Preparation method of nano cobalt oxide

A nano-cobalt oxide and cobalt salt technology, applied in nanostructure manufacturing, cobalt oxide/cobalt hydroxide, nanotechnology and other directions, can solve the problems of coarse cobalt oxide particle size, unfavorable for industrial production, uneven distribution, etc., and achieve cost Low, significant economic and social benefits, the effect of reducing the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

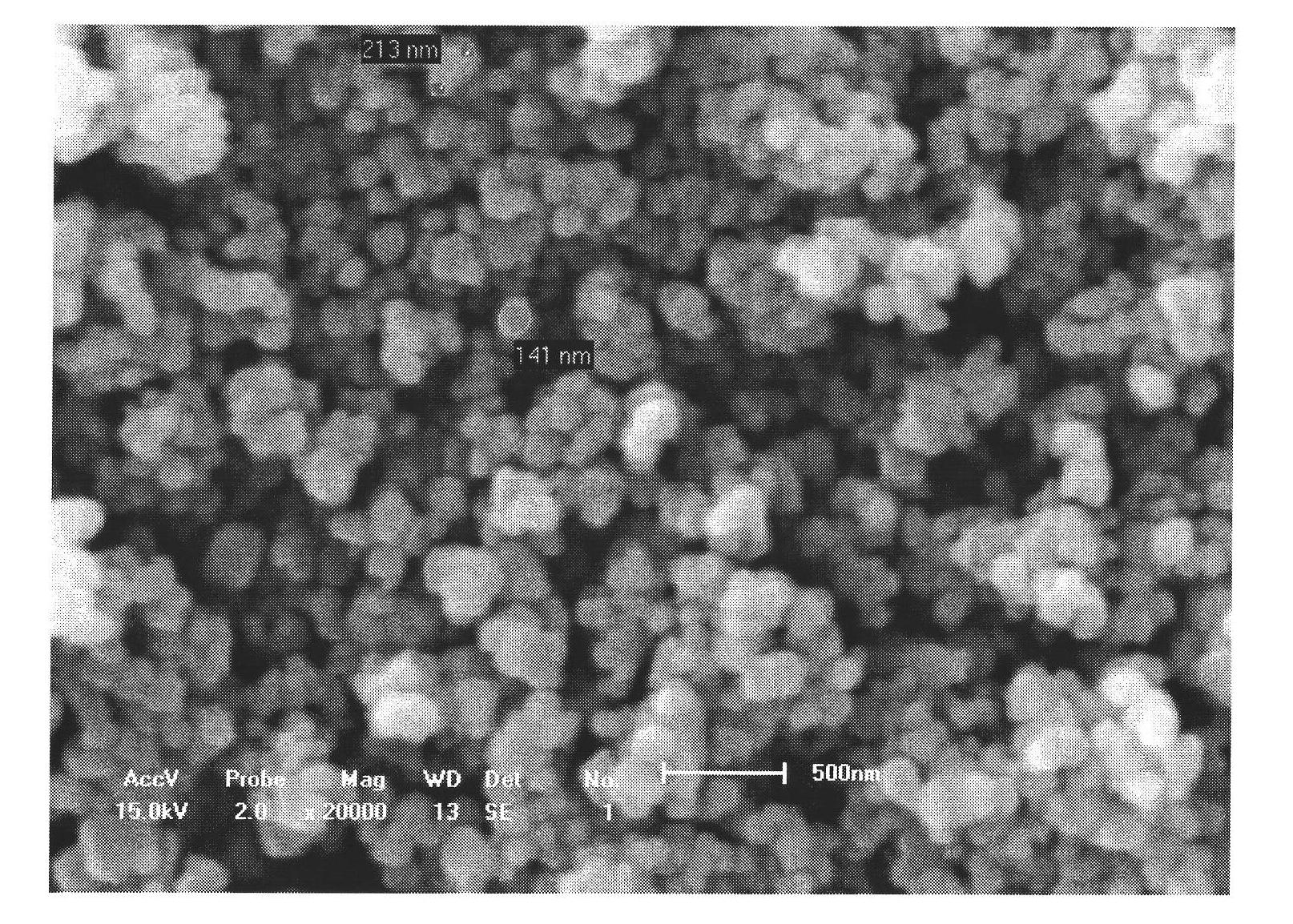

Embodiment 1

[0037] Use deionized water to prepare industrial-grade cobalt nitrate into a solution with a cobalt concentration of 60g / L. 4 HCO 3 Mixed with EDTA to form a saturated solution, the amount is Co:NH 4 HCO 3 :EDTA=1:2.3:0.1 (mole), add into the reaction vessel by co-current feeding method, control the feeding speed to 20ml / min, the synthesis reaction temperature is 60℃, the reaction pH value is 7.0, the stirring speed is 300rpm, the preparation For the precursor, the precursor is washed with 80℃ deionized water and dehydrated. The filter cake has a water content of 25%. It is directly filled into a bowl, placed in a calciner at a temperature of 250℃~600℃, calcined for 8h, crushed and classified to obtain oxidation Cobalt Co content 72.53%, loose density 0.32g / cm 3 , The average particle diameter is 160nm under the microscope of 20000 times. Its SEM image is as figure 1 Shown.

Embodiment 2

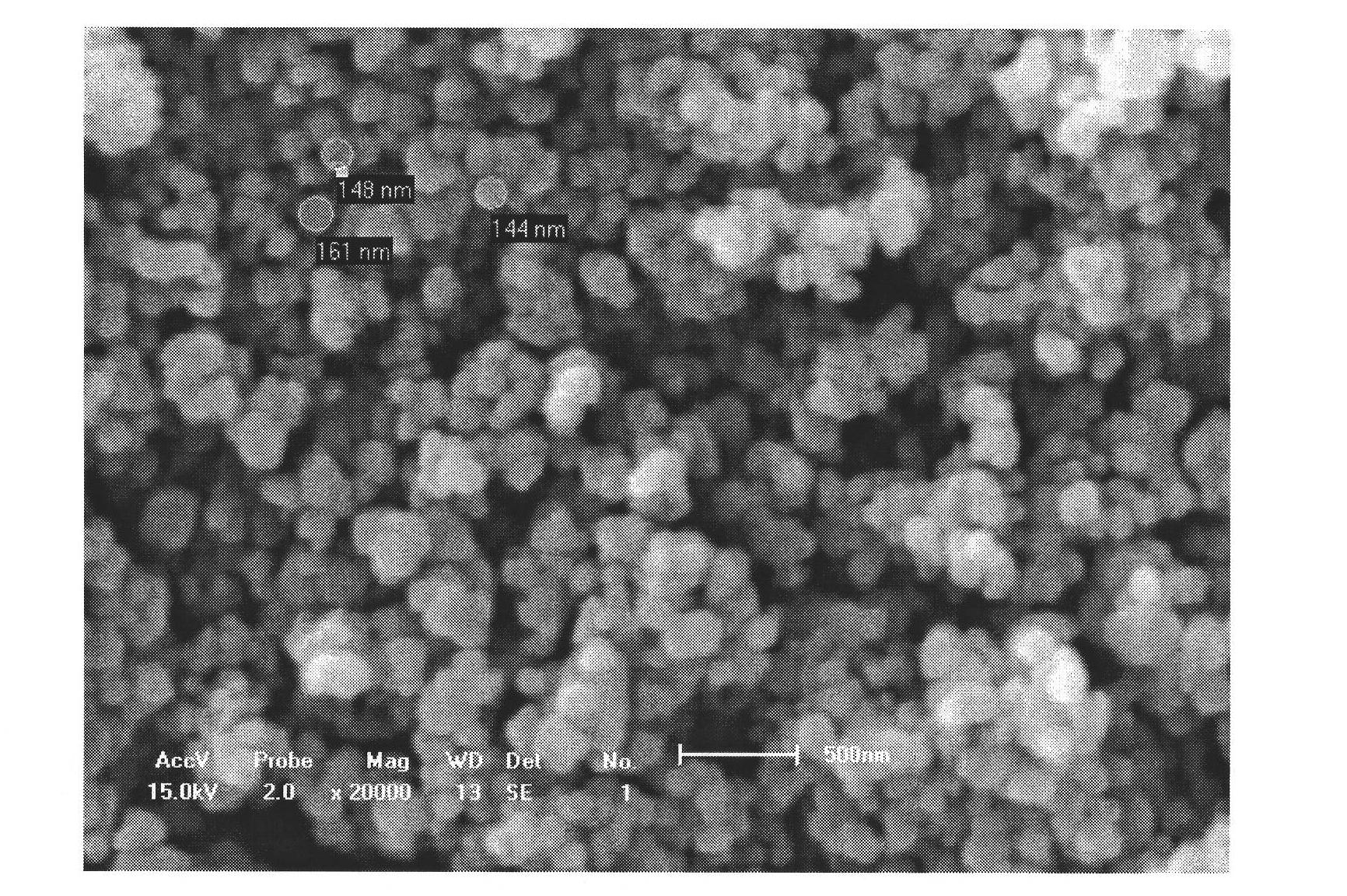

[0039] Use deionized water to prepare industrial-grade cobalt nitrate into a solution with a cobalt concentration of 80g / L. 4 HCO 3 And NH 3 ·H 2 O is made into a saturated solution, the amount is Co:NH 4 HCO 3 : NH 3 ·H 2 O=1:1.2:0.2 (mole), use co-current feeding method to add to the reaction vessel, control the feeding speed to 30ml / min, the synthesis reaction temperature is 70℃, the reaction pH value is 7.0, the stirring speed is 300rpm, the precursor is prepared The precursor is washed with 80°C deionized water and dehydrated. The filter cake has a water content of 25%. It is directly filled into a bowl, placed in a calciner at a temperature of 250°C to 600°C, calcined for 8 hours, crushed and classified to obtain cobalt oxide Co content 71.88%, bulk density 0.45g / cm 3 , The average particle diameter is 152nm under the microscope of 20000 times. Its SEM image is as figure 2 Shown.

Embodiment 3

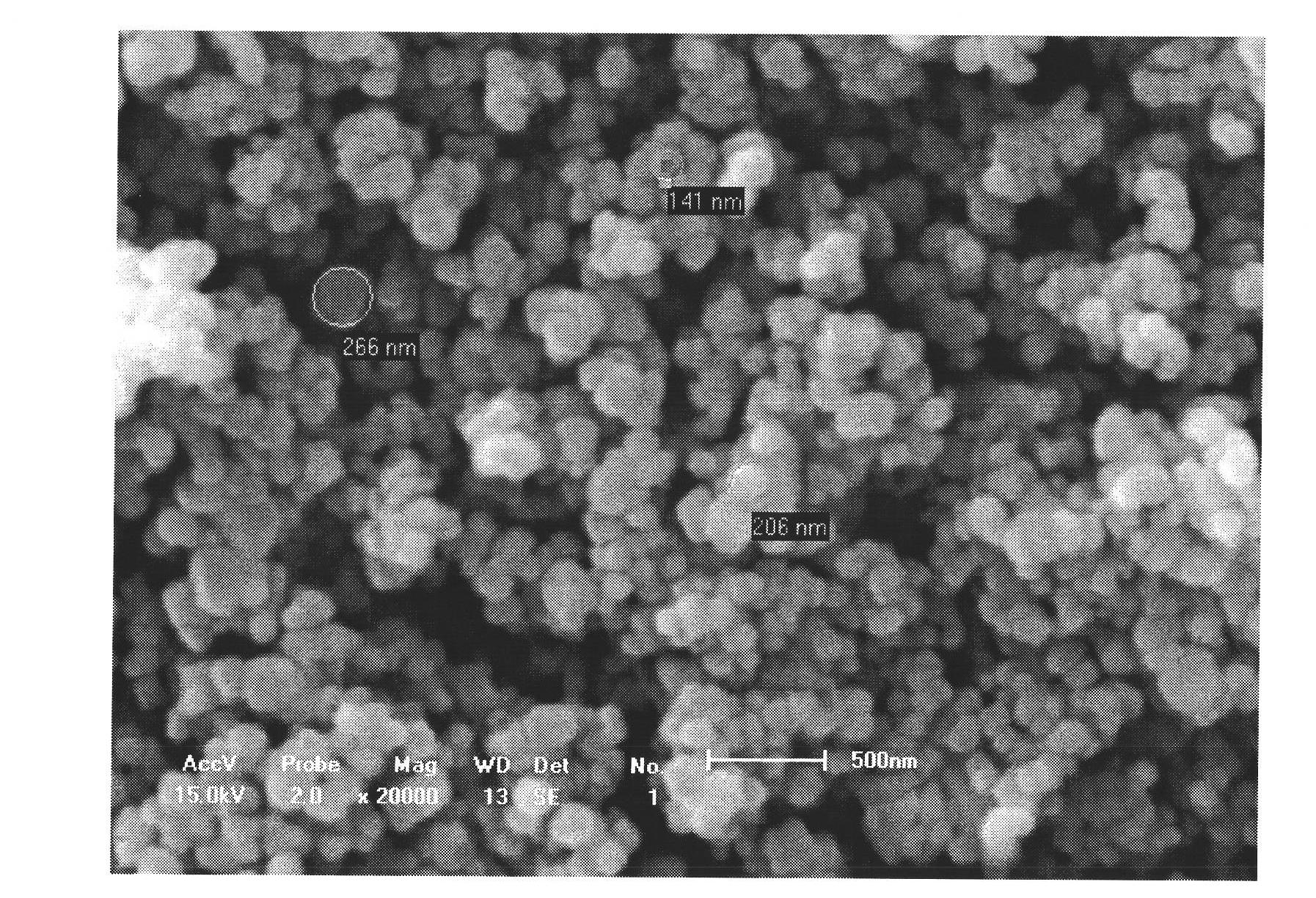

[0041] Use deionized water to prepare industrial-grade cobalt nitrate into a solution with a cobalt concentration of 100g / L. 2 CO 3 Mixed with EDTA to form a saturated solution, the amount is Co:Na 2 CO 3 :OP=1:2.0:0.06 (mole), use co-current feeding method to add to the reaction vessel, control the feeding speed to 16ml / min, the synthesis reaction temperature is 80℃, the reaction pH value is 7.0, and the stirring speed is 300rpm. For the precursor, the precursor is washed with 80℃ deionized water and dehydrated. The filter cake has a water content of 25%. It is directly filled into a bowl, placed in a calciner at a temperature of 250℃~600℃, calcined for 8h, crushed and classified to obtain oxidation Cobalt Co content 72.36%, bulk density 0.38g / cm 3 , The average particle diameter is 183nm under the microscope at 20000 times. Its SEM image is as image 3 Shown.

[0042] Compared with the prior art, the present invention has the following advantages:

[0043] (1) The manufacturing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com