Patents

Literature

290 results about "Crystal morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystal morphology definition, crystal morphology meaning | English dictionary. crystal. a a highly transparent and brilliant type of glass, often used in cut-glass tableware, ornaments, etc. a a crystalline element used in certain electronic devices as a detector, oscillator, transducer, etc.

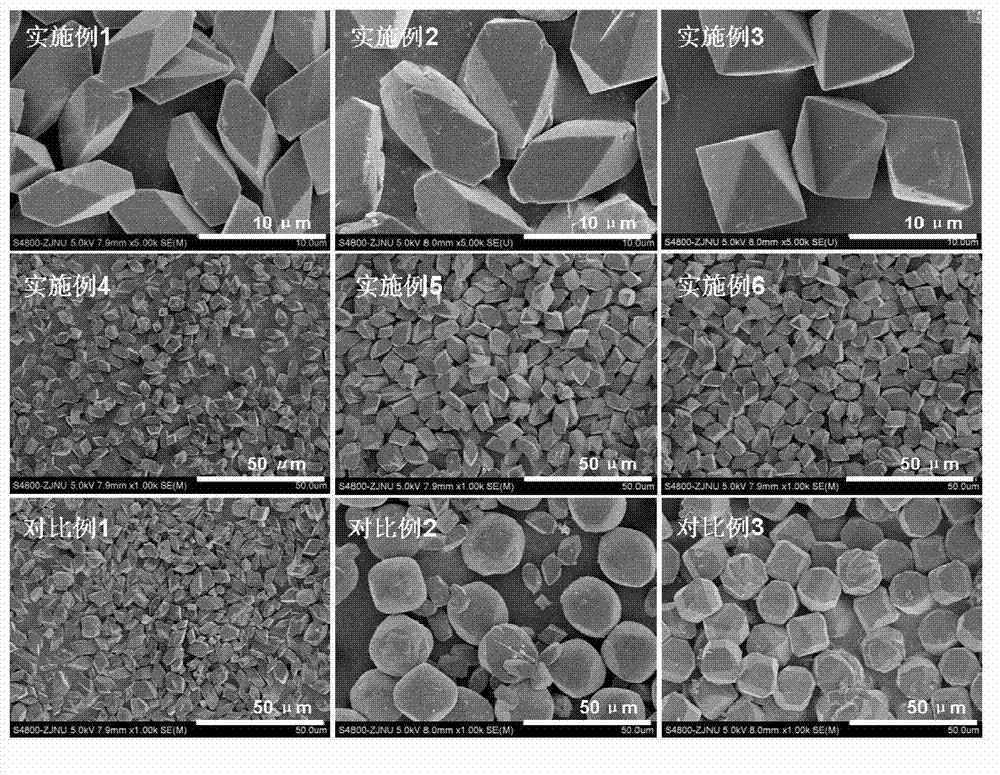

Method for regulating ZIF-8 crystal morphology by utilizing surfactant

InactiveCN107722046ARaw materials are cheap and easy to getLow costOrganic chemistry methodsGroup 2/12 organic compounds without C-metal linkagesCrystal morphologyRhombic dodecahedron

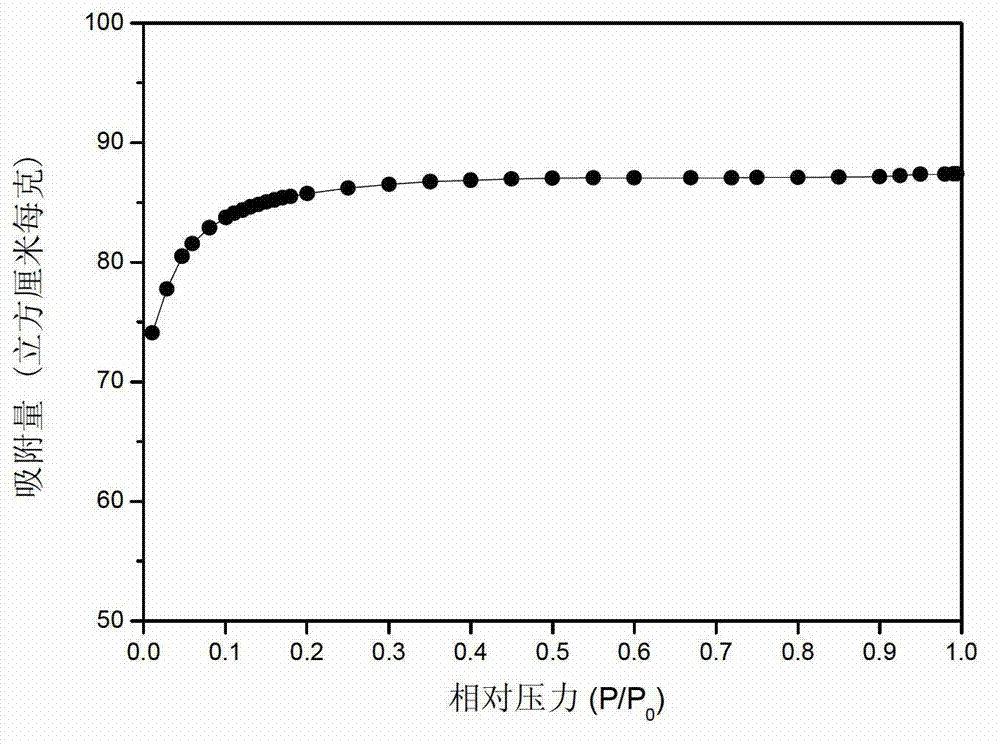

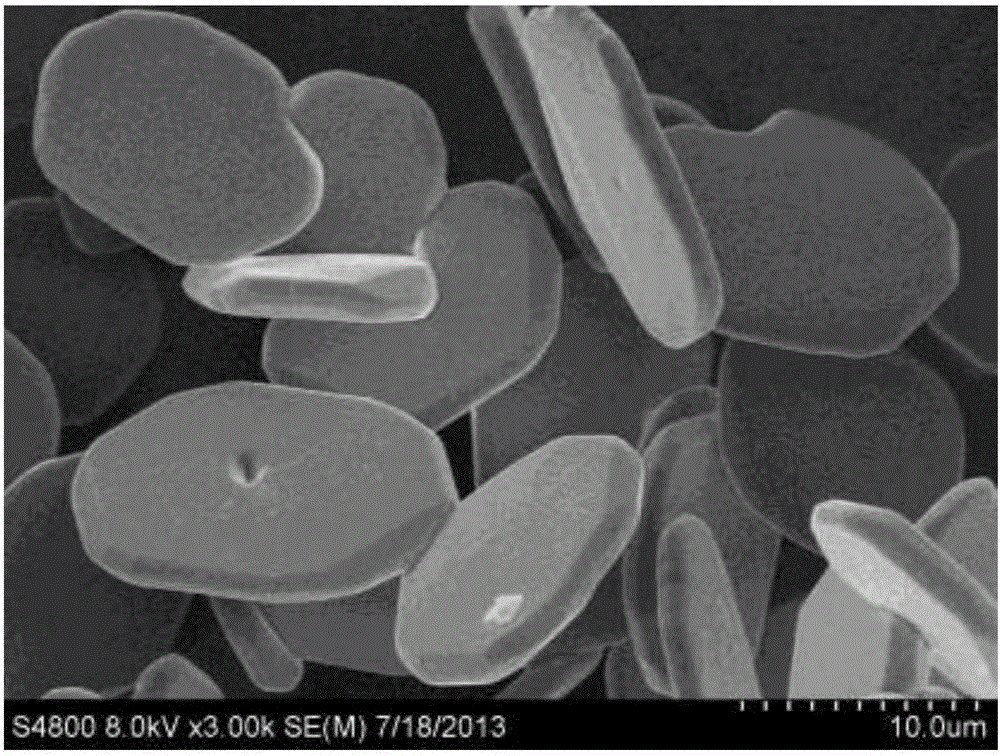

The invention provides a method for regulating ZIF-8 crystal morphology by utilizing a surfactant and belongs to the technical field of synthesis of porous materials. The method disclosed by the invention is mainly characterized in that the morphology and size of the ZIF-8 crystal are controlled by adding a certain amount of a surfactant. The specific preparation method comprises the following steps: respectively dissolving a zinc salt, a surfactant and dimethyl imidazole into a certain amount of water, stirring to enable the components to be fully dissolved, and preparing a solution; mixing adimethyl imidazole solution and a surfactant solution, fully stirring, finally adding a zinc salt solution, and mixing and stirring for 10 minutes; then transferring the mixed solution into a high temperature reactor, and reacting at a constant temperature for several hours; cooling, centrifuging, washing and drying, thereby obtaining the ZIF-8 crystal. The ZIF-8 crystal prepared by the method has excellent crystallinity and has five morphologies such as rhombic dodecahedron, cube, sheet, interpenetration twin and rod. The invention provides a novel method for controlling the morphology and size of MOFs materials.

Owner:NANJING UNIV OF TECH

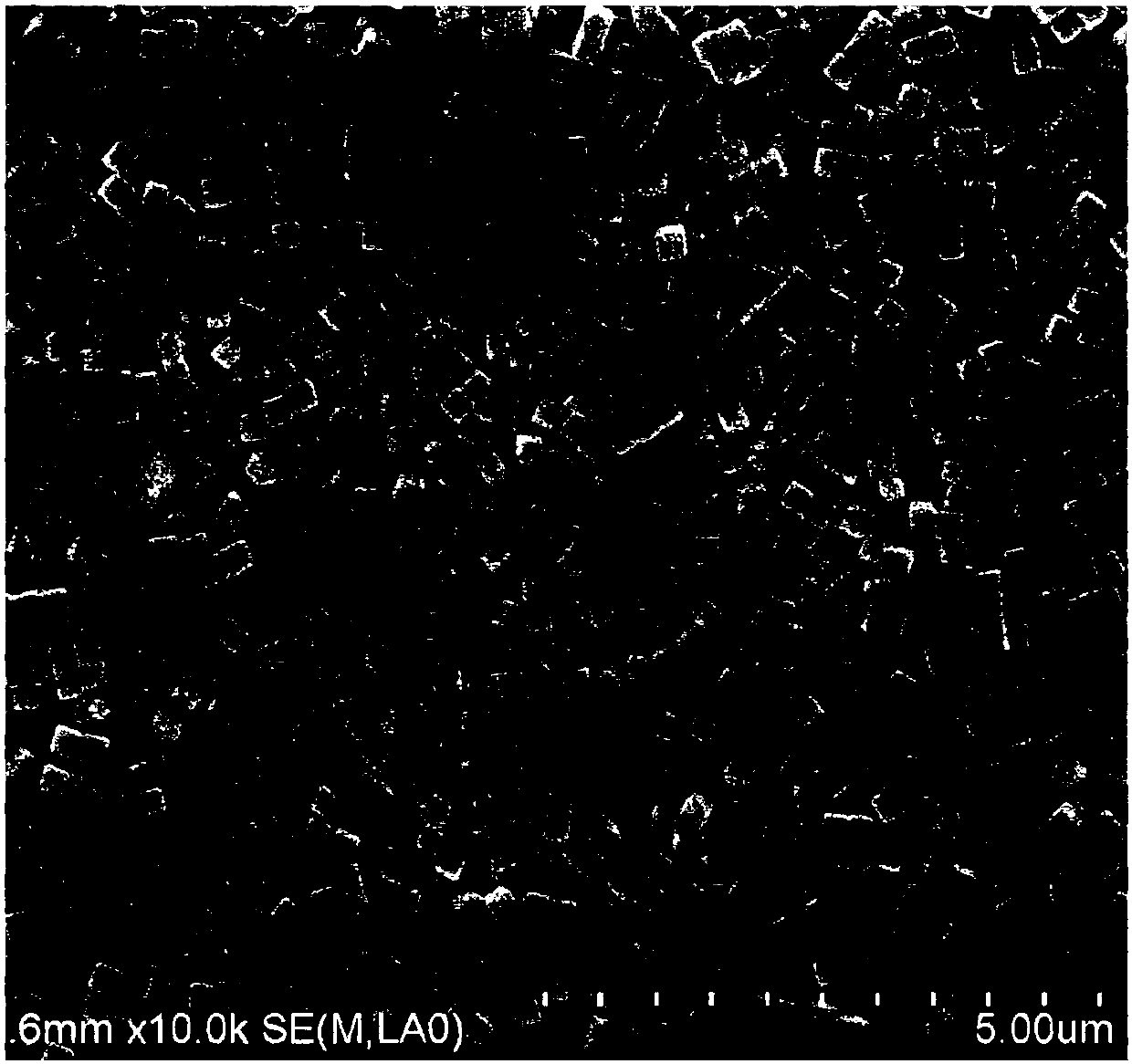

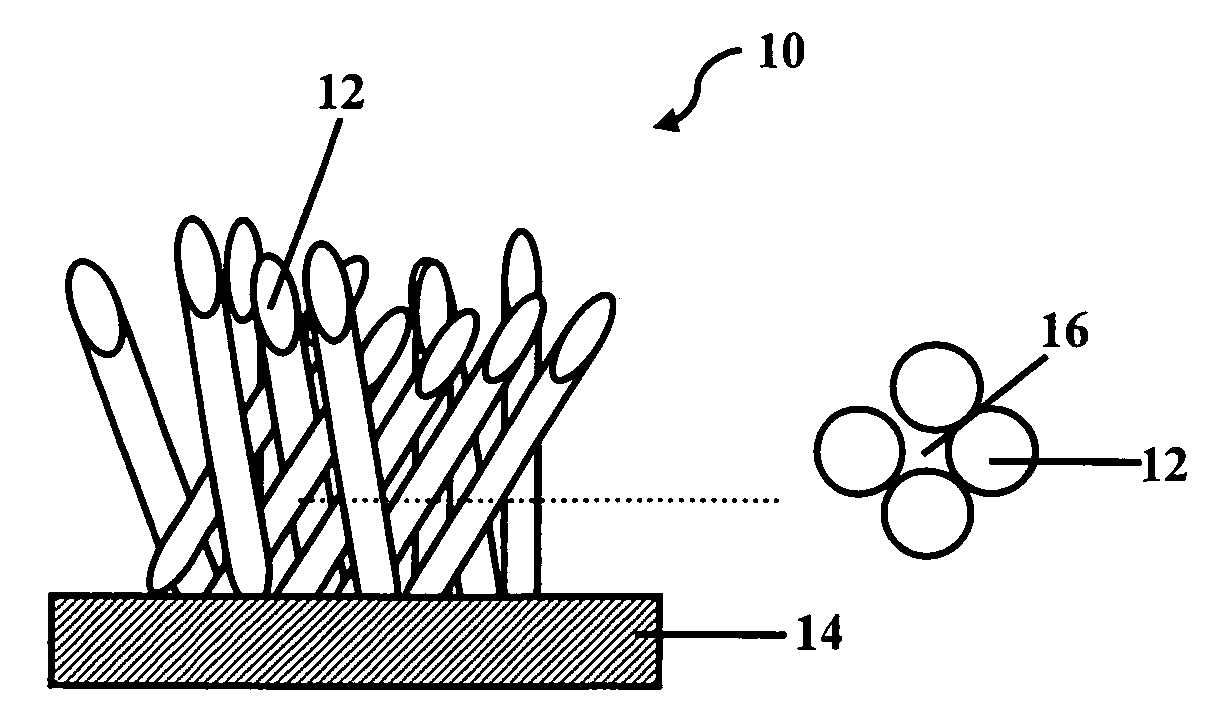

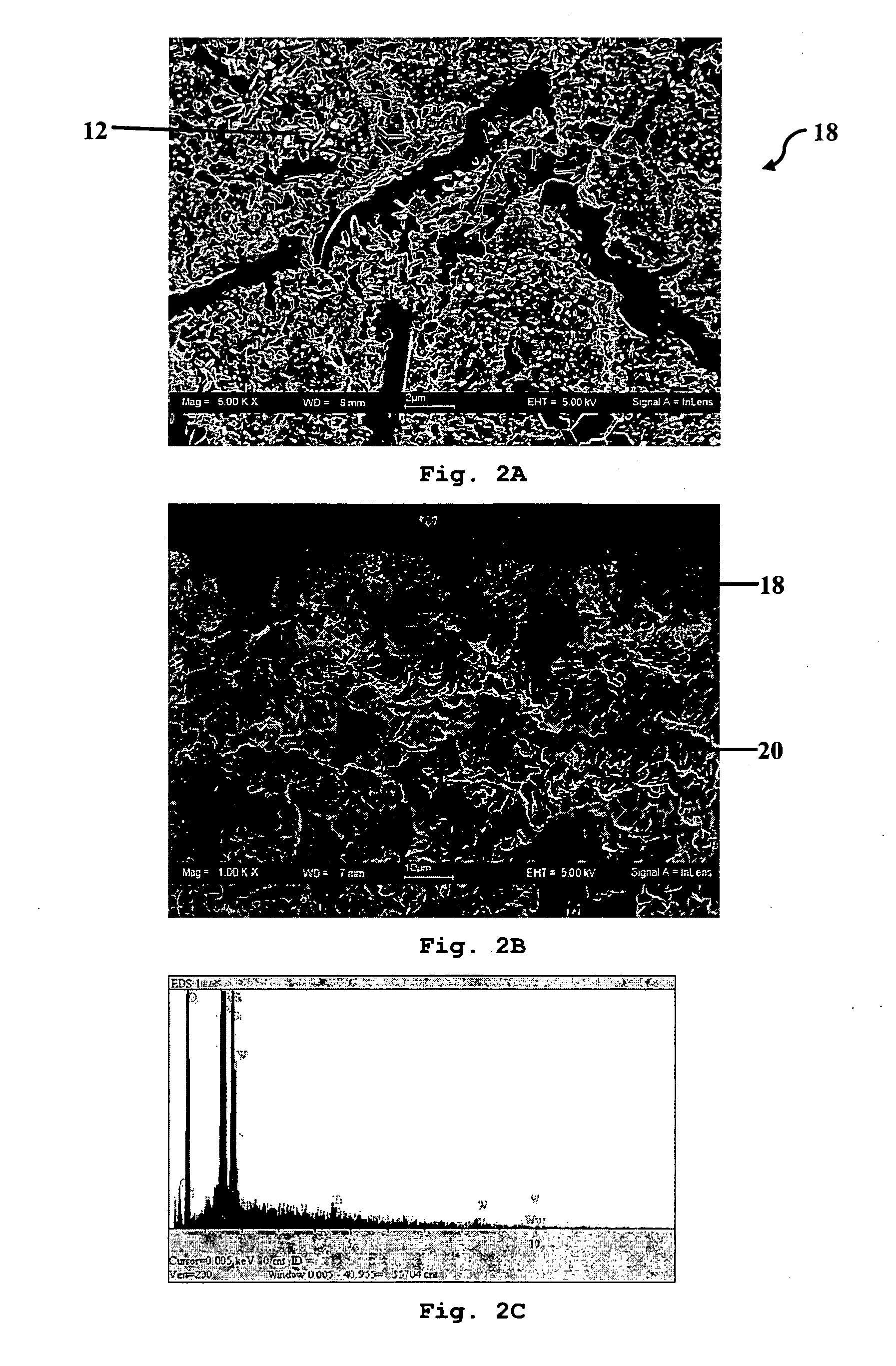

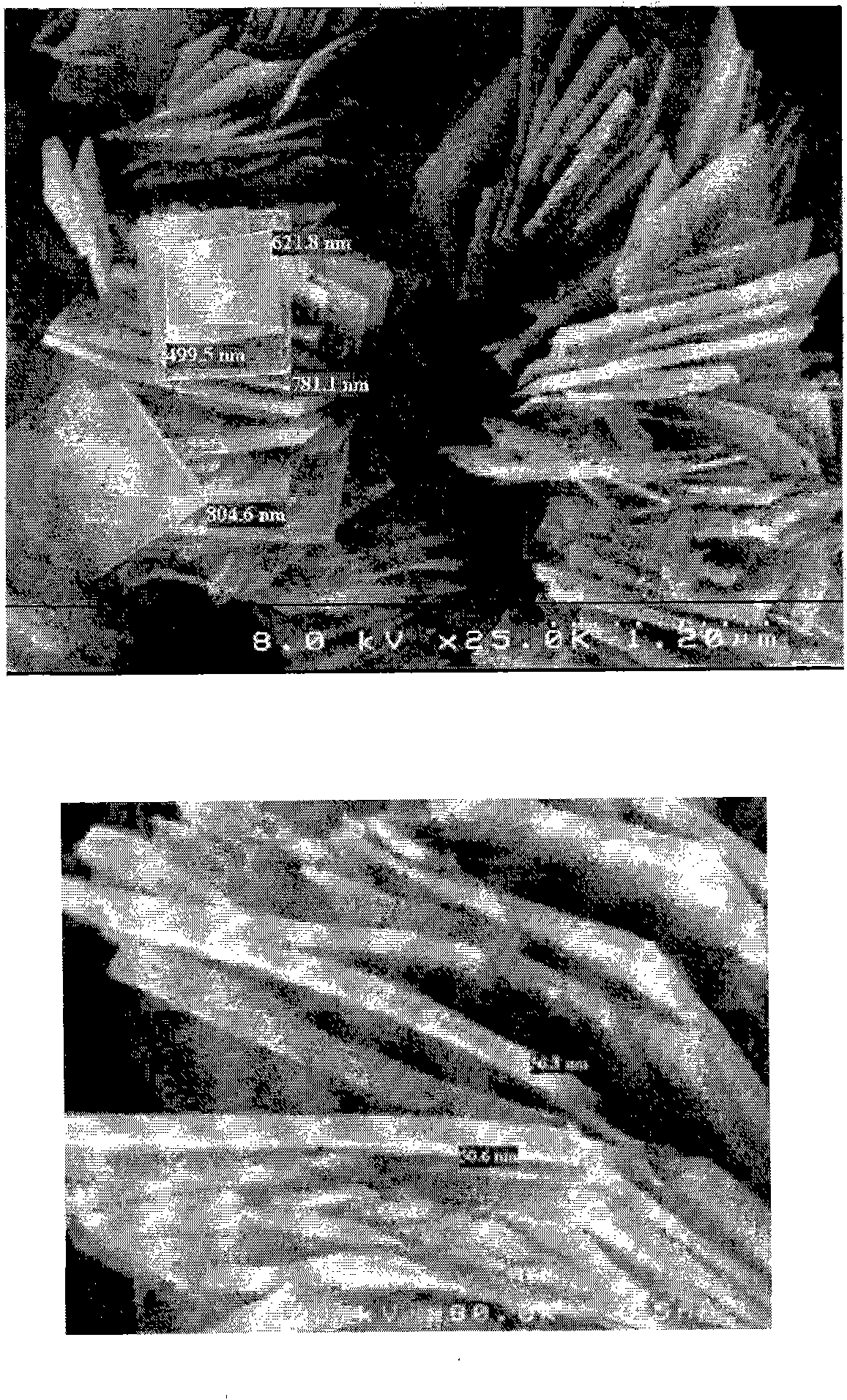

Nano-sized needle crystal mullite film and method of making

InactiveUS20080095690A1Uniform shapeUniform sizeSemi-permeable membranesPolycrystalline material growthCrystal morphologyUltrafiltration

The present invention provides ceramic films and ceramic membranes of high stability, high permeability, and large surface area, the films and membranes comprising mullite having whisker (i.e. needle-like) crystal morphology. The invention also discloses environmentally friendly methods of producing such films and membranes. The applications include, for example, membrane ultra-filtration of gas or liquid fluids, biological assays, cell culture surfaces and catalytic coatings on automotive honeycomb substrates.

Owner:CORNING INC

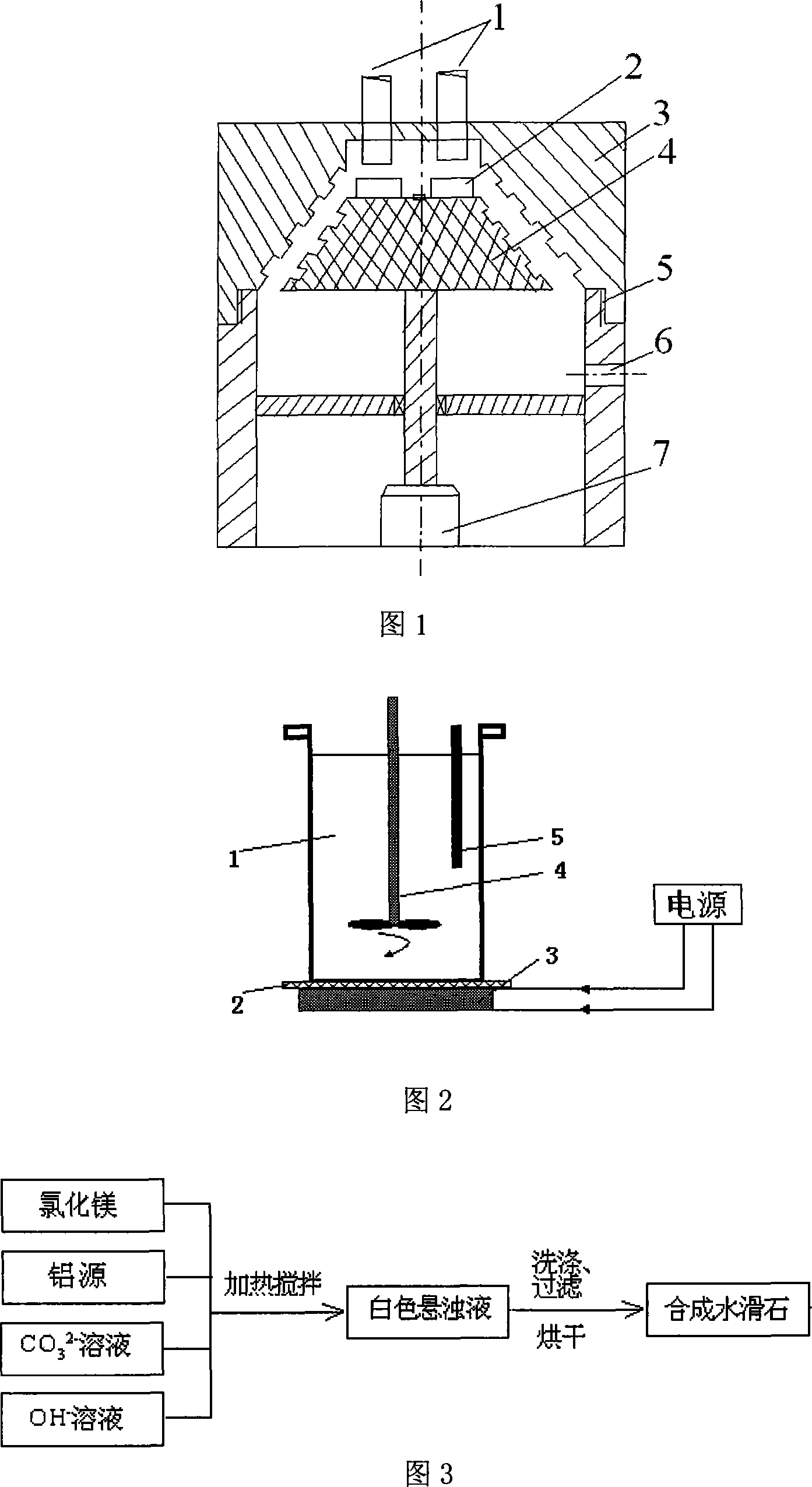

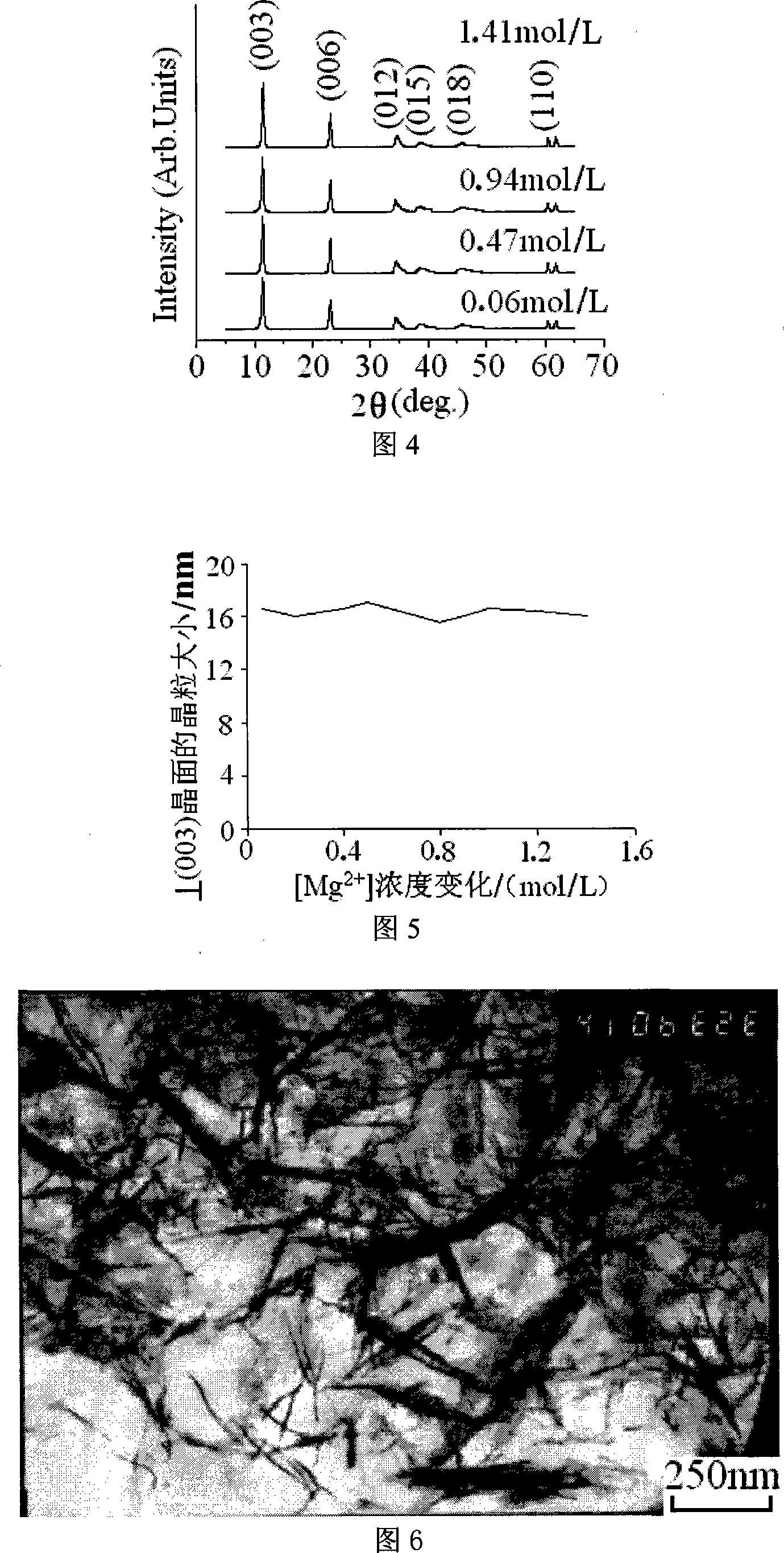

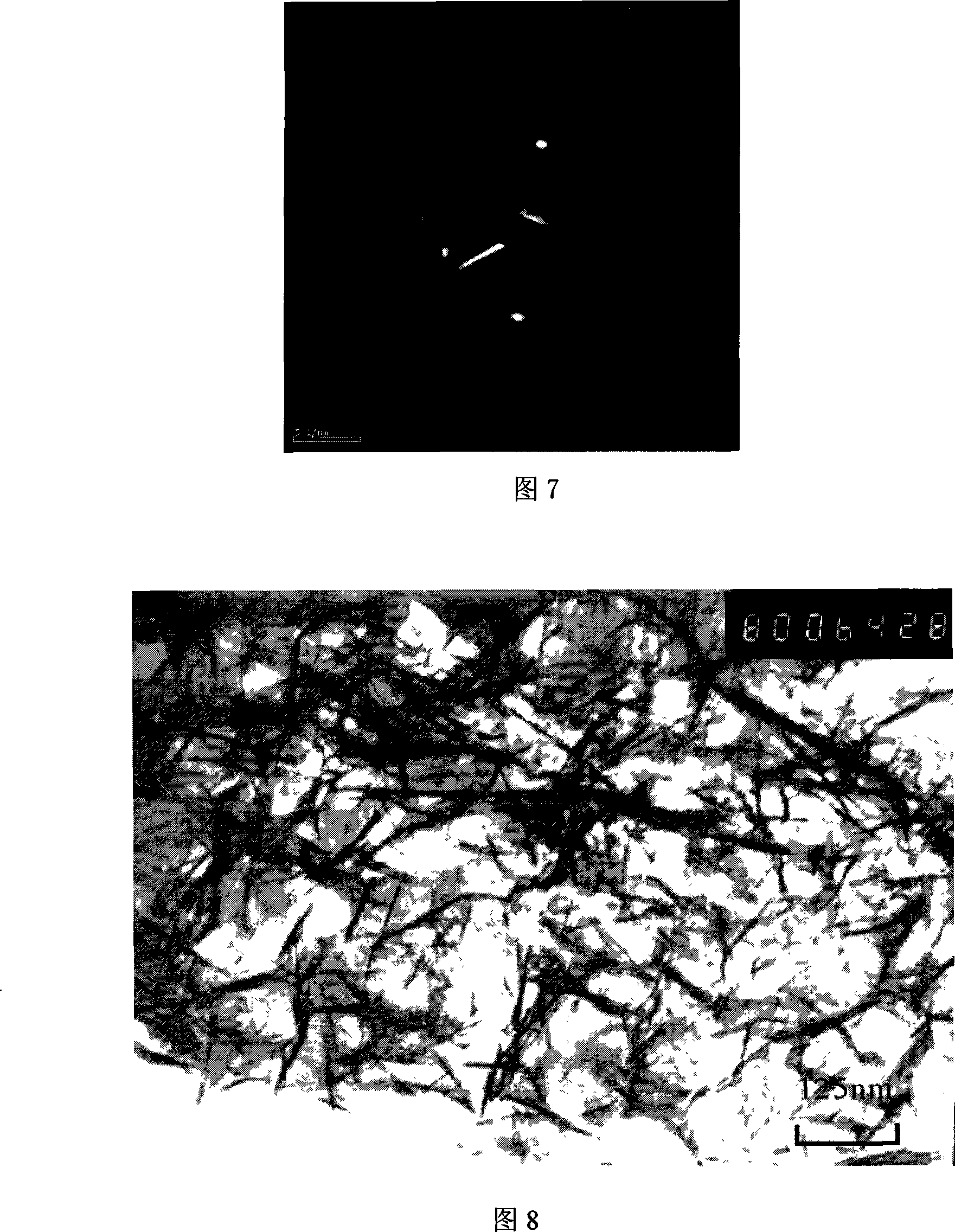

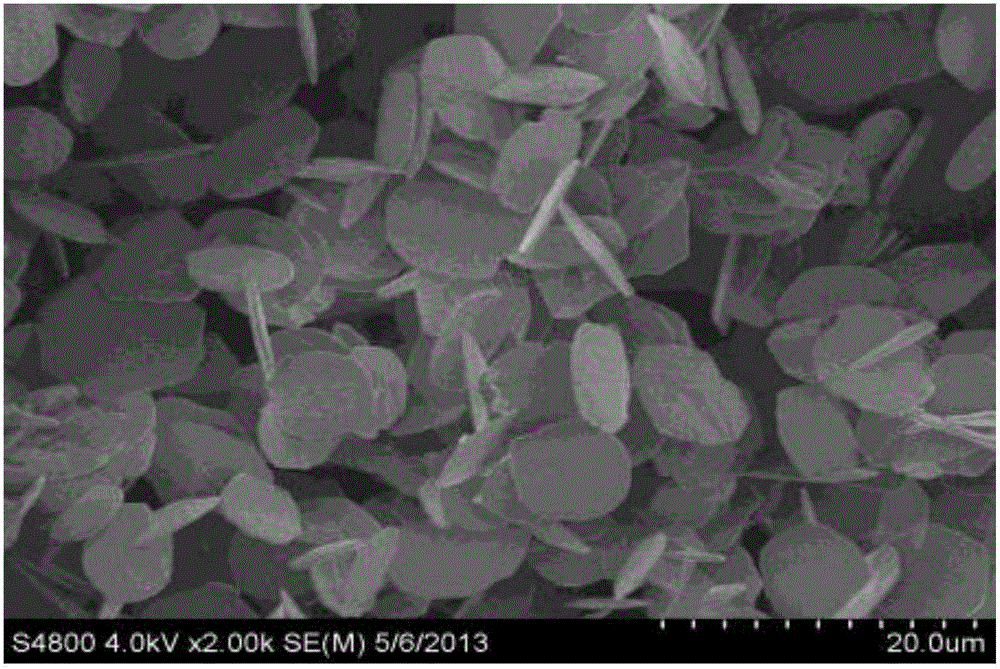

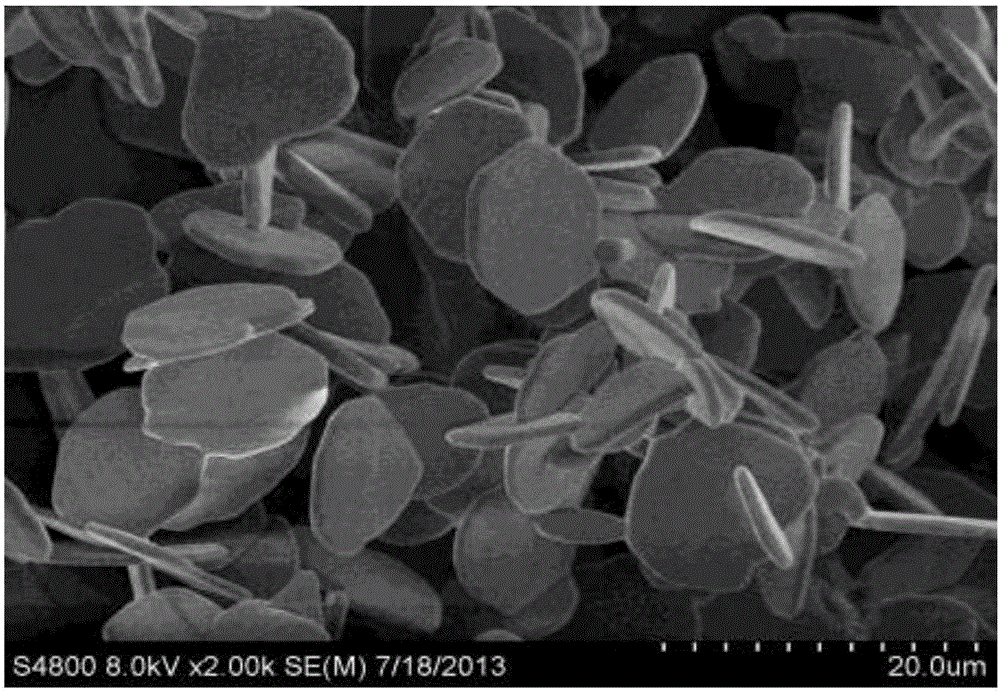

Needle, flake-shaped nano single crystal mg-al hydrotalcite Mg8Al2(OH)16CO3 4H2O preparation method

ActiveCN101187060AGood dispersionUniform sizePolycrystalline material growthSingle crystal growth detailsSingle crystalFire retardant

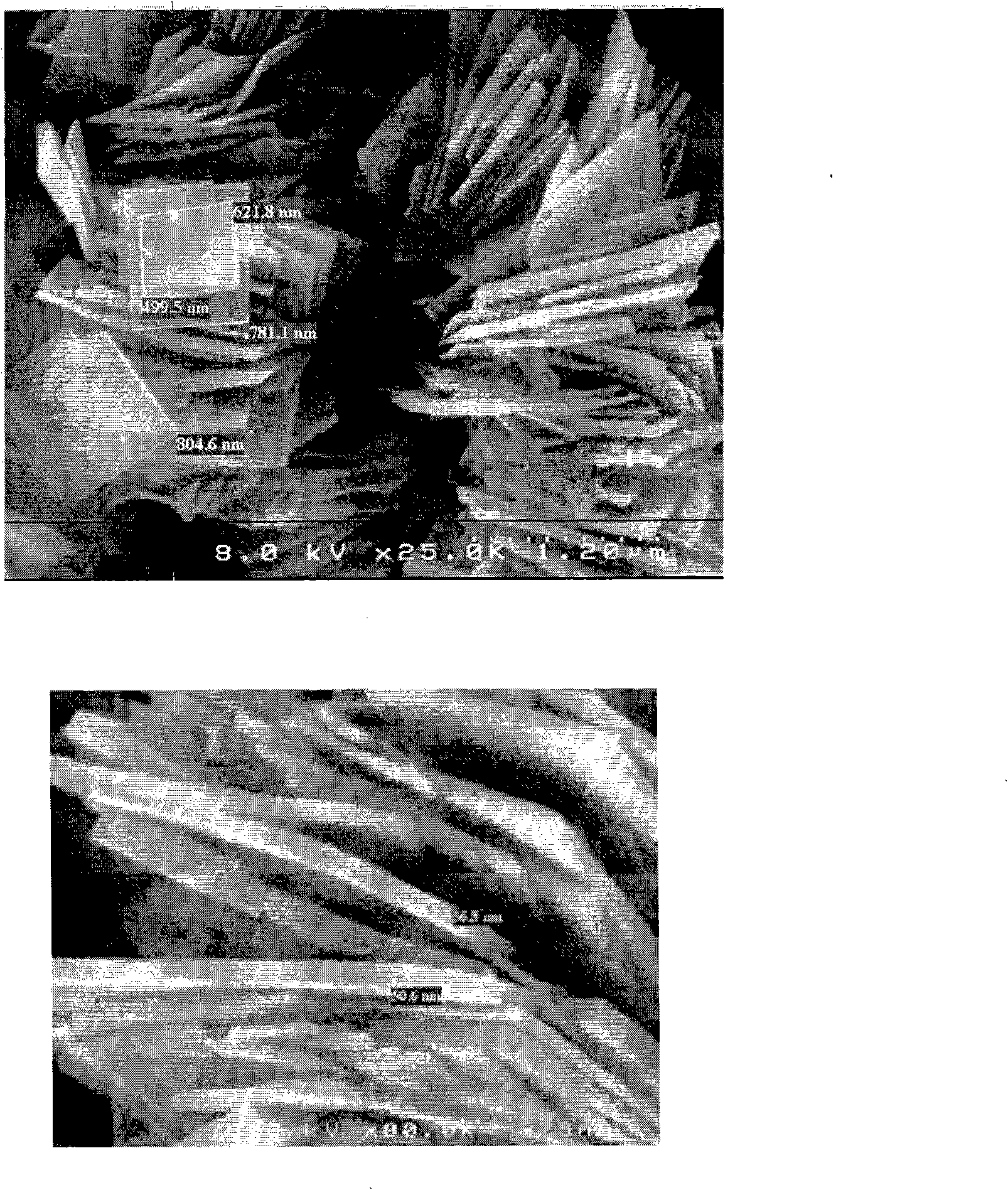

The invention discloses a process for preparing acicular, flake nano single crystal magnesia-alumina hydrotalcite Mg6Al2(OH)16C.4H2O, and the prepared Mg6Al2(OH)16CO3.4H2O is used as a flame retardant of power electronic devices. Acicular components comprise 0.06-1.41 mol / L crystal magnesium chloride, 0.02-0.47 mol / L aluminum salt, 0.3-4.5 mol / L sodium hydroxide and 0.094-1.368 mol / L sodium carbonate, and flake components are added with modifier basing on the above components. The invention has the process steps that the crystal magnesium chloride and the sodium hydroxide are firstly dissolved in deionized water and heated and stirred, and then the aluminum salt and sodium carbonate are added into the solution, the deionized water and the sodium hydroxide are added every 20 minutes during reaction, the time of reaction is 0.5-2 hours, and the solution is cooled until room temperature and is washed, filtered and dried. The crystal morphology of the prepared acicular nano single crystal magnesia-alumina hydrotalcite is that the diameter is 10-20 nanometer, the length is 60-130 nanometer, the diameter is 25-80 nanometer, and the length is 200-500 nanometer. The crystal morphology of the flake nano single crystal magnesia-alumina hydrotalcite is that the thickness is 10-20 nanometer, the diameter is 50-100 nanometer, the thickness is 20-30 nanometer, and the diameter is 60-200 nanometer. The process for preparation of the invention has short period and simple process, is prepared at atmospheric pressure, and is suitable for industrial production.

Owner:XIDIAN UNIV

Method for preparing superfine zinc tungstate antibacterial agent by ultrasonic molten salt method

The invention relates to a preparation method of compound inorganic antibacterial powder, which comprises the following steps: preparing aqueous Na2WO4 and Zn(NO3)2 solutions into a ZnWO4 precursor under an ultrasonic condition, wherein the concentrations of both the Na2WO4 solution and the Zn(NO3)2 solution are 0.2mol / L; calcining the precursor in sodium nitrate to obtain a cured product, and sufficiently soaking and washing the product in distilled water; and filtering, and drying to remove remaining molten salt so as to obtain ZnWO4 antibacterial powder. Compared with the simplex ultrasonic chemical preparation method, the ultrasonic molten salt preparation method has the advantages of regular crystal morphology and uniform particles of the ZnWO4 antibacterial powder, can prepare the ZnWO4 antibacterial agent having a particle size of 500nm or so and favorable antibacterial properties. Besides, by the invention, the facts that the high-cost silver antibacterial agent can be replaced, and the prepared antibacterial agent can be used in industries and fields of plastics, fibers, paint and the like are possible to come true.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

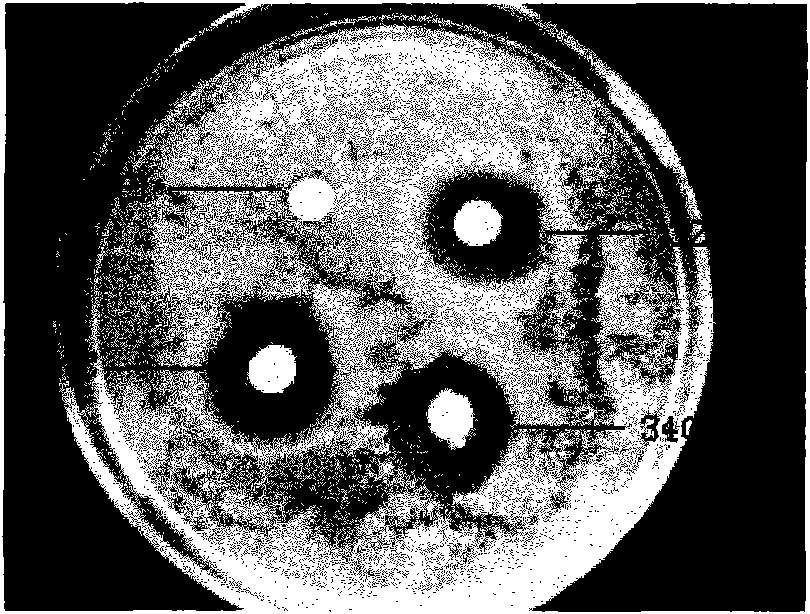

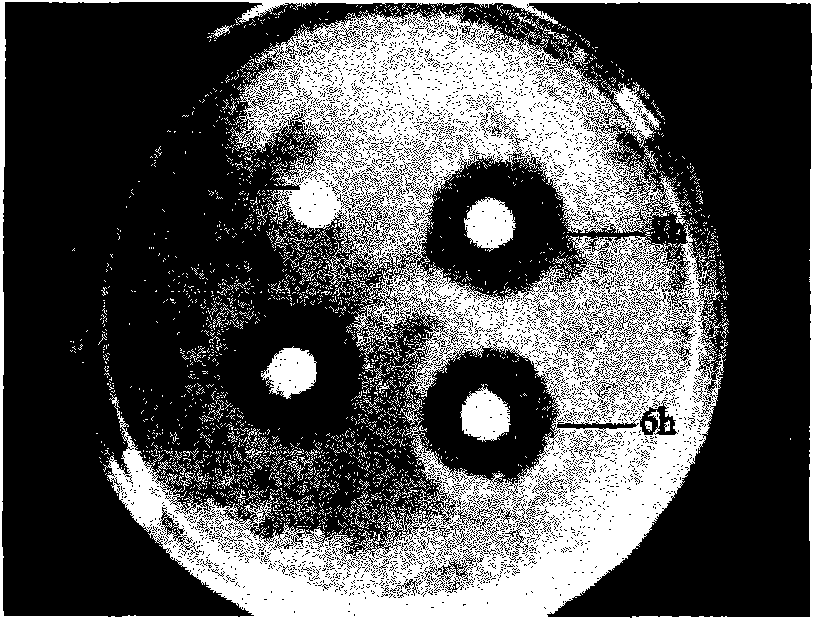

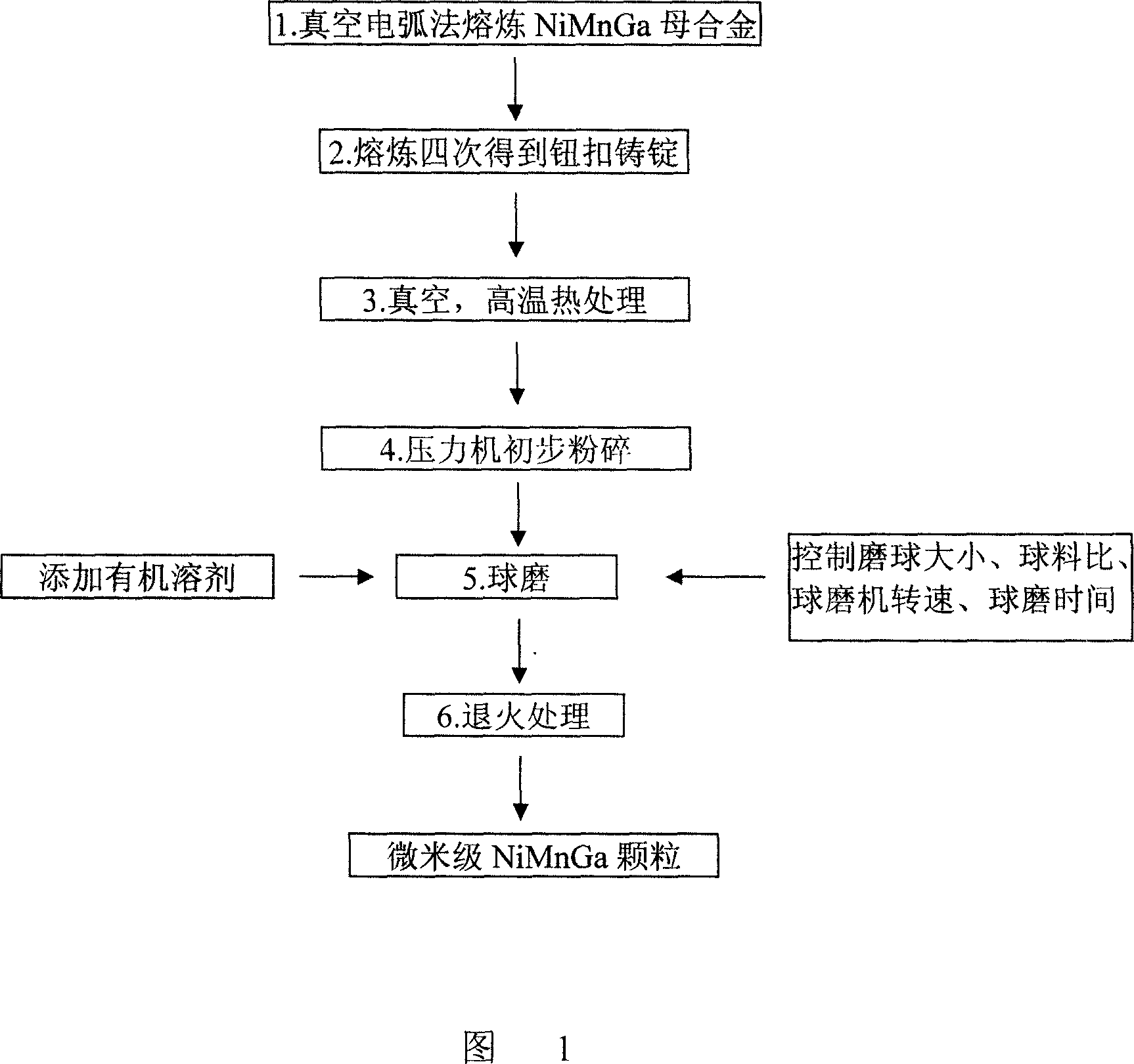

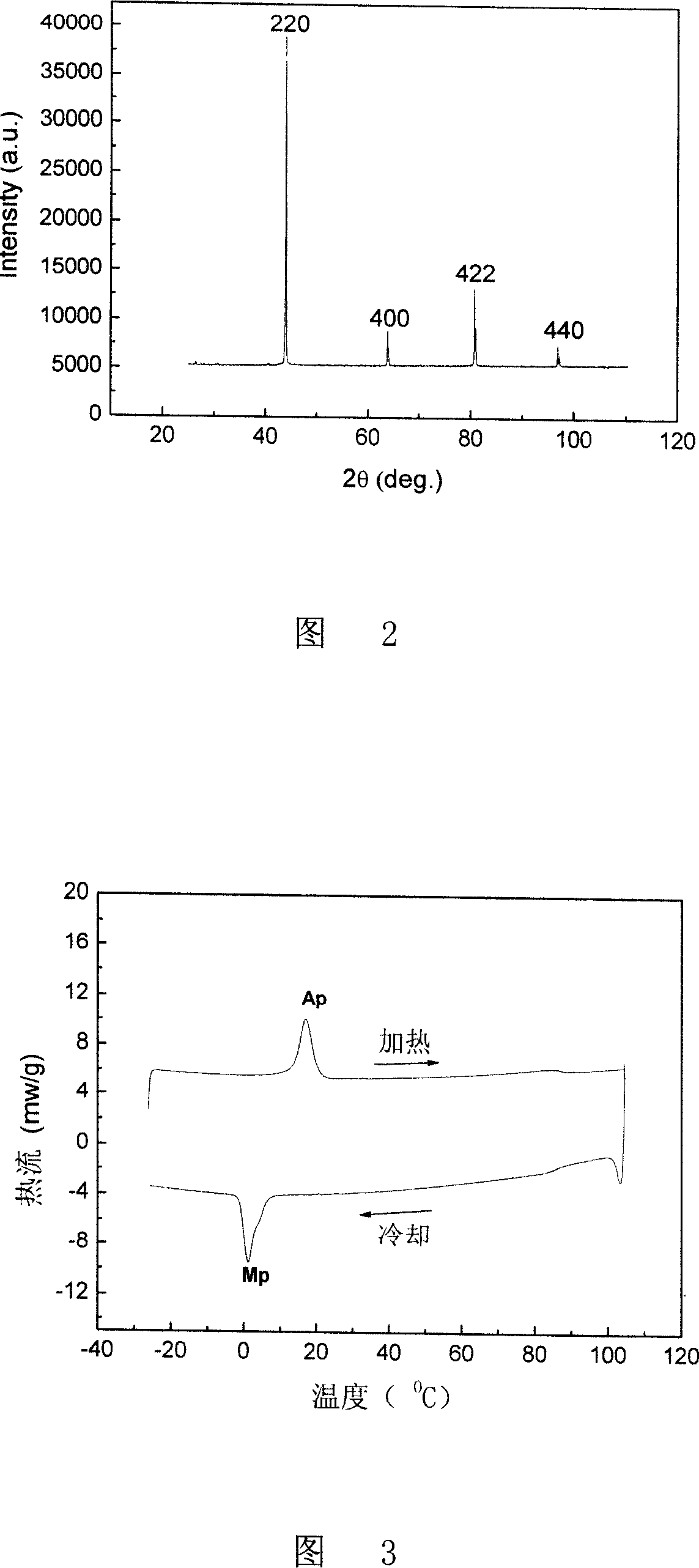

Preparation method of micrometer grade NiMnCa magnetic memory alloy grain

The invention involves a preparation method of NiMnGa magnetic memory alloy micron-scale particles. The invention uses planetary ball grinder, prepares micron-scale Ni48-55Mn24-30Ga20-25(at.%) magnetic memory alloy particles through controlling size of abrading-ball, ball-material rate, ball grinder rotary speed and ball grinding time and adding proper organic adjuvant, the particle size is controlled less than 100 microns, the particles has complete same phase-change behavior and crystal morphology with body material. The component of prepared NiMnGa magnetic memory alloy micron-scale particles using the invention is uniform, signal martensite phase and iron magnetic properties can be prepared just after short time heat treatment, the art is simple and the preparation time is short. The micron-scale NiMnGa magnetic memory alloy particles can be both raw material for preparing NiMnGa composite and a granular magnetic refrigerating material.

Owner:HARBIN ENG UNIV

Soluble extrusion magnesium alloy and preparation method thereof

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation of highly pure copper oxide from waste etchant

InactiveUS20010051103A1Oxygen/ozone/oxide/hydroxideGold compoundsCrystal morphologyAqueous sodium hydroxide

A method for recycling copper oxide includes: a first step in which a sodium hydroxide aqueous solution is added to acidic copper chloride waste etchant produced in the PCB industry, to obtain copper hydroxide slurry; and a second step in which the slurry obtained in the first step is heated and sintered to thereby prepare a needle-form copper oxide. Since copper oxide has a purity of more than 99.0 wt % and the needle-form crystal morphology, so that it has an excellent filtering ability and homogeneous particle size distribution.

Owner:MYUNG JIN CHEM

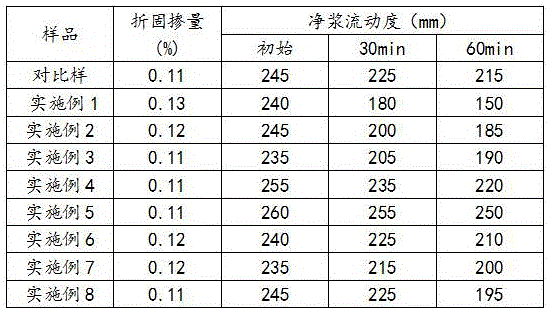

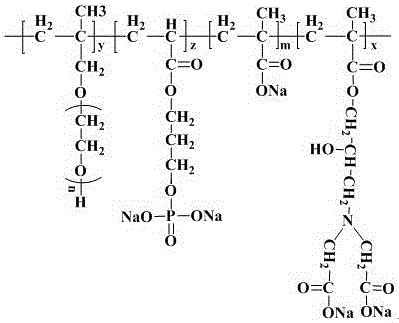

Phosphate containing high-adaptability polycarboxylate superplasticizer and preparation method thereof

The invention discloses a phosphate containing high-adaptability polycarboxylate superplasticizer and a preparation method thereof.The phosphate containing high-adaptability polycarboxylate superplasticizer is prepared through the steps that unsaturated polyether macromonomers, micromonomers, unsaturated phosphate monomers, 2-methacrylic acid-3(N,N-oxalic acid amine)-2 hydroxy propyl ester, an initiator and a chain transfer agent react with water at the temperature of 50-80 DEG C for 3-6 hours, a copolymer is obtained, then the pH value is adjusted to range from 6.0 to 7.0 with alkaline matter, and a settled solution is obtained.Compared with a polycarboxylate superplasticizer, the phosphate containing high-adaptability polycarboxylate superplasticizer has higher adsorption capacity, sulfate in cement can be effectively resisted, the dispersing power of polycarboxylate is greatly improved, the phosphate structure can change the crystal morphology formed at the initial stage of ettringite, and then collapse protecting performance is improved.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

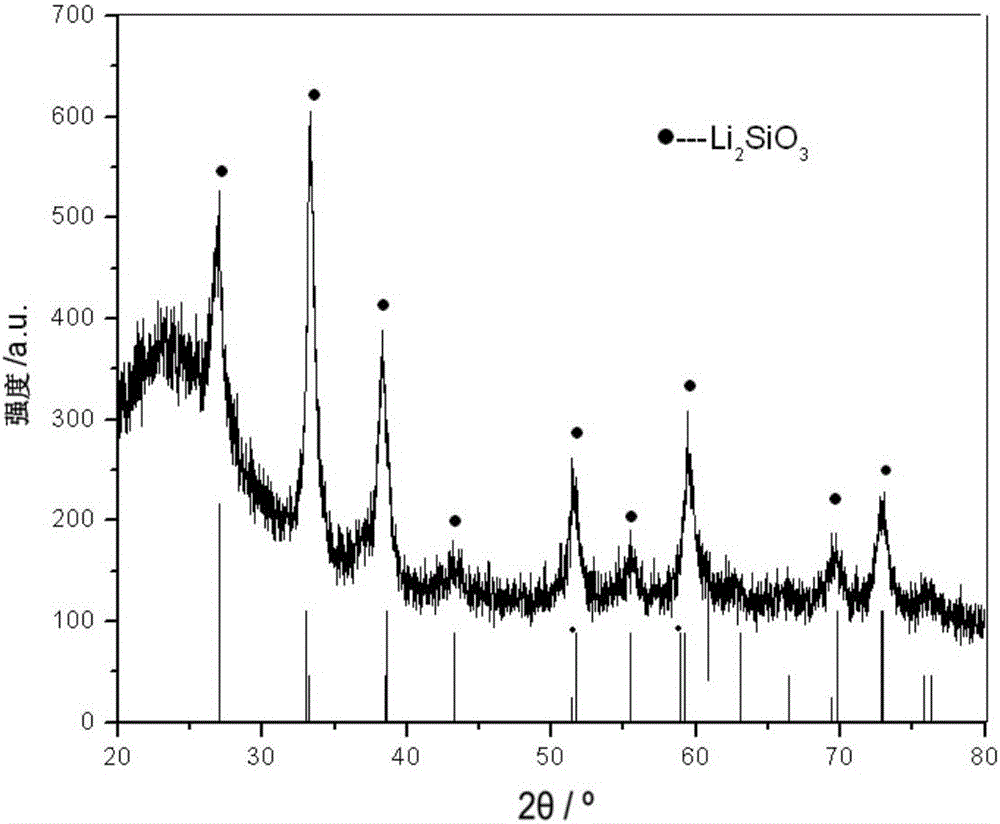

Lithium metasilicate glass ceramic and preparation method thereof

ActiveCN106277798ASimple production processLow requirements for production equipmentCrystal morphologyThermal insulation

Owner:SHENZHEN UPCERA DENTAL TECH

Three-dimensional copper oxide nanometer flower-based chip enzyme-free glucose sensor electrode as well as preparation method and application thereof

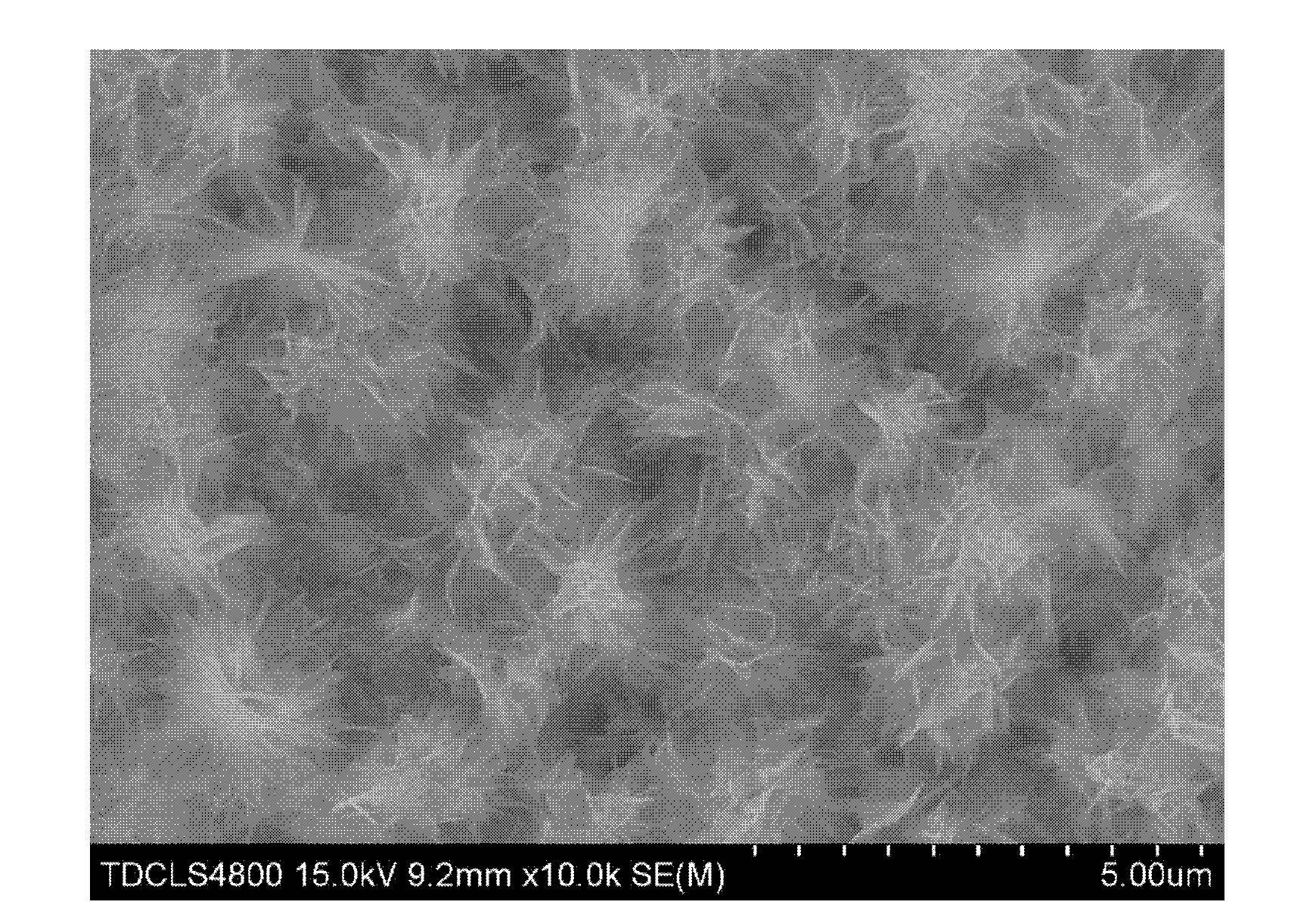

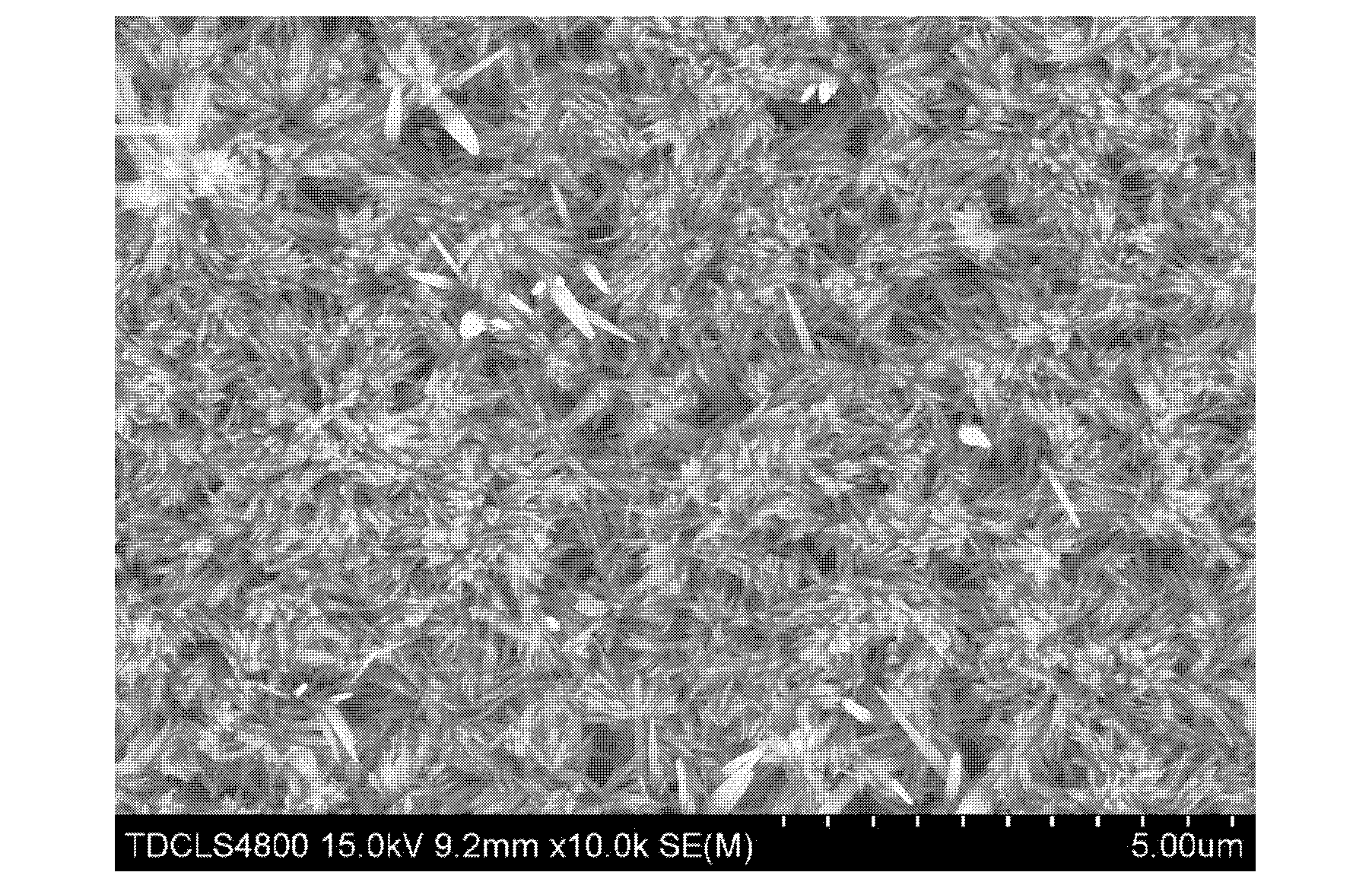

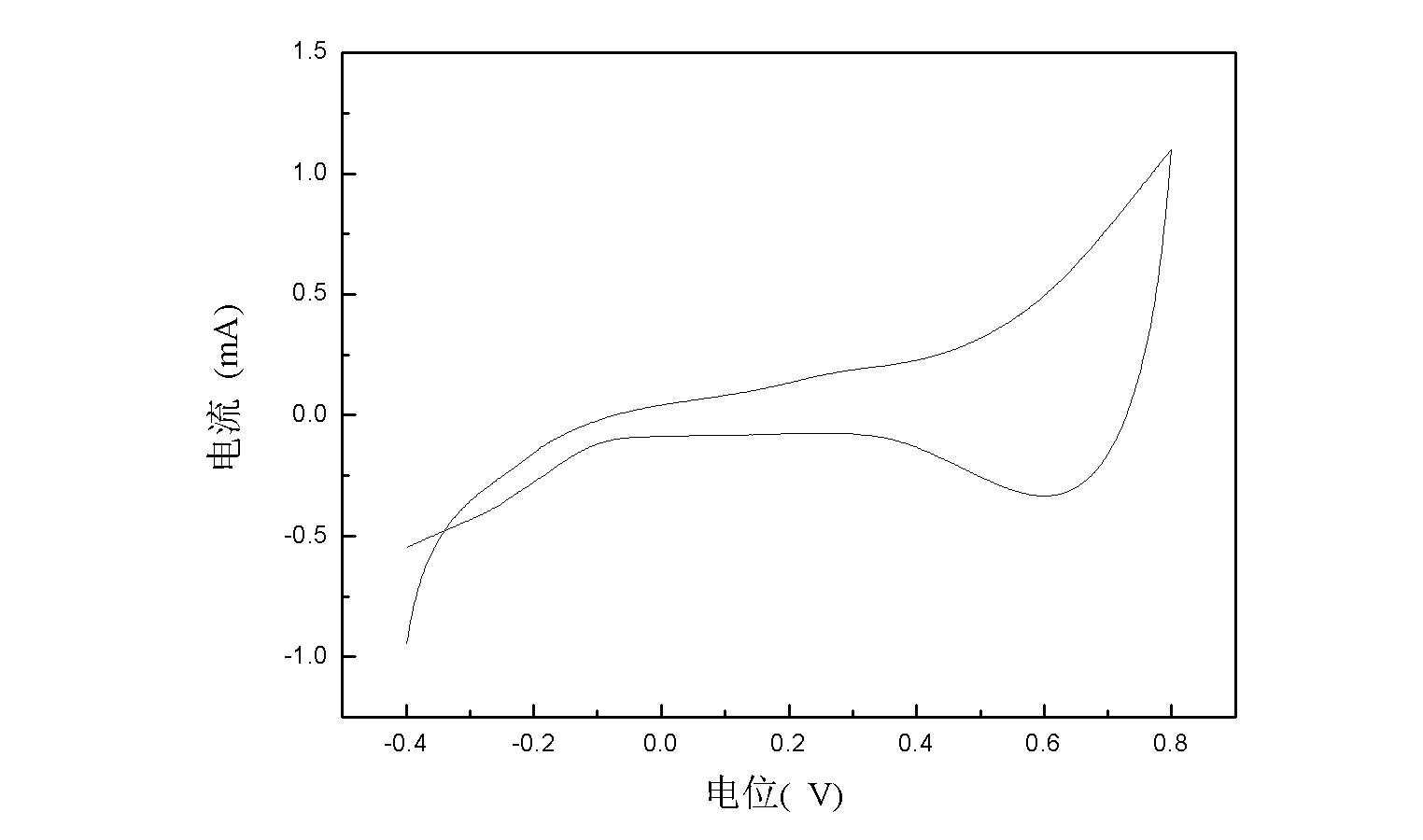

InactiveCN102156156AConform to the structureEasy to manufactureMaterial analysis by electric/magnetic meansGlucose sensorsCopper foil

The invention relates to a chip enzyme-free glucose sensor electrode based on three-dimensional copper oxide nanometer flowers as well as a preparation method and application thereof. In the invention, the nanometer flowers directly grow in situ on the surface of a copper foil; the nanometer flower-based chip enzyme-free glucose sensor electrode is composed of a copper foil substrate and a three-dimensional copper oxide nanometer flower array; and the three-dimensional copper oxide nanometer flowers with diameters of 10-20 microns exist in a crystal morphology and are uniformly and compactly distributed on the surface of the electrode. The preparation method comprises the steps of selecting a copper foil slice with a thickness of 0.2-0.5mm, putting the cleaned and dried copper foil into a KOH solution at a temperature about 30-40 DEG C for 3-9 days, after the reaction is completed, taking out a sample, repeatedly washing by utilizing distilled water and deionized water and drying at a room temperature. The three-dimensional copper oxide nanometer flower-based chip enzyme-free glucose sensor electrode can be applied to electronic equipment for continuously monitoring blood glucose concentration.

Owner:TIANJIN UNIV

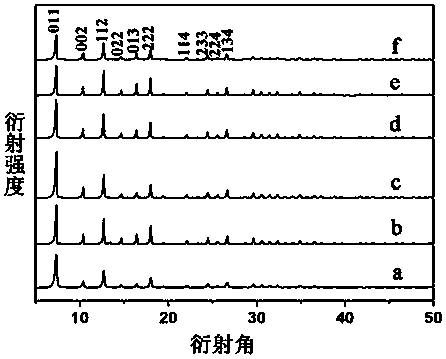

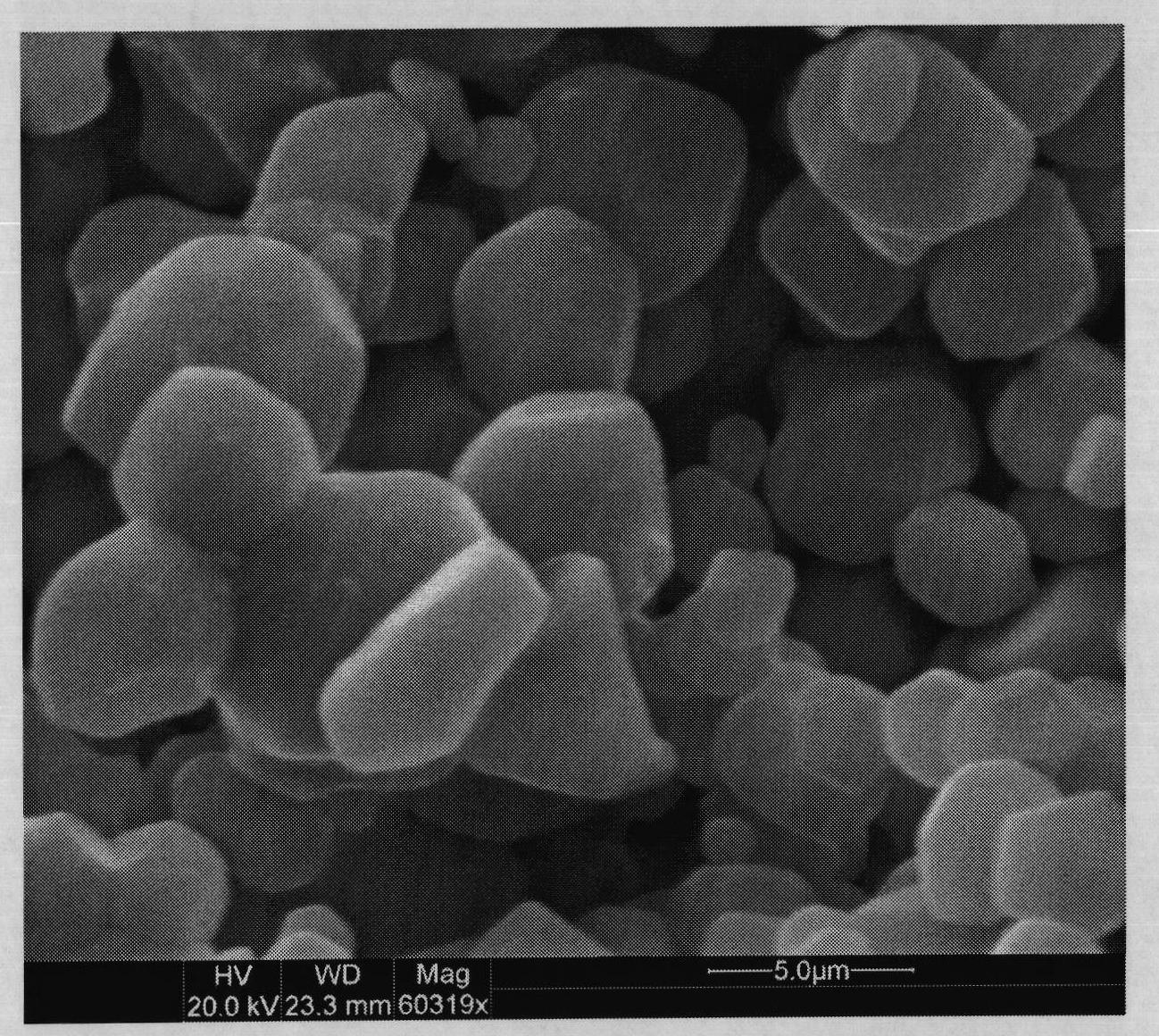

Method for preparing full-silicon DD3R zeolite molecular sieve with pure phase and uniform crystal morphology and size

InactiveCN102786065AOvercome uneven sizeOvercoming repetitivenessMolecular-sieve and base-exchange compoundsIonCrystal morphology

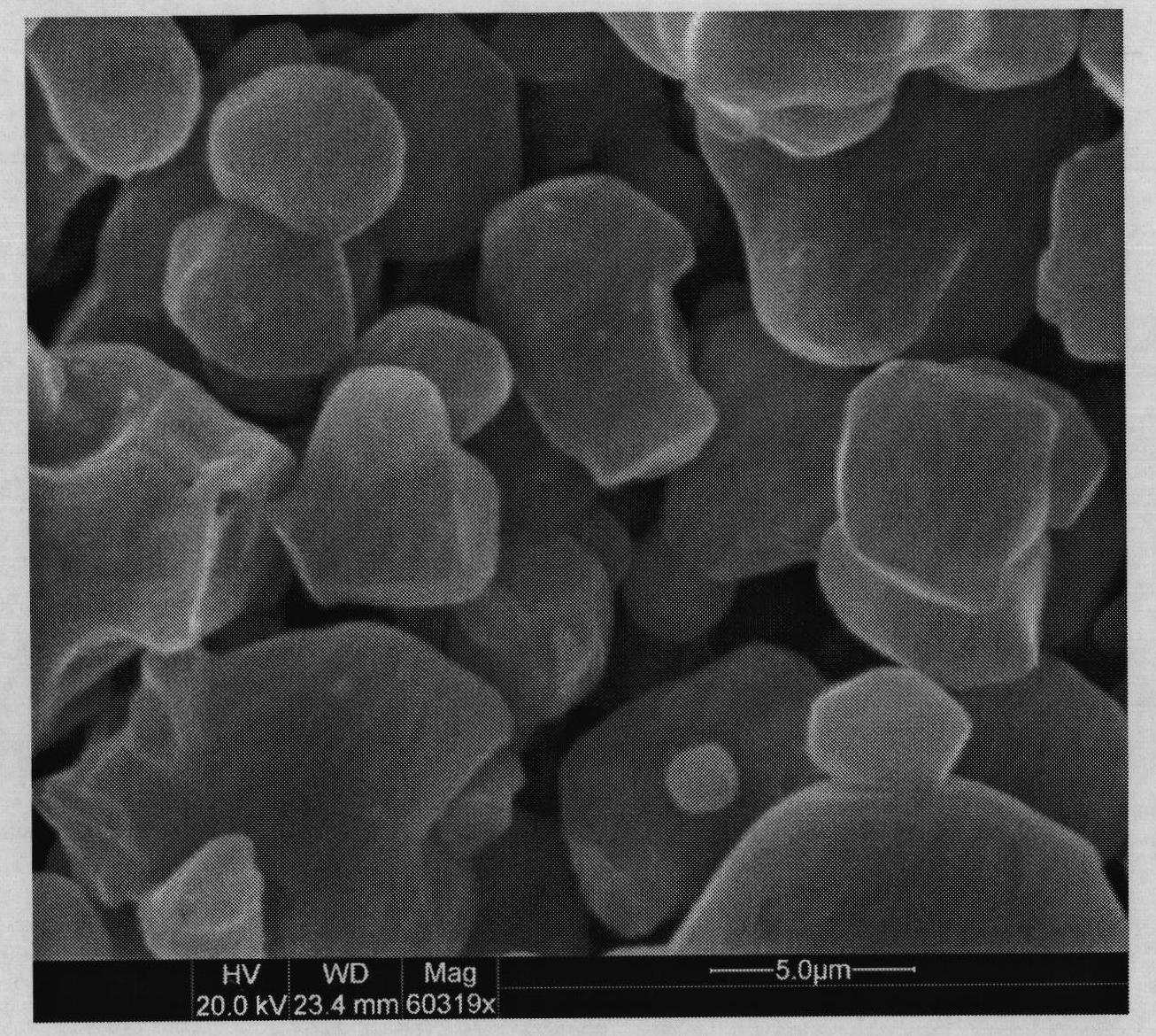

The invention discloses a method for preparing a full-silicon DD3R zeolite molecular sieve with a pure phase and uniform crystal morphology and size. The purpose of the invention is to provide the method for preparing the full-silicon DD3R zeolite molecular sieve with the pure phase and uniform crystal morphology and size. The method is simple in process, low in cost, good in repeatability and excellent in product quality. The method for preparing the full-silicon DD3R zeolite molecular sieve comprises the following steps: (1) adding an organic structure directingagent, a silicon source and a mineralizer into deionized water to mix and agitate; (2) adding a crystal seed to a mixing system obtained from the step (1); after mixing, agitating and aging, transferring the mixture into a hydrothermal reaction kettle to crystallize; (3), filtering and washing a sample obtained from the step (2), and obtaining the pure-phase DD3R zeolite molecular sieve with uniform crystal morphology and size after drying and baking the sample. The method has the characteristics that the crystallization time is short, the synthetic energy consumption is low, and the obtained pure-phase DD3R zeolite molecular sieve has excellent quality.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method for high-purity flaky alumina

ActiveCN105347377AHigh purityImprove doping uniformityAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium isopropoxideAmmonium bifluoride

The invention discloses a preparation method for high-purity flaky alumina, belonging to the technical field of preparation of special powder. The preparation method comprises the following steps: with high-purity aluminum isopropoxide with a purity of 99.999%, pure water and isopropanol as main raw materials and ammonium bifluoride or ammonium fluoride as a crystal morphology controlling agent, dissolving the high-purity aluminum isopropoxide in isopropanol to prepare a solution A; preparing a solution B from pure water, isopropanol and ammonium bifluoride; then gradually adding the solution A into the solution B drop by drop at a certain addition speed; carrying out a reaction under the conditions of heating and stirring so as to produce hydrated alumina; and then successively carrying out filtering, drying and roasting so as to obtain the high-purity flaky alumina. The high-purity flaky alumina prepared by using the method has crystal grain thickness of no more than 1.0 [mu]m, a radial size of 5 to 20 [mu]m, a smooth surface, a flaky shape, no agglomeration and crystal twinning, and good dispersibility, and can be used in fields like cosmetics, pearlescent pigment, high-grade coatings and fine ceramics.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

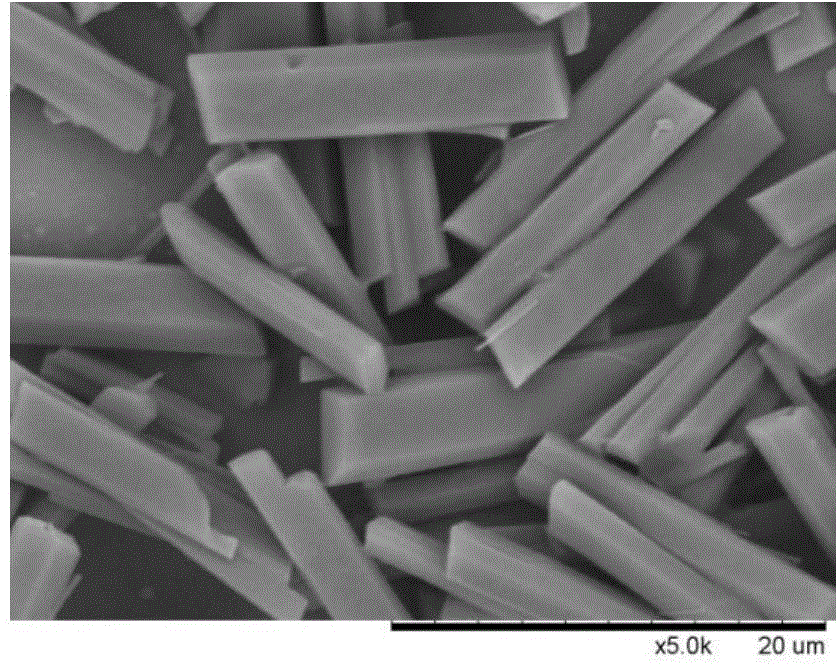

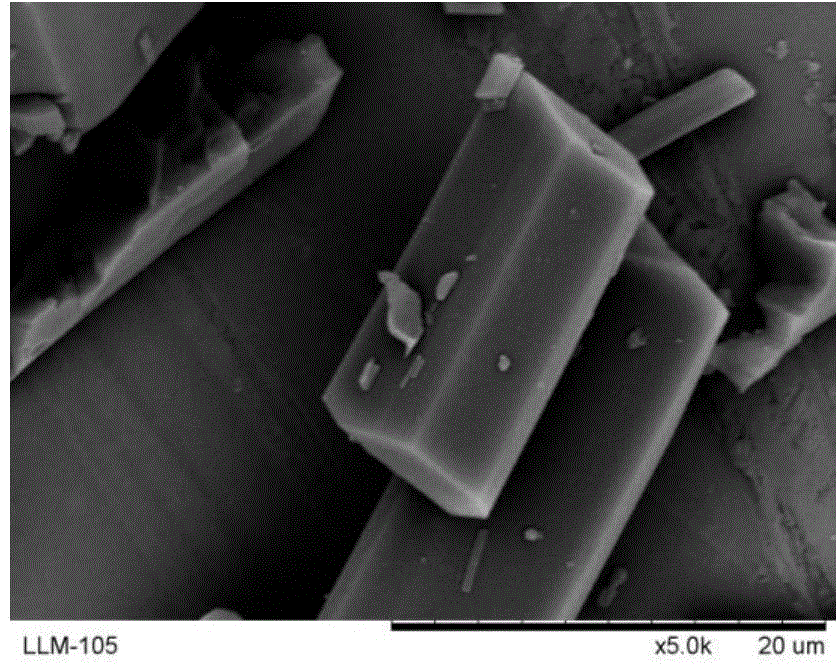

Preparation method of cubic short rod-like 1-oxygen-diamido-3,5-dinitro pyrazine explosive

ActiveCN103467217AEliminate Luanite defectsImprove subsequent processing and forming performanceNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNon solventCrystal morphology

The invention discloses a preparation method of a cubic short rod-like 1-oxygen-diamido-3,5-dinitro pyrazine (or 2,6-diamido-3,5-dinitro pyrazine-1-oxide with a code being LLM-105) explosive. According to the method, a solvent-non-solvent impinging jet crystallization mode is adopted; nitric acid (HNO3) is taken as a good solvent of LLM-105; the LLM-105 crystal is rapidly crystallized and separated out in a non-solvent containing a surfactant. By adopting the method disclosed by the invention, the cubic short rod-like LLM-105 crystal with regular crystal morphology can be obtained; the rod length of the LLM-105 crystal is 2-3 microns. The thermal performance of the LLM-105 crystal prepared by the method disclosed by the invention is obviously changed; thermal decomposition peak temperature is reduced to 343 DEG C from 350 DEG C; the LLM-105 crystal prepared by the method disclosed by the invention can be applied to a booster explosive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

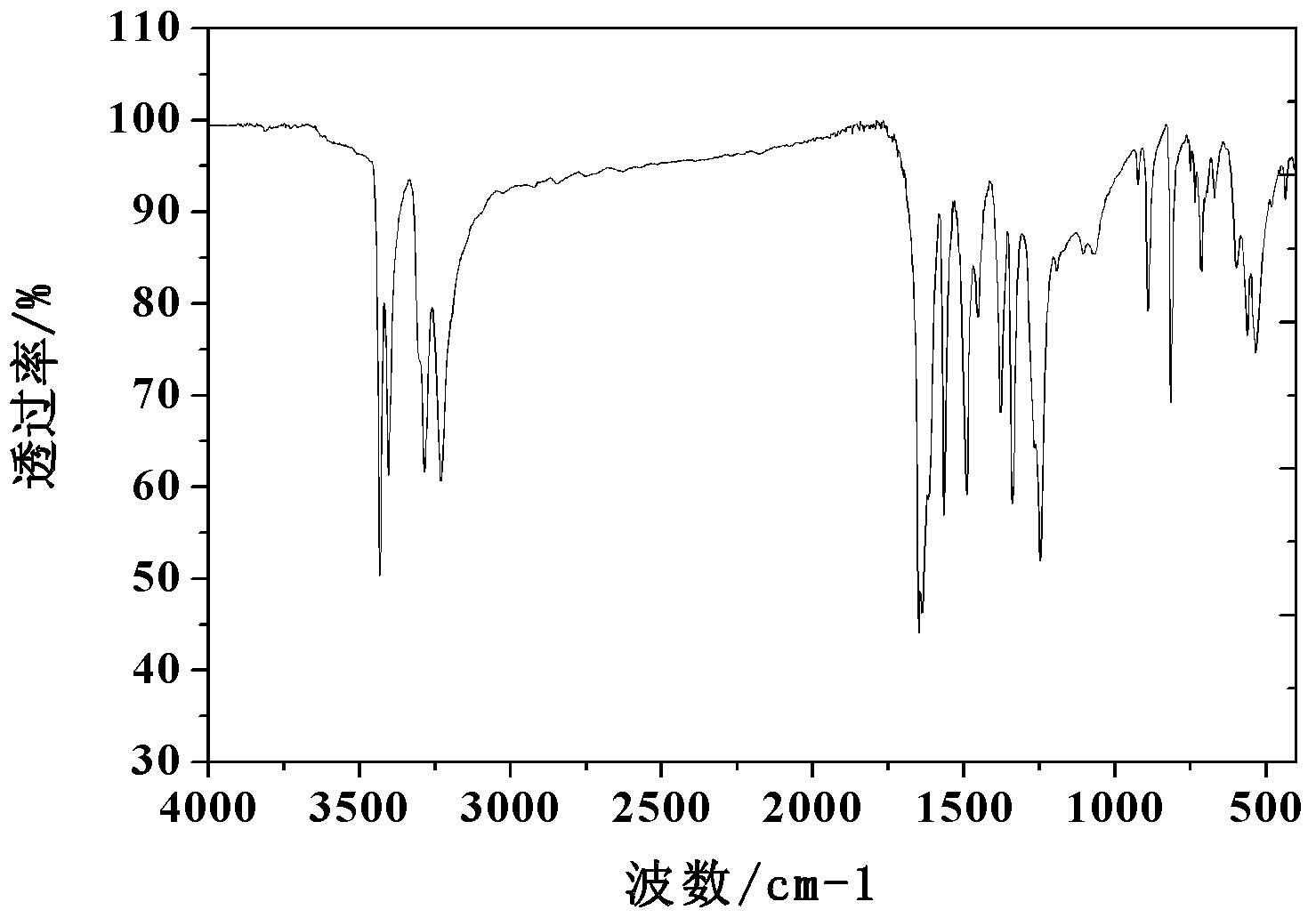

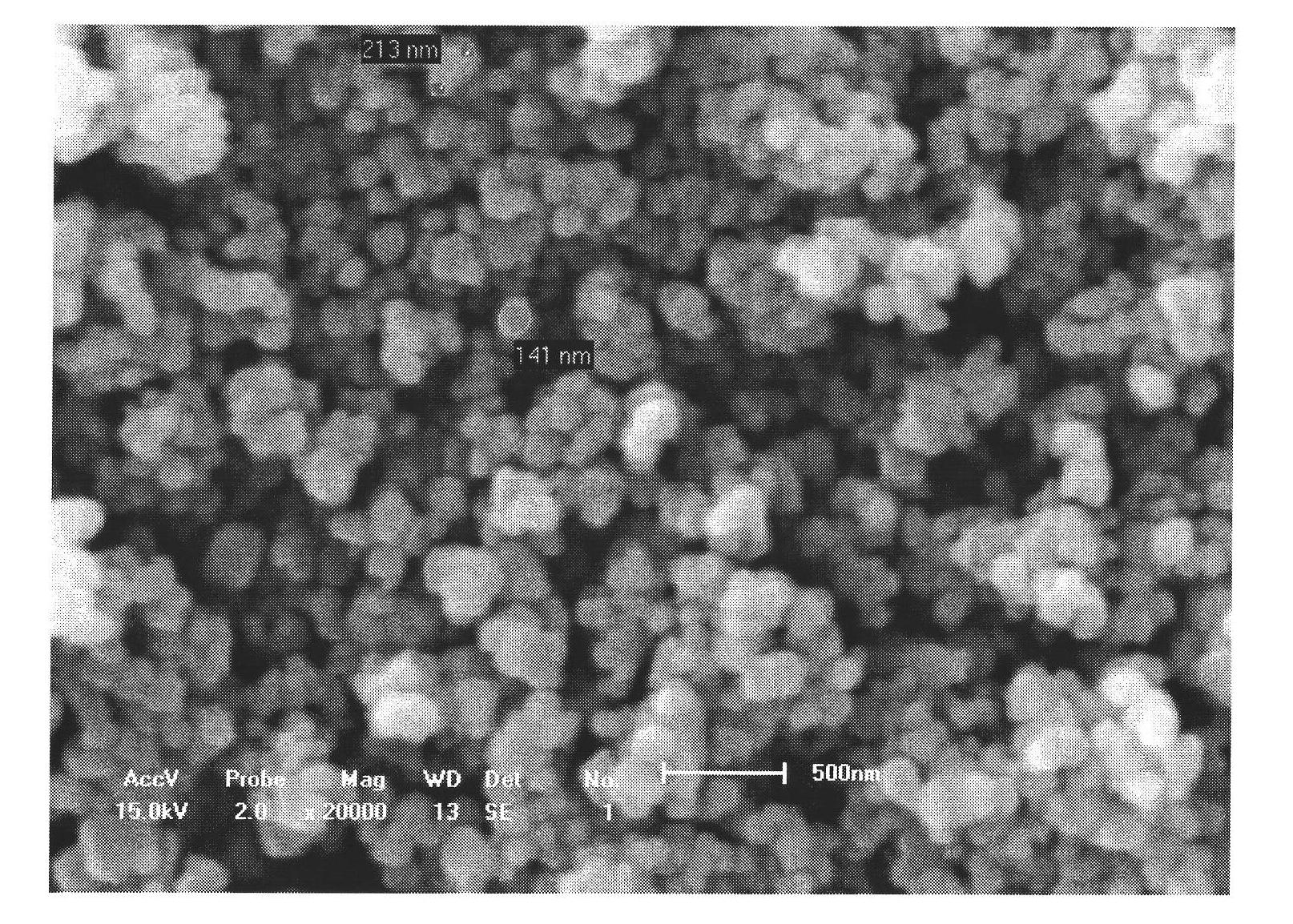

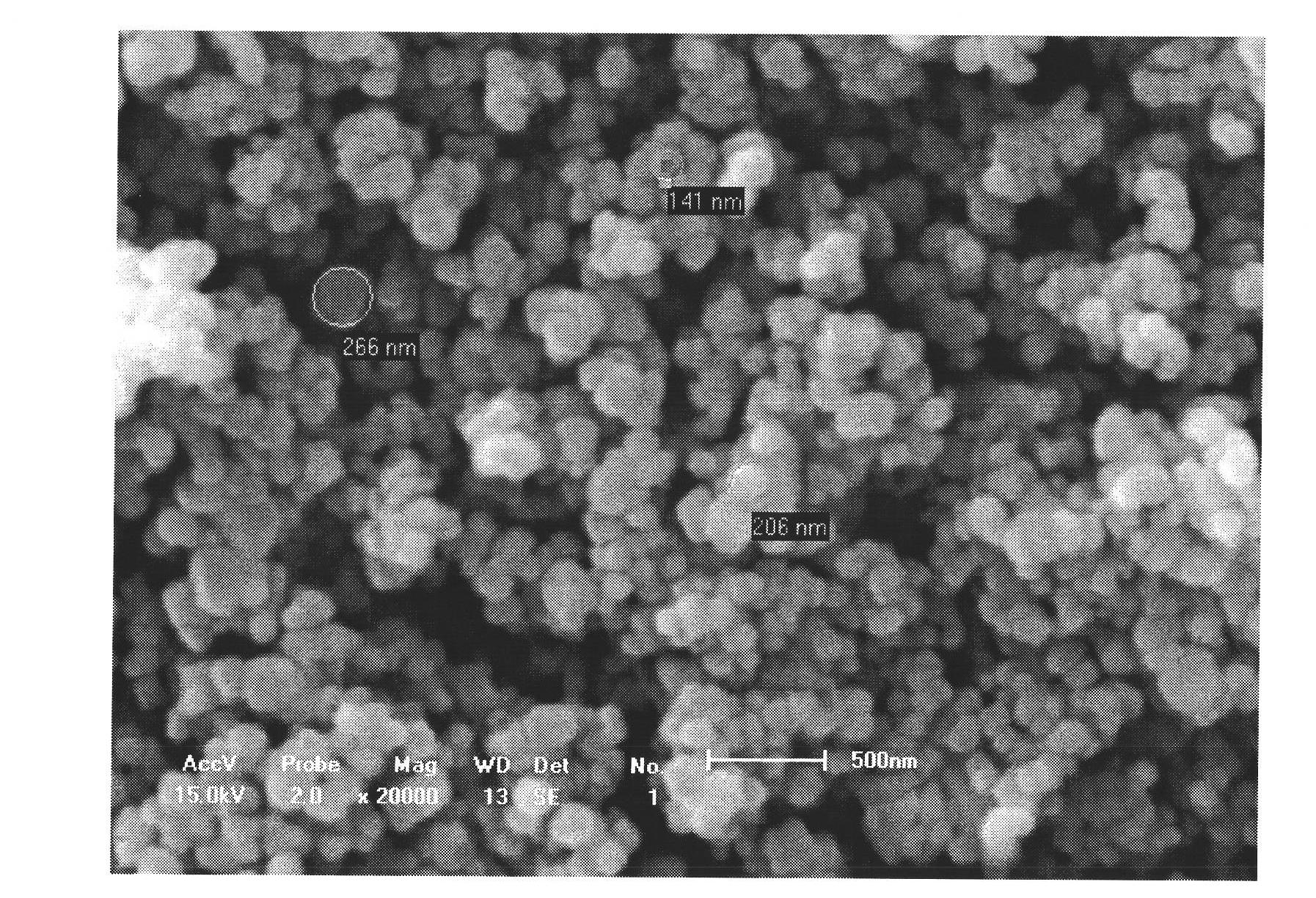

Preparation method of nano calcium carbonate capable of improving bonding strength of oxime-removing silicone sealant

ActiveCN103756366AImprove thixotropyHigh bonding strengthMaterial nanotechnologyNon-macromolecular adhesive additivesCrystal morphologyCarbonization

The invention relates to a preparation method of nano calcium carbonate capable of improving bonding strength of an oxime-removing silicone sealant. The preparation method has the characteristics that in the preparation process, the crystal morphology and growth rate of the crystal face are controlled according to the principle of crystallization to realize required crystal morphology and grain size; a certain amount of a dispersant is added into the carbonization process, and then strong stirring is performed, so that surface charge and steric hindrance are effectively controlled after nano calcium carbonate carbonization is terminated; surface treatment is carried out on nano calcium carbonate slurry under a certain process condition after particles in the nano calcium carbonate slurry are uniformly dispersed to further improve the steric hindrance and more uniformly disperse the particles; excellent nano calcium carbonate capable of improving bonding strength of the oxime-removing silicone sealant can be produced on an industrial device.

Owner:宣城新威华化工科技有限公司

Preparation of highly pure copper oxide from waste etchant

InactiveUS6649131B2Oxygen/ozone/oxide/hydroxideGold compoundsCrystal morphologyAqueous sodium hydroxide

A method for recycling copper oxide includes: a first step in which a sodium hydroxide aqueous solution is added to acidic copper chloride waste etchant produced in the PCB industry, to obtain copper hydroxide slurry; and a second step in which the slurry obtained in the first step is heated and sintered to thereby prepare a needle-form copper oxide. Since copper oxide has a purity of more than 99.0 wt % and the needle-form crystal morphology, so that it has an excellent filtering ability and homogeneous particle size distribution.

Owner:MYUNG JIN CHEM

Alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as preparation method for ceramic particles and application of ceramic particles

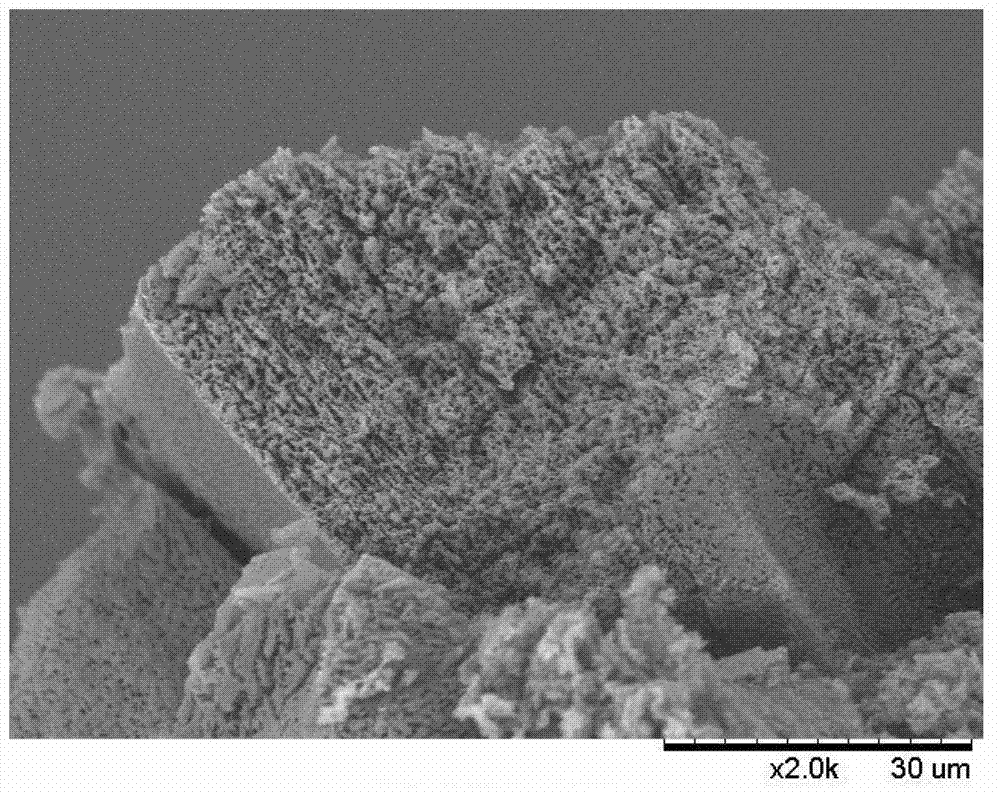

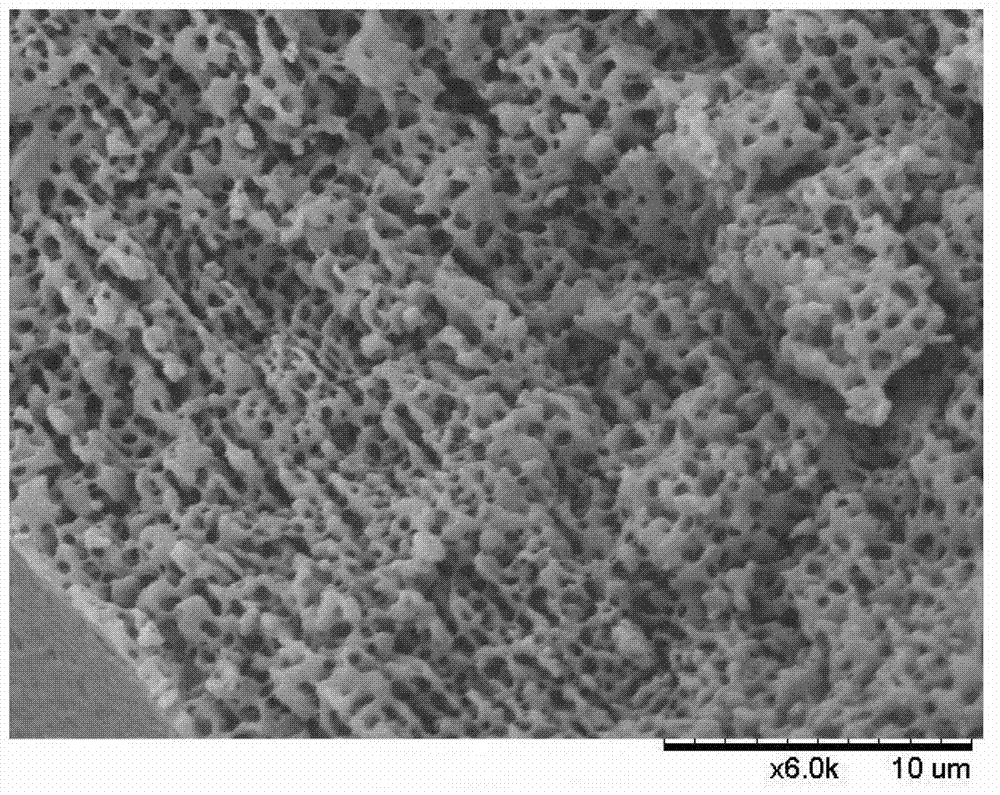

InactiveCN105622071AGood application effectGood grinding performanceLamellar crystalsCrystal morphology

The invention relates to alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as a preparation method for the ceramic particles and an application of the ceramic particles. The alpha-Al2O3 ceramic particles comprises magnetoplumbite lamellar crystals and aluminum oxide crystals, and the magnetoplumbite lamellar crystals are inserted in the aluminum oxide crystals in a penetration manner. The specific preparation method comprises the following steps: 1) dispersing low-cost industrial grade pseudo-boehmite to form slurry, then adding aqueous solutions of acid and additives, and stirring uniformly; 2) performing heat treatment on the slurry at 180-240 DEG C for 24-72 hours to obtain gel; 3) drying the gel, and grinding and screening the gel to form semi-finished products with different particle sizes; and 4) slowly heating the semi-finished products to 1,500-1,600 DEG C in a vacuum state, and keeping a target temperature for 2-4 hours to obtain the alpha-Al2O3 ceramic particles containing the lamellar microcrystals. The alpha-Al2O3 ceramic particles containing the lamellar microcrystals are good in toughness and good in primary crystal morphology controllability, and have excellent grinding performance; and the hardness value of the ceramic particles is greater than 20GPa and the ball-milling toughness of the ceramic particles is greater than 76%.

Owner:SHANDONG UNIV

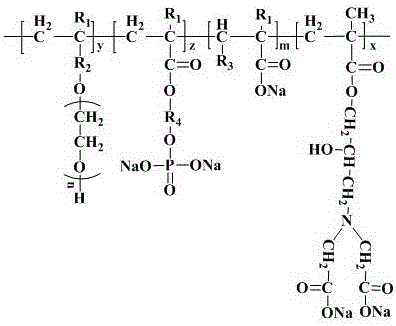

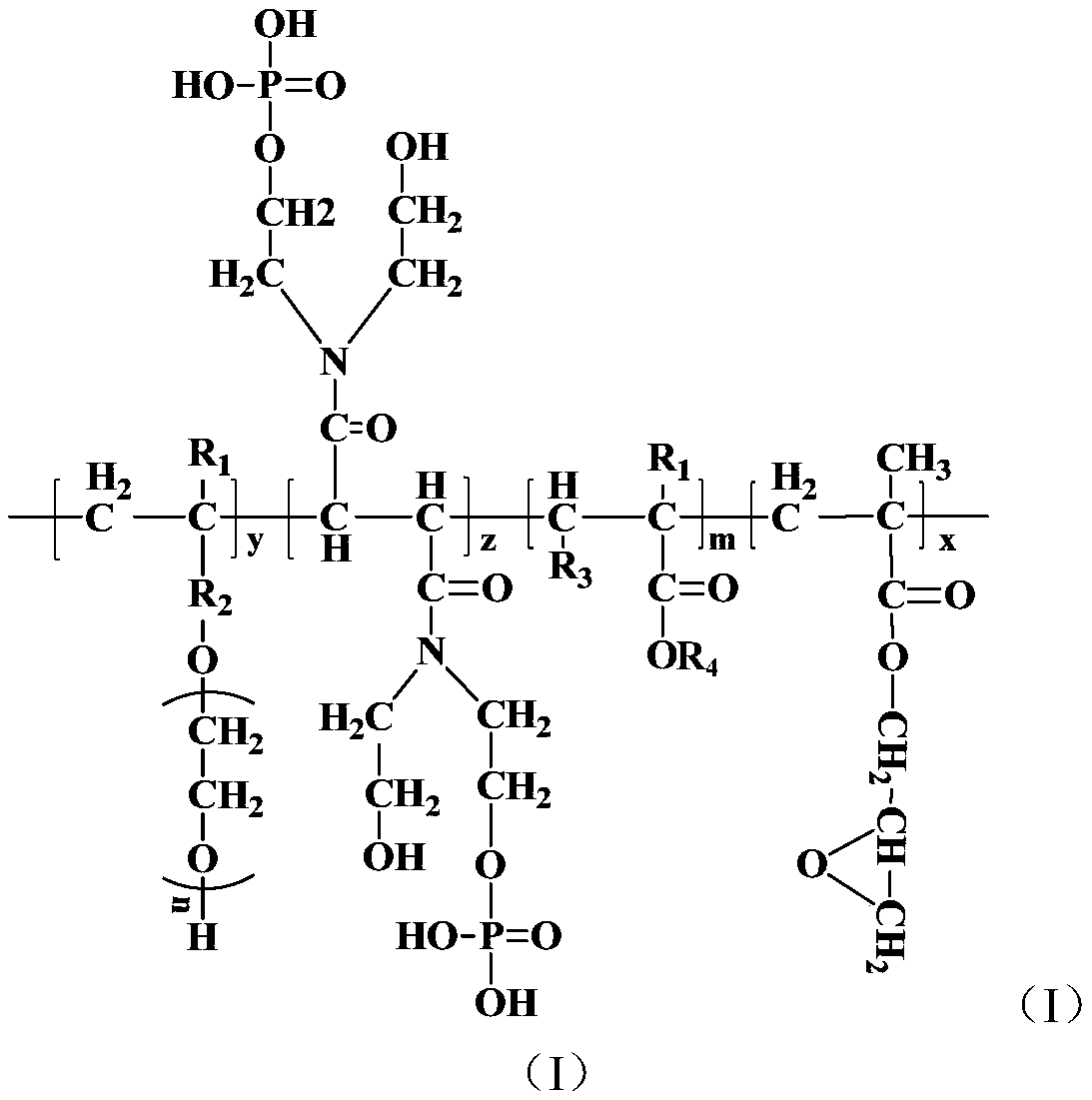

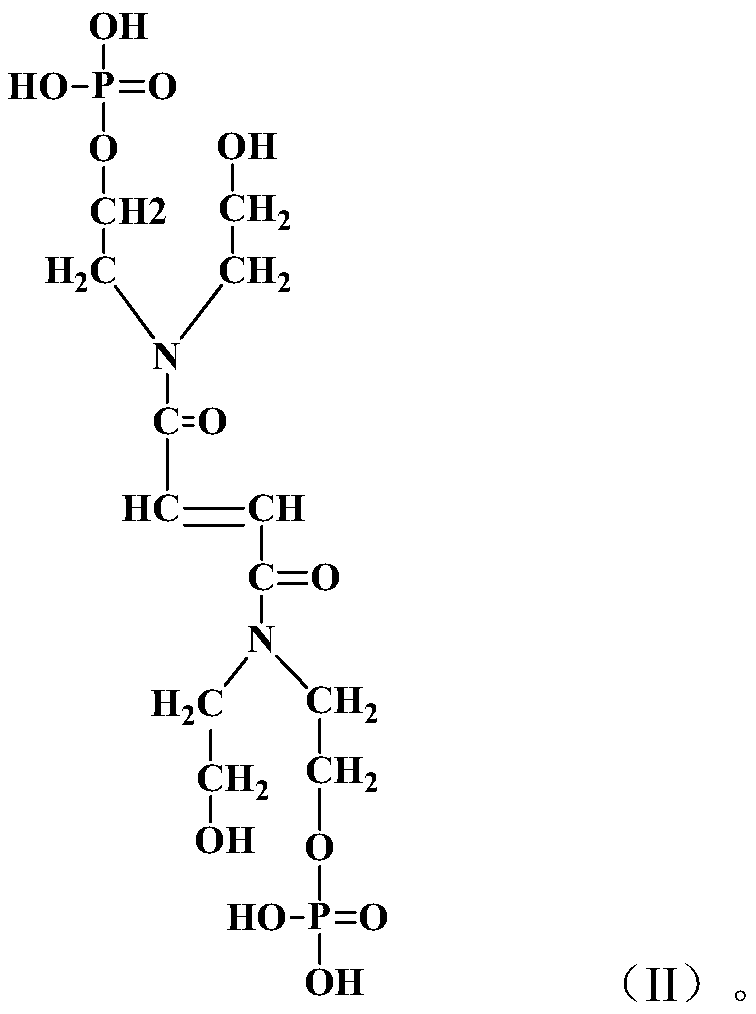

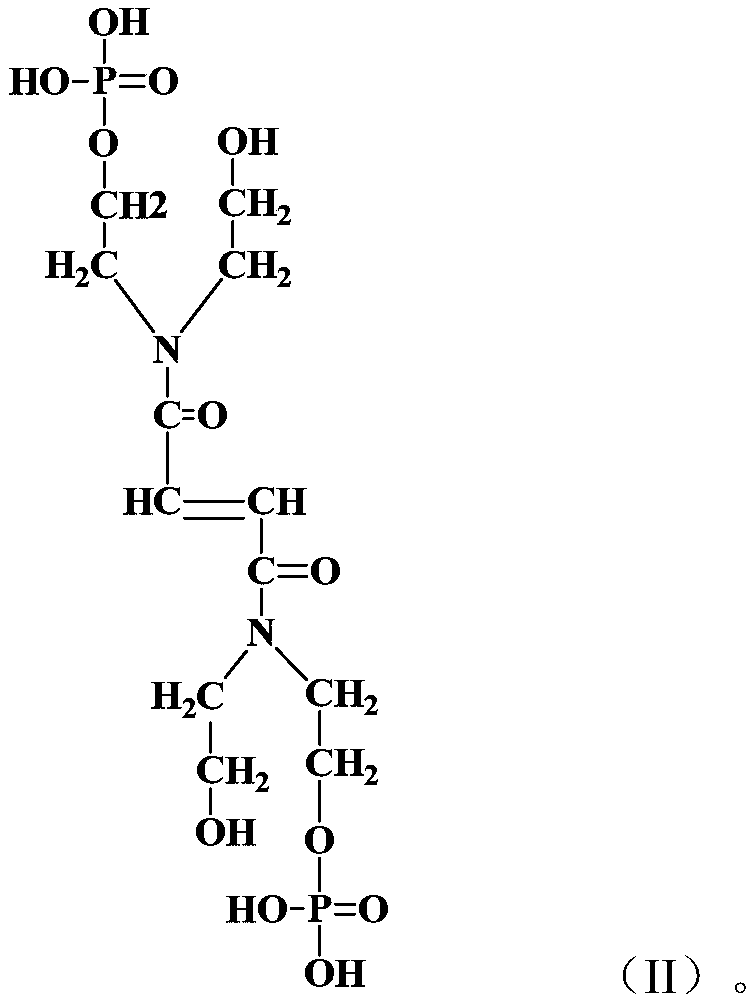

A phosphate-containing mud-resistant polycarboxylate water reducer and a preparing method thereof

A phosphate-containing mud-resistant polycarboxylate water reducer is provided and has a general chemical formula shown as a formula (I), wherein R1 is -H or -CH3, R2 is -CH2- or -CH2CH2-, R3 is -H, -COOH or -CH2COOH, R4 is -H or an alkali metal ion, and x, y, z, m and n are non-zero integers. The provided polycarboxylate water reducer has higher adsorption capacity than existing polycarboxylate water reducers, can effectively resist sulfates in cement, has greatly improved dispersion capability, and can change crystal morphology formed in the initial period of ettringite, thus improving slump loss resistance. The invention further provides a preparing method of the phosphate-containing mud-resistant polycarboxylate water reducer.

Owner:江西省建筑材料工业科学研究设计院

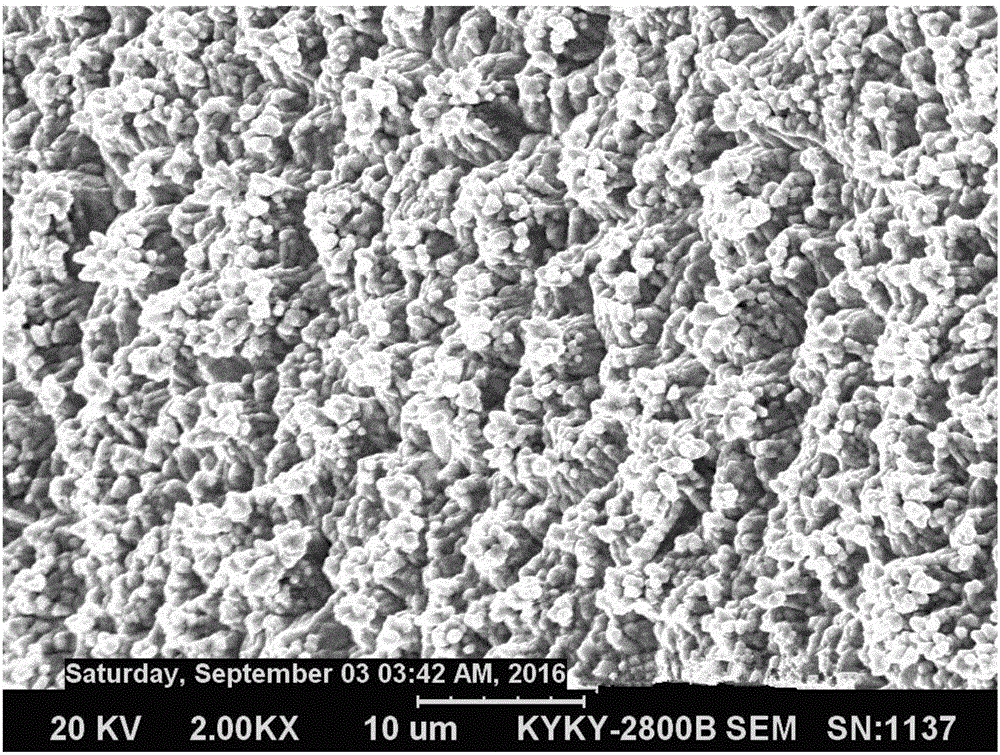

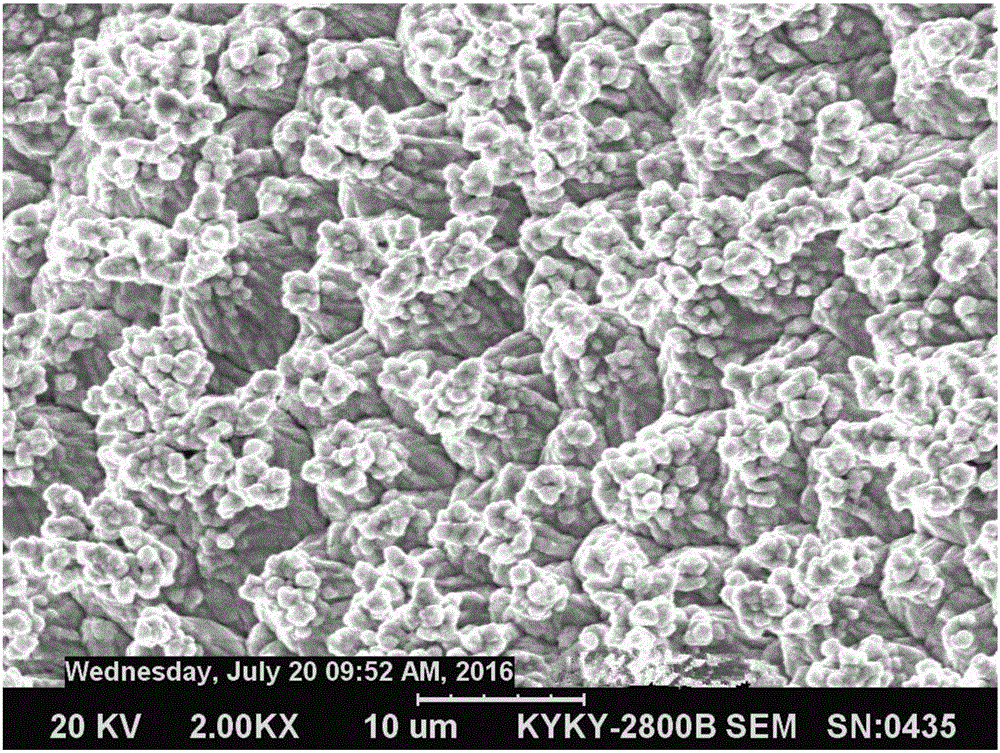

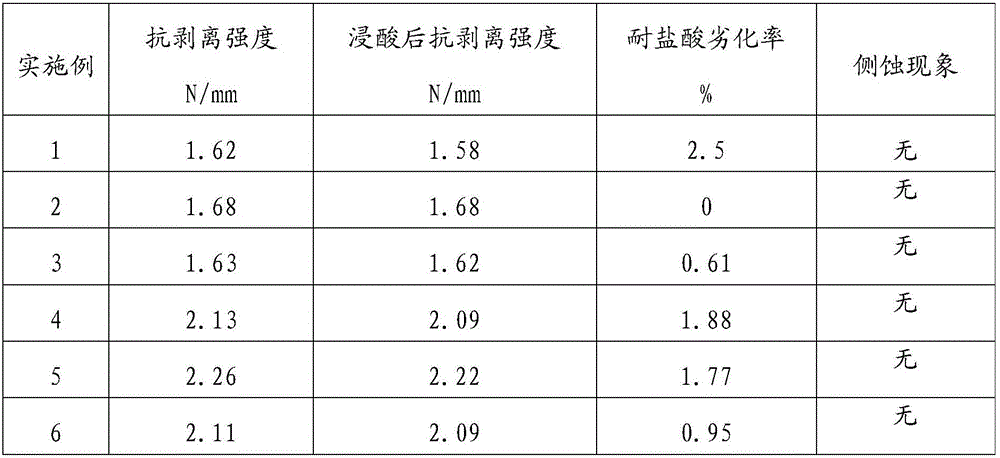

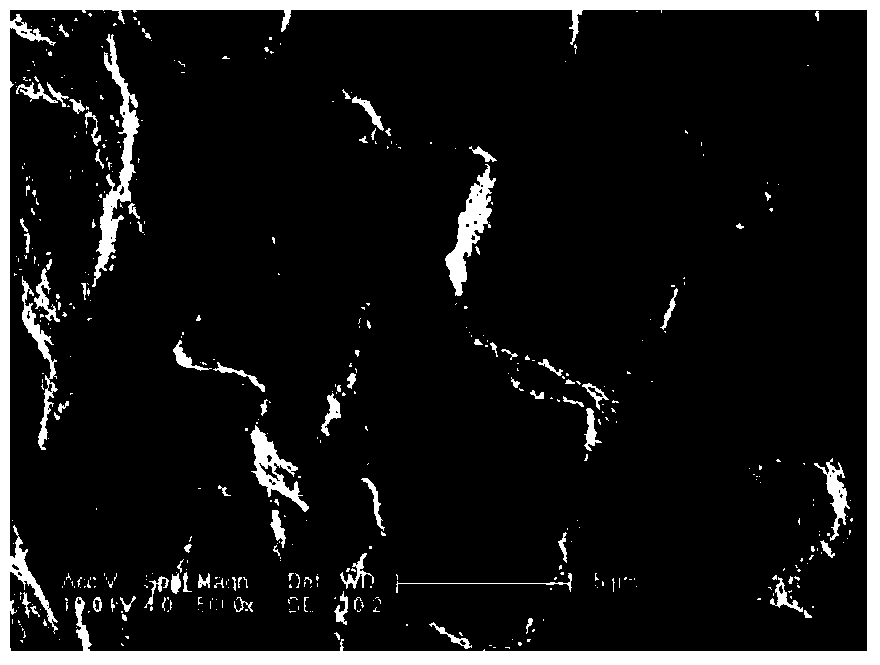

Surface treatment composite additive capable of improving corrosion resistance of copper foil

The invention belongs to the technical field of electrolytic copper foil processing and particularly relates to a surface treatment composite additive capable of improving the corrosion resistance of copper foil. Every liter of the aqueous solution of the composite additive contains 1.0-10 g of polyethylene glycol, 0.1-5.0 g of rare-earth salt, 0.1-15 g of sodium dodecyl benzene sulfonate and 0.2-3.0 g of chitosan. The prepared composite additive is good in control performance and high in stability. The composite additive is used during galvanization, and thus the crystal morphology of a coating can be changed. The coating on the surface of the produced copper foil is smooth and uniform, crystals are fine and compact, the hydrochloric acid degradation resistant rate of the copper foil is lower than 3%, and good corrosion resistance is achieved. In addition, the production process is simple and environmentally friendly, the cost is low, waste foil obtained after surface treatment can also be recycled, and the index of the copper foil is not influenced.

Owner:SHANDONG JINBAO ELECTRONICS

Preparation method for regenerating dental prosthetic material and acidic amino acid-induced demineralized dental enamel outer enamel prism thereof in situ

ActiveCN104000736AArranged in orderClosely arrangedImpression capsDentistry preparationsBiological activationTwo step

The invention discloses a method for regenerating a dental prosthetic material and an acidic amino acid-induced demineralized dental enamel outer enamel prism thereof in situ, and belongs to the technical field of in-situ regeneration of dental enamel outer enamel prisms. The preparation method is as follows: firstly, carrying out surface calcium activation onto a dental enamel surface, i.e., grafting calcium ions; then, forming calcium carbonate stable calcium ions step by step; finally, taking calcium carbonate stable calcium ions as foundation forms to synthesize hydroxyapatite crystals. Amino acid participates in the whole process, concentration of the amino acid added in a two-step process is consistent. The hydroxyapatite crystals deposited on the surface of the demineralized dental enamel are orderly and compact in sequence, and uniform in crystal morphology, so that obvious continued growth tendency of an artificial layer can be seen. The preparation method disclosed by the invention lowers protein extracting cost and harsh restrictions on an application environment, and is wide in prospect. The material prepared by the method disclosed by the invention can be applied to cosmetic dental for filling demineralization gaps, also can be used for repairing early-stage enamel demineralization, and can be used as a combined material for bottom pulp capping pit and fissure sealing, and the like.

Owner:JILIN UNIV

Method for preparing ordered porous energetic crystal material

ActiveCN103044173ASimple processMild reaction conditionsExplosive working-up apparatusNitrated pentaerythritol explosive compositionsCrystal morphologyRoom temperature

The invention discloses a method for preparing an ordered porous energetic crystal material. The method comprises the following steps of: dissolving a certain amount of energetic materials in a good solvent at room temperature; adding a certain amount of crystal morphology control agents into the solution in the previous step, stirring, dissolving, and slowly adding the solution in the previous step into a poor solvent of the energetic materials and the crystal morphology control agents under the magnetic stirring conditions; continuously stirring the solution in the previous step for a certain time, filtering, and obtaining a composite material of the energetic materials and the crystal morphology control agents; adding the obtained composite material into the solvent, wherein the solvent is a poor solvent of the energetic materials and a good solvent of the crystal morphology control agents; repeatedly washing and removing the crystal morphology control agents; and drying to obtain pure ordered porous energetic crystal material. The preparation method is simple in process flow and mild in reaction conditions and suitable for various energetic materials, the reaction conditions are easy to control, and the prepared ordered porous energetic crystal material has the purity of over 99.5 percent.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

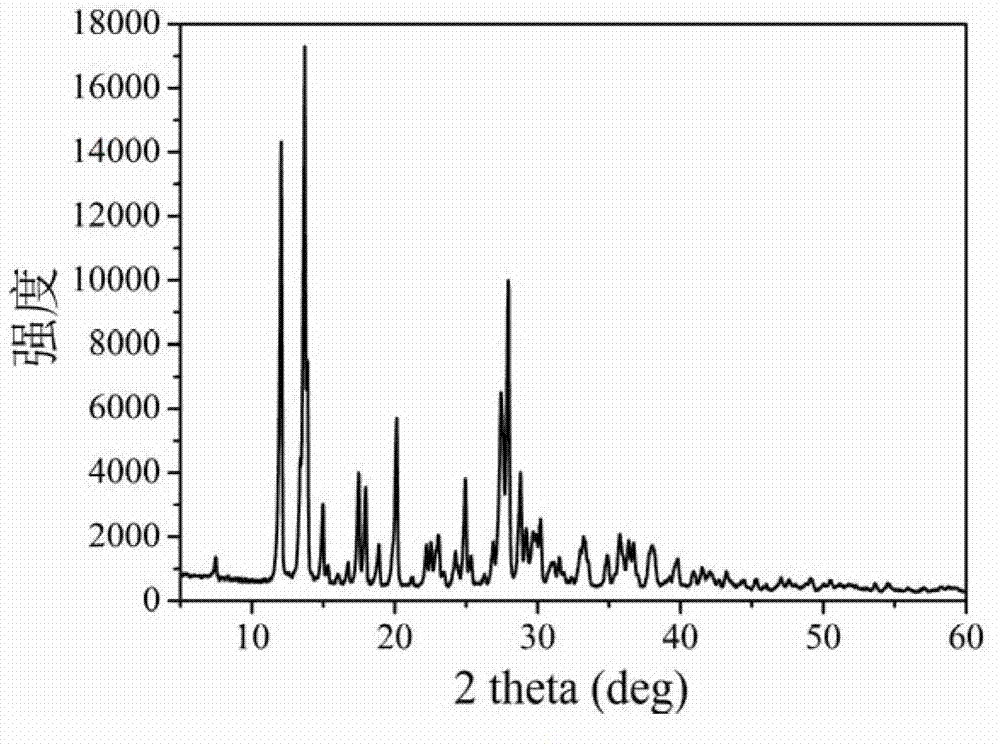

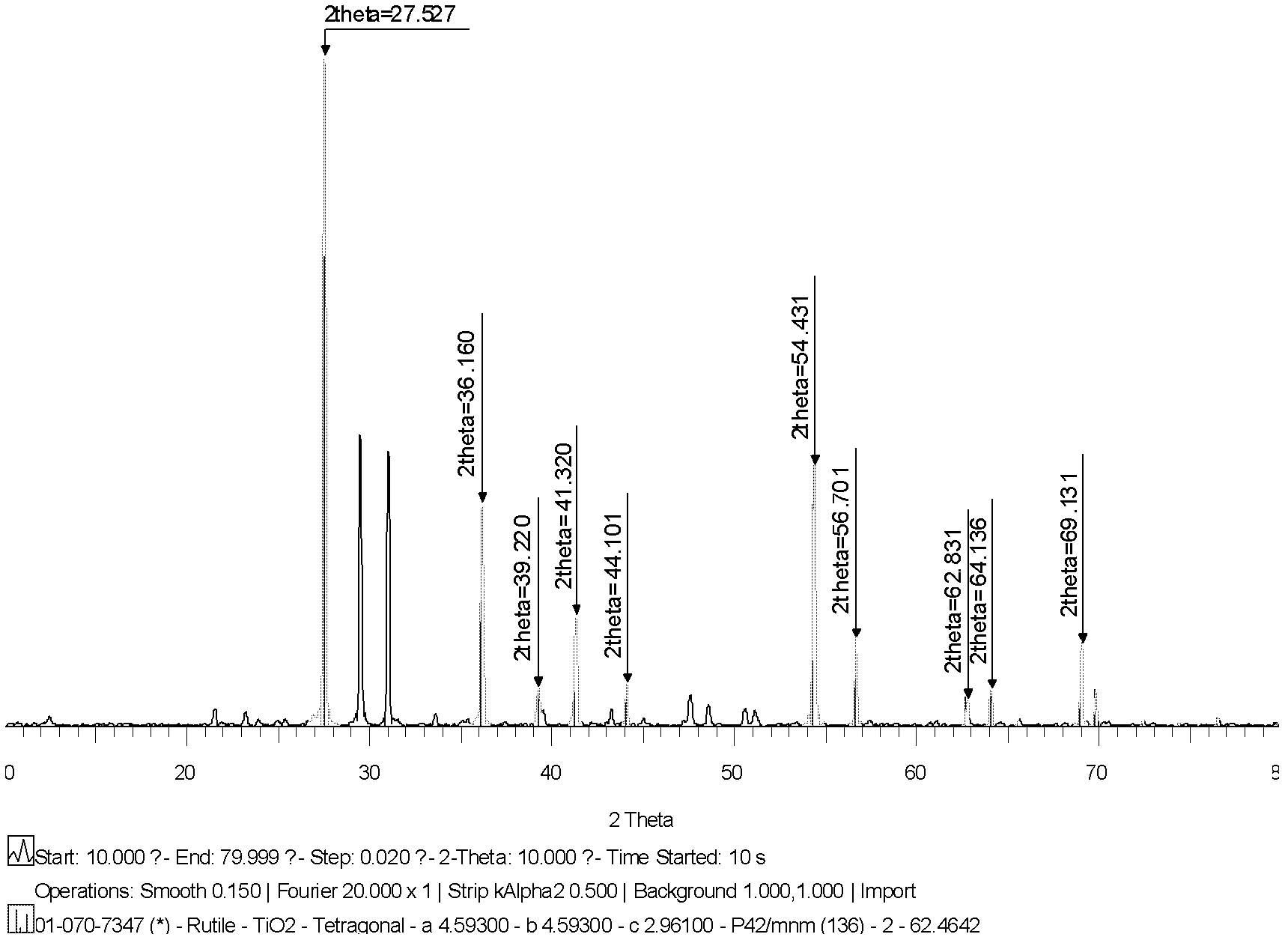

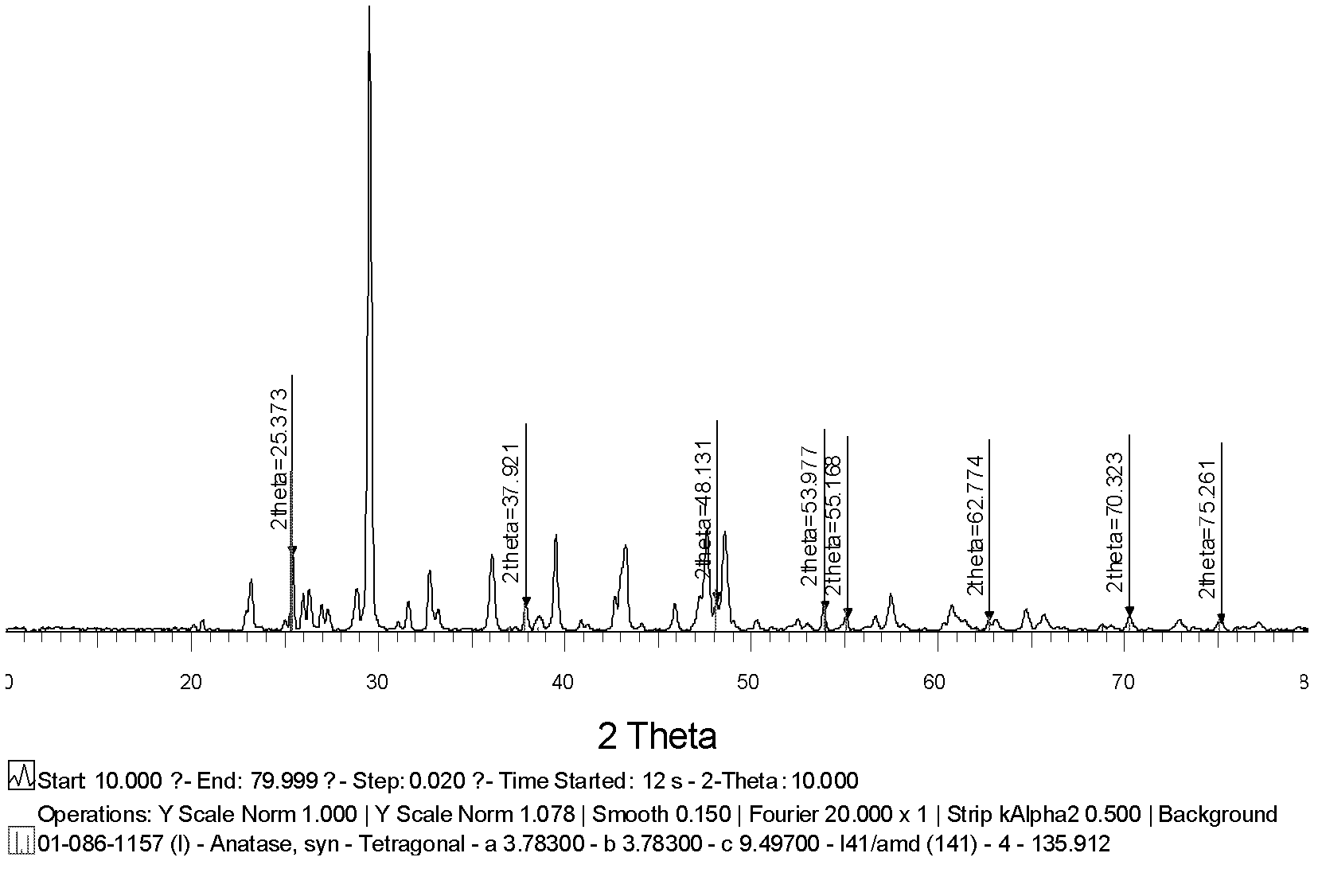

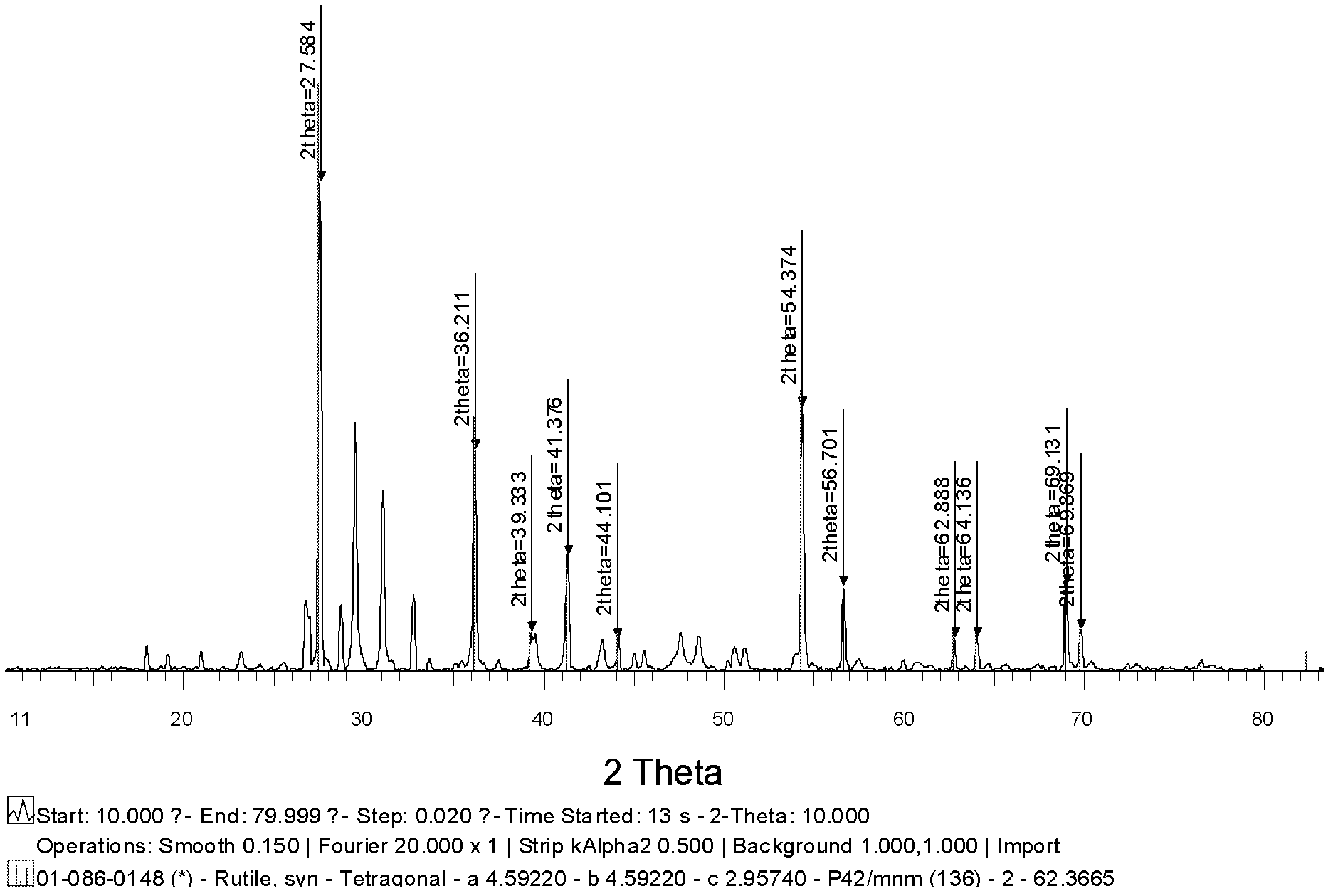

Identification and detection method for nanometer titanium dioxide in paints

InactiveCN102419280AThe experimental technique is accurate and reliableGood repeatabilityPreparing sample for investigationRaman scatteringUltravioletX-ray

The invention provides an identification and detection method for nanometer titanium dioxide in paints. According to the invention, qualitative and quantitative analysis of nanometer titanium dioxide in the paints is successfully carried out, and the technology of identification and detection of nanometer titanium dioxide in the paints is successfully realized through identification of the crystal structure and crystal microstructure characteristics of a nano-material and crystal morphology, particle size, distribution and the like of the nano-material by using powder X ray diffraction analysis (XRD), scanning electron microscope analysis (SEM) and spectral analysis. Meanwhile, the method of integrating sphere reflection is utilized to determine ultraviolet ray absorption of nanometer titanium dioxide in four paints, which provides reasonable evidence to the fact that nanometer titanium dioxide can be used as an additive for ultraviolet ray resisting or antibiosis paints.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

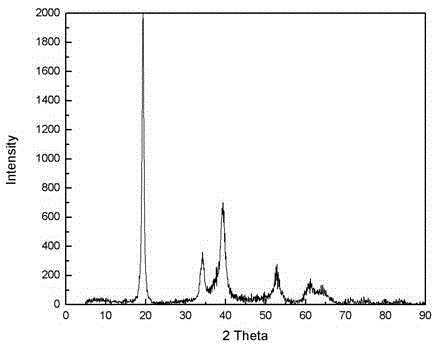

Preparation method for silicone-oil-based magnetic liquid

The invention discloses a preparation method for silicone-oil-based magnetic liquid. The preparation method for the silicone-oil-based magnetic liquid is mainly characterized in that 1, Fe3O4 is prepared with a coprecipitation method, and through comparison of physicochemical properties of Fe3O4, a ferric oxide crystal with good crystal morphology and magnetic performance is used for following decoration; 2, the surface of the ferric oxide crystal is coated with a SiO2 shell through a Stober method; 3, ferrite nanoparticles of a shell-core structure are obtained through the Fe3O4 magnetic particles covered by SiO2 and spread in silicone oil base liquid, and then the silicone-oil-based magnetic liquid is obtained. The obtained magnetic liquid can resist to high temperature and is high in saturation magnetization intensity, good in seal performance, high in pressure resisting capacity and long in sealing life.

Owner:ZIGONG ZHAOQIANG SEALING PROD IND

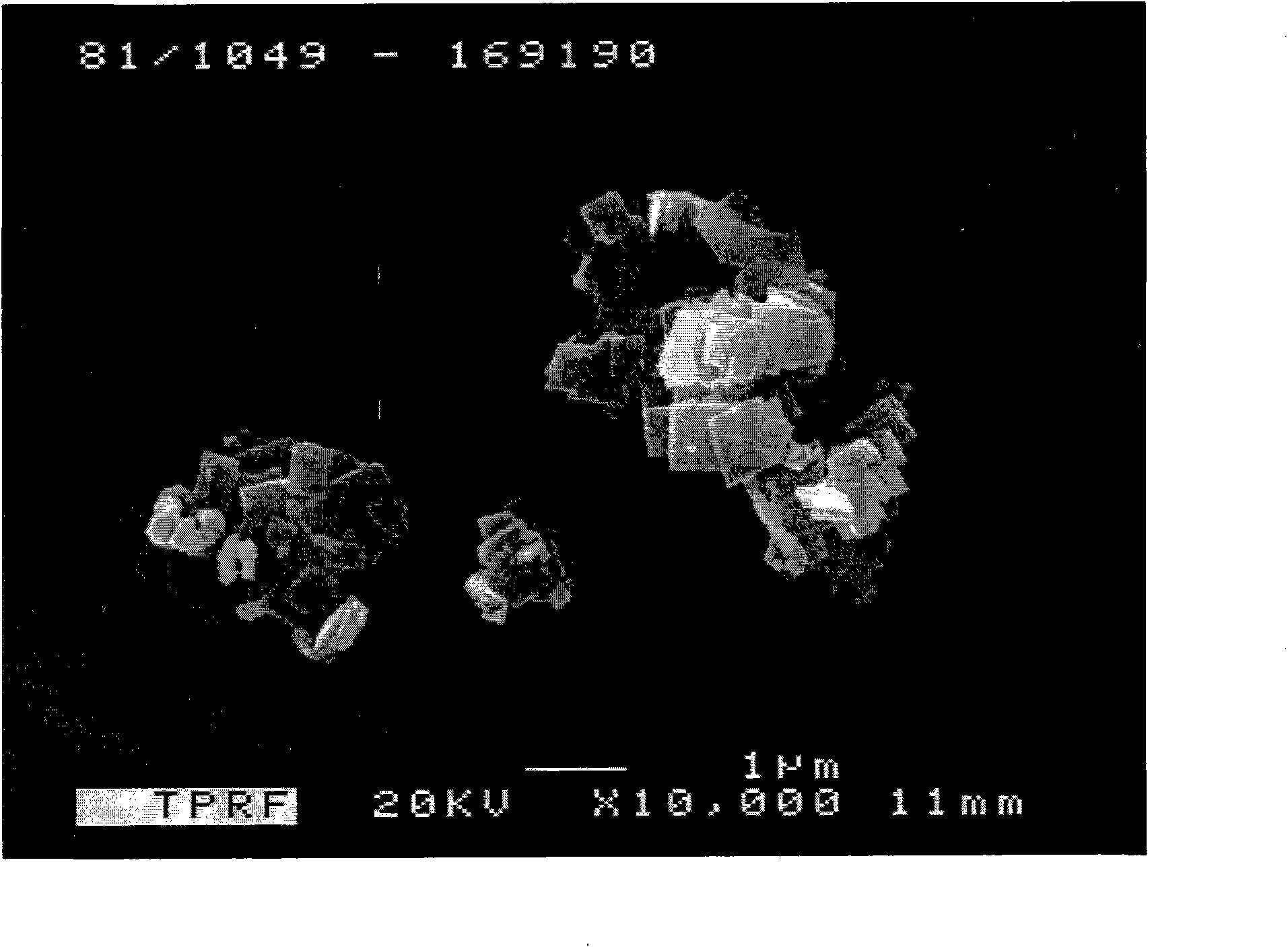

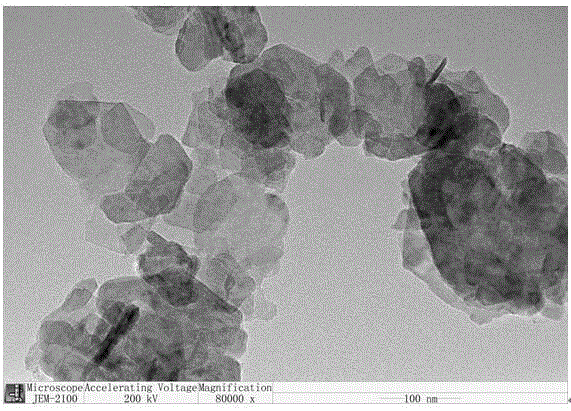

Preparation method of nano cobalt oxide

InactiveCN101982421AHigh densityHigh chemical purityNanostructure manufactureChemical industryForeign matterReaction temperature

The invention provides a preparation method of nano cobalt oxide, comprising the following steps: respectively preparing a cobalt raw material and precipitant into cobalt solution and precipitant solution by deionized water; adding the prepared cobalt solution with a certain concentration and the prepared precipitant solution with a certain concentration in accordance with a certain mole ratio toa reactor by using a parallel flow feed method; controlling the reaction temperature, the feed rate, the pH value and the stirring speed to prepare cobalt salt precursor; directly filling a water-containing filter cake into a bowl after washing and dehydrating; controlling the grain size and the crystal morphology through low-temperature dehydration, phase change calcination, mechanical pulverization and graded activation; and finally removing magnetic metallic foreign matters to obtain the nano cobalt oxide with high quality. The method is simple and easy to operate, has low cost, saves energy, is environmental friendly, and is applicable to industrial production; and the prepared cobalt oxide grains are fine and evenly distributed.

Owner:JIANGSU DONGXIN ENERGY TECH

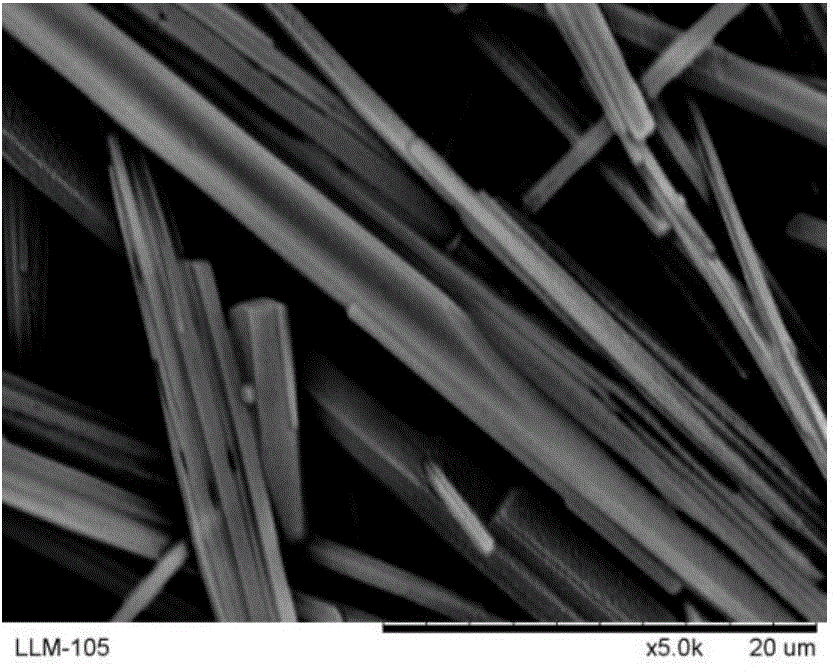

Morphology improvement method of LLM-105 explosives on basis of crystal-form modifying agent

The invention discloses a morphology improvement method of LLM-105 explosives on the basis of a crystal-form modifying agent. The morphology improvement method comprises the following steps of: firstly adding the LLM-105 explosives into a recrystallization solvent to obtain saturated solution of the LLM-105 explosives under the temperature of 20-150 DEG C, then adding one or more in a ketone-type crystal-form modifying agent, an acid-type crystal-form modifying agent, an amide-type crystal-form modifying agent, a polymer-type crystal-form modifying agent and an ion-liquid-type crystal-form modifying agent into the saturated solution of the LLM-105 explosives and stirring to be uniform; and finally, adopting a solvent-out crystallization method to obtain LLM-105 crystals. The morphology improvement method disclosed by the invention has the advantages that the crystal morphology of the LLM-105 explosives can be effectively improved; the prepared crystal of the LLM-105 explosives with regular morphology such as a rod shape, a needle shape and a block shape is prepared and obtained; the preparation method is simple in process route, is moderate in reaction condition and good in safety; and all the solvents can be recovered, so that environmental pollution can not be caused and the suitability for batch production is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for preparing metalloaluminophosphate (MEAPO) molecular sieve

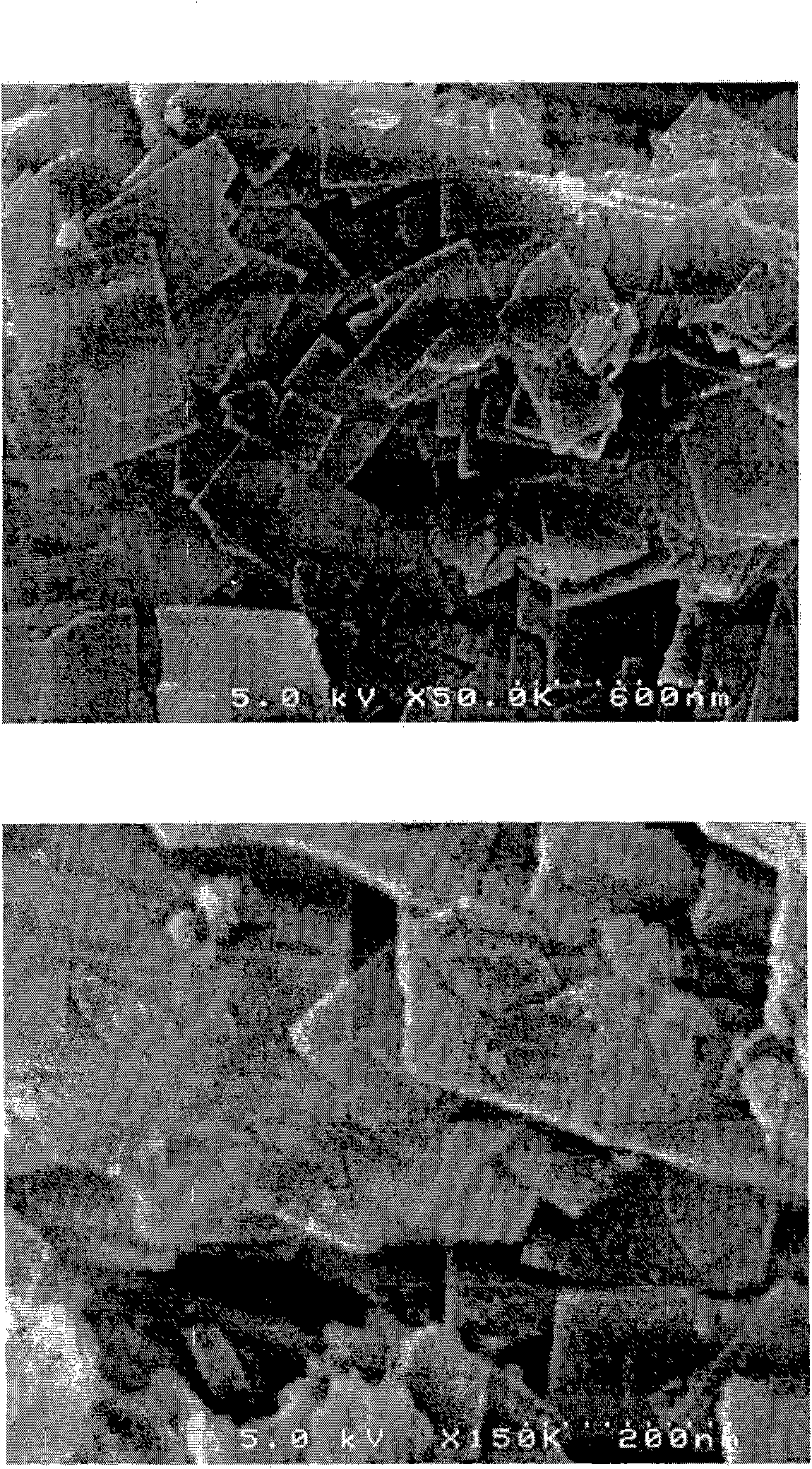

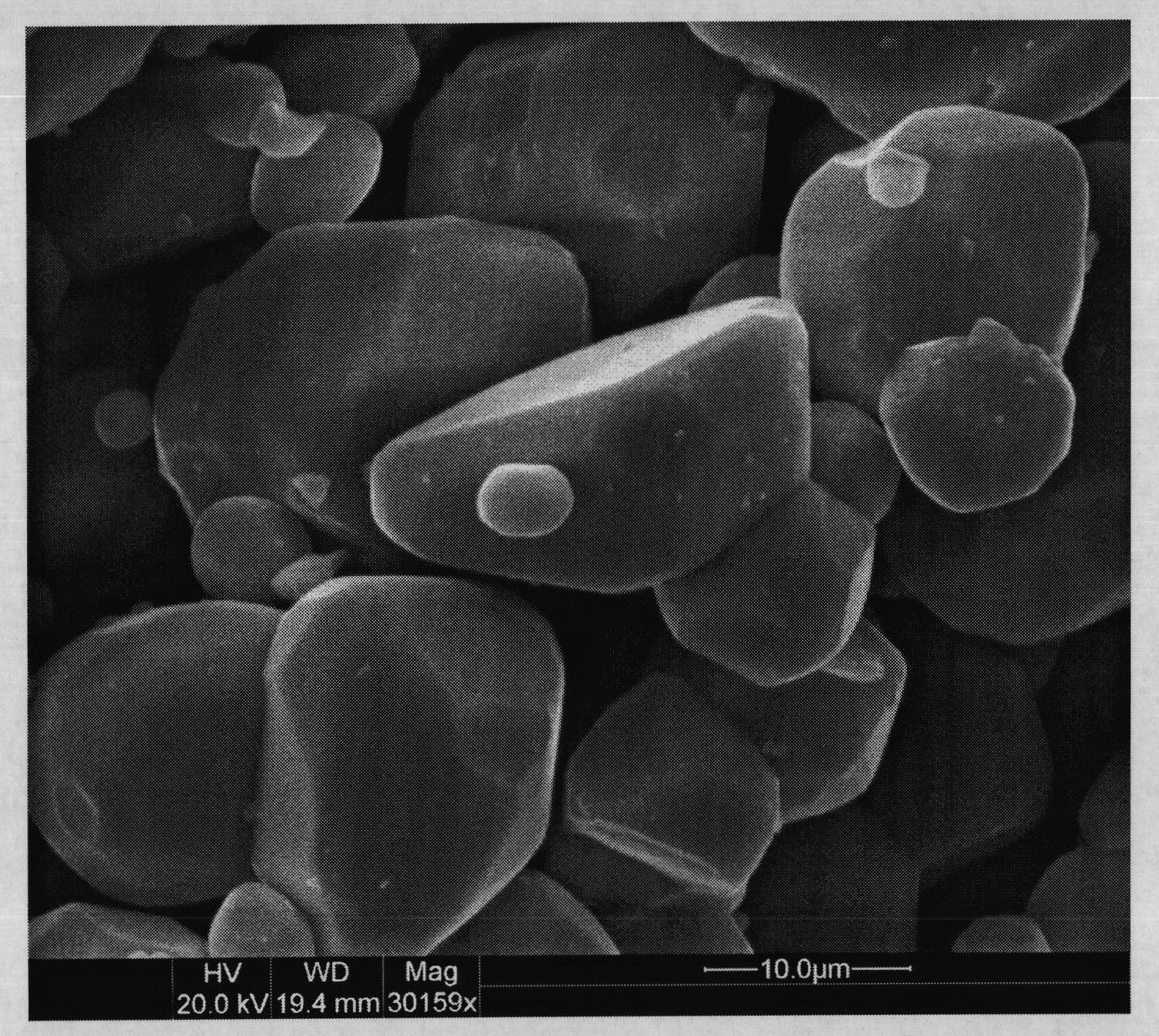

InactiveCN101679054AIncrease productionIncrease flexibilityMolecular sieve catalystsMolecular sieve catalystLamellar crystalsCrystal morphology

The present invention also relates to a method for preparing metalloaluminophosphate (MeAPO) molecular sieve said method comprising : a) forming a reaction mixture containing a texture influencing agent (TIA), an organic templating agent (TEMP), at least a reactive inorganic source of MeO2 insoluble in the TIA, reactive sources of Al2O 3 and P2O5, b) crystallizing the above reaction mixture thus formed until crystals of the metalloaluminophosphate are formed, c) recovering a solid reaction product, d) washing it with water to remove the TIA and e) calcinating it to remove the organic template.In a usual embodiment said reaction mixture has a composition expressed in terms of molar oxide ratios of: TEMP / Al2O3=0.3-5, more desirable 0.5-2 MeO2 / Al2O3= 0.005-2.0, more desirable 0.022-0.8 P2O5 / Al2O3=0.5-2, more desirable 0.8-1.2 TIA / Al2O3=3-30, more desirable 6-20. In a usual embodiment the metalloaluminophosphate (MeAPO) molecular sieves made with the above method have a lamellar crystal morphology having an empirical chemical composition on an anhydrous basis, after synthesis and calcination, expressed by the formula HxMeyAlzPkO2 wherein, y+z+k=1, x<=y, y has a value ranging from 0.0008 to 0.4 and more desirable from 0.005 to 0.18, z has a value ranging from 0.25 to 0.67 and more desirable from 0.38 to 0.55, k has a value ranging from 0.2 to 0.67 and more desirable from 0.36 to 0.54, said molecular sieve having predominantly a plate crystal morphology. In an advantageous embodiment the MeAPO made by the method of the invention have essentially a structure CHA or AEI or a mixture thereof. Preferably they have essentially the structure SAPO 18 or SAPO 34 or a mixture thereof. The present invention also relates to catalysts consisting of the above MeAPO molecular sieves madeby the method of the invention or comprising the above MeAPO molecular sieves made by the method of the invention.

Owner:TOTAL RES & TECH FELUY +1

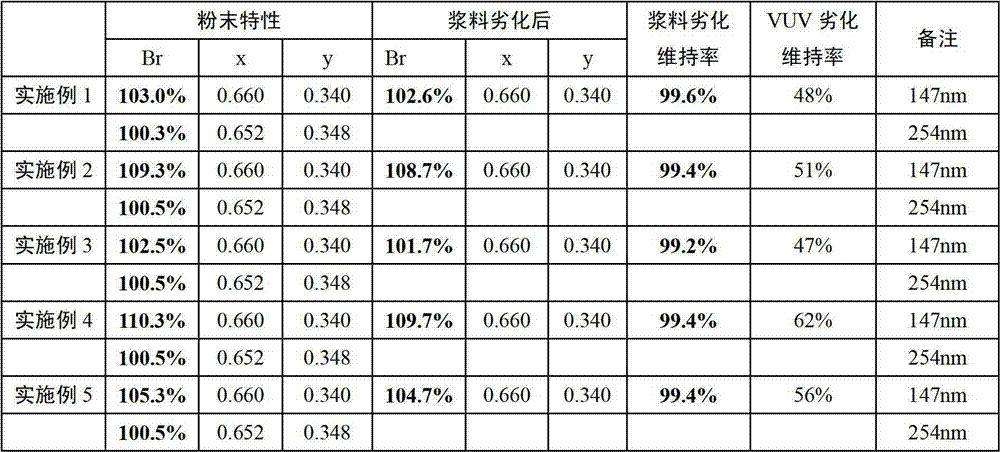

Preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to 3D PDP

InactiveCN102766457AReduce hydrolysisImprove surface integritySolid cathode detailsLuminescent compositionsRare earthYttrium

A preparation method for yttrium gadolinium europium oxide red fluorescent powder applicable to a 3D PDP (Plasma Display Panel) comprises the steps as follows: a rare earth oxalate coprecipitation body is prepared by adopting a coprecipitation method, rare earth metal oxide is balanced and dissolved in nitric acid or chlorhydric acid to form a rare earth metal salt solution; an oxalic acid solution or a carbonate solution is prepared and added into the rare earth metal salt solution to obtain rare earth metal oxalate or a carbonate precipitate; the carbonate precipitate is filtered and isolated, dried and burned to obtain a rare earth oxide coprecipitation body; the coprecipitation body is oxidized and burned to form a yttrium gadolinium europium oxide red fluorescent powder burned body; the rare earth oxide coprecipitation body is added with a cosolvent and is loaded in an aluminum oxide crucible and is burned under high temperature in an oxidizing furnace; after burned, the rare earth oxide coprecipitation body is shattered after burning to obtain a yttrium gadolinium europium finished product; and finally, the yttrium gadolinium europium oxide red fluorescent powder is obtained according to a downstream treatment process. The fluorescent powder prepared according to the method has the advantages of high lighting brightness, good color purity, complete crystal morphology, small powder center particle size, simple manufacturing method and low production cost, and is suitable for industrial production.

Owner:CAIHONG GRP ELECTRONICS CO LTD

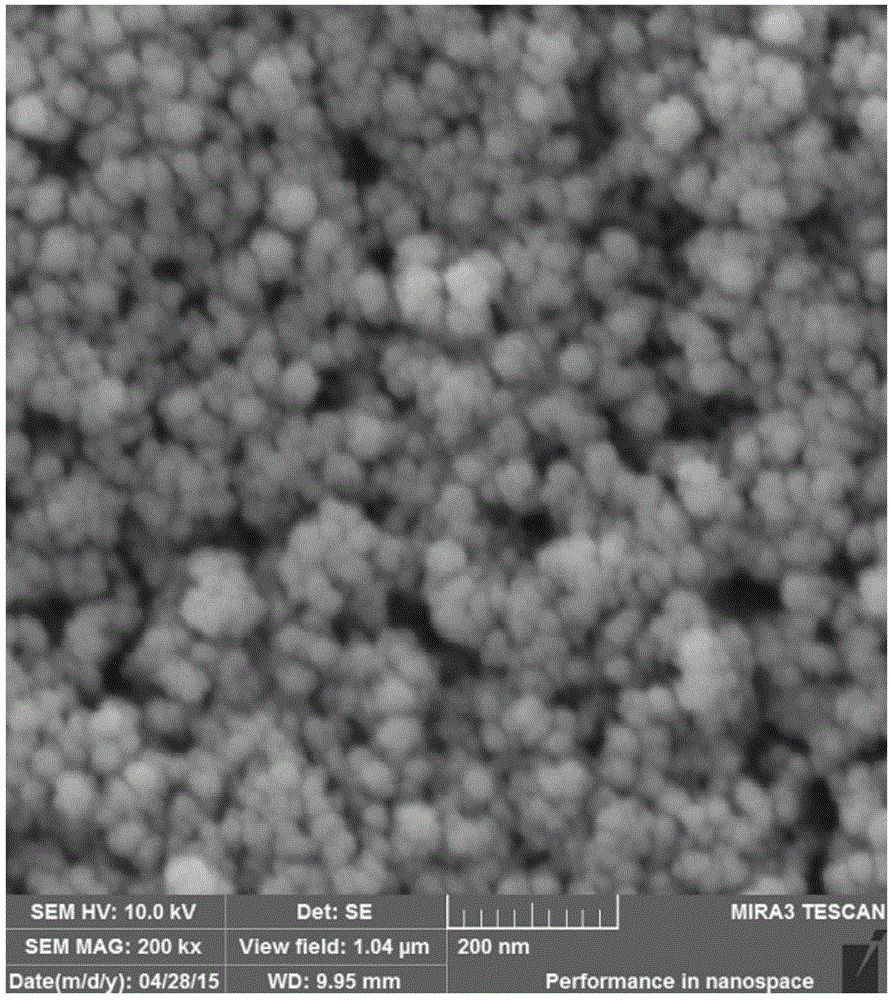

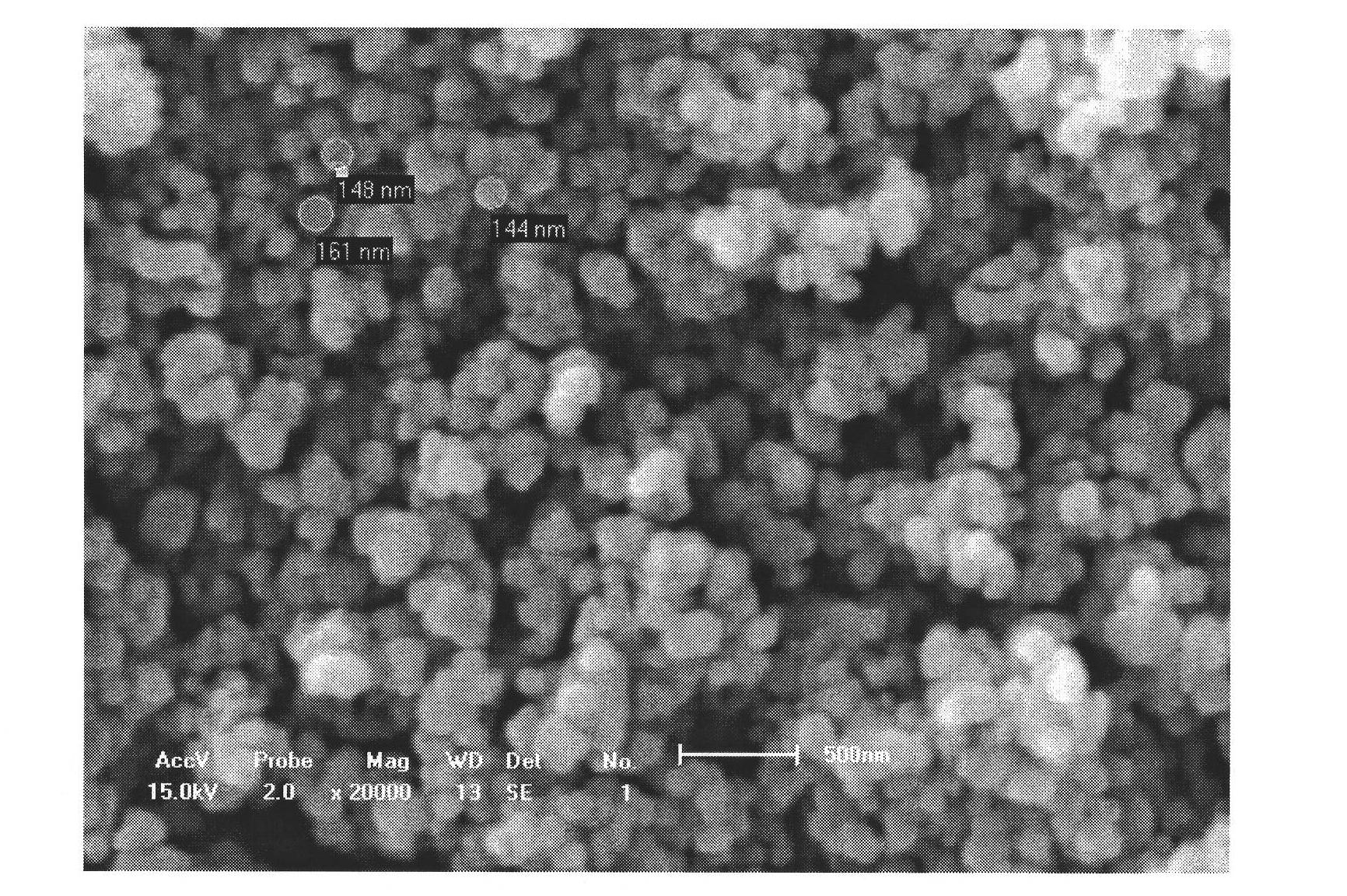

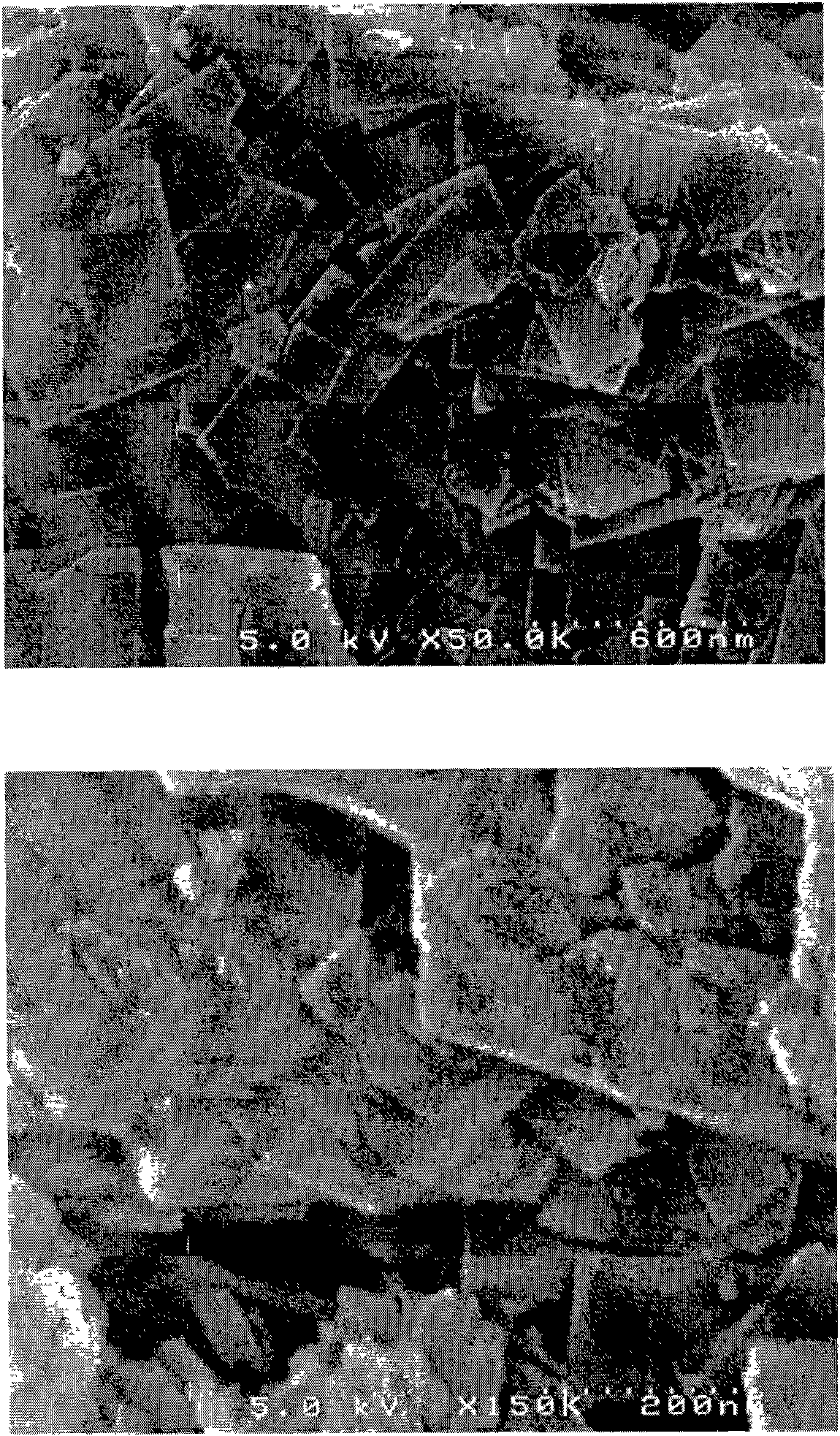

Preparation method of Ni-Co-Mn lithium ion battery electrode material

ActiveCN105271444AReduce capacityImprove electrochemical performanceCell electrodesNickel compoundsCrystal morphologySOLUTION/DROPS

The invention relates to a preparation method of a Ni-Co-Mn lithium ion battery electrode material and belongs to the field of a new energy technology. According to the invention, a mixed solution of sodium hydroxide and ammonia water is used as a precipitating agent, nickel sulfate, cobalt sulfate and manganese sulfate are used as metal salts, and a crystallization precipitation reaction is controlled to prepare a nickel-cobalt-manganese mixed hydroxide. Before adding a reaction solution drop by drop, a certain amount of polyvinylpyrrolidone-K30 is dissolved in a base solution to be used as a crystal-growing controlling agent; and then, under the protection of the inert gas nitrogen, crystal growth process of a resultant is controlled through synergism of ultrasonic cavatition and dispersion and the crystal-growing controlling agent. Then, the crystal morphology is controlled. The whole reaction process is carried out at normal pressure and at the temperature of less than 100 DEG C, and the reaction condition is mild. The coprecipitation product is a composite hydroxide nanosheet with a brucite structure, and no other impure phases are formed. The size of the nanosheet is 100-400 nm, and thickness is about 5-10 nm.

Owner:KUNMING UNIV OF SCI & TECH

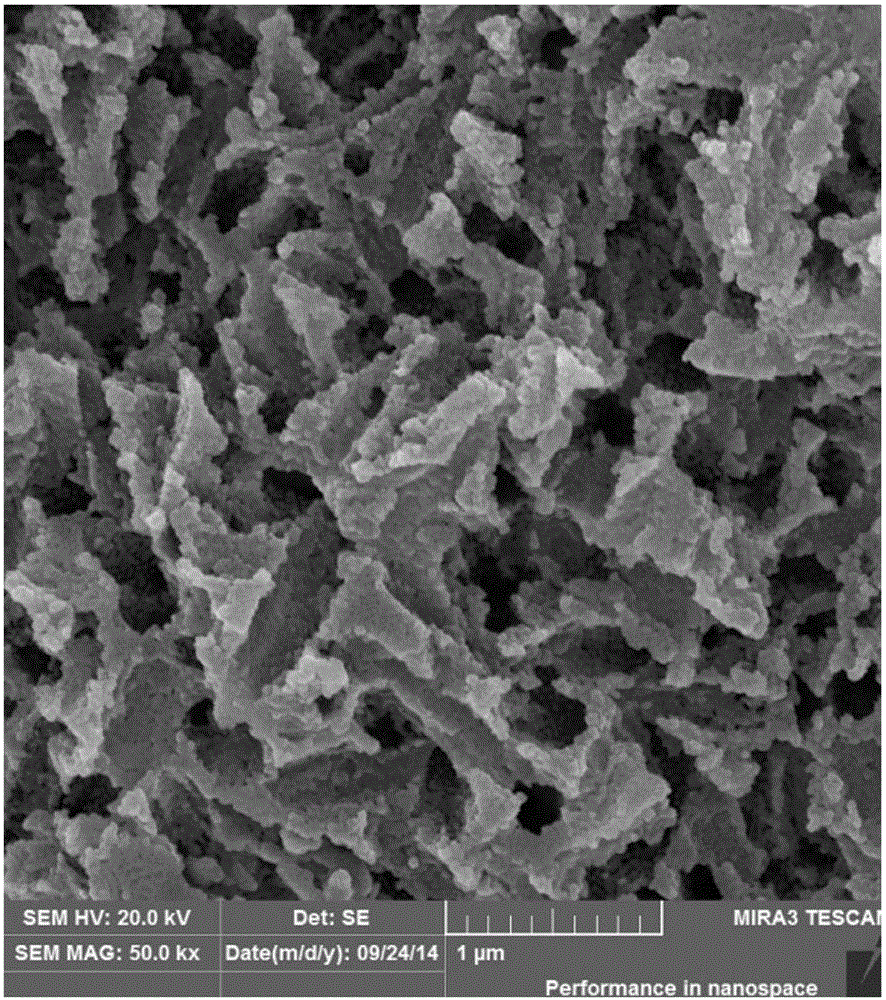

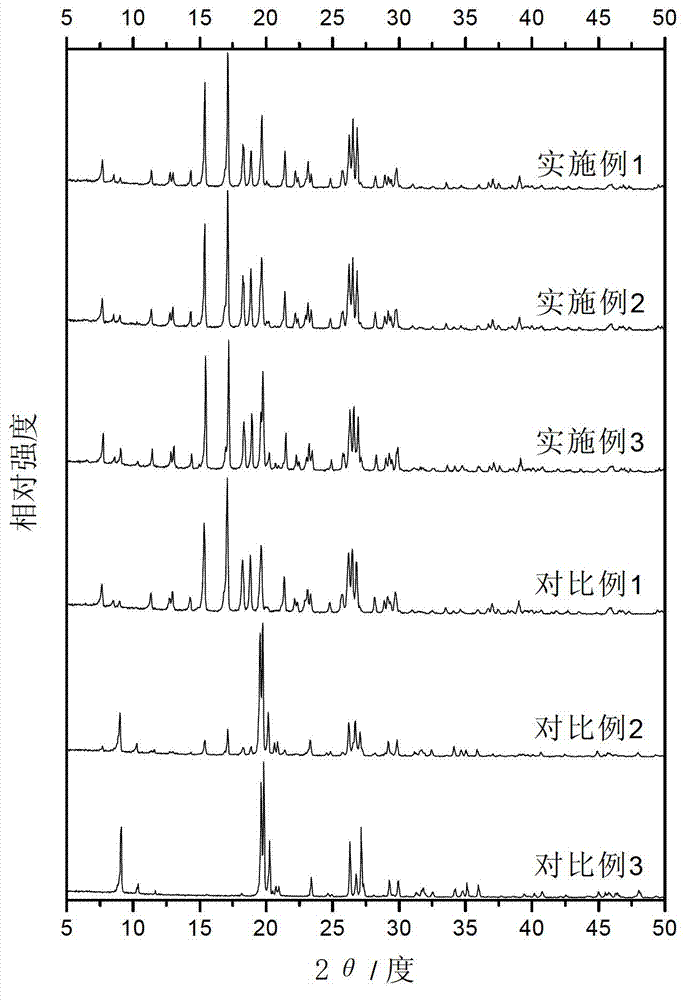

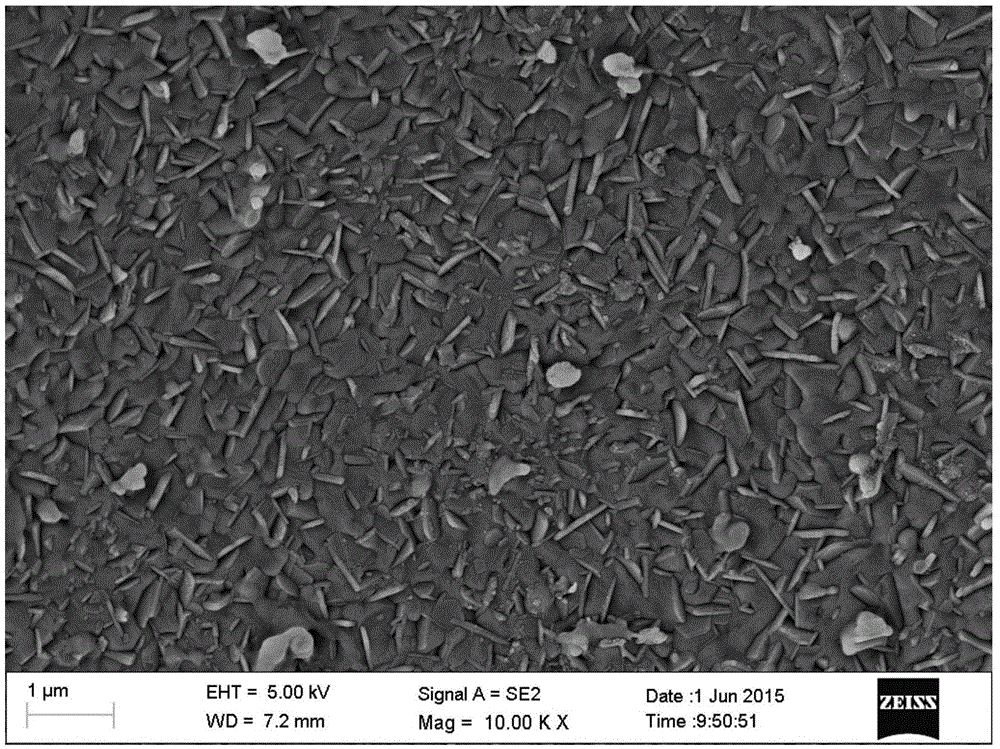

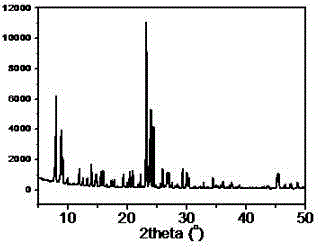

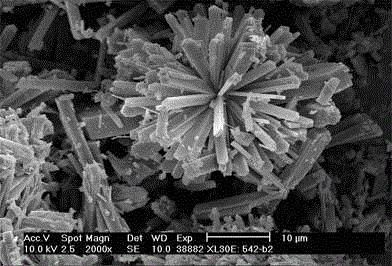

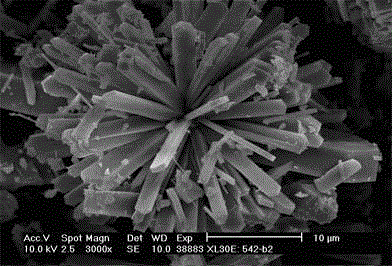

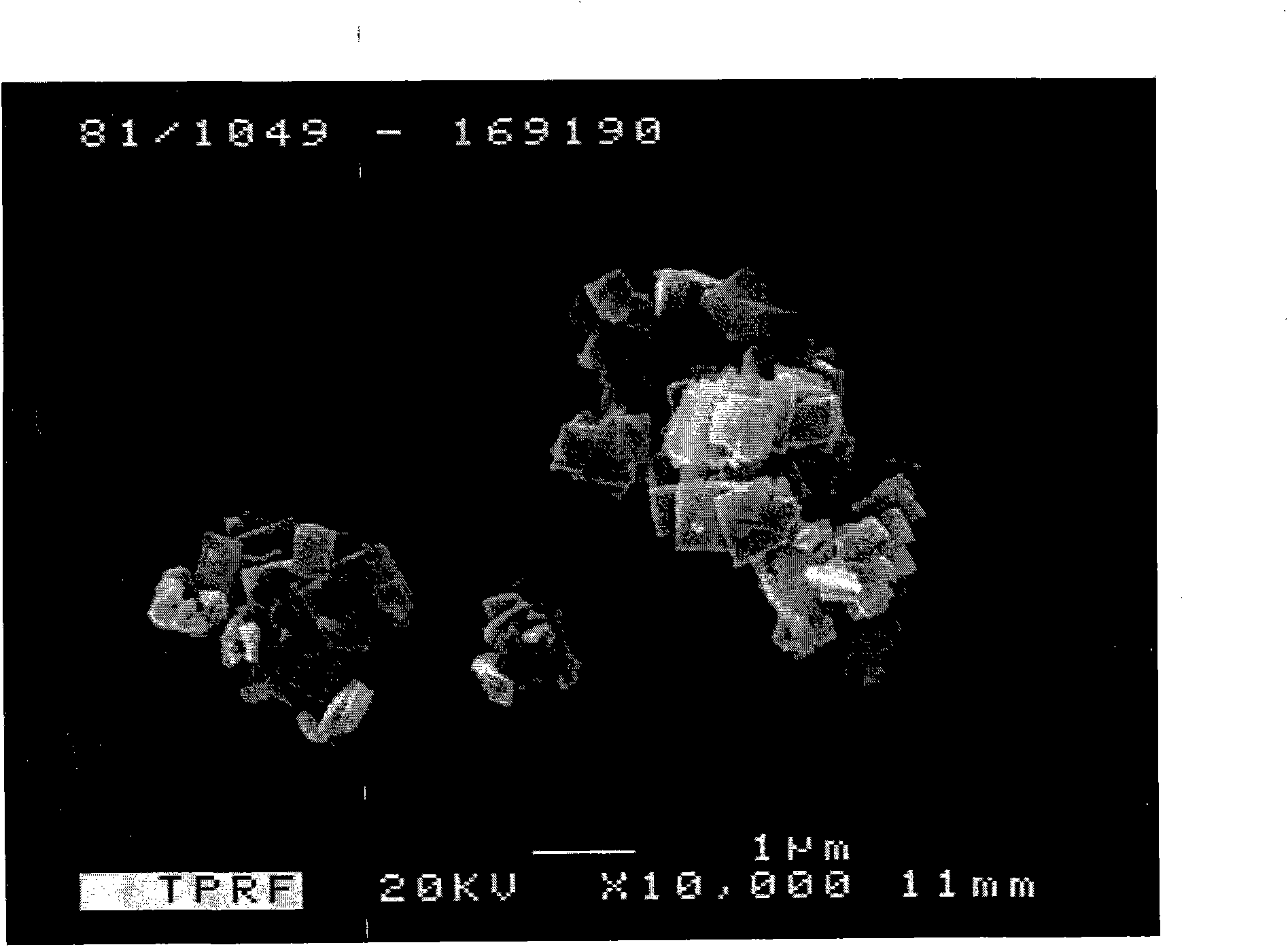

Synthesis method for ZSM-5 molecular sieve of special morphology

ActiveCN105293520AAdjust grain sizeControl shapePentasil aluminosilicate zeoliteMolecular sieveCrystal morphology

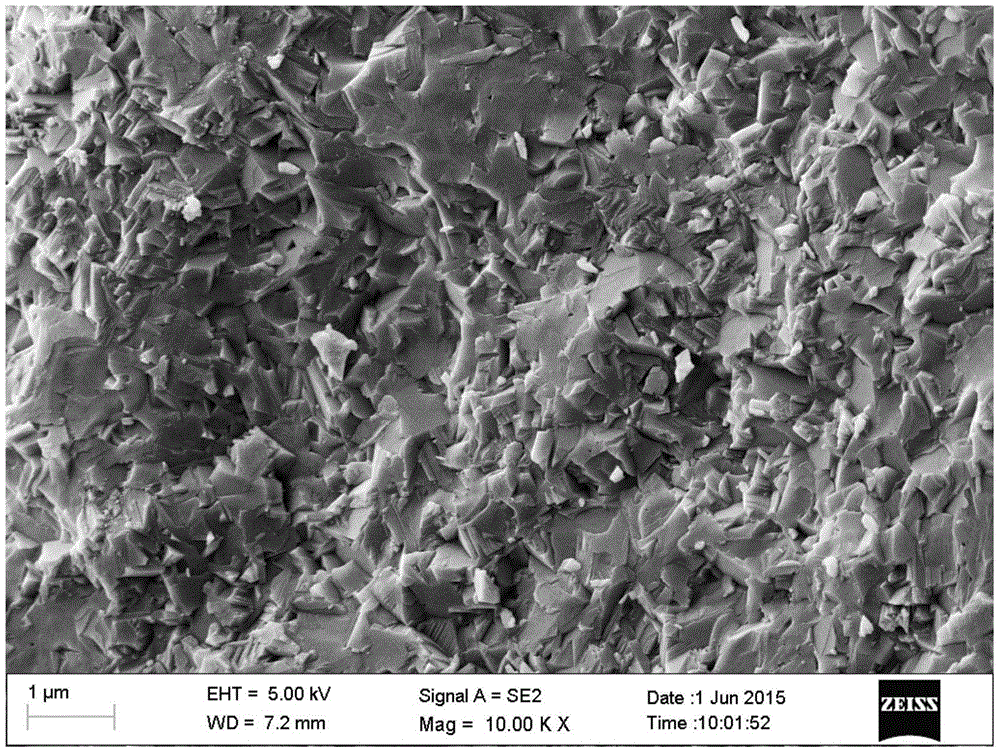

The invention belongs to the technical field of zeolite molecular sieve synthesis, in particular to a synthesis method for a ZSM-5 zeolite molecular sieve of a petaloid morphology. According to the synthesis method, morphology control is an important aspect in the field of molecular sieve synthesis; when MFI zeolite molecular sieve catalysts of different crystal morphologies are adopted in a catalytic reaction, all of the product selectivity, the reaction activity, the reaction stability and the like can be changed obviously along with the morphology difference. The invention further relates to a preparation method for ZSM-5 zeolite. The synthesis method provided by the invention has the advantages that the synthesis process is simple and convenient, and industrialization is easy to realize; meanwhile, a plurality of templates are applied, so as to effectively control the product crystallinity and the final morphology; sample XRD shows that the obtained product is the ZSM-5 molecular sieve of which the product crystallinity is high; sample SEM shows that zeolite has a special petaloid morphology, and thus can be utilized for industrial production of ZSM-5 zeolite of the special petaloid morphology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cobaltosic oxide with large grain size and high safety

InactiveCN101982422ARefined grain sizeGrain Size ControlCobalt oxides/hydroxidesCrystal morphologyForeign matter

The invention provides a method for preparing cobaltosic oxide with large grain size and high safety, comprising the following steps: preparing the raw material cobalt and a precipitant into cobalt solution and precipitant solution with deionized water, adding the cobalt solution and the precipitant solution which are prepared to certain concentration to a reaction vessel by the charging methods including cocurrent charging according to certain molar ratio, preparing the cobalt salt precursor by controlling the reaction temperature, charging speed, PH value and stirring speed, washing and dehydrating the precursor, directly putting the water-containing filter cake into a pot, spheroidizing and calcining the pot at high temperature, carrying out mechanical grinding, grading and activating, controlling the grain size and the crystal morphology and finally removing the magnetic metal foreign bodies, thus finally obtaining the high quality battery grade cobaltosic oxide. The method is simple in process, easy to operate, low in cost, energy-saving, environment-friendly and suitable for industrial production. The prepared cobaltosic oxide looks like spheroid and has large grain size, good powder flowability and uniform granularity.

Owner:JIANGSU DONGXIN ENERGY TECH

Metalloaluminophosphate molecular sieves with lamellar crystal morphology and their preparation

InactiveCN101679053AIncrease productionIncrease flexibilityMolecular sieve catalystsMolecular sieve catalystCrystal morphologyPhosphoric acid

The present invention relates to metalloaluminophosphate (MeAPO) molecular sieve with lamellar crystal morphology having an empirical chemical composition on an anhydrous basis, after synthesis and calcination, expressed by the formula HxMeyAlzPkO2 wherein, y+z+k=1 and x<=y, said molecular sieve having predominantly a plate crystal morphology in which the width (W) and the thickness (T) are such as : W / T is >= 10 and advantageously ranges from 10 to 100. In a preferred embodiment T is <= 0.15 mum, more desirably <=0.10 mum, more desirably <=0.08 mum, advantageously ranges from 0.01 to 0.07 mumand preferably from 0.04 to 0.07 mum. The above metalloaluminophosphate (MeAPO) molecular sieve can be made by a method which comprises : a) forming a reaction mixture containing a texture influencing agent (TIA), an organic templating agent (TEMP), at least a reactive inorganic source of MeO2 insoluble in the TIA, reactive sources of Al2O3 and P2O5, b) crystallizing the above reaction mixture thus formed until crystals of the metalloaluminophosphate are formed, c) recovering a solid reaction product, d) washing it with water to remove the TIA and e) calcinating it to remove the organic template. In an advantageous embodiment the MeAPO of the invention have essentially a structure CHA or AEI or a mixture thereof. Preferably they have essentially the structure SAPO 18 or SAPO 34 or a mixture thereof. The present invention also relates to catalysts consisting of the above MeAPO molecular sieves or comprising the above MeAPO molecular sieves. The present invention also relates to a process for making an olefin product from an oxygen-containing, halogenide-containing or sulphur-containing feedstock wherein said oxygen-containing, halogenide-containing or sulphur-containing feedstock is contacted with the above catalyst under conditions effective to convert the oxygen-containing, halogenide-containing or sulphur-containing feedstock to olefin products.

Owner:TOTAL RES & TECH FELUY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com