtain a hydrolysis product of which the yield reaches up to 70 percent based on total reducing sugar. The method has the advantages of mild operation condition, high reaction speed, reusability of the ionic liquid, low cost, simple process, environmental friendliness and the like, provides a new method for efficiently degrading the chitosan and the chitin, and develops a new path for preparing general oceanic chemicals and medicinal health-care products in large scale.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

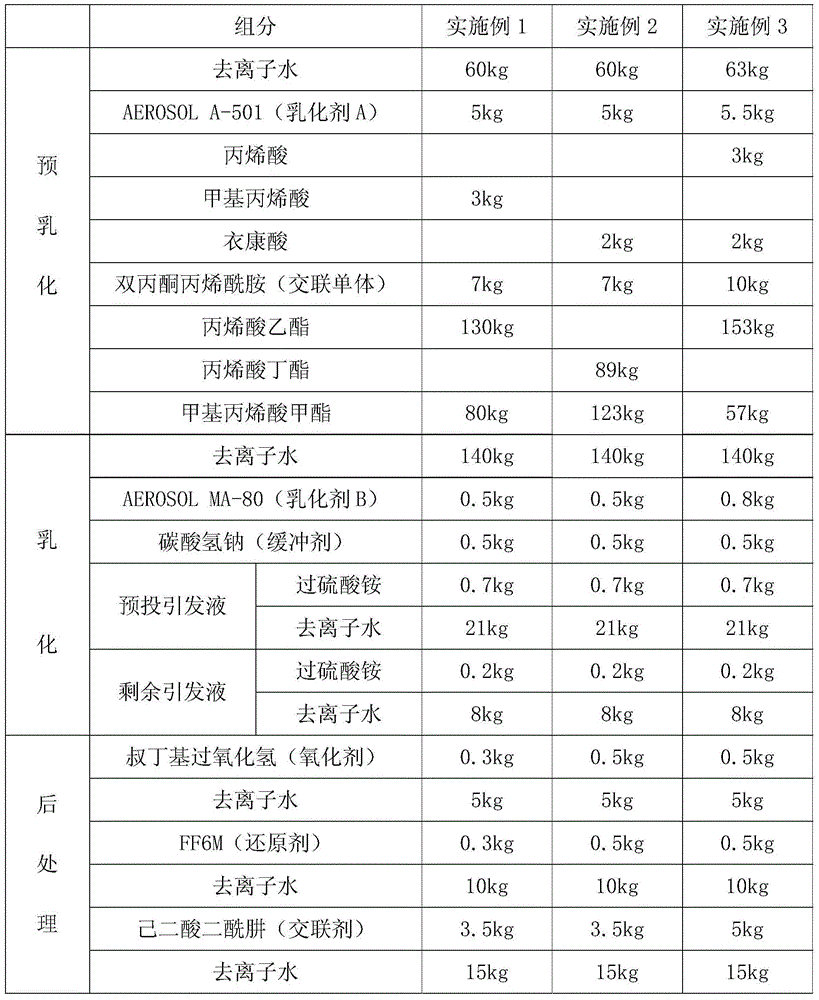

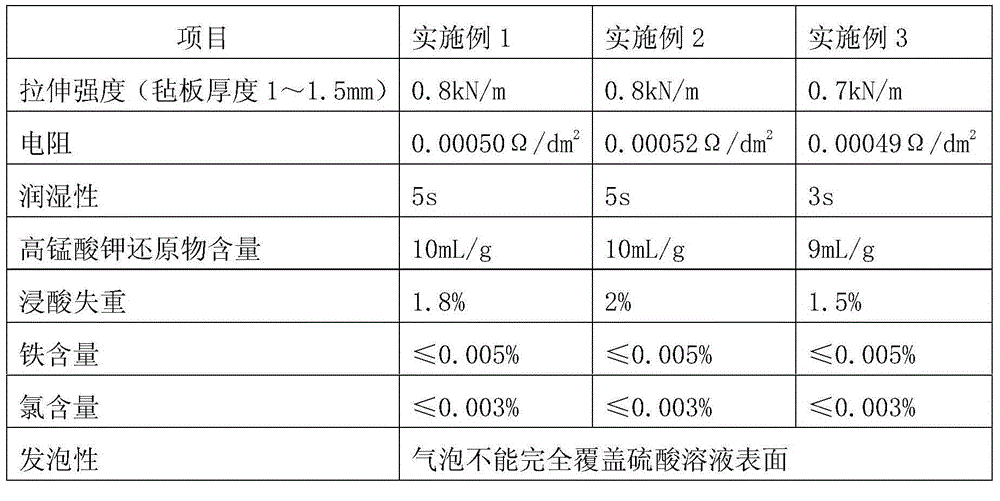

Self-crosslinking acrylate emulsion and preparation method thereof

ActiveCN103554349AImprove performanceIncrease surface areaEster polymer adhesivesFunctional monomerPotassium

The invention discloses self-crosslinking acrylate emulsion and a preparation method thereof. The self-crosslinking acrylate emulsion is prepared from (methyl) acrylate monomer, a functional monomer, a crosslinking monomer, a crosslinking agent, an emulsifying agent A, an emulsifying agent B, a buffering agent, an initiator, an oxidizer, a reducer and deionized water, wherein the reducer is an FF6M macromolecule polymerization novel reducer produced by a Bruegmann company in Germany, the emulsifying agent A is an emulsifying agent AEROSOL A-501 produced by a Cytel company in America, and the emulsifying agent B is an emulsifying agent AEROSOL MA-80 produced by the Cytel company in America; the preparation method of the self-crosslinking acrylate emulsion comprises pre-emulsification, emulsification and post treatment. A superfine glass fiber separating plate made by adopting the self-crosslinking acrylate emulsion is low in potassium hypermanganate reduzate content, high in liquid absorption speed, high in amount of absorbed liquid and excellent in performance.

Owner:CHANGZHOU TIANMA GROUP CO LTD

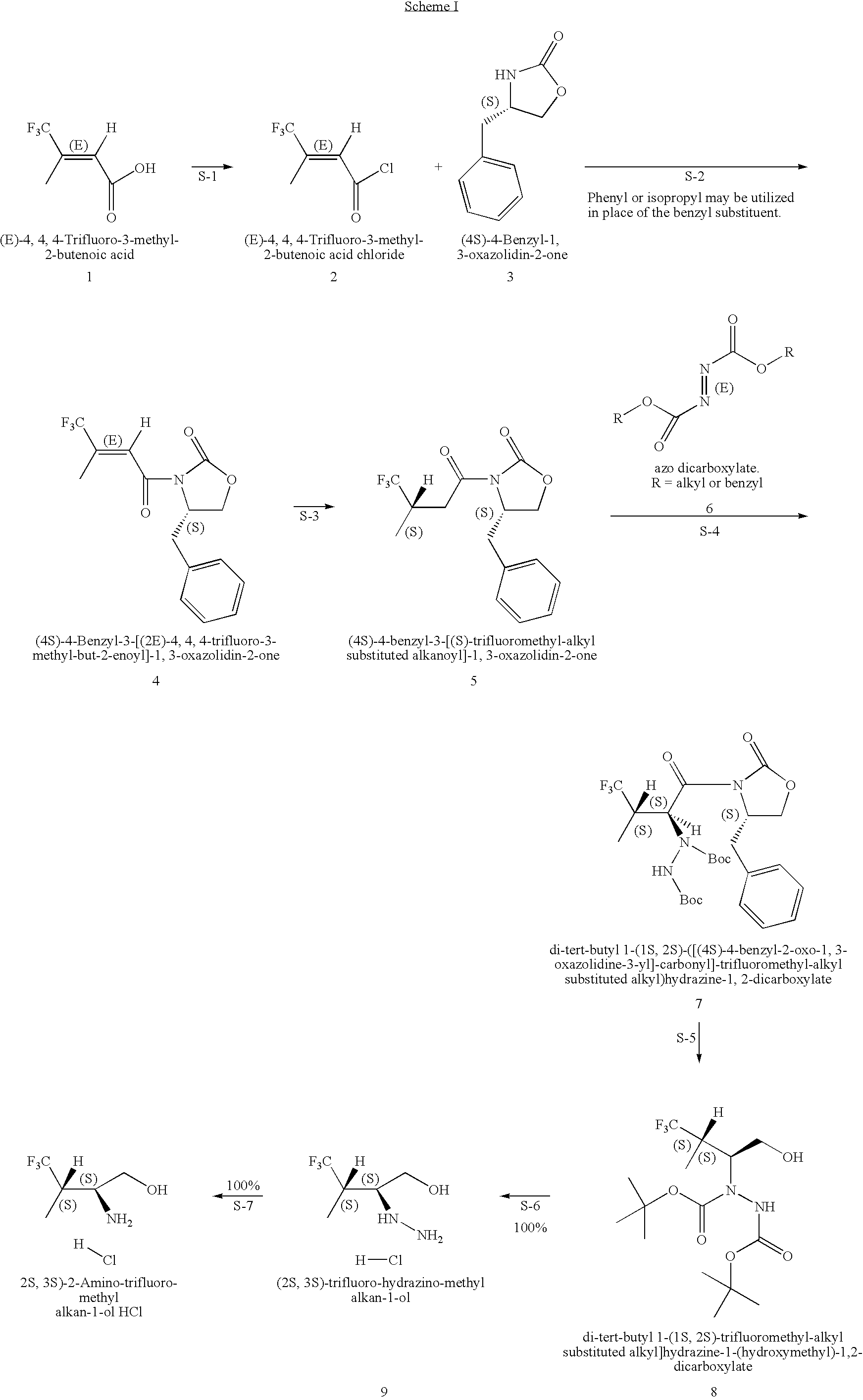

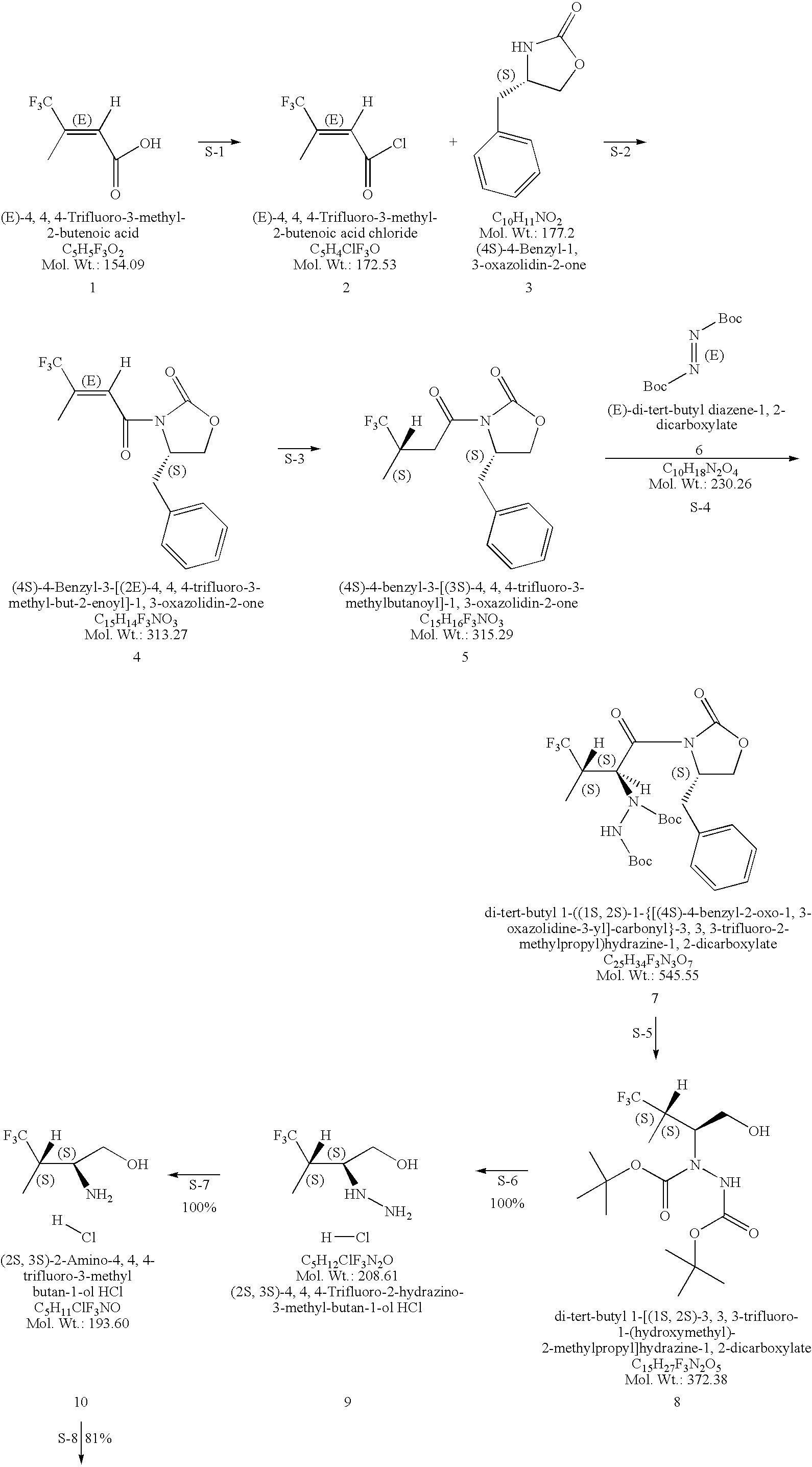

Production of chirally pure amino alcohol intermediates, derivatives thereof, and uses thereof

InactiveUS20070249869A1High chiral purityHigh chemical purityOrganic compound preparationOrganic chemistry methodsArylAlcohol

A method of selectively preparing a chiral 2S-amino alcohol useful in preparation of an amide sulfonated or acylated with alkyl, substituted aryl or substituted heteroaryl is described. The method involves reacting a di-tert-butyl diazene-1,2-dicarboxylate with a (4S)-4-benzyl-3-[(S)-trifluoromethyl-alkyl substituted alkanoyl]-1,3-oxazolidin-2-one to afford a di-tert-butyl 1-(1S,2S)-([(4S)-4-benzyl-2-oxo-1,3-oxazolidine-3-yl]-carbonyl}-trifluoromethyl-alkyl substituted alkyl)hydrazine-1,2-dicarboxylate. This dicarboxylate is then reduced to yield di-tert-butyl 1-(1S,2S)-[trifluoromethyl-alkyl substituted alkyl]hydrazine-1-(hydroxymethyl)-1,2-dicarboxylate. The resulting product is deblocked with an acid to yield the acid addition salt of (2S,3S)-trifluoro-hydrazino-methyl alkan-1-ol. The acid addition salt of (2S,3S)-trifluor-2-hydrazino-methyl alkan-1-ol is hydrogenated in the presence of a suitable metal catalyst to yield the amino alcohol (2S,3S)-2-amino-trifluoro-methyl alkan-1-ol HCl.

Owner:WYETH LLC

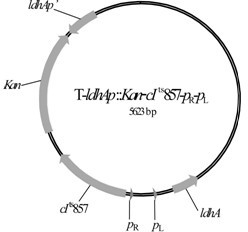

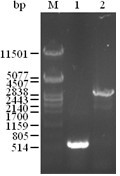

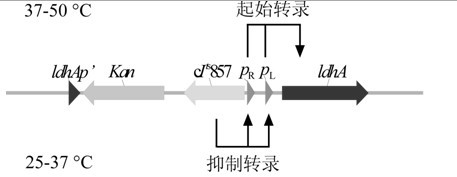

Strain producing dynamic controlling recombinant strain and method for preparing D-lactic acid with recombinant strain

ActiveCN102618478AHigh optical purityHigh yield and high optical purityBacteriaMicroorganism based processesBiotechnologyEscherichia coli

A Strain producing dynamic controlling recombinant strain and a method for preparing D-lactic acid with the recombinant strain belong to the technical field of genetically engineered agricultural microorganisms. The recombinant strain is named (Escherichia coli)B0013-070B, and is preserved in the China center for type culture collection, and the preservation number is CCTCCNO:M2012071. A lactate dehydrogenase gene promoter ldhAp in the genome of the strain is replaced with a culture environment / nutritional factors control-type promoter. Through the utilization of the recombinant strain, fermentation is conducted for 28 to 40 hours in stages at 25 to 50 DEG C, and the level of producing D-lactic acid reaches 12.5%; the optical purity lives up to 99.9%; and the chemical purity reaches to 98.4%. The dynamic controlling to the D-lactic acid dehydrogenase encoding gene expression on D-lactic acid high-producing strain B0013-070 chromosomes is conducted, so that the gene expression is controlled only through changing the fermentation temperature during the D-lactic acid production process to achieve the purpose of efficiently synthesizing D-lactic acid through taking glucose as a raw material. After simple modification, the invention can be used for producing important microbial metabolites in other industries.

Owner:SHANDONG BAISHENG BIOTECH

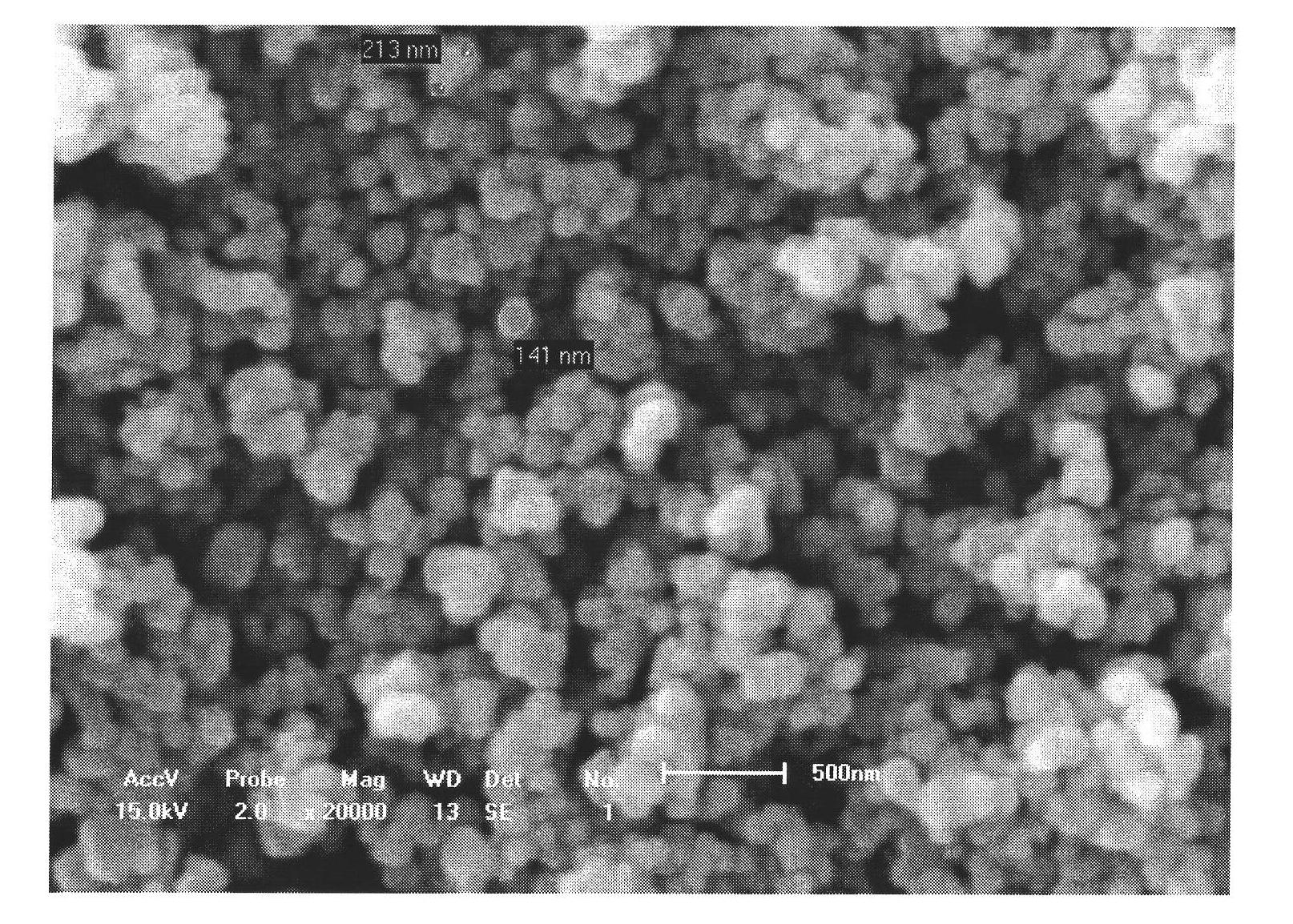

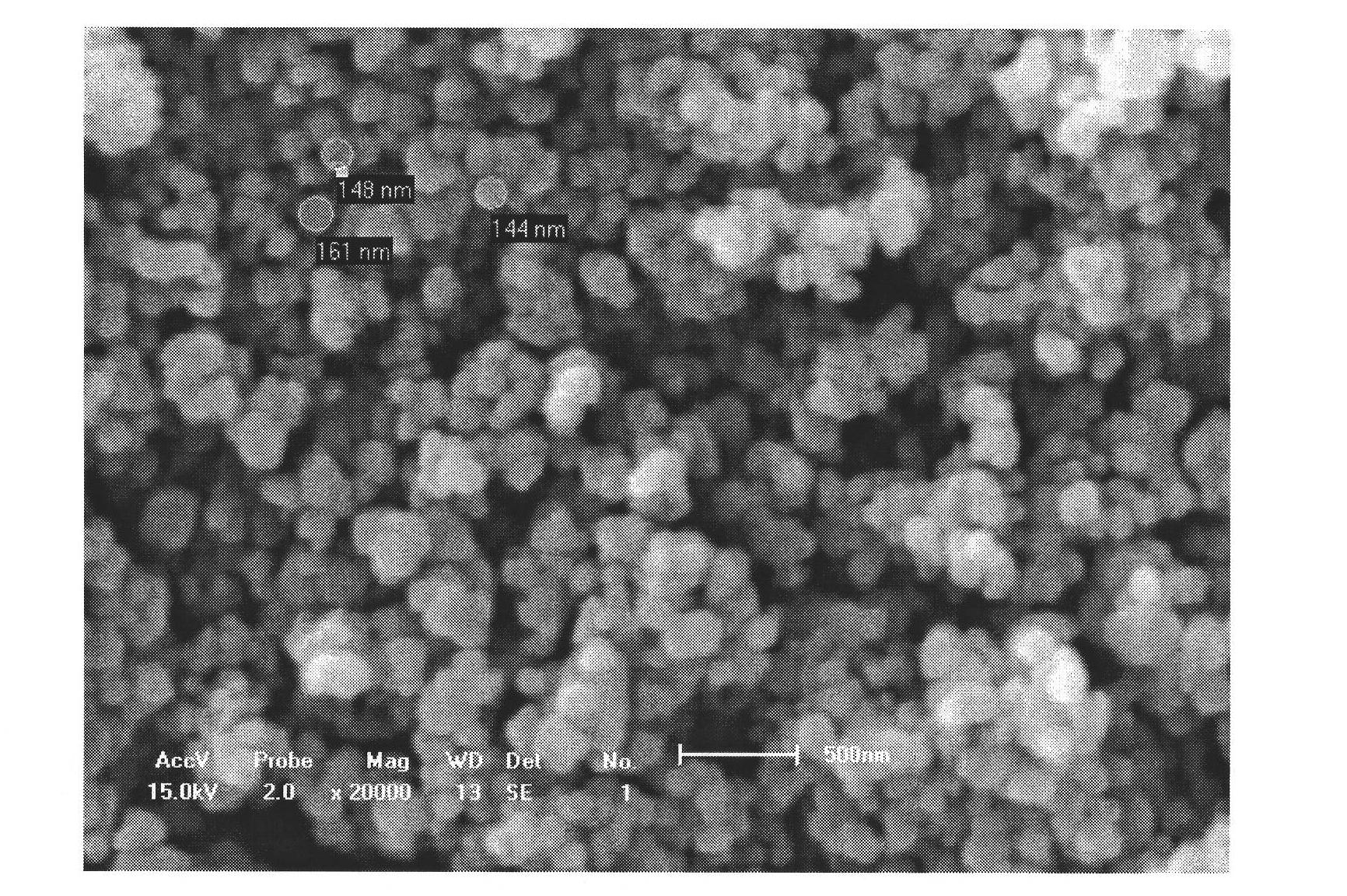

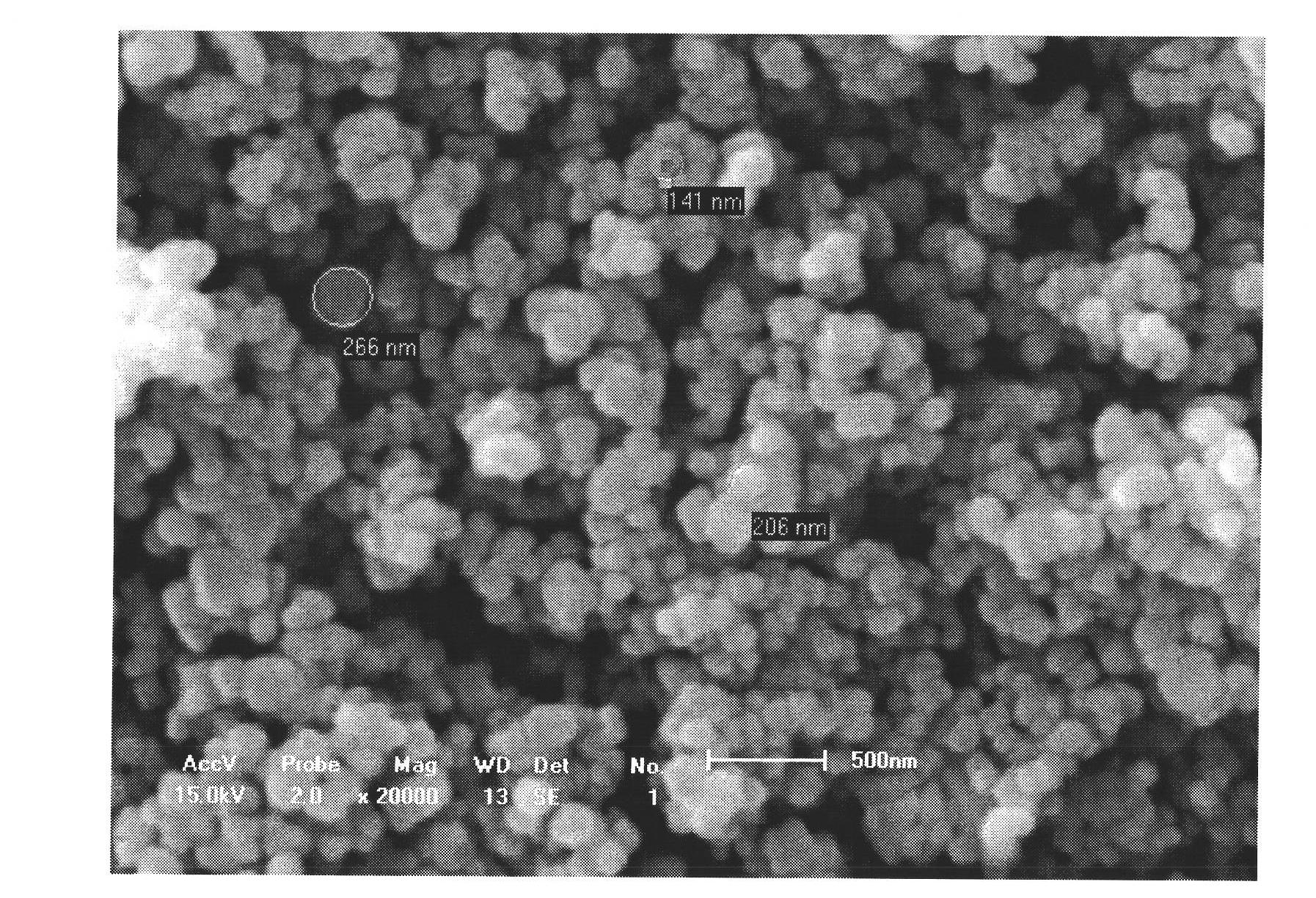

Preparation method of nano cobalt oxide

InactiveCN101982421AHigh densityHigh chemical purityNanostructure manufactureChemical industryForeign matterReaction temperature

The invention provides a preparation method of nano cobalt oxide, comprising the following steps: respectively preparing a cobalt raw material and precipitant into cobalt solution and precipitant solution by deionized water; adding the prepared cobalt solution with a certain concentration and the prepared precipitant solution with a certain concentration in accordance with a certain mole ratio toa reactor by using a parallel flow feed method; controlling the reaction temperature, the feed rate, the pH value and the stirring speed to prepare cobalt salt precursor; directly filling a water-containing filter cake into a bowl after washing and dehydrating; controlling the grain size and the crystal morphology through low-temperature dehydration, phase change calcination, mechanical pulverization and graded activation; and finally removing magnetic metallic foreign matters to obtain the nano cobalt oxide with high quality. The method is simple and easy to operate, has low cost, saves energy, is environmental friendly, and is applicable to industrial production; and the prepared cobalt oxide grains are fine and evenly distributed.

Owner:JIANGSU DONGXIN ENERGY TECH

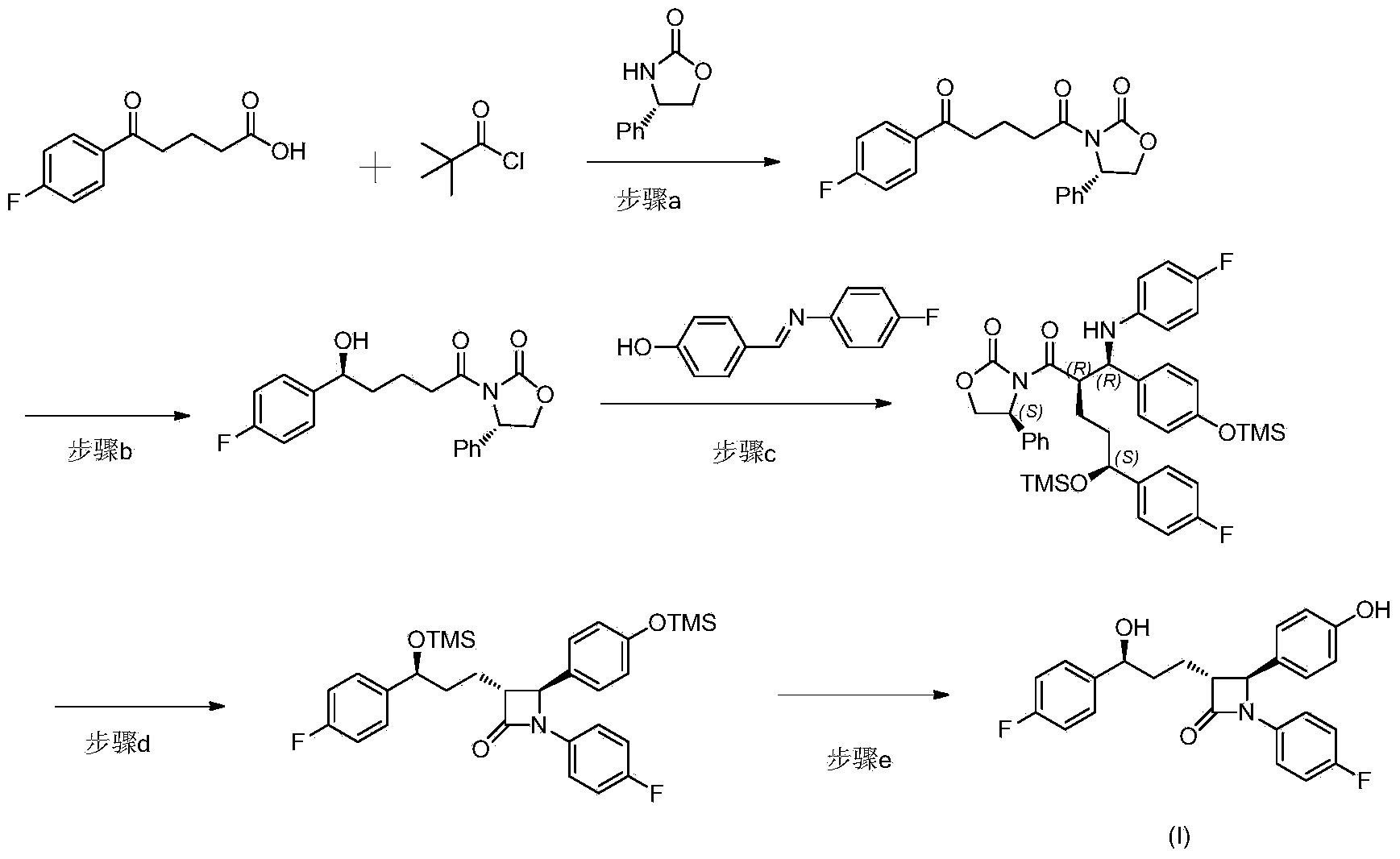

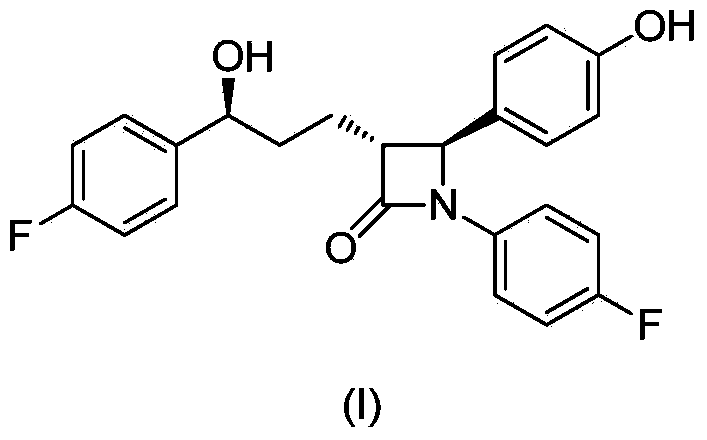

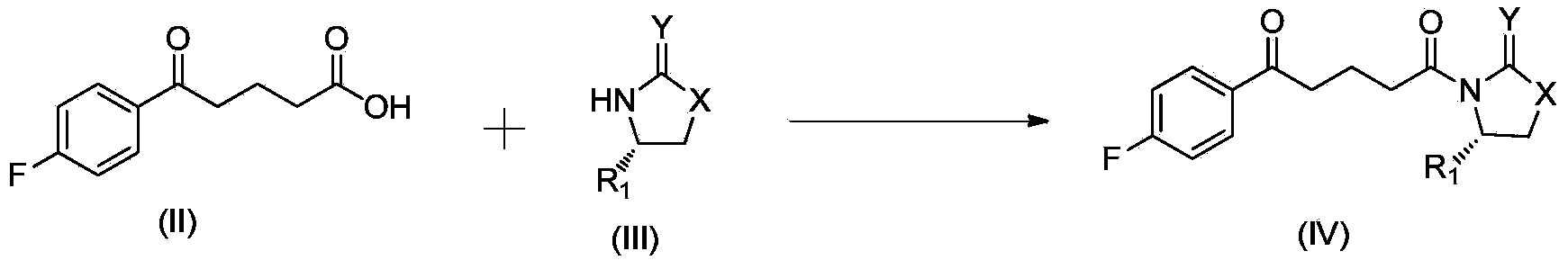

Stereselective synthesis method for lipid-lowering drug ezetimibe

ActiveCN103965089AHigh chemical purityHigh optical purityOrganic chemistryBulk chemical productionLipid lowering drugSynthesis methods

The invention provides a stereselective synthesis method for a lipid-lowering drug ezetimibe shown in formula I. The method comprises the following steps: a, P-fluorobenzoyl butyric acid shown in formula II reacts with a chiral auxiliary shown in formula III to obtain ketone shown in formula IV; b, under the existence of a chiral catalyst, the ketone shown in formula IV is reduced to chiral alcohol shown in formula V; c, chiral alcohol shown in formula V reacts with a silicyl protective agent to obtain a protected compound shown in formula VI, and then the compound shown in formula VI and imine shown in formula VII are subjected to addition and protecting groups are removed, so that a compound shown in formula VIII and a diastereomer thereof shown in formula IX are obtained, and through recrystallization with an appropriate solvent, an optically pure compound shown in formula VIII is obtained; d, the compound shown in formula VIII is protected with an acylation reagent, so that a compound shown in formula X is obtained, and amide shown in formula X is cyclized with a fluorinion catalyst, so that protected lactam shown in formula XI is obtained; then protecting groups are removed, and the ezetimibe shown in formula I is obtained.

Owner:SHANGHAI FANGNAN PHARMA

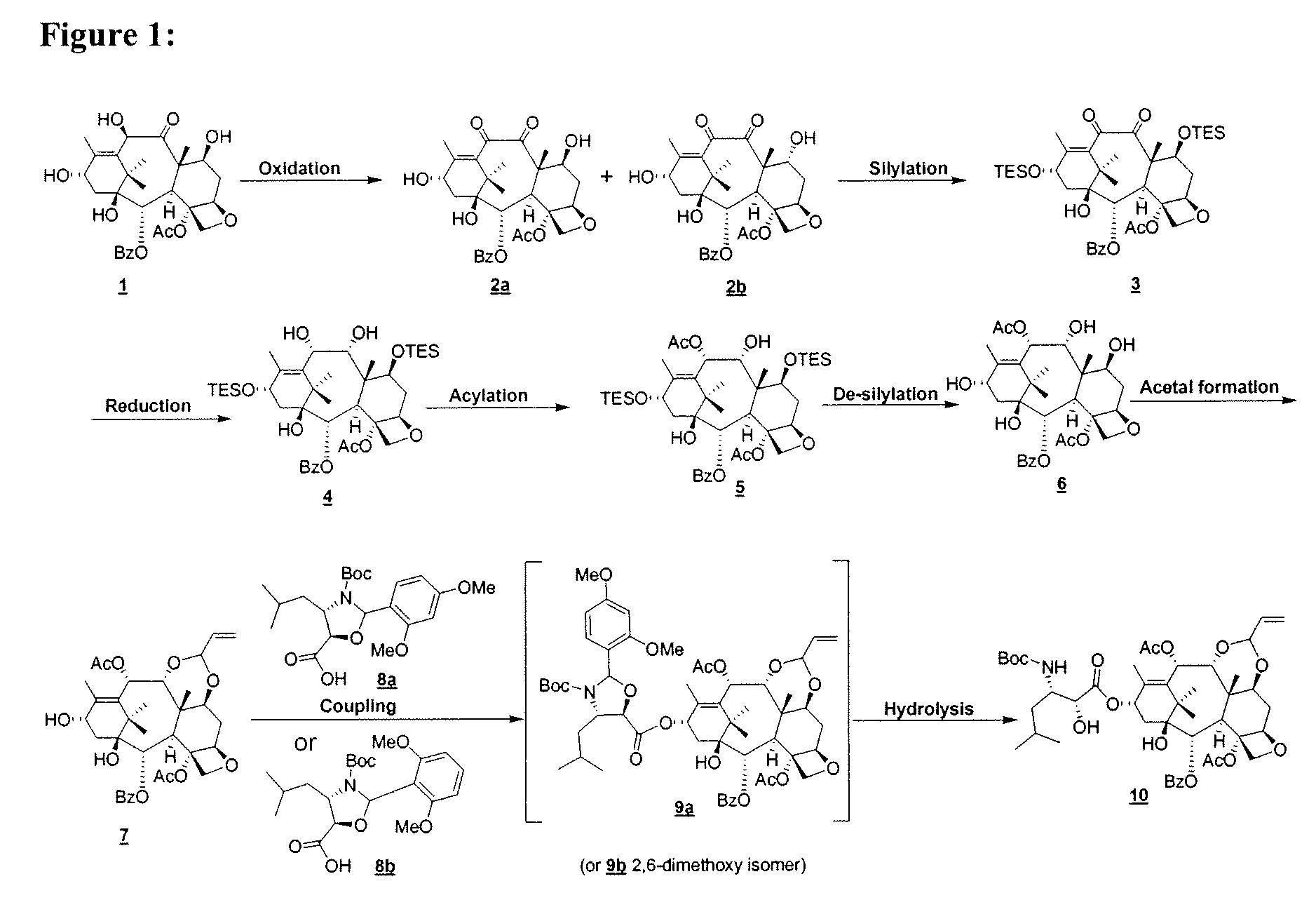

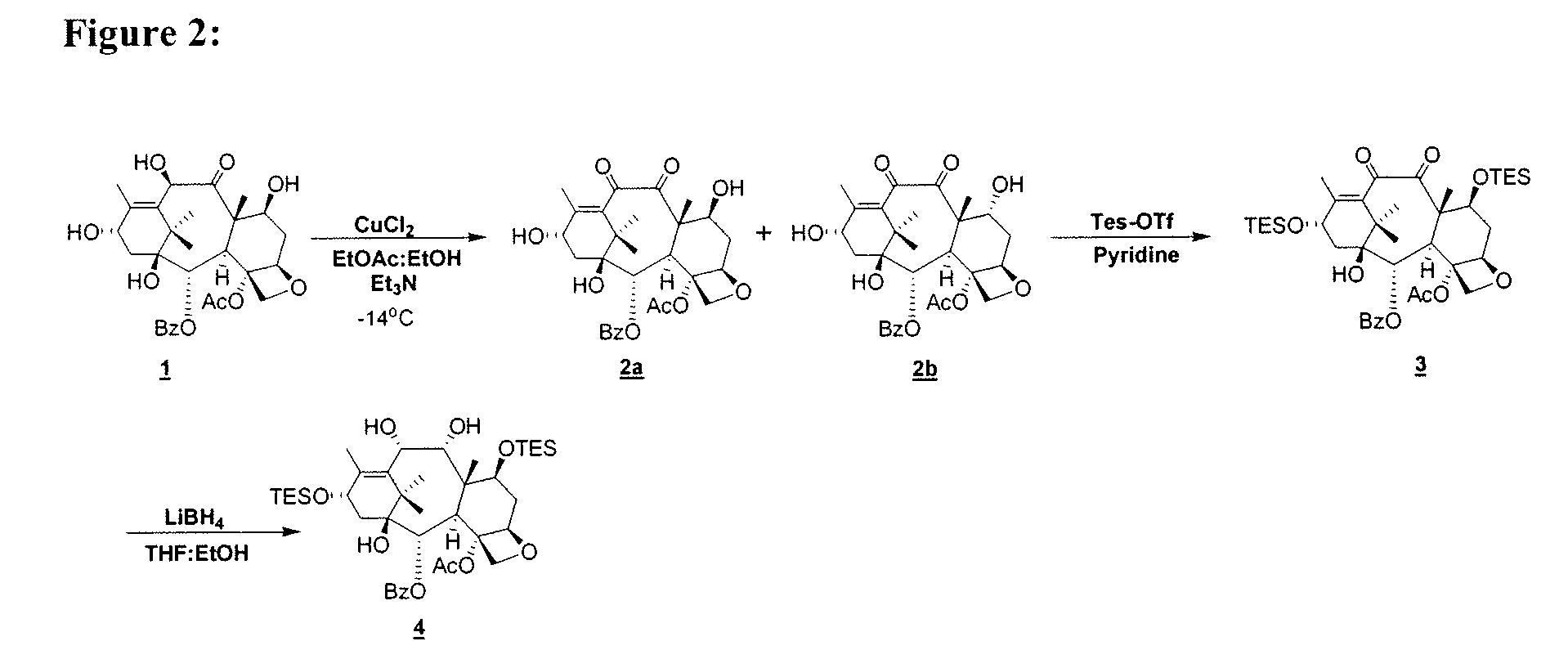

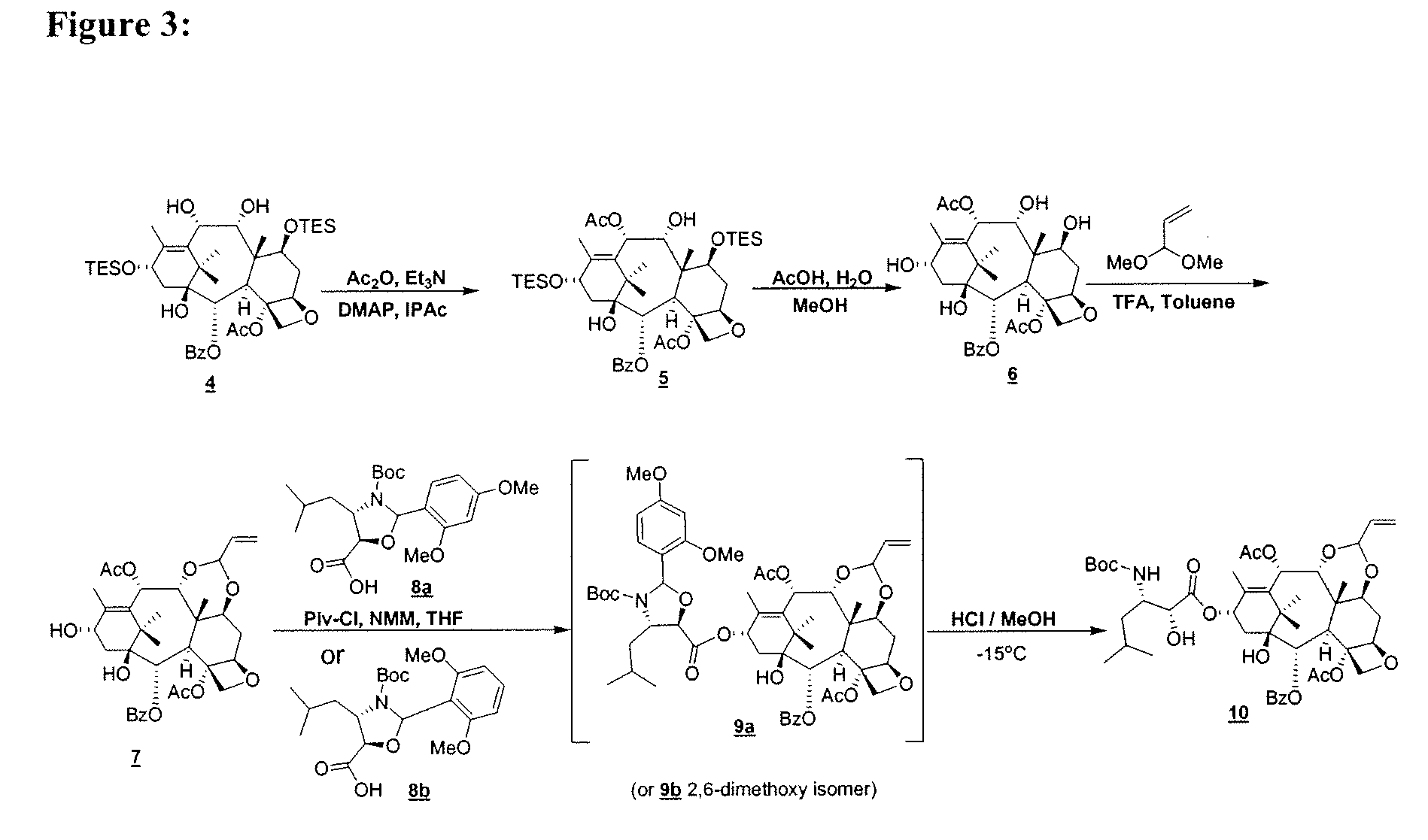

Convergent Process for the Synthesis of Taxane Derivatives

InactiveUS20070225510A1High yieldHigh chemical purityOrganic chemistryAntineoplastic agentsMedicinal chemistryTaxane derivative

Owner:TAPESTRY PHARMACEUTICALS INC

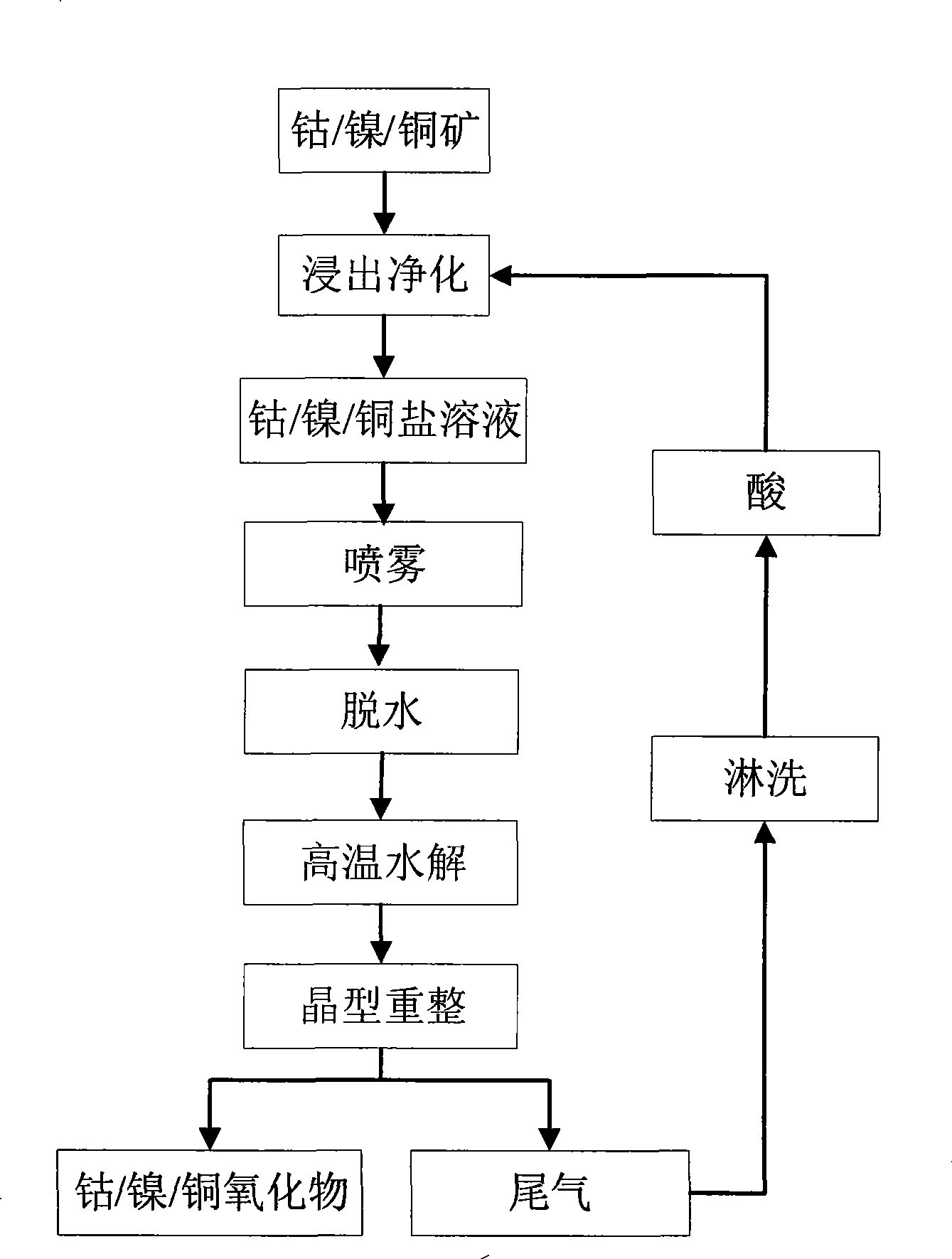

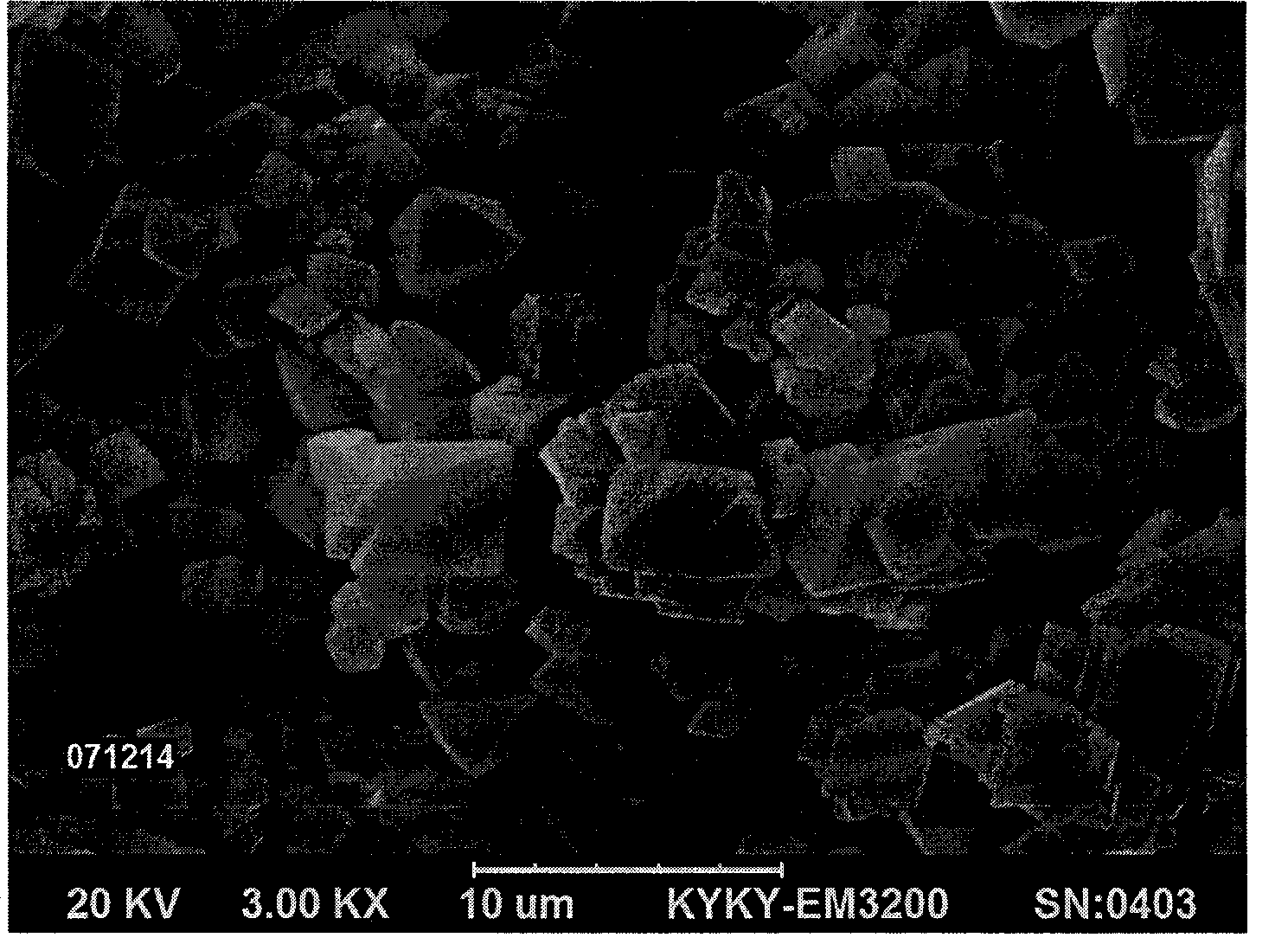

Novel methods for preparing cobalt oxide, nickel oxide and copper oxide

ActiveCN101367555AImprove liquidityUniform particle sizeCopper oxides/halidesNickel oxides/hydroxidesCopper oxideHydrolysis

The invention relates to a method for preparing cobalt oxide, nickel oxide and copper oxide, in particular relates to a method for preparing the oxide of the cobalt (Co3O4, Co2O3), the oxide of the nickel (NiO), the oxide of the copper (CuO), and the like. The minerals containing the cobalt, the nickel or the copper are adopted as the raw material; after the minerals is dipped and purified to get high-purity cobalt salt, nickel salt or copper salt solution; the salt solution is made into the mist-shaped liquid drop in the mist spraying way; the cobalt oxide, the nickel oxide or the copper oxide can be prepared through the dehydration, high-temperature hydrolysis and the crystal-shape re-shaping; the tail gases such as the vapor and the acid gases that are generated in the hydrolysis process are absorbed by a leaching tower to get the acid, and the acid is returned to be used for the dipping and purification process of the minerals, thereby realizing the comprehensive cycling application in the preparation process. The method can also be used for processing the waste material containing the cobalt, the nickel or the copper. The invention has the advantages of advanced process, stable production, low cost, no waste water discharging, environmental protection, high purity of the product, uniform granularity, high crystallization, and the like.

Owner:ZHEJIANG HUAYOU COBALT

Preparation method of high-temperature-resistant boehmite

ActiveCN105836770AImprove conversion rateHigh chemical purityAluminium oxides/hydroxidesElectro conductivityHigh pressure

The invention discloses a preparation method of high-temperature-resistant boehmite. The preparation method includes the steps of: slurrying an aluminum compound with water with addition of a crystal seeding agent and a washing additive, uniformly mixing the components and feeding the mixture into a high-pressure kettle, controlling the temperature increasing rate at 1-3 DEG C / min, and performing a reaction at 150-250 DEG C for 2-6 h, decreasing the temperature, and separating, washing and drying a product to obtain the high-temperature-resistant boehmite. The preparation method is simple and has high yield and low production cost. The boehmite is high in conversion rate, has concentrated particle distribution, is more than 350 DEG C in 1% dehydration temperature, has high chemical purity and is not more than 25 [mu]S / cm in electric conductivity.

Owner:中铝山东有限公司

Multipurpose polyester film and preparation method thereof

The invention relates to a multipurpose polyester film and a preparation method thereof. The preparation method adopts a biaxial orientation technique and comprises the following steps: 1. preparation of functional assistants; 2. precrystallization and drying; 3. melt extrusion: the precrystallized and dried PET (polyethylene terephthalate) slices and the functional assistants are heated and molten by an extruder, and the melt is uniformly delivered to a die head for slab casting under the push of extrusion pressure; 4. slab casting: the uniform and stable melt from the extrusion system runs on rotating quenching rollers through the die head to form an amorphous slab; 5. longitudinal stretching and lateral stretching: the cast slab is subjected to longitudinal stretching after entering a longitudinal stretching machine, and subjected to lateral stretching after entering a lateral stretching machine; and 7. pulling, slicing, corona treatment, rolling and inspection. The method has wide application range, such as environment-friendly films, twist wrap films, high-brightness films, insulation films, capacitive films, car protecting films, bronzing films, aluminizing films and composite packaging films.

Owner:福建百宏高新材料实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com